Creep-resisting and aging-resisting rubber tie plate under rail and preparation method thereof

A kind of rubber pad, anti-aging technology, applied in the direction of track, fixed rail, construction, etc., can solve the problem of not meeting the technical requirements of under-rail rubber pad, low aging resistance, no special requirements for dynamic and static stiffness ratio and fatigue performance, etc. problems, to achieve the effect of saving maintenance costs, improving creep resistance, and improving aging resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

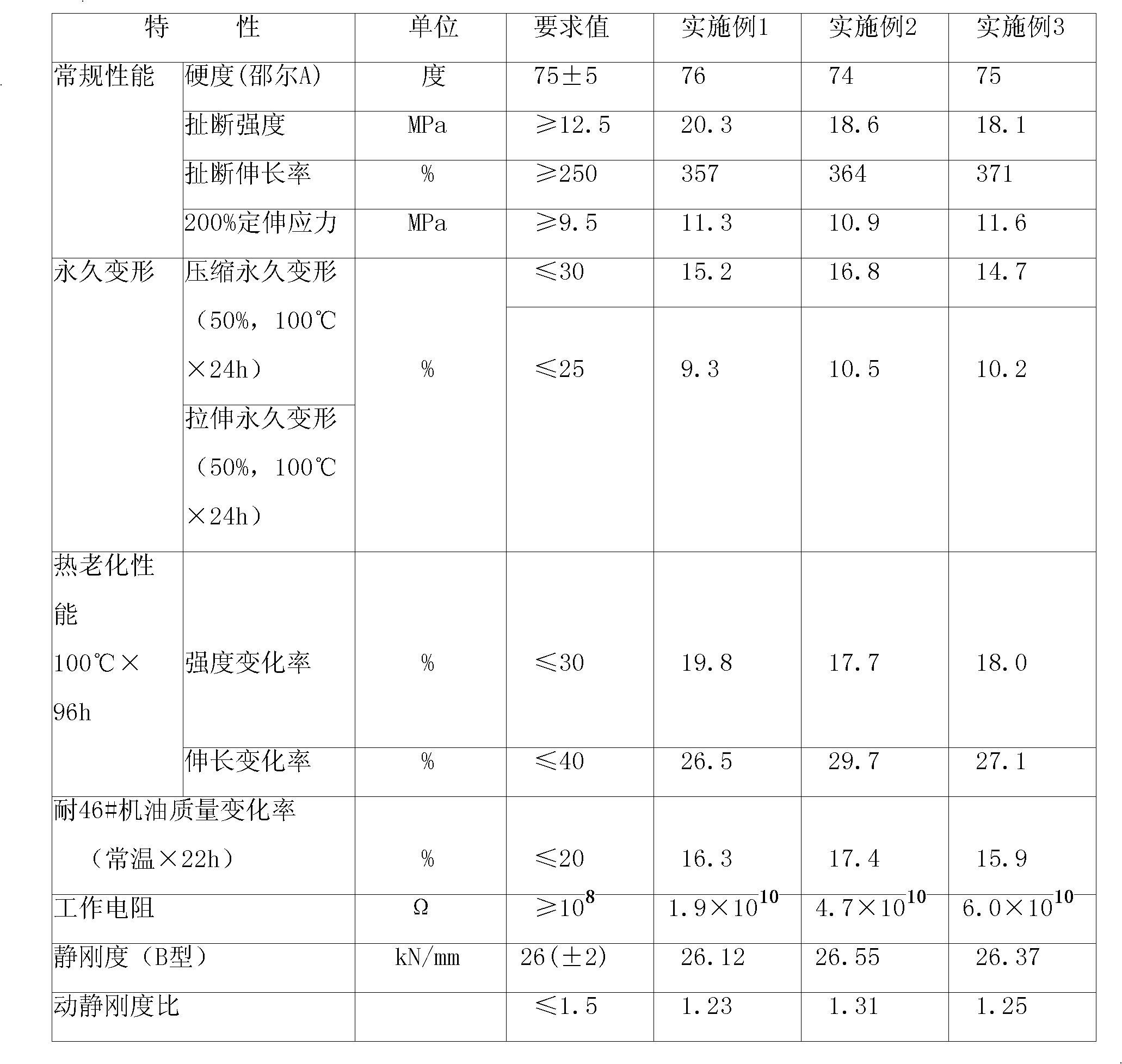

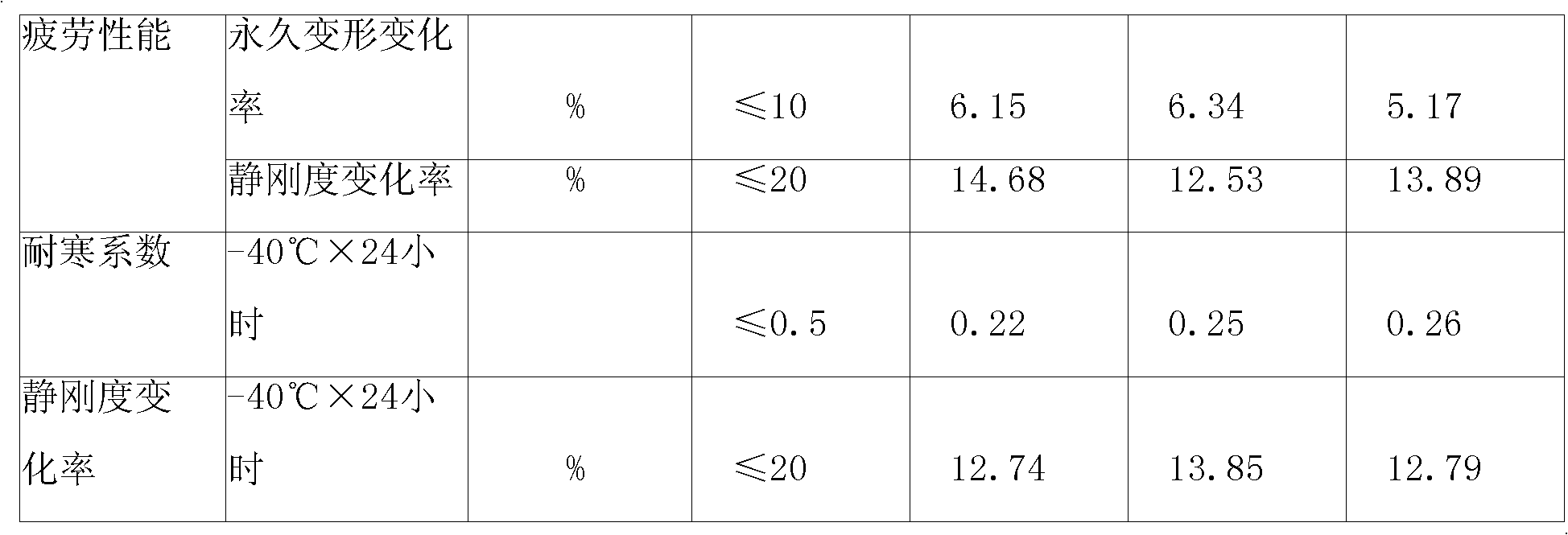

Examples

Embodiment 1

[0056] Below in conjunction with specific embodiment, the present invention is described in further detail: Embodiment 1, a kind of anti-creep and anti-aging rubber backing plate under the rail, carry out batching with the proportioning of parts by weight:

[0057] 85 parts of natural rubber

[0058] Butadiene rubber 15 parts

[0059] Carbon black 30 parts

[0060] White carbon black 40 parts

[0061] Organic modified montmorillonite 15 parts

[0062] Sulfur 1.8 parts

[0063] Accelerator M 1.0 parts

[0064] Accelerator DM 1.5 parts

[0066] 2 parts stearic acid

[0067] Anti-aging agent RD 1.5 parts

[0068] Antiaging agent AW 1 part

[0069] Anti-aging agent 1 part

[0070] Anti-scorch agent CTP 0.5 parts

[0071] Surface modifier 4 parts.

Embodiment 2

[0072] Embodiment 2, a kind of anti-creep and anti-aging rubber backing plate under the rail, ingredients are carried out in proportion by weight:

[0073]90 parts of natural rubber

[0074] Butadiene rubber 10 parts

[0075] Carbon black 40 parts

[0076] White carbon black 35 parts

[0077] 9 parts of organically modified montmorillonite

[0078] Sulfur 1.5 parts

[0079] Accelerator M 1.0 parts

[0080] Accelerator DM 1.0 parts

[0082] 1.5 parts of stearic acid

[0083] Anti-aging agent RD 2 parts

[0084] Antiaging agent AW 1.5 parts

[0085] Anti-aging agent D 1.5 parts

[0086] Anti-scorch agent CTP 0.8 part

[0087] Surface modifier 3 parts.

Embodiment 3

[0088] Embodiment 3, a kind of anti-creep and anti-aging rubber backing plate under the rail, ingredients are carried out in proportion by weight:

[0089] 95 parts of natural rubber

[0090] Butadiene rubber 5 parts

[0091] Carbon black 50 parts

[0092] White carbon black 25 parts

[0093] Organic modified montmorillonite 6 parts

[0094] Sulfur 2.5 parts

[0095] Accelerator M 1.0 parts

[0096] Accelerator DM 1.5 parts

[0097] Zinc oxide 5 parts

[0098] 1.5 parts of stearic acid

[0099] Anti-aging agent RD 1 part

[0100] Antiaging agent AW 2 parts

[0101] Anti-aging agent D 1.8 parts

[0102] Anti-scorch agent CTP 1 part

[0103] Surface modifier 2 parts

[0104] An embodiment of the preparation method of a creep-resistant and aging-resistant under-rail rubber backing plate of the present invention, the production method is as follows:

[0105] 1) batching: according to any kind of proportioning batching in embodiment 1-3, accurately weigh raw material; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com