Patents

Literature

154results about How to "Improve fault diagnosis ability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Multifunctional remote fault diagnosis system for electric control automobile

ActiveCN102183945AReduce the cost of after-sales serviceImprove the efficiency of after-sales serviceElectric testing/monitoringInteraction interfaceNetwork management

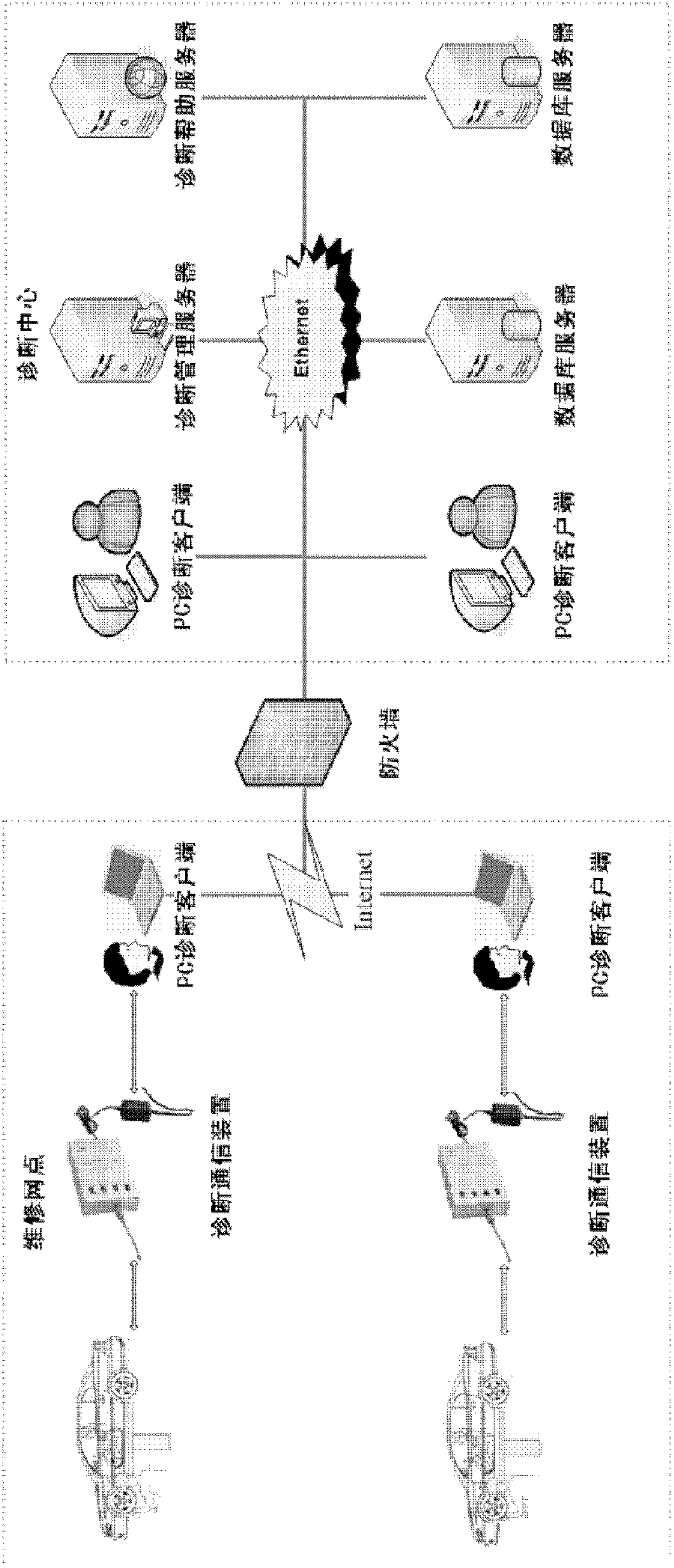

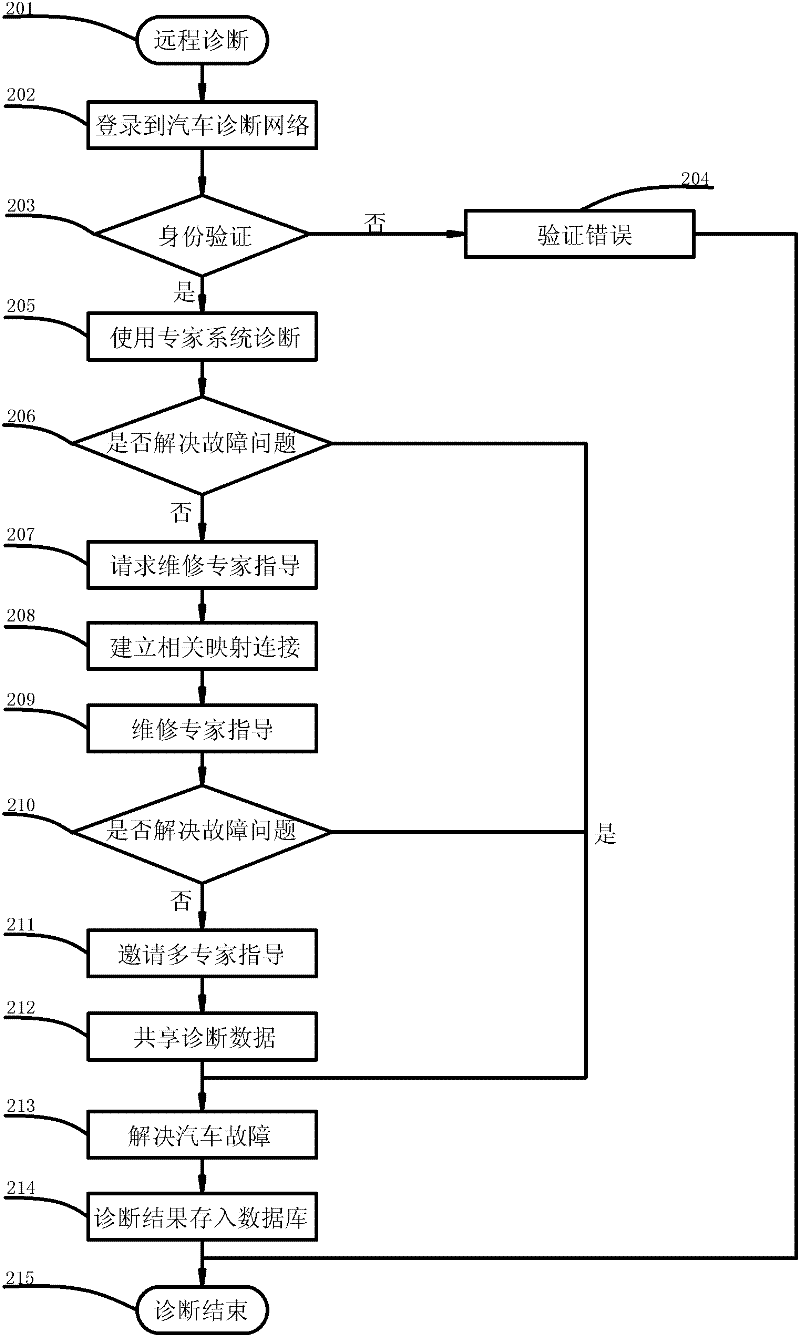

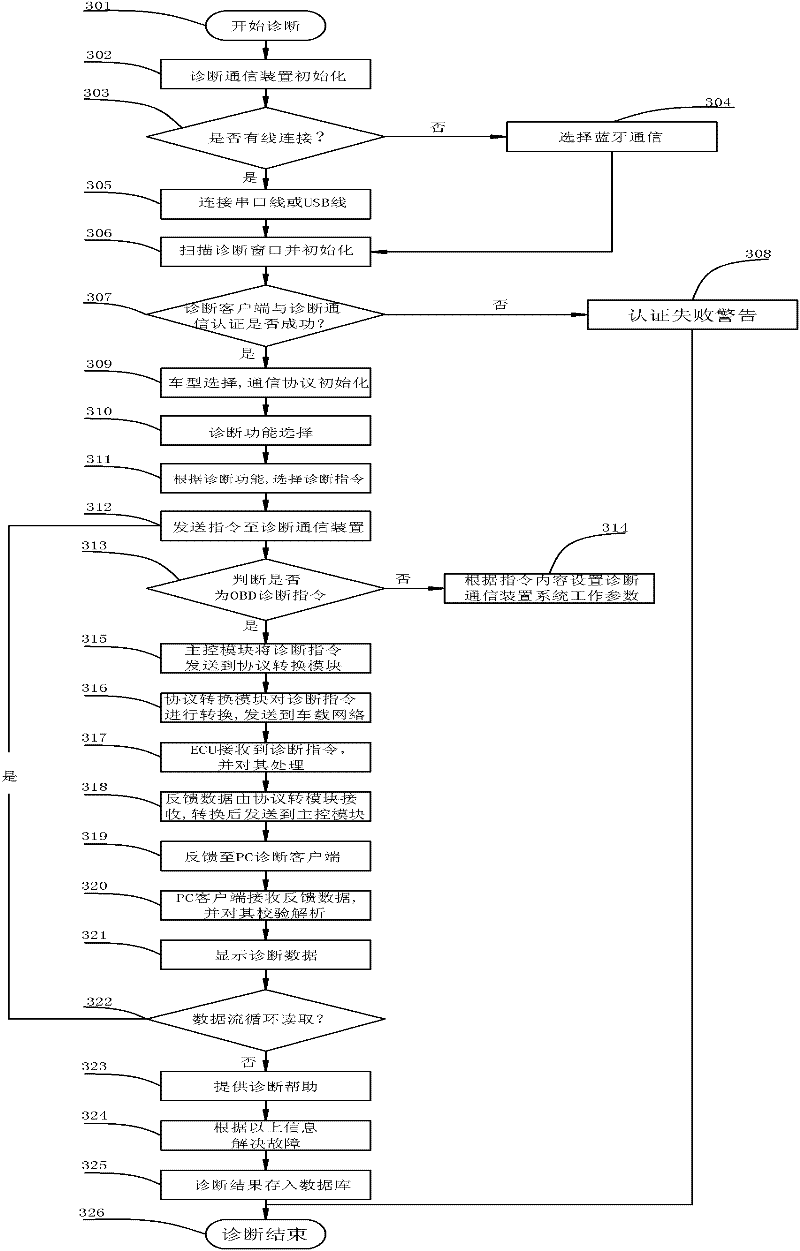

The invention relates to a multifunctional remote fault diagnosis system for an electric control automobile. The multifunctional remote fault diagnosis system comprises a remote fault diagnosis service center, PC (Personal Computer) diagnosis client sides and a diagnosis communication device. The remote fault diagnosis service center serves as a key of the system and is mainly used for realizing an automobile fault diagnosis network management function and an automobile remote fault diagnosis assistance function; the PC diagnosis client sides are mainly used for providing specific automobile diagnosis application functions and remote diagnosis interfaces for users with different rights through human-computer interaction interfaces; and the diagnosis communication device is mainly used for realizing the data communication between the PC diagnosis client sides and a vehicle-mounted network and providing diagnosis data service for upper applications. By means of the multifunctional remote fault diagnosis system, with the remote fault diagnosis service center as a core and all PC diagnosis client sides as nodes, an automobile fault diagnosis network is established; automobile diagnosis data sharing is realized by means of the diagnosis communication device; multifunctional automobile remote fault assistance and fault elimination help can be provided; automobile fault information is subjected to statistic analysis; and a reliable automobile quality report is provided for an automobile manufacturer.

Owner:WUHAN UNIV OF TECH +1

Elevator fault diagnosis and early-warning method based on data drive

InactiveCN102765643AAutomatic acquisitionImprove diagnostic efficiencyElevatorsData streamReliability engineering

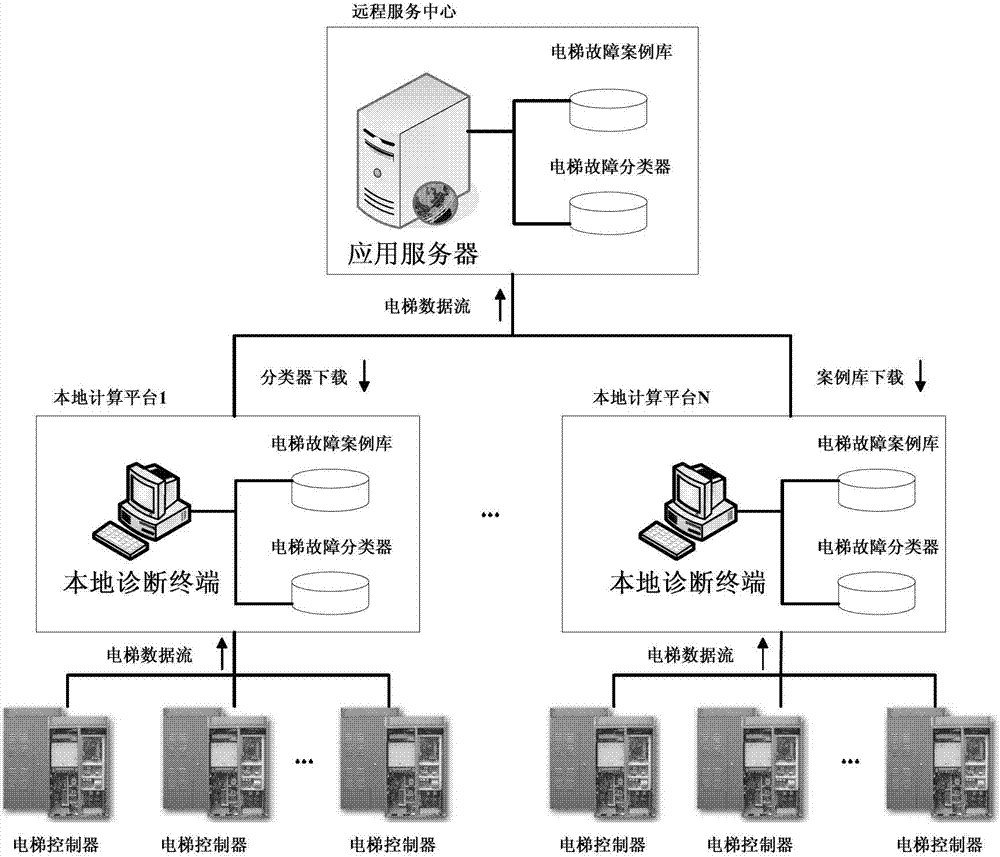

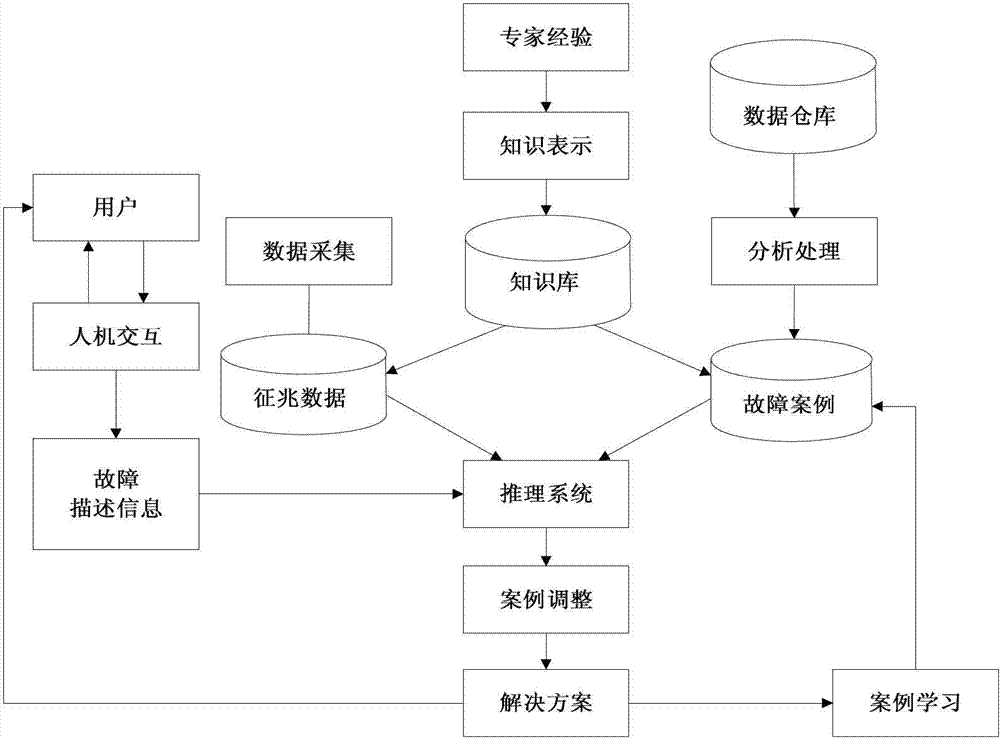

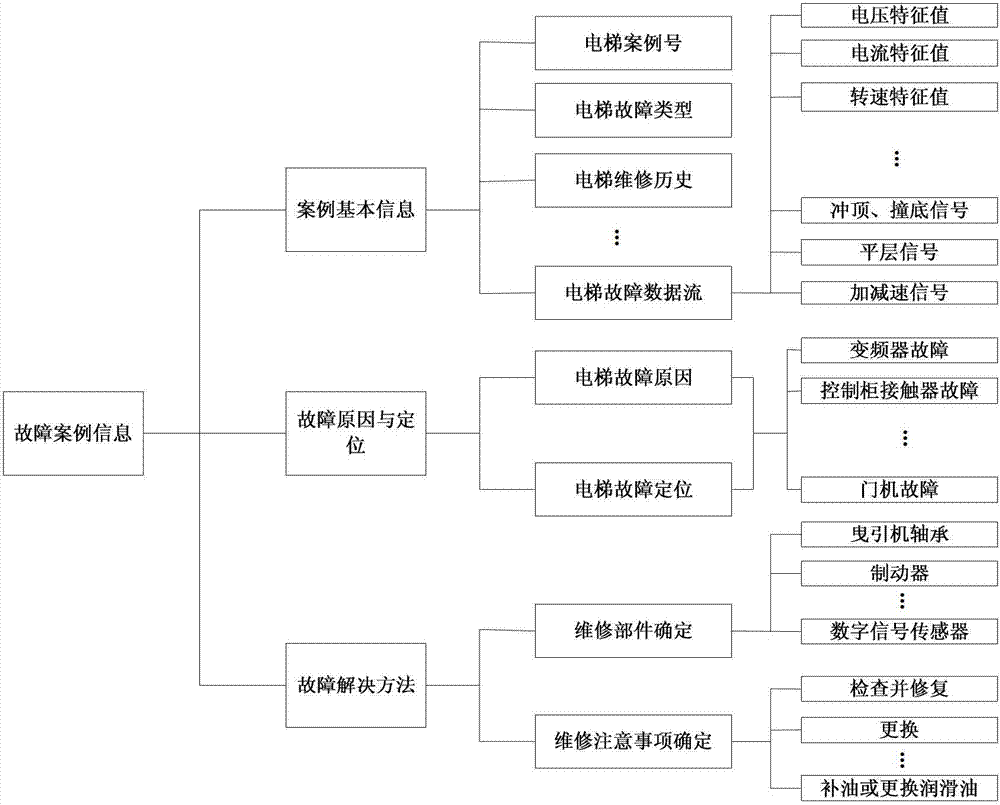

The invention relates to the field of elevators. In order to early discover and diagnose A elevator fault, the invention adopts the technical scheme that an elevator fault diagnosis and early-warning method based on data drive is achieved by means of a remote service center, a fault diagnosis and prediction terminal and an elevator controller, and the method comprises the steps as follows: firstly, elevator fault data are mined to obtain characteristic information in an elevator fault data stream, and the mined result is stored in an elevator fault case base of the fault diagnosis and prediction terminal; secondly, an elevator fault knowledge base on the fault diagnosis and prediction terminal is updated by the elevator fault case base; thirdly, the case retrieval is carried out on the characteristic of a new elevator fault problem, and the fault diagnosis is carried out on the elevator system by adopting the fault diagnosis method based on the case-base reasoning; and finally information with the characteristic that is most similar with that of the new elevator fault problem is acquired through retrieval of the knowledge or the case in the elevator fault knowledge base to solve the diagnosis problem. The method is mainly suitable for manufacturing and designing image sensors.

Owner:TIANJIN UNIV

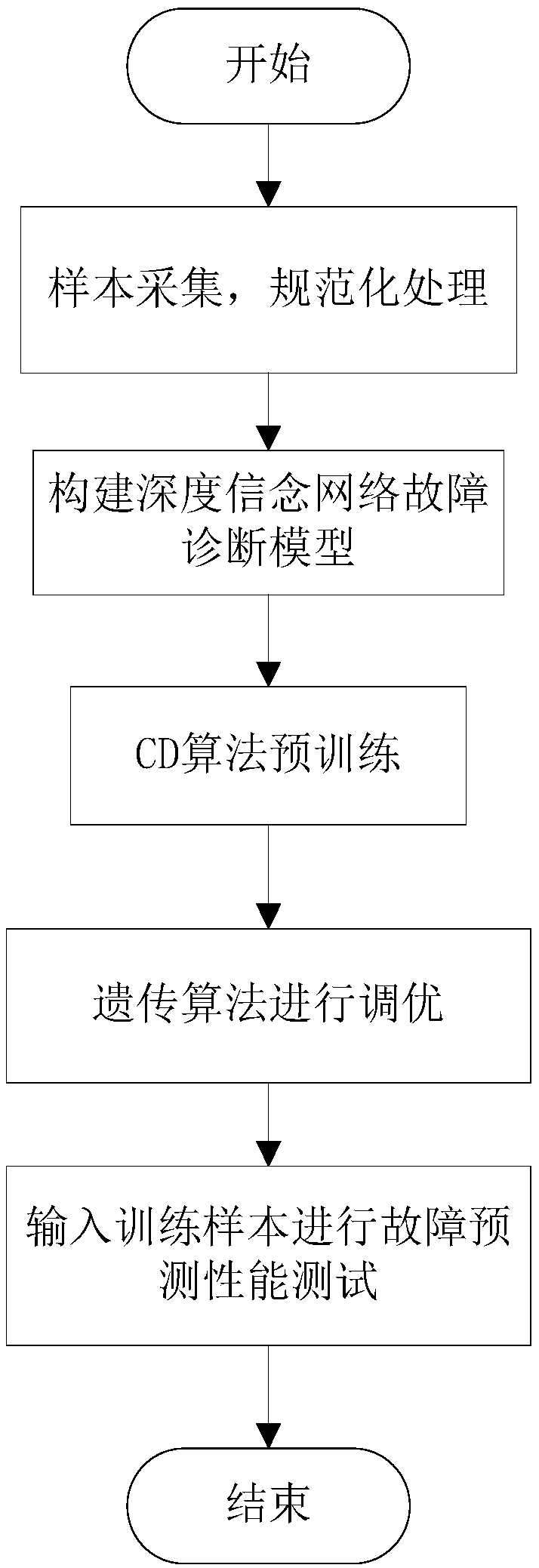

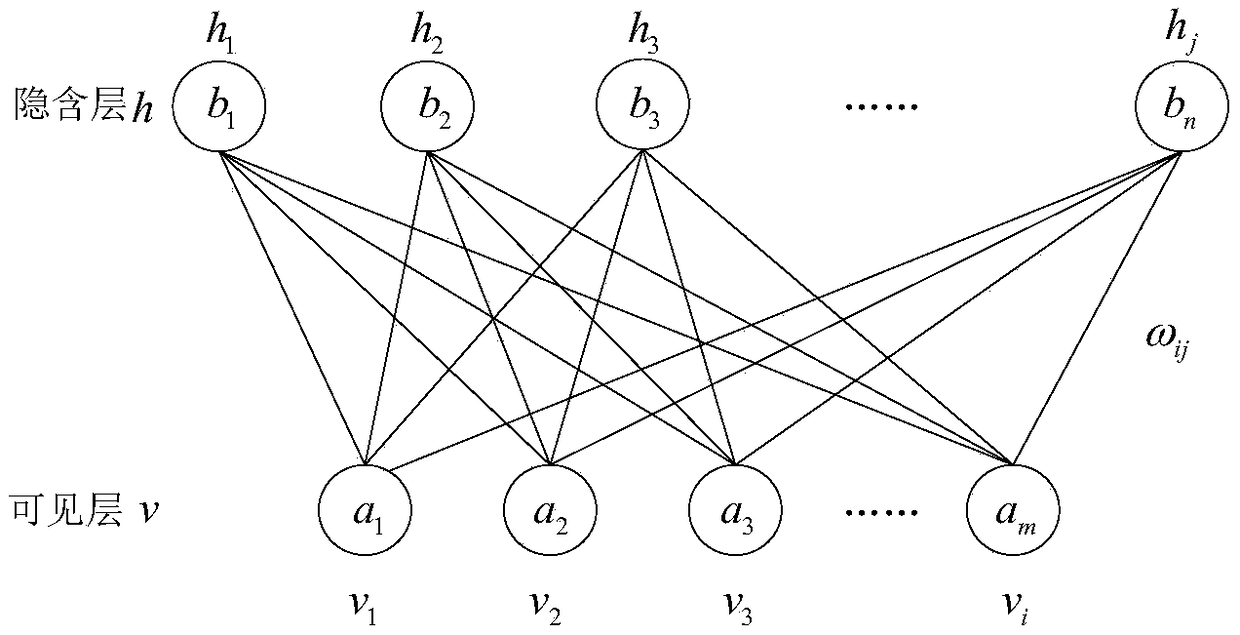

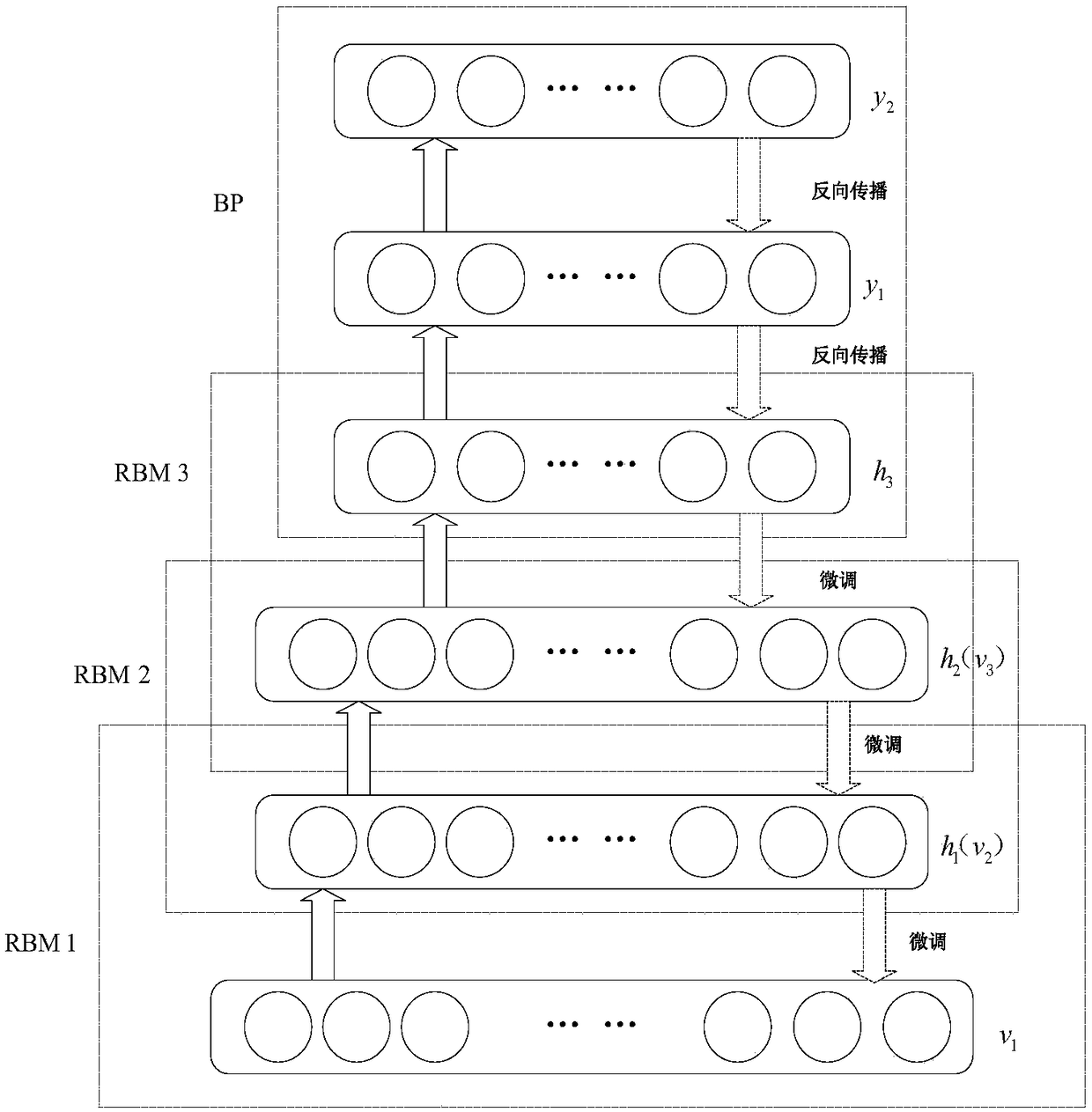

A fault diagnosis method of high voltage circuit breaker based on depth belief network

ActiveCN109086817AImprove utilization efficiencyImprove the accuracy of judgmentCharacter and pattern recognitionNeural architecturesDeep belief networkAlgorithm

The invention discloses a fault diagnosis method of a high-voltage circuit breaker based on a depth belief network, which comprises the following steps: step 1, selecting a data sample required by anexperiment, and dividing the unified standardized sample data into a test sample and a training sample according to a specific proportion; Step 2: building and initializing the DBN deep belief networkfault diagnosis model; Step 3, inputting a large number of unlabeled samples or unlabeled samples in the pre-training set from the bottom of the model, and pre-training the RBM in the model by usinglayer-by-layer unsupervised greedy learning; Step 4: the whole model being fine-tuned by genetic algorithm; Step 5, the fault diagnosis model of the high-voltage circuit breaker obtained by training being classified to the fault samples of the test set in step 1, so as to obtain the fault classification result, and the diagnosis accuracy rate of the model being counted. The invention discloses a fault diagnosis method of a high-voltage circuit breaker based on a depth belief network, which can train a large amount of data samples to realize the fault diagnosis function of the high-voltage circuit breaker.

Owner:XI'AN POLYTECHNIC UNIVERSITY

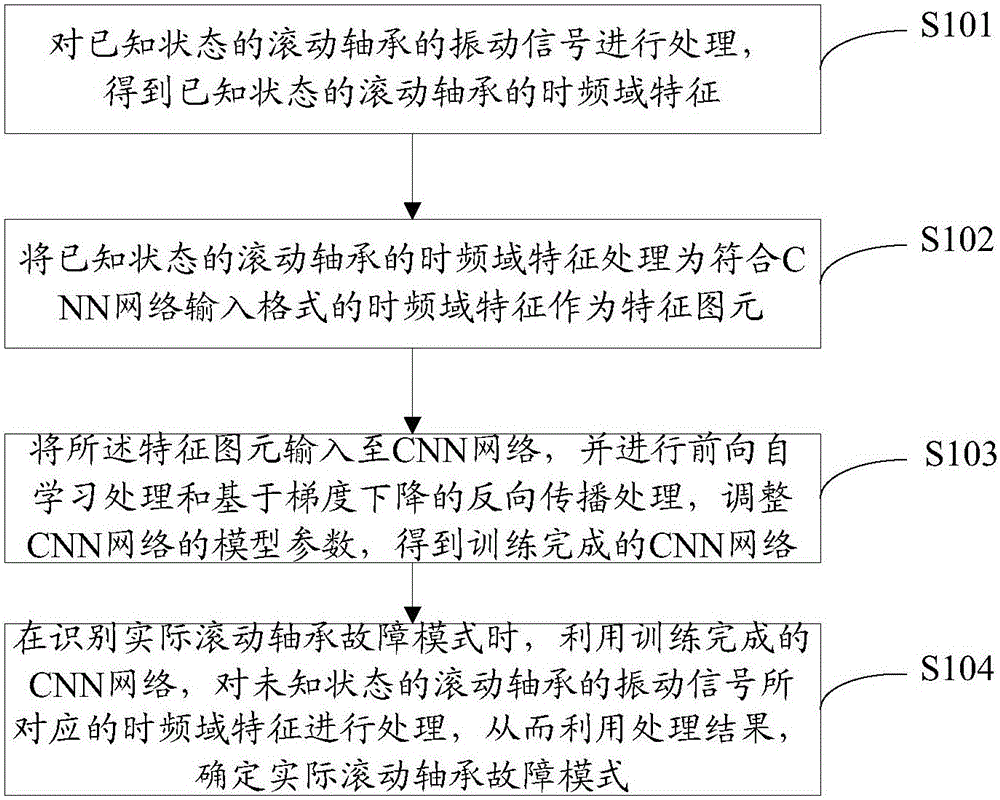

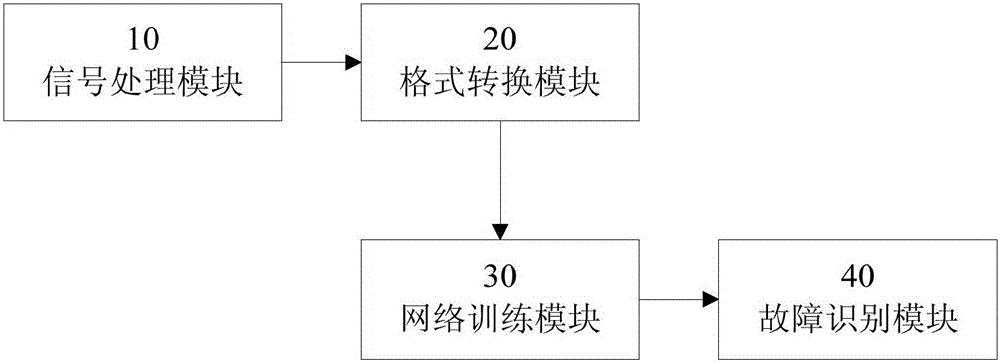

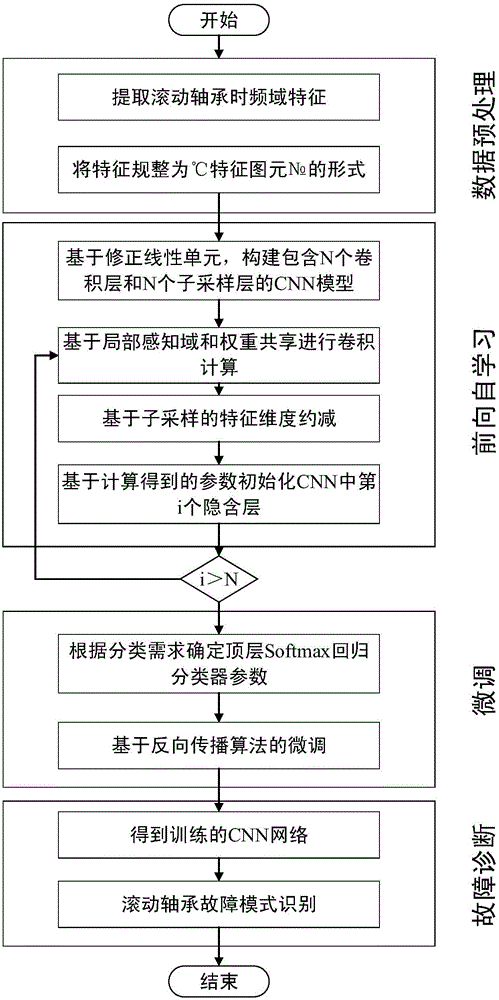

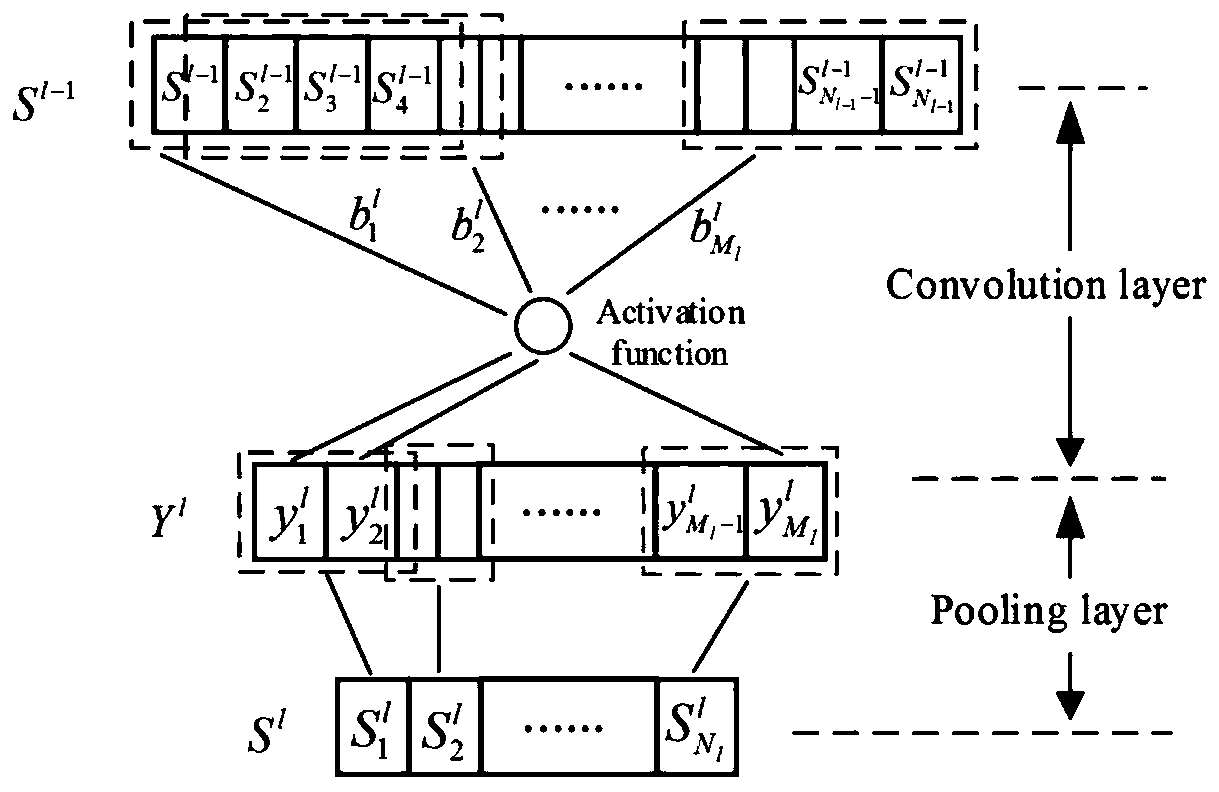

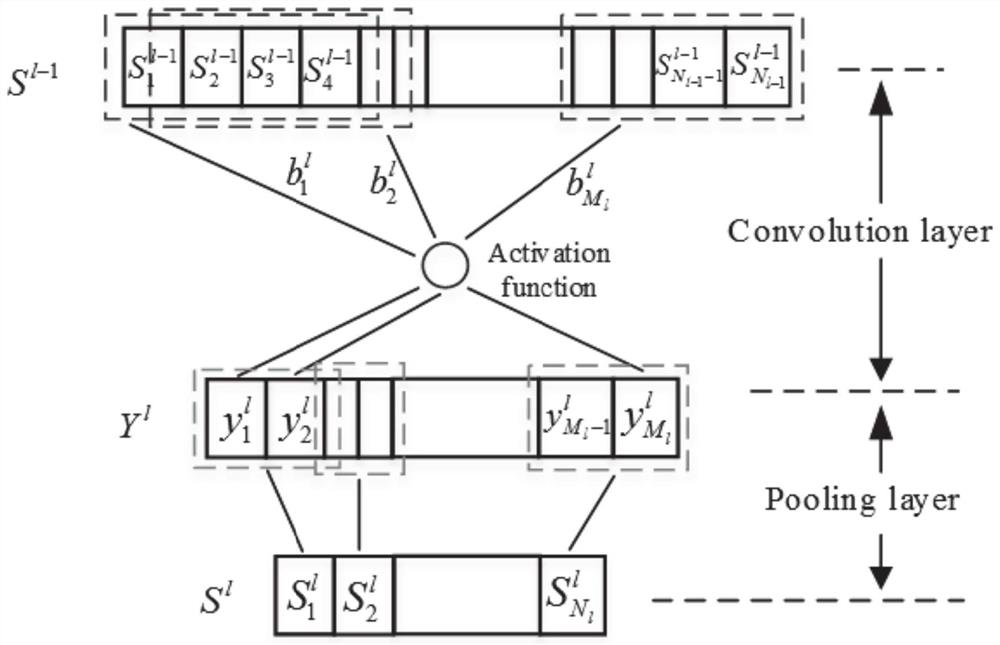

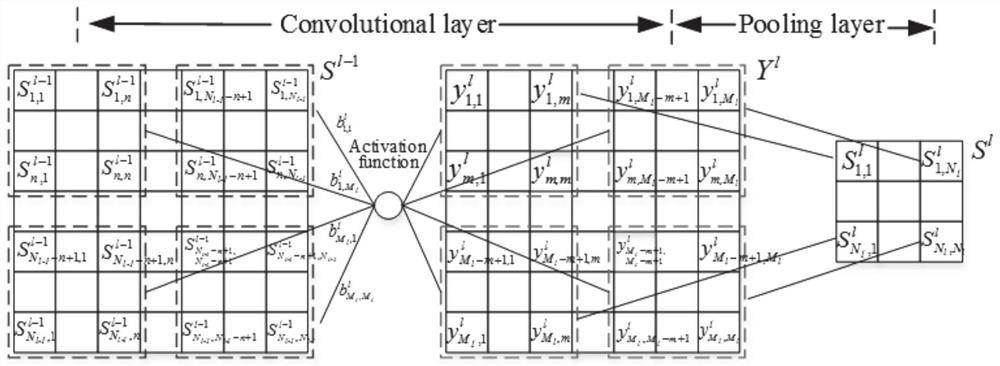

Overlay convolutional network-based rolling bearing failure mode recognition method and device

ActiveCN107526853AImprove self-learning abilityImprove fault diagnosis abilityGeometric CADMachine bearings testingPattern recognitionInformation layer

Owner:北京恒兴易康科技有限公司

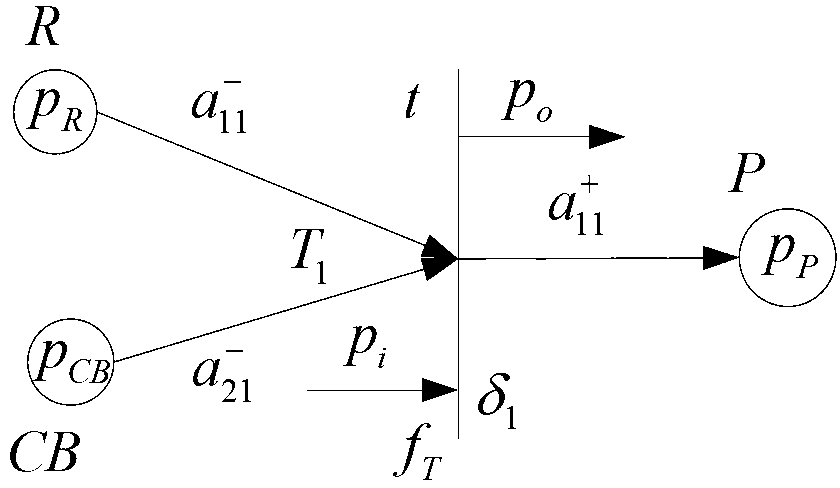

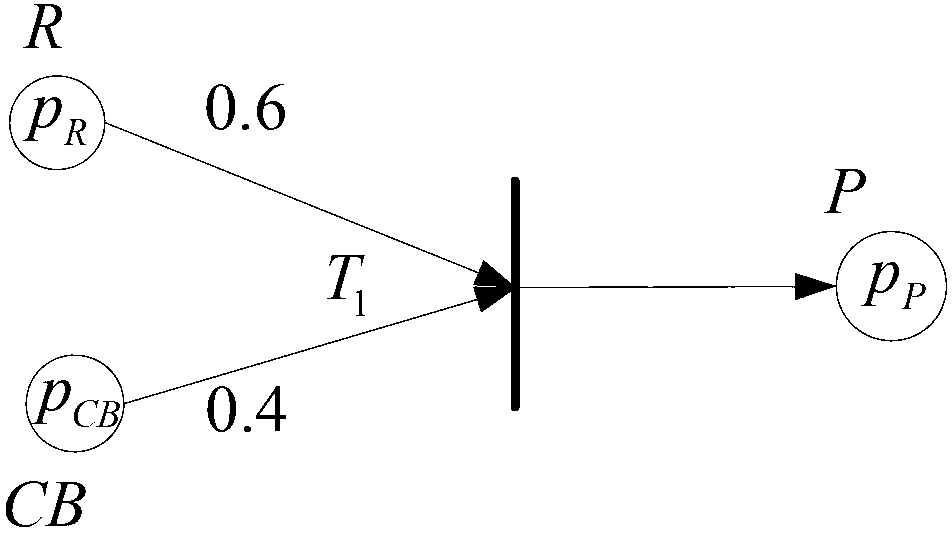

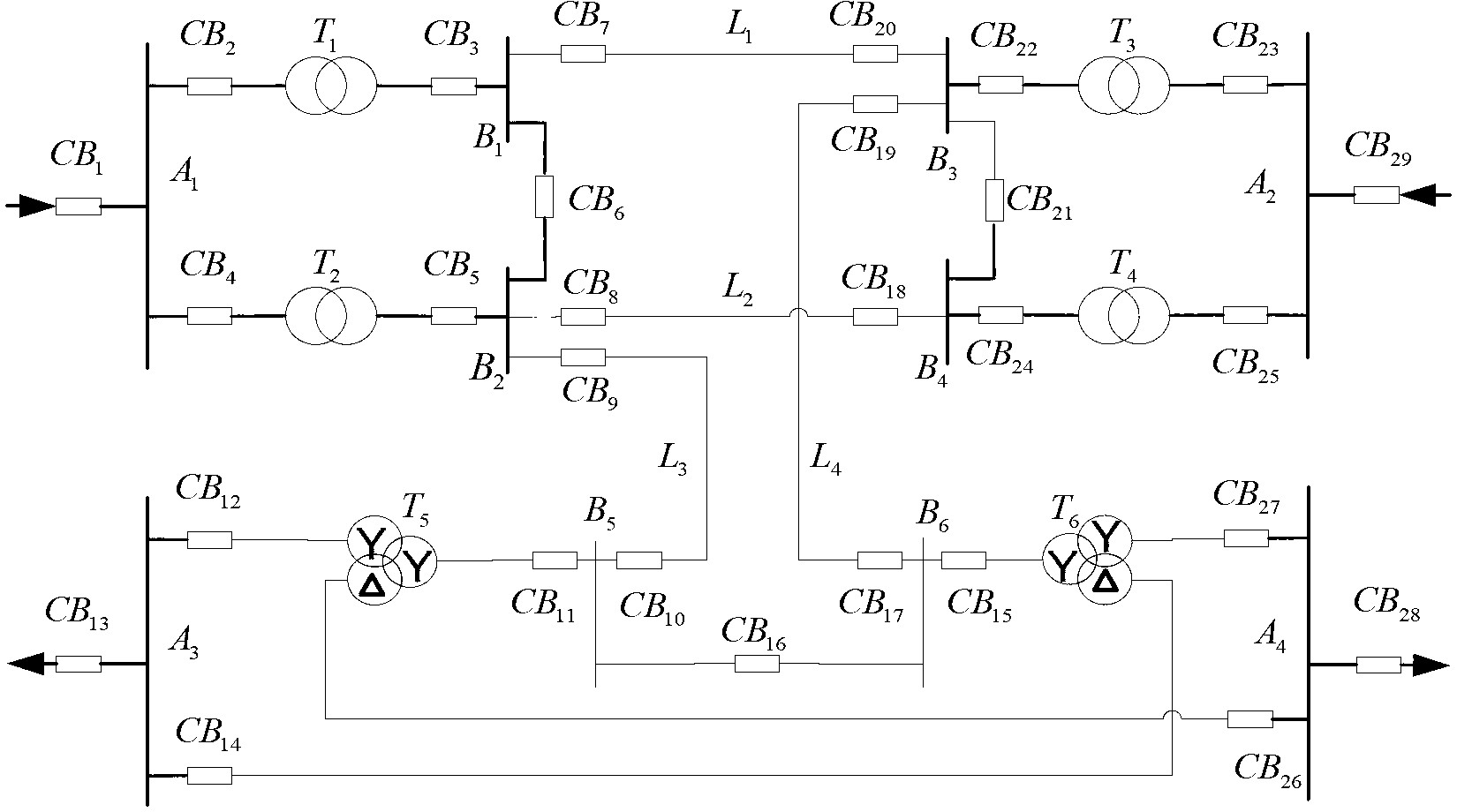

Power system fault diagnostic method based on probability Petri net

ActiveCN103308824AImprove accuracy and reliabilityImprove performanceFault locationPower gridDependability

The invention discloses a power system fault diagnostic method based on a probability Petri net. The power system fault diagnostic method comprises the following steps of: when a power system is in fault, identifying whether fault information is true fault information or not, preprocessing the true fault information, generating a fault suspicious component library, and forming a correlated suspicious component sublibrary; extracting suspicious components in the fault suspicious component library by a monitoring center, and generating a suspicious component fault tree; establishing a probability Petri net model of outgoing lines of the suspicious components in all directions; carrying out fault diagnosis, so as to obtain fault diagnosis results; and judging fault conditions of the suspicious components corresponding to fault diagnosis results, if the suspicious components belong to the associated suspicious components, executing credibility comparison, so as to obtain fault components, and if not, regenerating the fault tree. With the adoption of the power system fault diagnostic method based on the probability Petri net, an optimal function parameter of a transition function is given based on a probability Petri net theory, the unreliability of the components is introduced, and the fault diagnosis method containing credibility evaluation is provided, so that the power system fault diagnostic method is higher in reliability and accuracy, and can be well applied in actual power grids.

Owner:NORTHEASTERN UNIV +2

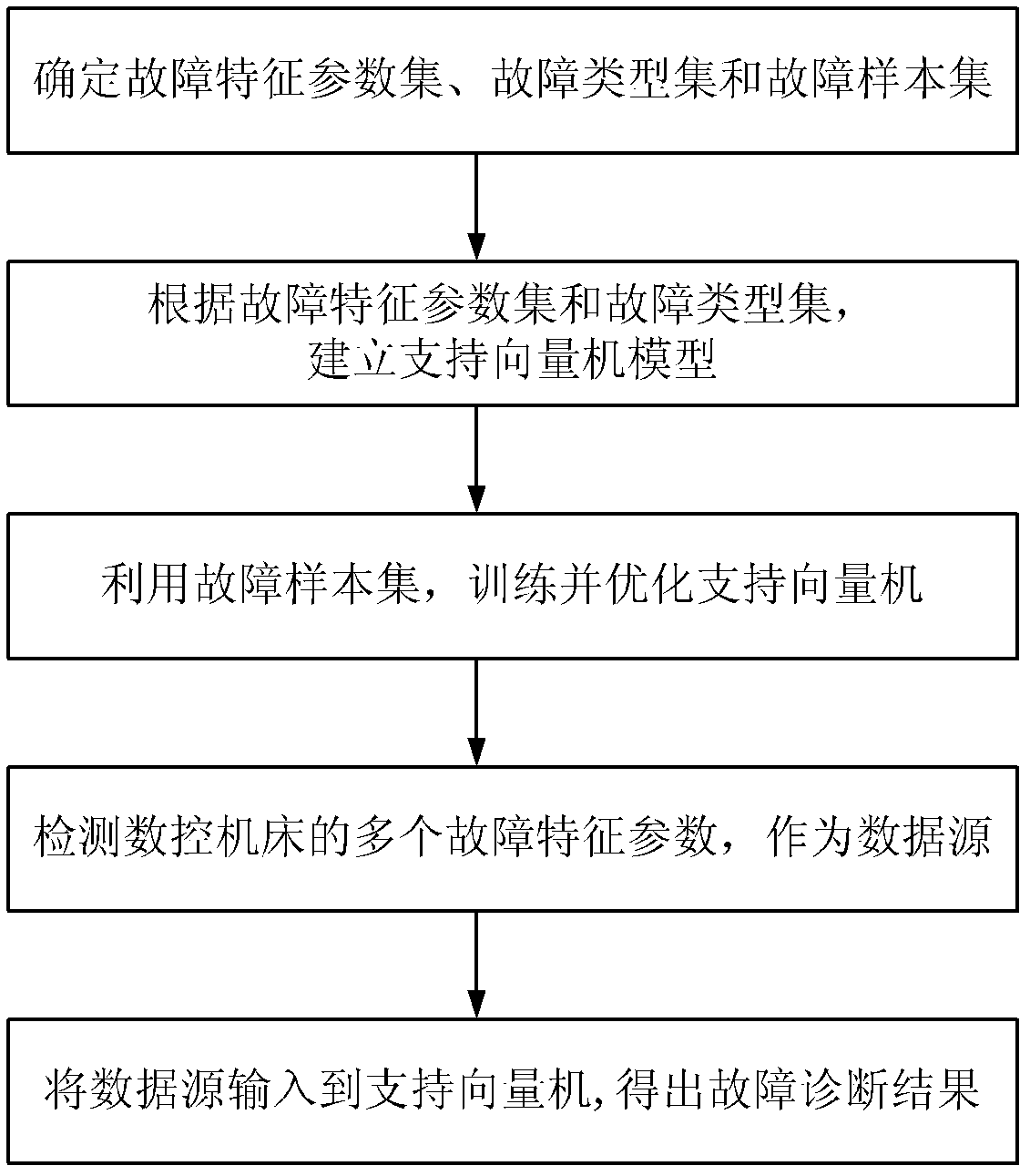

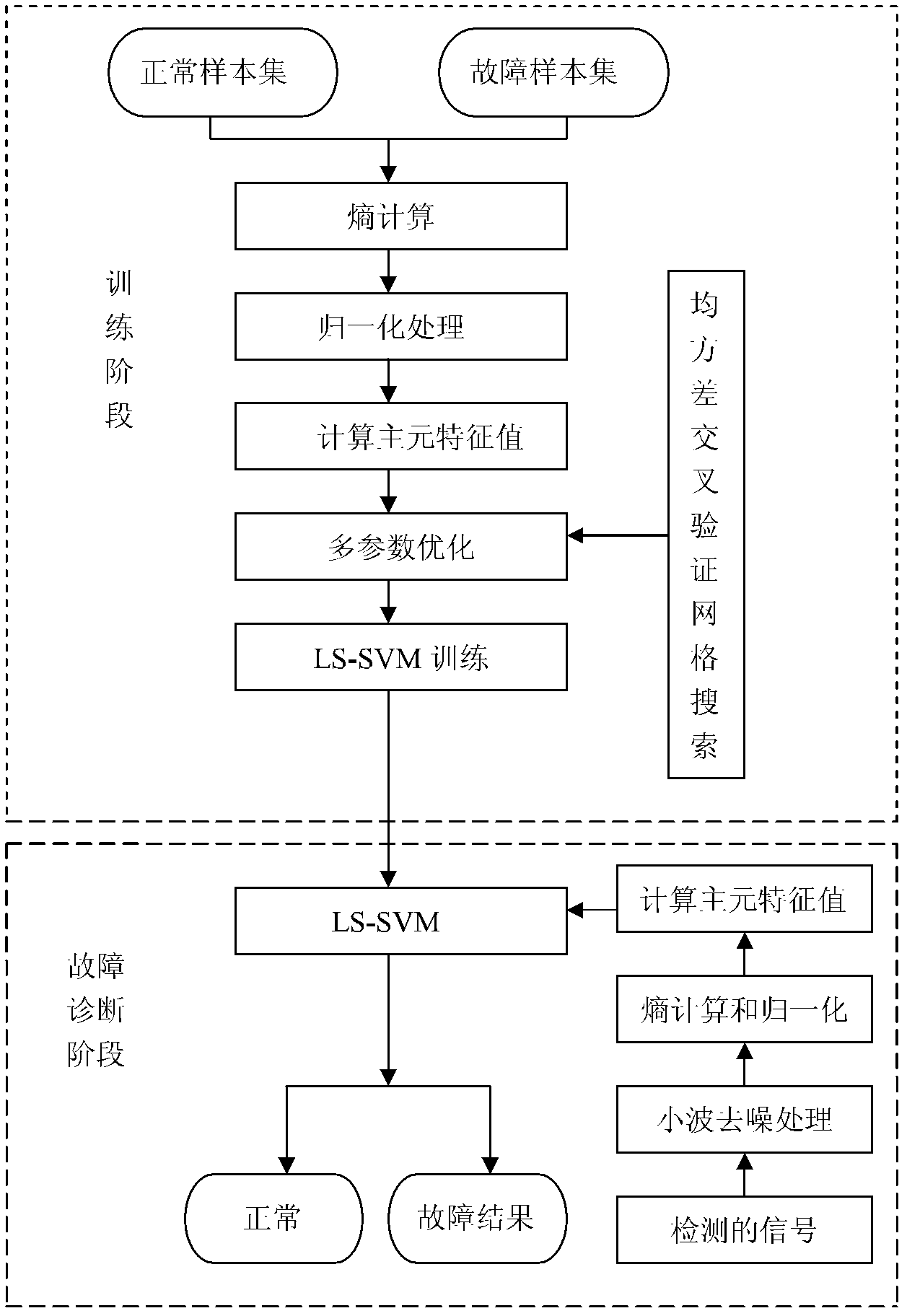

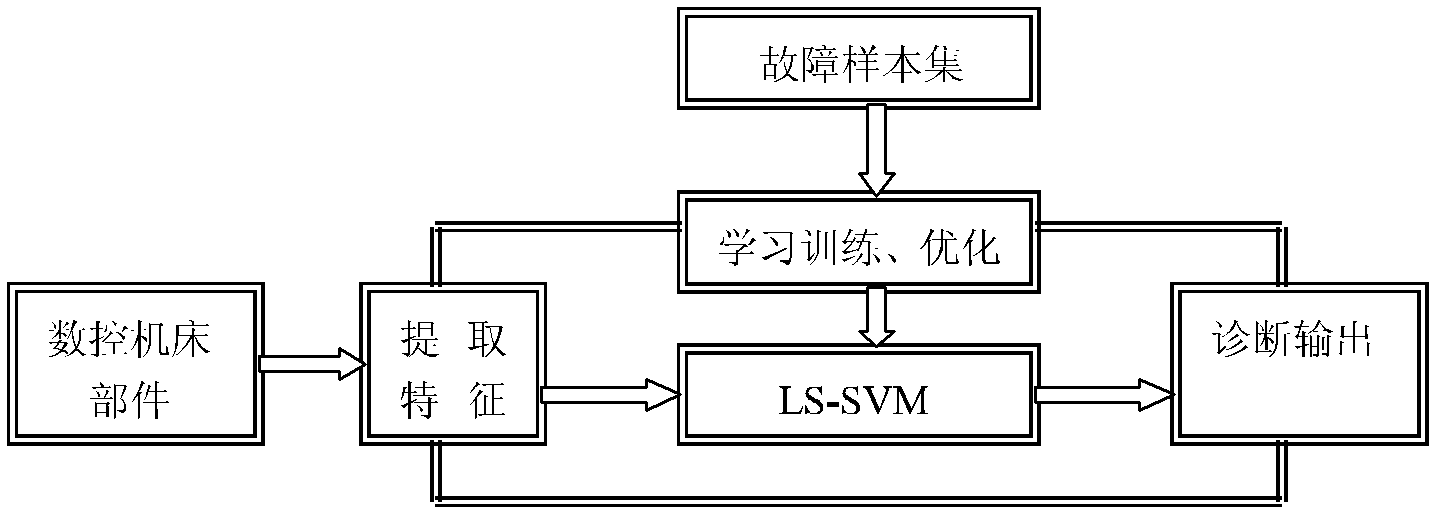

Intelligent fault diagnosis method for numerical control machine

InactiveCN102566505AEffective fault diagnosisStrong fault diagnosis abilityProgramme controlComputer controlDiagnosis methodsLeast squares support vector machine

The invention provides an intelligent fault diagnosis method for a numerical control machine, which comprises the following steps: (1) determining a fault characteristic parameter set, a fault type set and a sample set; (2) according to the fault characteristic parameter set and the fault type set, establishing a support vector machine model; (3) training and optimizing a support vector machine by utilizing the sample set; (4) detecting a plurality of fault characteristic parameters of the numerical control machine and using the plurality of fault characteristic parameters as a data source of fault diagnosis; and (5) inputting the data source into the optimized support vector machine to obtain a fault diagnosis result. In the invention, according to the occurrence mechanism and the characteristics of faults of parts of the numerical control machine, when the parts of the numerical control machine have the faults, the numerical control machine is detected and detection data is input into the least squares support vector machine after being processed, so that a diagnosis result can be obtained. According to the invention, the rapid and effective fault diagnosis for the numerical control machine is implemented and the intelligent fault diagnosis method also has strong fault diagnosis capacity, high diagnosis rate and low misdiagnosis rate.

Owner:WENZHOU UNIVERSITY

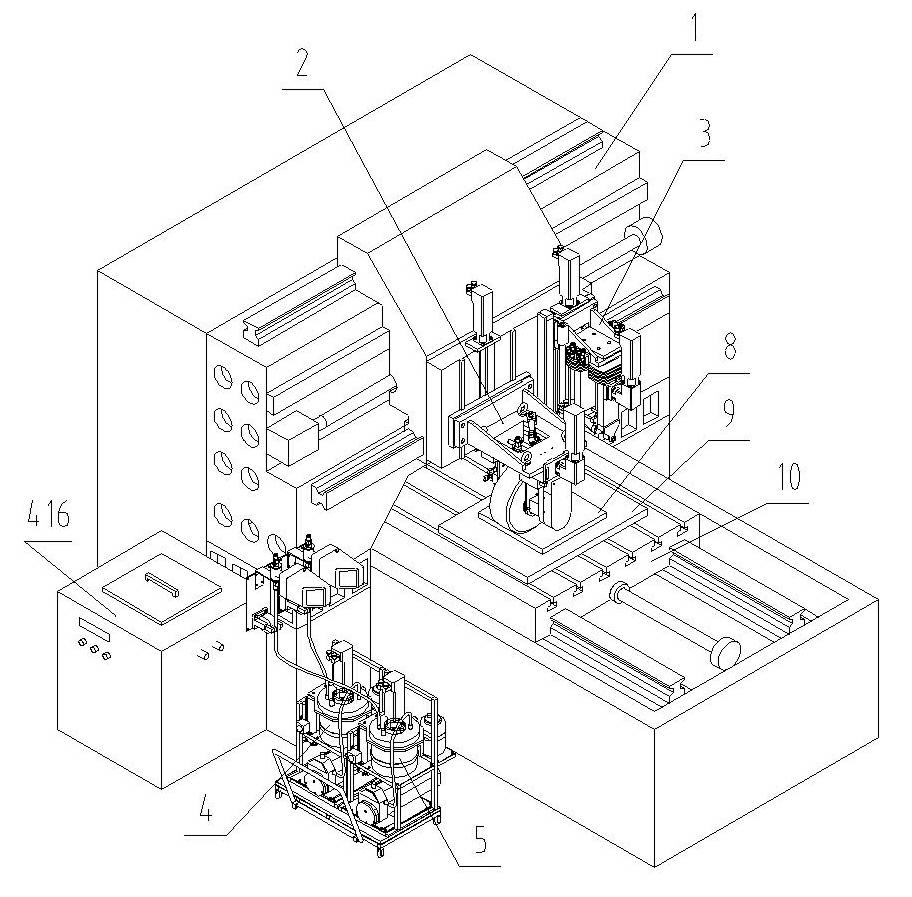

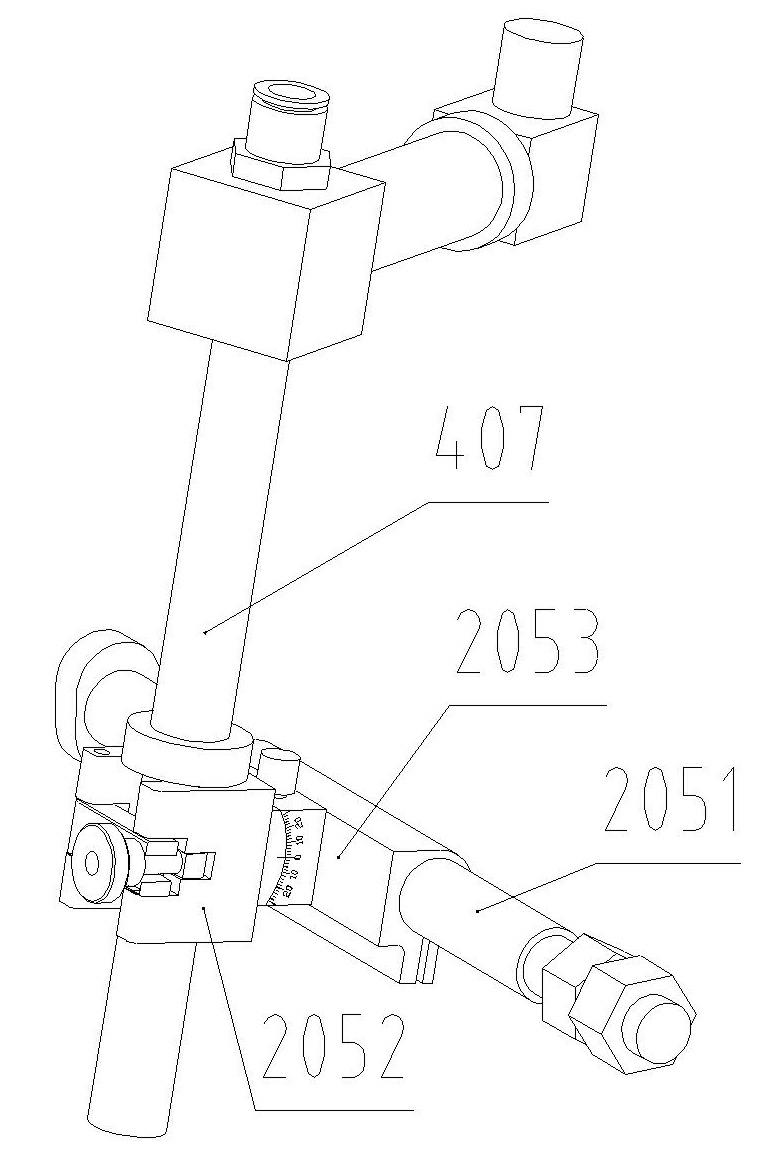

Double-flexible-grinding-head magnetorheological polishing device

ActiveCN102632435AEfficient removalEffectively match processing efficiencyGrinding drivesGrinding feed controlMagnetic currentEngineering

The invention discloses a double-flexible-grinding-head magnetorheological polishing device. In the device, a vertical gantry of a bed body and an X-axis are both fixed on a horizontal base; a worktable is fixed on a sliding block of the X-axis; a Y-axis is fixed on a horizontal beam of the vertical gantry; and a first Z-axis and a second Z-axis are arrangedon the Y-axis in parallel. A large flexible grinding head is installed on the first Z-axis; and a small flexible grinding head is arranged on the second Z-axis. A high-flow circulation system connected with the large flexible grinding head and a low-flow circulation system connected with the small flexible grinding head are arranged on a trolley. A control cabinet is arranged at the rear part of the vertical gantry; and a circulation system cabinet and a cleaning system are arranged at the side surface of the vertical gantry. The double-flexible-grinding-head magnetorheological polishing device provided by the invention has the advantages of high accuracy, high rigidness, high stability and high dynamic property. The double-flexible-grinding-head magnetorheological polishing device not only can be used for processing of large-caliber phase elements, but also can be used for high-accuracy processing of large-caliber planar optical elements within the range of full caliber. The optimal matching of the processing efficiency and the processing accuracy can be realized.

Owner:INST OF MACHINERY MFG TECH CHINA ACAD OF ENG PHYSICS

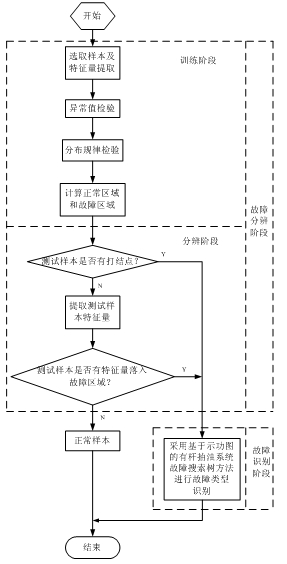

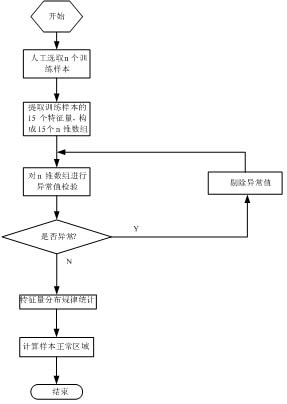

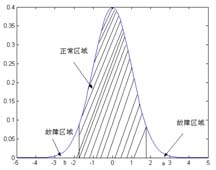

Method for hierarchically diagnosing fault of rod-comprising oil pumping system based on indicator diagram

InactiveCN102011576AImprove fault diagnosis abilityImprove management efficiencySurveyDrilling rodsMechanical modelsFault recognition

The invention discloses a method for hierarchically diagnosing a fault of a rod-comprising oil pumping system based on an indicator diagram. The method comprises two stages, namely a fault distinguishing stage and a fault recognizing stage, and comprises the following steps of: dividing the indicator diagram into a fault class and a non-fault class according to a statistical law of the normal sample at the fault distinguishing stage; and recognizing a fault type of a fault sample by a search tree method for recognizing the fault of the rod-comprising oil pumping system based on the indicator diagram. By the method, the fault diagnosis performance of a fault diagnosis system is improved, a mechanical model of the rod-comprising oil pumping system does not need establishing or resolving, the problem of a training set is solved, and the basic features of the rod-comprising oil pumping system can be reflected.

Owner:HOHAI UNIV +1

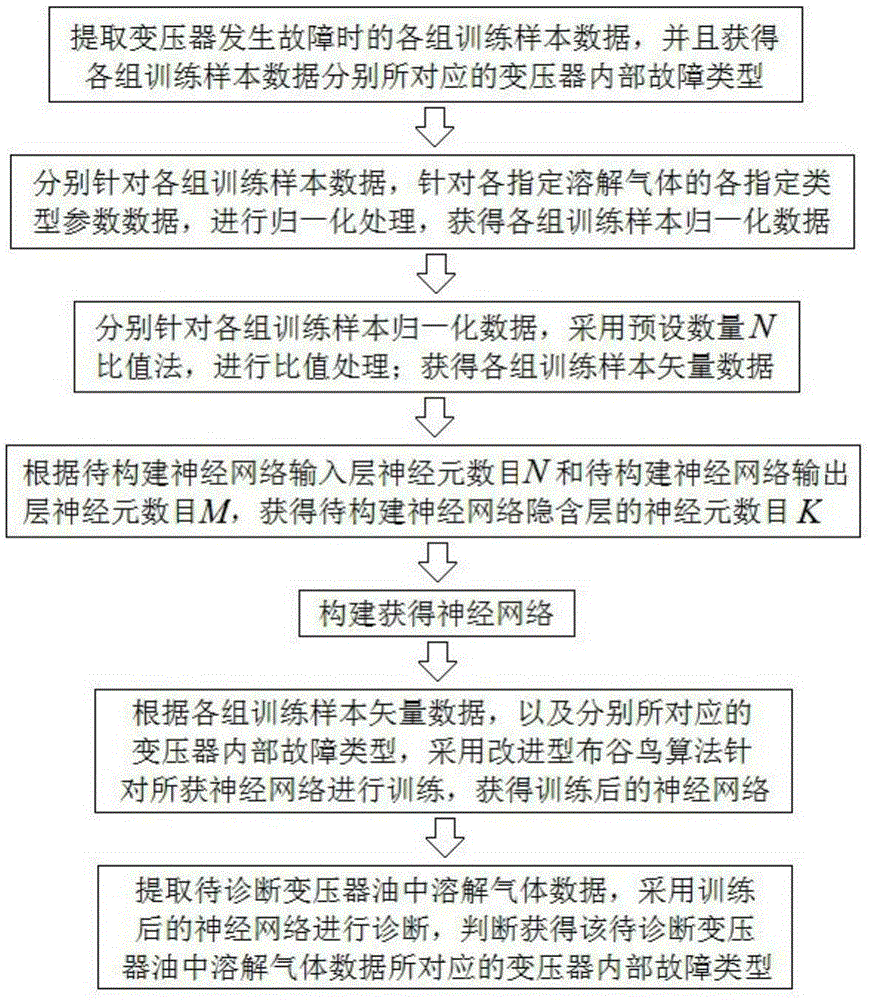

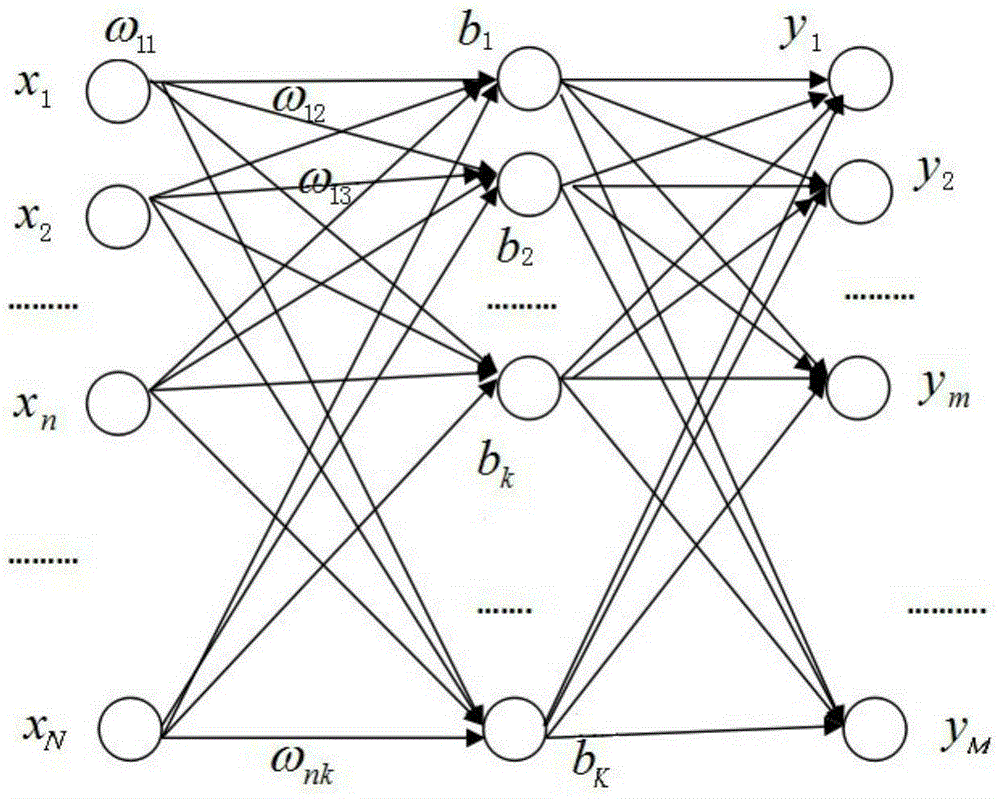

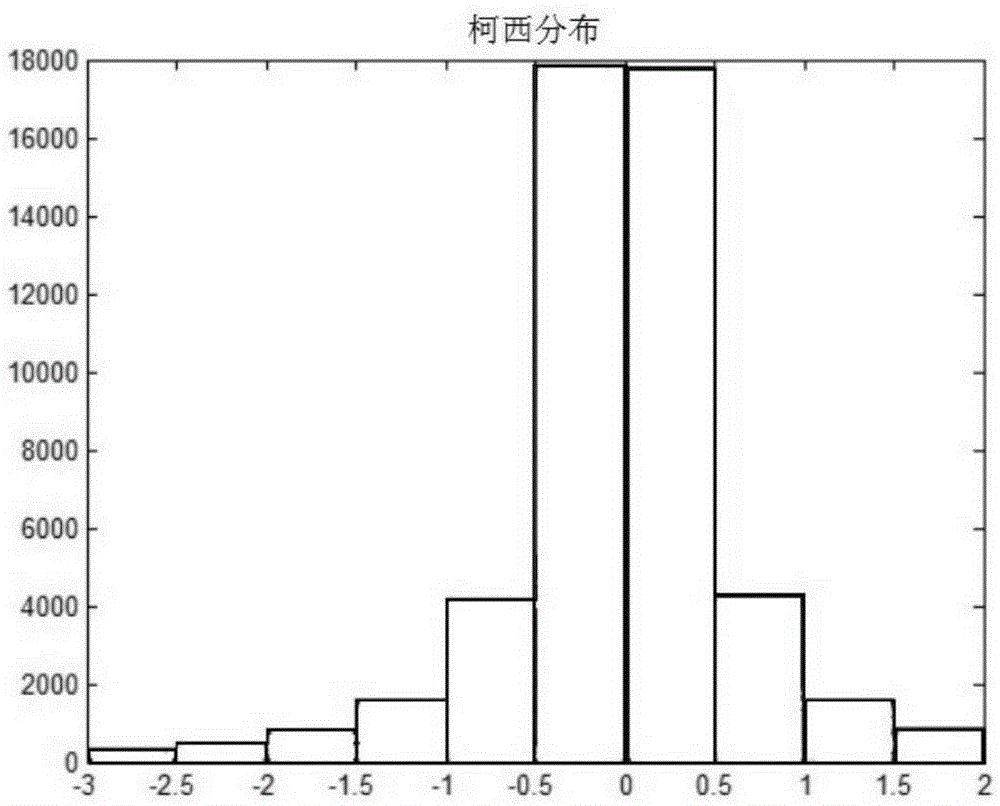

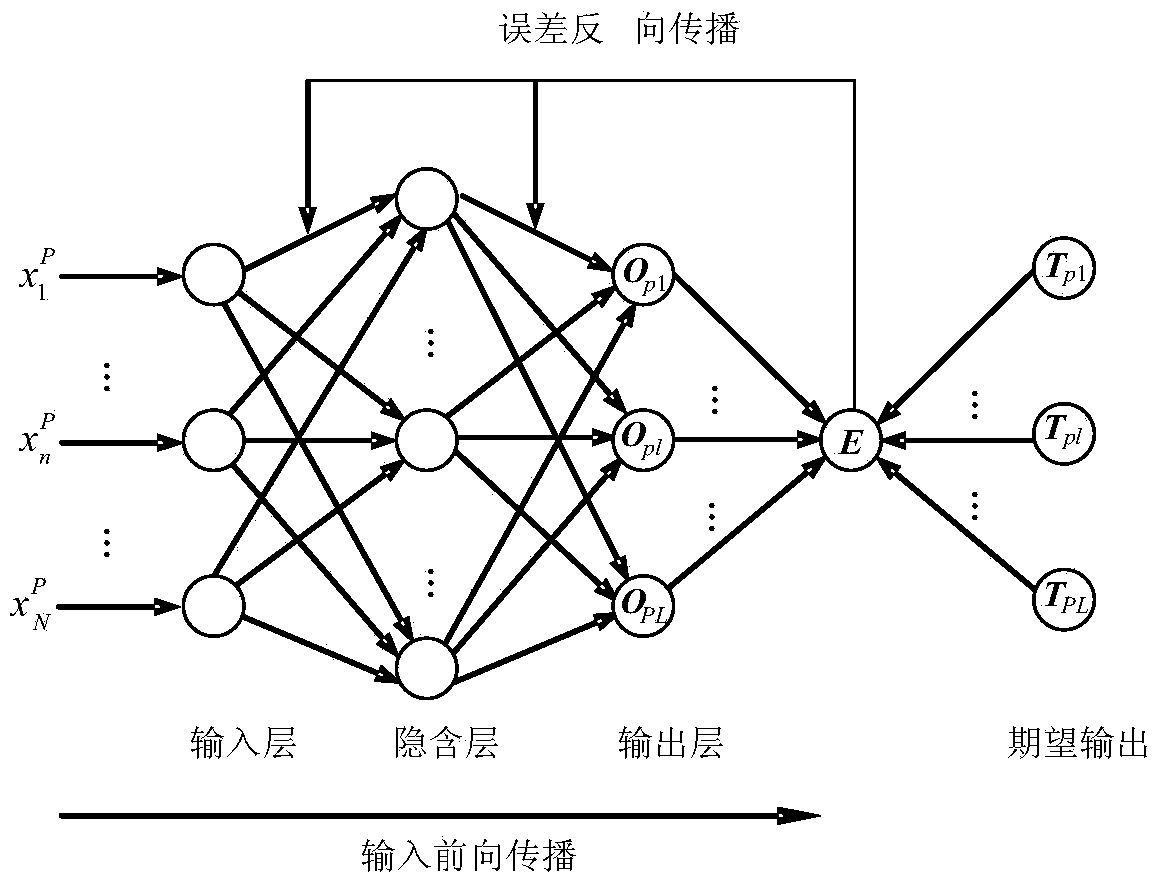

Transformer fault diagnosis method based on neural network

ActiveCN105353255ASolve the local convergence problemFast convergenceElectrical testingBiological neural network modelsHidden layerNerve network

The invention relates to a transformer fault diagnosis method based on a neural network. The method comprises the following steps: analyzing fault reasons, and extracting a sample set of dissolved gas in transformer oil and a corresponding a fault type inside a transformer; determining the number of Neurons in a neural network hidden layer according to experience and a successive optimization searching method, and building a neural network; adopting an improved Cuckoo optimization algorithm to train the neural network; and finally utilizing the trained neural network to diagnose a fault of the transformer. The entire design method has the characteristics of high search precision and high global search capability, and effectively improves the accuracy of fault diagnosis for a transformer.

Owner:NANJING UNIV OF POSTS & TELECOMM

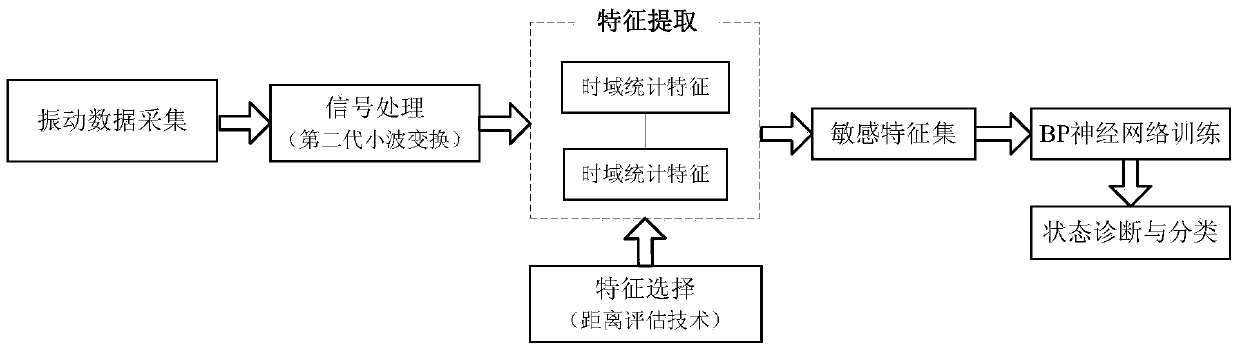

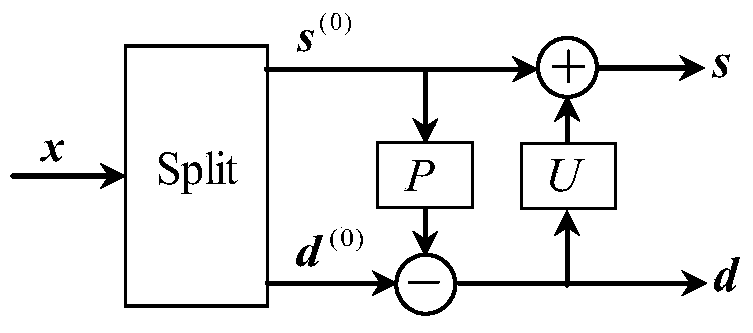

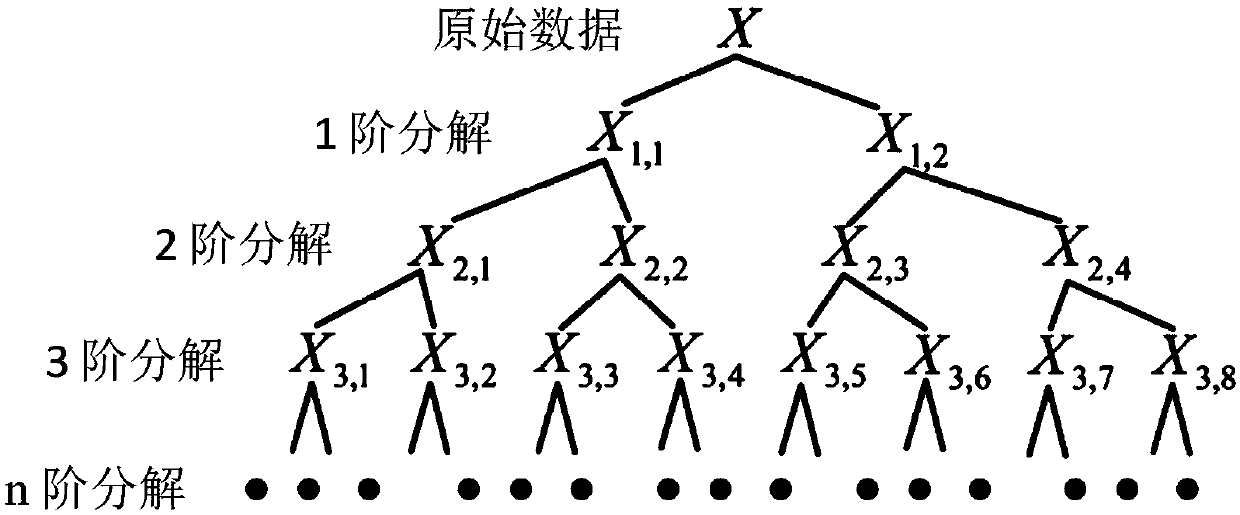

Bearing fault diagnostic method based on second generation wavelet transform and BP neural network

InactiveCN104198184AImprove fault diagnosis abilityHigh classification and diagnosis accuracyMachine bearings testingBiological neural network modelsPattern recognitionTime domain

The invention relates to a bearing fault mixing intelligent diagnostic method based on second generation wavelet transform and a BP neural network. The bearing fault diagnostic method based on the second generation wavelet transform and the BP neural network includes steps: firstly, using the second generation wavelet transform to resolve a bearing original vibration signal measured by a sensor; secondly, extracting time domain statistical features and frequency domain statistical features from the resolved signal so as to form a combined feature set, and then performing feature evaluation on the extracted feature set so as to obtain a sensitive feature set; using the sensitive feature set as input of the BP neural network for network training, and building a fault diagnostic model based on the BP neural network so as to achieve classification and diagnosis of faults. The bearing fault diagnostic method based on the second generation wavelet transform and the BP neural network and the fault diagnostic model based on the BP neural network are used in the classification and the diagnosis of the bearing faults, and results indicate that the bearing fault diagnostic method based on the second generation wavelet transform and the BP neural network is high in classification and diagnosis accuracy, high in speed and high in efficiency, effectively improves bearing fault diagnostic effects, and is conveniently used in engineering practice.

Owner:AIR FORCE UNIV PLA

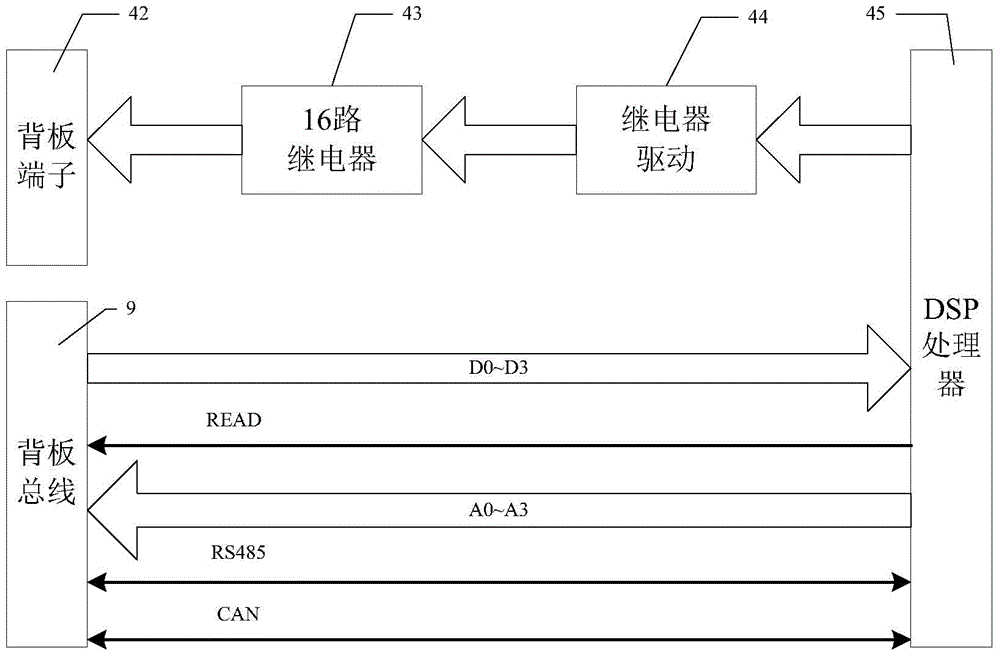

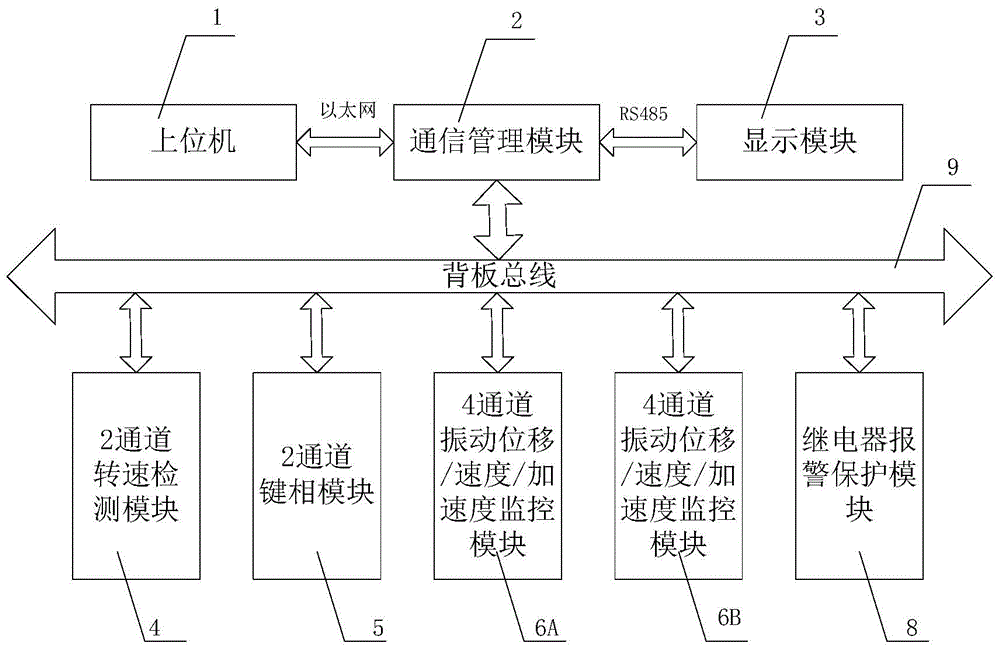

Intelligent online monitoring protection device

ActiveCN103914044AThe problem of few solutions and few monitoring parametersSolve the problem of low data transfer speedTotal factory controlProgramme total factory controlSignal onOriginal data

The invention provides an intelligent online monitoring protection device which comprises an upper computer, a display module, a communication management module, a rotation speed detection module, a key phase module, at least one vibration displacement / speed / acceleration monitoring module, a relay warning protection module and a communication back plate. A back plate bus is arranged on the communication back plate, the communication management module receives original data detected and transmitted by all the function modules and extracts characteristic data, concentrated storage and management are conducted, comparison judging is conducted on the characteristic data and a pre-set threshold range, and the threshold range reflects equipment operation data under the normal state of equipment. The relay warning protection module conducts warning through sound and / or optical signals on the basis of a judgment result of the characteristic data from the communication management module. The intelligent online monitoring protection device is wide in application range, high in data transmission speed, comprehensive in monitoring parameter and good in monitoring real-time performance, multiple channels are provided, the performance of a processor is high and a fault diagnosing function is achieved.

Owner:NANJING NORTH OPTICAL ELECTRONICS

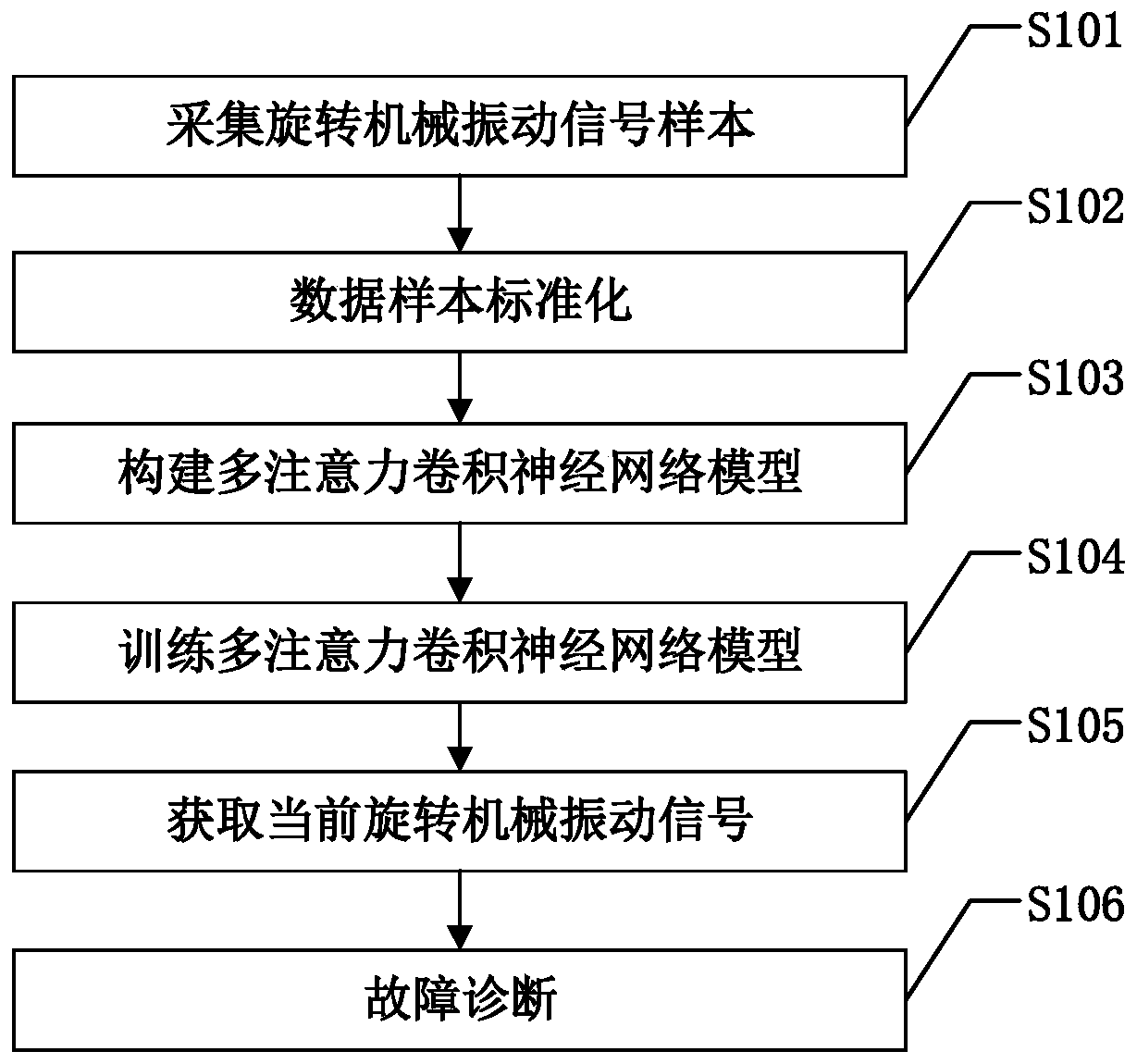

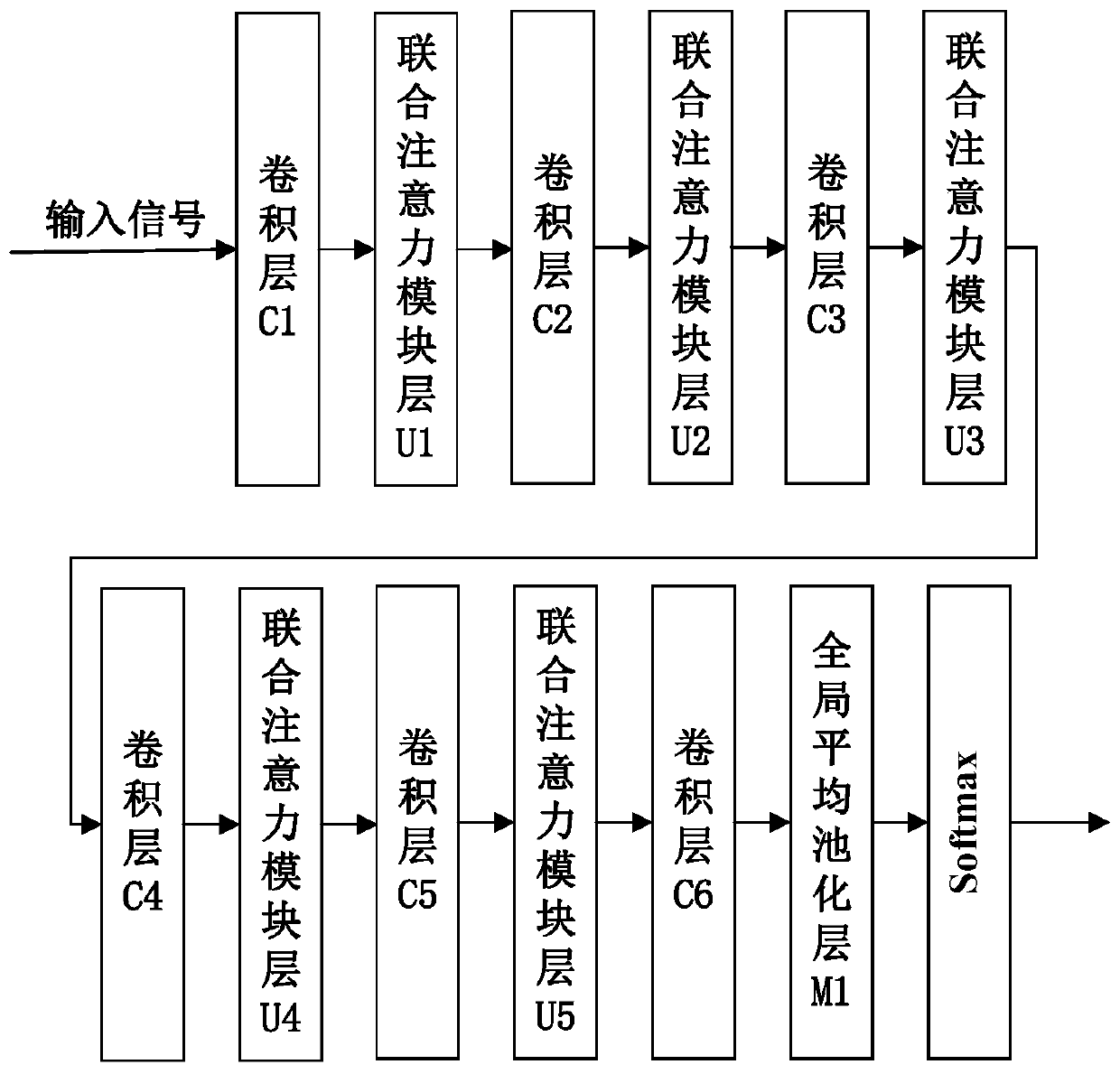

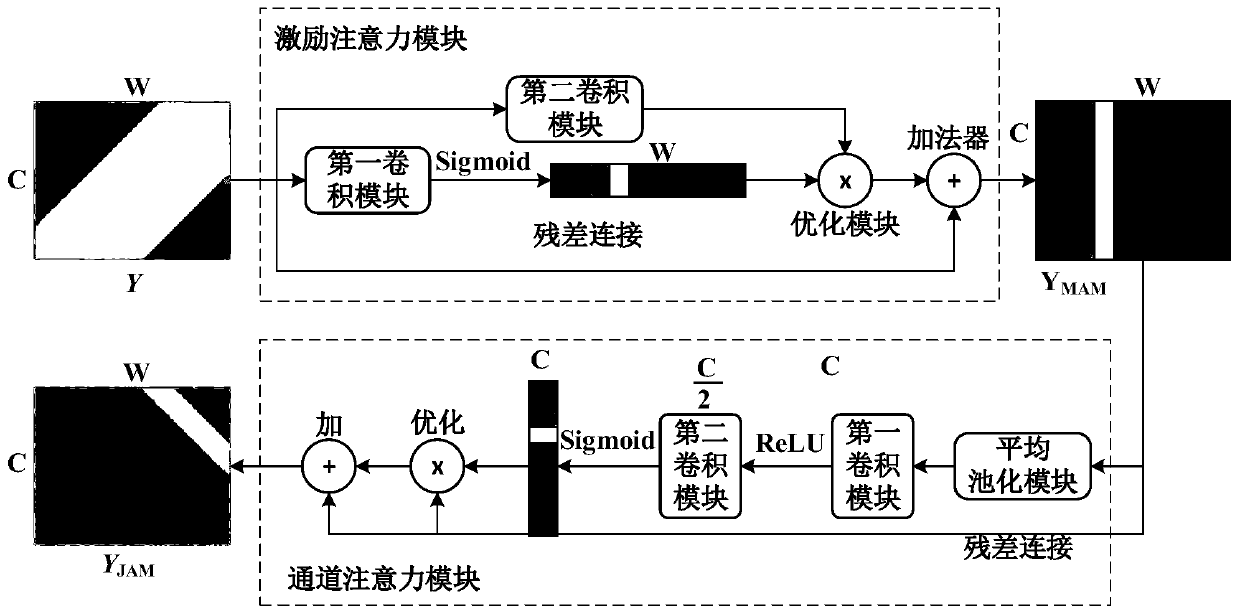

Rotating machinery fault diagnosis method based on multi-attention convolution neural network

ActiveCN110672343AEasy to learnSuppression of extraneous noiseStructural/machines measurementNeural architecturesAlgorithmNetwork on

The invention discloses a rotating machinery fault diagnosis method based on a multi-attention convolution neural network. Firstly, acceleration vibration signals of rotating machinery without faultsand with different faults under different operation states are collected, fault state labels are set according to the fault states corresponding to each acceleration vibration signal, standardizationprocessing is carried out on each acceleration vibration signal, a multi-attention convolution neural network model is trained as a training sample, the multi-attention convolution neural network model comprises six convolution layers, five combined attention modules, a global average pooling layer and a Softmax layer, and then current acceleration vibration signals of the rotating machinery are collected and sent to the multi-attention convolution neural network model for fault diagnosis. According to the method, the attention modules are introduced into the convolution neural network so as to enhance the learning of the network on distinguishing characteristics and the fault impact signal sections, irrelevant noise is restrained, and the fault diagnosis performance is improved.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

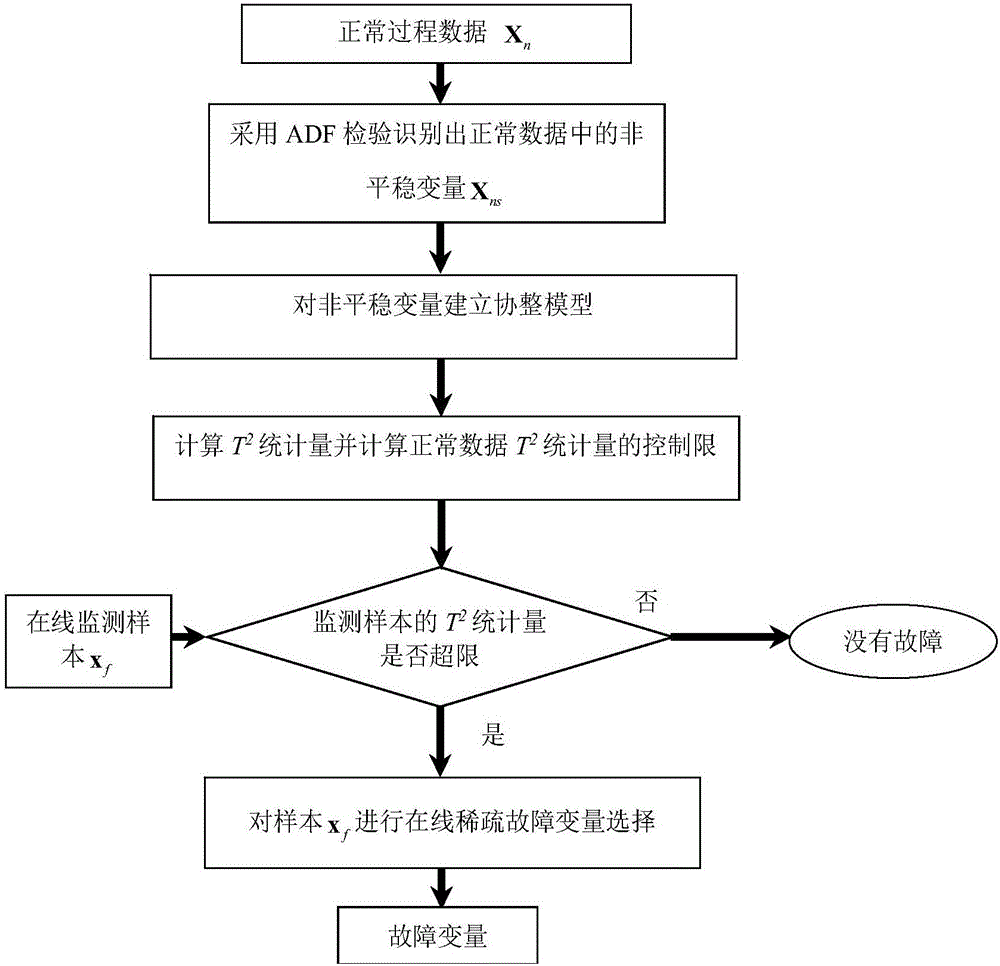

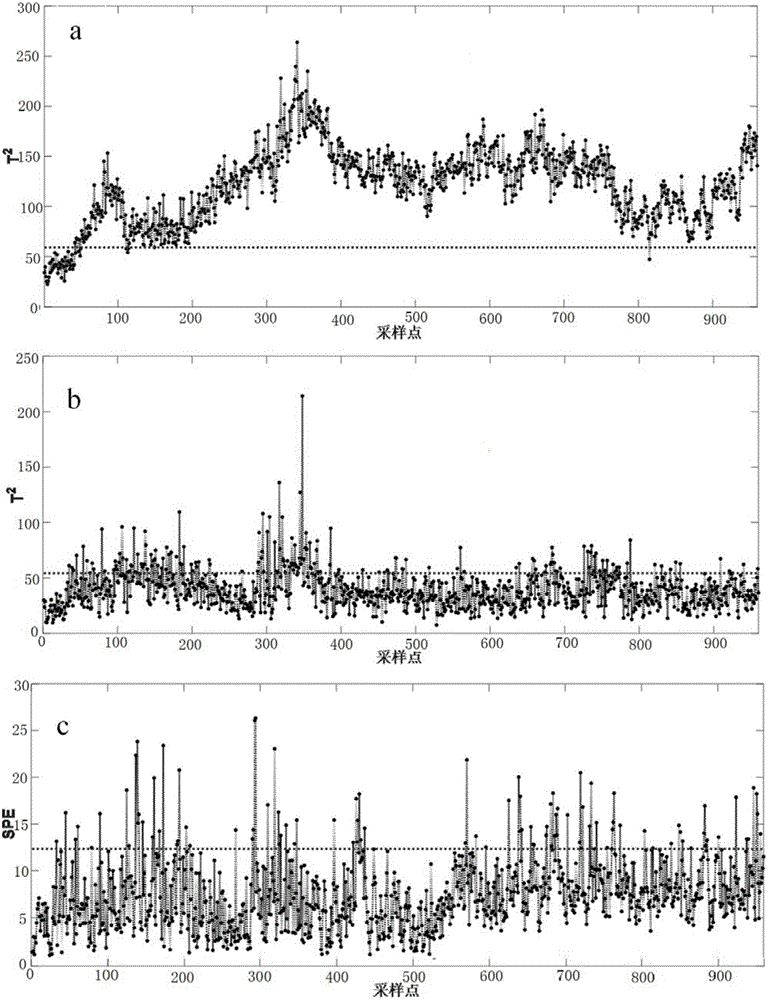

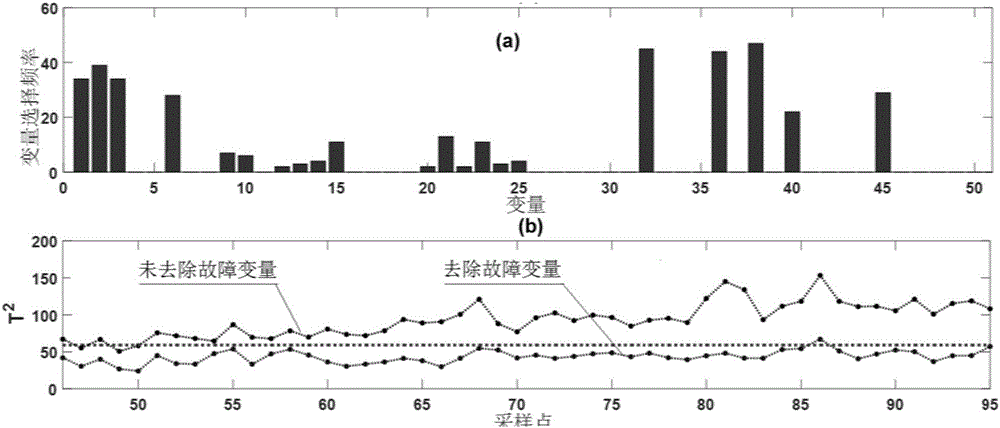

Fault detection method and fault diagnosis method for the non-stationary process of large coal-fired generator set

ActiveCN106680012AStrong non-stationary propertyOvercoming the disadvantages of non-stationary process handlingStructural/machines measurementDiagnosis methodsSite engineer

The invention discloses a fault detection method and fault diagnosis method for the non-stationary process of a large coal-fired generator set. The fault detection method and fault diagnosis method for the non-stationary process of a large coal-fired generator set integrate a co-integration analysis method with a sparse variable selection method for fault detection and on-line diagnosis, aiming at the classical non-stationary process of the large coal-fired generator set. The fault detection method and fault diagnosis method for the non-stationary process of a large coal-fired generator set can directly automatically isolate fault variables on line in real time, and do not need any historical fault information at the same time. The fault detection method and fault diagnosis method for the non-stationary process of a large coal-fired generator set effectively solve the problem of difficulty in fault detection and on-line diagnosis during the non-stationary process, thus greatly improving the performance of fault detection and on-line diagnosis during the non-stationary process, being conductive to accurate and quick repair of faults for a field engineer so as to guarantee safety of the large coal-fired generator set and improve the production benefit.

Owner:ZHEJIANG UNIV

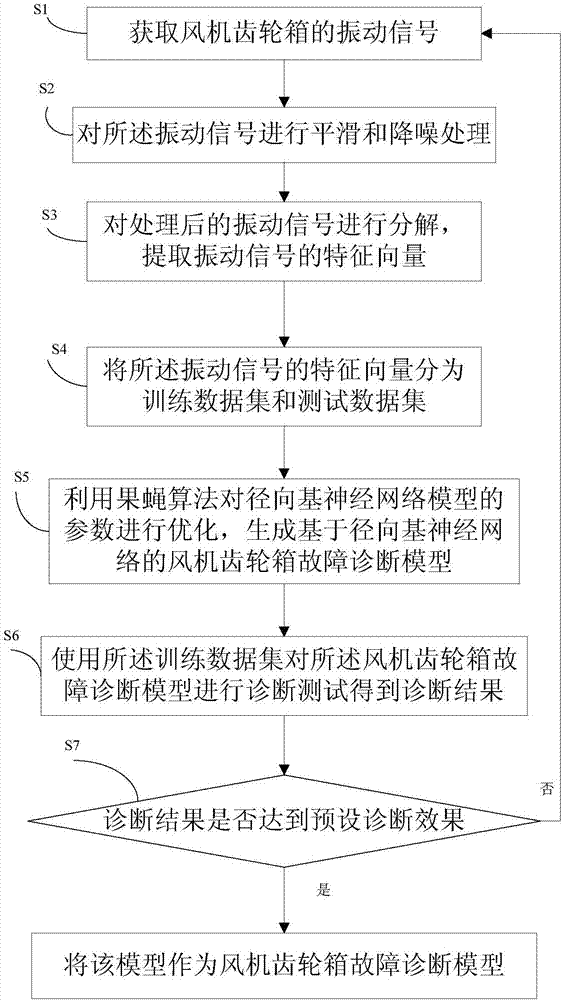

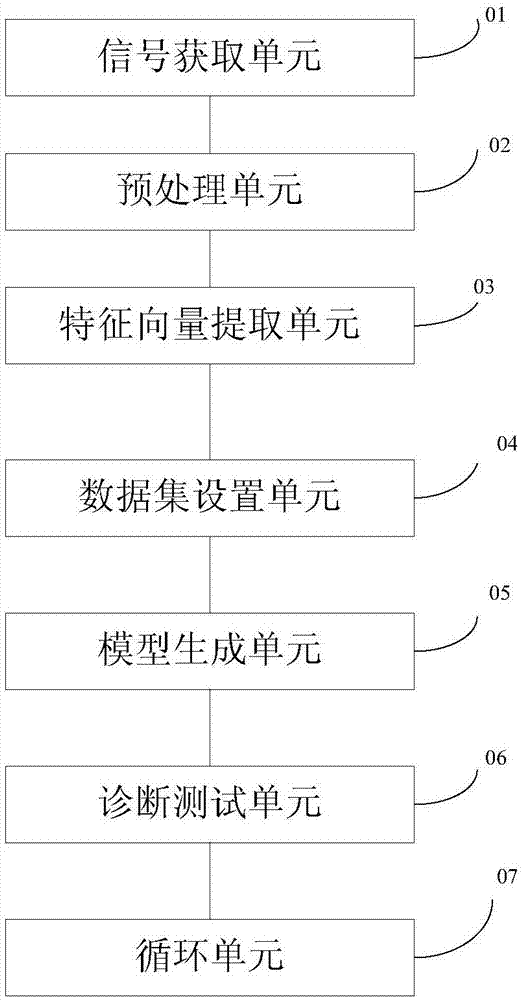

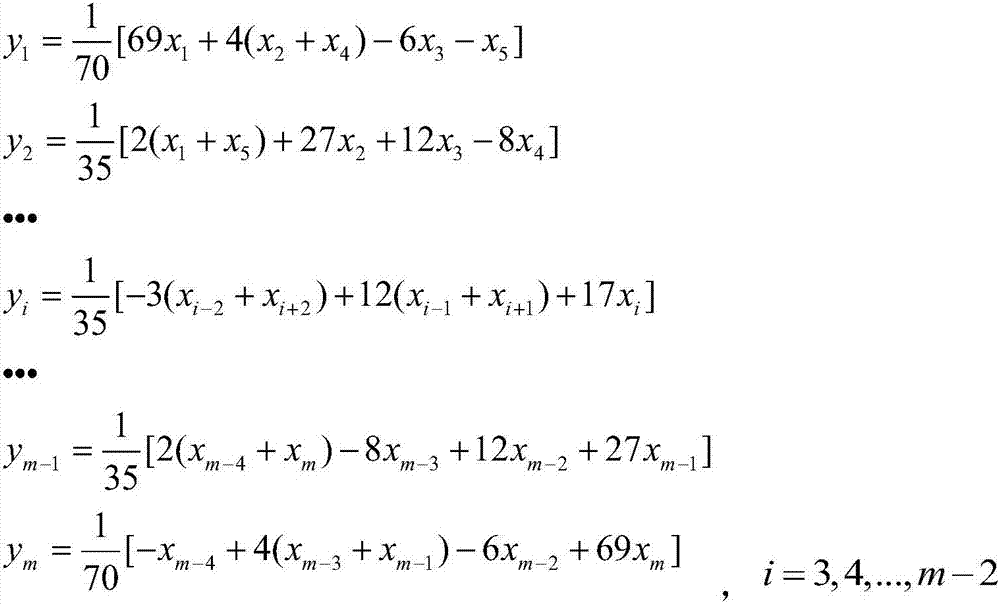

Fan gear box fault diagnosis model establishing method and device

InactiveCN106932196AImprove fault diagnosis abilityImprove accuracyMachine gearing/transmission testingNeural learning methodsFeature vectorData set

The invention provides a fan gear box fault diagnosis model establishing method used for establishing a fan gear box fault diagnosis model. The method comprises a step of obtaining a vibration signal of a fan gear box and then carrying out smoothing and denoising processing on the vibration signal, a step of decomposing the processed vibration signal and extracting the characteristic vector of the vibration signal, a step of dividing the characteristic vector of the vibration signal into a training data set and a testing data set, and a step of using a Drosophila algorithm to optimize a parameter of a radial basis function (RBF) neural network model, inputting the characteristic vector of the vibration signal in the training data set to obtain the optimal value of the parameter, generating the fan gear box fault diagnosis model based on a radial basis function neural network and carrying out test. In the scheme, the optimization algorithm is introduced for the characteristic of the RBF neural network, through introducing the artificial intelligence analysis technology, the extracted characteristic value is processed further, thus the efficiency of fault diagnosis is improved, and stop losses caused by faults are reduced.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

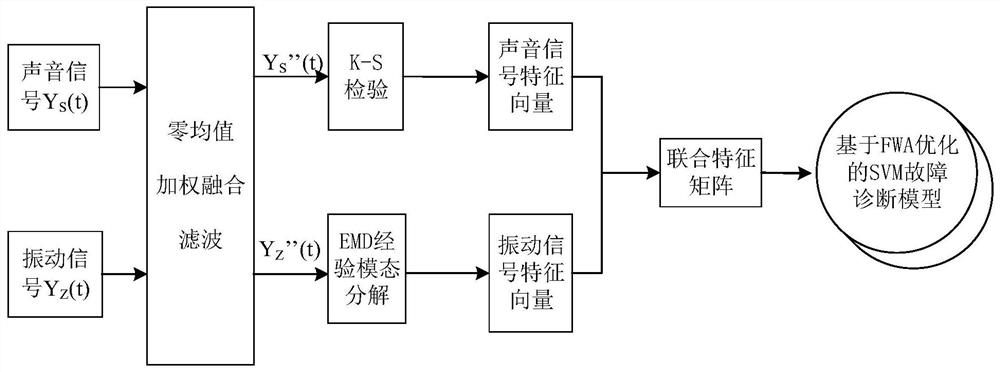

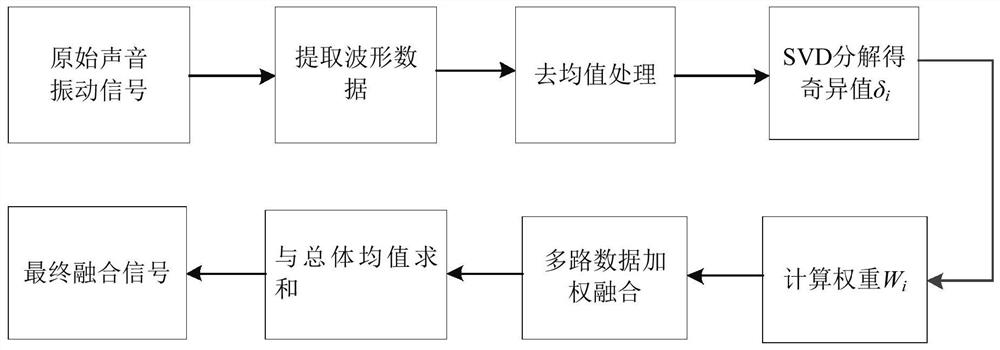

High-voltage circuit breaker fault diagnosis method based on multi-feature optimization fusion

PendingCN112255538ACancel noiseSmall amount of calculationCharacter and pattern recognitionCircuit interrupters testingFeature vectorNoise

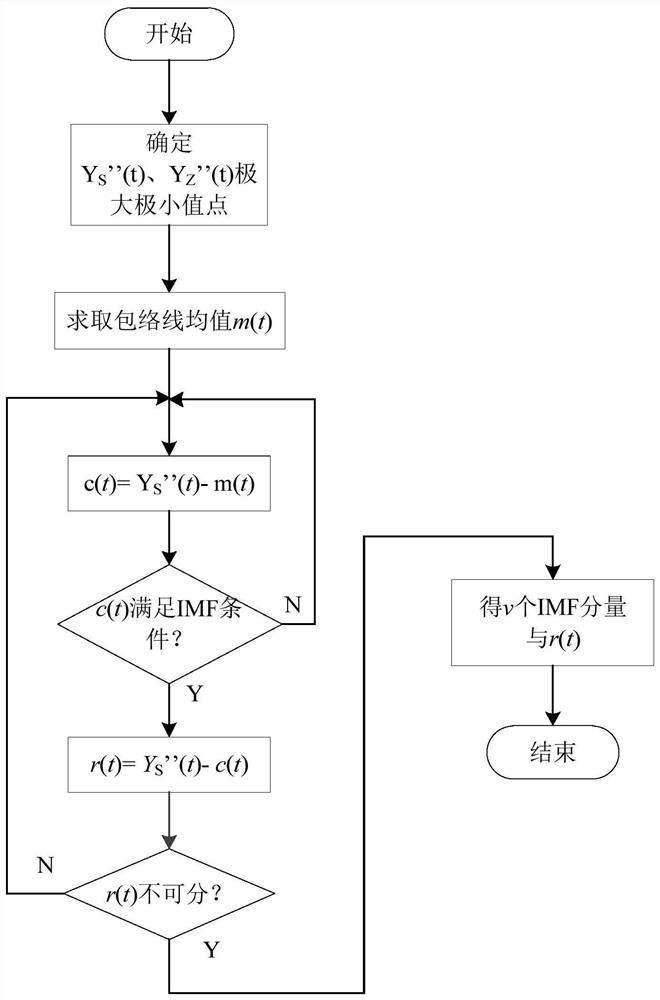

The invention discloses a high-voltage circuit breaker fault diagnosis method based on multi-feature optimization fusion. The method comprises the steps of: acquiring multiple groups of initial soundsignals YS(t) and vibration signals YZ(t) emitted in the switching-on and switching-off process of a circuit breaker; denoising, weighting and fusing each group of initial sound signals YS(t) and vibration signals YZ(t) to obtain a group of sound signals YS''(t) and vibration signals YZ''(t); extracting a feature vector of the sound signal YS''(t) by adopting a K-S test method; extracting a feature vector of the vibration signal YZ''(t) by adopting an EMD empirical mode decomposition method; fusing the feature vector of the sound signal YS''(t) and the feature vector of the vibration signal YZ''(t) into a feature matrix sample; selecting sample feature matrixes under various operation conditions of normal and fault states from the feature matrix samples in proportion; and inputting the selected sample feature matrixes to obtain a fault diagnosis result based on an FWA optimized SVM fault diagnosis model. According to the invention, through the concept of multi-sensor data fusion, the noise is effectively eliminated through weighted fusion of the data, so that the data is closer to a real value, and the fault diagnosis effect is effectively improved.

Owner:HAIXI POWER SUPPLY COMPANY OF STATE GRID QINGHAI ELECTRIC POWER +1

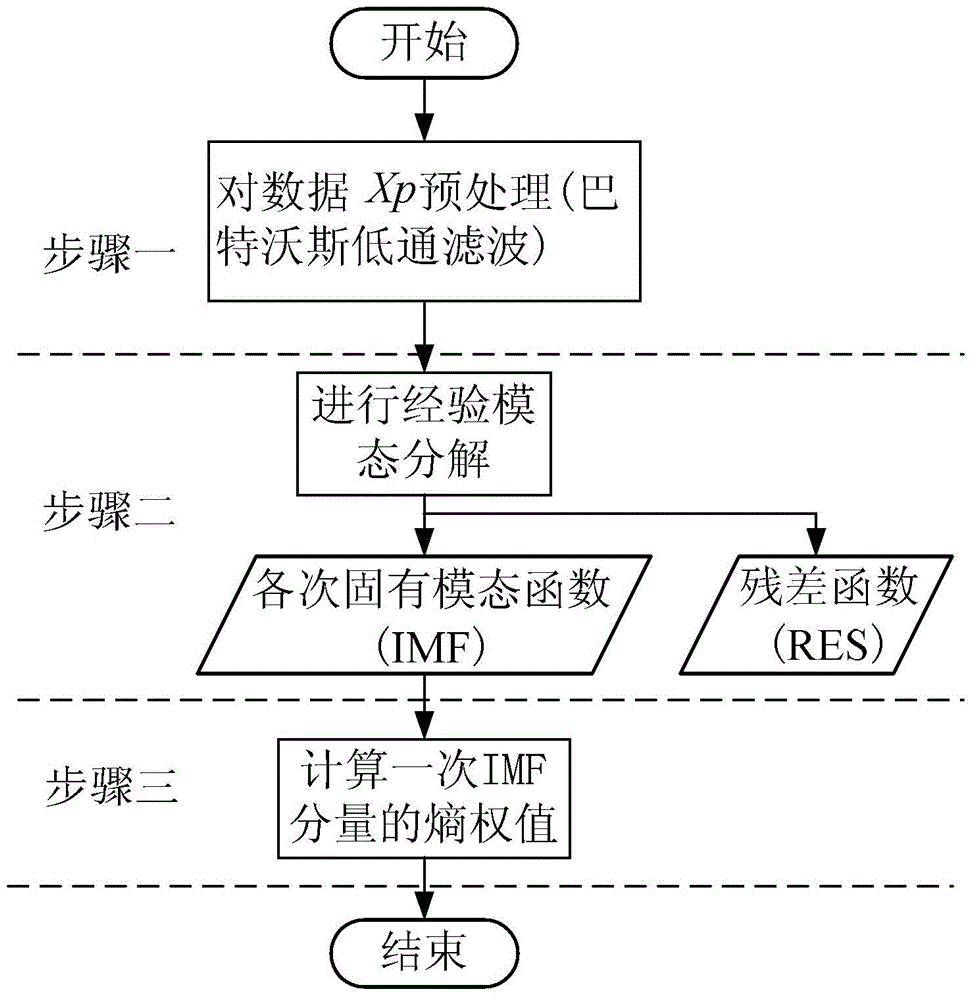

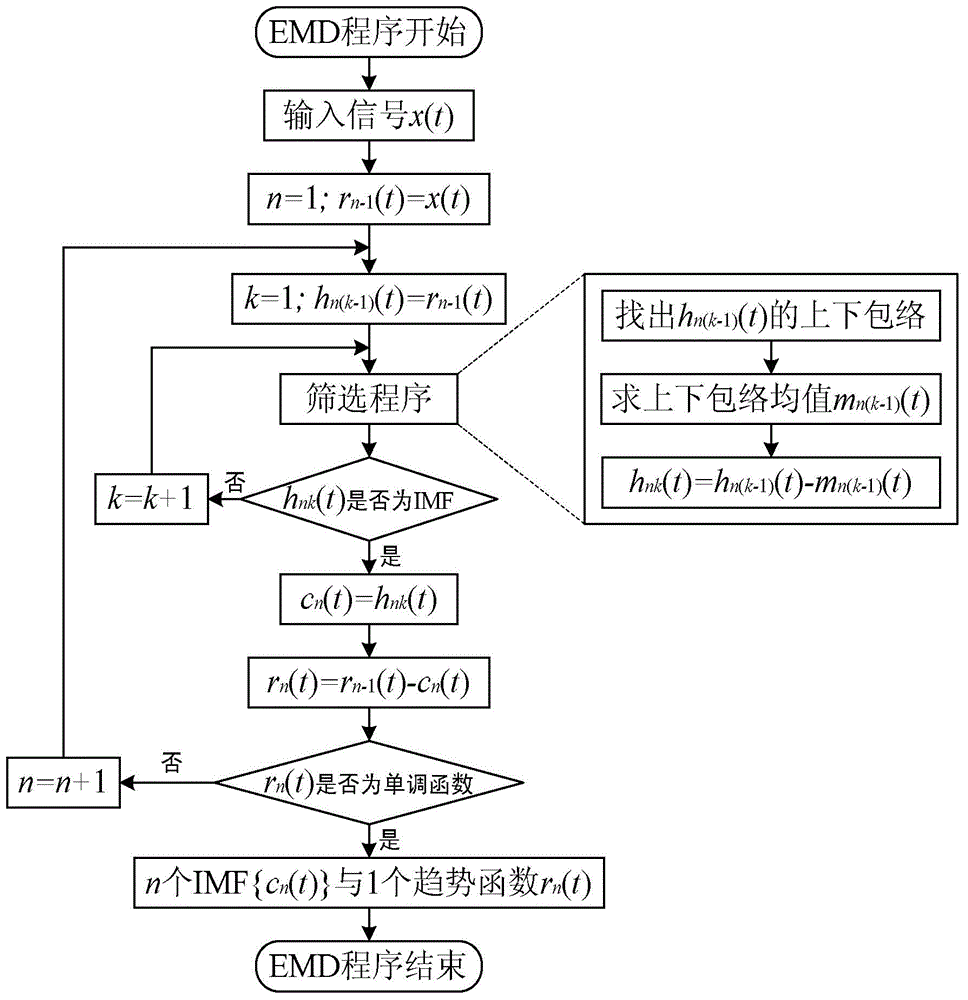

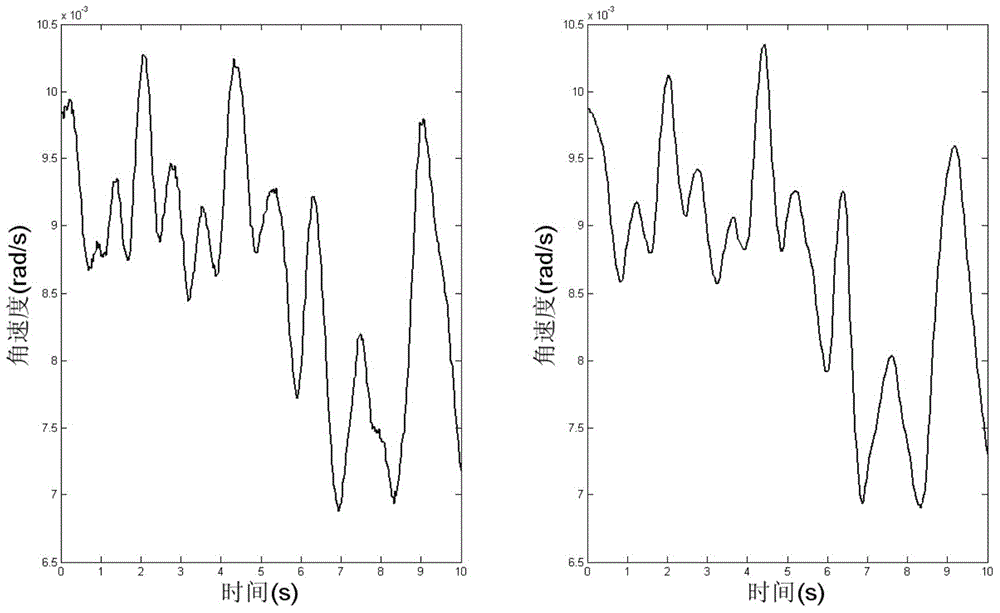

Gyroscope fault diagnosis method based on EMD (Empirical Mode Decomposition) and entropy weight

The invention provides a gyroscope fault diagnosis method based on EMD (Empirical Mode Decomposition) and entropy weight and relates to a gyroscope fault diagnosis method, belonging to the gyroscope fault diagnosis field. The method solves the problems that an existing gyroscope fault diagnosis method has limited practicability and effectiveness, the gyroscope running condition can not be well monitored, single signal fault detection self-adaptability is poor and the detection process is complex. The typical fault diagnosis method-EMD is introduced and is a single signal time domain processing method, that is, fault feature information is only extracted from an angular velocity signal of the gyroscope on one axis each time, and then fault diagnosis is achieved by creative use of the entropy weight concept, therefore, fault diagnosis can be achieved well, and finally, the effectiveness of the proposed method is subjected to simulation verification. The method is suitable for satellite gyroscope fault diagnosis.

Owner:HARBIN INST OF TECH

Bearing fault diagnosis method and system based on multi-scale information fusion

ActiveCN111275007AImprove accuracyImprove fault diagnosis abilityMachine bearings testingCharacter and pattern recognitionNetwork structureBearing vibration

The invention discloses a bearing fault diagnosis method and system based on multi-scale information fusion. The method comprises the steps that a vibration signal and a torque signal of a bearing tobe subjected to fault diagnosis are acquired; fourier transform is carried out on the obtained vibration signal and torque signal of the bearing subjected to fault diagnosis; and inputting the vibration signal and the torque signal of the bearing subjected to fault diagnosis obtained after Fourier transform into the multi-scale information fusion fault diagnosis model, and outputting the fault type of the bearing to be subjected to fault diagnosis. The network structure provided by the invention can effectively extract complementary fault features in the bearing vibration signal and the torquesignal, and improves the accuracy of fault diagnosis to a great extent.

Owner:SHANDONG UNIV

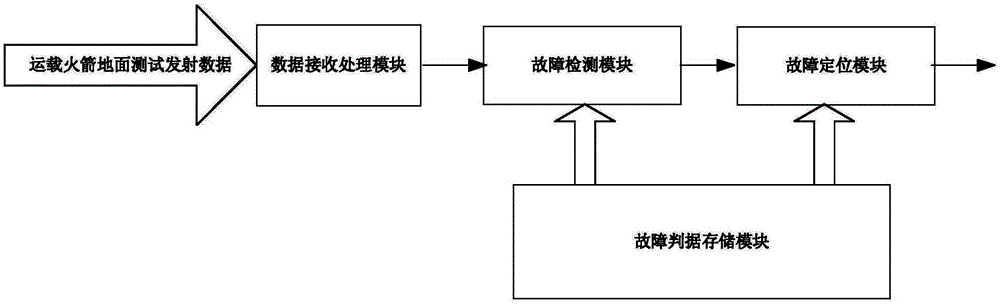

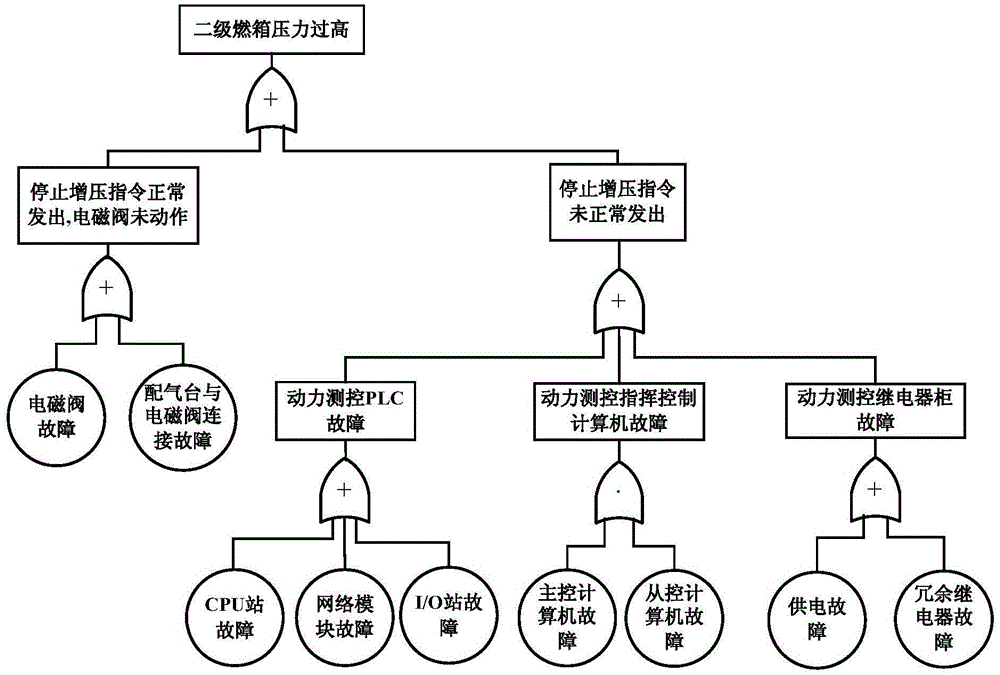

Multi-strategy fault diagnosis system for carrier rocket test launching process

ActiveCN105486526AImplement common servicesReduce development costsStructural/machines measurementUniversal serviceMathematical model

The invention provides a multi-strategy fault diagnosis system for the carrier rocket test launching process. The multi-strategy fault diagnosis system comprises a data reception and processing module, a fault detection module, a fault locating module, a rule algorithm plug-in, a fault tree algorithm plug-in, a mathematic model algorithm plug-in and a fault criteria storage module. A general carrier rocket fault diagnosis and reasoning framework is established to enable object information and diagnosis strategy to be separated, thereby realizing universal service between data acquisition, data processing and fault diagnosis, providing general basis for concrete applications of different diagnosis and reasoning methods and improving system diagnosis capability.

Owner:BEIJING INST OF ASTRONAUTICAL SYST ENG +1

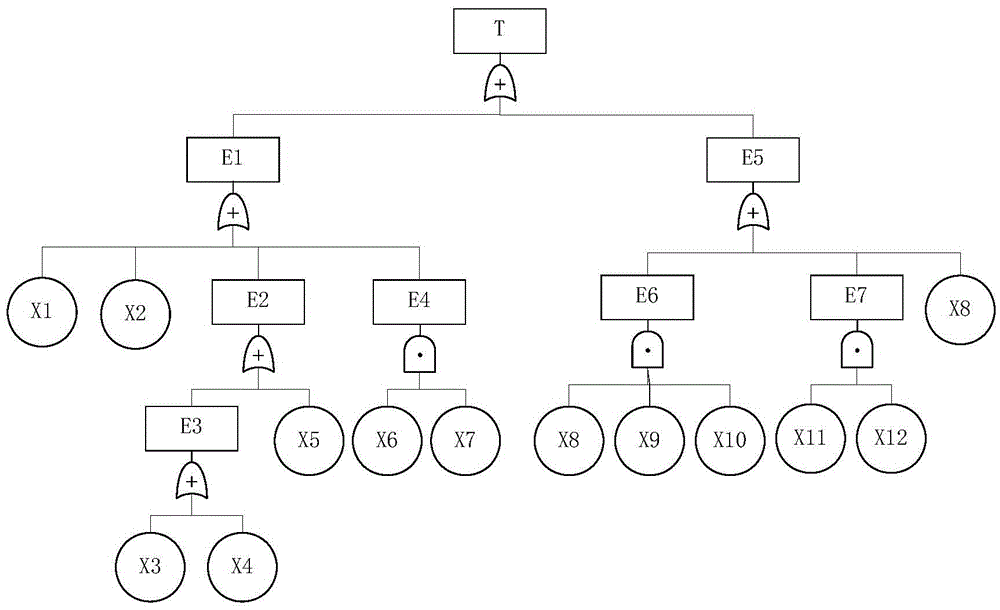

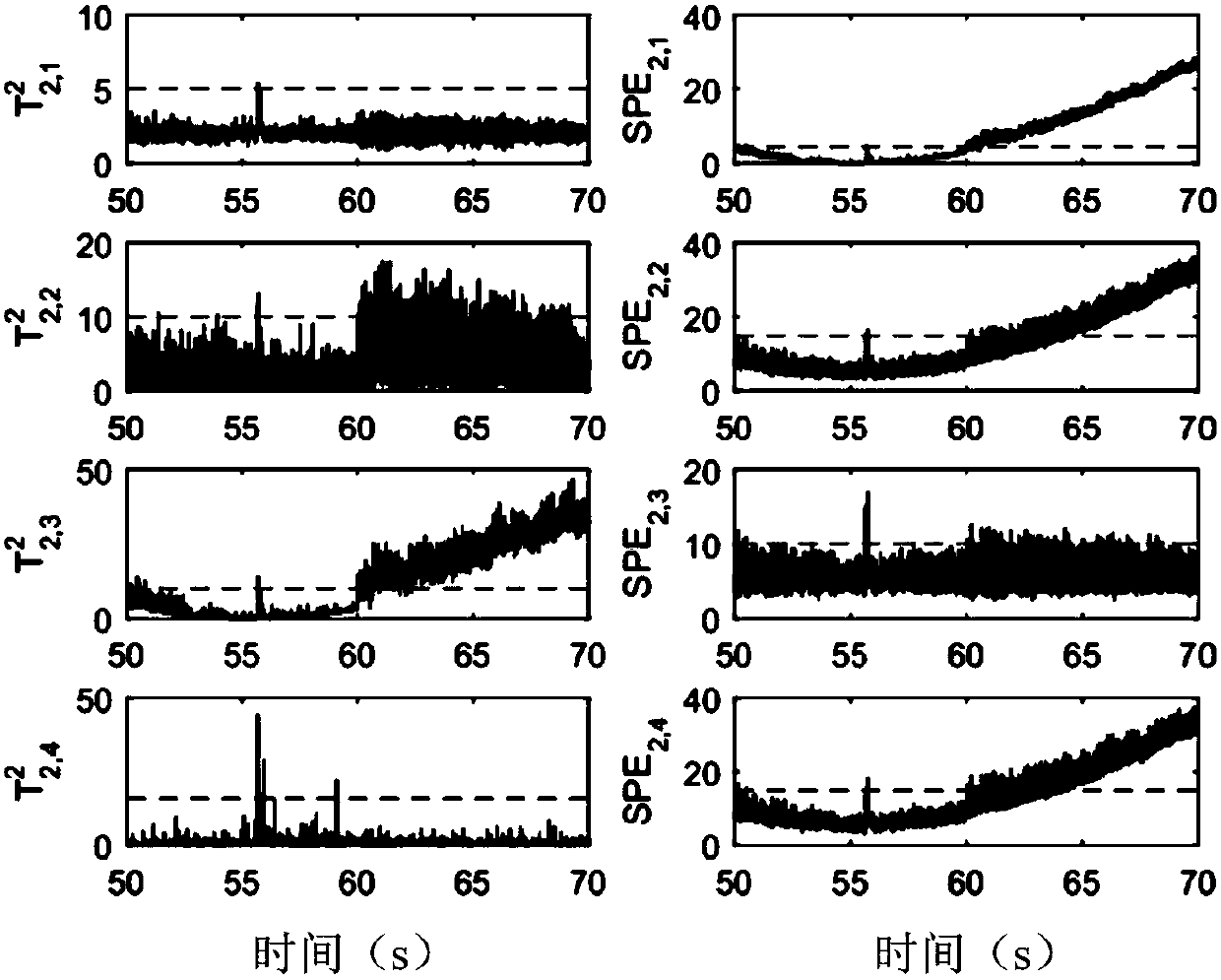

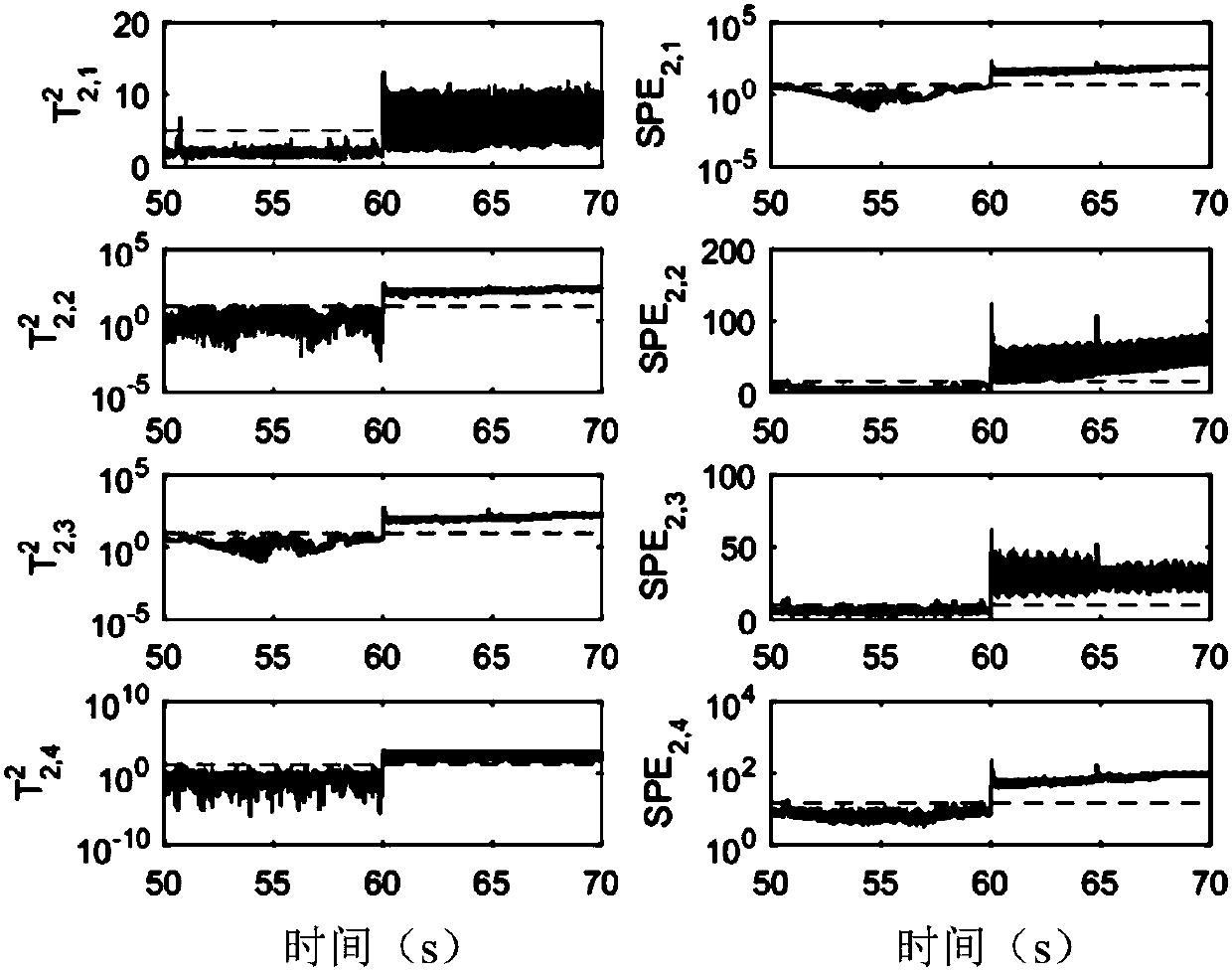

System design method for minor fault detection and position of electrical traction system

ActiveCN108490923AMeet real-time requirementsEffective Early Failure DetectionProgramme controlElectric testing/monitoringSystems designPerformance index

The invention discloses a system design method for minor fault detection and position of an electrical traction system. The method comprises the following steps: 1) establishing an off-line data model: collecting sensor steady-state operation data of the electrical traction system and carrying out pretreatment on the off-line data; calculating values of a principal component and a residual component in different layers of subspaces of the data obtained after pretreatment and a load vector; determining and calculating a performance index and a probability density function of a principle component analysis method and a fault detection threshold; and 2) on-line fault diagnosis: processing online data; calculating a performance index of the principal component and the residual component in different layers of subspaces; and through the obtained fault detection threshold, constructing a probability matrix and carrying out fault diagnosis through Bayesian reasoning. The method can carry outeffective multi-feature description on tiny signals of an electrical drive device before occurrence of a fault, and can also carry out real-time online fault diagnosis under the condition that the model and parameters of the electrical drive system are unknown.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

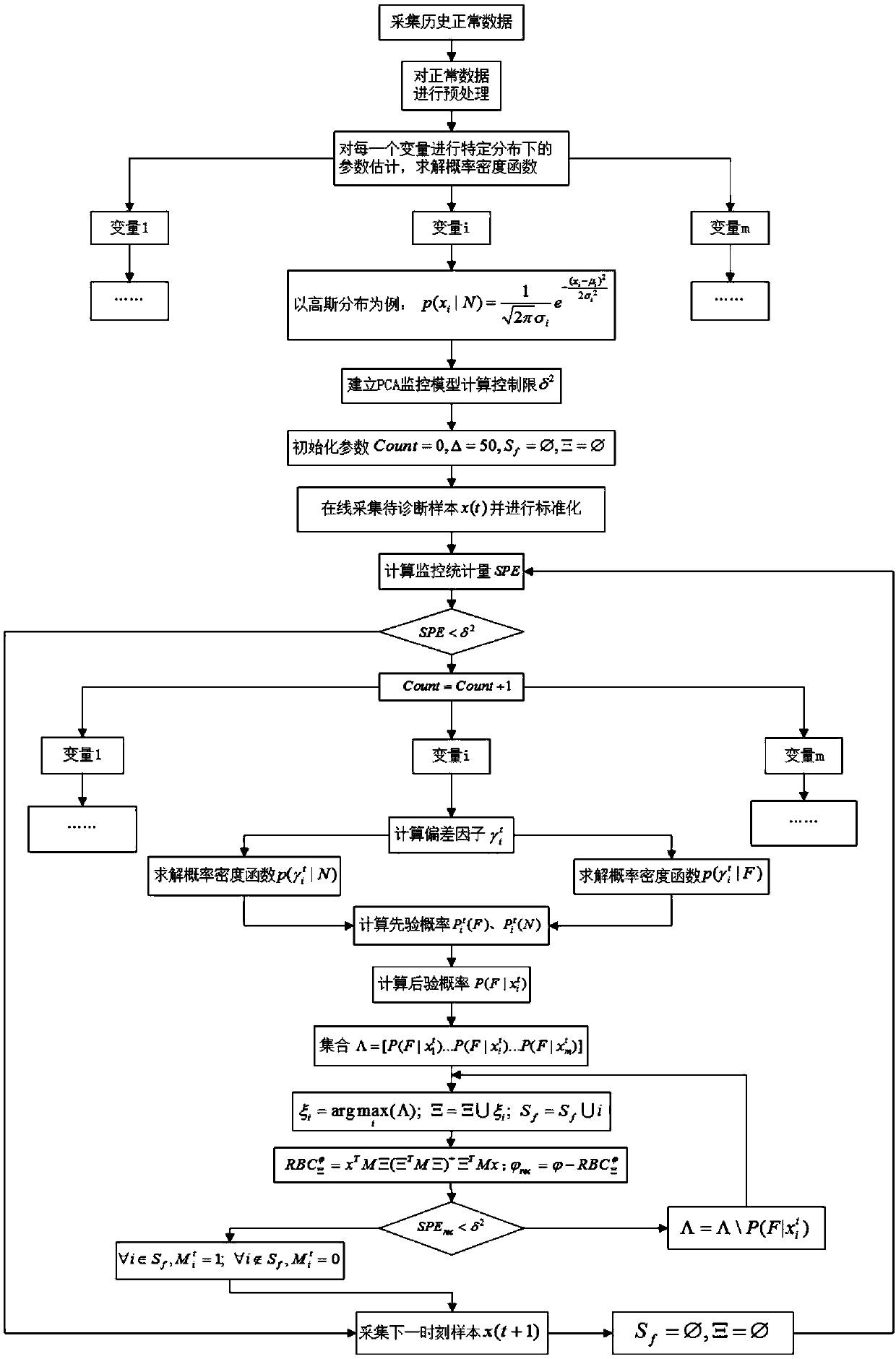

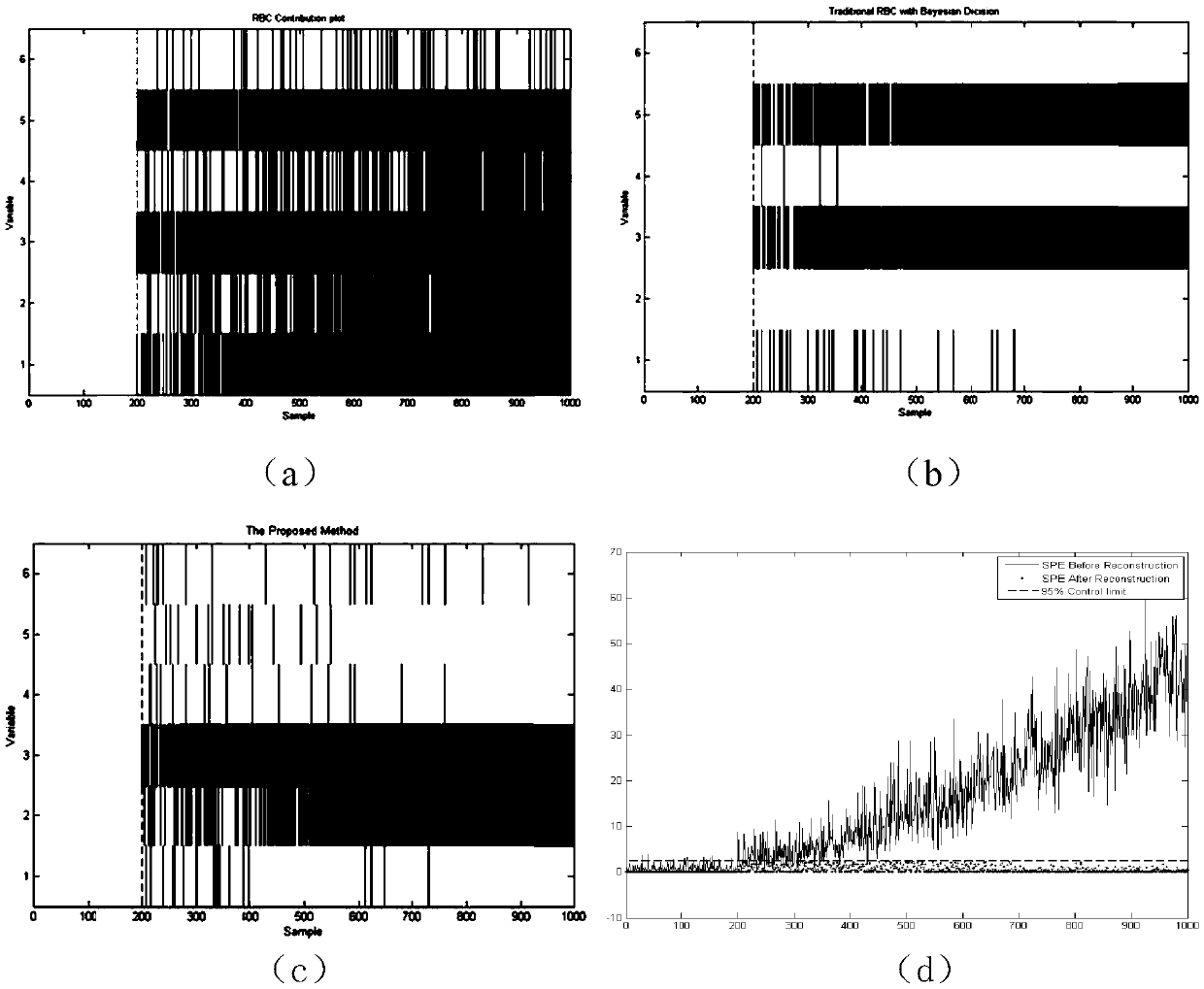

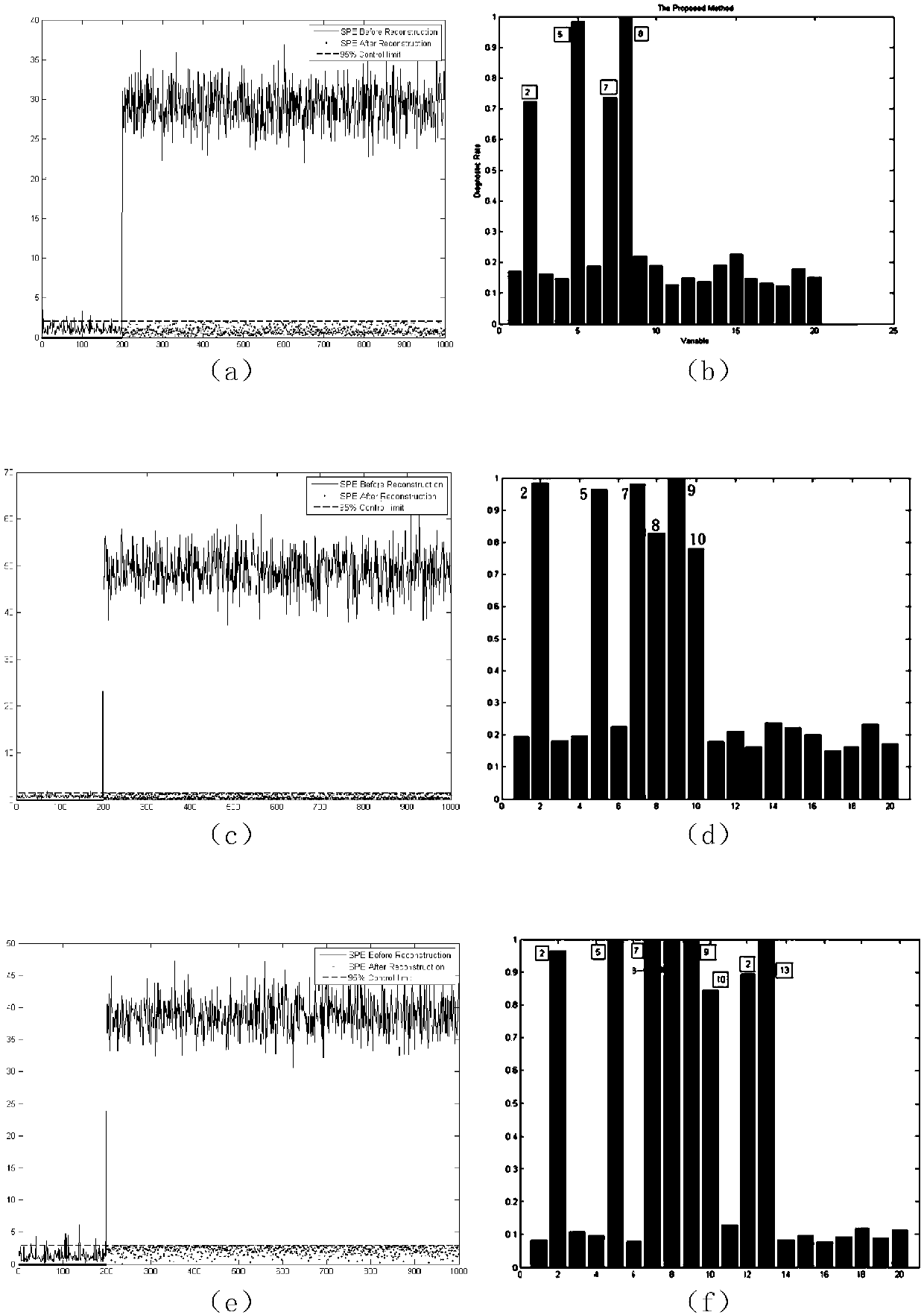

Industrial process fault diagnosis method for complex fault

ActiveCN109062189AImprove diagnosis rateImprove practicalityElectric testing/monitoringNormal densityNormal mode

The invention discloses an industrial process fault diagnosis method for a complex fault. The method comprises the steps of collecting sample data in a normal mode and building a fault monitoring model; solving parameters by using maximum likelihood estimation, thereby obtaining probability density functions of variables i; collecting a to-be-diagnosed sample and calculating a statistical quantity; when it is detected that the fault occurs, calculating deviation factors of the variables, and performing training to obtain conditional probability density functions of the deviation factors, thereby calculating out posterior probabilities; and selecting the variable with the highest posterior probability to perform multi-dimensional reconstruction, thereby finding out the fault variable. According to the method, the calculation amount is small, and the industrial process fault diagnosis can be accurately carried out under the complex fault. The method is remarkable for an industrial process result, and effectively aims at the complex fault problems of small faults, multi-variable simultaneous faults, excessively high variable dimension and the like.

Owner:HUAZHONG UNIV OF SCI & TECH

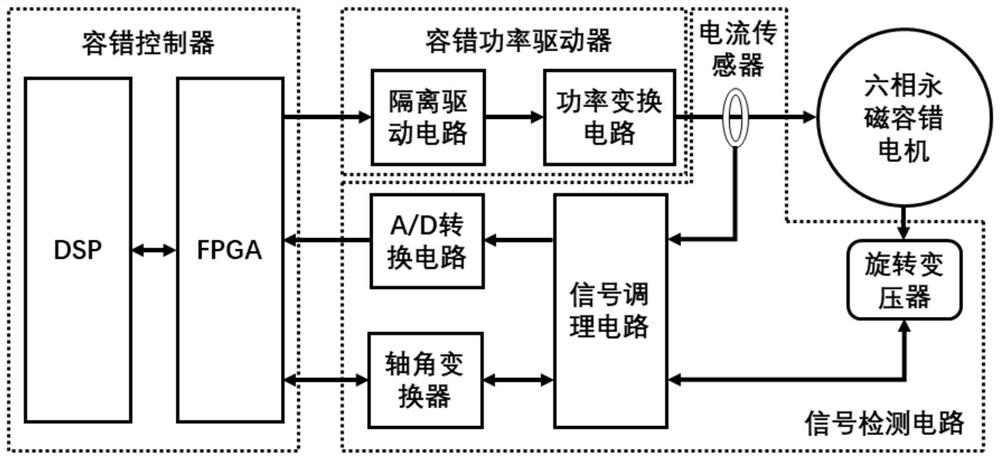

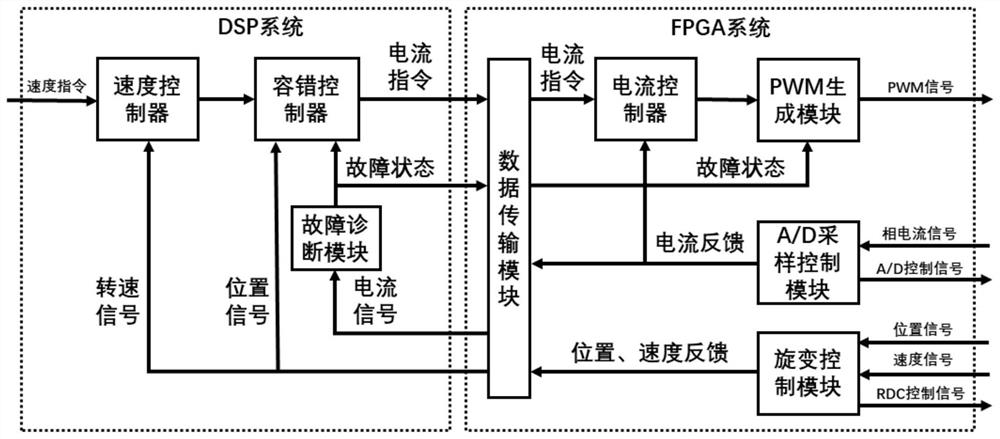

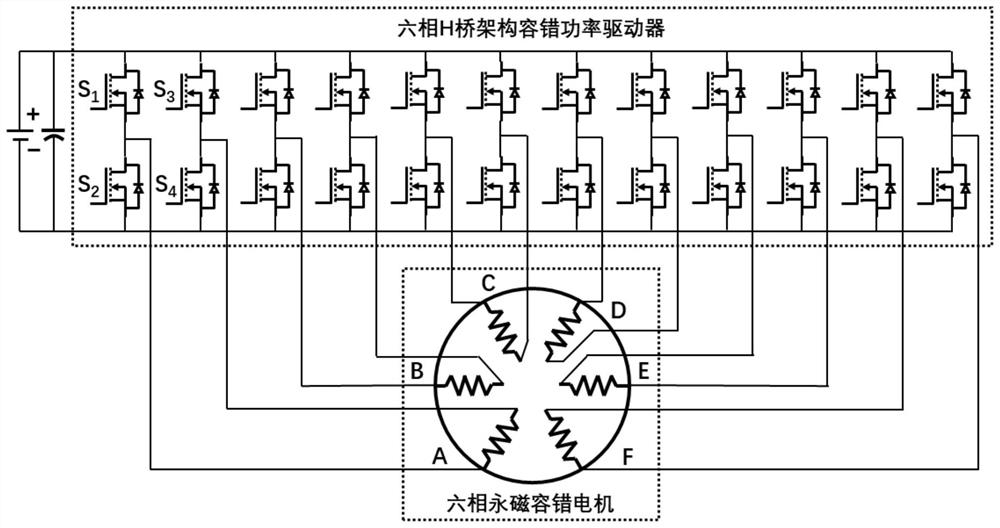

Six-phase permanent magnet fault-tolerant motor system power tube open-circuit fault diagnosis method

ActiveCN111830435ASimplify complexityAvoid misdiagnosisContinuity testingDynamo-electric machine testingPhase currentsControl engineering

The invention discloses a six-phase permanent magnet fault-tolerant motor system power tube open-circuit fault diagnosis method. The method comprises steps of conducting park vector transformation onthe six-phase current to obtain current vectors in two orthogonal subspaces; and calculating a current vector average value in a period, realizing open-circuit fault detection of the power tube by judging whether the current vector module value average value exceeds a fault threshold or not, and realizing positioning of the fault power tube according to positive and negative polarities of the current vector real part average value and the imaginary part average value. According to the method, additional hardware equipment does not need to be added, the utilization of the zero-sequence orthogonal subspace current vector ensures strong robustness of the fault diagnosis method to the rotating speed and the load sudden change. The fault location only needs to effectively simplify the operationaccording to the positive and negative polarities of the location variable, the method can simultaneously realize the power tube open-circuit fault diagnosis of the permanent magnet fault-tolerant motor system in normal and open-circuit / short-circuit fault-tolerant operation, and the fault diagnosis capability of the permanent magnet fault-tolerant motor system in the case of primary and secondary open-circuit faults is significantly improved.

Owner:BEIHANG UNIV

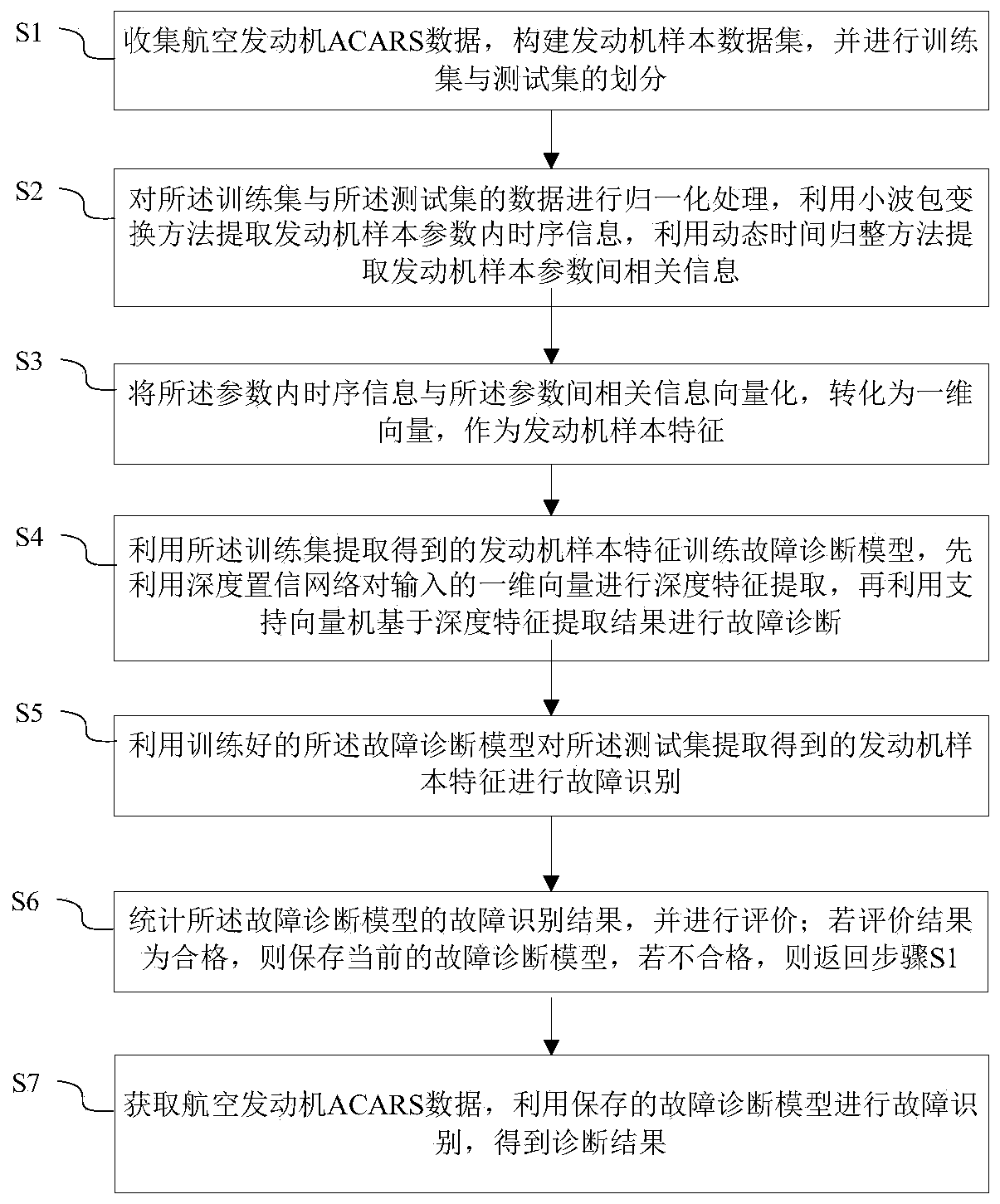

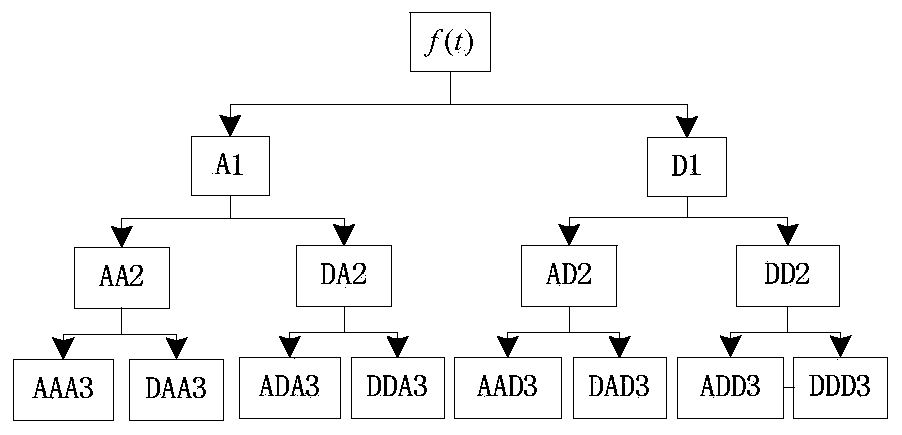

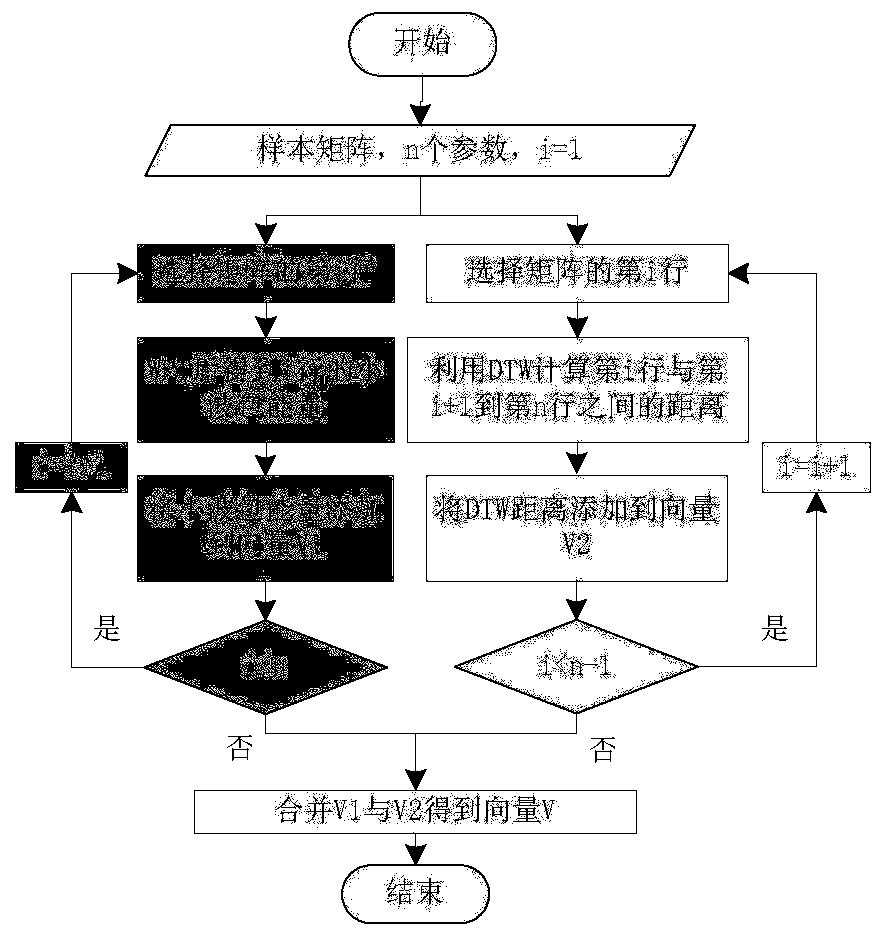

DBN-based multi-dimensional time sequence information driven aeroengine fault diagnosis method

InactiveCN110285976AImprove fault diagnosis abilityInternal-combustion engine testingHigh dimensionalMulti dimensional

The invention relates to a DBN-based multi-dimensional time sequence information driven aeroengine gas path fault diagnosis method which comprises the following steps: collecting aeroengine ACARS data; normalization processing, using the wavelet packet transform method to extract the time sequence information of the parameters and using the dynamic time integration method to extract the correlation information between the parameters; vectorizing the time sequence information in the parameters and the correlation information between the parameters and converting the information into one-dimensional vectors; training a fault diagnosis model, wherein the fault diagnosis model firstly extracts the depth features of the input one-dimensional vectors by using BBN and then diagnoses the fault based on the results of the depth feature extraction by using SVM; using the trained fault diagnosis model to identify the faults of the engine sample features extracted from the test set; performing statistics and evaluation on the fault identification result of the fault diagnosis model; and performing fault identification on the aeroengine ACARS data by using the stored fault diagnosis model so as to obtain the diagnosis result. This method can make full use of the multi-dimensional time sequence information of data and effectively process the high-dimensional features of the data.

Owner:HARBIN INST OF TECH AT WEIHAI

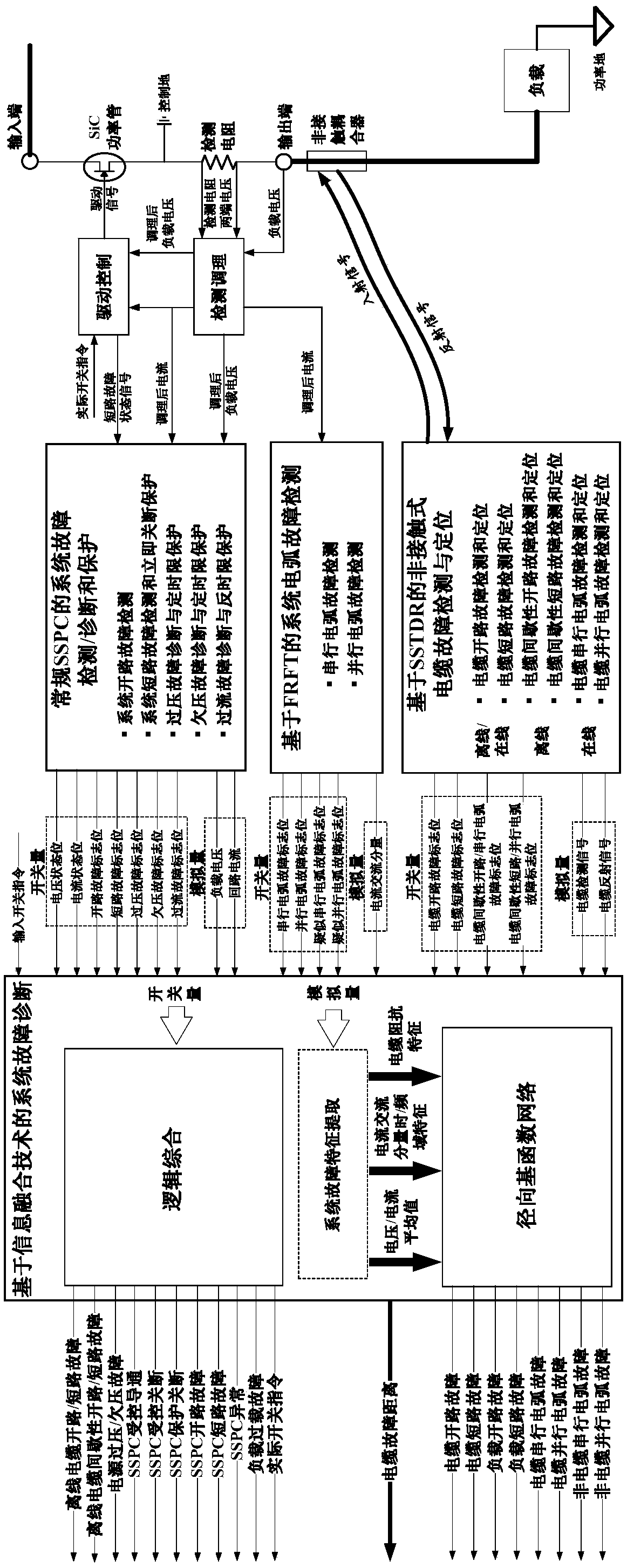

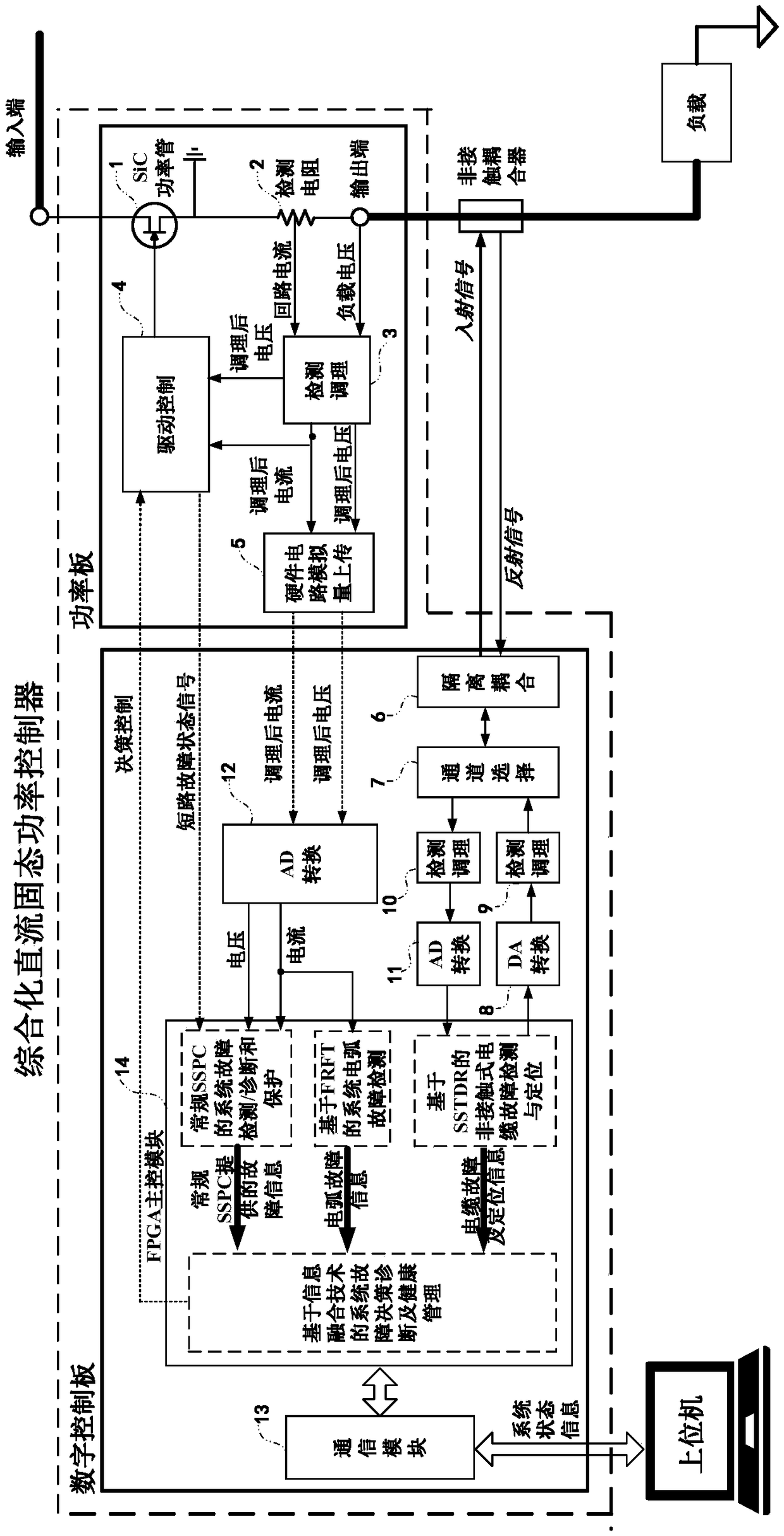

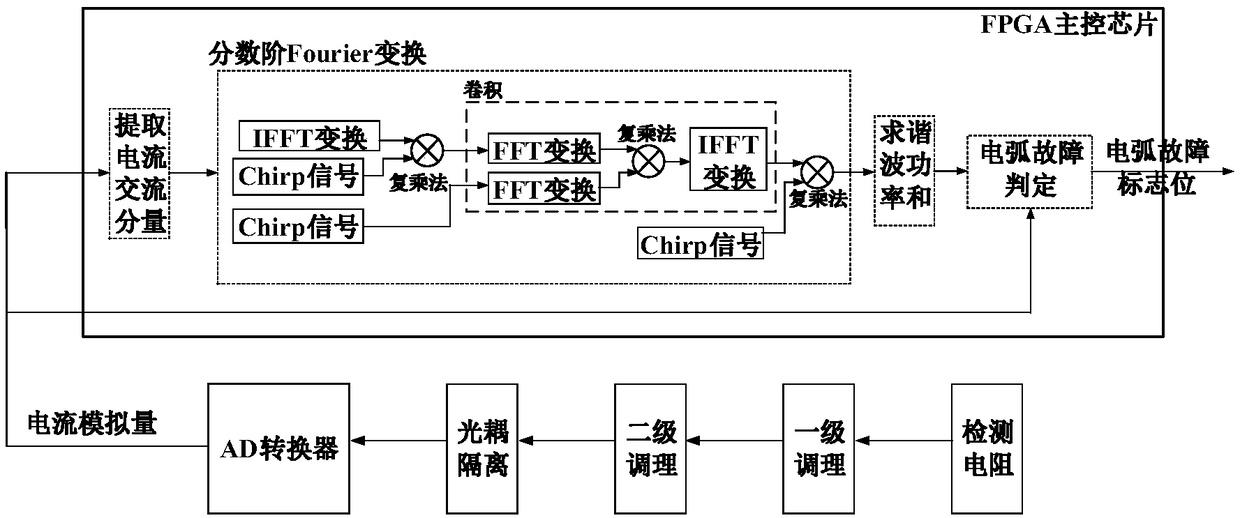

Integrated DC solid state power controller and fault decision-making diagnosis method

ActiveCN108803560AImprove detection rateSolve the problem of fault decision diagnosisElectric testing/monitoringOvervoltageTime lag

The invention discloses an integrated DC solid state power controller and a fault decision-making diagnosis method. The controller comprises a power board and a digital control board, wherein the power board is mainly responsible for system state detecting, conditioning, signal uploading and SSPC (Solid State Power Controller) driving and protection control; and the digital control board integrates related circuits for arc fault detection and cable fault detection and location, detects a conditioned system state signal based on multiple sensors, completes local fault diagnosis for the conventional SSPC such as fixed-time-lag power supply overvoltage-undervoltage fault protection, BIT self-checking of the SSPC, inverse-time-lag overload protection and additional local fault diagnosis such as system arc fault detection and cable fault detection and location in a concurrent manner in an FPGA main control module, and finally realizes decision-making diagnosis and health management for thesystem state based on a multi-source technology integration technology. The integrated DC solid state power controller can realize the enhanced system fault detection and health management ability, and improves the system safety, reliability, testability and maintenance.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

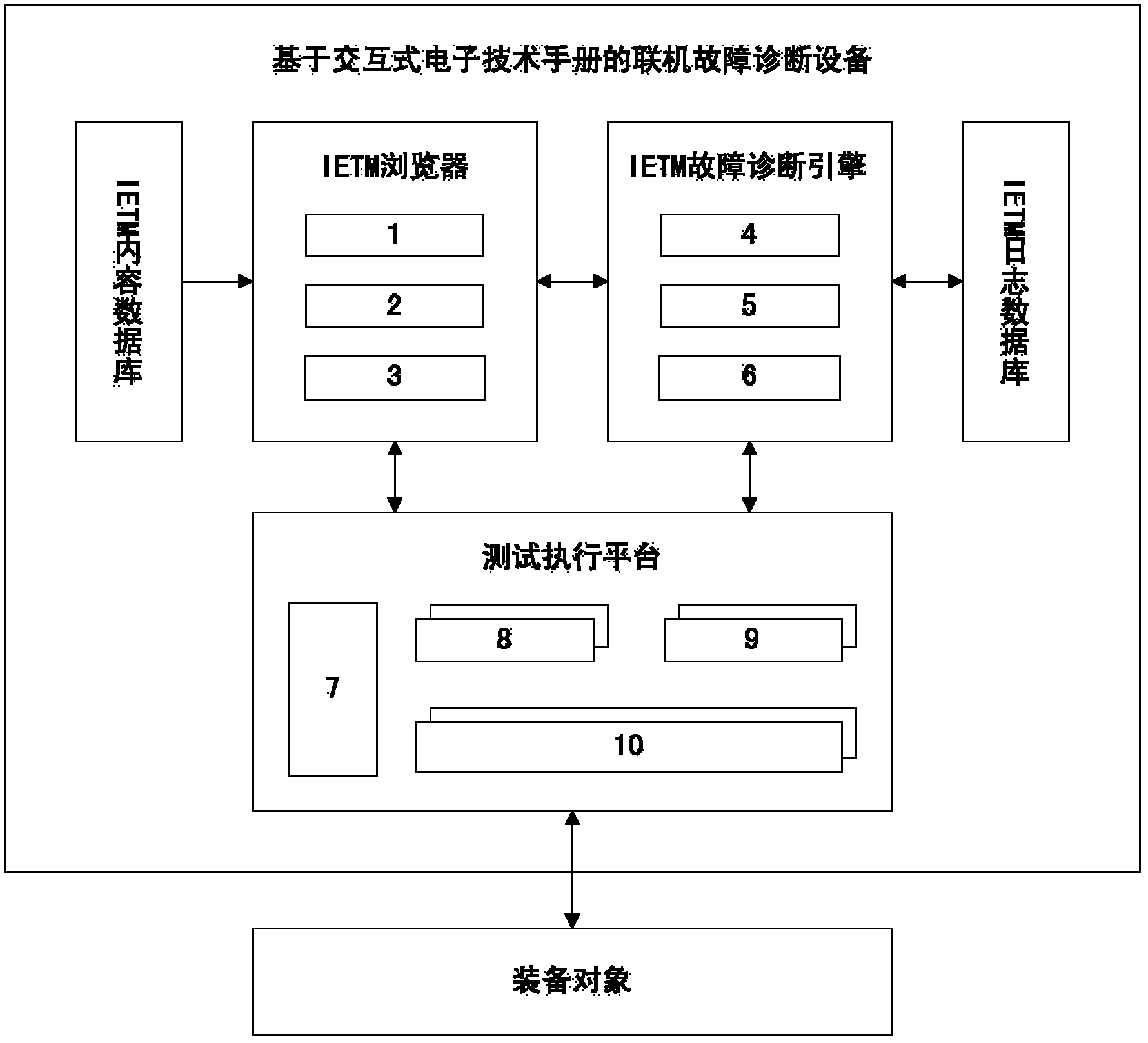

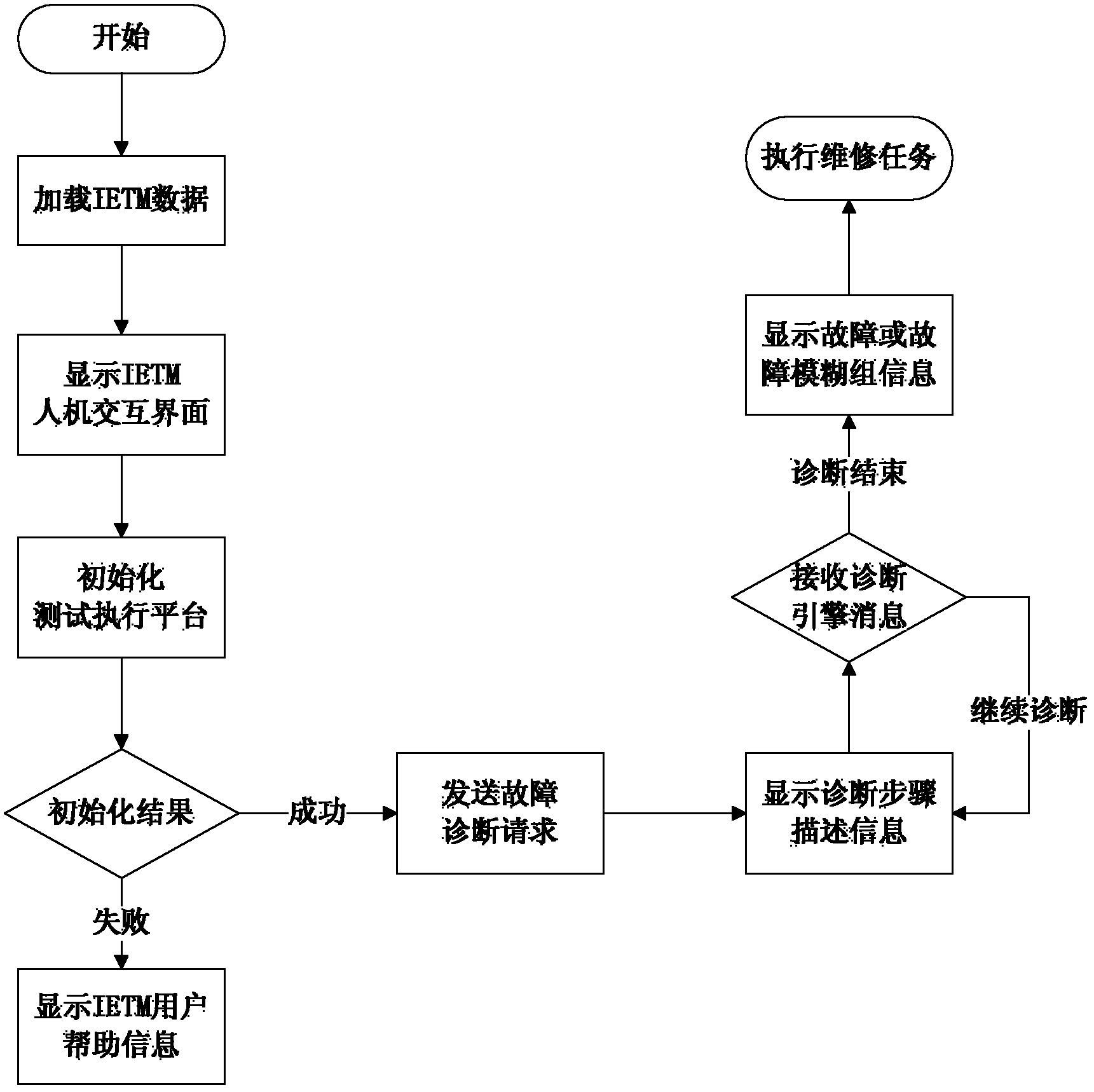

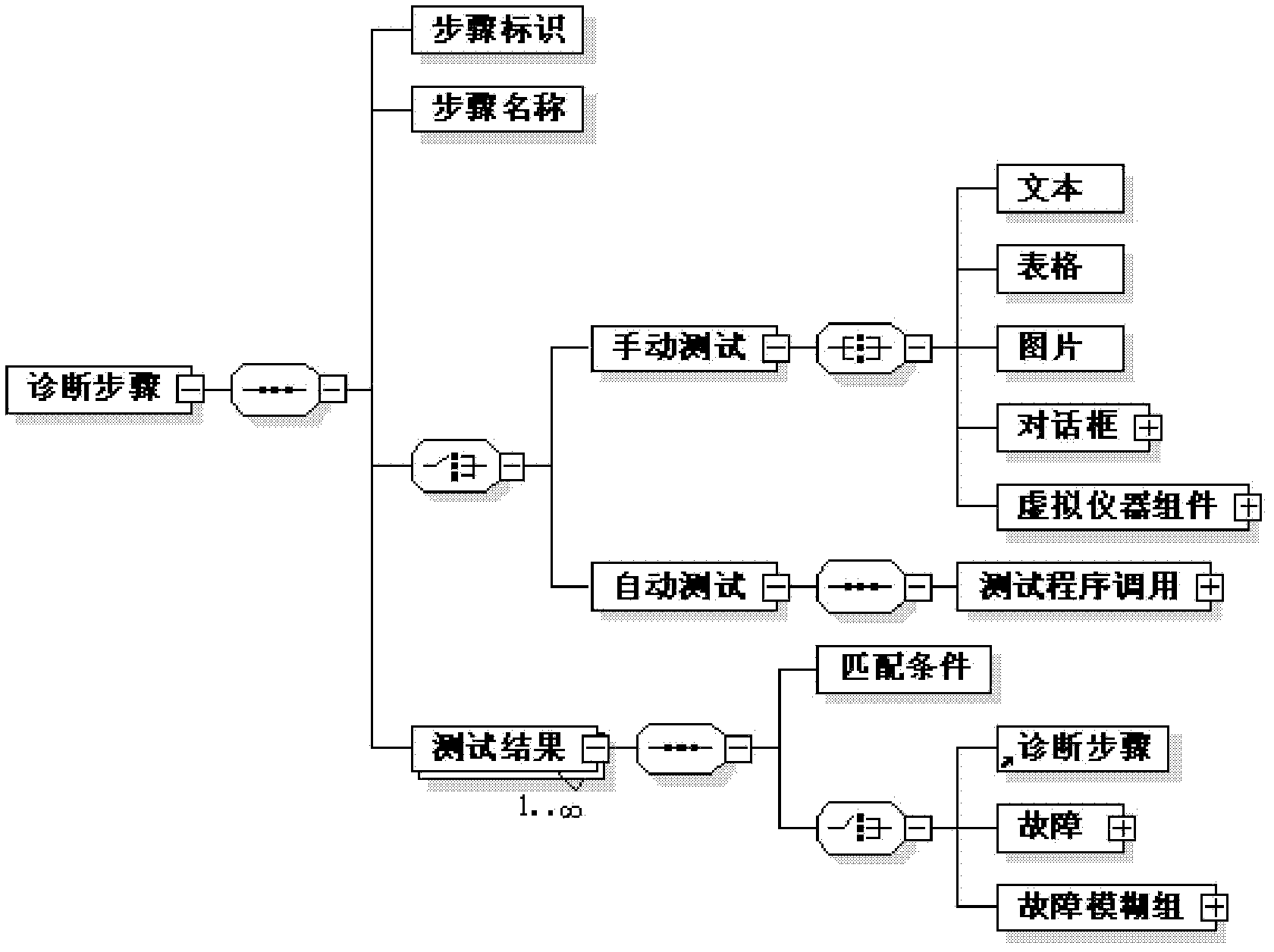

Interactive electronic technical manual-based online fault diagnosis equipment and online fault diagnosis method

ActiveCN102664748AImprove fault diagnosis abilityEasy to operateData switching networksDiagnosis methodsInteraction interface

The invention discloses interactive electronic technical manual (IETM)-based online fault diagnosis equipment and an online fault diagnosis method. The equipment comprises five parts: an IETM content database, an IETM browser, an IETM fault diagnosis engine, an IETM log database and a test execution platform. According to the invention, an IETM is used as a core and a humanized interaction interface of the IETM is utilized to encapsulate a complicated fault diagnosis process, so that it is easy for a user to use and operate; the fault diagnosis engine and a test execution platform are integrated in the IETM, thereby substantially improving the fault diagnosis capability of the IETM; the equipment has a good modularity characteristic, so that it is easy to carry out updating and replacement of the fault diagnosis engine and the test execution platform; and the diagnosis method enables process information of the fault diagnosis and test data to be completely recorded, so that it is beneficial to analyze a fault cause after the fault occurrence. Moreover, the equipment with good portability can be applied to various equipment maintenance working sites; and the equipment enables maintenance personnel to be effectively guided to remove faults, thereby improving equipment maintenance working efficiency.

Owner:NAT UNIV OF DEFENSE TECH

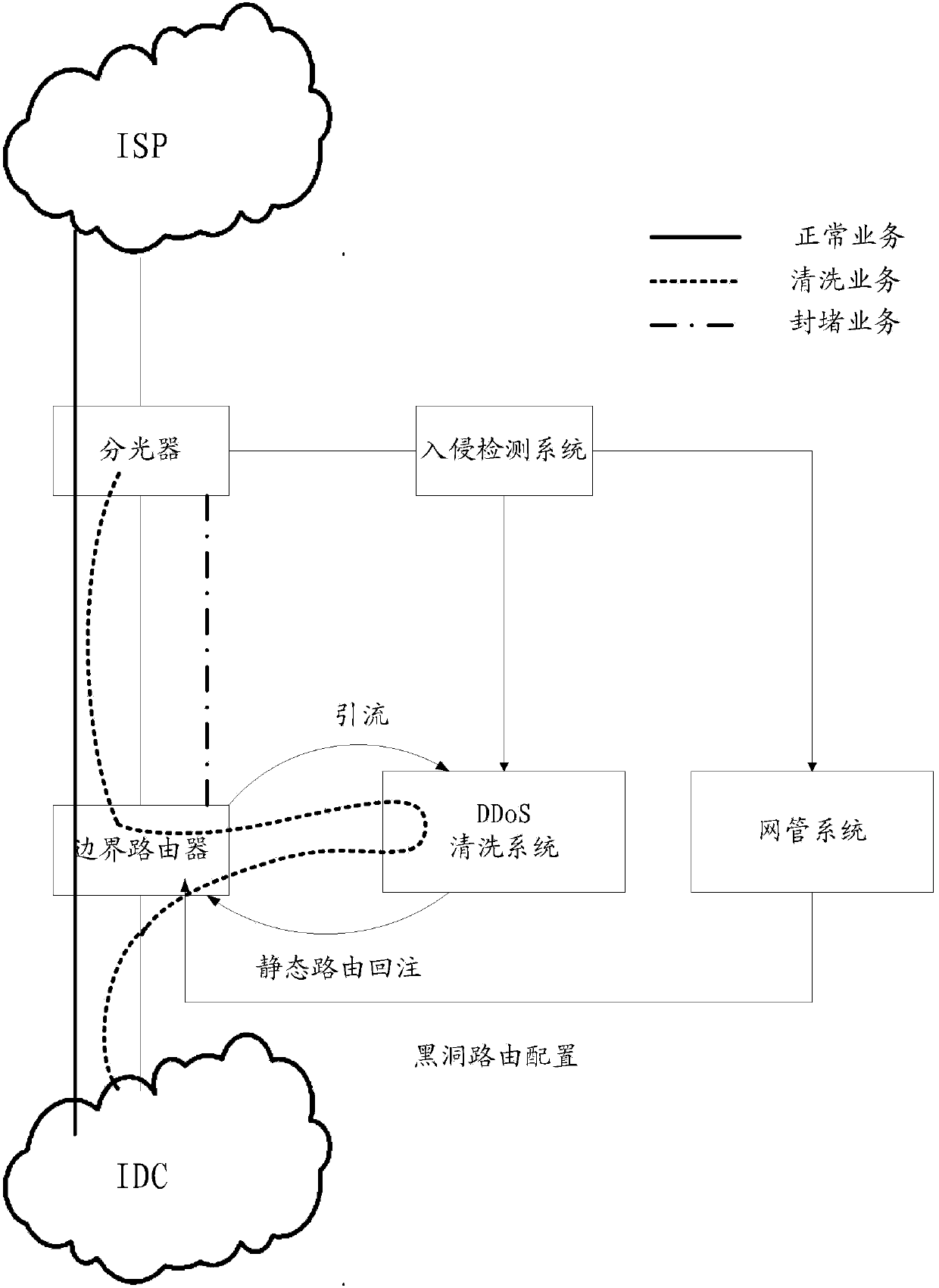

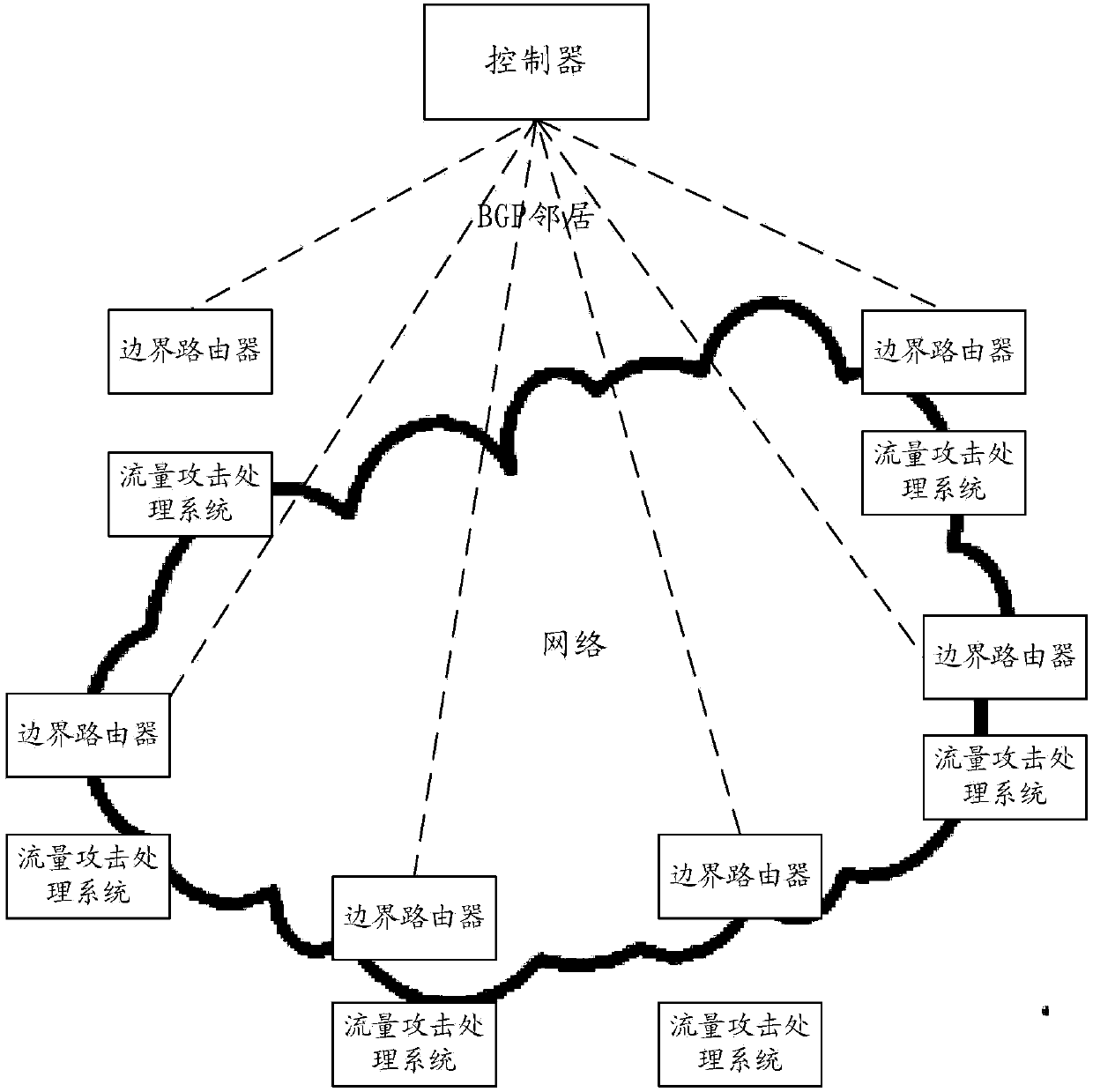

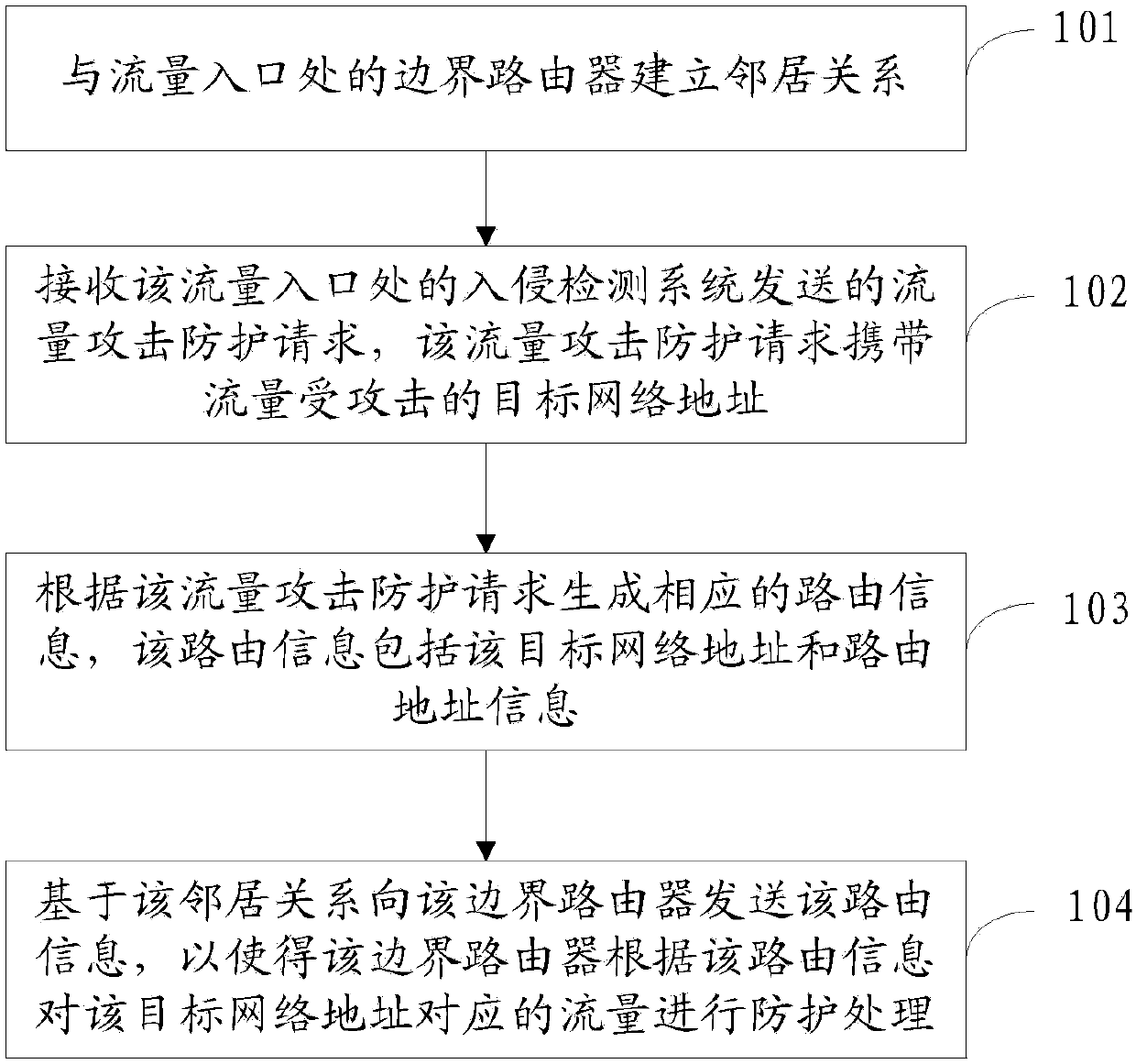

Traffic attack protection method and system, traffic attack protection control device and traffic attack protection processing device

ActiveCN107743109AReduce demandSimplified cleaning systemTransmissionTraffic capacityMaintainability

The embodiment of the invention discloses a traffic attack protection method and system, a traffic attack protection control device and a traffic attack protection processing device. According to theembodiment of the invention, a neighbourship is established with a border router at a traffic entrance; a traffic attack protection request sent by an intrusion detection system at the traffic entrance is received, wherein the traffic attack protection request carries a target network address of which traffic is attacked; corresponding routing information is generated according to the traffic attack protection request, wherein the routing information comprises the target network address and routing address information; and the routing information is sent to the border router based on the neighbourship, so the border router carries out protection processing on the traffic corresponding to the target network address according to the routing information. According to the scheme, the reliability, stability, maintainability and protection timeliness of the traffic attack protection system can be improved.

Owner:TENCENT TECH (SHENZHEN) CO LTD

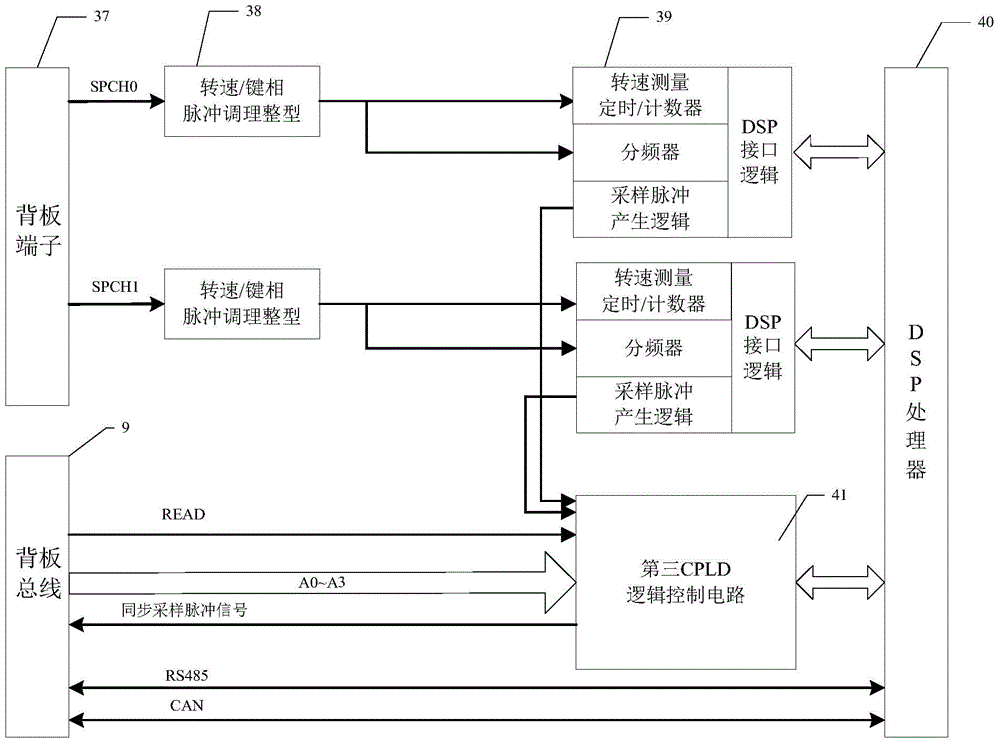

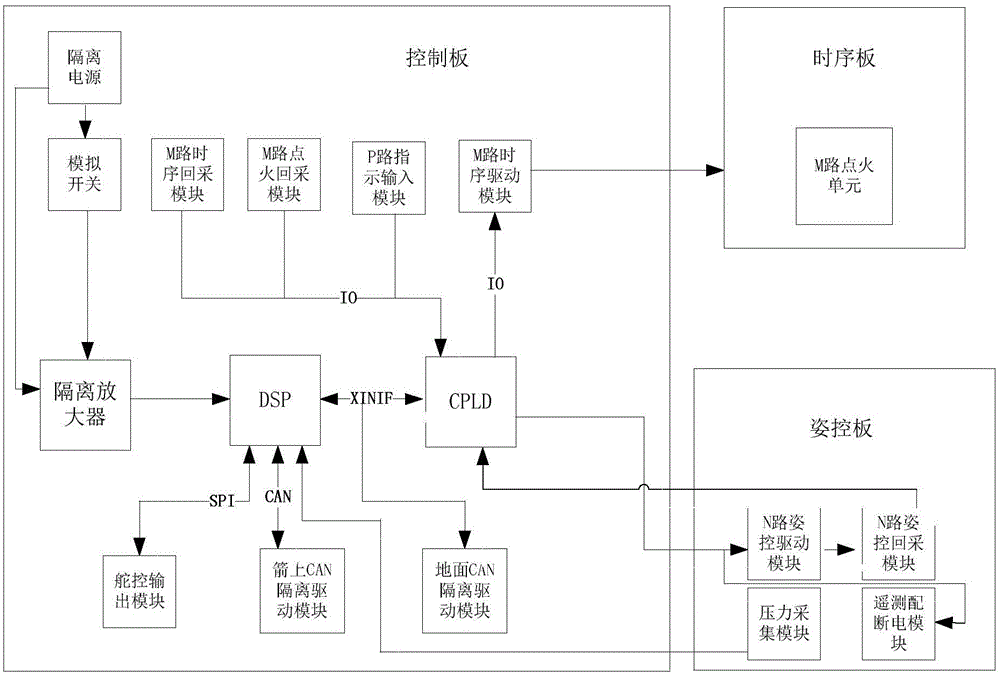

Universal controller of spaceflight carrier rocket

ActiveCN106325292AImprove reliabilityImprove anti-interference abilityCosmonautic vehiclesCosmonautic partsAttitude controlComplex programmable logic device

The invention discloses an universal controller of a spaceflight carrier rocket, comprising a control plate, a time sequence plate and an attitude control plate, wherein the time sequence plate comprises M paths of ignition units; the attitude control plate comprises N paths of attitude control drive modules, N paths of attitude control recovery modules, pressure collection modules and remote -measuring power distribution and interruption modules; the control plate comprises a processor DSP (Digital Signal Processor), a programmable logic controller CPLD (Complex Programmable Logic Device), an isolated power supply, an analogue switch, an isolation amplifier, M paths of time sequence recovery modules, M paths of ignition recovery modules, P paths of indication input modules, M paths of time sequence drive modules, a rudder control output module, a rocket-borne CAN isolation drive module, and a ground CAN isolation drive module. The controller is characterized in that controllers in four cabins are combined into one universal controller and has the advantages of modular design, good universality and strong compatibility.

Owner:THE GENERAL DESIGNING INST OF HUBEI SPACE TECH ACAD

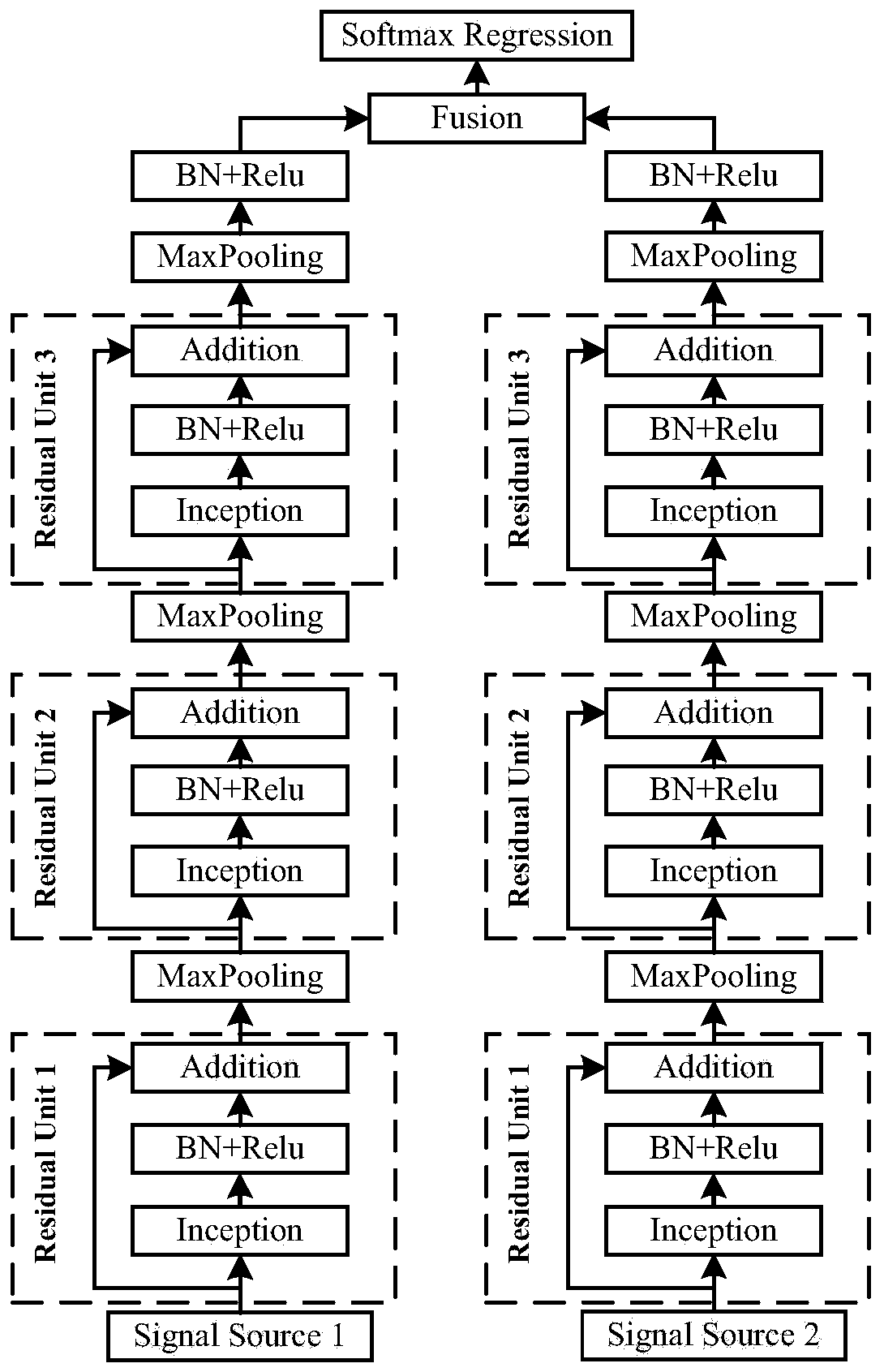

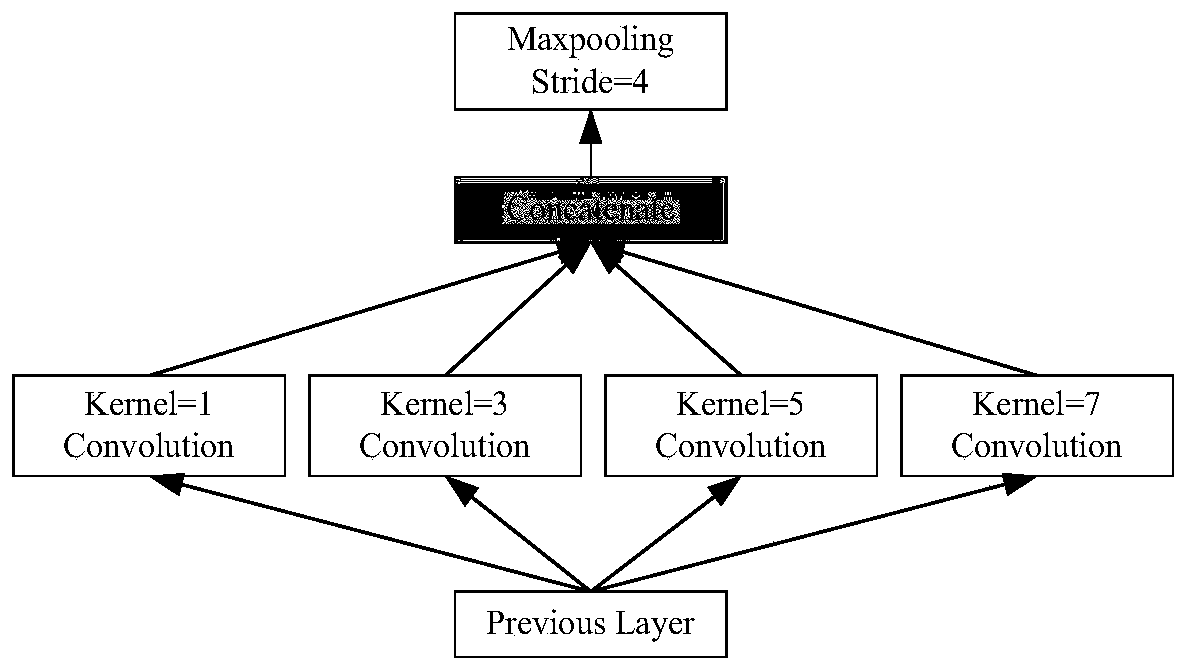

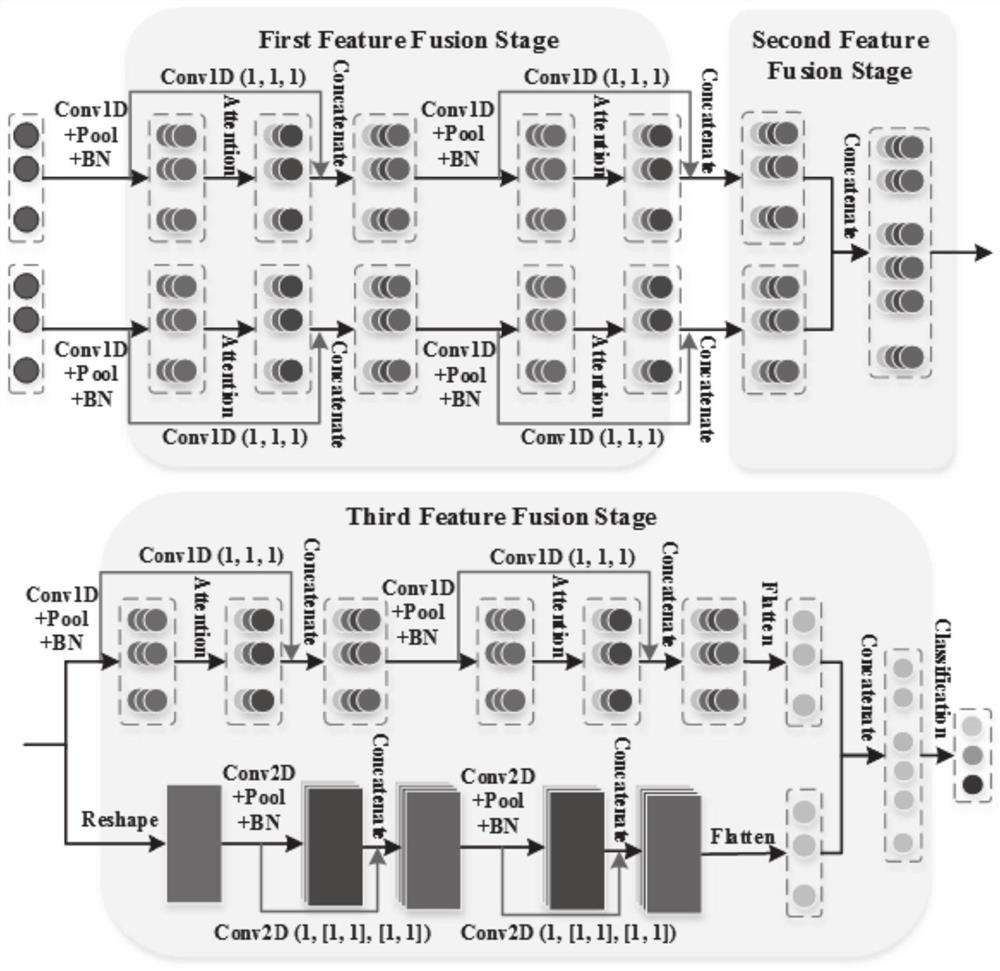

Three-stage feature fusion rotary machinery fault diagnosis method based on multi-modal data

ActiveCN112926641AReduce redundant informationImprove fault diagnosis abilityMachine part testingCharacter and pattern recognitionEngineeringNetwork model

The invention provides a three-stage feature fusion rotary machine fault diagnosis method based on multi-modal data. The method comprises the steps: obtaining the operation state parameter data of a machine, and obtaining the data of at least two modals; inputting the obtained modal data into a preset neural network model to obtain a final fault classification result; wherein the preset neural network model at least sequentially comprises three stages of first self-feature fusion, mutual feature fusion and second self-feature fusion; according to the method, a three-stage feature fusion method including a one-dimensional convolutional neural network and a two-dimensional convolutional neural network is adopted, multi-scale features are fused and fault diagnosis is carried out, the two-dimensional convolutional neural network extracts correlation between feature mapping maps, an attention mechanism can carry out different weight distribution on the feature maps, and the fault diagnosis accuracy is improved. Important information is highlighted, redundant information is reduced, and the fault diagnosis performance is greatly improved.

Owner:SHANDONG UNIV

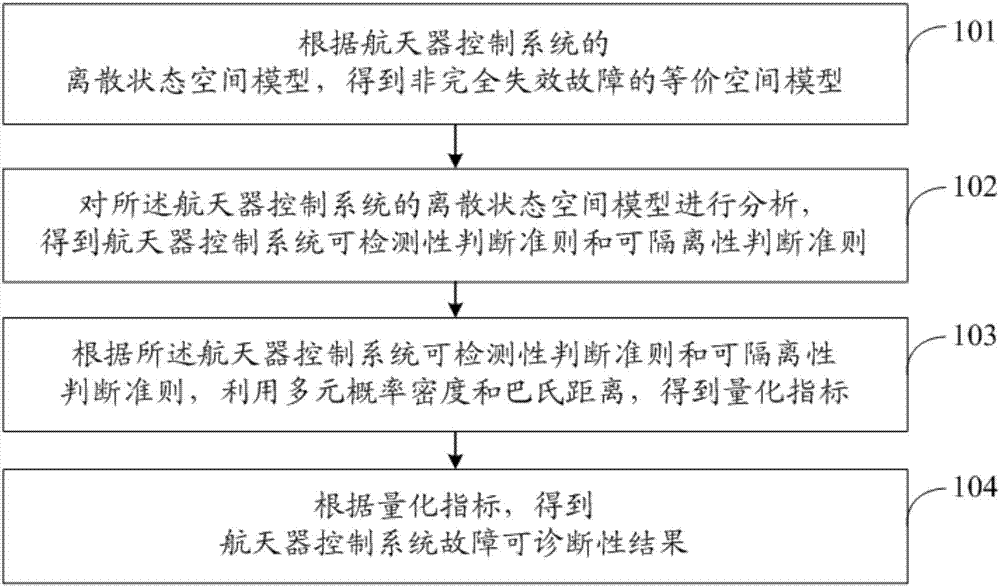

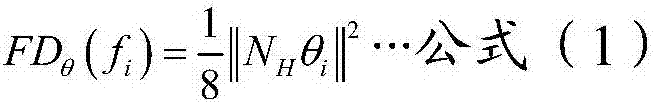

Diagnostic quantification method with consideration of incomplete failure of spacecraft control system

ActiveCN107544460AImprove fault diagnosis abilitySimple designElectric testing/monitoringSpace vehicle controlSystem configuration

The present invention discloses a diagnostic quantification method with the consideration of a incomplete failure of a spacecraft control system. A diagnostic quantification problem is transformed into a multivariate distribution similarity judgment problem in mathematical statistics, and an equivalent space model of the incomplete failure is obtained. Then concrete judgment criteria of the detectability and isolability of the incomplete failure are given. Finally, according to the judgment criteria, a diagnostic quantification index of the incomplete failure is proposed by using a Bhattacharyya distance, and an analysis result is obtained based on the diagnostic quantification index. The influence of system uncertainty in spacecraft control system on-orbit actual work is considered, according to the obtained result, a designer can conveniently understand weak links of the system, the guide of the design of a diagnosis algorithm and system configuration is facilitated, thus the fault diagnosis ability of the spacecraft control system can be improved to the maximum at a ground design stage, and finally a target of improving the system overall comprehensive design ability is achieved.

Owner:BEIJING INST OF CONTROL ENG

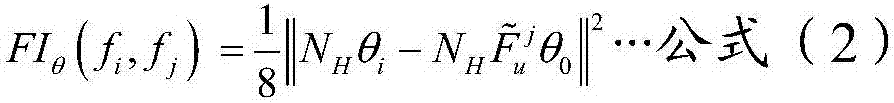

Aero-engine ignition control system with monitoring device

ActiveCN105201656ASimple structureImprove reliabilityGas turbine plantsRocket engine plantsDesign technologyAirplane

The invention provides an aero-engine ignition control system with a monitoring device, and relates to the design technology of aero-engines. The aero-engine ignition control system with the monitoring device is used for controlling ignitor plugs of an engine, on the basis of control through a dual-redundancy ignition relay of an engine electronic controller, a path of ignition relay is added on an interface unit of the engine of aircraft equipment, the relays of each ignitor plug are increased to three, and the ignition function of the engine can be achieved through closing of each relay. The contact state and the front end input ignition voltage quality of the ignition relay installed in an EEC are monitored in real time through the EEC, the contact state and the front end input ignition voltage quality of the ignition relay in an EIU are monitored in real time through the EIU, monitored information is fed back to the EEC through a bus, and the EEC monitors the three ignition relays and outputs a merged current finally. By means of the aero-engine ignition control system with the monitoring device, the reliability of the engine ignition system is improved, testability and the fault diagnosis capability of the engine are improved, and the safety of an aircraft is enhanced.

Owner:XIAN AIRCRAFT DESIGN INST OF AVIATION IND OF CHINA

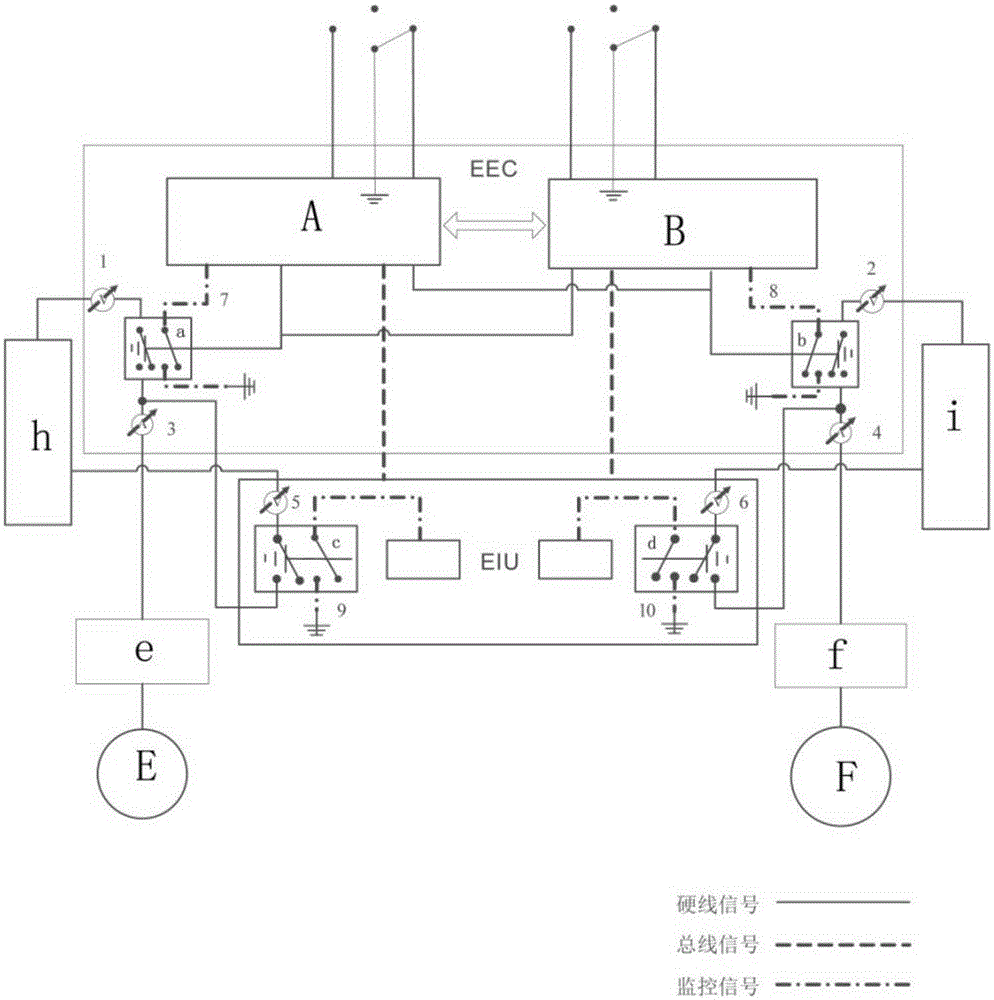

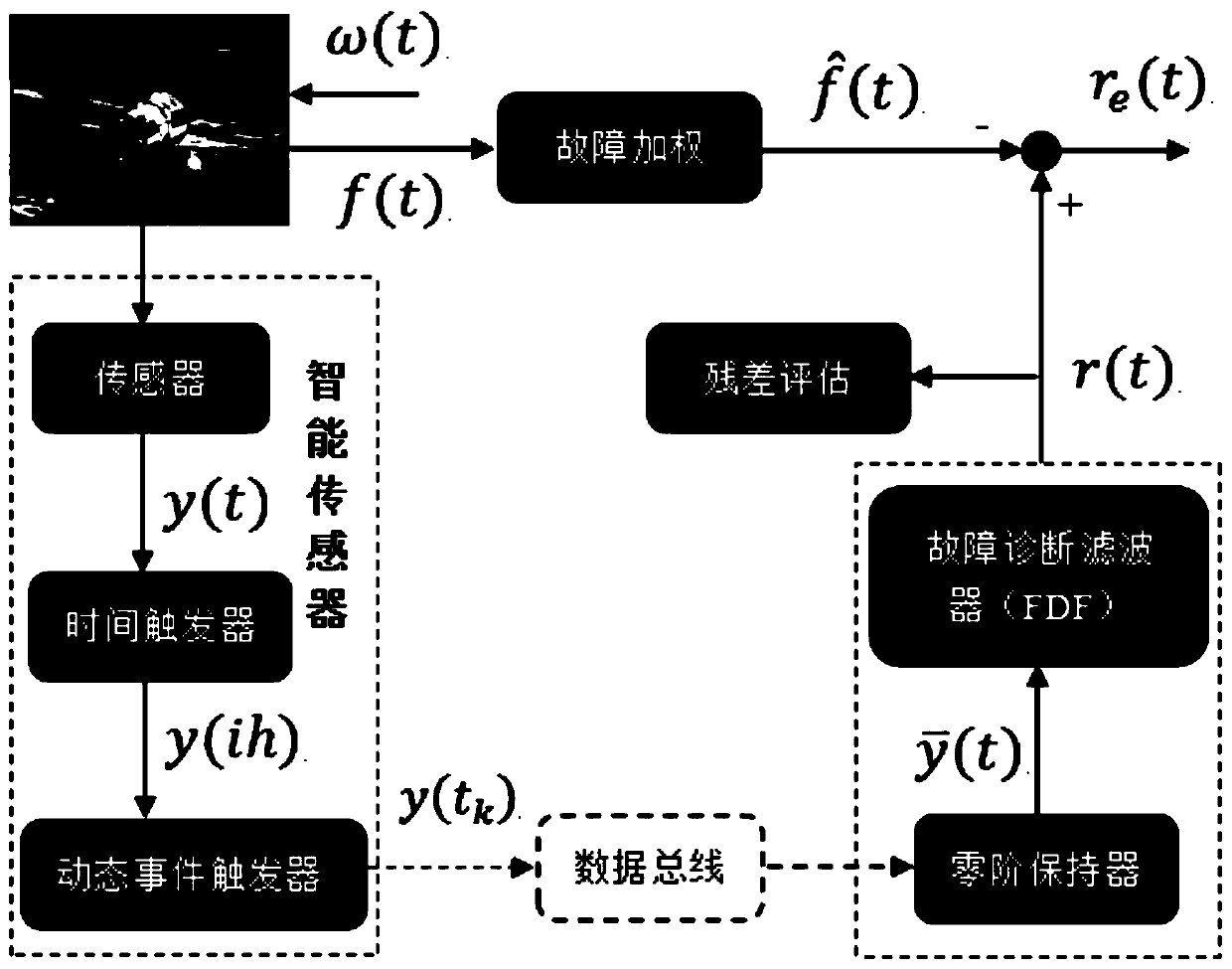

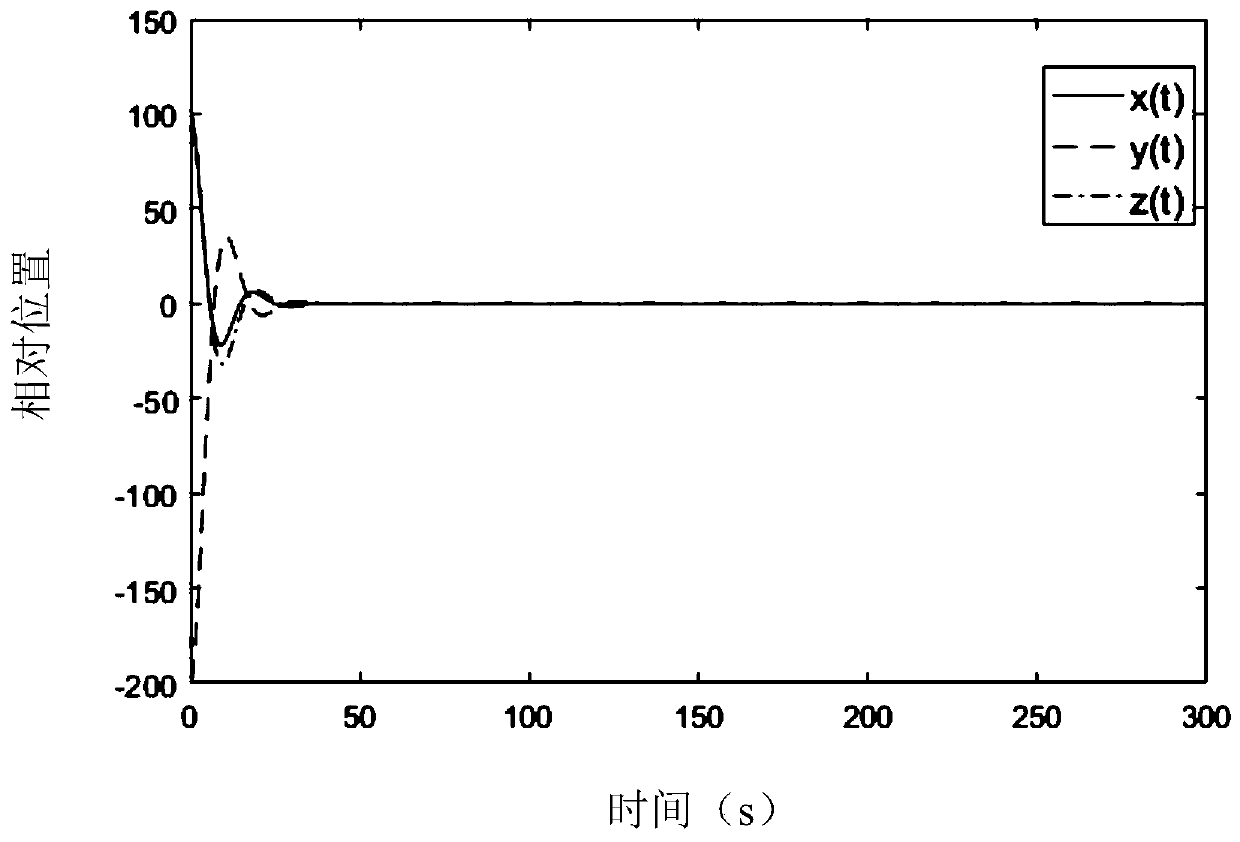

Spacecraft rendezvous fault diagnosis and filter design method based on event driving

ActiveCN110414125AImprove fault diagnosis abilityEasy to controlSpecial data processing applicationsData transmissionSpacecraft rendezvous

The invention discloses a spacecraft rendezvous fault diagnosis and filter design method based on event driving, and relates to the spacecraft rendezvous fault diagnosis and filter design method. Theinvention aims to solve the problems of high bus bandwidth occupancy rate and high data transmission energy consumption in the conventional spacecraft rendezvous system. The method comprises the following steps: 1, establishing a state space model of a spacecraft rendezvous system; 2, designing a weighted fault function; 3, designing an FDF gain matrix based on dynamic event driving, and establishing an augmented residual error system under the event driving condition; 4, obtaining a residual signal and control input according to the gain matrix of the FDF; 5, designing a dynamic event drivingmechanism to enable the gain matrix obtained in the step 3 to be established; 6, designing a residual evaluation function according to the residual signal; and 7, designing a residual evaluation function threshold, and completing fault diagnosis of the spacecraft rendezvous system according to the residual evaluation function. The method is applied to the field of spacecraft rendezvous fault diagnosis and filter design.

Owner:HARBIN INST OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com