Patents

Literature

88results about How to "Effective fault diagnosis" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

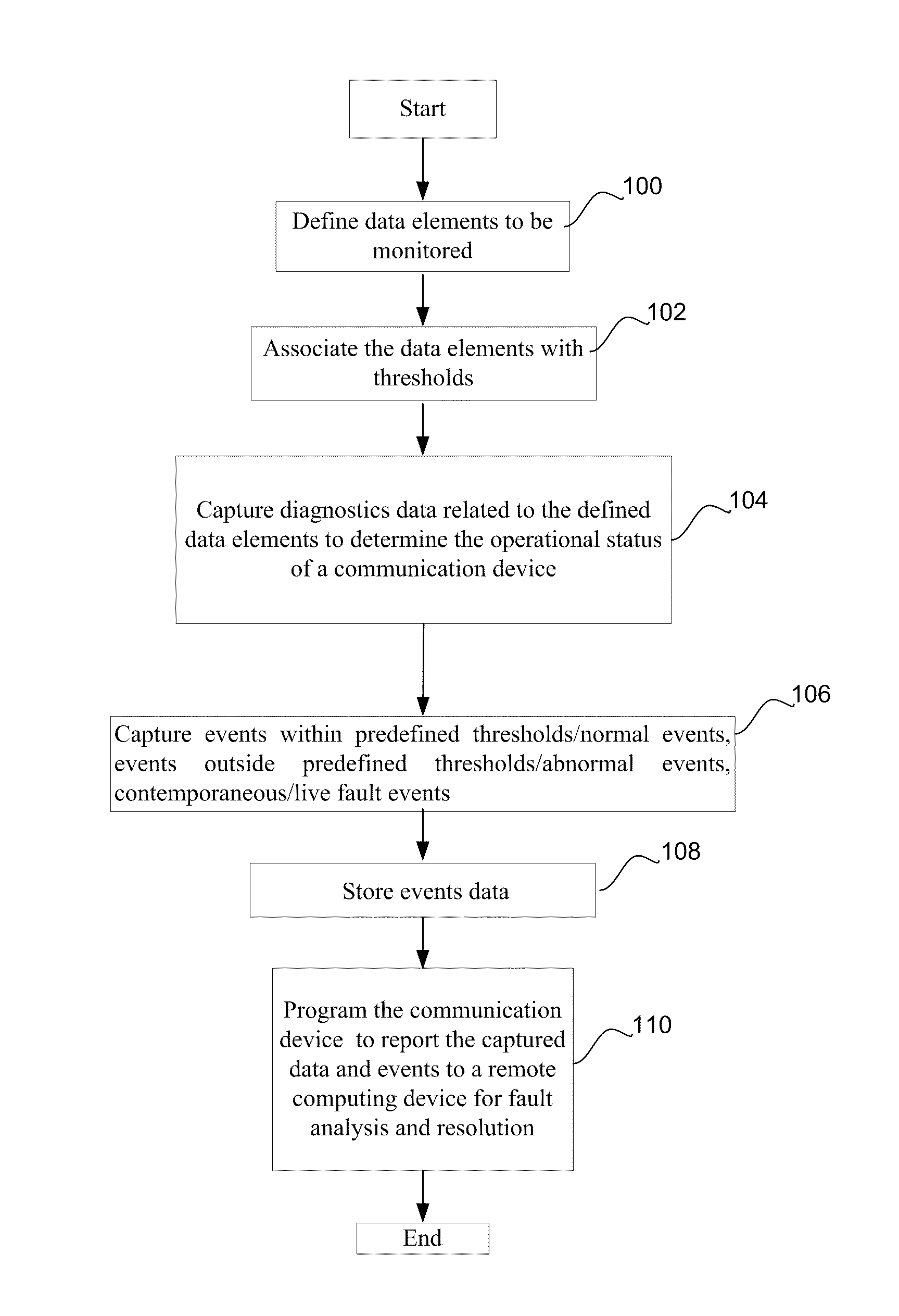

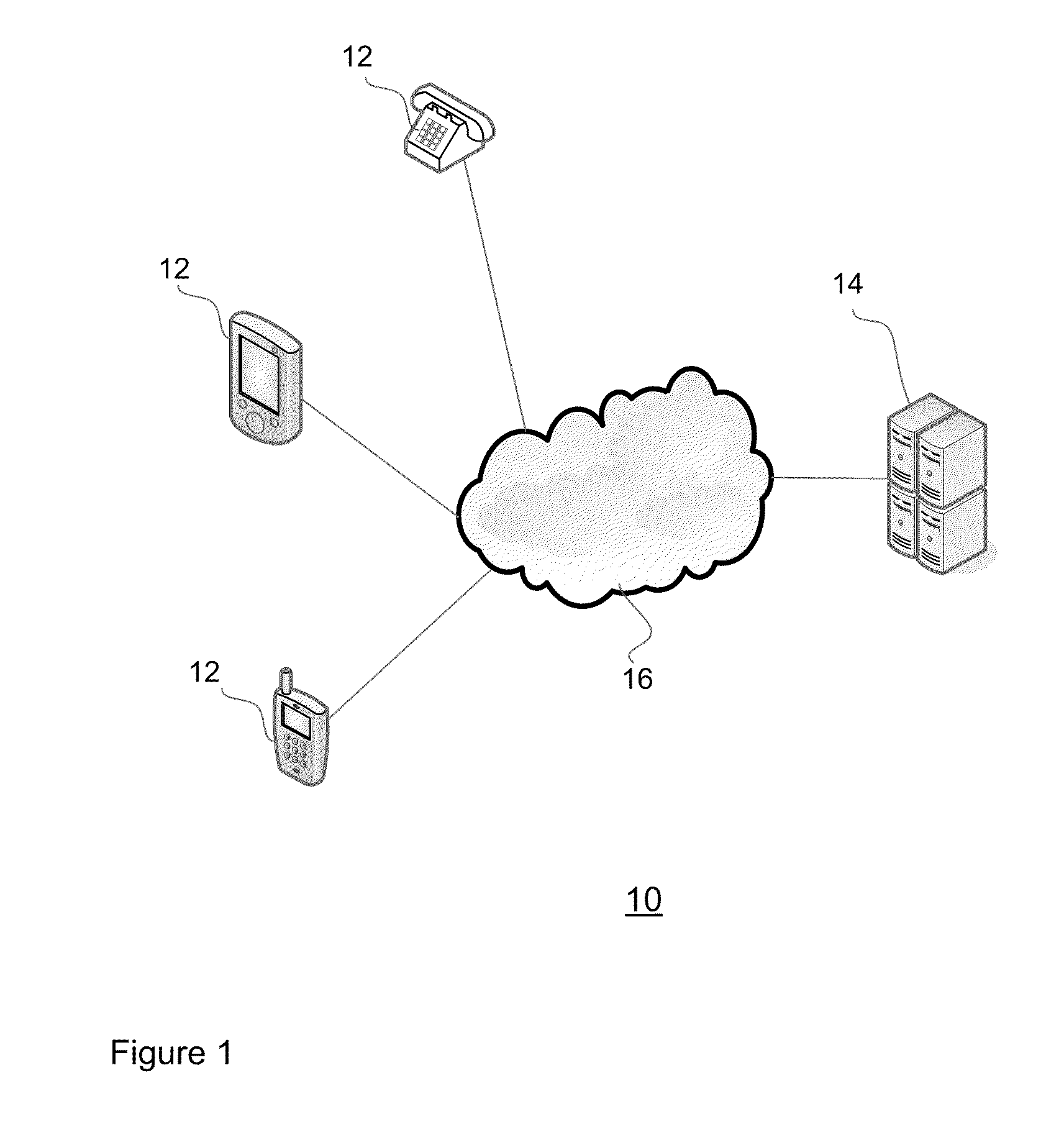

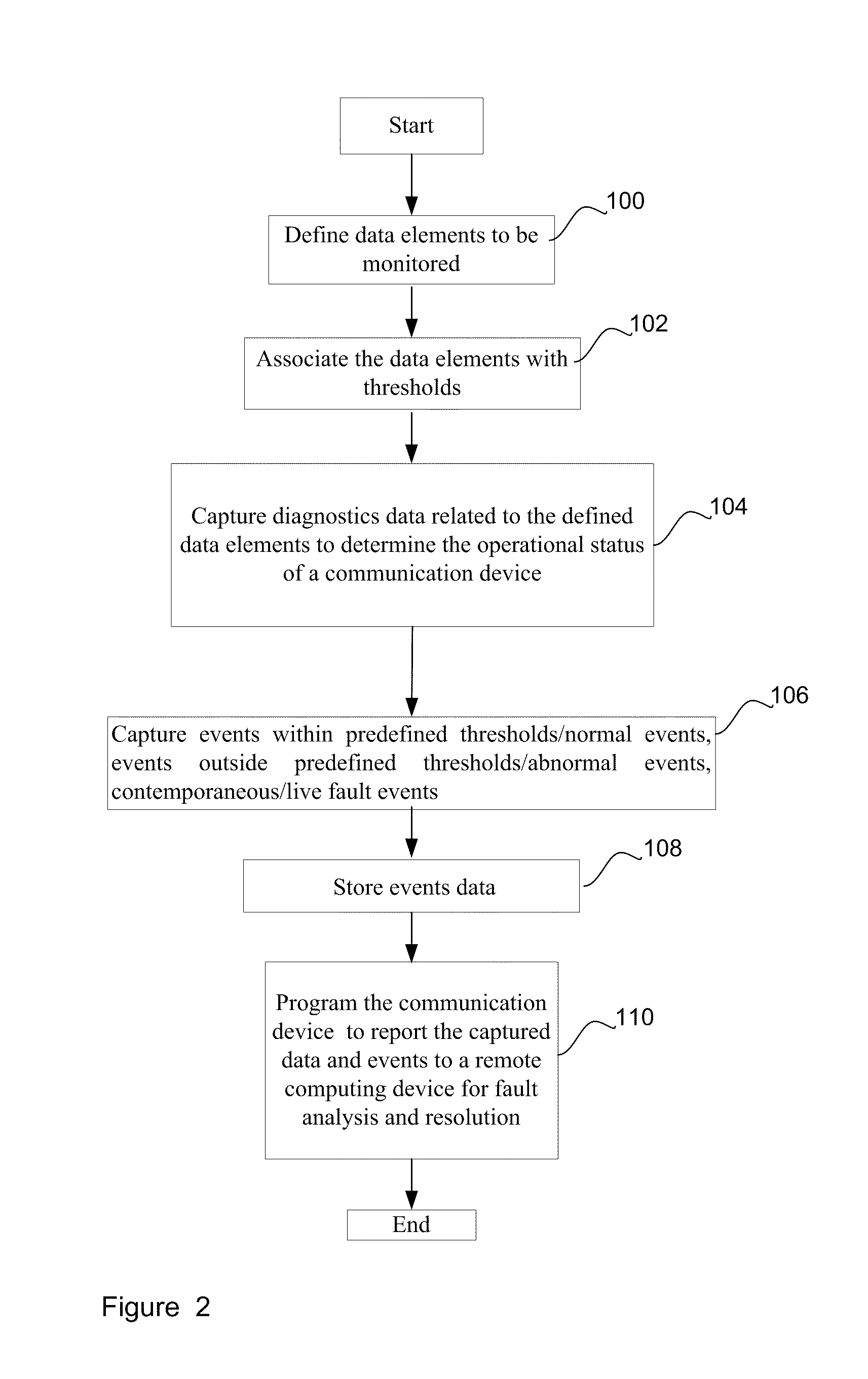

Diagnostics methods for a communications device

ActiveUS20110060948A1Effective fault diagnosisEfficient troubleshootingEnergy efficient ICTFault responseComputer hardwareData element

A method facilitating the support of a communications device via diagnostic tools on the communications device and a remote computing device of monitoring predefined data elements associated with the operation of said communications device.

Owner:MITEL

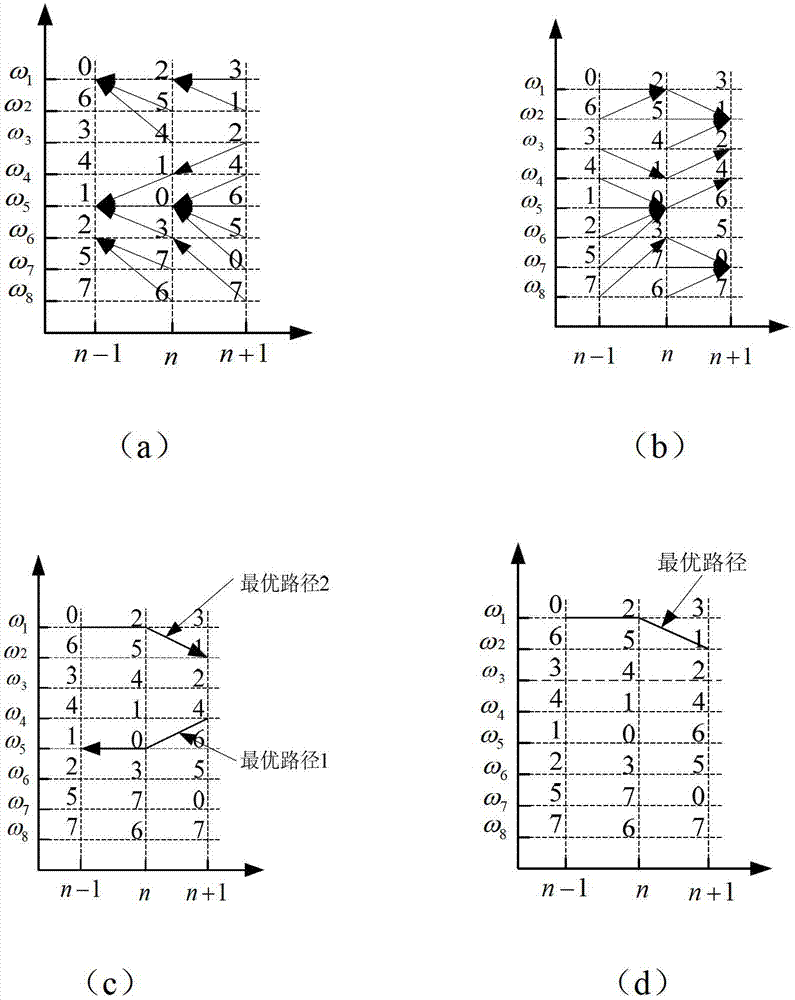

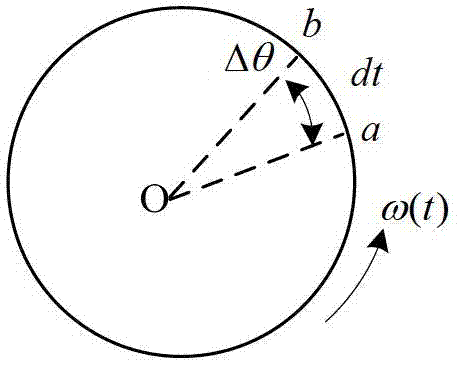

Gear failure keyless phase angle domain average computing order analysis method

ActiveCN103499443ATroubleshoot hard-to-diagnose problemsAccurate estimateMachine gearing/transmission testingVibration accelerationWigner ville

The invention provides a gear failure keyless phase angle domain average computing order analysis method. The method comprises the steps that low-pass phase-protection filtering is conducted on collected accelerated speed signals, and time-frequency distribution of the signals is calculated through smooth pseudo Wigner-Ville distribution; the instantaneous frequency of a gear case rotary shaft is estimated according to a Viterbi optimal path search algorithm, key phase signals are used for estimating a model to conduct point-by-point integration on the instantaneous frequency, and an estimated key phase signal is obtained, calculation order analysis is conducted on the vibration accelerated speed signals through equal angle resampling and the angular domain average technology, and the order spectrum based on instantaneous frequency estimation is obtained. The order spectrogram can effectively reflect the feature information of gear case failures. The gear failure keyless phase angle domain average computing order analysis method integrates the advantages of the smooth pseudo Wigner-Ville distribution, the Viterbi optimal path search algorithm, the angular domain average technology and the calculation order analysis, and can effectively conduct fault diagnosis on a gear case working on the working station of variable speeds.

Owner:XI AN JIAOTONG UNIV

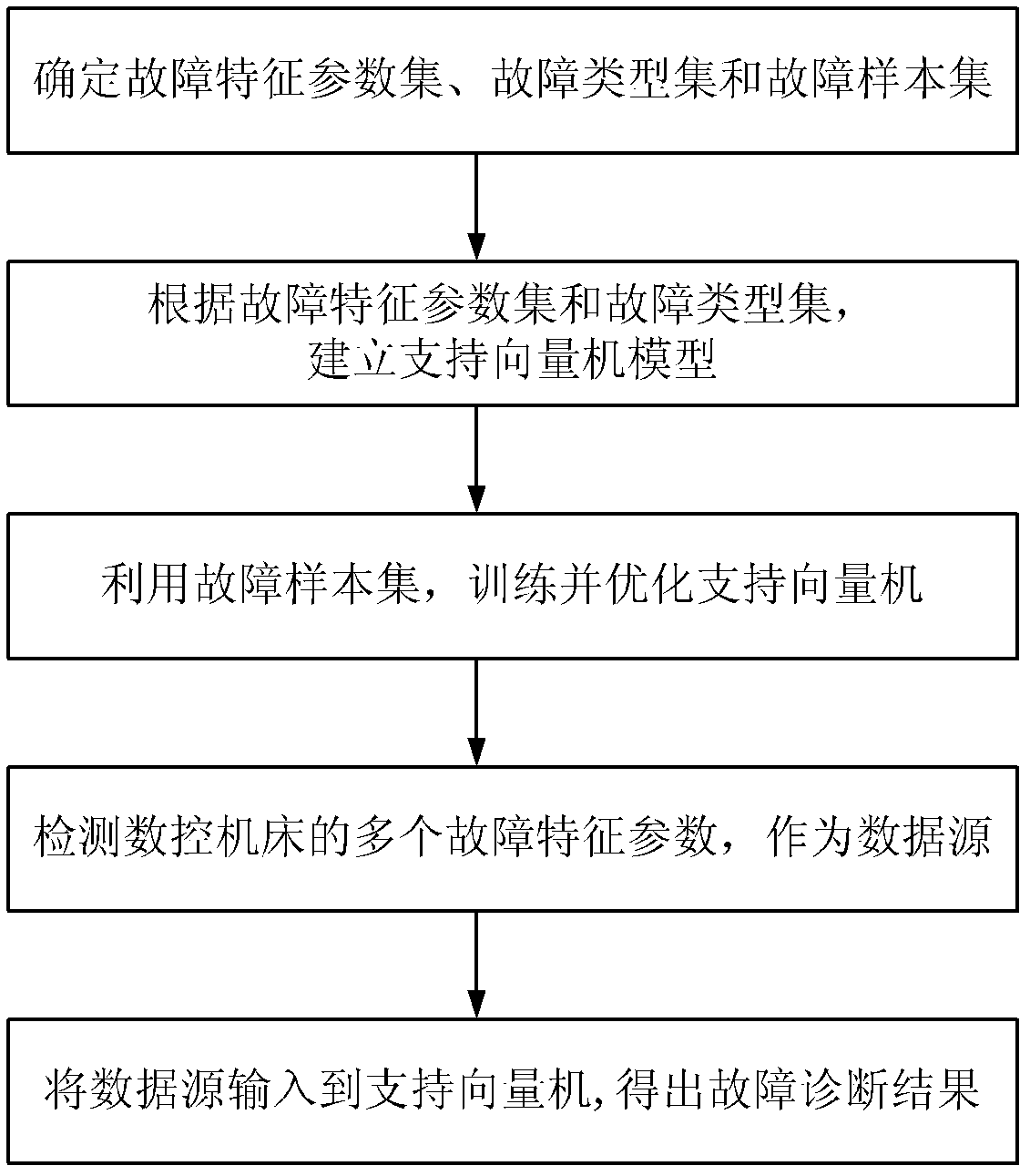

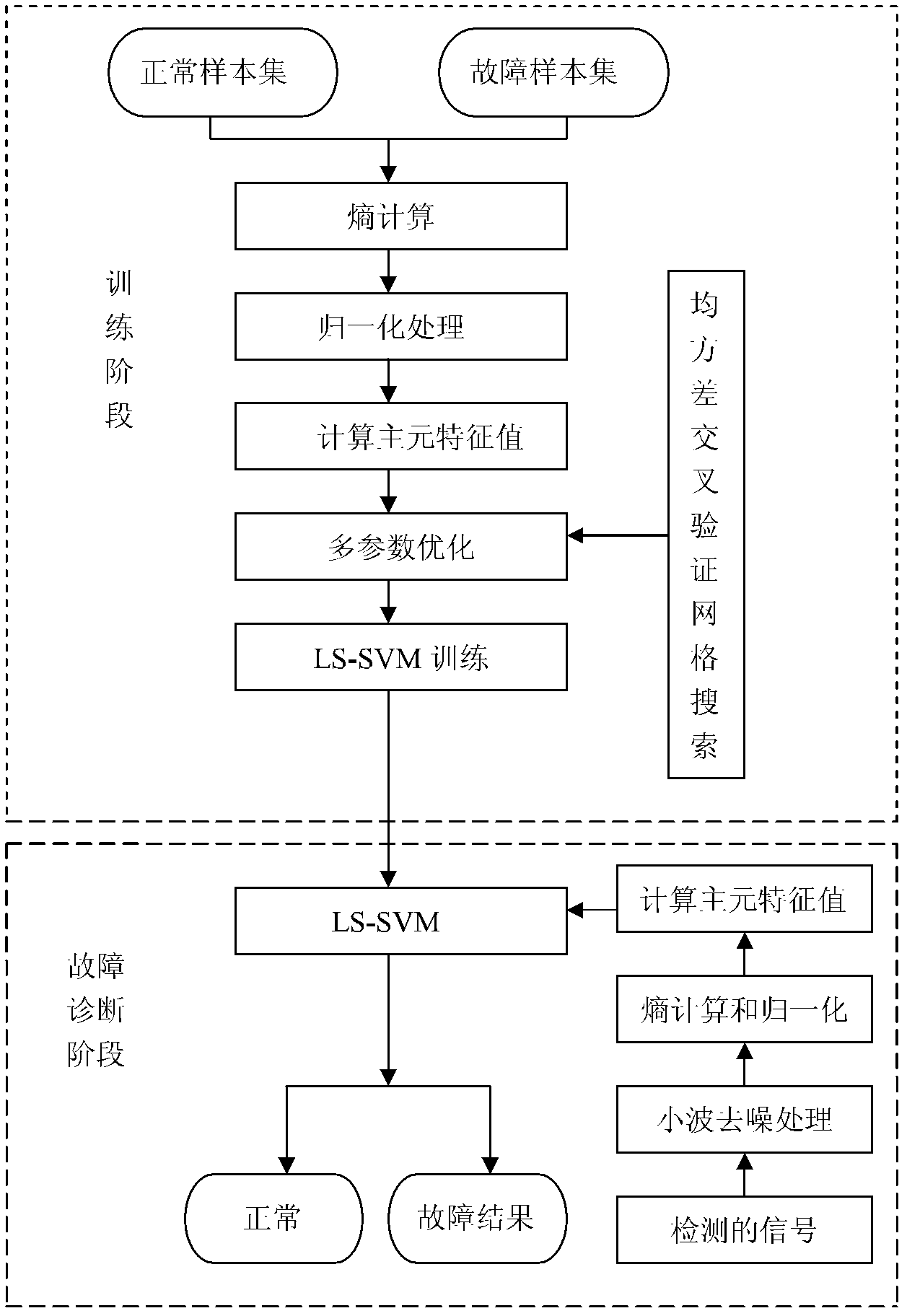

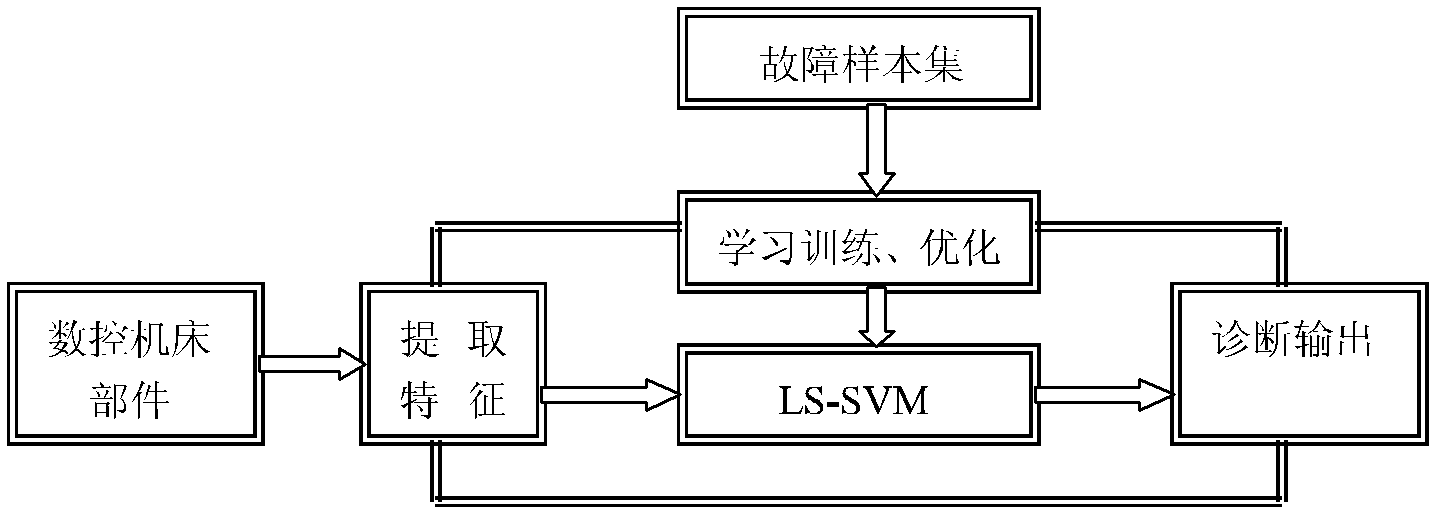

Intelligent fault diagnosis method for numerical control machine

InactiveCN102566505AEffective fault diagnosisStrong fault diagnosis abilityProgramme controlComputer controlDiagnosis methodsLeast squares support vector machine

The invention provides an intelligent fault diagnosis method for a numerical control machine, which comprises the following steps: (1) determining a fault characteristic parameter set, a fault type set and a sample set; (2) according to the fault characteristic parameter set and the fault type set, establishing a support vector machine model; (3) training and optimizing a support vector machine by utilizing the sample set; (4) detecting a plurality of fault characteristic parameters of the numerical control machine and using the plurality of fault characteristic parameters as a data source of fault diagnosis; and (5) inputting the data source into the optimized support vector machine to obtain a fault diagnosis result. In the invention, according to the occurrence mechanism and the characteristics of faults of parts of the numerical control machine, when the parts of the numerical control machine have the faults, the numerical control machine is detected and detection data is input into the least squares support vector machine after being processed, so that a diagnosis result can be obtained. According to the invention, the rapid and effective fault diagnosis for the numerical control machine is implemented and the intelligent fault diagnosis method also has strong fault diagnosis capacity, high diagnosis rate and low misdiagnosis rate.

Owner:WENZHOU UNIVERSITY

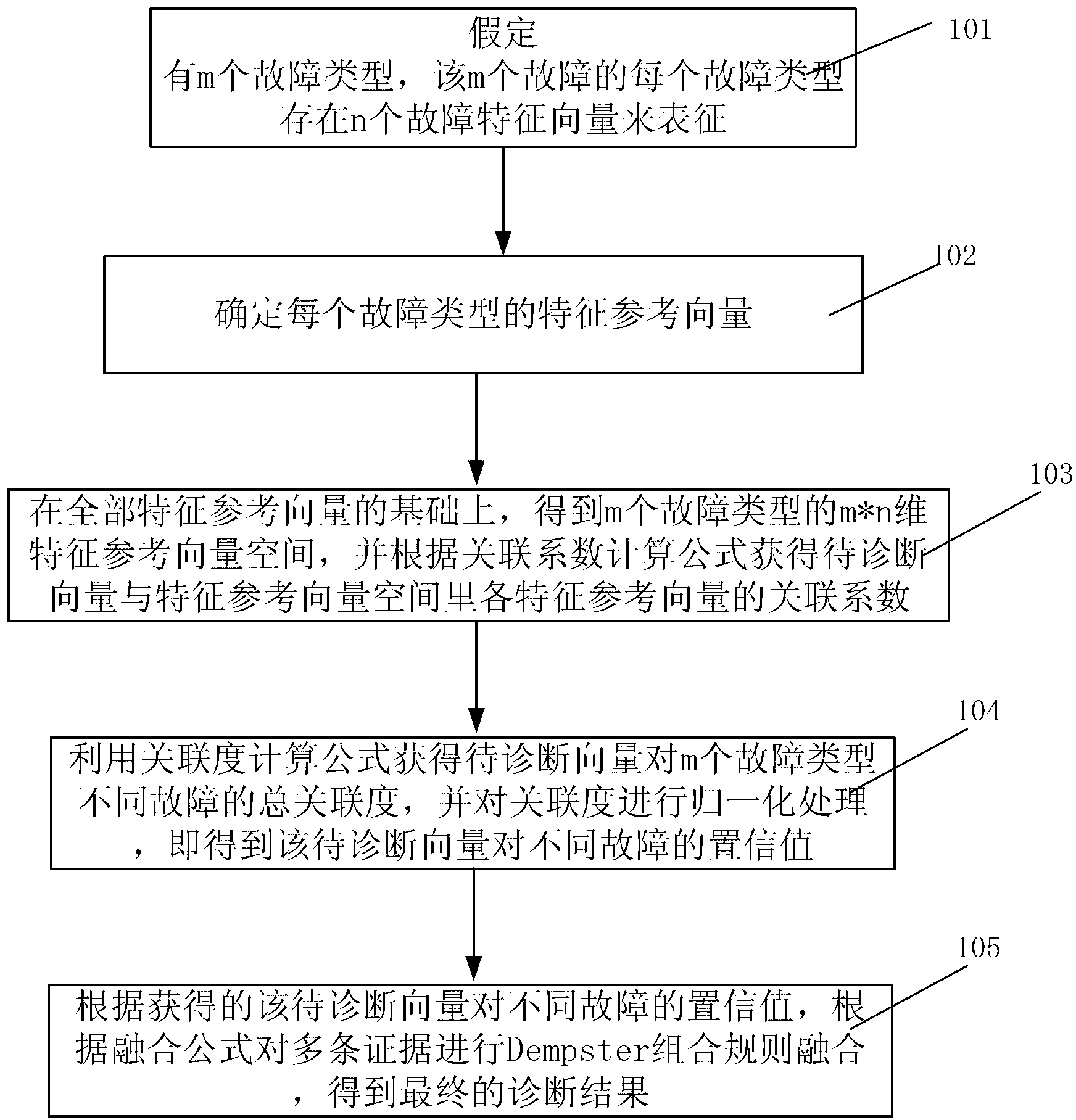

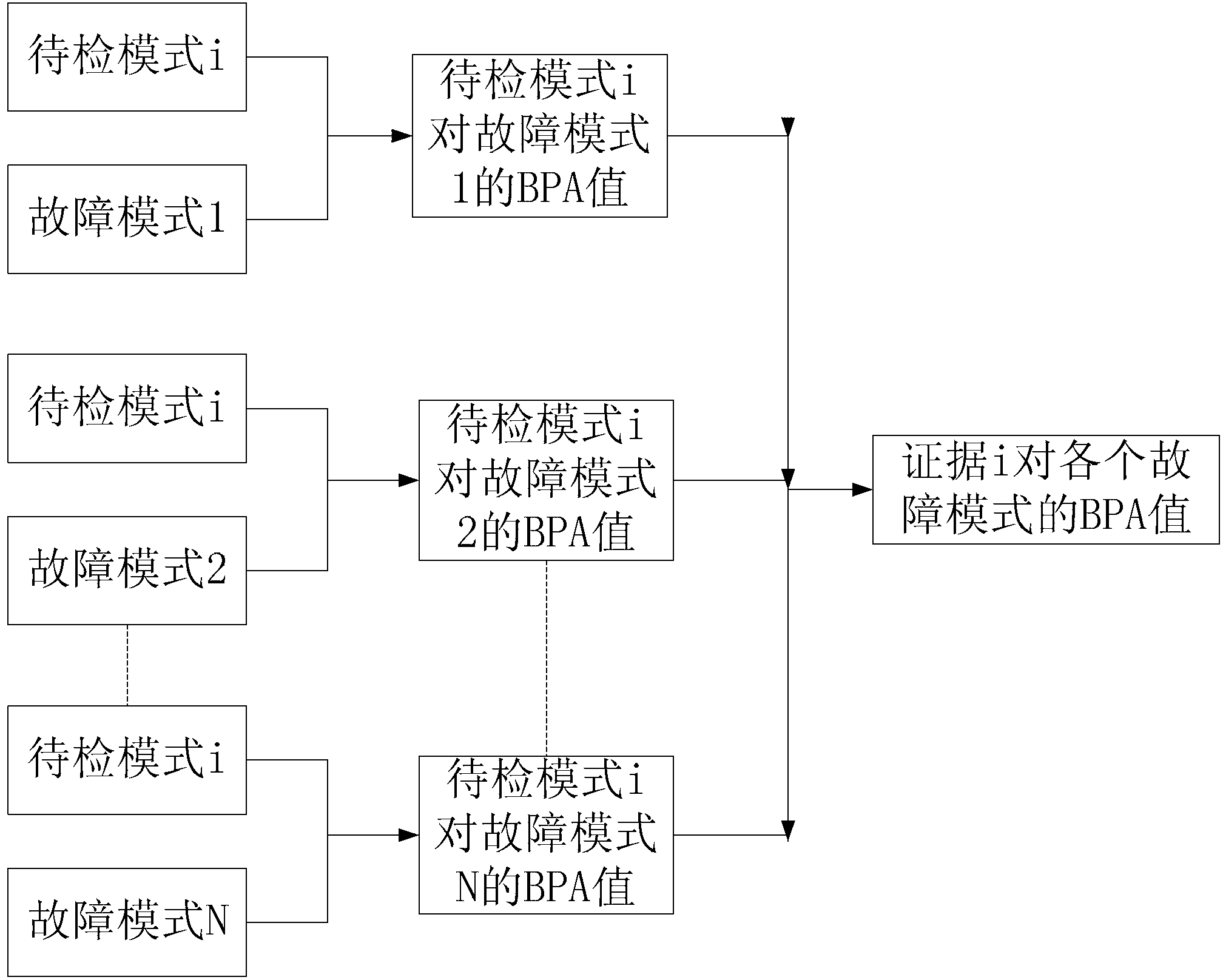

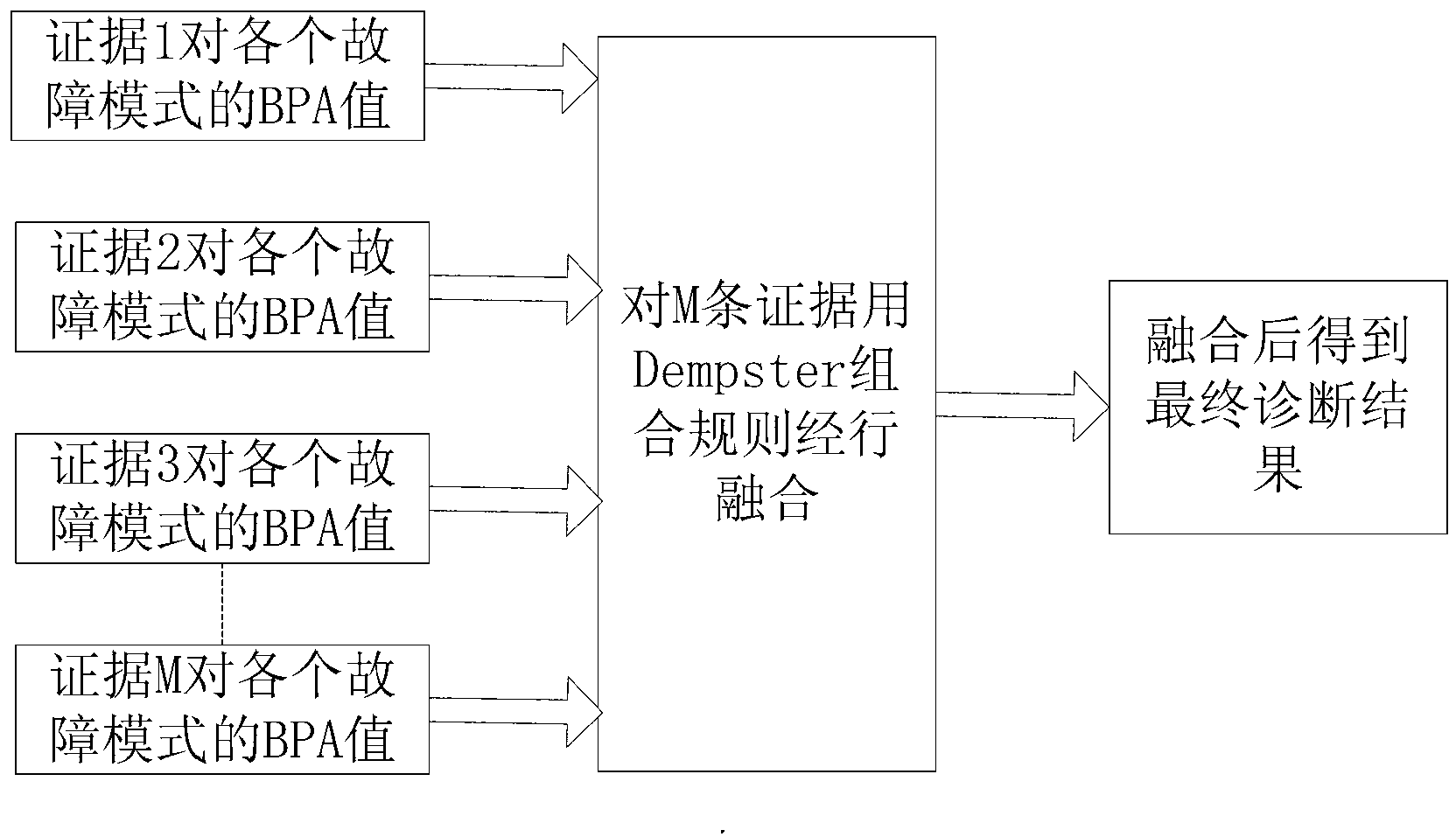

Wind turbine generator system fault diagnosis method and device based on gray correlation

InactiveCN103308855AConfidenceFault diagnosis is convenient and effectiveDynamo-electric machine testingReference vectorEuclidean vector

The invention discloses a wind turbine generator system fault diagnosis method and device based on gray correlation. The method comprises the following steps of supposing that m fault types exist, wherein each fault type can be represented by n fault character vectors; determining a character reference vector of each fault type, obtaining m*n dimensional character reference vector spaces of m fault types on the basis of all character reference vectors, and obtaining correlation coefficients of various character reference vectors in to-be-diagnosed vectors and character reference vector space according to a correlation coefficient calculation formula; obtaining total correlation degree of the to-be-diagnosed vectors to different faults of the m fault types by a correlation degree calculation formula, and performing normalized processing on the correlation degree to obtain a confidence value of the to-be-diagnosed vector in different faults; and performing Dempster combination rule fusion on multiple evidences according to a fusion formula to obtain the final diagnosis result. By adopting the method and the device provided by the invention, the confidence degree of the fault mode is greatly enhanced, thus the fault diagnosis can be carried out conveniently and effectively.

Owner:SHANGHAI DIANJI UNIV

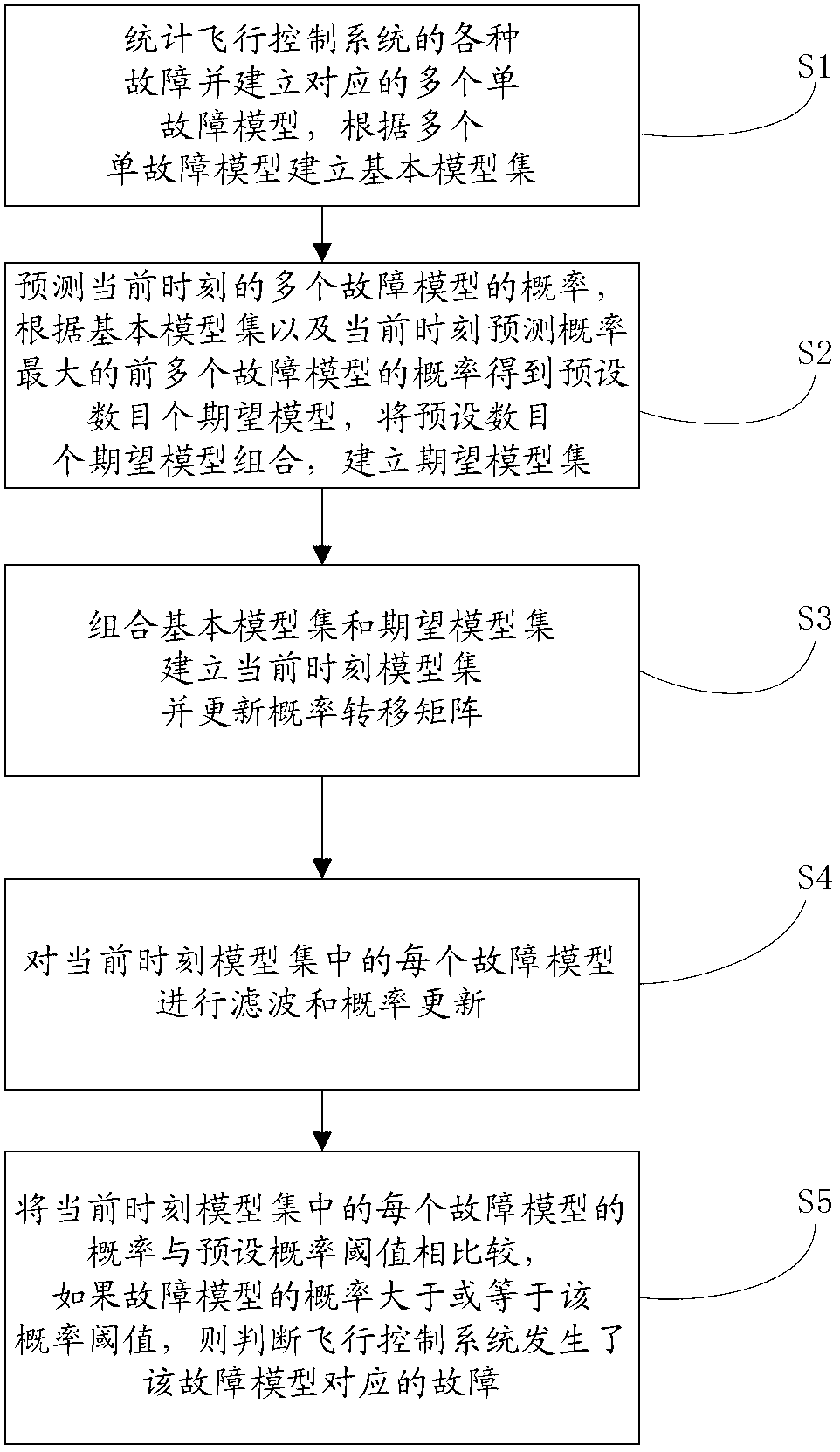

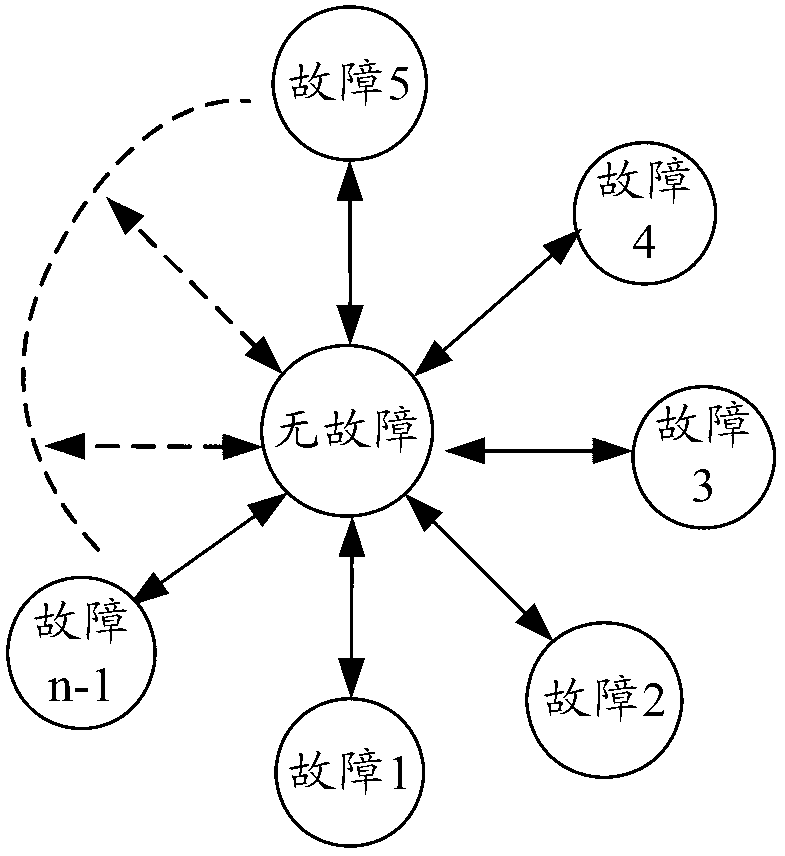

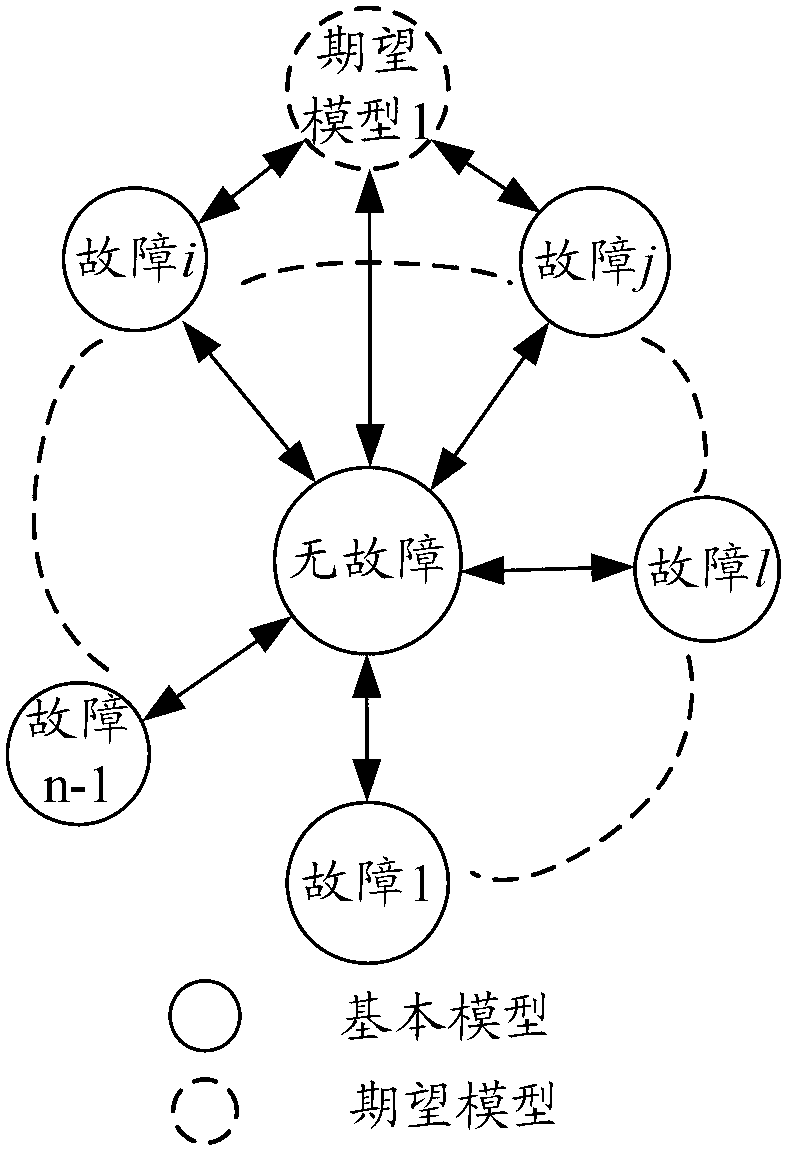

Method and device for diagnosing faults of multi-mode flight control system

ActiveCN102707708ARealize online adaptive updateSolve huge problemsElectric testing/monitoringFault modelMultiple fault

The invention provides a method for diagnosing faults of a multi-model flight control system based on expected model expansion, comprising the following steps: making a statistic of various faults of the flight control system, and building a basic model collection; forecasting the probability of the multiple fault models at the current time, and building an expected model collection; combining the basic model collection with the expected model collection to build a fault model collection at the current time; filtering each fault model in the model collection at the current time, and updating the probability; if the probability of certain fault model in the model collection at the current time is more than or equal to the preset probability threshold value, judging that the flight control system has the fault corresponding to the fault model. The invention further provides a device for diagnosing the faults of the multi-model flight control system based on expected model expansion, comprising a basic model collection building module, an expected model collection building module, a model collection at the current time building module, a filtering and probability updating module and a fault judging module. The invention further provides a flight control system.

Owner:TSINGHUA UNIV

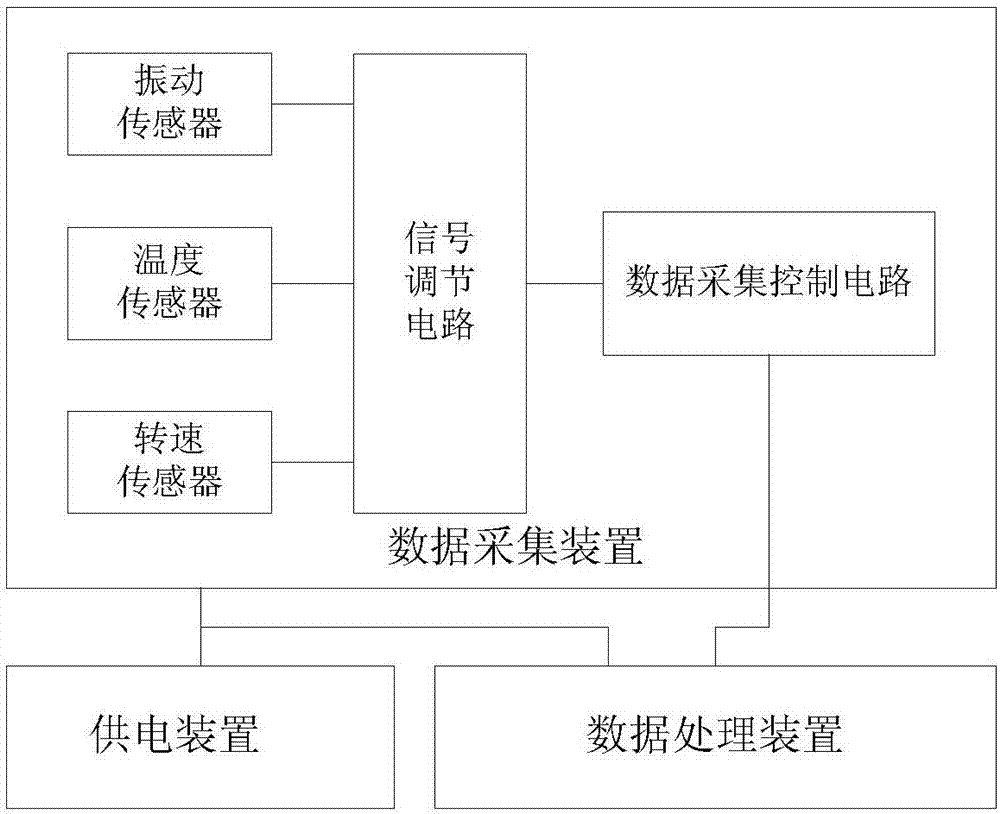

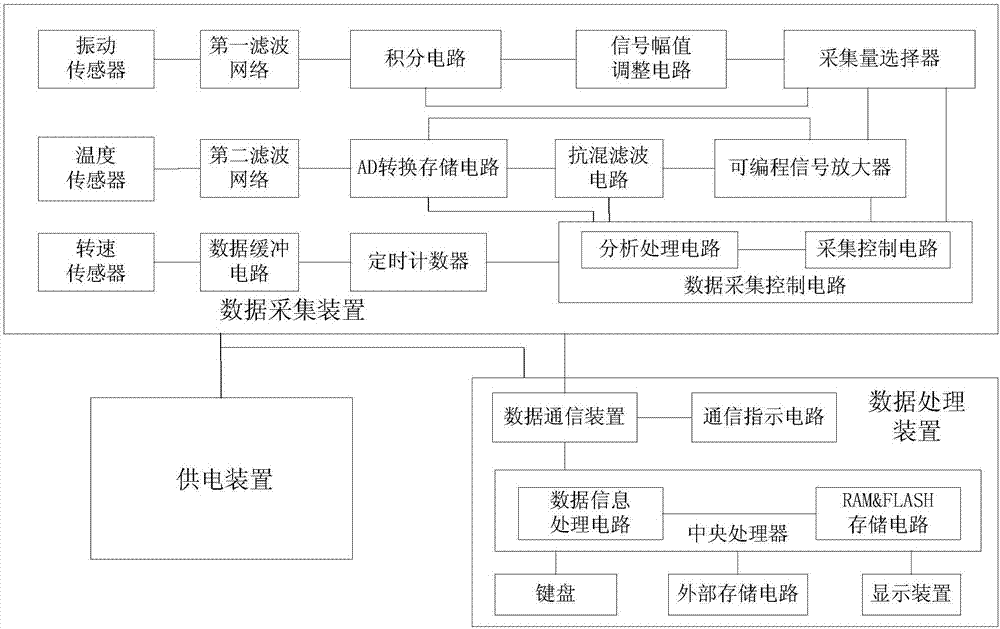

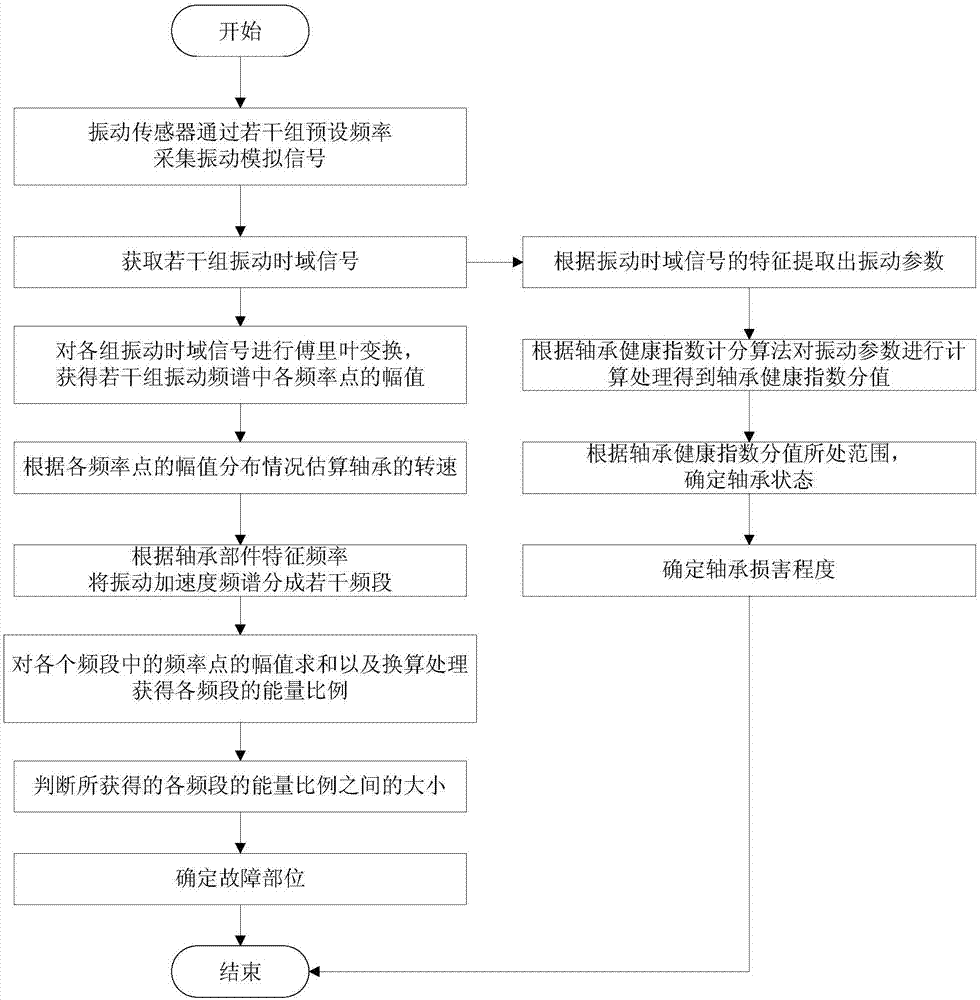

Intelligent and quick fault diagnosis instrument for bearing and diagnosis method thereof

InactiveCN107167318AHigh degree of intelligenceUnleash your work potentialMachine bearings testingTime domainData acquisition

The invention relates to an intelligent and quick fault diagnosis instrument for a bearing and a diagnosis method thereof. The fault diagnosis instrument comprises a data acquisition device and a data processing device which are connected with each other. The data acquisition device comprises a vibration sensor. The data acquisition device acquires a vibration analog signal of a processed bearing based on the vibration sensor. The data processing device acquires the vibration analog signal through a plurality of preset frequencies and obtains a plurality of sets of vibration time domain signals, and then the data processing device performs a series of processing analysis on each vibration time domain signal for finally determining a fault part. The intelligent and quick fault diagnosis instrument and the diagnosis method thereof can generate a clear fault description which comprises a bearing fault development period, a bearing damage part and bearing damage degree. The intelligent and quick fault diagnosis instrument and the diagnosis method further have advantages of high intelligence degree, and low dependence for a professional skill and experience of an operator.

Owner:北京时代龙城科技有限责任公司

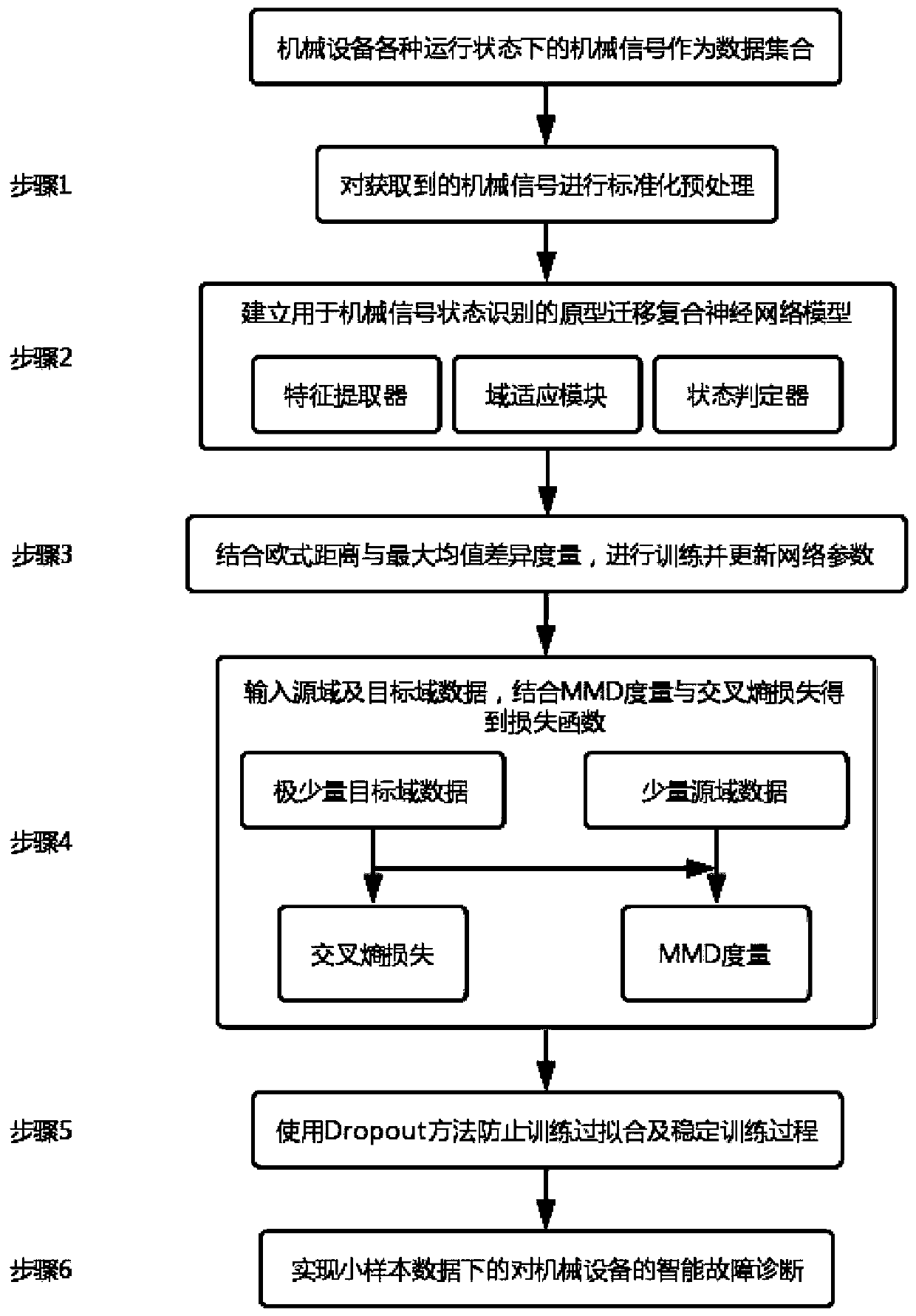

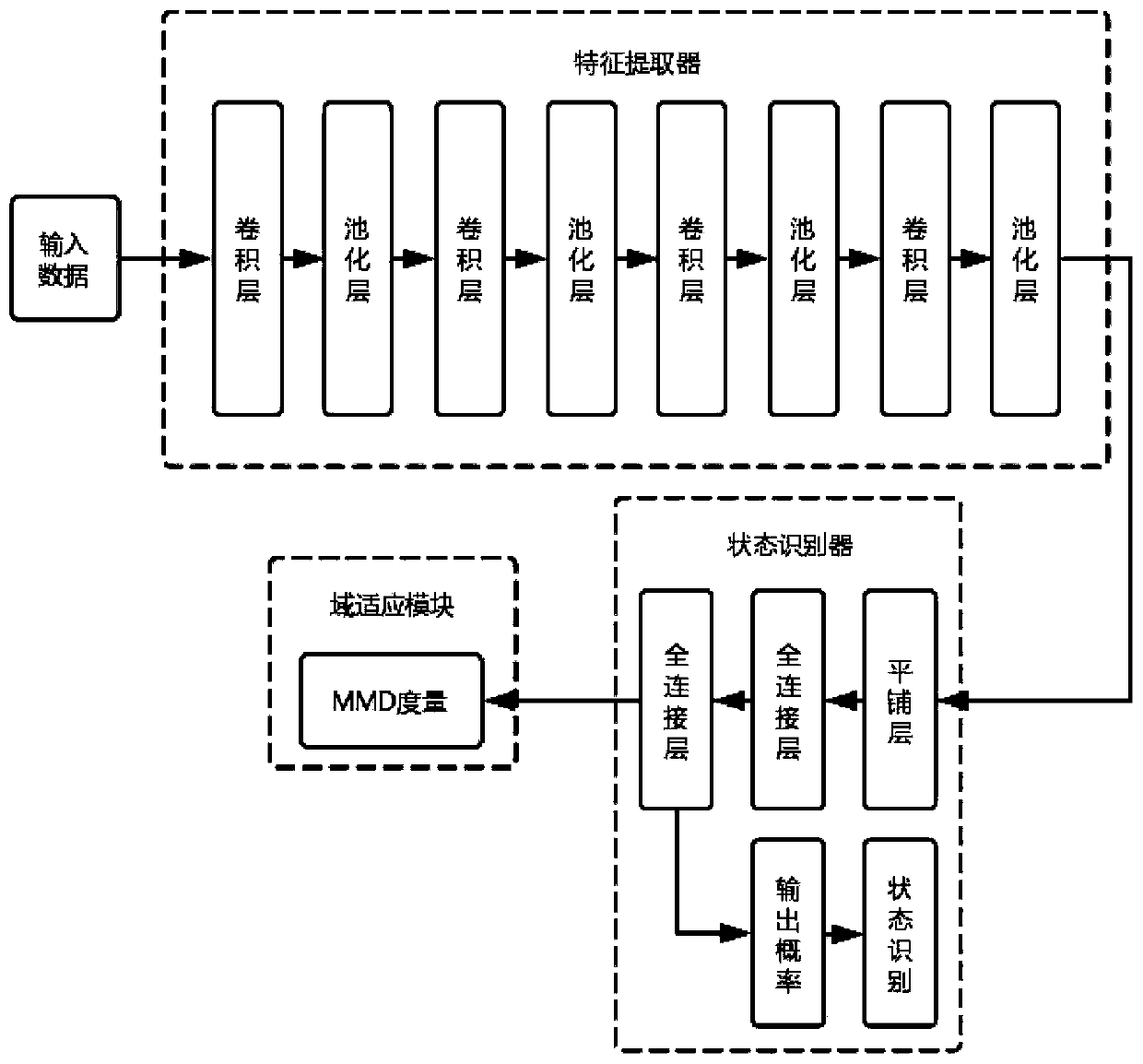

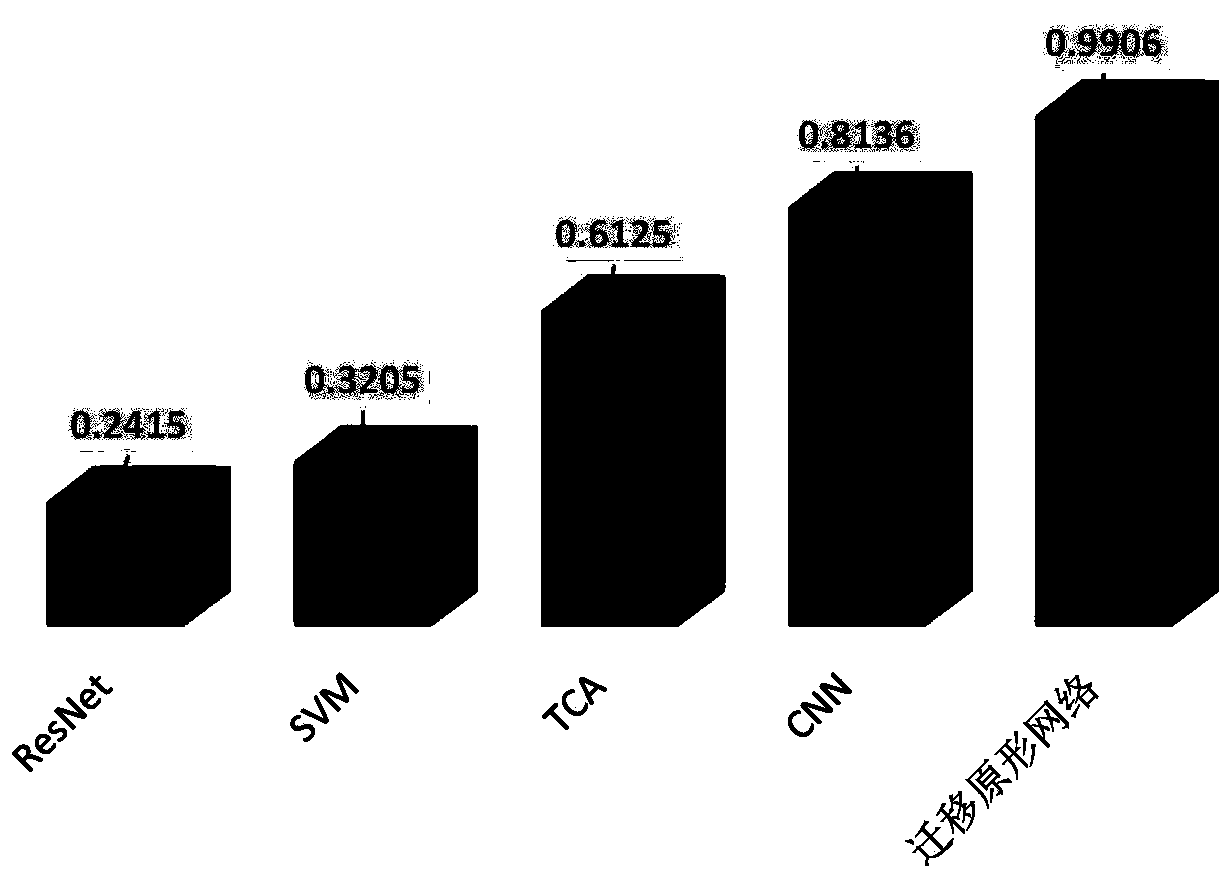

Mechanical fault intelligent diagnosis method based on migration prototype network under small sample

InactiveCN110533070AImprove generalization abilityEffective fault diagnosisCharacter and pattern recognitionNeural architecturesSmall sampleNerve network

The invention discloses a mechanical fault intelligent diagnosis method based on a migration prototype network under a small sample. The deep convolutional neural network is used to carry out featureextraction and operation state identification on the mechanical signal, sensitive features in the mechanical signal can be effectively extracted, and dependence of a traditional feature extraction process on artificial experience is eliminated. According to the method, the principle of prototype clustering is used, effective features of signals are obtained under the condition that the number of available samples is extremely small, and dependence of a traditional machine learning method on huge data volume is eliminated. according to the method, the transfer learning principle is used, and the generalization ability of the network is further improved by means of related source domain data with different feature distribution. By combining the deep convolutional neural network, the prototype network and the transfer learning thought, fault diagnosis can be effectively carried out on the mechanical equipment under the small sample data, and the fault diagnosis accuracy of the mechanicalequipment under the small sample data is improved.

Owner:XI AN JIAOTONG UNIV

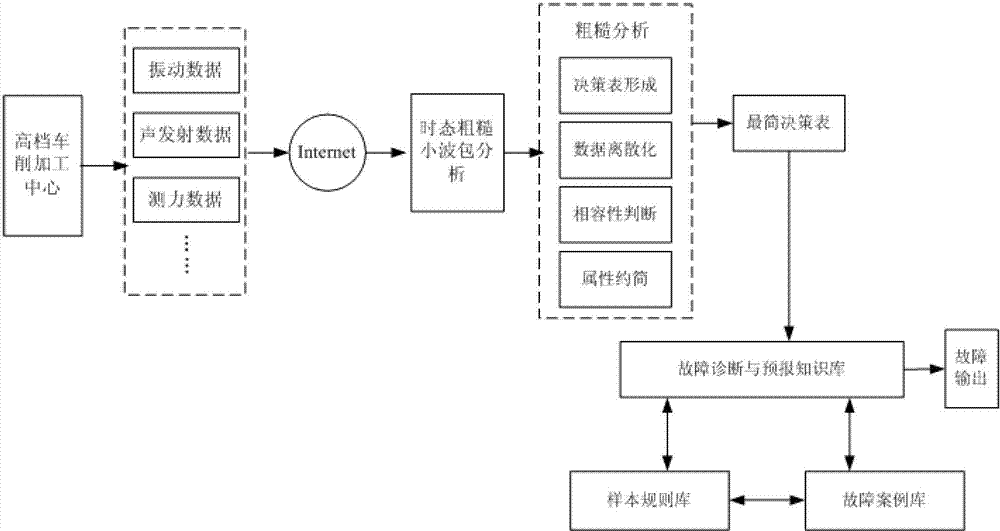

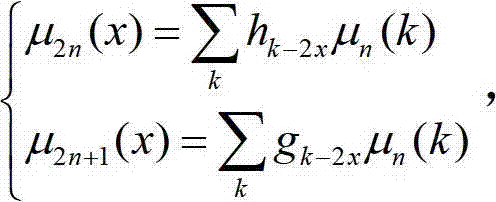

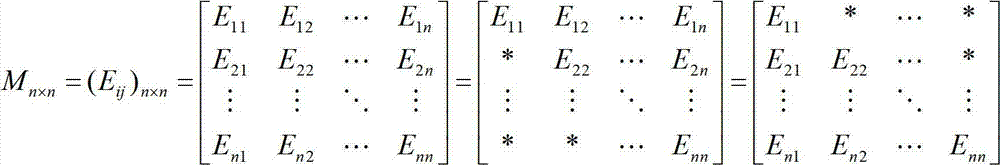

Knowledge base construction method oriented to fault diagnosis and fault prediction of numerical control machine tool

ActiveCN102736562AEliminate distractionsSimplify the expression of fault characteristicsProgramme controlComputer controlFeature vectorNumerical control

The invention relates to a knowledge base construction method oriented to fault diagnosis and fault prediction of a numerical control machine tool. The method comprises the following steps of: step 1, performing real-time monitoring on a high-grade turning center through a remote monitoring device, and obtaining multiple groups of vibration data Xj(t) representing different fault types, wherein j is the number of acquired vibration data groups, and n is a positive integer; step 2, orderly executing temporal rough wavelet packet analysis on the multiple groups of vibration data Xj(t), obtaining an energy feature vector T' as a condition attribute, and taking the fault type as a decision attribute to construct a fault knowledge primary decision table; step 3, executing discernibility matrix-based fault feature attribute reduction on the fault knowledge primary decision table to generate a rule and form a knowledge base; and step 4, taking the confidence level of the rule as an evaluation index to measure and evaluate the final rule. The method provided by the invention can provide effective guarantee for fault diagnosis and fault prediction, and can be widely used in the high-grade turning center.

Owner:BEIJING INFORMATION SCI & TECH UNIV

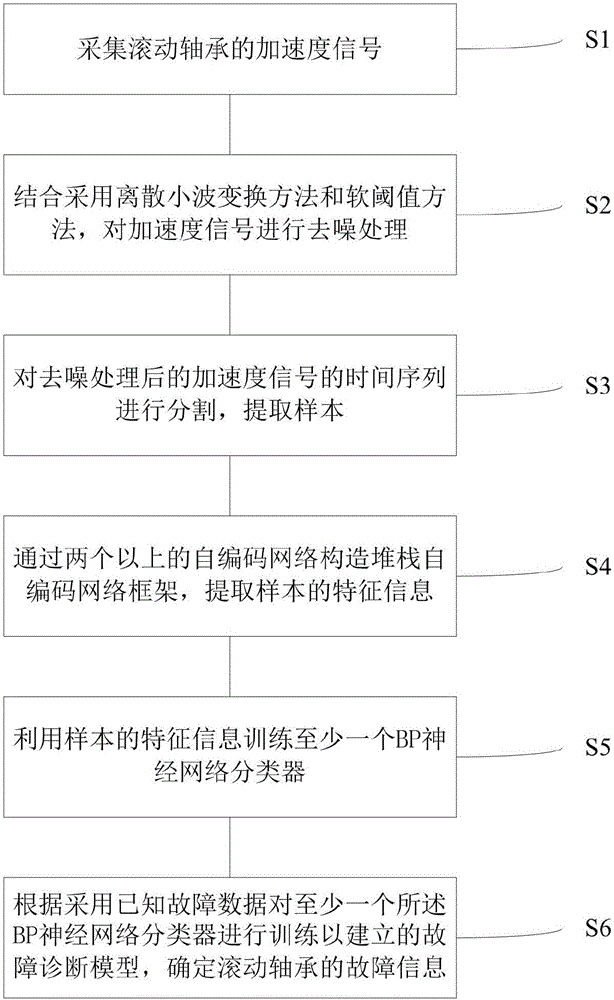

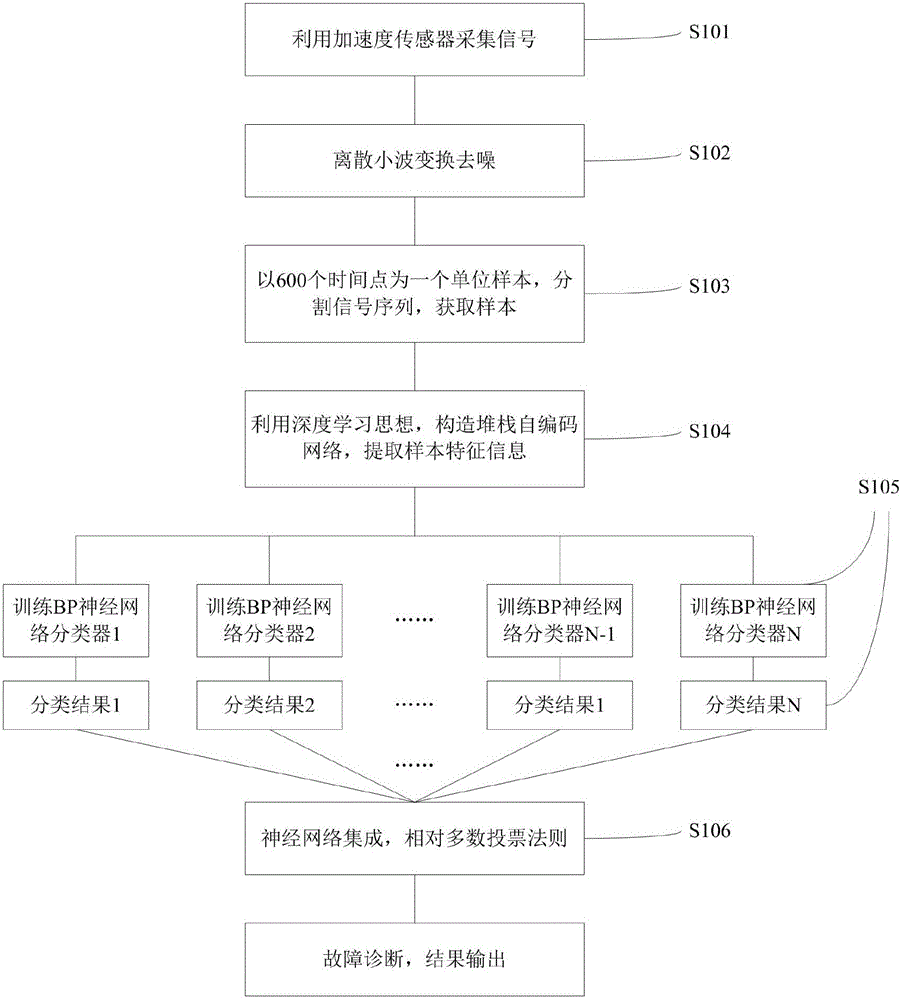

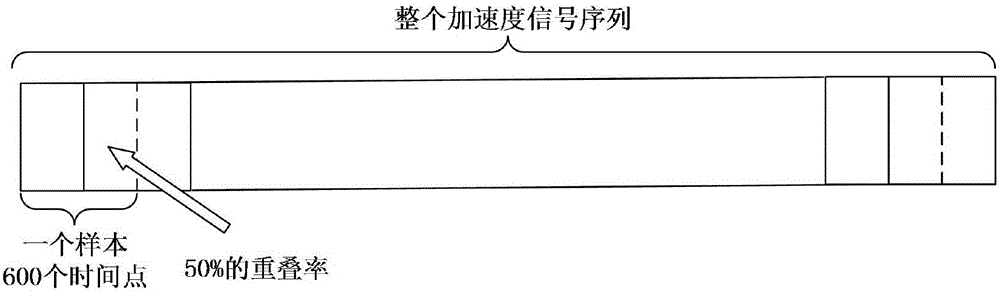

Diagnosis method of rolling bearing fault

ActiveCN105973595AAccurate fault diagnosisEffective fault diagnosisMachine bearings testingCharacter and pattern recognitionNerve networkRolling-element bearing

The invention discloses a diagnosis method of a rolling bearing fault. The method comprises the following steps of S1, collecting an acceleration signal of a rolling bearing; S2, using a discrete wavelet transform method and a soft threshold method in a combination mode and carrying out de-noising processing on the acceleration signal; S3, carrying out segmentation on a time sequence of the acceleration signal after the de-noising processing and extracting a sample; S4, through more than two self-encoding networks, constructing a stack self-encoding network framework, and extracting characteristic information of the sample; S5, using the characteristic information of the sample to train at least one BP nerve network classifier; and S6, according to a fault diagnosis model established through using known fault data to train the at least one BP nerve network classifier, determining fault information of the rolling bearing. By using the diagnosis method of the rolling bearing fault, accuracy of the fault diagnosis is greatly increased.

Owner:SHENZHEN GRADUATE SCHOOL TSINGHUA UNIV

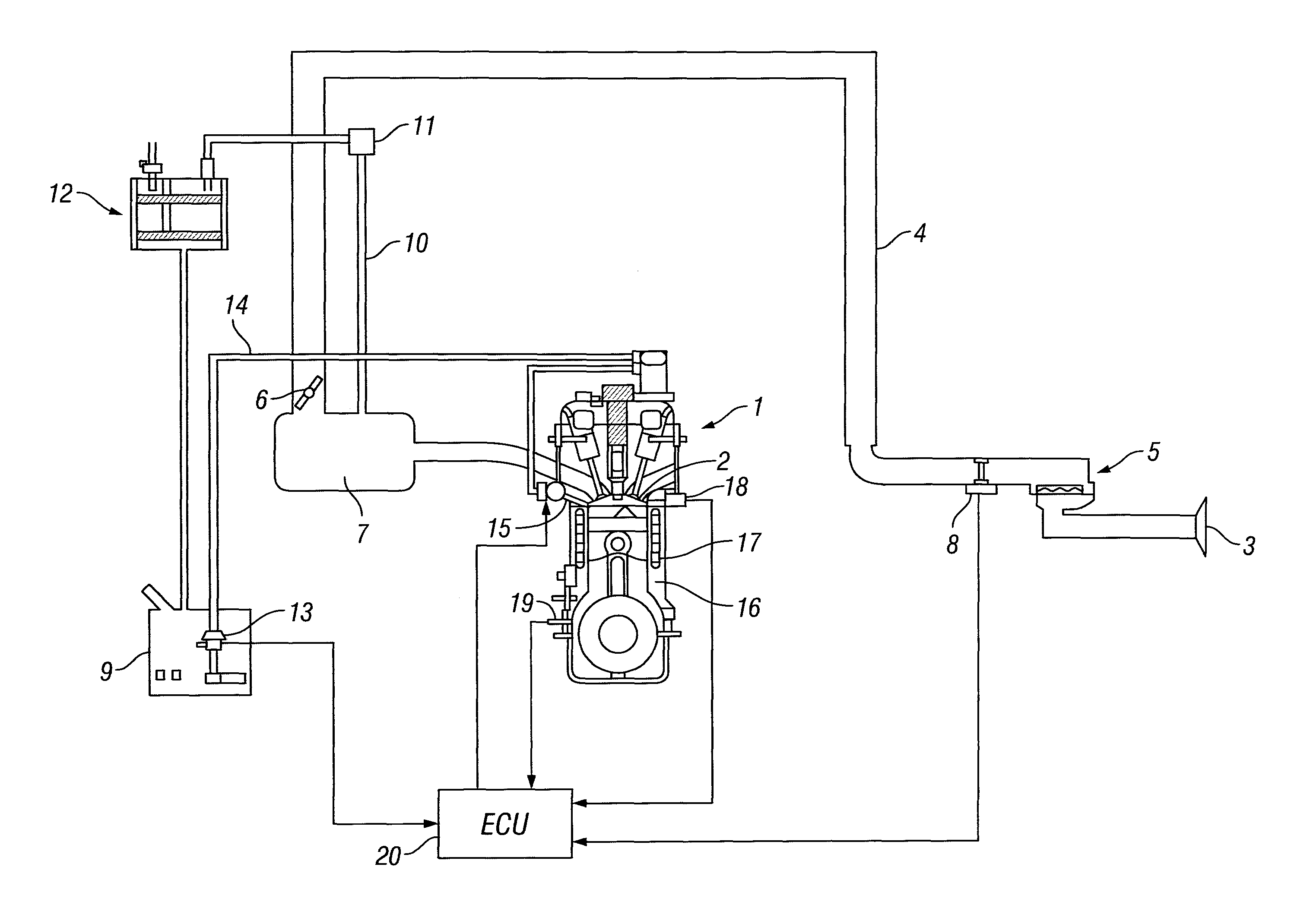

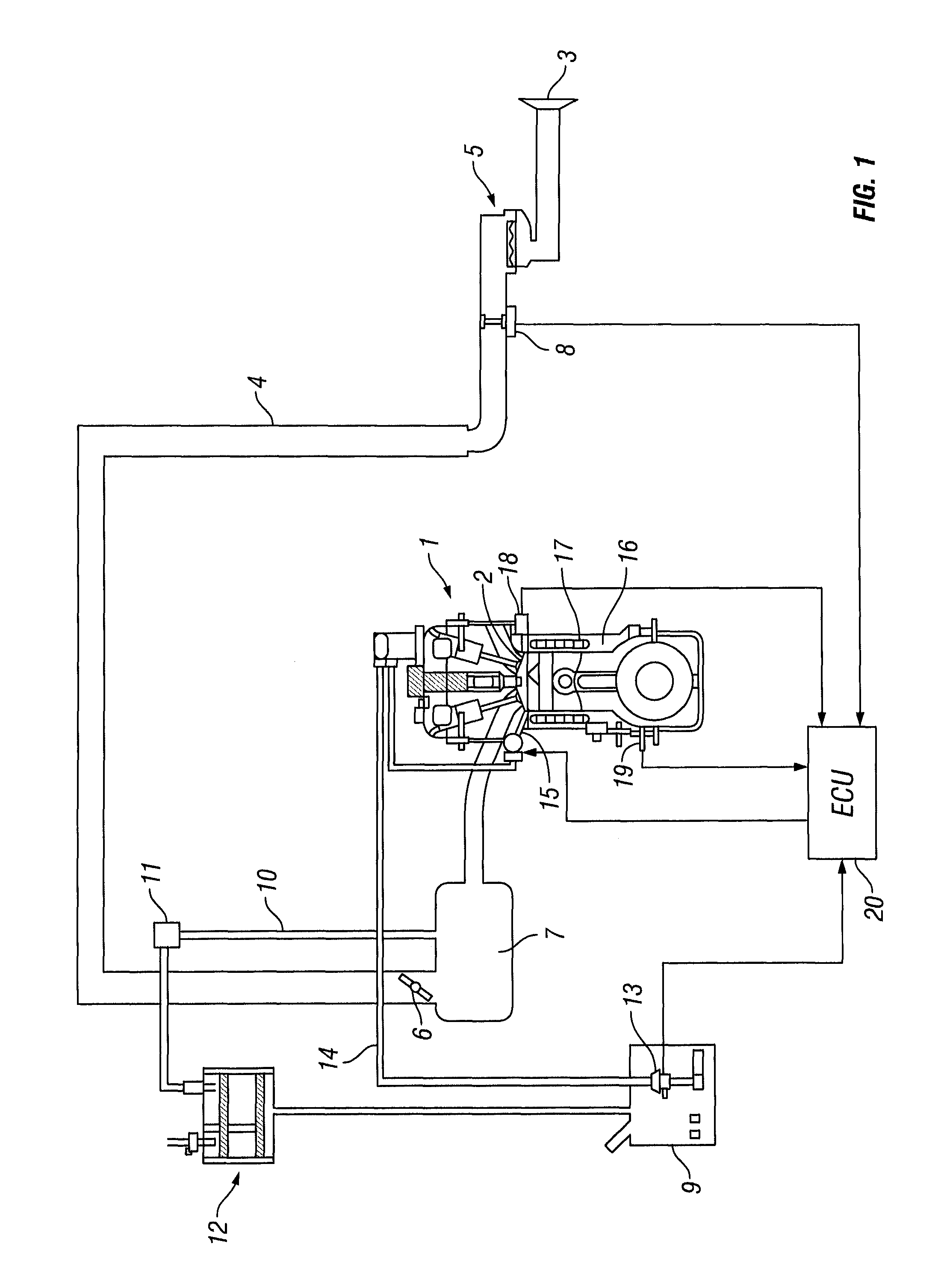

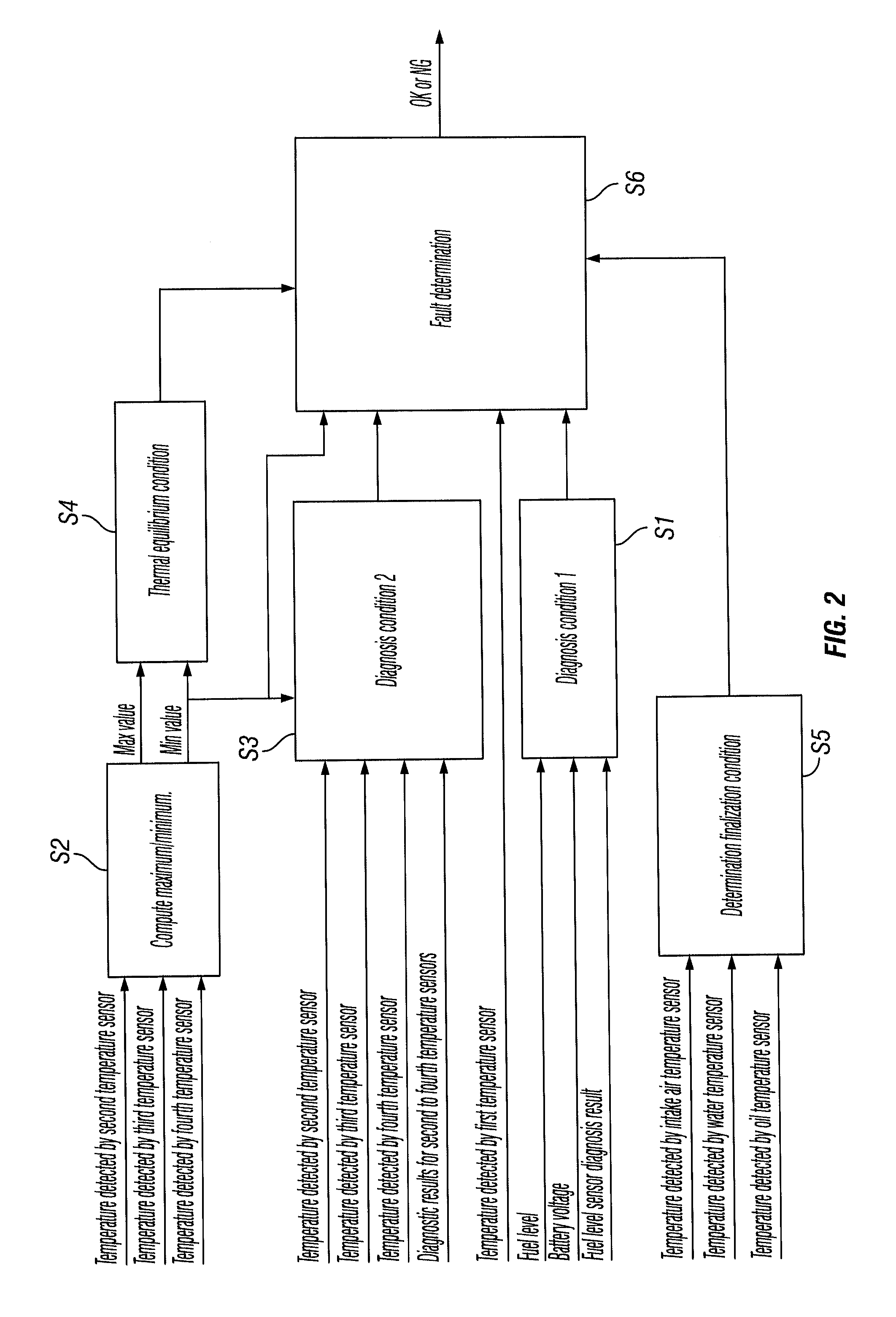

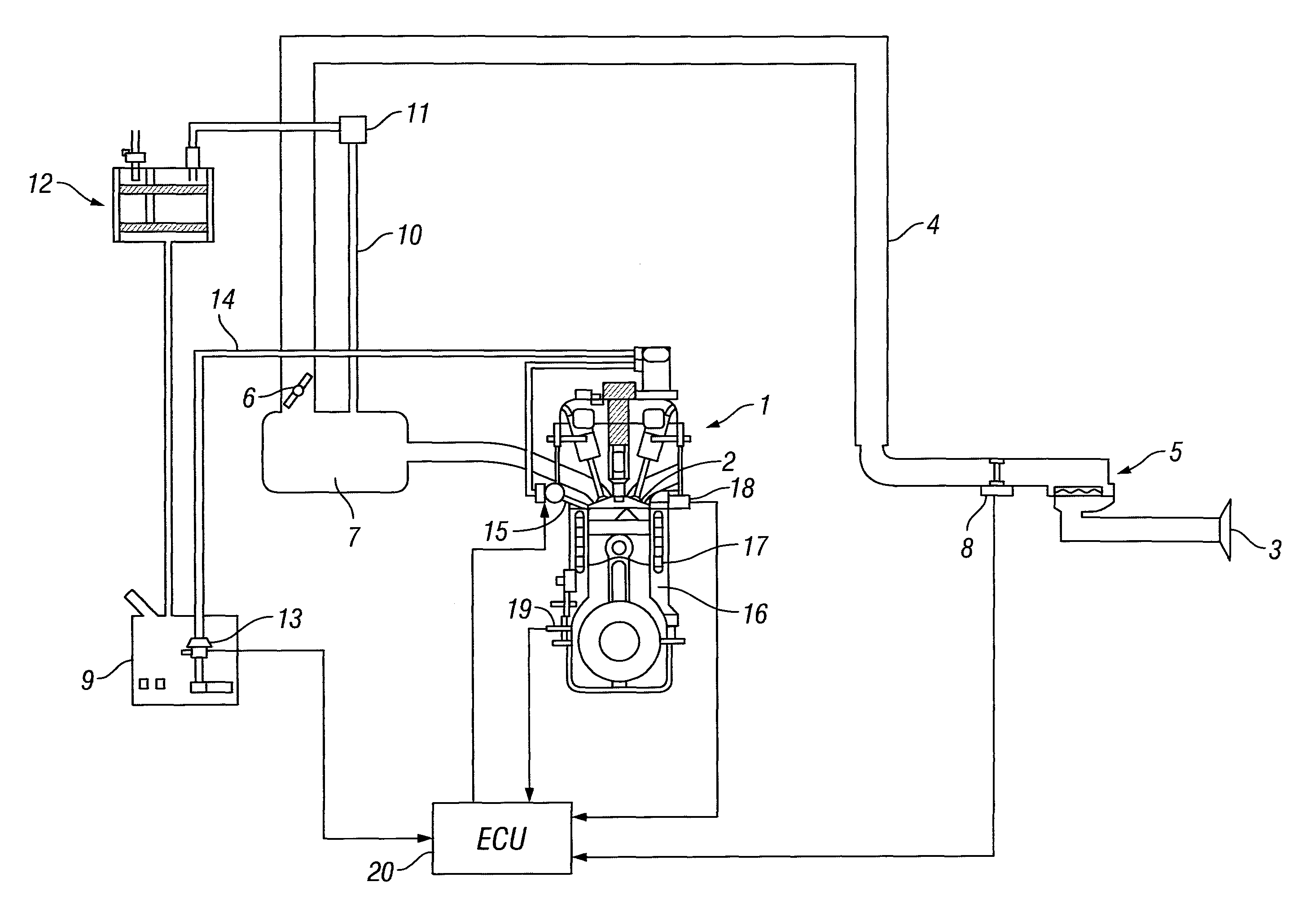

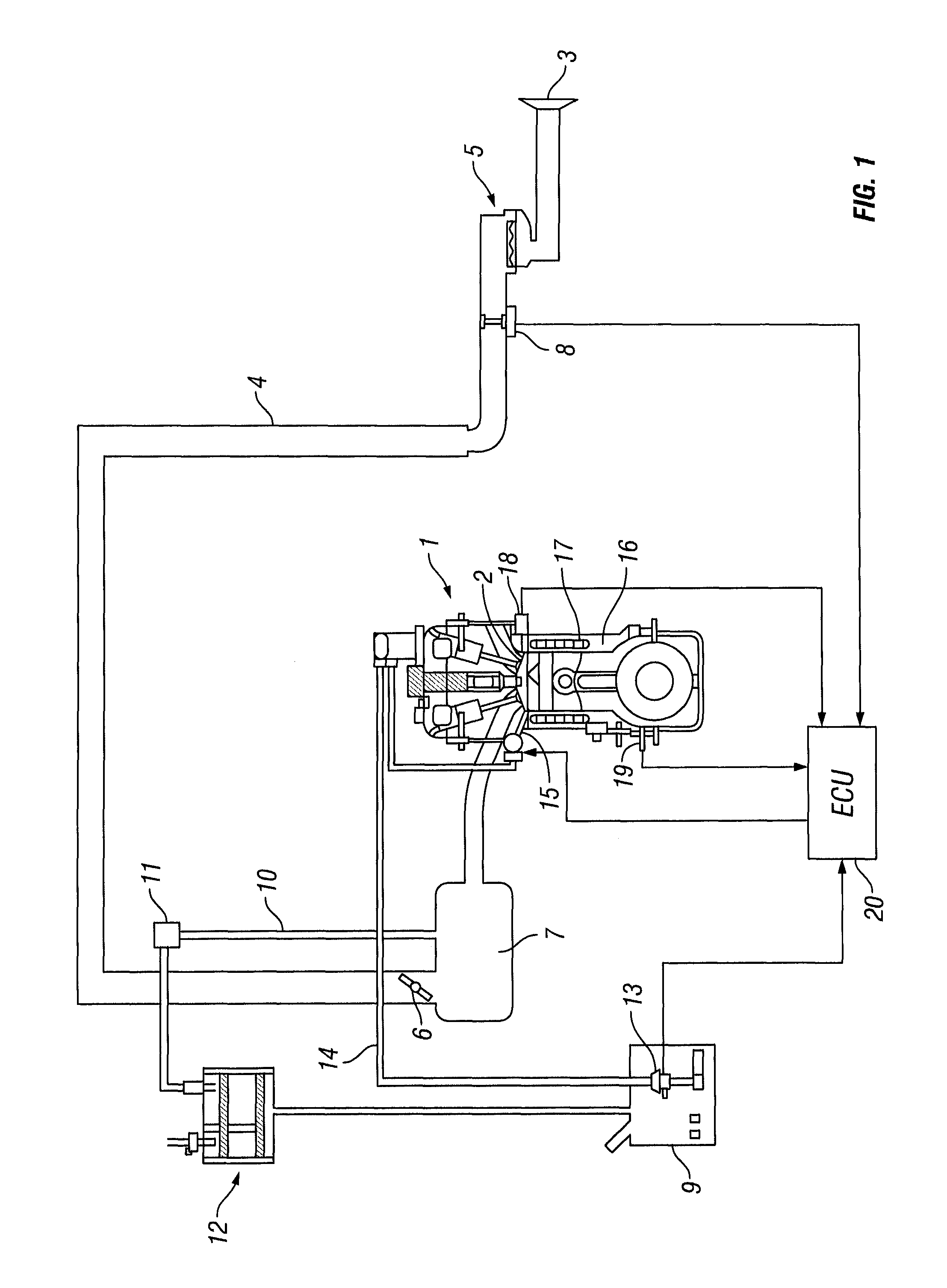

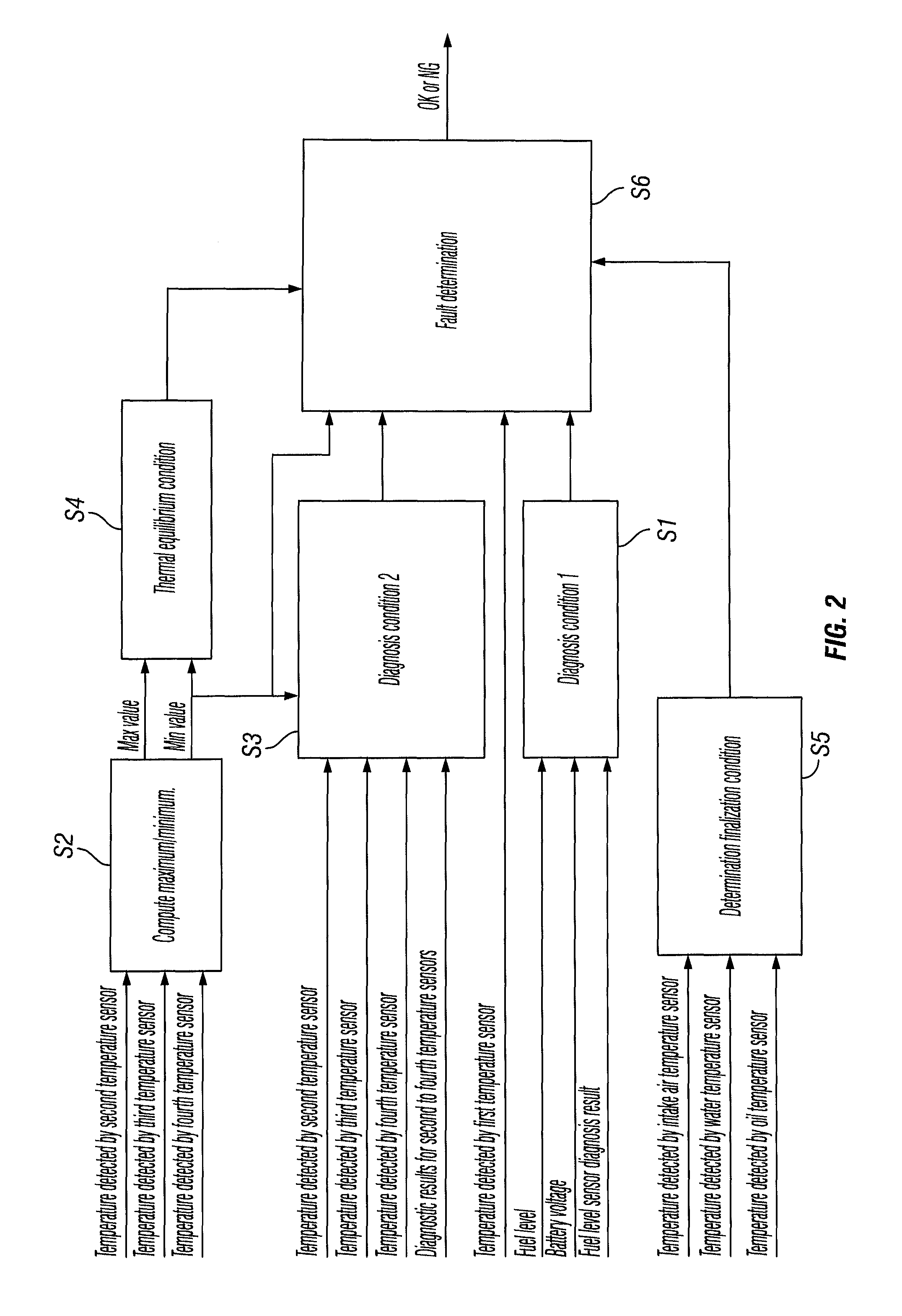

Fault diagnosis device for temperature sensor

ActiveUS20130058373A1Effective fault diagnosisEfficient executionElectrical controlInternal combustion piston enginesEngineeringInternal combustion engine

A fault diagnosis device conducts a fault diagnosis in a temperature sensor. At starting an internal combustion engine, a thermal equilibrium condition may be established and temperature deviations of temperatures detected by at least two reference temperature sensors from each other may be equal to or less than a predetermined value, with the temperatures detected by the reference temperature sensors being greatly deviated from one detected by a temperature sensor being diagnosed. In this case, if the temperatures detected by the reference temperature sensors do not drop by a predetermined temperature or more from starting the engine until a predetermined time elapses, the fault diagnosis device determines that the temperature sensor being diagnosed is faulty.

Owner:NISSAN MOTOR CO LTD

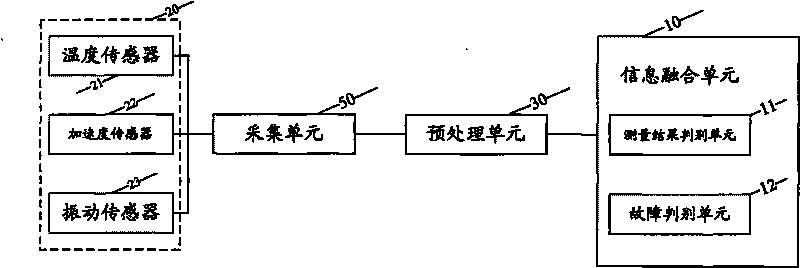

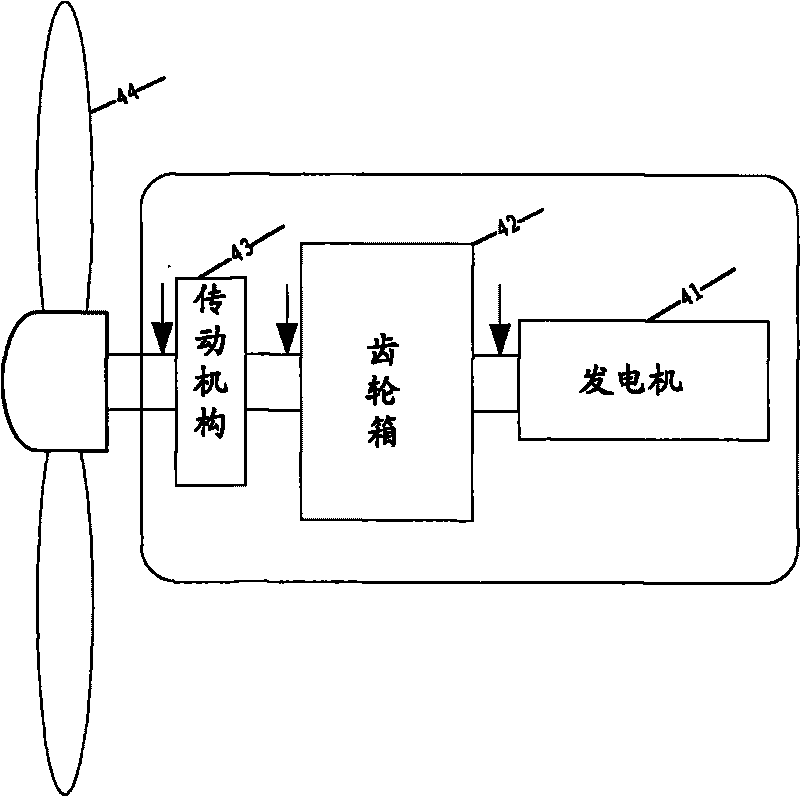

Multi-source information fusion based state monitoring system and method of wind-driven generator

InactiveCN101696906AEfficient integrationEffective fault diagnosisEngine testingWind drivenMonitoring system

The invention discloses multi-source information fusion based state monitoring system and method of a wind-driven generator. The monitoring system comprises a plurality of sensors, an acquisition unit and an information fusion unit, wherein the sensors are used for inducing different type measurement information of the wind-driven generator; the acquisition unit acquires the measurement information of each sensor; and the information fusion unit receives the measurement information of each sensor and carries out fusion operation according to the measurement information to obtain a final measurement result. The plurality of sensors are used in the monitoring system to respectively acquire the state information of the wind-driven generator, then to effectively fuse the measurement information to obtain final data; and more accurate measurement signals can be obtained from the information of all the sensors by effectively fusing the information of the sensors when all the sensors can normally work; and failure symptoms are extracted from other sensors to replace the measurement signals of the failure sensors when a part of the sensors are broken down and can not normally work, and the self failures of the sensors also can be defined and diagnosed at the same time according to the extracted failure symptoms.

Owner:SHANGHAI DIANJI UNIV

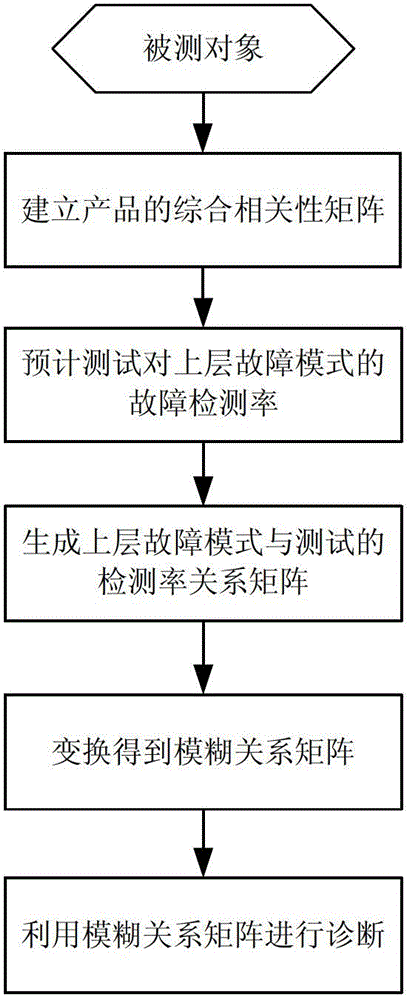

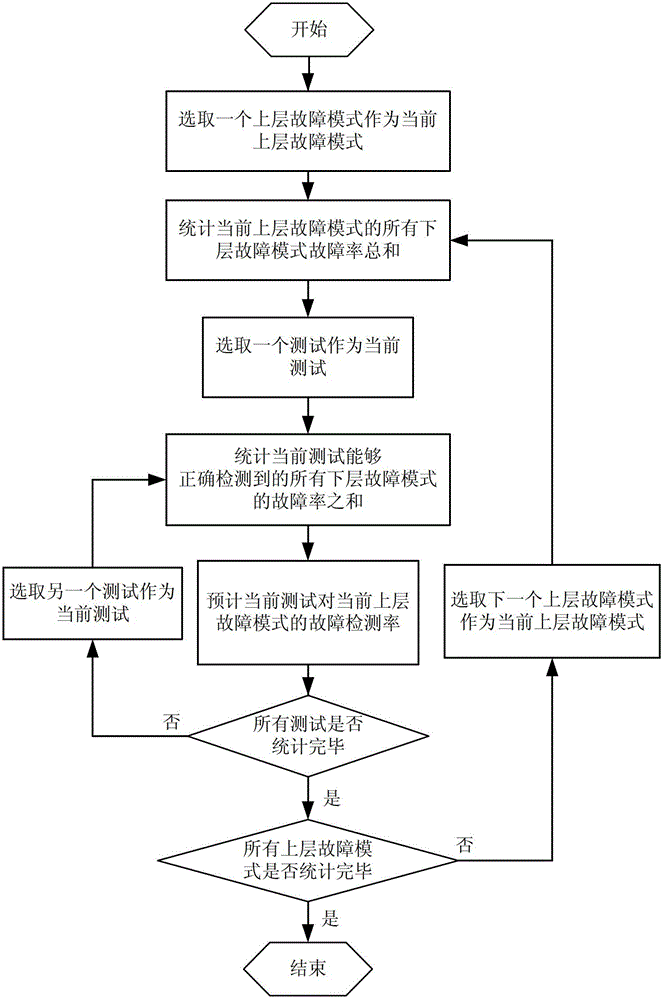

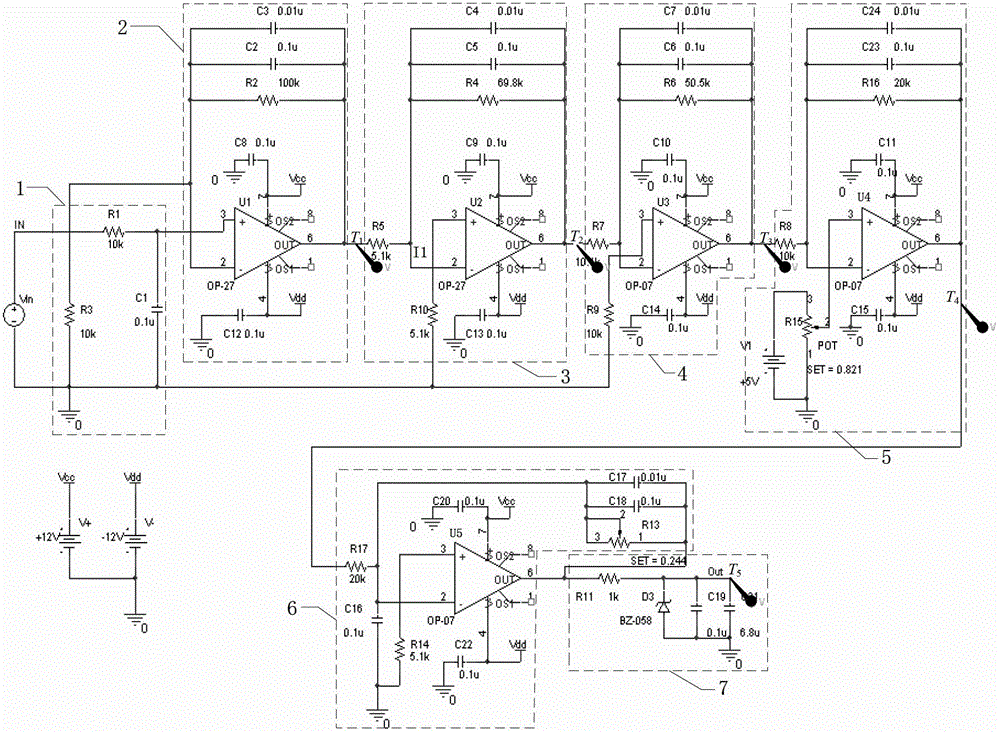

Fuzzy relation matrix generating method based on comprehensive correlation matrix

ActiveCN102722471AImprove accuracyEffective fault diagnosisComplex mathematical operationsAlgorithmFault detection rate

The invention provides a fuzzy relation matrix generating method based on a comprehensive correlation matrix, which can be used for fuzzy fault diagnosis. The method comprises the following steps of: carding fault modes of a product to acquire upper fault modes and corresponding lower fault modes, acquiring each test according to test configuration, establishing the comprehensive correlation matrix, predicting the fault detection rate of each upper fault mode according to each test, generating a detection rate relation matrix of the upper fault modes and the tests, transforming the detection rate relation matrix to acquire a fuzzy relation matrix, and performing product fault diagnosis by using the fuzzy relation matrix. The fuzzy relation matrix generated by using the method can be applied to fault diagnosis in the product, and solves the problem that the diagnosis accuracy declines because the optional characteristic elements of the artificial subordinate function are unreasonable in the conventional fuzzy relation matrix construction method.

Owner:北京恒兴易康科技有限公司

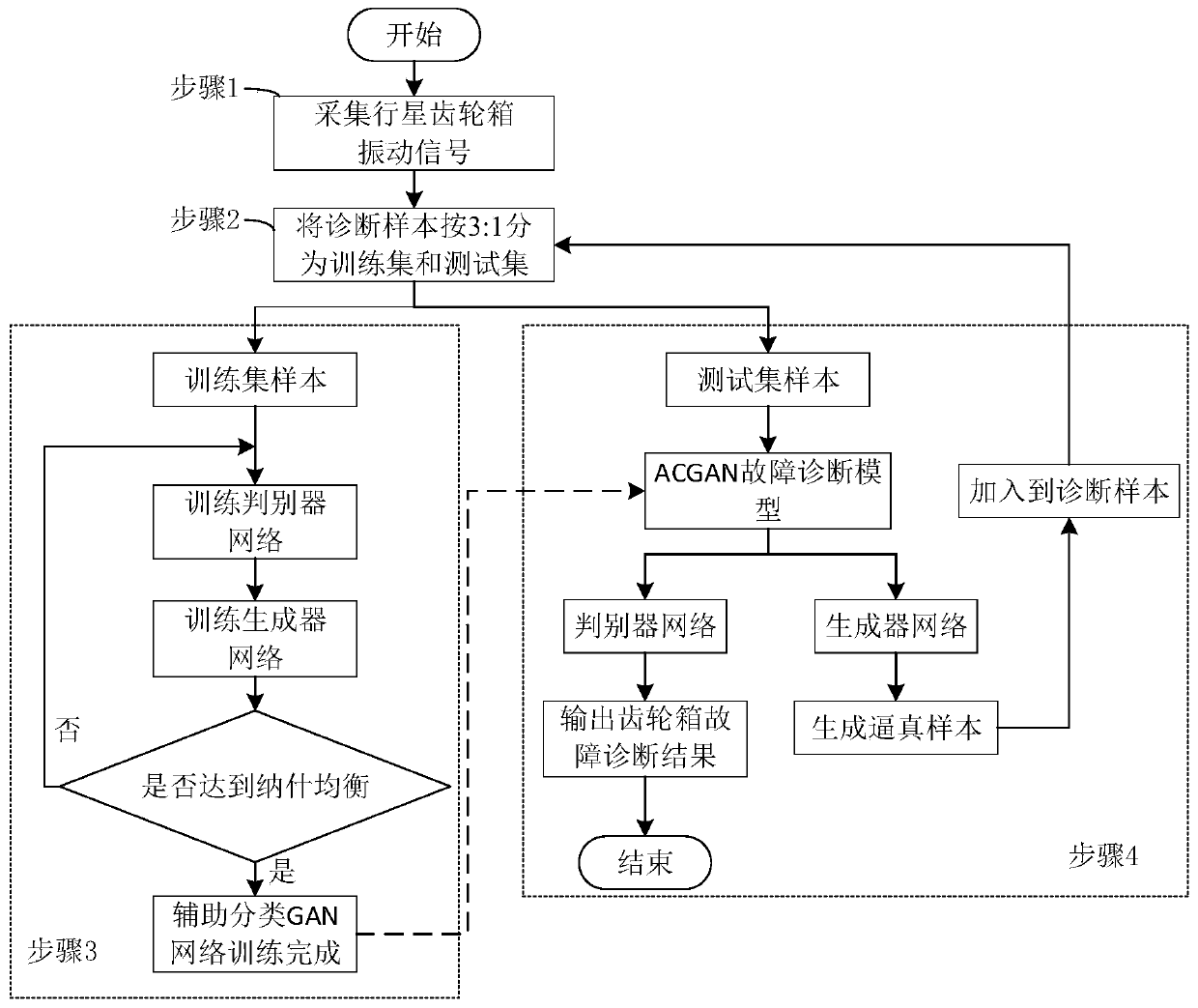

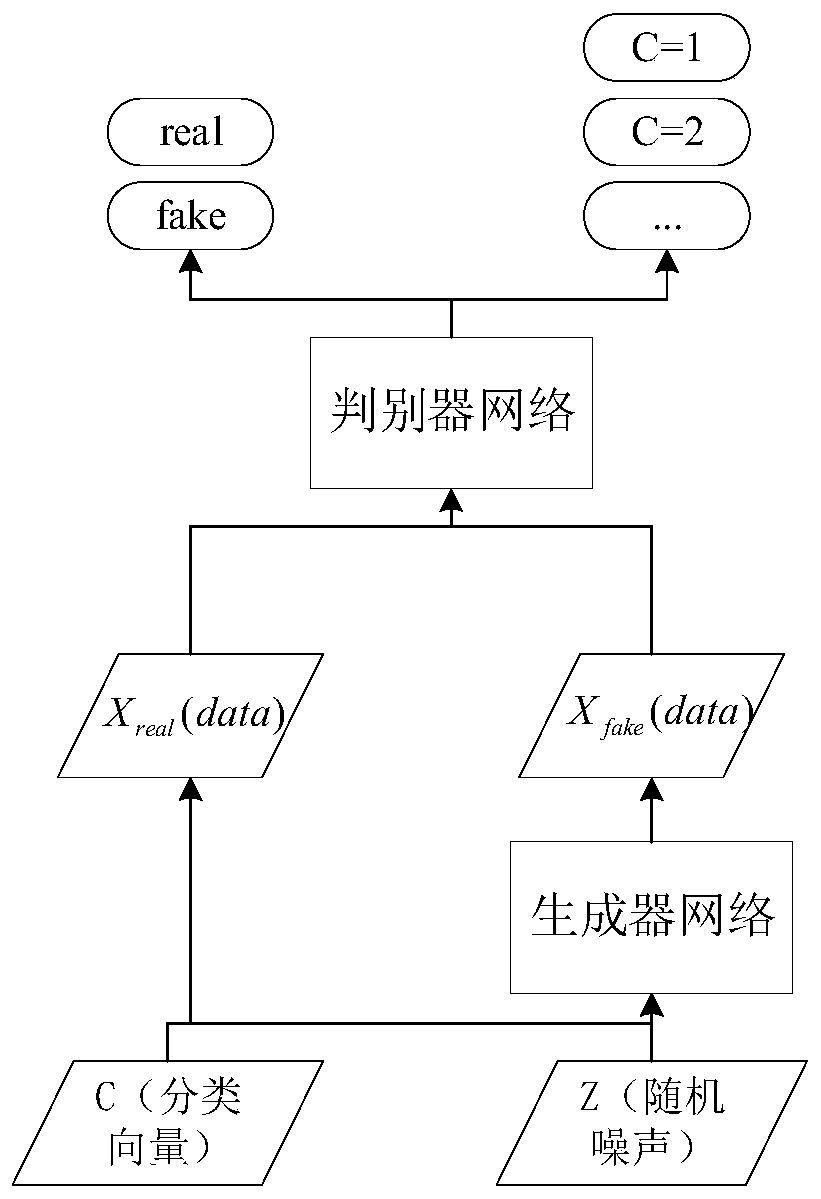

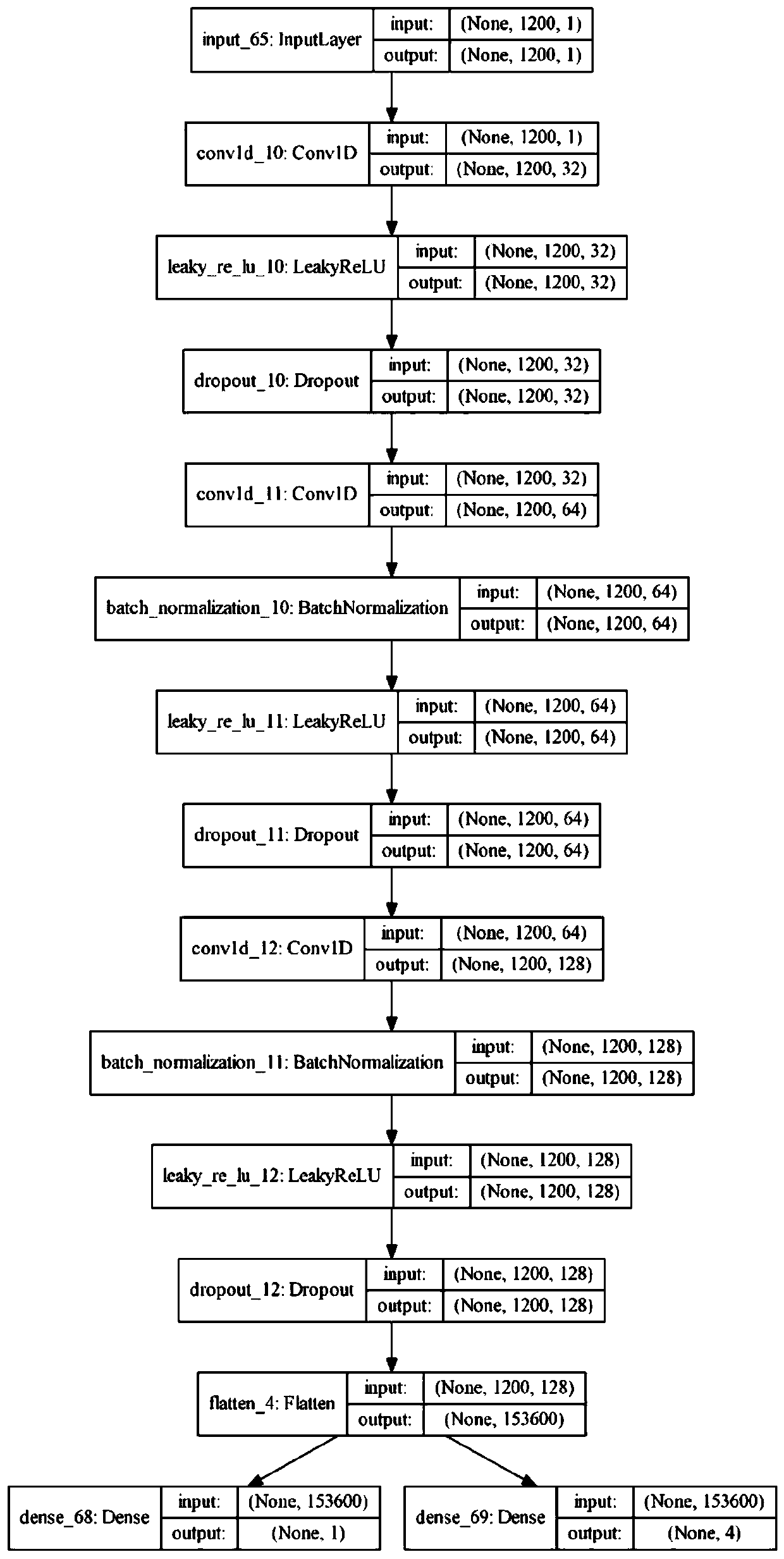

Wind turbine planetary gear box fault diagnosis method based on ACGAN

ActiveCN111337243AEffective fault diagnosisHigh precisionMachine part testingOriginal dataSimulation

The invention relates to a wind turbine planetary gear box fault diagnosis method based on ACGAN. The method comprises the following steps: collecting a vibration signal of a planetary gear box as a diagnosis sample; dividing the diagnosis sample into a training set sample and a test set sample according to a set proportion; inputting the training set sample into the ACGAN for adaptive training, obtaining parameters of a discriminator network and a generator network in the ACGAN until the ACGAN reaches Nash equilibrium, and storing the trained parameters of the discriminator network and the generator network in the ACGAN; taking the trained ACGAN as a fault diagnosis model, inputting the ACGAN into a test set sample, generating a realistic sample by a generator network, and adding the realistic sample into a diagnosis sample; and enabling the discriminator network to output a gearbox fault diagnosis result. Compared with the prior art, the method has the advantages that the original data training network can be directly used, the feature vectors are automatically extracted, and the accuracy of model recognition and classification is high; meanwhile, the generalization ability is extremely high, and fault diagnosis can be effectively carried out on the planetary gear box of the wind turbine generator.

Owner:SHANGHAI UNIVERSITY OF ELECTRIC POWER

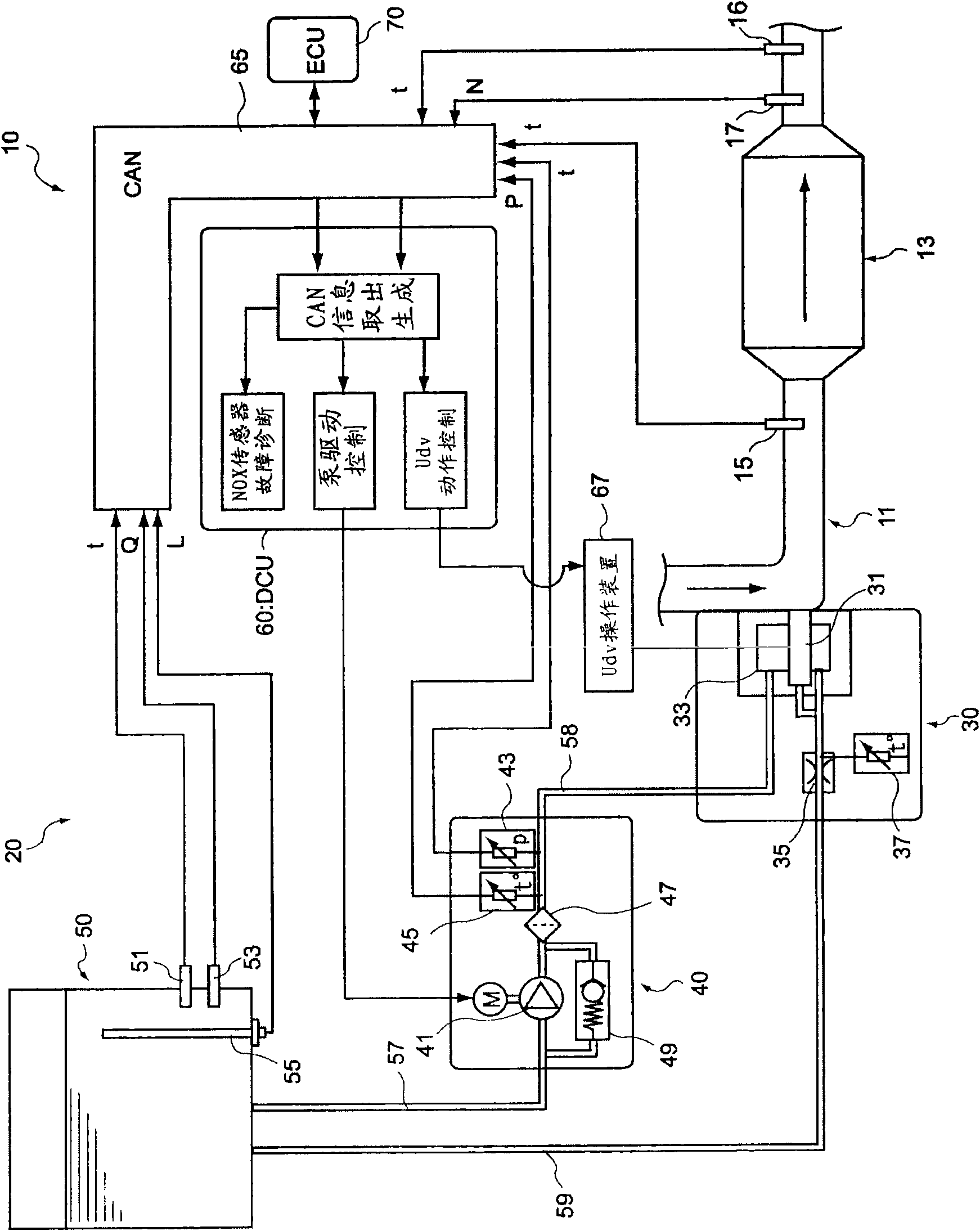

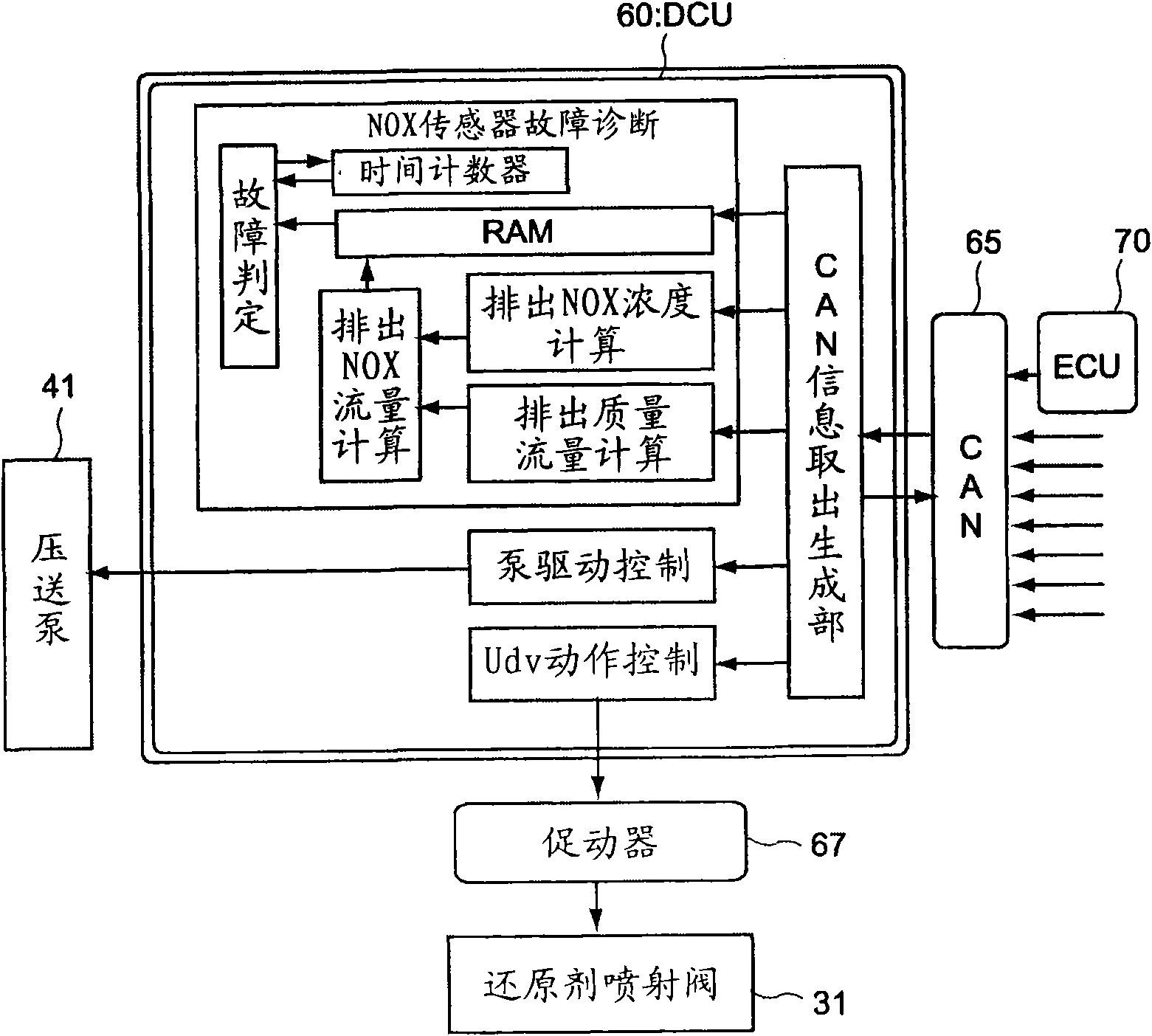

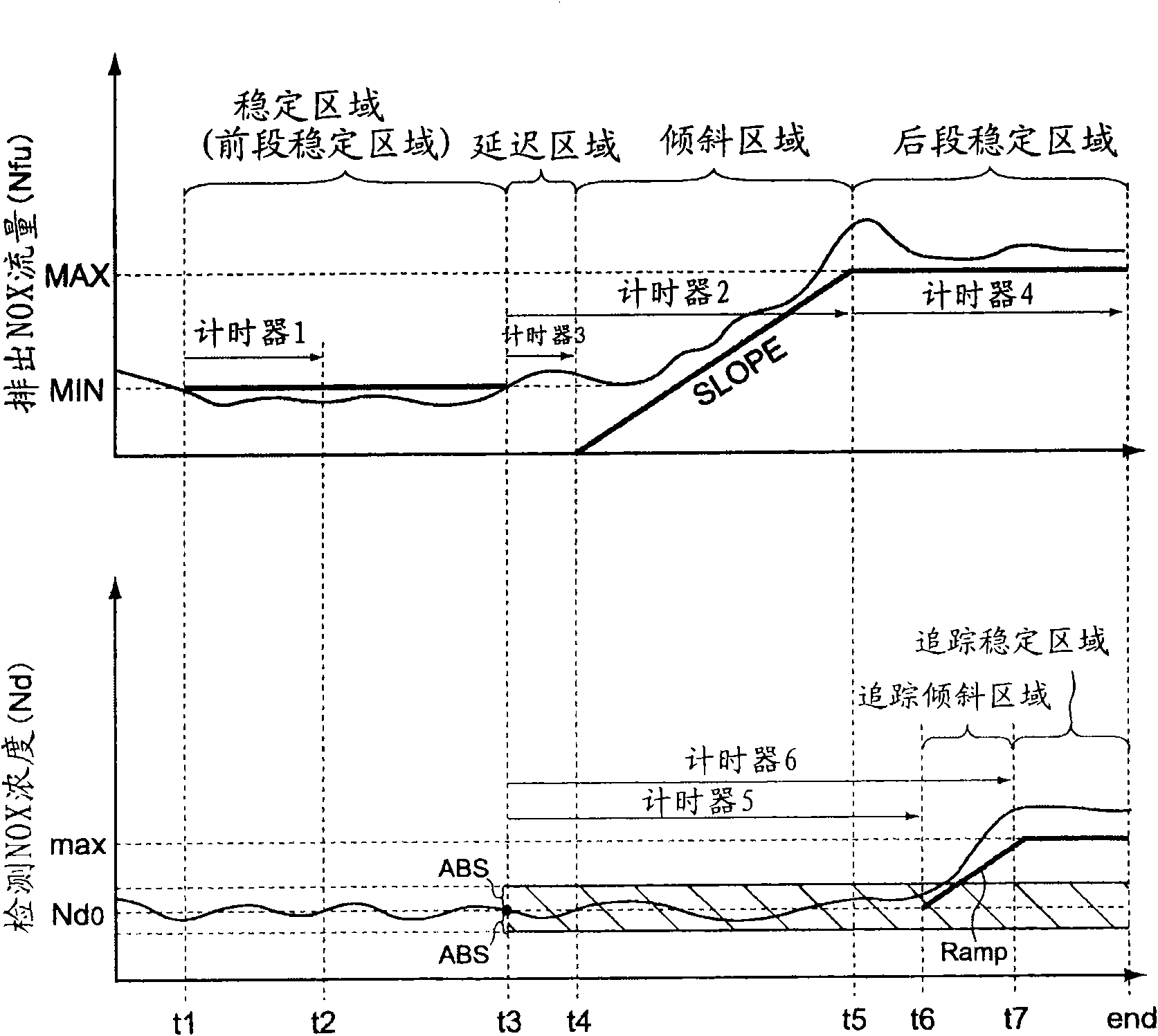

Breakdown diagnosing device and breakdown diagnosing method of nox sensor

ActiveCN101600863AImprove reliabilityImprove purification efficiencyNitrous oxide captureElectrical controlEngineeringOperation mode

There is provided an NO x sensor trouble diagnosis device and an NO x trouble diagnosis method that can perform trouble diagnosis on a timely basis without intentionally creating any diagnosis mode during operation of an internal combustion engine and without deterioration of drivability and fuel consumption. The device includes an exhaust NO x flow rate calculating and storing means for calculating and storing an exhaust NO x flow rate discharged from an internal combustion engine per unit time, detected NO x concentration storing means for storing a detected NO x concentration detected by an NO x sensor, and trouble determining means for defining a reference pattern as a time-lapse variation reference of the exhaust NO x flow rate and a follow pattern as a time-lapse variation reference of the detected NO x concentration detected by the NO x sensor, and determining whether the detected NO x concentration undergoes a transition while having a predetermined relation with the follow pattern when the exhaust NO x flow rate undergoes a transition while having a predetermined relation with the reference pattern in a case where the internal combustion engine is in a normal operation mode, thereby determining the responsiveness of the NO x sensor.

Owner:BOSCH CORP

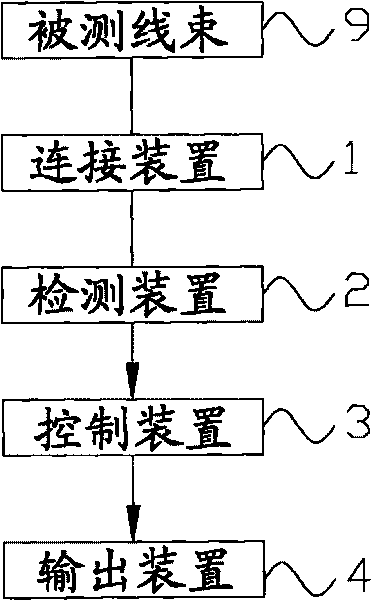

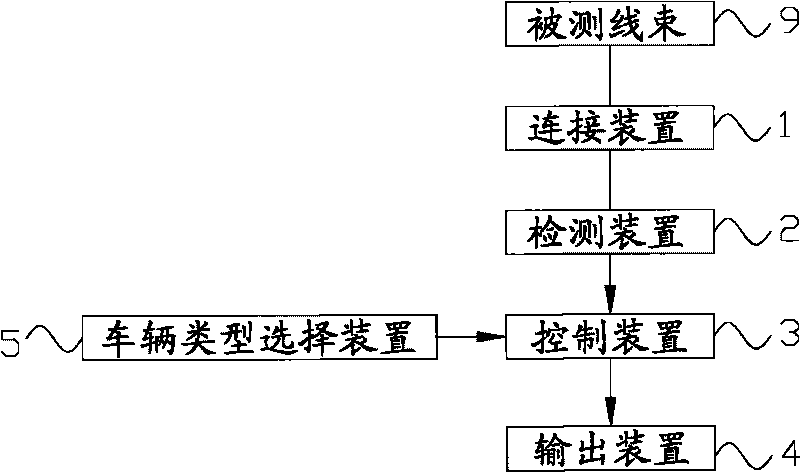

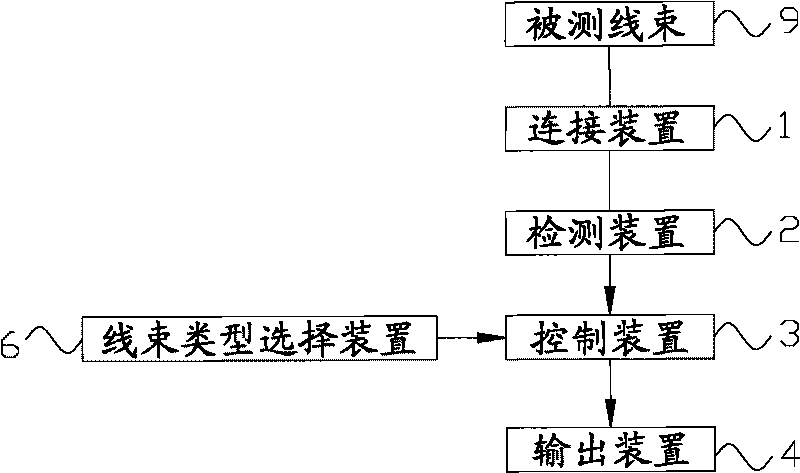

Fault diagnosis system and method

ActiveCN101762769AEasy to troubleshootEffective fault diagnosisElectrical testingElectronic control systemOutput device

The invention discloses a fault diagnosis system, which is used for detecting the fault of a wiring harness vehicle; the fault diagnosis system comprises a connecting device (1), a detecting device (2), a controlling device (3) and an output device (4); the connecting device (1) is connected with the detecting device (2) and a tested wiring harness (9) of the wiring harness vehicle; each line state of the tested wiring harness (9) is detected by the detecting device (2); a detecting signal is received by the controlling device (3) and is compared with a pre-stored standard of the tested wiring harness (9) by the controlling device to judge the state of the tested wiring harness (9); the state of the tested wiring harness (9) is output by the output device (4). The connection of a wiring harness and the detecting device (2) can be conveniently realized by the fault diagnosis system in the invention, the pre-stored standard in the controlling device (3) is corresponding to each line of the tested wiring harness (9), thereby conveniently realizing the detection of an electronic control system of the wiring harness vehicle and improving the detection efficiency. The invention further discloses a fault diagnosis method.

Owner:SANY HEAVY IND CO LTD (CN)

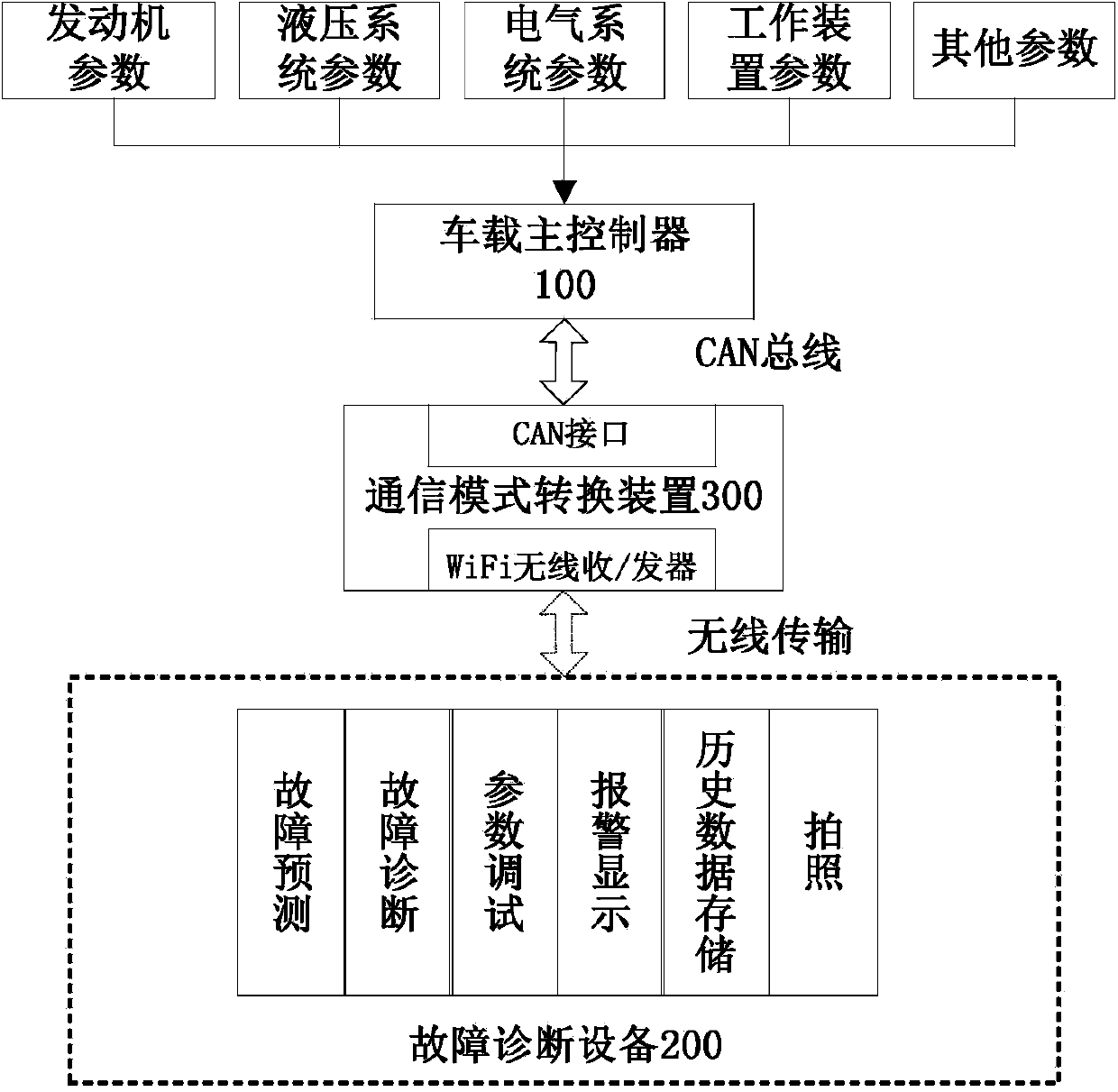

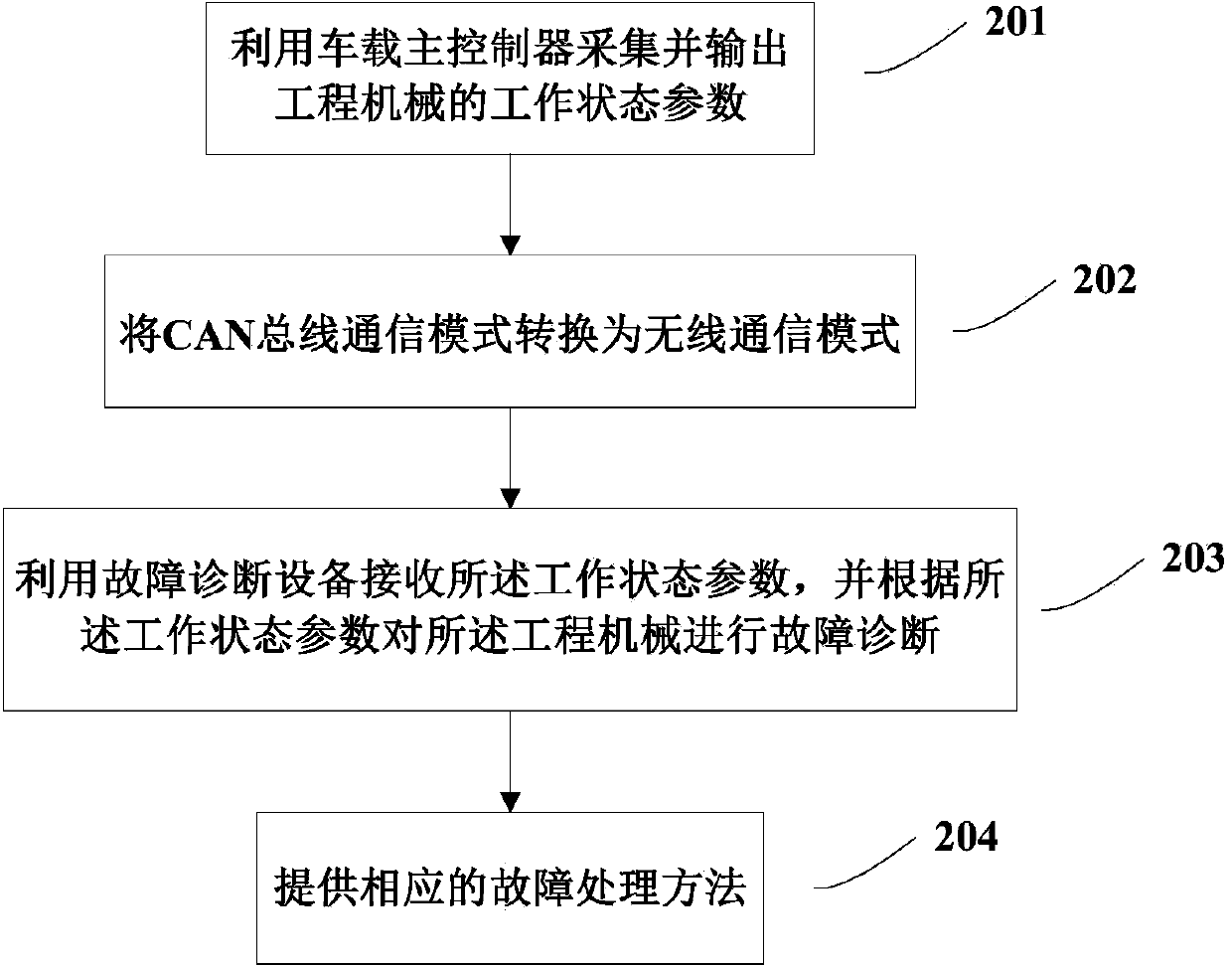

Engineering machine intelligent fault diagnosis system and method and engineering machine

InactiveCN103439944AEffective fault diagnosisLow costTotal factory controlProgramme total factory controlWork statusControl equipment

The invention discloses an engineering machine intelligent fault diagnosis system and method and an engineering machine. The engineering machine intelligent fault diagnosis system comprises a vehicle-mounted main controller and a fault diagnosis device, wherein the vehicle-mounted main controller is used for collecting and outputting work state parameters of the engineering machine, and the fault diagnosis device is used for receiving the work state parameters and carrying out fault diagnosis on the engineering machine according to the work state parameters. By means of the technical scheme, the vehicle-mounted main controller inside a cab in the engineering machine can be directly used for collecting the work state parameters for the fault diagnosis, a single-chip microcomputer or other control devices are not required to be additionally arranged for collection, the cost is low, the development period is short, the fault diagnosis can be effectively carried out on the engineering machine, the maintenance level is improved, and the machine-stop losses are reduced.

Owner:ZOOMLION HEAVY IND CO LTD

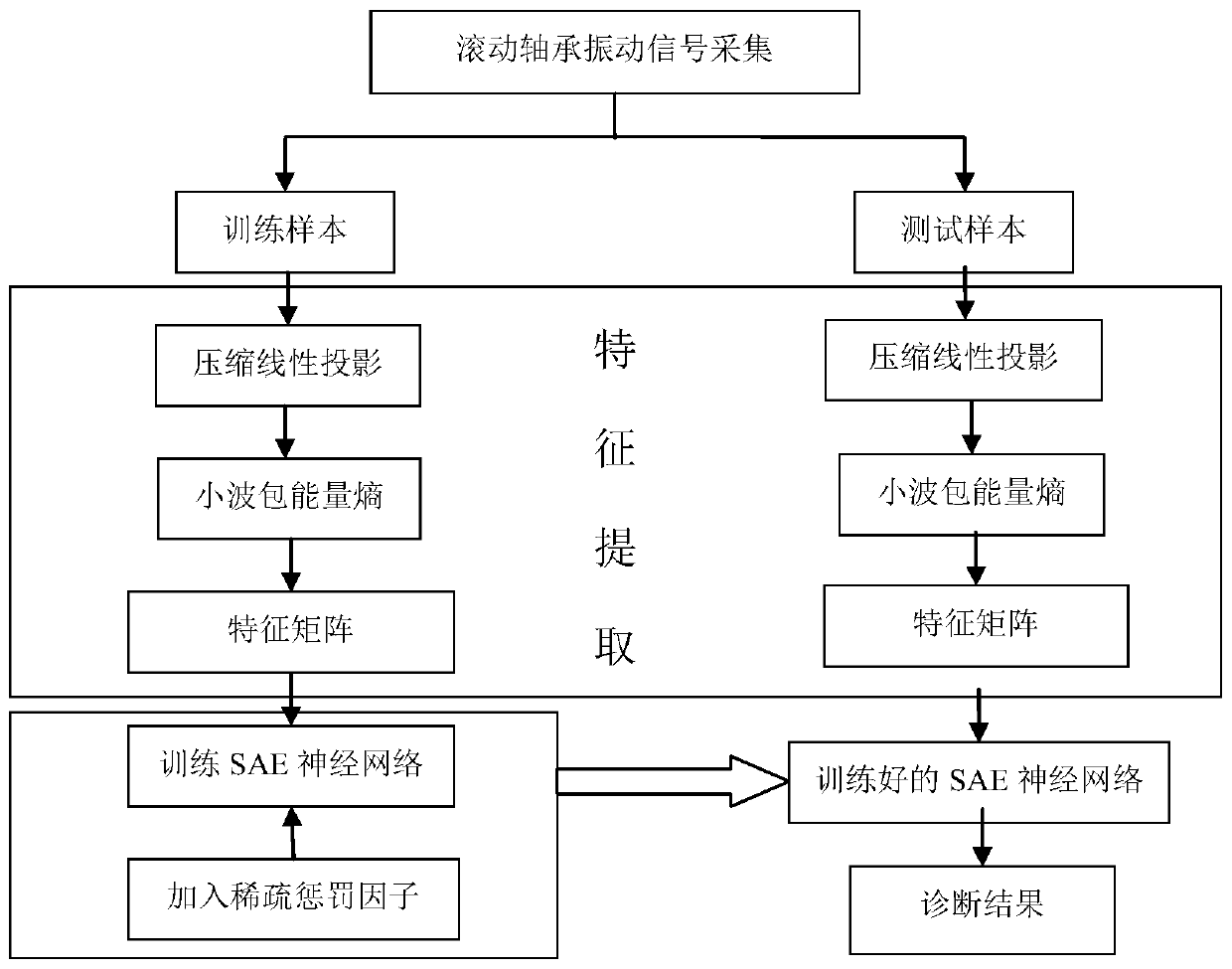

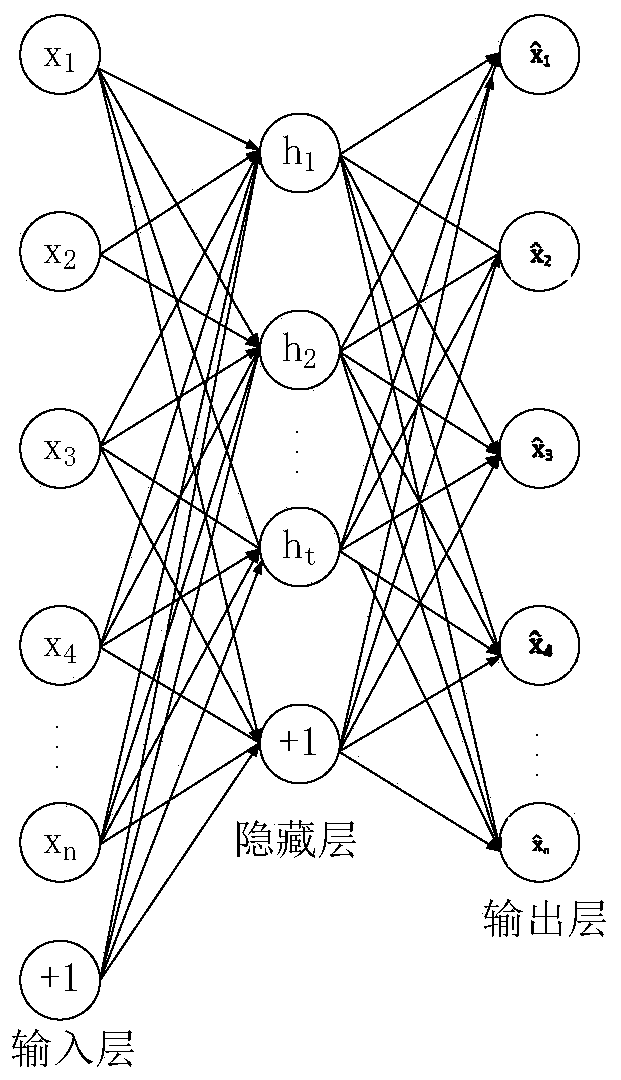

Sparse self-encoding rolling bearing fault diagnosis method

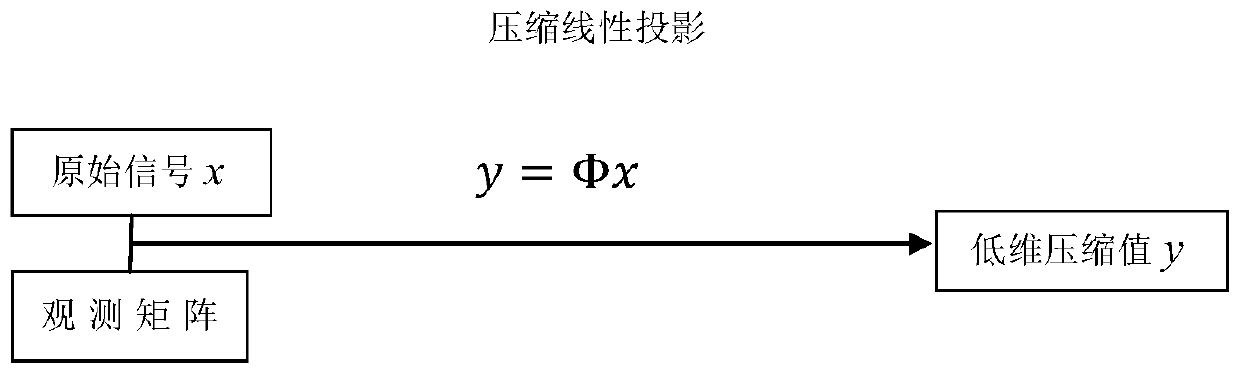

ActiveCN110346141AReduce dimensionalityQuality improvementMachine part testingFeature vectorHidden layer

The invention discloses a sparse self-encoding rolling bearing fault diagnosis method. The method specifically comprises the following steps: S1, acquiring original vibration data of a rolling bearingin each fault state, performing linear projection on each kind of vibration data through compressed sensing, and combining compressed signals after linear projection of each fault type into a multi-fault type low-dimensional compressed signal matrix; S2, determining wavelet packet energy entropy of the multi-fault type low-dimensional compressed signal matrix to form a feature vector matrix for bearing fault diagnosis; S3, inputting the feature vector matrix of the rolling bearing under multiple fault types into a sparse automatic encoder for training, and further extracting the weight from an input layer to a hidden layer as a feature matrix; and S4, classifying features extracted by a sparse automatic coding neural network through a neural network classifier, and finishing fault diagnosis classification of the rolling bearing. According to the method, the diagnosis complexity is reduced, the diagnosis time is shortened, and the high diagnosis precision is ensured.

Owner:秦皇岛东辰科技有限公司

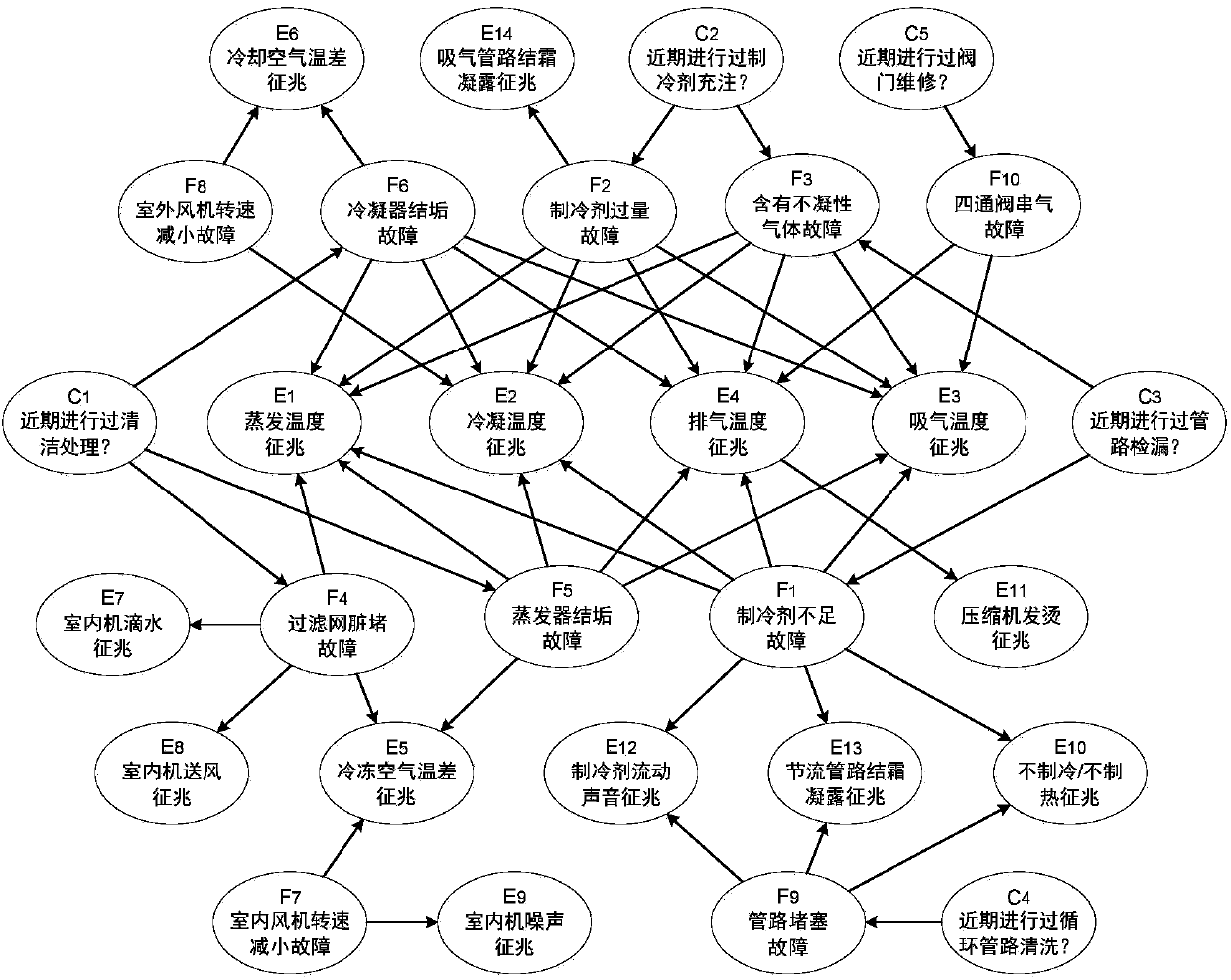

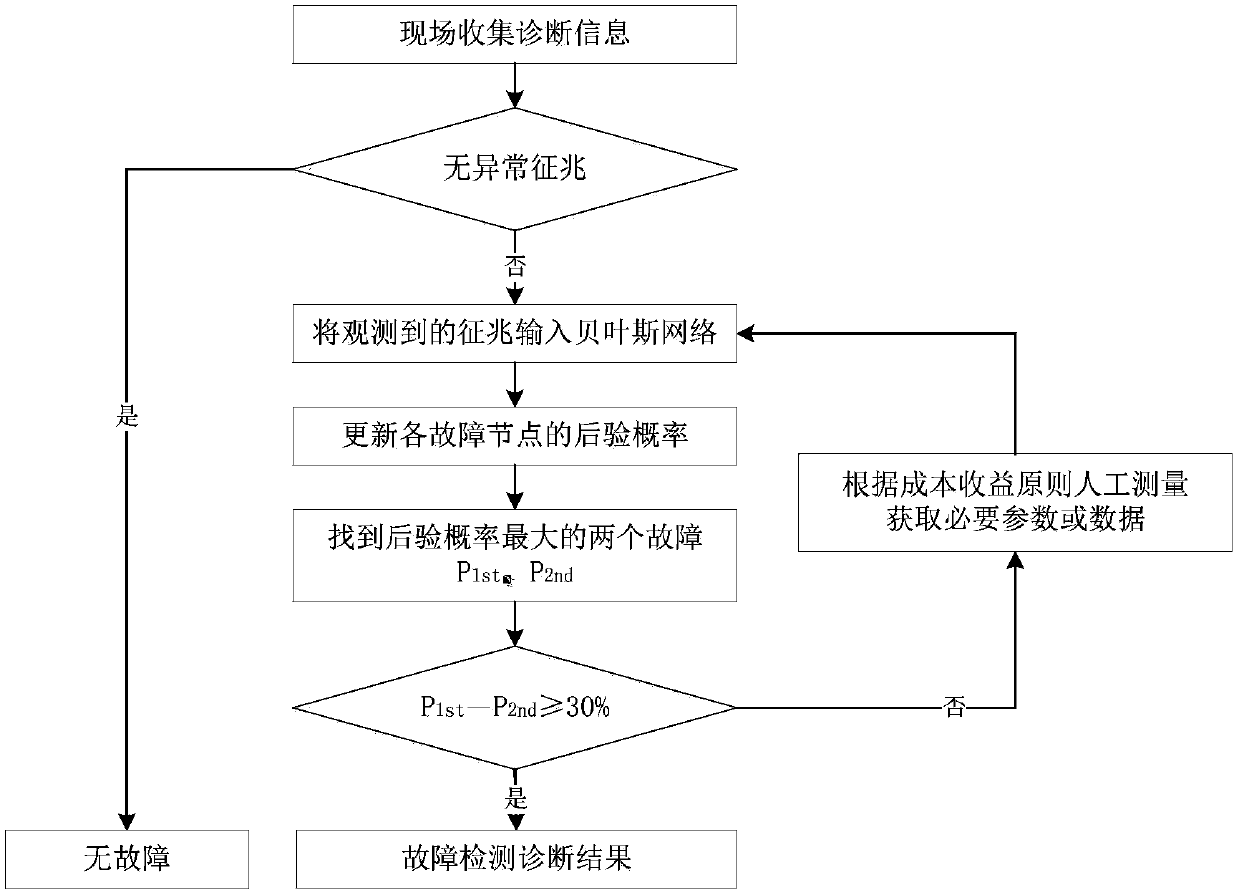

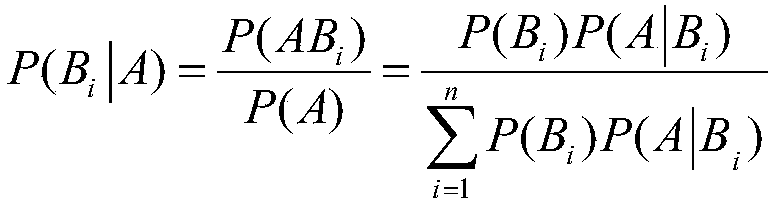

Household air conditioner fault diagnosis method based on Bayesian network

ActiveCN107806690AEffective fault diagnosisLow costSpace heating and ventilation safety systemsLighting and heating apparatusDiagnosis methodsCausality

The invention provides a household air conditioner fault detection and diagnosis method based on the Bayesian network. The structure of the Bayesian network qualitatively describes the complicated causal relationship between most typical faults of household air conditioners and dependence occurrence conditions and fault symptoms thereof. The condition probability table represented by a directed edge of the Bayesian network qualitatively describes the probability value in the causal relationship. By means of the method, qualitative diagnosis information and quantitative data can be integrated,the knowledge and experience of industry experts and the additive information of diagnosis objects are sufficiently utilized, the fault diagnosis efficiency and accuracy are improved, and accurate fault diagnosis is achieved under the condition that diagnosis information is incomplete and inaccurate. The Bayesian network provided by the invention can effectively detect and diagnose most faults ofthe household air conditioners.

Owner:ZHEJIANG UNIV

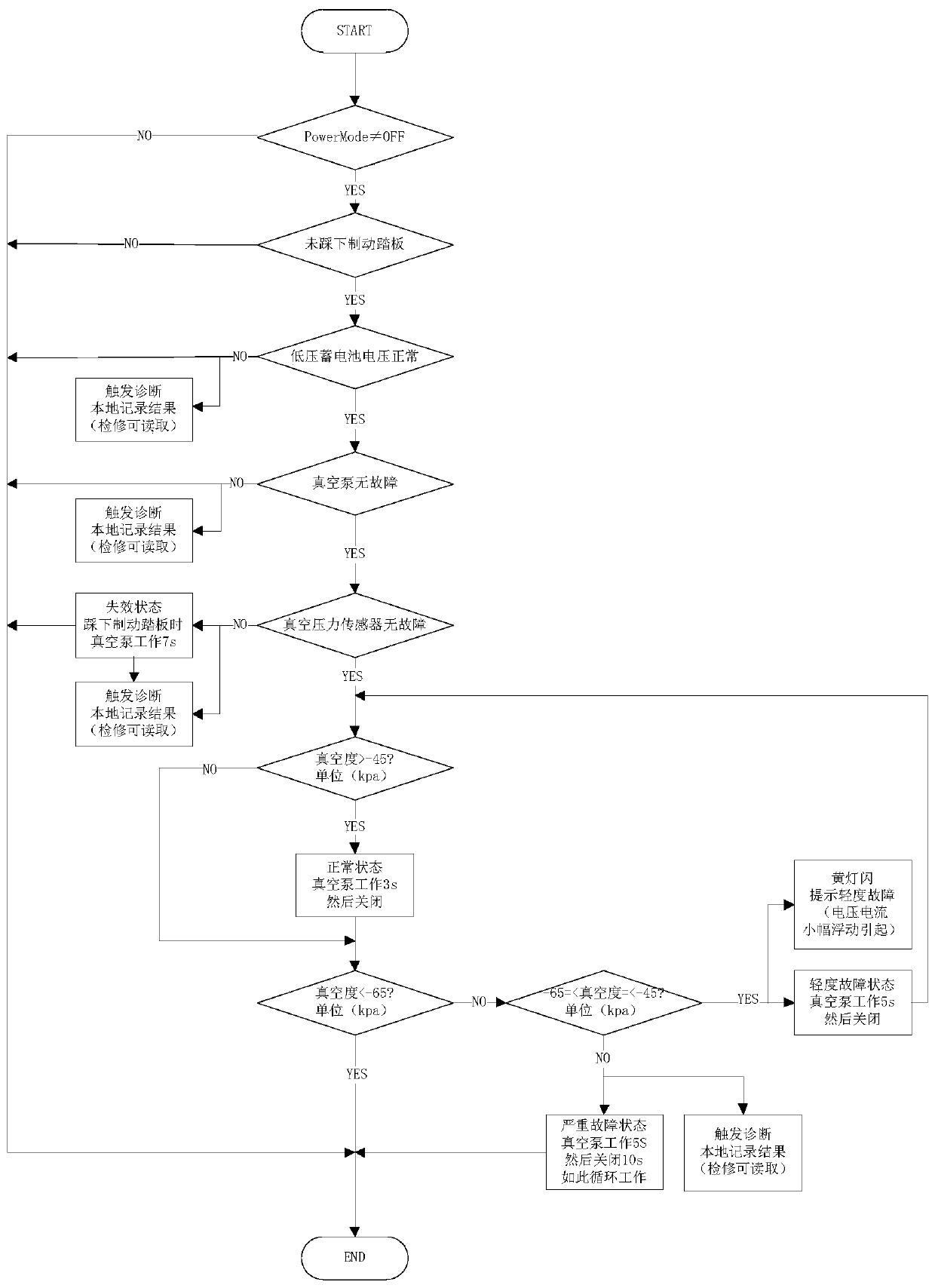

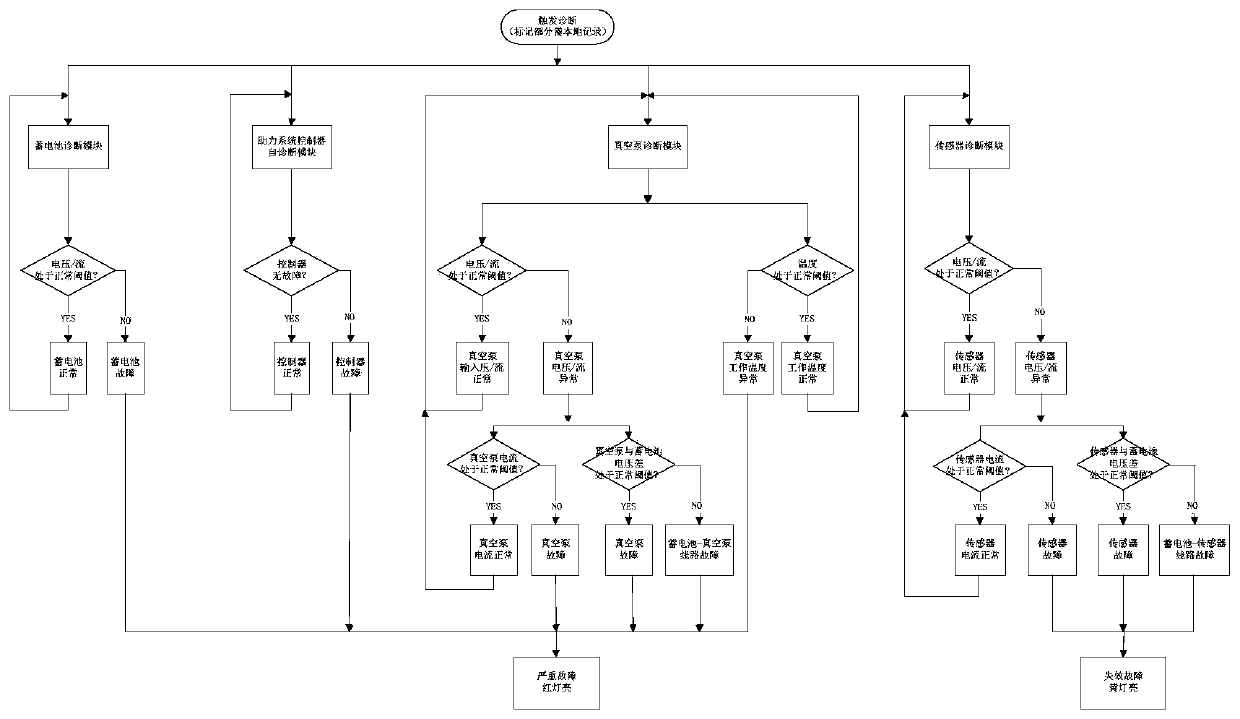

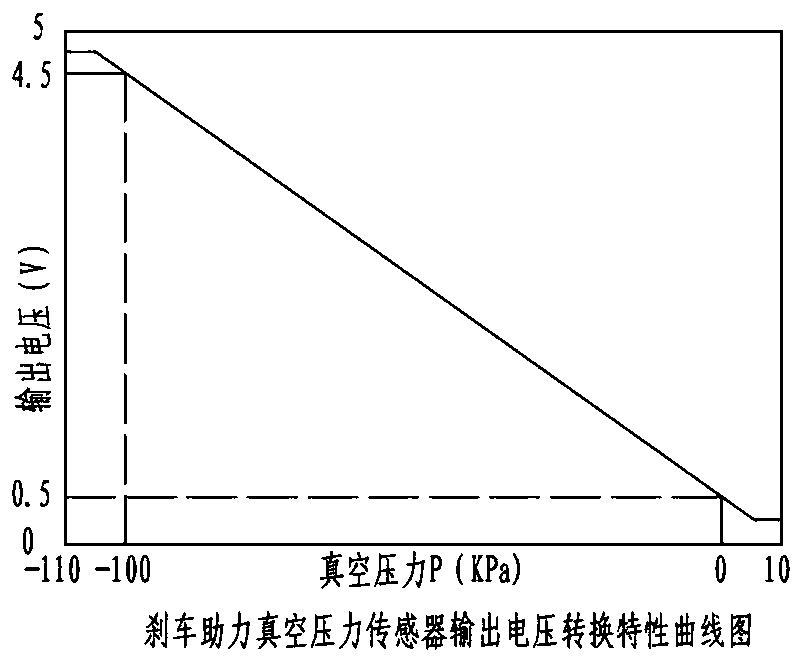

Fault diagnosis and control method of automobile vacuum pump

ActiveCN111591276ALow costStrong developabilityBraking action transmissionBrake safety systemsControl engineeringSystem controller

The invention discloses a fault diagnosis and control method of an automobile vacuum pump system. The method comprises the steps: after a vehicle is started and a brake pedal is not stepped on, executing the starting fault detection step of a vacuum pump system, and respectively detecting the fault states of a low-voltage storage battery, a power assisting system controller, a vacuum pump and a vacuum degree sensor in the vacuum pump system; then storing fault codes and giving out fault warning. The method has the advantages that the diagnosis accuracy is high, the control is reasonable, and the control and diagnosis of the vacuum pump system can be more comprehensively and reliably realized.

Owner:YIBIN COWIN AUTO CO LTD

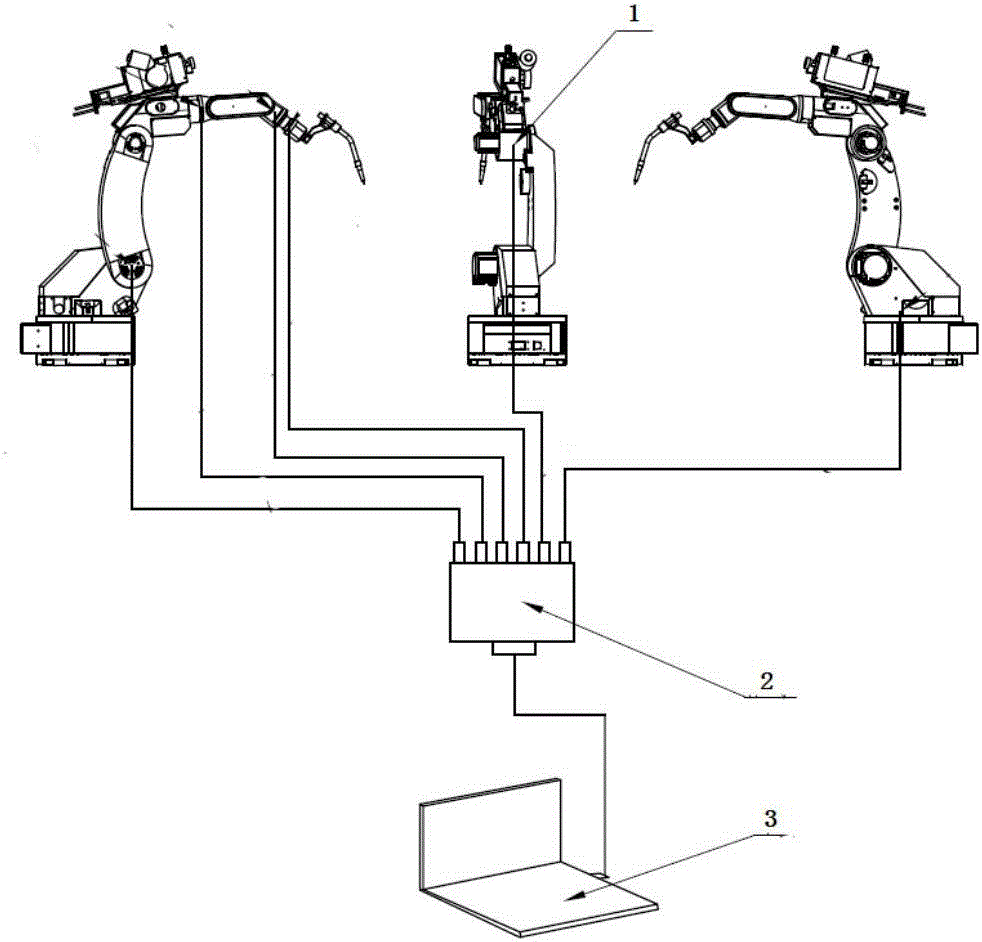

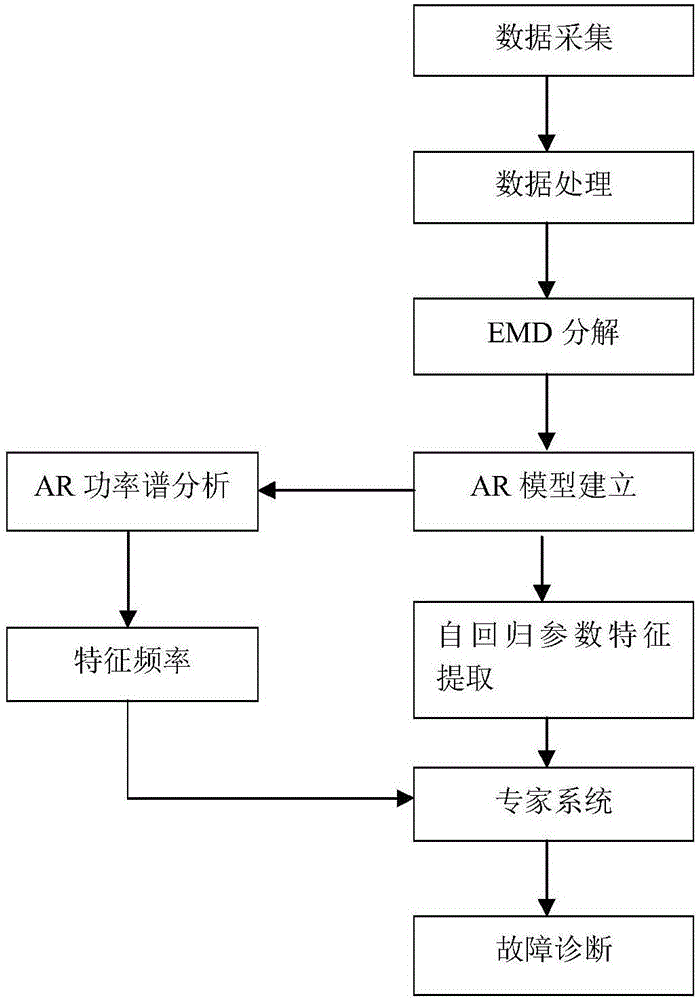

Six-axis industrial robot fault diagnosis method and system based on AR model

InactiveCN106599794AKeen fault diagnosisSensitive detectionCharacter and pattern recognitionFeature vectorFeature extraction

The invention discloses a six-axis industrial robot fault diagnosis method and a system based on an AR model. A vibration acceleration sensor is arranged at a specific position on a moving part of each axis, the acquired vibration acceleration signals are used for building an autoregressive model AR, the autoregressive model AR is used for acquiring the fault feature vector of the industrial robot, the fault feature vector is imported to an expert system for fault diagnosis. The sensitivity of autoregressive parameters of the autoregressive model AR towards the state change law and the high resolution of the AR power spectrum are used for fault feature extraction, and sensitive and effective fault diagnosis and detection on the industrial robot are carried out; the problems that the six-axis industrial robot is difficult in fault diagnosis, long in diagnosis period and inaccurate in diagnosis can be effectively solved; and the fault judgment range is greatly reduced, and the fault diagnosis time is saved.

Owner:NANJING PANDA ELECTRONICS +2

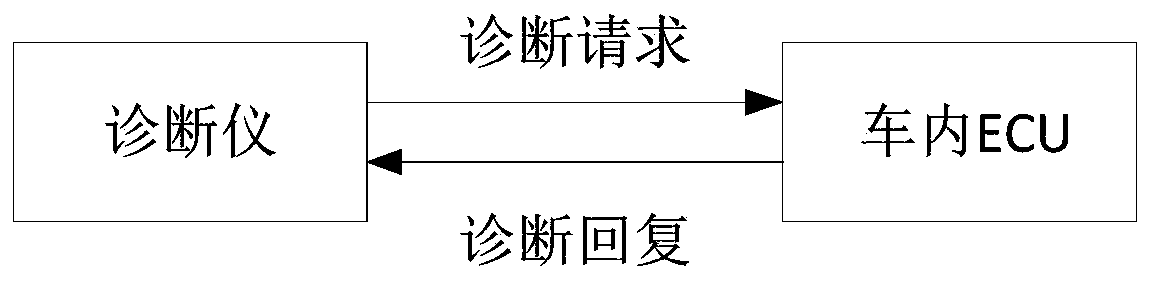

Fault diagnosis method, information determination method as well as corresponding device and equipment

ActiveCN110162009AEffective fault diagnosisEffective diagnosisProgramme controlElectric testing/monitoringDiagnosis methodsFailure diagnosis

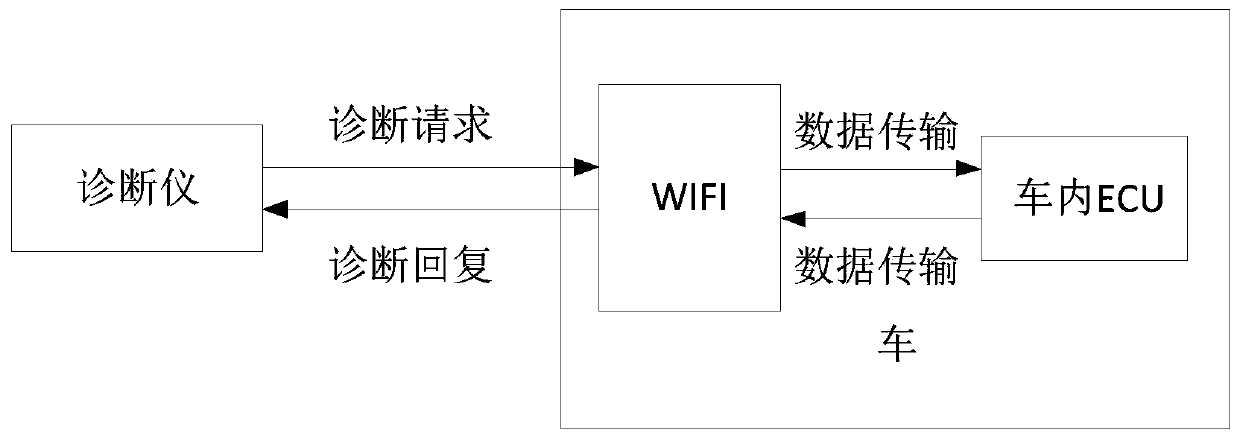

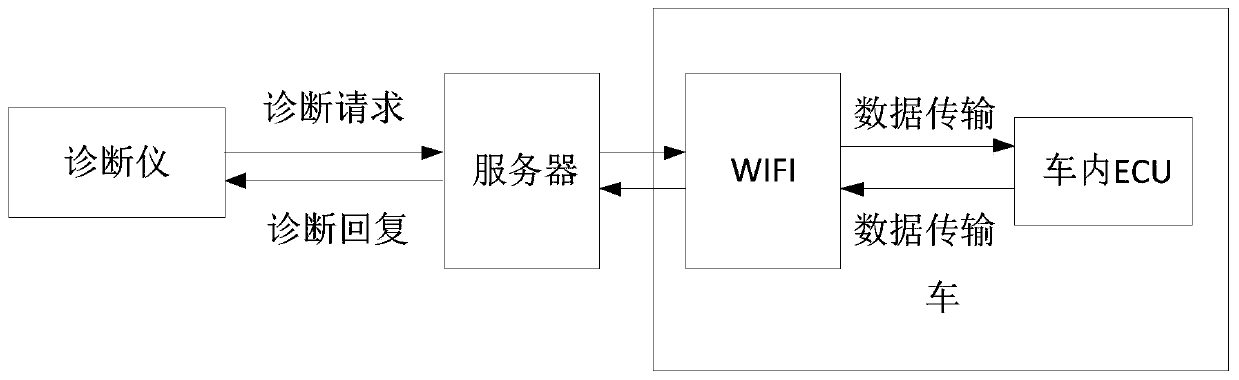

The embodiment of the invention discloses a fault diagnosis method, an information determination method as well as a corresponding device and equipment. The method comprises the following steps: analyzing a prestored encryption diagnostic protocol packet, acquiring at least one diagnostic protocol, wherein the encryption diagnostic protocol packet is determined and sent by a diagnosis server in advance, sending a diagnosis request containing the diagnostic protocol to a to-be-diagnosed vehicle, so as to enable the to-be-diagnosed vehicle to perform fault diagnosis on a corresponding function according to the received diagnosis request, performing interaction on the to-be-diagnosed vehicle and a user terminal based on a near field communication protocol, and receiving and displaying a faultdiagnosis result, sent by the to-be-diagnosed vehicle, in a set display mode. Compared with the prior art, the embodiment of the invention takes the user terminal as an intermediary, the diagnosis server firstly interacts with the user terminal, the diagnosis protocol is stored in the user terminal, when diagnosis is required, the to-be-diagnosed vehicle interacts with the user terminal by virtueof the near field communication protocol, and effective fault diagnosis is realized.

Owner:CHINA FIRST AUTOMOBILE

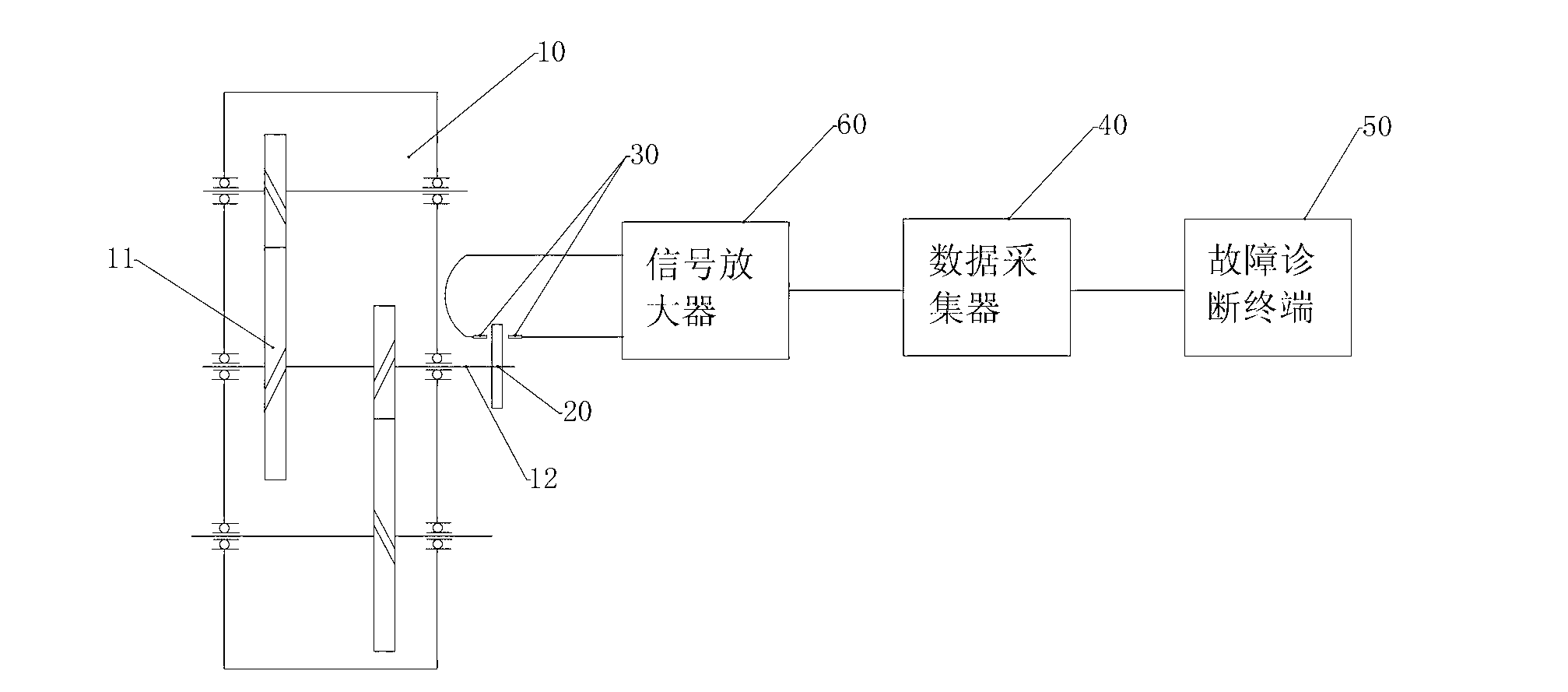

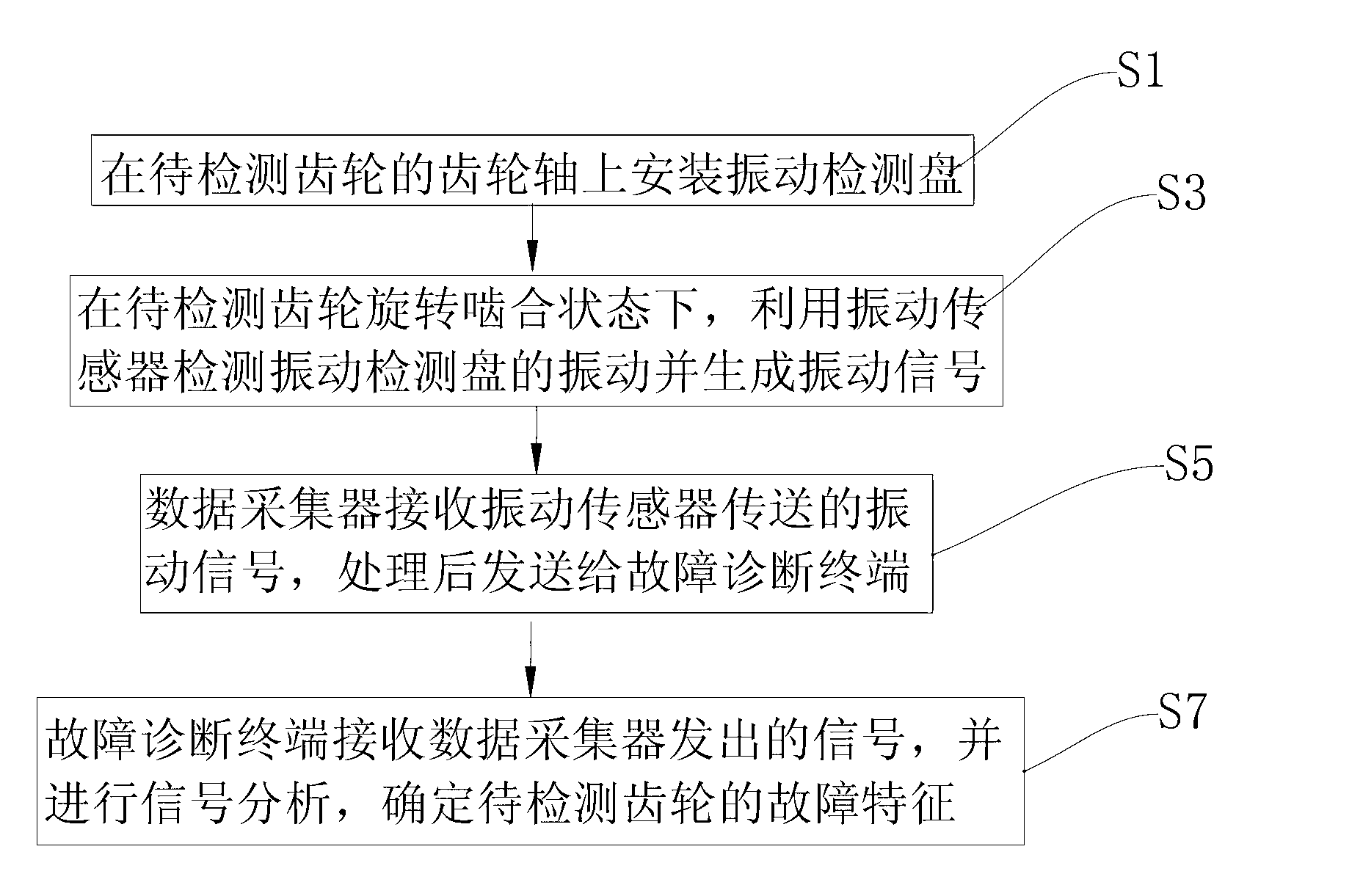

Gear fault diagnosis device and method

ActiveCN103308305AExtract fault featuresExclude vibrationMachine gearing/transmission testingDrive shaftData acquisition

The invention provides a gear fault diagnosis device and method. The gear fault diagnosis device comprises a vibration detection disc, a vibration sensor, a data collector and a fault diagnosis terminal, wherein the vibration detection disc is mounted on a transmission shaft of a gear to be detected; the vibration sensor is used for detecting the vibration of the vibration detection disc; the data collector is connected with the vibrator sensor; and the fault diagnosis terminal is connected with the data collector. According to the gear fault diagnosis device and method disclosed by the invention, the vibration detection disc is mounted on the transmission shaft of the gear to be detected, and the transmission shaft is vibrated along the vibration of the gear to be detected; the vibration detection disc is vibrated along the vibration of the transmission shaft; the vibration detection disc can reflect a vibration condition of the gear to be detected so as to get rid of influences of the vibration of a box body of a gearbox or the vibration of other vibration sources of a system; and the vibration of the vibration detection disc is detected through the vibration sensor, and a fault characteristic of the gear to be detected can be accurately extracted through analysis and treatment of the data collector and the fault diagnosis terminal, so that effective diagnosis of gear faults is realized.

Owner:CHINA AVIATION POWER MACHINE INST

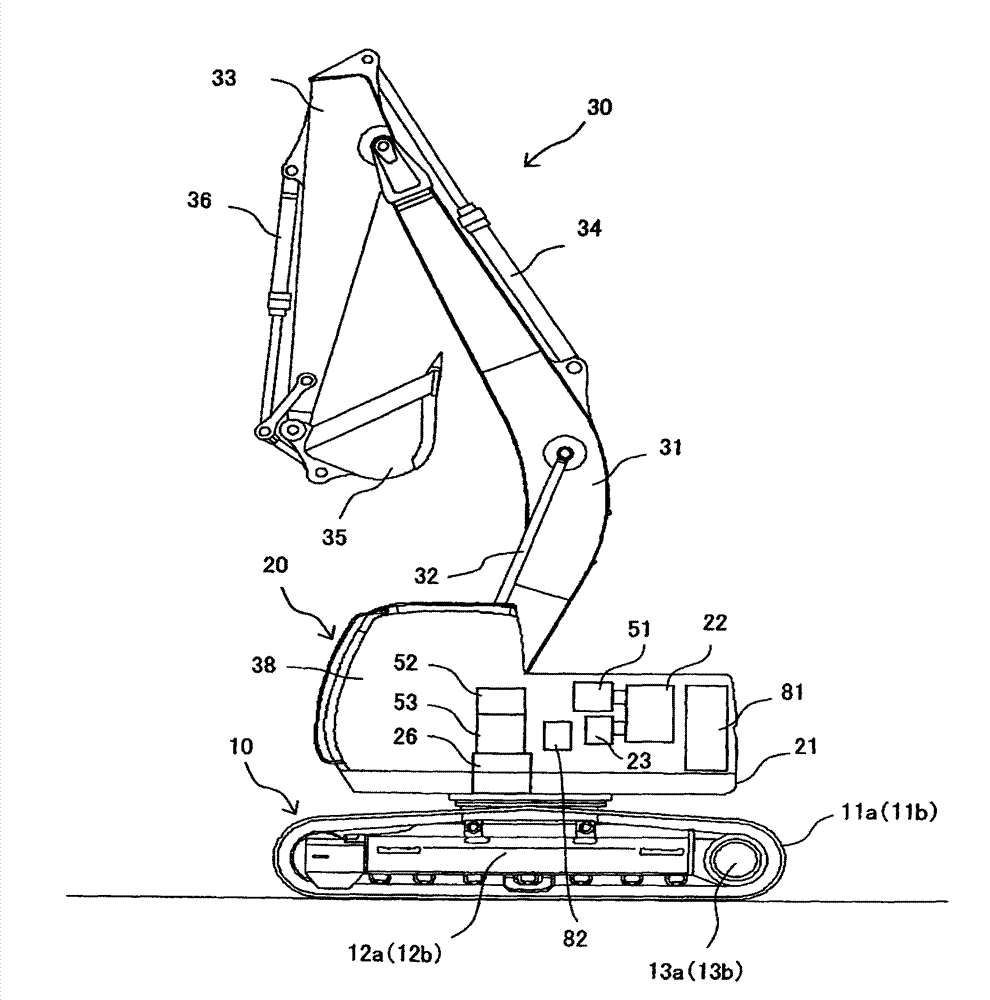

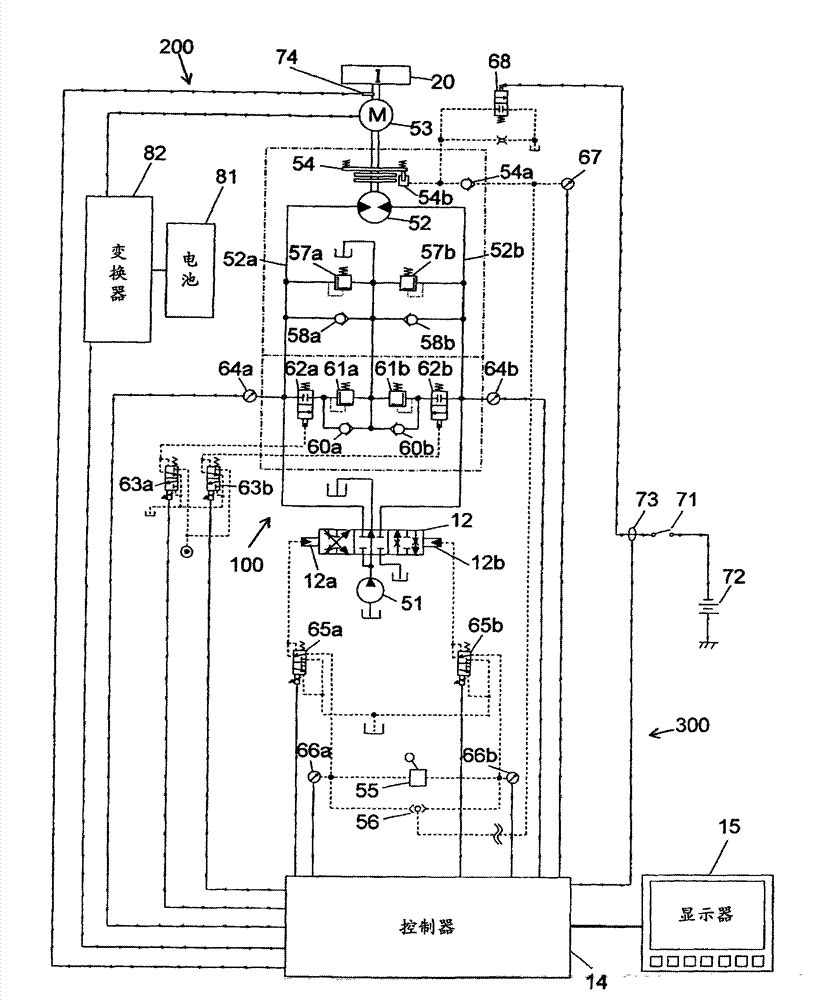

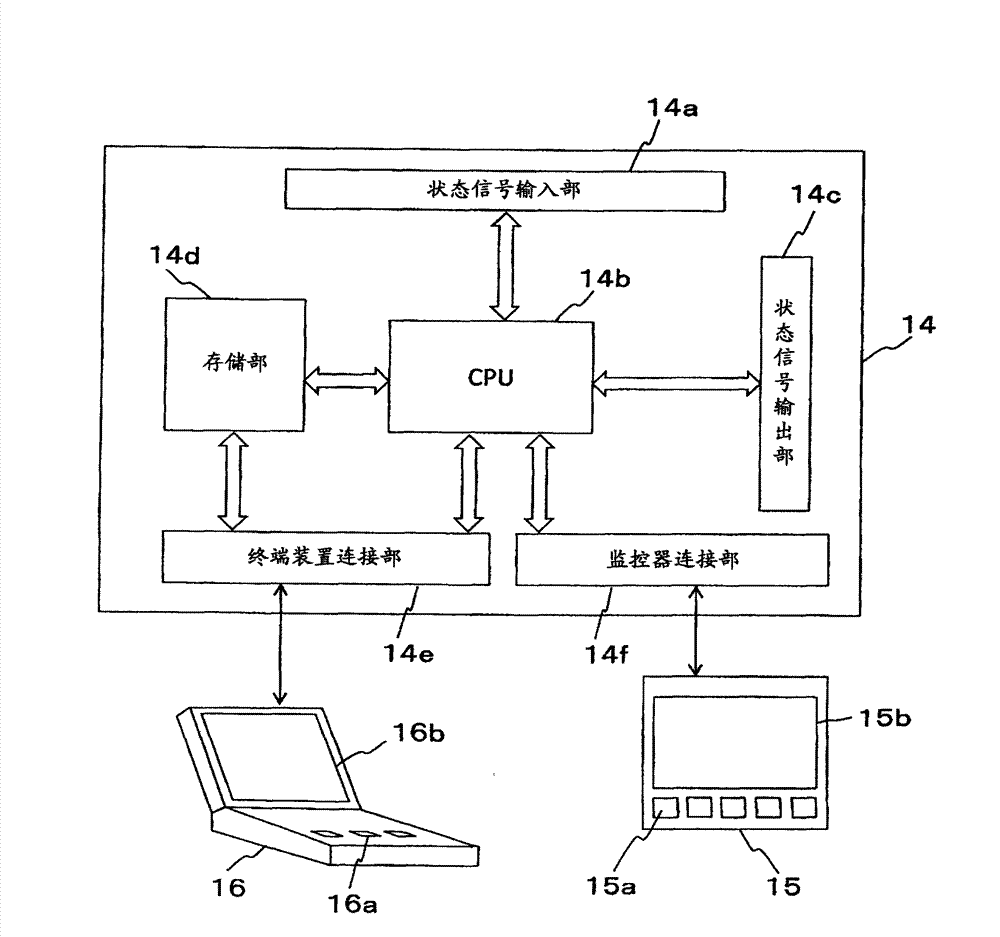

Information management system for construction machine

ActiveCN102787624AEffective fault diagnosisElectric winding testingSoil-shifting machines/dredgersSolenoid valveDisplay device

The present invention provides an information management system suitable for a construction machine, which drives a solenoid valve separately from normal control to thereby make it possible to perform failure diagnosis for the solenoid valve and each sensor easily and with satisfactory accuracy. A controller(14) has a failure diagnosis mode selected by a control panel(15a) of a display device(15). When the failure diagnosis mode is selected by the control panel and instructions for failure diagnosis related to a specific solenoid valve of a plurality of solenoid valves(63a,63b,65a,65b) are given, the controller(14) outputs a failure diagnosis drive signal to the specific solenoid valve, inputs an output value from a sensor related to the specific solenoid valve among a plurality of sensors, and displays, based on the output value from the specific sensor, information as to whether the specific solenoid valve(63a,63b,65a,65b) and the specific sensor are normal on a display device(15).

Owner:NIHON KENKI CO LTD

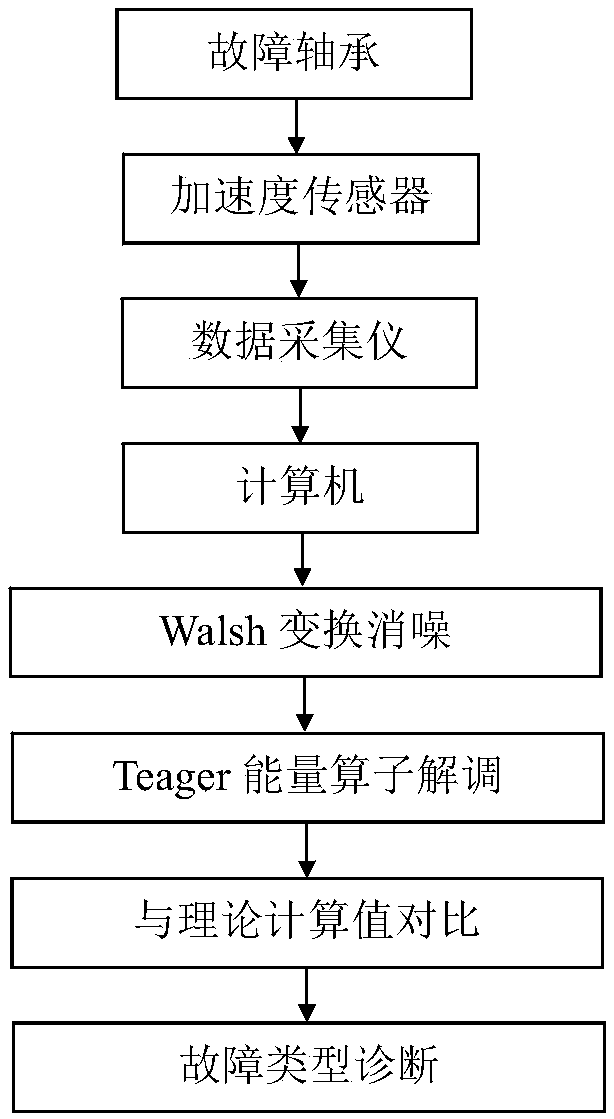

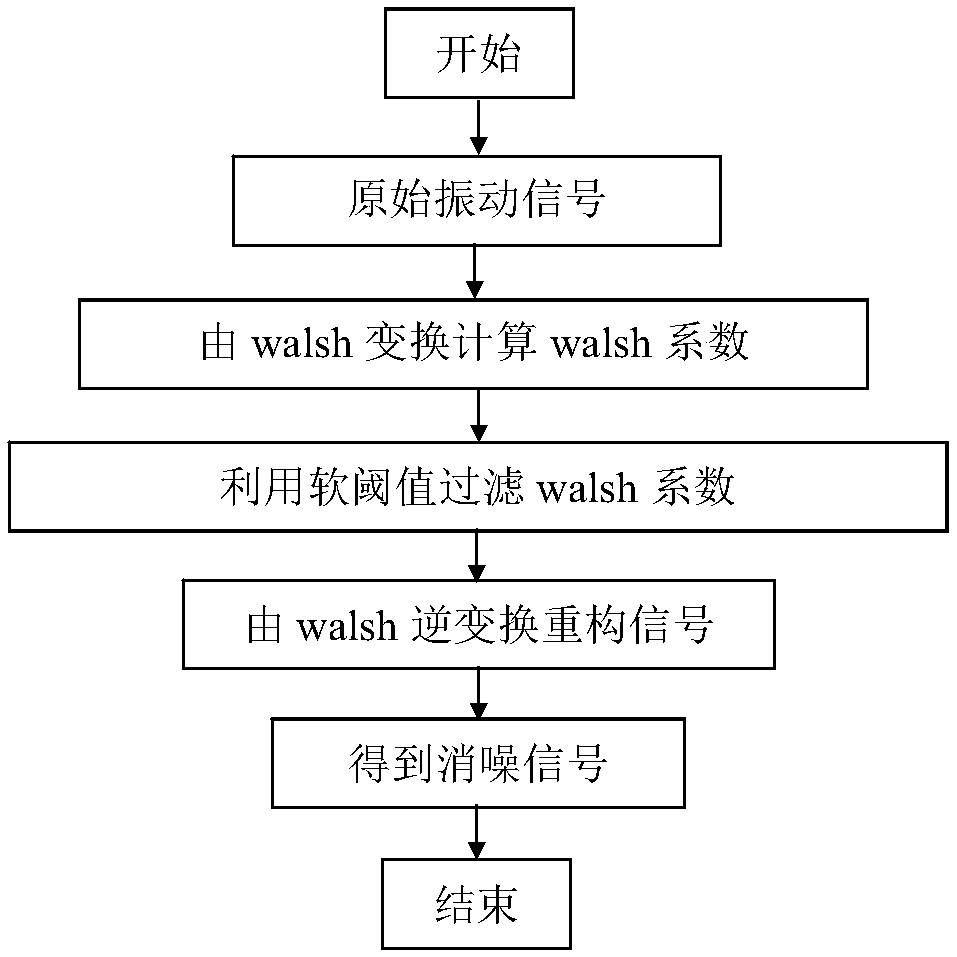

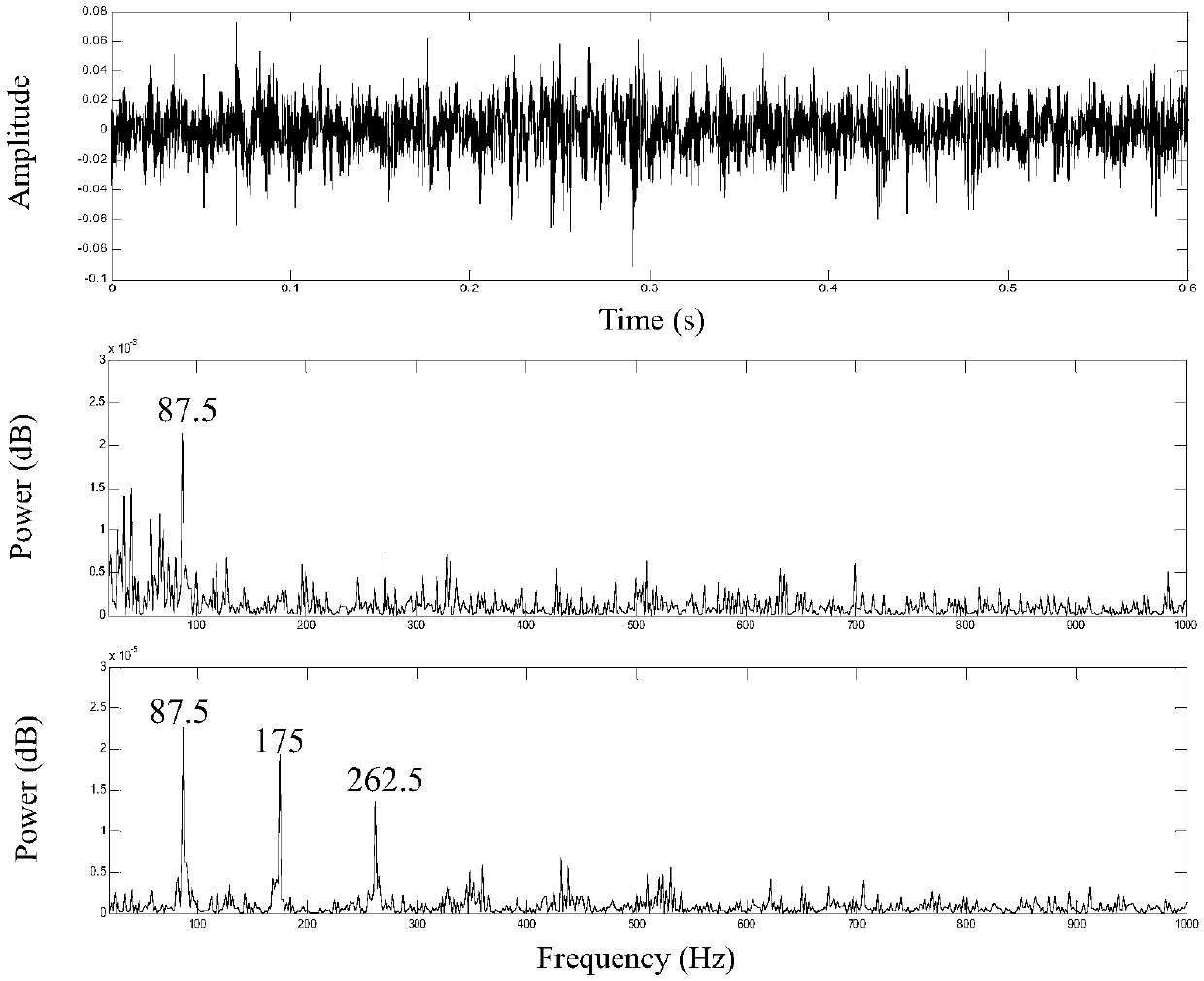

Bearing fault diagnosis method based on Walsh transform and Teager energy operator

ActiveCN107831012ARealize measurementRealize detectionMachine bearings testingResearch ObjectDiagnosis methods

The invention belongs to the field of mechanical equipment fault diagnosis. The invention discloses a rolling bearing fault diagnosis method based on the Walsh transformation and Teager energy operator. The specific contents are as follows: first, an acceleration sensor is fixed on a bearing seat under test, the acceleration sensor is connected with a data acquisition instrument to obtain a bearing vibration signal, then a bearing fault diagnosis is performed, and subjecting the signal to Walsh transform denoising; fault features are extracted by Teager energy operator demodulation; and the bearing fault type is positioned and identified by comparing with a theoretical calculating value. The invention takes the vibration signal as the research object, combines the Walsh transform denoisingand the Teager energy operator demodulation, and proposes the novel bearing fault diagnosis method. The bearing fault diagnosis method in the invention can effectively diagnose the fault type of a rolling bearing and has the advantages of high diagnostic accuracy.

Owner:WENZHOU UNIVERSITY

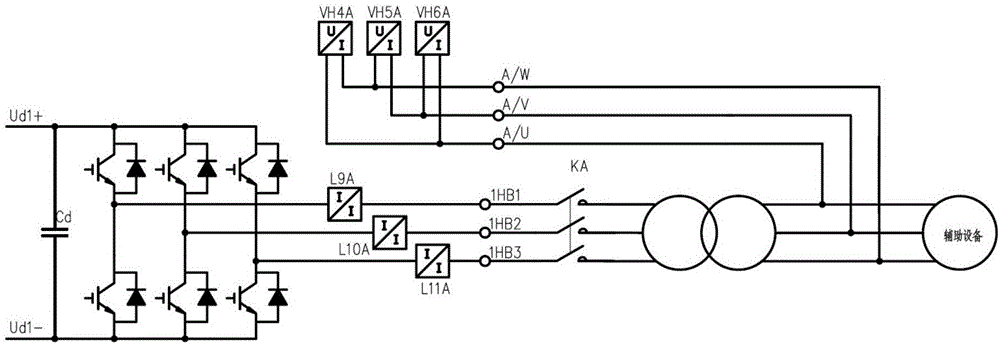

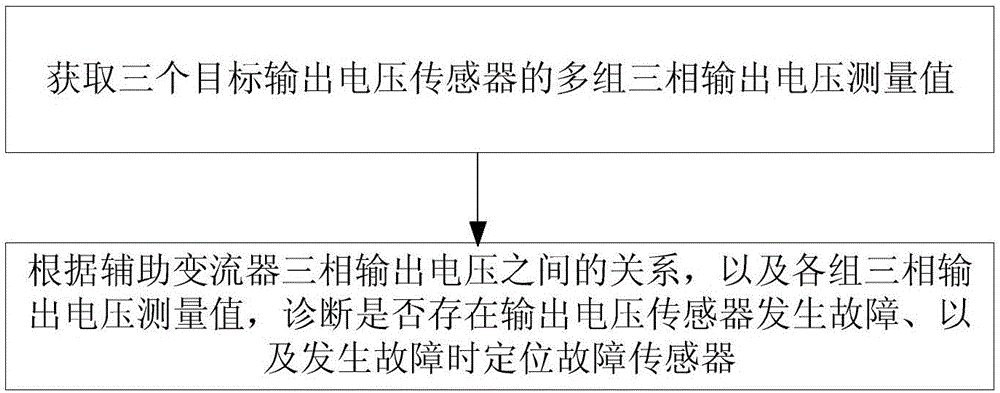

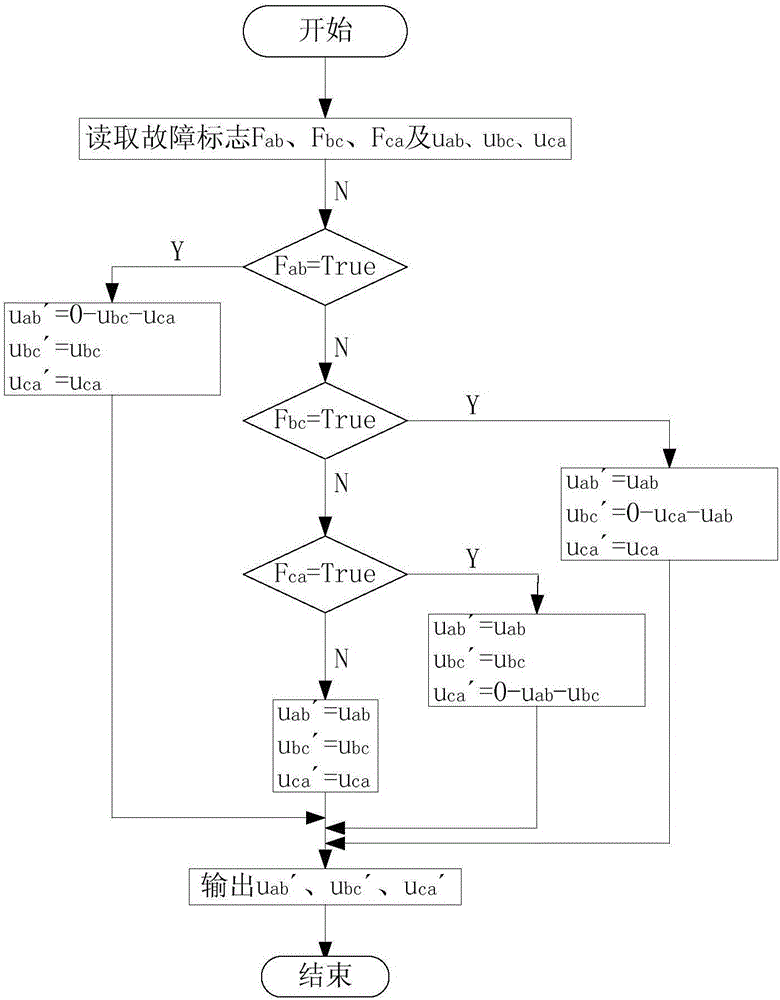

Output voltage sensor fault diagnosing method of auxiliary current transformer and fault tolerance control method

ActiveCN106569160ANo additional costEasy to implementVoltage measurements onlyFault toleranceDiagnosis methods

The invention discloses an output voltage sensor fault diagnosing method of an auxiliary current transformer and a fault tolerance control method. The fault diagnosing method includes the steps of 1) real-time obtaining three-phase output voltage measuring signals of three target output voltage sensors connected with a motor-vehicle auxiliary current transformer; and 2) diagnosing the existence of failed output voltage sensors according to the relation between three-phase output voltage of the auxiliary current transformer and the three-phase output voltage measuring signals obtained in the step 1) and positioning the failed sensors when failure occurs. According to the fault tolerance control method, when sensor failure occurs, the voltage value of corresponding phases of the failed sensor is estimated according to the relations between three-phase output voltage and the sensor measuring signal estimated values under normal work conditions. The method is simple, and the required cost is low. Failure of output voltage sensor of the auxiliary current sensors can be timely diagnosed and the specific fault points can be positioned. The diagnosis precision and efficiency are high.

Owner:ZHUZHOU CSR TIMES ELECTRIC CO LTD

Fault diagnosis device for temperature sensor

ActiveUS9004751B2Effective fault diagnosisEfficient executionThermometer detailsElectrical controlEngineeringInternal combustion engine

A fault diagnosis device conducts a fault diagnosis in a temperature sensor. At starting an internal combustion engine, a thermal equilibrium condition may be established and temperature deviations of temperatures detected by at least two reference temperature sensors from each other may be equal to or less than a predetermined value, with the temperatures detected by the reference temperature sensors being greatly deviated from one detected by a temperature sensor being diagnosed. In this case, if the temperatures detected by the reference temperature sensors do not drop by a predetermined temperature or more from starting the engine until a predetermined time elapses, the fault diagnosis device determines that the temperature sensor being diagnosed is faulty.

Owner:NISSAN MOTOR CO LTD

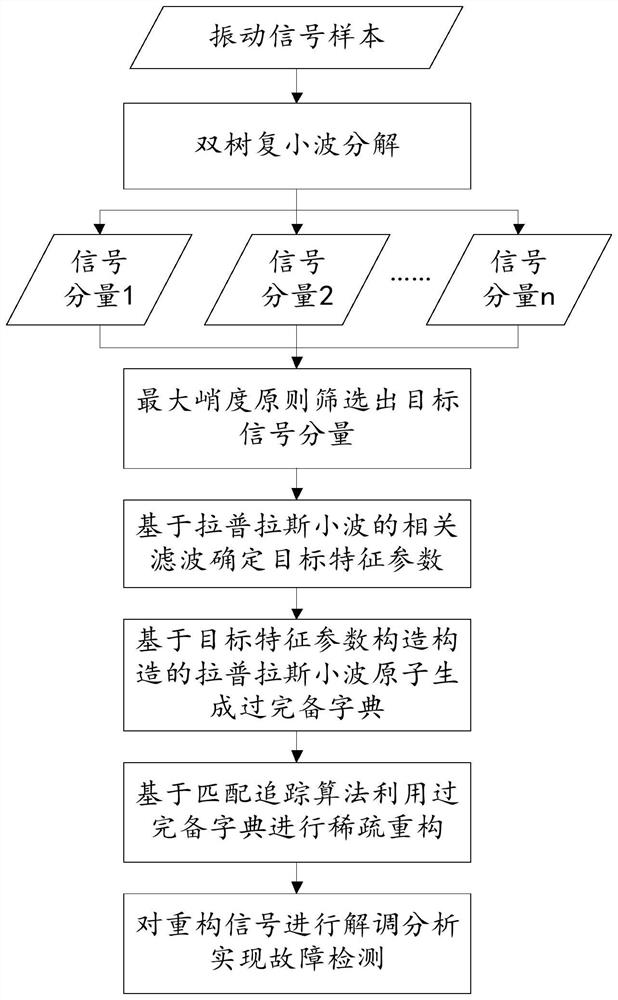

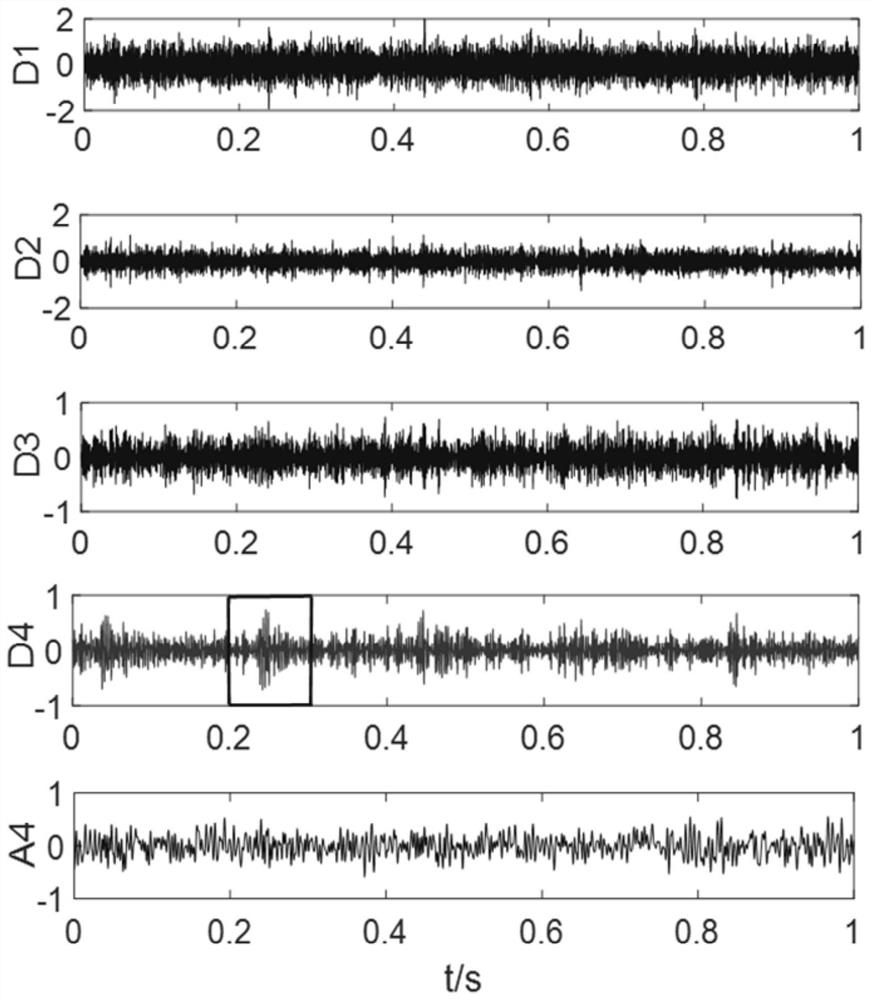

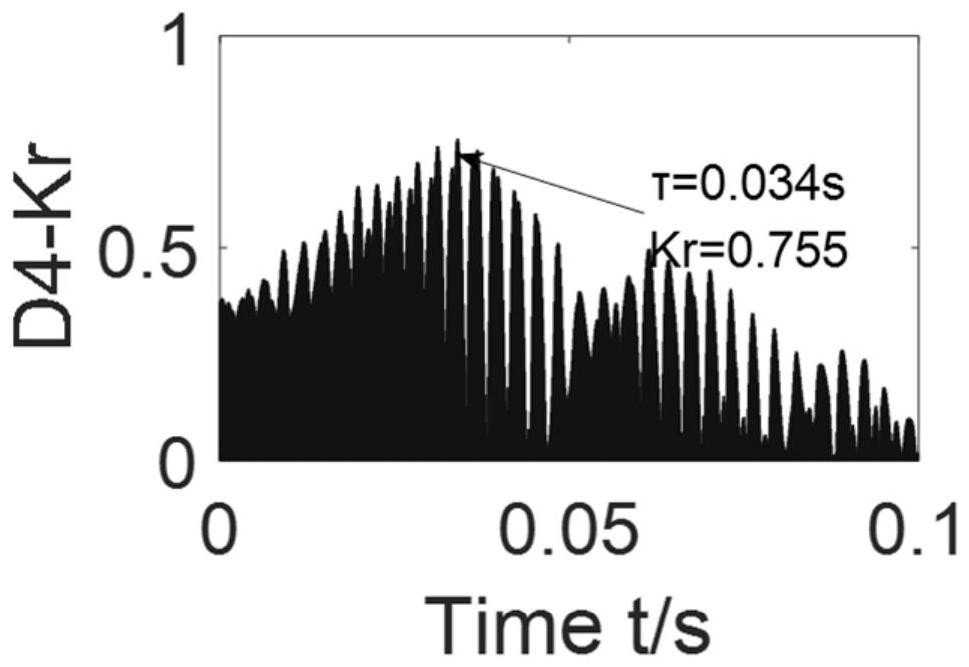

Gear fault detection method based on improved sparse decomposition algorithm

InactiveCN111678691AReduce redundancyEasy pretreatmentMachine part testingAlgorithmWavelet decomposition

The invention discloses a gear fault detection method based on an improved sparse decomposition algorithm, and relates to the technical field of fault detection. The method is based on traditional sparse reconstruction based on a parameter dictionary, and preprocessing of signals and optimization design of a parameter dictionary are added; signal preprocessing is realized by combining dual-tree complex wavelet decomposition with a maximum kurtosis principle; the influence of noise on subsequent processing is greatly reduced; target characteristic parameters are determined based on related filtering of Laplace wavelets so as to construct an over-complete dictionary; the dictionary redundancy can be effectively reduced, the designed dictionary is enabled to be more similar to the fault features, and finally, a matching pursuit algorithm is combined to realize extraction of the impact features in the vibration signals to realize fault detection; and the method can improve the calculationefficiency of sparse representation and realize effective fault diagnosis.

Owner:JIANGNAN UNIV

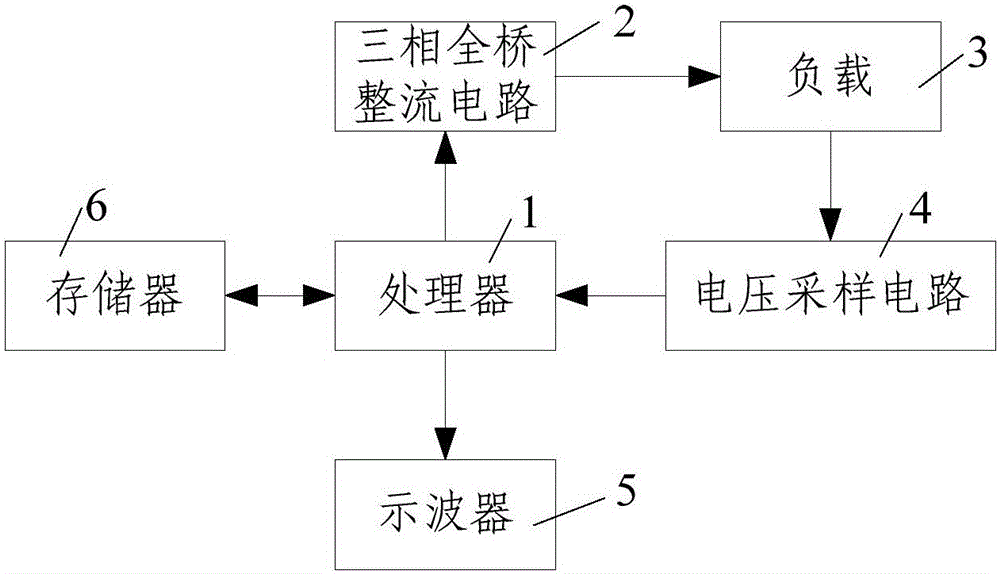

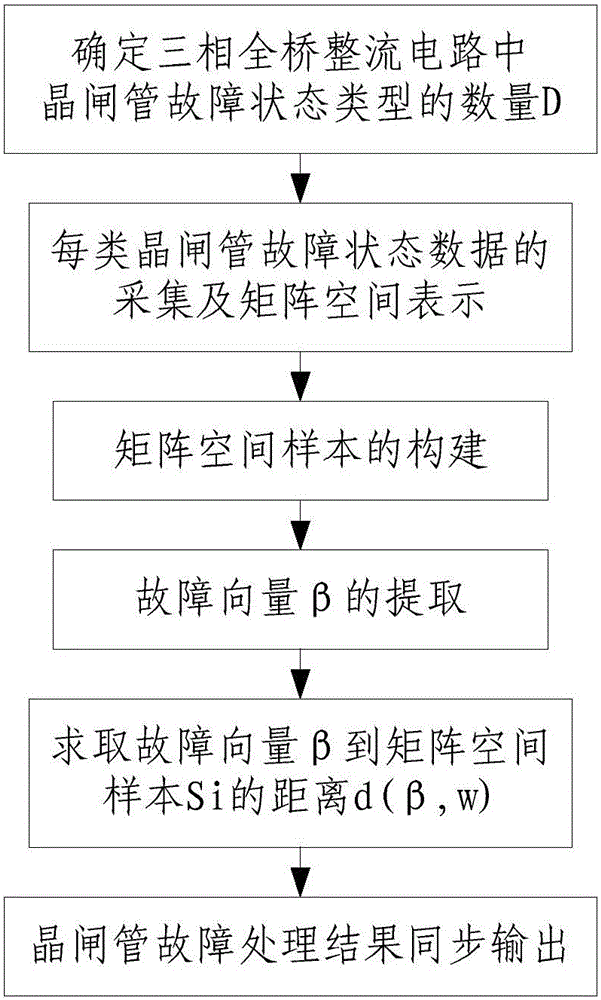

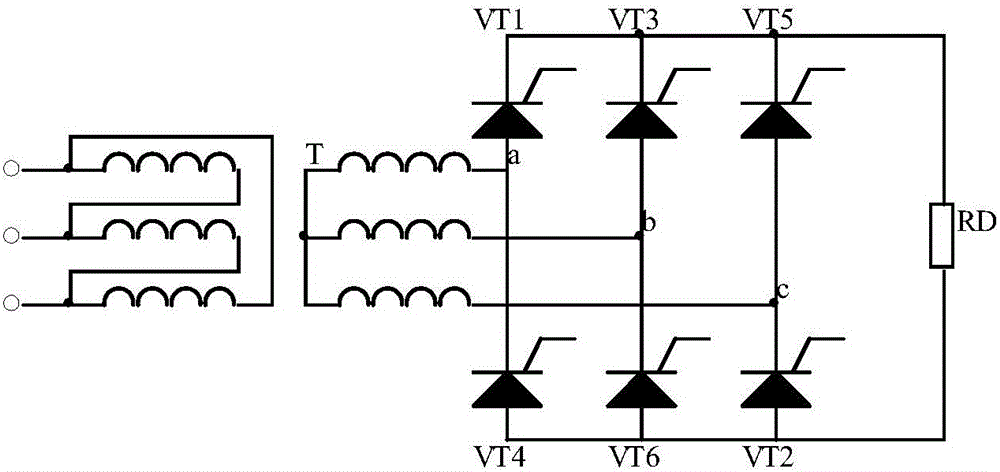

Method for fault diagnosis of three-phase full-bridge rectifier circuit thyristor

InactiveCN106054053AThe method steps are simpleReasonable designIndividual semiconductor device testingThyratronEngineering

The invention discloses a method for fault diagnosis of a three-phase full-bridge rectifier circuit thyristor. The method comprises steps of: 1, constructing a thyristor fault sample set: 101, determining the quantity D of thyristor fault state types in a three-phase full-bridge rectifier circuit; 102, acquiring each type of thyristor fault state data and expressing a matrix space; 103, constructing a matrix space sample; 2, classifying and positioning a thyristor fault: 201, extracting a fault vector beta; 202, solving the distance d(beta, w) from the fault vector beta to the matrix space sample Si; 203, completing the calculation process of the value of d(beta, w); and 3, synchronously outputting a thyristor fault processing result. The method is novel in design; the fault is classified and positioned by adopting a method of vector-to-subspace distance, so that the method is high in precision, small in calculation amount, intuitive, quick and effective, overcomes the defect of weak normalization capability of a neural network detection method in the prior art, and eliminates local minimum points.

Owner:XIAN UNIV OF SCI & TECH

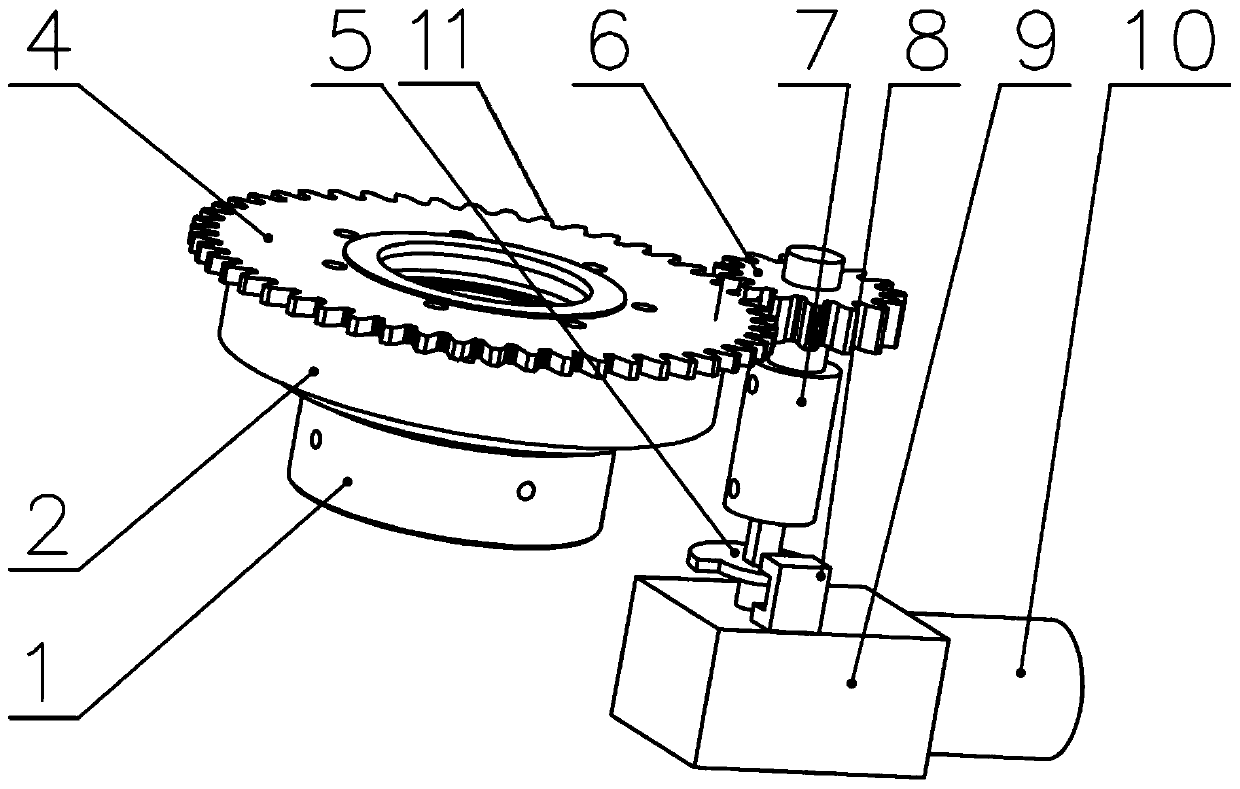

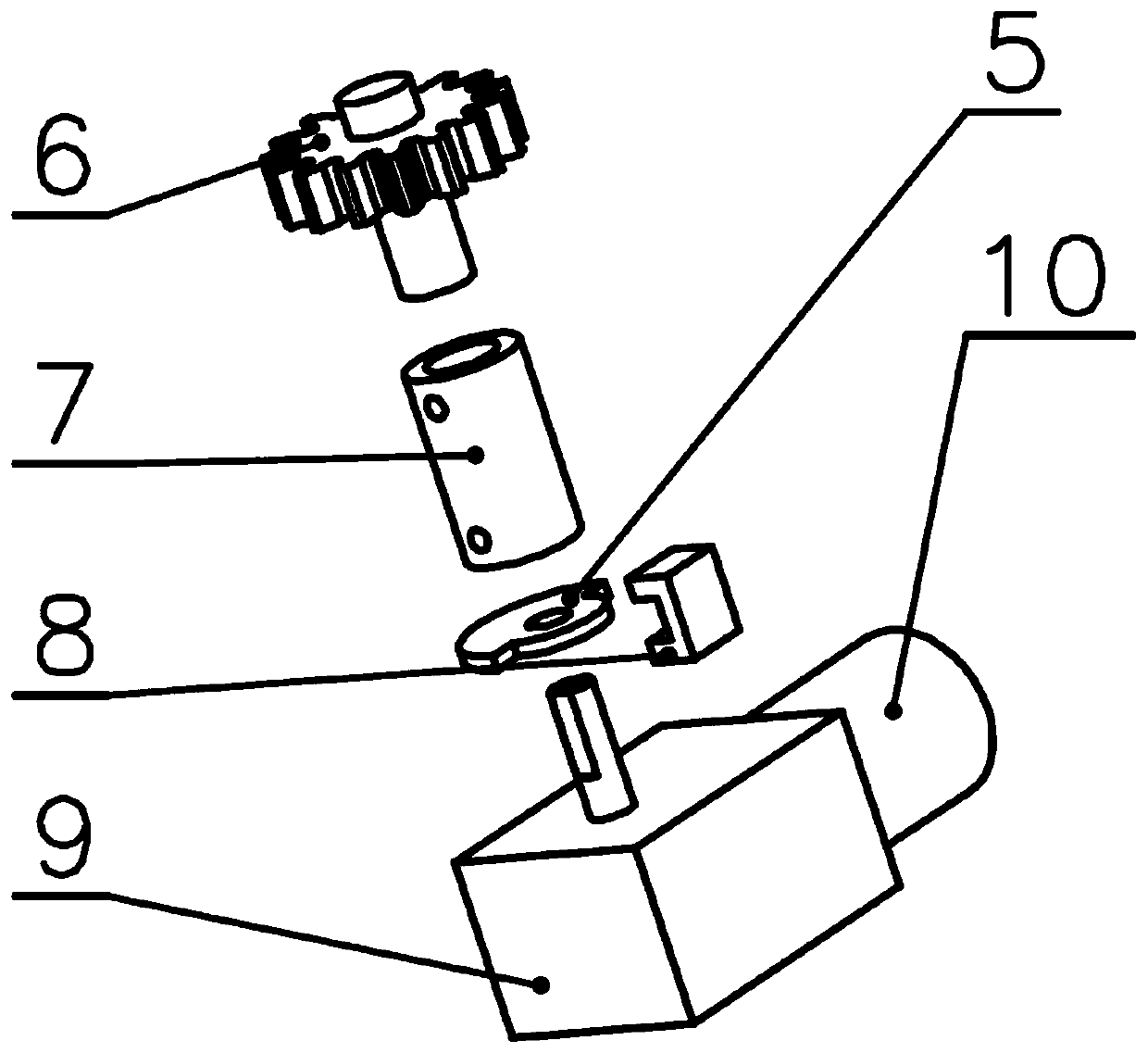

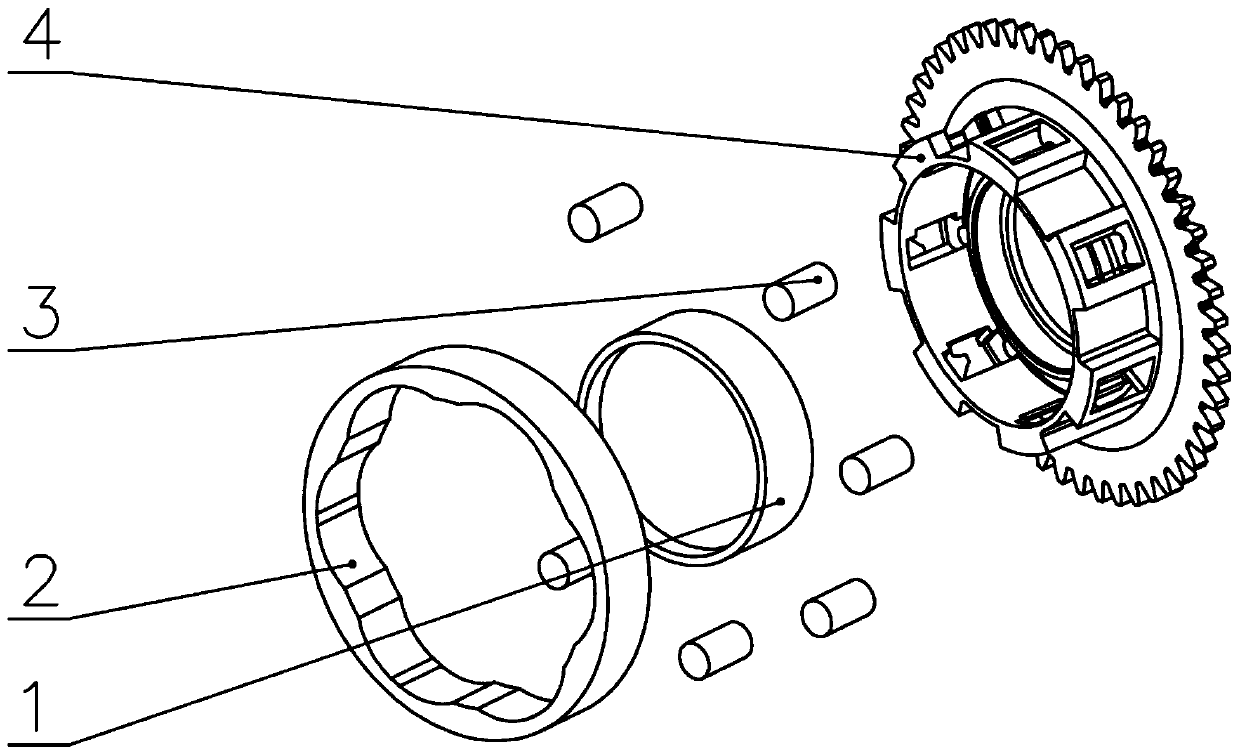

Bidirectional controllable overrunning clutch and control method thereof

PendingCN109882525AReduce complexityReduce axial sizeFreewheel clutchesControl engineeringEngineering

The invention provides a bidirectional controllable overrunning clutch. The bidirectional controllable overrunning clutch consists of a retainer driving assembly, a roller executing assembly and a control assembly, wherein the control terminal of the retainer driving assembly is coaxially and fixedly connected with a retainer of the roller executing assembly; in the roller executing assembly, a plurality of fusiform spaces are formed between the outer wall of an inner ring and the inner wall of an outer ring, wherein two ends of each fusiform space are narrow, and the middle part of each fusiform space is wide; a plurality of toggling frames are arranged perpendicular to the end surface of the retainer, in the circumferential direction of the retainer; the retainer is arranged between theinner ring and the outer ring in a sleeving manner; the toggling frames of the retainer are in one-to-one correspondence with the fusiform spaces; rollers are correspondingly mounted in the toggling frames of the retainer; under the driving of the rotating of the retainer, each roller moves in a circumferential direction in the corresponding fusiform space between the corresponding inner ring andthe corresponding outer ring; and the control assembly is in control connection with the retainer driving assembly to control the retainer driving assembly to drive the retainer to rotate in an axialdirection. The bidirectional controllable overrunning clutch disclosed by the invention is stable and reliable in performance, simple and compact in structure and good in control performance.

Owner:JILIN BOCHENG DRIVETRAIN TECH CO LTD

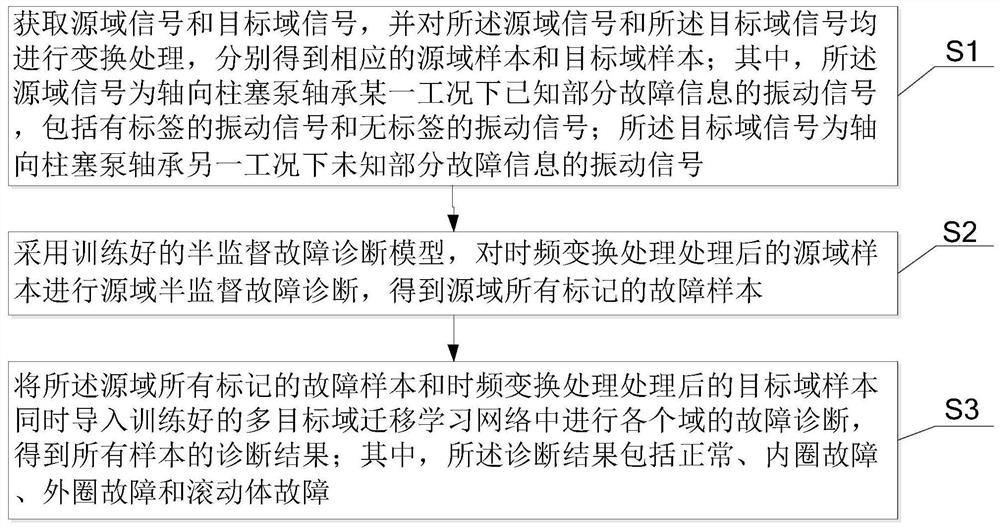

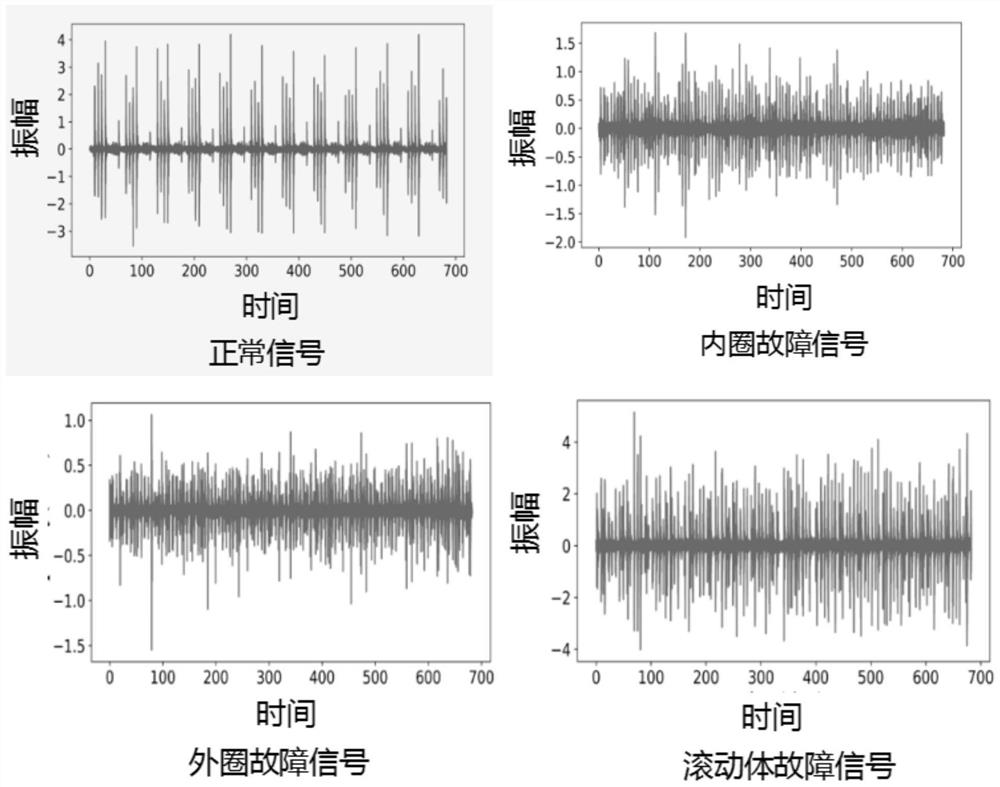

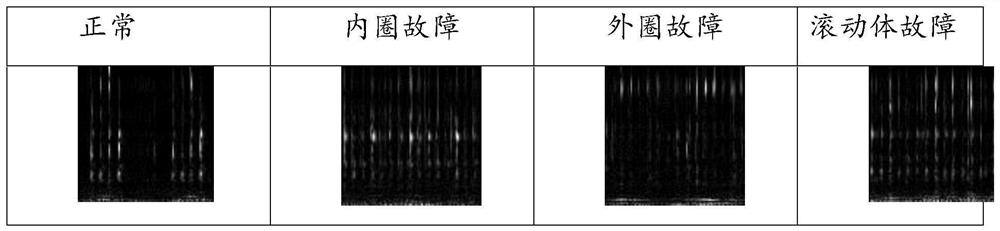

Multi-domain semi-supervised fault diagnosis method and device for axial plunger pump bearing

ActiveCN112729835ATroubleshoot Cross-Domain Issues in TroubleshootingEasy to identifyMachine part testingSustainable transportationControl engineeringLearning network

The invention provides a multi-domain semi-supervised fault diagnosis method for an axial plunger pump bearing, and the method comprises the steps: obtaining a source domain signal and a target domain signal, and carrying out the conversion of the source domain signal and the target domain signal, and obtaining a source domain sample and a target domain sample; wherein the source domain signal is a vibration signal of known partial fault information under a certain working condition; the target domain signal is a vibration signal of fault information of an unknown part under another working condition; performing source domain semi-supervised fault diagnosis on the source domain samples after the time-frequency transformation processing by adopting the trained semi-supervised fault diagnosis model to obtain all marked fault samples of the source domain; importing all the marked fault samples of the source domain and the target domain samples subjected to time-frequency transformation processing into a trained multi-target domain transfer learning network at the same time for fault diagnosis of each domain to obtain diagnosis results of all the samples; wherein the diagnosis result comprises normality, an inner ring fault, an outer ring fault and a rolling body fault. By implementing the invention, the problem of cross-domain fault diagnosis of the existing axial plunger pump bearing can be solved.

Owner:WENZHOU UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com