Breakdown diagnosing device and breakdown diagnosing method of nox sensor

A technology of fault diagnosis device and sensor, which is applied in the direction of diagnosis device, chemical instrument and method, noise reduction device, etc. of exhaust treatment device, which can solve problems affecting drivability, fuel consumption degradation, etc., and achieve reliability improvement and high-efficiency failure The effect of diagnosis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

[0045] 1. NO X Sensor Fault Diagnosis Device

[0046] (1) The overall composition of the exhaust purification system

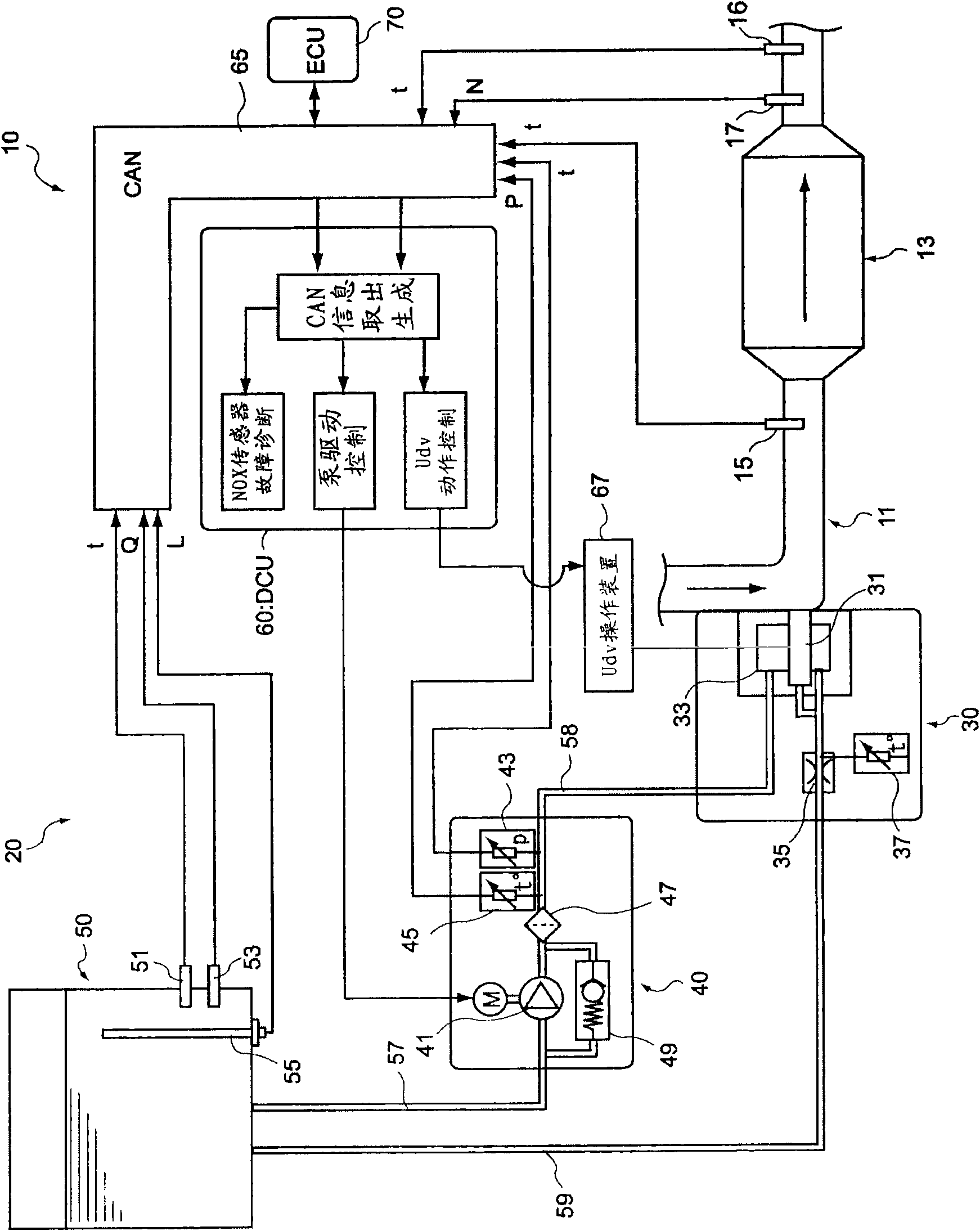

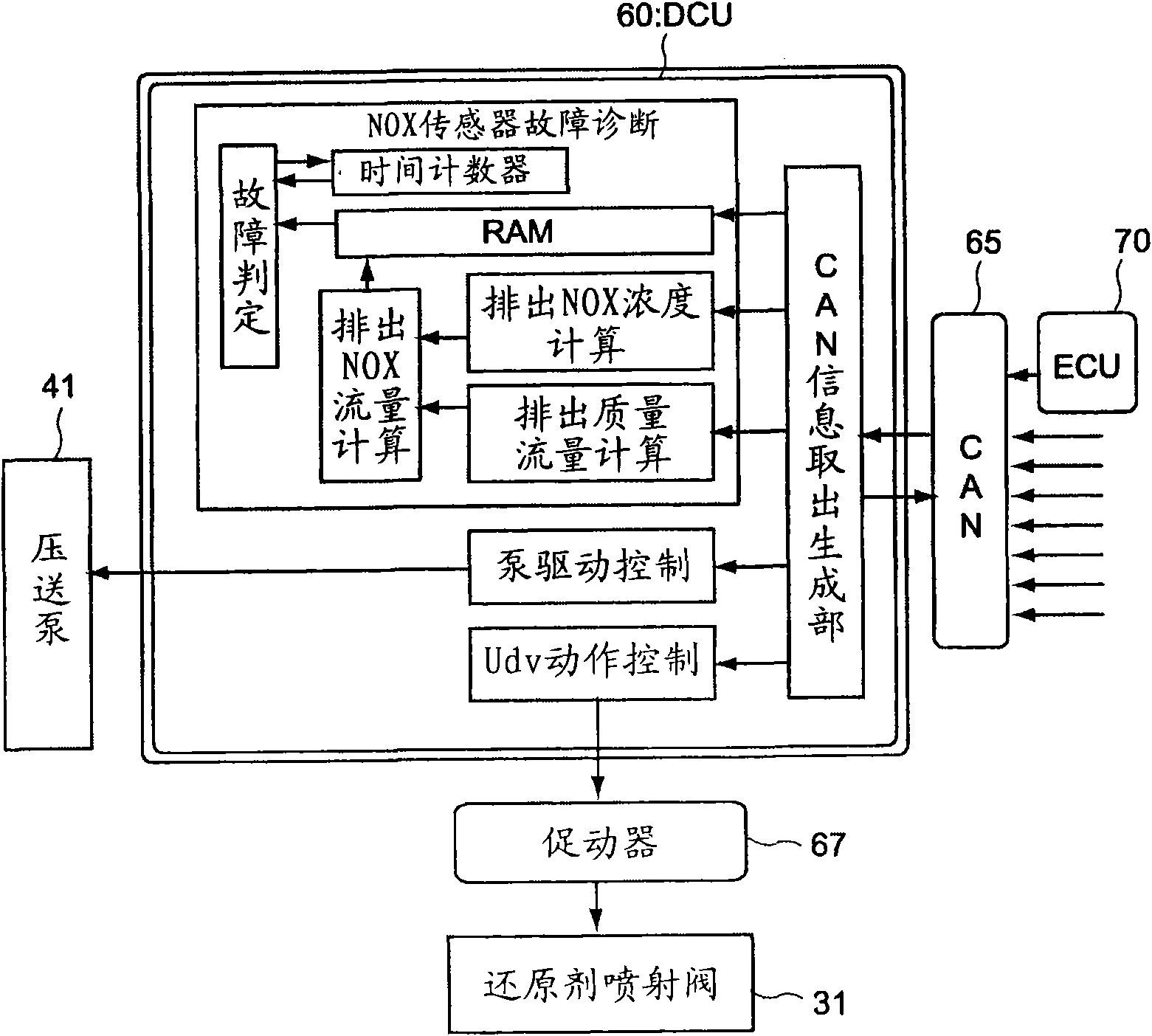

[0047] First, refer to figure 1 Description of the NO with the first embodiment of the present invention X A configuration example of an exhaust purification system (hereinafter, sometimes simply referred to as a "system") of a fault diagnosis device for a sensor.

[0048] figure 1 The exhaust purification system 10 shown uses urea aqueous solution as a reducing agent, and makes the exhaust gas pass through the NO together with the reducing agent. X Catalyst 13 to selectively reduce NO X Exhaust purification system 10. The exhaust purification system 10 has: NO X The catalyst 13 is arranged in the middle of the exhaust passage 11 connected to the internal combustion engine and is used for selectively reducing NO contained in the exhaust gas X ; Reductant supply device 20, containing for NO X The upstream side of the catalyst 13 injects the reducing ...

no. 2 Embodiment approach

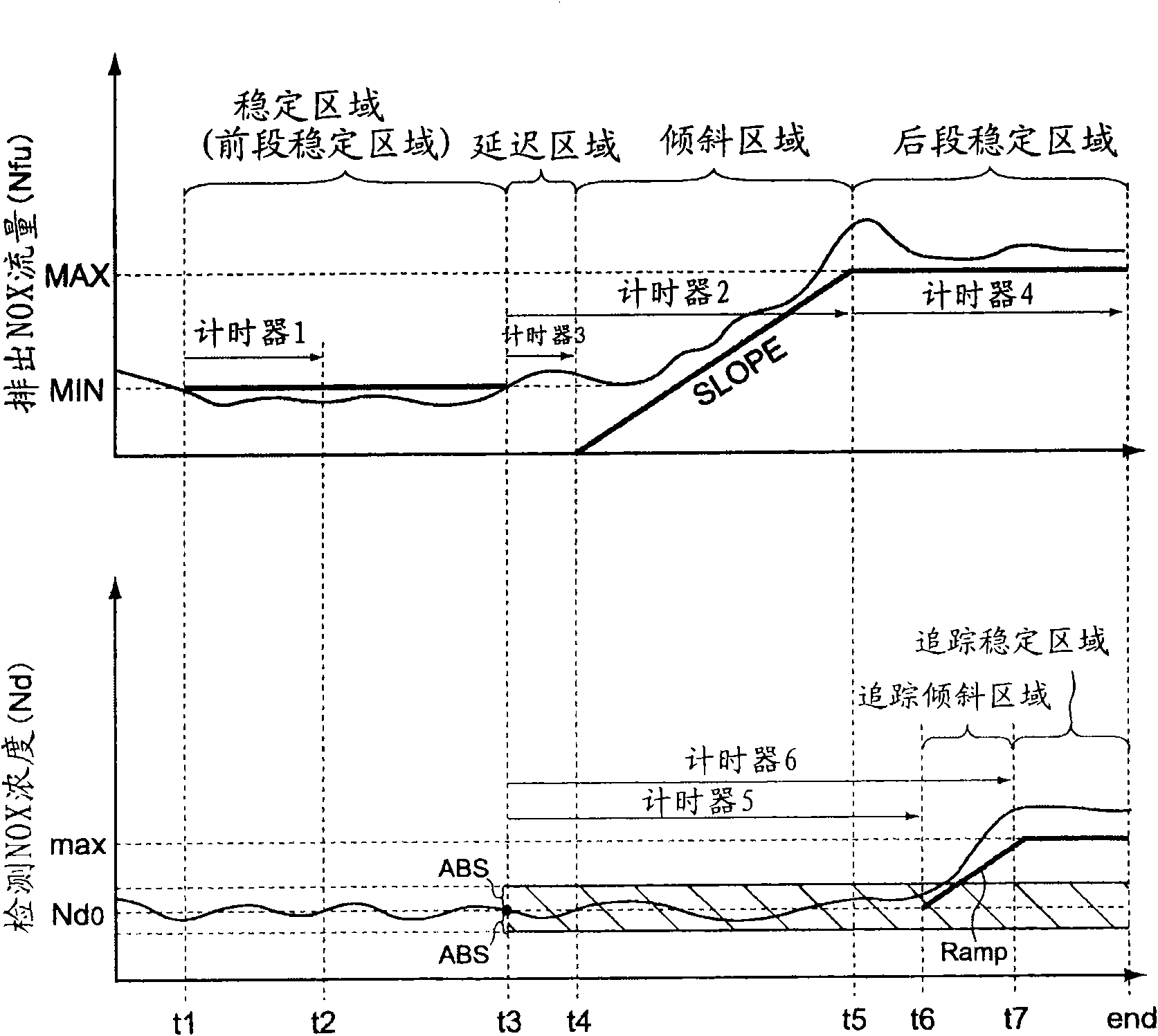

[0111] NO in this embodiment X The method of fault diagnosis of the sensor, as described above, is the NO X Catalysts with relatively small capacity for NO in SCR systems X Sensor fault diagnosis method. That is to say, in this embodiment, when increasing the exhaust NO X After flow to by configuring in NO X NO on the downstream side of the catalyst X NO detected by the sensor X The flow tracking time is shortened, and the elapsed time of timer 2 is set longer than the elapsed time of timer 5 .

[0112] Below, according to Figure 7 ~ Figure 9 The flow of the present invention will be described focusing on points different from those of the first embodiment.

[0113] In this embodiment, until the timers 2, 3, 5, and 6 are activated, the same steps as steps S100 to S113 in the first embodiment are performed (see Figure 4 ). After the timers 2, 3, 5, and 6 are operated, the steps between step S154 and step S161 are carried out in the same manner as the steps between st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com