Bidirectional controllable overrunning clutch and control method thereof

An overrunning clutch, controllable technology, applied in the direction of one-way clutches, clutches, mechanical equipment, etc., can solve problems such as inability to quickly diagnose faults, difficult product modification and maintenance, and large axial space requirements, and achieve processing technology Mature, reduced development and use costs, easy to deploy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

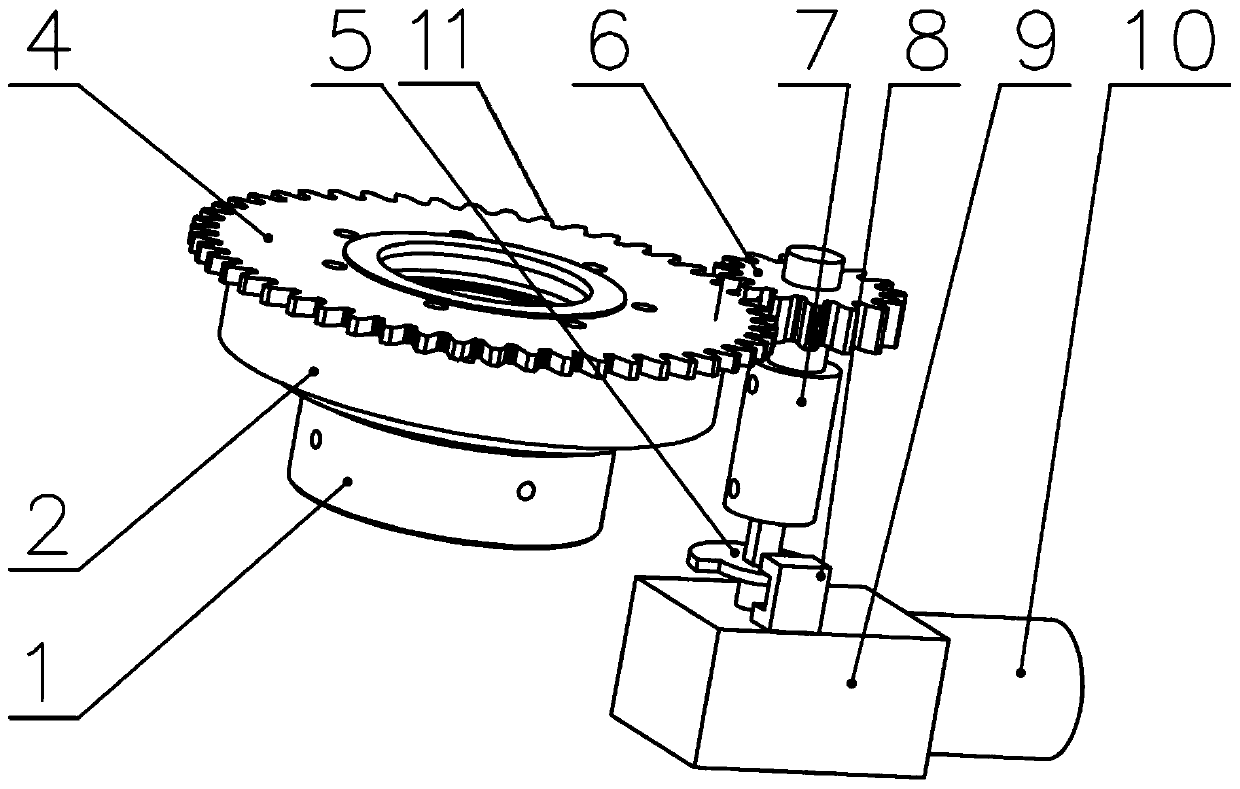

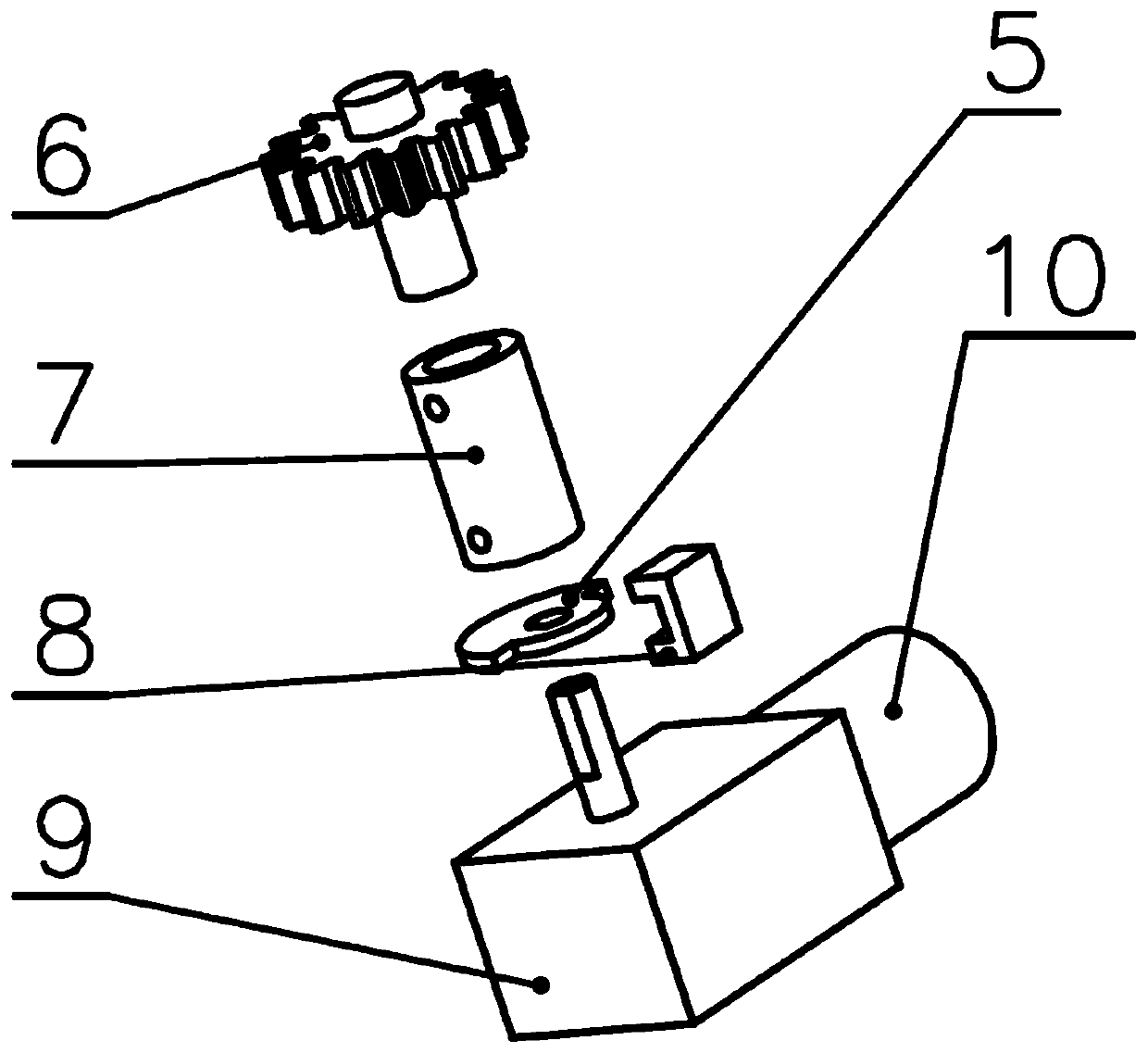

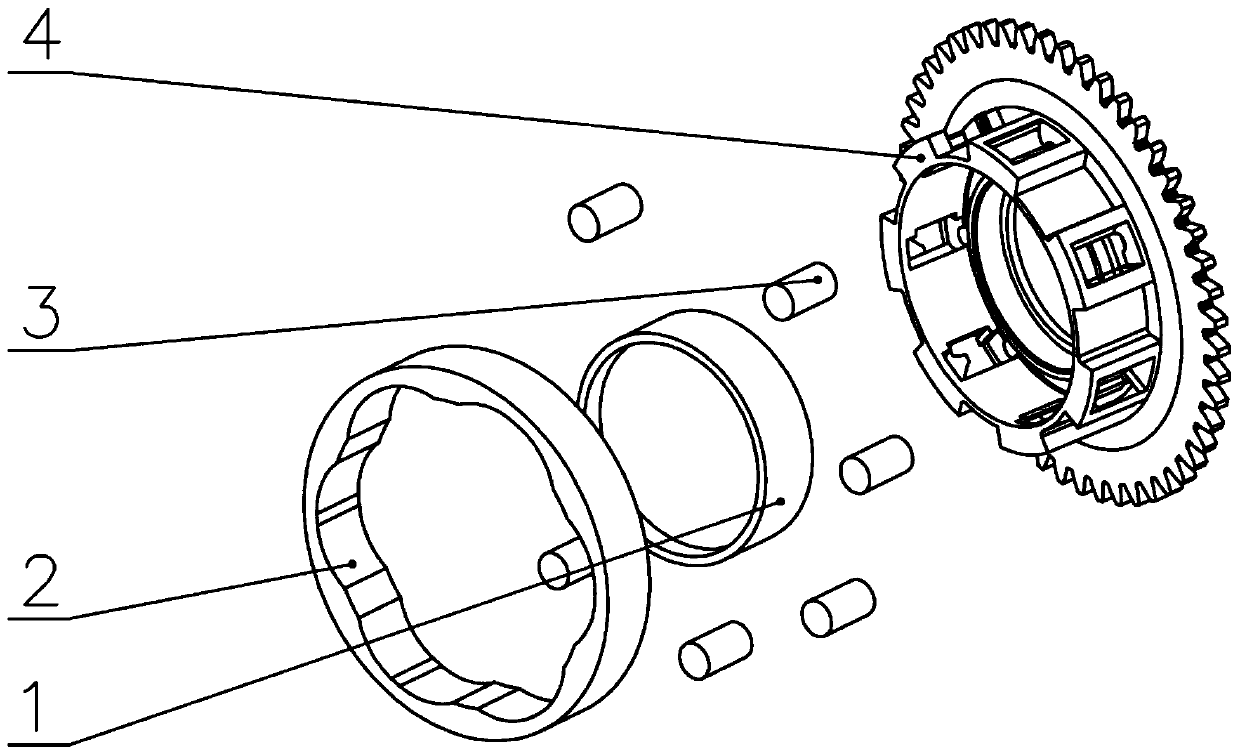

[0055] This embodiment discloses a two-way controllable overrunning clutch, which is composed of a cage drive assembly, a roller actuator assembly and a control assembly.

[0056] like figure 1 and figure 2 As shown, the cage driving assembly is composed of a driving motor 10 , a worm gear reducer 9 , a flexible coupling 7 , a driving gear 6 and a driven gear 11 . Wherein, the drive motor 10 is used as the power source of the cage drive assembly to output the rotational driving force outwards, and the output shaft of its power output end is coaxially fixedly connected with the input shaft of the worm gear box 9, and the worm gear box 9 The output shaft is coaxially connected with the gear shaft of the driving gear 6 through a flexible coupling 7, and the worm gear reducer 9 is fixed on the gearbox housing. The driving gear 6 meshes with the driven gear fixed on the end face of the cage 4 .

[0057] In the cage drive assembly, the drive motor 10 provides energy through the ...

Embodiment 2

[0070] This embodiment discloses a two-way controllable overrunning clutch, which is composed of a cage drive assembly, a roller actuator assembly and a control assembly.

[0071] like Figure 4 and Figure 5 As shown, the cage driving assembly is composed of a push-pull electromagnet 15 , a rigid coupling 14 , a connecting rod 13 , a pin 12 and a bar-shaped groove plate 16 . Wherein, the push-pull electromagnet 15 is used as the power source of the cage drive assembly to output a linear push-pull driving force outwards, and the push-pull rod at the output end of the push-pull electromagnet 15 is rigidly connected with one end of the connecting rod 13 through a rigid coupling 14, so The push-pull electromagnet 15 is fixed on the gearbox housing, the other end of the connecting rod 13 is provided with a counterbore, and the pin 12 is fixedly installed in the counterbore at the end of the connecting rod 13 through interference fit, The strip grooved plate 16 is fixedly mounted...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com