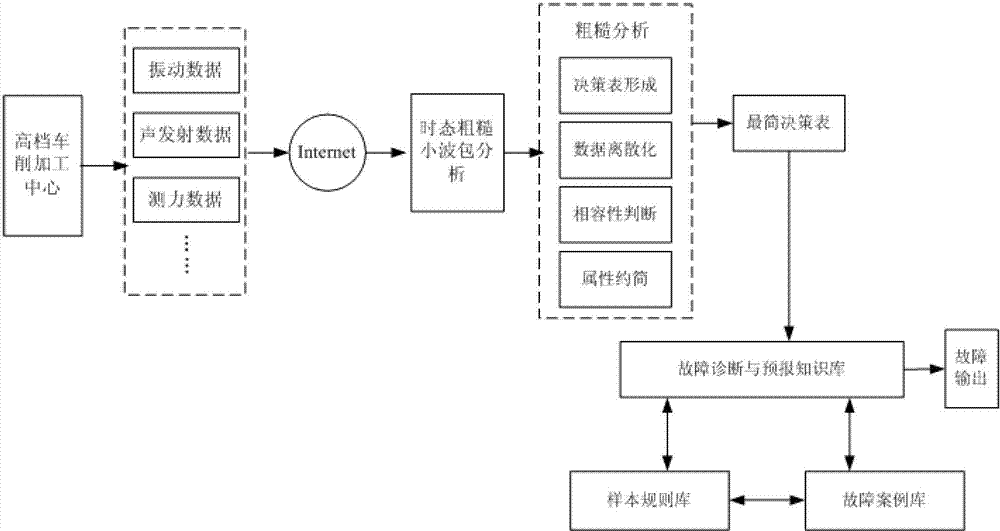

Knowledge base construction method oriented to fault diagnosis and fault prediction of numerical control machine tool

A technology of fault diagnosis and CNC machine tools, which is applied in the direction of program control, computer control, general control system, etc., can solve the problems of increasing detection cost, affecting the accuracy of fault identification, and lack of fault knowledge base construction research.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0046]Embodiment: Taking the high-grade turning machining center as the object, the failure simulation test of typical functional components is carried out, and the vibration acceleration signal sample acquisition test is completed by using the SN01840 type acceleration sensor. The fault simulation test of the whole machine is divided into three categories: spindle eccentric fault, gear wear fault, screw bearing fault. A vibration acceleration sensor is installed in the spindle box of the machine tool, and the data is collected and analyzed by the data acquisition analyzer of the Beijing Oriental Vibration and Noise Technology Research Institute. The sampling frequency is 4096Hz. The failure simulation test adopts three methods of simulating the eccentricity of the main shaft by adding a heavy object on the main shaft, loosening the gears in the gearbox to simulate the loosening of the gears and installing a damaged screw bearing to simulate the damage of the screw bearing. Se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com