Patents

Literature

166 results about "Gear wear" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

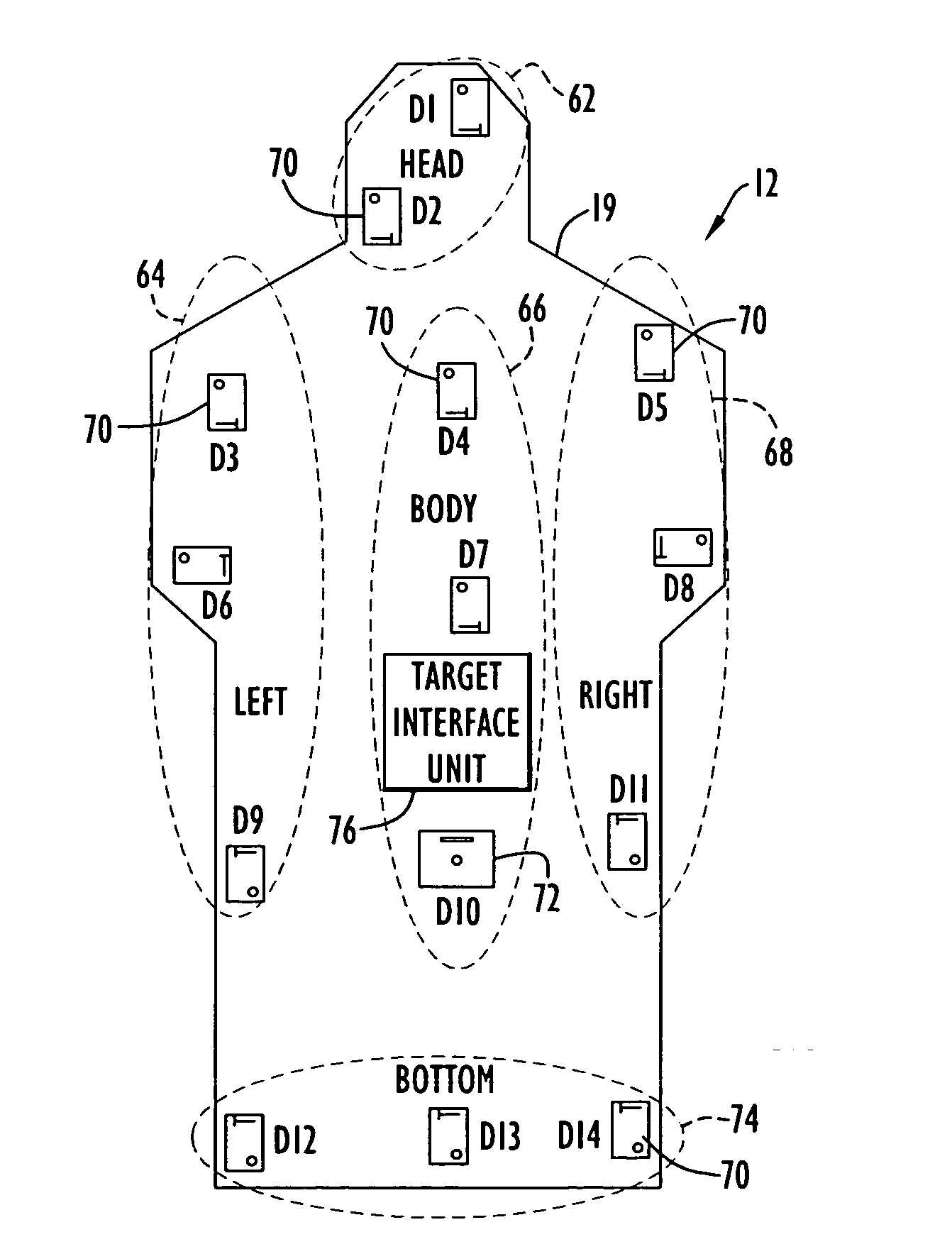

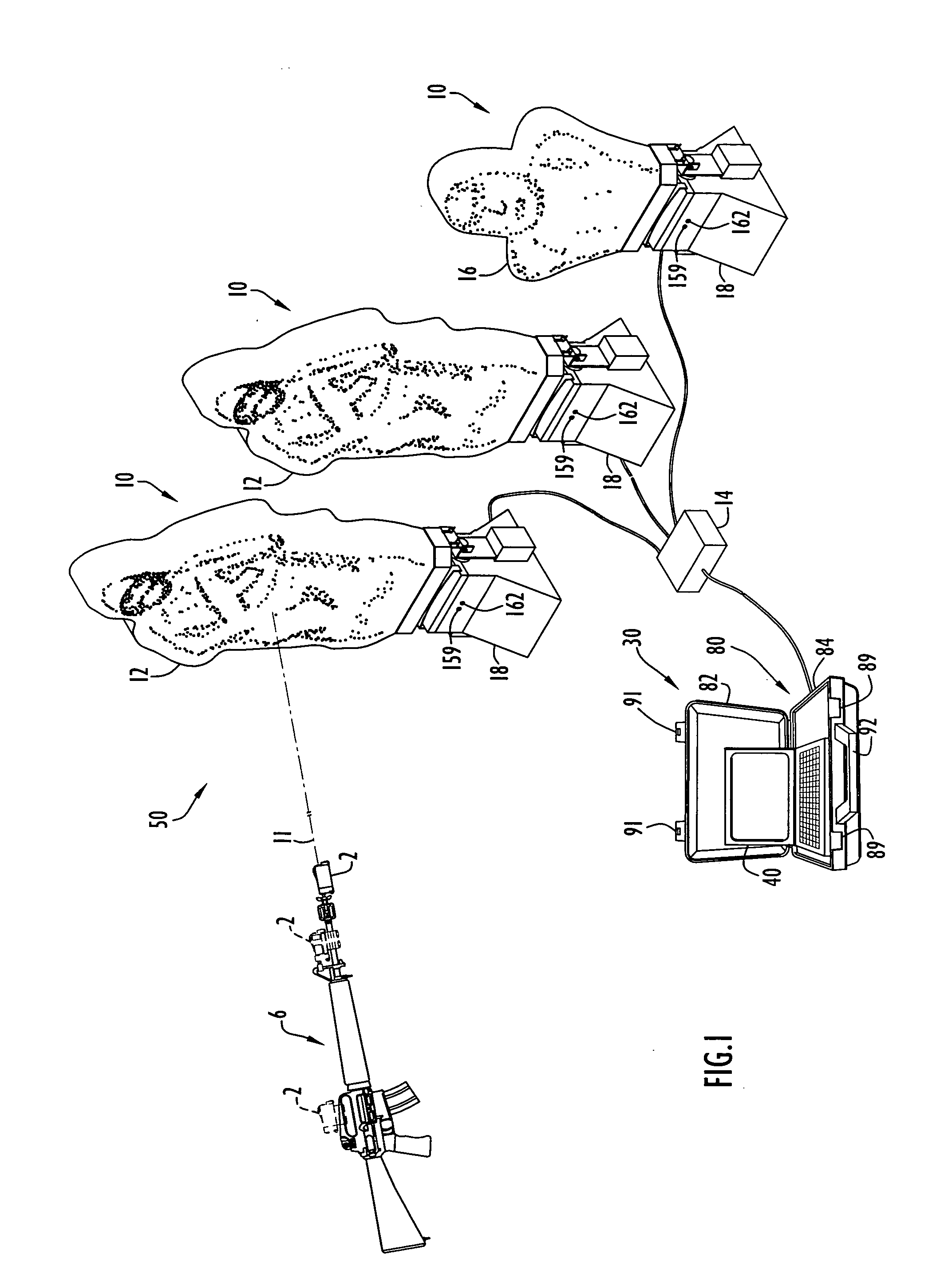

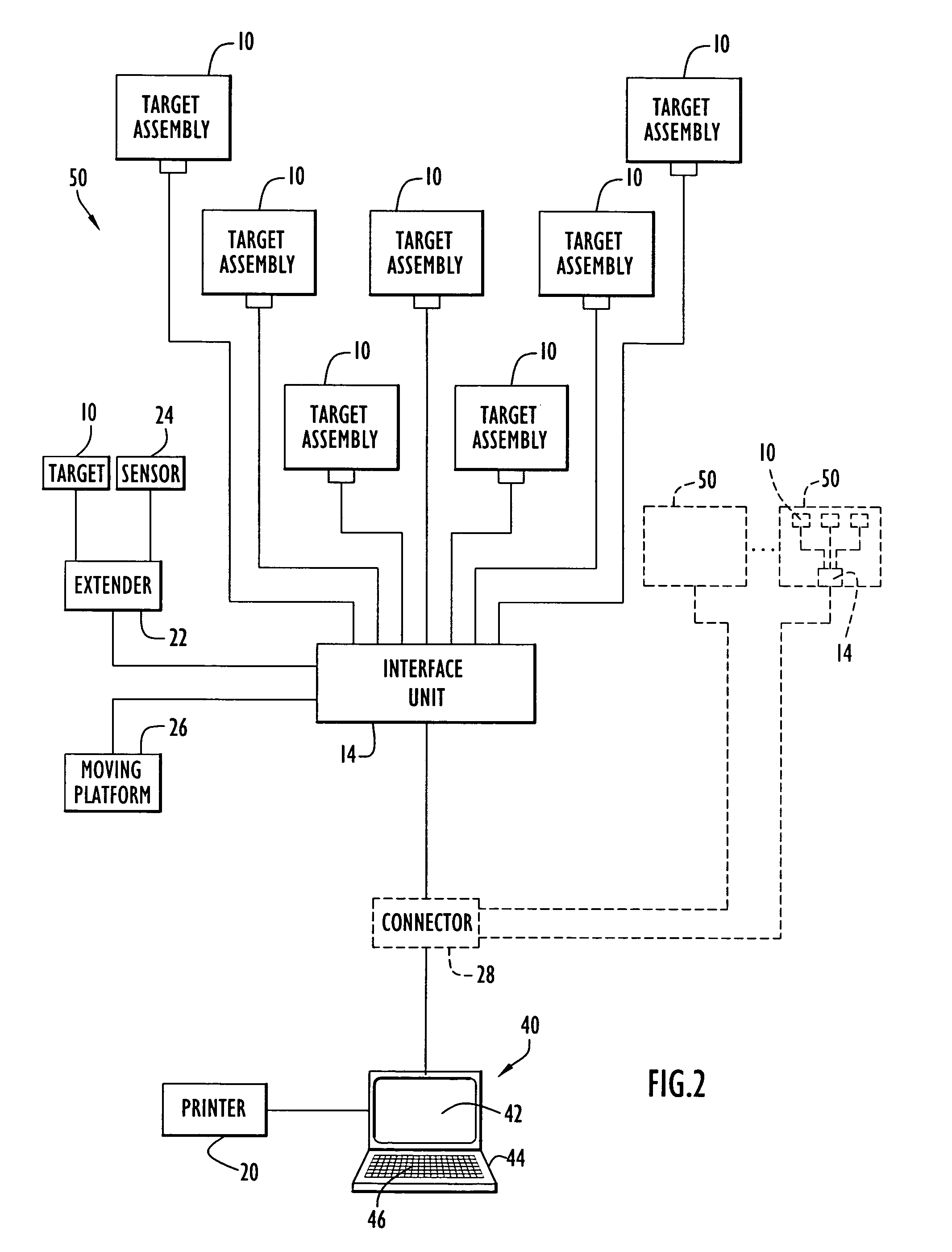

Firearm laser training system and method employing various targets to simulate training scenarios

InactiveUS20050153262A1Improve accuracyEasy to detectAiming meansTraining adaptationControl signalComputerized system

A firearm laser training system according to the present invention includes a laser assembly, actuable target assemblies and a computer system. The laser assembly is attached to a user firearm to project a laser beam toward the target. The target assemblies raise and lower targets in accordance with control signals from the computer system. Targets are raised to indicate intended targets, and are lowered in response to the beam impacting the raised targets or upon expiration of an interval without a beam impact. A corresponding target assembly forwards information to the computer system for display via wired or wireless communications. In addition, the training system may employ stationary target assemblies and / or laser-detecting body gear worn by exercise participants. The target assemblies and body gear communicate impact information to the computer system via wireless communications and may be utilized to create various training scenarios for firearm training.

Owner:KENDIR O TANSEL

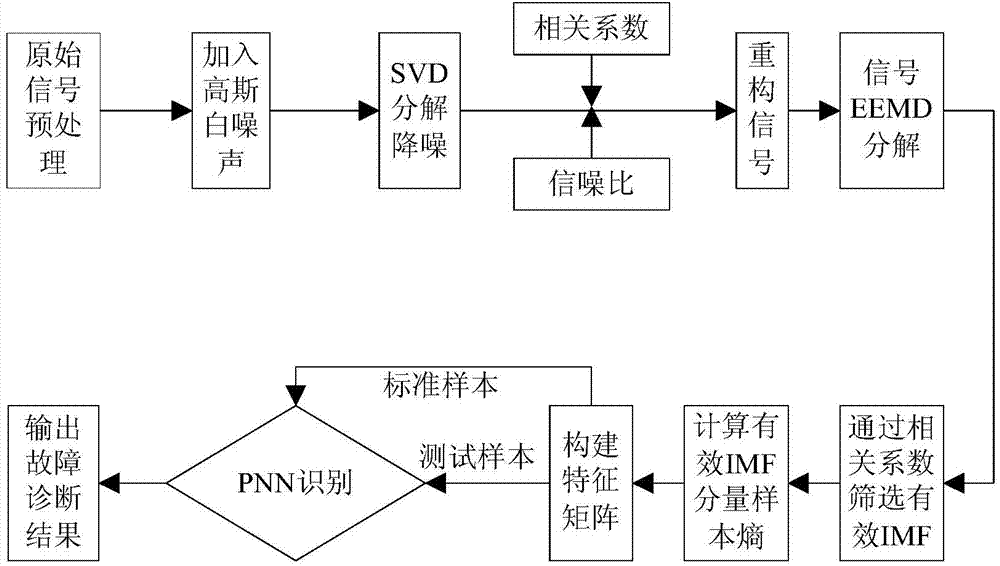

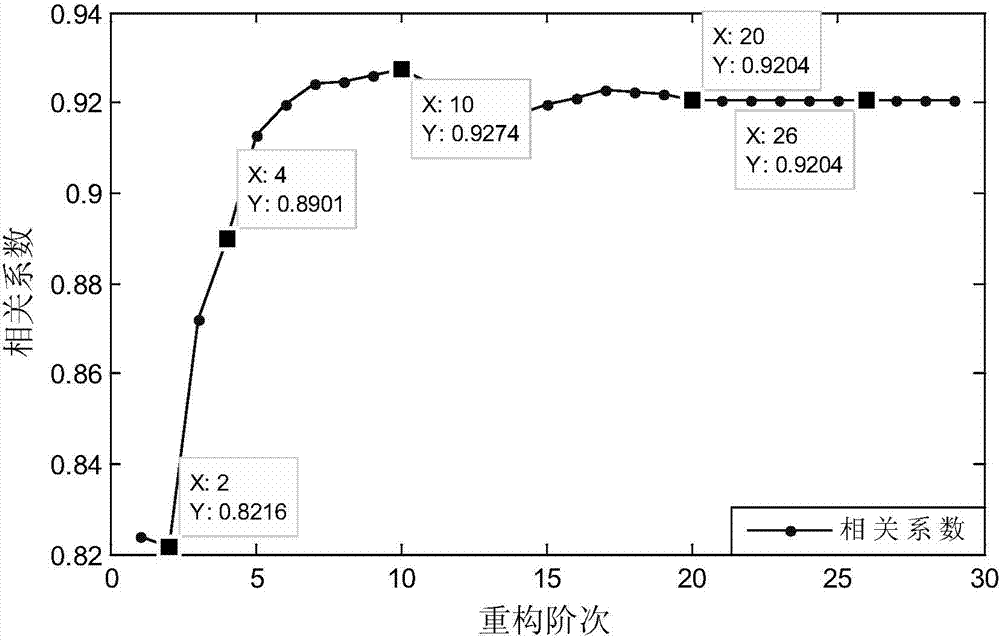

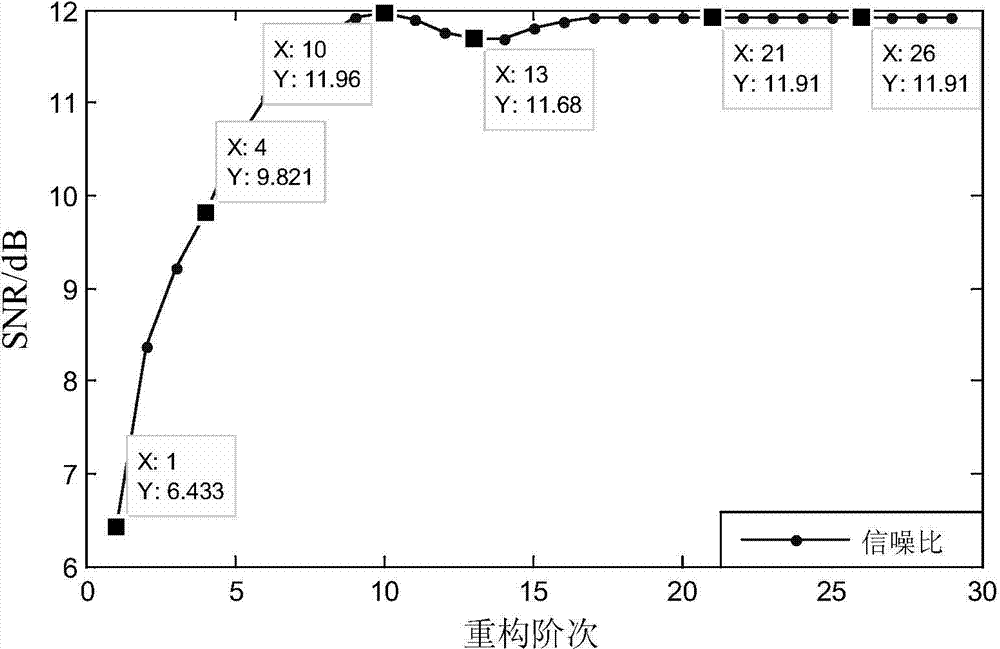

Gear fault diagnosis method based on SVD decomposition and noise reduction and correlation EEMD entropy features

InactiveCN104748961AImprove signal-to-noise ratioAccurate extractionMachine gearing/transmission testingBiological neural network modelsDecompositionEngineering

The invention discloses a gear fault diagnosis method based on the SVD decomposition and noise reduction and correlation EEMD entropy features. The method includes utilizing an acceleration vibration sensor to acquire experimental platform gear vibration signals including four types of faults, namely gear normality, gear tooth breaking, gear tooth missing and gear wearing; performing noise reduction on the signals, of four gear states, containing simulated strong noise background of Gaussian white noise by the SVD decomposition method with correlation analysis and noise ratio optimization; decomposing the four types of noises by the EEMD method after noise reduction, and selecting valid IMF components according to correlative coefficients; performing sample entropy calculation on the valid IMF components, and establishing feature vectors composed of the IMF samples; identifying the four different types of gear faults through a PNN neural network. The method is effective and is capable of recognizing the gear fault types on the strong-noise background effectively.

Owner:CHINA UNIV OF MINING & TECH

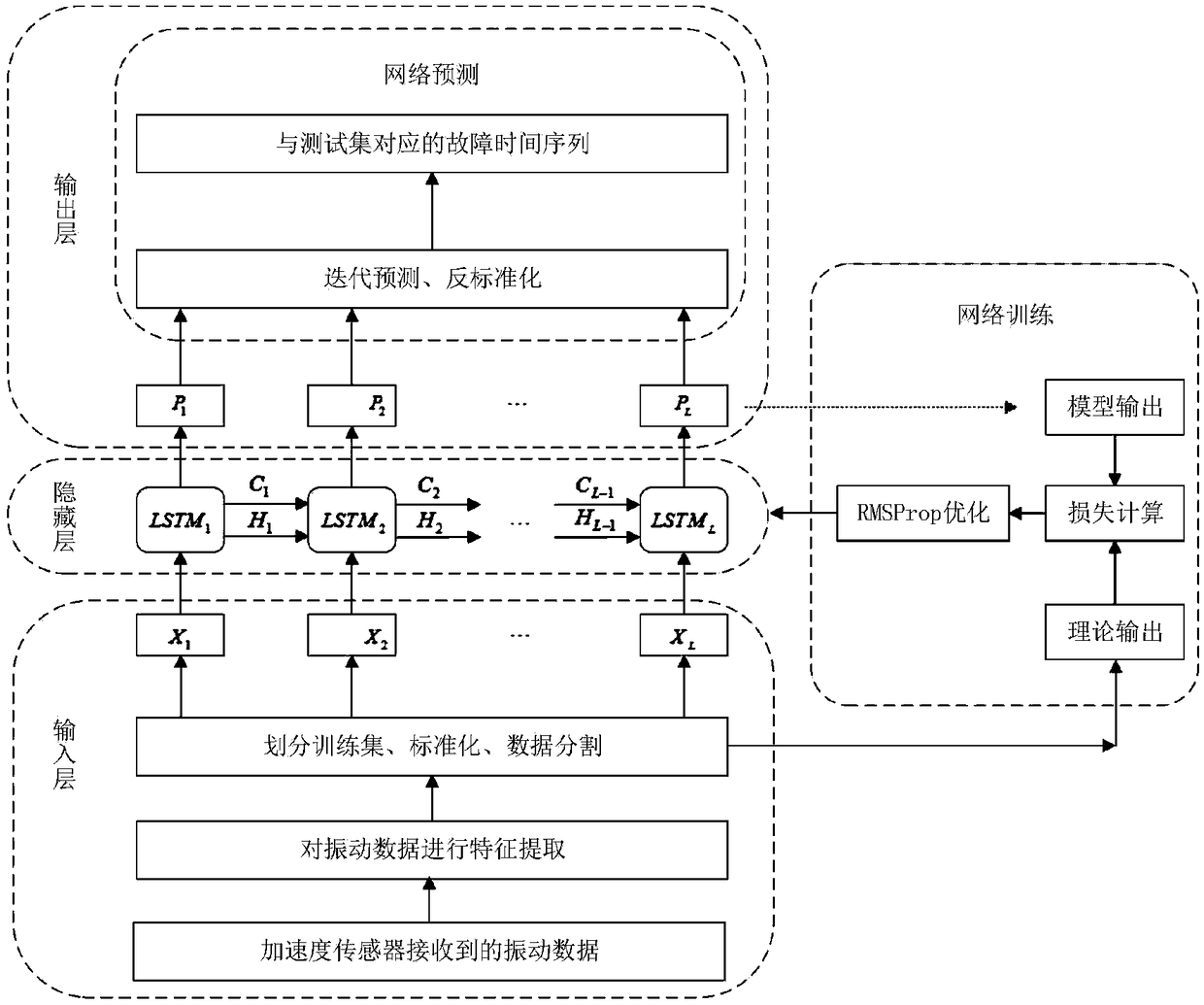

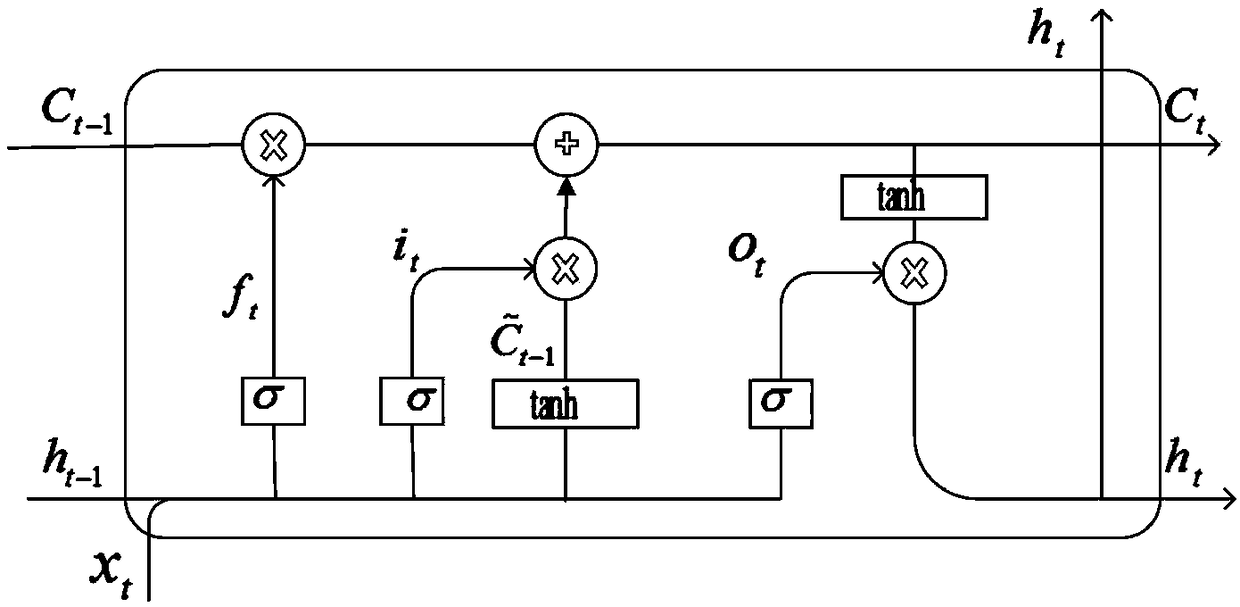

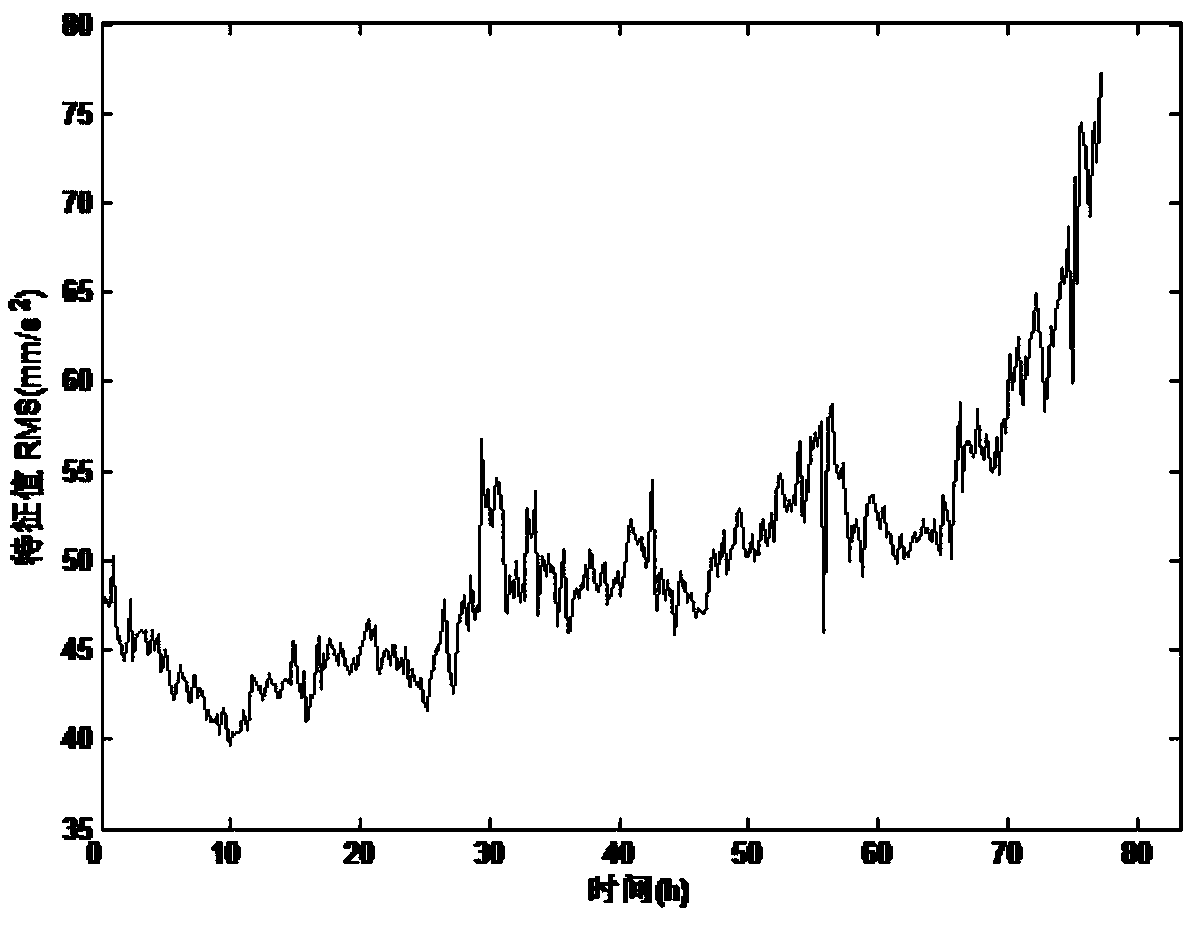

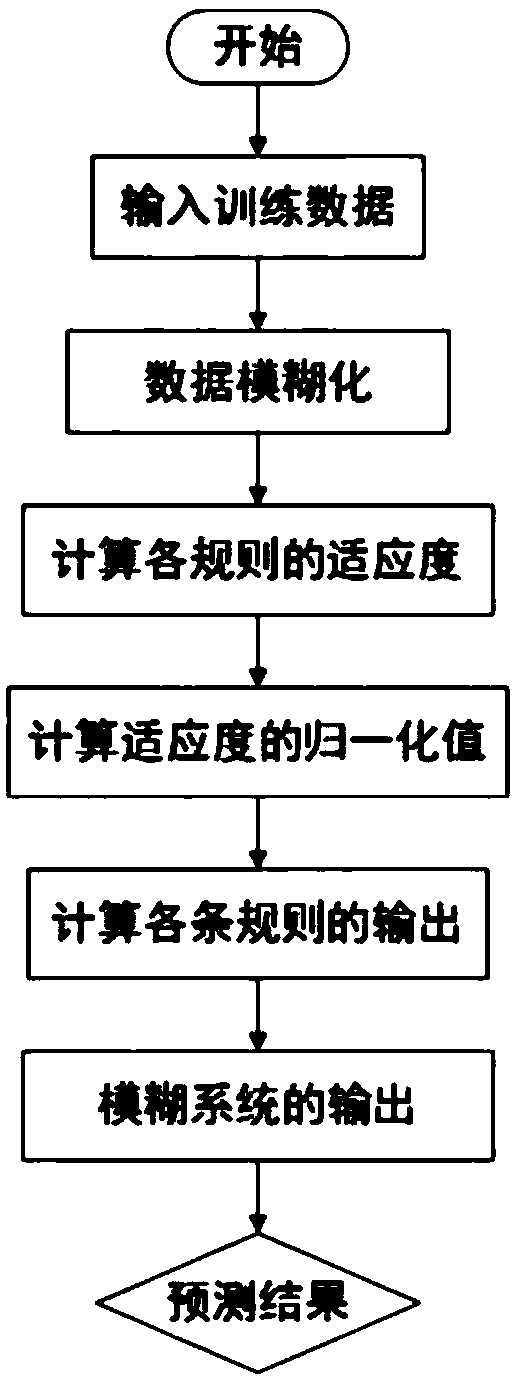

Gear residual life predicting method based on long short-term memory

InactiveCN109343505AImprove accuracyMachine gearing/transmission testingElectric testing/monitoringFeature extractionAlgorithm

The invention provides a gear residual life predicting method based on long short-term memory, and belongs to the field of big data and intelligent manufacturing. The problems that the existing RNN algorithm cannot solve long-term dependence and recurrent neural network is prone to gradient exploding or gradient vanishing are solved. The specific steps of using the algorithm are as follows: 1, monitoring the degradation of a power gear in real time with a sensor; 2, extracting features of the gear fatigue state, and evaluating the gear wear degradation performance; 3, establishing a real-timemonitoring data prediction model of the gear bending fatigue based on LSTM; 4,optimizing parameters based on the LSTM prediction model; 5, predicting the gear residual life based on gear state estimation and a known gear fault threshold. The gear residual life predicting method based on long short-term memory has the advantages that the gear degradation state and the real-time residual life can beaccurately predicted, and the basis for predictive maintenance of the gear is provided.

Owner:TAIYUAN UNIVERSITY OF SCIENCE AND TECHNOLOGY

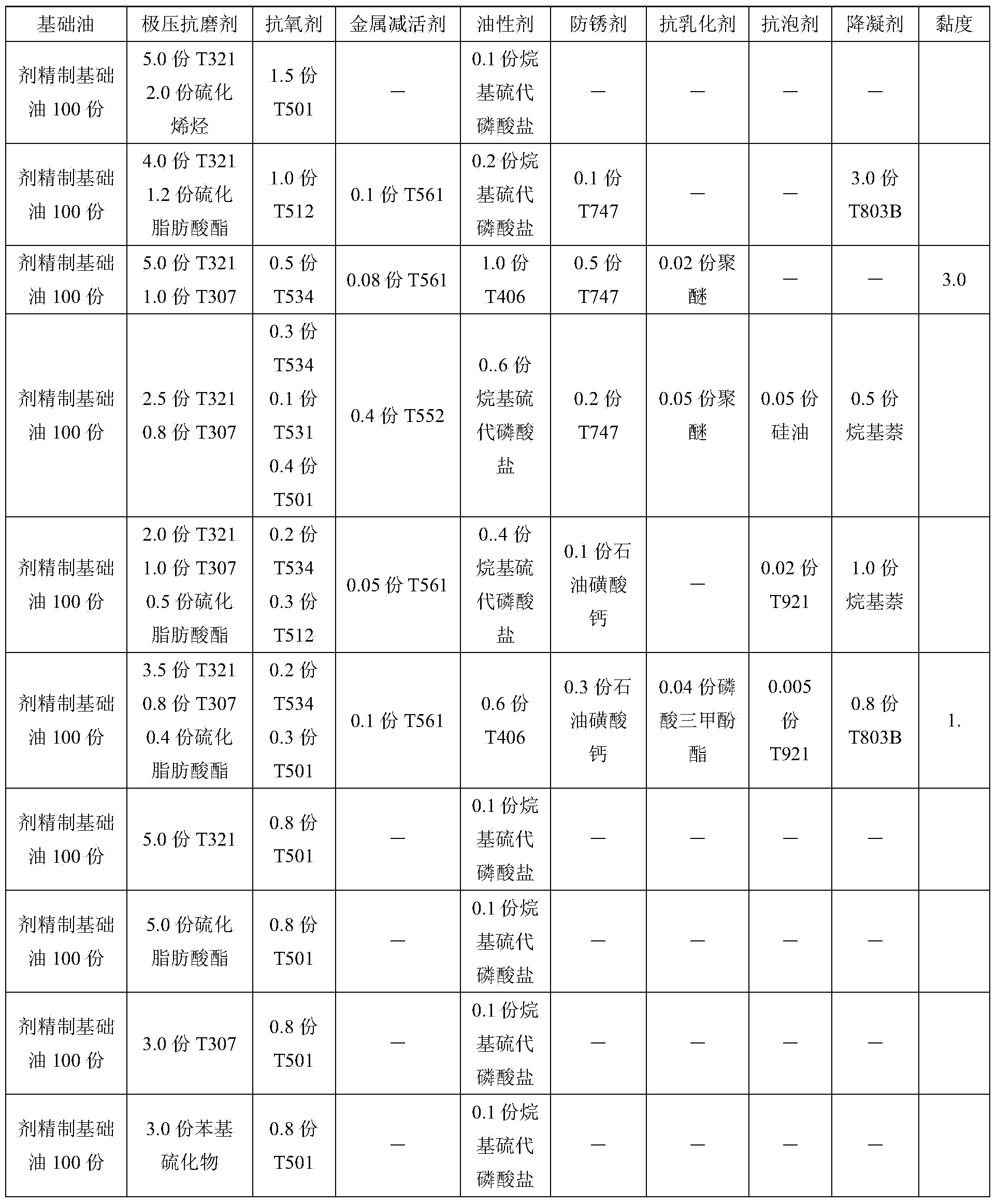

Gear oil composition and applications thereof

The invention relates to a gear oil composition and applications thereof, mainly solving problems of abnormal gear wear and poor oxidation stability of an oil product which are caused by that the extreme pressure property of industrial gear oil in the prior art fails to satisfy a part of using requirements of the metallurgy industry. According to the technical scheme adopted by the gear oil composition, the gear oil composition comprises following components by weight: a) 100 parts of mineral base oil; b) 0.1-10.0 parts of an anti-wear reagent at extreme pressure; c) 0.01-2.0 parts of an antioxidant; d) 0.01-0.5 part of a metal deactivator and e) 0.01-1.5 parts of an oiliness agent, wherein the anti-wear reagent at extreme pressure is a mixture of sulfurized isobutylene and at least one selected from sulfurized olefin, phenyl sulfide, sulfurized aliphatic ester or amine thiophosphate diester; and the antioxidant is at least one selected from 2,6-di(tertbutyl)-p-cresol, 3.5-di(tertbutyl)-4-hydroxy phenyl acrylate, pentaerythrite tetra[beta-(3,5-di-tert-butyl-4-hydroxyphenyl)-propionate], N-phenyl-1-naphthylamine or alkylated diphenylamine. By the technical scheme, the problems are solved well and the gear oil composition can be used for industrial production.

Owner:CHINA PETROLEUM & CHEM CORP

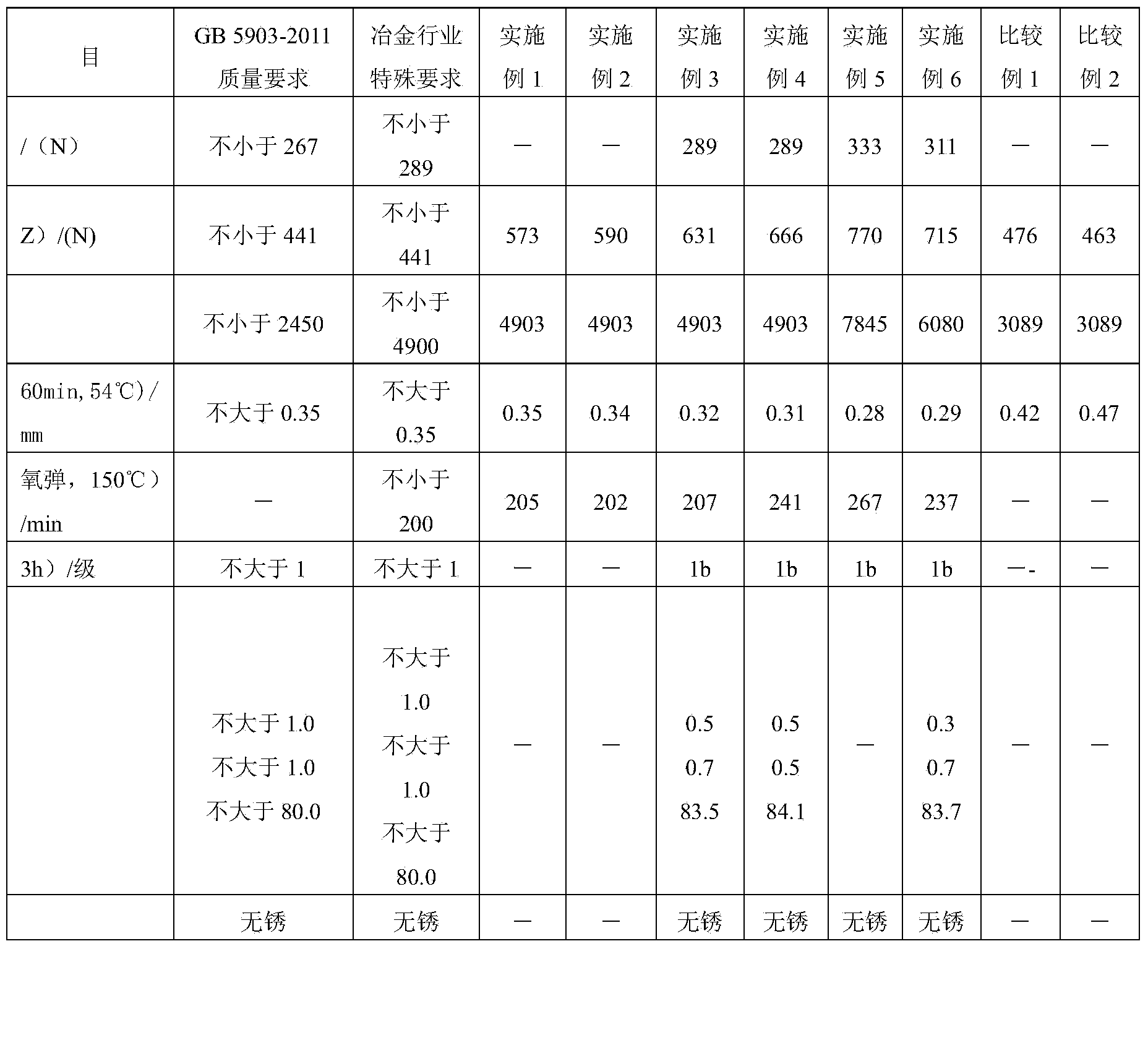

Multi-leaf collimator and a radiotherapy unit provided with the same

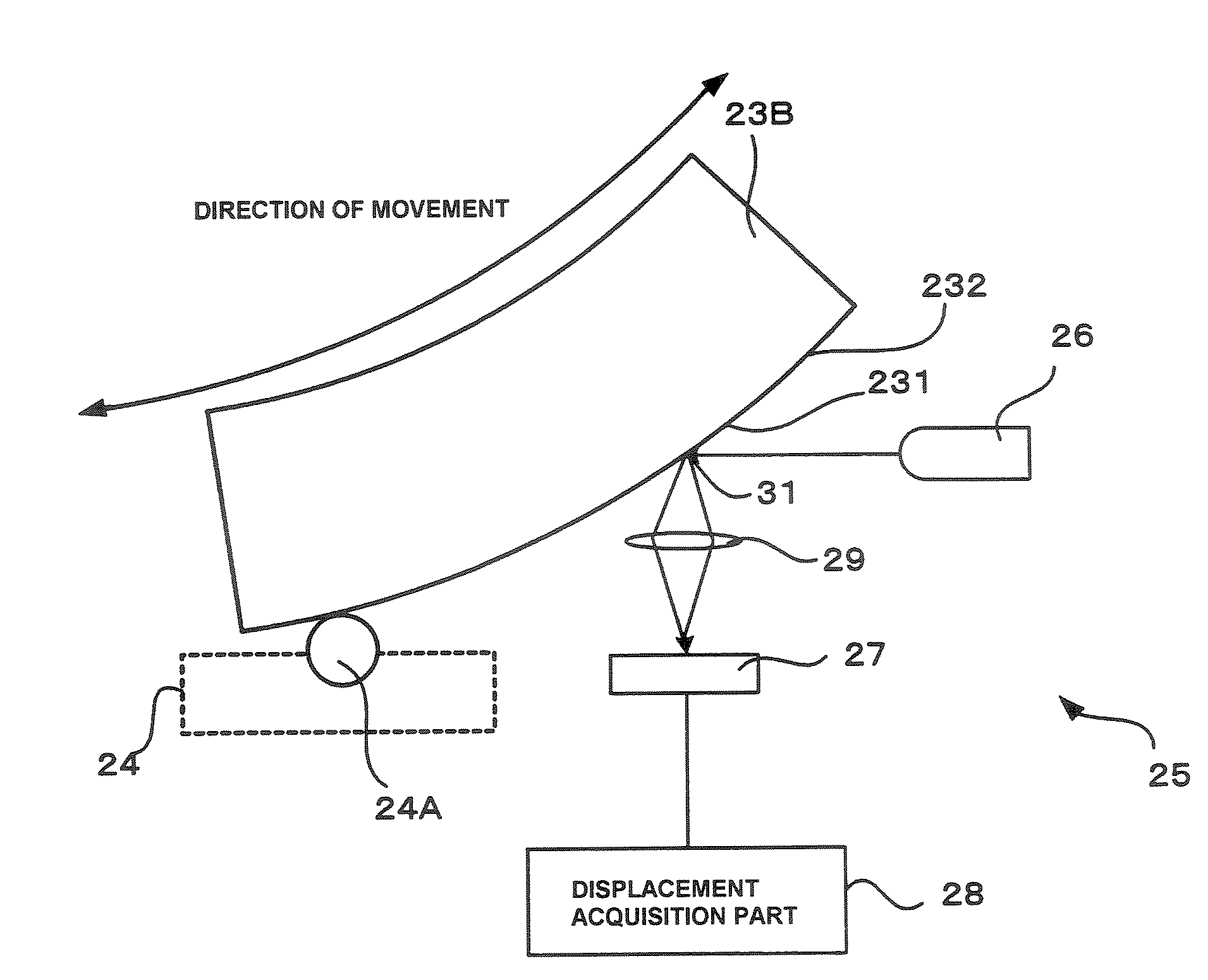

InactiveUS20070176126A1InhibitionImprove accuracyElectrode and associated part arrangementsPhotometryMulti leaf collimatorRadiotherapy unit

A multi-leaf collimator that narrows a radiation field to a predetermined shape is provided with leaf blocks movable in the direction of the radiation field and having pattern images drawn along the direction of movement on a predetermined surface, and detection part acquiring an image of fixed-point via fixed-point observation in the direction of that predetermined surface and for detecting displacement of said leaf blocks based on the arranged locations of the pattern images existing in this image of fixed-point. Moreover, it is provided with detection part acquiring an image of fixed-point via fixed-point observation in the direction of that predetermined surface and for detecting the locations of the leaf blocks based on the arranged locations of the pattern images existing in this image of fixed-point. According to the present invention, displacement and locations of leaf blocks can be detected without making contact, and displacement due to the effect of backlash and gear wear or errors in detecting locations can be prevented. Therefore, regardless of backlash, the locations of the leaf blocks can be detected with high precision, and the radiation field can be matched to the shape of an affected part with high precision.

Owner:TOSHIBA MEDICAL SYST CORP

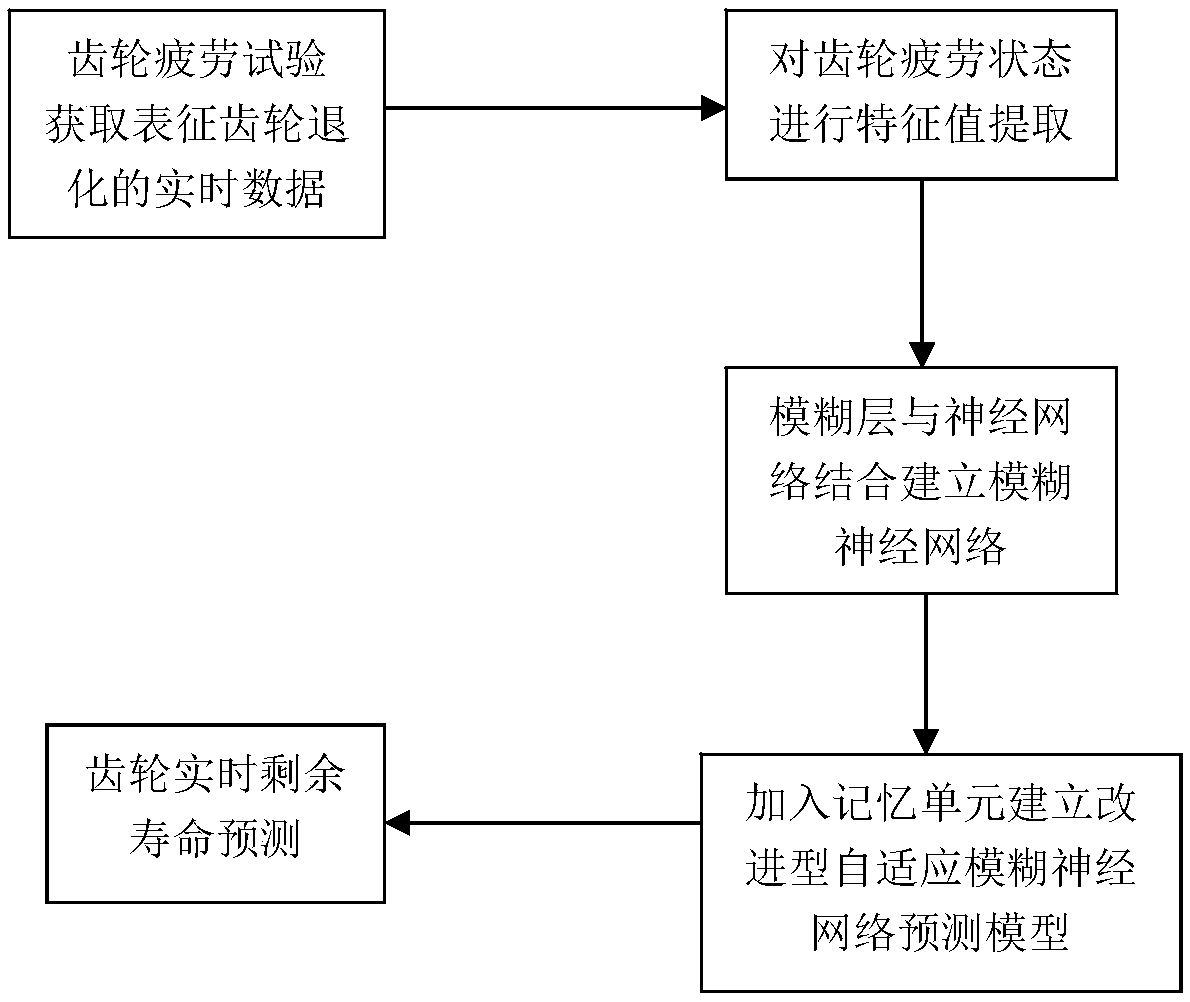

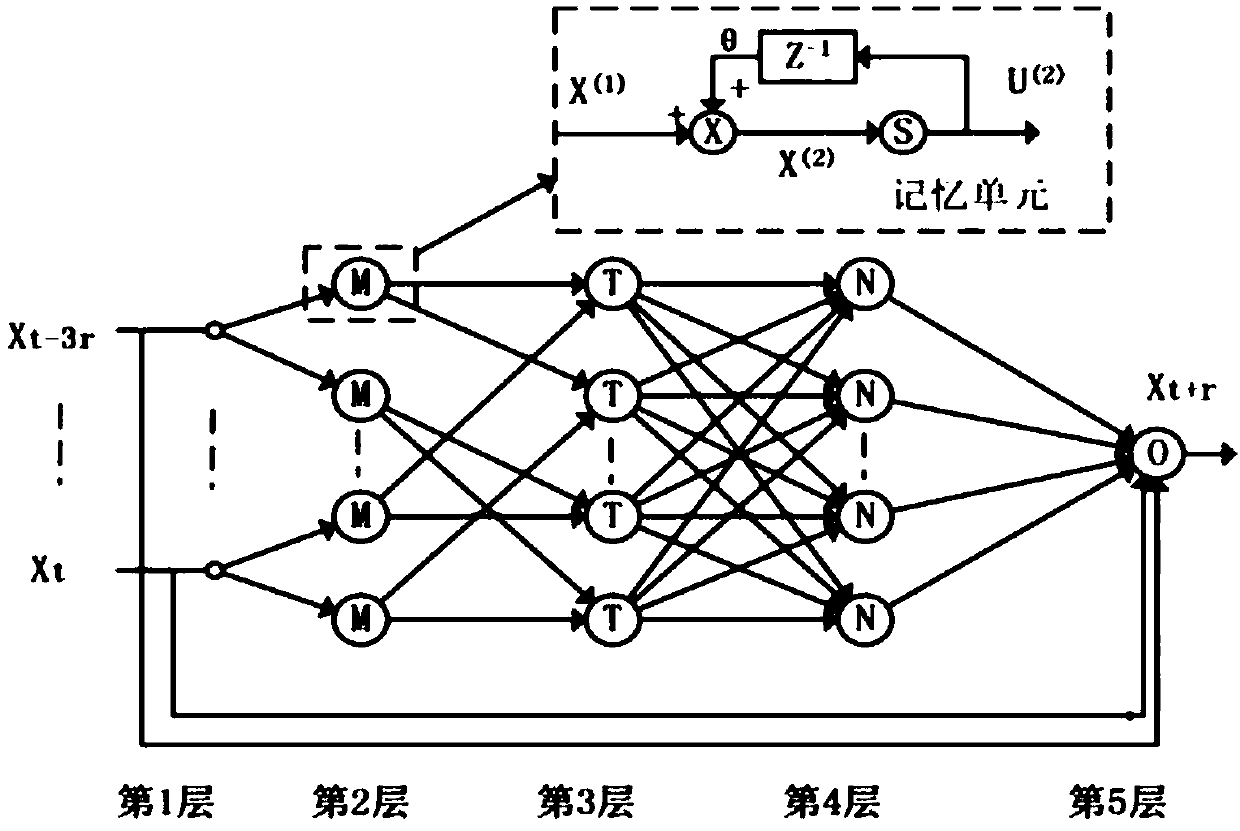

Adaptive fuzzy neural network gear remaining life prediction method

ActiveCN108645615AImprove forecast accuracyFast convergenceMachine gearing/transmission testingBiological neural network modelsNODALMechanical reliability

The invention provides an improved adaptive fuzzy neural network gear remaining life prediction method, and belongs to the technical field of mechanical reliability. The method is characterized by comprising the following implementation steps: 1, gear degradation is monitored in real time by using a vibration sensor; 2, feature extraction of the gear fatigue state is performed, and degradation assessment is performed on the gear wear degradation performance; 3, the fuzzy system and the neural network are combined, the defects of the fuzzy control system are compensated by using the neural network self-learning mechanism and a fuzzy information fuzzy neural network is established; 4, the memory unit is added to all the nodes of the fuzzy processing layer, the information of the last momentis memorized and applied to the output of the present moment and the information is constantly saved, information forward and backward correlation is enhanced, the deviation between the prediction value and the actual value is reduced and the improved adaptive fuzzy neural network prediction system is established; and 5, the gear remaining life is predicted according to the trained improved adaptive fuzzy neural network. The advantages are that the gear degradation state and the real-time remaining life can be effectively predicted so as to provide the basis for gear preventive maintenance.

Owner:TAIYUAN UNIVERSITY OF SCIENCE AND TECHNOLOGY

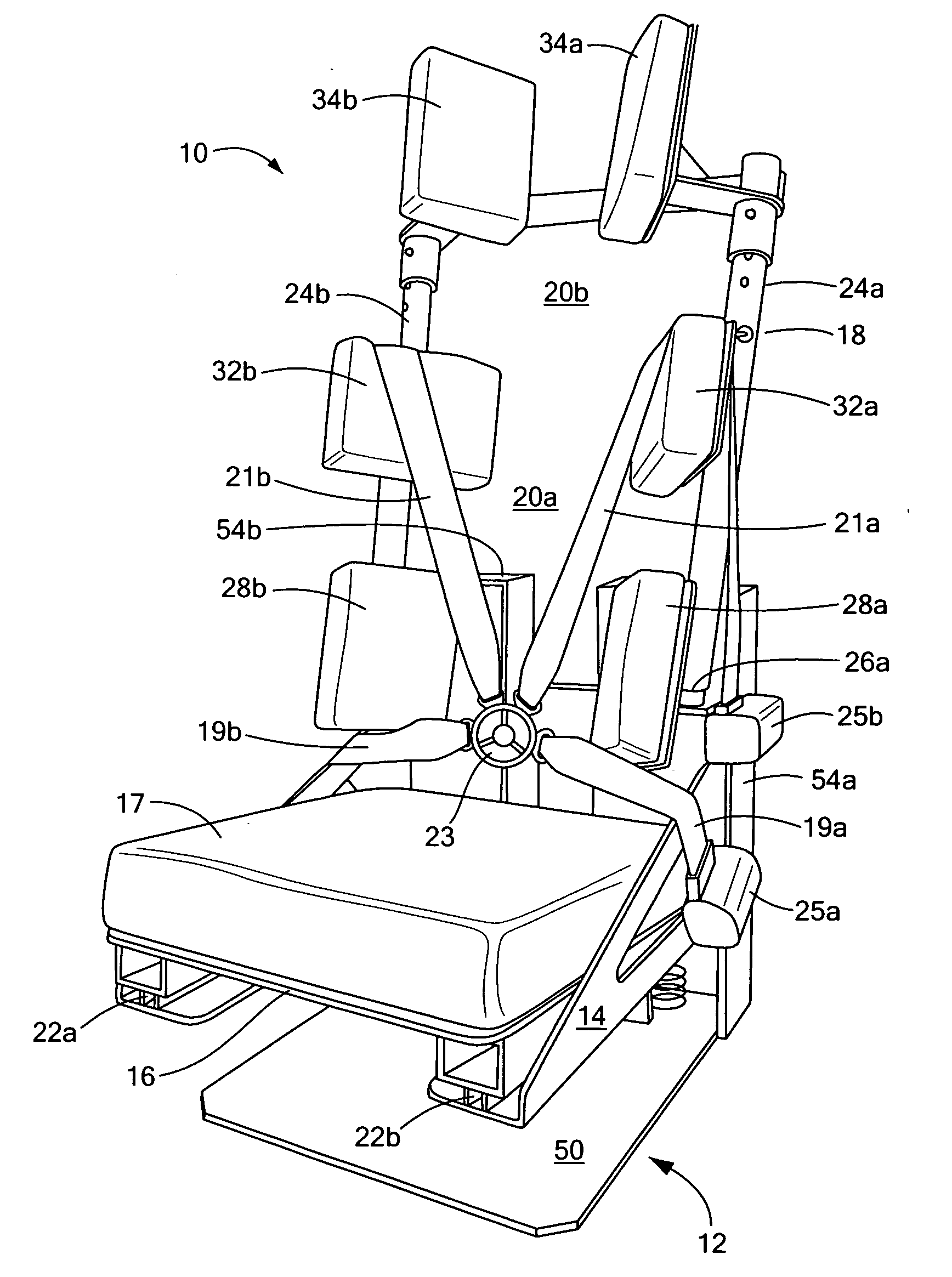

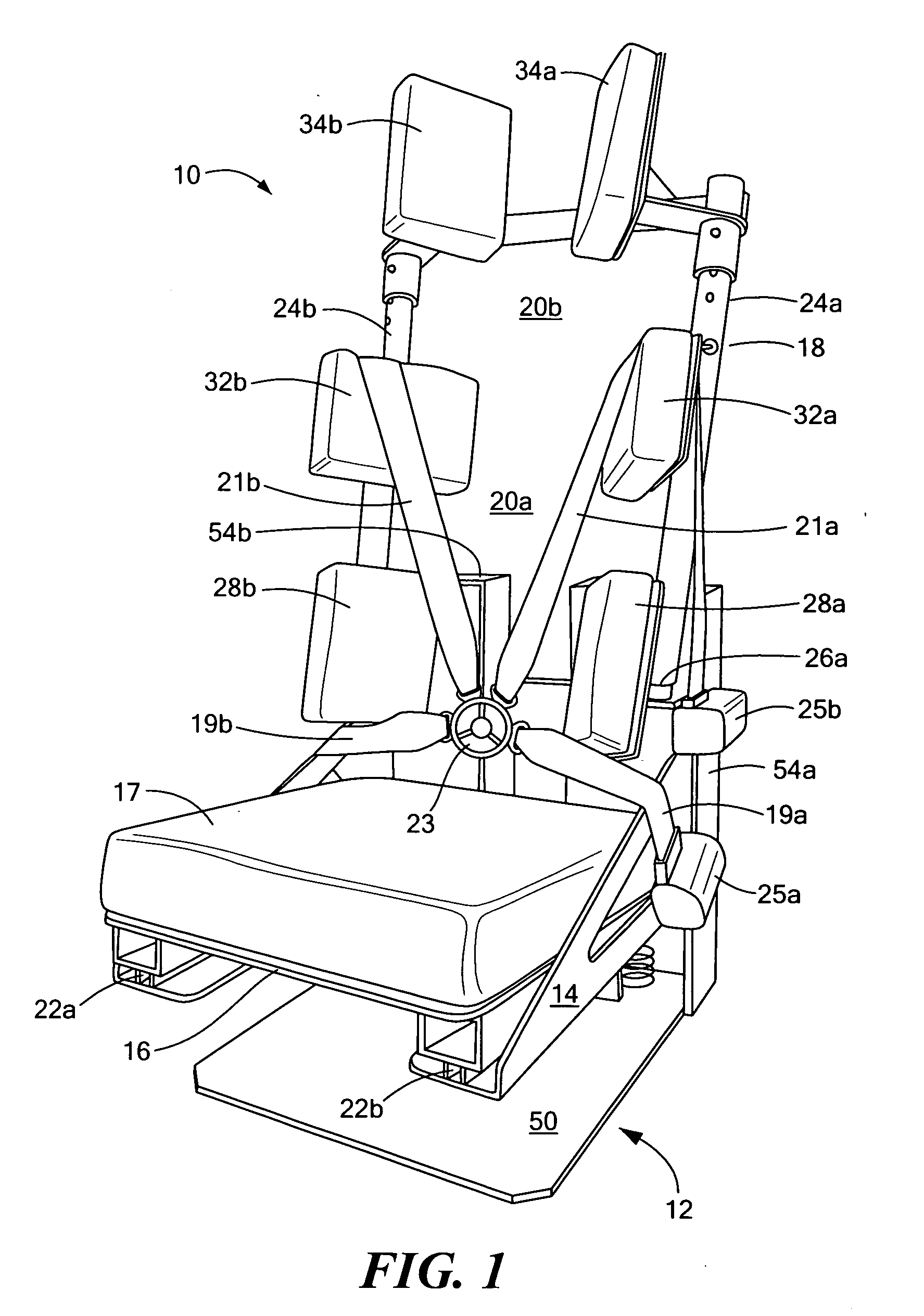

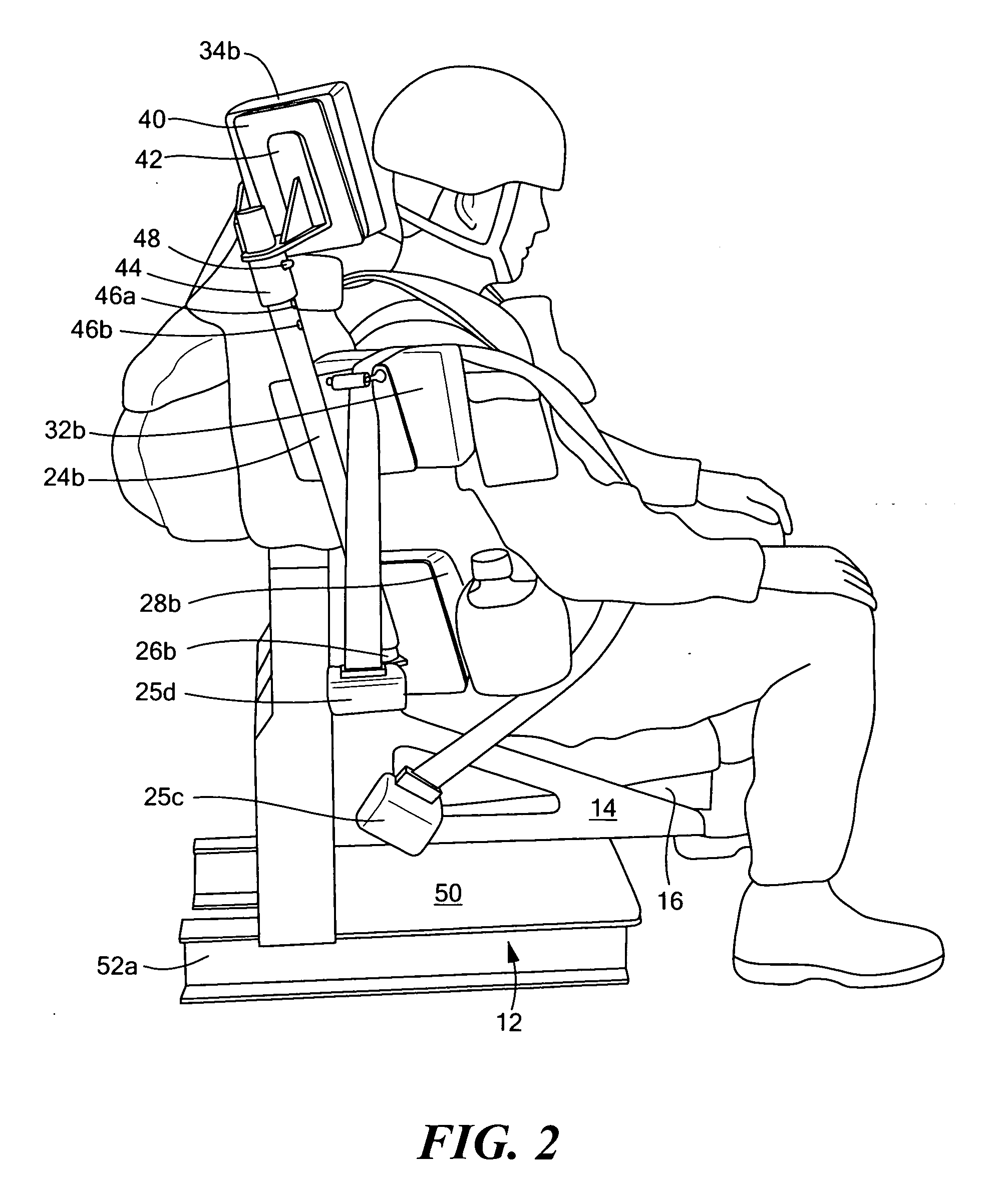

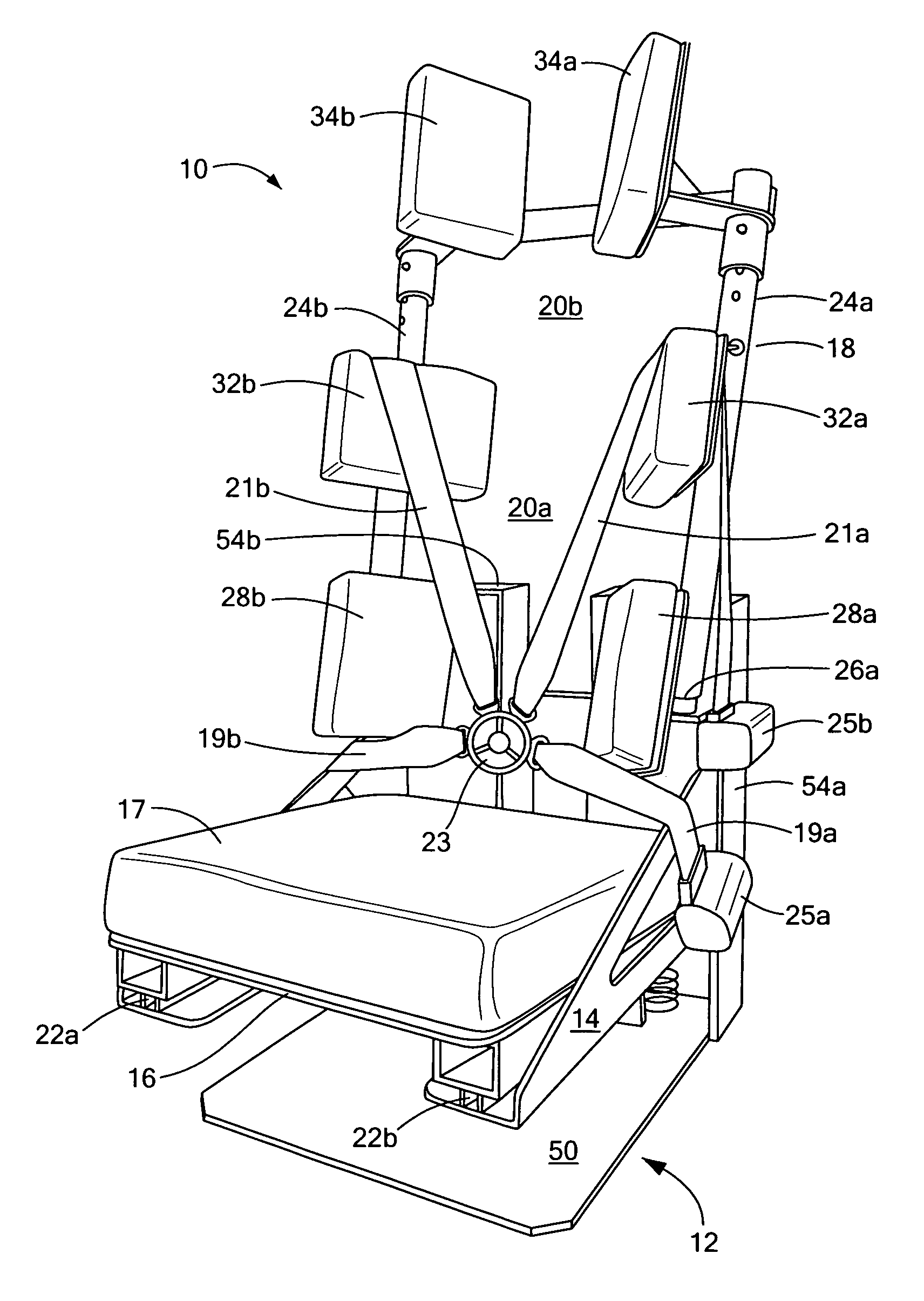

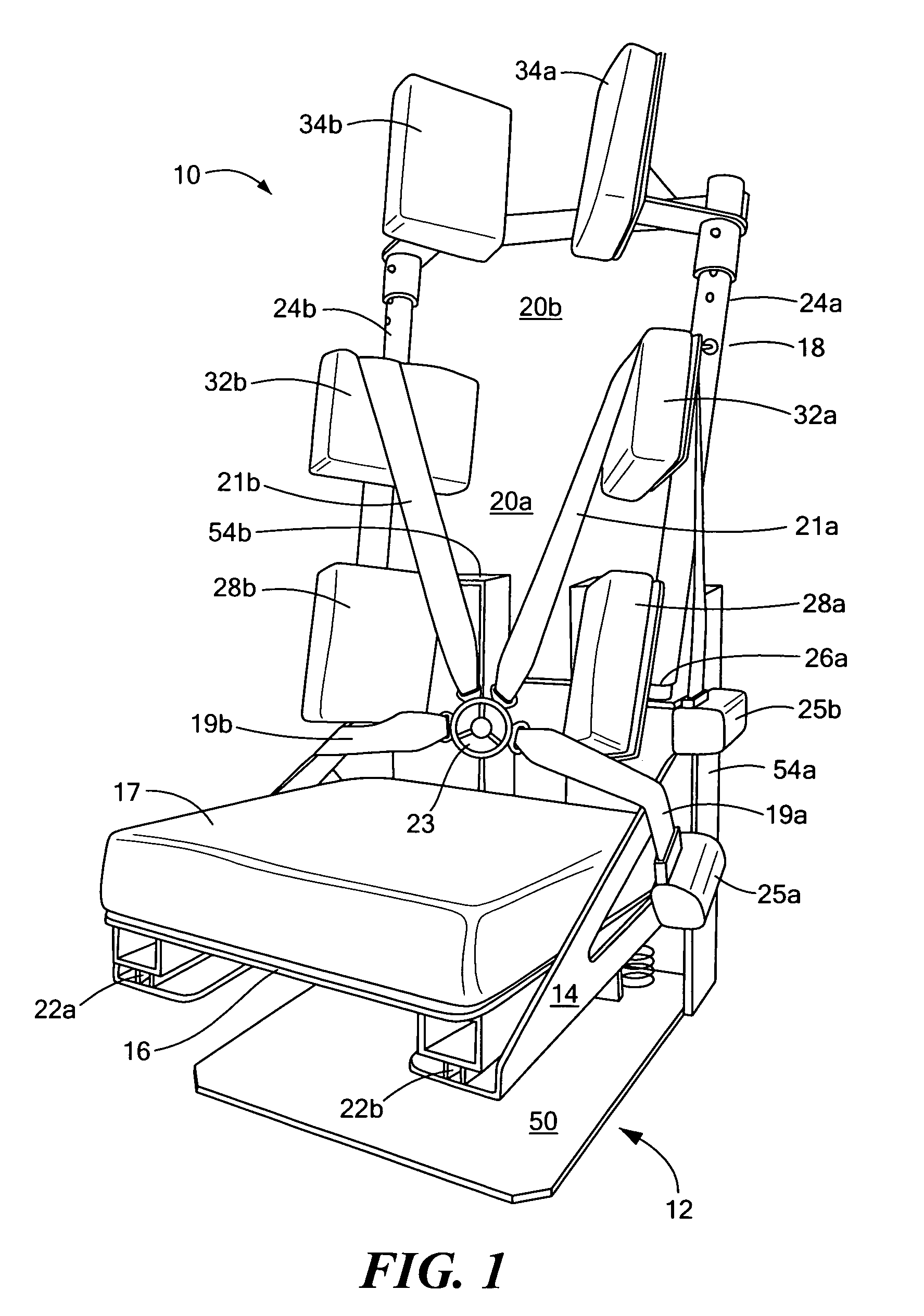

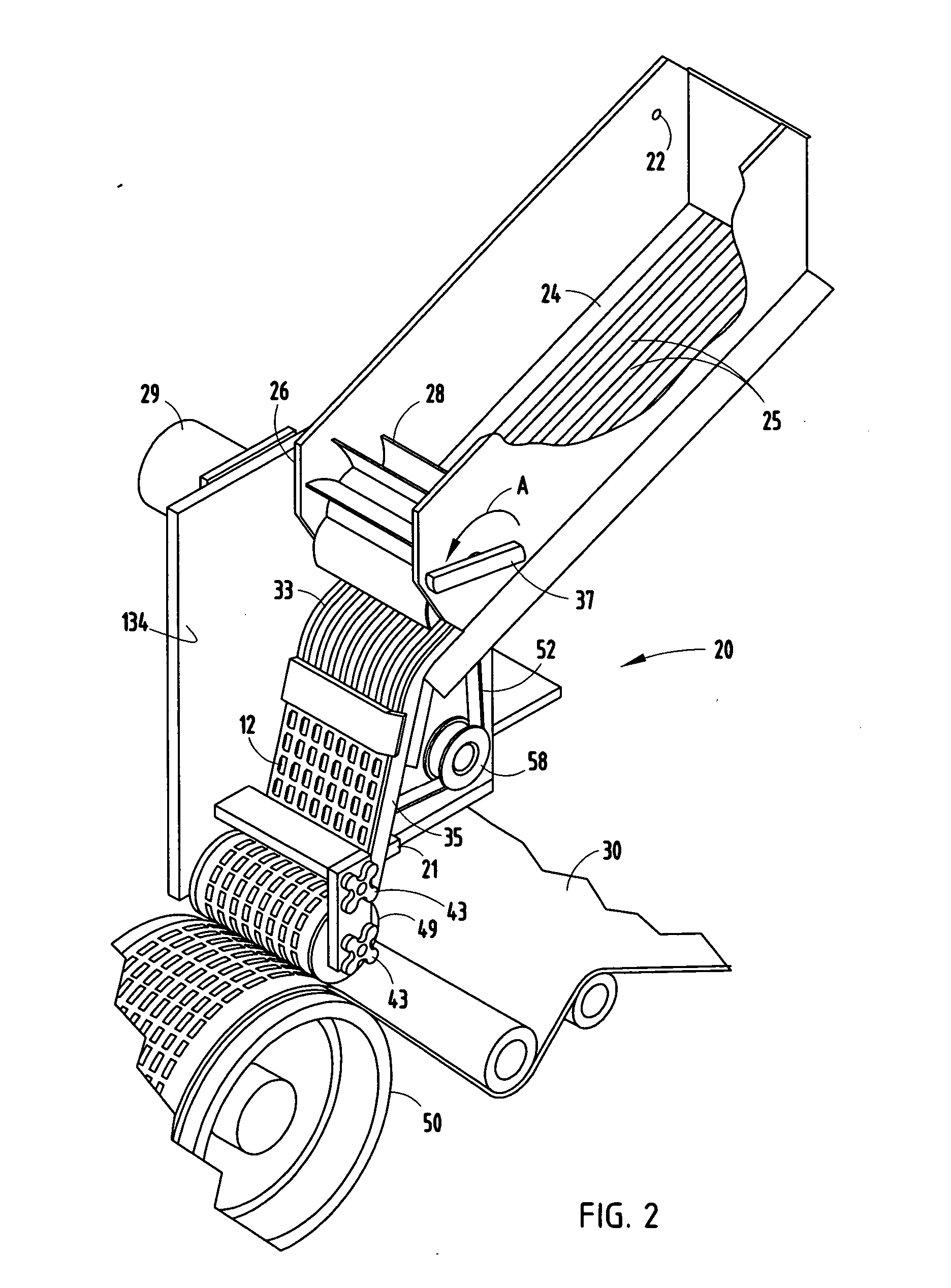

Blast mitigating seat

ActiveUS20100301647A1Space minimizationReduce the impactVehicle seatsArmoured vehiclesEngineeringGear wear

A blast mitigating seat features a base and a seat frame. The seat frame includes a pan and a backrest including an open area for gear worn by a user. A first damping subsystem between the base and the seat frame has a first force / stroke relationship and a second damping subsystem between the base and the seat frame has a second force / stroke relationship.

Owner:FOSTER-MILLER

Multi-leaf collimator and a radiotherapy unit provided with the same

InactiveUS7629599B2InhibitionImprove accuracyElectrode and associated part arrangementsPhotometryFixation pointMulti leaf collimator

Owner:TOSHIBA MEDICAL SYST CORP

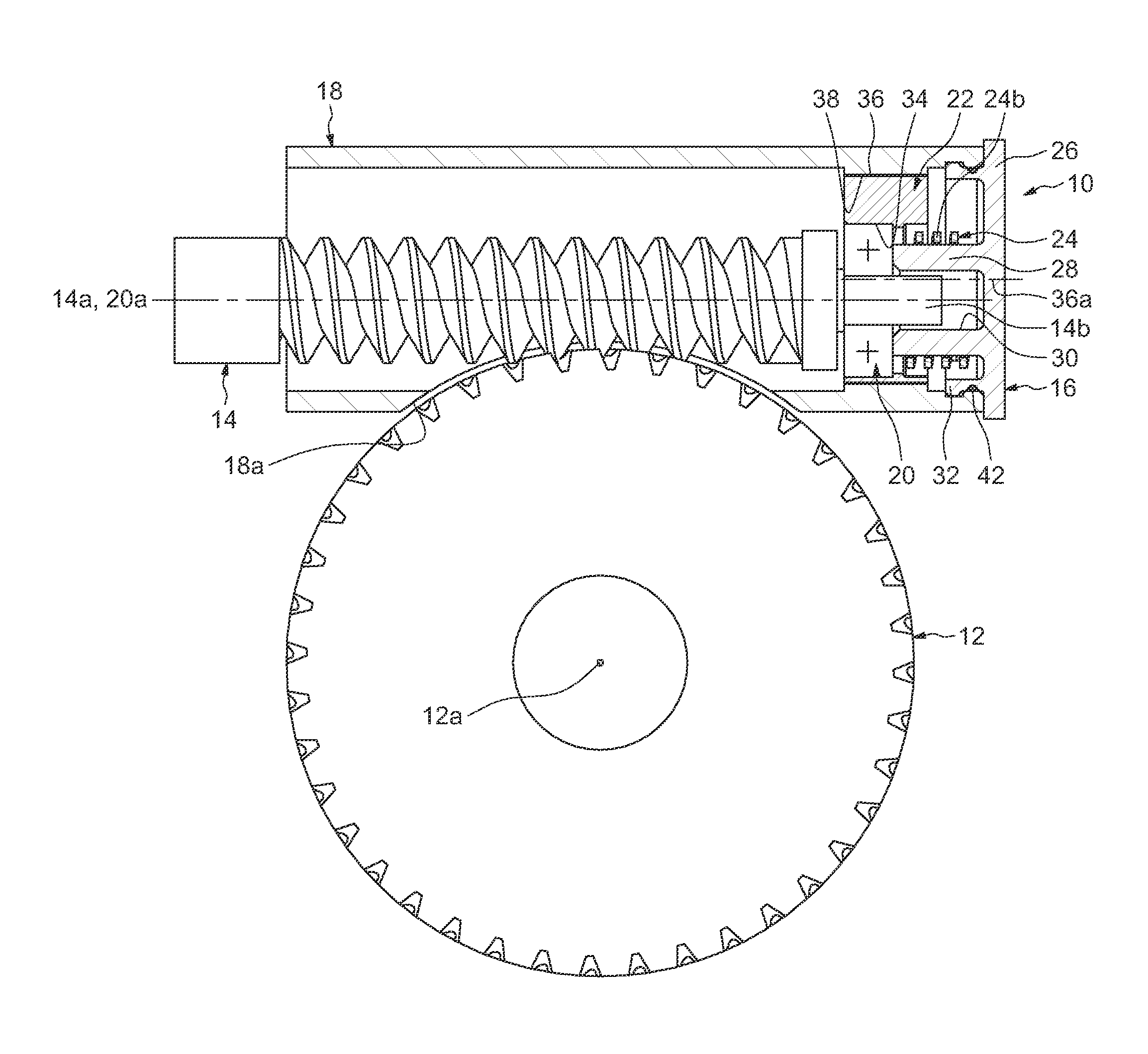

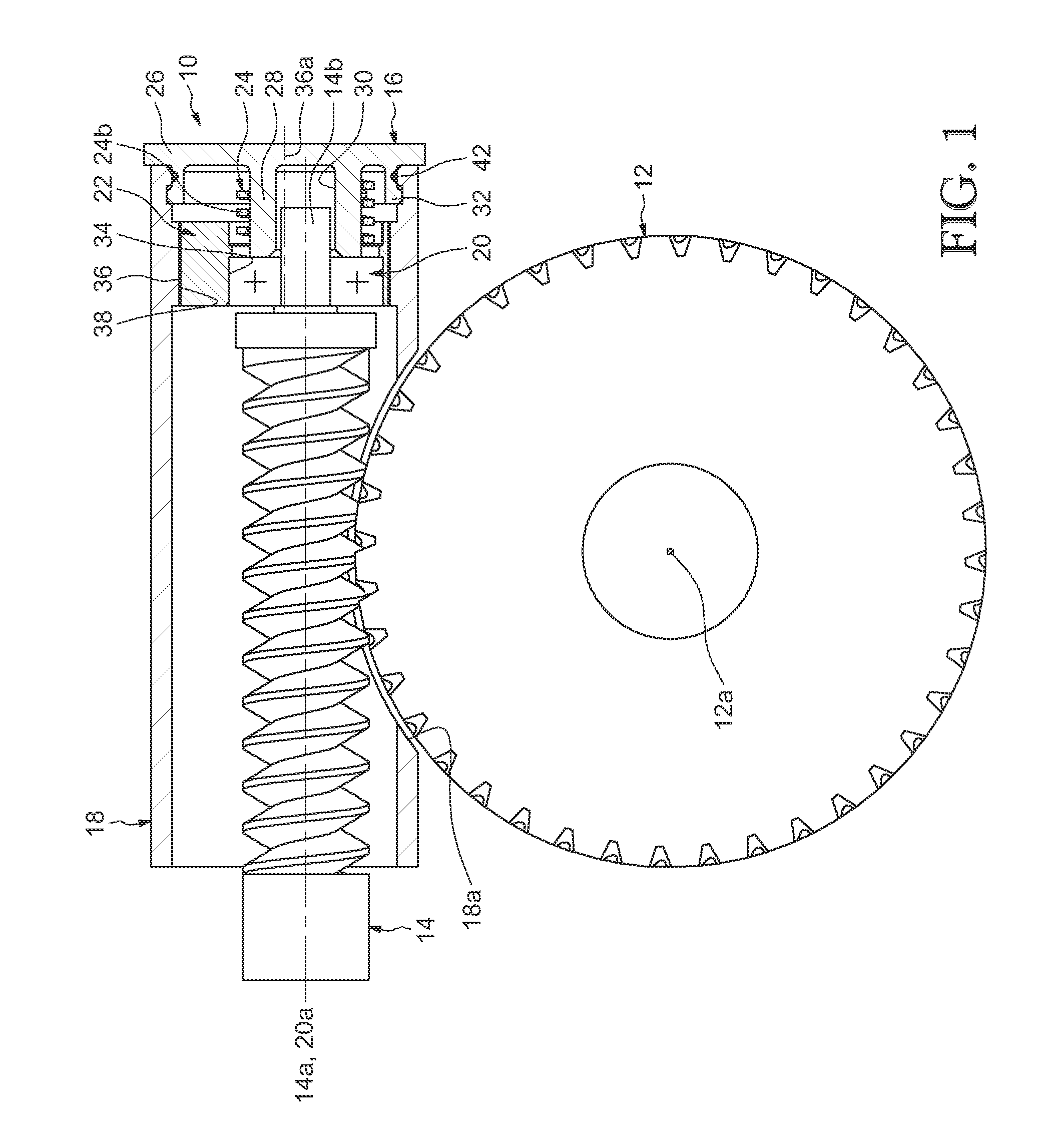

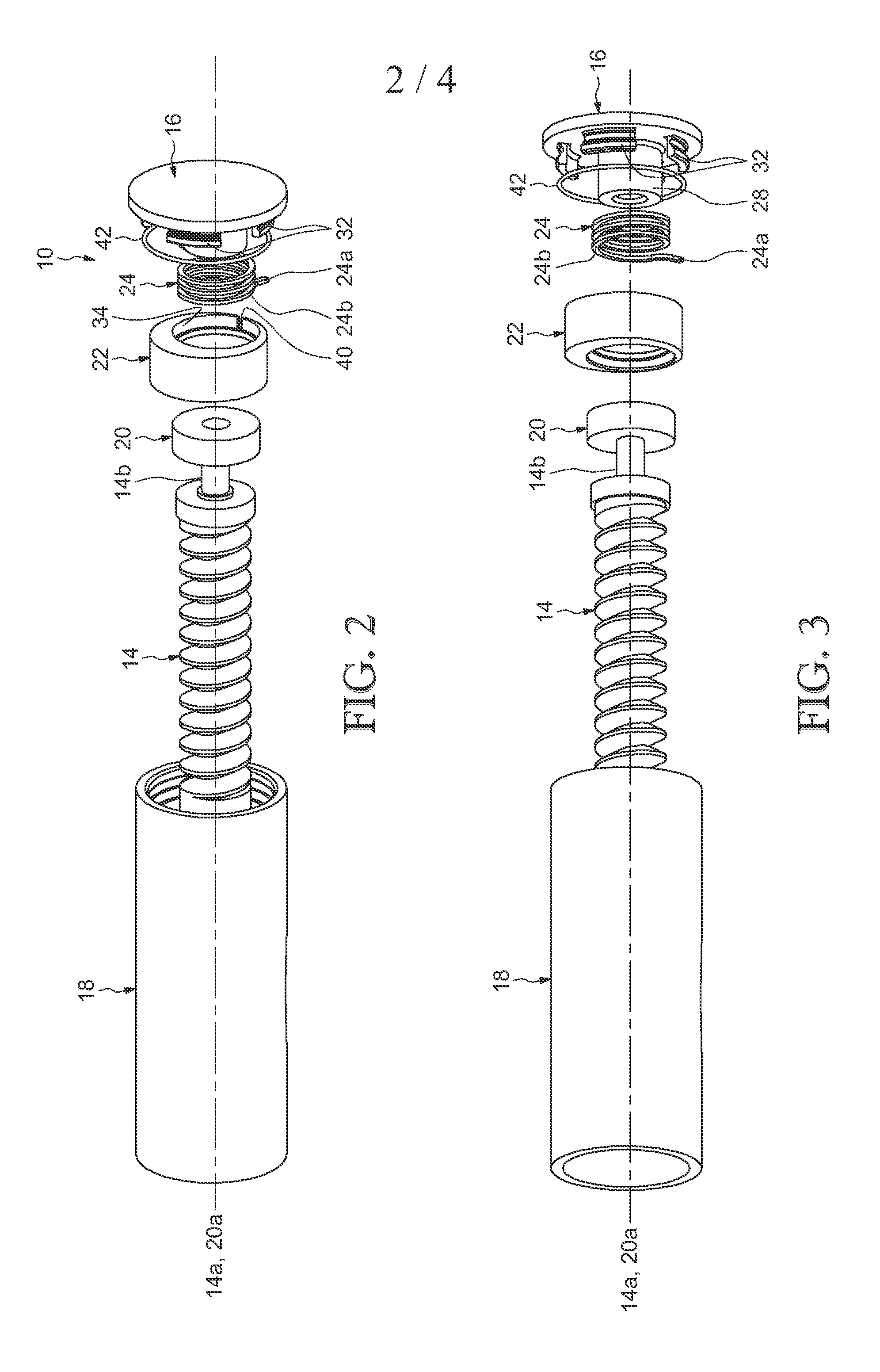

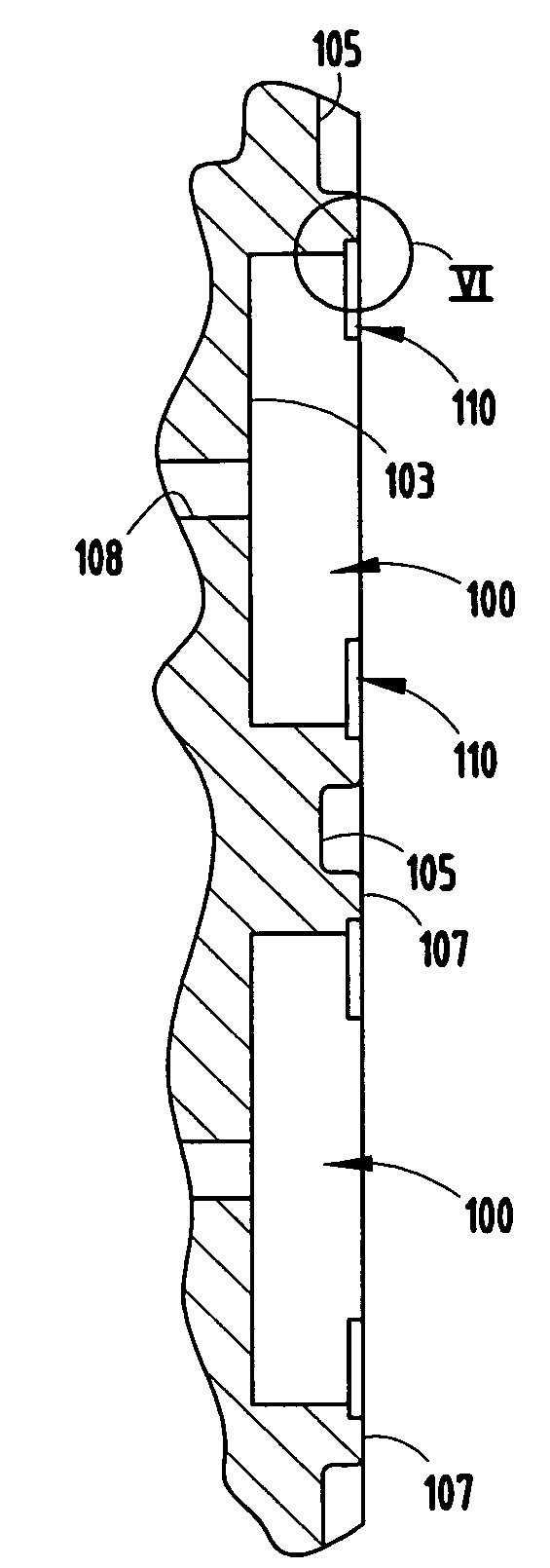

Wear-Compensation Device For A Gear

ActiveUS20120227526A1Limit wearEasy to installToothed gearingsGearing detailsGear wheelTorsion spring

The wear-compensation device for a gear comprises a fixed support capable of being fixed axially on an external element in order to keep the device on the said external element, a bearing designed to be mounted on a shaft comprising one of the wheels of the gear, an eccentric mounted on the bearing and designed to be in contact with the external element, the said eccentric being able to move angularly relative to the fixed support. The device also comprises a torsion spring mounted axially between the fixed support and the eccentric and capable of exerting a circumferential preload force on the said eccentric, the said spring comprising a first end mounted inside a recess of the eccentric and a second end interacting with the fixed support.

Owner:AB SKF

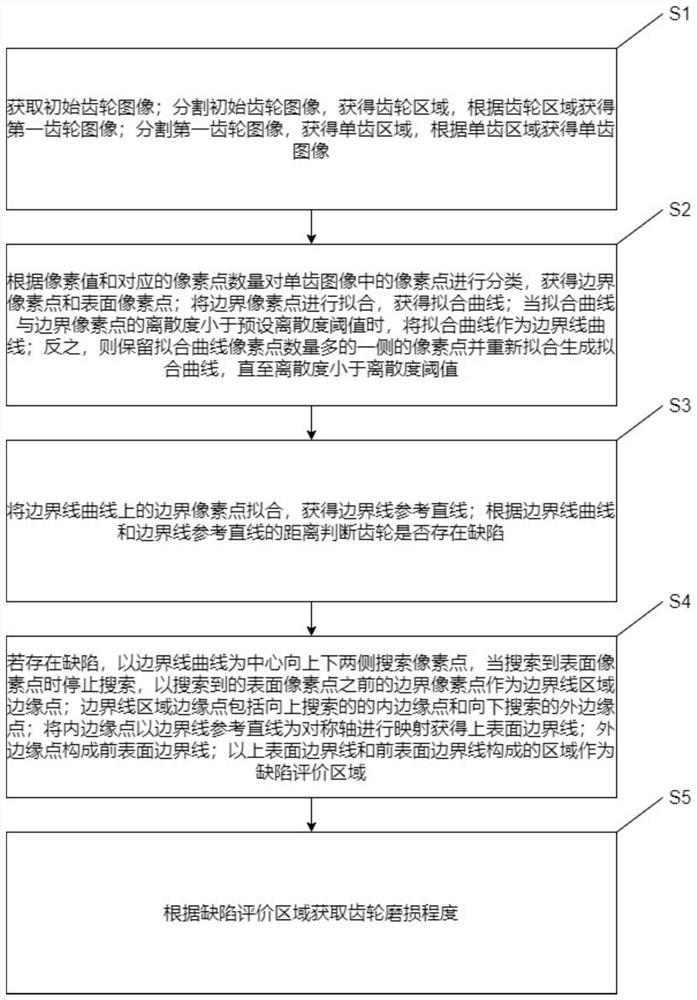

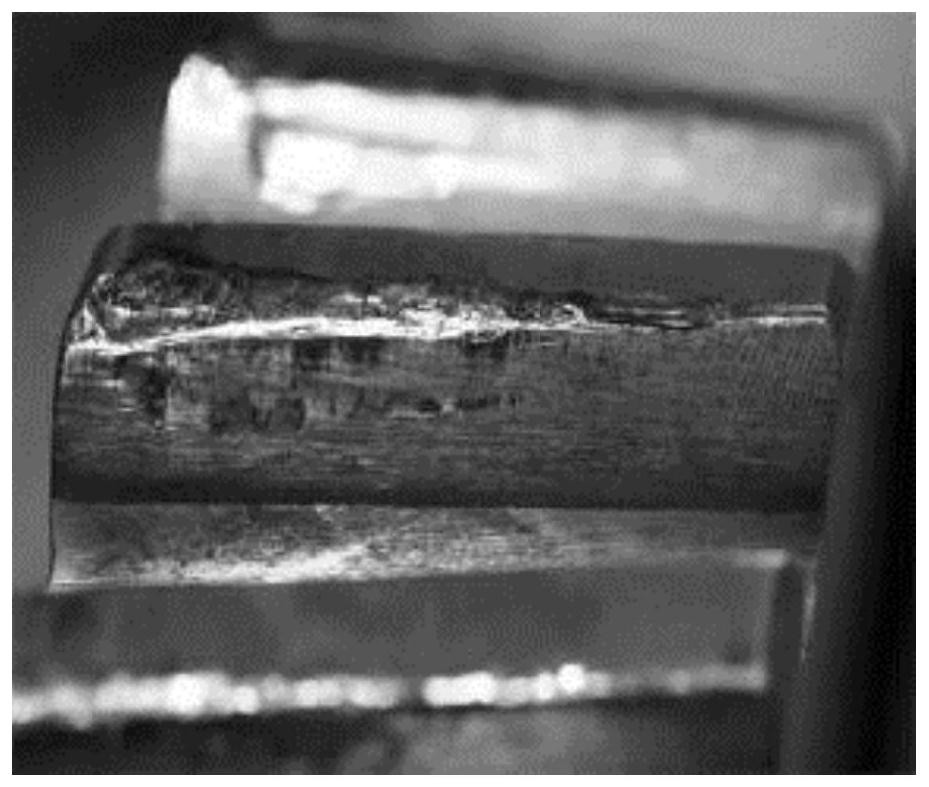

Gear surface defect detection method and system based on image processing

ActiveCN113658133AAvoid detection errorsImprove detection accuracyImage enhancementImage analysisImaging processingGear wear

The invention relates to the technical field of image processing and mechanical part detection, in particular to a gear surface defect detection method and system based on image processing. The method comprises the following steps: extracting a single-tooth image from an initial gear image; classifying the pixel points in the single-tooth image according to the pixel values and the corresponding number of the pixel points to obtain boundary pixel points and surface pixel points; fitting the boundary pixel points to obtain a boundary curve; obtaining a boundary reference straight line according to the boundary pixel points on the boundary curve; determining whether the gear has a defect according to the similarity of the boundary reference straight line and the boundary curve; if the defect exists, performing up-down search by taking the boundary curve as a center to obtain boundary area edge points; determining a defect evaluation area through the boundary area edge points; and obtaining the gear wear degree according to the defect evaluation area. According to the method, the gear wear degree is evaluated by obtaining the boundary information, and the defect detection accuracy is ensured.

Owner:江苏鑫丰源机电有限公司

Blast mitigating seat

A blast mitigating seat features a base and a seat frame. The seat frame includes a pan and a backrest including an open area for gear worn by a user. A first damping subsystem between the base and the seat frame has a first force / stroke relationship and a second damping subsystem between the base and the seat frame has a second force / stroke relationship.

Owner:FOSTER-MILLER

Plastic wiredrawing machine rolling control method and rolling system

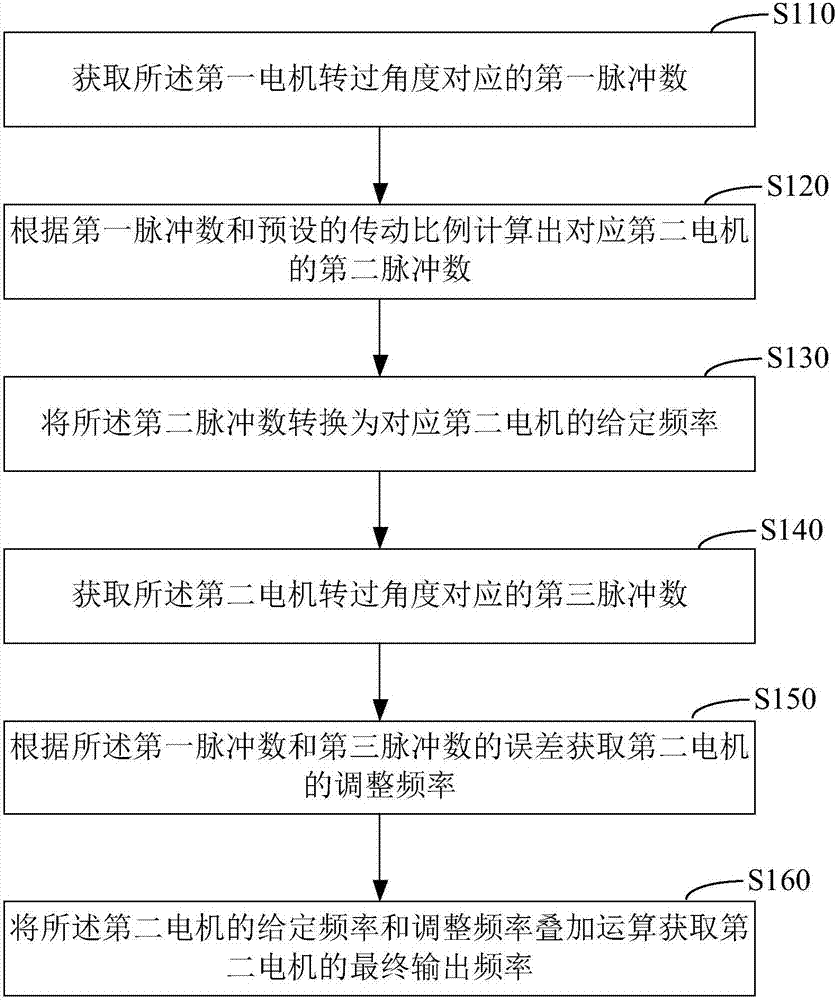

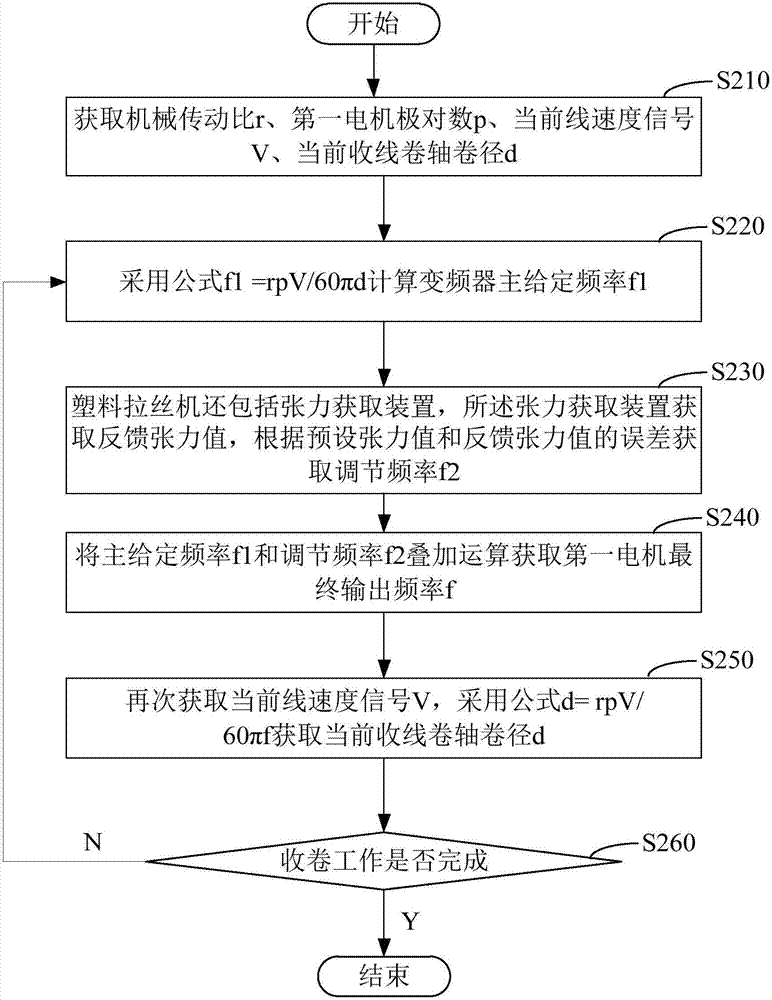

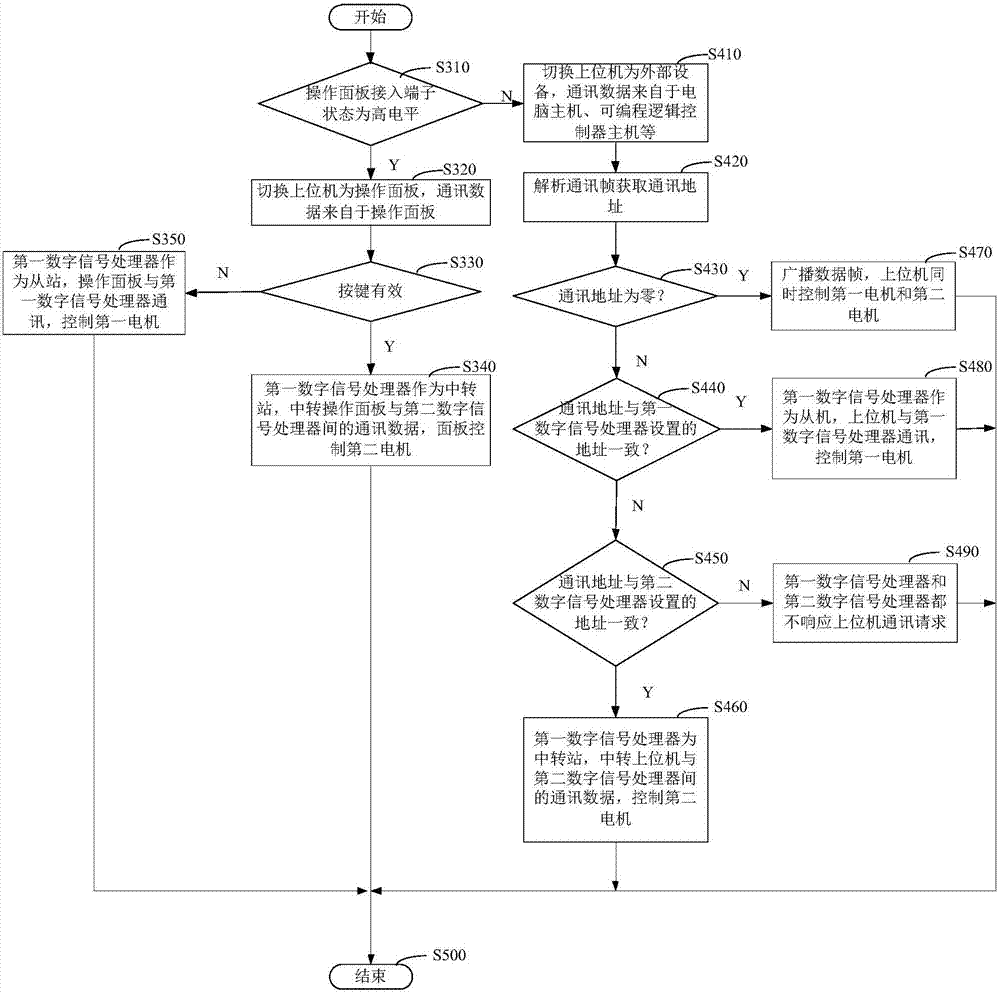

The invention relates to a plastic wiredrawing machine rolling control method and a rolling system. A plastic wiredrawing machine comprises a first motor for driving rolling of a winding reel, a second motor for driving a spiral reciprocating lead screw to complete rolling figure molding and a frequency changer for controlling the first motor and the second motor. The method comprises the steps that a first pulse number corresponding to the rotating angle of the first motor is obtained; a second pulse number corresponding to the second motor is calculated according to the first pulse number and the preset transmission proportion; the second pulse number is converted into the given frequency corresponding to the second motor; a third pulse number corresponding to the rotating angle of the second motor is obtained; the adjusting frequency of the second motor is obtained according to the error of the first pulse number and the second pulse number; and the given frequency and the adjusting frequency of the second motor are subject to stacked operation to obtain the final output frequency of the second motor. Rolling figure molding is not driven by gear connection any more and is singly driven by the second motor, the gear abrasion phenomenon does not exist, and the equipment stability is improved.

Owner:SHENZHEN HPMONT TECH

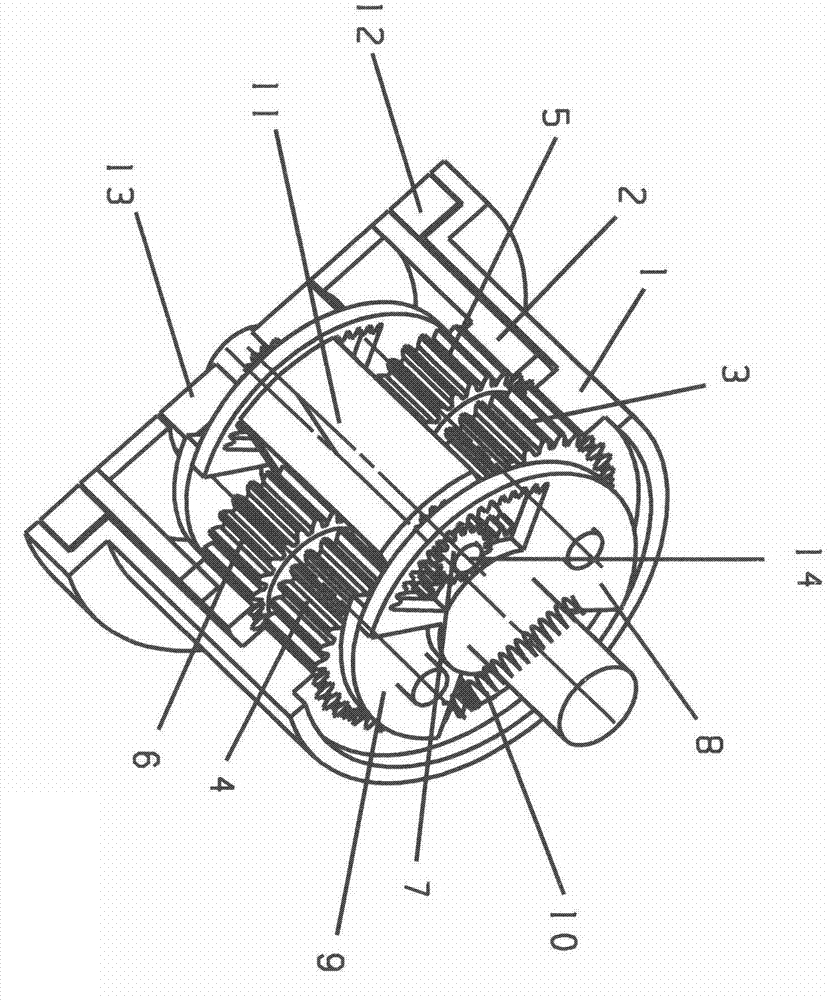

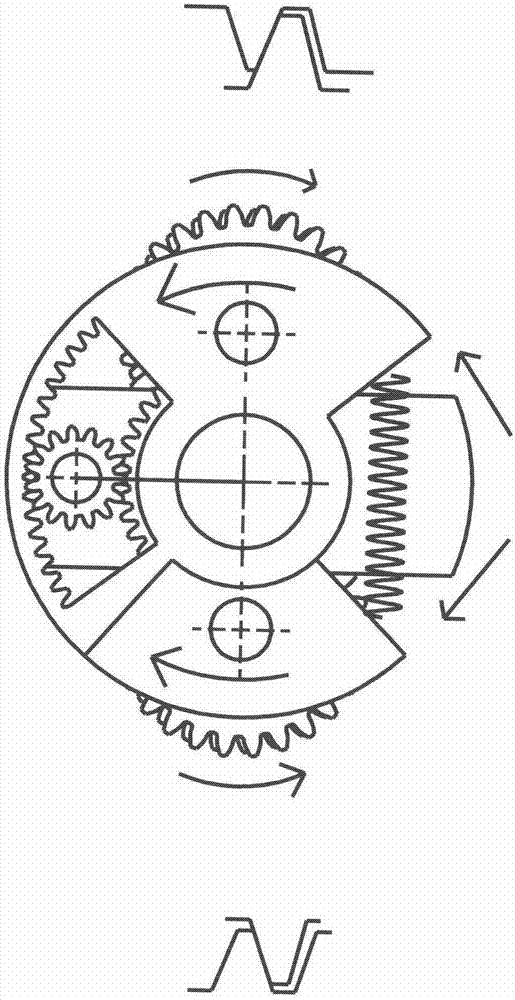

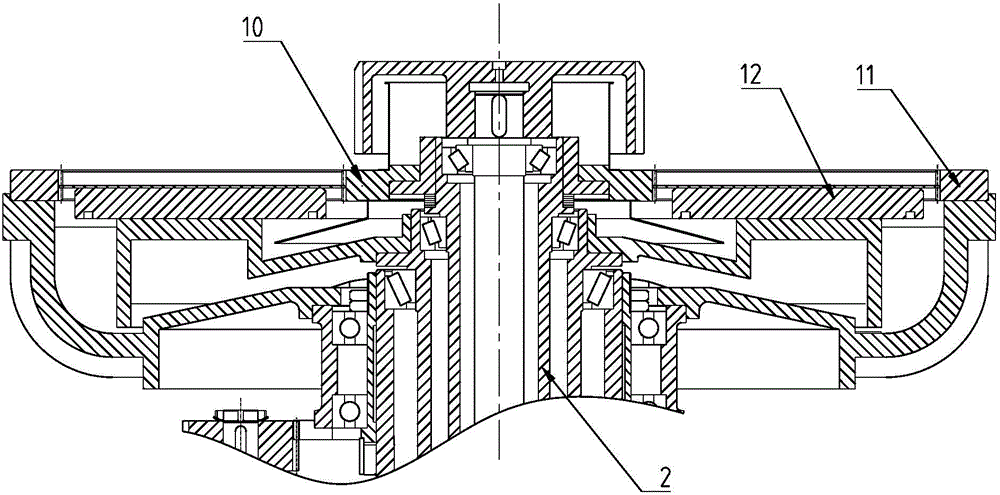

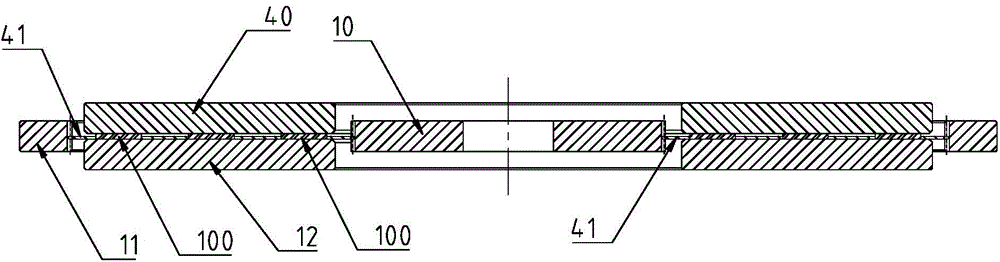

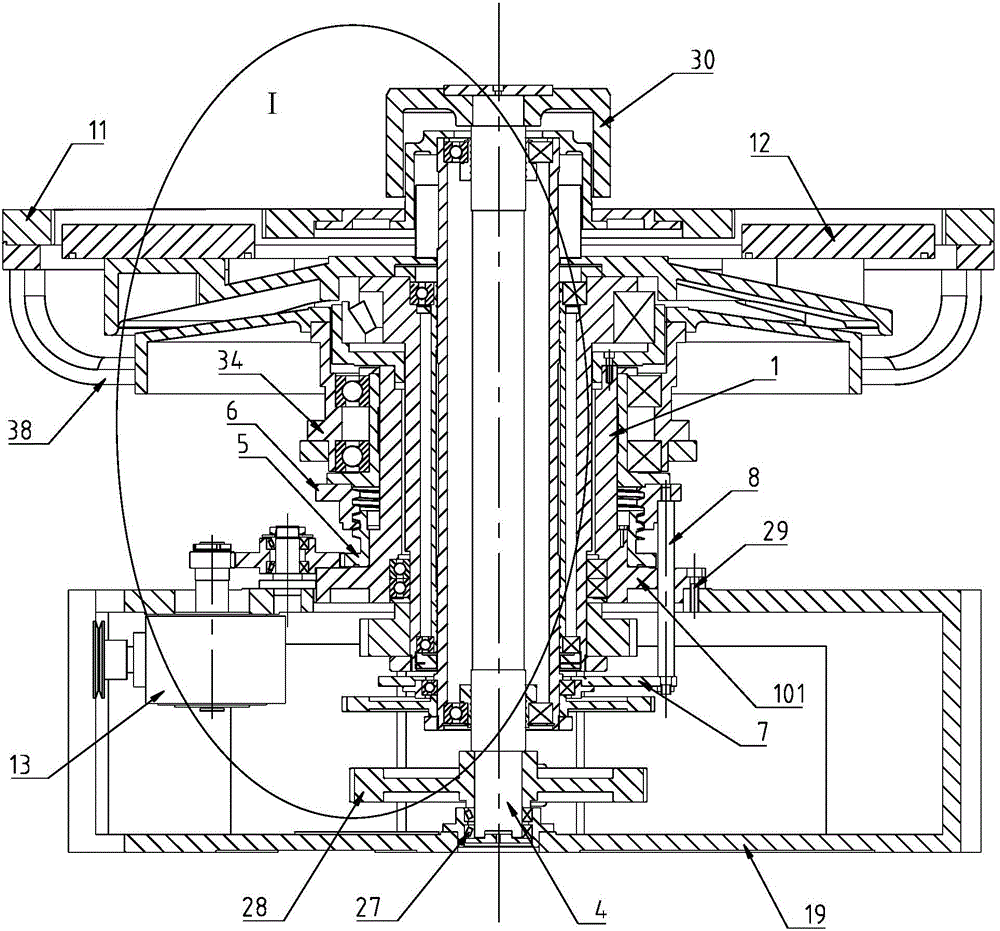

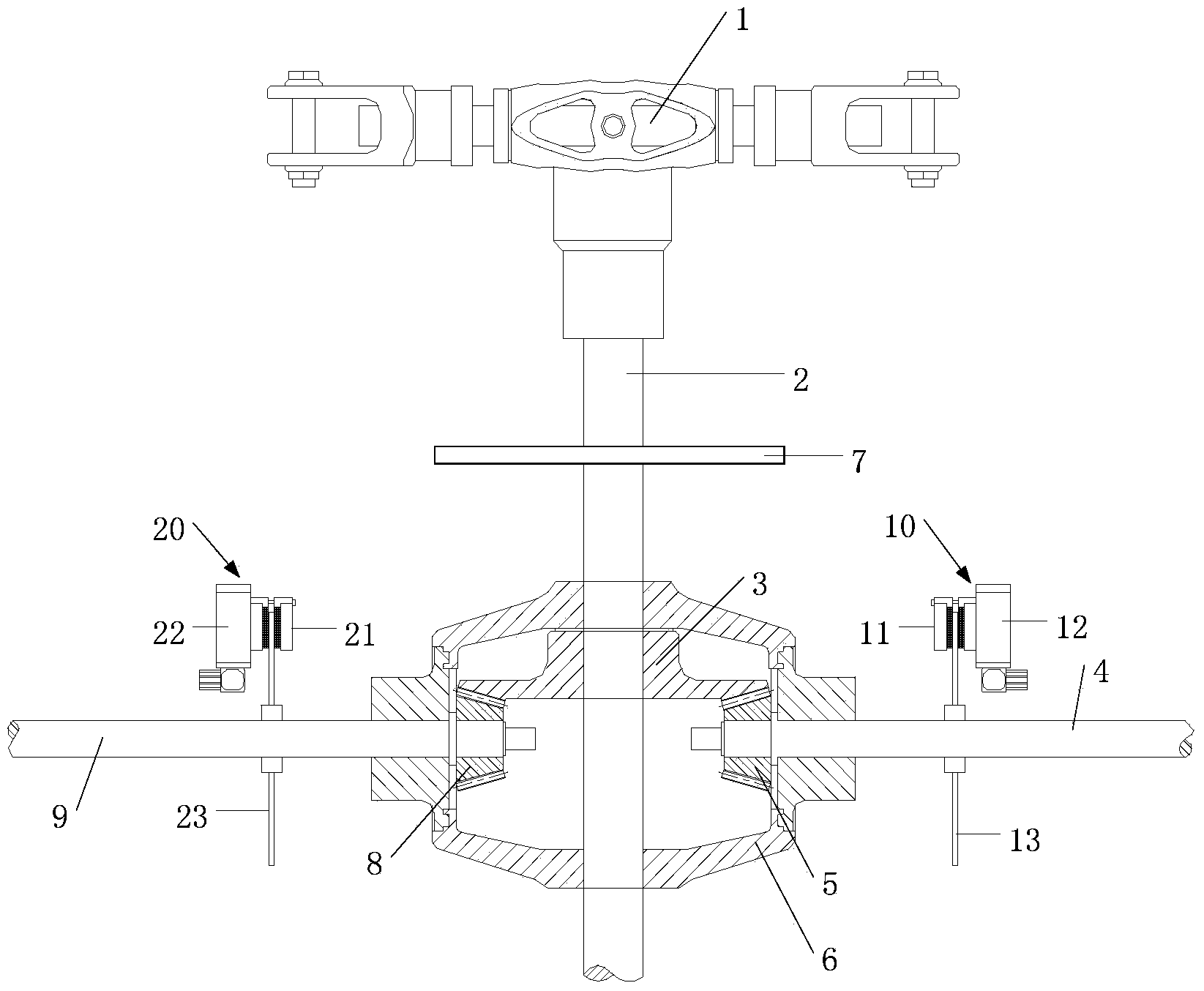

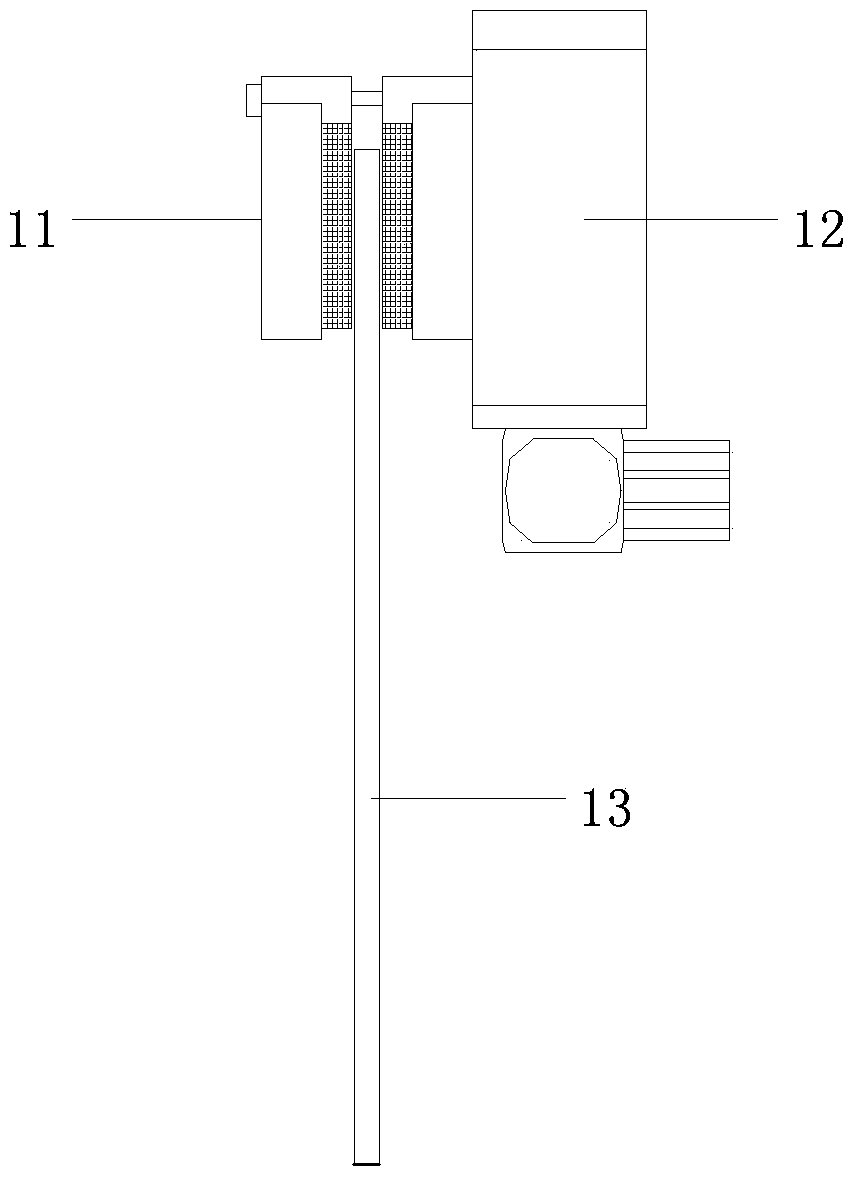

Prepressing compensation anti-backlash speed reducer

The invention discloses a prepressing compensation anti-backlash speed reducer, and belongs to high-precision speed reduction transmission and location parts. The prepressing compensation anti-backlash speed reducer is applied to all the fields of mechanical industry. In order to overcome the problems that for existing mainstream speed reducers such as RV speed reducers, harmonic speed reducers, planetary speed reducers and cycloidal speed reducers, zero backlash or the backlash compensation function under gear abrasion does not exist, the requirement for the machining precision is high, and the technology is complicated, the prepressing compensation anti-backlash speed reducer is developed, the problems of the existing mainstream speed reducers can be effectively solved, zero backlash transmission and automatic compensation of backlashes can be achieved, and the compensation torque is large. According to the prepressing compensation anti-backlash speed reducer, differential gear transmission is adopted, and the prepressing compensation anti-backlash speed reducer has the advantages of being small in size, high in speed ratio and high in transmission rigidity and stability; by means of the prepressing compensation anti-backlash speed reducer, backlashes produced in gear engagement can be compensated, and backlashes caused by abrasion in the usage process can be compensated automatically; the input end prepressing is combined with the differential gear transmission, output end anti-backlash overturning torque proportionally increases along with the increase of the speed ratio.

Owner:葛立志

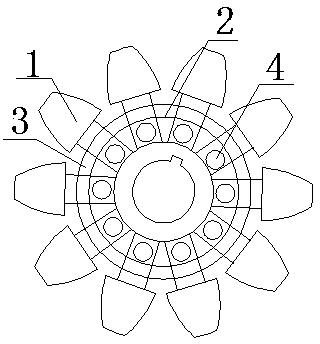

Novel combined type gear

InactiveCN103542067ASimple structureCompact and reasonablePortable liftingGearing elementsAgricultural engineeringGear tooth

The invention relates to the technical field of mechanical transmission parts, in particular to a novel combined type gear. The novel combined type gear comprises gear teeth, locating plates, gear bodies and high-strength bolts. The gear teeth are fixedly connected with the gear bodies through the locating plates. The high-strength bolts are arranged between the gear teeth and the locating plates. The novel combined type gear is simple, compact and reasonable in structure, convenient and fast to assemble, and reliable in connection. Connection between the gear bodies of the gear is compact, the fit clearance is small, when the gear is abraded and needs to be replaced, the gear can be directly disassembled and replaced, the maintenance difficulty caused by gear abrasion can be overcome, and the novel combined type gear is convenient to maintain and easy to apply, popularize and use, and saves cost and maintenance time.

Owner:CHANGZHOU WUJIN JINCHENG GEAR

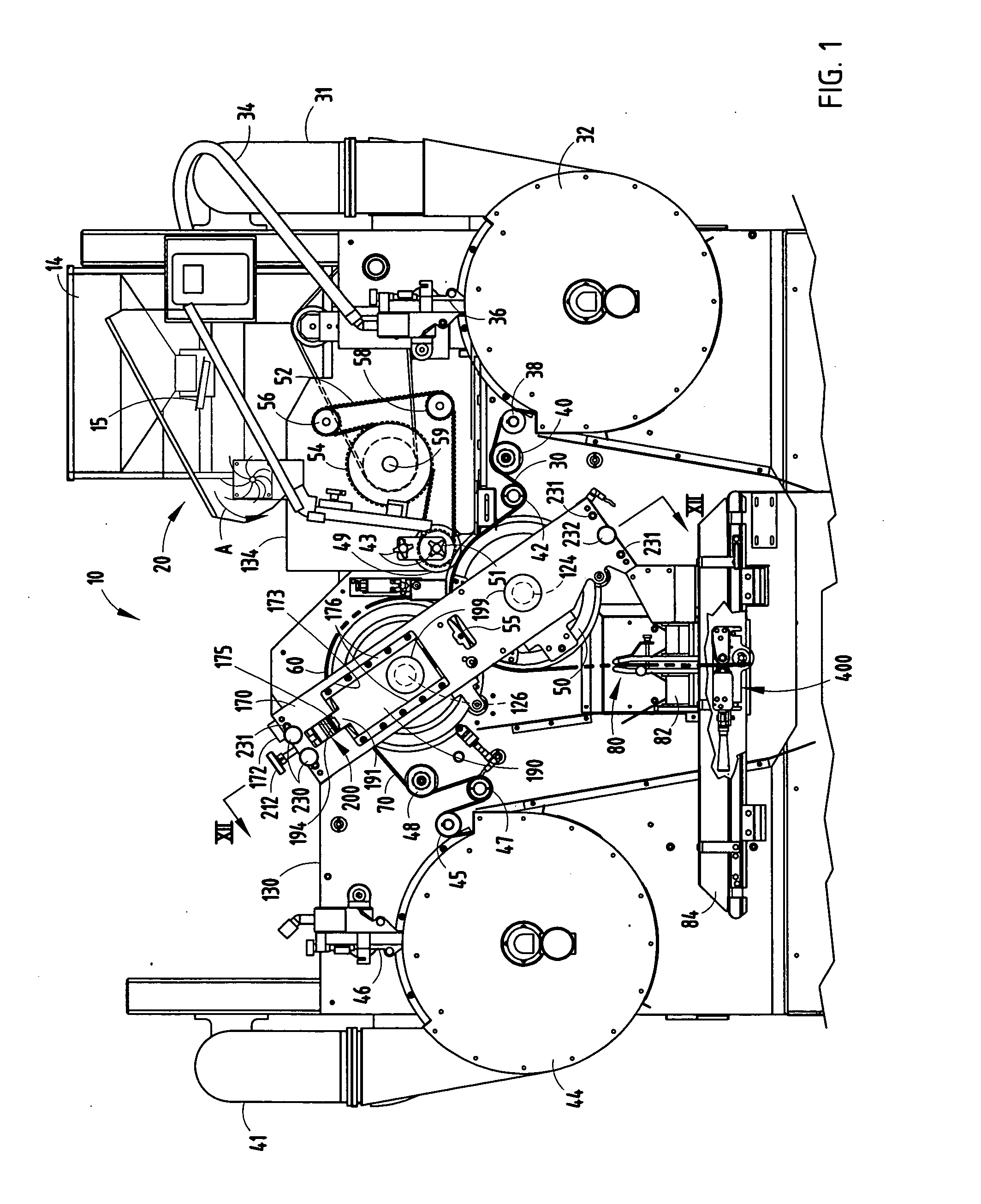

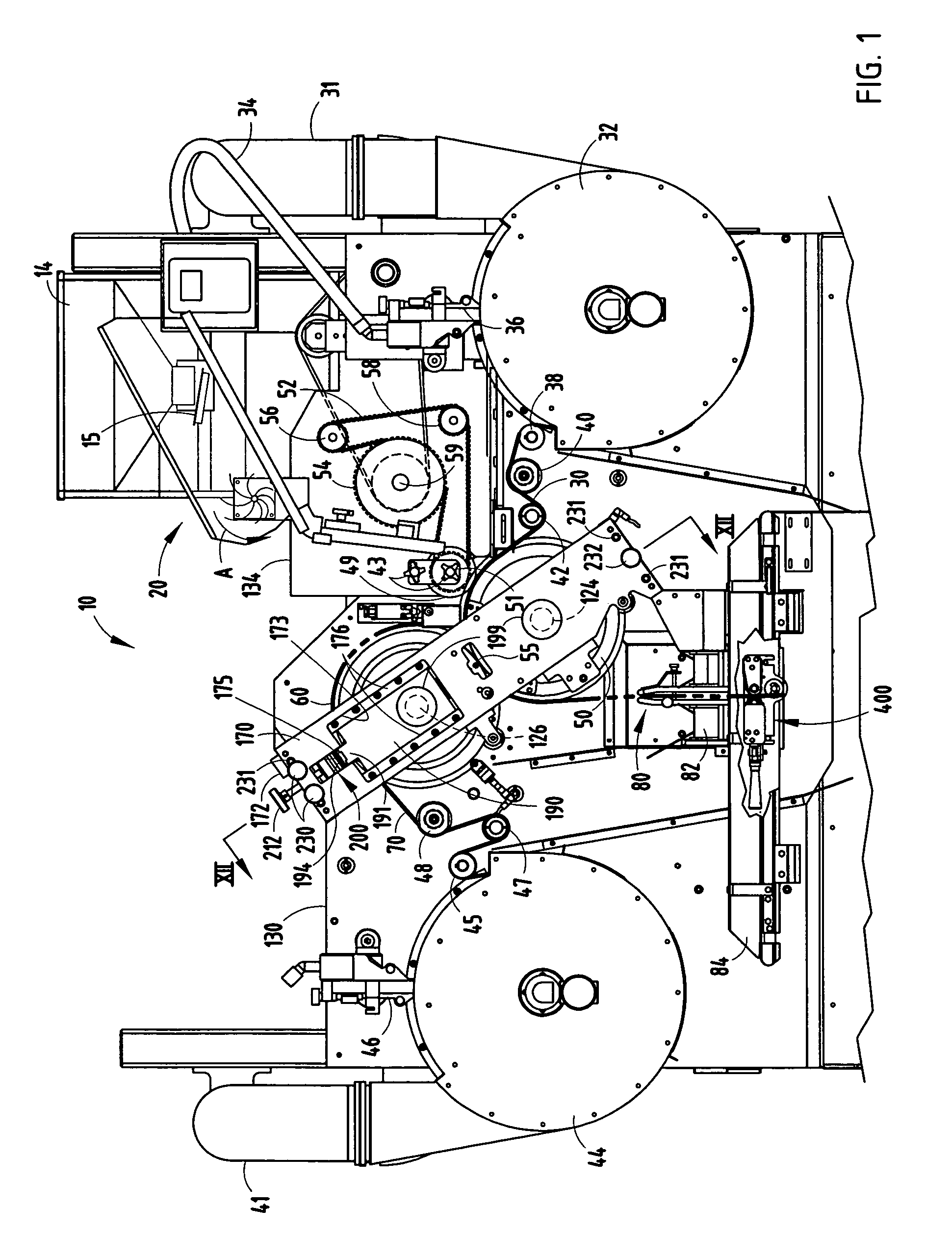

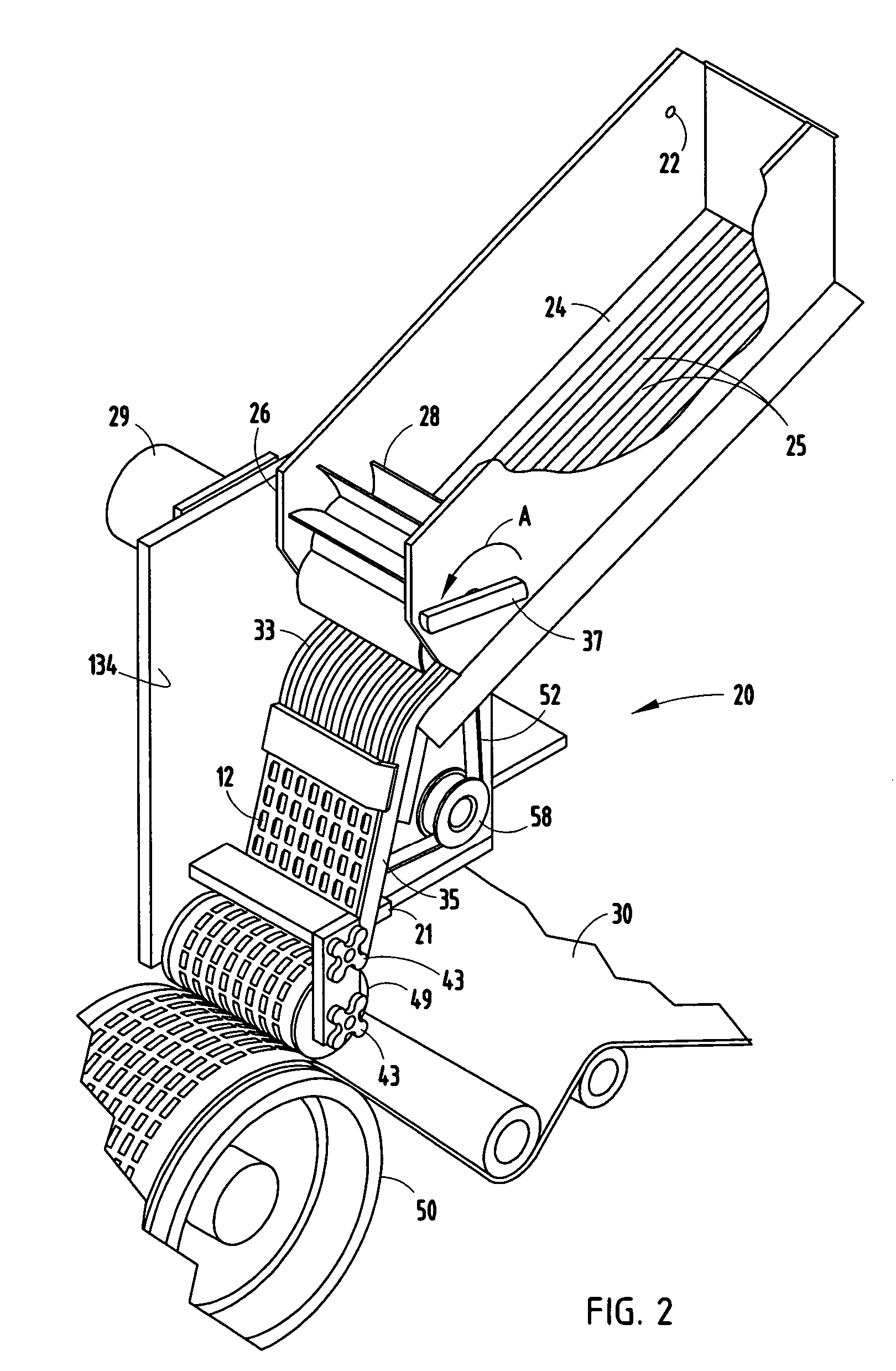

Tablet encapsulating machine

InactiveUS20050034428A1Improve sealingAvoid excessive wearPharmaceutical product form changePackaging automatic controlDrive shaftCoupling

An encapsulating machine includes a pair of offset die rolls with one die roll mounted on slides urged by an adjustable fulcrum spring toward the other die roll. An offset drive coupling between the axle of the die roll and the associated drive shaft allows independent movement of the die axle to compensate for die wear. A split gear between die roll shafts accommodates for backlash and gear wear. Precise pulley-driven timing belts and phase adjusters extend between the die roll drive and a tablet feed roll to synchronize the clocked introduction of tablets onto film of one of the die rolls for encapsulation at the co-acting nip between the die rolls. The die cavities for tablets include a step-cut to improve the sealing of films around the tablets and a circumferential rub rail on opposite edges of each die prevents excessive wear of the die cavity lands.

Owner:L PERRIGO

Inner and outer gear lifting system of planetary gear type two-sided lapping/polishing machine

ActiveCN104924210AUniform wearExtended service lifePolishing machinesGrinding drivesLower limitGear wheel

The invention discloses an inner and outer gear lifting system of a planetary gear type two-sided lapping / polishing machine. The inner and outer gear lifting system comprises a control circuit and a lifter driven by a motor through a lifting driving gear. The control circuit comprises a motor forward and reverse rotation control circuit, an upper limit proximity switch, a lower limit proximity switch, a circle counting proximity switch, a circle counting sensing board and a lifting sensing board. The lifting sensing board is fixed on the lifter, and the circle counting sensing board is mounted and fixed on the lifting driving gear. The signal output end of the upper limit proximity switch, the signal output end of the lower limit proximity switch and the signal output end of the circle counting proximity switch are connected with corresponding control signal input ends of a controller of the motor forward and reverse rotation control circuit. According to the inner and outer gear lifting system, the height of an inner gear and an outer gear can be conveniently adjusted, and the adjusting process can be carried out anytime; parts do not need to be dismounted in the adjusting process, and equipment assembling precision cannot be changed so that stability of a machine tool in long-time work can be guaranteed; abrasion of the inner gear and the outer gear is even, and the service life is greatly prolonged.

Owner:SHENZHEN SAPPHIRE AUTOMATION EQUIP

Split type gear

InactiveCN103573964ASimple structureCompact and reasonablePortable liftingGearing elementsLeft halfAgricultural engineering

The invention relates to the technical field of mechanical transmission components, in particular to a split type gear. The split type gear comprises a left half gear body, a right half gear body, C-shaped grooves, C-shaped protrusions, fixing strips and bolts. The C-shaped grooves and the C-shaped protrusions are formed on the left half gear body and the right half gear body and fixedly connected through the fixing strips. Two ends of the fixing strips are fixedly connected with the left half gear body and the right half gear body through the bolts. The split type gear is simple, compact and reasonable in structure, convenient and fast to assemble and reliable in connection. Connection between the gear bodies is compact, and a matching gap is small. When the gear is abraded and needs replacing, the gear can be directly detached. Repairing difficulty caused by gear abrasion is eliminated, repairing is convenient, cost is saved, maintaining time is saved, and the split type gear is easy to apply, popularize and use.

Owner:常州市格里森前进齿轮有限公司

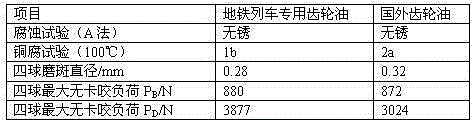

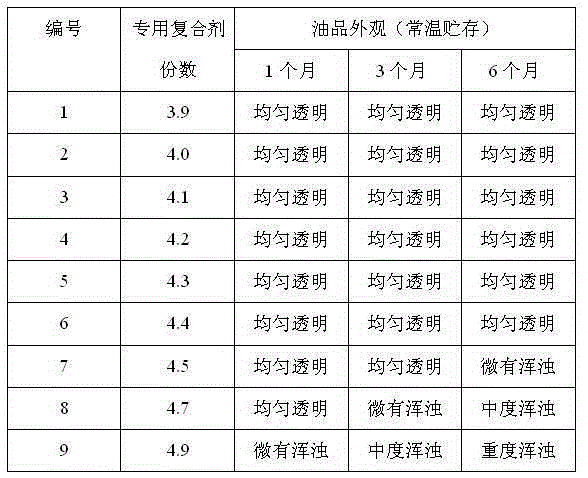

Subway train special gear oil and preparation method

InactiveCN105296115APrevent severe heatImprove high temperature stabilityAdditivesHigh torqueHeavy duty

A subway train special gear oil is particularly suitable for using in high temperature and extreme pressure work status of a subway train in frequent start, braking and high-speed operation, has excellent high temperature stability, resistance to extreme pressure and anti-wear properties and high temperature oxidation resistance, ensures subway train gearboxes maintain stable oil films under very heavy duty conditions, reduces noise, prevents gear wear, can effectively prevent and subway train low rotation speed / high torque wear and intense heat produced in high-speed operation, and is especially suitable for using in high temperature and extreme pressure work status of the subway train in frequent start, braking and high-speed operation. By use of the subway train special gear oil, the gear oil change period may be extended by more than 20%, and the subway operating cost is reduced.

Owner:JIANGXI KIRBY LUBRICANT PROD

Wind power generation acceleration sensing system

InactiveCN101196174AExtend your lifeMachines/enginesWind motor monitoringResonanceElectric generator

The invention provides a method for the sensing of acceleration in wind power generation, which comprises a generator and a sensor. A permanent acceleration vibration sensor is positioned on a wind power generator unit for permanent monitoring; once abnormal condition occurs, the damaged parts can be repaired as soon as possible to reduce the loss to the minimum. The permanent acceleration vibration sensor positioned on the wind power generator unit is able to detect the gear failure, gear wearing, vibration of blade wheel, electronic failure, imbalance, misalignment, loosing and resonance, thereby effectively prolonging the service life of the invention.

Owner:苏州市南极风能源设备有限公司

Brake device of unmanned aerial vehicle rotor wing

The invention relates to a brake device of an unmanned aerial vehicle rotor wing. The brake device comprises a drive shaft, a concentric drive gear, a brake disc A, a driven shaft, a concentric driven gear and a brake disc B. The concentric drive gear is fixedly connected to the output end of the drive shaft, the brake disc A is arranged on the drive shaft, the concentric driven gear is fixedly connected to the input end of the driven shaft, and the brake disc B is arranged on the driven shaft. The rotor wing comprises a rotor wing head and a main shaft, and a concentric main shaft gear is arranged on the main shaft. A brake component A is arranged on the brake disc A of the brake device, and a brake component B is arranged on the brake disc B. The drive gear and the driven gear are symmetrically arranged in a concentric mode, the main shaft gear is respectively meshed with the drive gear and the driven gear, and the main shaft gear, the drive gear and the driven gear are spiral beveled gears. In the prior art, when the main shaft gear brakes for deceleration, abrasion, caused by relative torsion and stress concentration, to the main shaft gear is reduced, and stability is improved when the rotor wing decelerates for transmission.

Owner:天津凤凰智能科技有限公司

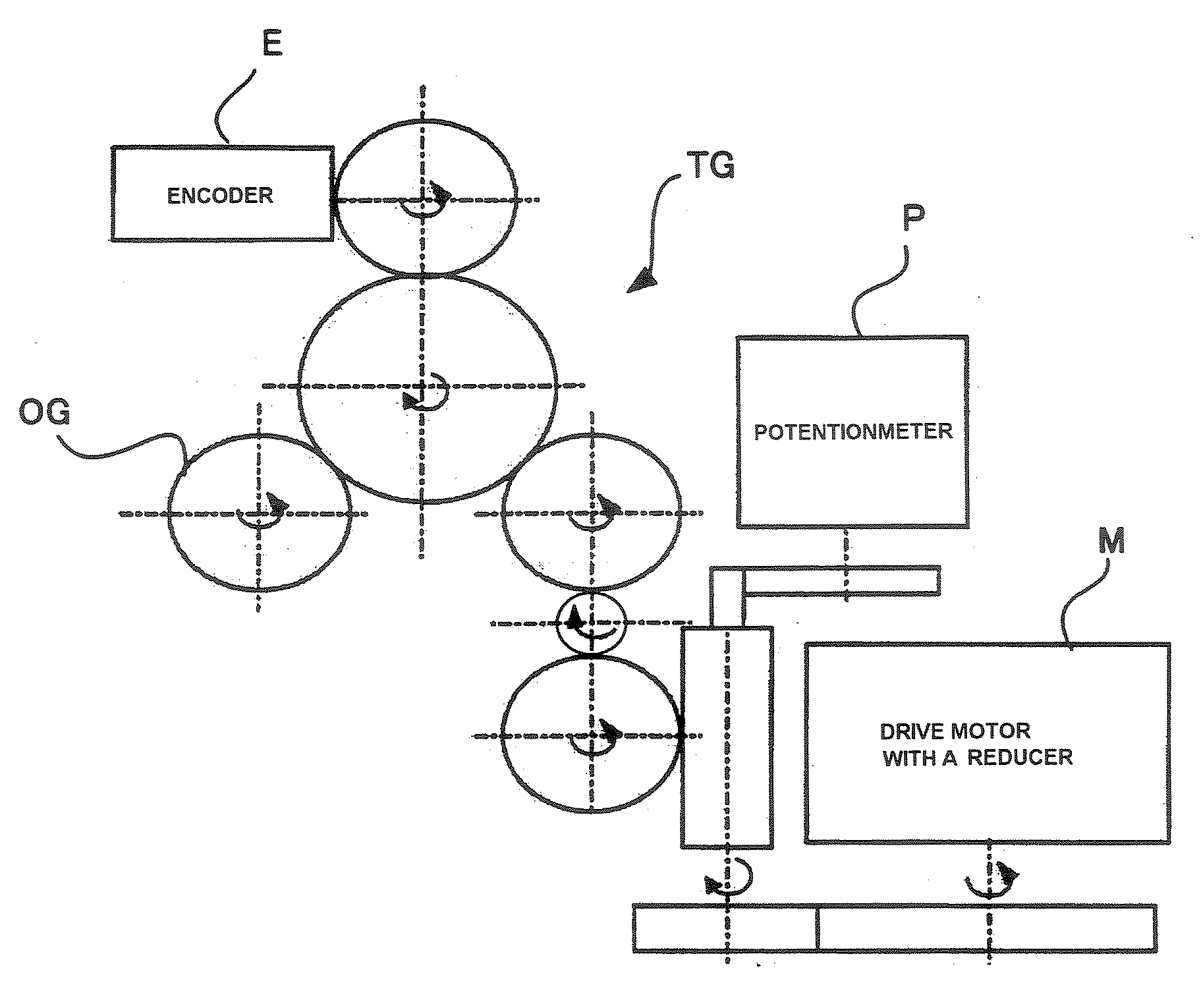

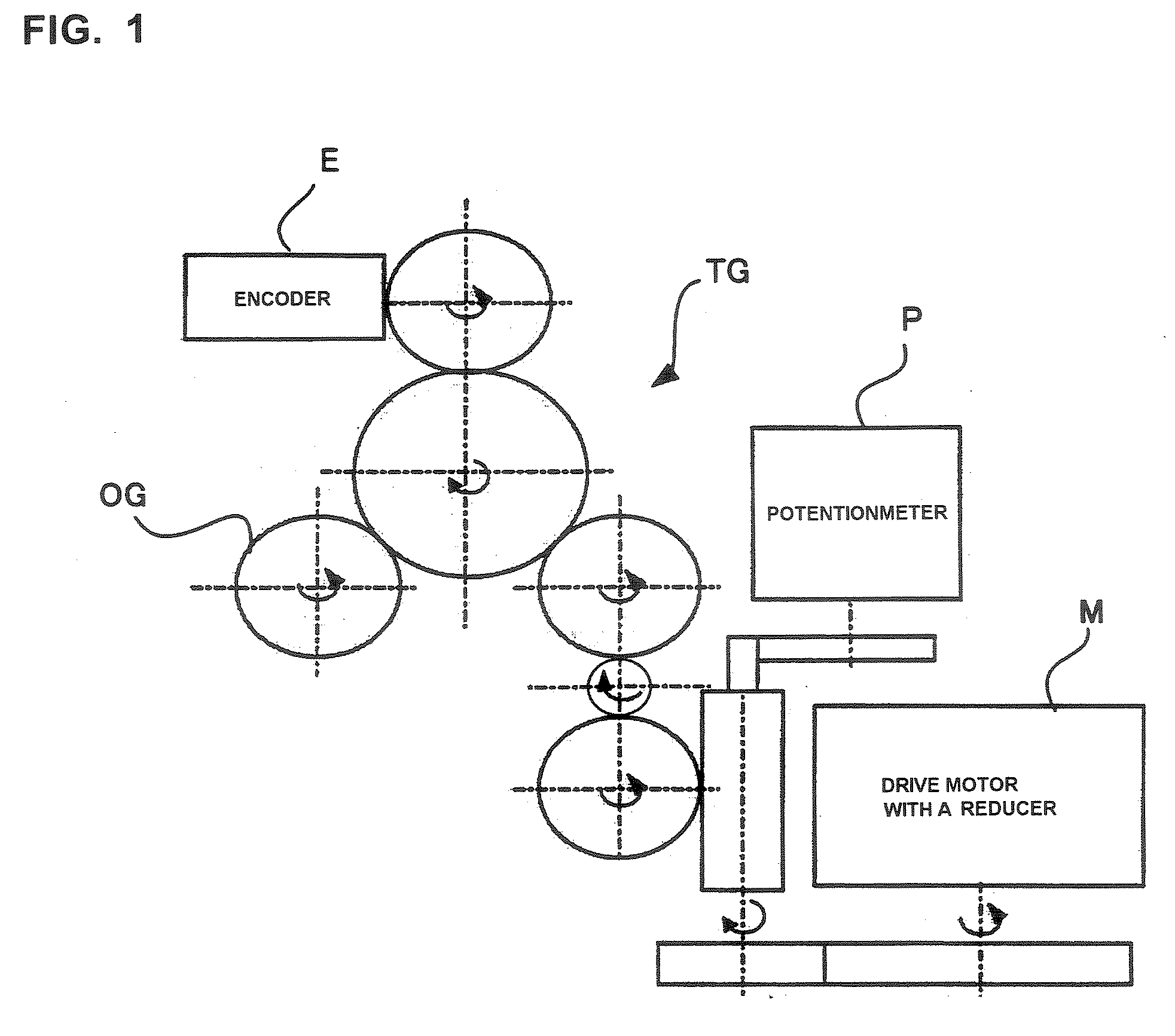

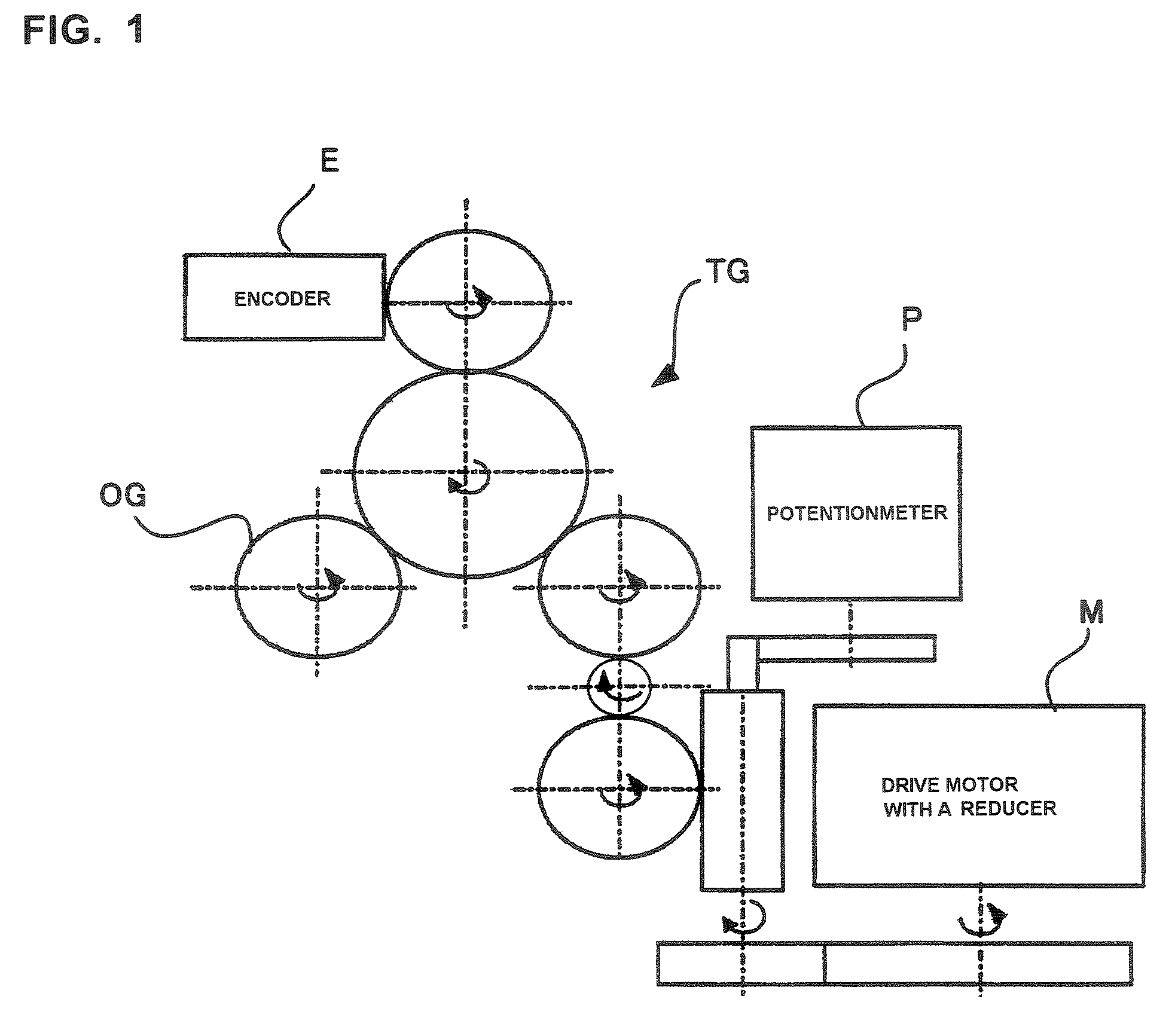

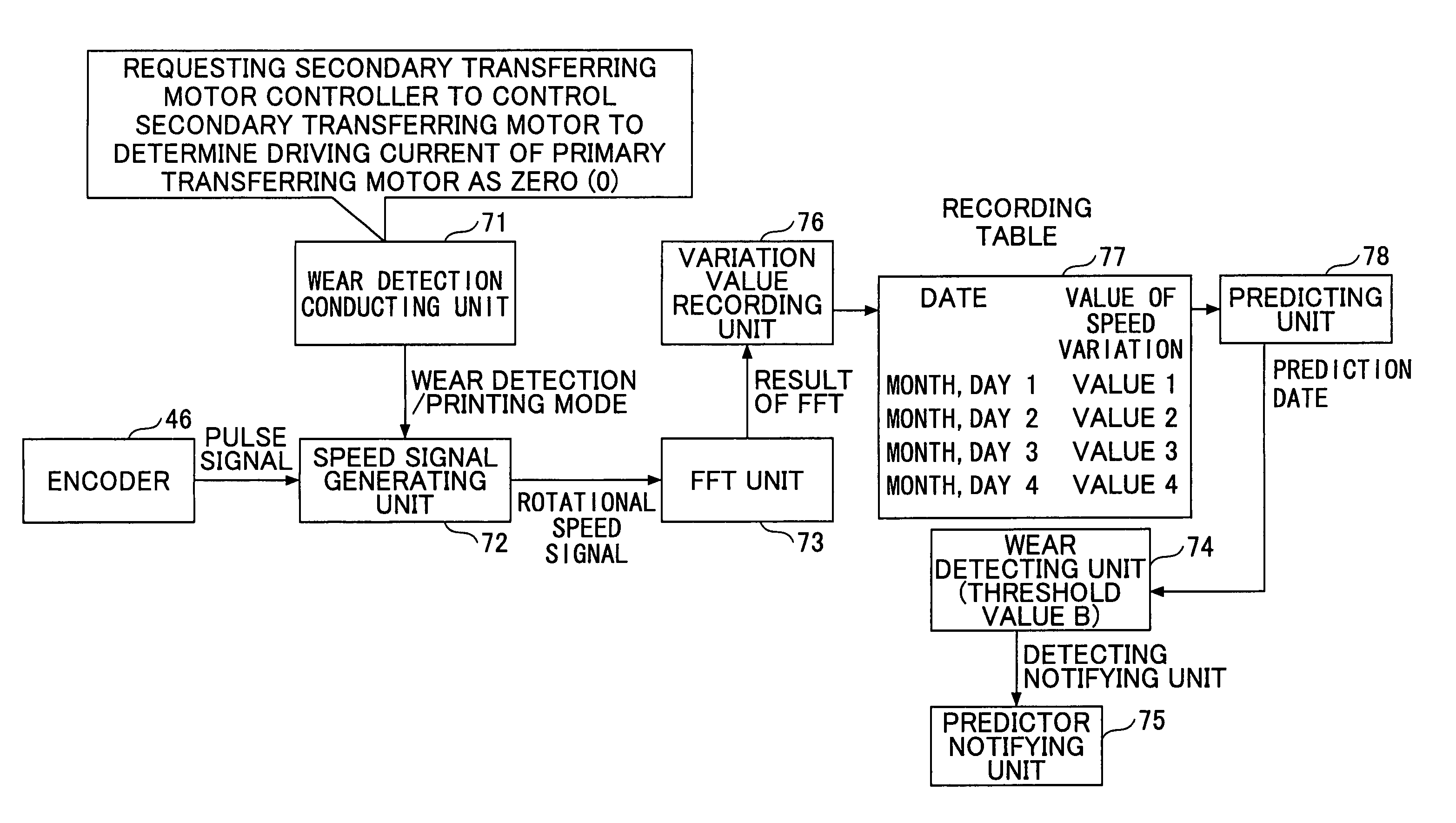

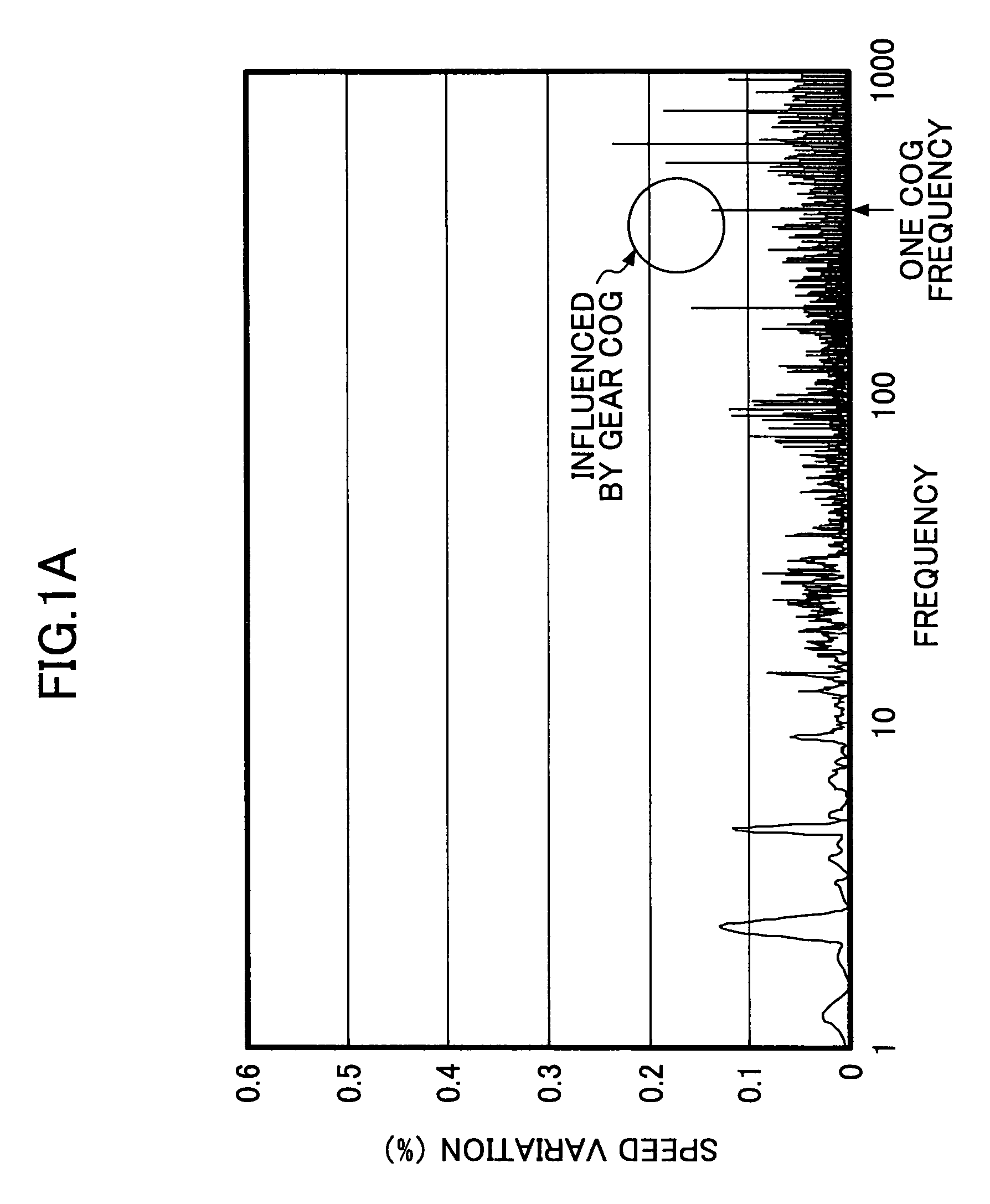

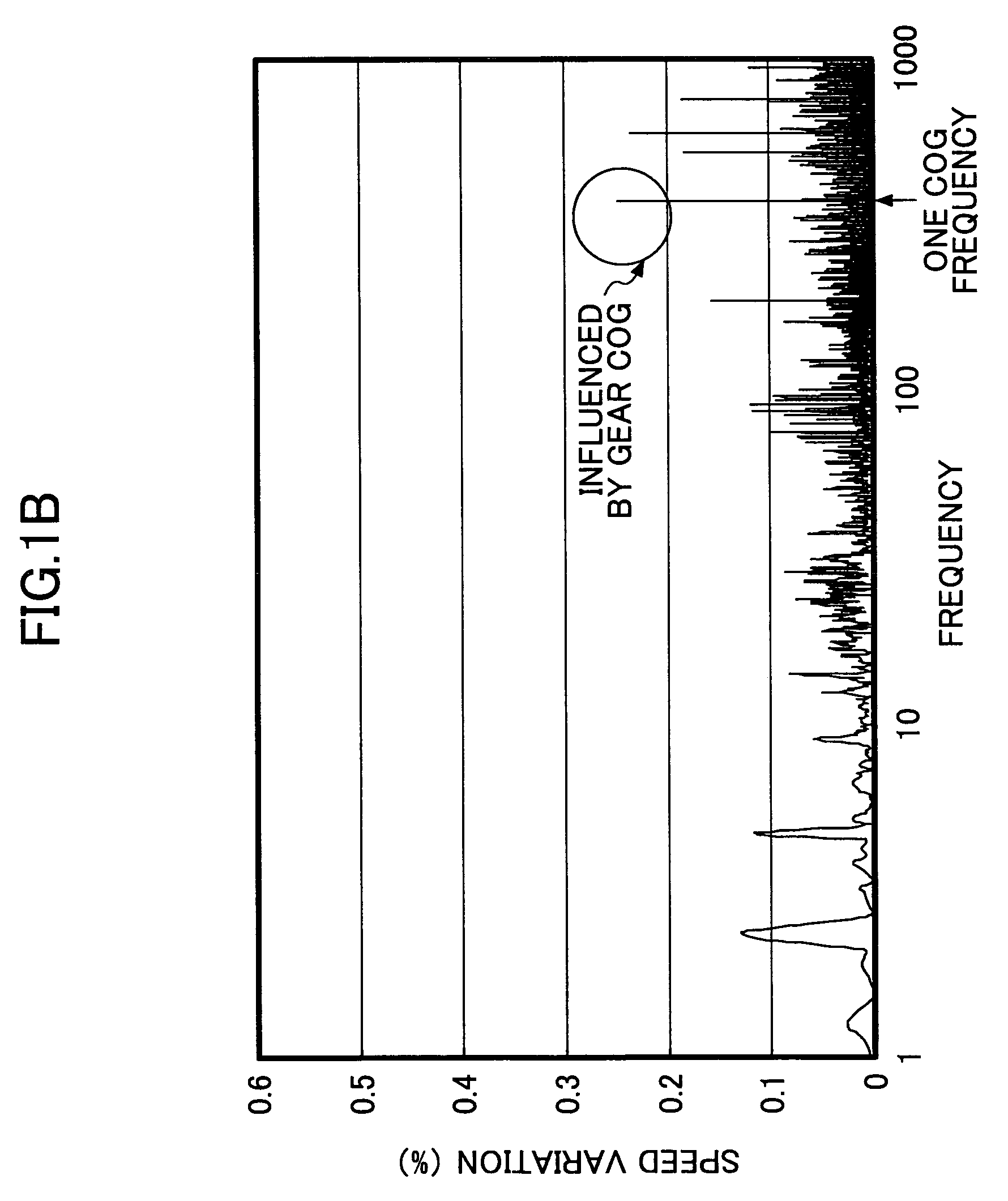

Control device, image forming device, wear detecting method, program, and storage device

InactiveUS8326549B2Early wearPlug gaugesTesting/monitoring control systemsRotation velocityImage formation

A control device includes a transmission unit including a first gear rotating with a motor shaft and a second gear rotating with a rotating roller which drives a rotated body, a speed detecting unit for detecting the rotational speed of the rotated body or rotating roller, a motor controlling unit for maintaining a constant motor shaft rotational speed based on the rotational speed, a converting unit for converting the rotational speed to a relationship between a frequency contained in a variation of the rotational speed in association with time and a variation value of the rotational speed, and a wear detecting unit for detecting a predictor of wear of cogs in at least one of the first and second gears when the variation value at a specified frequency, determined based on the number of the cogs of the first gear and the motor shaft rotational speed, exceeds a threshold value.

Owner:RICOH KK

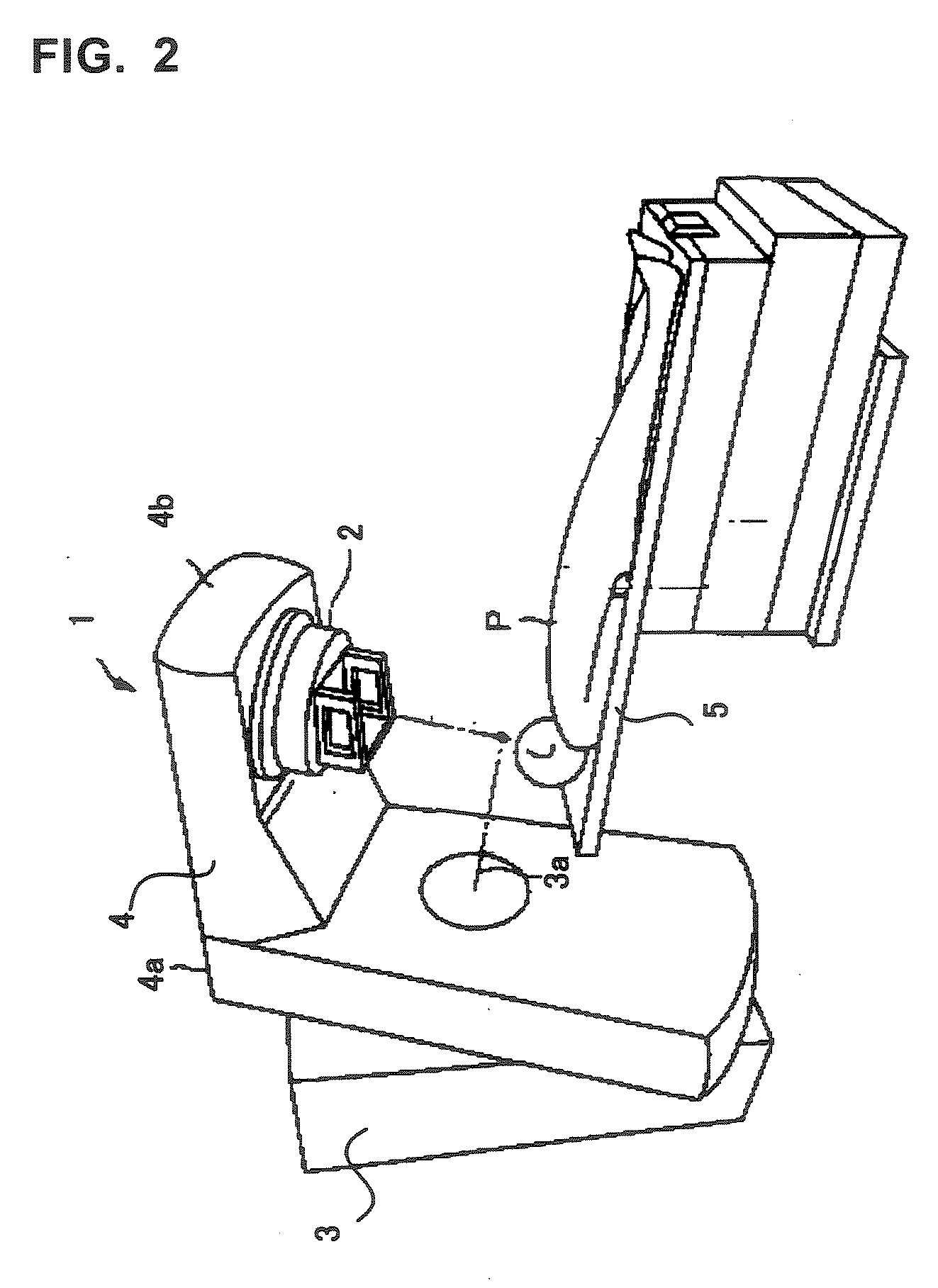

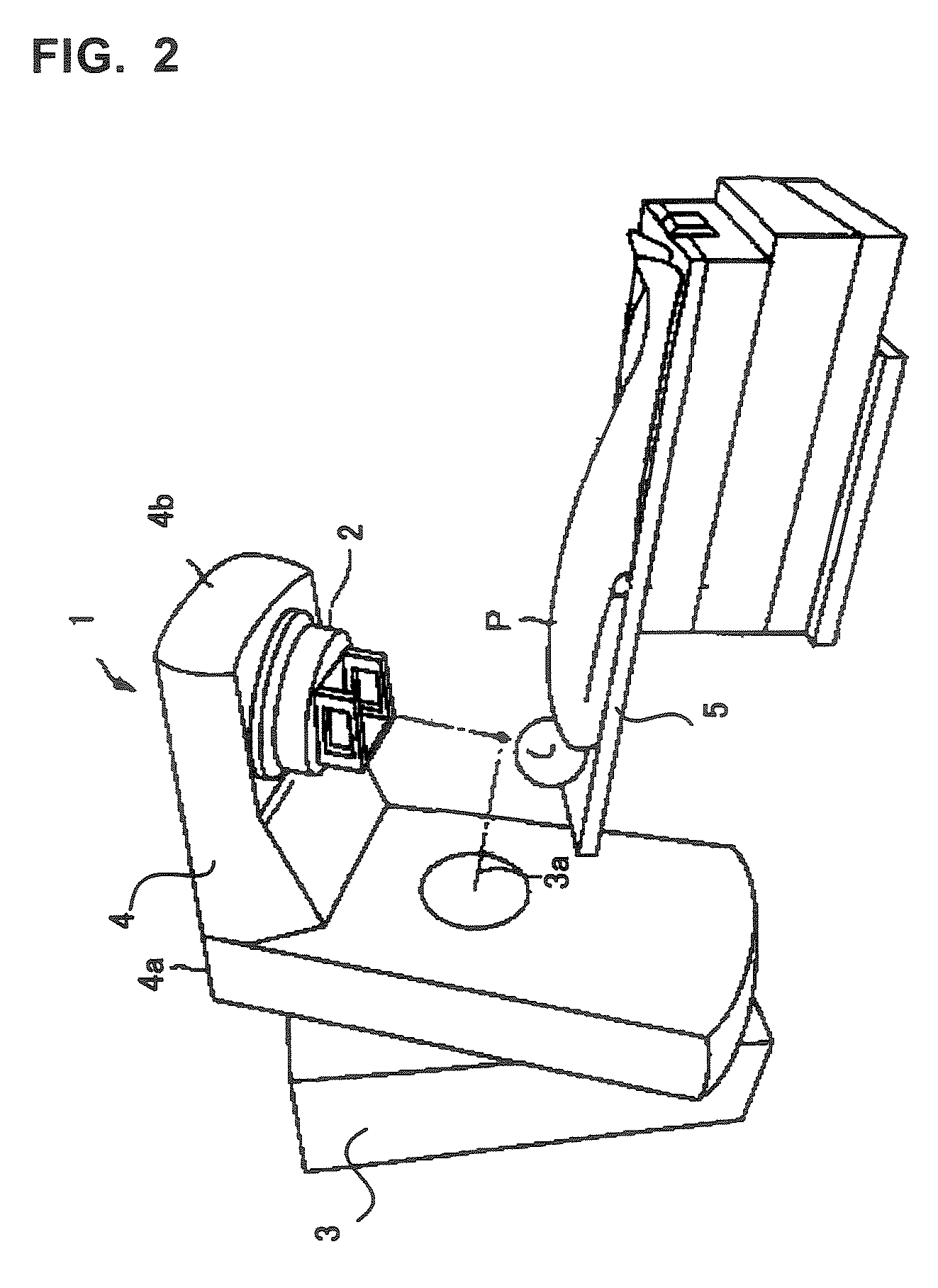

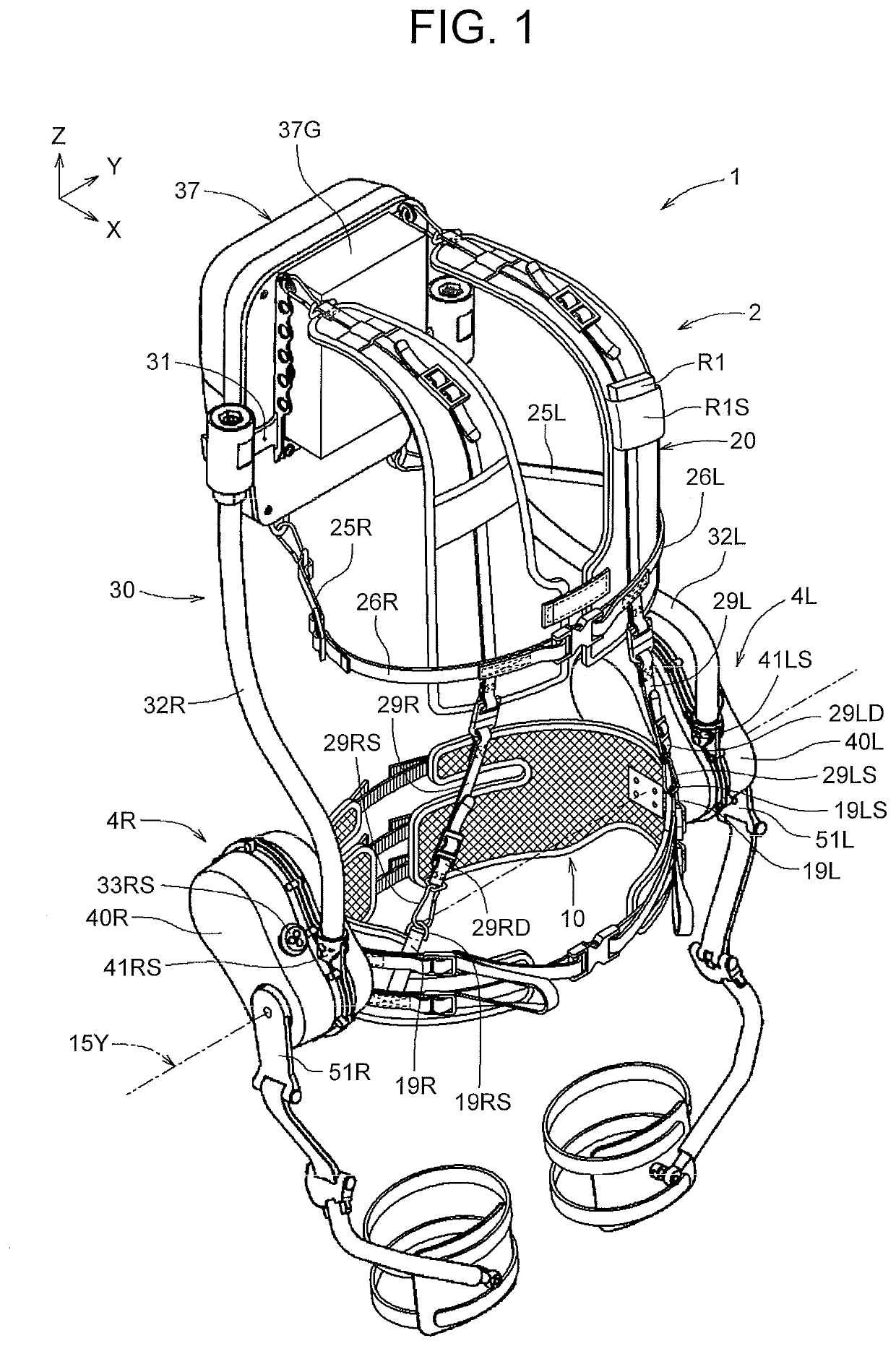

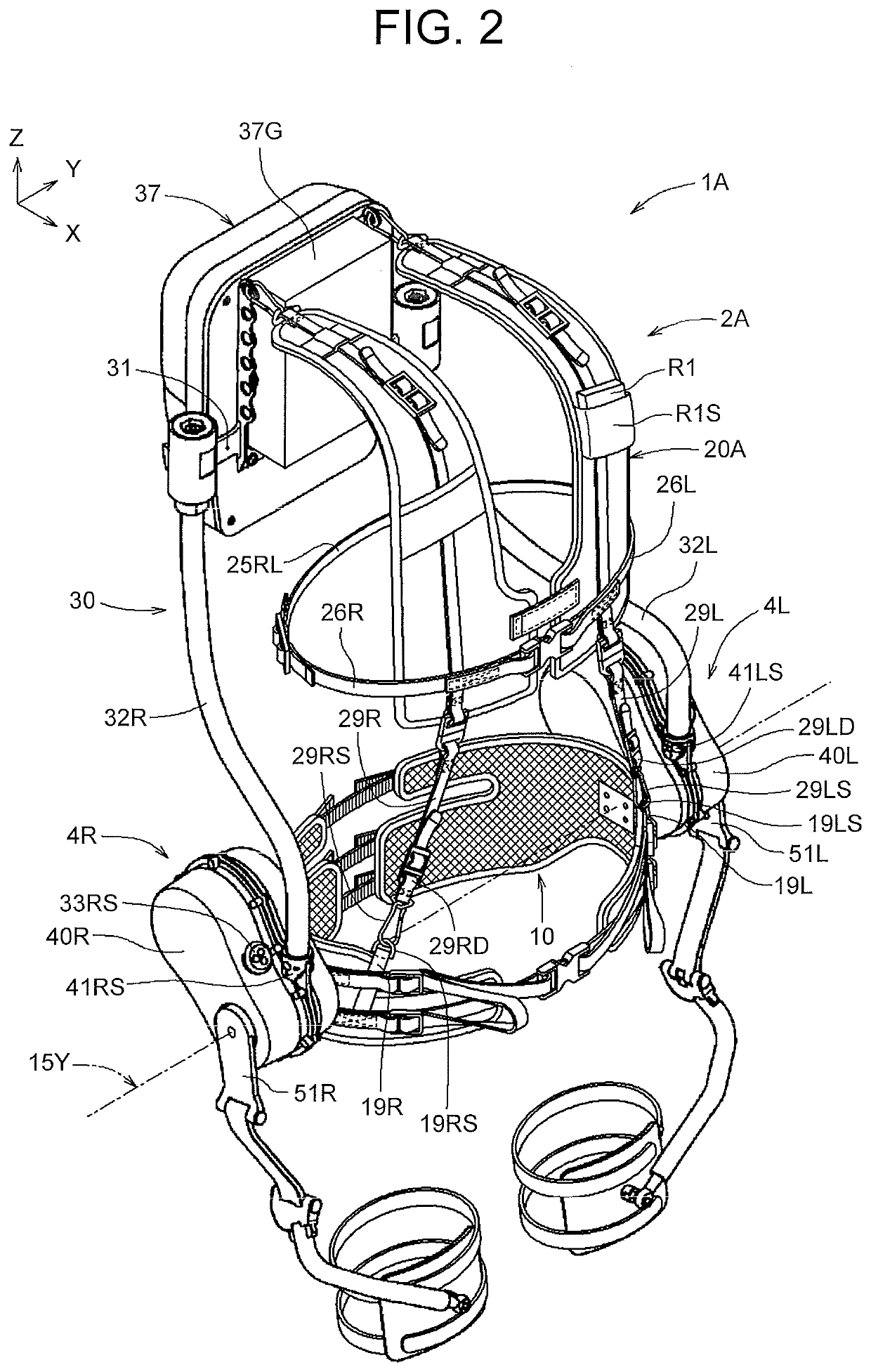

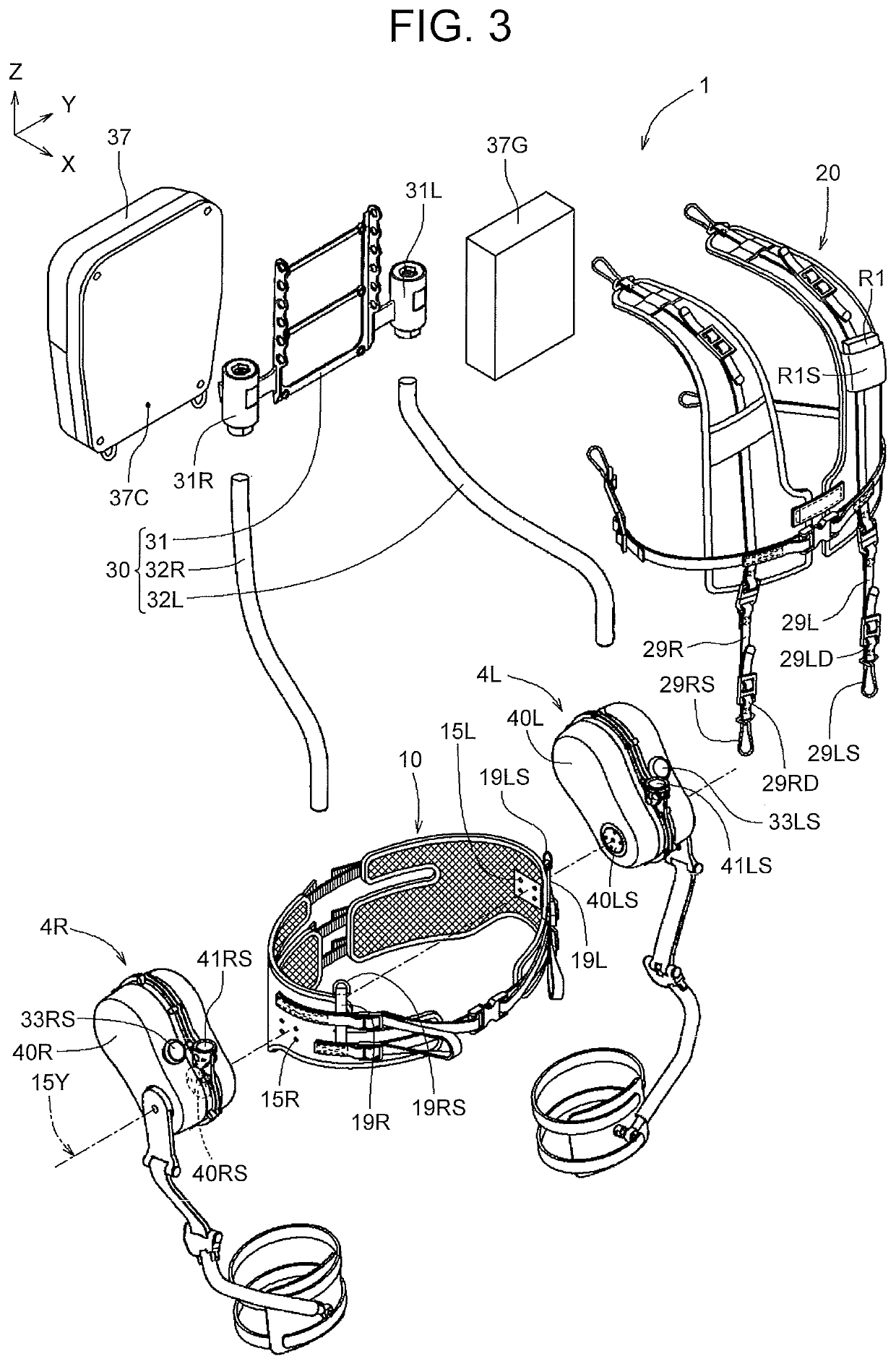

Assist device

InactiveUS20190358808A1Smooth changeEasy to wearProgramme-controlled manipulatorChiropractic devicesThighEngineering

An assist device includes: body gear worn at least around hips of a person being assisted; an actuator unit attached to the body gear and worn on thighs of the person being assisted; an angle detection part configured to detect a forward leaning angle of the hips relative to the thighs of the person being assisted; and a controller configured to control the actuator unit. The actuator unit is configured to generate an assisting torque that assists the person in moving his or her thighs relative to the hips or moving his or her hips relative to the thighs. The controller is configured to execute at least one of first control and second control.

Owner:JTEKT CORP

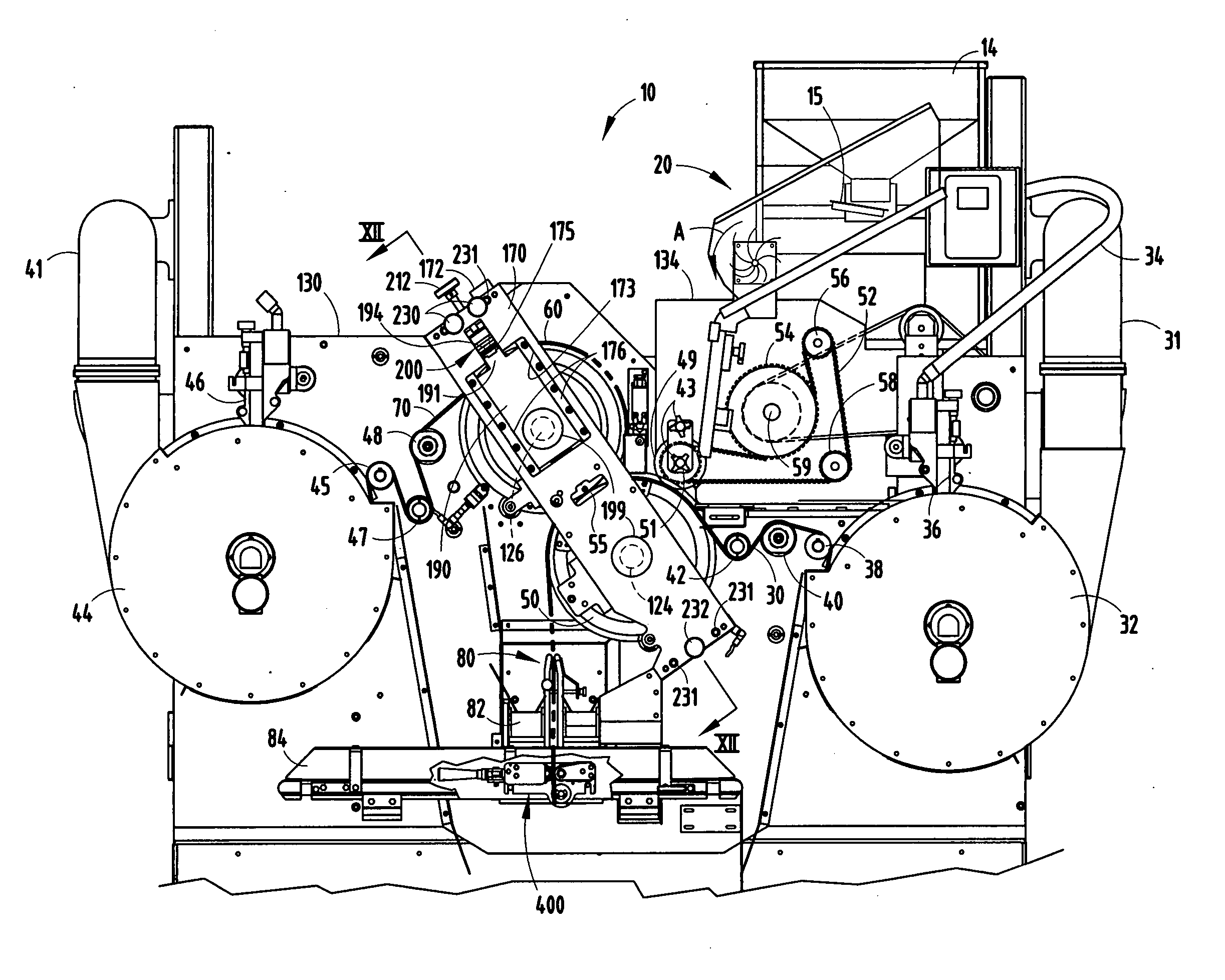

Tablet encapsulating machine

InactiveUS7228676B2Improve sealingAvoid excessive wearPharmaceutical product form changeCoatingsIndependent motionDrive shaft

An encapsulating machine includes a pair of offset die rolls with one die roll mounted on slides urged by an adjustable fulcrum spring toward the other die roll. An offset drive coupling between the axle of the die roll and the associated drive shaft allows independent movement of the die axle to compensate for die wear. A split gear between die roll shafts accommodates for backlash and gear wear. Precise pulley-driven timing belts and phase adjusters extend between the die roll drive and a tablet feed roll to synchronize the clocked introduction of tablets onto film of one of the die rolls for encapsulation at the co-acting nip between the die rolls. The die cavities for tablets include a step-cut to improve the sealing of films around the tablets and a circumferential rub rail on opposite edges of each die prevents excessive wear of the die cavity lands.

Owner:L PERRIGO

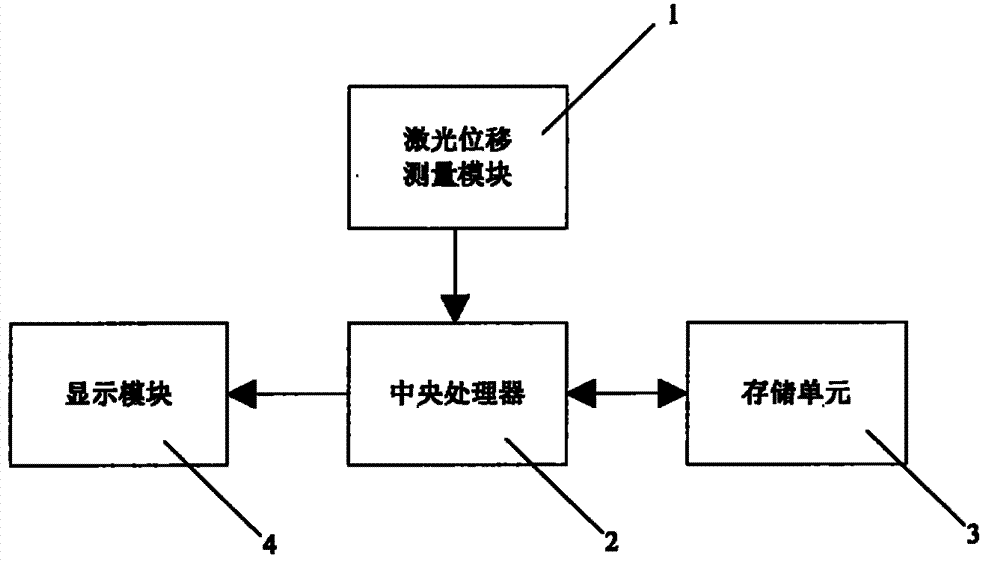

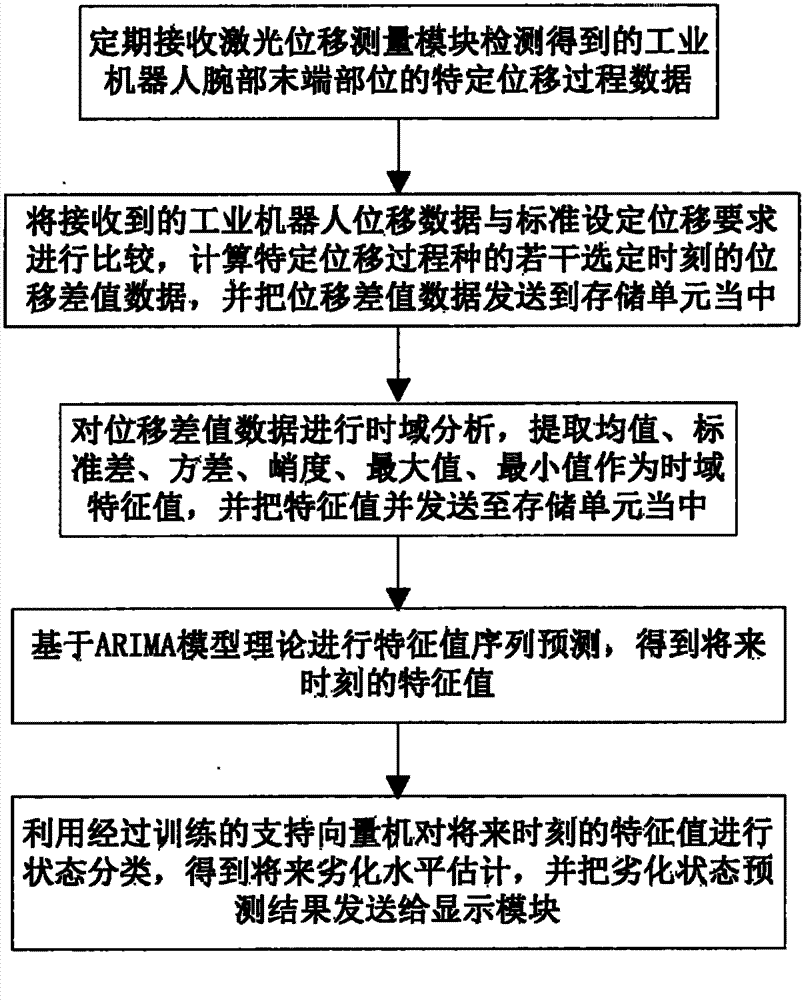

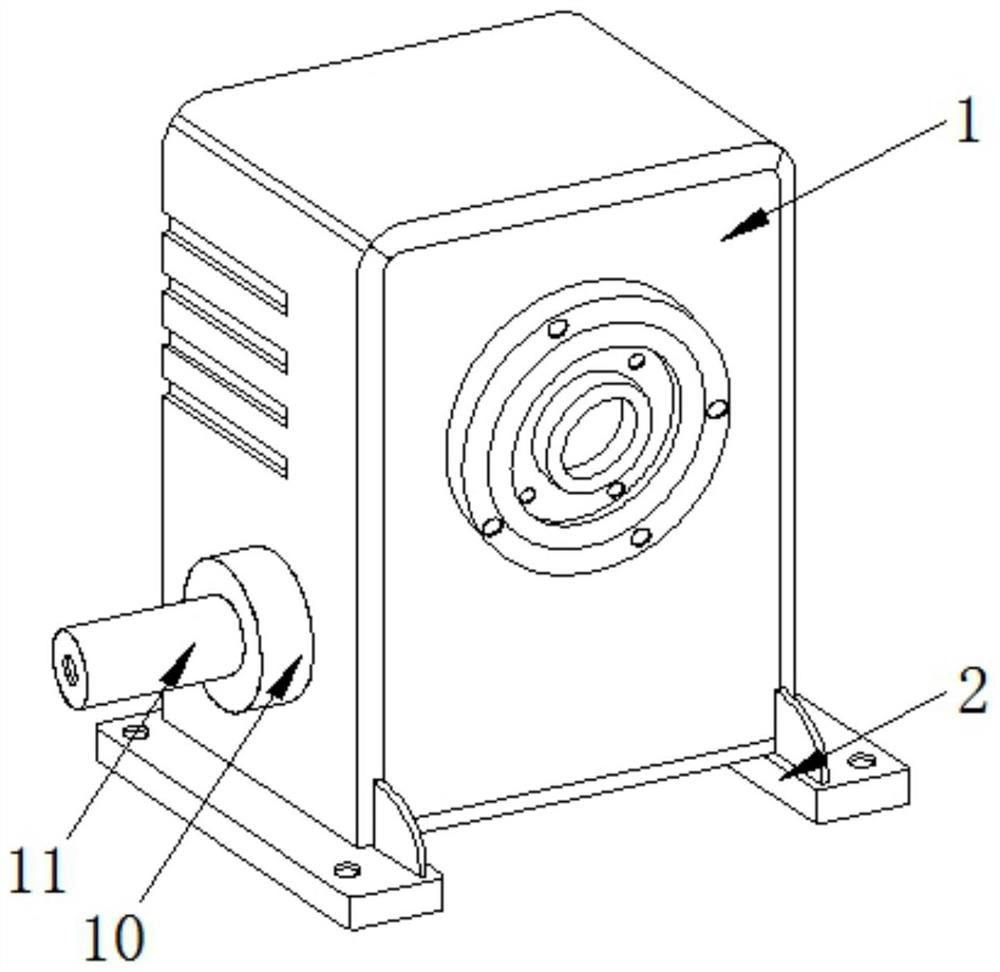

Fault predication device of six-axis multi-joint industrial robot

A fault predication device of a six-axis multi-joint industrial robot comprises a laser displacement measuring module, a central processor, a storage unit and a display module. The central processor sequentially executes the following steps: periodically receiving specific displacement process data of wrist end portions of the industrial robot, wherein the specific displacement process data is obtained by the detection of the laser displacement measuring module; comparing the displacement process data with a standard set displacement requirement, calculating displacement difference value data of a plurality of selected moments, and sending the displacement difference value data to the storage unit; applying time domain analysis, mean value extraction, standard deviation, square deviation, or the like to the displacement difference value data for obtaining a plurality of time domain characteristic values, and sending the time domain characteristic values to the storage unit; predicting a characteristic value sequence based on an ARIMA model for obtaining characteristic values of future moments; utilizing trained support vectors to classify states of the characteristic values of the future moments, so as to obtain a future degradation level estimation; and sending the degradation state prediction result to the display module. The fault predication device of the six-axis multi-joint industrial robot can predict the reduction gear wear-out failure of the industrial robot.

Owner:CHINA JILIANG UNIV

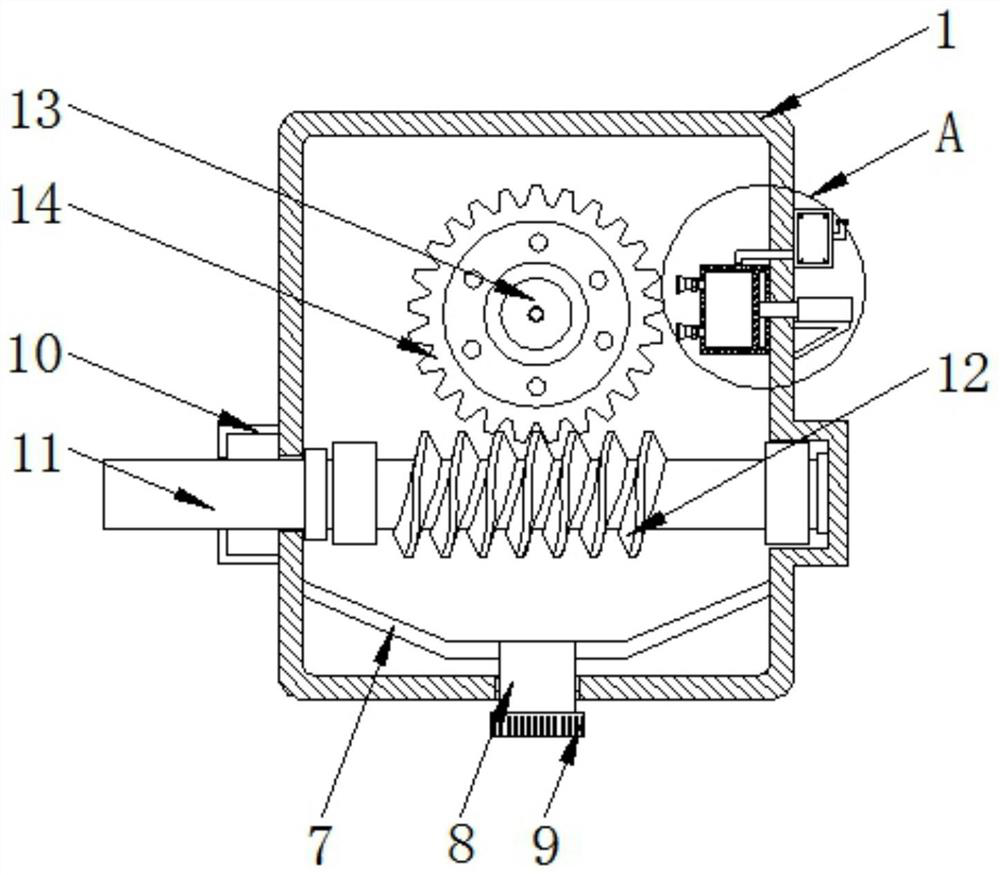

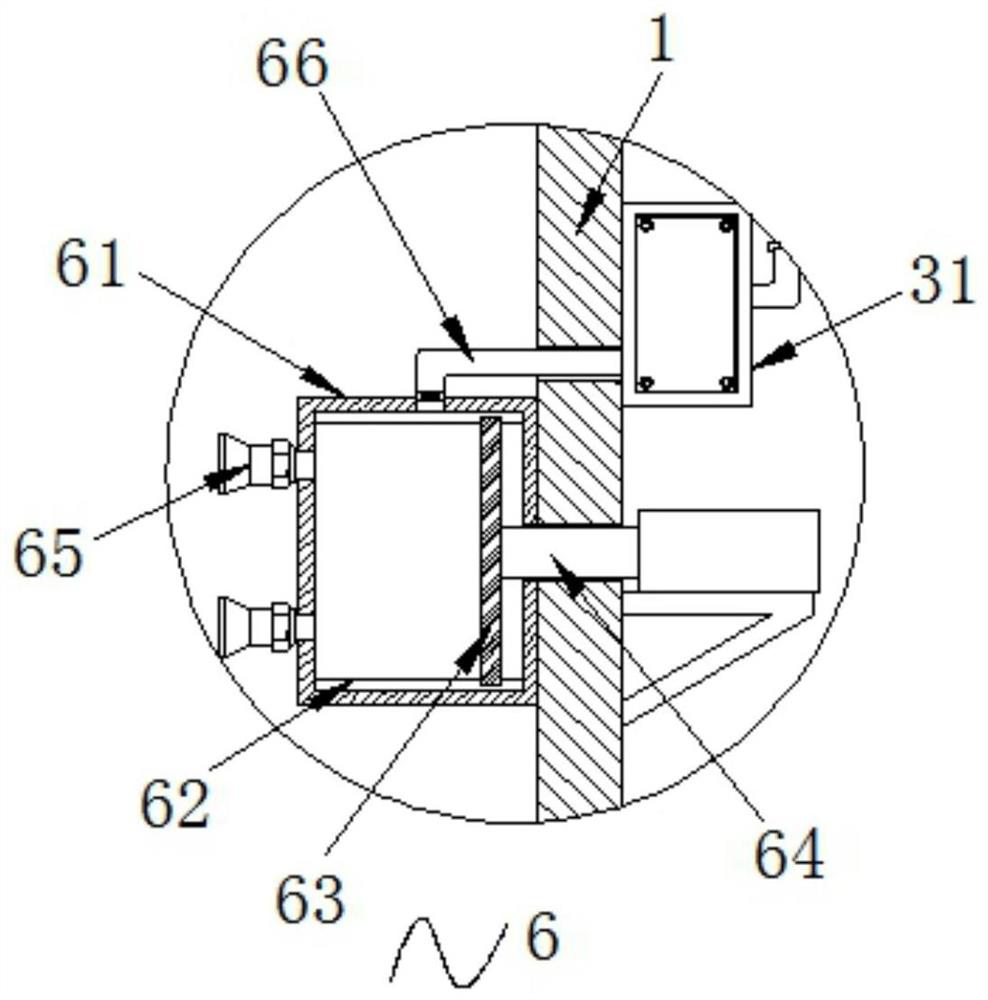

Multifunctional aluminum alloy worm and gear speed reducer and using method thereof

InactiveCN113074238AAvoid wear and tearDoes not affect normal useGearboxesGear lubrication/coolingGear wheelEngineering

The invention discloses a multifunctional aluminum alloy worm and gear speed reducer and a using method thereof, and relates to the technical field of speed reducers. The multifunctional aluminum alloy worm and gear speed reducer comprises a box body and mounting plates fixed to the two sides of the bottom of the box body, a filtering mechanism is arranged at the top of the right side of the box body, a noise reduction mechanism is arranged in the box body, and a heat dissipation mechanism is arranged on the back face of the inner wall of the box body; and a lubricating mechanism is arranged on the right side of the inner wall of the box body and comprises a shell, and the right side of the shell is fixedly connected with the top of the right side of the inner wall of the box body. According to the multifunctional aluminum alloy worm and gear speed reducer and the using method thereof, a piston is pushed by an air cylinder to move in the shell, under the pressure effect of the piston, lubricating oil is sprayed out through an atomization spray head to evenly lubricate a rotating worm gear, the speed reducer can conduct lubricating work without stopping working, and thus the speed reducer is used normally, gear abrasion can be prevented, and the service life of the speed reducer is prolonged.

Owner:杭州誉球机械有限公司

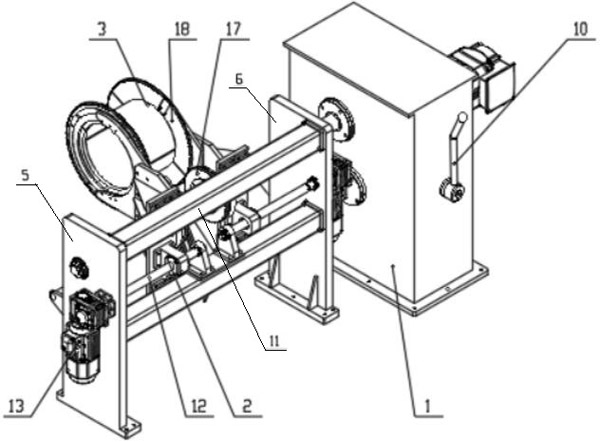

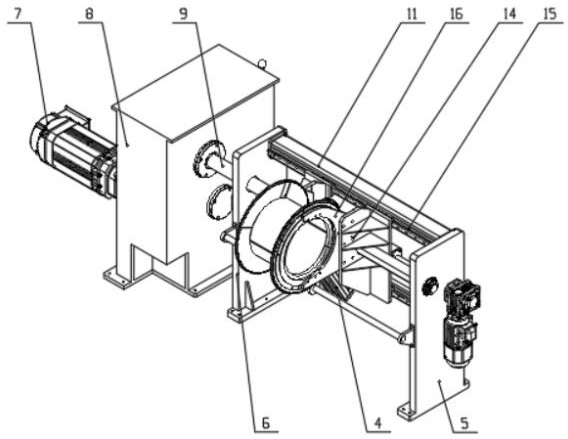

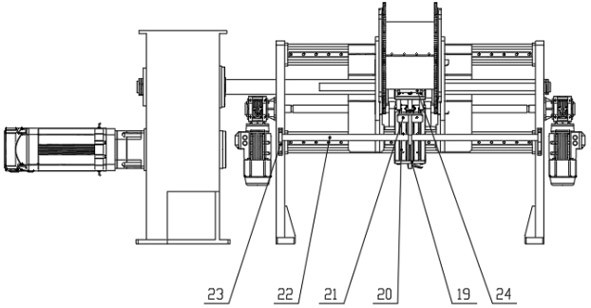

Winding device of amorphous three-dimensional wound core transformer wire foil integrated winding machine and operation method of winding device

The invention relates to a winding device of an amorphous three-dimensional wound core transformer wire foil integrated winding machine and an operation method of the winding device. The winding device comprises a main shaft transmission box, a winding gear set moving device, a winding gear set, a coil pressing device, a left wall plate, a right wall plate and a control assembly. The left wall plate and the right wall plate are arranged side by side with the main shaft transmission case, the winding gear set moving device is located between the left wall plate and the right wall plate, the winding gear set is driven by the winding gear set moving device to transversely move to adapt to coils of different heights, and the coil pressing device is designed between the left wall plate and theright wall plate and located below the coils. According to the device, the technology that the coil is completely suspended through the winding gear set is adopted, damage to an iron core in the winding process is avoided, the center distance between a driving gear and a driven gear is fixed, the coils vibrates in the winding process, the gear abrasion speed and noise generated in the coil windingprocess are reduced, and the winding speed and coil quality are improved; and integrated winding of a low-voltage foil type coil and a high-voltage wire type coil can be realized.

Owner:CECEP XIAN QIYUAN MECHANICAL & EIECTRICAL EQUIP CO LTD

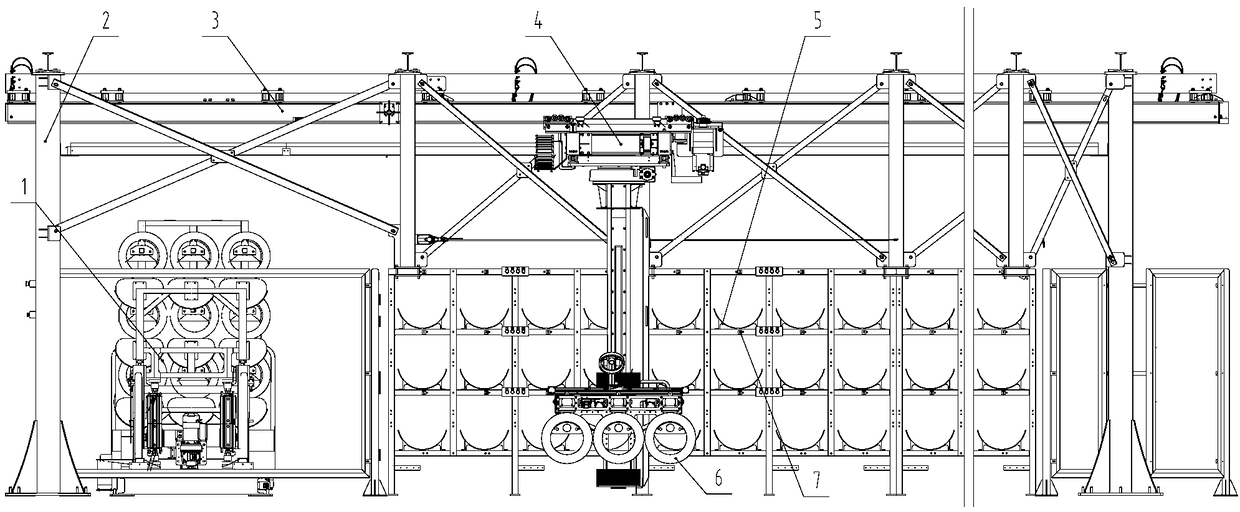

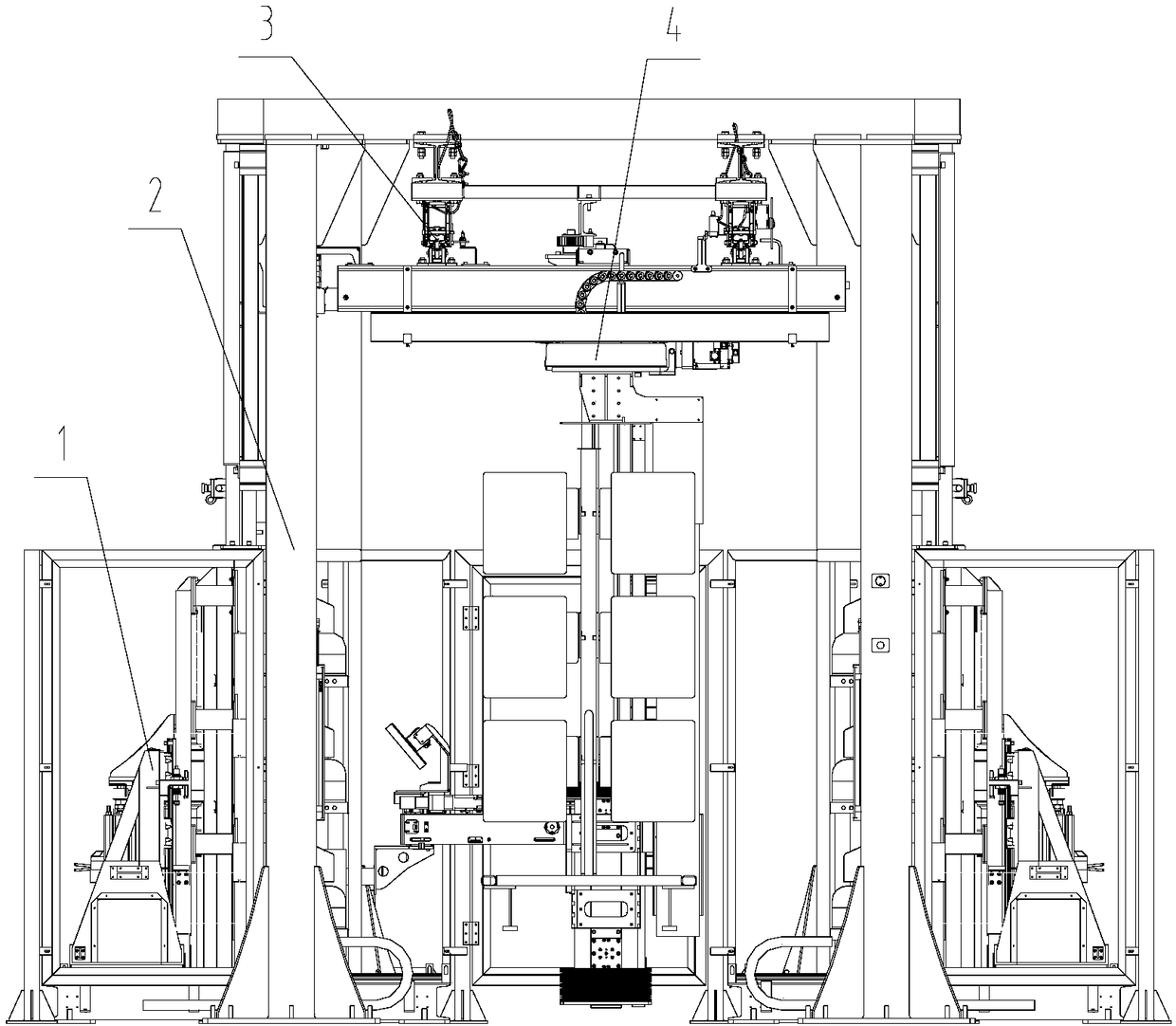

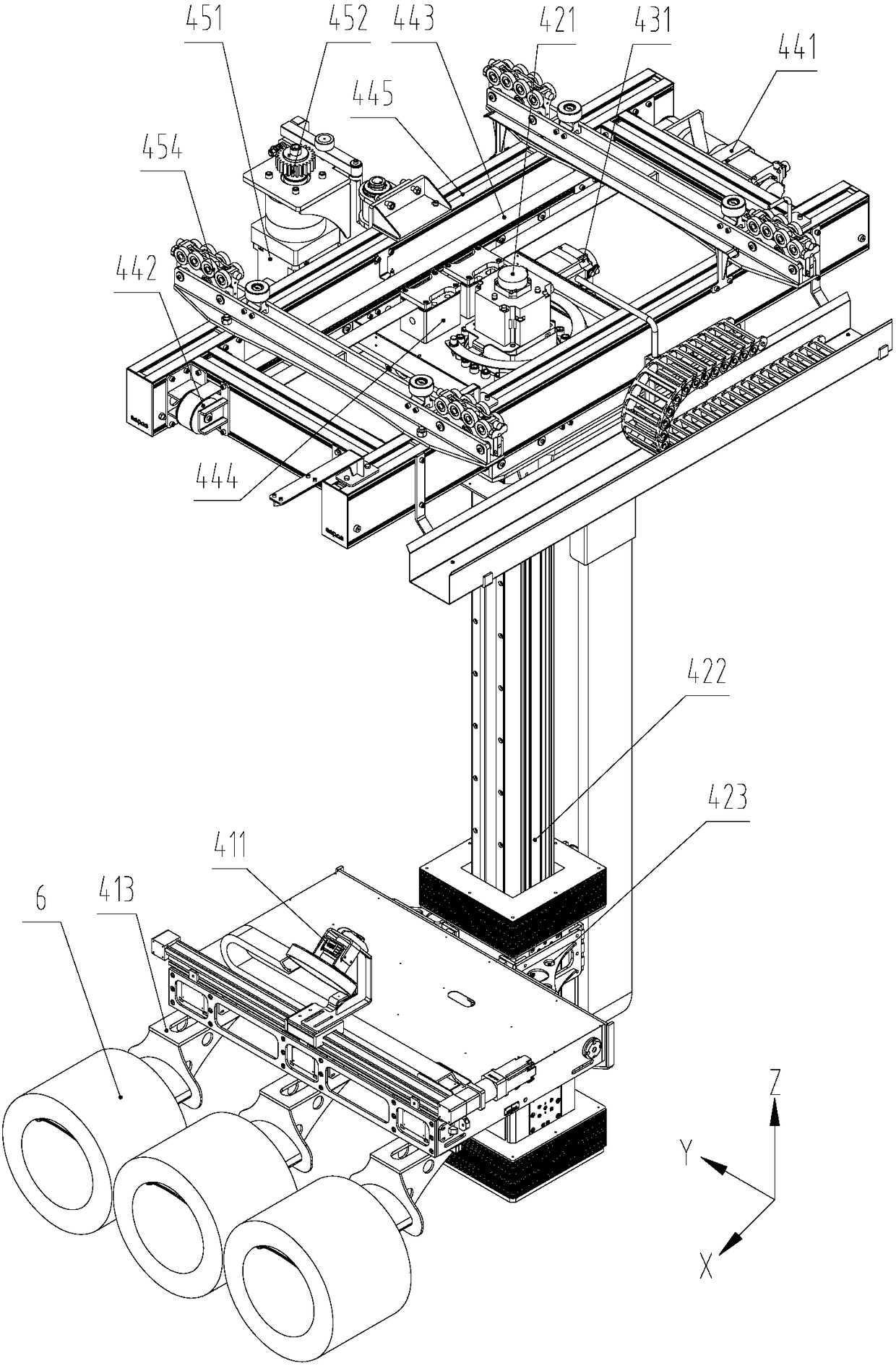

Chopped fiber automatic yarn feeding system based on visual accurate positioning

PendingCN108100640AAvoid wear and tearExtended service lifeConveyorsControl devices for conveyorsVision basedGear wear

The invention relates to a chopped fiber automatic yarn feeding system based on visual accurate positioning. The chopped fiber automatic yarn feeding system based on visual accurate positioning comprises a rack (2), a yarn storage shelf (1) for storing a to-be-taken yarn roll (6), a transverse guide rail (3) installed on the rack and used for guiding an automatic yarn taking and placing trolley (4), and the automatic yarn taking and placing trolley (4) for placing the yarn roll (6) grasped from the yarn storage shelf (1) onto a specified yarn holder (5); and the automatic yarn taking and placing trolley (4) has access to a control system. The chopped fiber automatic yarn feeding system based on visual accurate positioning has the advantages that as for a traveling part, a servo motor is adopted to drive a gear to travel along a rack, the acceleration or deceleration time is short, the running speed is high, and the positioning precision is high; and meanwhile, abrasion to the gear caused by an installation error of the rack is avoided and the service life of the gear is prolonged.

Owner:TAISHAN FIBERGLASS INC

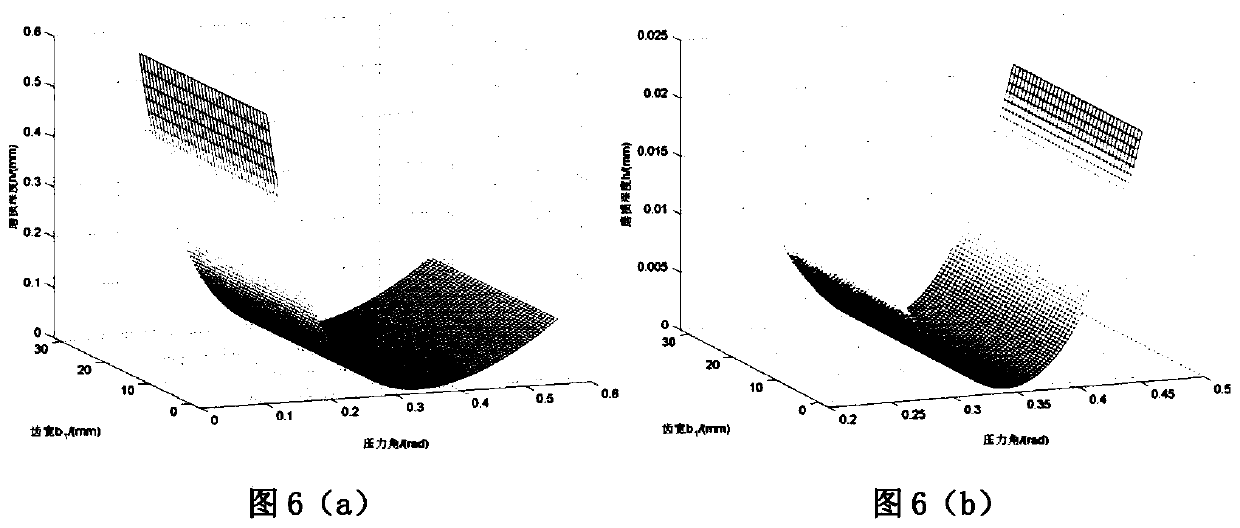

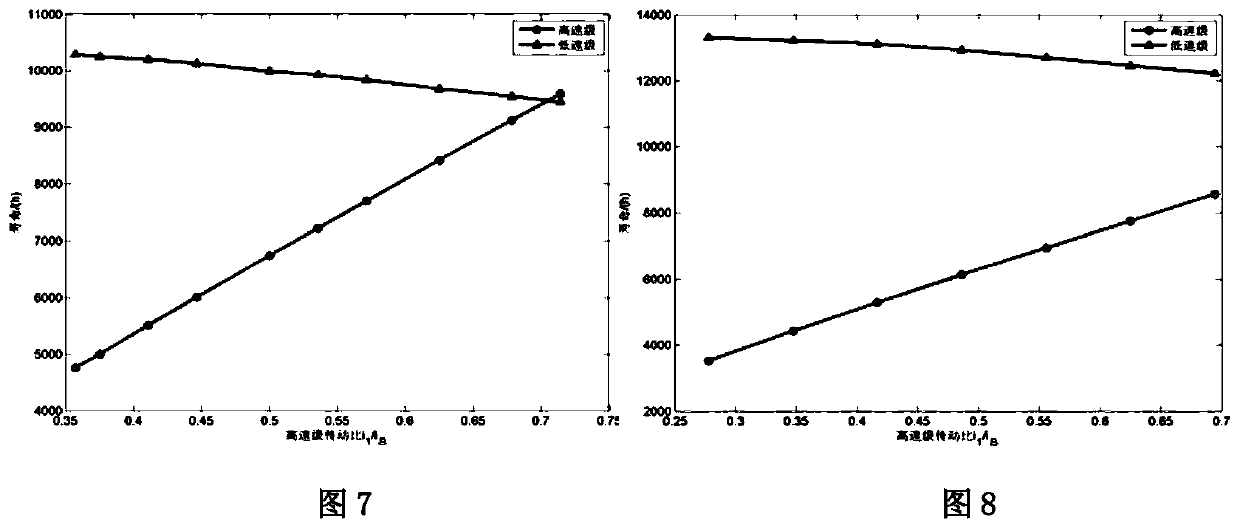

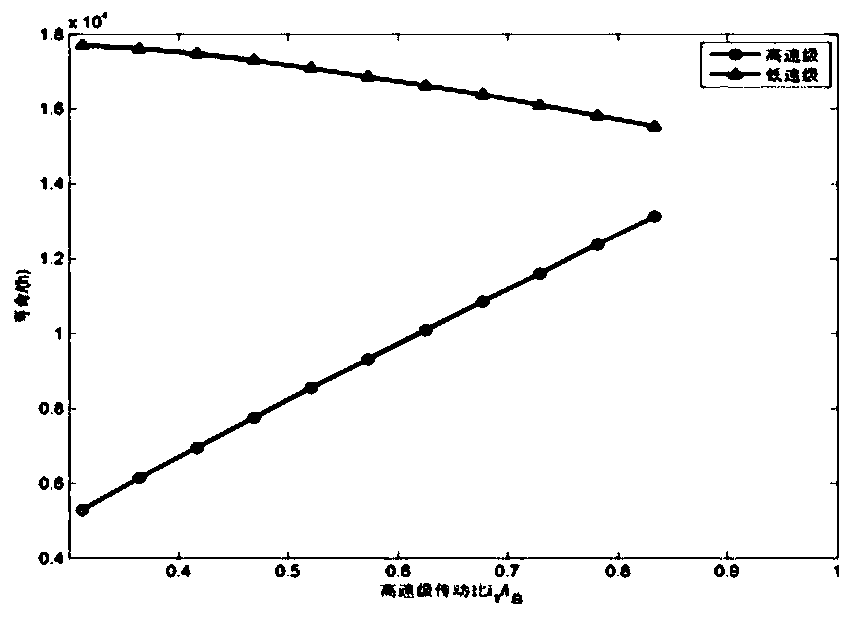

Parameter-optimized metallurgical crane speed reducer gear service life evaluation method

ActiveCN111062103AReduce wear rateExtended service lifeGeometric CADManufacturing computing systemsReduction driveGear wheel

The invention discloses a parameter-optimized metallurgical crane speed reducer gear service life evaluation method, and belongs to the technical field of equipment service life evaluation. The methodcomprises the following steps: constructing a tooth profile wear amount calculation formula based on an Archard's wear calculation model; for front and rear stages of transmission gears of the speedreducer, keeping the total transmission ratio and the number of driving gear teeth of each stage unchanged, adjusting the transmission ratio of each stage within a reasonable gear number range, and sequentially calculating the tooth profile abrasion loss and the overall service life; aiming at the same-stage gear in the speed reducer, under the condition that the transmission center distance is not changed, adjusting the modulus and the number of two gear teeth, calculating the tooth profile abrasion loss, and observing the change trend of the tooth profile abrasion loss; and introducing a displacement coefficient, so that the aims of reducing the tooth profile abrasion loss and prolonging the service life are fulfilled. By adjusting the basic parameters of the gear, the abrasion rate of asingle gear is reduced, the abrasion loss difference value between the driving gear and the driven gear of the same-stage gear and the abrasion loss difference value between the gears of different stages are reduced, the service life of the gear is prolonged, and the equal abrasion between the gears is achieved.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

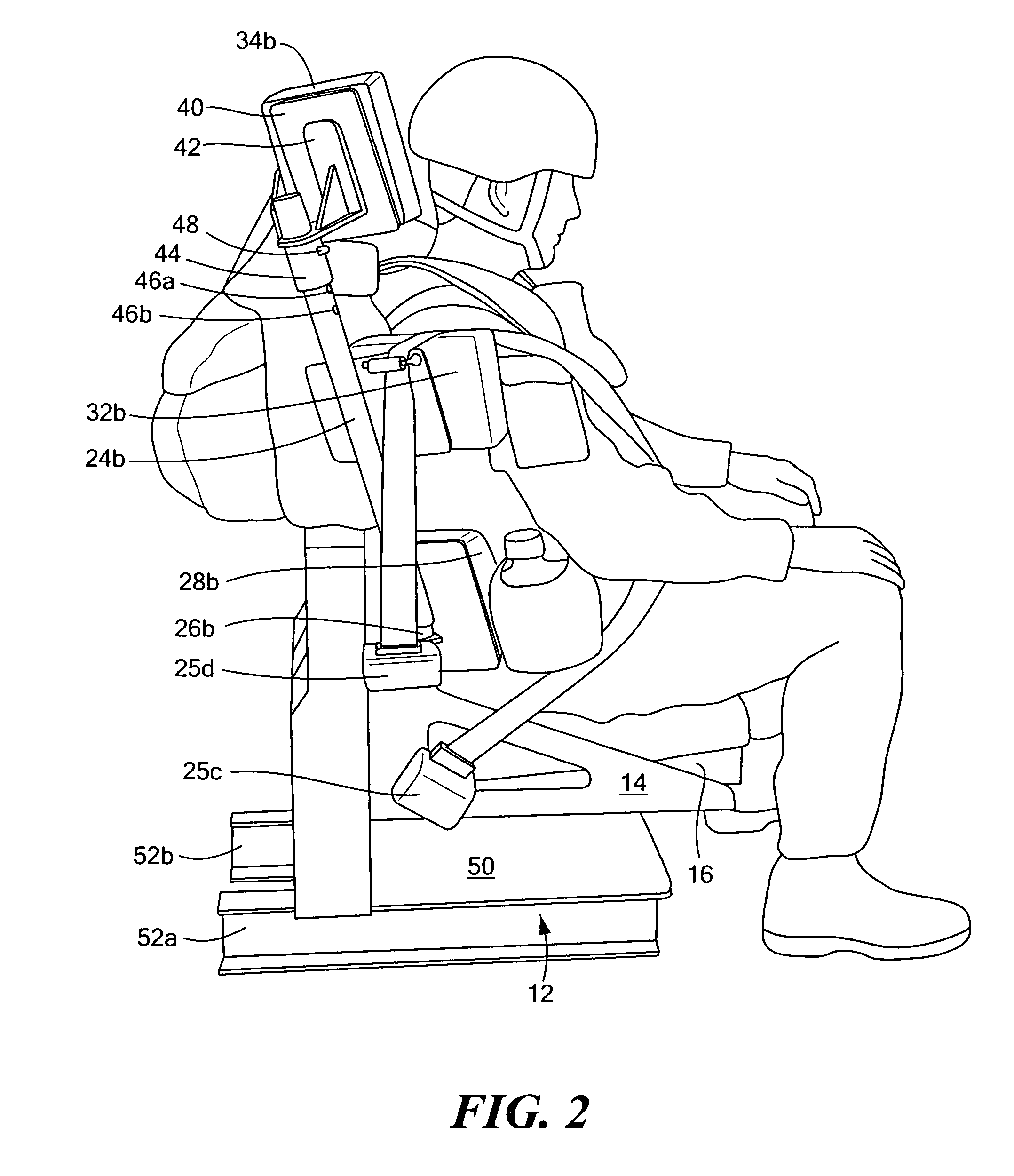

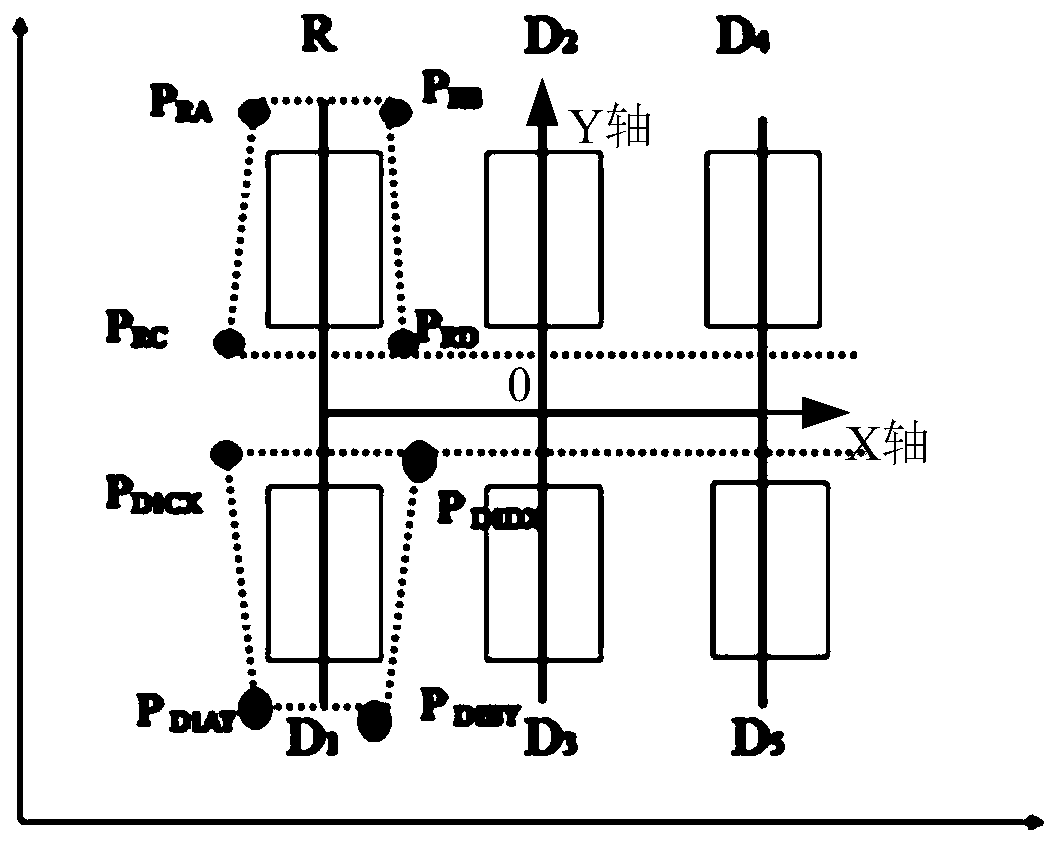

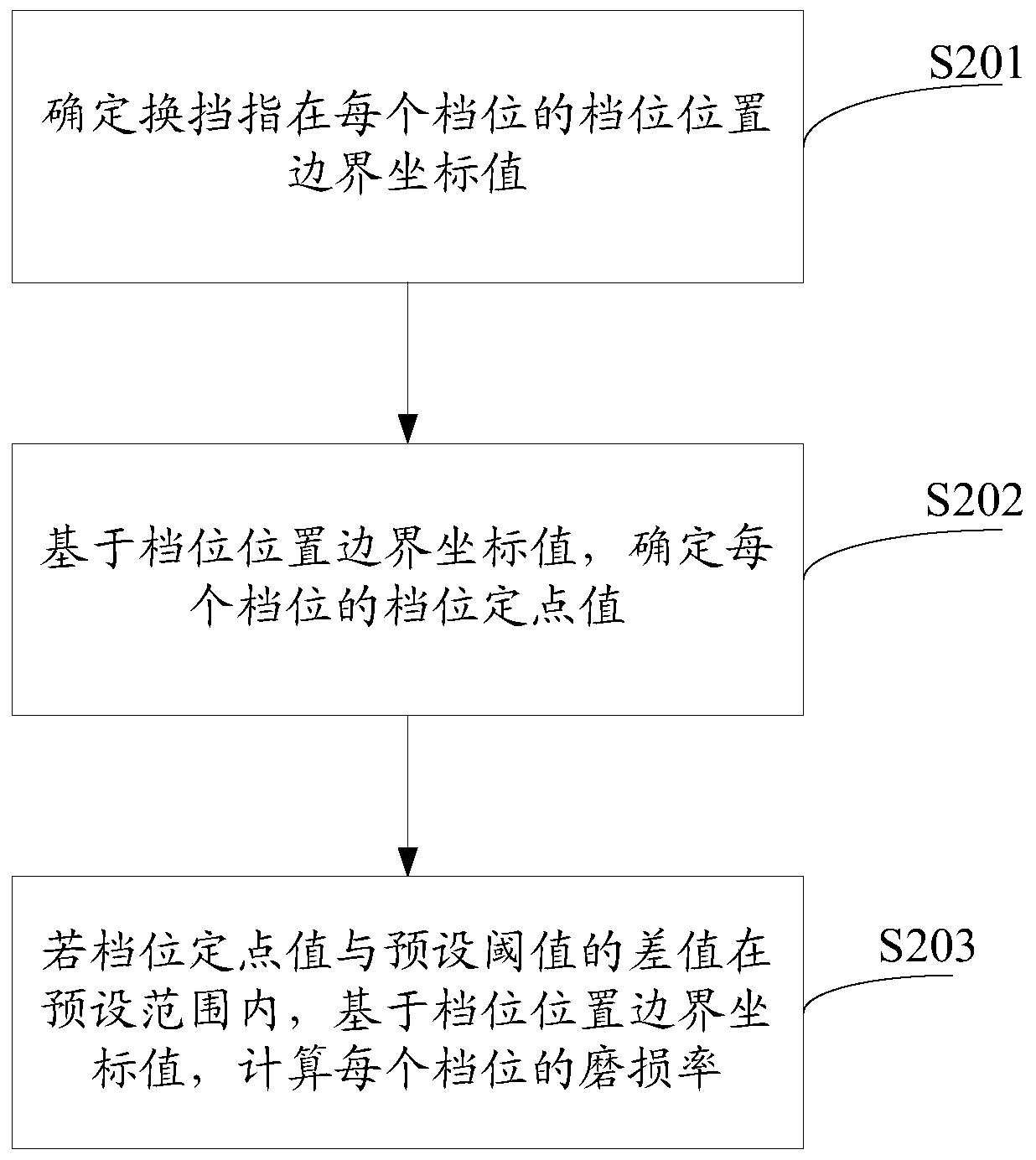

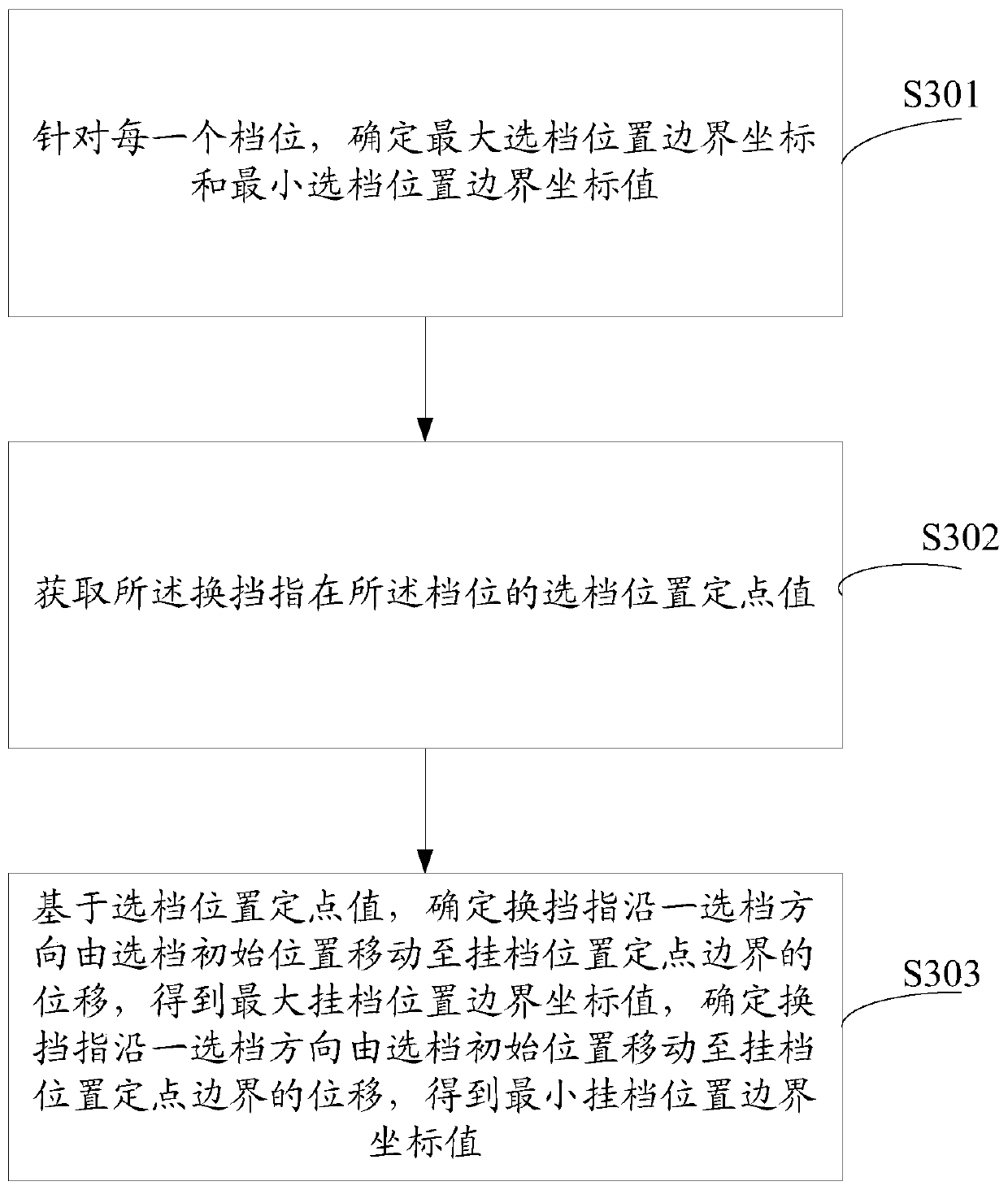

Method and system for calculating gear wear rate of automatic transmission

ActiveCN109854717ATimely assessment of wear rateImprove driving safetyGearing controlGearing detailsAutomatic transmissionEngineering

The invention provides a method and system for calculating gear wear rate of an automatic transmission. The method comprises the following steps that gear position boundary coordinate values of all gears for gear shifting are determined; a gear fixed point value of each gear is determined on the basis of the gear position boundary coordinate values, and the gear fixed point values comprise gear selecting position fixed point values and gear engaging position fixed point values; the gear fixed point values are compared with a preset threshold value; if the difference between the gear fixed point values and the preset threshold value is within a preset range, the wear rate of each gear is calculated on the basis of the gear position boundary coordinate values. According to the scheme, the wear rate of each gear is calculated by determining the gear position boundary coordinate values of all gears for gear shifting, the phenomena that a transmission is opened manually, and the wear rate of each gear is evaluated manually are avoided, the gear wear rate can be evaluated in time, the driving safety of an automobile is improved, the labor cost is reduced, and the detection time is shortened.

Owner:WEICHAI POWER CO LTD

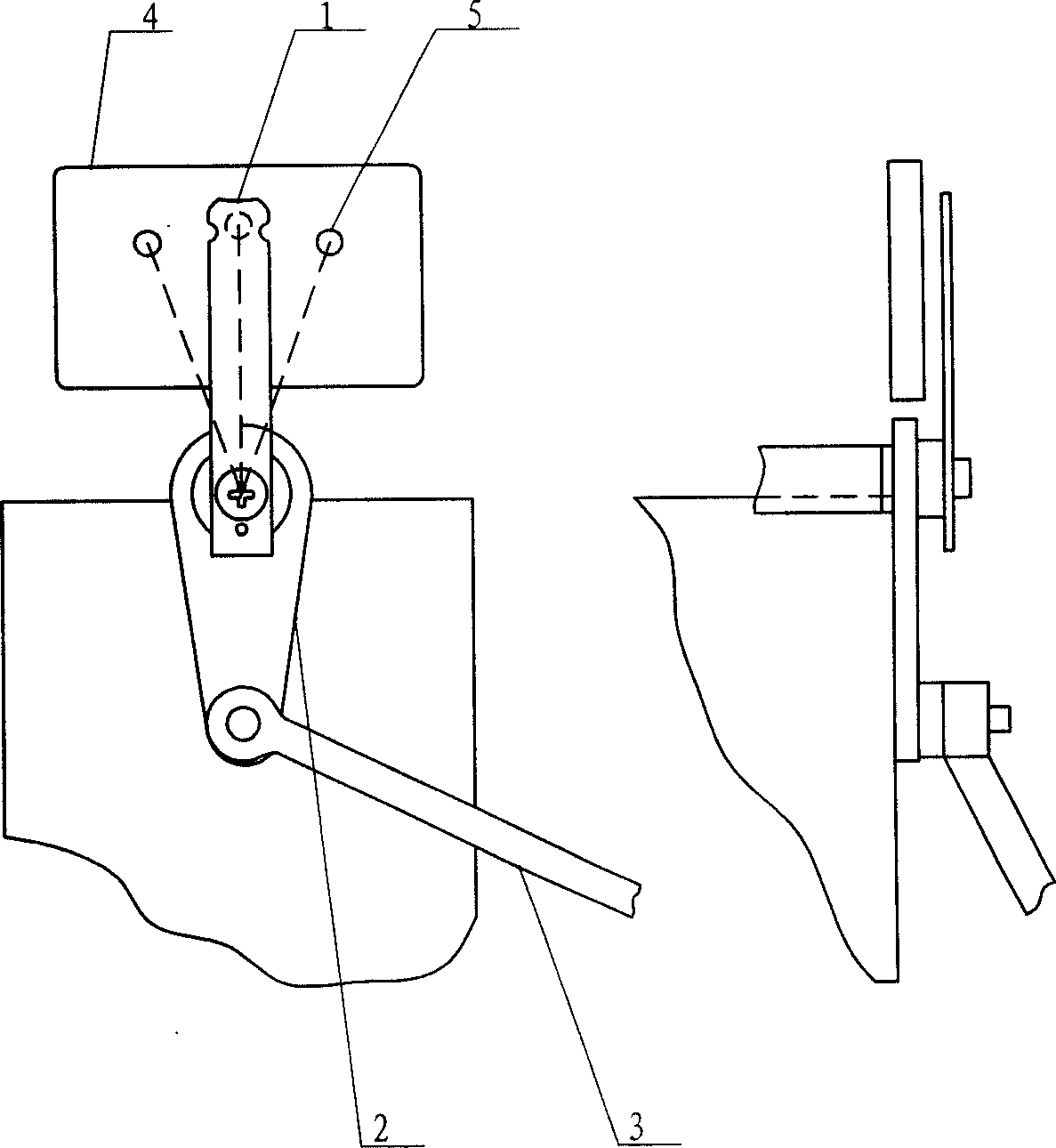

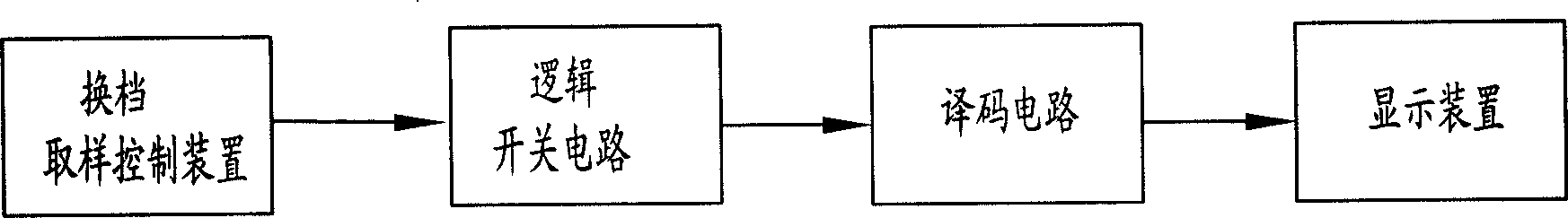

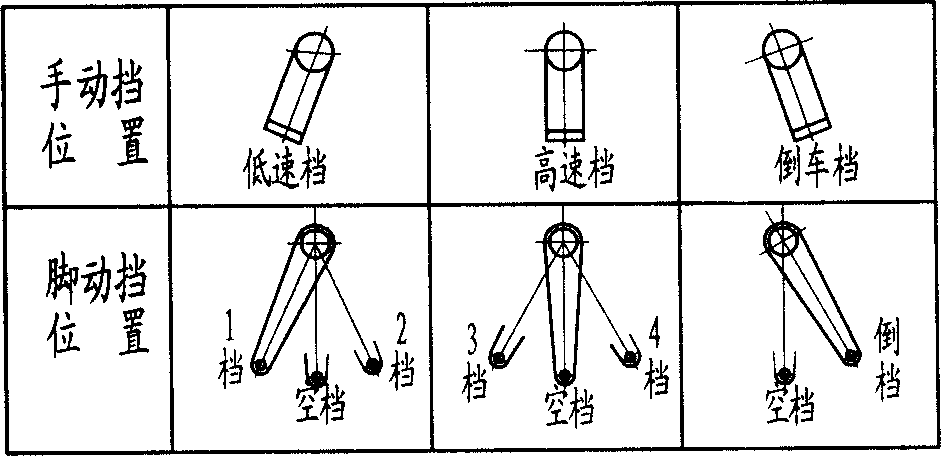

Gearshift display device

InactiveCN1749070AGuaranteed service lifeQuick and accurate responseSignalling/lighting devicesDisplay deviceInductor

The present invention discloses a kind of gearshift display device for showing gearshift clearly. The gearshift display device has combined hand and foot gearshift sampling controller with magnetic inductor to sample the gearshift signal, logic switch circuit, decoder circuit, and display unit to show gearshift in sound and light form. The present invention makes it possible for the driver to know the gearshift clearly, and this is favorable to safety running and prolonged vehicle life. The present invention is suitable for various kinds of motorcycle, prowl car, beach vehicle and other motored vehicles widely.

Owner:GUANGDONG TAYO MOTORCYCLE TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com