Prepressing compensation anti-backlash speed reducer

A technology of reducer and deceleration transmission, which is applied in the direction of mechanical equipment, transmission device parts, gear transmission devices, etc., and can solve the problems that the reducer has no zero-clearance gap compensation function, complicated process, and high processing precision.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

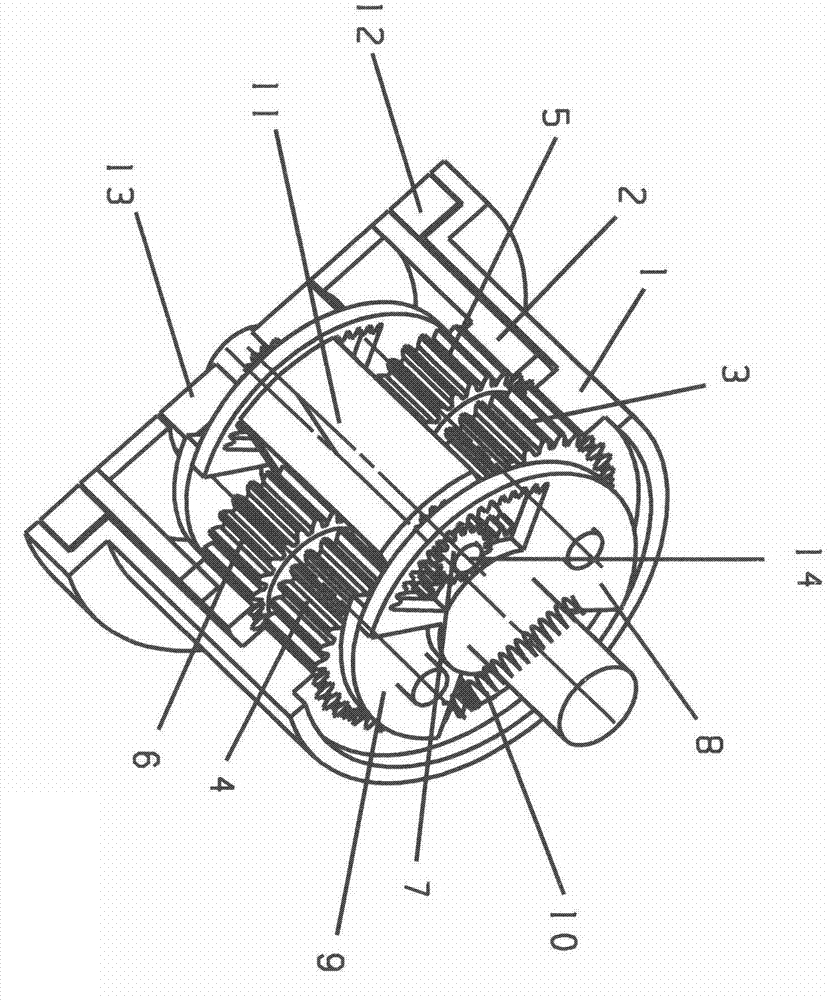

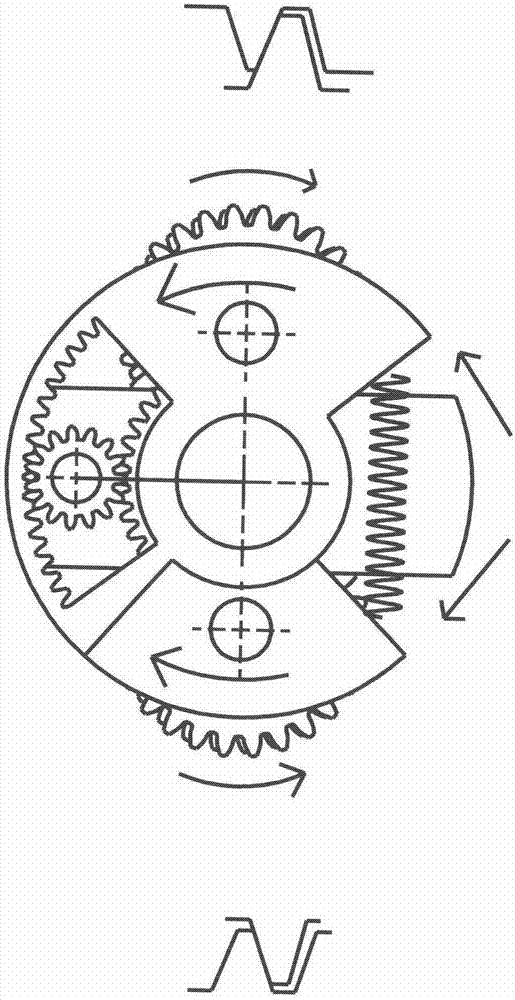

[0009] The structure and principle of the preload compensation anti-backlash reducer will be described below with reference to the accompanying drawings.

[0010] first reference figure 1 Structure, 1 fixed ring gear is fixed to the shell, 2 movable ring gear is fixed to the output end, 3 and 4 are planetary gears meshing with the fixed ring gear, 5 and 6 are planetary gears meshing with the movable ring gear, 3 and 5, 4 and 6 are two groups of gears with different numbers of coaxial fixed teeth. In order to ensure the meshing of each group of tooth shapes, it is necessary to require that the difference in the number of teeth of the outer ring teeth and the planetary teeth is the same, and the number of teeth of the fixed outer ring teeth and the movable outer ring teeth must be different. The speed ratio and direction can be changed by changing the number of teeth of the movable outer ring, fixed outer ring and the difference between the number of outer ring teeth and planet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com