Winding device of amorphous three-dimensional wound core transformer wire foil integrated winding machine and operation method of winding device

A three-dimensional wound iron core and transformer technology, which is used in inductor/transformer/magnet manufacturing, coil manufacturing, electrical components, etc., can solve problems such as easy discovery, high manufacturing and maintenance costs, complex structure, etc. The number of turns can be adjusted to avoid the effect of coil vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

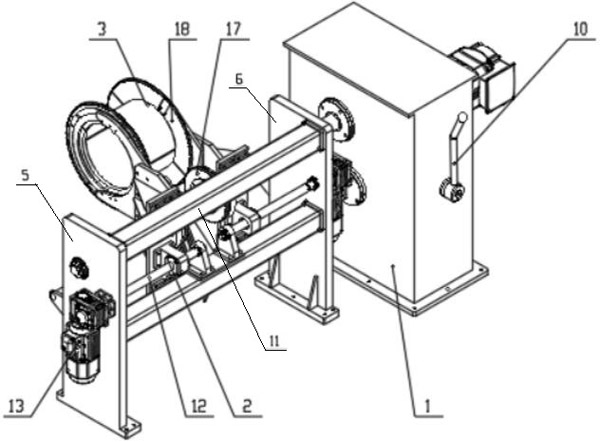

[0061] figure 1The winding device of an amorphous three-dimensional wound core transformer wire and foil integrated winding machine shown includes a main shaft transmission box 1, a winding gear set moving device 2, a winding gear set 3, a coil pressing device 4, and a left wall plate 6 and the right wallboard 5; it is not difficult to see from this figure that the left wallboard 6, the right wallboard 5 and the main shaft transmission box 1 are arranged side by side to set the basic layout for the assembly of the whole device, and the natural winding gear set moving device 2 and the The winding gear set 3 that suspends the coil is placed between the left wallboard 6 and the right wallboard 5; and the coil pressing device 4 is placed between the left wallboard 6 and the right wallboard 5, and is located in the The bottom is used to compress the coil when winding the foil low-voltage coil to prevent the coil from loosening during the winding process. During actual operation, t...

Embodiment 2

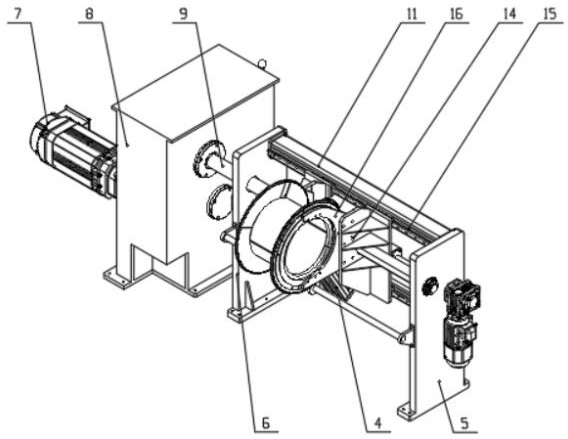

[0064] combined with figure 2 It can be seen that the winding gear set 3 is two groups, arranged symmetrically in the axial direction of the main shaft 9, including a carriage 14, a linear guide rail 15, a support frame 16, a driving gear 17 and a driven gear module 18; two of the linear guide rails 15 are respectively installed on the beam 11 between the left wallboard 6 and the right wallboard 5; the carriage 14 is installed on the linear guide rail 15, and can slide along the length direction of the guide rail on the linear guide rail 15; the end of the support frame 16 is " C”-shaped structure; one end of the support frame 16 is installed on the carriage 14, and the other end is installed with a driven gear module 18, which is meshed with the driving gear 17; the driving gear 17 is set on the main shaft 9, and It can slide axially on the main shaft 9.

[0065] And the winding gear group moving device 2 is installed on the crossbeam 11; This winding gear group moving devi...

Embodiment 3

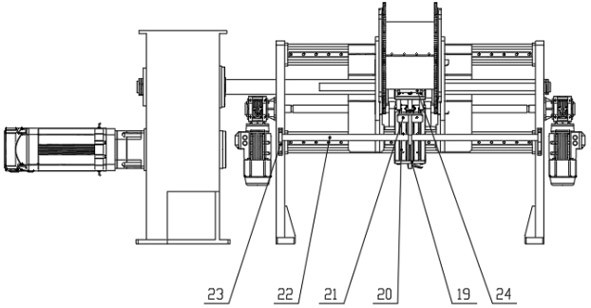

[0068] combined with image 3 It can be seen that the coil pressing device 4 is installed between the left wallboard 6 and the right wallboard 5, and is located at the lower part of the coil. The coil pressing device 4 consists of a lower support 19, a cylinder 20, an upper support 21, a guide rod 22, a The rod installation support 23 and the pressing wheel 24 are composed; one end of the lower support 19 is connected with the linear guide rail 15 on the beam 11, and the other end is connected with the rear end of the cylinder 20; one end of the upper support 21 is connected with the front end of the cylinder 20, and the other end is connected with the guide rod 22 are hinged; the cylinder 20 ends are equipped with pinch wheels 24; Stretch down.

[0069] Such as Figure 4 As shown, when working, the iron core is fixed to a fixed position, the driven gear module 18 is installed on the iron core column, and the pair of winding gear sets 3 are adjusted to a suitable width by ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com