Fault predication device of six-axis multi-joint industrial robot

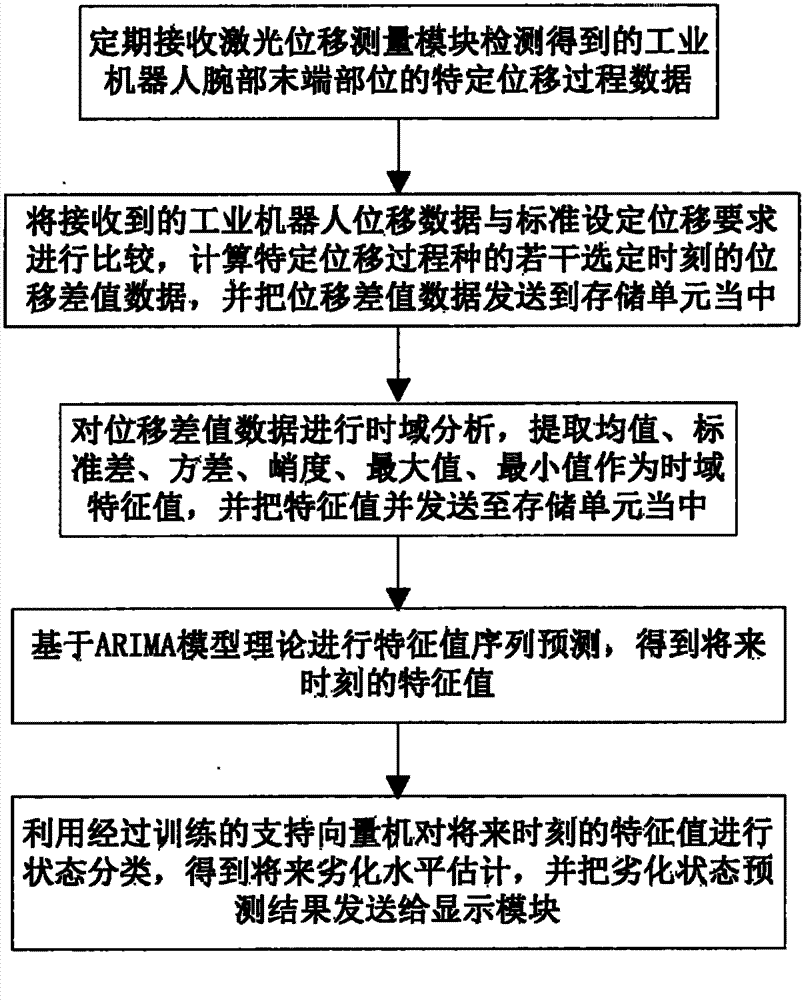

A technology for industrial robots and fault prediction, applied in manipulators, manufacturing tools, etc., can solve the problems of robot performance degradation information unable to give reasonable state prediction, vibration signal interference data volume, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

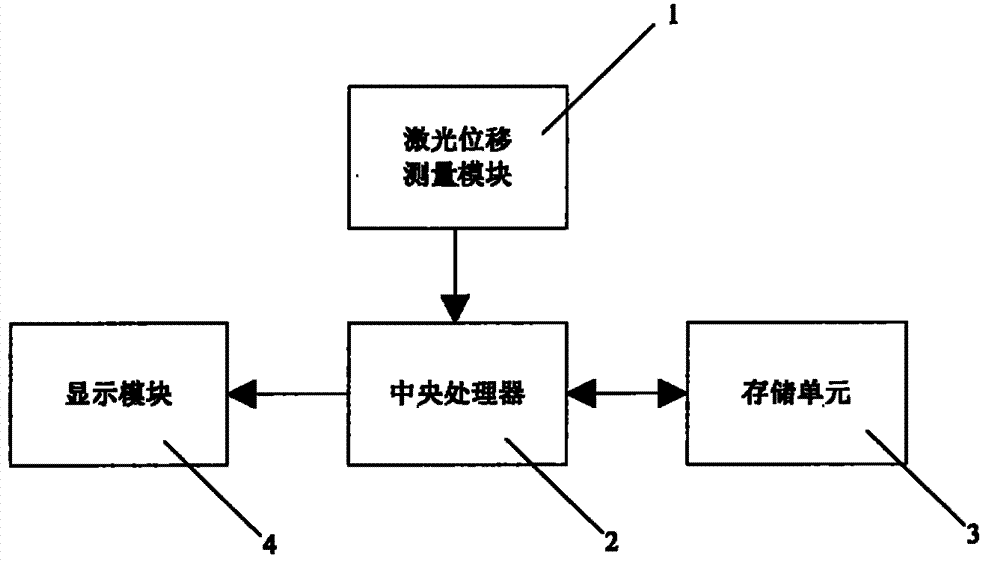

[0021] Such as figure 1 As shown, the present invention includes four components: a laser displacement measurement module 1 , a central processing unit 2 , a storage unit 3 and a display module 4 . This specific embodiment is aimed at the fault prediction application of the six-axis multi-joint industrial robot IRB1410 reducer wear of the ABB company, and the robot is used for welding operations. Therefore, the laser displacement measurement module 1 of the present invention adopts the one-dimensional laser displacement sensor M18 of Lyence Company, and the central processing unit 2 and storage unit 3 of the present invention select Advantech industrial computer IPC-510, and the display module 4 is a DELL brand display . Advantech industrial computer IPC-510 runs windows XP system.

[0022] The laser displacement measurement module 1 of the present invention is installed and fixed within the working range of the industrial robot, but does not affect the normal process action...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com