Large tubular structure piece platform scribing method

A technology for large cylinders and structural parts, which is applied in the field of platform marking of large cylindrical structural parts, can solve the problems of inability to operate on the installation site, and it is difficult to meet the high-precision installation requirements of large cylindrical structural parts, so as to reduce the difficulty of construction. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

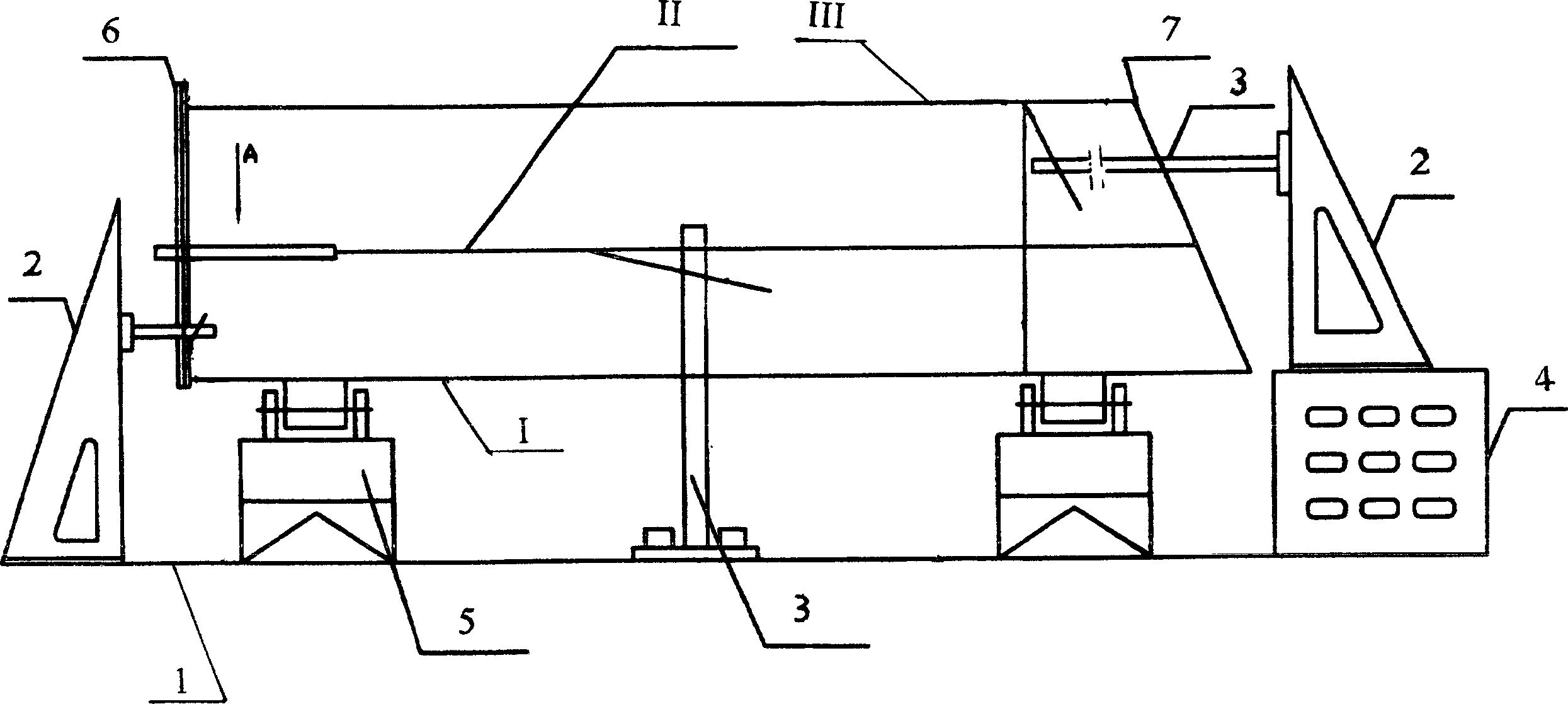

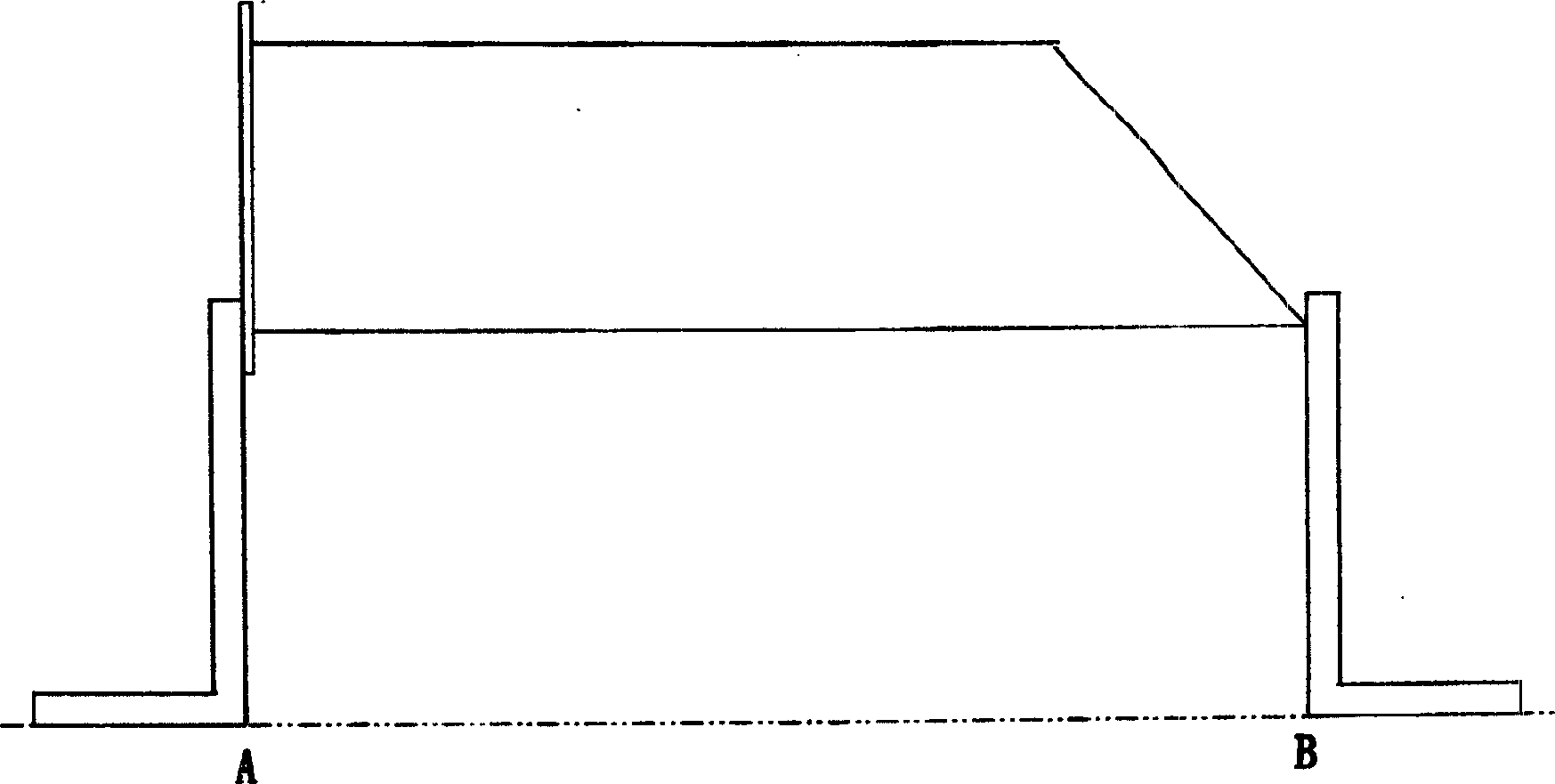

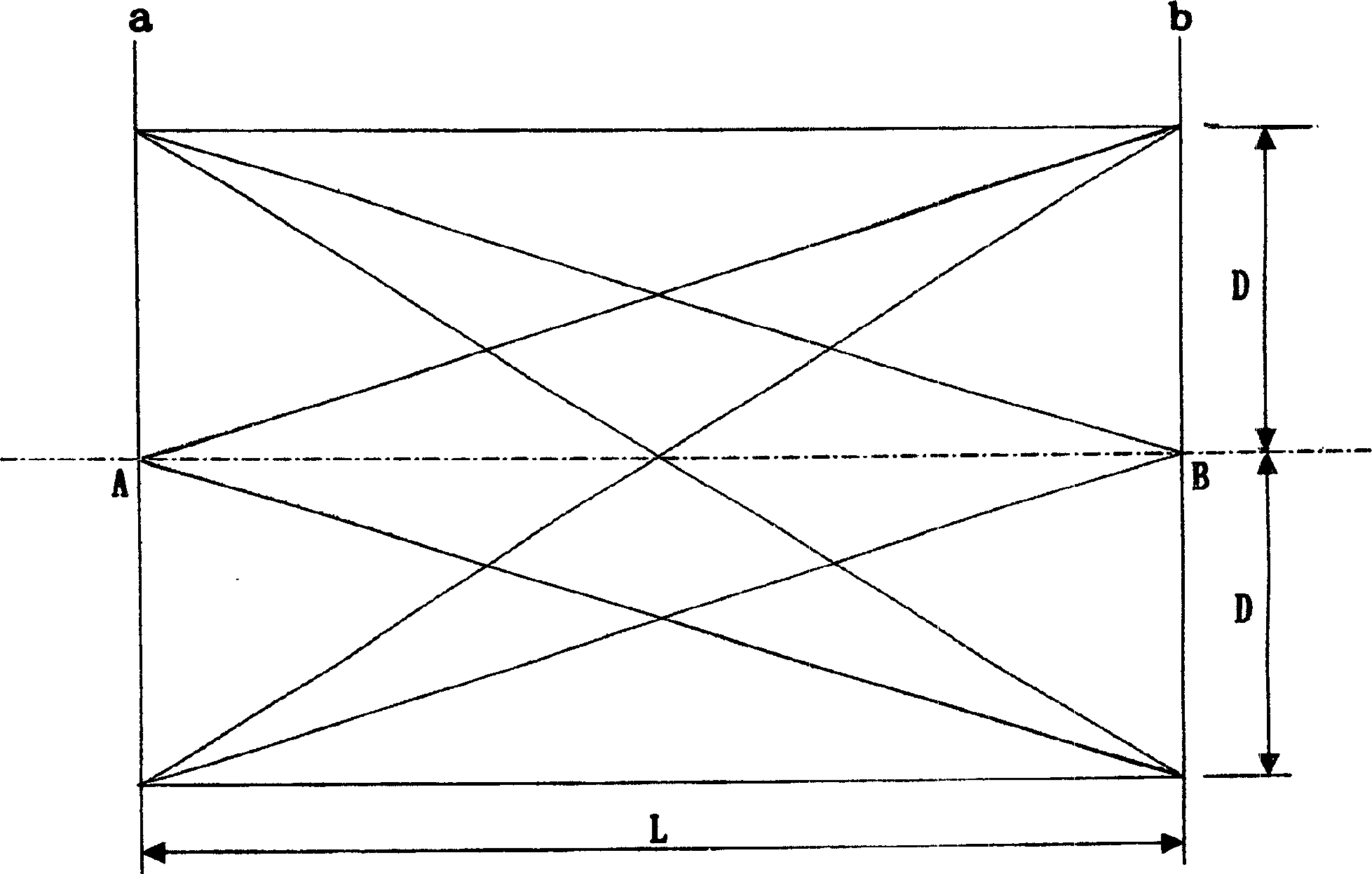

[0022] This example is a typical large-scale cylindrical structural member, which is divided into an outer cylinder and an inner cylinder. For the structure of the outer cylinder, see figure 1 , the inner cylinder structure see Figure 7 .

[0023] Platform marking tool for large cylindrical structural members, figure 1 As shown, the platform 1 is 16200×4500mm, and the flatness is less than 0.2mm. The marking plate 3 is modified to increase the weight of the base of the marking plate, increase the height of the pillar, and install and weld two handles at the bottom of the pillar. The purpose is to Avoid shaking when marking as much as possible. Bending plate 2 and square box 4 are purchased by required size. Roller wheel 5 is a self-made special tool.

[0024] The method for scribing lines on a platform of a large cylindrical structural member includes the following process steps:

[0025] 1. Place the rotary tire 5 on the platform 1, adjust the distance between the two rot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com