Patents

Literature

278 results about "Pressure work" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

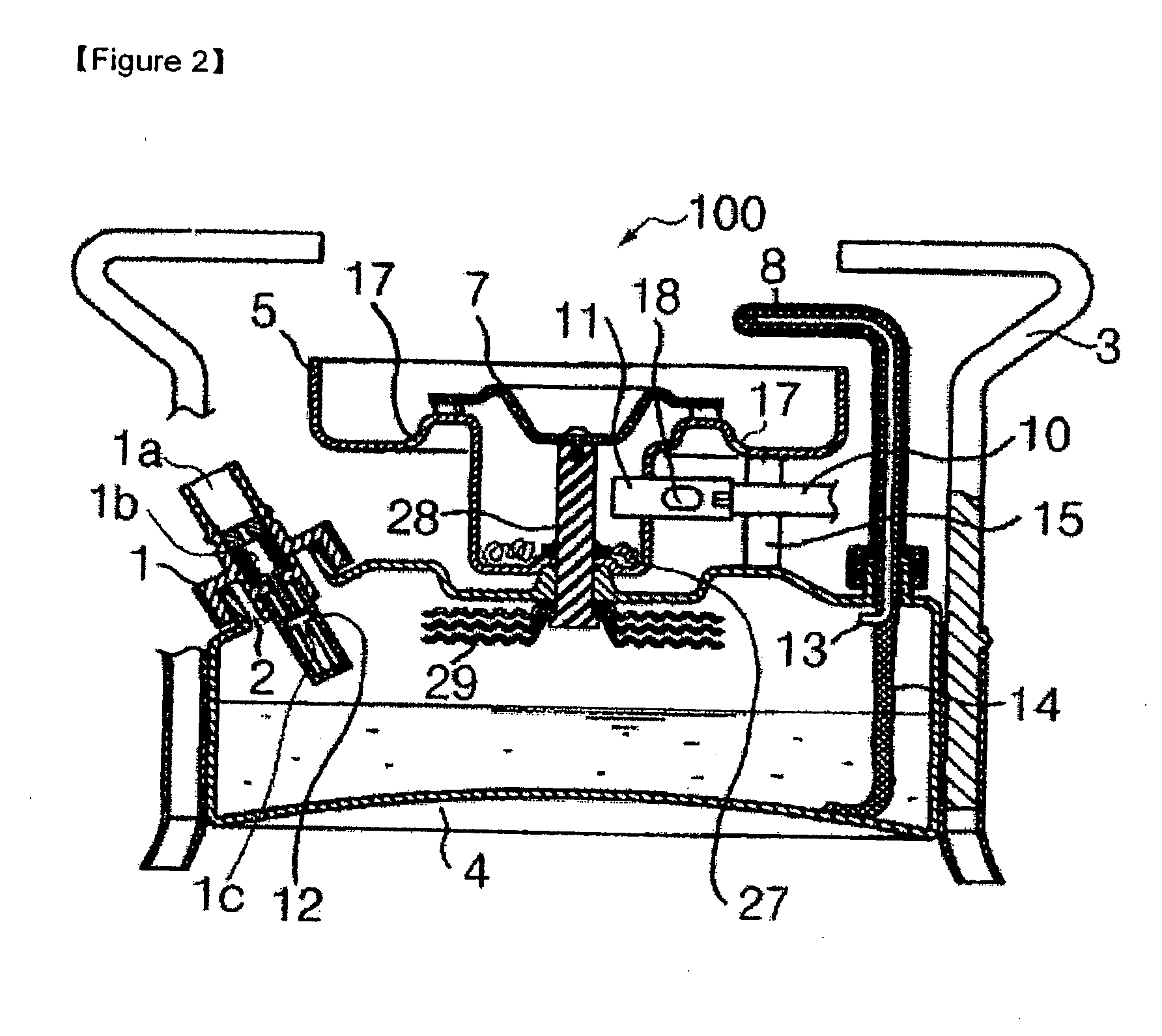

Cooking utensil

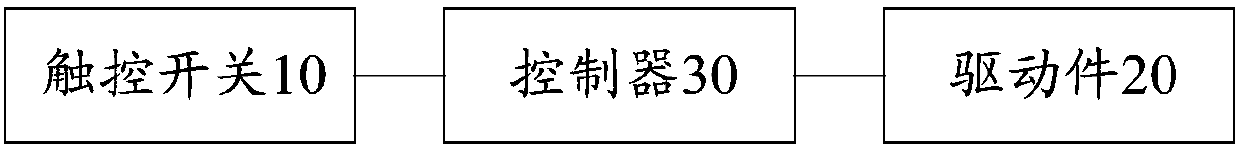

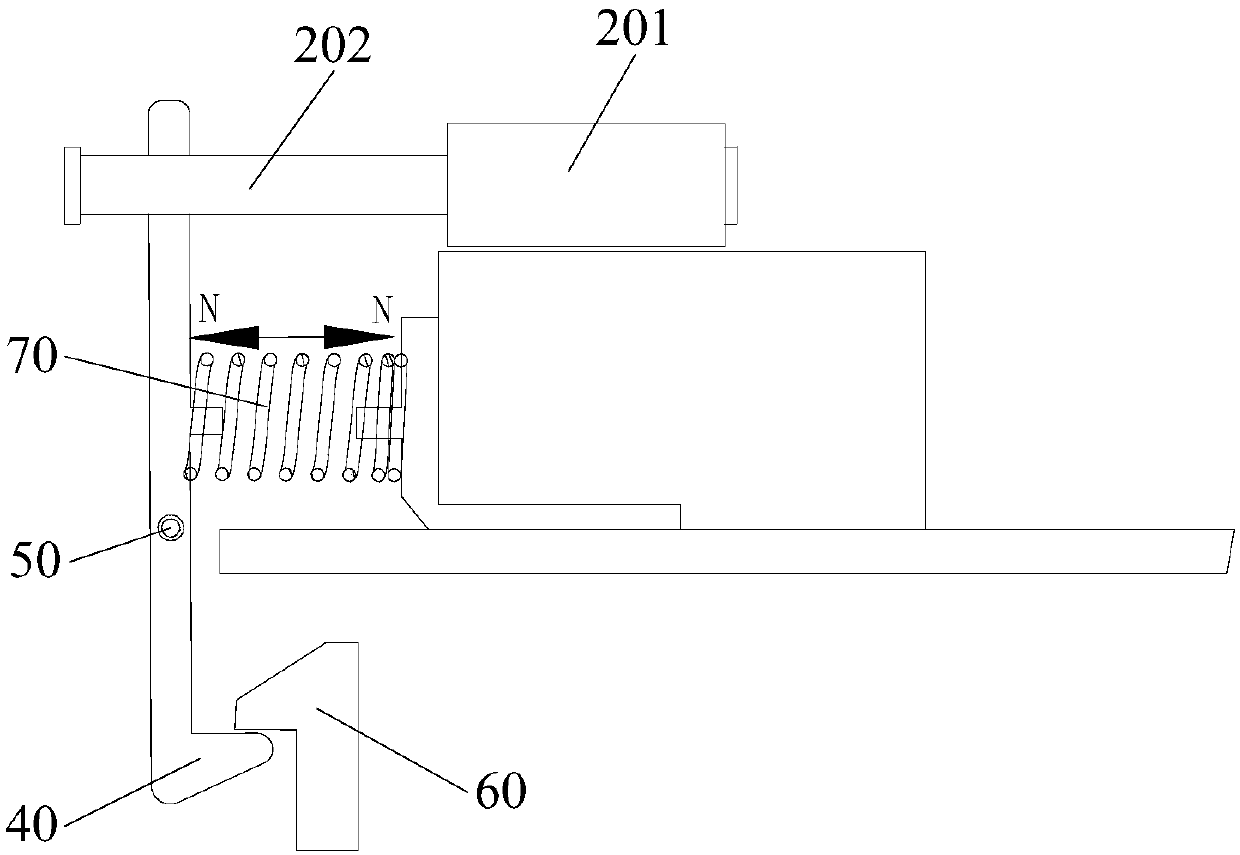

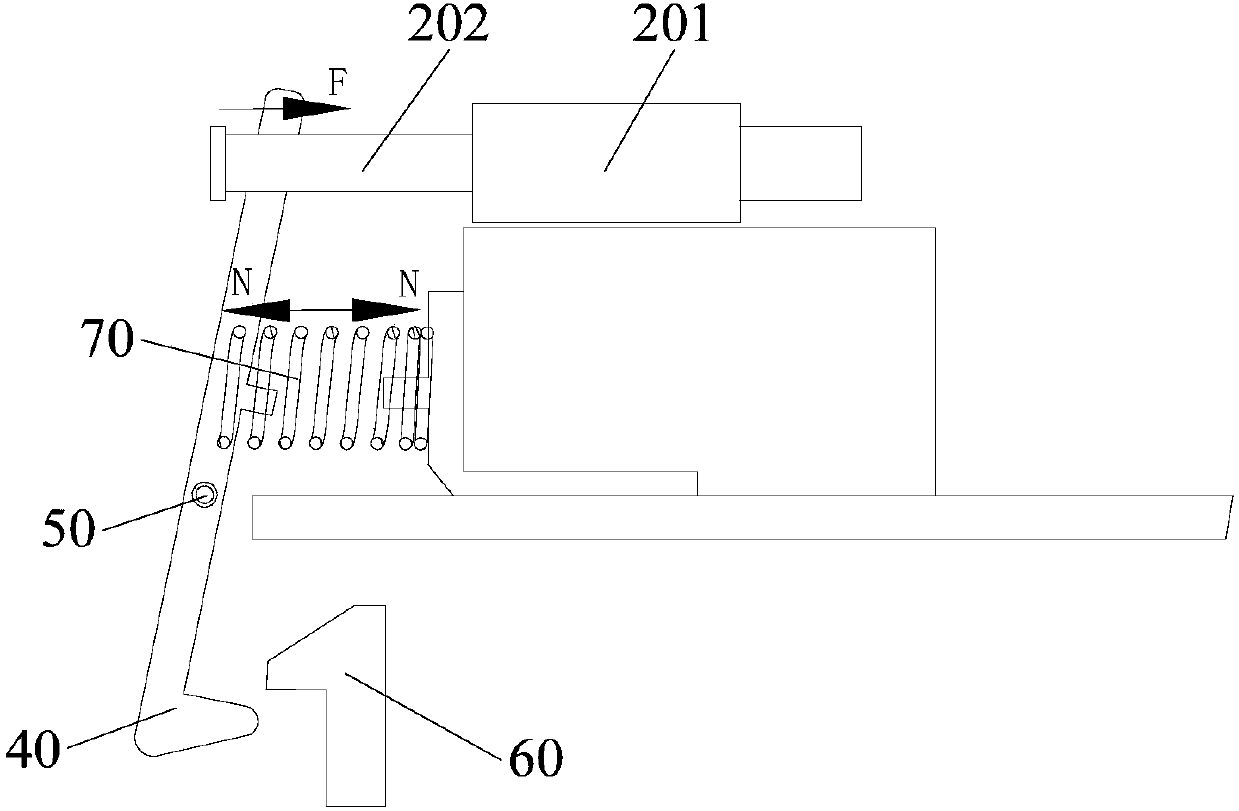

The invention provides a cooking utensil which comprises a touch switch, a driving part and a controller. The touch switch is arranged on the body or a cover body of the cooking utensil and used for sending an uncovering signal. The driving part is used for driving the cover body to open. The controller is electrically connected with the touch switch and the driving part and used for receiving theuncovering signal and controlling the driving part to move so as to open the cover body. When a user touches the touch switch, the driving part is driven through the controller for uncovering, a locking structure is loosened and breaks away from a fastened position, accordingly automatic uncovering is achieved, and an uncovering button structure conventionally exposed on the appearance face of the product is omitted in the uncovering way, so that a whole interface of the product is simpler. In addition, in this uncovering way, an uncovering operation can be selected or not according to the working environments in the cooking utensil, for example, pressure intensity, the cooking utensil has higher safety, and especially the risk is prevented that the cooking utensil is forcedly uncovered due to misoperation of a user during under-pressure work and accordingly explodes and scalds a user.

Owner:FOSHAN SHUNDE MIDEA ELECTRICAL HEATING APPLIANCES MFG CO LTD

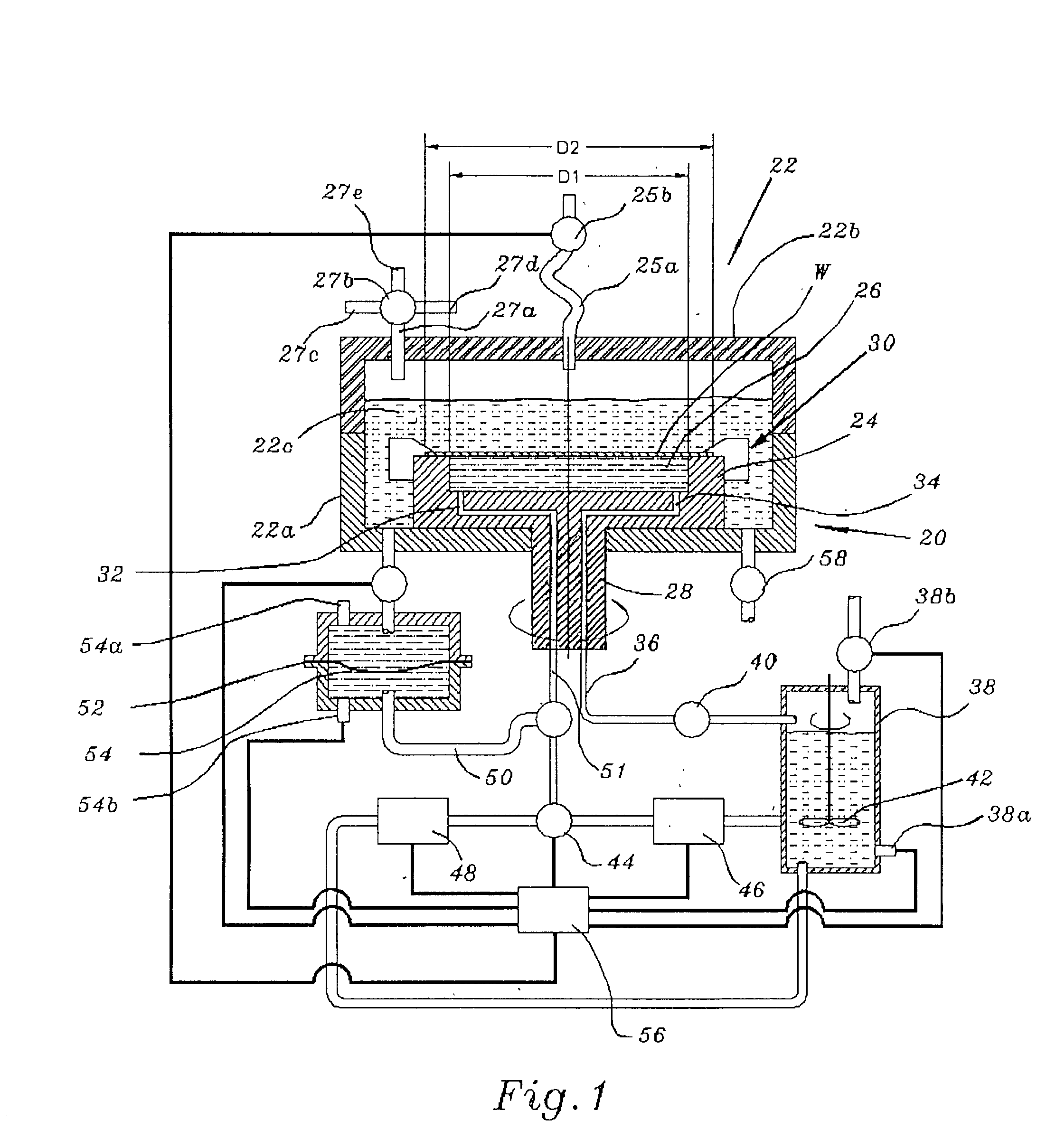

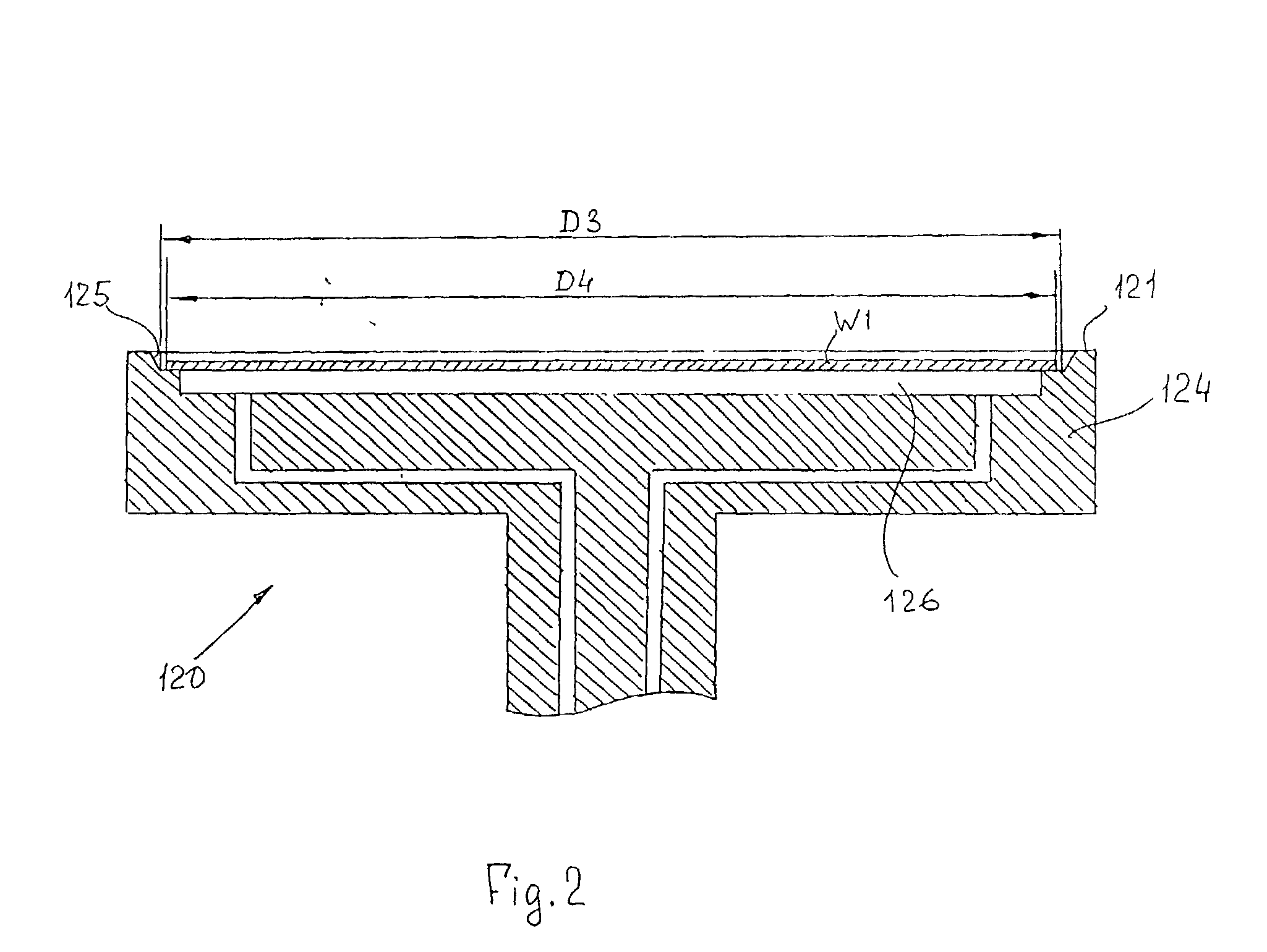

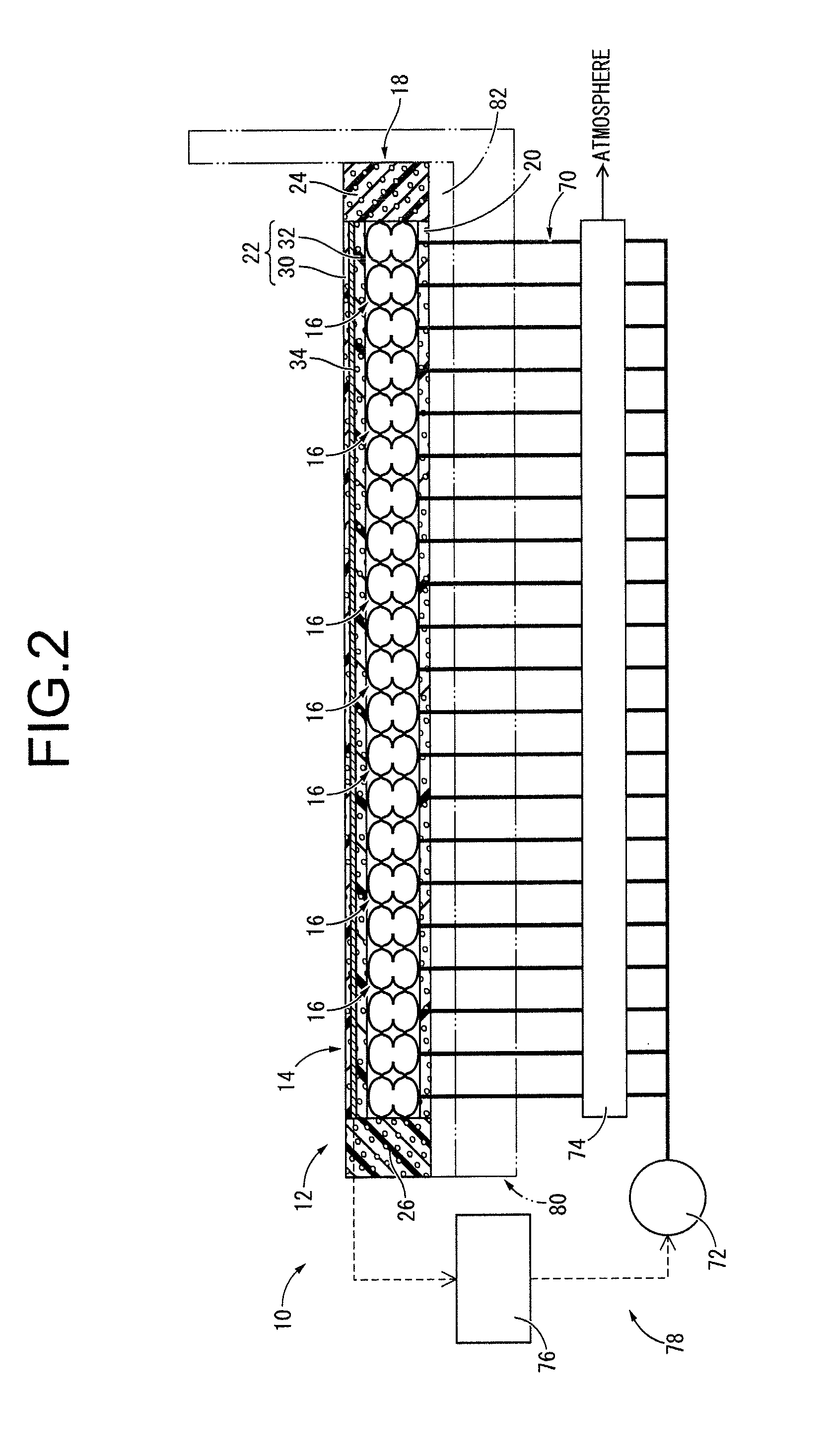

Temperature-controlled substrate holder for processing in fluids

InactiveUS20040084143A1Quick changeLiquid surface applicatorsDrying gas arrangementsTemperature controlFirst Fill

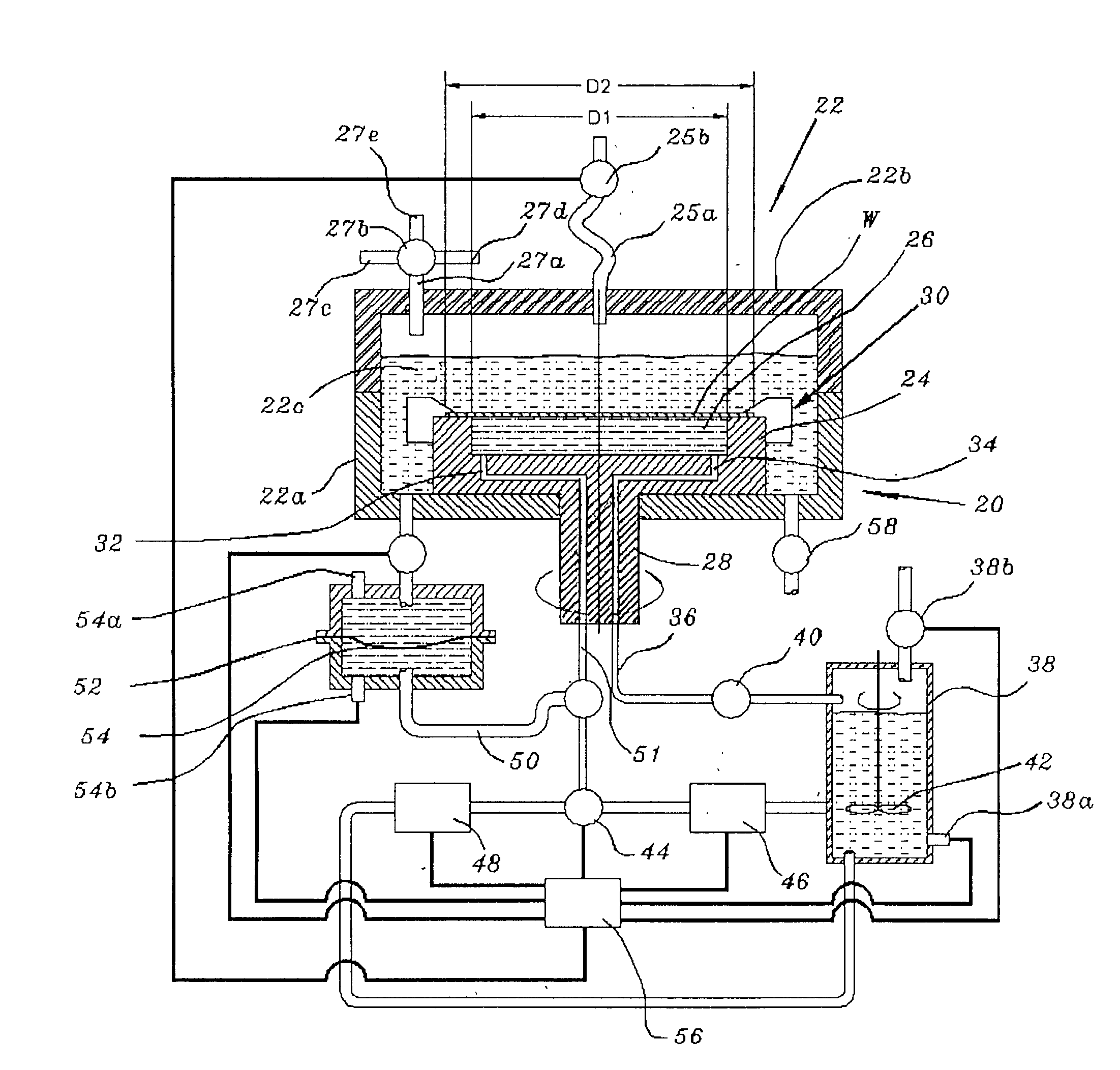

A substrate holder has a disk-like body with a central recess having diameter smaller than the diameter of the substrate placed onto the upper surface of the holder. The substrate can be clamped in place by the clamps of the edge-grip mechanism or placed into a seat without the use of clamps. In both cases, the substrate forms a partial wall that confines the heating / cooling recess or chamber. The aforementioned recess is filled with a cooling or heating liquid (depending on the mode of metal deposition) selectively supplied from a liquid heating or cooling system. In order to ensure in the working chamber above the substrate a pressure slightly higher than the pressure in the cooling / heating recess, the working chamber is first filled with the working solution under the atmospheric pressure, and then the recess is filled with a heating or cooling liquid with simultaneous increase of pressure in the working chamber to a level slightly exceeding the pressure in the recess. The substrate holder of the invention provides direct heat / cool-exchange between the heating / cooling medium and the substrate and allows instantaneous change of temperature of the heating / cooling liquid.

Owner:LAM RES CORP

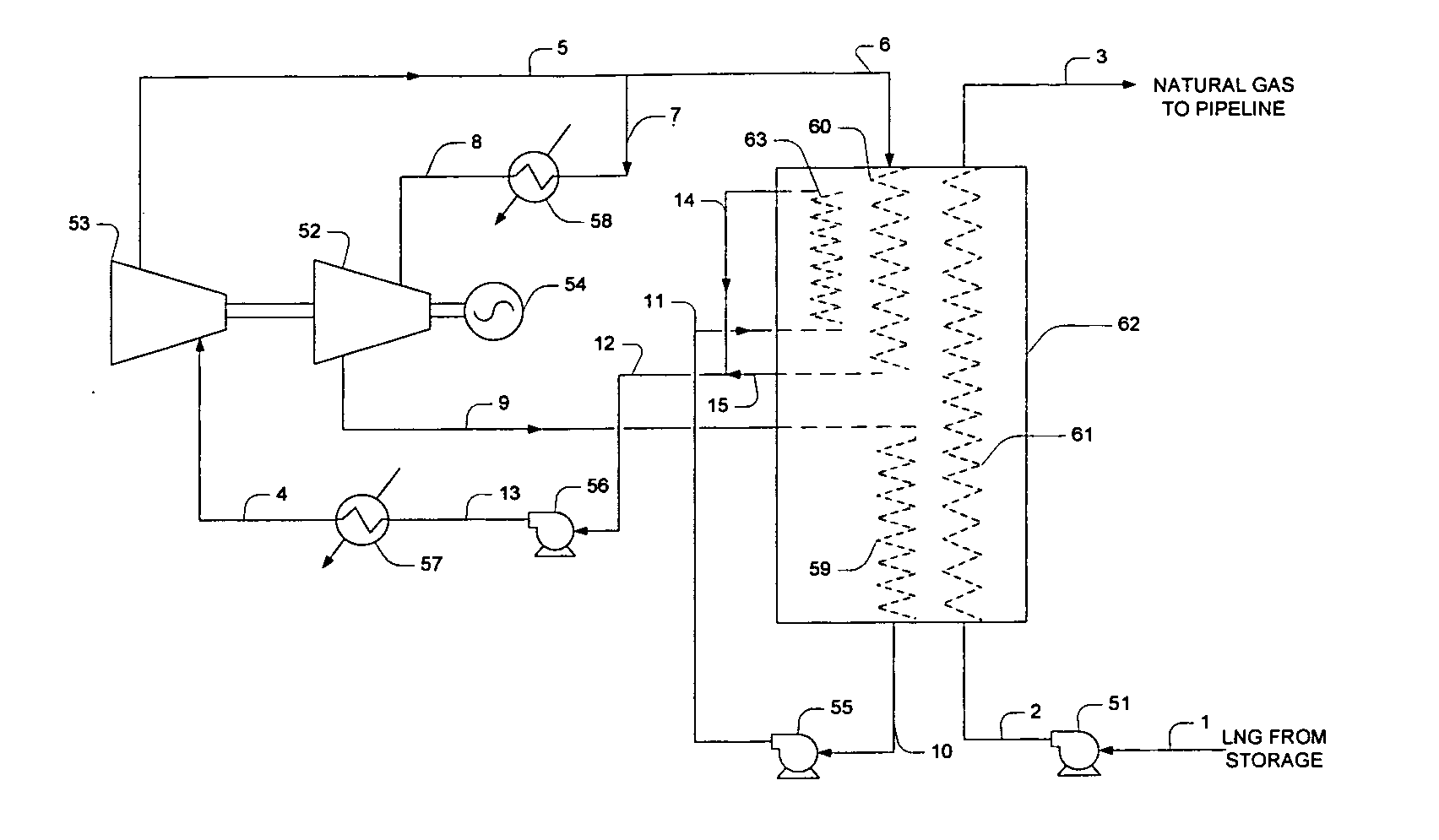

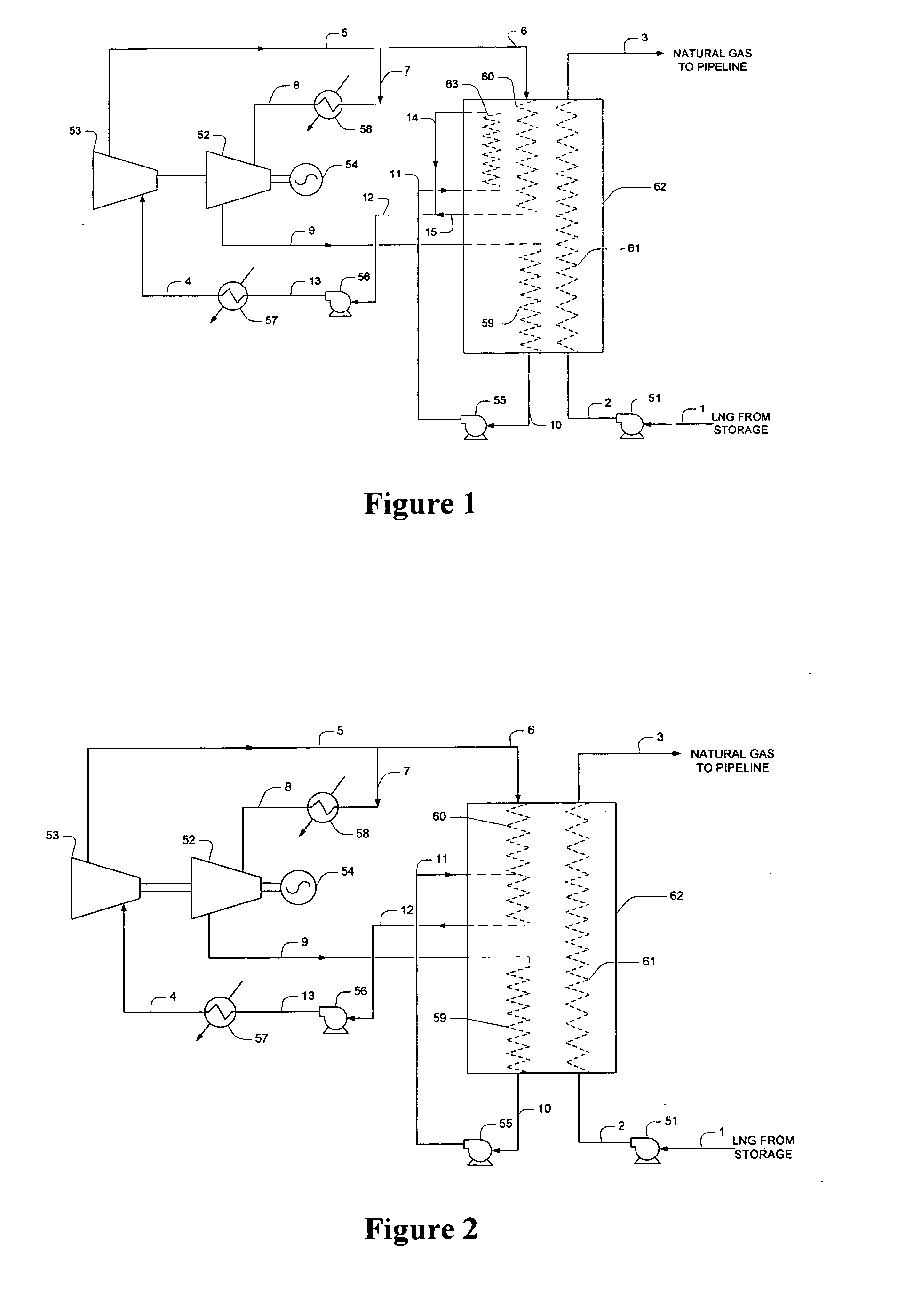

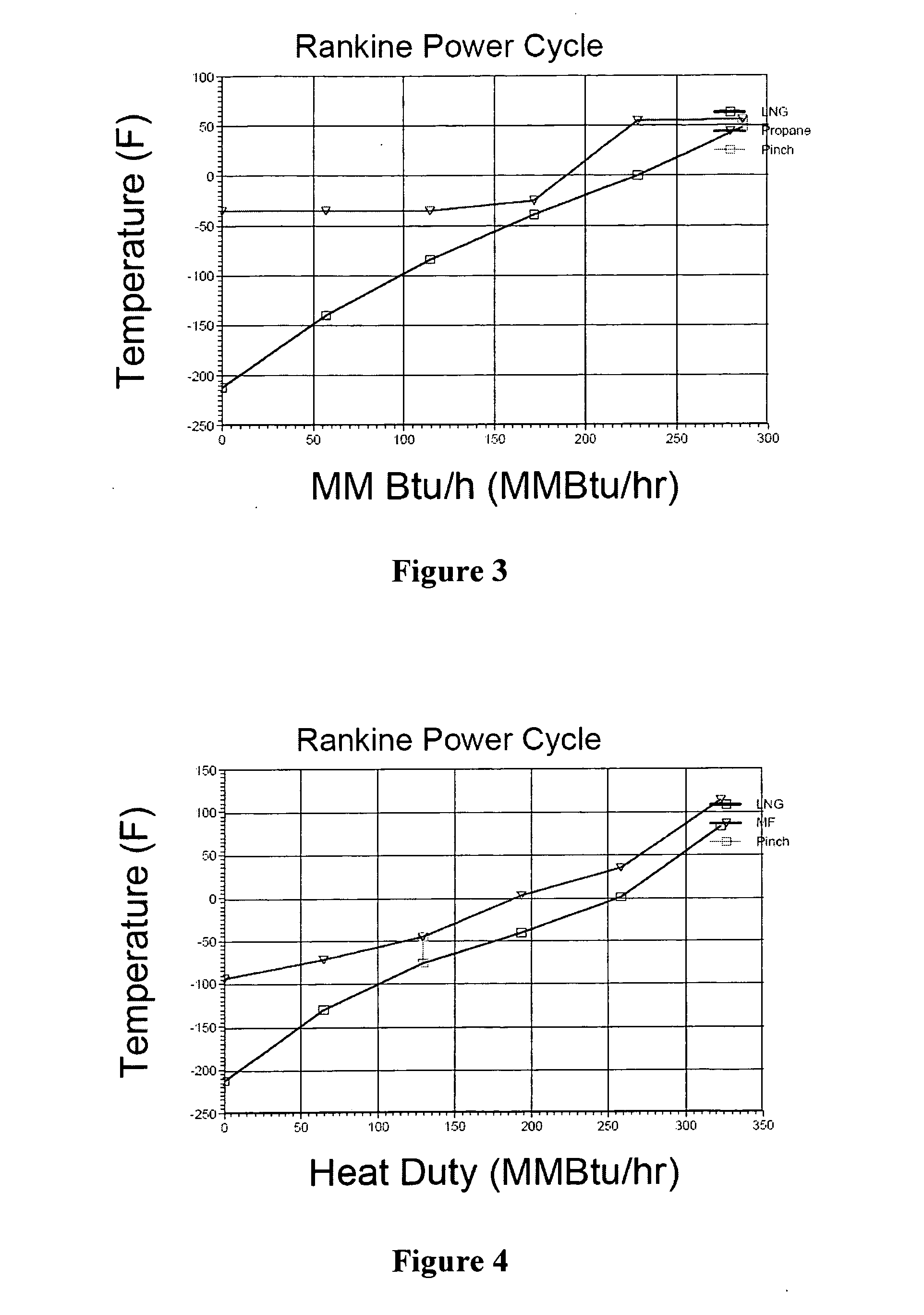

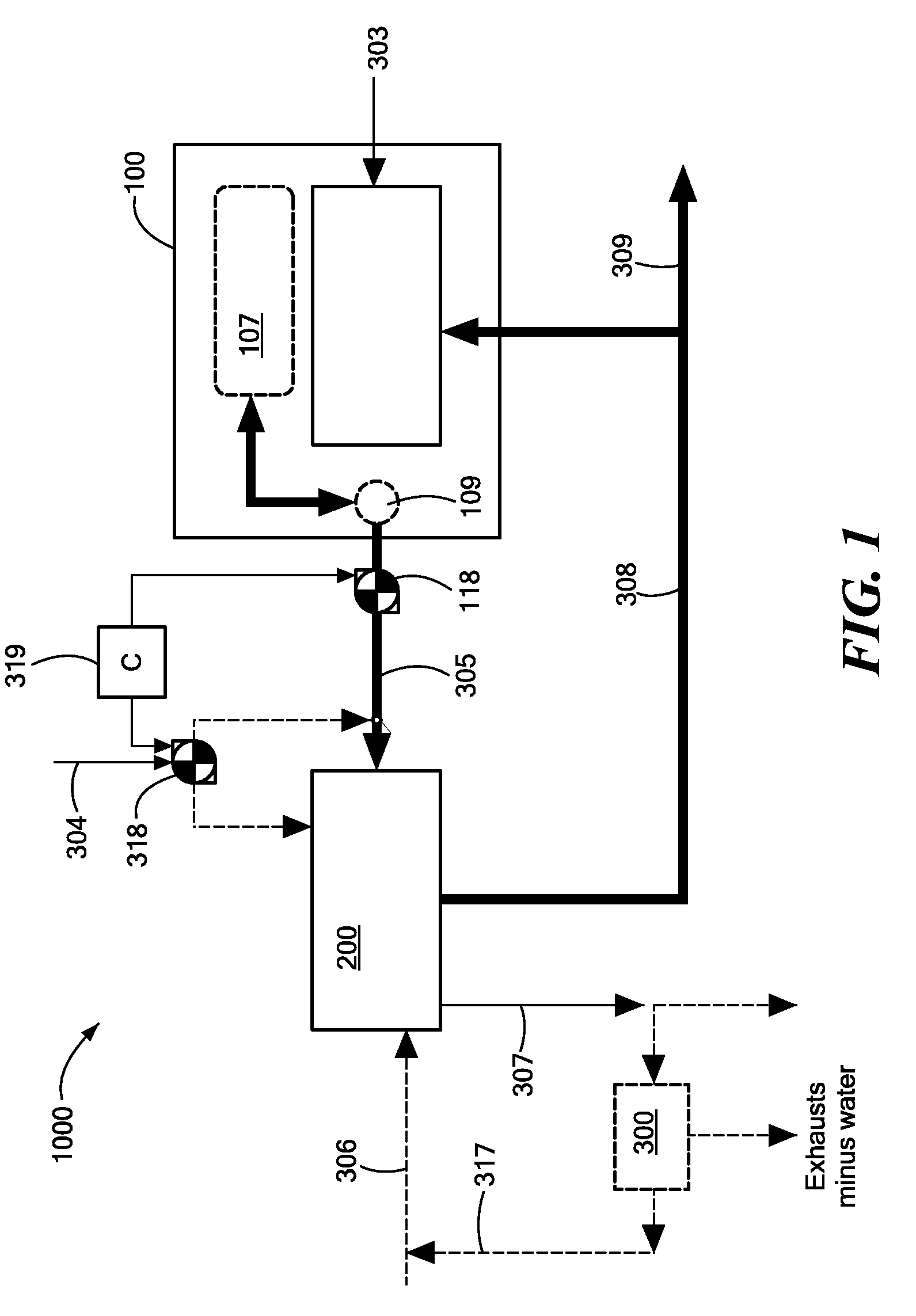

LNG Regasification And Power Generation

LNG is regasified with concurrent power production in systems and methods where the refrigeration content of the LNG condenses a low pressure working fluid vapor and in which the combined refrigeration content of the warmed LNG and low pressure working fluid condensate condenses an intermediate pressure working fluid vapor.

Owner:FLUOR TECH CORP

Deacidifying method for paper cultural relics

InactiveCN102242530AAvoid damageDeacidification achievedOld paper after-treatmentInfusion methodNitrogen

The invention discloses a de-acidifying method for paper cultural relics, which comprises the following steps of: 1) flatly spreading acidified paper cultural relics on a flat board; 2) injecting an ion source reagent including OH- and Ca<2+> into a bubbler, and importing a mixed gas of helium gas and nitrogen to serve as a carrier gas, and transmitting the ion source reagent to a plasma spray gun; 3) turning on a plasma excitation pulse power source, forming ion flames containing OH- and Ca<2+> at the muzzle of the plasma spray gun; and spraying the ion flames to scan the surface of the flattened paper cultural relics to perform deacidifying processing. In the method disclosed by the invention, a plasma discharging form is adopted under normal temperature and normal pressure work conditions, thereby complex and expensive vacuum equipment are avoided being used, and damages of an aqueous solution infusion method to a paper body are avoided; and the method disclosed by the invention can be used for realizing rapid large-area deacidifying processing and has the advantages of uniformity for de-acidification, stable process, and suitability for industrialized large-scale production.

Owner:ZHEJIANG UNIV

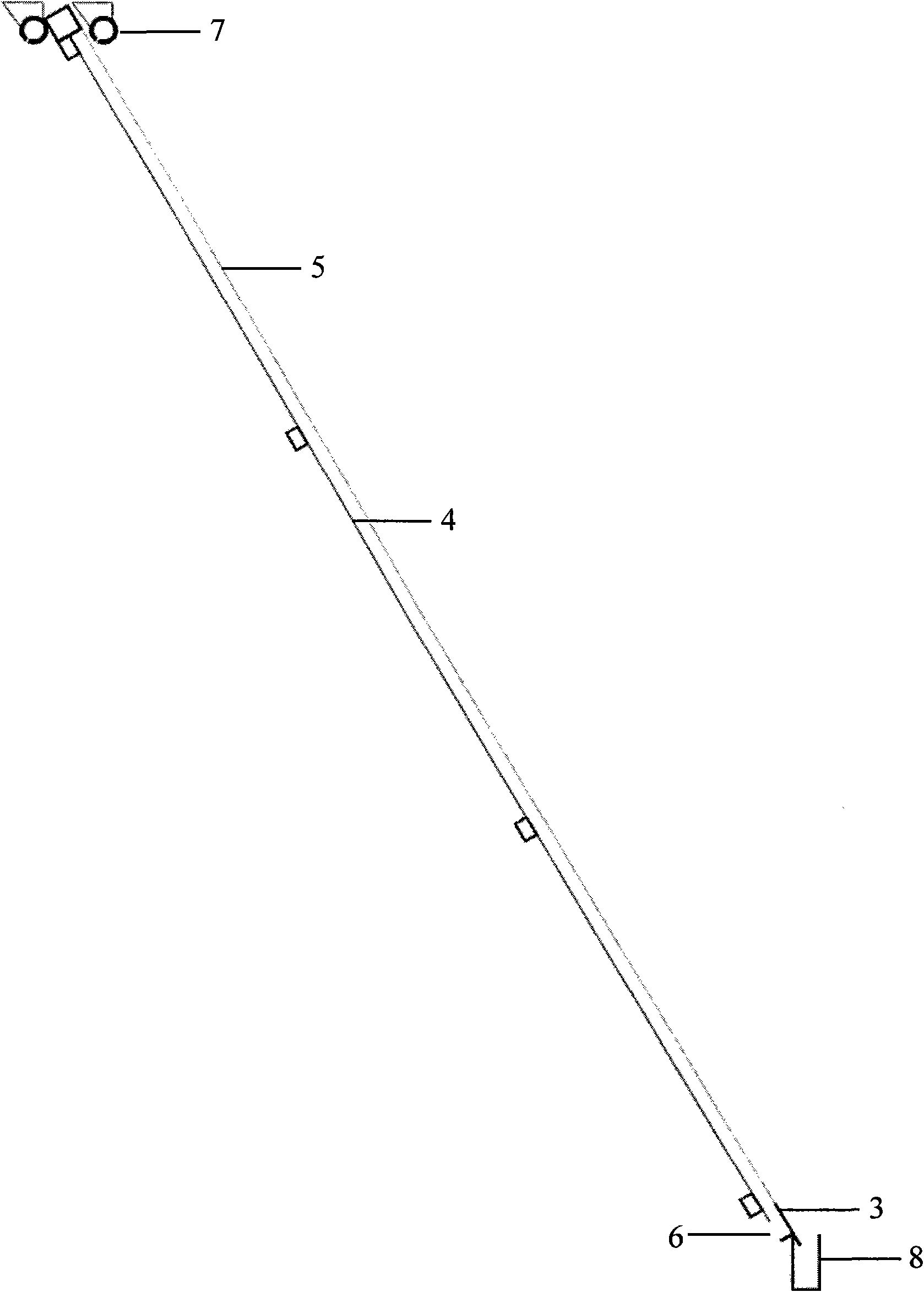

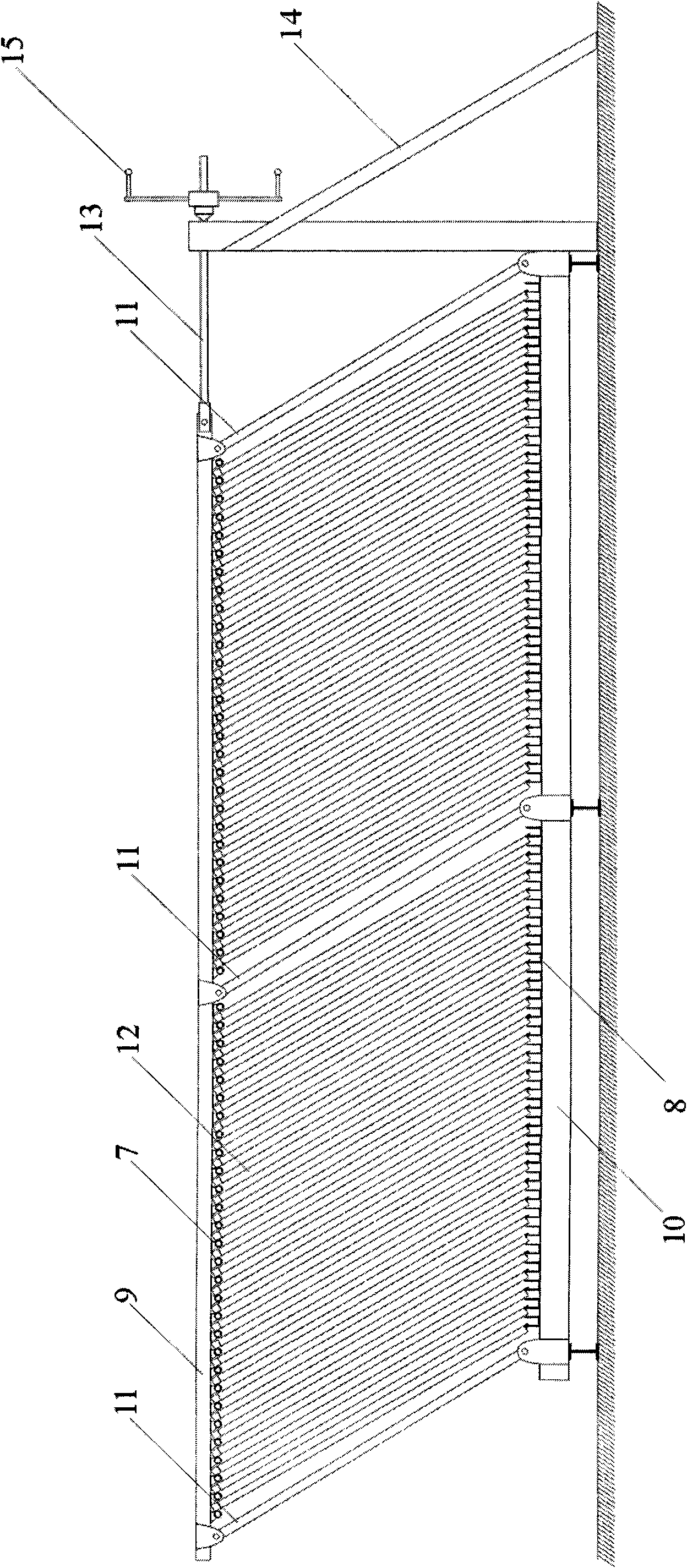

Branchial filter

InactiveCN101537276ARealize self-flow separationImprove filtering effectStationary filtering element filtersEngineeringAlgae

The invention relates to a high-densification slope filter which is developed by imitating the principle that a chub branchial filters hydroplankton. A group of (100 or more) unit hydra-screens with the thickness of 40mm are densely arranged on a support frame which can adjust inclination degree with a center distance of 100mm, the surface of each unit hydra-screen sprays a stock solution by a spraying pipe arranged on the top of each unit hydra-screen, and a small liquid collection groove arranged on the bottom of each unit hydra-screen collects concentrated solutions on the screen to form a branchial filtering unit; two branchial filtering units are placed in parallel, a liquid collection groove arranged on the lower middle part of a gap between the two branchial filtering units collects concentrated solution from both sides of the small liquid collection groove positioned below each unit hydra-screen, and a main liquid feeding pipe positioned on the upper part of the gap supplies original liquid to the spraying pipe on the top of each unit hydra-screen at the two sides through branched pipes so as to form a branchial filter. The branchial filter works depending on the pressure (about 20kpa), the concentrated solution on the screen is automatically collected through the small liquid collection groove and a total liquid collection groove, then filtered by the screen and finally discharged to the ground. The invention can be used for the primary concentration and filtering of suspending liquid and especially suitable for the primary filtering of a ship borne algae collecting system.

Owner:NANJING INST OF GEOGRAPHY & LIMNOLOGY

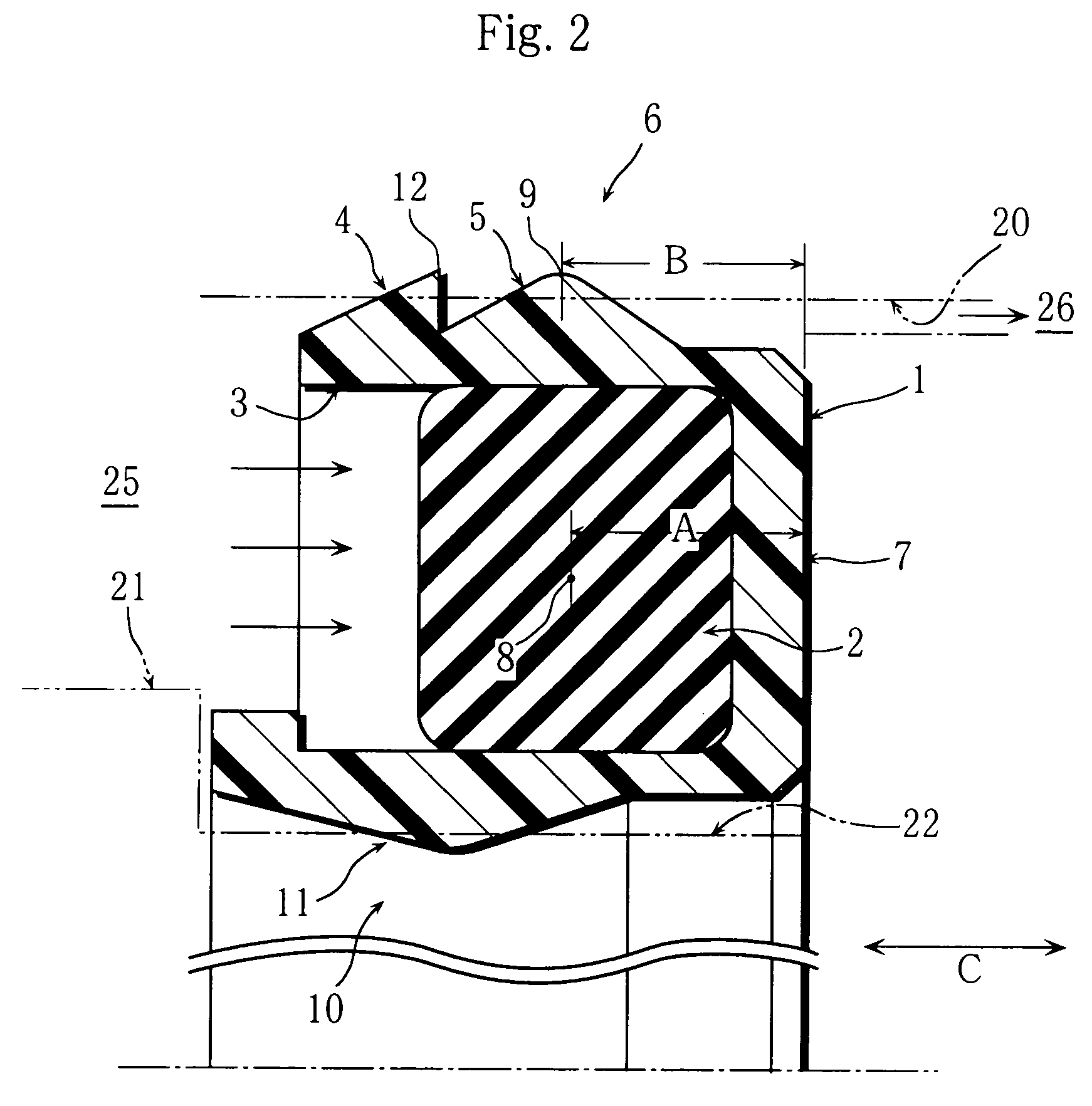

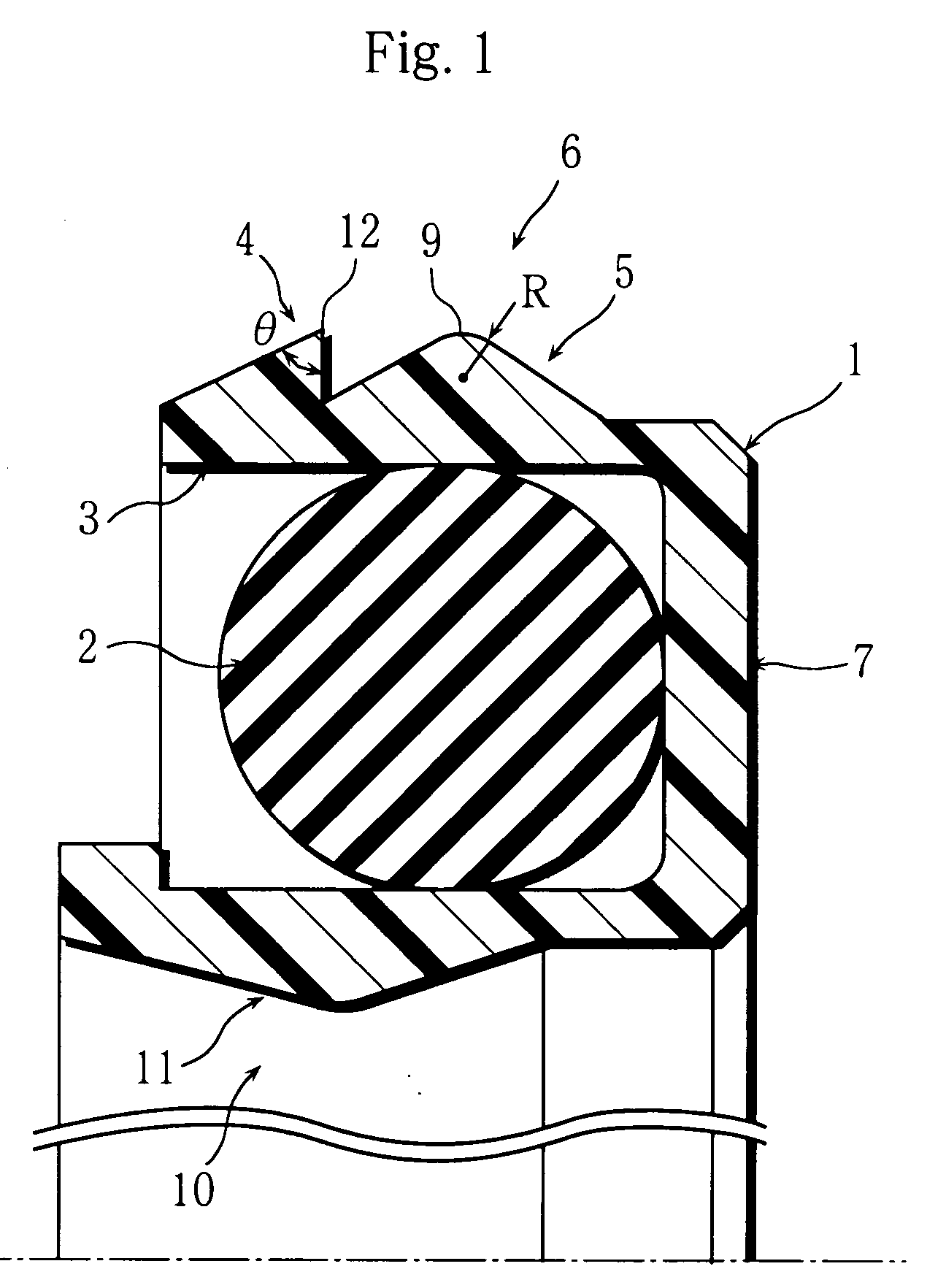

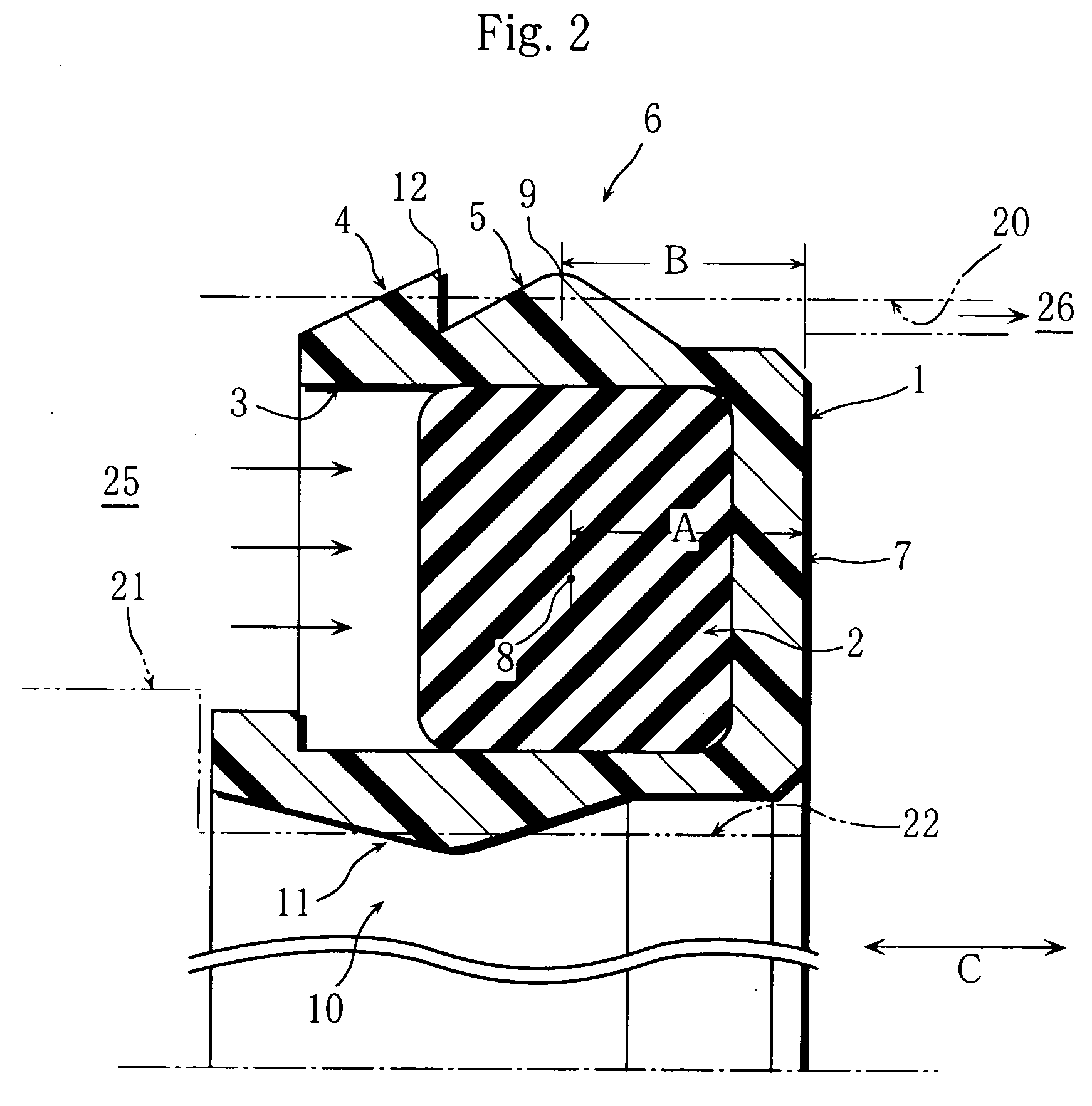

Sealing material

Owner:MITSUBISHI CABLE IND LTD

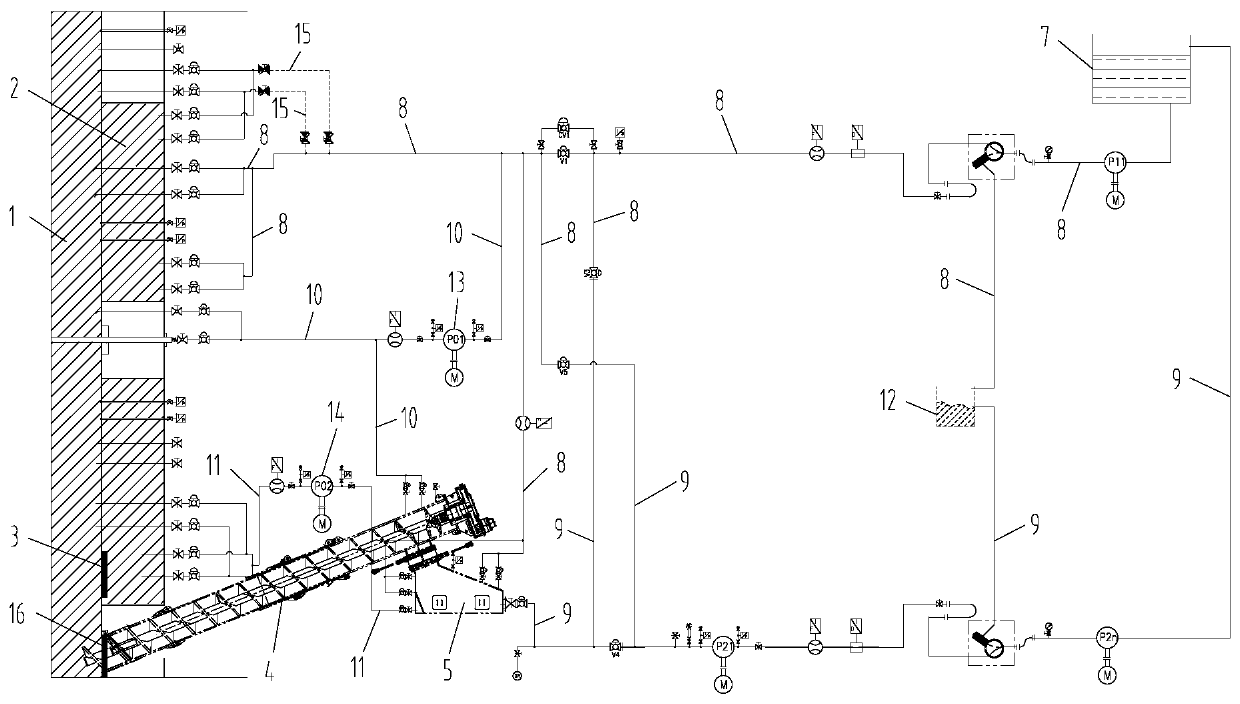

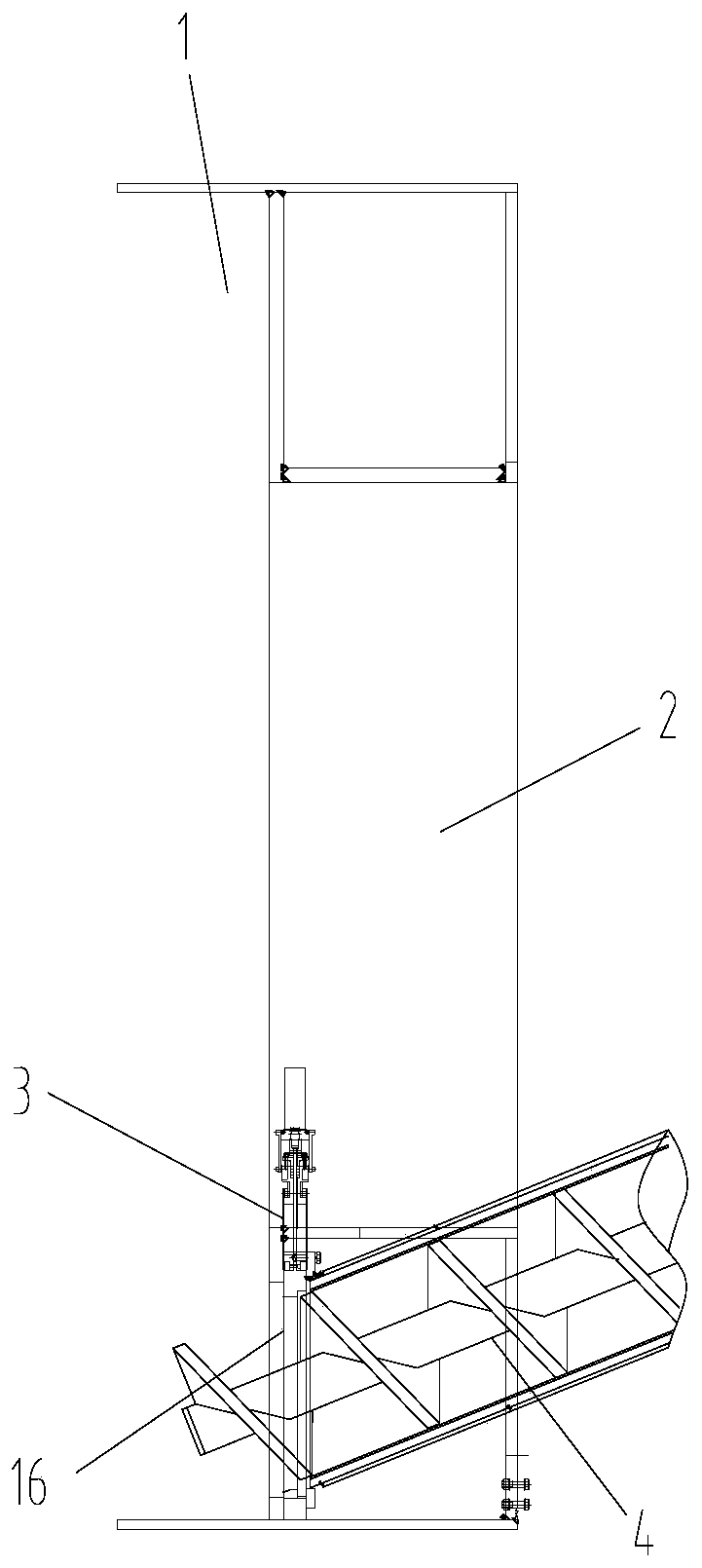

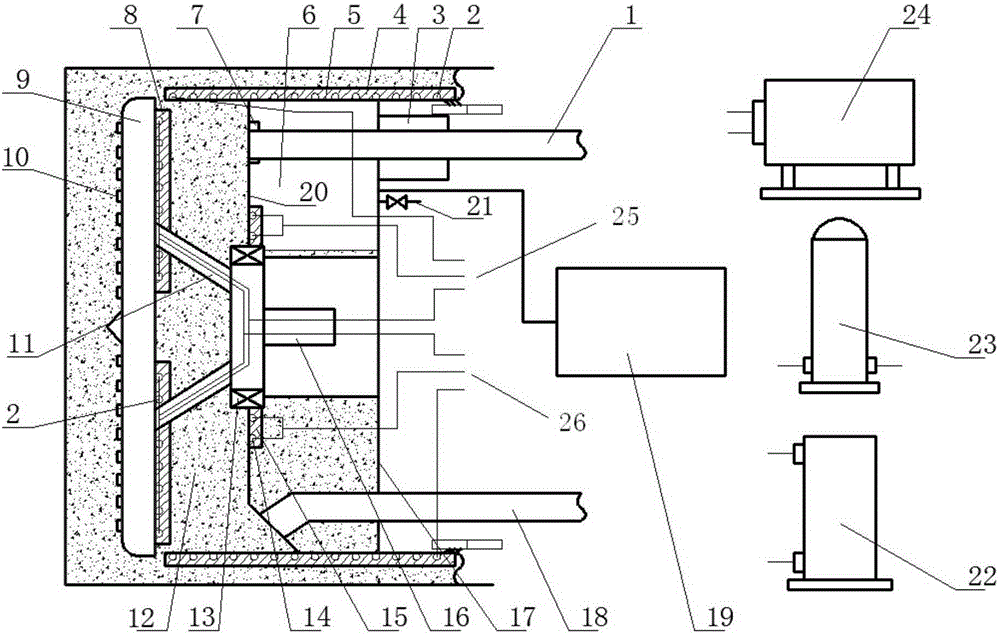

Shield tunneling machine with mud water mode and earth pressure mode

PendingCN110306991AApplicable to a wide range of formationsExcavation mode with many functionsTunnelsEngineeringShield tunneling

The invention discloses a shield tunneling machine with a mud water mode and an earth pressure mode. The shield tunneling machine comprises a mud water chamber, an air cushion chamber, a hydraulic communication valve, a screw conveyor, a mud box, a belt conveyor, a mud inlet pipeline, a mud discharge pipeline, a first circulating flushing pipeline and a second circulating flushing pipeline, wherein the mud water chamber is arranged between a cutter head and a shield body; the air cushion chamber is disposed between the mud water chamber and the shield body; the hydraulic communication valve isarranged between the mud water chamber and the air cushion chamber; the inlet of the screw conveyor connected to the bottom of the mud water chamber; the mud box and the belt conveyor are detachablyconnected to the outlet of the screw conveyor; the first circulating flushing pipeline can deliver the mud in the mud inlet pipeline to the central portion of the cutter head, and the second circulating flushing pipeline can deliver the mud in the mud box to the mud water chamber and the air cushion chamber. When the shield tunneling machine is in the mud water work mode, the hydraulic communication valve is turned on, the mud water chamber communicates with the air cushion chamber, and the outlet of the screw conveyor is connected to the mud box; when the shield tunneling machine is in the earth pressure work mode, the hydraulic communication valve is turned off, the mud water chamber blocks the air cushion chamber, and the outlet of the screw conveyor is connected to the belt conveyor. The shield tunneling machine has the advantages of wide applicable stratum range, multiple functions of the tunneling mode, high precision of pressure control and the like.

Owner:TIANHE MECHANICAL EQUIP MFG

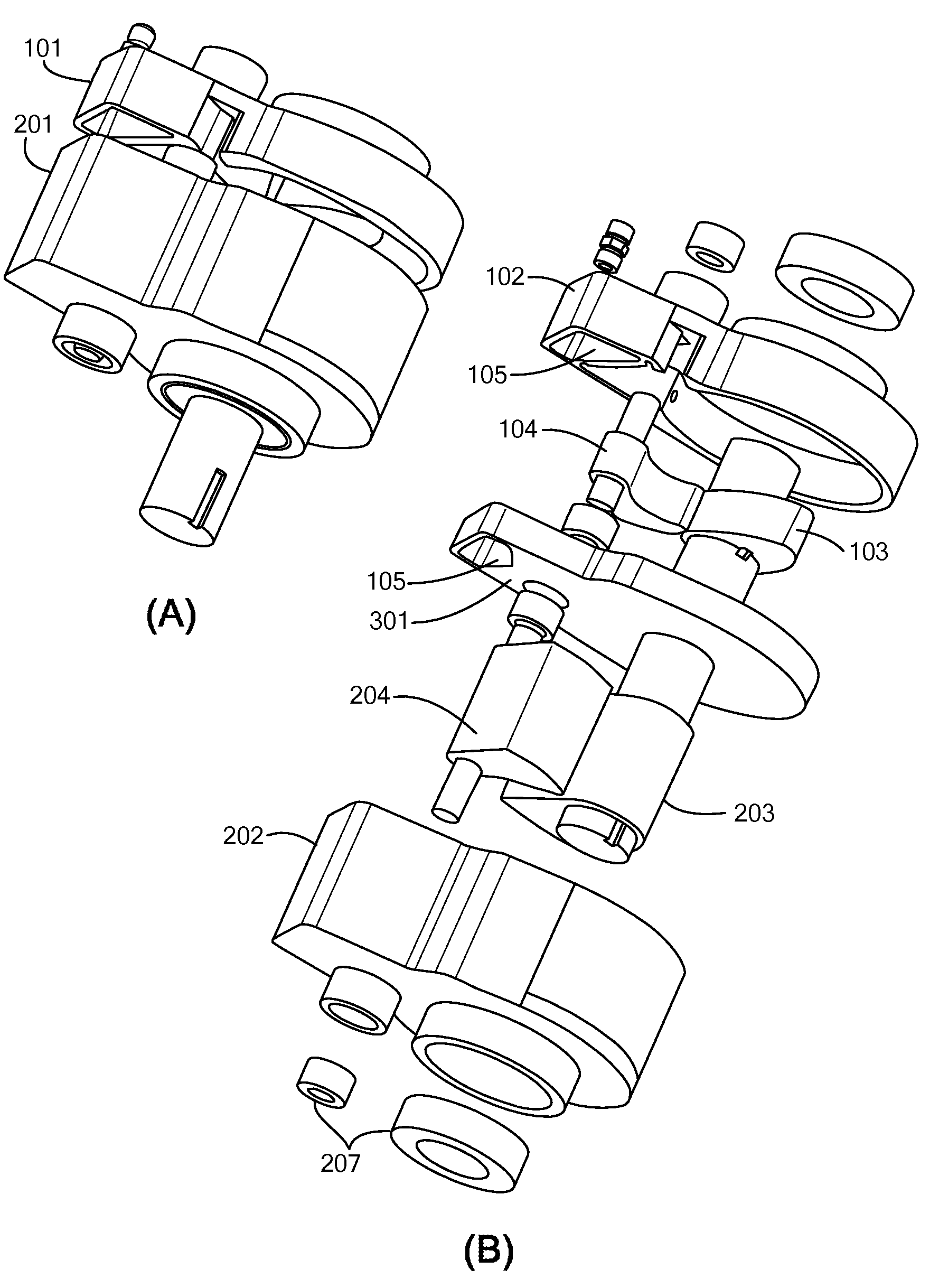

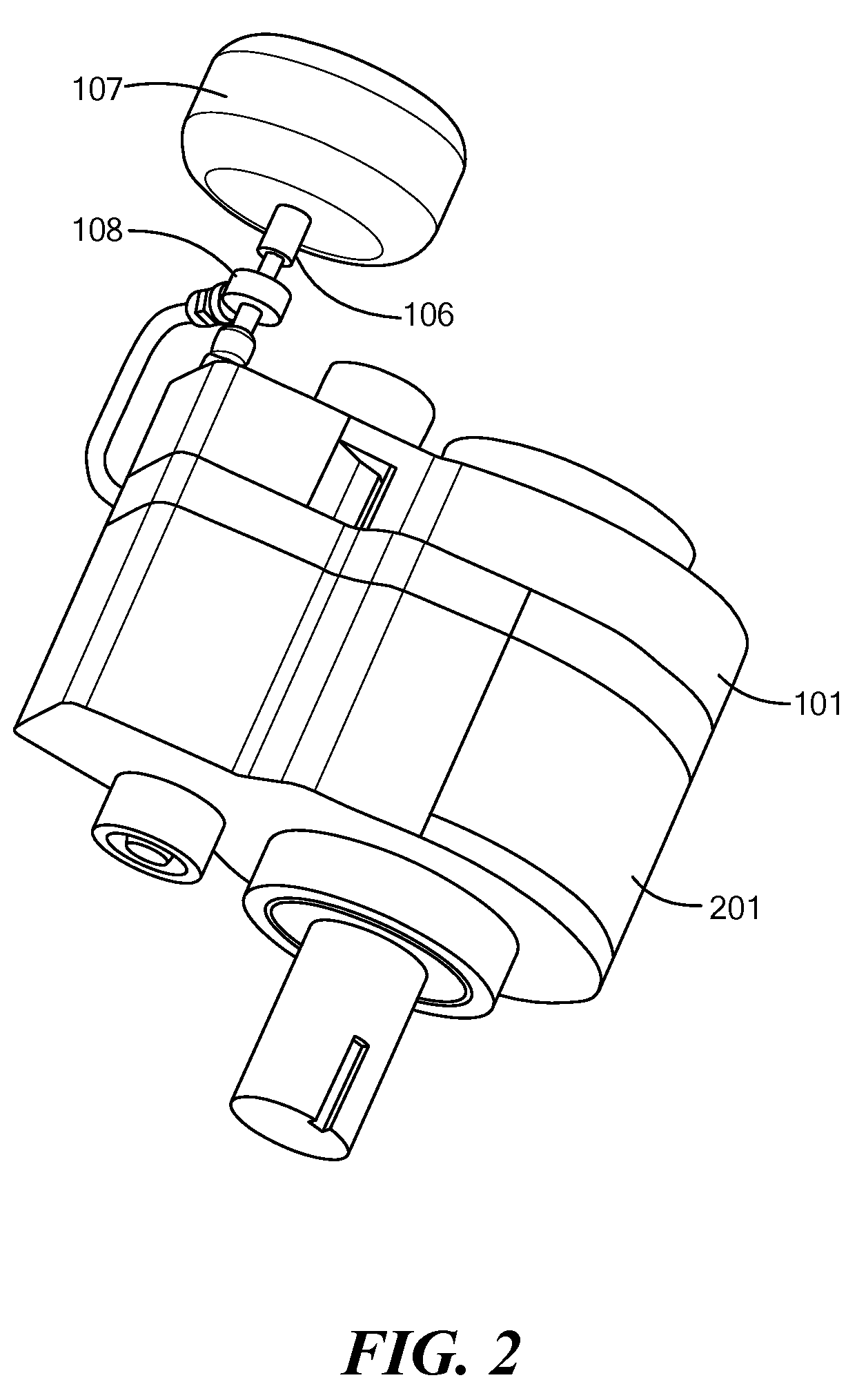

Hybrid cycle rotary engine

ActiveUS7909013B2Efficient mixingElectrical controlInternal combustion piston enginesReciprocating motionRotary engine

An internal combustion engine includes in one aspect a source of a pressurized working medium and an expander. The expander has a housing and a piston, movably mounted within and with respect to the housing, to perform one of rotation and reciprocation, each complete rotation or reciprocation defining at least a part of a cycle of the engine. The expander also includes a septum, mounted within the housing and movable with respect to the housing and the piston so as to define in conjunction therewith, over first and second angular ranges of the cycle, a working chamber that is isolated from an intake port and an exhaust port. Combustion occurs at least over the first angular range of the cycle to provide heat to the working medium and so as to increase its pressure. The working chamber over a second angular range of the cycle expands in volume while the piston receives, from the working medium as a result of its increased pressure, a force relative to the housing that causes motion of the piston relative to the housing.

Owner:LIQUIDPISTON INC

Sealing material

Owner:MITSUBISHI CABLE IND LTD

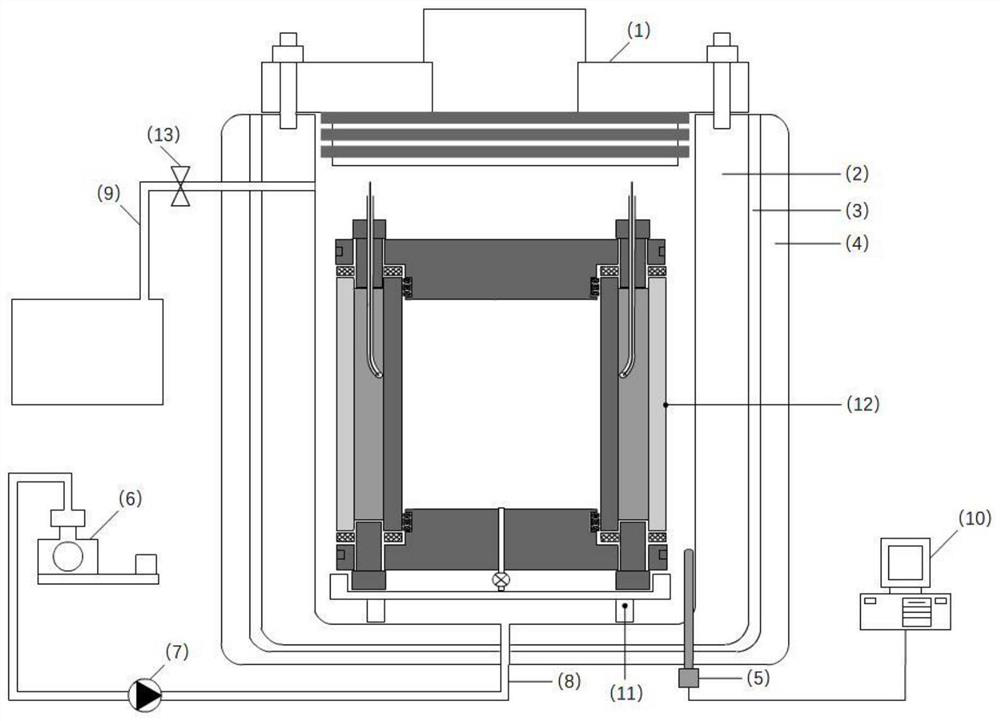

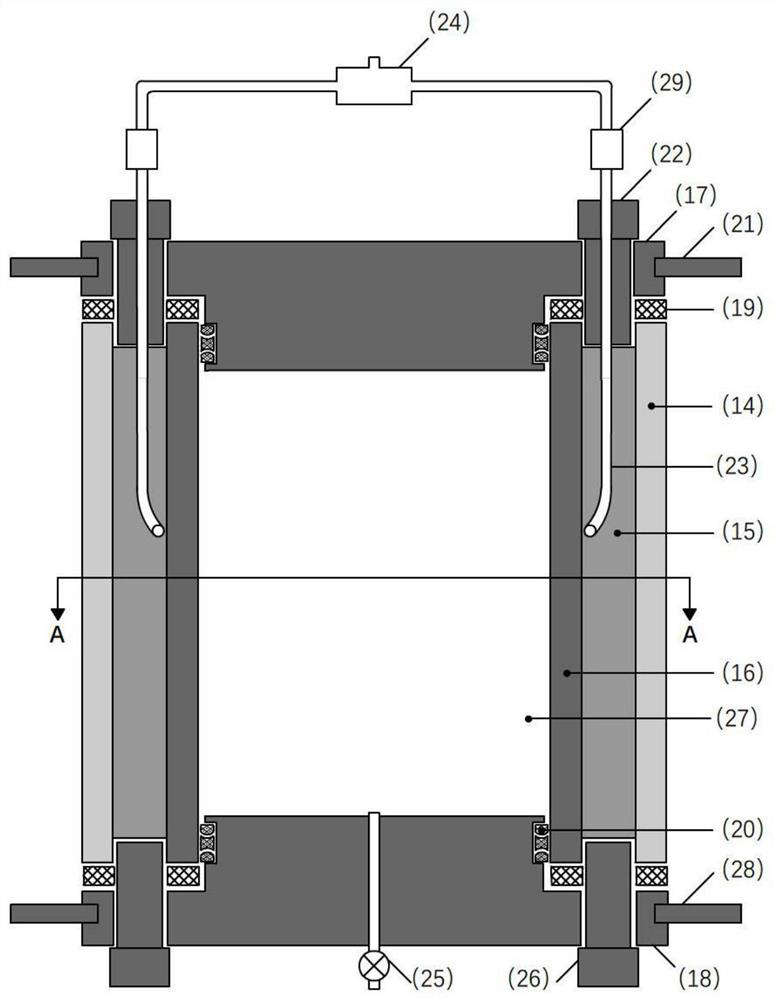

High-temperature high-pressure casing cement sheath stratum sealing integrity evaluation device and method

ActiveCN111927435AStable supportDetection of fluid at leakage pointMeasurement of fluid loss/gain rateControl systemWell cementing

Owner:SOUTHWEST PETROLEUM UNIV

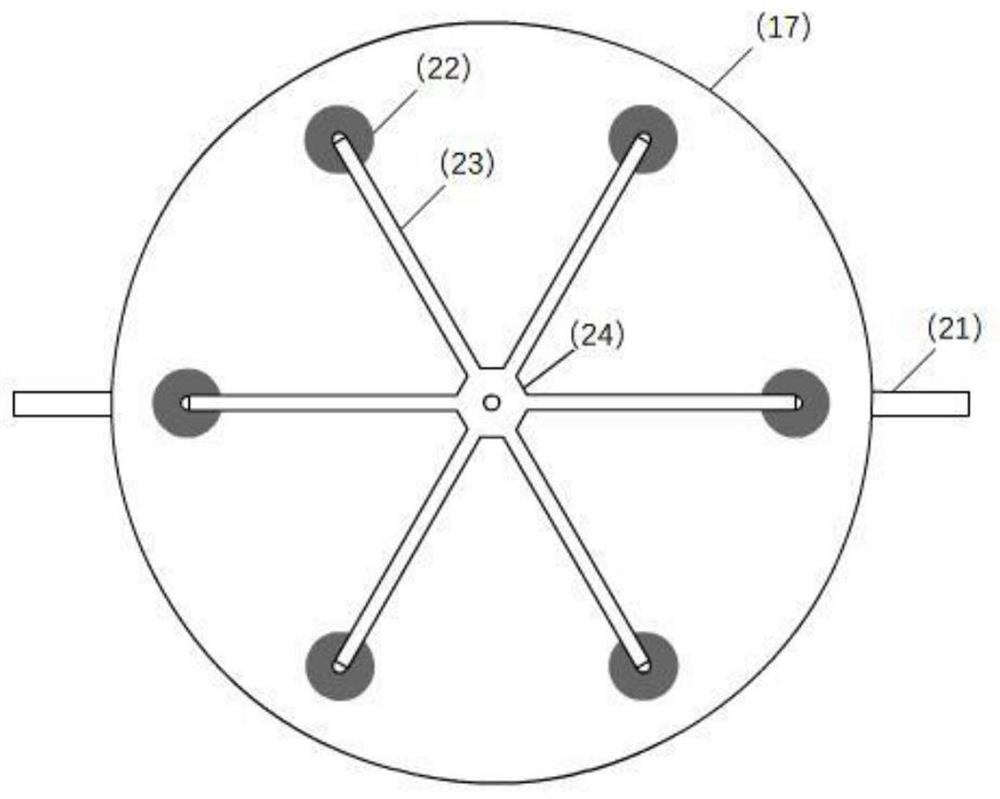

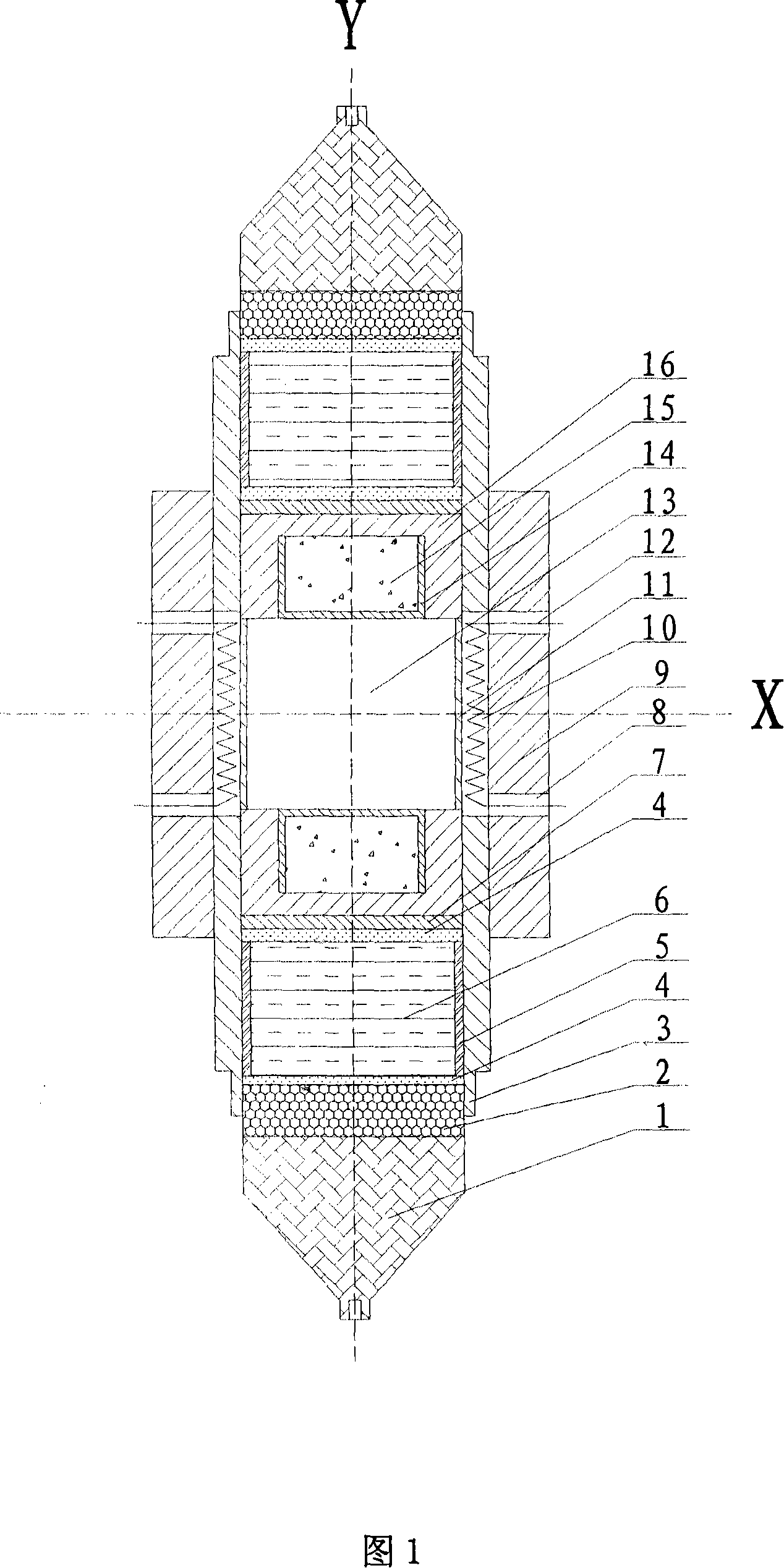

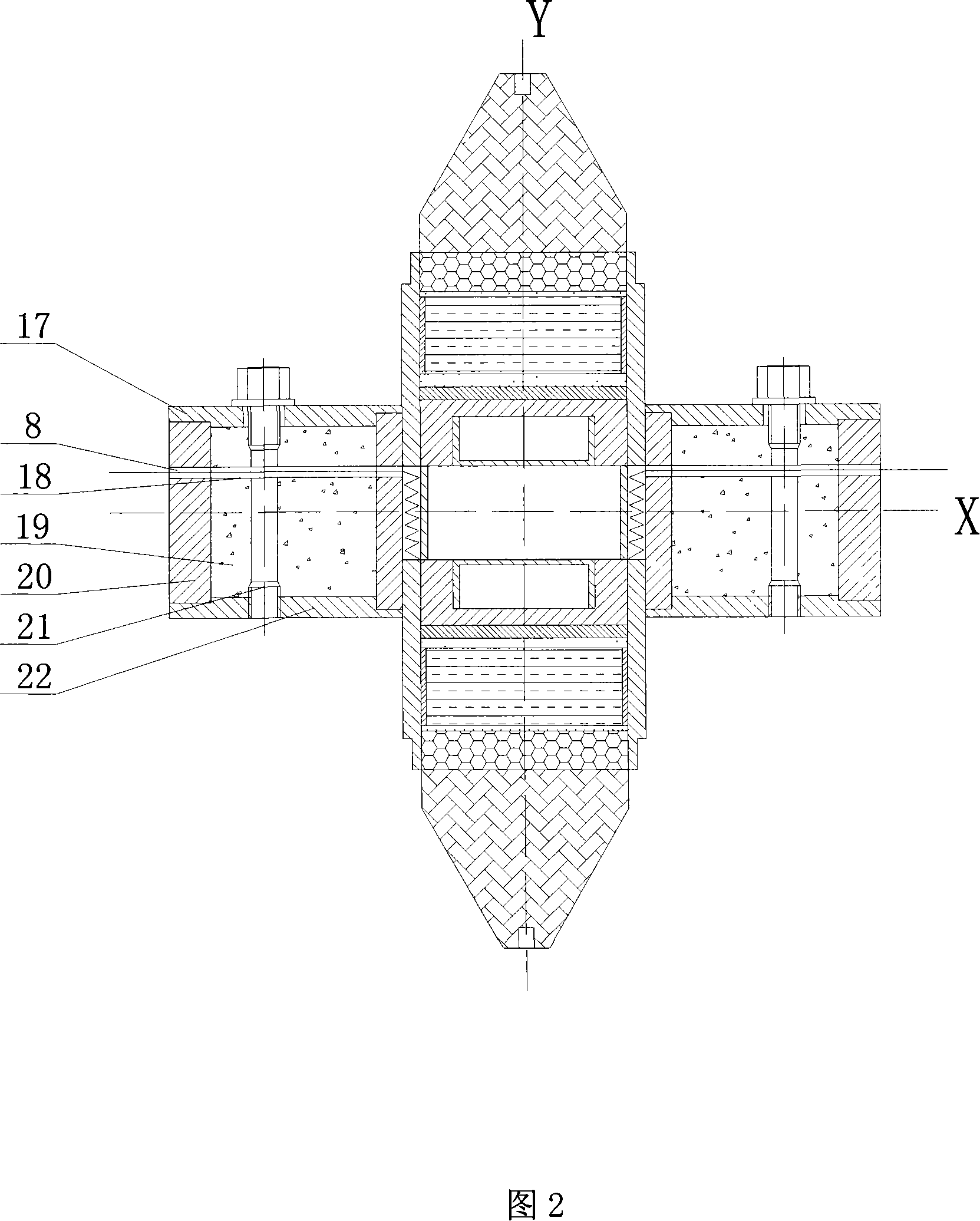

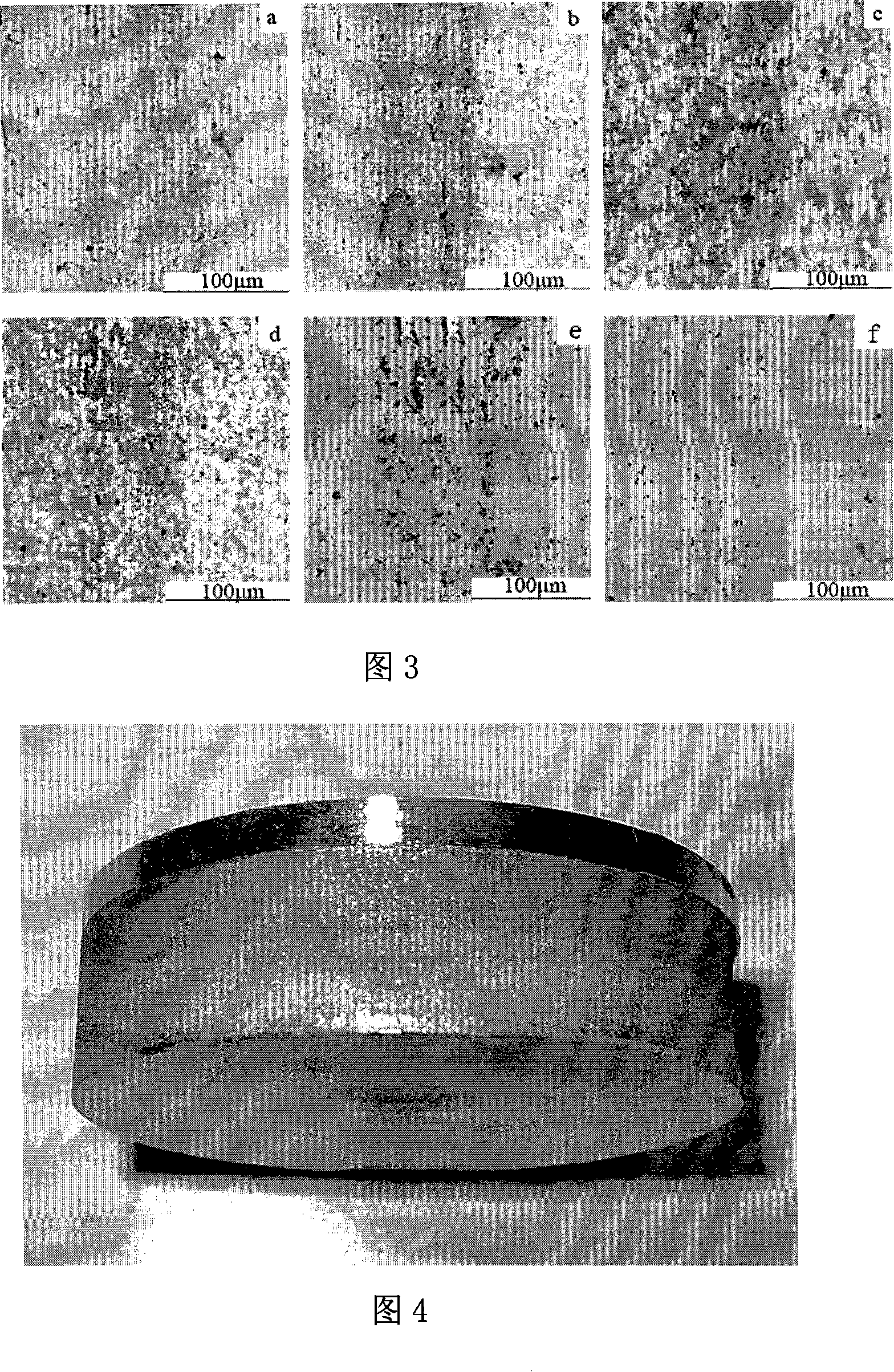

Self-spreading pre-heating powder aqueous medium bidirectional blasting and concreting device

InactiveCN101138788AReduce strong reflectionsImproving the quality of explosive consolidationShock waveSelf-propagating high-temperature synthesis

A two-way explosion concrete device of self-spread preheat powder aqueous medium is used for manufacturing a high-density hard concrete metal or ceramic compound materials and functionally gradient materials of the ceramic compound materials, which consists of a plane wave generator, a high grade energy main charge, a pressure work steel tube, a waterseal unit, a wave impedance match unit, an outer protection tub or a protective unit, a self-spread dust electrical heating unit and a protective unit of sample. The present invention is designed to provide the two-way explosion concrete device of self-spread preheat powder aqueous medium that can produce a high-energy explosive detonated by plane detonation wave produced by two plane wave generators with symmetry layout and two-way explosion by making use of aqueous medium to transfer a plane explosive shock wave and self-spread high temperature synthetic reaction preheat powder.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Aluminium magnesium ferroalloy for molten steel deoxidization desulfuration and alloying and preparation method thereof

The present invention discloses one kind of Al-Mg-Fe alloy for deoxidizing and desulfurizing molten steel. The Al-Mg-Fe alloy is produced through special pressure working, rather than smelting in a common induction furnace. It is one kind of energy-saving high purity alloy with alloy recovering rate as high as 100 %, no pollution and capacity of lowering steel deoxidizing and desulfurizing cost. It is suitable for deoxidizing and desulfurizing molten steel for making different steel products.

Owner:赵宇

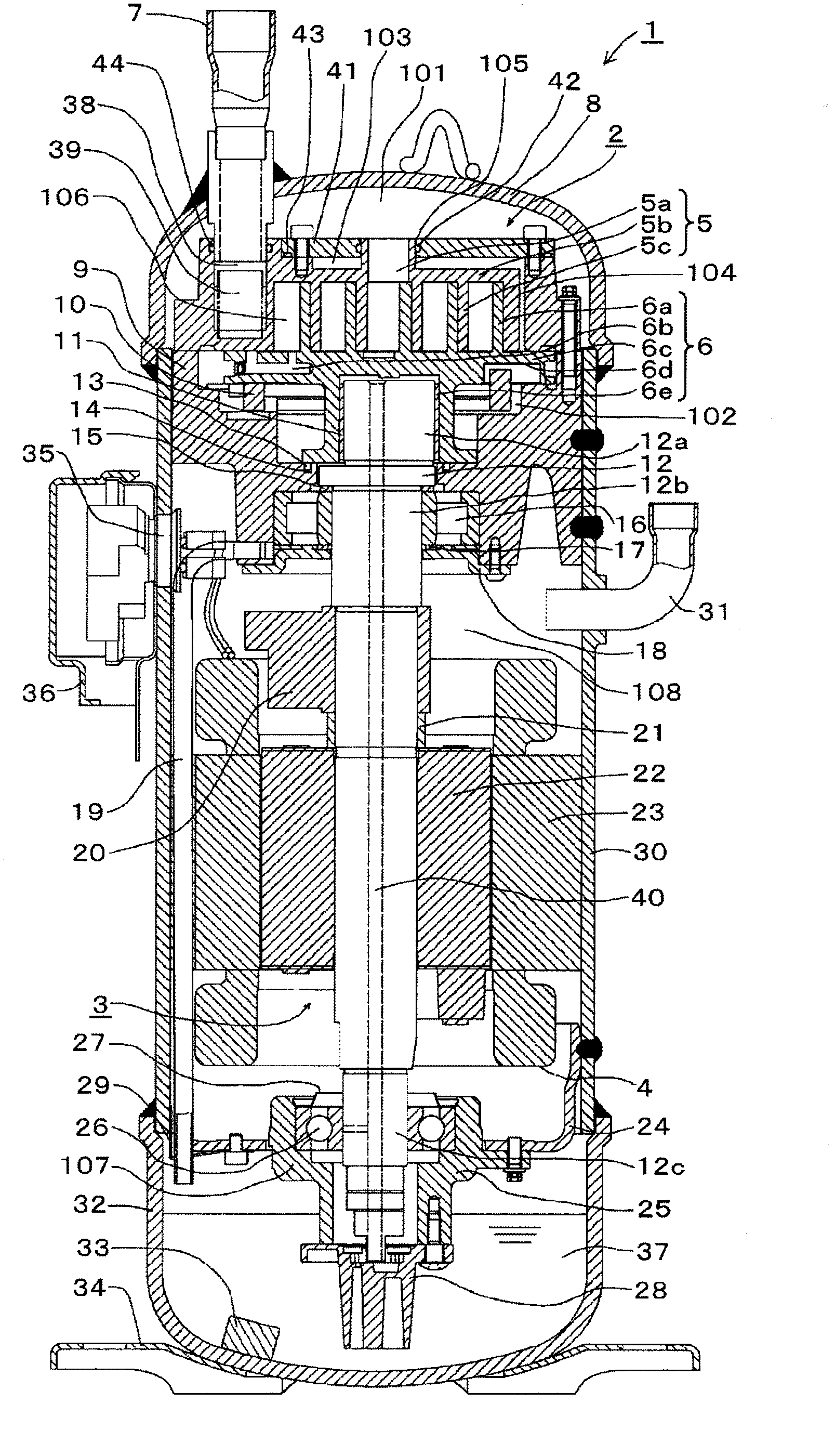

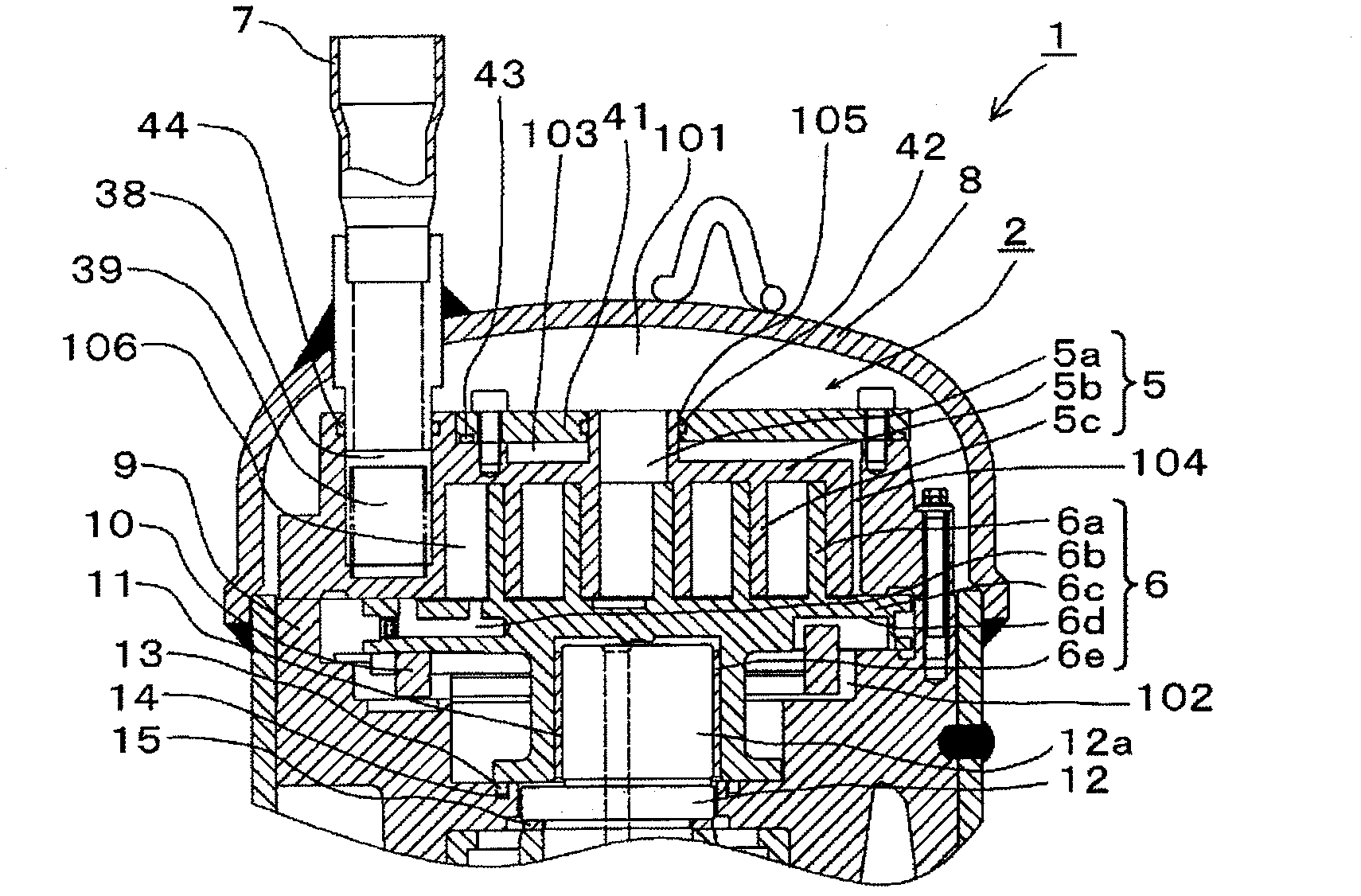

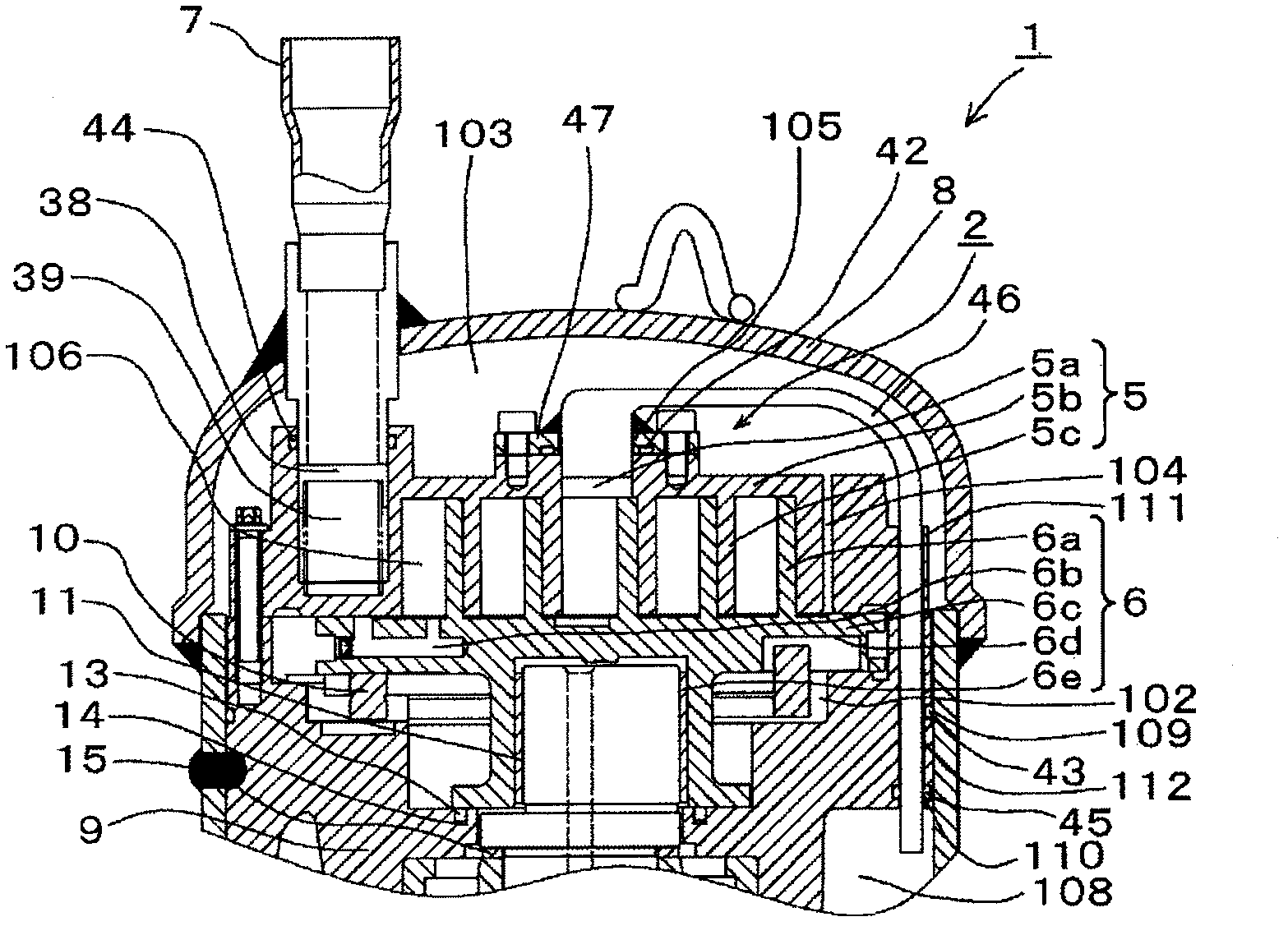

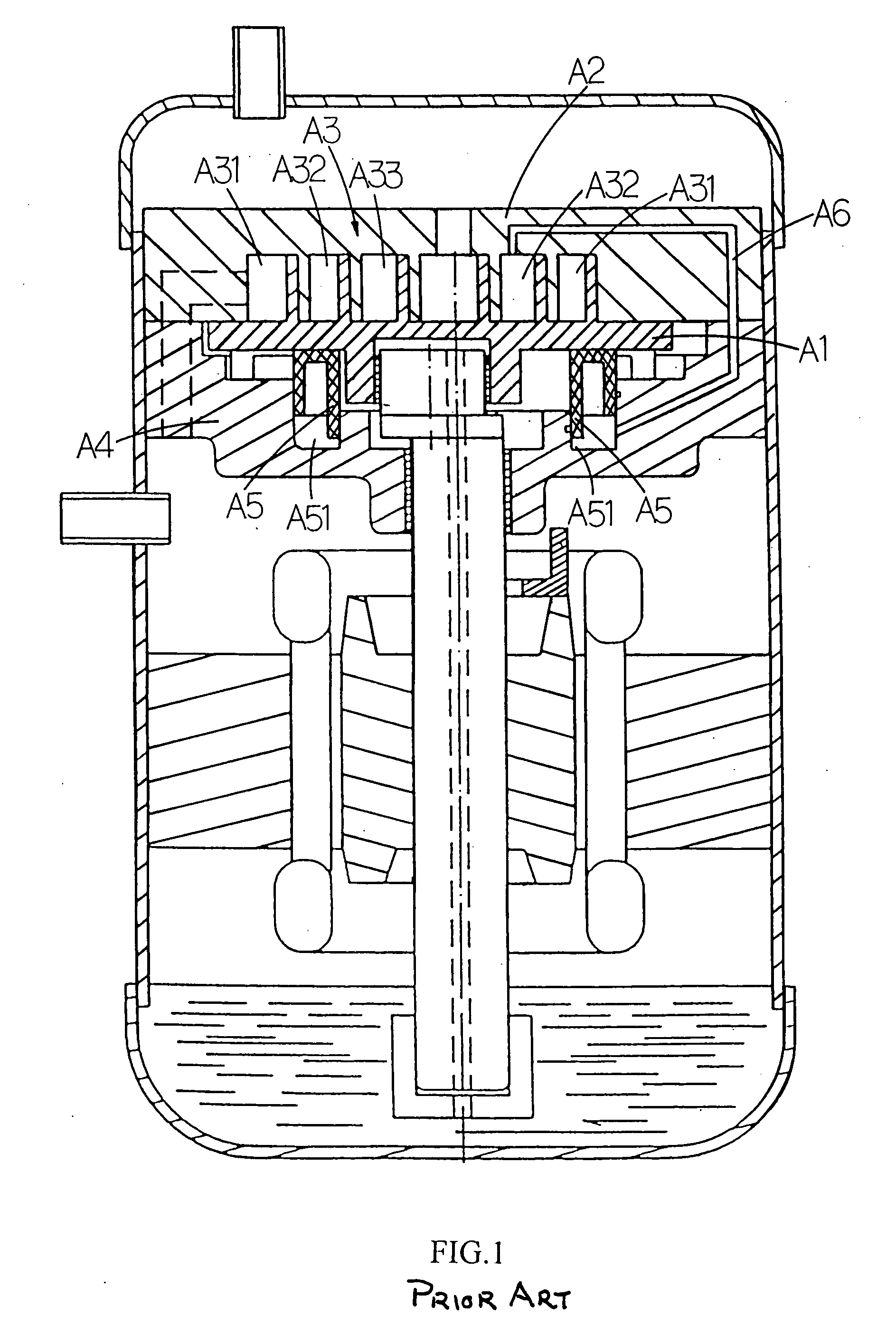

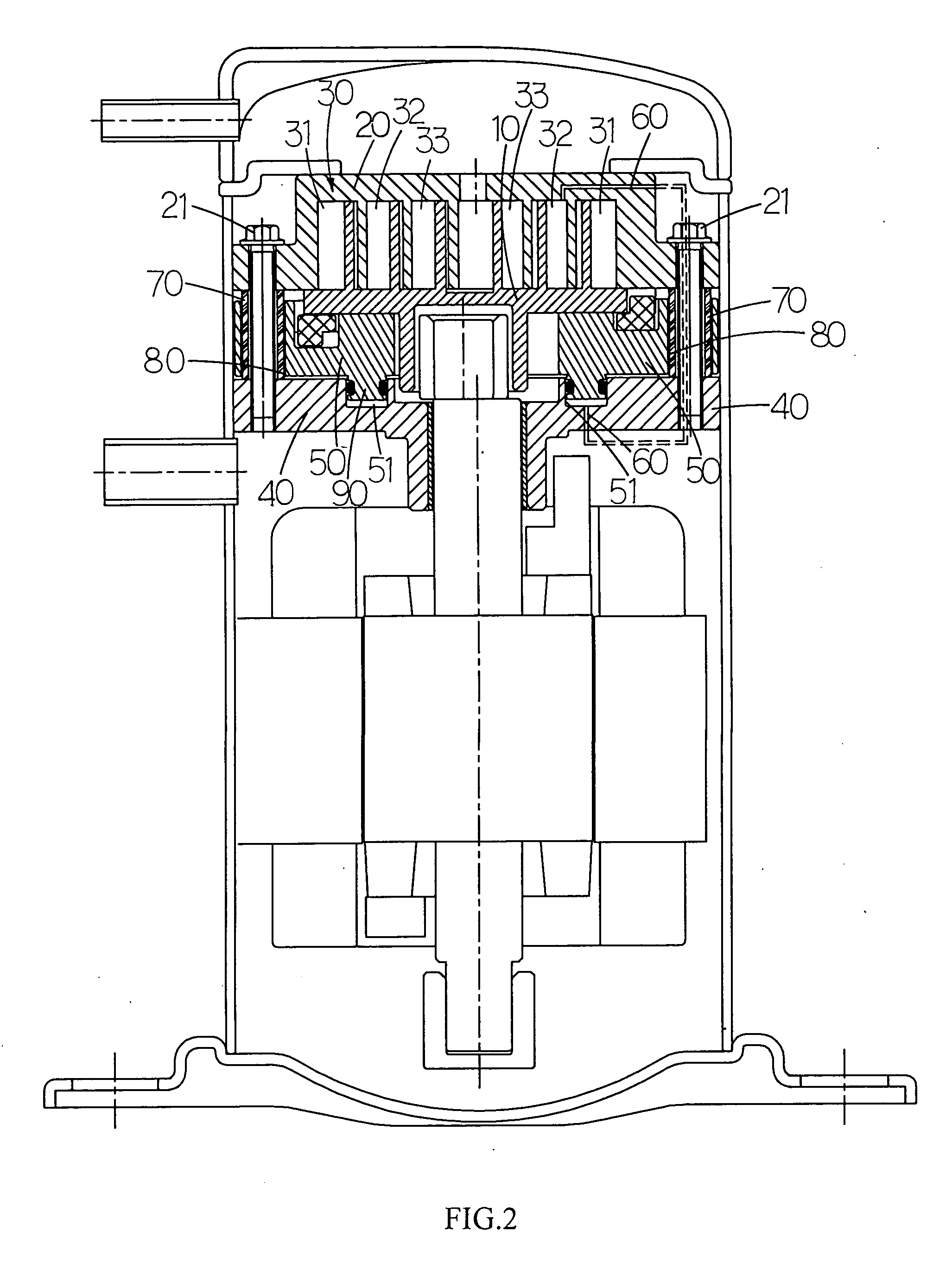

Vortex Compressor

ActiveCN102400915AImprove reliabilityImprove efficiencyRotary piston pumpsRotary piston liquid enginesTooth rootPressure work

Provided is a vortex compressor. In the conventional vortex compressor, the fixed vortex disk top board bears the force generated by the pressure inside an enclosed space (compressing room) formed by two vortex disks at the scroll body side. At the side opposite to the scroll body, the fixed vortex disk top board bears the force generated by the pressure inside an ejecting pressure space. Affected by the combined force, the fixed vortex disk top board is deformed and forms a downward projection shape. On the other hand, the return vortex disk is deformed and forms an upward projection shape affected by the pressure worked on the backside of the return vortex disk. As the deformation may cause the tooth crest and the tooth root at the central section of the scroll body to contact with each other, the conventional vortex compressor increases the sliding loss, leads to the decrease of the performance, and reduces the reliability due to the sintering upon the sliding surface or due to the locking. The utility model aims at providing a vortex compressor featuring high reliability and efficiency. To achieve this objective, the upper portion of the top board of the fixed vortex disk is provided with a top board chamber and a connecting path which communicates the top board chamber with the backpressure chamber.

Owner:HITACHI JOHNSON CONTROLS AIR CONDITIONING INC

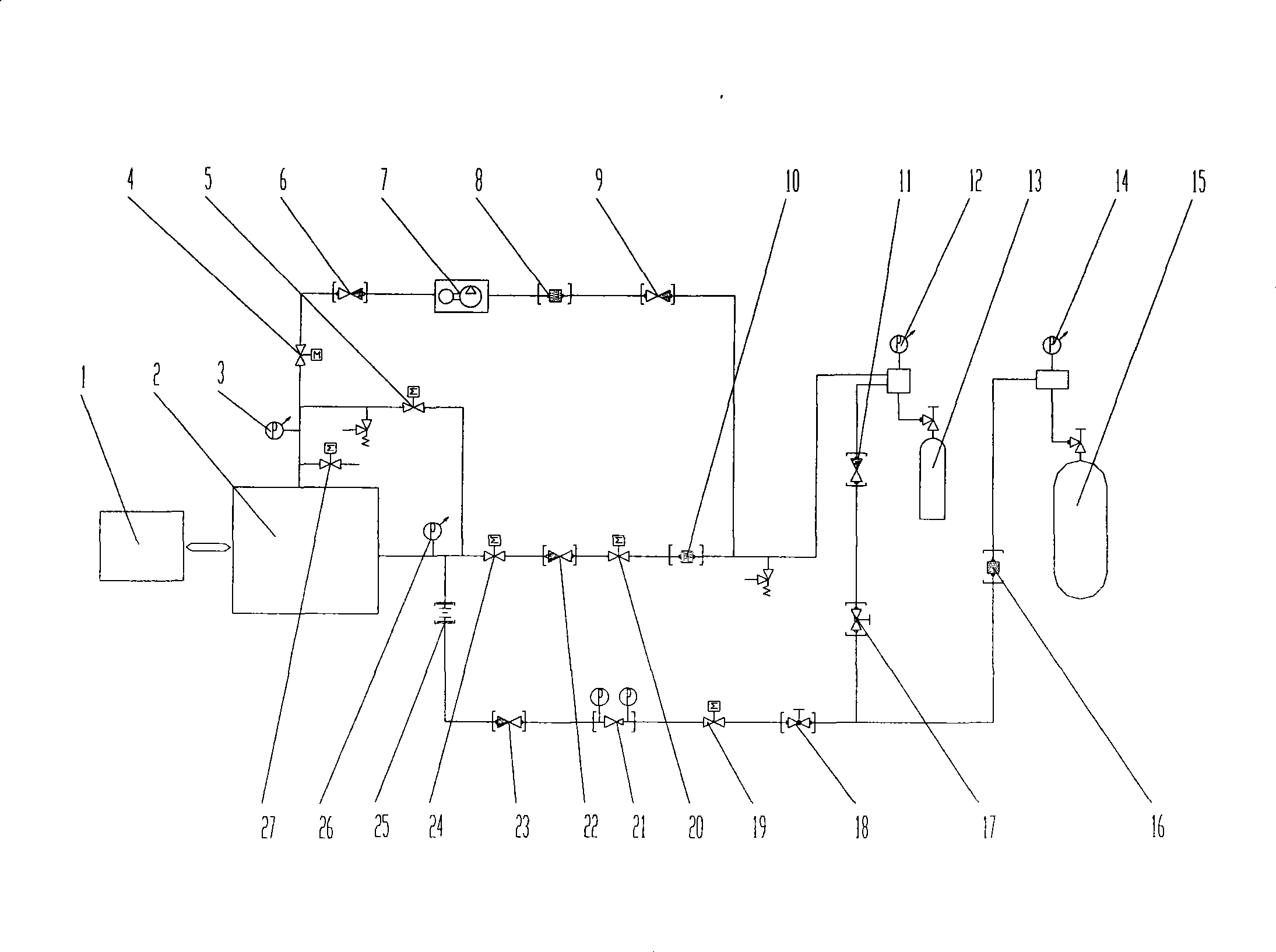

Stirling engine working substance system

InactiveCN101413461AHigh control precisionQuick responseHot gas positive displacement engine plantsHydrogenEngineering

Owner:SHANGHAI MICROPOWERS

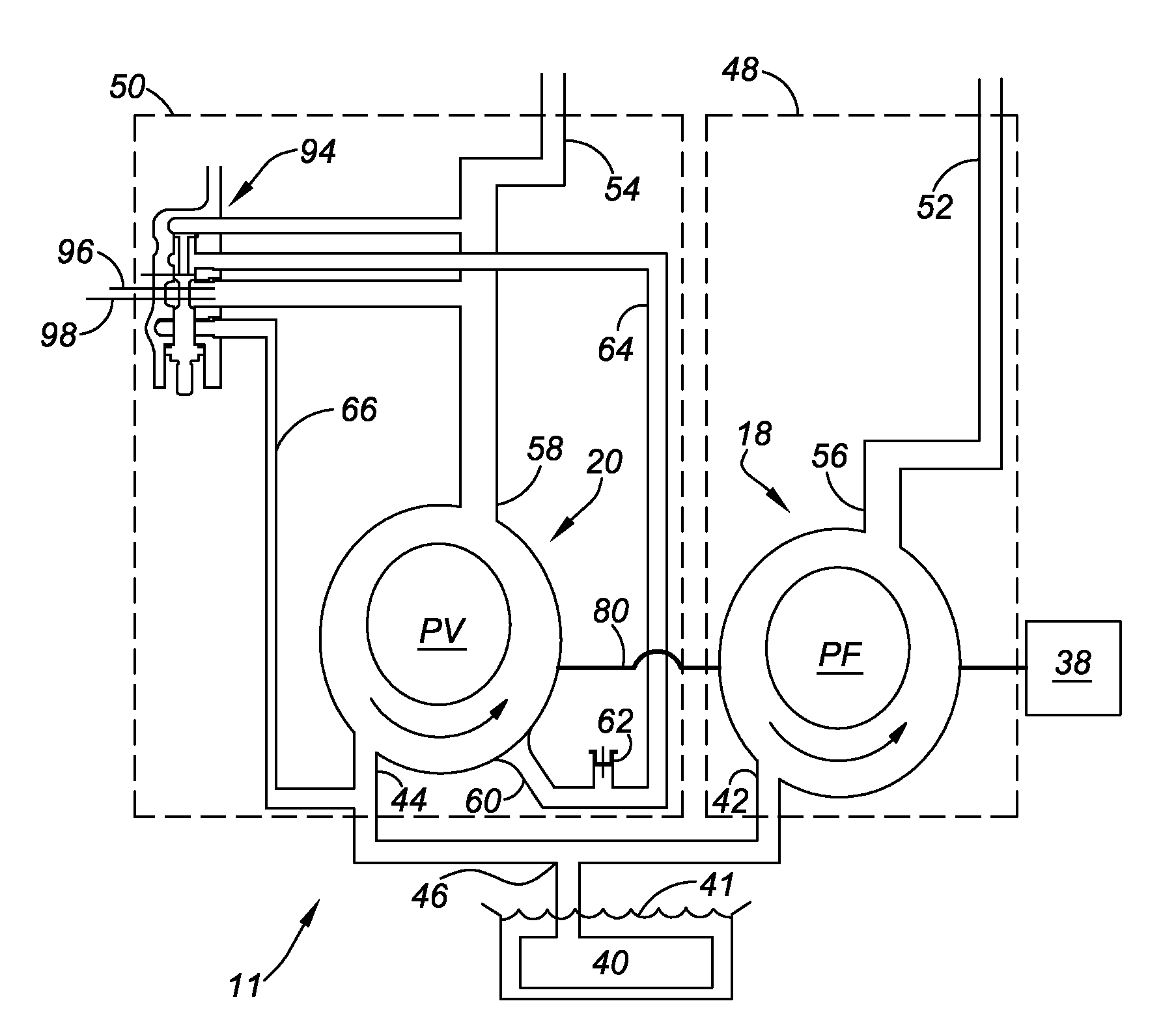

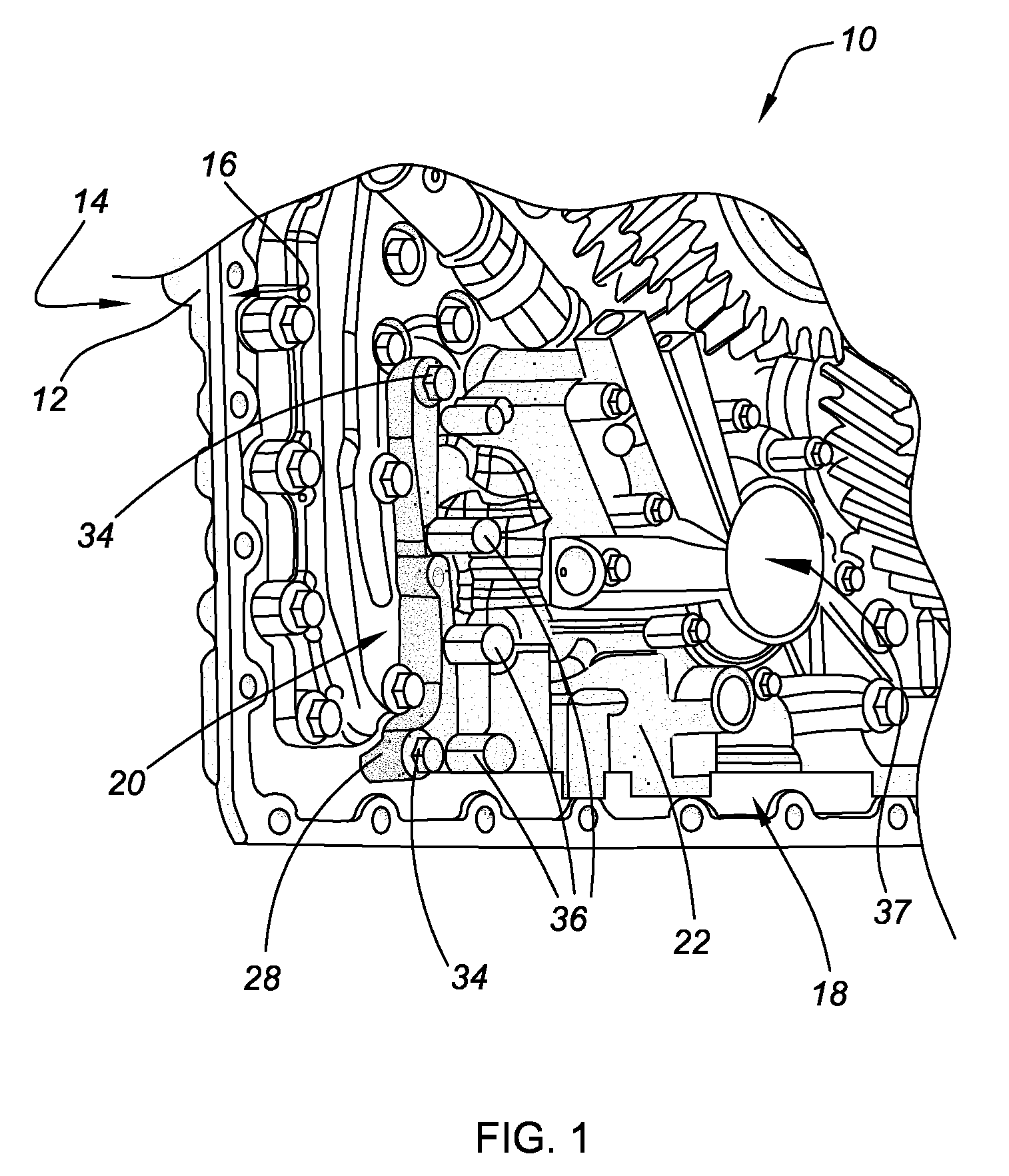

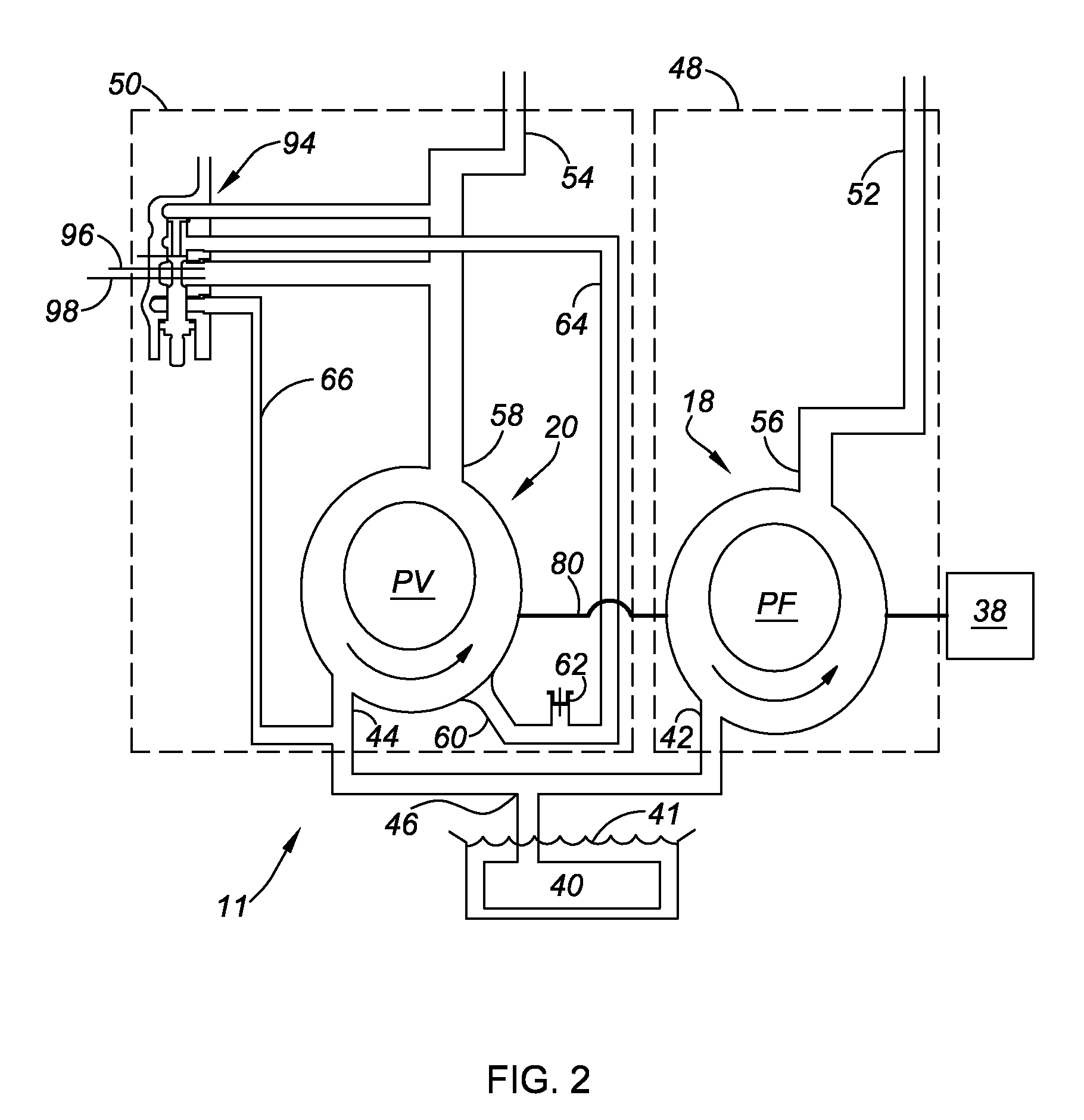

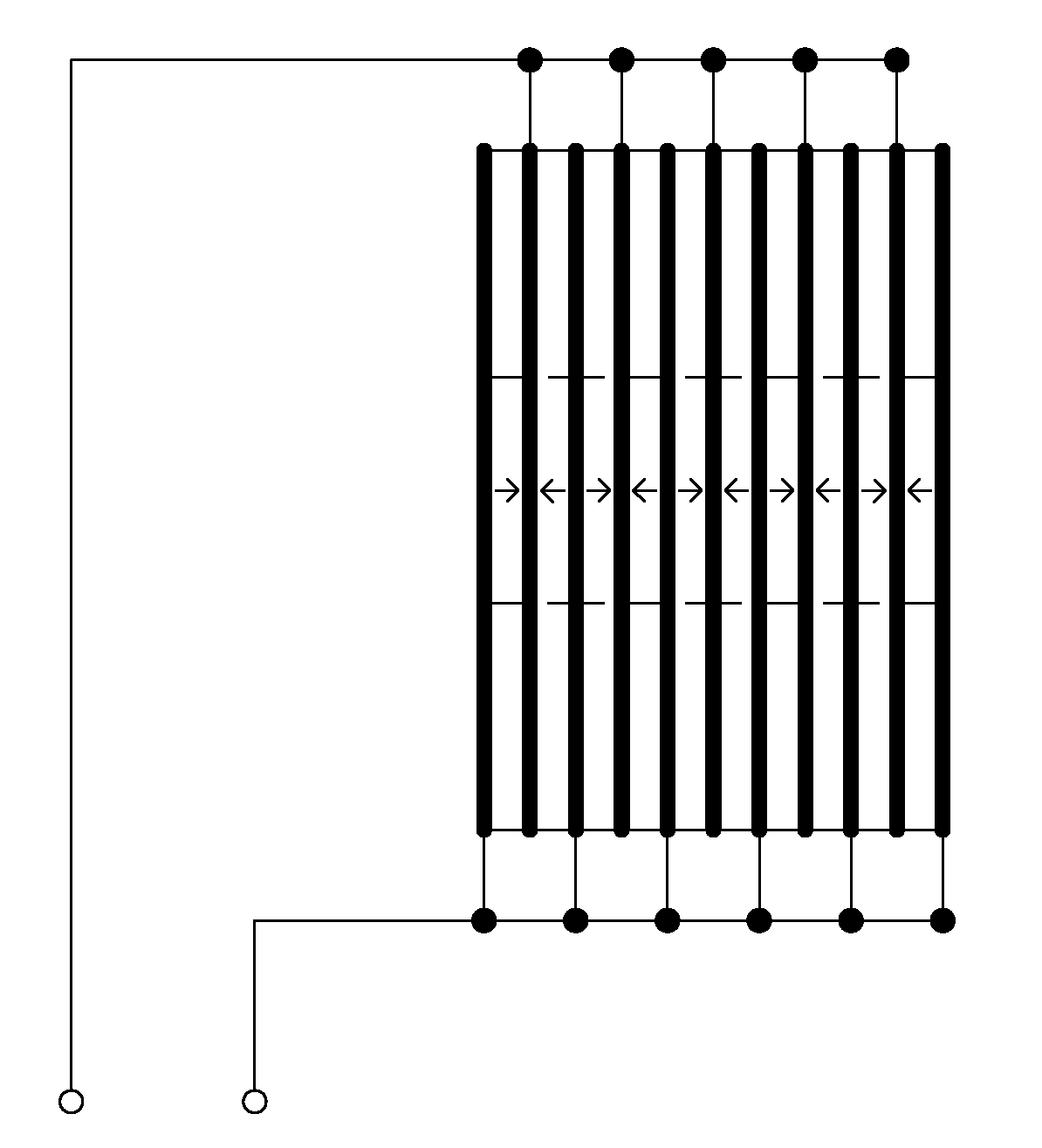

Split-Pressure Dual Pump Hydraulic Fluid Supply System for a Multi-Speed Transmission and Method

ActiveUS20080247882A1Reduce trafficMaximizes performance and efficiency and dependabilityEngine of arcuate-engagement typeOscillating piston enginesEngineeringHigh pressure

A split-pressure, dual-pump system for supplying hydraulic fluid to a multi-speed transmission is provided. The system includes a low-pressure work circuit operatively connected to a fixed displacement pump, and a high-pressure work circuit operatively connected to a variable displacement pump. The system also includes a regulator valve fluidly coupled to the variable displacement pump via a decrease circuit and an overage circuit for regulating the flow of fluid to the high-pressure work circuit. The invention consists of separating the high-pressure needs of the system into a separate work circuit from the low-pressure needs of the system, and optimizing pump design separately for each work circuit to maximize transmission efficiency and reduce parasitic losses. A method of supplying hydraulic fluid to a multi-speed transmission at variable flow and pressure is also provided.

Owner:GM GLOBAL TECH OPERATIONS LLC

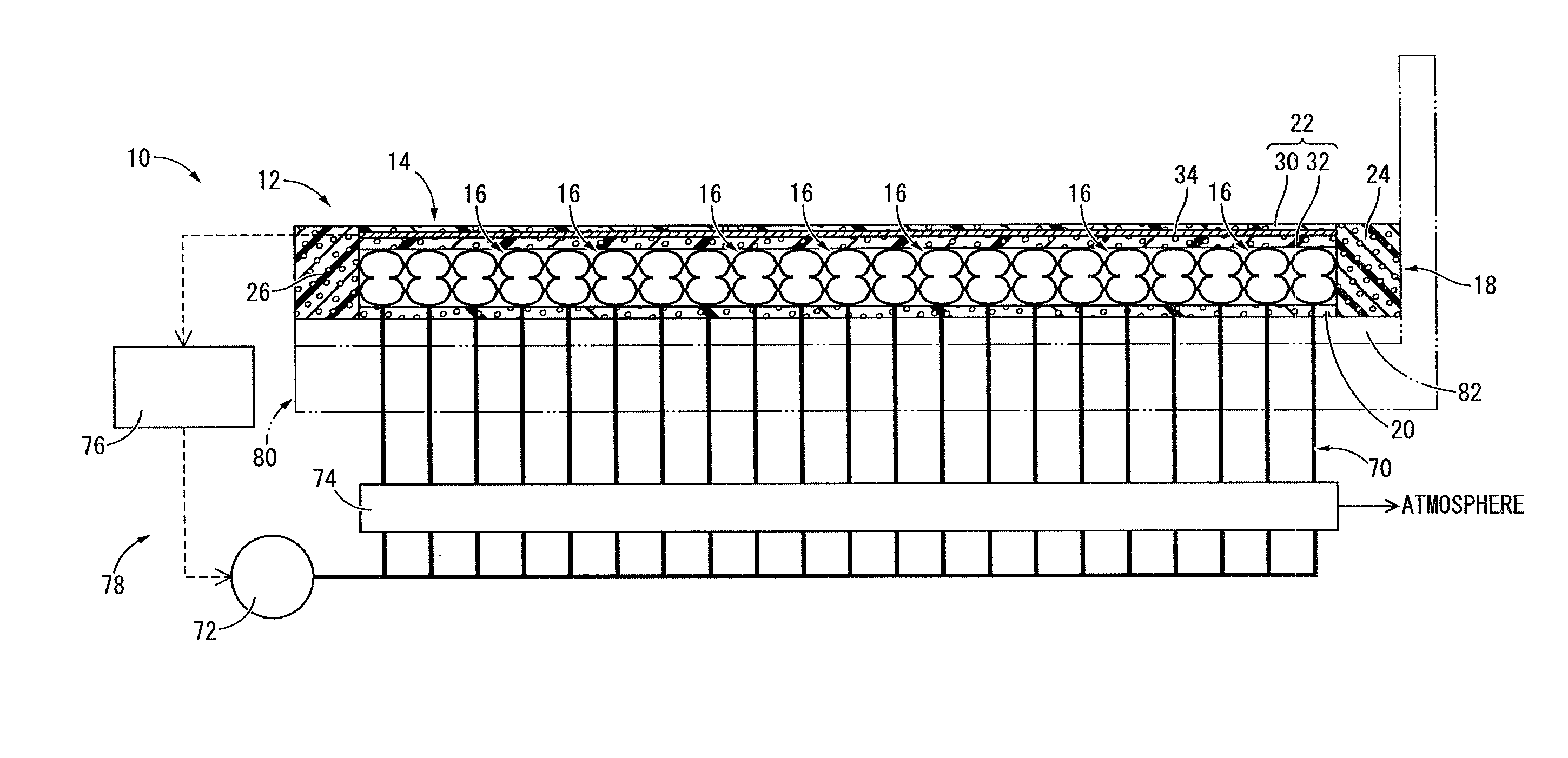

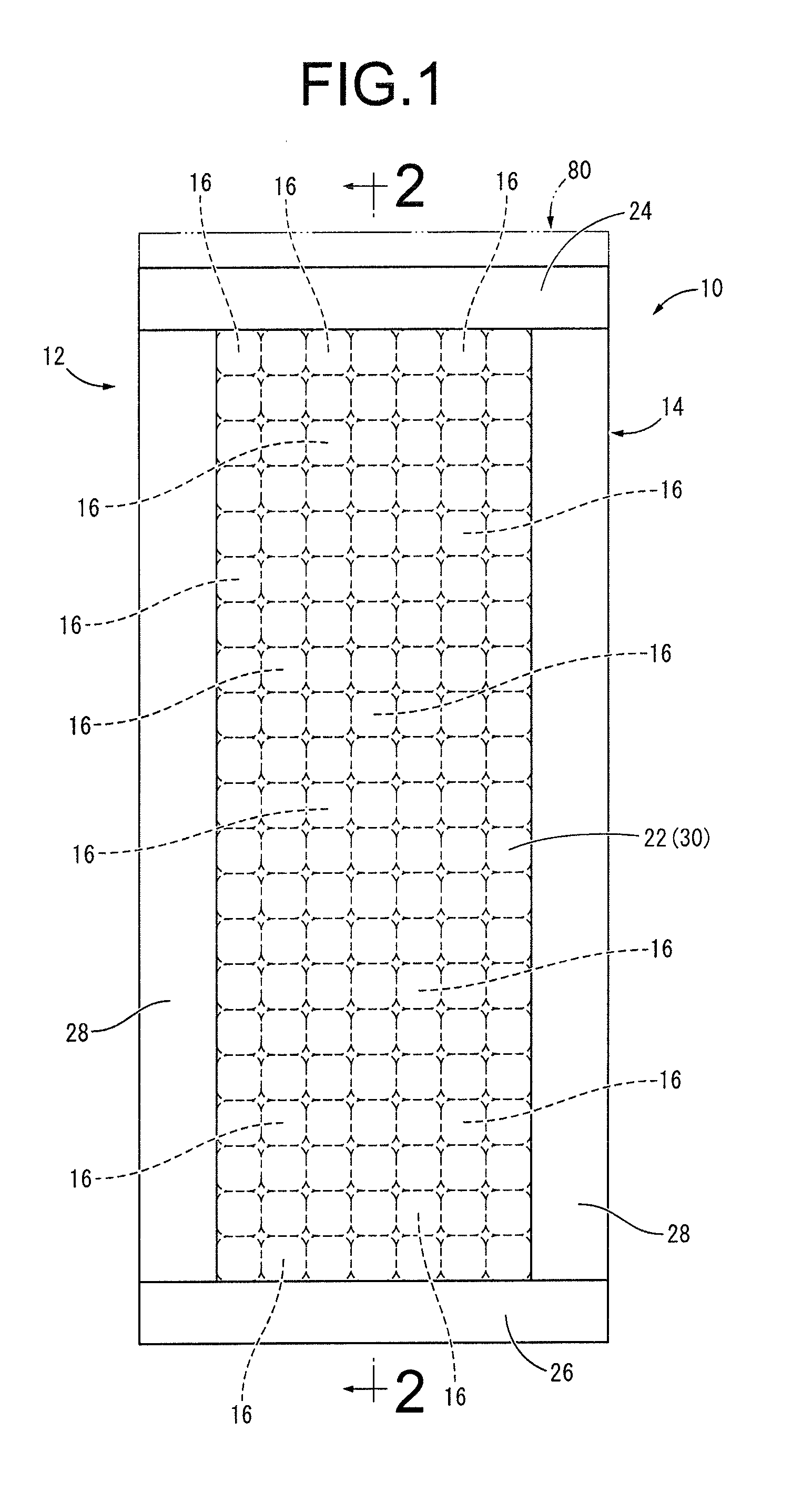

Mattress

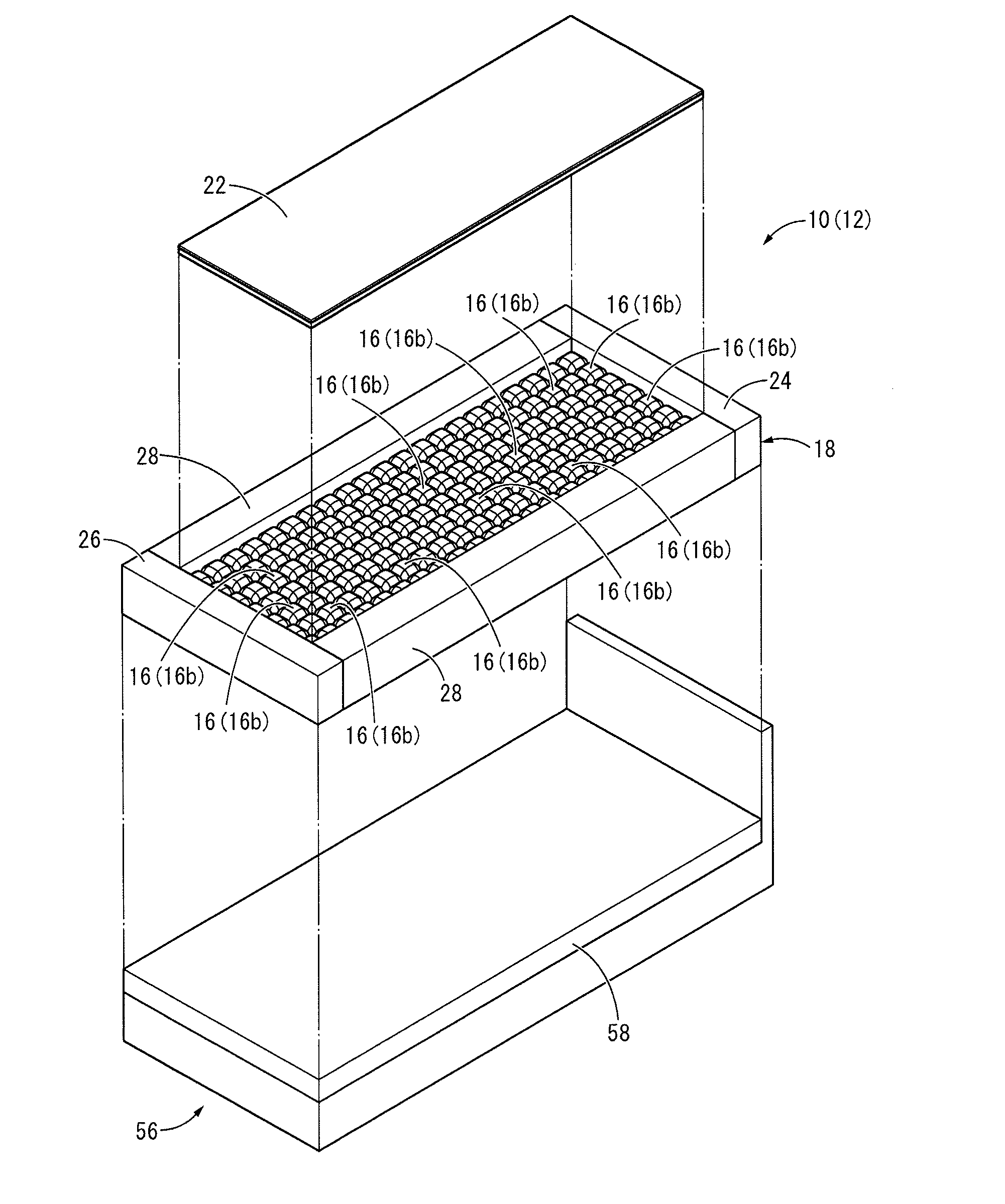

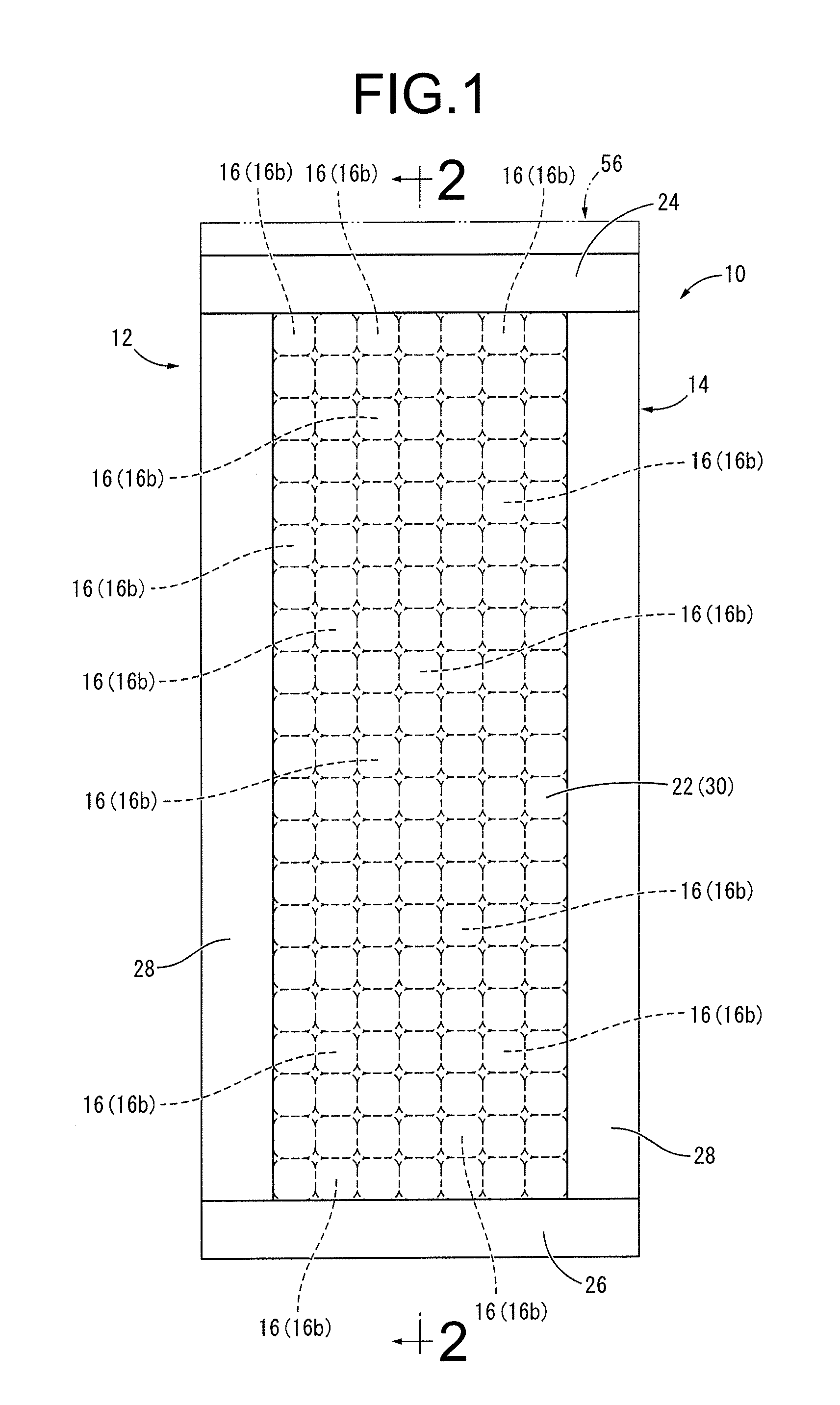

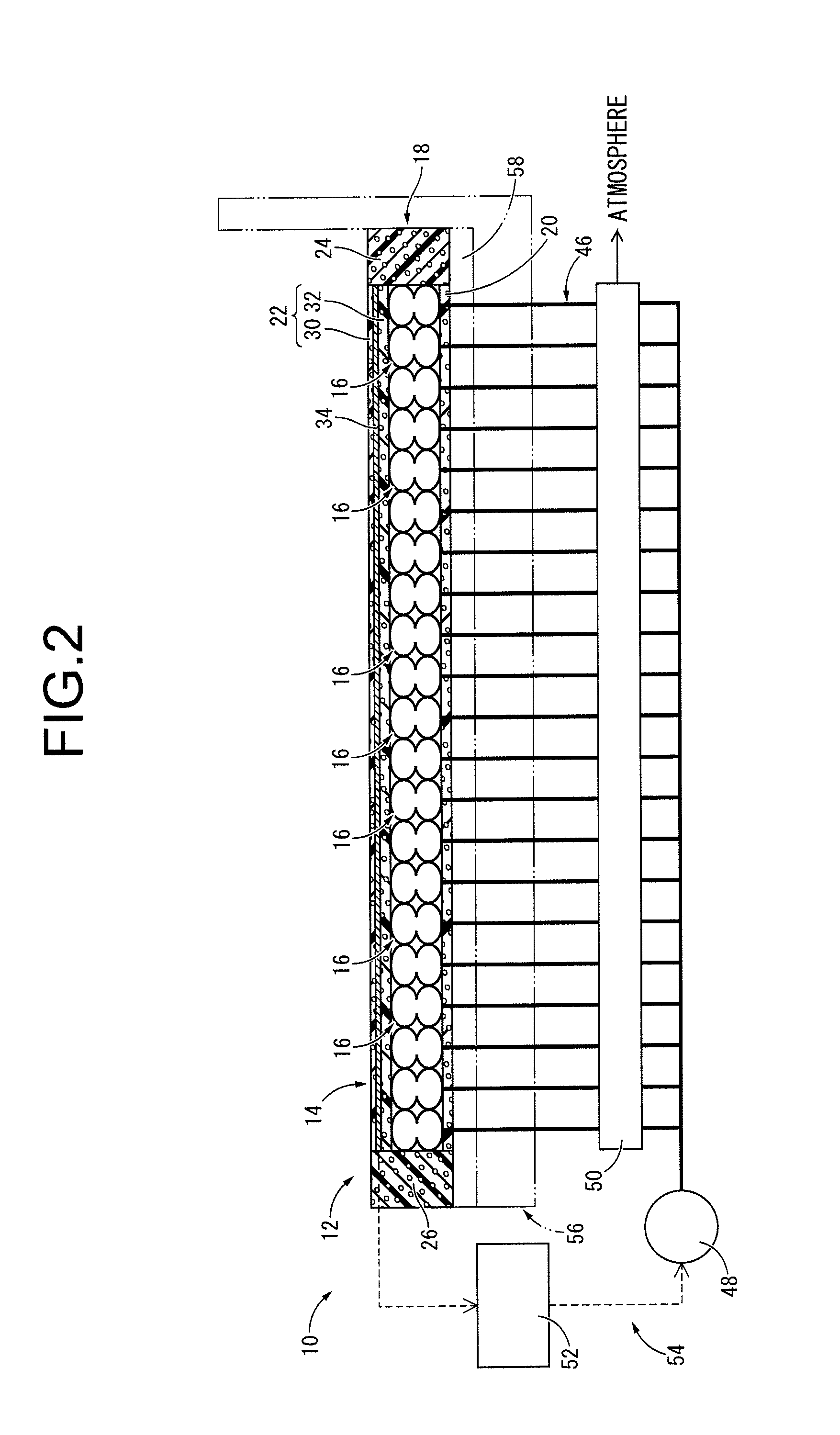

InactiveUS20140013514A1Pressure on bodyOptimize allocationStuffed mattressesSpring mattressesEngineeringPressure controlled ventilation

A mattress including a plurality of cells aligned and disposed on a body pressure working surface of a substrate that supports a human body; and a pressure control member that changes a height of each cell by adjusting a pressure in a fluid chamber formed within the cell. The cells are configured such that as the each cell is inflated by fluid supplied to the fluid chamber within the cell, the height of the each cell increases and a width dimension of the each cell in a direction of alignment decreases, and that peripheral portions of adjacent cells in the direction of alignment are overlapped with each other prior to cell inflation.

Owner:SUMITOMO RIKO CO LTD

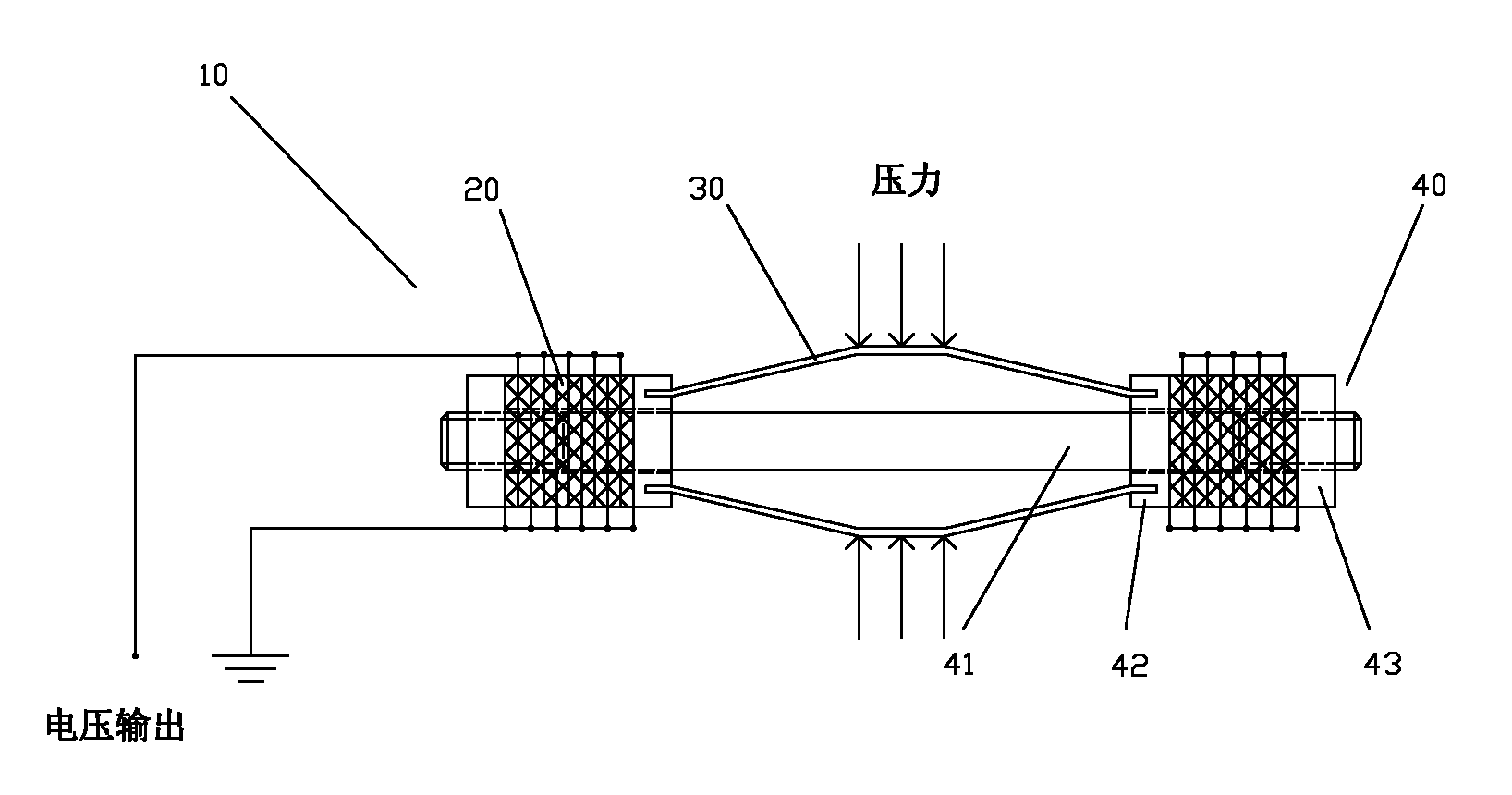

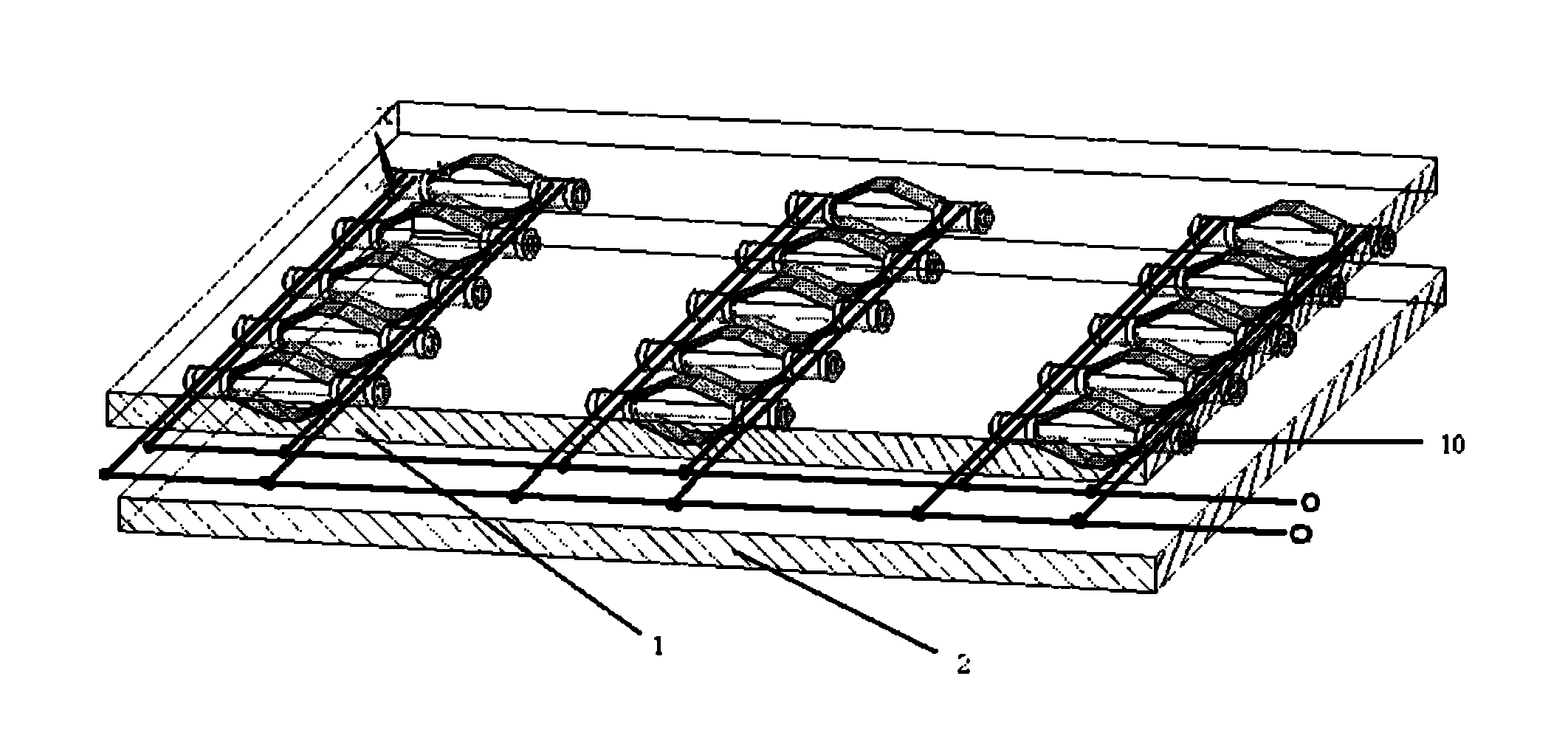

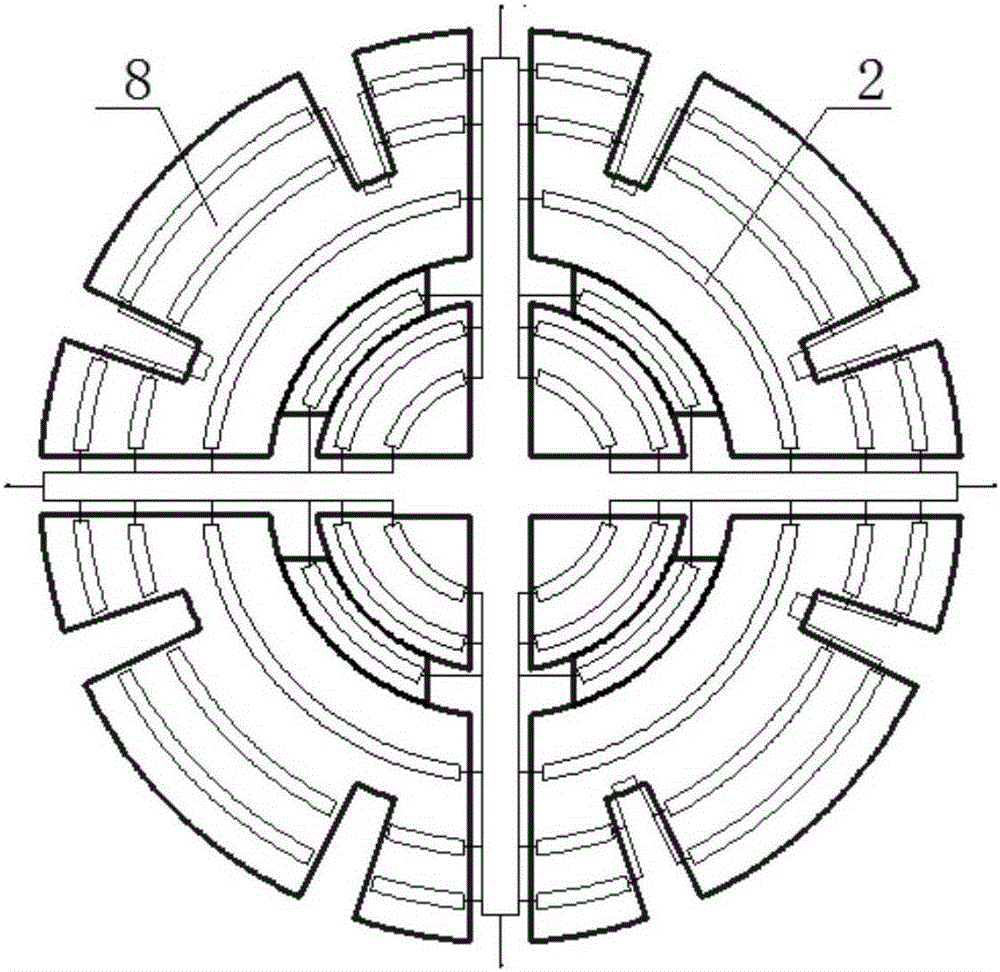

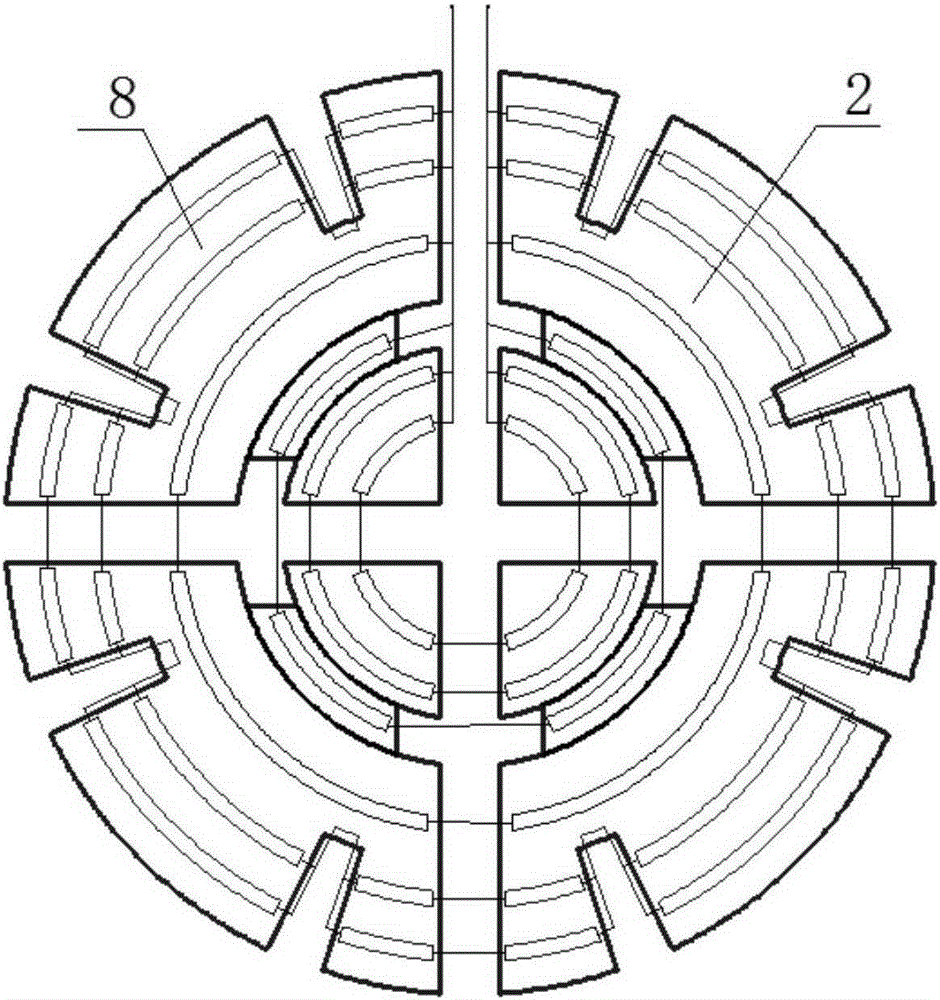

Force-electricity energy converter and array thereof

InactiveCN101854130ACompact structureSimple structurePiezoelectric/electrostriction/magnetostriction machinesMobile vehicleElectricity

The invention discloses a force-electricity energy converter and an array thereof. The energy converter works in a bending-pressing mode and converts vibration of an environment or energy generated when a human body walks into electric energy by using a piezoelectricity principle. The energy converter of the invention comprises a pair of piezoelectric units and a pair of bow-shaped elastic elements, wherein the piezoelectric units and the elastic elements are fixed by pre-loading devices; and the elastic elements convert a transverse force (or outside vibration) applied by the outside to an elastic strip into longitudinal (axial) pressure which is applied to the piezoelectric units and is amplified in the bending-pressing mode and then the piezoelectric units efficiently generate electricity through the piezoelectric effect. The invention further relates to the array of the force-electricity energy converter. The array is used for converting mechanical energy which is generated when the human body (including other moving vehicles) operates on a plate into the electric energy and outputting the electric energy. The force-electricity energy converter and the array thereof have the advantages of simple structure, low resonant frequency and low manufacturing cost and can guarantee to work for a long term under the high-pressure working condition.

Owner:PEKING UNIV

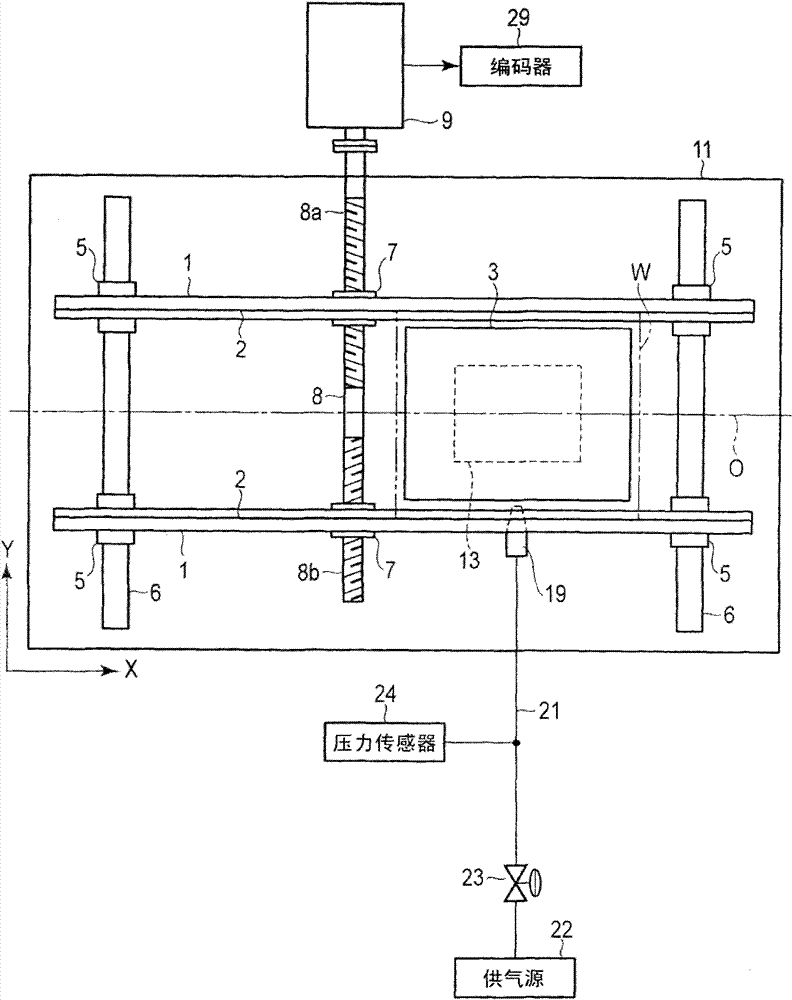

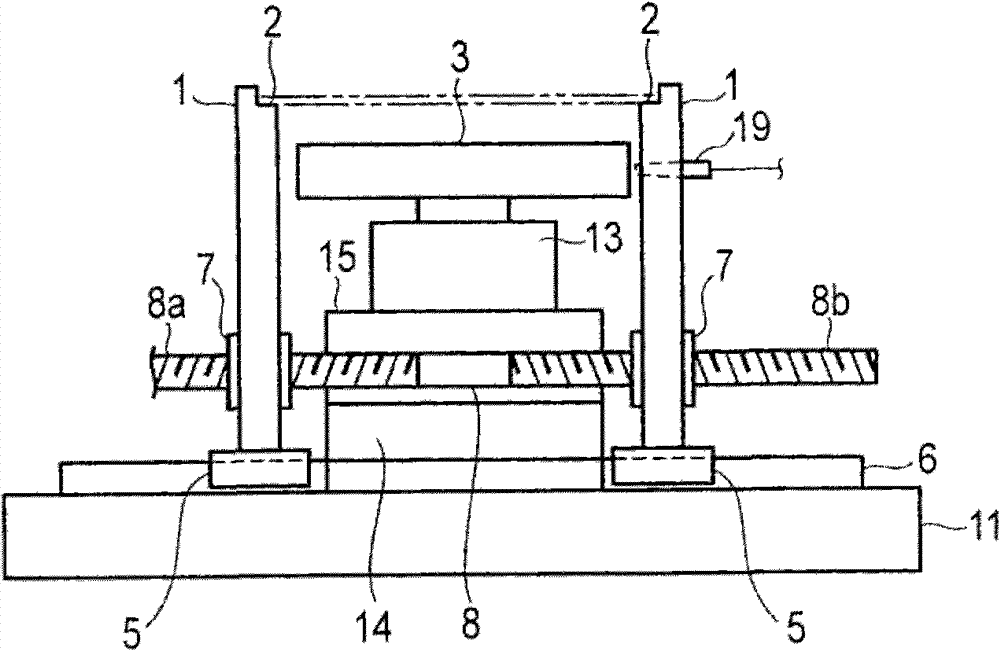

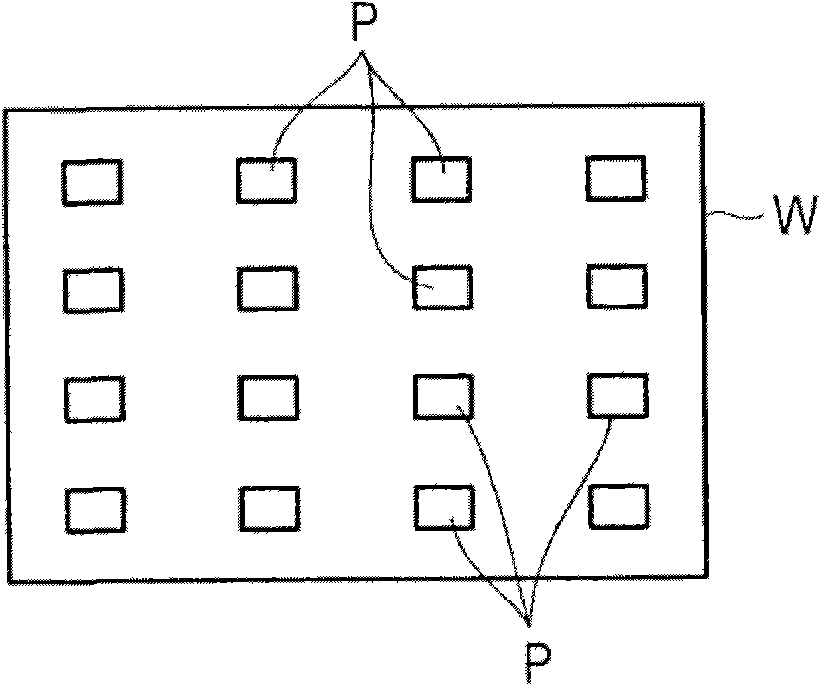

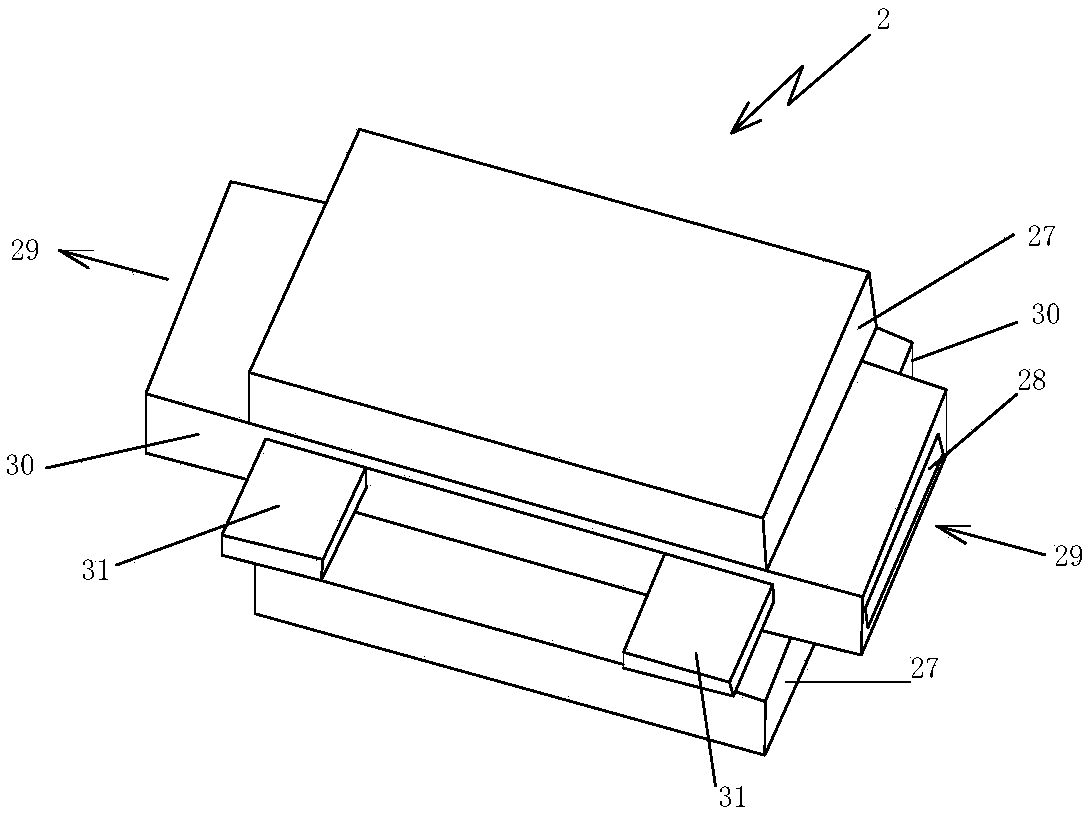

Substrate conveying apparatus and method

ActiveCN102760677AConveyorsSemiconductor/solid-state device manufacturingEngineeringAtmospheric pressure

The invention provides a substrate conveying apparatus and method. The substrate conveying apparatus comprises the following components: a spaced rotary drive source (9) provided with a pair of guide rails (1), a workbench (3) supporting the lower portion of the substrate at two end portions in the width direction supported by the pair of guide rails, a nozzle body (19) that makes the positive / negative air pressure work on the end face in the width direction of the workbench between the guide rails, a pressure sensor (24) used for detecting the pressure changes of the gas resulting from the interval change of the nozzle body and the side face of the workbench by making the air pressure work on the side face of the replaced workbench and driving the guide rails equipped with the nozzle body in the direction approaching the side face of the workbench, when the substrate size is changed and the workbench is changed into a workbench having different width size, and a control apparatus used for detecting the pressure changes of the gas flowing through the nozzle body via a pressure sensor, controlling the driving of a rotary drive source, and setting the space for a pair of guide rails.

Owner:SHIBAURA MECHATRONICS CORP

Mattress

InactiveUS20130263379A1Improve usabilityAvoid problemsStuffed mattressesSpring mattressesHuman bodyEngineering

The objective of the present invention is to provide a mattress including a plurality of cells provided on a body pressure working surface of a substrate that supports a human body, and a pressure control means that changes a setting of a height of each cell by adjusting a pressure in a fluid chamber formed within the cell. An elastic cushion layer is provided on a body pressure working surface of the cells, and a constricted portion is formed in a middle in the height of the each cell so that the body pressure working surface of the cell is allowed to tilt following deformation of the cushion layer as a result of the cells' precession-deformation at the constricted portion.

Owner:SUMITOMO RIKO CO LTD +1

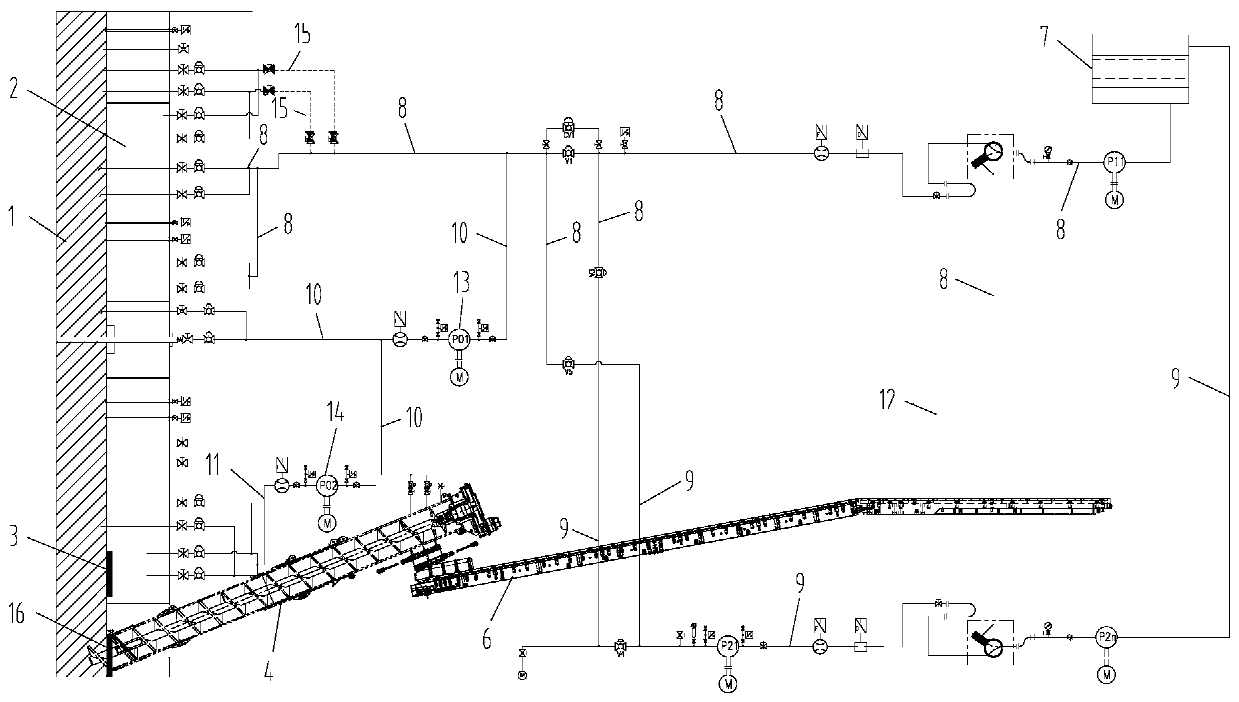

Slurry balance shield machine with freezing function

ActiveCN105298506AAvoid problems such as pressing into the warehouse and changing toolsAvoid influenceTunnelsSlurryHigh heat

The invention discloses a slurry balance shield machine with the freezing function. A freezing unit, a storage tank and a heating device are independently arranged or are added to an accessory system behind the slurry balance shield machine; freezing circulation pipes are added in a cutter head or on the side face of the cutter head, or in a shield body or on the outer side of the shield body, and therefore liquid, semi-liquid and solid substances within a certain range around the cutter head, in a slurry warehouse and around the shield body can be frozen. Heating pipelines are additionally arranged on the side, close to an air cushion chamber, of a front partition plate, high-temperature heat conduction liquid is input into the heating pipelines and the freezing pipelines through the heating device, and therefore a main driving unit and a center rotating connector can be protected and a frozen area can be molten. The slurry balance shield machine with the freezing function performs maintaining operation under the normal pressure work condition, and the phenomenon of entering the warehouse for tool changing under pressure in the maintaining process of the slurry balance shield machine is avoided.

Owner:CHINA RAILWAY CONSTR HEAVY IND +2

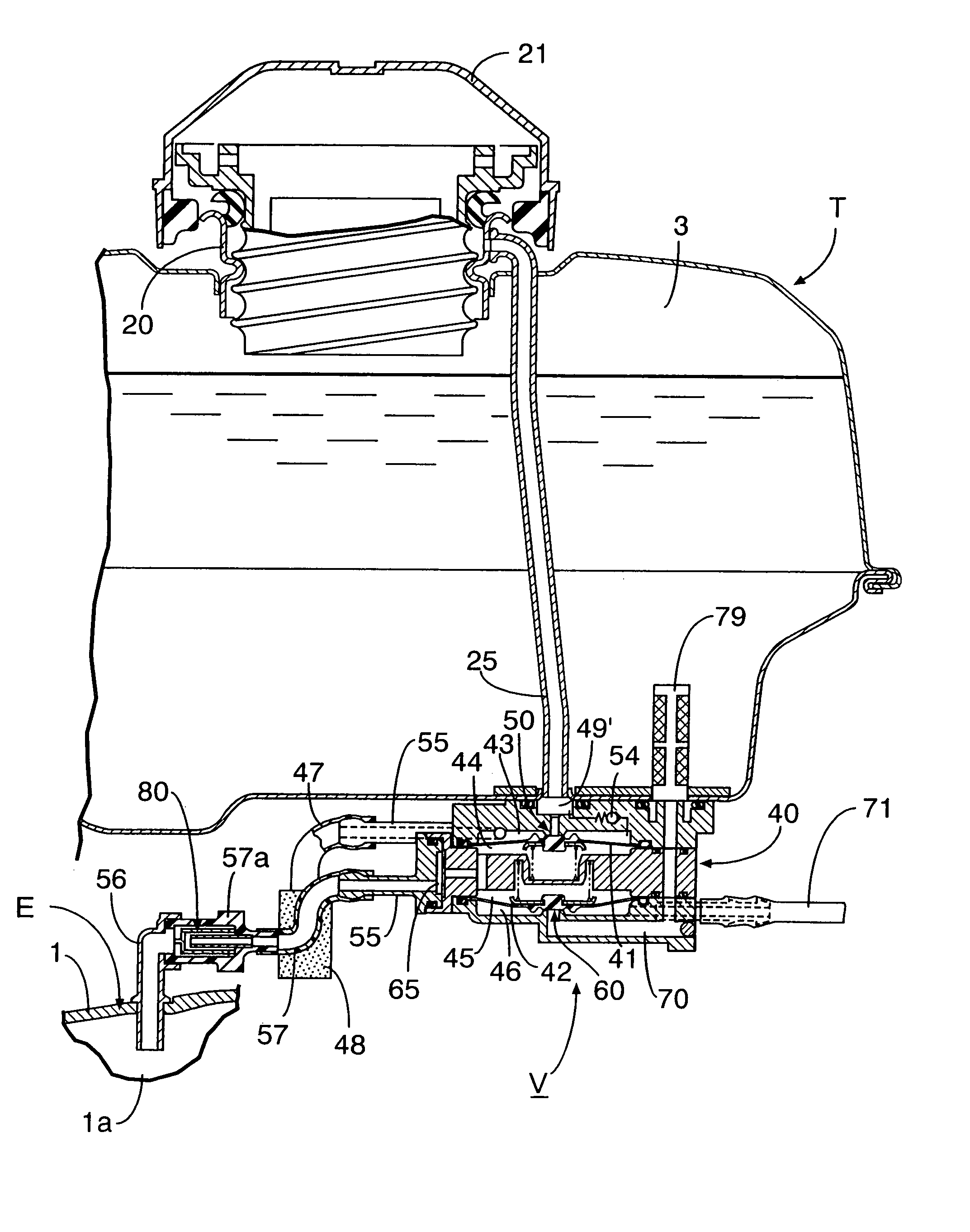

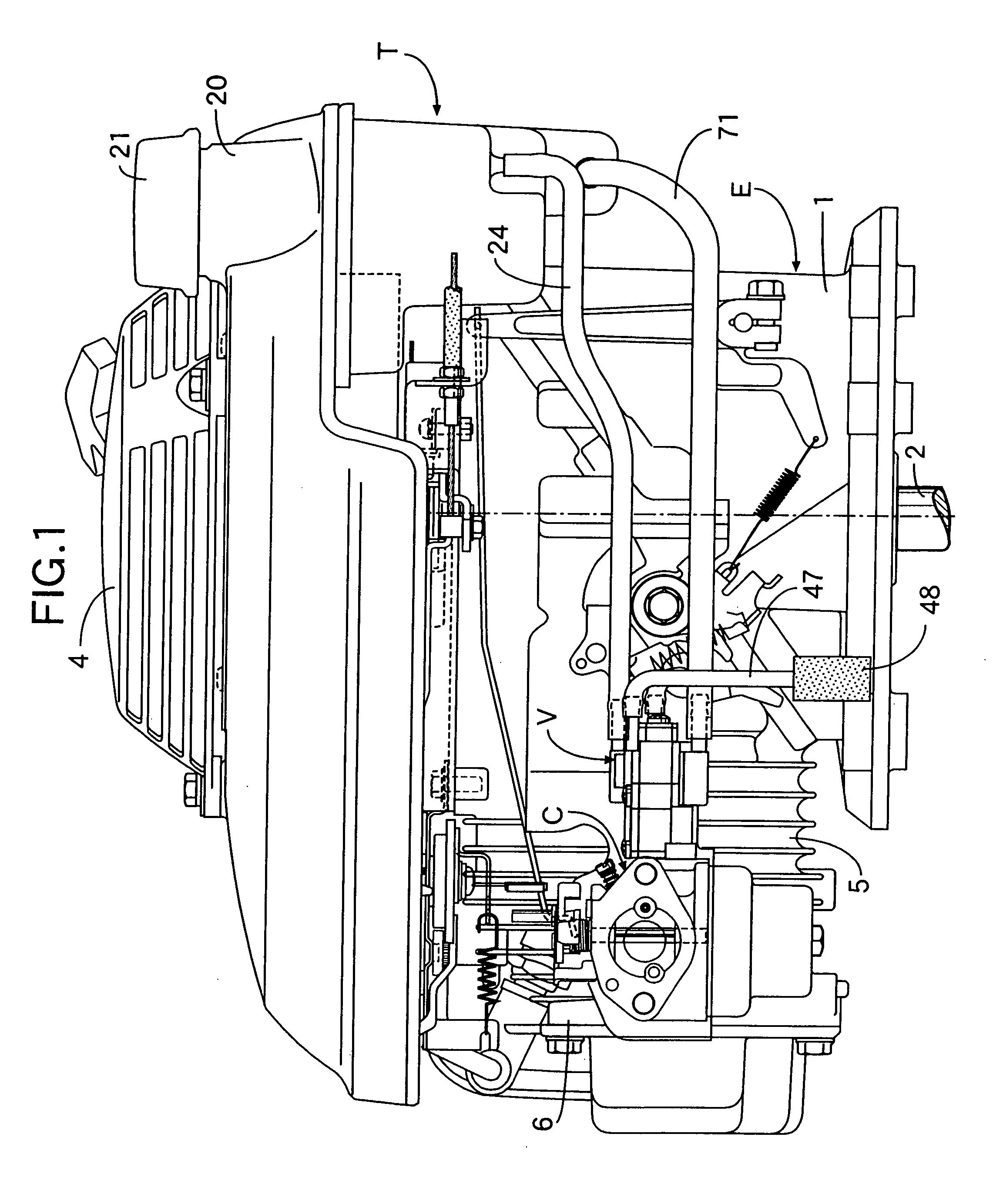

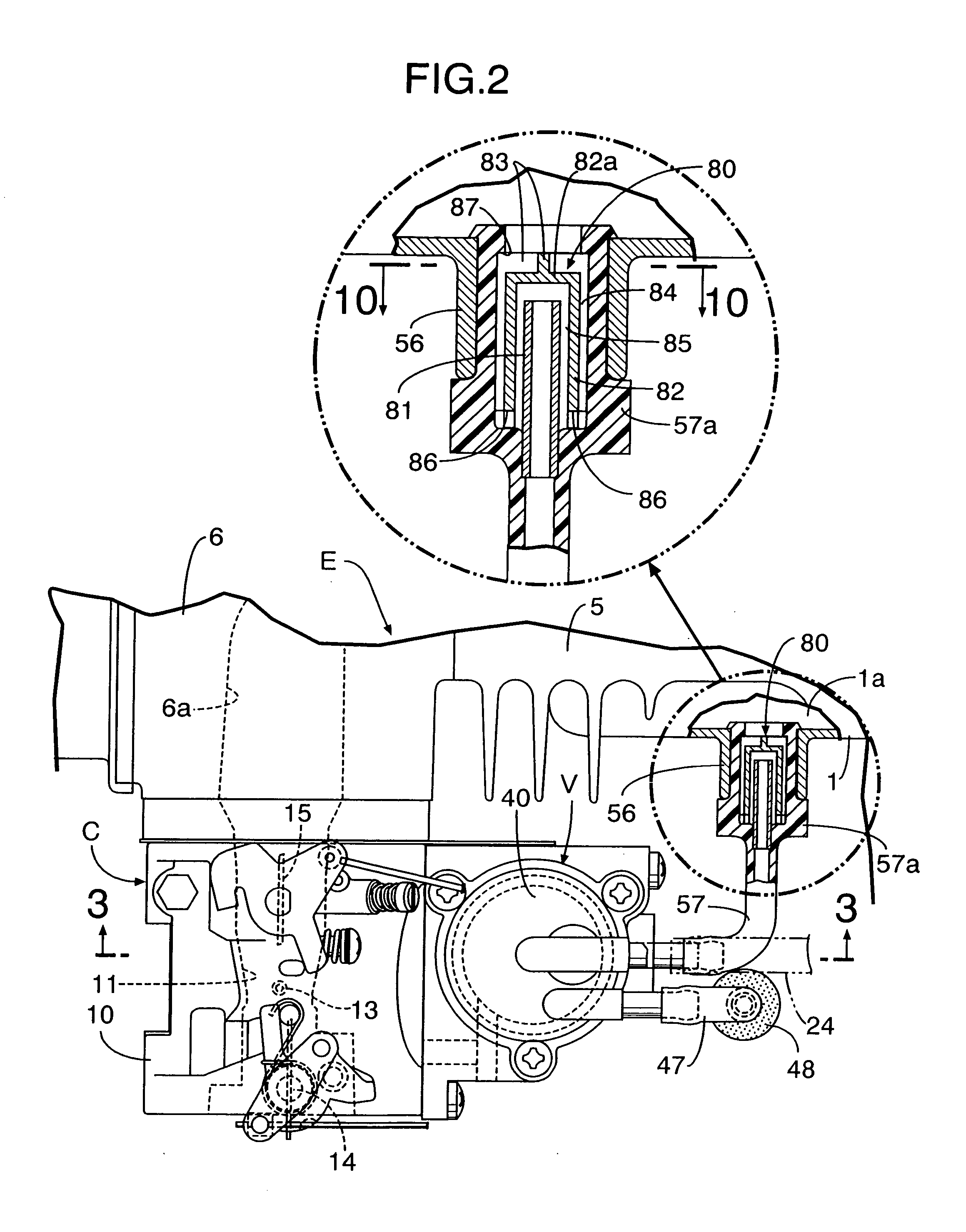

Fuel supply control system for engine

InactiveUS20050028781A1Reliable transmissionSimple structureLighting and heating apparatusUsing liquid separation agentPressure workFuel supply

In a fuel supply control system for an engine in which a valve housing is provided with a negative pressure working chamber, and a negative pressure responsive-type control valve operable to be opened and closed in response to generation and extinction of a negative pressure in the negative pressure working chamber, the control valve being incorporated into a fuel passage between a fuel tank and a carburetor, the negative pressure working chamber being in communication with a negative pressure generating section in the engine through a negative pressure conduit, an oil flow-out preventing device is provided in a connecting portion for connecting the negative pressure generating section and the negative pressure conduit to each other. The oil flow-out preventing device is adapted to cut off the communication between the negative pressure generating section and the negative pressure conduit by a lubricating oil received from the negative pressure generating section, when the engine is inclined at a given angle or more. Thus, in an operational attitude of the engine, the transmission of the negative pressure from the negative pressure generating section to the negative pressure conduit is not obstructed, and even when the engine is inclined at the given angle or more in an operation-stopped state of the engine, the lubricating oil in the engine can be prevented from flowing out toward the negative pressure conduit.

Owner:HONDA MOTOR CO LTD

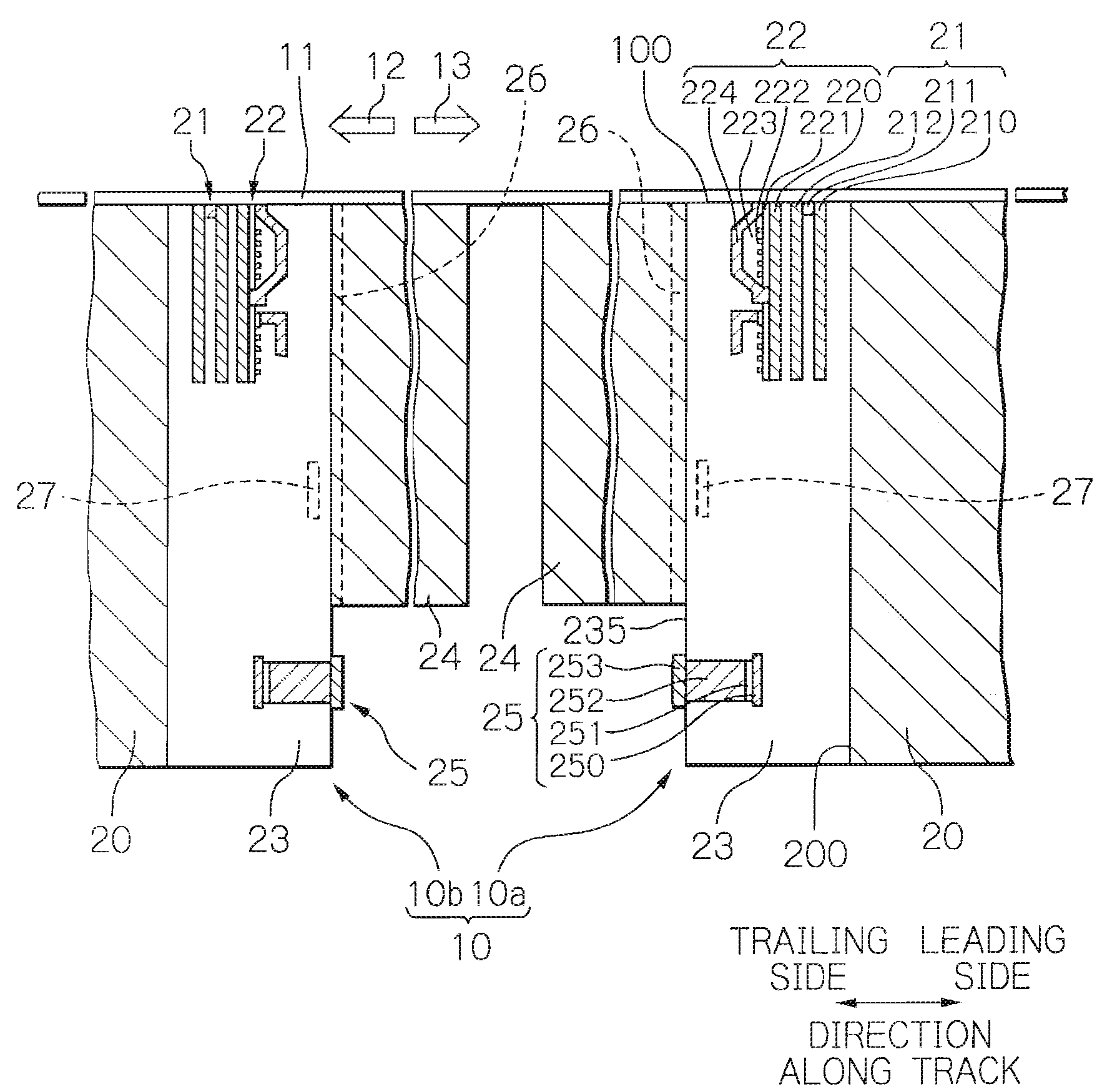

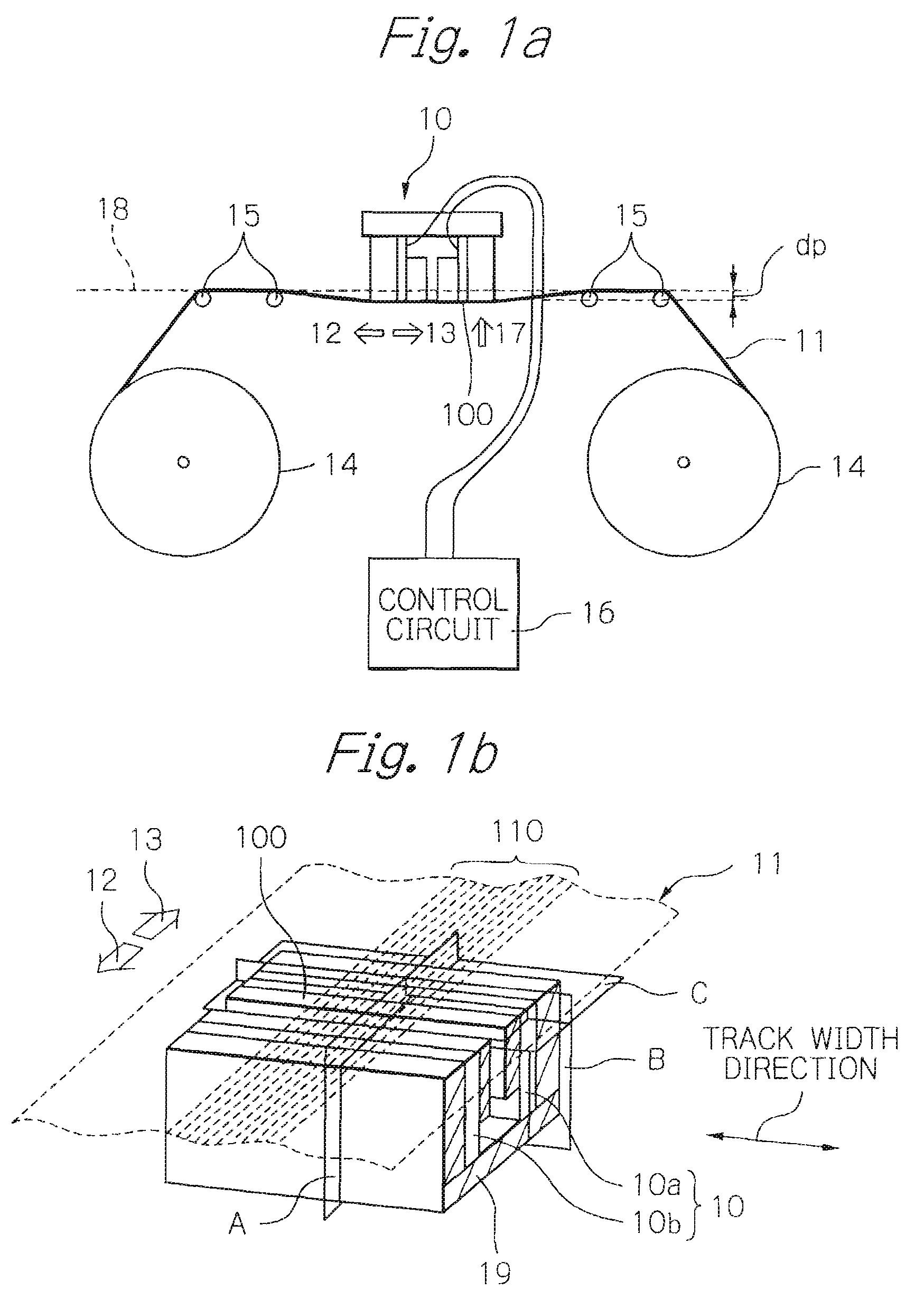

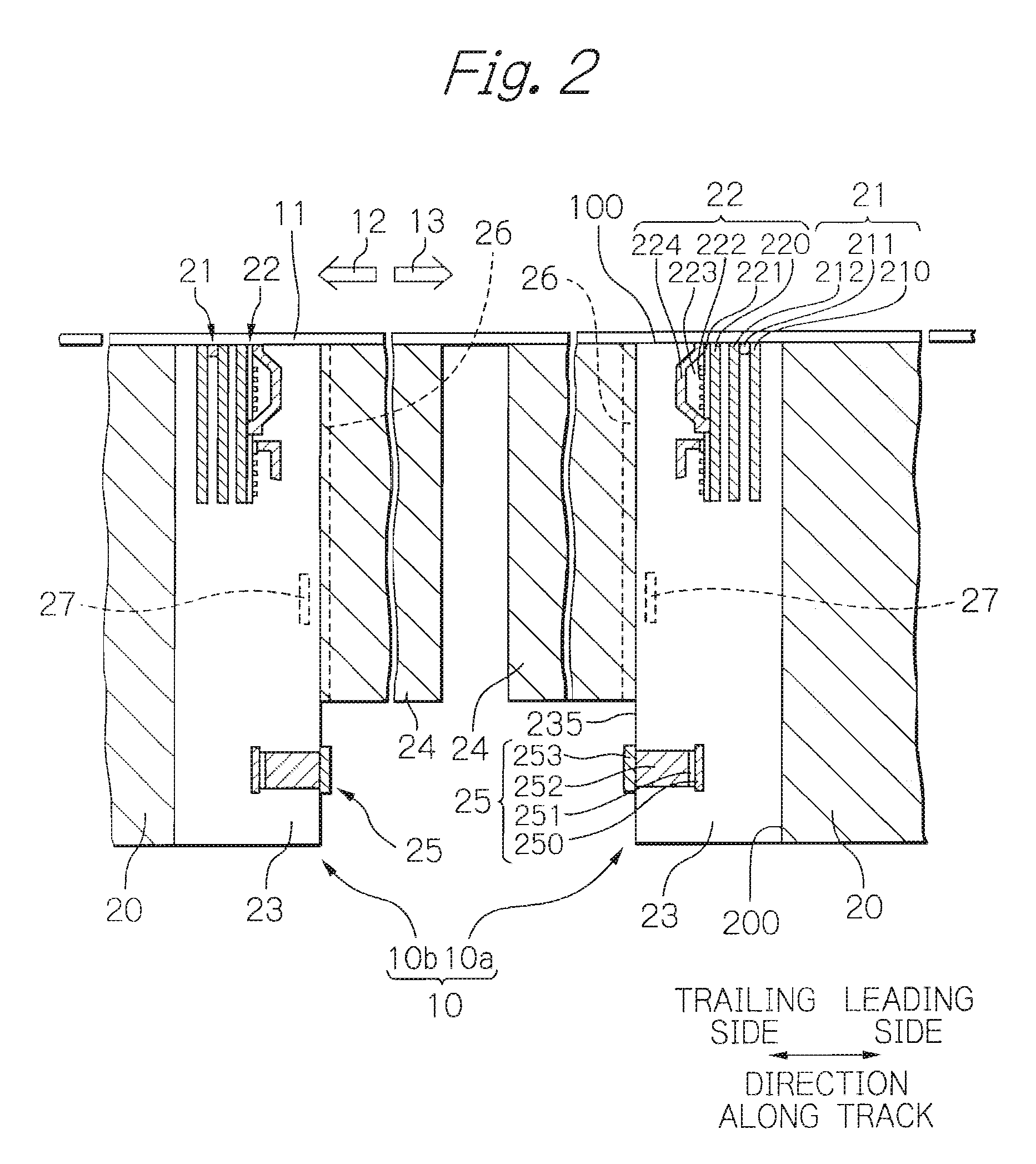

Thin-film magnetic head with through holes reaching medium-opposed surface

InactiveUS20090154024A1PressureMagnetic spacing can be stably controlledManufacture head surfaceFluid-dynamic spacing of headsEngineeringElectrical and Electronics engineering

Owner:TDK CORPARATION

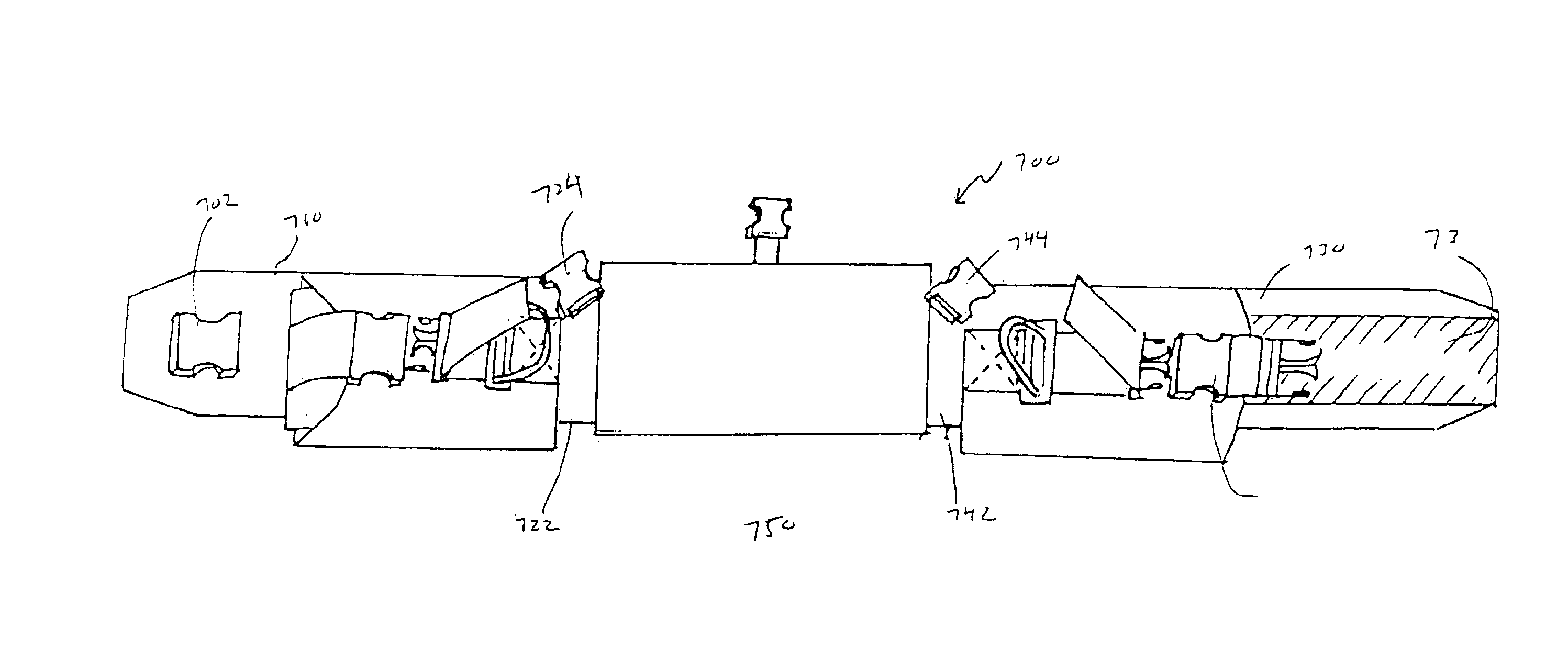

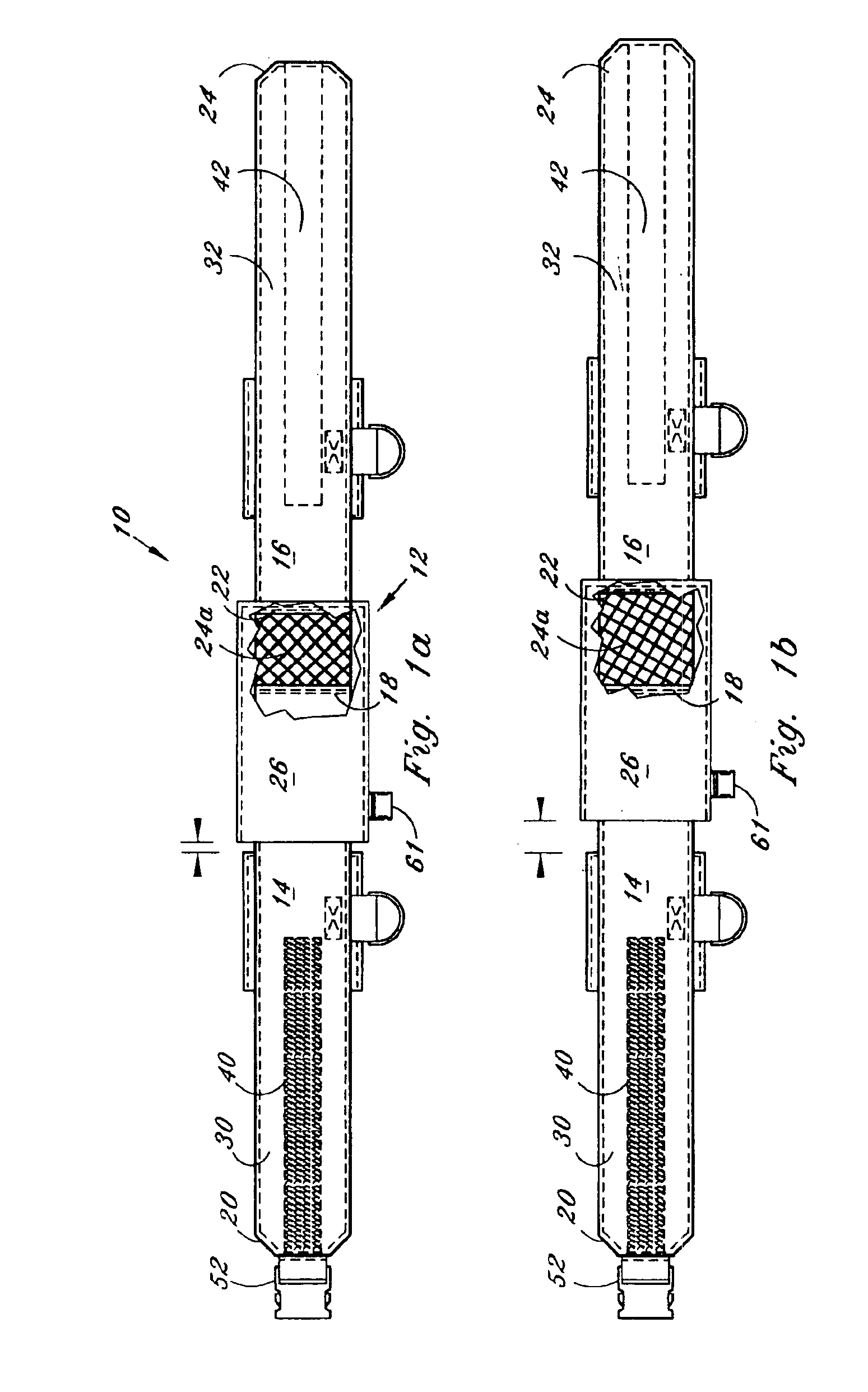

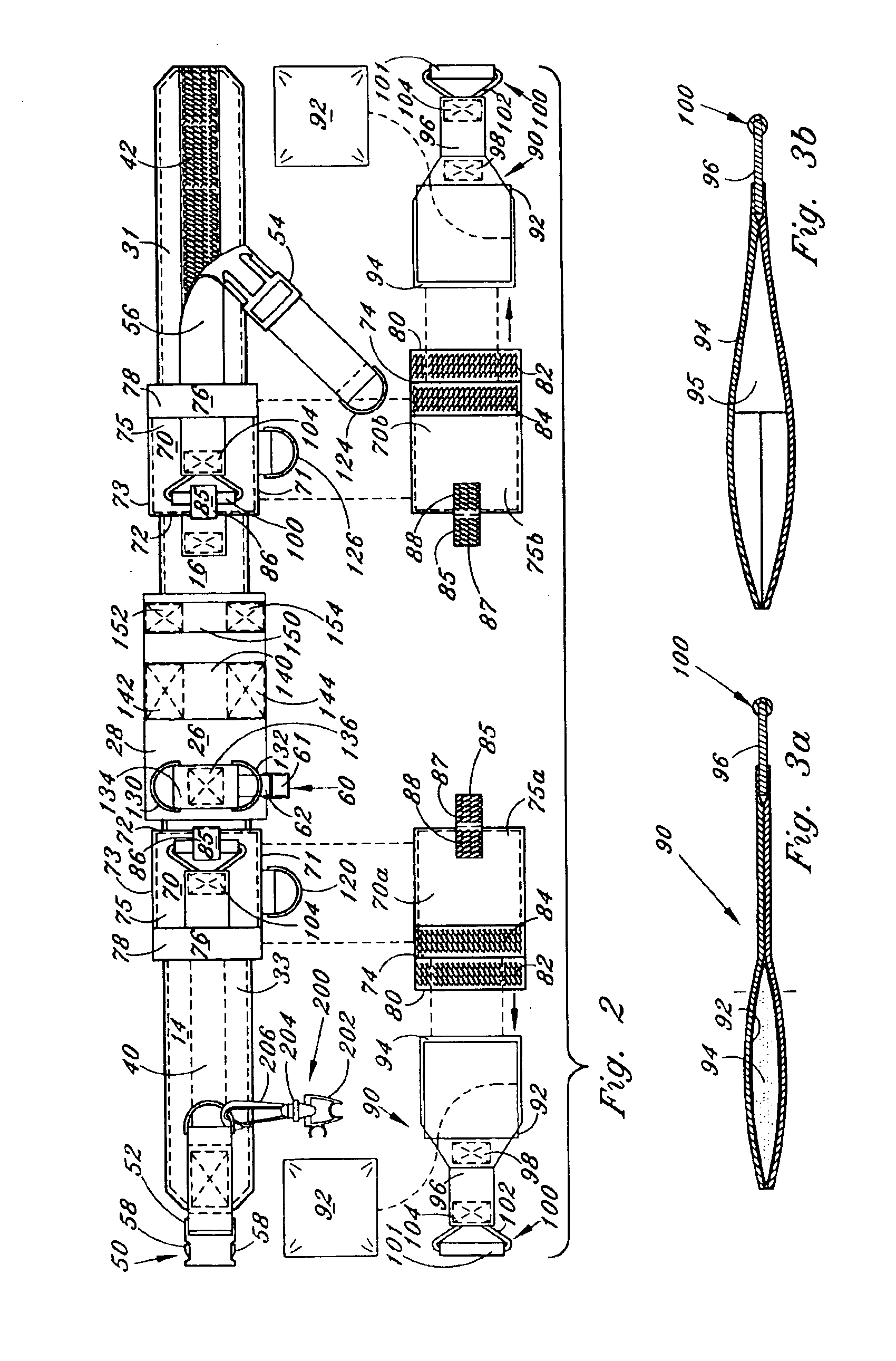

Buoyancy compensator, utility backpack, transport harness or like garment with adjustable one size component for use by a wide range of individuals

A girth adjustable waist belt that easily converts to a diver's buoyancy compensator with / without integrated weight system and can also easily convert to a utility backpack and belt in which one single size will fit the general population is provided. The mega-adjustable feature also provides secure yet expandable lower back and abdominal support offering physical protection in stressful work conditions. A dive belt is also provided for use by divers during underwater activities, such as scuba diving. The belt comprises a body member and a rapid release weight system which is quickly removal while the belt remains in place on the diver. The belt can also provide for horizontally mounted supplemental air supply system, for use in the event a main air supply is lost or not wanted. In all embodiments, an elastic depth compensator can be built into the belt, insuring a snug fit of the belt at any depth. The belt has a plurality of D-rings for convenient equipment management. A quick release tow clip is attached to the belt and may be used in conjunction with a surface air supply system for pulling the surface air supply system.

Owner:TREBOR IND

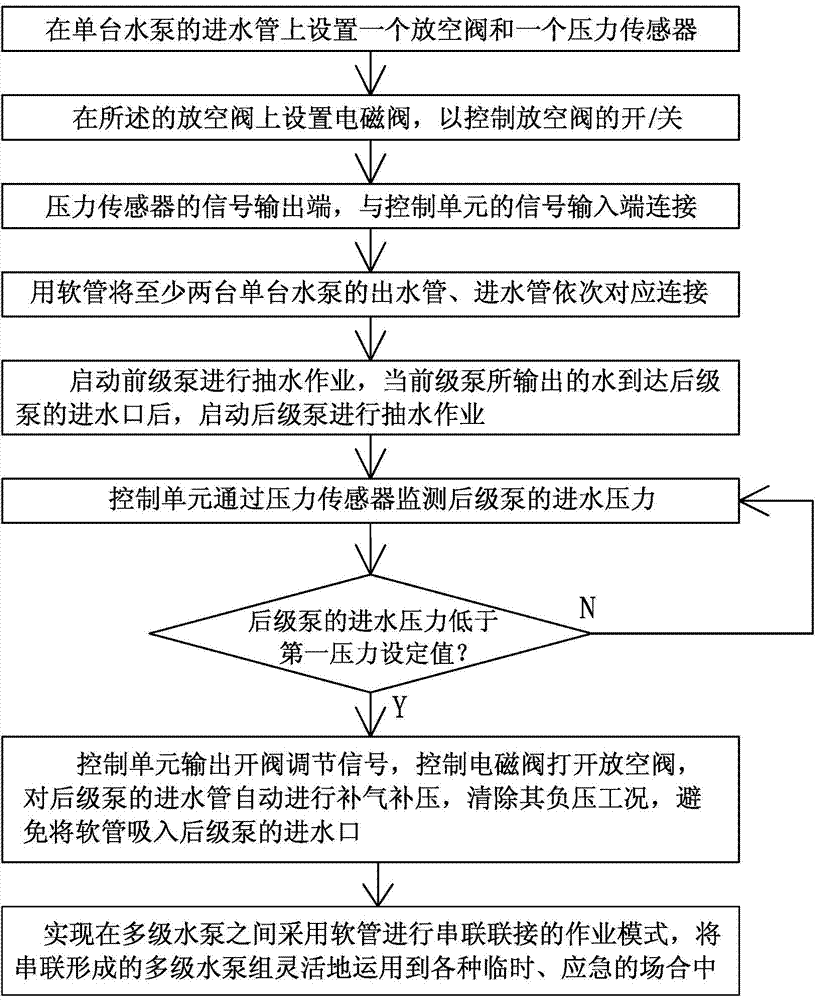

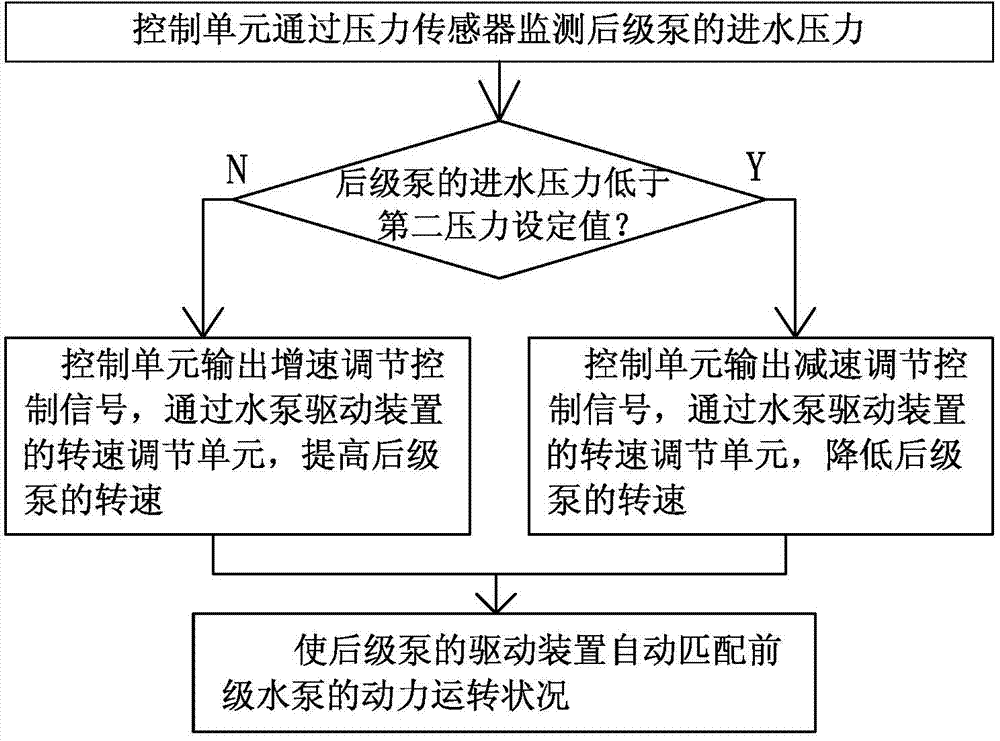

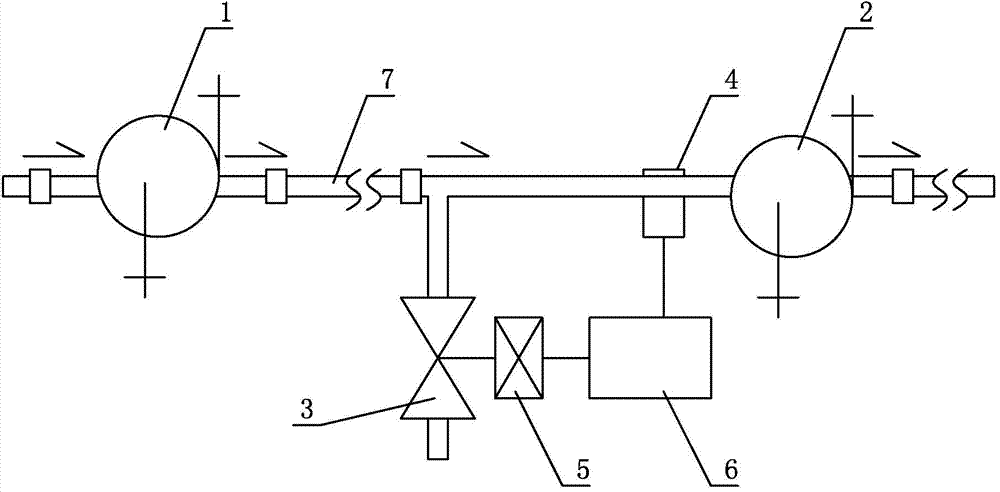

Method for serially connecting a plurality of water pumps by using hoses

ActiveCN103758764AAvoid the phenomenon of inhalation into the water inletImplementing the Job Mode for Serial JoinsPump installationsNon-positive displacement fluid enginesInlet pressureOperation mode

The invention relates to a method for serially connecting a plurality of water pumps by using hoses and belongs to the field of a non-positive displacement pump. An emptying valve and a pressure sensor are arranged on a water pump water inlet pipe; an electromagnetic valve is arranged on the emptying valve; a signal output end of the pressure sensor is connected with a signal input end of a control unit; a signal output end of the control unit is connected with a control input end of the electromagnetic valve; water inlet and outlet pipes of at least two water pumps are correspondingly connected by using the hoses; a water outlet pipe port of a preceding stage pump is correspondingly connected with a water inlet pipe port of a succeeding stage pump; during operation of the water pumps, the control unit monitors water inlet pressure of the succeeding stage pump through the pressure sensor; when the water inlet pressure of the succeeding stage pump is lower than a pressure set value, the control unit controls the electromagnetic valve to open the emptying valve to automatically supplement air and pressure for the water inlet pipe of the succeeding stage pump, so that negative pressure working conditions of the water inlet pipe of the succeeding stage pump can be removed, and the hoses are prevented from being sucked by the water inlet of the succeeding pump; by means of the method, an operation mode of serially connecting the multi-stage pumps by using the hoses is achieved; the method can be widely applied to the field of design and manufacture of a movable water pump.

Owner:潘红兵

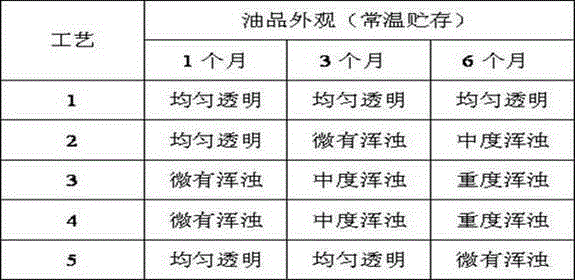

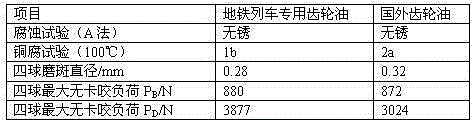

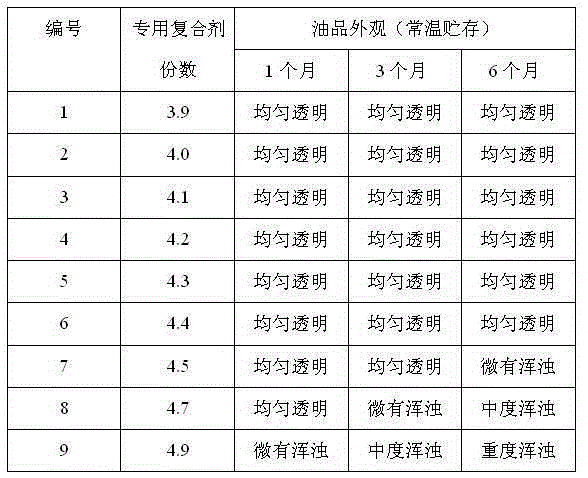

Subway train special gear oil and preparation method

InactiveCN105296115APrevent severe heatImprove high temperature stabilityAdditivesHigh torqueHeavy duty

A subway train special gear oil is particularly suitable for using in high temperature and extreme pressure work status of a subway train in frequent start, braking and high-speed operation, has excellent high temperature stability, resistance to extreme pressure and anti-wear properties and high temperature oxidation resistance, ensures subway train gearboxes maintain stable oil films under very heavy duty conditions, reduces noise, prevents gear wear, can effectively prevent and subway train low rotation speed / high torque wear and intense heat produced in high-speed operation, and is especially suitable for using in high temperature and extreme pressure work status of the subway train in frequent start, braking and high-speed operation. By use of the subway train special gear oil, the gear oil change period may be extended by more than 20%, and the subway operating cost is reduced.

Owner:JIANGXI KIRBY LUBRICANT PROD

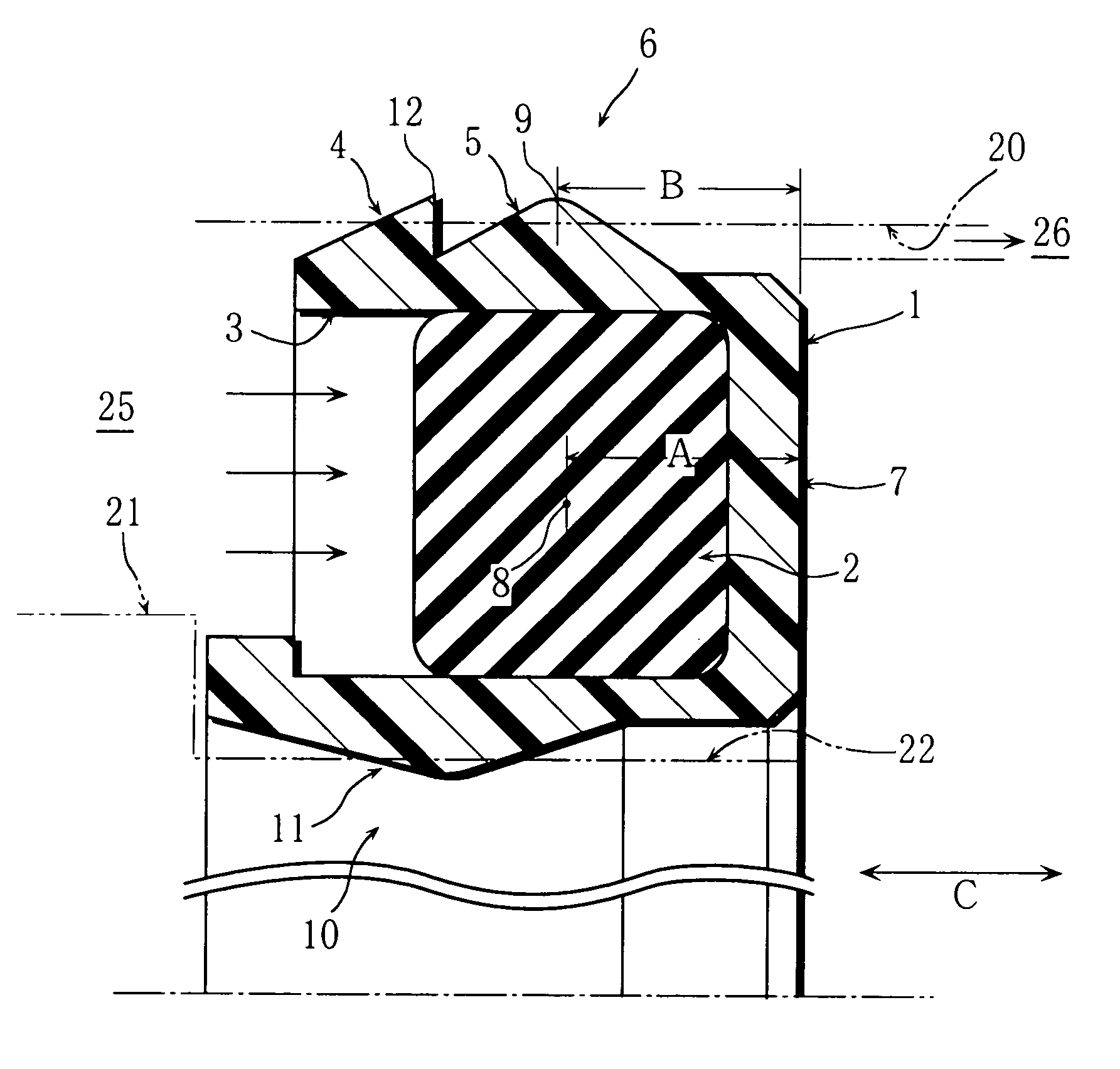

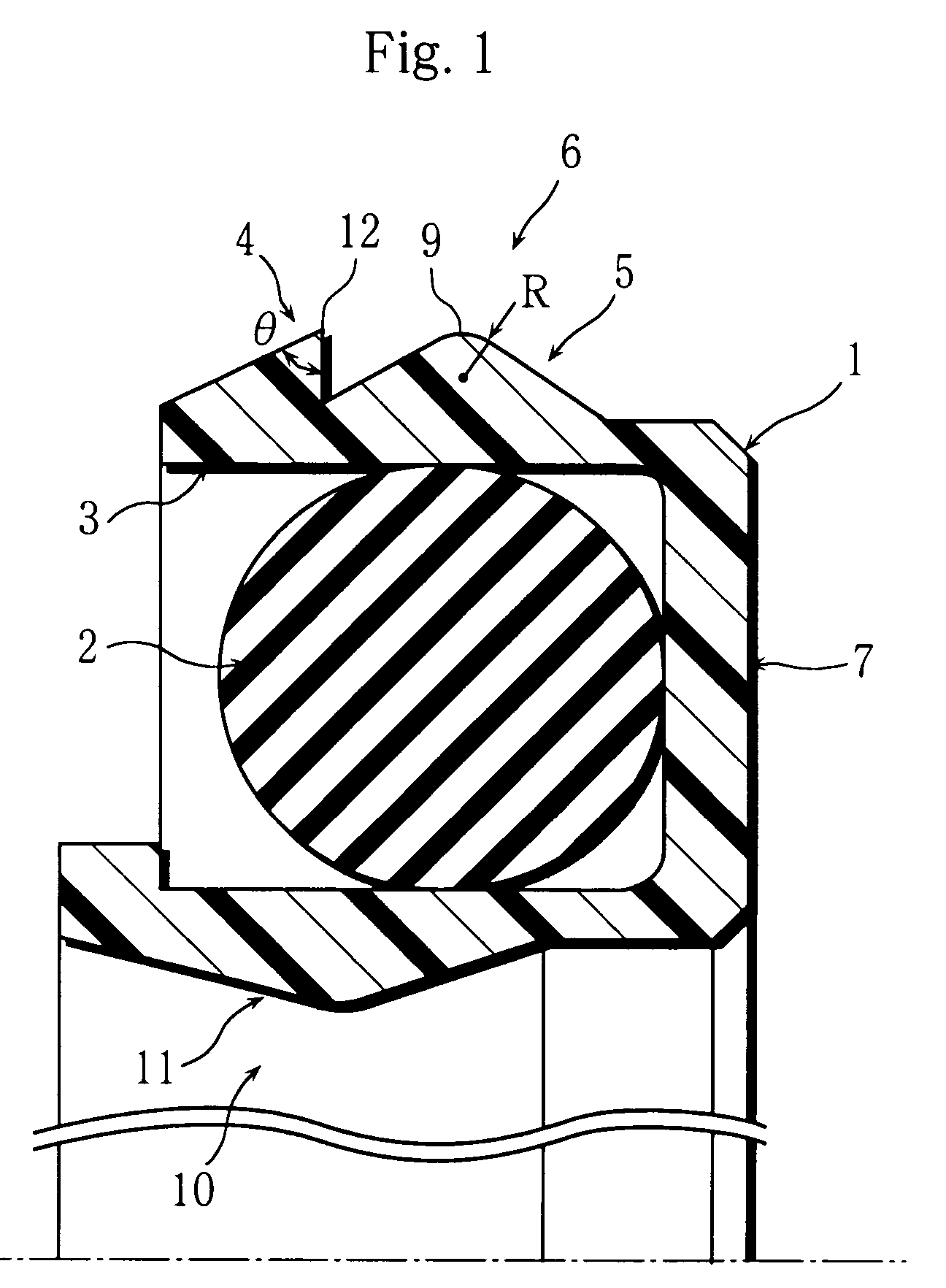

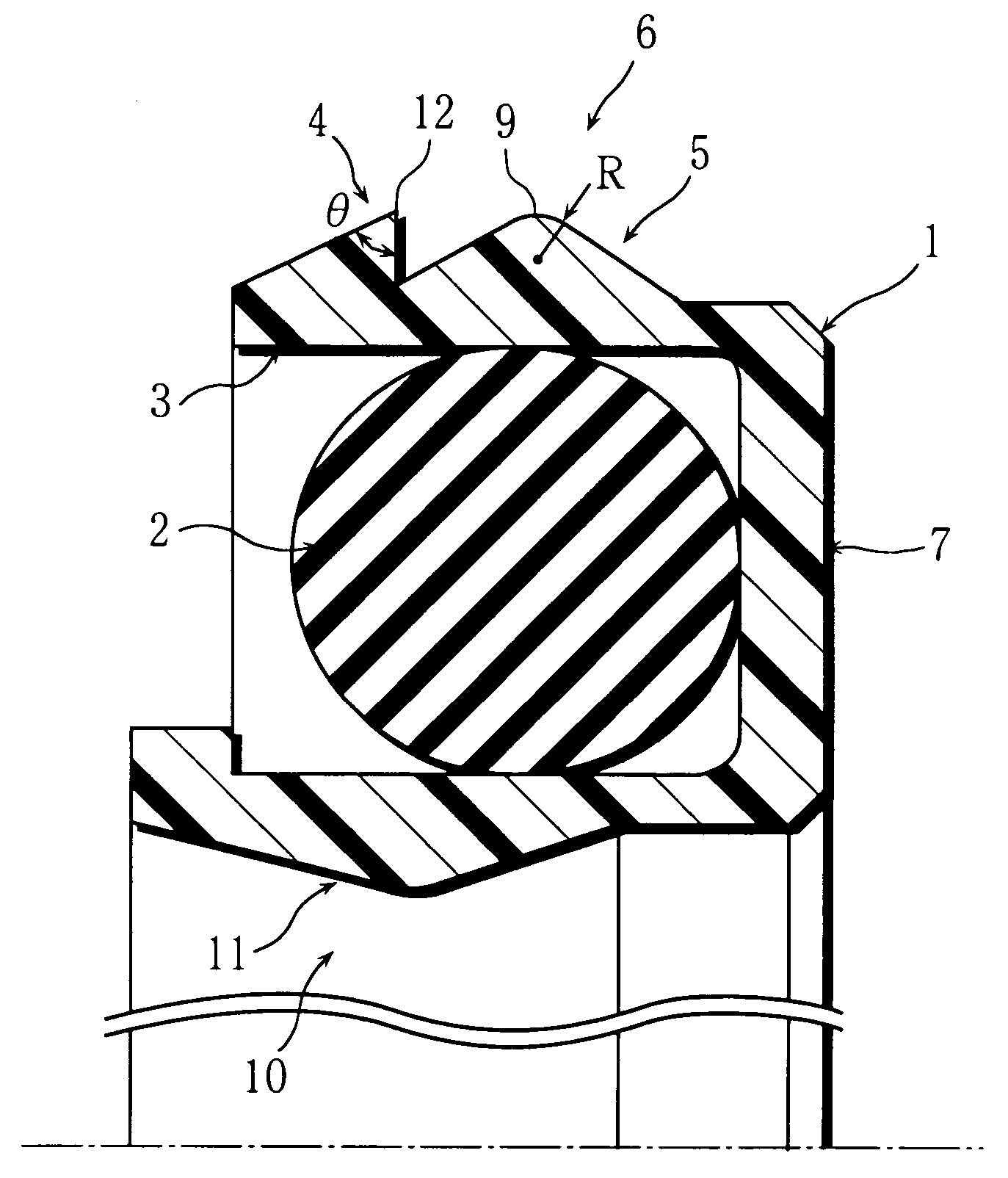

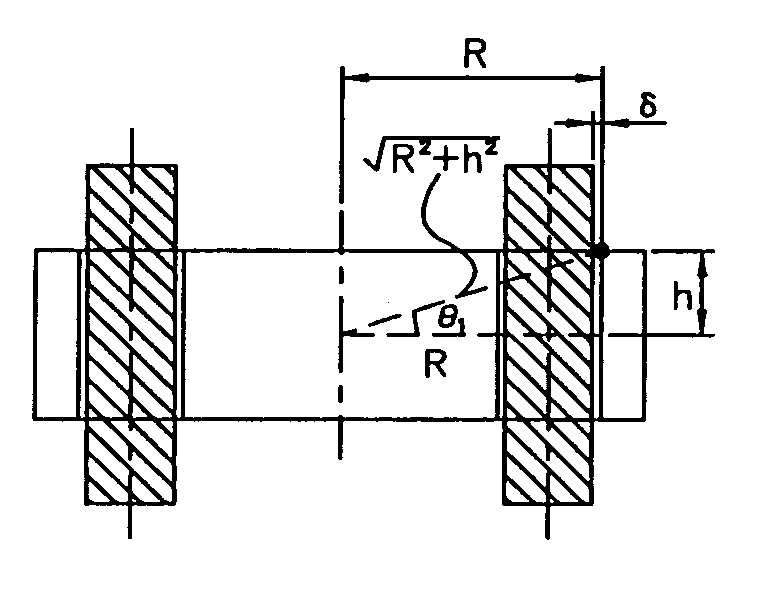

Axial compliant means for a scroll machine

InactiveUS20050025652A1Improve sealingDecrease possible slantEngine of arcuate-engagement typeOscillating piston enginesPressure workWorking fluid

An axial compliant means for a scroll machine, wherein a second scroll revolves around a first scroll to form multiple compression chambers including a low pressure chamber, a medium pressure chamber and a high pressure chamber with working fluid pressure in them increasing gradually and radial-inwardly; a piston with multiple guided holes being subject to pressure of the working fluid connecting to one of those compression chambers through a flow passage is pushed-sliding straight by corresponding multiple guiding posts and pushing both of the scrolls to be axially in touch and sealed with each other.

Owner:RECHI PRECISION

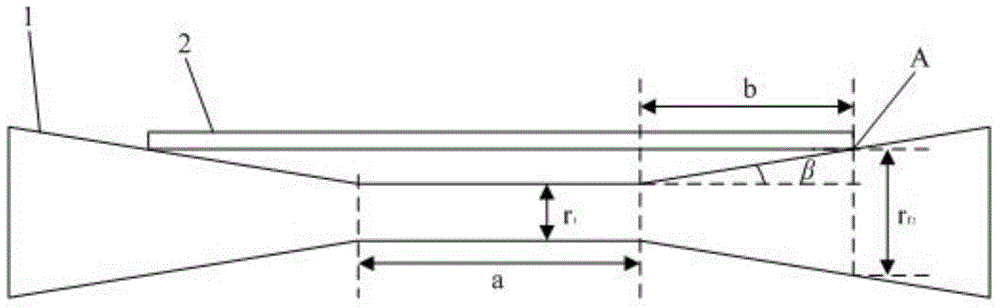

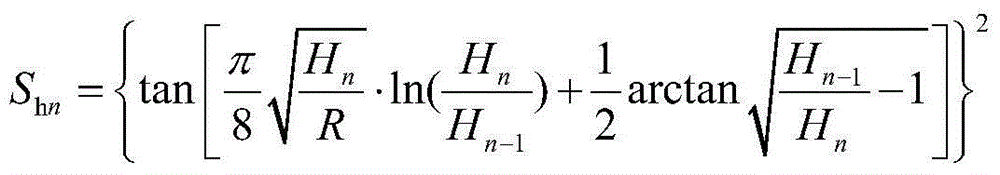

Speed cooperative control method for heavy and medium plate mill and conical roller beds

ActiveCN104942014AExtended service lifeNot easy to stainMetal rolling arrangementsRoll speed control deviceSlip coefficientEngineering

The invention discloses a speed cooperative control method for a heavy and medium plate mill and conical roller beds and relates to the technical field of metal pressure working. The speed cooperative control method for the heavy and medium plate mill and the conical roller beds includes the following steps that according to a roller bed rolling parameter of a plate, a forward slip coefficient in a plate rolling process is calculated, and the roller bed rolling parameter is obtained from a rolling mill two-stage process model set system; speeds of the plate rolled in the roller bed at the inlet position and the outlet position of a rolling mill are calculated through the rotating speed of a roller of the rolling mill and the obtained forward slip coefficient; the rotating speeds of the rolling mill at the inlet and the outlet conical roller beds are calculated respectively according to the inlet speed and the outlet speed of the plate, the width of the plate and the geometrical shape parameters of the conical roller beds, the calculated rotating speed values are sent to a roller bed motor transmission system for execution, and therefore speed setting is conducted respectively for the front and the rear conical roller beds of the rolling mill. The speed cooperative control method for the heavy and medium plate mill and the conical roller beds solves the problems that the contact portion of the plate and the conical roller beds is poor in linear speed, and the surface quality of the plate and the service life of the roller beds are seriously affected.

Owner:GUANGXI LIUZHOU YINHAI ALUMINUM IND

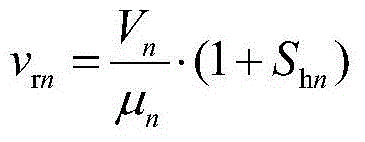

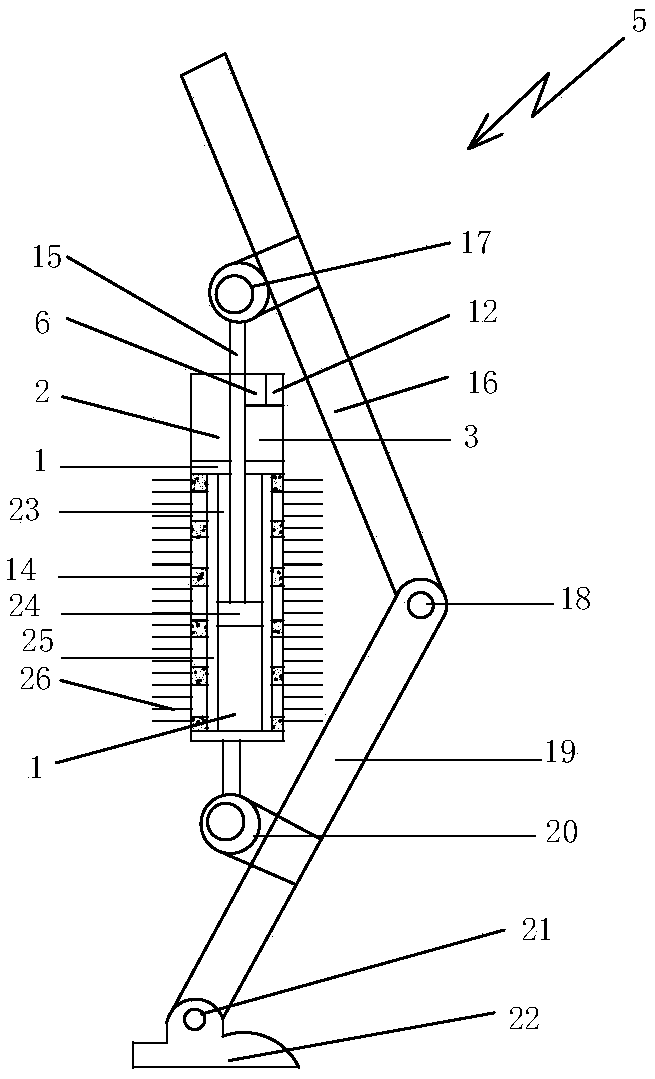

Liquid metal pressure-driven type robot joint and self-generating electricity device

InactiveCN108657305AImprove performanceHigh temperature resistantBatteries circuit arrangementsElectric powerPressure.driveLiquid metal

The invention discloses a liquid metal pressure-driven type robot joint and self-generating electricity device. The liquid metal pressure-driven type robot joint and self-generating electricity devicecomprise a thermal-temperature-difference electricity generation liquid metal pressure working cylinder, a liquid metal magnetofluid generator, a servo valve, a magnetic pump, a robot joint body, a sensor, an intelligent controller, a one-way valve, a filter, an overflow valve and a liquid metal storage tank, a super capacitor. The liquid metal pressure working cylinder and a thermal-temperature-difference generator are combined to form an integrated structure, and the thermal-temperature-difference electricity generation effect is produced. The thermal-temperature-difference electricity generation liquid metal pressure working cylinder and the liquid metal magnetofluid generator are combined, and liquid metal of the robot joint device passes through a magnet and cuts a magnetic force line to produce liquid metal magnetofluid electricity generation effect. Therefore, the robot joint device has the dual self-generating electricity functions of thermal temperature difference electricitygeneration and magnetofluid electricity generation, and provides the electric energy guarantee for the walking motion of a robot.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

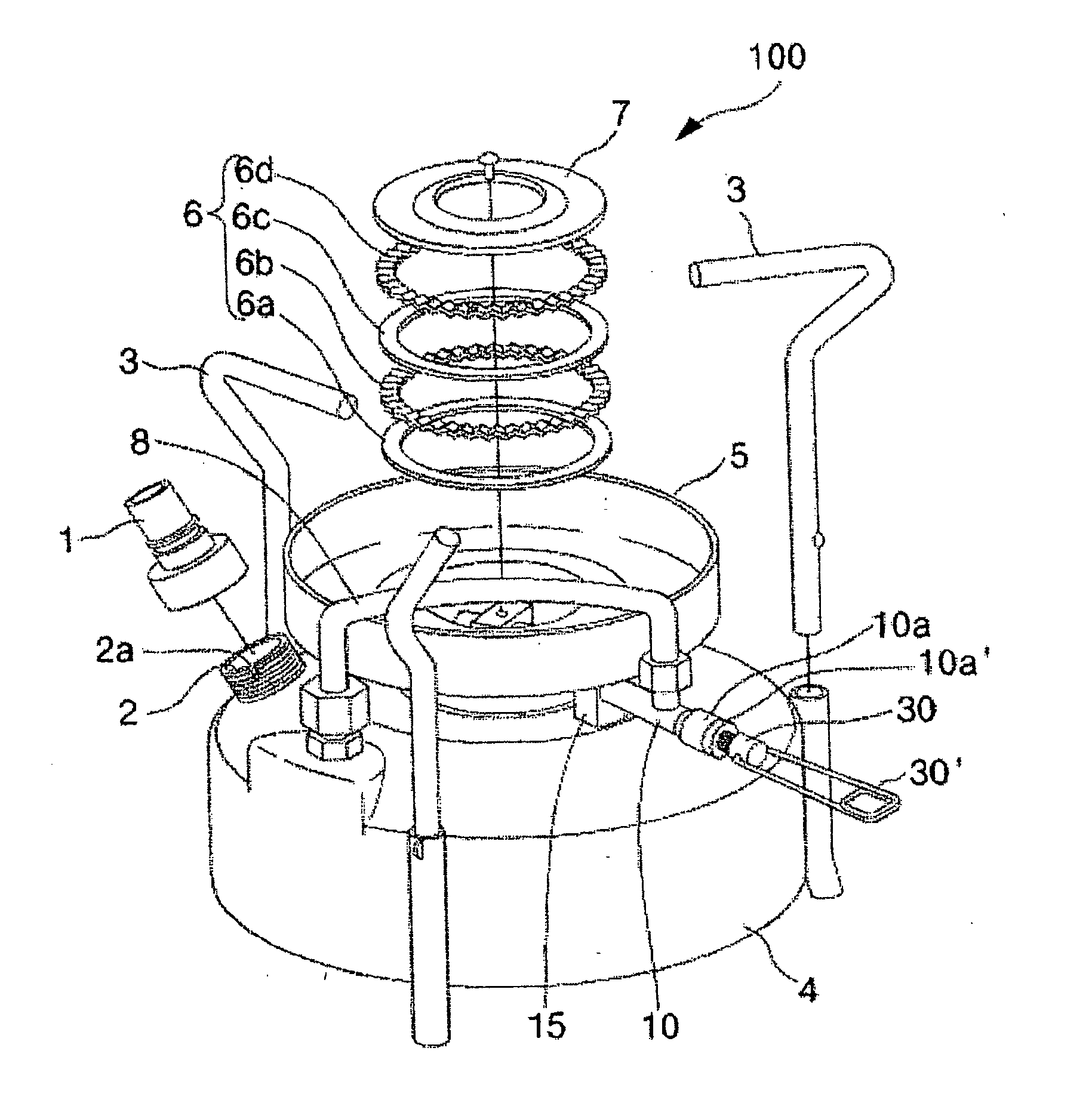

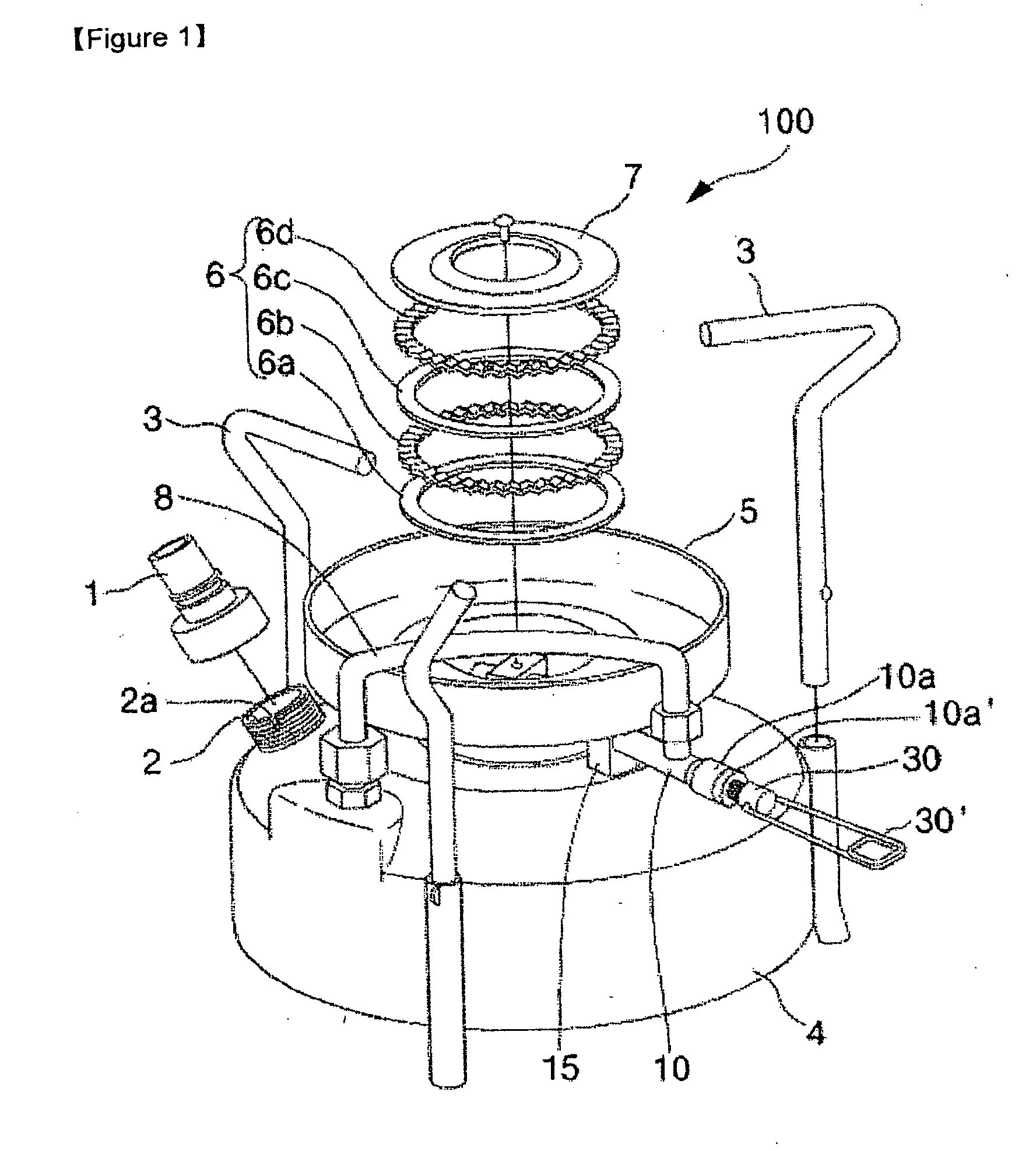

Portable no-pump multi-fuel stove

InactiveUS20050224067A1Eliminate processingUnnecessary energy consumptionStoves/ranges foundationsDomestic stoves or rangesCombustionGasoline

Disclosed is a portable no-pump multi-fuel stove that may use gasoline and butane together. Butane gas is injected above gasoline in the fuel tank so that the butane gas is combusted at an initial ignition stage, thereby eliminating the need of preheating resulting from incomplete combustion of gasoline at an initial ignition stage in a conventional gasoline stove. Once a certain amount of butane is combusted, though butane is not supplied, gasoline is continuously inhaled, vaporized and injected by means of vapor pressure in the fuel tank and osmotic pressure of the inhaling member without any gasoline pressuring work. The nozzle is not easily separated but easily exchanged. The gas discharge hole is formed downward at one side of the fuel injection hole. The inhaling member is filled to a middle portion of the entire length of the preheating tube so that the stove has small and light structure.

Owner:PARK YONG IL

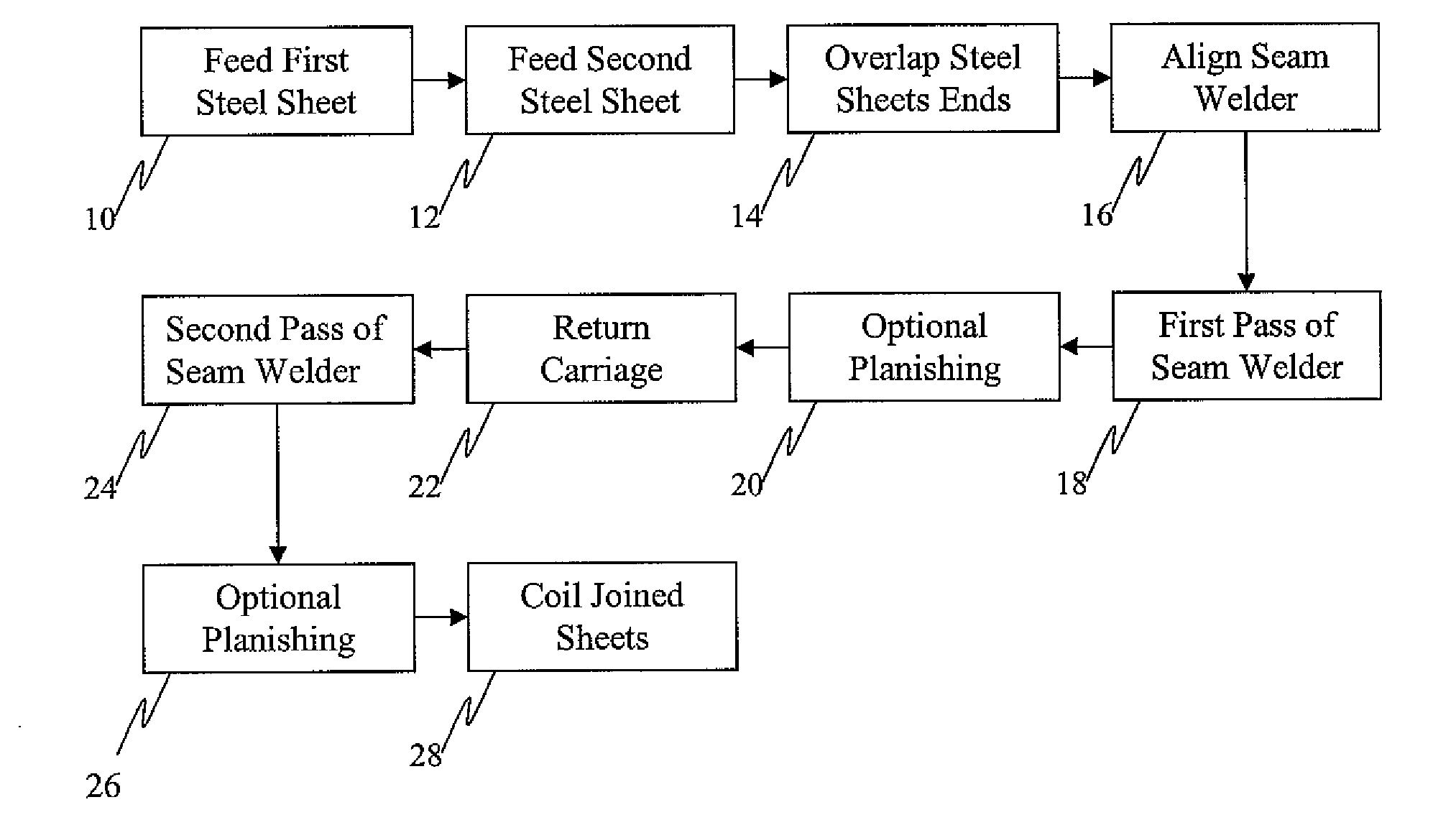

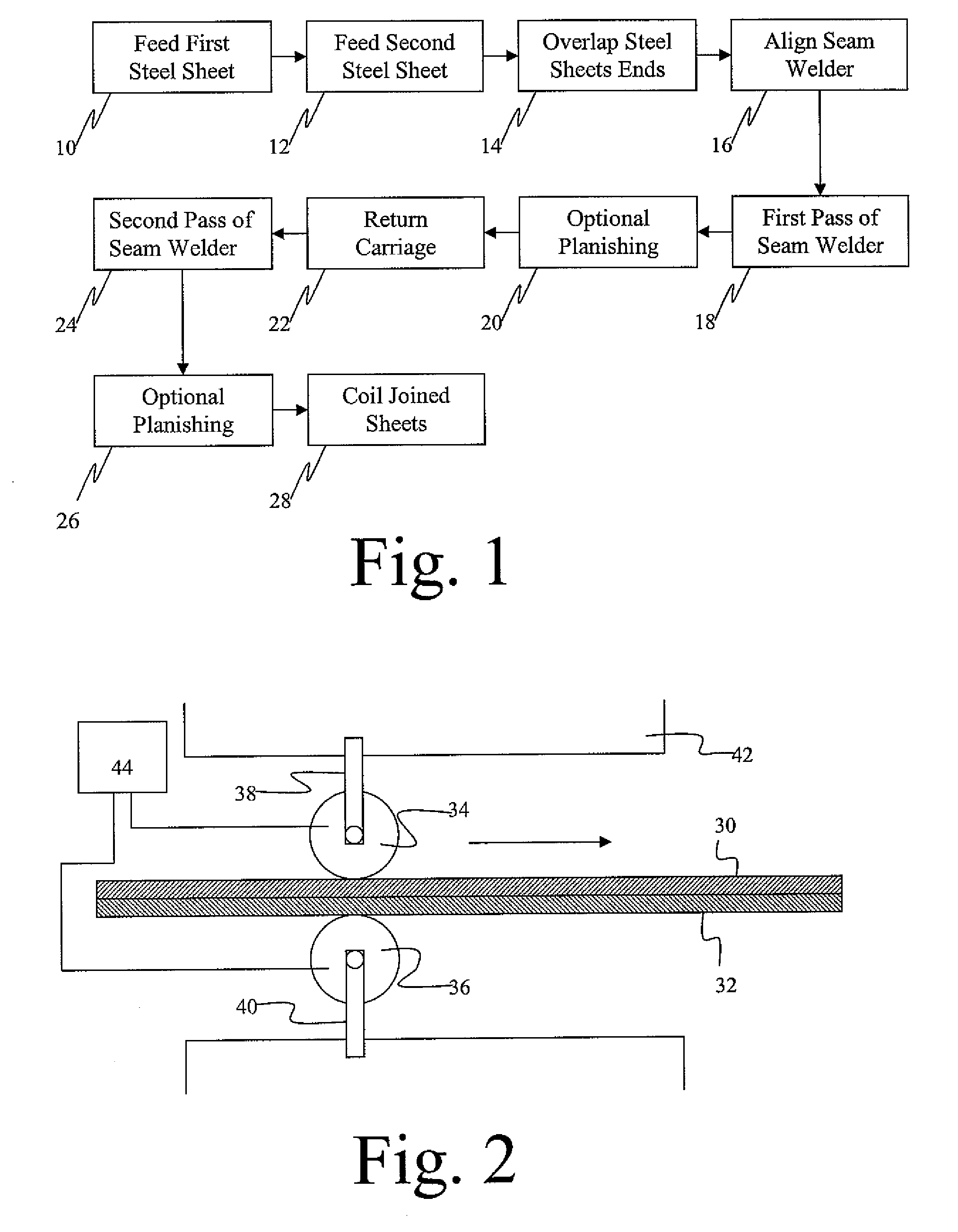

Seam welding

A process is provided for scam welding advanced high strength steel sheets together. Respective end portions of first and second advanced high strength steel sheets are placed in overlapping contact with one another, and subjected to first and second weld passes. In the first weld pass, a seam welder including weld electrodes operate at a first-pass applied current and a first-pass pressure and are moved relative to the overlapping end portions at a first-pass carriage speed to establish a weld seam containing a weld nugget with a martensite phase. In the second weld pass, the weld electrodes operate at a second-pass applied current and a second-pass pressure and move relative to the weld seam at a second-pass carriage speed selected to fuse microcracks, lap openings, and porosity in the seam, relieve the residual stress in the joint, and temper the martensite phase of the weld nugget, and thereby form a weld joint.

Owner:CLEVELAND CLIFFS STEEL TECH INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com