Force-electricity energy converter and array thereof

A transducer array and transducer technology, applied in the direction of electrical components, generators/motors, piezoelectric effect/electrostrictive or magnetostrictive motors, etc., can solve the problem of low piezoelectric performance and cannot withstand large Pressure, high resonance frequency and other problems, to achieve the effect of reducing resonance frequency, large energy output, and long working life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with specific embodiments.

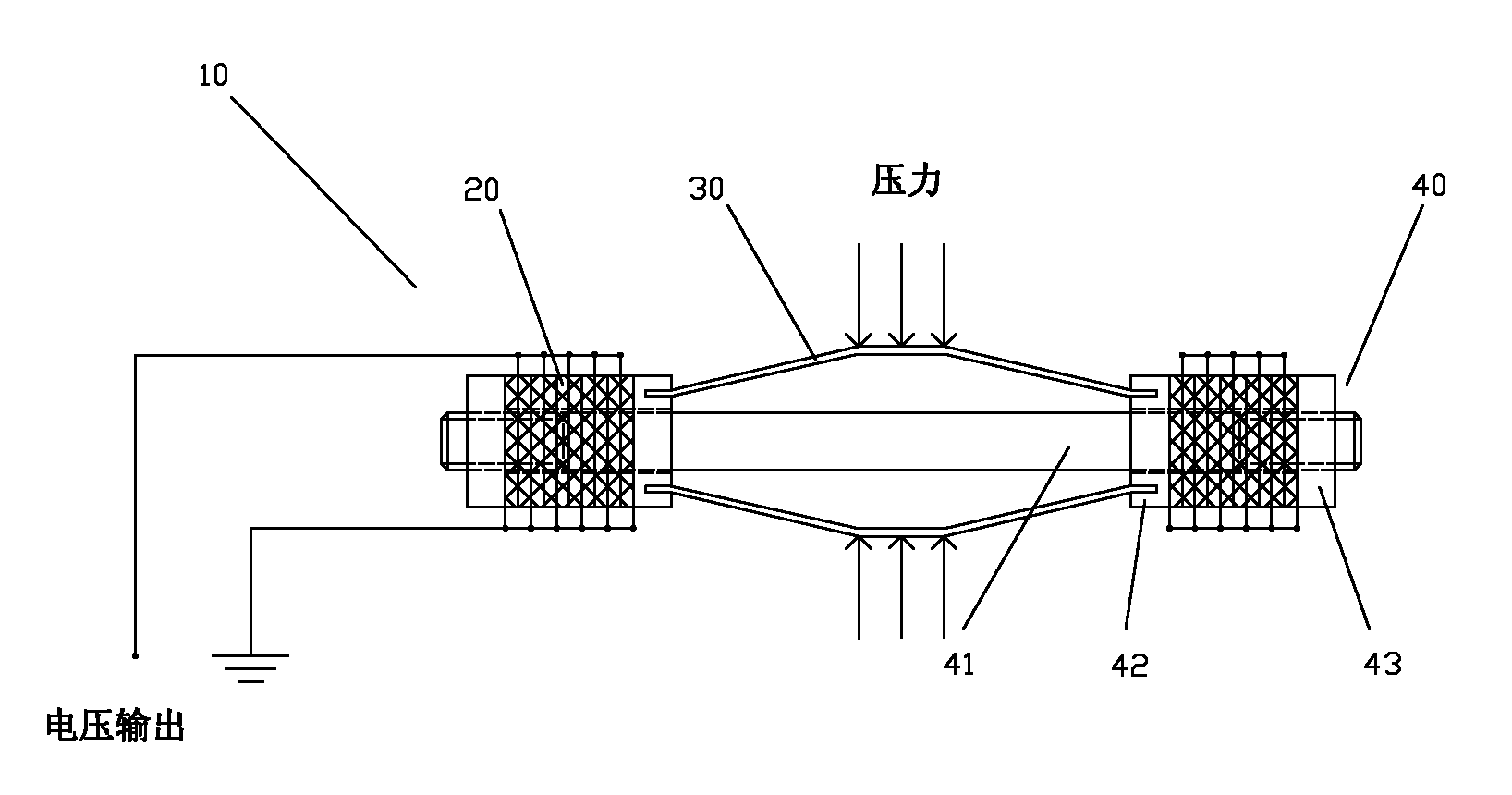

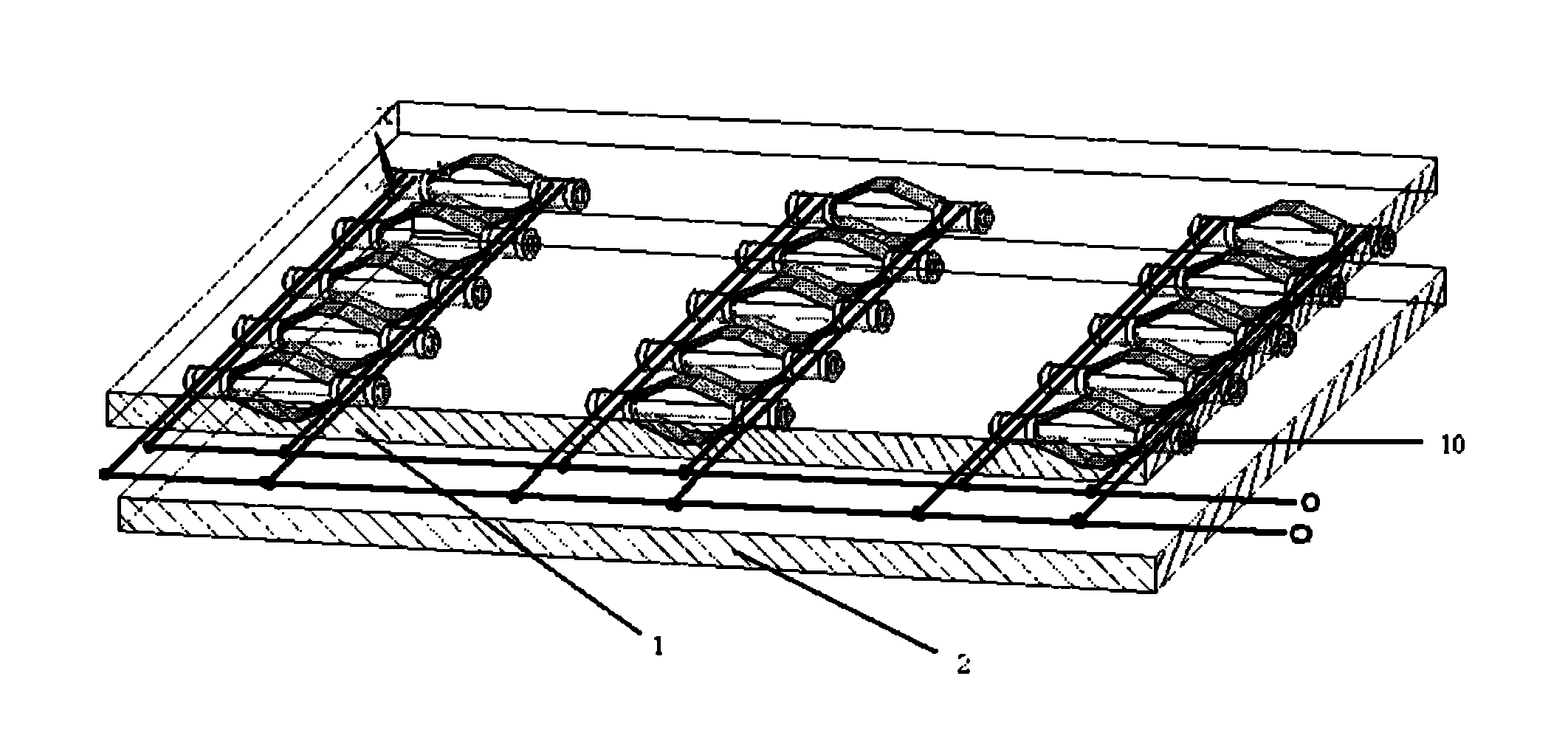

[0018] Depend on figure 1 It can be seen that the shown force-electric transducer unit 10 includes a pair of piezoelectric stacks 20 with a central inner hole, a pair of slightly arched elastic elements 30 placed between the two piezoelectric stacks, and A pretensioning device 40 for assembling the piezoelectric stack 20 and the elastic element 30 .

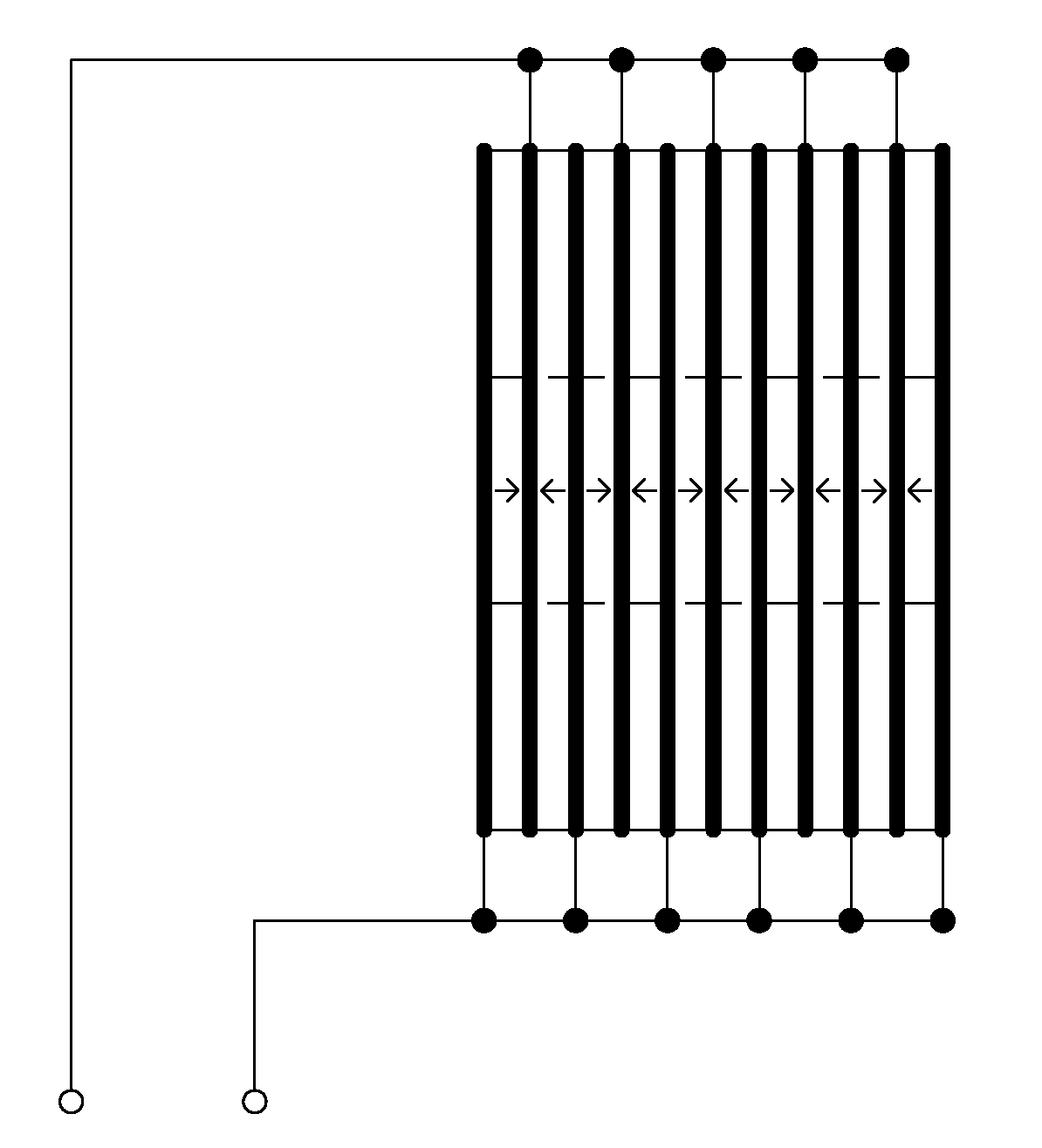

[0019] figure 2 for figure 1 A schematic structural diagram of the piezoelectric stack 20 of the force-electric transducer 10 is shown. The piezoelectric stack 20 can be composed of multiple annular piezoelectric ceramic sheets or piezoelectric single crystals and thin copper sheets (adhesively bonded by epoxy resin) in the axial direction, or can be prepared by electrode-ceramic co-sintering method multilayer piezoelectric ceramics; the piezoelectric element in the piezoelectric stack 20 is preferably an even number, pol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com