Branchial filter

A filter and filter unit technology, applied in the direction of fixed filter elements, filter separation, chemical instruments and methods, etc., can solve the problems of limited filter area, large space occupation, high energy consumption, etc., to reduce energy consumption and improve treatment capacity, low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

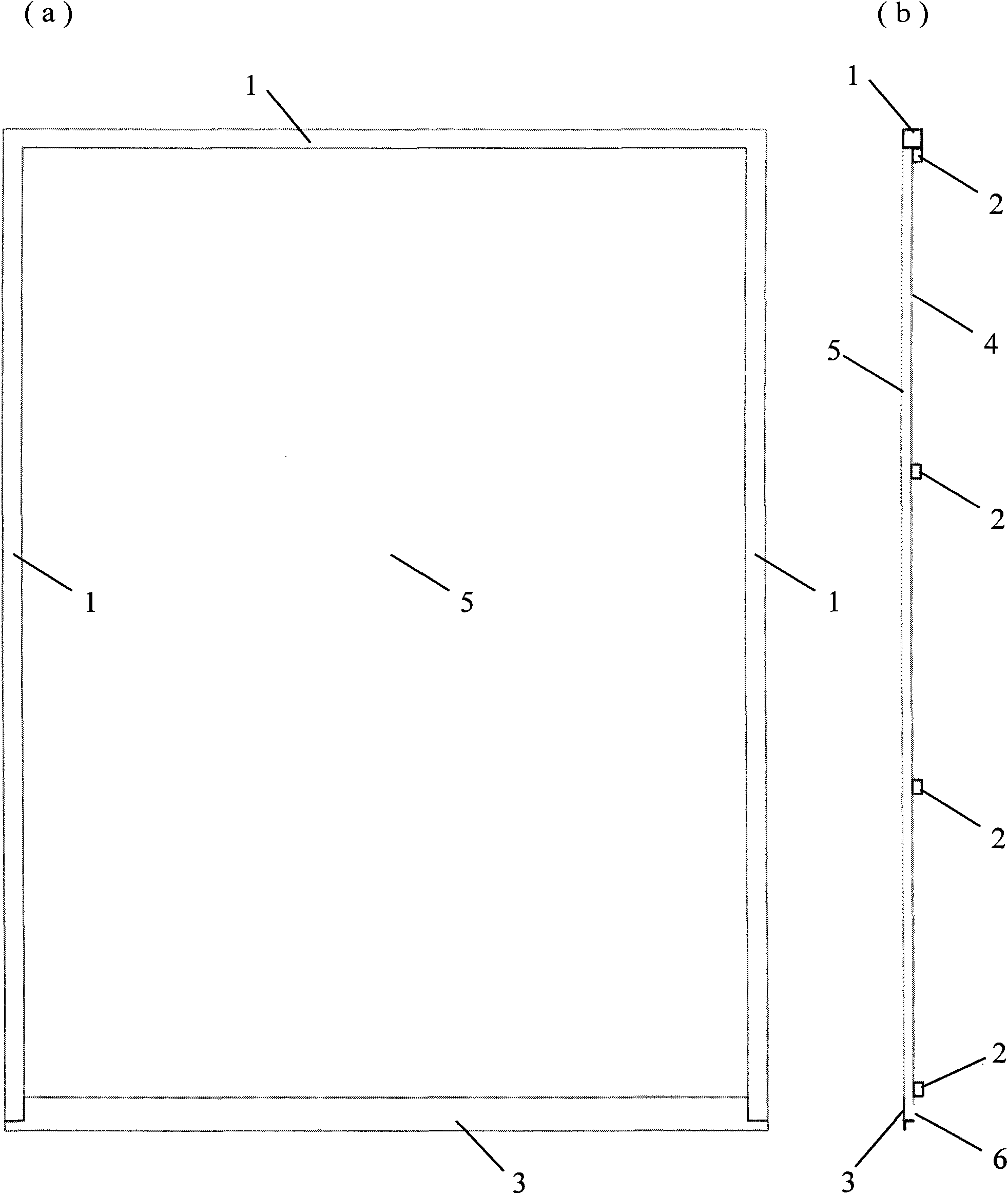

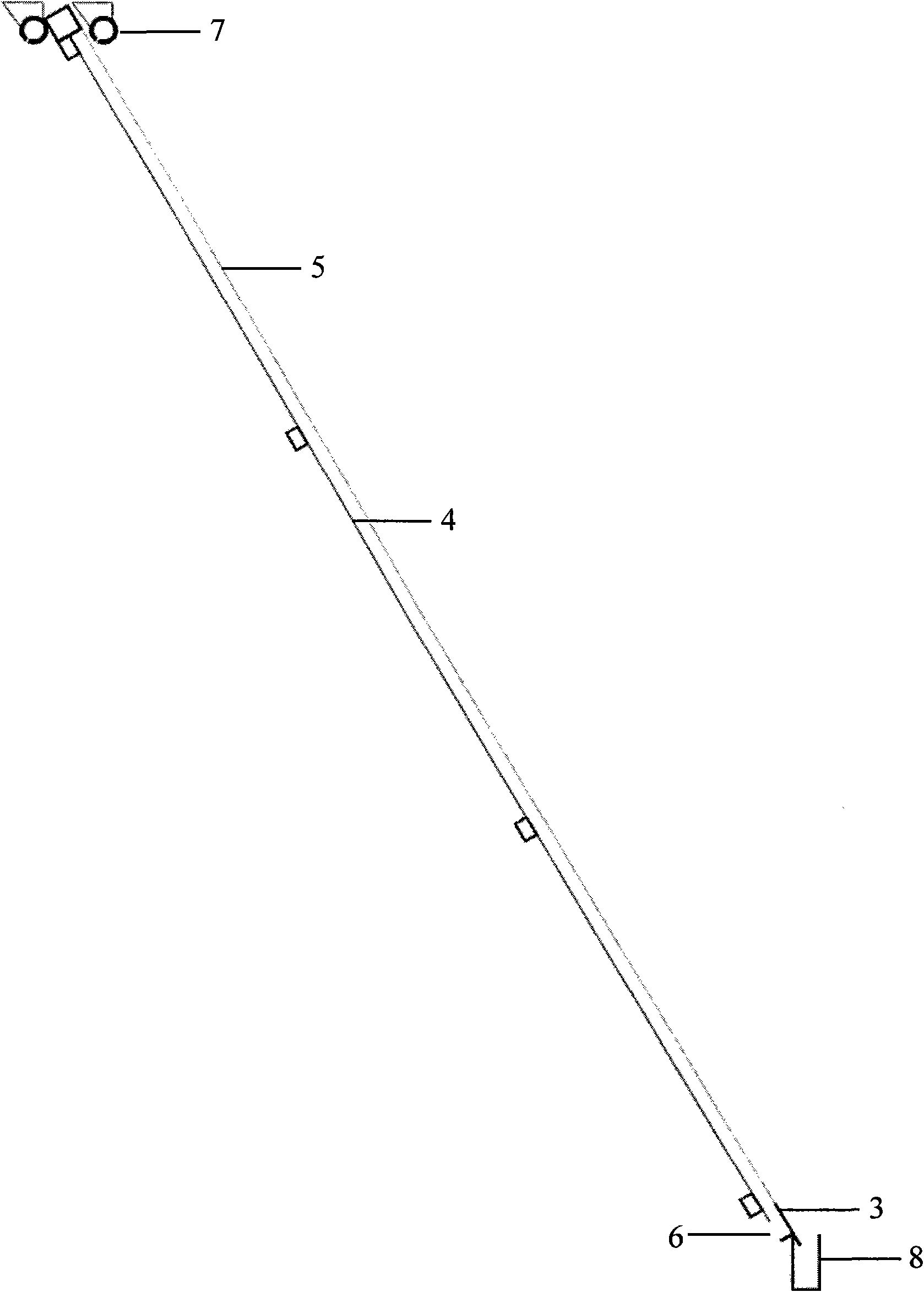

Method used

Image

Examples

Embodiment Construction

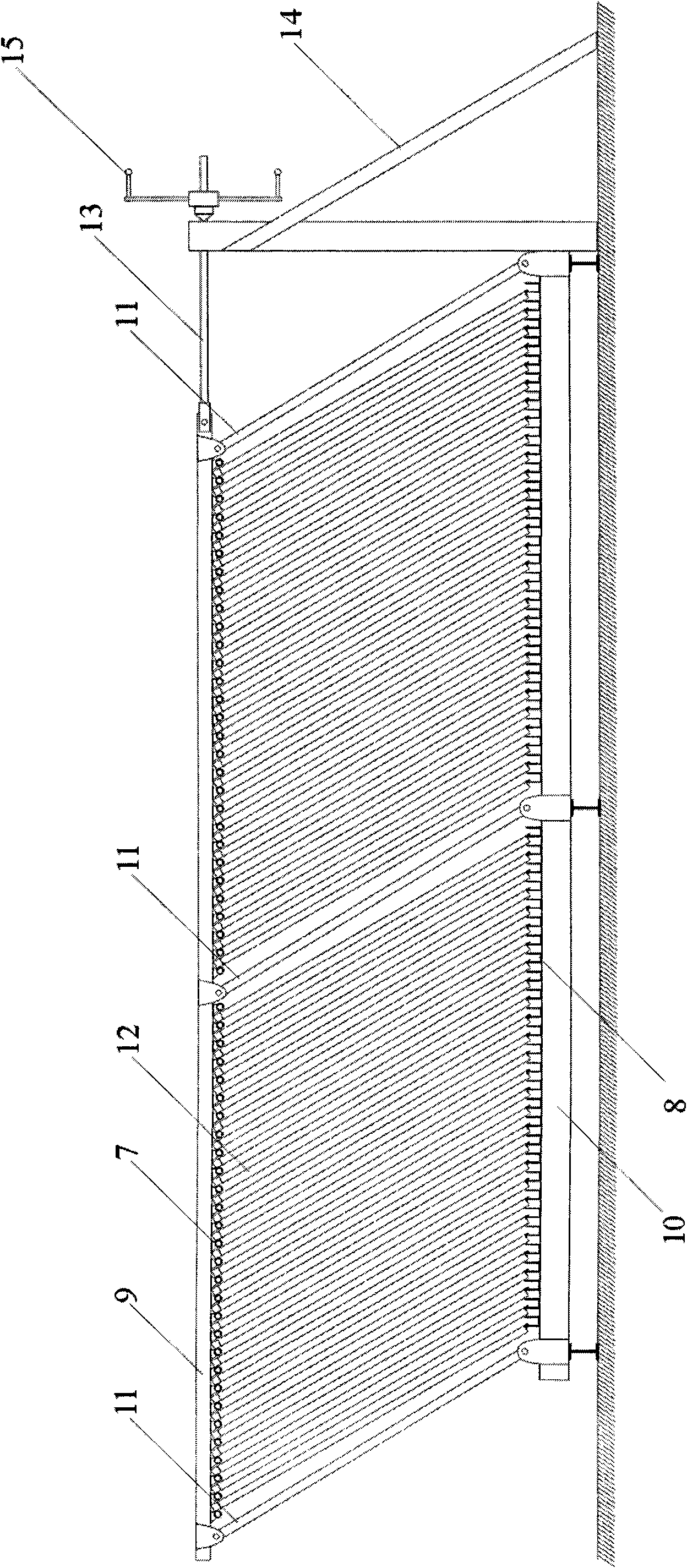

[0038] The present invention carries out engineering application according to the following steps:

[0039] (1) Arrange the main liquid collecting tank and the liquid inlet main pipe along the center line of the site. The bottom of the general liquid collecting tank is embedded in the ground, and the liquid inlet main pipe is installed at a height of about 1m above the general liquid collecting tank.

[0040] (2) Install the gill filter unit support frame, spray pipe and small liquid collection tank on both sides, and install the liquid inlet branch pipe.

[0041] (3) Make unit inclined screens, and insert all unit inclined screens into the support frame from both sides.

[0042] (4) Open the main gate valve of the liquid inlet and adjust to an appropriate flow rate (the design flow rate of the gill filter).

[0043] (5) According to the filtering conditions, adjust the inclination of the gill filter unit to achieve the best filtering effect.

[0044] (6) Close the gate valv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com