Patents

Literature

34results about How to "Filtration flow is large" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

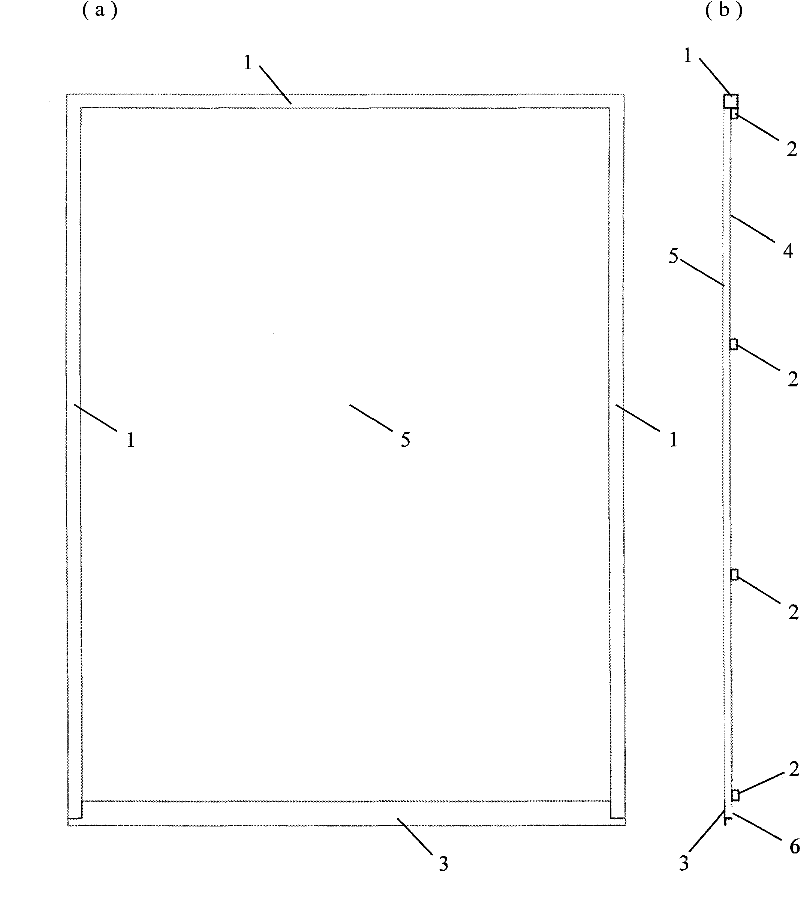

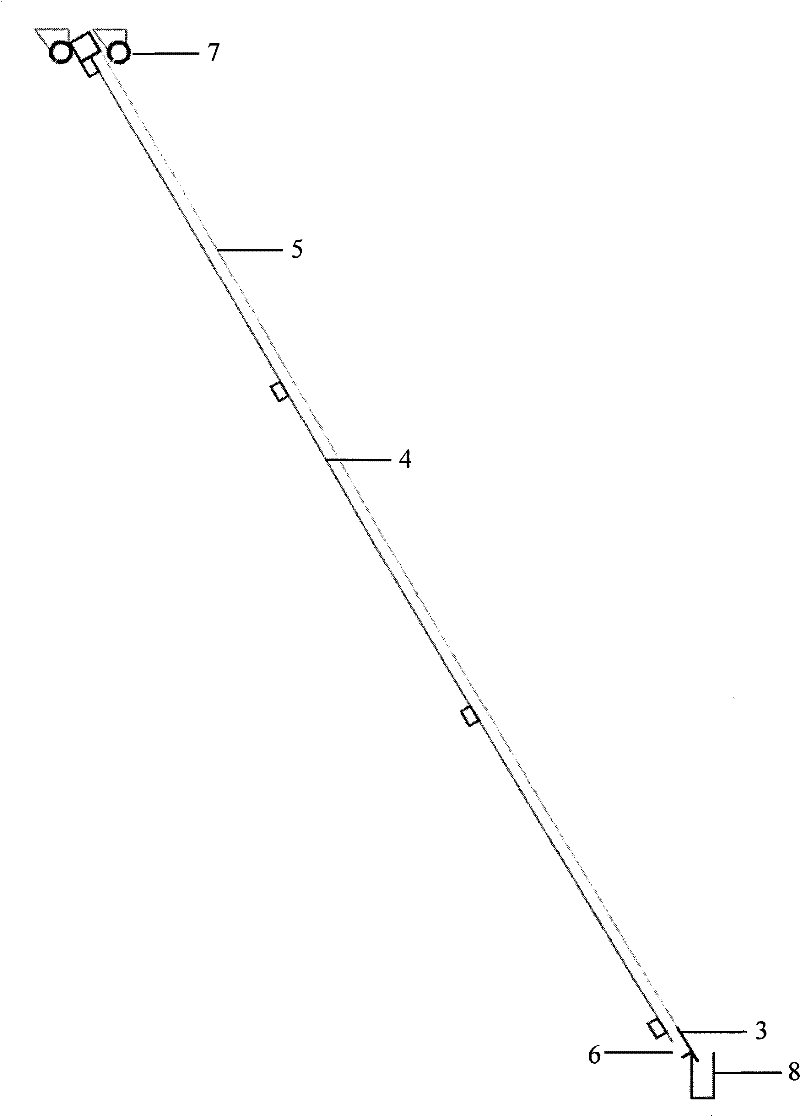

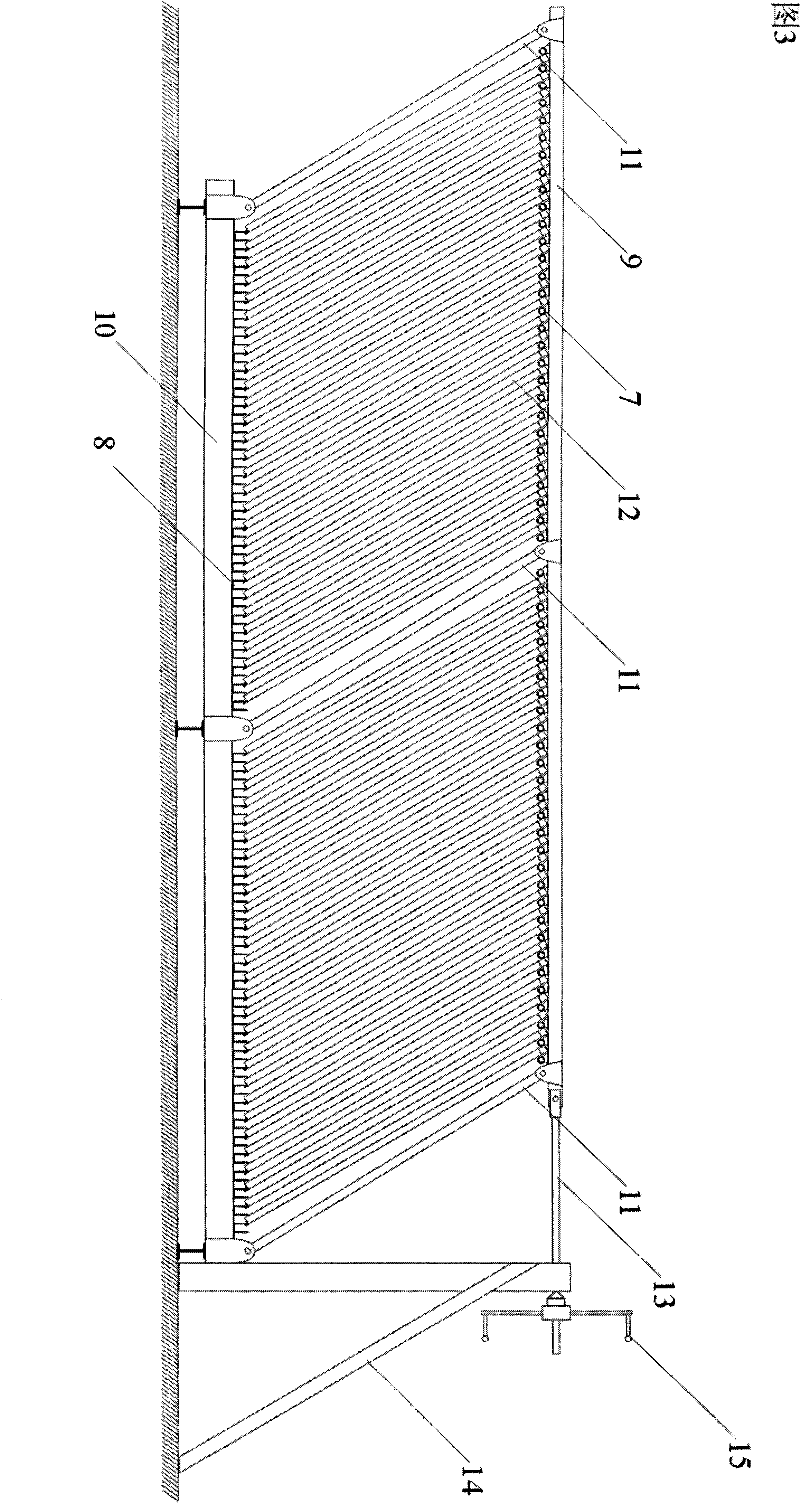

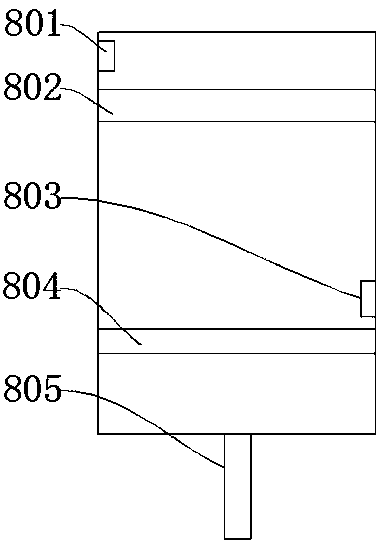

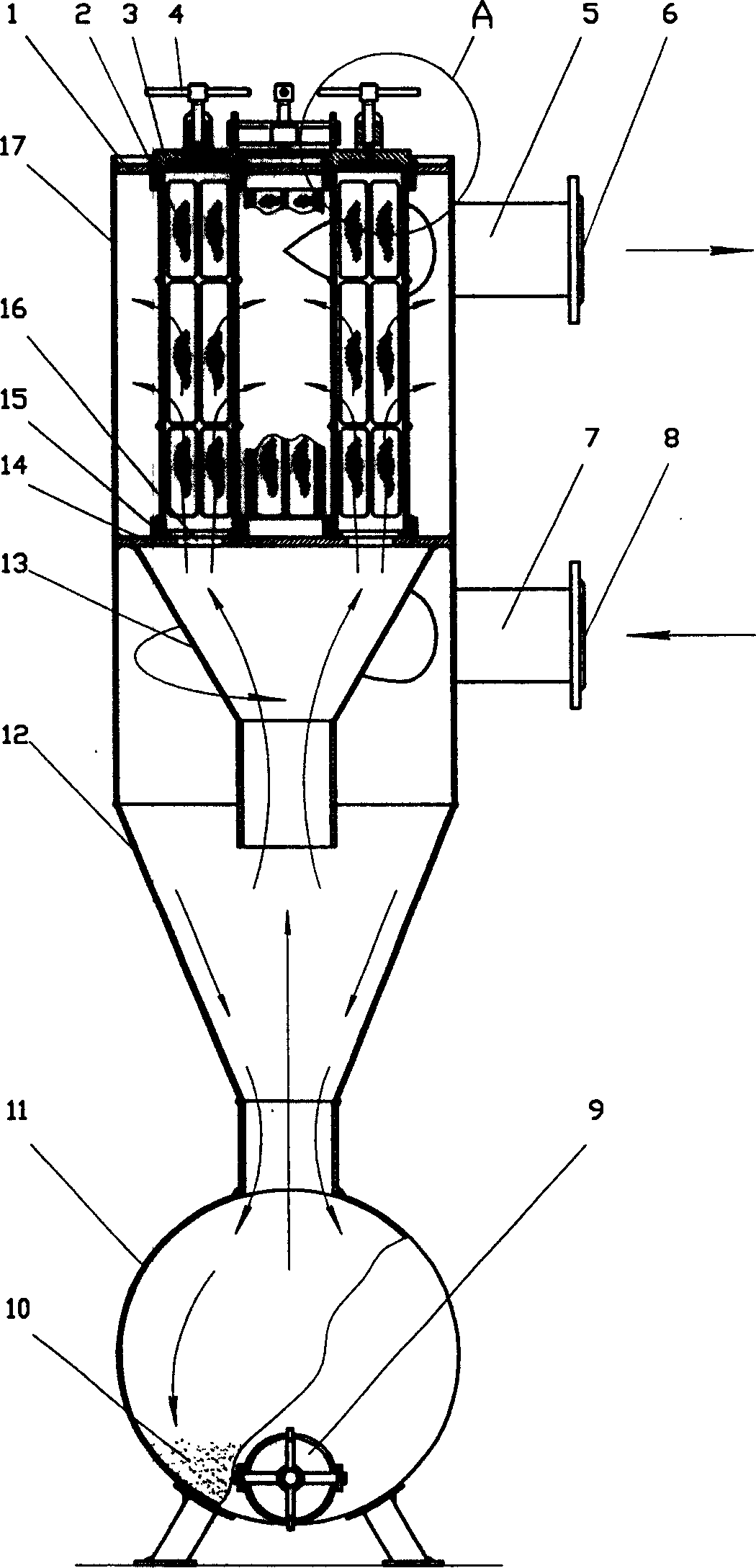

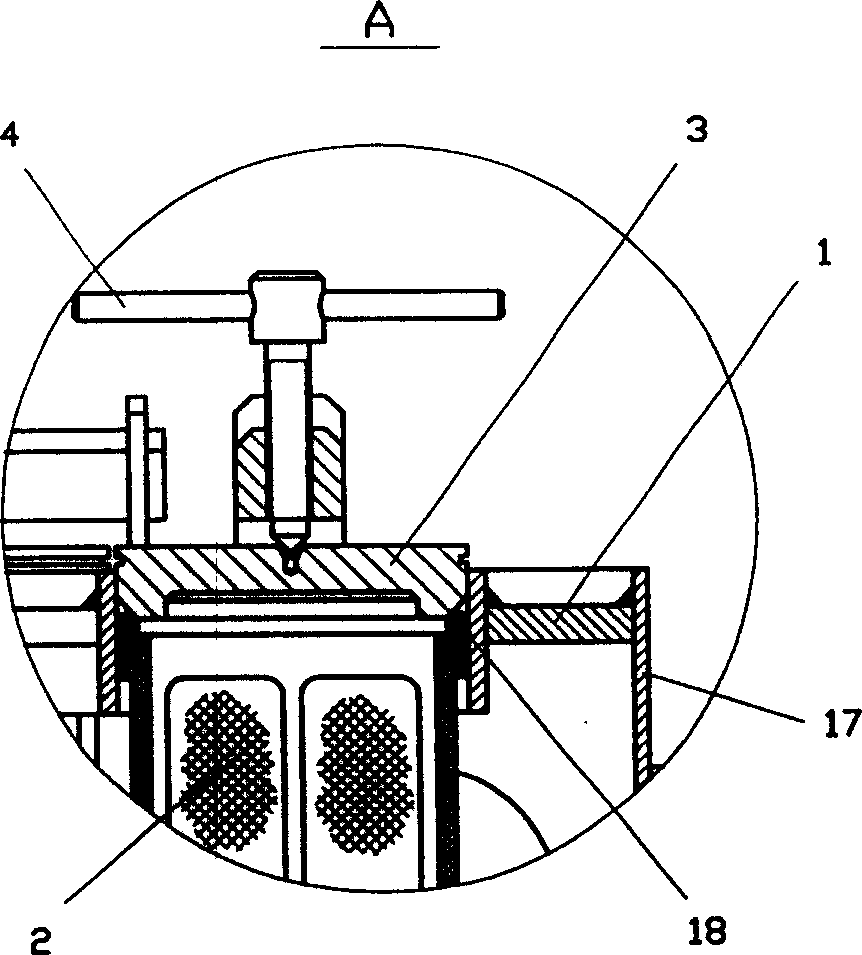

Branchial filter

InactiveCN101537276ARealize self-flow separationImprove filtering effectStationary filtering element filtersEngineeringAlgae

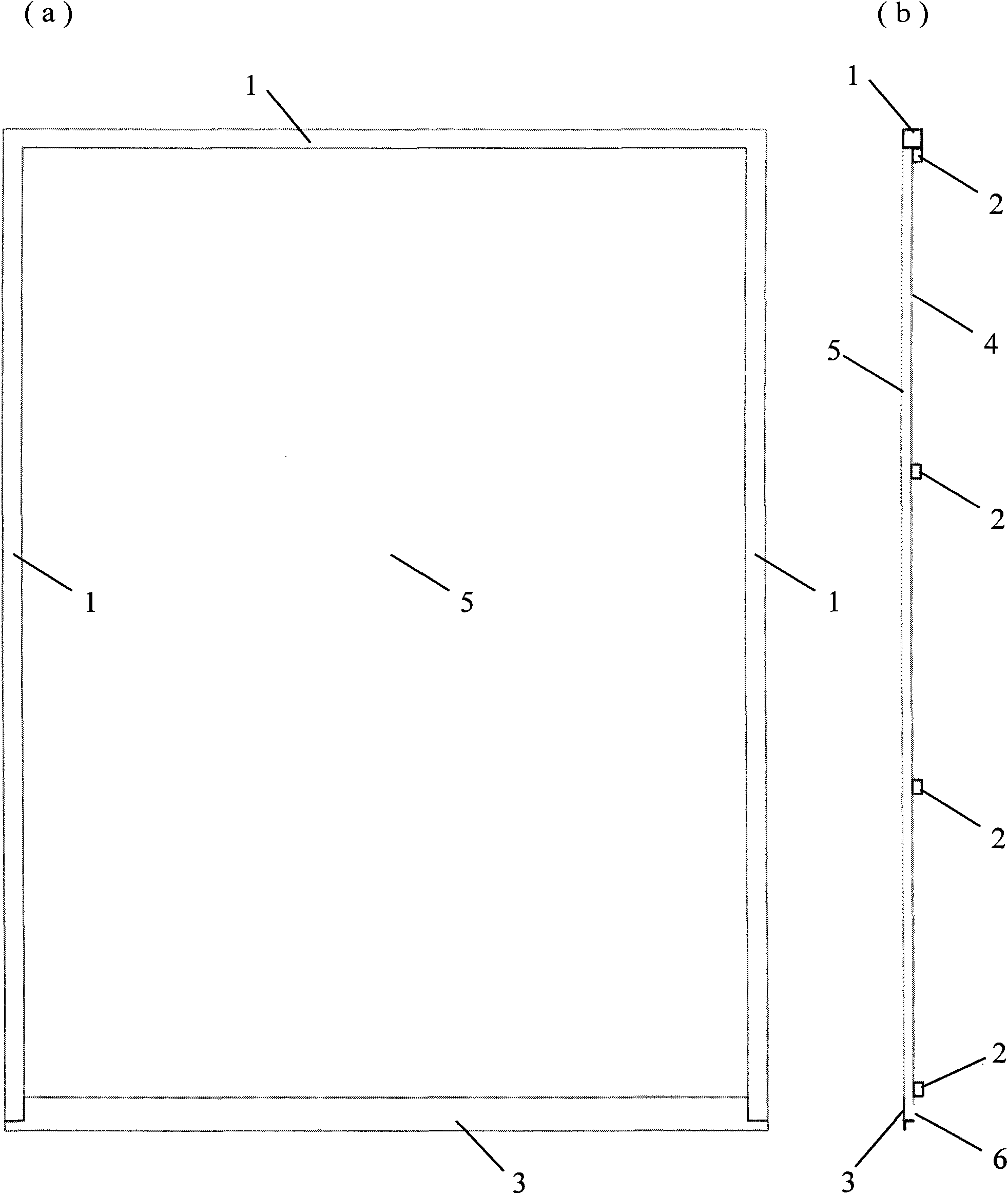

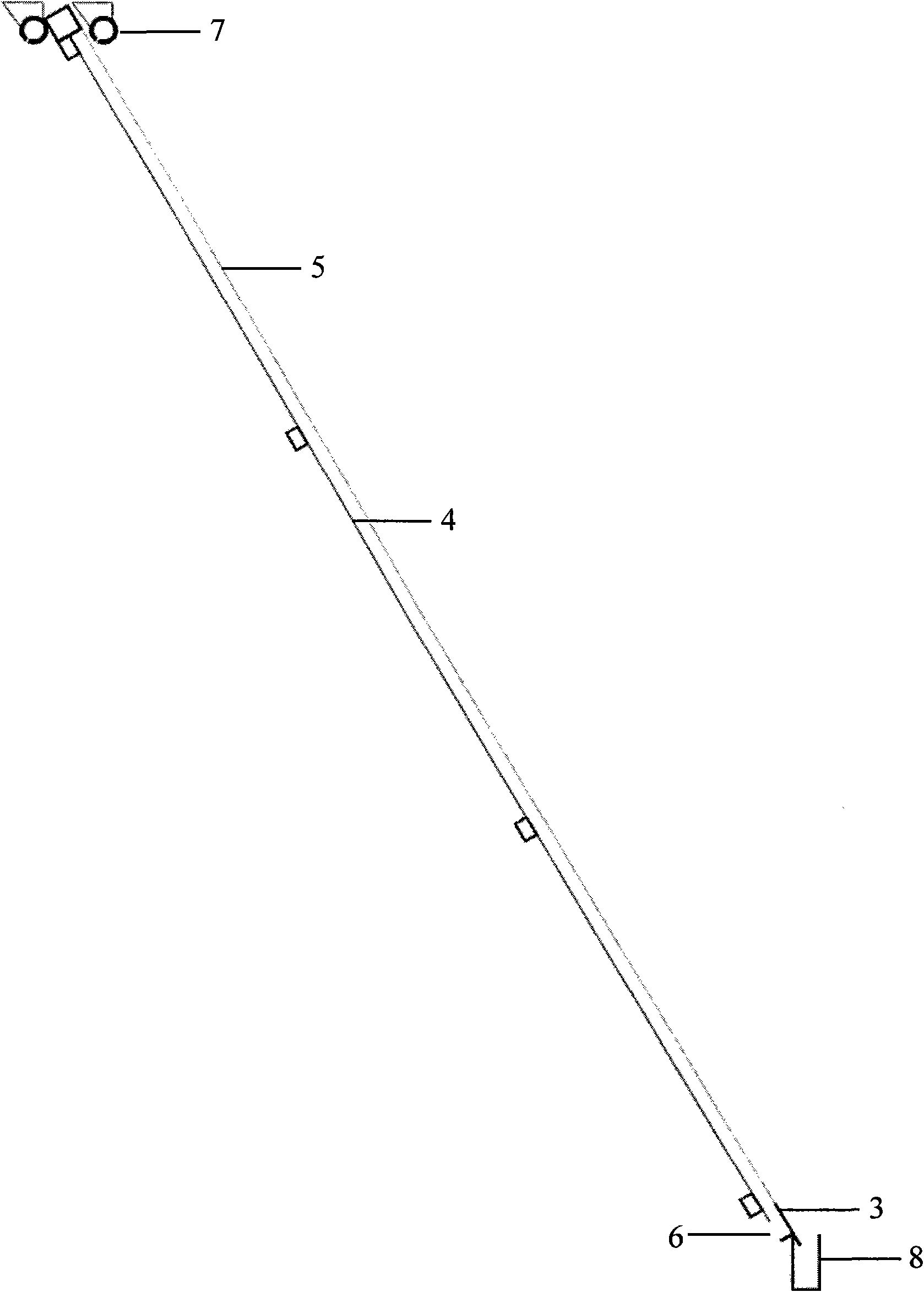

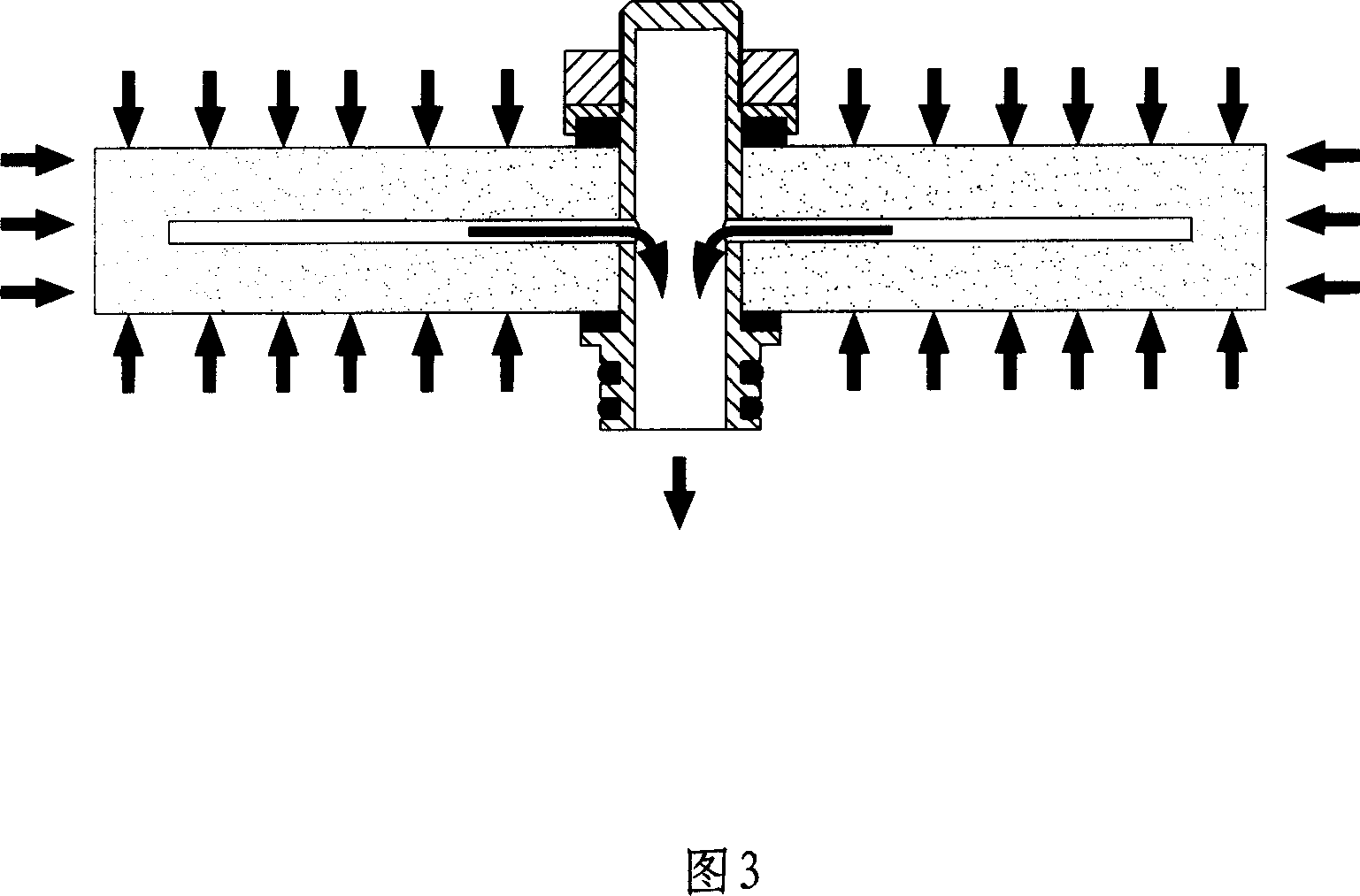

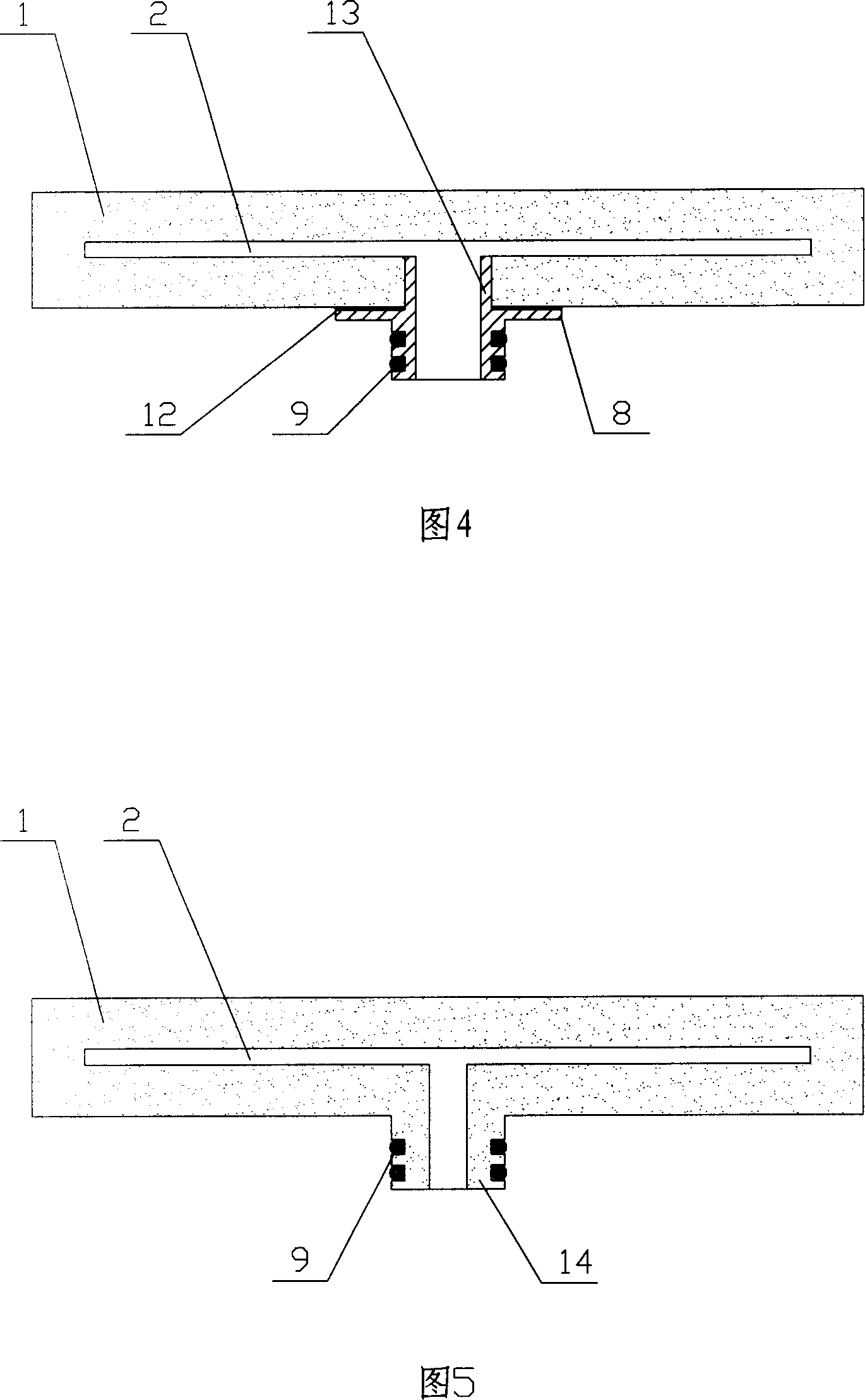

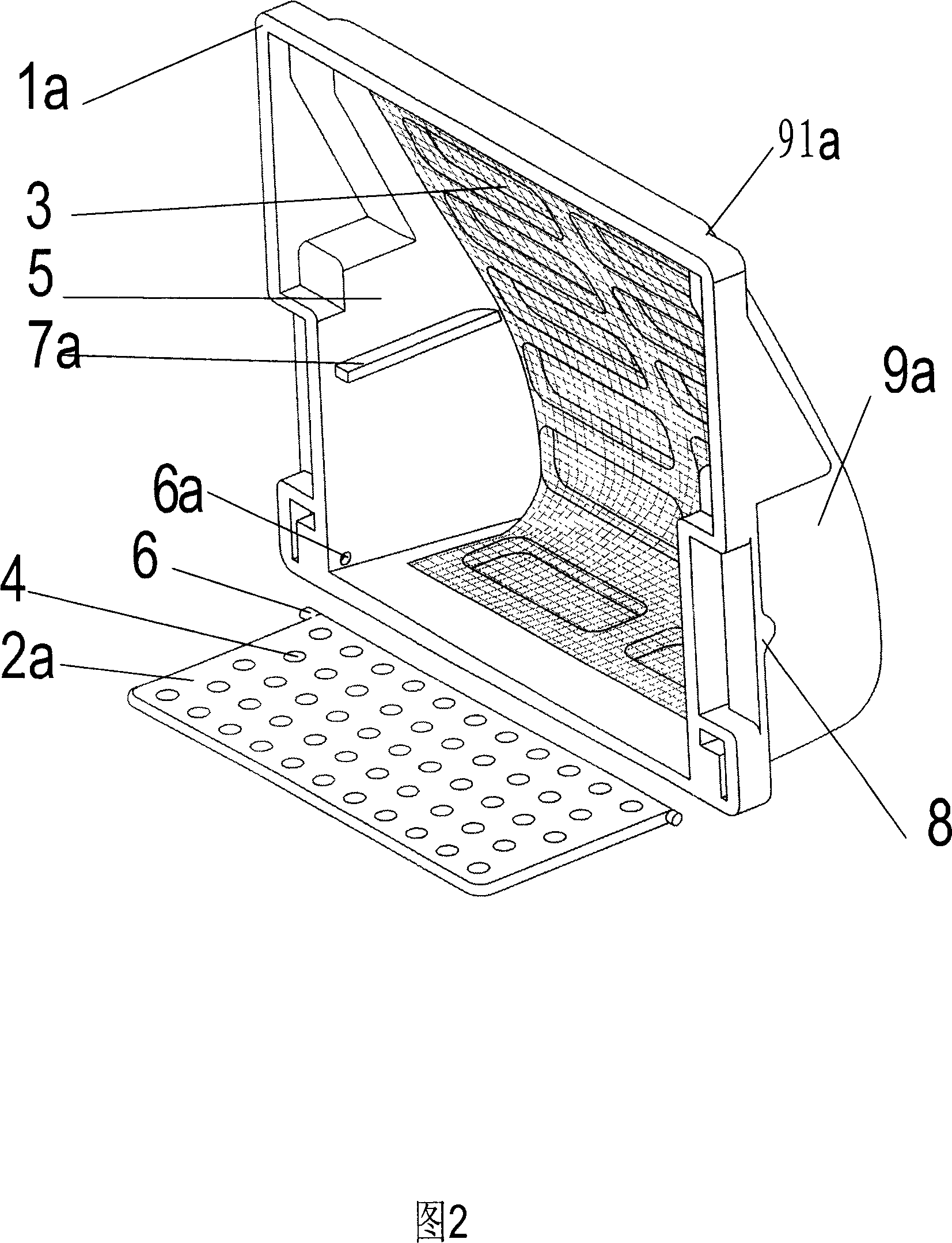

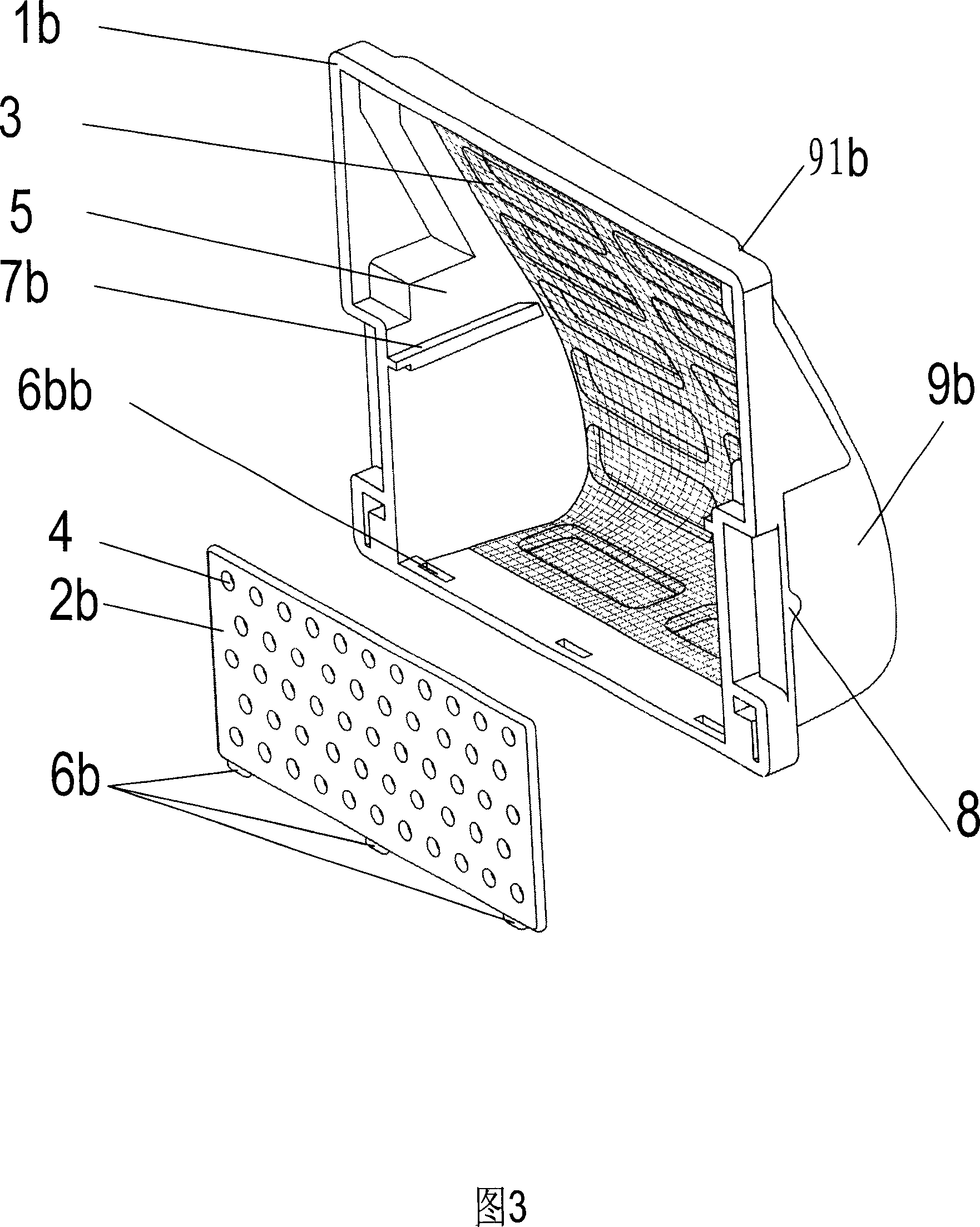

The invention relates to a high-densification slope filter which is developed by imitating the principle that a chub branchial filters hydroplankton. A group of (100 or more) unit hydra-screens with the thickness of 40mm are densely arranged on a support frame which can adjust inclination degree with a center distance of 100mm, the surface of each unit hydra-screen sprays a stock solution by a spraying pipe arranged on the top of each unit hydra-screen, and a small liquid collection groove arranged on the bottom of each unit hydra-screen collects concentrated solutions on the screen to form a branchial filtering unit; two branchial filtering units are placed in parallel, a liquid collection groove arranged on the lower middle part of a gap between the two branchial filtering units collects concentrated solution from both sides of the small liquid collection groove positioned below each unit hydra-screen, and a main liquid feeding pipe positioned on the upper part of the gap supplies original liquid to the spraying pipe on the top of each unit hydra-screen at the two sides through branched pipes so as to form a branchial filter. The branchial filter works depending on the pressure (about 20kpa), the concentrated solution on the screen is automatically collected through the small liquid collection groove and a total liquid collection groove, then filtered by the screen and finally discharged to the ground. The invention can be used for the primary concentration and filtering of suspending liquid and especially suitable for the primary filtering of a ship borne algae collecting system.

Owner:NANJING INST OF GEOGRAPHY & LIMNOLOGY

Preparation method of ceramic balls loaded with nano copper-zinc-silver

The invention provides a preparation method of ceramic balls loaded with nano copper-zinc-silver. The preparation method comprises the following steps of: adsorbing a certain quantity of copper, zinc and silver metal ions with ceramic powder; uniformly mixing with a binding agent by stirring; granulating with a granulator; performing drying and microwave sintering on ceramic balls; and introducing reducing gas in the sintering process to reduce the metal ions so as to obtain ceramic balls loaded with nano copper-zinc-silver. The ceramic balls have the porosity of 30-50 percent and the particle size adjustable in the range of 0.2-20 millimeters. As proved by standard labeling testing, the removing rate of residual chlorine is over 99 percent, the removing rates of heavy metal ions such as Pb<2+>, Hg<2+>, Cd<2+>, Cr<6+> and As<5+> are over 99 percent, and the degerming rate is over 99.99 percent. The preparation method has the advantages of high purification speed, good purification effect and the like.

Owner:XIAMEN RUNNER IND CORP

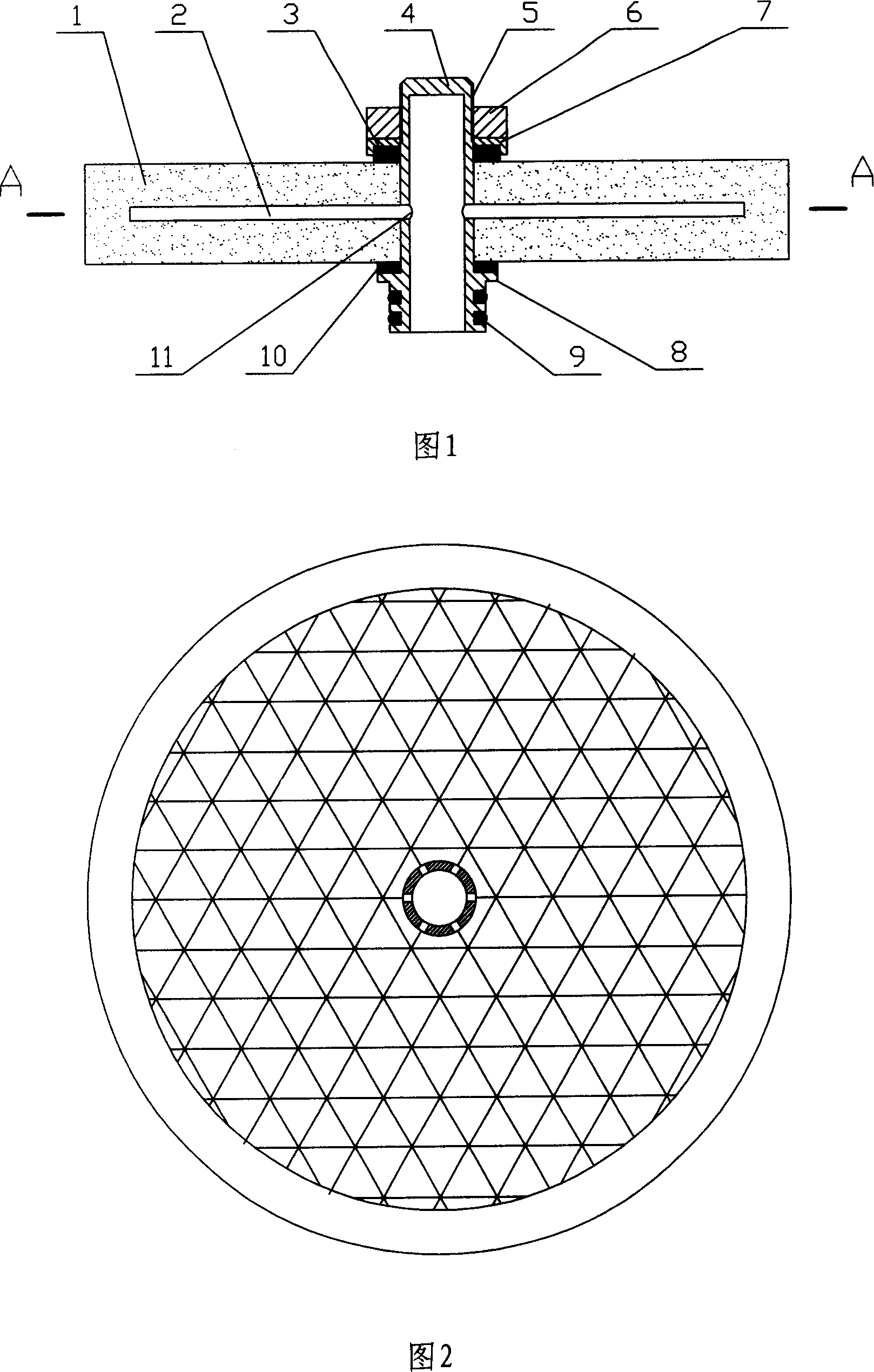

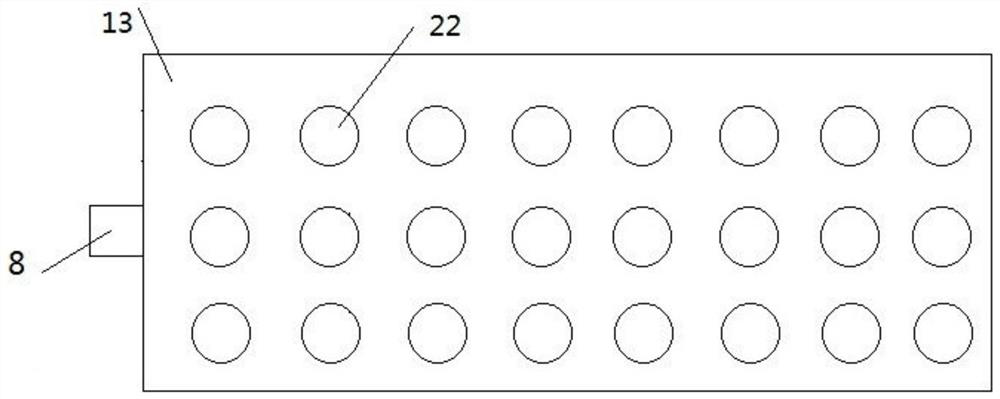

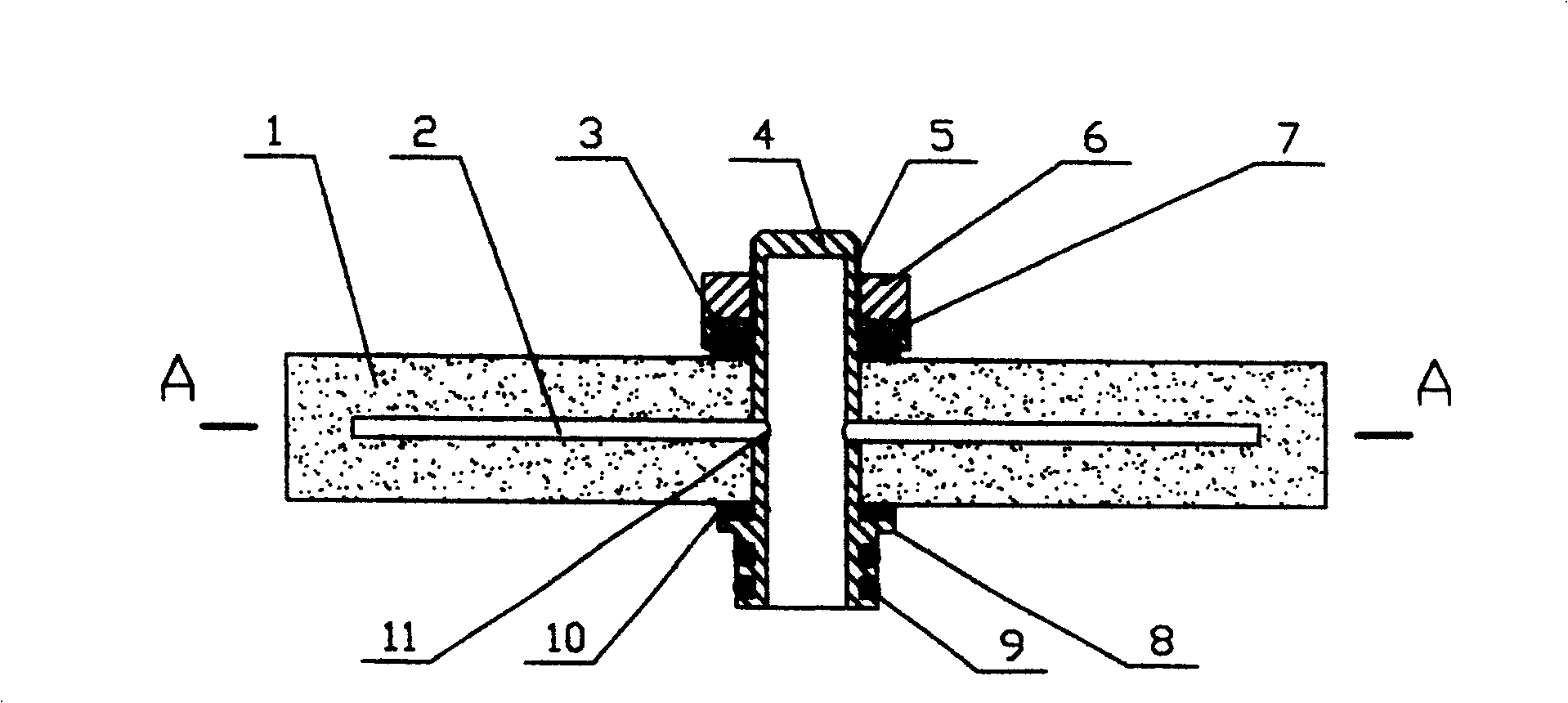

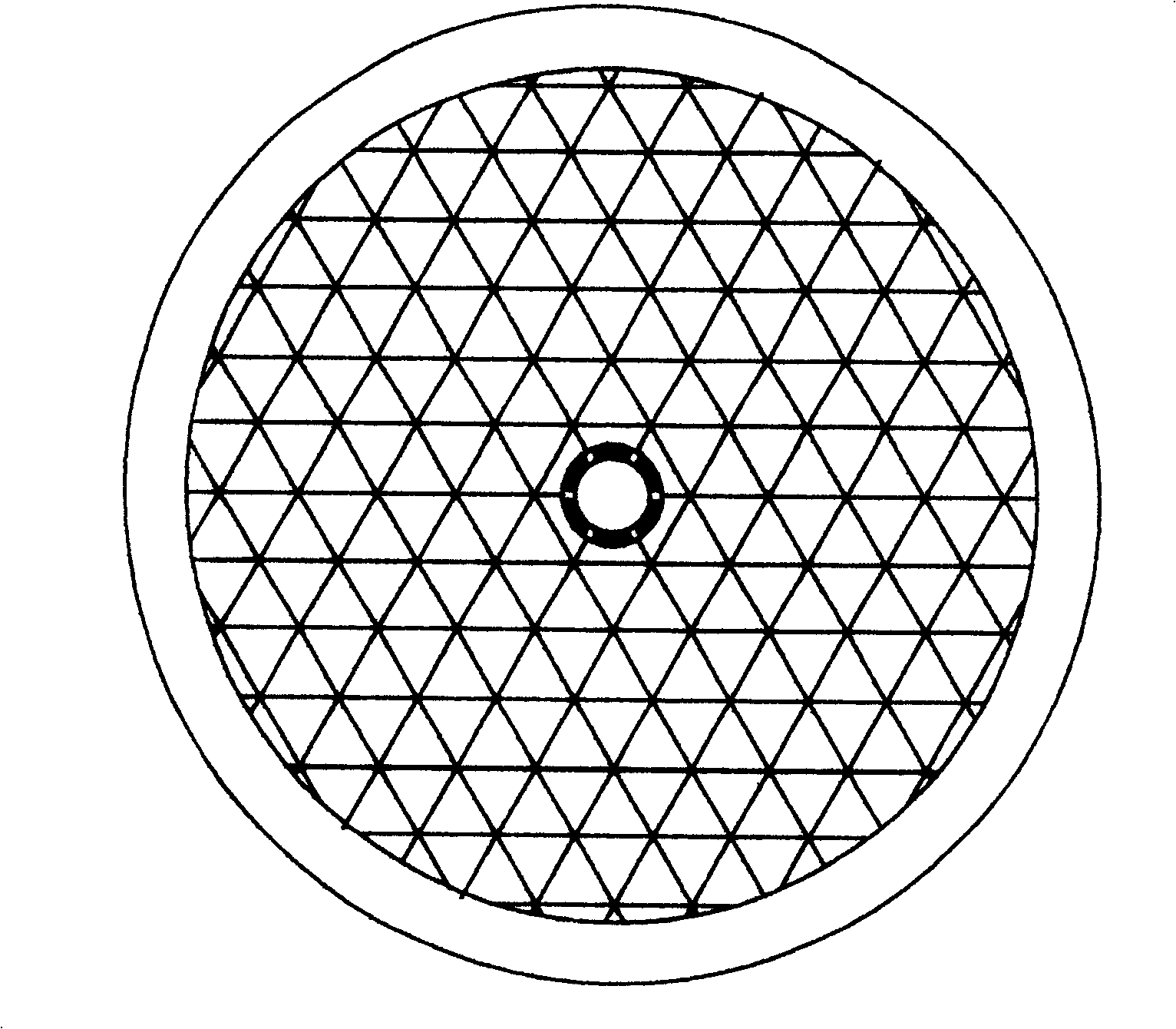

Plate type and two surface filtration type micro-porous ceramic structure

InactiveCN101002994AFiltration accuracy does not decreaseThe effluent quality remains unchangedFiltration separationMetallurgyFiltration

A plate-shaped millipore ceramic structure with dual filtering surfaces for cleaning water by high filtering throughput is prepared through making a reticular porous plate with the material able to be converted to gas at high temp putting it in the ceramic blank, and high-temp calcining to gasify said plate to form the reticular channels.

Owner:宁波杜康陶瓷有限公司

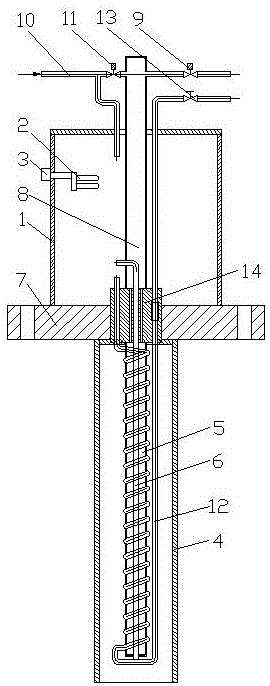

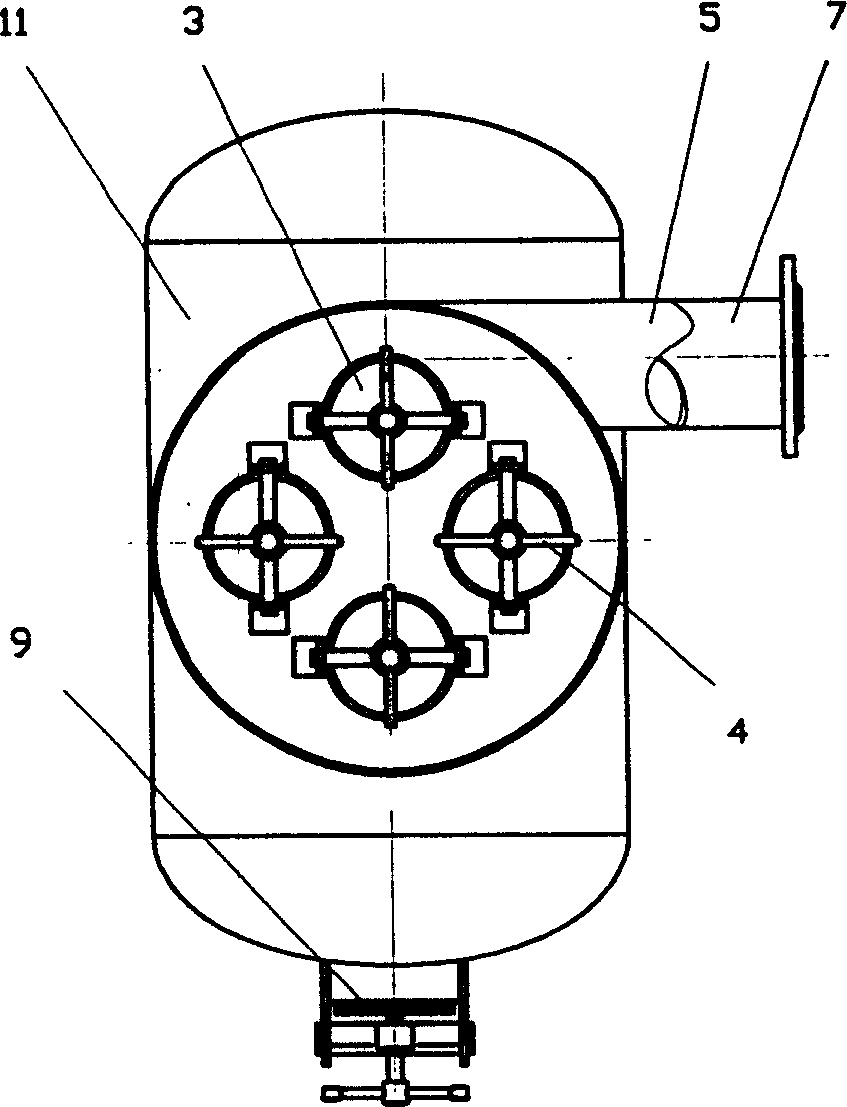

Bulk flow and self-cleaning net type filter

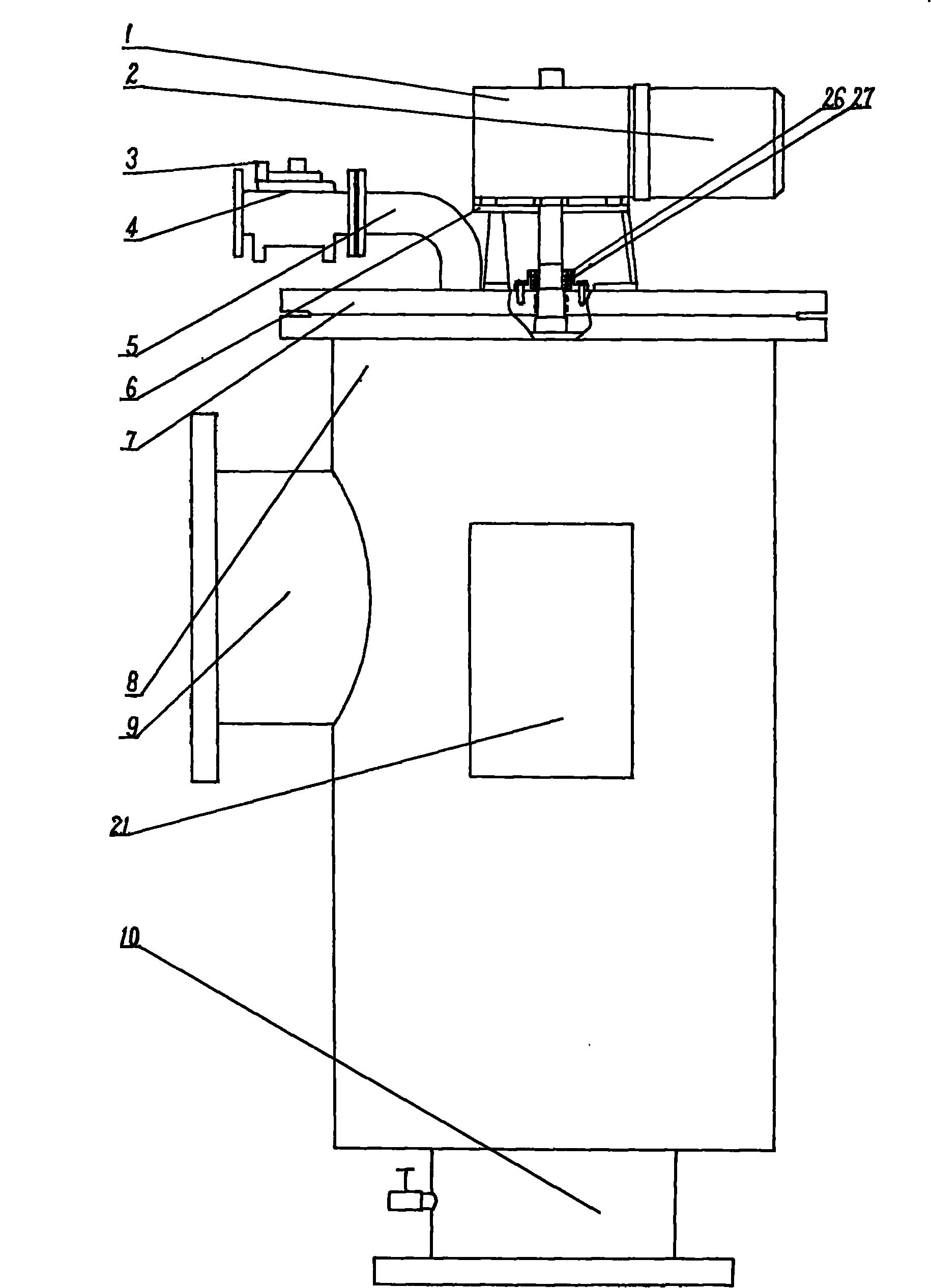

InactiveCN102039065AHigh degree of automationFiltration flow is largeStationary filtering element filtersControl systemSewage

The present invention relates to a bulk flow and self-cleaning net type filter comprising a tank body, a power system, a control system and a filter chamber. The bottom of the tank body is provided with a water inlet, one side of the tank body is provided with a water outlet, and the top of the tank body is provided with a sewage draining exit and a power system, and a filter chamber connected with the power system, the control system and the water outlet respectively is arranged inside the tank body. The filter is characterized in that the filter chamber comprises a cuneate filter canister and a rotating stainless steel wire brush unit arranged in the cuneate filter canister; the cuneate filter canister is connected with the water inlet; the rotating stainless steel wire brush unit comprises central upper, middle and lower wire brush shafts that are connected to each other, and three sets of steel wire brushes that are arranged at the central brush shafts vertically; the upper and lower shafts of the wire brush are connected with the top and the bottom of the filter chamber respectively; every two steel wire brushes are at a 120 DEG angle to each other. The filter is advantageous in simple structure, sensitive self-cleaning control system and excellent sewage draining effect.

Owner:GANSU DAYU WATER SAVING

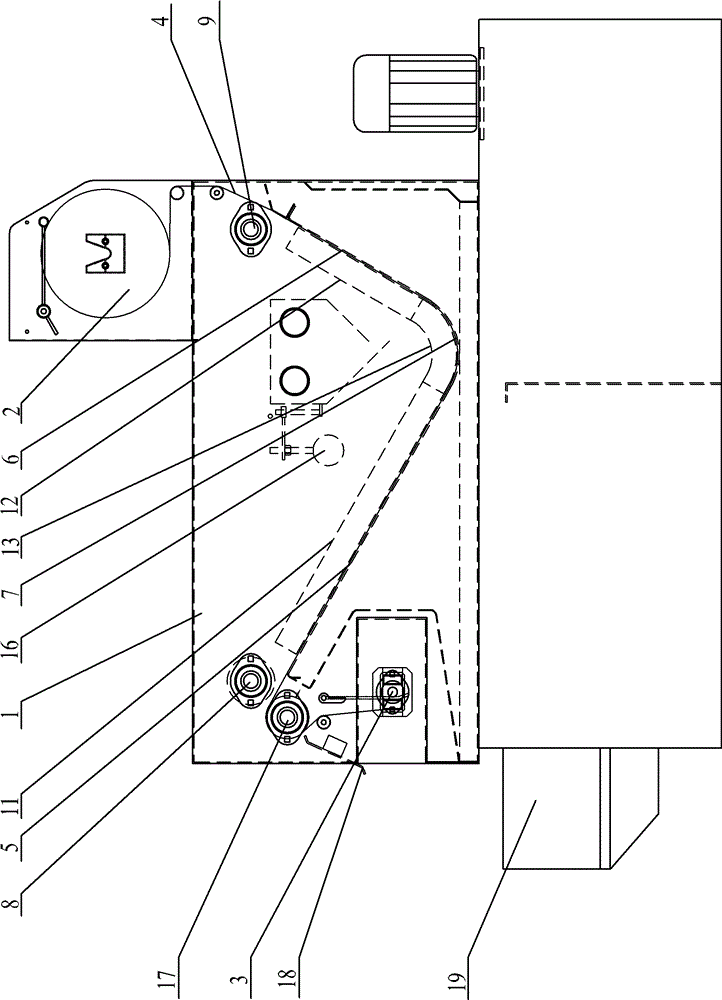

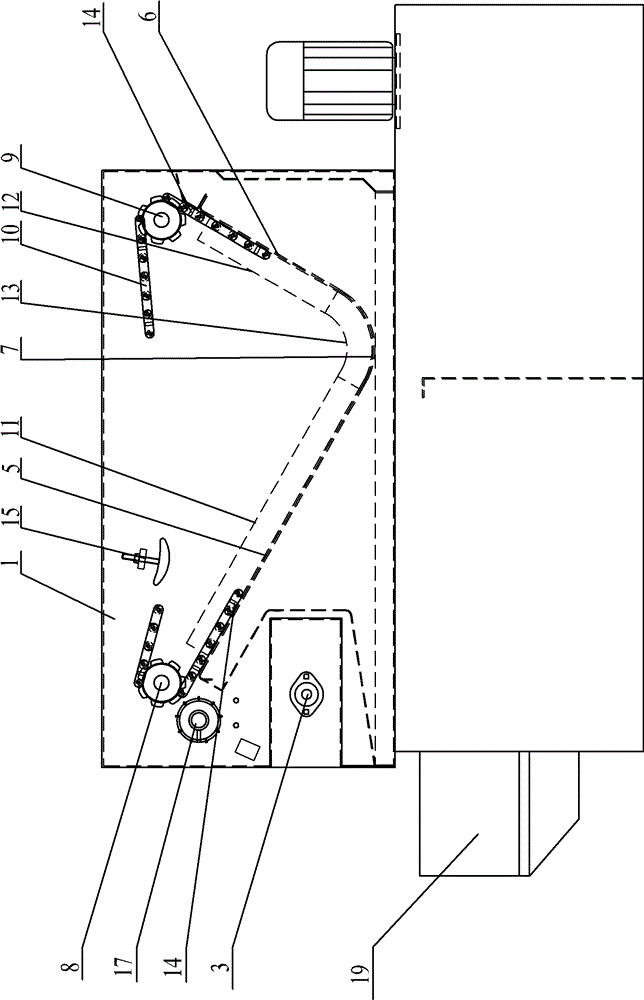

Automatic filter cloth scraping filter

ActiveCN102179087ANot easy to wasteAvoid easy cloggingStationary filtering element filtersEngineeringSecond screen

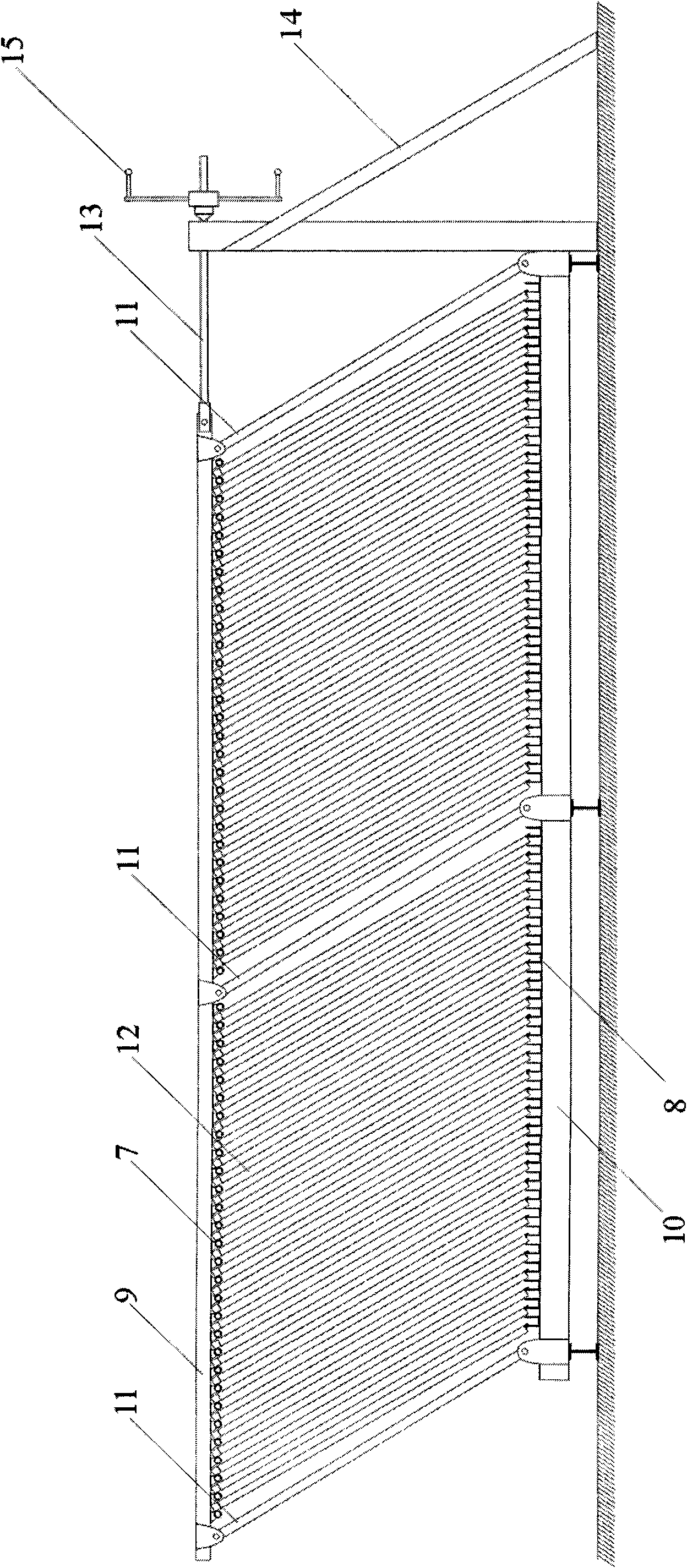

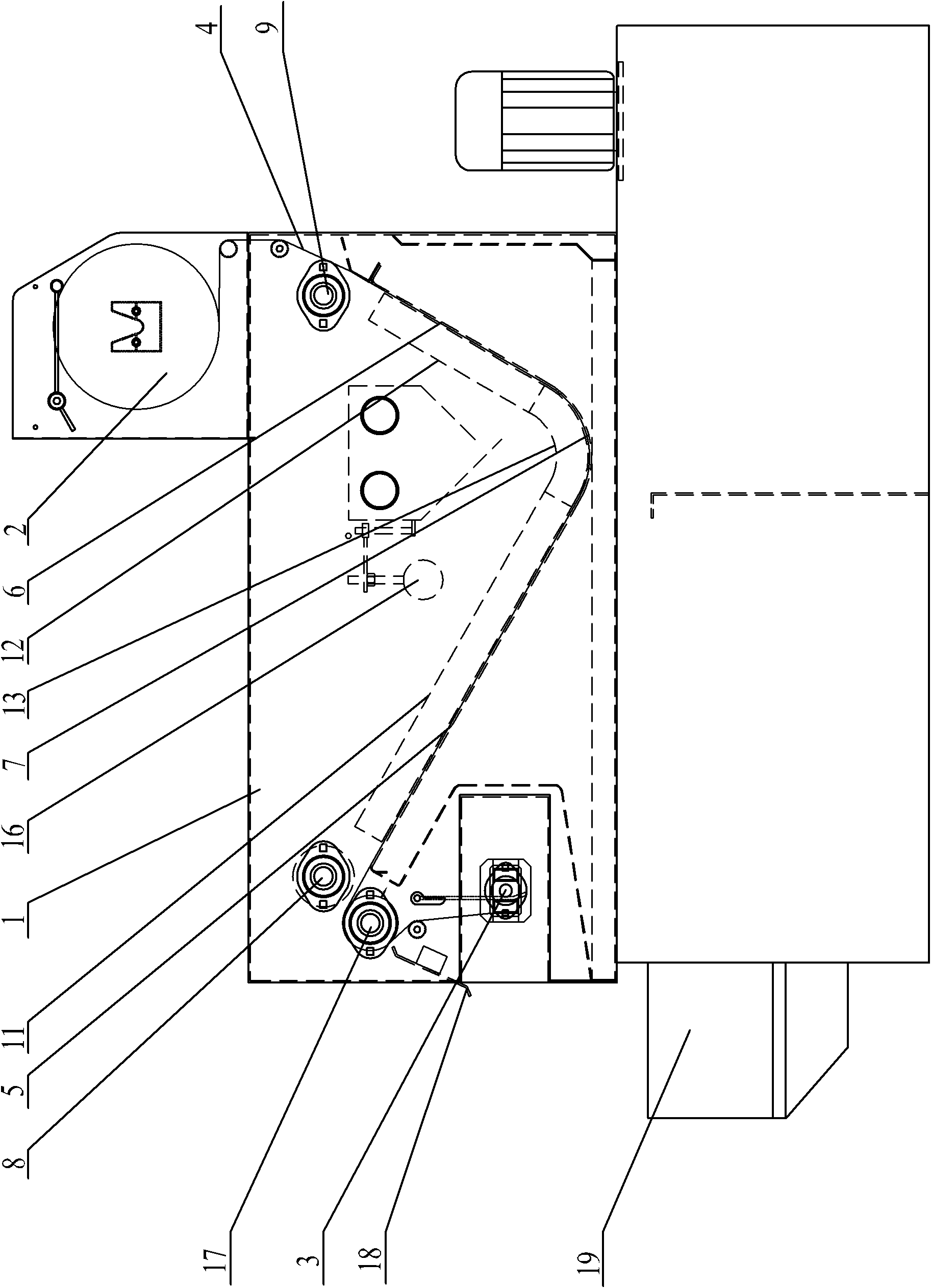

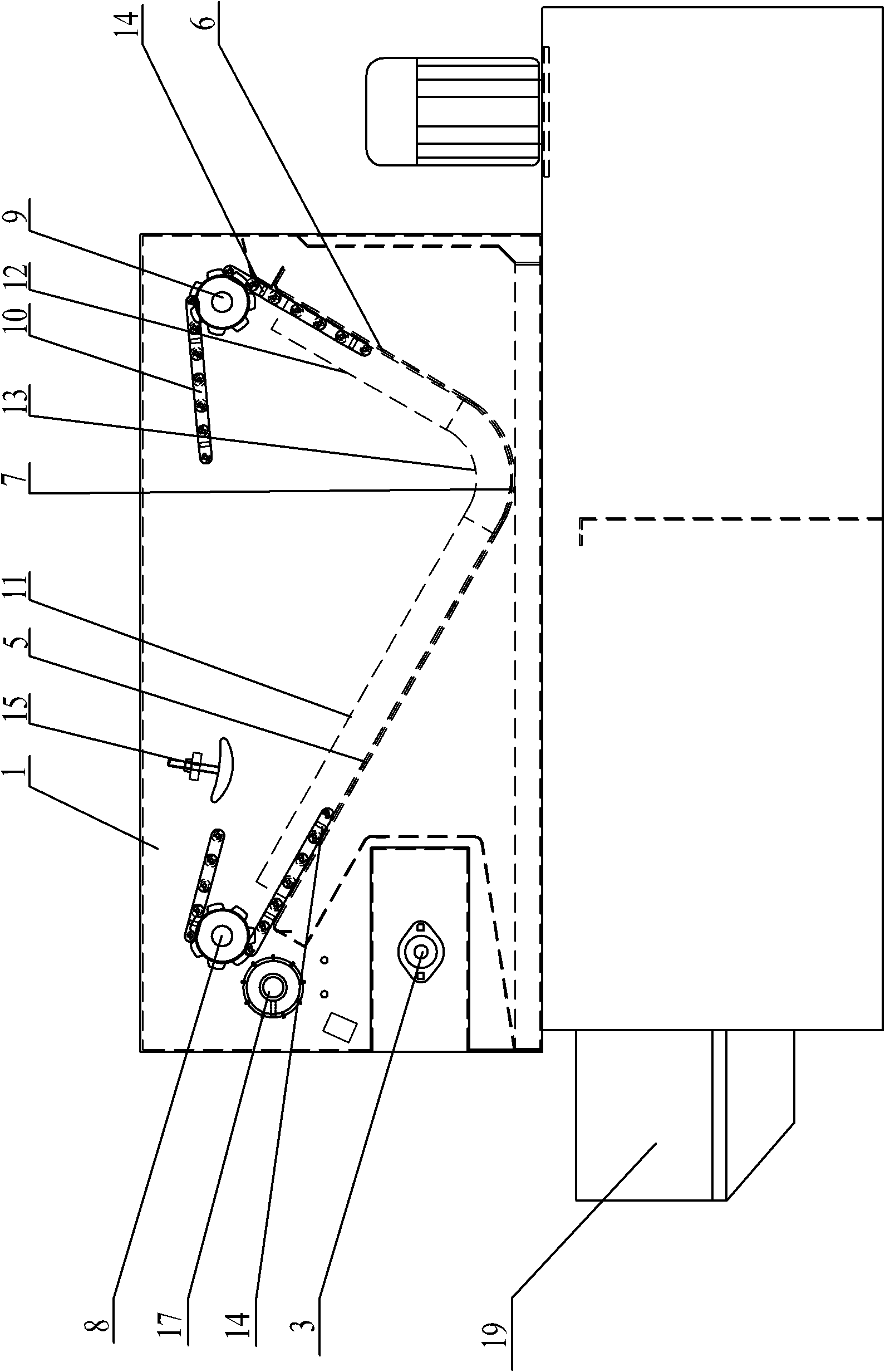

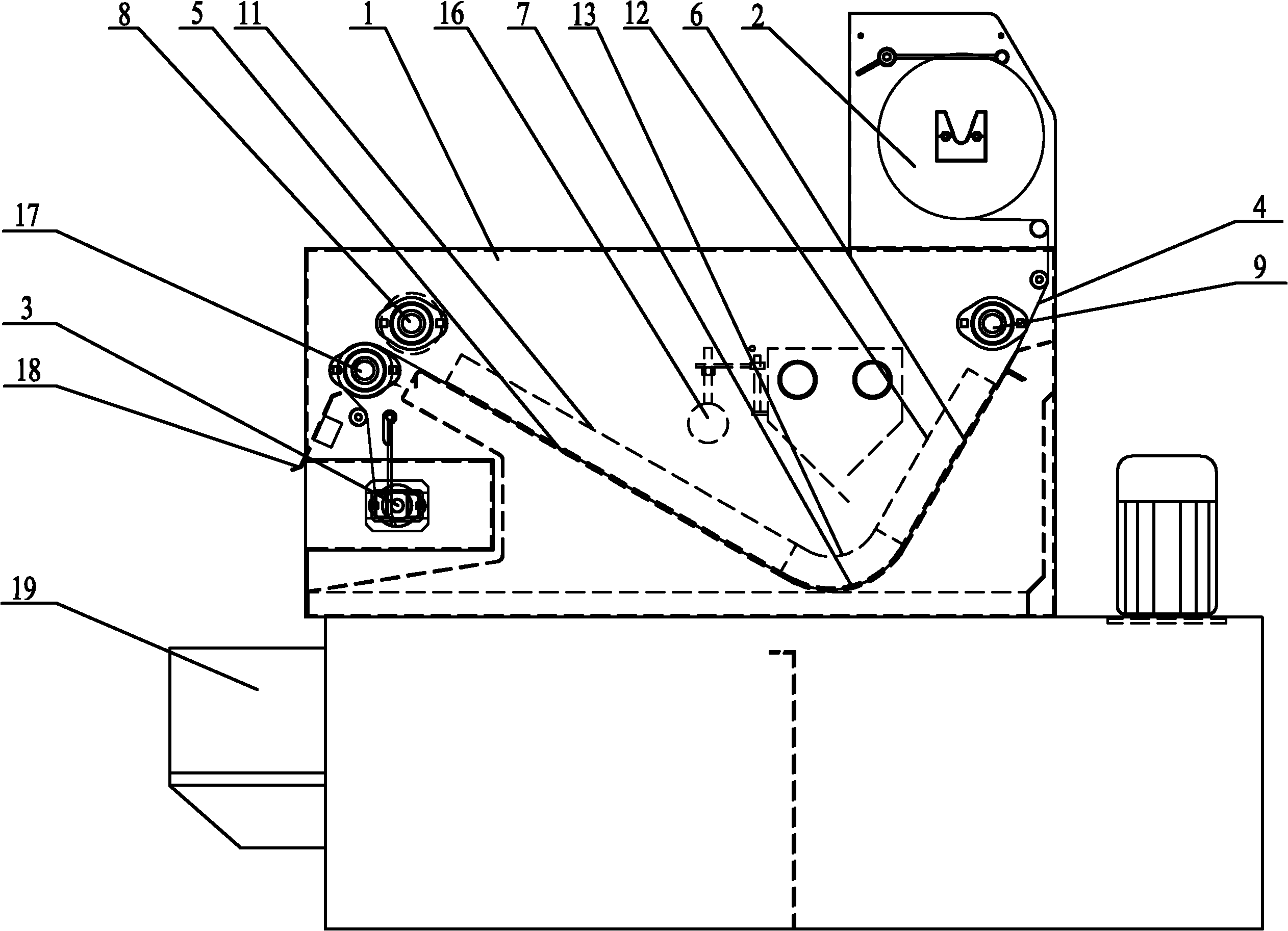

The invention relates to an automatic filter cloth scraping filter wherein an unreeling mechanism and a reeling mechanism are mounted on a shell; filter cloth is wound on the unreeling mechanism and the reeling mechanism; a V-shaped filter cloth supporting leakage tank formed by connecting a first screen plate, a second screen plate and an arc connecting screen plate is fixed on the shell; a first chain wheel and a second chain wheel are in rotatable connection with the shell at the top end position of the first screen plate; scraping plates are mounted on chains; a chain limiting groove is formed by combining the space between the bottom end of a first limiting plate and the upper surface of the first screen plate, the space between the bottom end of a second limiting plate and the upper surface of the second screen plate and the space between the bottom end of a third limiting plate and the upper surface of the arc connecting screen plate; the middle pieces of the chains are restricted in the chain limiting groove; and the middle piece of the filter cloth is clamped between the chains in the chain limiting groove and the filter cloth supporting leakage tank. When the automatic filter cloth scraping filter is at work, all filter cloth can be used as far as possible, the filter cloth is not prone to be wasted, the blockage is not prone to happen, the filter flow rate is higher, and the degree of automation is high.

Owner:无锡强工机械工业有限公司

Branchial filter

InactiveCN101537276BFiltration flow is largeSuitable for primary separationStationary filtering element filtersEngineeringAlgae

Owner:NANJING INST OF GEOGRAPHY & LIMNOLOGY

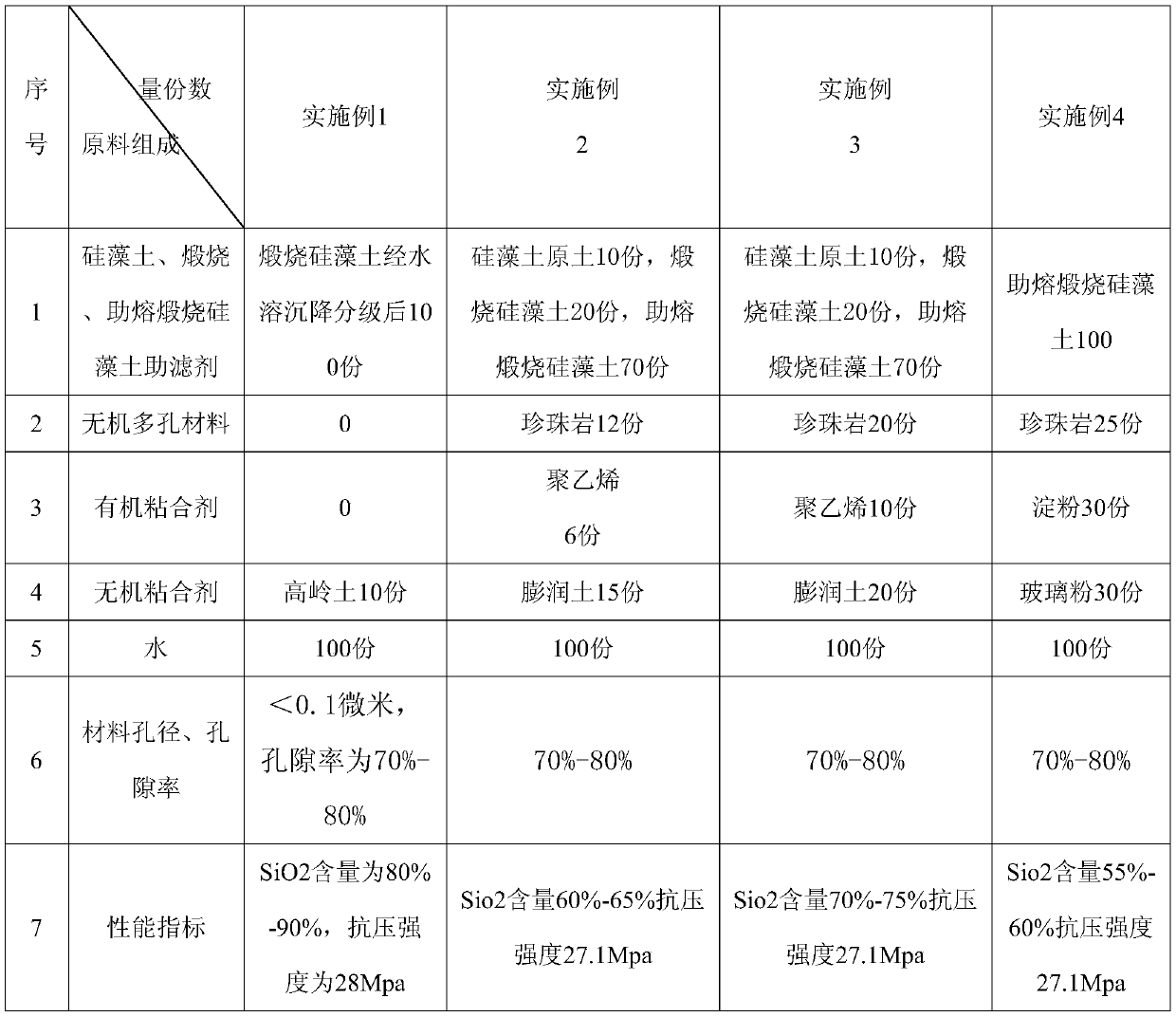

Diatomite functional material and preparation method thereof

The invention provides a diatomite functional material and a preparation method thereof, and belongs to the technical field of diatomite materials. The diatomite functional material is prepared from the components in parts by weight: 100 parts of one or two mixtures of diatomite or a diatomite filter aid, 0-25 parts of an inorganic porous material, 0-30 parts of an organic binding agent, 10-30 parts of an inorganic binding agent, 100 parts of water, and the content of SiO2 in the diatomite is greater than 60%. The diatomite functional material is based on the diatomite with the organic bindingagent and the inorganic binding agent and prepared through mixing, molding, calcining, shaping, carving or printing and other processes; and the preparation method has the advantages of being simple,convenient to use, wide in application range, large in filtration flow, high in precision, good in effect, stable in chemical property, high in pressure and corrosion resistance strength, long in service life and the like, the content of SiO2 in the material is greater than 80%, porosity is greater than 70%, and the compressive strength is 20-30 MPa.

Owner:邱连旺

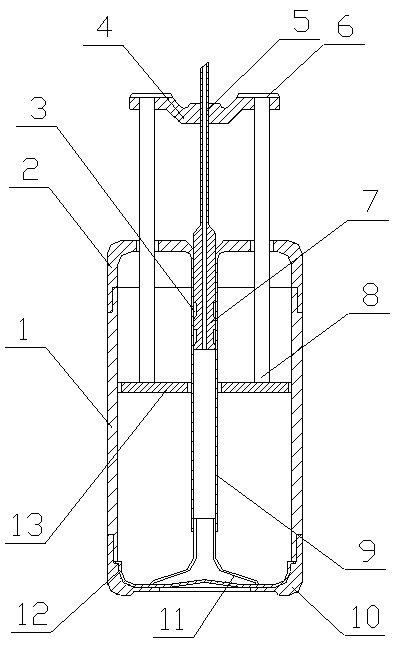

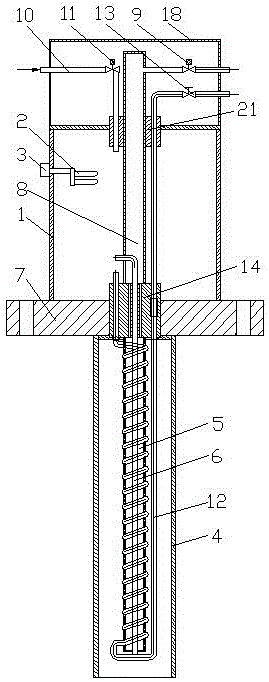

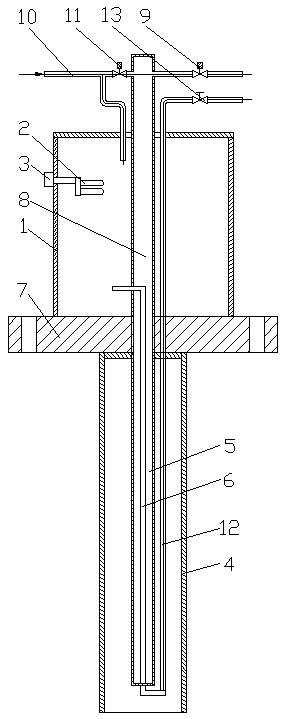

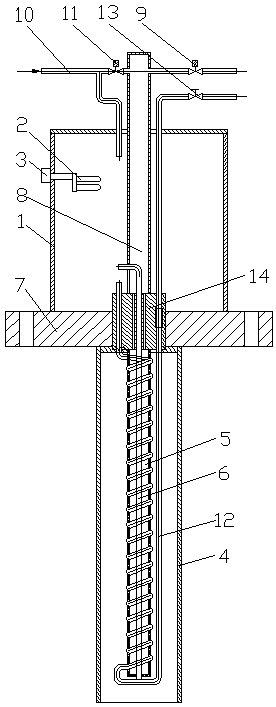

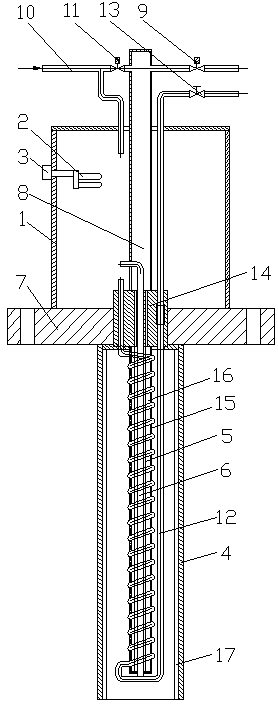

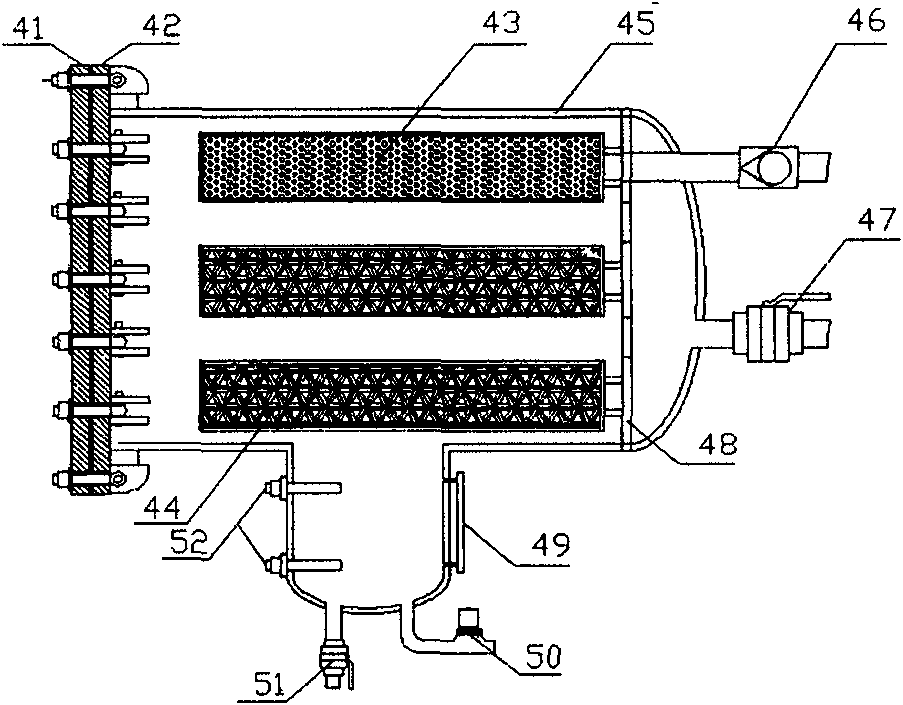

Fully-automatic shell-and-tube type reverse-washing filter and filtering method thereof

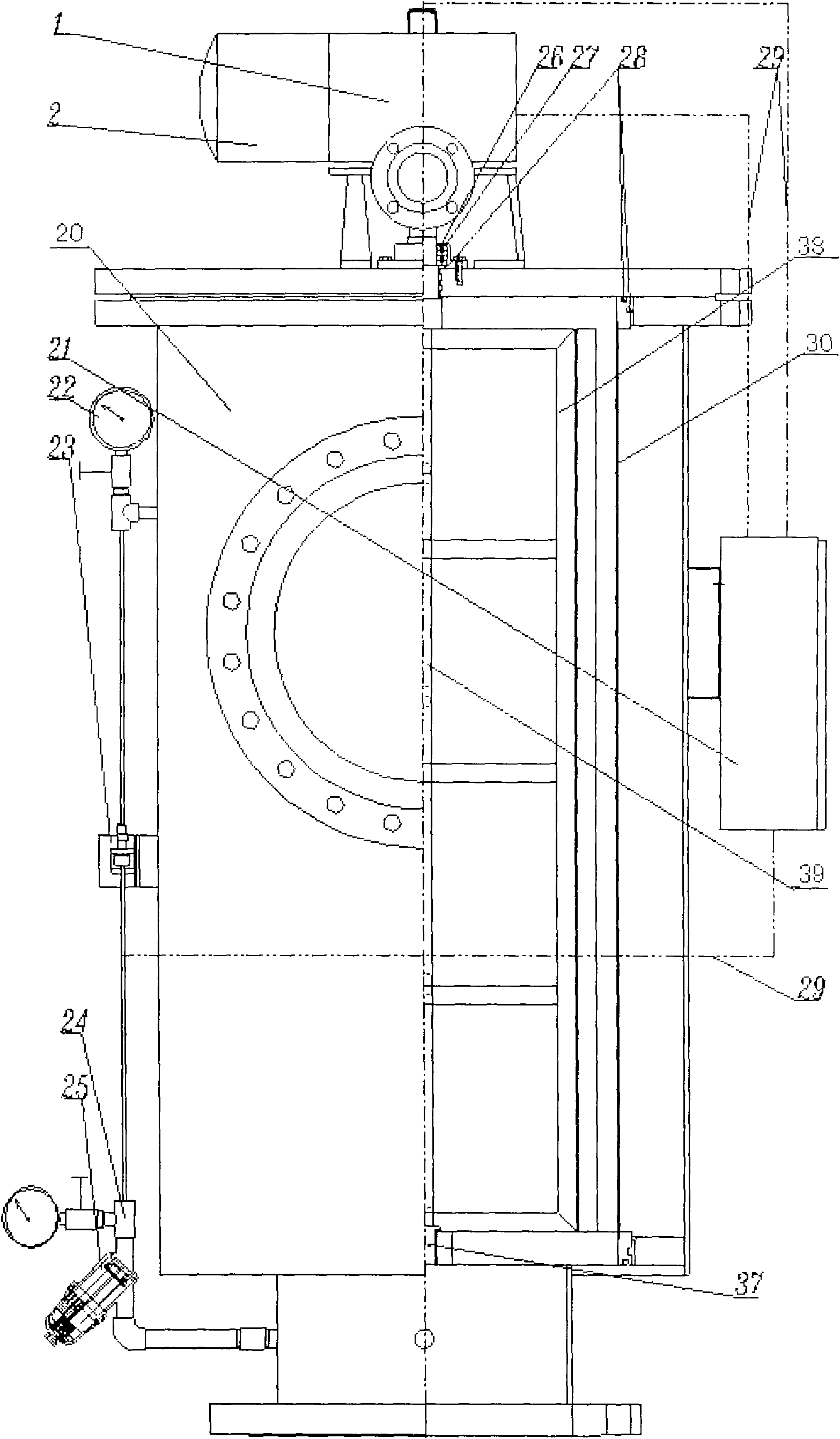

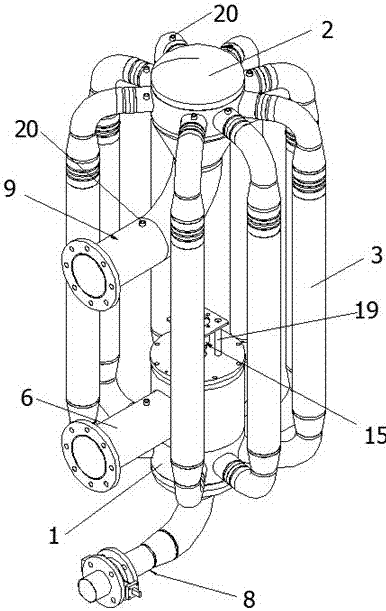

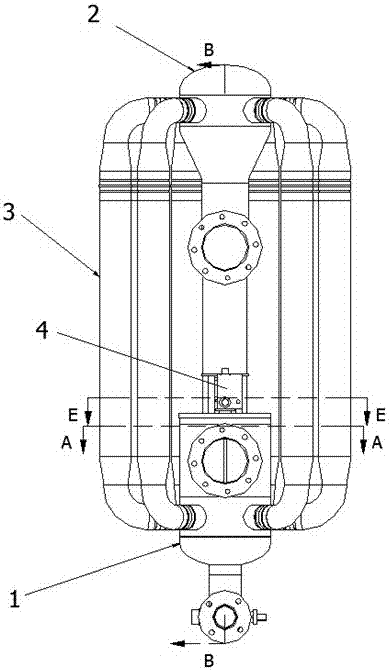

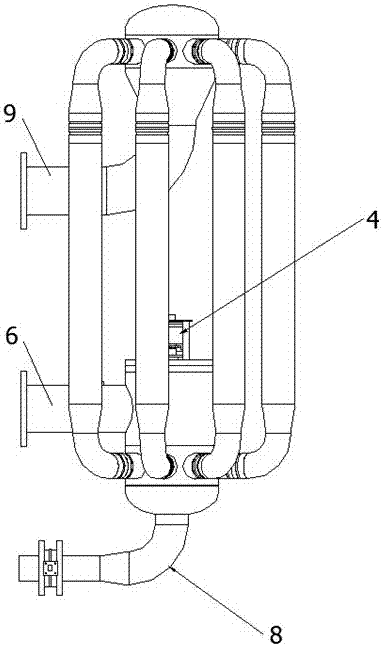

InactiveCN107096272AFiltration flow is largeSmall footprintUltrafiltrationStationary filtering element filtersWater dischargeTubes types

The invention discloses a fully-automatic shell-and-tube type reverse-washing filter and a filtering method thereof. The fully-automatic shell-and-tube type reverse-washing filter comprises an inlet branched seal head, an outlet branched seal head, a plurality of filtering tube, a steering mechanism and a controller; a water inlet pipeline is arranged at the upper part of the inlet branched seal head; a plurality of water inlet holes are formed in the seal head wall of the lower part of the inlet branched seal head in the circumferential direction uniformly; a dirt discharge pipeline is arranged at the bottom of the inlet branched seal head; a water discharge pipeline is arranged at the lower part of the outlet branched seal head; a plurality of water outlet holes are formed in the seal heal wall of the upper part of the outlet branched seal head in the circumferential direction; a pressure sensor is arranged on each of the water inlet pipeline, the water discharge pipeline and each filtering tube; all the pressure sensors are electrically connected with the controller. The fully-automatic shell-and-tube type reverse-washing filter has large filtering flow, can meet the filtering requirement with filtering precision being 1 to 610 microns and is widely applied; in the process of reversely washing the blocked filtering tube, other filtering tube still can perform filtering operation, so the working efficiency of the filter is improved.

Owner:上海伶尔亿环境工程有限公司 +1

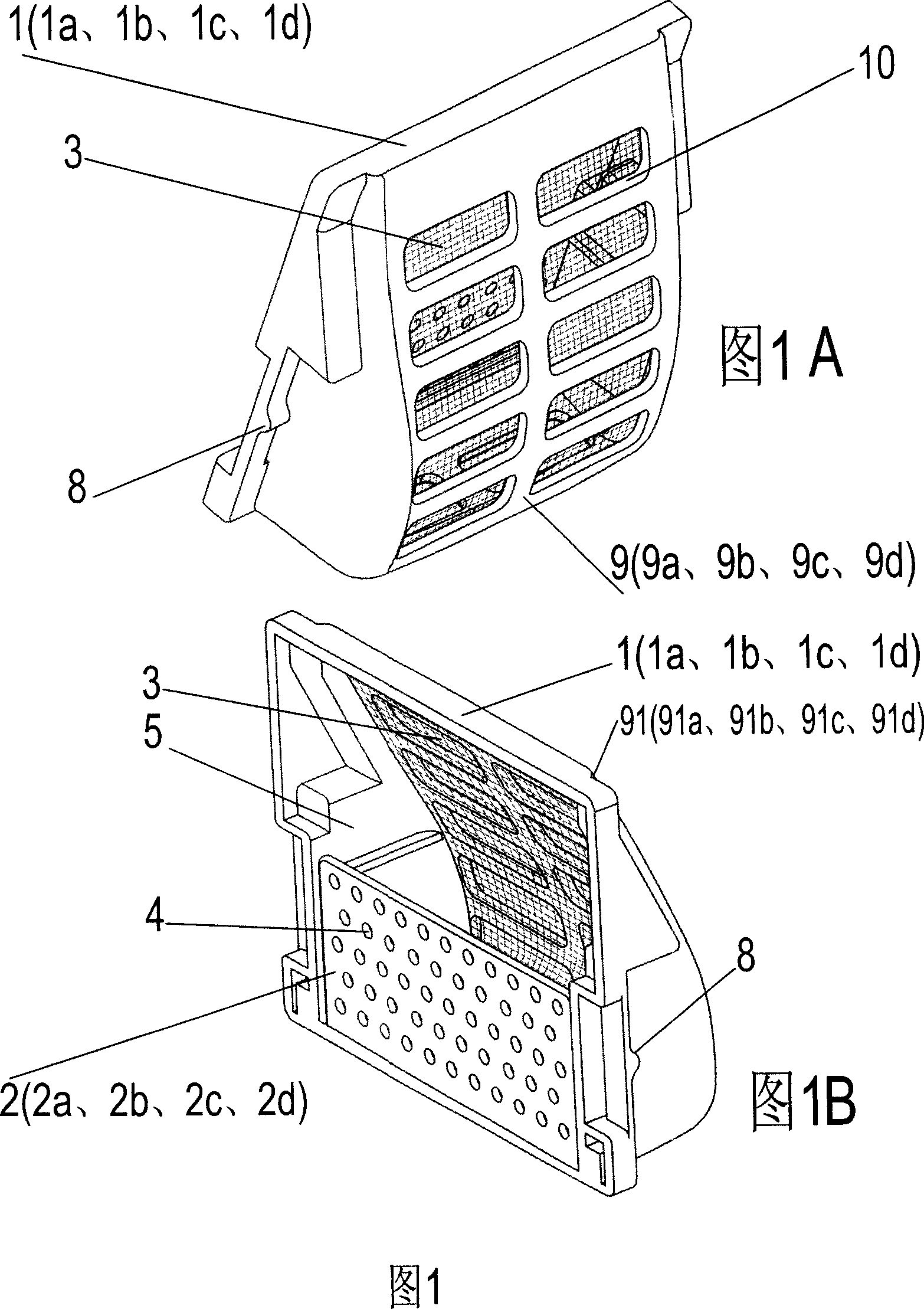

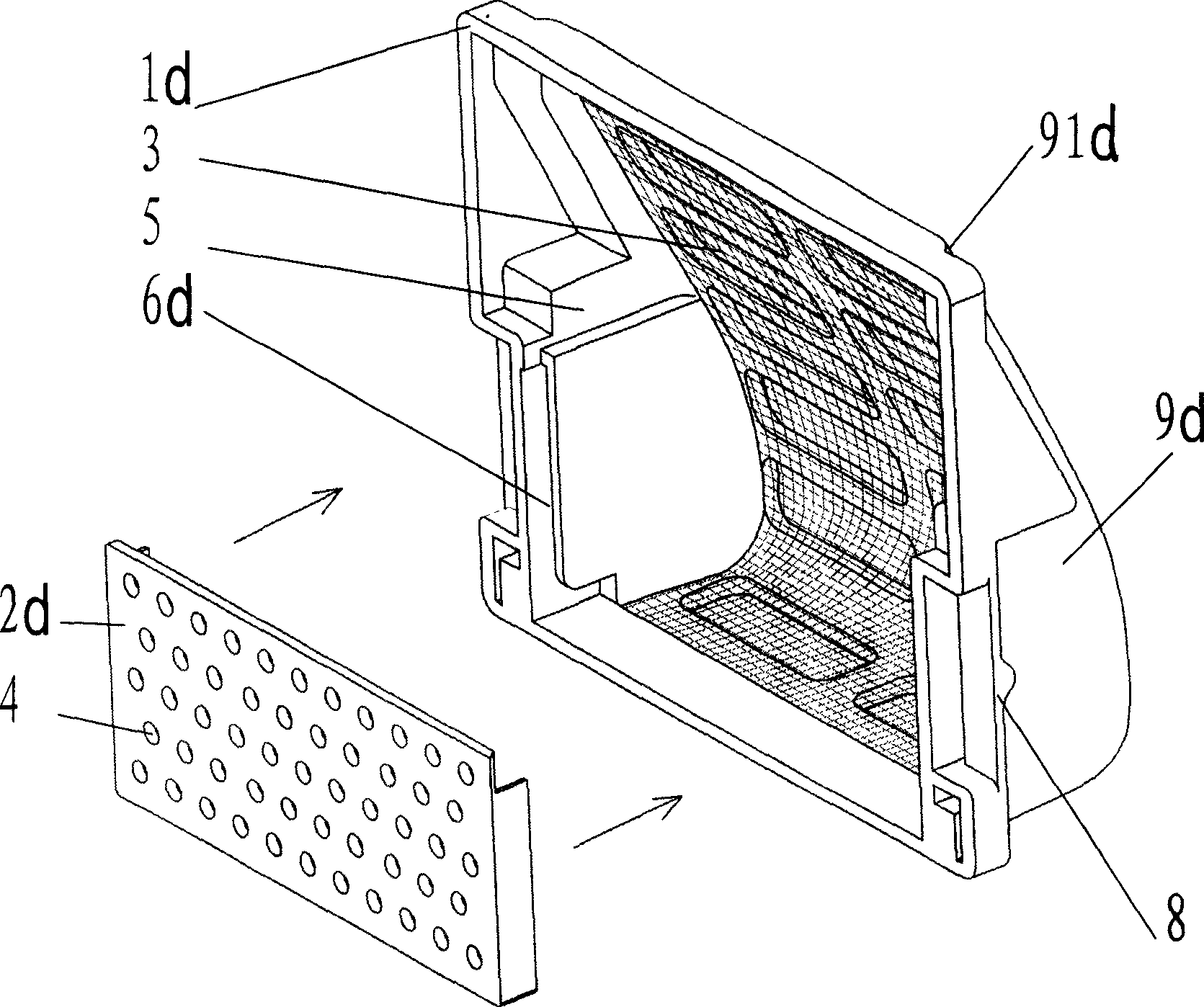

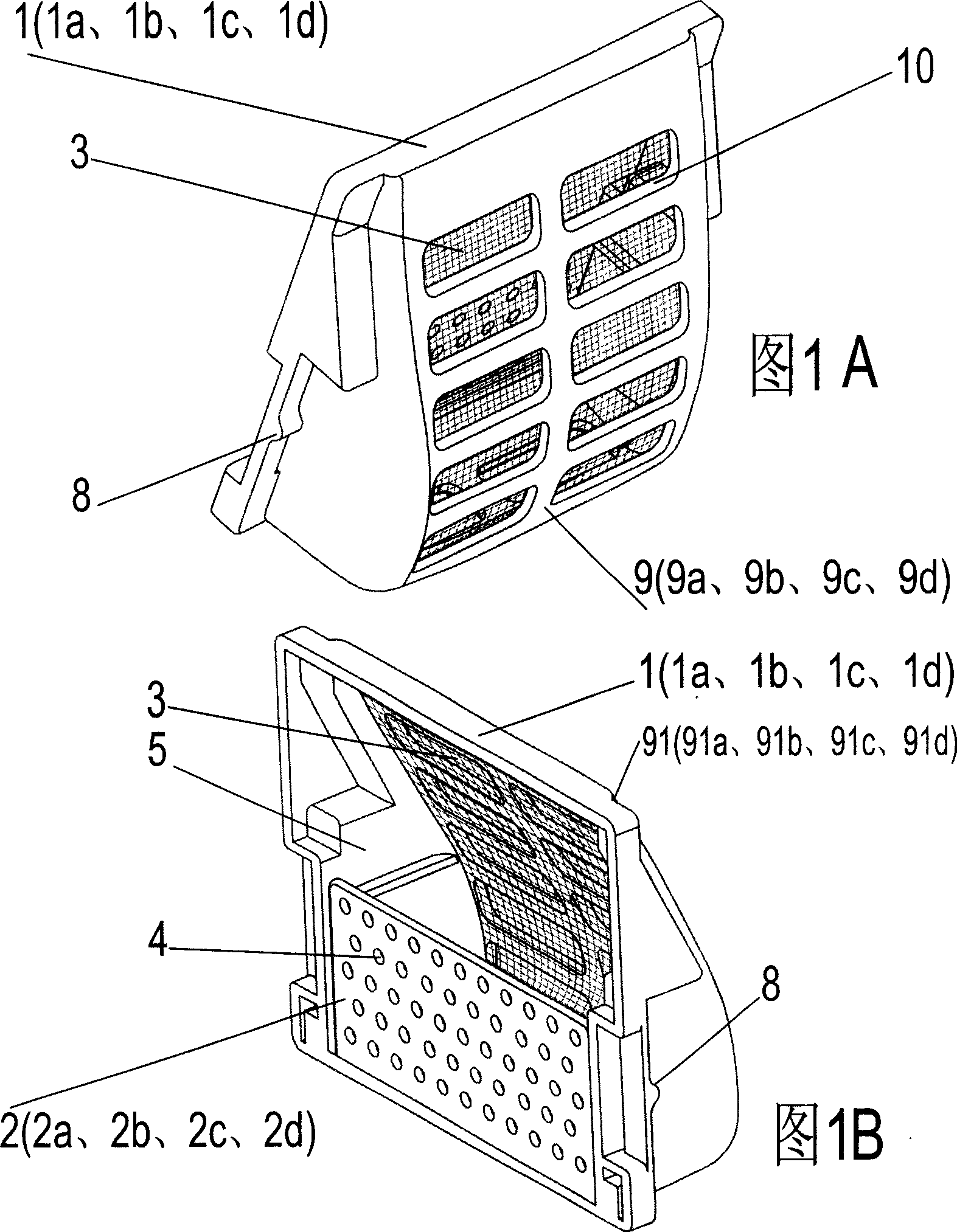

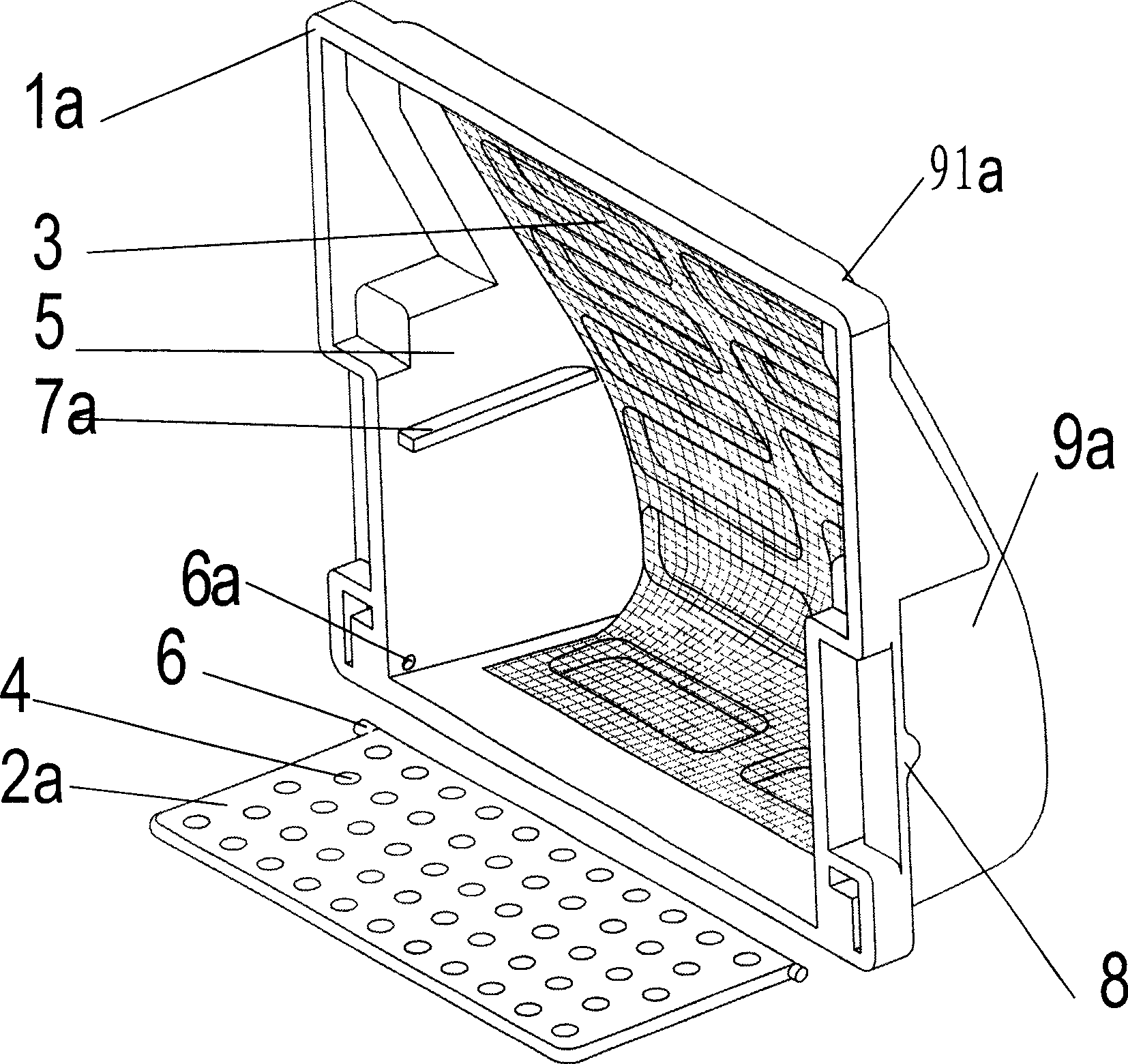

Waste water filter for washing machine

InactiveCN1978747AFiltration flow is largeEasy to cleanOther washing machinesTextiles and paperWater filterWash water

The invention relates to washing machine wash water filter. It includes front face toward washing barrel and laid filter screen, back board set in spouting slot outlet, side wall connected the front face with the back board each of which can be dismountable parts, fixed part set in the side wall. The most simple is to do injection molding forming integration for the front face and the side wall. The back board is dismountable to conveniently take out the filter residue. The filter not only has the action of the traditional bag net type filter, but also can conveniently clean residue, be more durable and beautiful.

Owner:江门市洗衣机厂

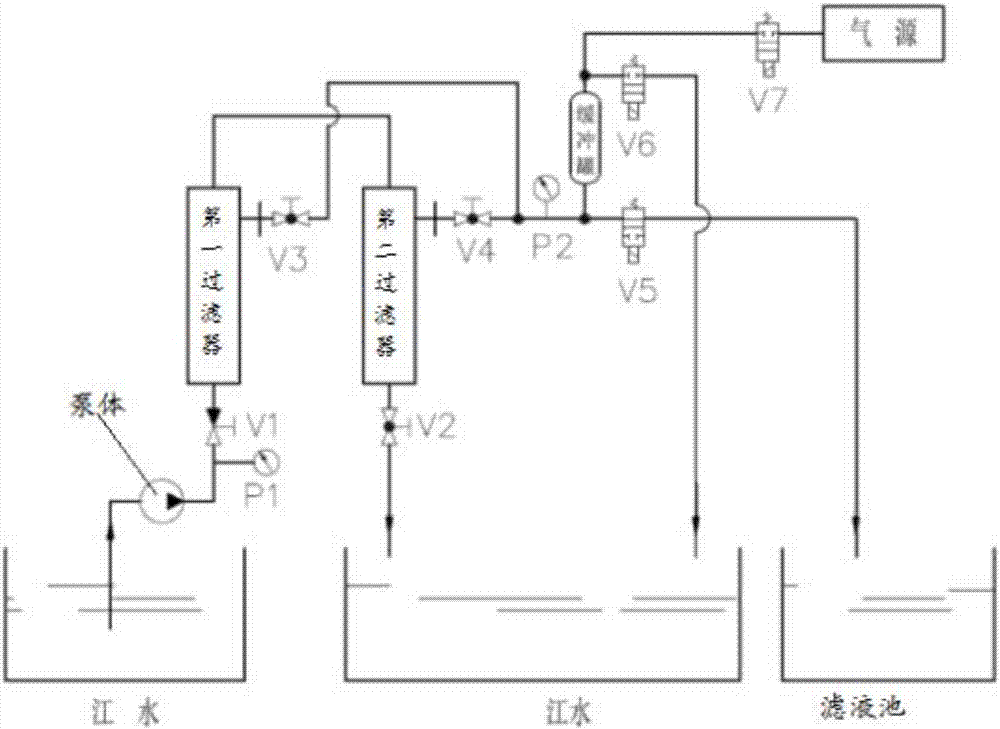

River water filtering device for ship and self-flushing method thereof

The invention provides a river water filtering device for a ship and a self-flushing method thereof. The river water filtering device for the ship comprises a first filter, a second filter, a buffer tank, a filtrate pond and a gas source. A water return port of the first filter is connected to a water inlet of the second filter, a water outlet of the first filter communicates with a water outlet of the second filter, a water outlet of the second filter separately communicates with the buffer tank and the filtrate pond, a normally opened electromagnetic valve is also arranged between the filtrate pond and the second filter, and a drain pipe is arranged on the top of the buffer tank. According to the river water filtering device for the ship, provided by the invention, the buffer tank, a normally closed electromagnetic valve and the normally opened electromagnetic valve form a backflushing storage space. The first filter and the second filter can be flushed by adjusting the opening and closing states of the normally closed electromagnetic valve, the normally opened electromagnetic valve and the gas source.

Owner:武汉中舟环保设备股份有限公司

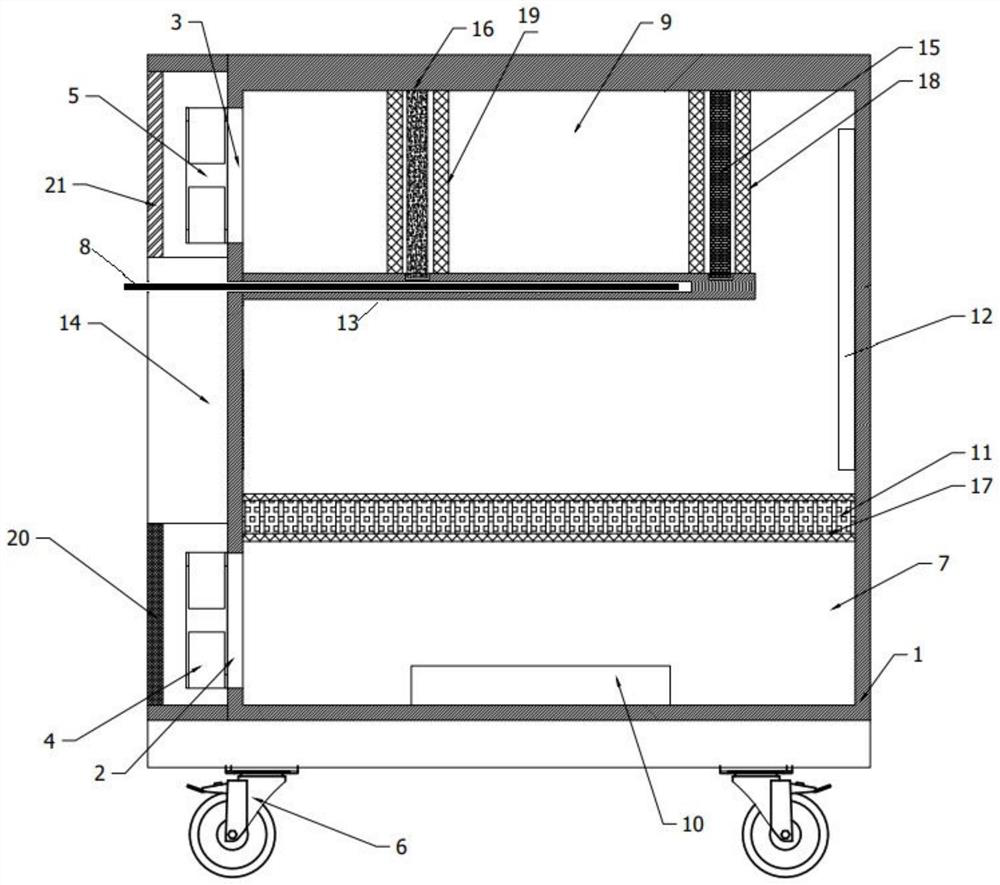

Aerosol adsorption sterilizer

PendingCN112755674AAvoid harmAchieve coexistenceGas treatmentDispersed particle filtrationHEPAActivated carbon

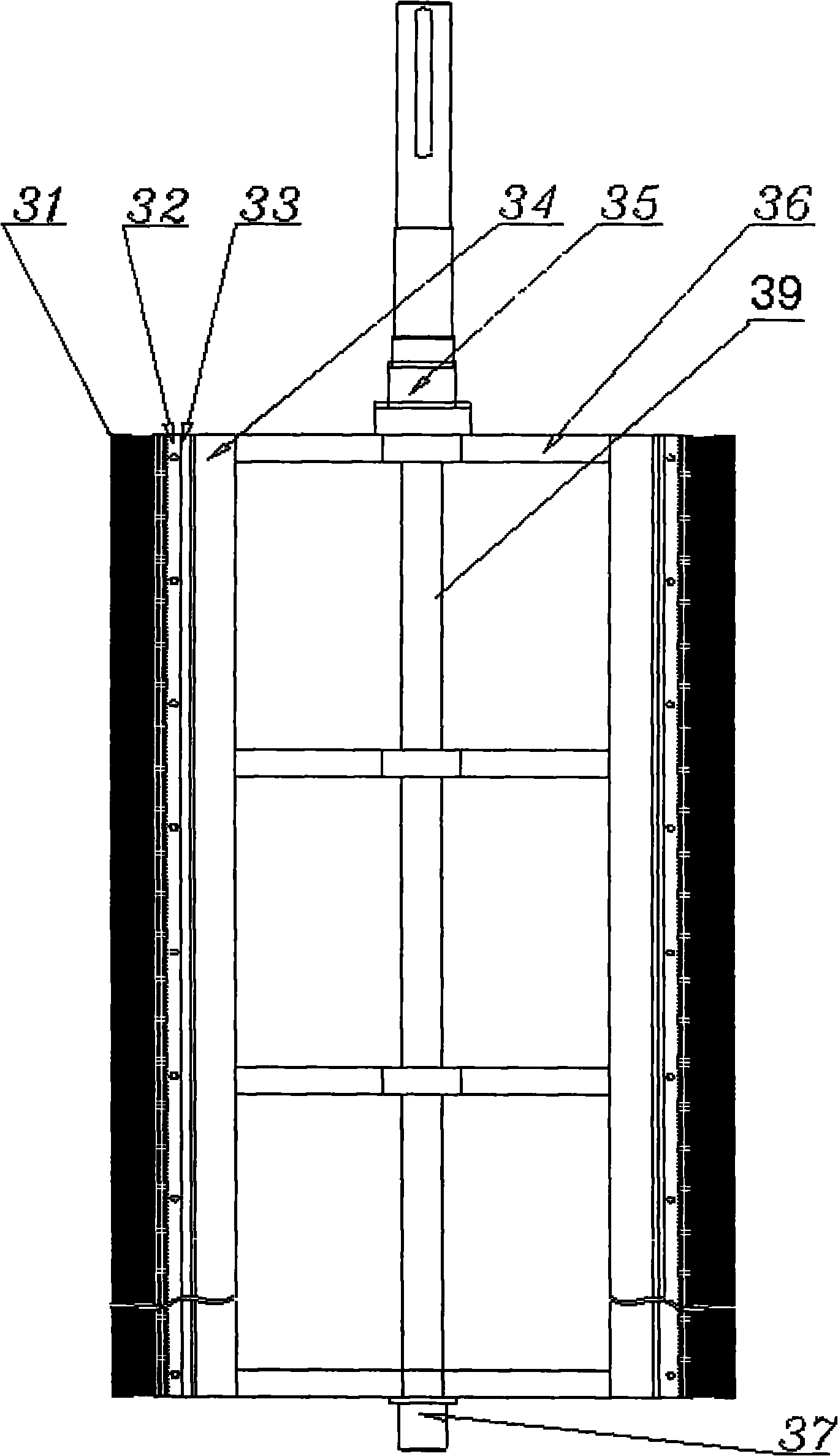

The present invention discloses an aerosol adsorption sterilizer which comprises a shell, an air inlet is formed in the bottom of the shell, an air outlet is formed in the top of the shell, a first adsorption filtering cavity is formed in the lower portion of the shell, a plasma generator is connected to the bottom of the first adsorption filtering cavity, and a first adsorption layer is connected to the top of the first adsorption filtering cavity; an ultraviolet lamp is connected to the side wall of the upper middle portion of the shell, a second adsorption filtering cavity is formed in the upper portion of the shell, a non-communicated supporting frame is arranged on the lower portion of the second adsorption filtering cavity, a second adsorption layer and an activated carbon adsorption layer are sequentially connected to the supporting frame, and the supporting frame is of a hollow structure; and a plurality of through holes are formed in the part, under the second adsorption filtering cavity, of the supporting frame. The aerosol adsorption sterilizer can efficiently adsorb harmful aerosol particles in air and is good in sterilization effect. Meanwhile, the system can change the filtering structure according to needs, the service life of the HEPA filter element is prolonged, and the filtering flow is increased.

Owner:唐山皓骞科技有限公司

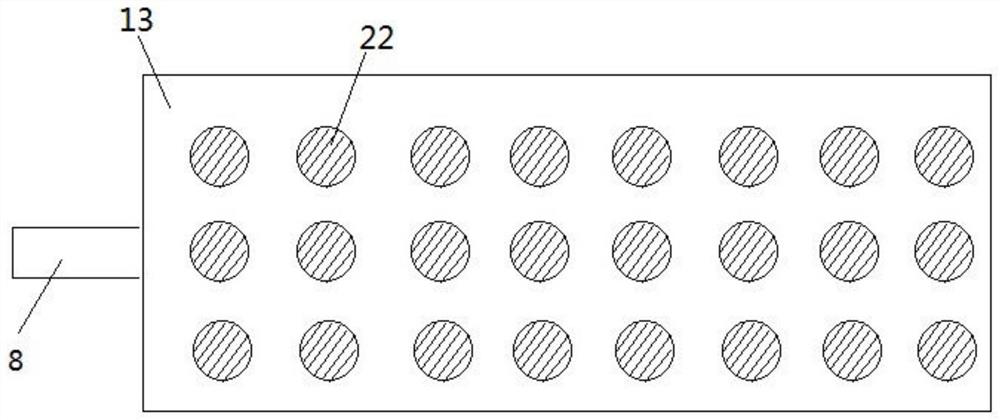

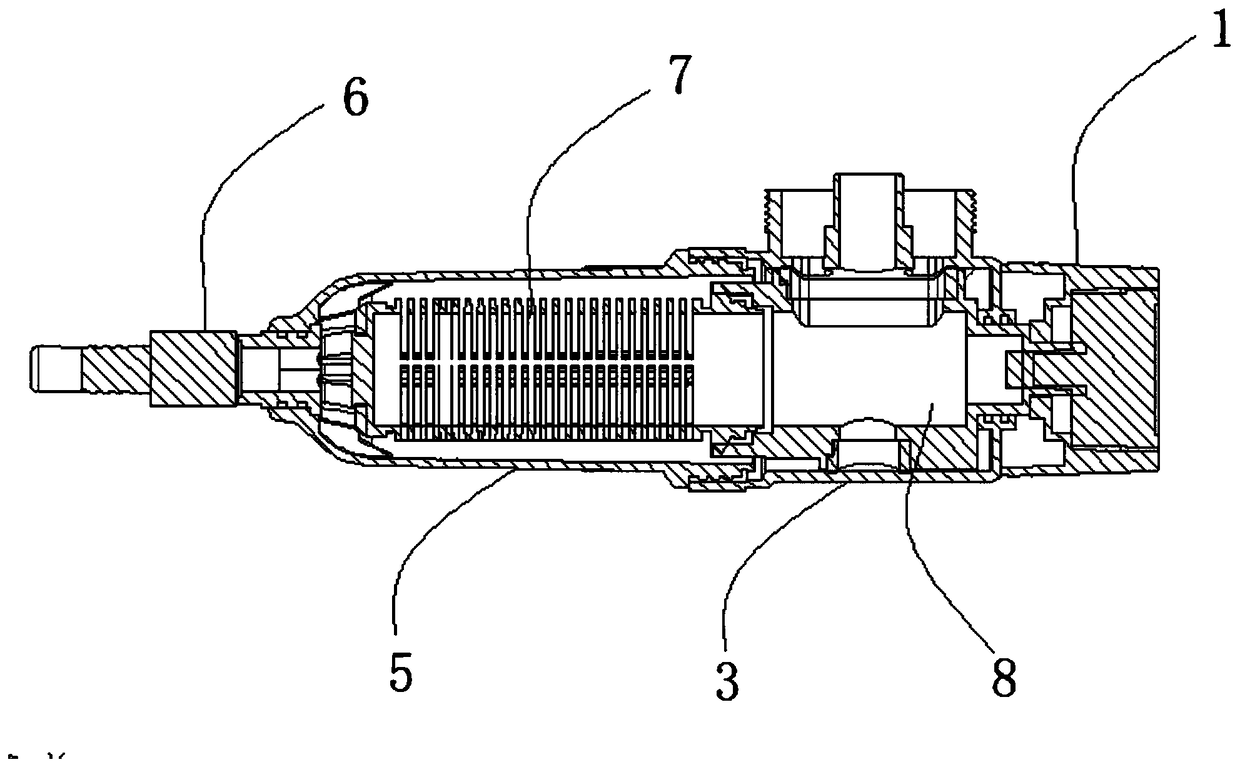

Injector

ActiveCN109364333ANot easy to fall offPrevent retractionInfusion syringesMedical devicesEngineeringSyringe needle

The invention discloses an injector. According to the injector, the injection amount of a syringe needle is controlled, the syringe needle is supported, and medicine liquid is filtered through a filter net cover of the bottom. The syringe needle can be supported in the injection process, and the syringe needle is prevented from falling off or being further injected in skin. The injector is characterized in that the two ends of a cylinder are of open structures respectively, a bottom end cover is detachably arranged at the bottom of the cylinder and clamped to the bottom of the cylinder, and afront end cover is detachably arranged at the top of the cylinder and clamped to the top of the cylinder; two through holes are formed in the front end cover, a piston plate is arranged in the cylinder and fits the inner wall of the cylinder, and one end of one of two push rods is connected with the piston rod separately; the other end of one of the two push rods penetrates through the two throughholes in the front end cover, a fixing rack is connected with the other end of one of the two push rods and composed of a middle connection block and two connection plates, and the two connection plates are placed at the two sides of the middle connection block respectively and correspondingly connected with the other end of one of the two push rods respectively.

Owner:XUZHOU BLUE LAKE INFORMATION TECH CO LTD

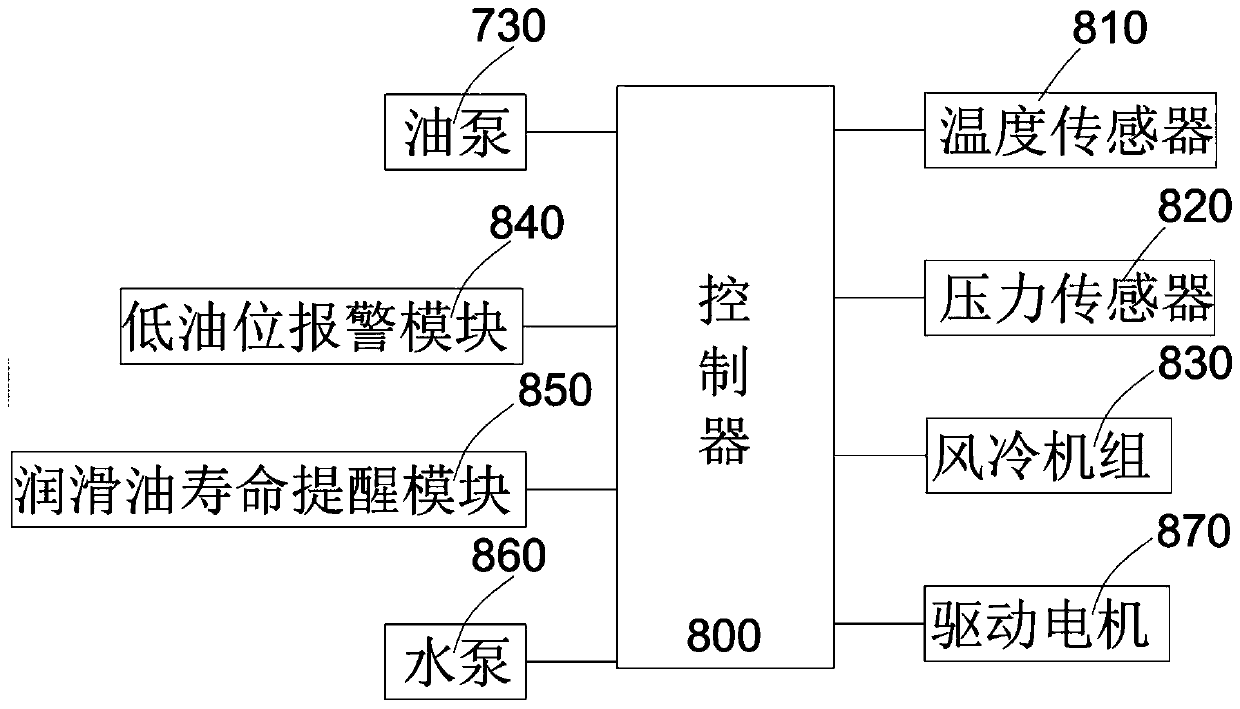

Diesel generator state control system and method

ActiveCN110374715AConvenient condition monitoringImprove operational reliabilityInternal combustion piston enginesLubrication temperature controlControl systemEngineering

The invention discloses a diesel generator state control system and method. A first pressure sensor is disposed inside the filter core of a lubricating oil filter mechanism, and the first pressure sensor is used to measure the oil pressure inside the filter core. A first temperature sensor is arranged in a pipeline at the front end of a return oil inlet and used for measuring the temperature of the lubricating oil at an inlet of the filtering mechanism. The input end of a controller is respectively connected with the first pressure sensor, the first temperature sensor and a driving motor; theoutput end of the controller is connected with a lubricating oil life reminding module; the controller adjusts the rotating speed of the driving motor according to feedback values of the first pressure sensor; and vanes cause the lubricant to flow toward the second end of the filter core. The invention solves the technical problem of incapability of controlling the working state of the diesel engine.

Owner:CHANGSHU GUORUI TECH CO LTD

Oak barrel liquor clarification method and clarification device thereof and oak barrel liquor production method and production system

PendingCN110791405AEffectively removes the tasteEffectively removes colorAlcoholic beverage preparationAlcohol contentPulp and paper industry

The invention relates to a liquor production method, and particularly discloses an oak barrel liquor clarification method which comprises the step of performing membrane filtration on oak barrel liquor; wherein the barrier molecular weight of a filter membrane used in the membrane filtration step is 250,000-300,000 Daltons. The method has the advantages that the technical problem of turbidity of the liquor in an oak barrel after pulp addition and alcohol content reduction and during storage on the premise of keeping the original taste and color of the oak barrel liquor is solved. The method has the advantages that the filtering precision is high, the filtering flow is large, the color, flavor and taste of the oak barrel liquor are not damaged, the turbidity of the oak barrel liquor can beeffectively removed after the oak barrel liquor is filtered by a device, the oak barrel liquor is not turbid again after being frozen for 72 hours at the temperature of-10 DEG C, and the freezing resistance and low-temperature stability are effectively improved.

Owner:SICHUAN UNIVERSITY OF SCIENCE AND ENGINEERING

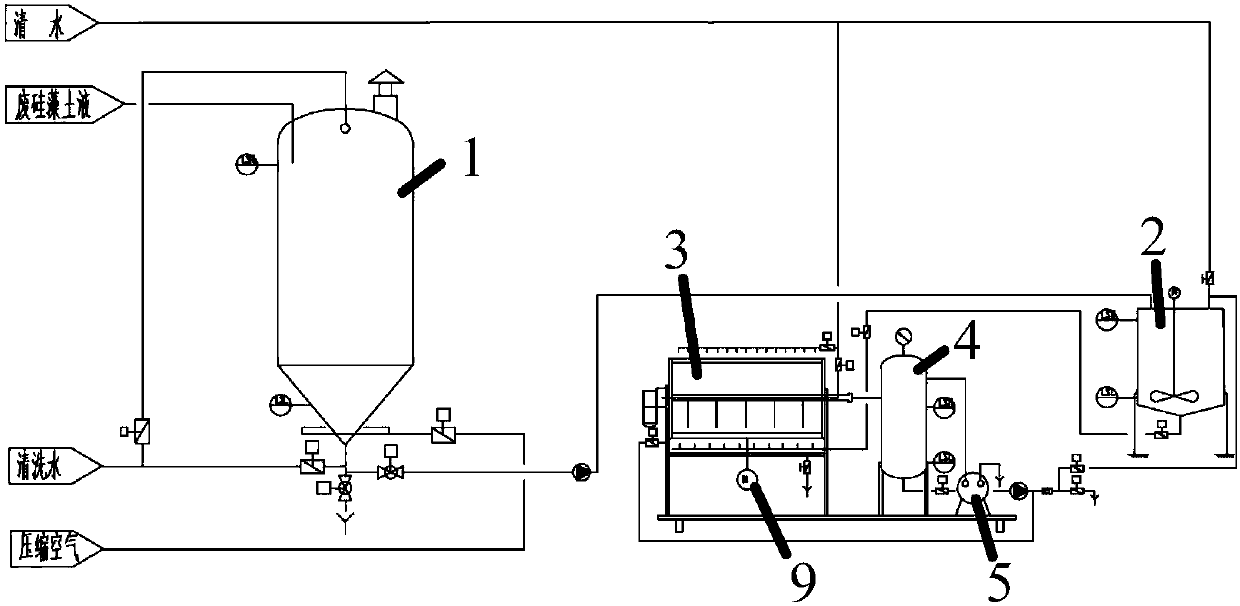

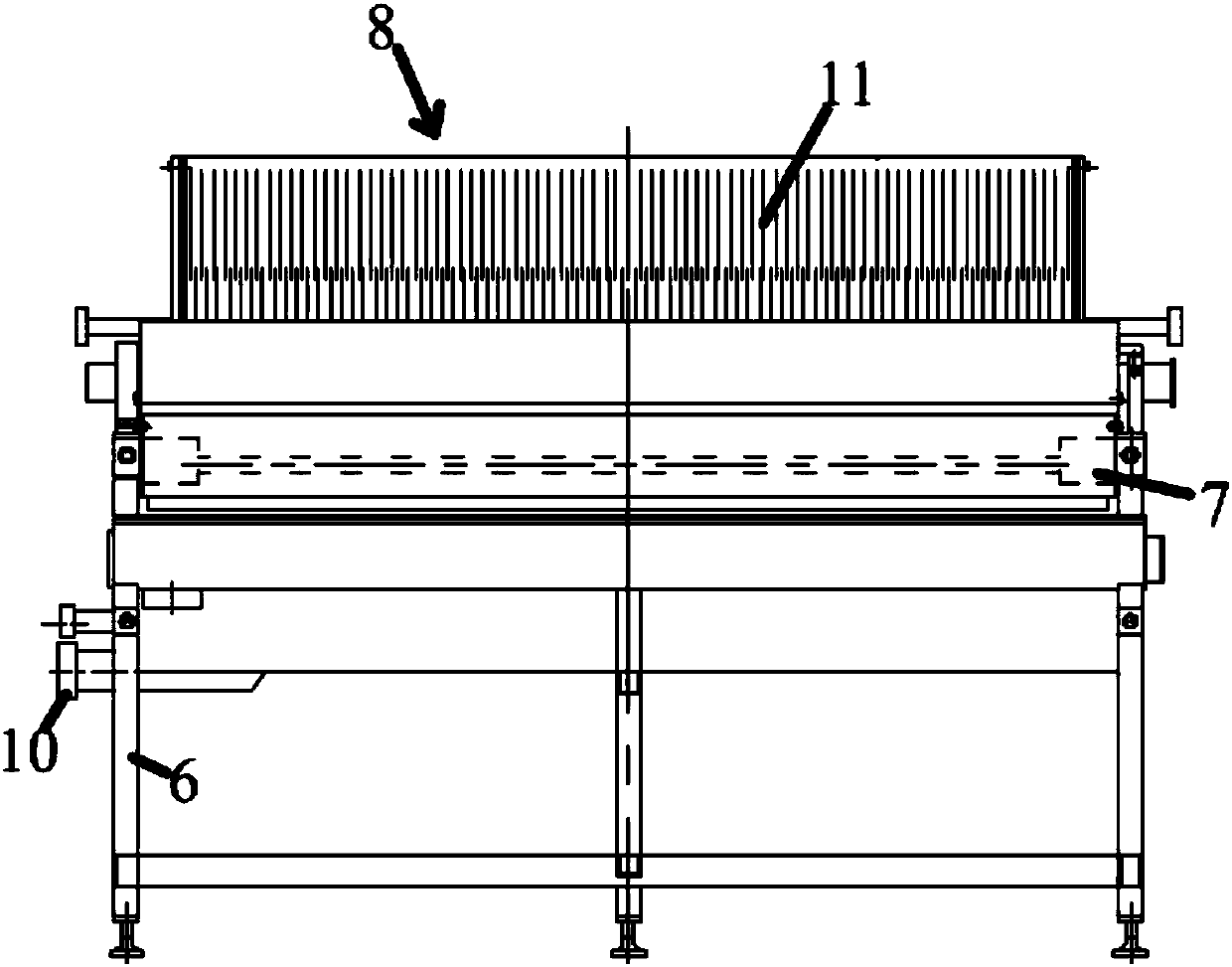

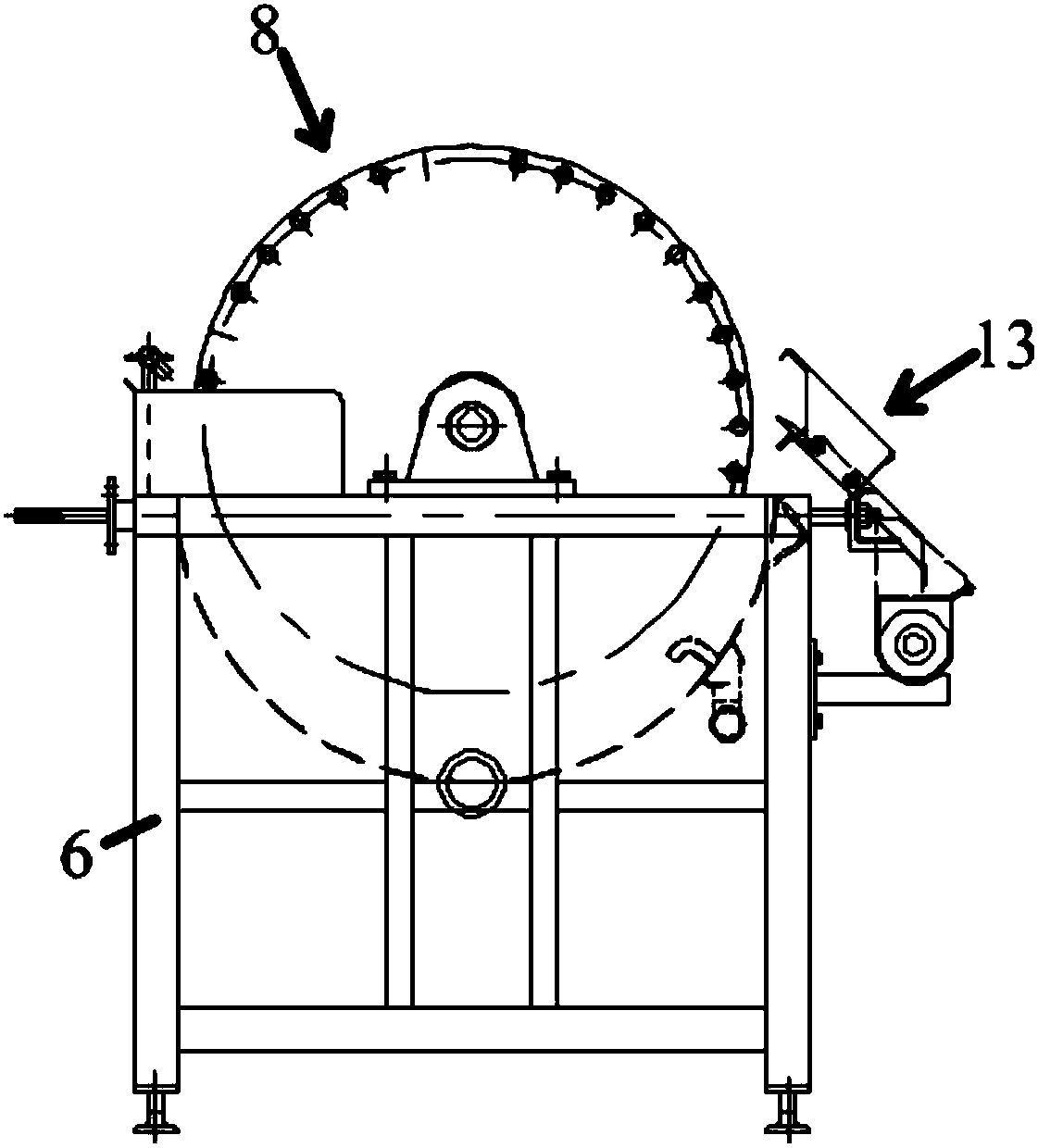

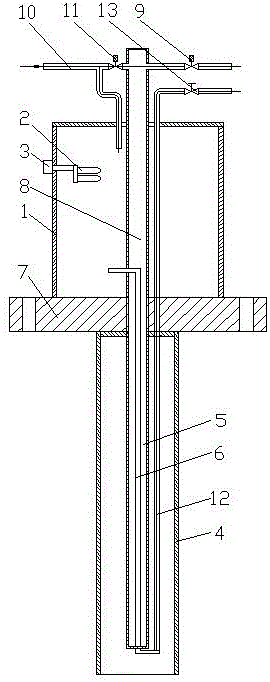

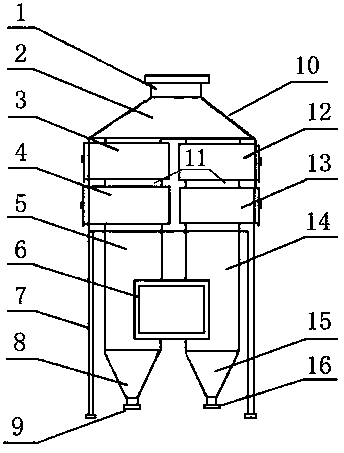

Vacuum drum filtering system

InactiveCN107596763ALarge effective filter gapFiltration flow is largeMoving filtering element filtersHigh densityFixed frame

The invention relates to a vacuum drum filtering system. The vacuum drum filtering system comprises a waste diatomite storage tank, a mixing tank, a vacuum drum filter, a raw material temporary storage vat and a vacuum pump which are sequentially connected, wherein the vacuum drum filter comprises a bracket, a revolving drum and a filter net, and the bracket is arranged in filter tank; the revolving drum is in transmission connection with the power mechanism and is rotatably arranged on the bracket, a sewage discharging pipe connected with the filter tank is arranged on the revolving drum, anda discharging pipe connected with the raw material temporary storage vat is arranged on the revolving drum; and the filter net is arranged in the revolving drum and comprises a plurality of metal wires with wedge-shaped cross sections and a plurality of fixed ribs, the fixed ribs are annularly arrayed to form a columnar fixed frame, and the metal wires are arranged on the columnar fixed frame atcertain intervals. According to the vacuum drum filtering system, the problems that the valid filtering gaps in the surface of a filter pipe on a filtering surface of an existing drum are few, the filter flow of a unit area is low, the high-density accumulation of precipitates is easily caused due to the strong obstruction property, and therefore, vacuum drum filtering equipment is low in workingefficiency and short in service life are solved.

Owner:WENZHOU JINGGONG BEER COMPLETE EQUIP

Full-automatic sampling method

ActiveCN105973655AImprove analysis accuracyPrevent water condensation and liquefactionWithdrawing sample devicesGas analysisSolenoid valve

The invention discloses a full-automatic sampling method and belongs to the technical field of gas analysis. The method comprises the following steps: a, allowing a filter of a full-automatic sampling device to stretch into a to-be-sampled industrial pipeline; b, closing a blowback solenoid valve by virtue of a PLC (Programmable Logic Controller), introducing instrument air or nitrogen into a heating bath thermostat, and opening an electric heater; opening a needle valve, and discharging the heated instrument air or nitrogen by virtue of a blow-down pipe; c, filtering the sample gas by a filter, allowing the sample gas to enter a sampling pipe, and opening a sampling solenoid valve to take sample gas by virtue of the PLC; and d, opening the blowback solenoid valve and closing the sampling solenoid valve by virtue of the PLC after the sample gas is taken out, and performing blowback cleaning on the filter by using the instrument air or nitrogen. According to the sampling method disclosed by the invention, a heat balance can be maintained by the heating bath thermostat, so that the sample gas is always positioned at a relatively high temperature, the sample gas is kept undistorted, the sampling stability is guaranteed, the sampling efficiency is improved, and the subsequent gas analysis precision is further improved.

Owner:成都市倍诚分析技术有限公司

Sewage treatment apparatus for environmental engineering

InactiveCN109293055AEasy to handleFiltration flow is largeFatty/oily/floating substances removal devicesSpecific water treatment objectivesSludgeFiltration

The invention discloses a sewage treatment apparatus for environmental engineering. The sewage treatment apparatus comprises a sludge outlet, a heavy metal recovery box, a centrifugal mud sucking pump, a sludge placing box, a sewage inlet, an electromagnetic control valve and a first-stage treatment box, wherein the sewage inlet is arranged above an operation control box, the electromagnetic control valve is arranged above the sewage inlet, the first-stage treatment box is arranged above the electromagnetic control valve, a second-stage treatment box is arranged below the first-stage treatmentbox, an oxygen manufacturing machine is installed below the second-stage treatment box, a third-stage treatment box is installed below the oxygen manufacturing machine, a purified water outlet is installed below the third-stage treatment box, and a sludge outlet valve is installed below the purified water outlet. The sewage treatment apparatus of the present invention can effectively treat sewagecontaining oil stains and silt, and further has characteristics of high filtration flow rate, high degreasing efficiency and high filtration precision.

Owner:陈玉东

Advanced treatment and recycling technology of printing and dyeing wastewater

InactiveCN104891743AReduce foulingReduce organic contentWater contaminantsMultistage water/sewage treatmentTurbidityReverse osmosis

The invention discloses an advanced treatment and recycling technology of printing and dyeing wastewater. In the technology, a wastewater collecting and adjusting tank, a biochemical aerobic system, a secondary sedimentation tank, a tertiary flocculation and sedimentation tank, an MBR membrane bioreactor, a bag filter and a reverse osmosis membrane system are adopted. According to the technology, organic matters are treated by the biochemical aerobic system to be decomposed into small molecules from macromolecules, so that the separation and purification of the reverse osmosis membrane to sewage are facilitated, and the pollution and blockage of the organic matters to a membrane component are prevented; suspended matters and turbidity can completely meet the water inflowing requirement of the membrane component of the reverse osmosis membrane through four-stage continuous filtering by the secondary sedimentation tank, the tertiary flocculation and sedimentation tank, the MBR membrane bioreactor and the bag filter; the design of the process route is economical and reasonable, and the possibility of the pollution blockage of a printing and dyeing wastewater reverse osmosis membrane treatment system can be greatly reduced.

Owner:SHANGHAI FENGXIN ENVIRONMENTAL PROTECTION TECH

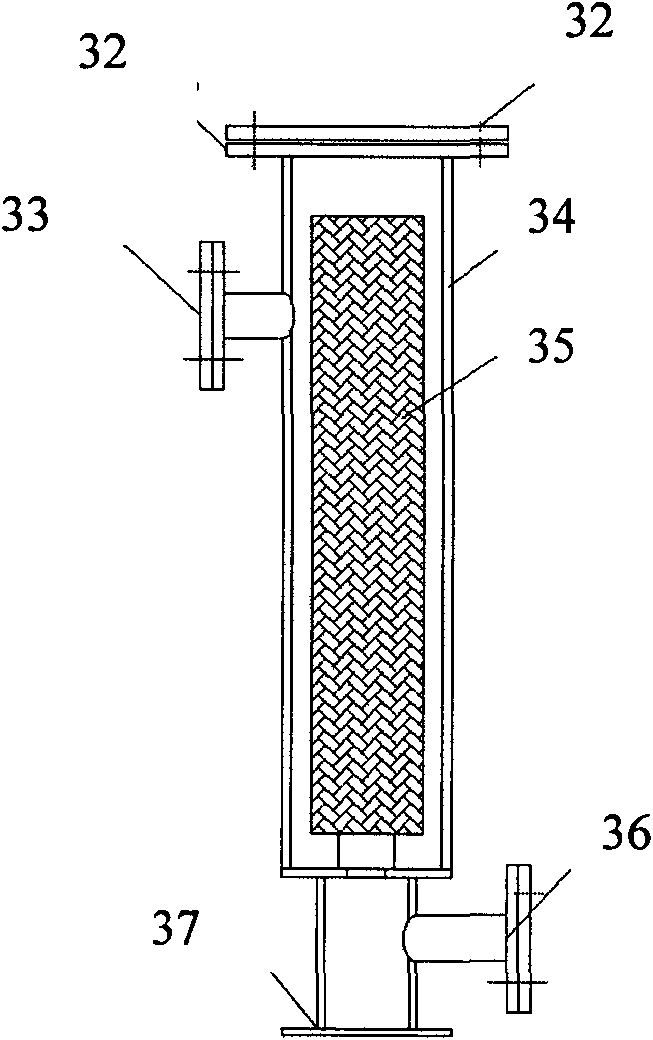

A fully automatic sampling device

The invention discloses a full-automatic sampling device, and belongs to the technical field of gas analysis. The full-automatic sampling device comprises a filter, and is characterized by further comprising a heat bath thermostat, wherein the heat bath thermostat comprises a stainless steel cylinder, an electric heater and a temperature control setter; the filter comprise a stainless steel tube and a stainless steel woven filter element; a heating tube is arranged inside the stainless steel woven filter element; the stainless steel tube and the stainless steel cylinder are connected through a flange; a sampling tube is arranged inside the stainless steel cylinder; a solenoid valve is connected with the sampling tube; the sampling tube is communicated with the sampling stainless steel woven filter element; a gas inlet tube is connected with the stainless steel cylinder; a back blowing solenoid valve is connected with the gas inlet tube; an escape pipe is arranged inside the stainless steel tube; a needle valve is connected with the escape pipe. Due to adoption of the heat bath thermostat, heat balance can be maintained, a sample gas is kept at relatively high temperature in the whole sampling process, moisture in the sample gas can be prevented from condensation and liquidation, the sample gas can be prevented from distortion, sampling stability can be ensured, and the sampling efficiency can be improved.

Owner:成都市倍诚分析技术有限公司

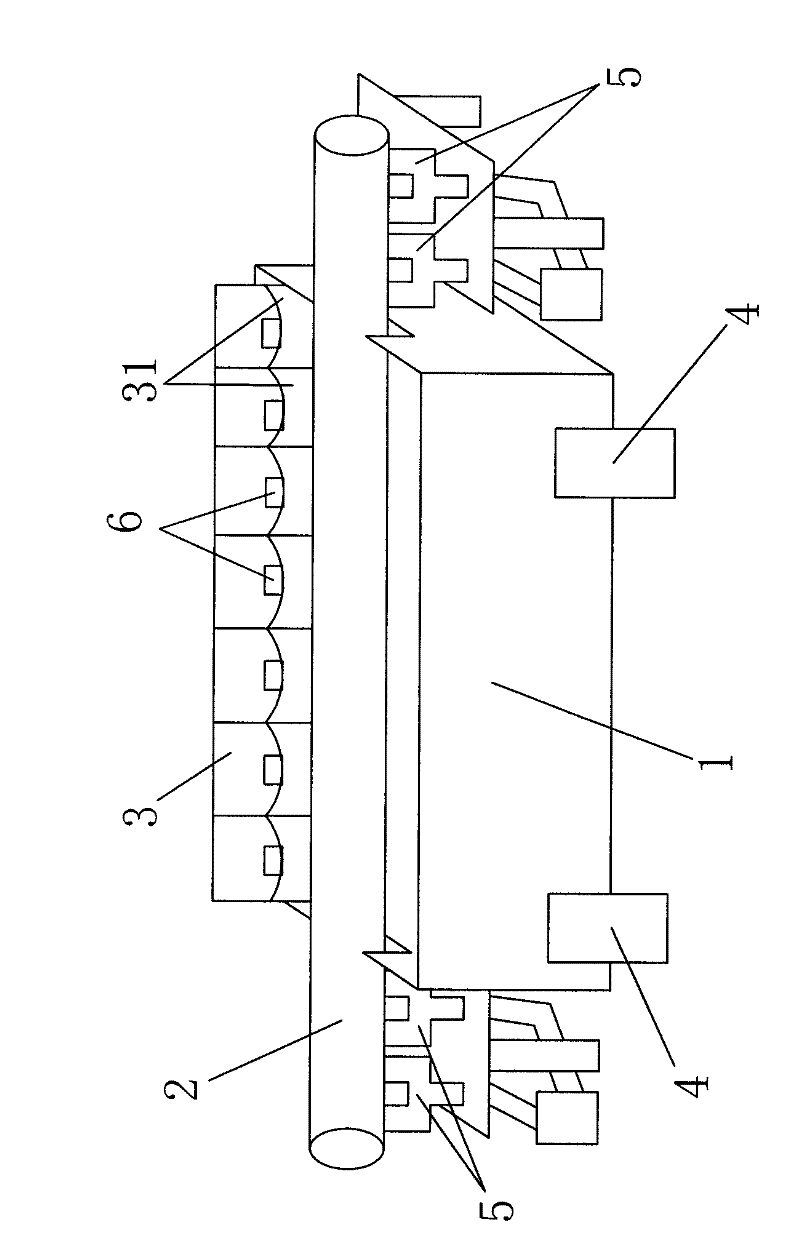

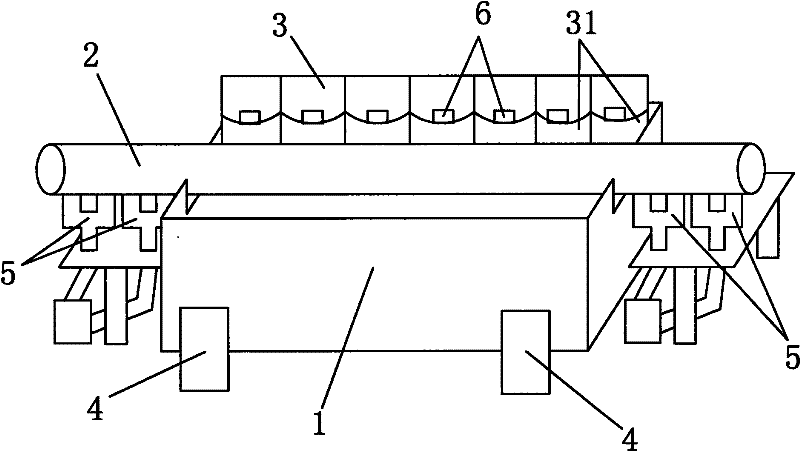

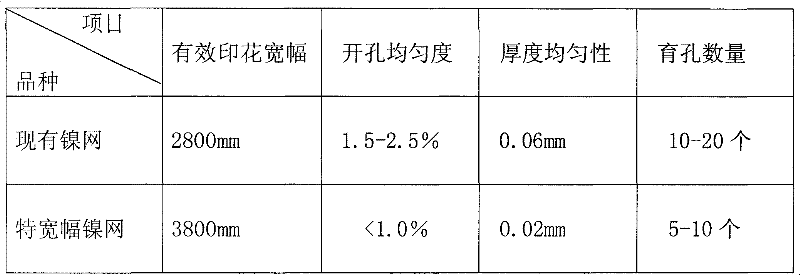

Production technology for extra-width printing nickel screen and electrical nickel-plating bath

ActiveCN101781787BIncrease the number of filter pumpsIncreasing the number of filter pumps increases the filtration flow of the bath liquid during the net making processJewelleryCopper coatingTitanium

The invention discloses production technology for an extra-width printing nickel screen, which comprises the following steps: I, preparing molds: (1) customizing a base mold; (2) electroplating a copper coating on the base mold; (3) rolling lattice points on the external layer of the base mold; and (4) electroplating a nickel coating on the base mold to produce a screen mold; and II, preparing the nickel screen by using the prepared molds: (1) carrying out primary nickel plating to prepare a single screen; (2) removing the screen; and (3) carrying out secondary nickel plating on the single screen. The electrical nickel-plating bath adopted by the production technology comprises a plating bath body, wherein a cathode tube and a titanium basket having a plurality of baskets are arranged in the plating bath body; more than one filter pumps are arranged outside the plating bath body; a water inlet and a water outlet of the filter pump are respectively connected with the plating bath body;a carbon brake is fixedly arranged below the top of the cathode tube; the bottom of the carbon brake is connected with a power supply, and the top of the carbon brake is contacted with the cathode tube; and nickel cubes are put in the baskets of the titanium basket, and the number of the nickel cube is uniformly reduced from the middle of the titanium basket to the two sides of the titanium basket. The extra-width printing nickel screen prepared by the production technology and the electrical nickel-plating bath has the advantages of good uniformity of opening, even thickness and large aperture.

Owner:金昌宇恒镍网股份有限公司

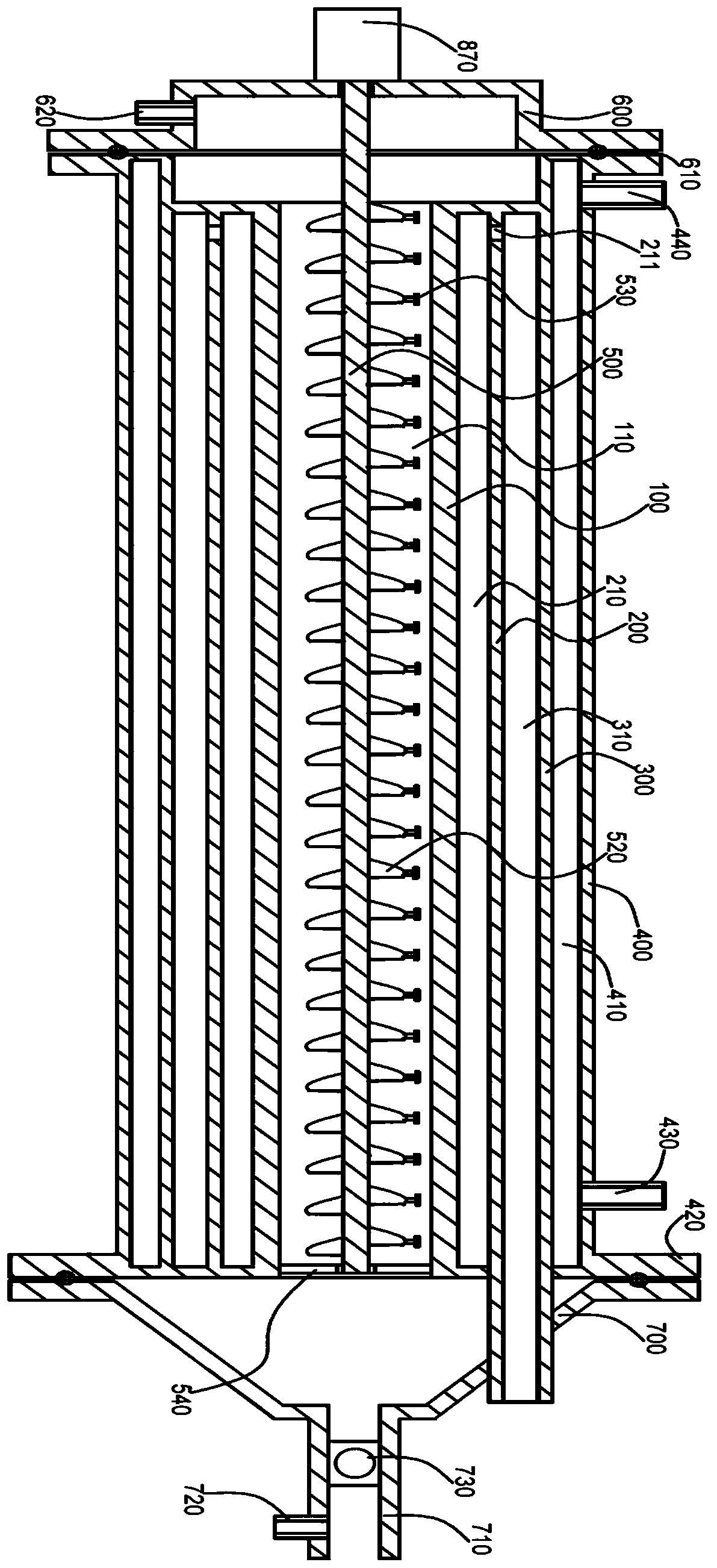

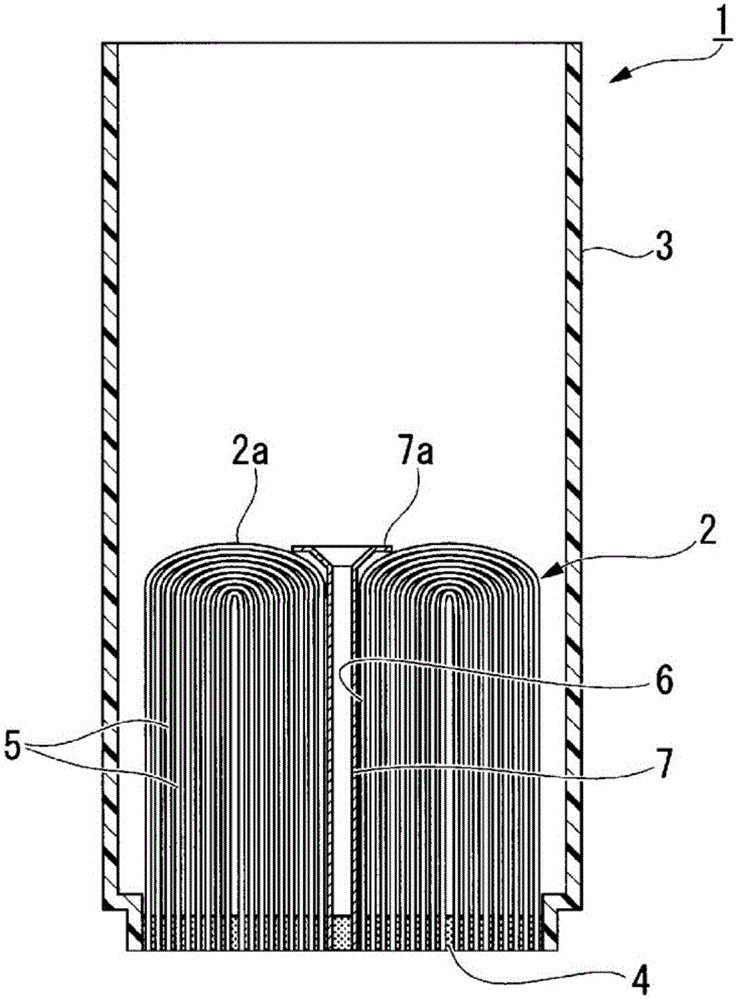

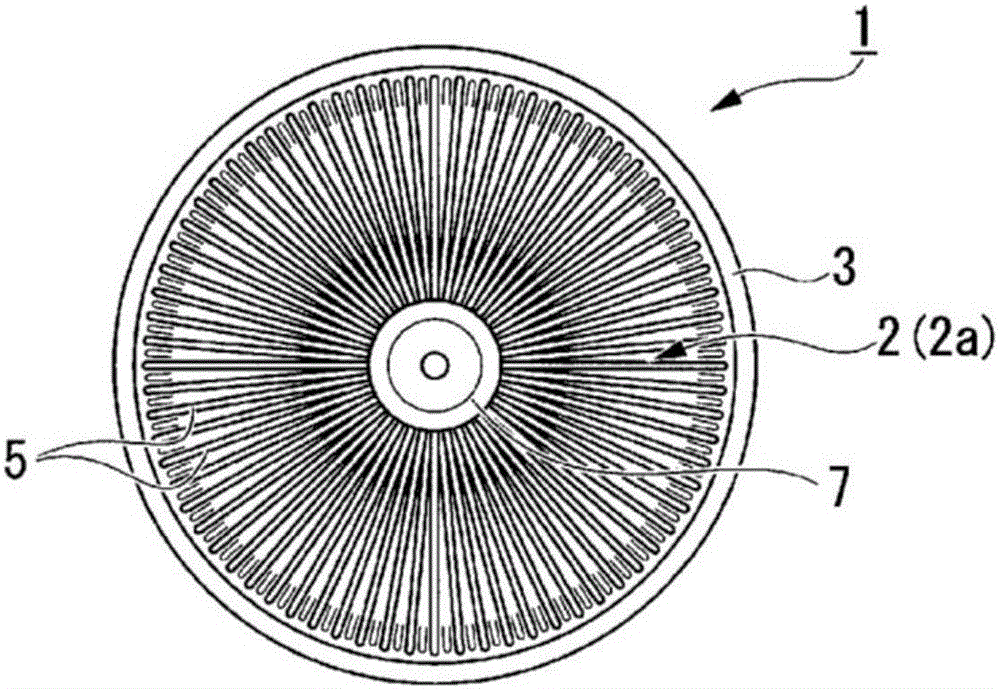

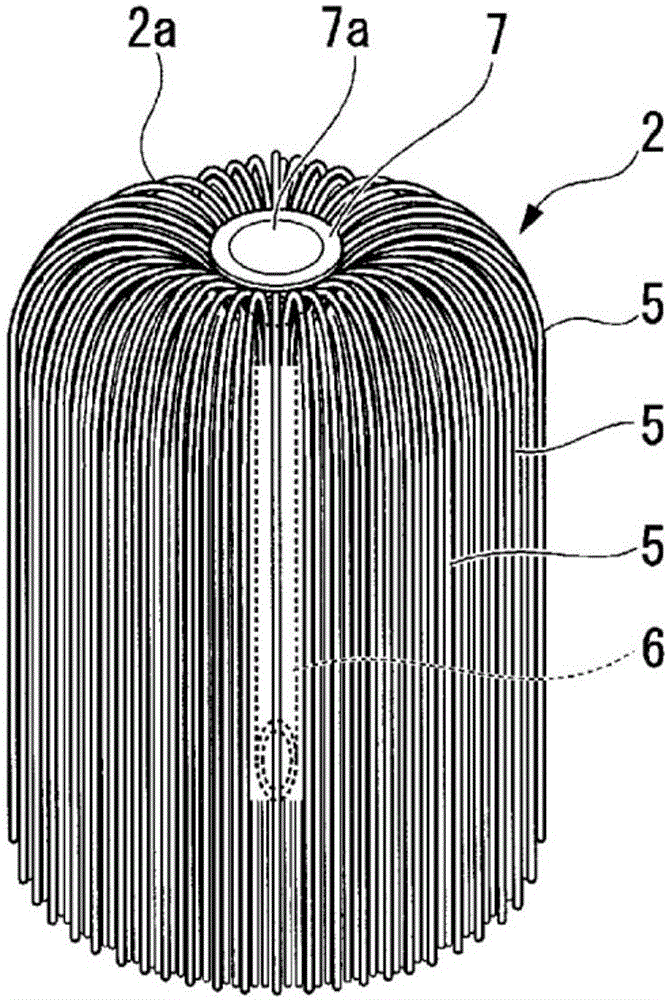

Hollow fiber membrane module and manufacturing method therefor

InactiveCN106457156AImprove filling efficiencyImprove flowMembranesSemi-permeable membranesEngineeringMechanical engineering

This hollow fiber membrane module (1) is configured so that a hollow fiber membrane bundle (2), formed by bending multiple hollow fiber membranes (5) into a U-shape, is filled into a cylindrical case (3) and a fixing resin (4) is injected into the case (3) to fix the side of the hollow fiber membrane bundle (2) opposite a bent section (2a) thereof to the bottom of the case (3). The hollow fiber membranes (5) are bent into a U-shape inside of the case (3) and at a substantially central part of the hollow fiber membrane bundle (2), a void portion (6) is formed along the height direction of the case (3). A core rod is inserted into the void portion (6).

Owner:MITSUBISHI CHEM CORP

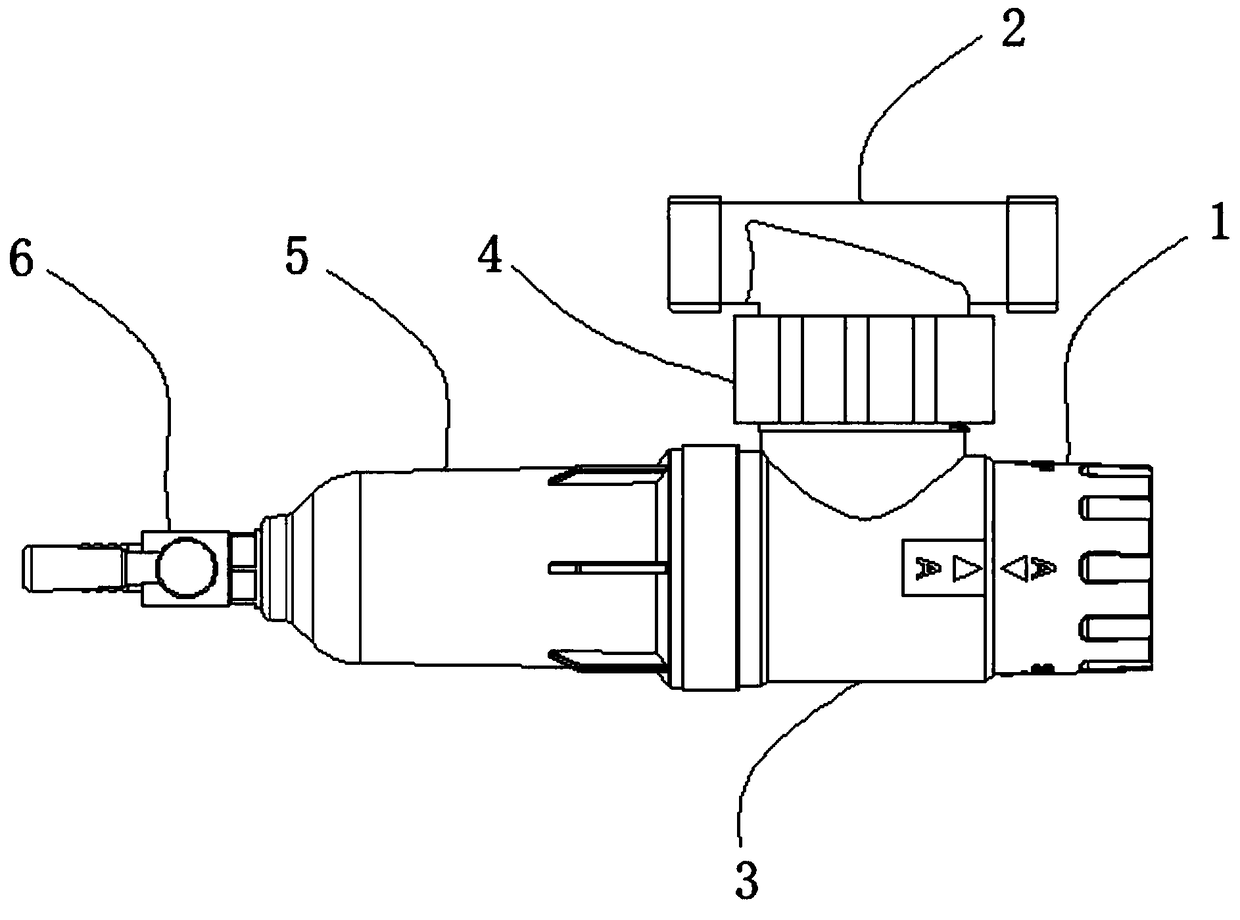

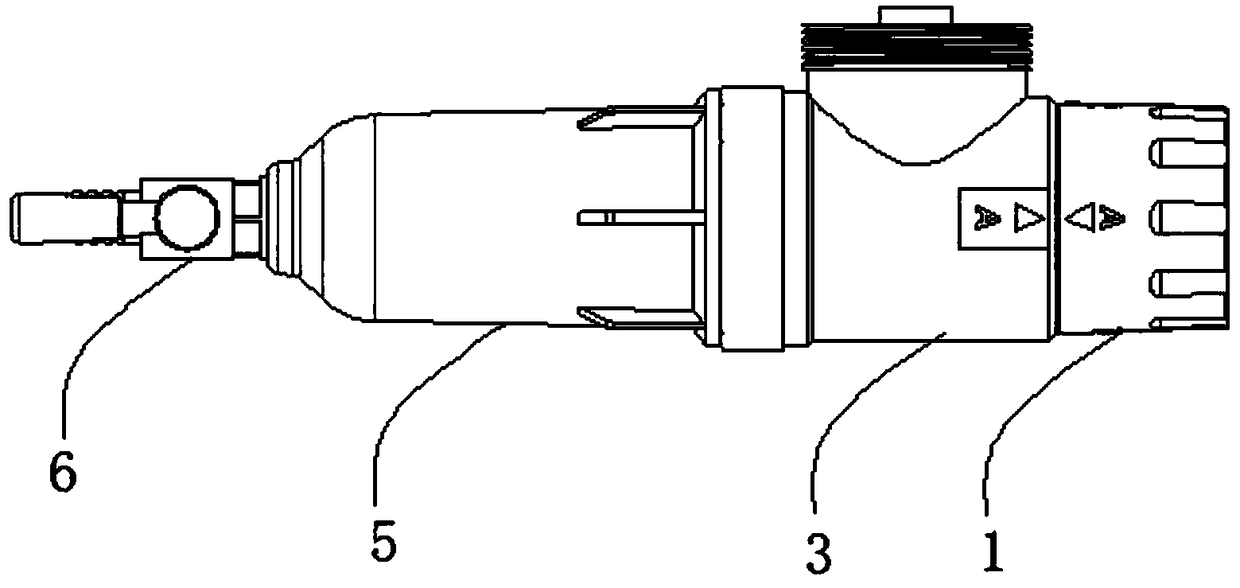

Universal multifunctional pre-filter

PendingCN108905338AFiltration flow is largeEasy to operateStationary filtering element filtersPre filteringEngineering

The invention discloses a universal multifunctional pre-filter, which comprises a regulating handle, a dual-channel valve, a water inlet and outlet support, an eccentric connecting nut, a filter housing, a blow-down valve, a filter and a regulating valve. The filter is loaded into the filter housing, the regulating valve is installed in the water inlet and outlet support, then the water inlet andoutlet support is connected to the filter housing, the regulating handle is in connection with the regulating valve 8 so as to be convenient for adjusting the working mode of the filter by an angle rotation mode, and the dual-channel valve is in connection with the water inlet and outlet support through the eccentric connecting nut. The universal multifunctional pre-filter provided by the invention can reach one of the filtering, backwashing and closing functions as long as rotating the angle position of the adjusting knob, also can achieve dismantling of the filter housing and the filter forcleaning under a closed state, and has the characteristics of large filter flow, simple operation, convenient application and simple maintenance process.

Owner:诸暨市来诺环境科技有限公司

Waste water filter for washing machine

InactiveCN1978747BFiltration flow is largeEasy to cleanOther washing machinesTextiles and paperWater filterWash water

The invention relates to washing machine wash water filter. It includes front face toward washing barrel and laid filter screen, back board set in spouting slot outlet, side wall connected the front face with the back board each of which can be dismountable parts, fixed part set in the side wall. The most simple is to do injection molding forming integration for the front face and the side wall. The back board is dismountable to conveniently take out the filter residue. The filter not only has the action of the traditional bag net type filter, but also can conveniently clean residue, be more durable and beautiful.

Owner:江门市洗衣机厂

Plate type and two surface filtration type micro-porous ceramic structure

A plate-shaped millipore ceramic structure with dual filtering surfaces for cleaning water by high filtering throughput is prepared through making a reticular porous plate with the material able to be converted to gas at high temp putting it in the ceramic blank, and high-temp calcining to gasify said plate to form the reticular channels.

Owner:宁波杜康陶瓷有限公司

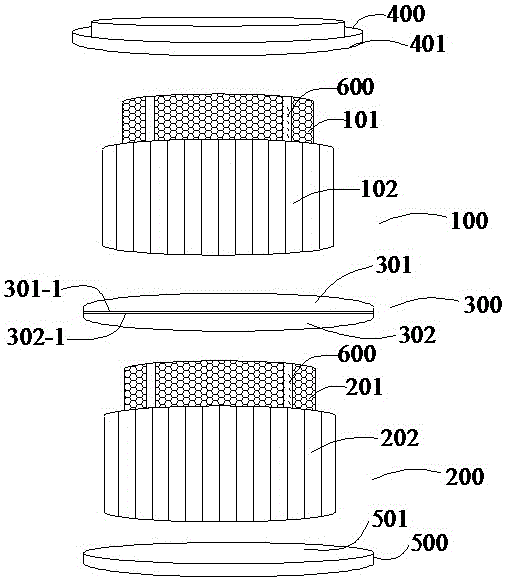

Butt-joint powder filter

InactiveCN106731317AImprove sealingSafe and widely usedDispersed particle filtrationTransportation and packagingButt jointEngineering

The invention discloses a butt-joint powder filter. The butt-joint powder filter comprises a first filter barrel, a second filter barrel and a butt-joint cover main body, wherein the first filter barrel comprises a first filter element and a filter element upper cover arranged on the top of the filter element; the second filter barrel comprise a second filter element and a filter element lower cover arranged on the bottom of the second filter element; and the butt-joint main body is placed between the first filter barrel and the second filter barrel and performs butt-joint on the first filter barrel and the second filter barrel to form a main filter barrel. By this way, the butt-joint powder filter disclosed by the invention is efficient in sealing property and safe and wide in use, can enlarge the filter space and increase the filter flow, greatly enhances the clogging capacity, and guarantees great increase of the filter efficiency, so that high-capacity dust is efficiently filtered.

Owner:无锡市玉净净化科技有限公司

Preparation method of ceramic balls loaded with nano copper-zinc-silver

The invention provides a preparation method of ceramic balls loaded with nano copper-zinc-silver. The preparation method comprises the following steps of: adsorbing a certain quantity of copper, zinc and silver metal ions with ceramic powder; uniformly mixing with a binding agent by stirring; granulating with a granulator; performing drying and microwave sintering on ceramic balls; and introducing reducing gas in the sintering process to reduce the metal ions so as to obtain ceramic balls loaded with nano copper-zinc-silver. The ceramic balls have the porosity of 30-50 percent and the particle size adjustable in the range of 0.2-20 millimeters. As proved by standard labeling testing, the removing rate of residual chlorine is over 99 percent, the removing rates of heavy metal ions such as Pb<2+>, Hg<2+>, Cd<2+>, Cr<6+> and As<5+> are over 99 percent, and the degerming rate is over 99.99 percent. The preparation method has the advantages of high purification speed, good purification effect and the like.

Owner:XIAMEN RUNNER IND CORP

Automatic filter cloth scraping filter

ActiveCN102179087BNot easy to wasteAvoid easy cloggingStationary filtering element filtersEngineeringSecond screen

The invention relates to an automatic filter cloth scraping filter wherein an unreeling mechanism and a reeling mechanism are mounted on a shell; filter cloth is wound on the unreeling mechanism and the reeling mechanism; a V-shaped filter cloth supporting leakage tank formed by connecting a first screen plate, a second screen plate and an arc connecting screen plate is fixed on the shell; a first chain wheel and a second chain wheel are in rotatable connection with the shell at the top end position of the first screen plate; scraping plates are mounted on chains; a chain limiting groove is formed by combining the space between the bottom end of a first limiting plate and the upper surface of the first screen plate, the space between the bottom end of a second limiting plate and the upper surface of the second screen plate and the space between the bottom end of a third limiting plate and the upper surface of the arc connecting screen plate; the middle pieces of the chains are restricted in the chain limiting groove; and the middle piece of the filter cloth is clamped between the chains in the chain limiting groove and the filter cloth supporting leakage tank. When the automatic filter cloth scraping filter is at work, all filter cloth can be used as far as possible, the filter cloth is not prone to be wasted, the blockage is not prone to happen, the filter flow rate is higher, and the degree of automation is high.

Owner:无锡强工机械工业有限公司

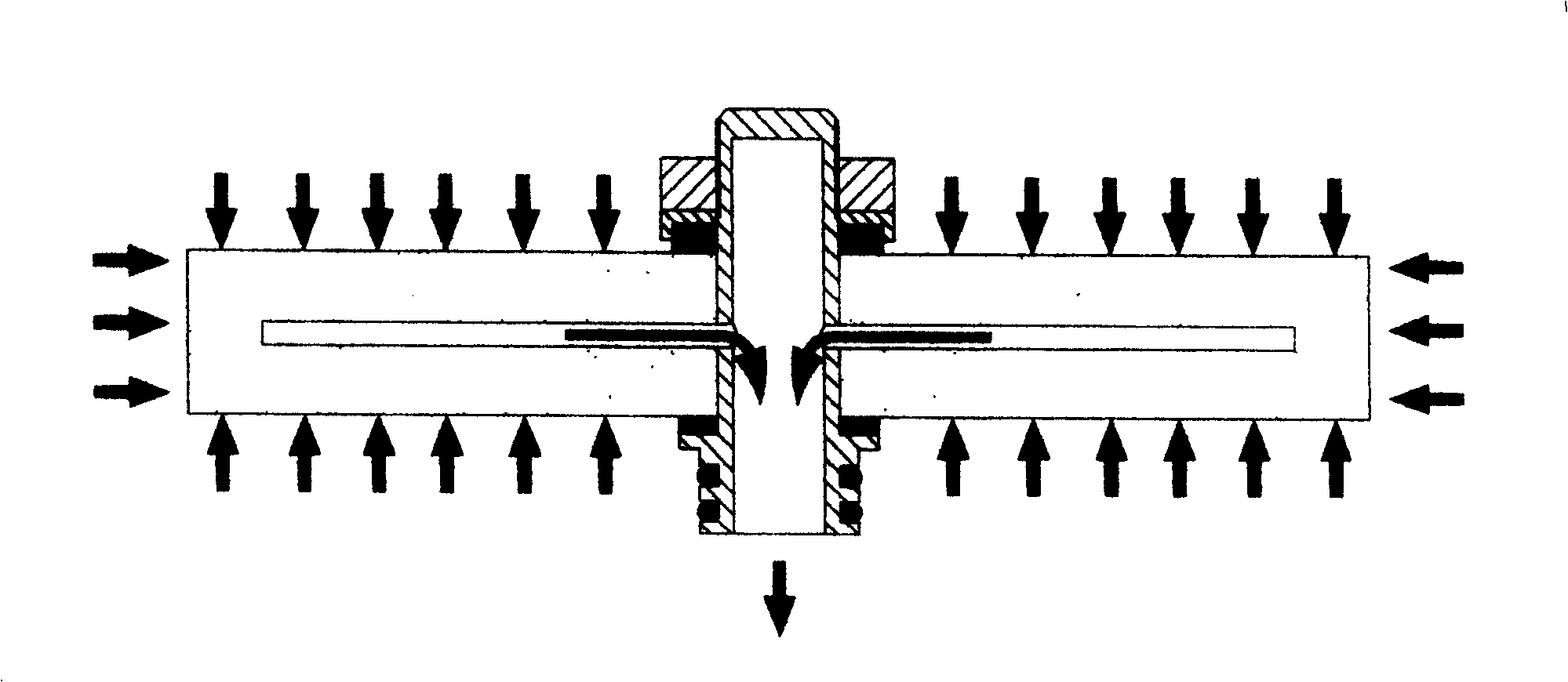

Assembled filter for micro-irragation

InactiveCN1241671CLow cost to manufacture and useSmall water resistanceWatering devicesCultivating equipmentsWater saving irrigationStreamflow

A combined filter for the water-saving irrigation is composed of a centrifugal sand-water separating chamber with water inlet and outlet and a sand collector. It features that said centrifugal sand-water separating chamber has one or more filter cores. Its advantages are high filtered flow and low cost.

Owner:INST OF GENETICS & DEVELOPMENTAL BIOLOGY CHINESE ACAD OF SCI

Gas purification device

InactiveCN109966859AImprove adsorption efficiencyFiltration flow is largeGas treatmentDispersed particle separationActivated carbonBenzene

The invention discloses a gas purification device, which comprises an air outlet pipe, a purification collection cover, a pull-type activated carbon filter layer a, a pull-type activated carbon filterlayer b, a gas cylinder a, an air inlet, device legs, a dust residue collecting bucket a, a dust residue discharging pipe a, a device body, a connecting pipe, a pull-type activated carbon filter layer c, a pull-type activated carbon filter layer d, a gas cylinder b, a dust residue collecting bucket b and a dust residue discharging pipe b. The double cylinders and double-layer pull-type activatedcarbon filter layers are used for organic waste gas filtration, and the device has the advantages of large filtration flow rate and high adsorption efficiency. The double-layer pull-type activated carbon filter layers have the advantage of convenient replacement of a filter element, and organic waste gas containing odor enters the gas cylinder a and the gas cylinder b, and an upper double-layer pull-type activated carbon filter layer effectively adsorbs organic waste gas such as benzene, alcohols, ketones, esters, gasoline and the like in the exhaust gas, and the device can be applied to a plurality of mixed exhaust gases containing odors.

Owner:谢绍光

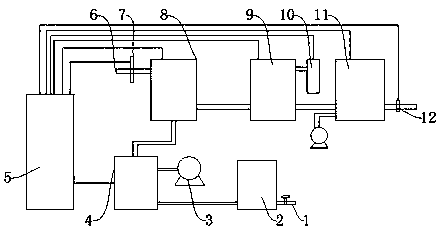

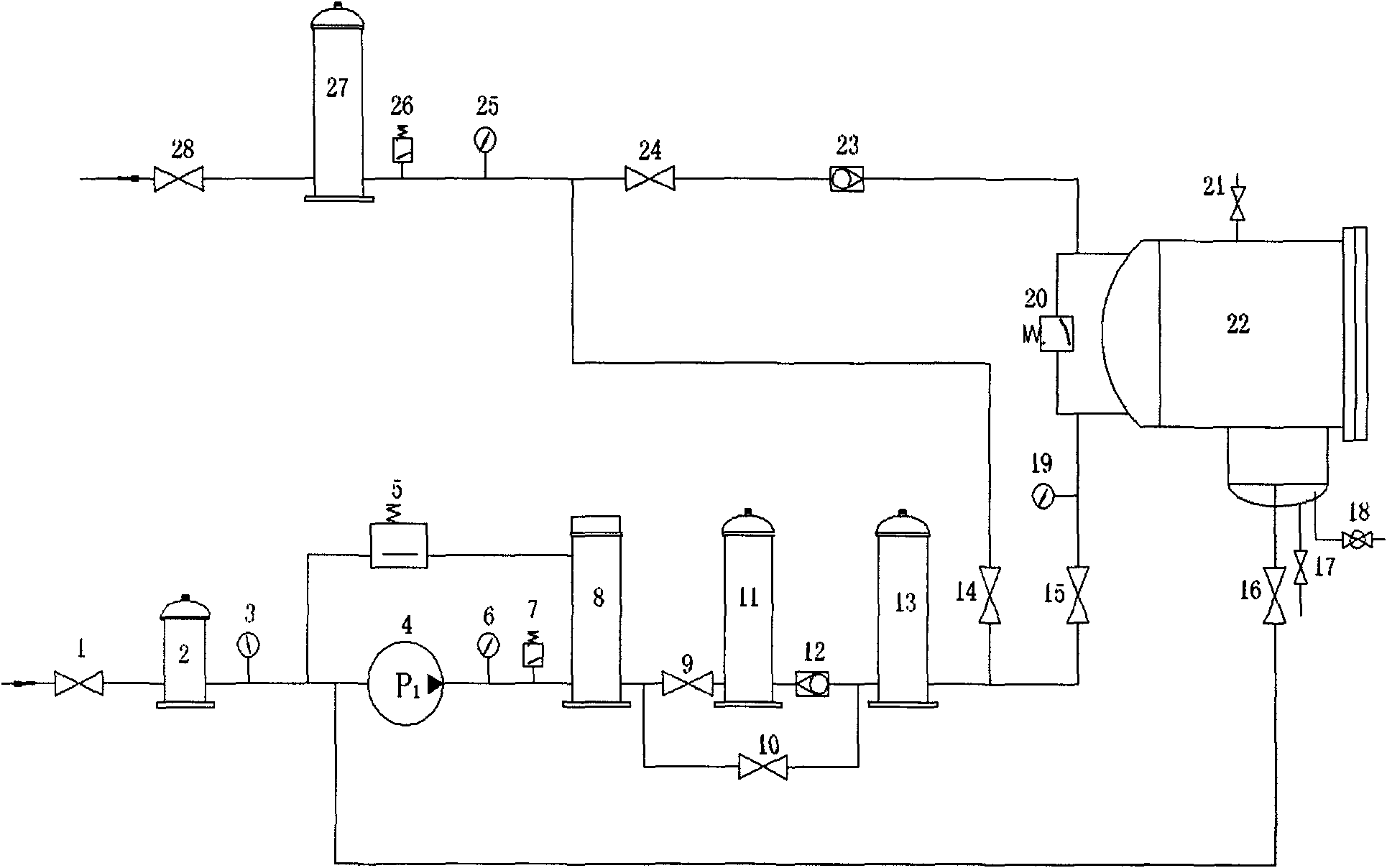

Oil purifying system

The invention relates to an oil purifying system in which dirty oil enters an inlet filter through an inlet valve, oil enters an oil transfer pump through the inlet filter, and flows out from the oil transfer pump and enters a heater. When emulsification phenomenon exists, the oil enters a filter element type emulsion-breaking device through a first switching valve for emulsion-breaking process, and enters a primary filter through a check valve; when no emulsification phenomenon exists, the oil directly enters the primary filter after the first switching valve and a second switching valve areclosed; if the oil dose not contain water, the oil enters a high-precision filter through a third switching valve after being output from the primary filter; if the oil contains water, the oil entersa coalescing separator through a second pressure gauge which is used for testing pressure of the coalescing separator after the third switching valve is closed and a fourth switching valve is opened;the oil enters the high-precision filter through a third pressure gauge and differential pressure controller after being separated out water by the coalescing separator; the oil after being carried out purification treatment flows out through an outlet valve and returns to an inlet on the upper part of an oil tank to achieve a purification cycle.

Owner:王庆生

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com