Production technology for extra-width printing nickel screen and electrical nickel-plating bath

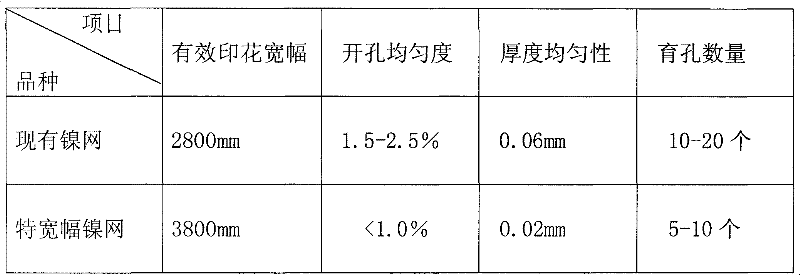

A production process and electro-nickel tank technology, applied in jewelry and other directions, can solve the problems of inability to print extra-wide textiles, poor uniformity of openings, uneven thickness of nickel layer, etc. , the effect of reducing the content of impurities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

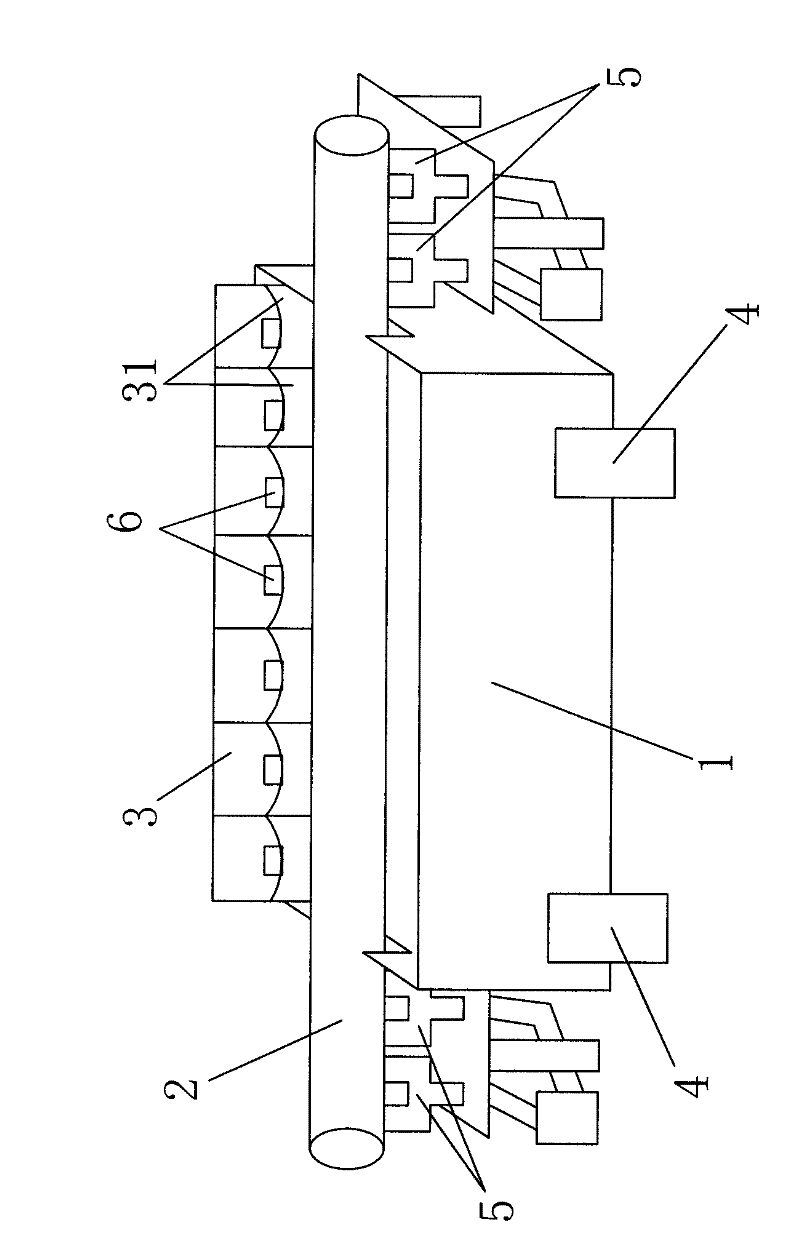

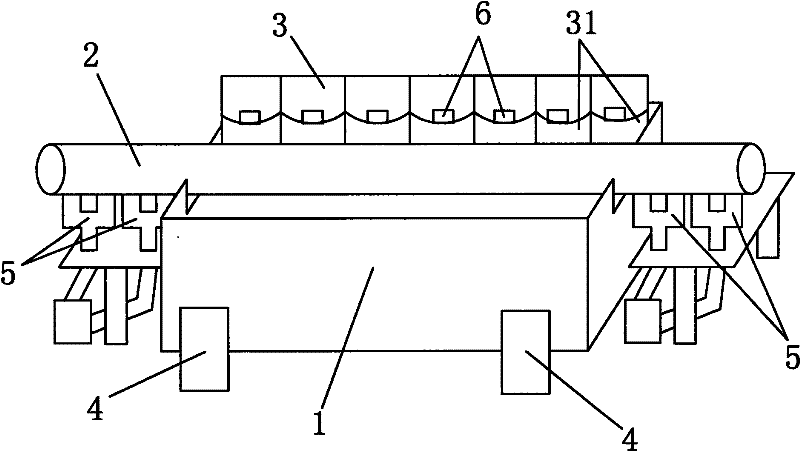

[0021] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0022] The production process of extra-wide printing nickel screen comprises the following steps in turn:

[0023] 1. Preparation of printing nickel mesh mold;

[0024] (1) Customize the iron base mold, and carry out lathe processing, degreasing and cleaning on it;

[0025] (2) Copper plating on the outer layer of the base mold, cleaning, sizing, degreasing, and polishing;

[0026] (3) roll dots on the outer layer of the base mold, clean, dry, and apply insulating glue;

[0027] (4) Electroplate the nickel layer outside the copper layer of the base mold to make a mesh mold, wherein a carbon brake is fixed below the top of the cathode tube in the electro-nickel tank, the bottom end of the carbon brake is connected to a power supply, and the top is in contact with the cathode tube. At the same time, put nickel blocks into the titanium basket i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com