Method for preparing micro-nano porous structure on titanium or titanium alloy surface

A porous structure, titanium alloy technology, applied in metal material coating process, ion implantation plating, coating, etc., can solve the problems of difficult preparation of porous structure, difficult to control pore size, easy peeling, etc., to achieve broad application prospects, Promotes value addition and differentiation, and improves surface energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

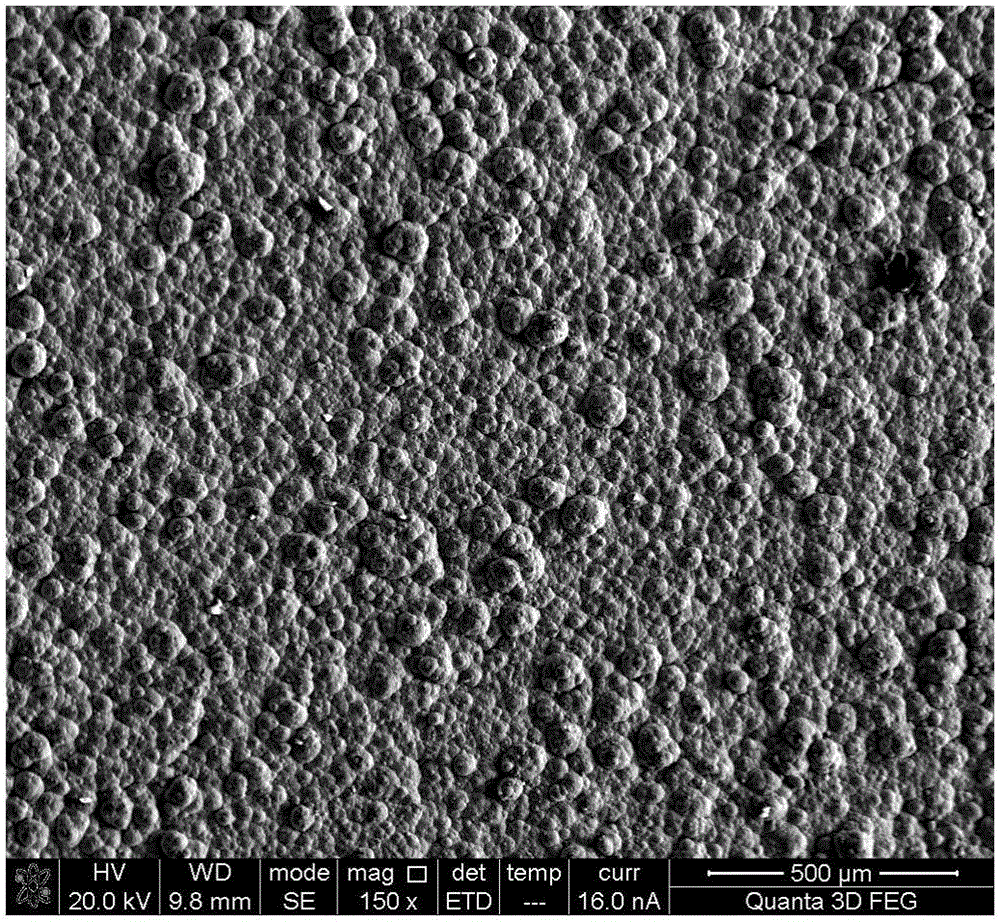

[0034] Copper plating is carried out on the surface of a titanium sheet of 15 by 10 mm, and the micro-nano porous surface is formed when the heat treatment temperature is 500 ° C. The specific steps are as follows:

[0035] (1) The surface of the titanium sheet is cleaned. Grinding treatment: Grind the sample with 400#, 800#, 1200# metallographic sandpaper respectively until the surface of the titanium sheet has a metallic luster; water washing: first clean the polished titanium sheet with acetone for 15 minutes; then use deionized water for ultrasonic cleaning 15min; pickling: soak the washed titanium sheet in acid for 1min at room temperature to remove the oxide film on the titanium surface; water washing: rinse the acid-etched titanium sheet with deionized water until there is no pickling solution on the surface.

[0036](2) A layer of copper coating is electroplated on the surface of the titanium sheet. Activation: soak the washed titanium sheet in an activation solution ...

Embodiment 2

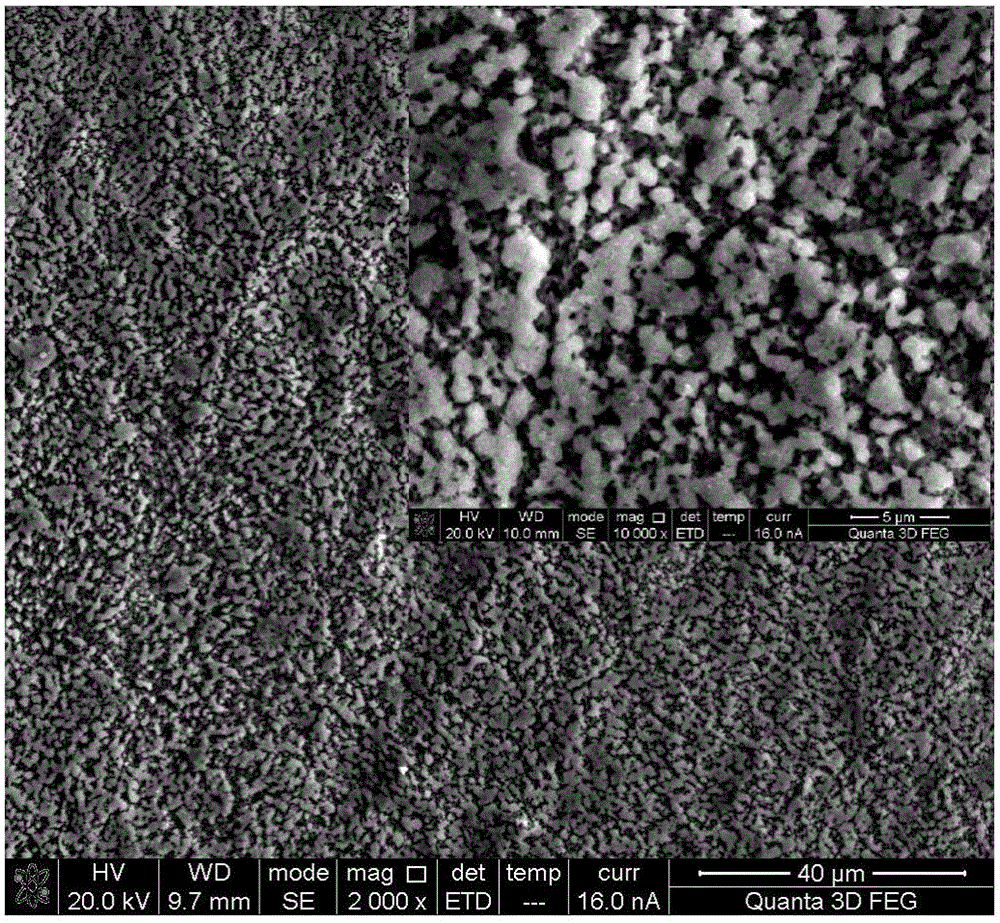

[0043] Magnetron sputtering a layer of copper coating on the surface of a 15 by 10 mm titanium sheet, and the surface is micro-nano porous formed when the heat treatment temperature is 800 ° C. The specific steps are as follows:

[0044] (1) The surface of the titanium sheet is cleaned. Grinding treatment: Grind the titanium sheet with 400#, 800#, and 1200# metallographic sandpaper respectively until the surface of the titanium sheet has a metallic luster; washing: first clean the polished titanium sheet with acetone ultrasonically for 15 minutes; then use deionized water to ultrasonically clean it Cleaning for 15 minutes; pickling: soak the washed titanium sheet in acid for 1 minute at room temperature to remove the oxide film on the titanium surface; water washing: rinse the acid-etched titanium sheet with deionized water until there is no pickling solution on the surface.

[0045] (2) Magnetron sputtering a layer of copper coating on the surface of the titanium sheet. (1) ...

Embodiment 3

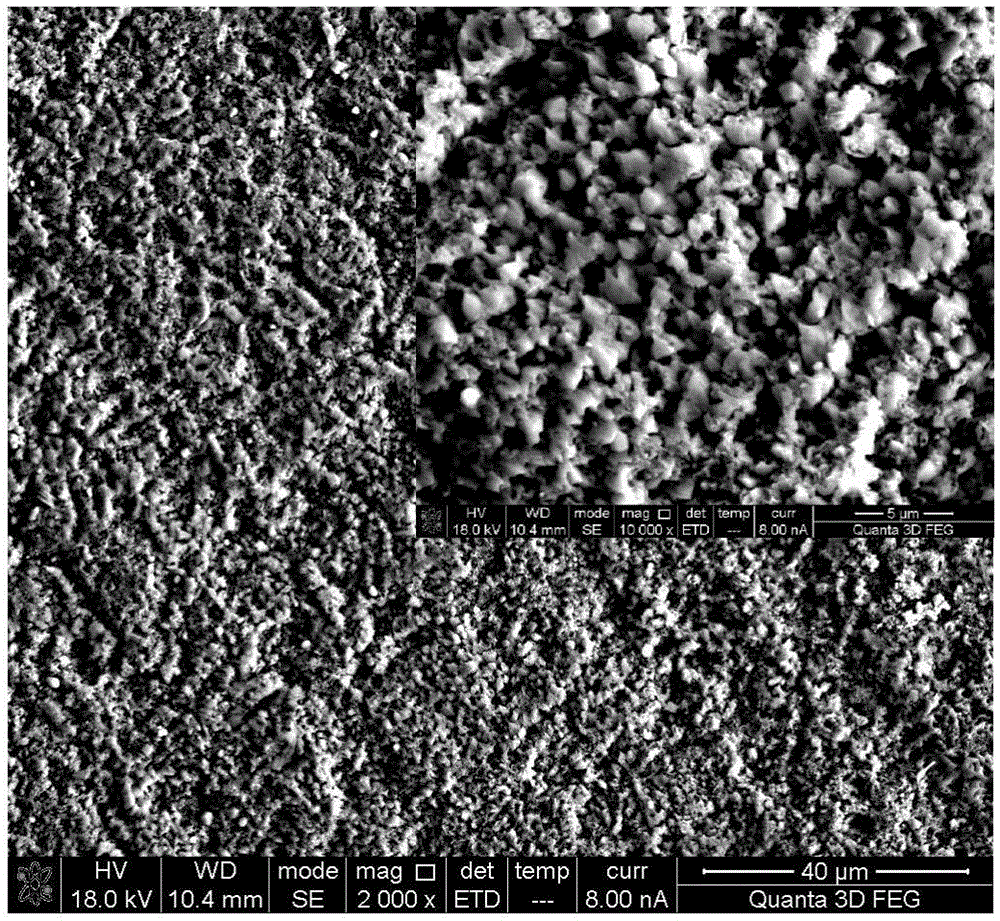

[0052] A layer of copper coating is electroplated on the surface of a titanium aluminum vanadium (Ti-6Al-4V) alloy sheet of 15 by 10 mm, and the micro-nano porous surface is formed when the heat treatment temperature is 500 ° C. The specific steps are as follows:

[0053] (1) Weigh 30g of 300 mesh titanium-aluminum-vanadium (Ti-6Al-4V) powder, put the powder into a graphite mold with a diameter of 20mm, use spark plasma sintering equipment, sintering temperature is 650°C, and holding time is 10min to prepare samples ; Then cut the sample wire into thin slices with a size of 15 by 10mm.

[0054] (2) Surface cleaning treatment of titanium alloy sheet. Grinding treatment: Grind the titanium sheet with 400#, 800#, and 1200# metallographic sandpaper respectively until the surface of the titanium alloy sheet has a metallic luster; washing: first clean the polished titanium alloy sheet with acetone for 15 minutes; then use deionized Ultrasonic cleaning with water for 15 minutes; pic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture size | aaaaa | aaaaa |

| Aperture size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com