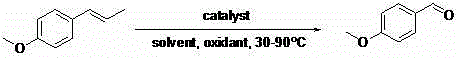

Preparation method of anisaldehyde

A technology of anisaldehyde and anethole, which is applied in the field of nanoscale iron oxide catalyzing the oxidation of anethole to prepare anisaldehyde, can solve the problems of inability to meet industrialized production, the natural degree of anisaldehyde is reduced, and the production efficiency of products is low, and the surface effect is remarkable, Low-cost, easy-to-control effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] 0.074g of γ-Fe with a particle size of 50nm 2 o 3 and 20mL of acetonitrile were added to a 100mL flask at 60 o Stir quickly with magnetons to nanometer γ-Fe at C 2 o 3 Disperse evenly in the reaction system, and then add 1.48g of anethole and 10mL of 30% hydrogen peroxide solution in sequence. After the reaction, the catalyst is sucked out with a magnet, and the liquid phase is extracted with ethyl acetate, and the obtained ethyl acetate phase is concentrated under reduced pressure. Anisaldehyde with a yield of 27.8% can be obtained.

Embodiment 2

[0021] 0.008g of γ-Fe with a particle size of 20nm 2 o 3 and 20mL of methanol were added to a 100mL flask at 70 o Stir quickly with magnetons to nanometer γ-Fe at C 2 o 3 Disperse evenly in the reaction system, and then add 0.74g of anethole and 15mL of 30% hydrogen peroxide solution in sequence. After the reaction, the catalyst is sucked out with a magnet, and the liquid phase is extracted with ethyl acetate, and the obtained ethyl acetate phase is concentrated under reduced pressure. The yield of anisaldehyde of 25.4% can be obtained.

Embodiment 3

[0023] 0.016g of γ-Fe with a particle size of 80nm 2 o 3 and 20mL of ethanol were added to a 100mL flask at 60 o Stir quickly with magnetons to nanometer γ-Fe at C 2 o 3 Disperse evenly in the reaction system, and then add 2.22g of anethole and 6mL of 30% hydrogen peroxide solution in sequence. After the reaction, the catalyst is sucked out with a magnet, and the liquid phase is extracted with ethyl acetate, and the obtained ethyl acetate phase is concentrated under reduced pressure. Anisaldehyde with a yield of 19.1% can be obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com