Patents

Literature

31results about How to "Avoid problems such as corrosion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

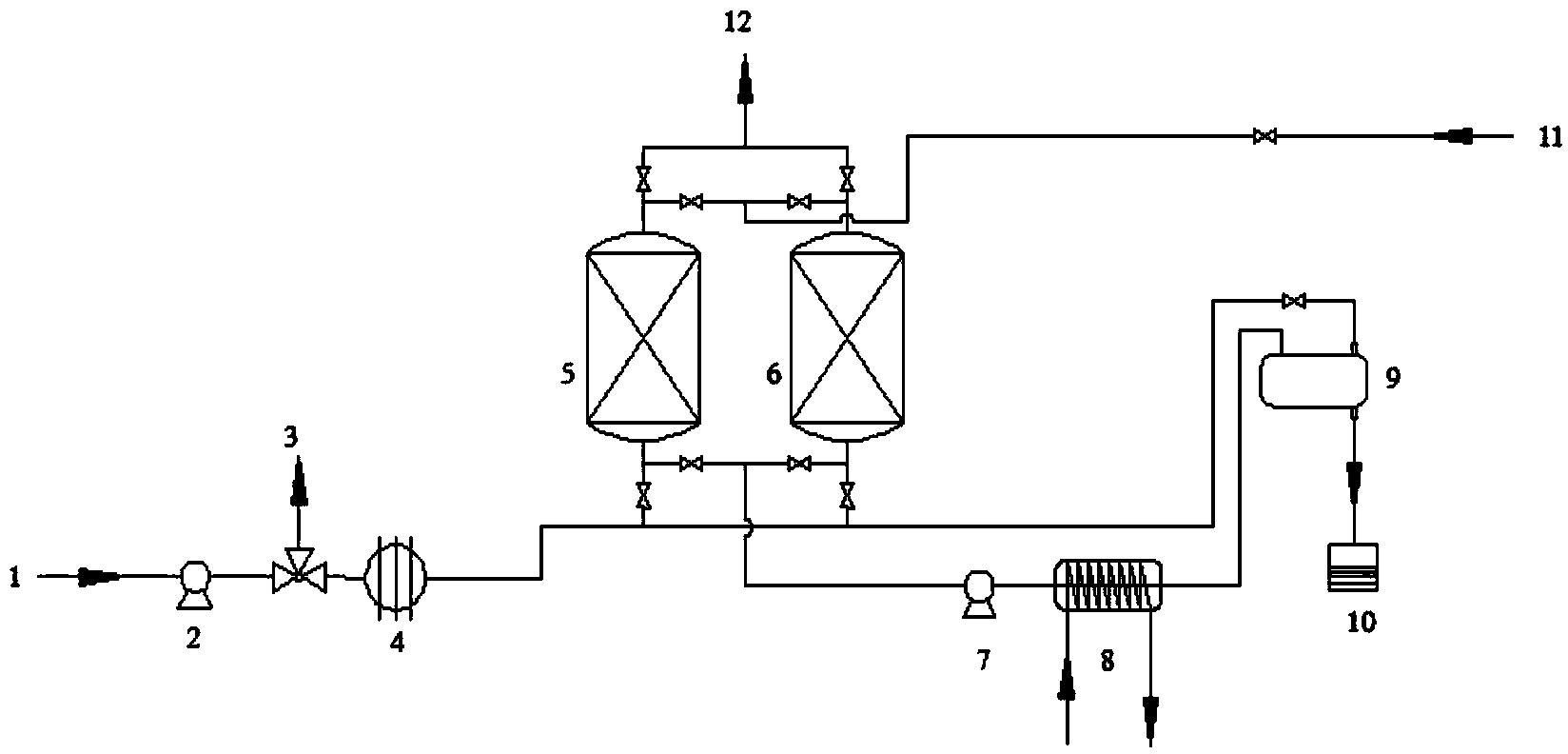

Nitrogen purging-assisted organic exhaust gas recycling method through pressure swing adsorption of adsorbent resin

ActiveCN104107621ALarge volume adsorption capacityNo chemical reactionDispersed particle separationSolubilityCollection system

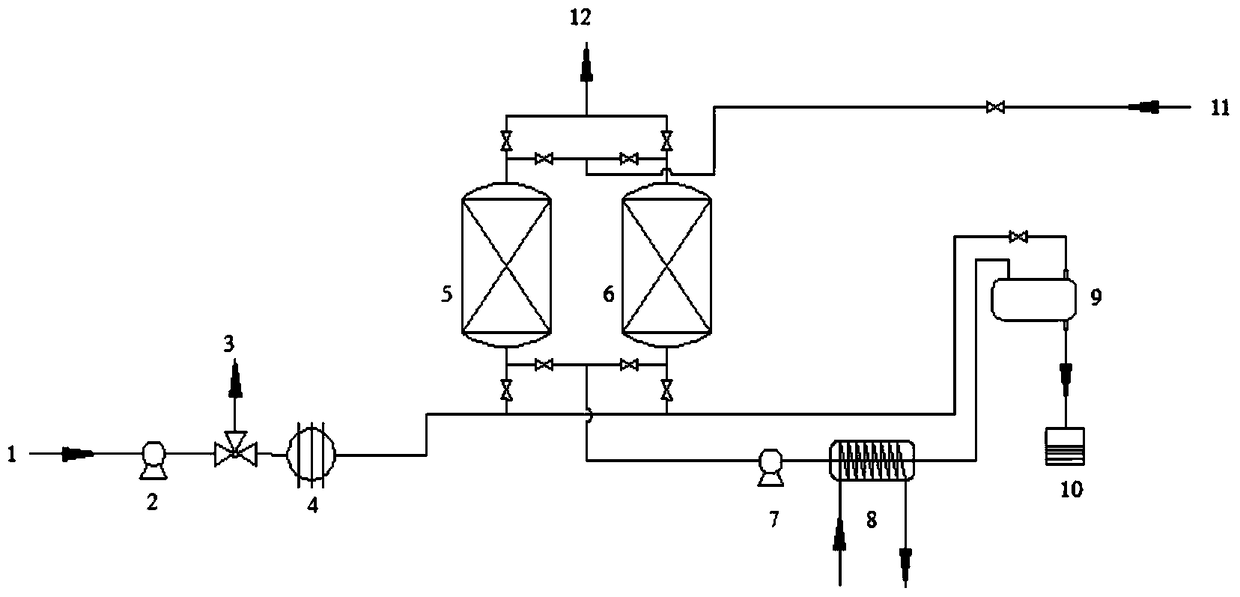

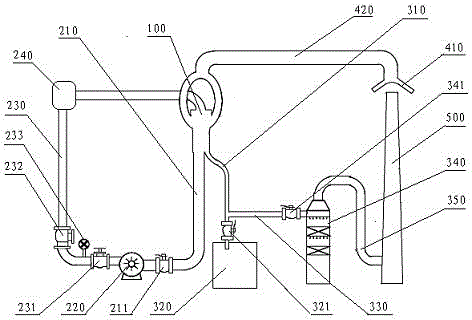

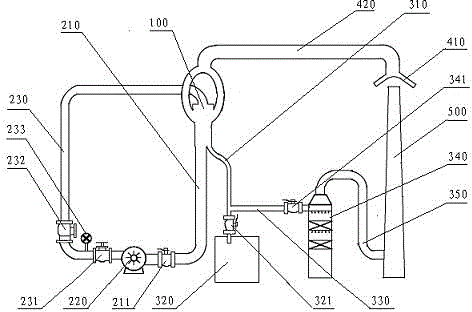

The invention discloses a nitrogen purging-assisted organic exhaust gas recycling method through the pressure swing adsorption of adsorbent resin. The organic exhaust gas recycling method comprises the following steps: (1) adsorption, namely performing adsorption when exhaust gas including volatile organic compounds (VOCs) enters an adsorber filled with the macroporous adsorption resin by a gas collection system; (2) desorption, namely vacuumizing the adsorbent resin in the adsorber and purging the adsorbent resin by using nitrogen in an auxiliary manner to desorb the adsorbed VOCs from the adsorbent resin to obtain the desorbed gas; and (3) recycling, namely condensing or absorbing the desorbed gas to recycle the VOCs. The adsorbent adopted by the method disclosed by the invention is the macroporous adsorption resin, the surface of the macroporous adsorption resin has no catalytic performance and has the characteristics of being easy to regenerate, high in mechanical strength, great in volumetric adsorption capacity and the like. A adsorption technique assisted by nitrogen purging in vacuum at normal temperature is high in adsorption efficiency and has the very excellent recycling effect on VOCs gas which can be easily oxidized and hydrolyzed or is high in solubility.

Owner:NANJING UNIV

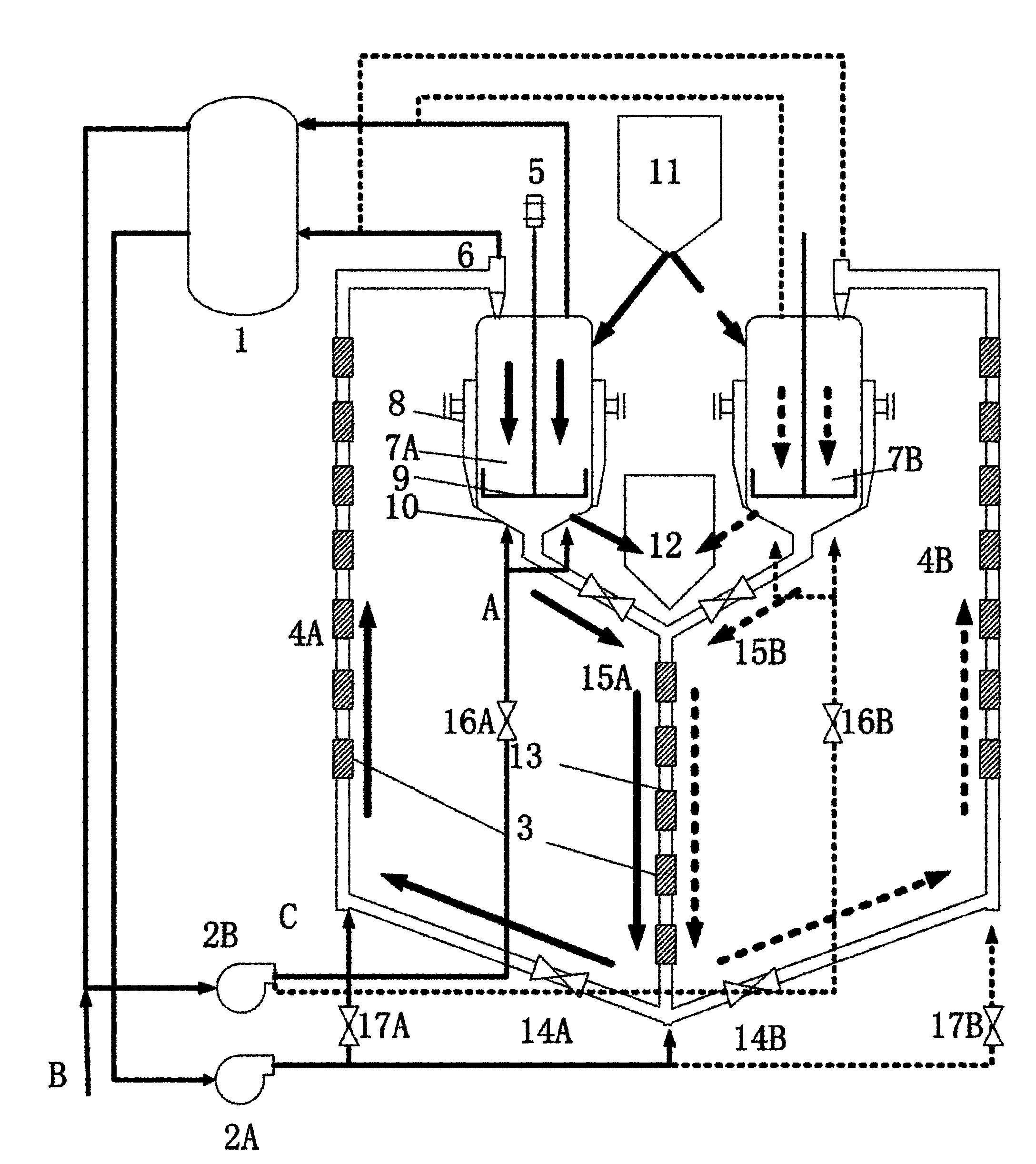

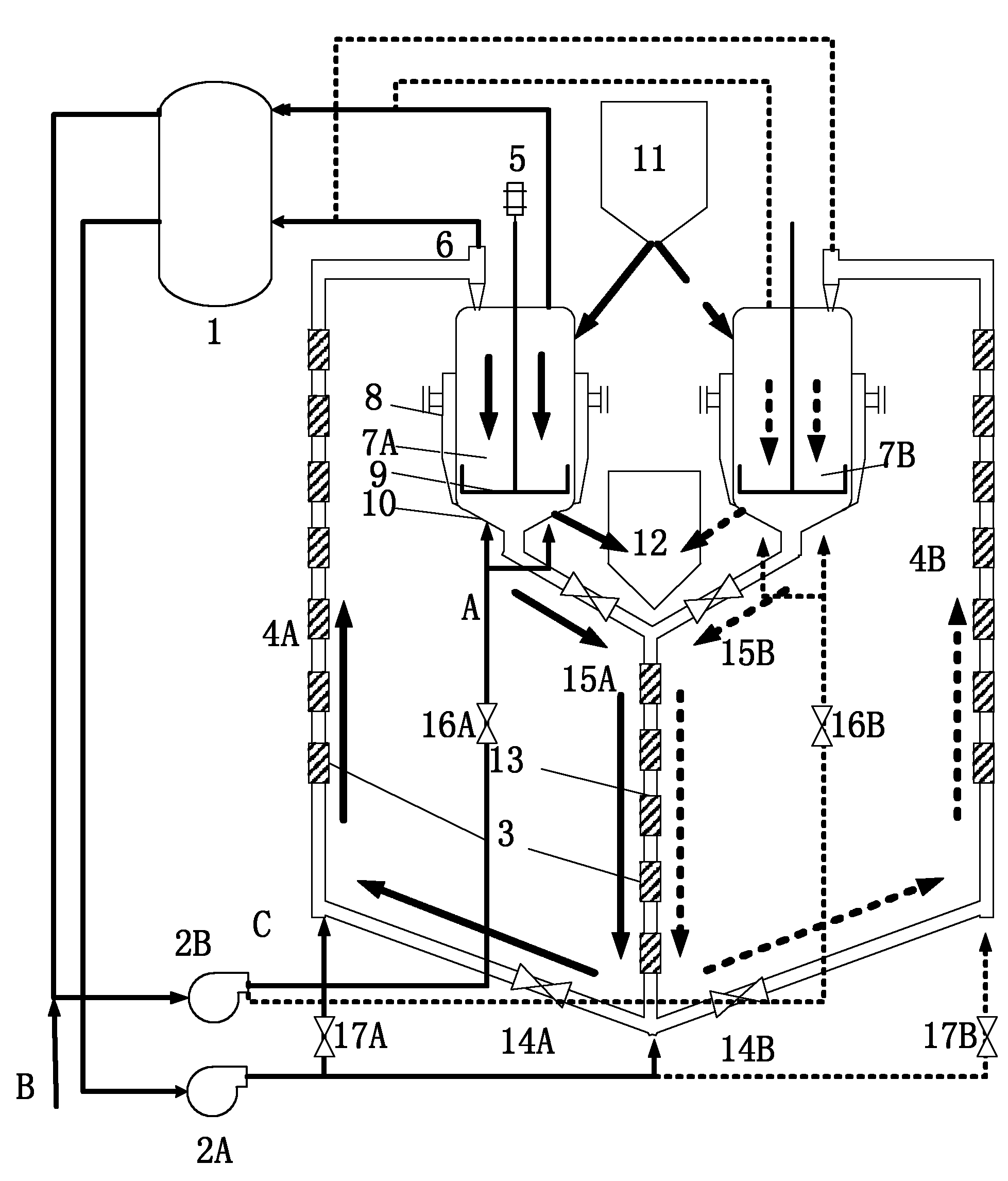

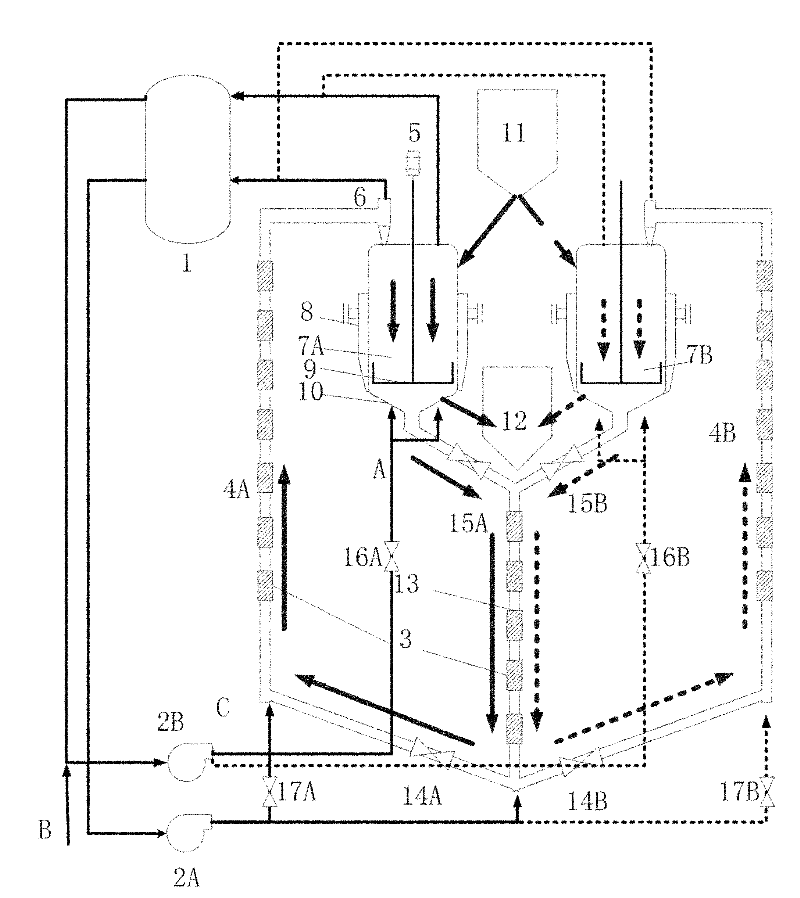

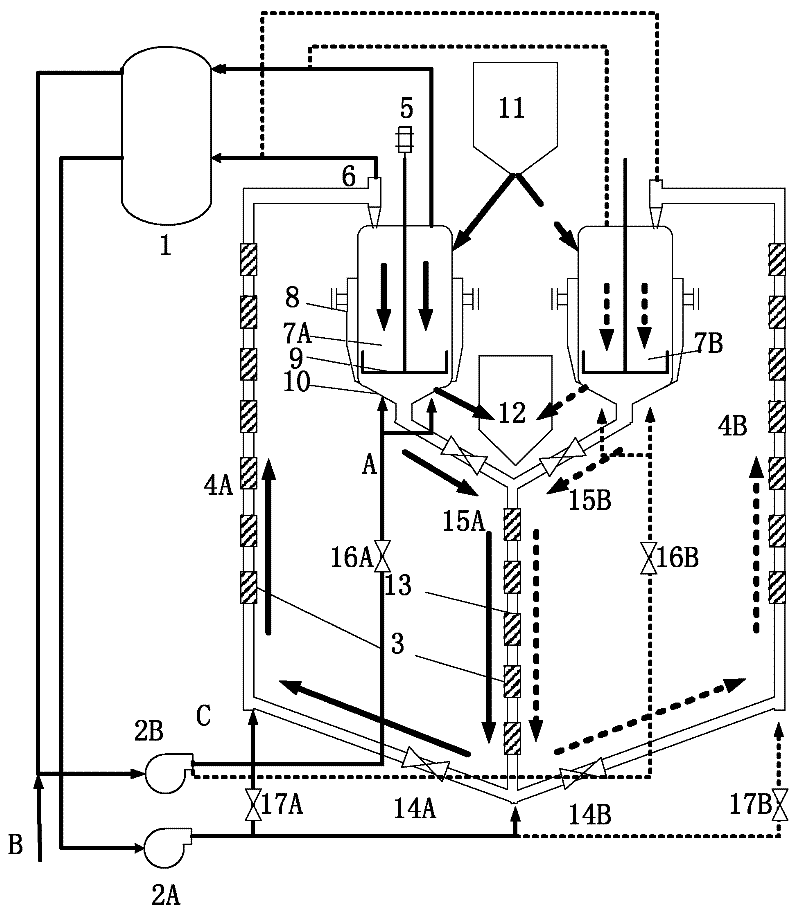

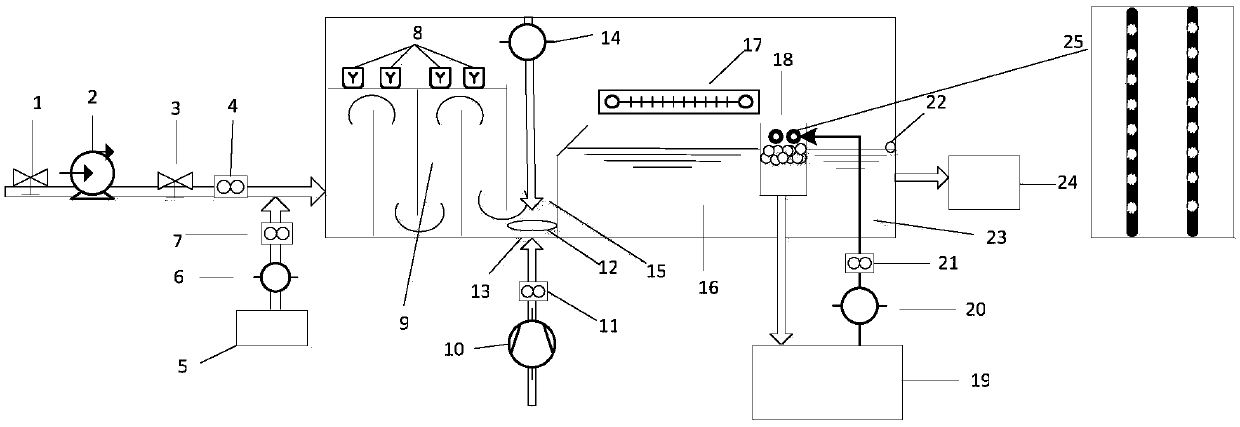

Method and device for continuously producing chlorinated polyvinyl chloride by low-temperature plasma circulating bed

ActiveCN102161718ARealize continuous productionAvoid problems such as corrosionEnergy based chemical/physical/physico-chemical processesFluidized bedChlorinated polyvinyl chloride

The invention discloses a method and device for continuously producing chlorinated polyvinyl chloride by a low-temperature plasma circulating bed, relating to a production technology and equipment for macromoleclar polymer chlorinated polyvinyl chloride. The device comprises a chlorinated polyvinyl chloride particle storage bin, a chlorinated polyvinyl chloride storage bin, two parallel fluidized bed reactors, two parallel riser reactors, a downer, a tail gas purifier and two circulating fans which are respectively used for transporting riser conveying gas and transporting raw material gas. In the device, the low-temperature plasma is utilized to simultaneously activate chlorine and PVC (poly vinyl chloride) raw material particles to quickly chloridize PVC in the circulating fluidized bed; and meanwhile, two groups of fluidized bed reactors are adopted for operation in turn to realize continuous production. Thus, the problems of low production efficiency and the like brought by that the reactor stops and unloads can be avoided, the phenomenon that fans, tail gas processors and the like are restarted after stopping can be eliminated, energy consumption is saved, and the service life of equipment is prolonged.

Owner:TSINGHUA UNIV

Device for real-time measurement of fluid conductivity by use of electromagnetic method

InactiveCN104777196AAccurate measurementAvoid driftingMaterial resistanceCoaxial cableElectromagnetic interference

The invention belongs to the technical field of electromagnetic induction, in particular relates to a device for real-time measurement of fluid conductivity by use of electromagnetic method, and aims at the conditions of low fluid conductivity, and little effect on the amplitude of electromagnetic mutual inductance signals; the device uses a method of excitation frequency adjusting and phase component extracting to replace the amplitude for extraction of useful information to the maximum in order to obtain the most accurate measurement results; aiming at the condition that the measurement of fluid conductivity by use of the electromagnetic method is susceptible to the interference of the surrounding electromagnetic environment, the device uses a method of real-time calibration and probe shielding to prevent measurement result drift caused by electromagnetic interference; and aiming at the problem that the high frequency signal transmission is susceptible to noise interference when the fluid conductivity is low and the excitation signal frequency is high, the device uses a method of coaxial cable shielding for signal transmission to ensure the signal stability and reliability.

Owner:NO 8357 RES INST OF THE THIRD ACADEMY OF CHINA AEROSPACE SCI & IND

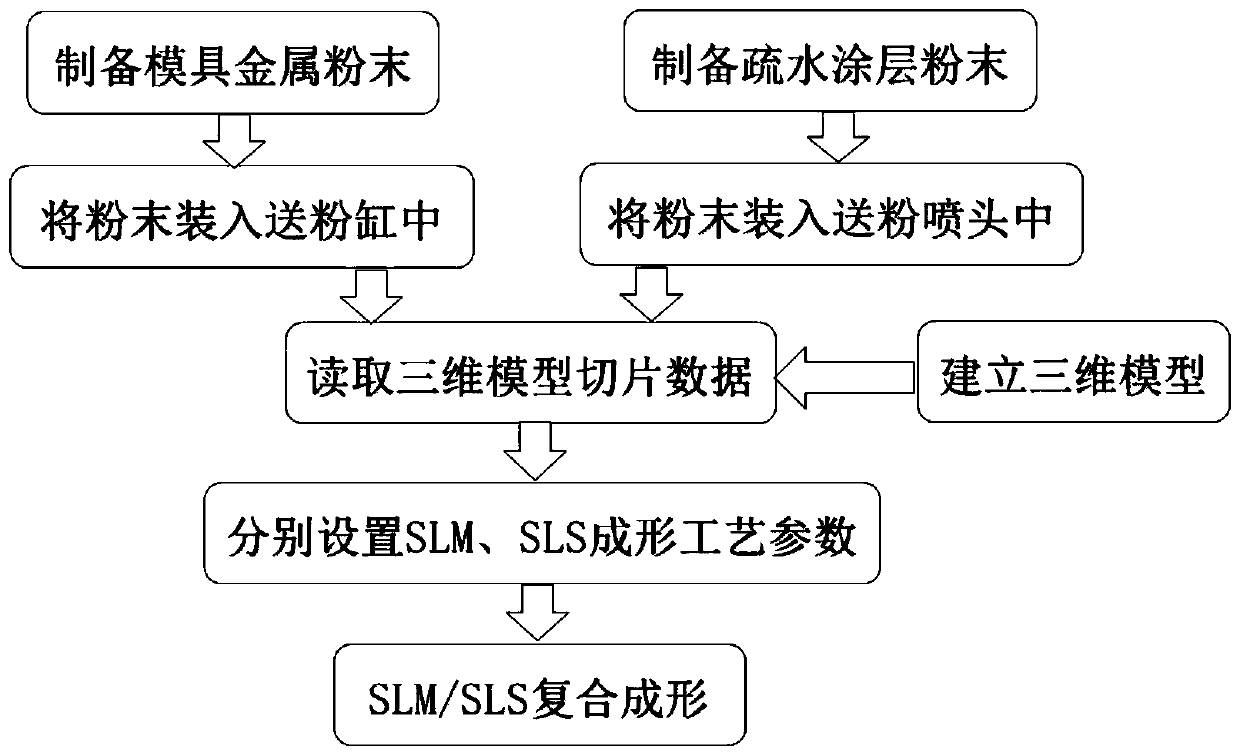

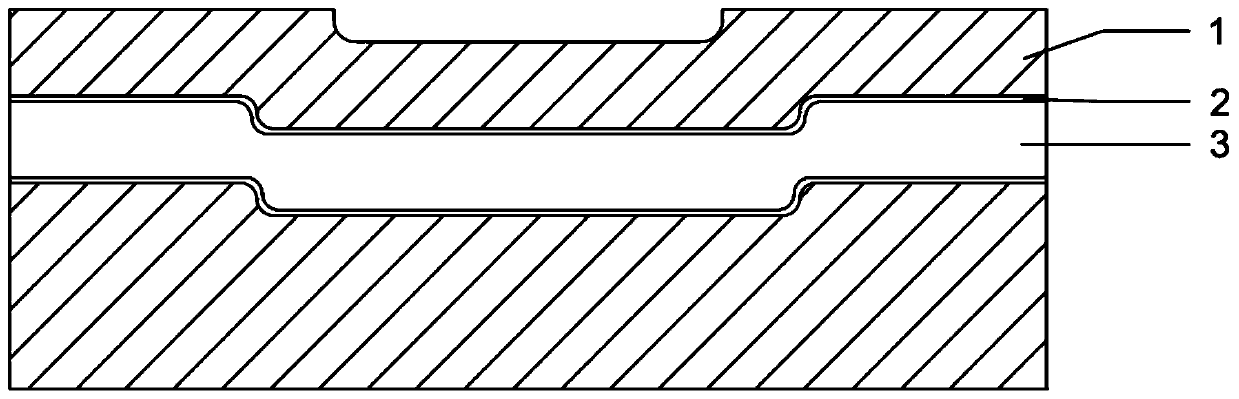

Conformal cooling channel with hydrophobic effect and production method thereof

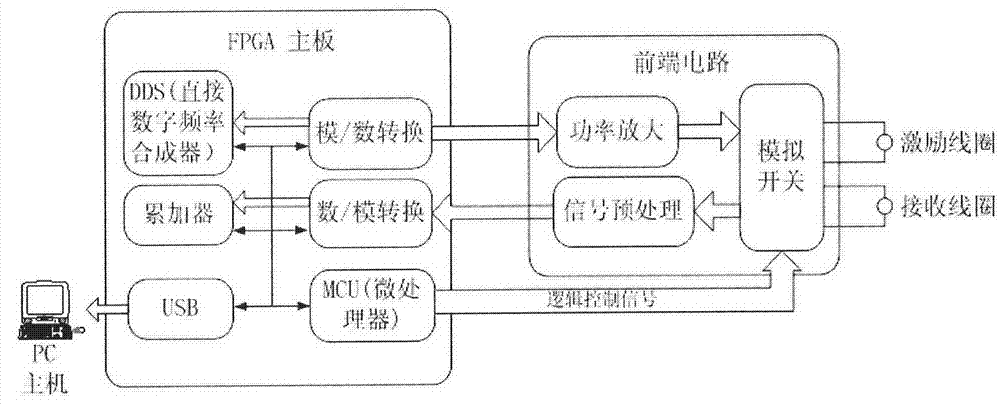

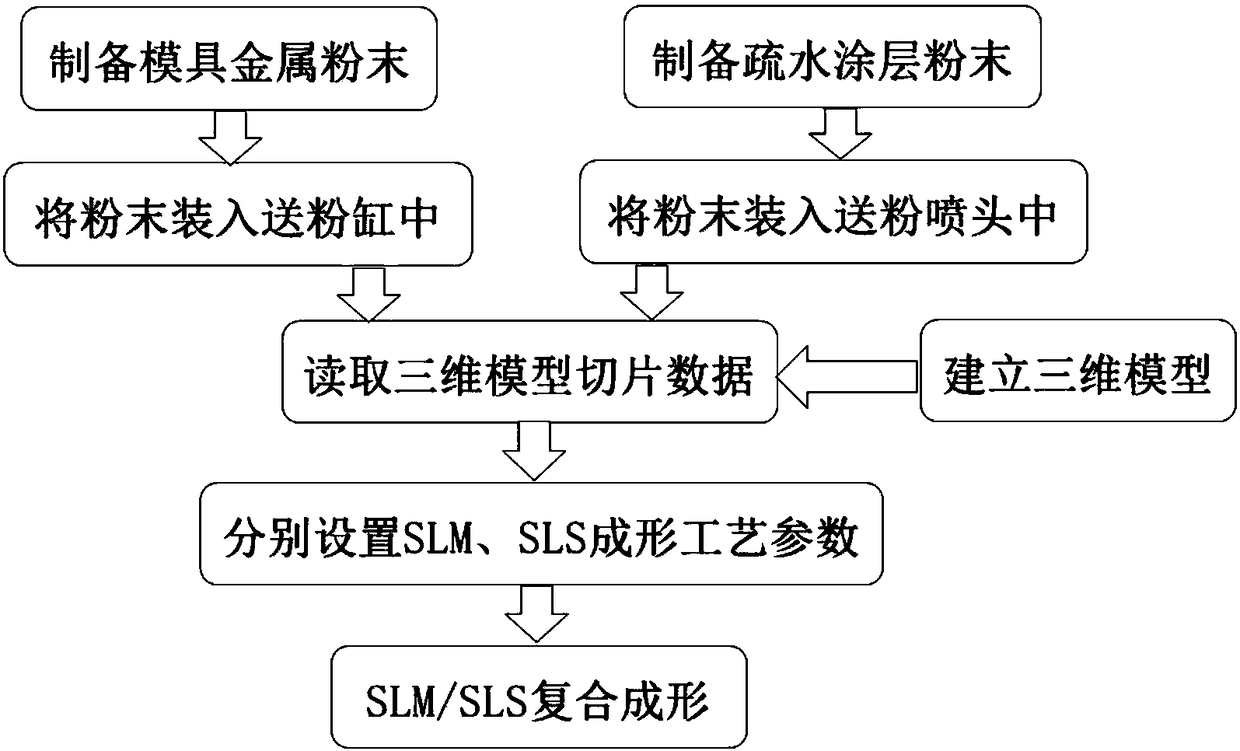

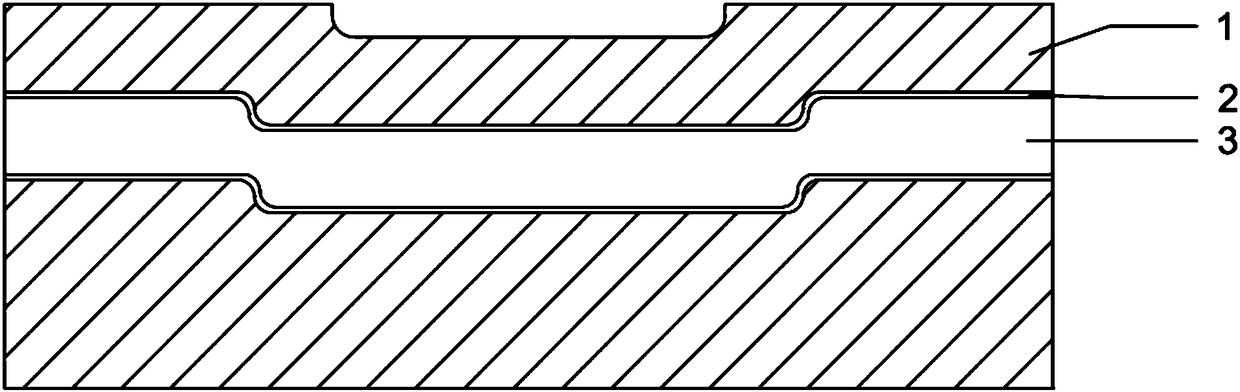

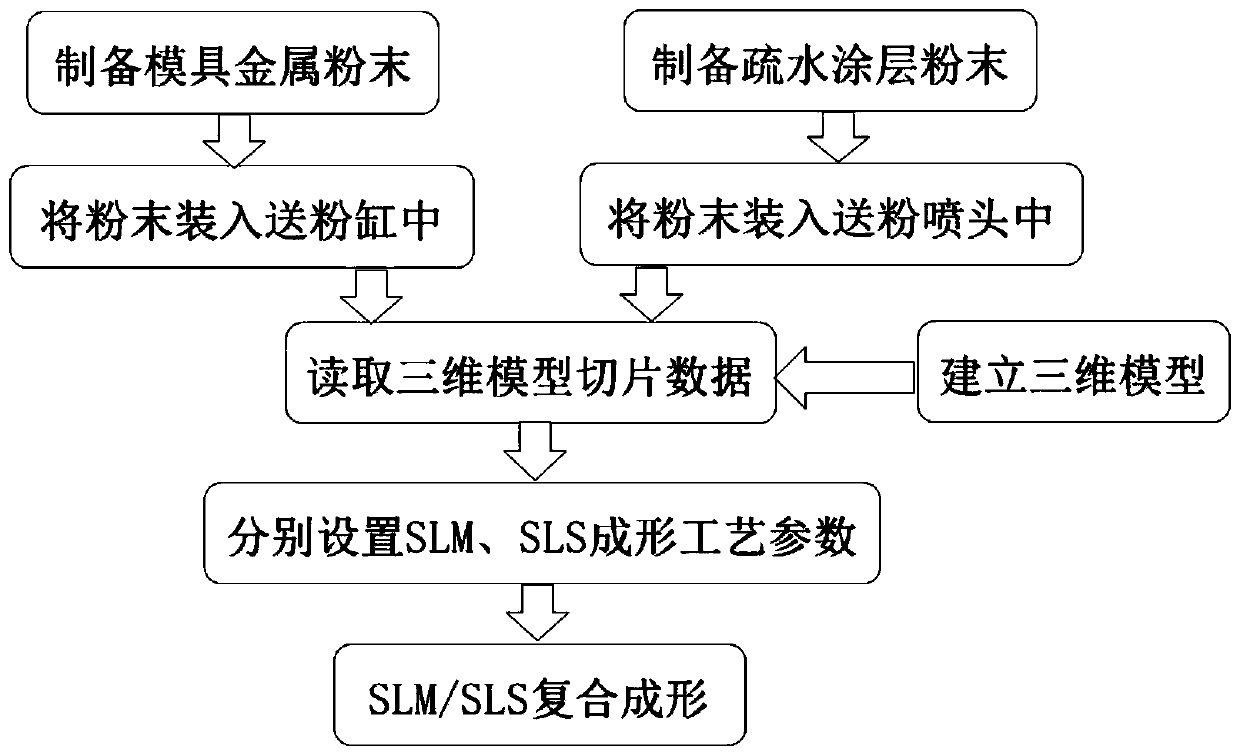

ActiveCN108372305AAvoid cloggingAvoid normal workAdditive manufacturing apparatusIncreasing energy efficiencySelective laser meltingMaterial type

The invention discloses a conformal cooling channel with hydrophobic effect and a production method thereof. The method comprises the following steps: (1) preparing hydrophobic coating powder materials; (2) designing a three-dimensional model with a conformal cooling channel die, and performing slicing treatment; (3) placing die metal powder and hydrophobic coating powder; (4) carrying out shapingtreatment, specifically comprising first performing shaping on the die metal powder by using an SLM (selective laser melting) technology, then performing shaping on the hydrophobic coating powder byusing an SLS technology to form a powder leveling layer; (5) repeating step (4) until the whole conformal cooling channel is completed; (6) taking off the shaped die. Through improving and optimizingthe key material types of inner wall hydrophobic coating and corresponding specific shaping technology, the conformal cooling channel with hydrophobic coating can be obtained, and the technical problems that the cooling efficiency of a die cooling system is low, the conformal cooling channel is easy to block, the surface metal is easy to corrode and the like are solved.

Owner:HUAZHONG UNIV OF SCI & TECH +1

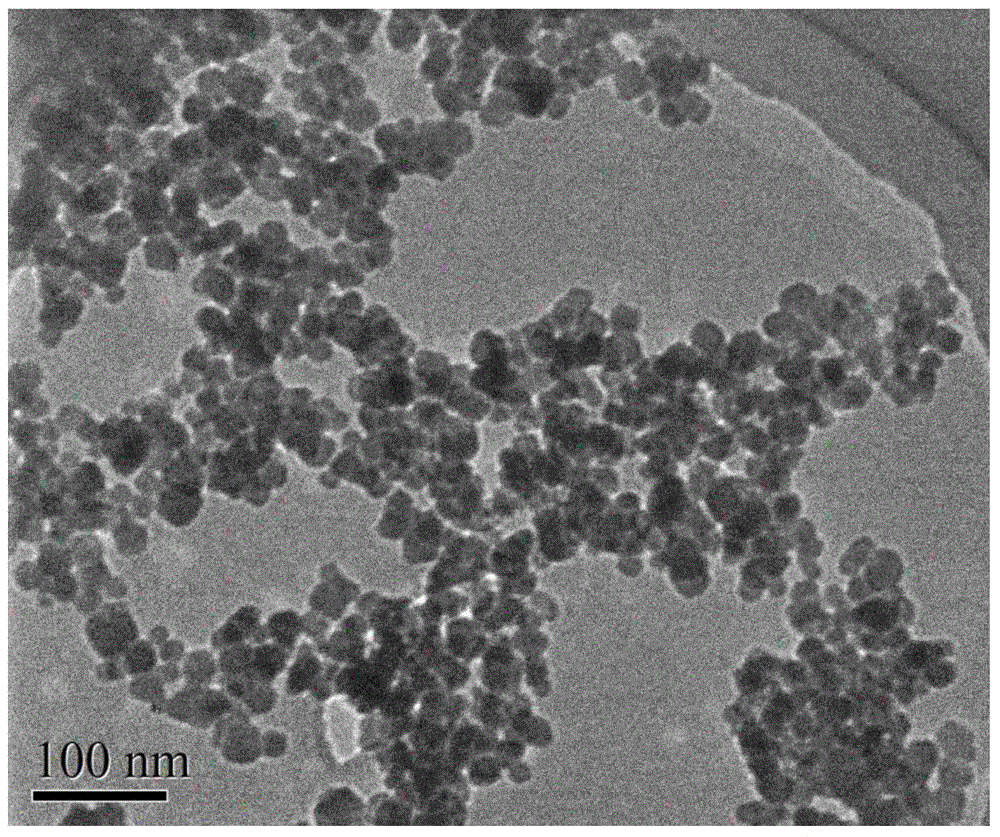

Method for preparing nanoscale ferroferric oxide from steel pickling wastewater

ActiveCN104876357AAvoid problems such as corrosionTo achieve the purpose of resource managementMaterial nanotechnologyFerroso-ferric oxidesSodium metasilicateRoom temperature

The invention relates to a method for preparing nanoscale ferroferric oxide from steel pickling wastewater. The method comprises the following steps: filtering steel pickling wastewater to remove suspended solids out of wastewater; oxidizing partial divalent iron ions in wastewater into trivalent iron ions, controlling the molar ratio of divalent iron ions to trivalent iron ions to be (1: 1.7)-(1:1.9), and stopping adding an oxidant; controlling the concentration of an aid in wastewater at 1g / L-5g / L; adding a pH regulator to regulate the pH value of wastewater to be 10-12; adding 2g / L-4g / L of sodium metasilicate; further heating the obtained solution to 60-80 DEG C, maintaining the temperature for 1-3 hours, and naturally cooling to the room temperature; after carrying out solid-liquid separation, washing and drying obtained solid powder, so as to obtain nanoscale ferroferric oxide. According to the method, steel pickling wastewater can be subjected to effective resourceful treatment, and nanoscale ferroferric can be prepared by virtue of divalent iron ions contained in wastewater.

Owner:TIANJIN UNIV +1

Method and device for continuously producing chlorinated polyvinyl chloride by low-temperature plasma circulating bed

ActiveCN102161718BRealize continuous productionAvoid problems such as corrosionEnergy based chemical/physical/physico-chemical processesChlorinated polyvinyl chlorideFluidized bed

The invention discloses a method and device for continuously producing chlorinated polyvinyl chloride by a low-temperature plasma circulating bed, relating to a production technology and equipment for macromoleclar polymer chlorinated polyvinyl chloride. The device comprises a chlorinated polyvinyl chloride particle storage bin, a chlorinated polyvinyl chloride storage bin, two parallel fluidizedbed reactors, two parallel riser reactors, a downer, a tail gas purifier and two circulating fans which are respectively used for transporting riser conveying gas and transporting raw material gas. In the device, the low-temperature plasma is utilized to simultaneously activate chlorine and PVC (poly vinyl chloride) raw material particles to quickly chloridize PVC in the circulating fluidized bed; and meanwhile, two groups of fluidized bed reactors are adopted for operation in turn to realize continuous production. Thus, the problems of low production efficiency and the like brought by that the reactor stops and unloads can be avoided, the phenomenon that fans, tail gas processors and the like are restarted after stopping can be eliminated, energy consumption is saved, and the service life of equipment is prolonged.

Owner:TSINGHUA UNIV

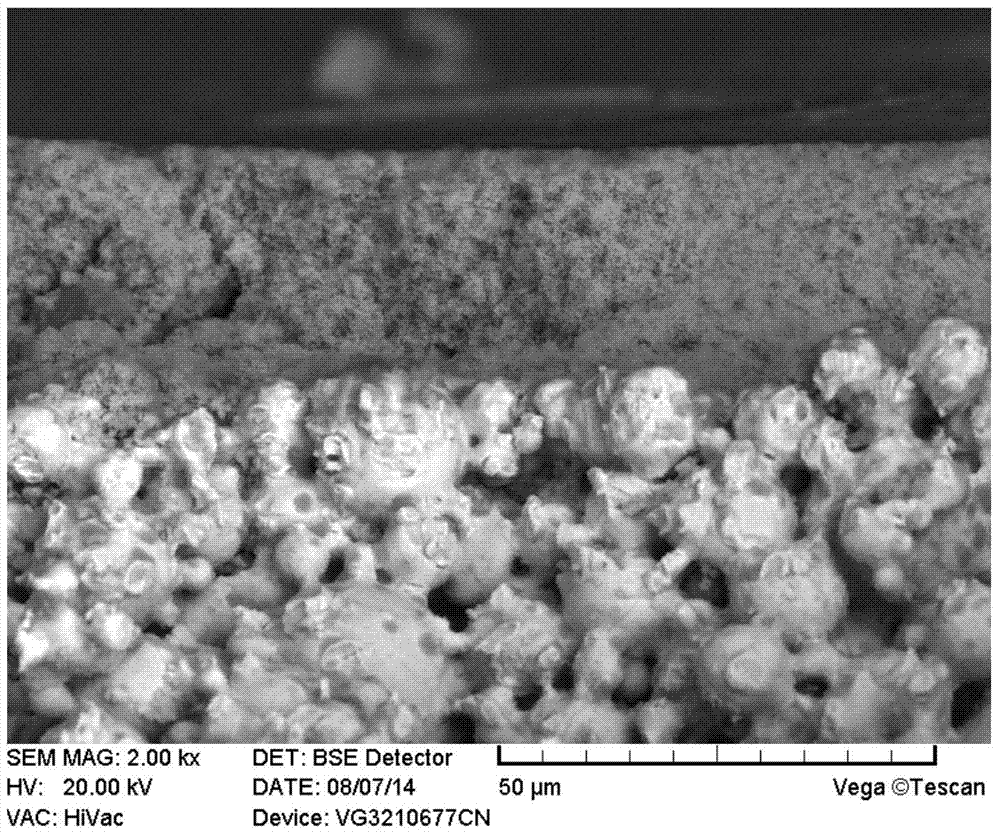

Method for preparing porous oxide film on metal carrier surface

ActiveCN104630771AImprove film-forming propertiesAvoid corrosionMetallic material coating processesElectrochemical responseSurface finishing

The invention discloses a method for preparing a porous oxide film on a metal carrier surface. The method comprises the following steps: I, performing surface processing on a metal carrier to remove oxide skin and impurities on the surface of the metal carrier; II, selecting oxide and oxide sol according to a to-be-prepared porous oxide film, and then uniformly mixing raw materials to prepare slurry; III, coating the slurry to the surface of the surface-treated metal carrier; IV, drying and putting the metal carrier in a sintering furnace, preserving the temperature and sintering under a reducing atmosphere, and obtaining a porous oxide film with thickness not larger than 100 microns on the surface of the metal carrier after cooling with the furnace. The method improves the film-forming performance of the porous oxide on the metal carrier surface in the film-forming process, avoids problems of corrosion and the like as electrochemical reaction is possibly caused by adopting a water-soluble sol system during a film layer drying period, shortens the film-layer drying process time, and reduces the sintering temperature of the film layer. The prepared porous oxide film is bonded with the metal substrate very well.

Owner:WESTERN BAODE TECH CO LTD

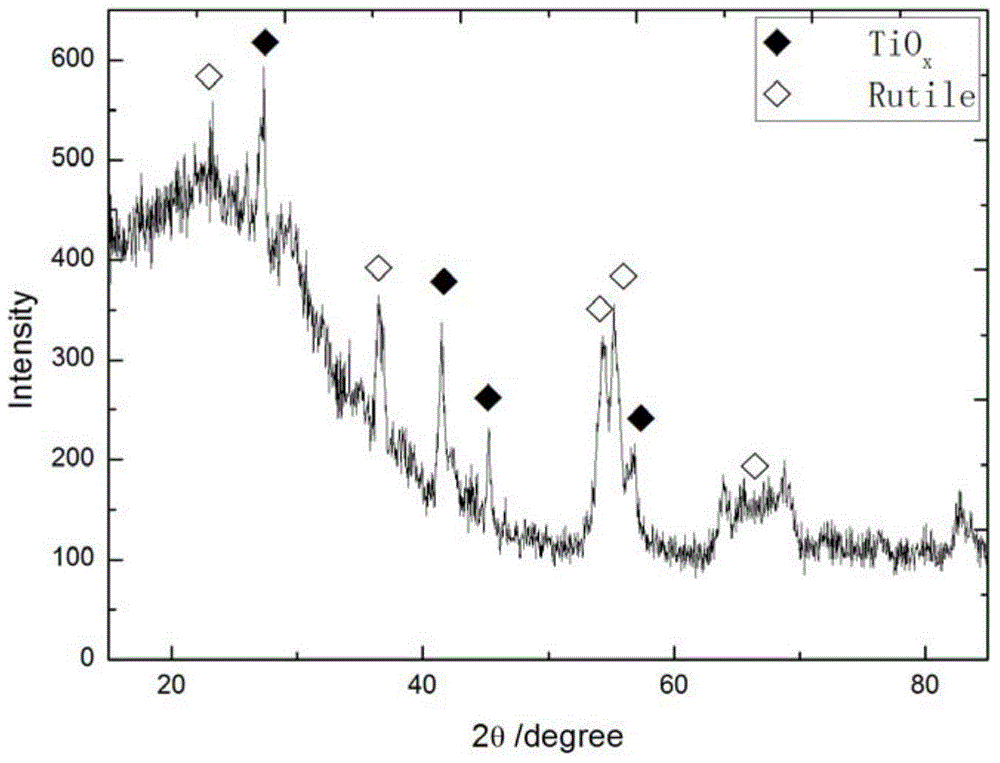

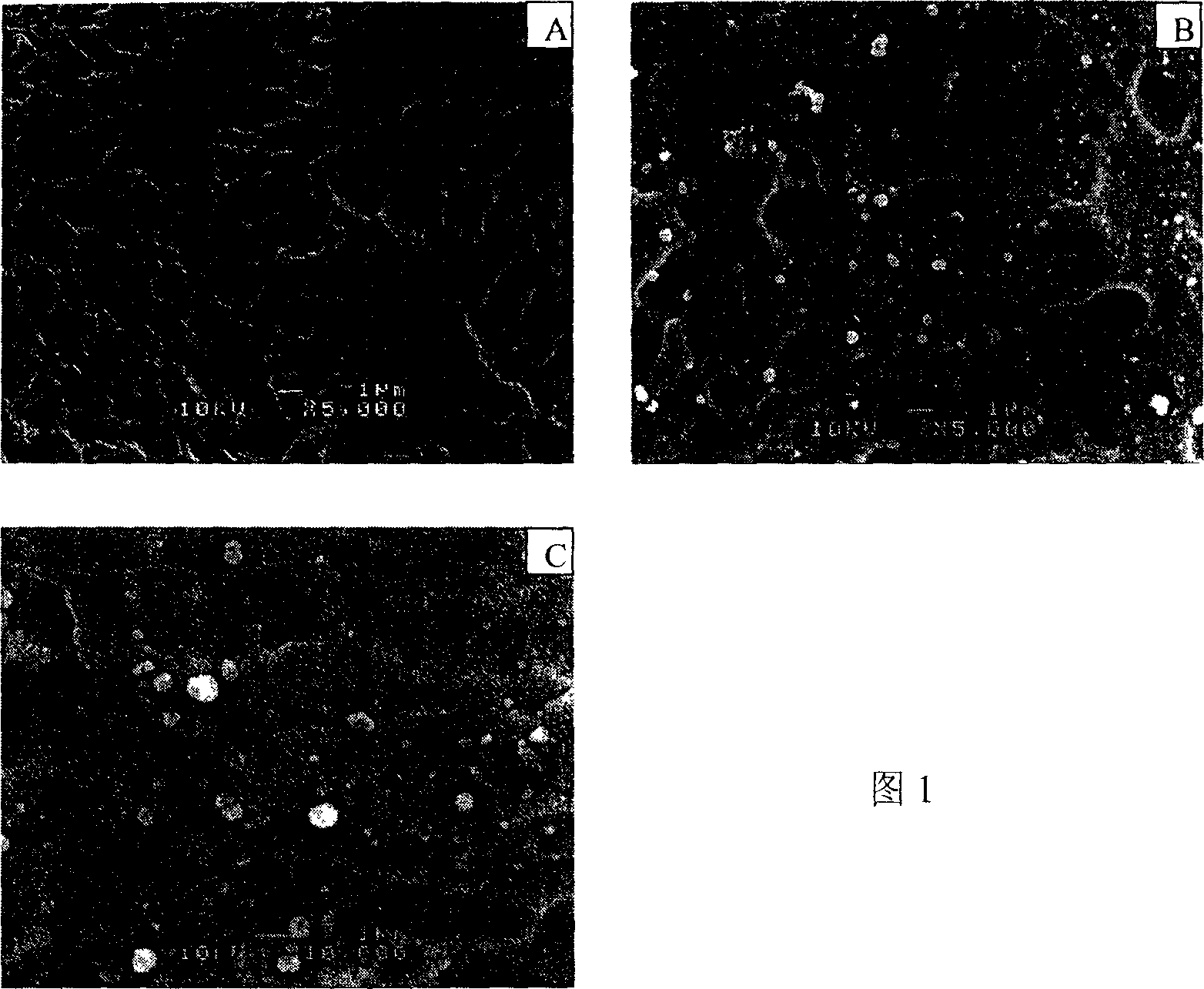

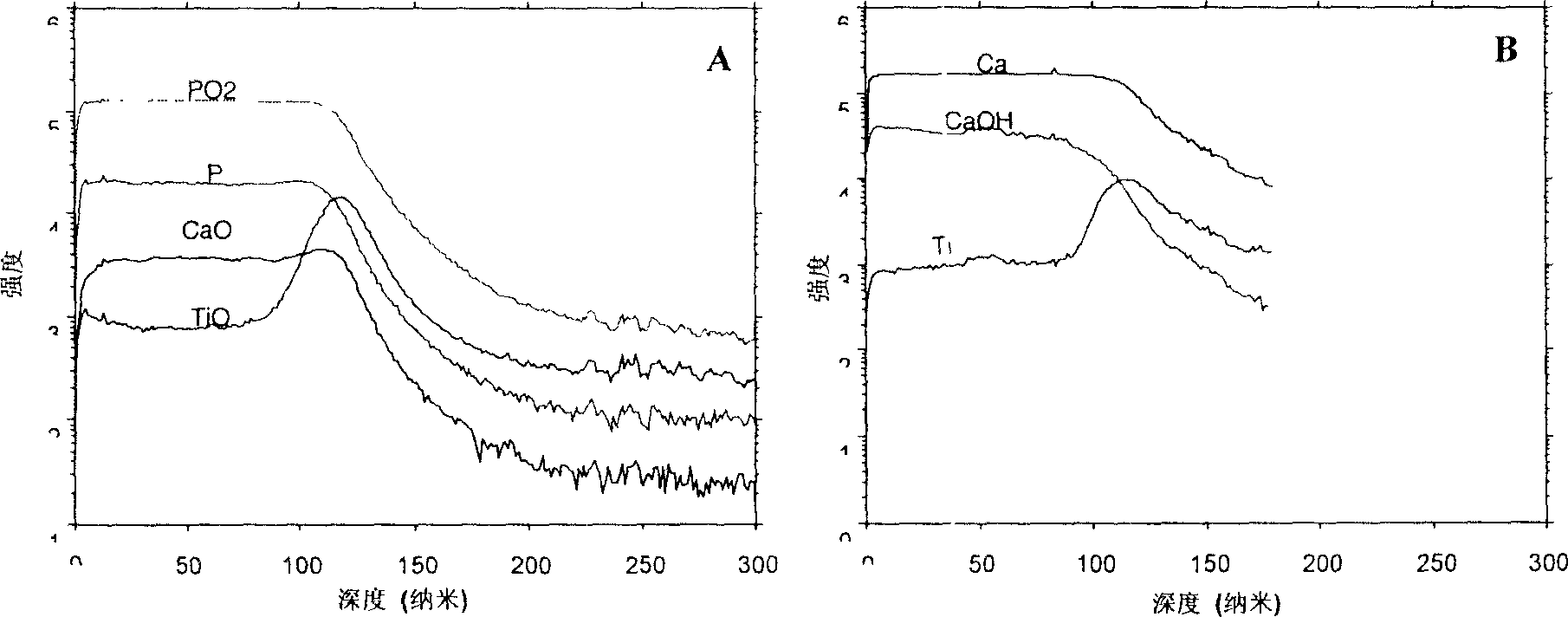

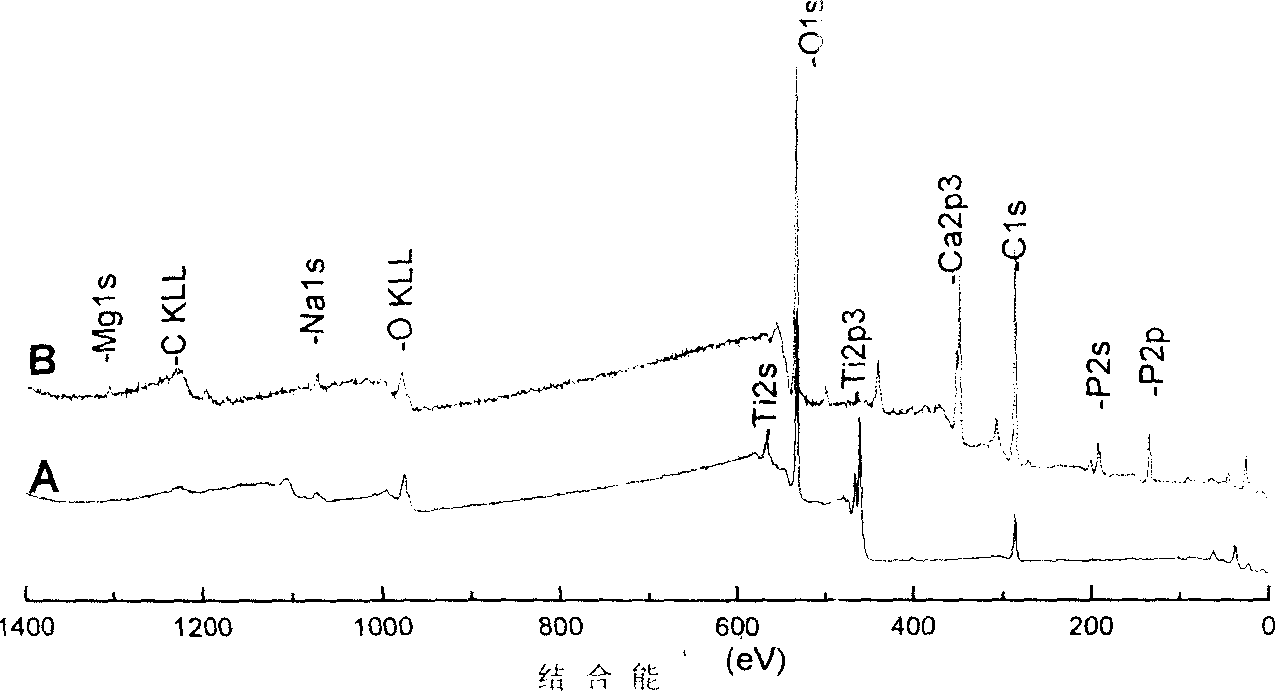

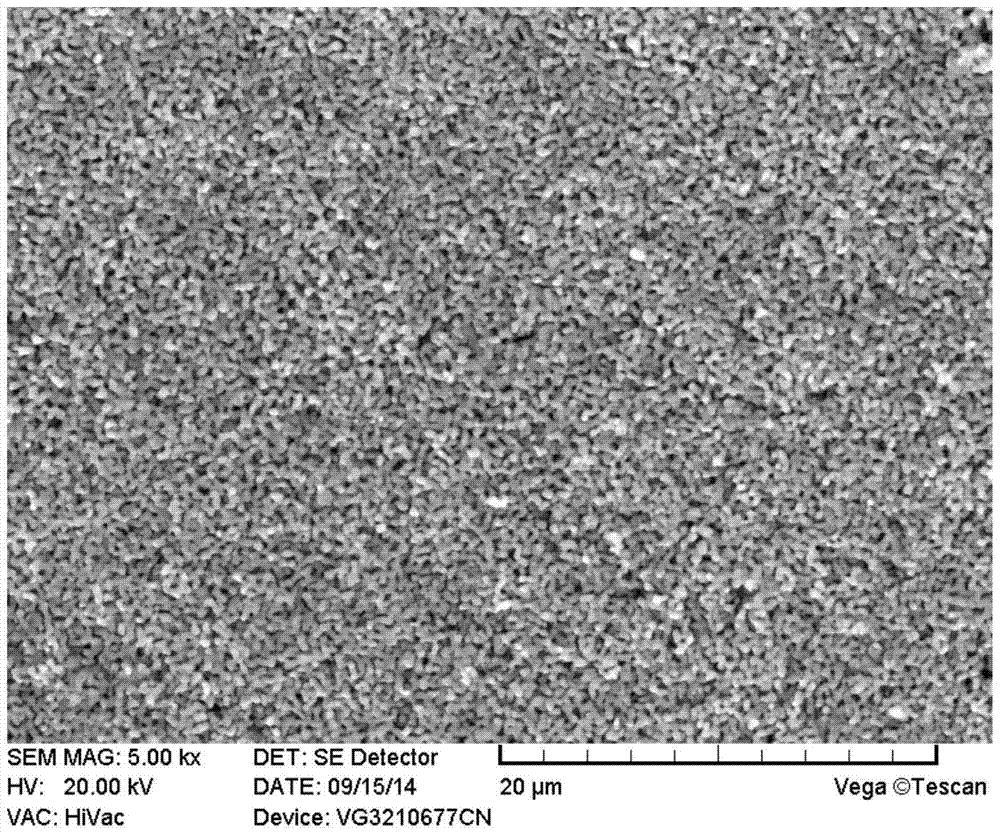

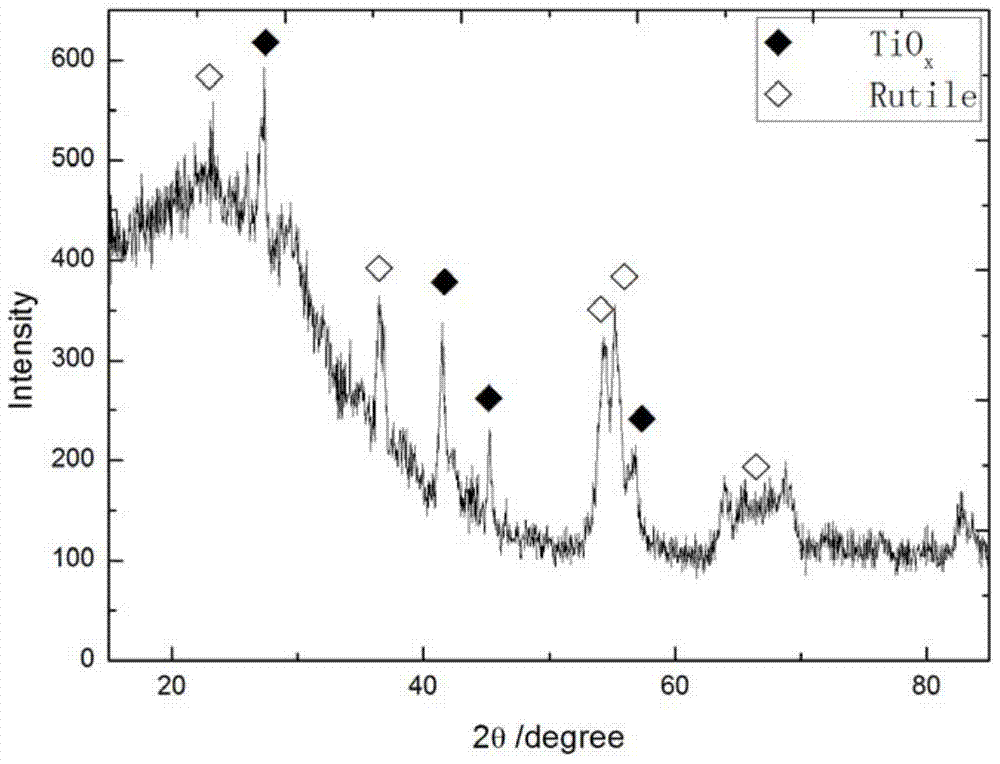

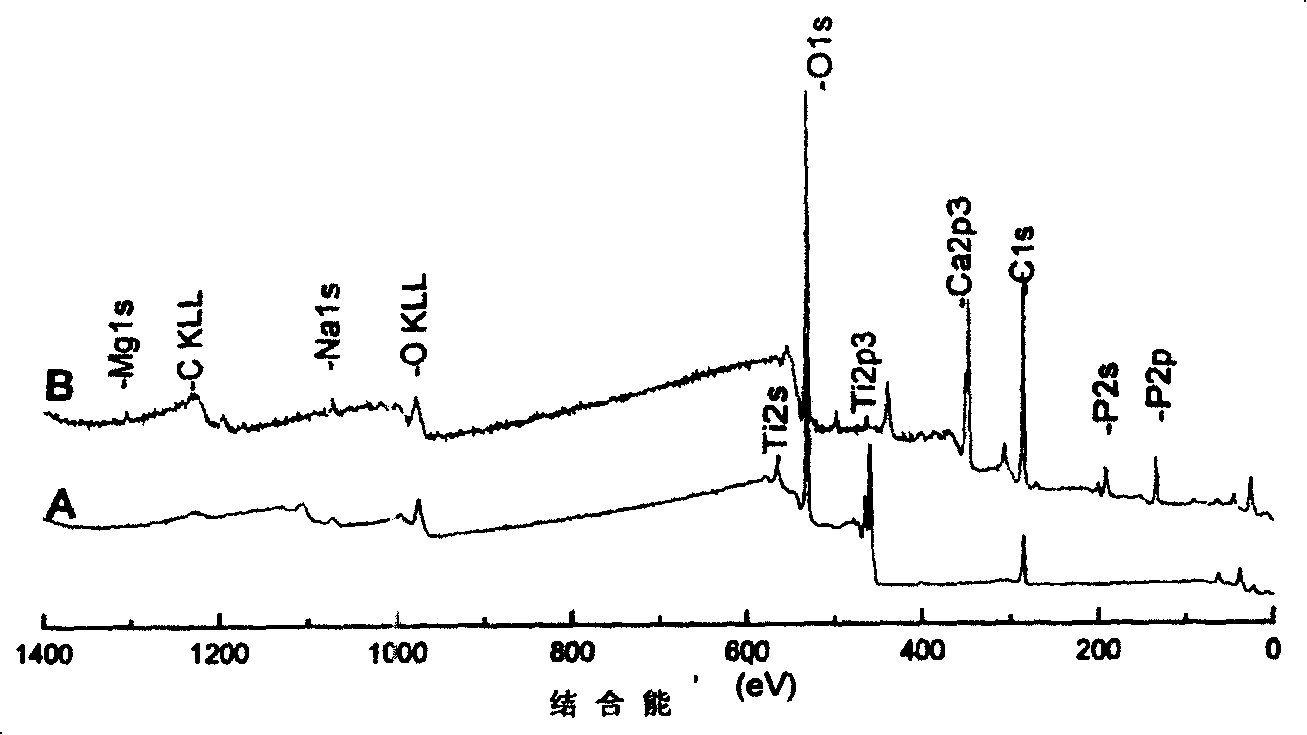

Surface activating method of medical metal material

InactiveCN1680632AAvoid impact on mechanical propertiesAvoid problems such as corrosionElectrolytic inorganic material coatingSupporting electrolytePhosphate

A surface-active method of metal material for medical use. It adopts three poles system. Negative pole is metal material. Positive pole is inert material. Fit them and reference electrode to electrolyte solution containing supported electrolyte solution. Soluble calcium salt and phosphate at pH2.5-6.5.Hold negative potential to be at -1 to -4V by way of constant potential or apply to electronic current 1-5Ma at constant value for 2 to 20min. Get sample of negative pole, wash and dry it.

Owner:SICHUAN UNIV

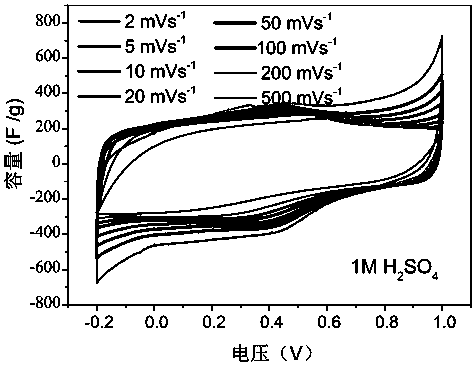

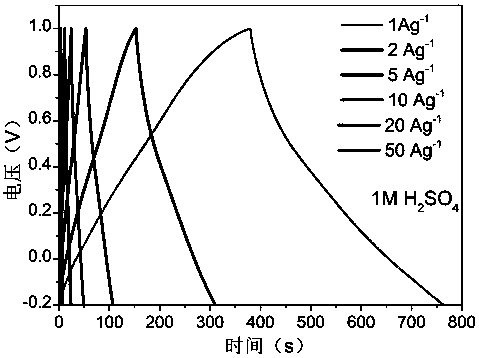

Preparation method, product and application of nitrogen-phosphorus co-doped porous carbon material

InactiveCN110790274AAvoid pollutionAvoid corrosionCarbon compoundsHybrid capacitor electrodesPorous carbonTube furnace

The invention relates to a preparation method, a product and application of a nitrogen-phosphorus co-doped porous carbon material. The nitrogen-phosphorus co-doped porous carbon material is prepared by taking phytic acid and a filamentous biomass material as raw materials and adopting a high-temperature sintering method. The preparation method specifically comprises the following steps: uniformlymixing the filamentous biomass and phytic acid according to a certain ratio; putting the raw materials into a blast oven for drying, transferring the dried materials into a tubular furnace, heating to900 DEG C in an inert gas atmosphere at a heating rate of 5-10 DEG C / min, keeping the temperature for 2 hours, naturally cooling to room temperature, taking an obtained product out, cleaning with dilute nitric acid, and finally cleaning with deionized water to obtain the nitrogen-phosphorus co-doped porous carbon material. Phytic acid is used as an activating agent and an additive, so that environmental pollution is avoided, and the preparation method is simple and does not corrode equipment.

Owner:SHANGHAI NAT ENG RES CENT FORNANOTECH

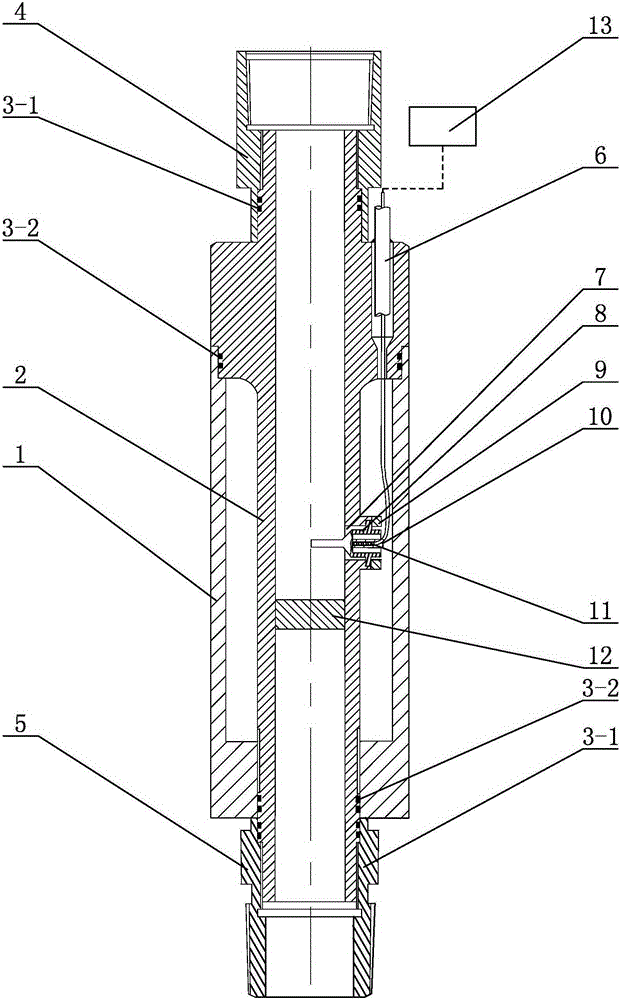

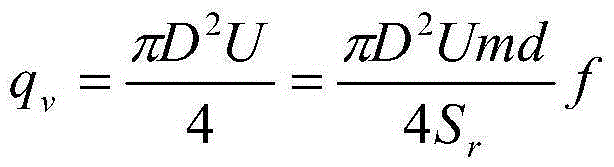

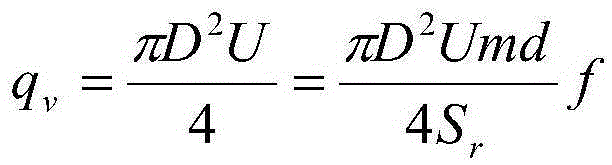

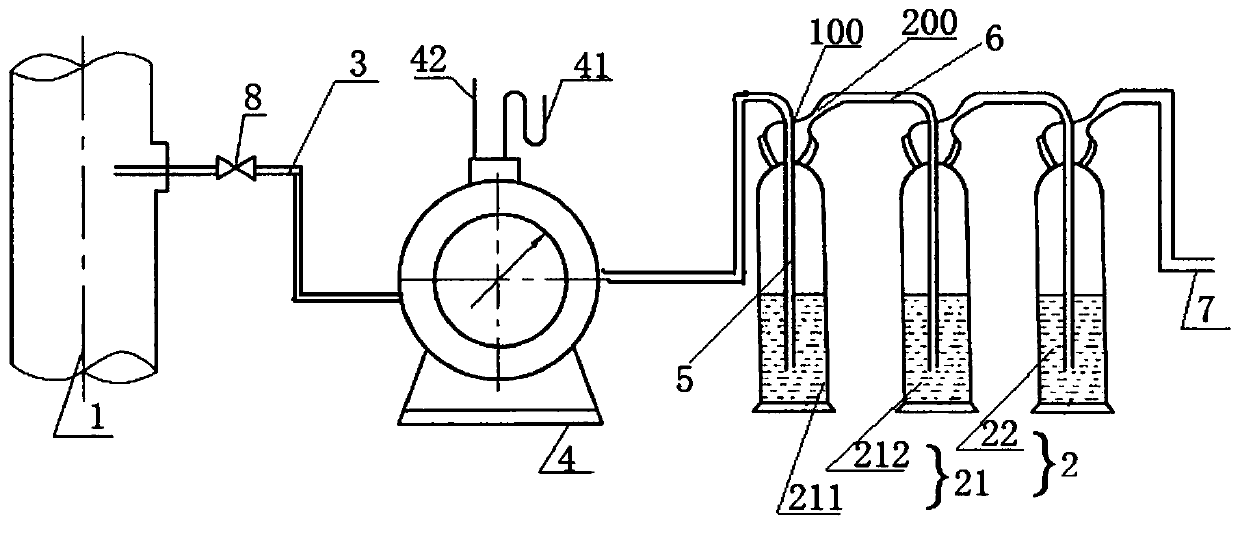

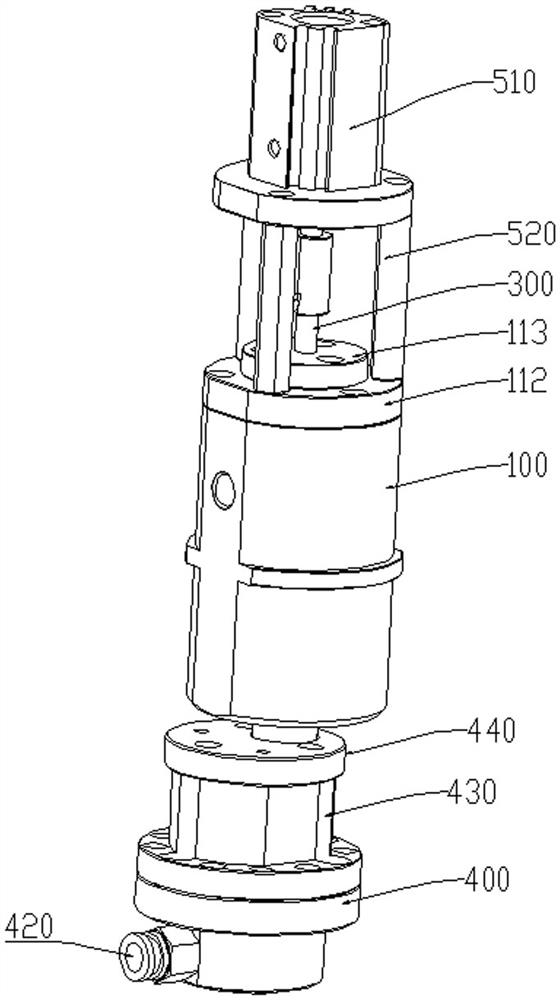

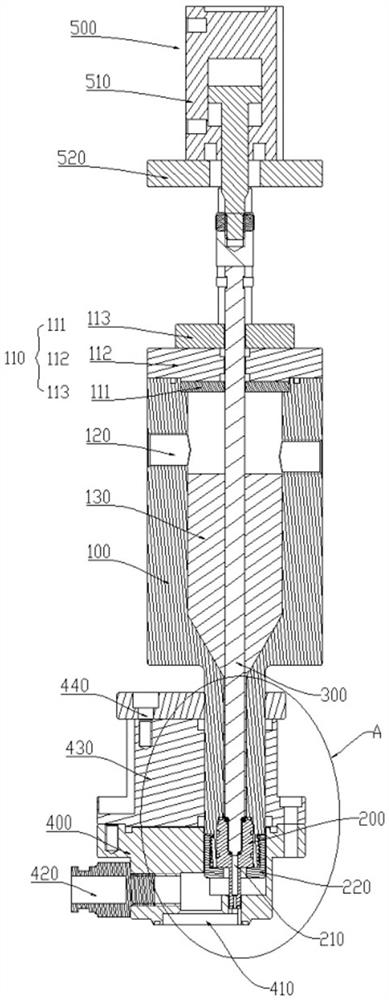

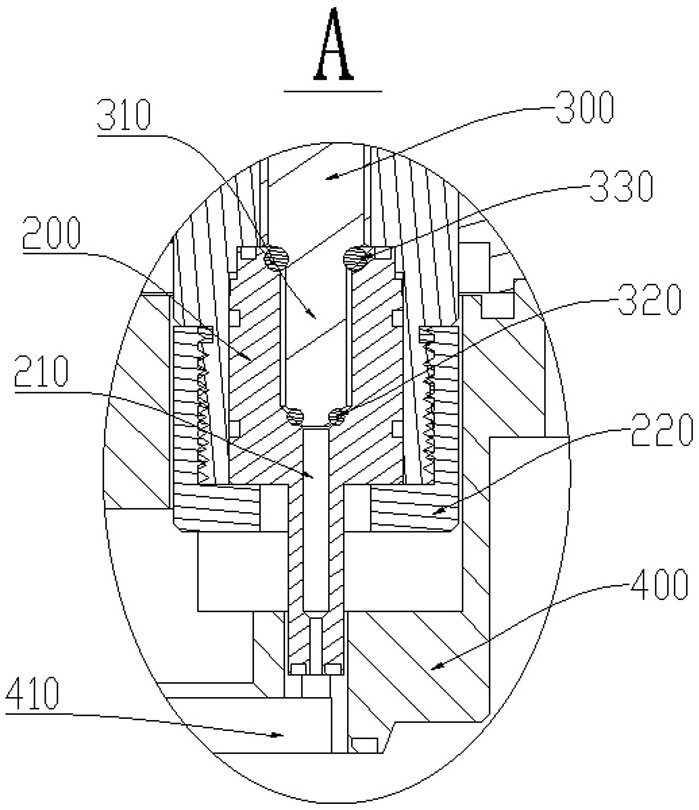

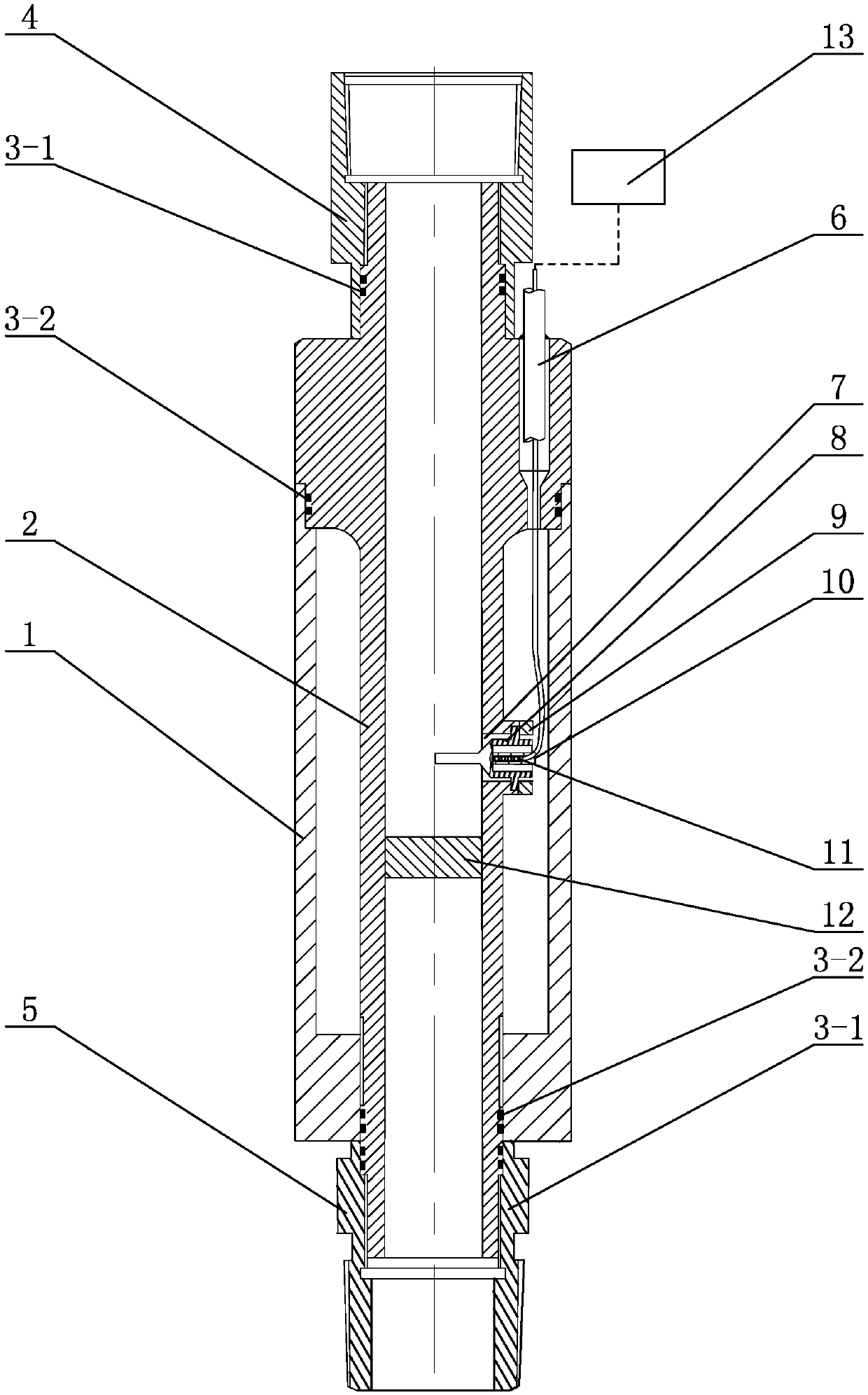

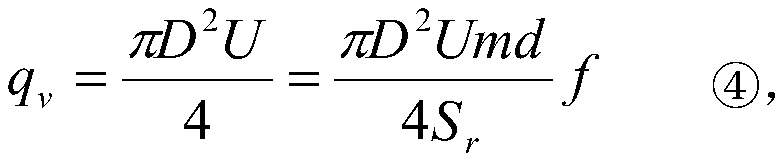

Underground optical fiber vortex-shedding flowmeter and underground flow measuring method

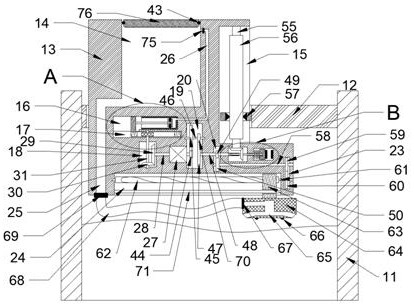

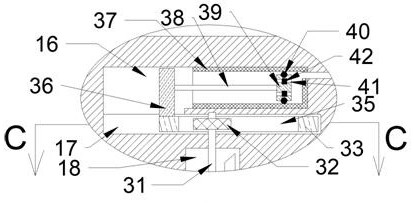

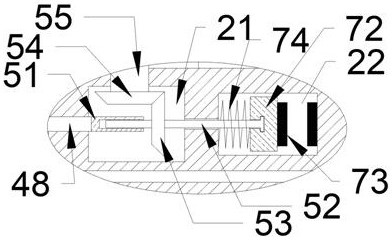

InactiveCN105352558AAvoid problems such as corrosionHigh sensitivityVolume/mass flow by dynamic fluid flow effectFiberGrating

The present invention discloses an underground optical fiber vortex-shedding flowmeter and an underground flow measuring method, and aims to solve the problems, of low measuring precision and poor stability, caused by situations that optical fibers are influenced by fluid corrosion and that measuring elements influence a flow field and flow inside a pipeline in a conventional flowmeter, and the problem that the conventional optical fiber flowmeter is complex in structure and cannot be used in high-temperature, high-voltage and high-erosion environments. An upper joint, a central tube and a lower joint are connected from top to bottom in turn, a housing sleeves an outer side wall of the central tube, a vortex shedder is arranged inside the central tube, a through hole is formed in the middle part of the outer side wall of the central tube, a probe is installed inside the through hole through a pressing plate, a central shaft is inserted inside the probe, a fiber bragg grating is arranged inside the central shaft, and one end of an armored cable is connected with the fiber bragg grating while the other end of the armored cable is connected with a fiber bragg grating demodulation instrument. The underground optical fiber vortex-shedding flowmeter is applied to the oil field equipment field.

Owner:HARBIN INST OF TECH

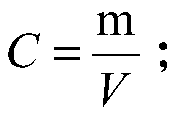

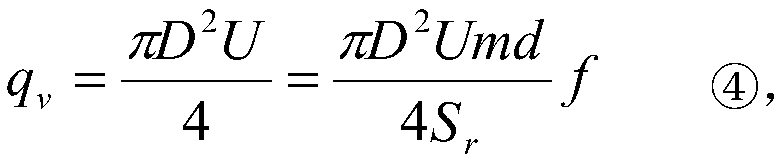

Detection method and detection for chlorine content in blast furnace gas

InactiveCN111089938AGuaranteed full absorptionEliminate distractionsChemical analysis using titrationPhysical chemistryChloride

The invention provides a detection method and a detection device for chlorine content in blast furnace gas. The detection method comprises the following steps of S1, acquiring the volume of to-be-detected blast furnace gas; S2, introducing the to-be-detected blast furnace gas into a first reaction solution and a second reaction solution in sequence, enabling the to-be-detected blast furnace gas tofully react with the first reaction solution, and filtering to obtain filtrate; and S3, detecting the mass of chloride ions in the filtrate by potentiometric titration, and calculating the chlorine content in the blast furnace gas, wherein the chlorine content is the concentration of chloride ions in unit volume of the blast furnace gas, and the calculation method is described as follows, in theformula, C is the chlorine content in the blast furnace gas, V is the volume of the to-be-detected blast furnace gas, and m is the mass of chlorine in the blast furnace gas with the volume V. By adopting multiple absorption, the chlorine in the blast furnace gas is completely absorbed, and hydrogen sulfide and carbon dioxide are completely converted into precipitates to eliminate interference on chlorine ion determination; the mass of chloride ions in the filtrate is measured by potentiometric titration, the operation is simple and rapid, and the result is accurate.

Owner:湖南华菱涟源钢铁有限公司

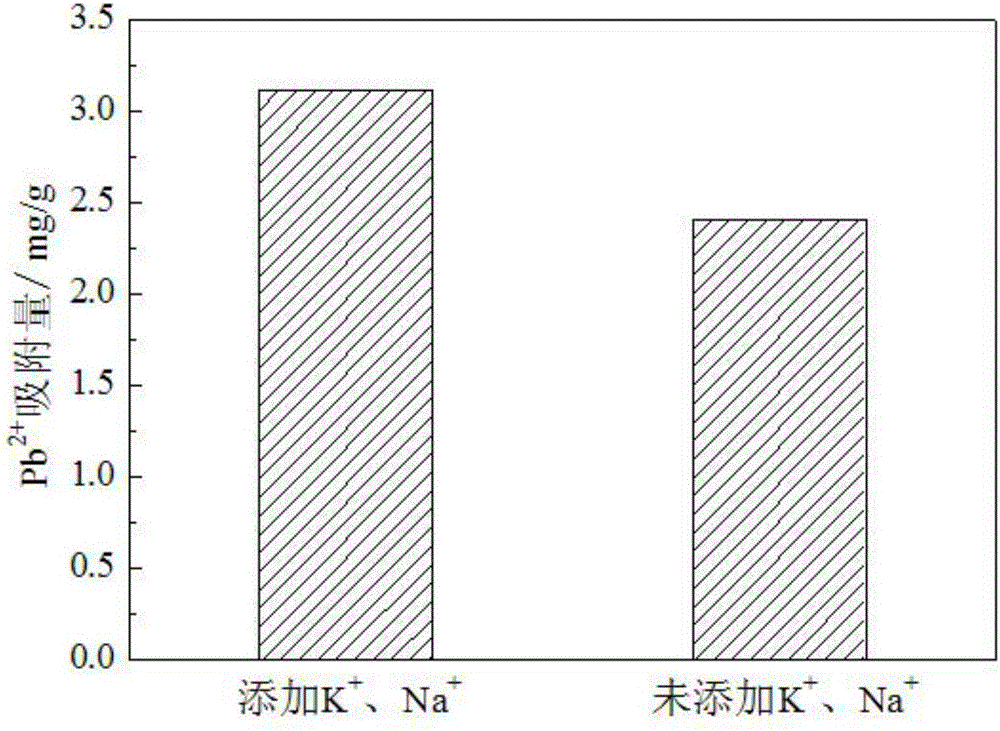

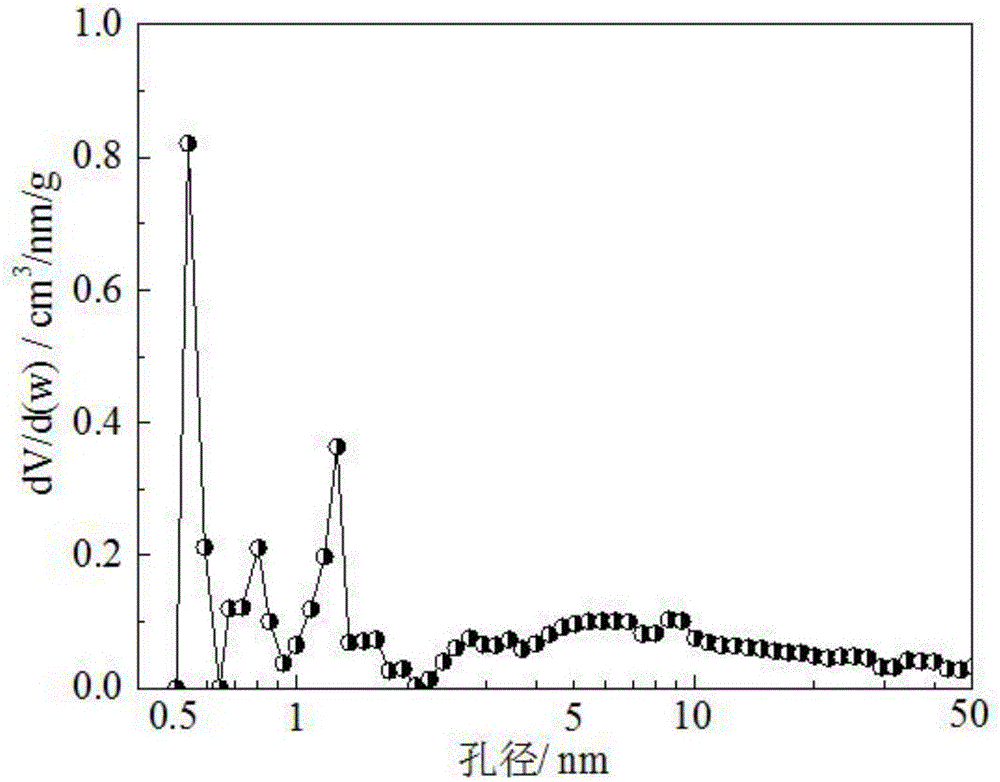

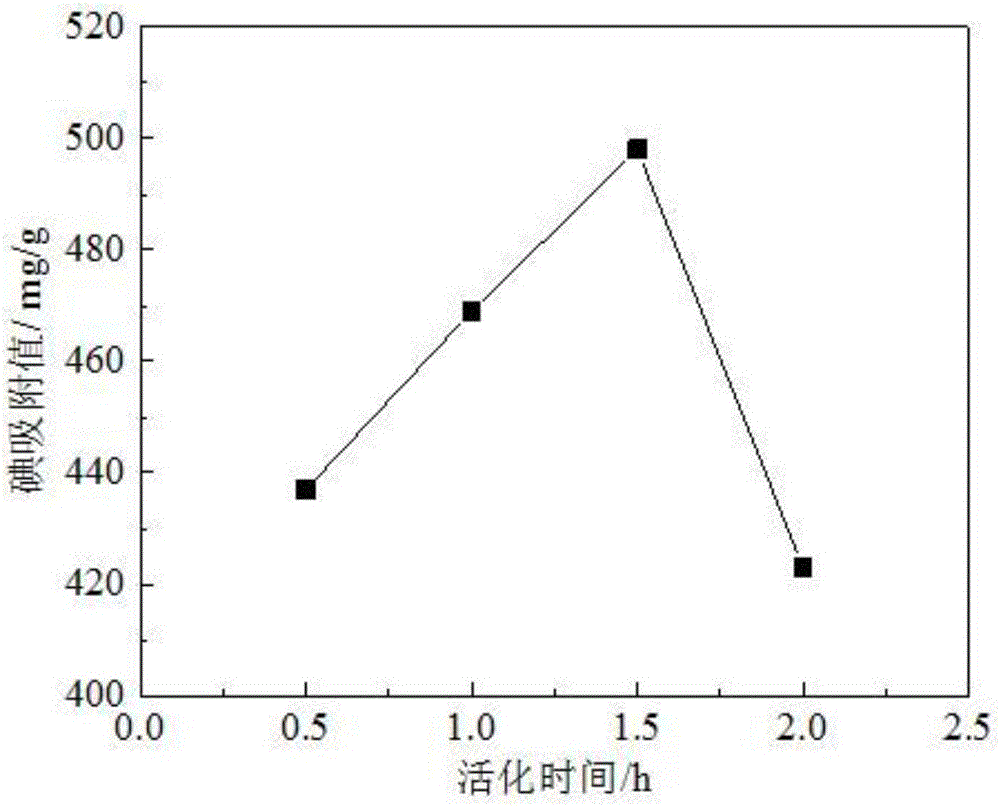

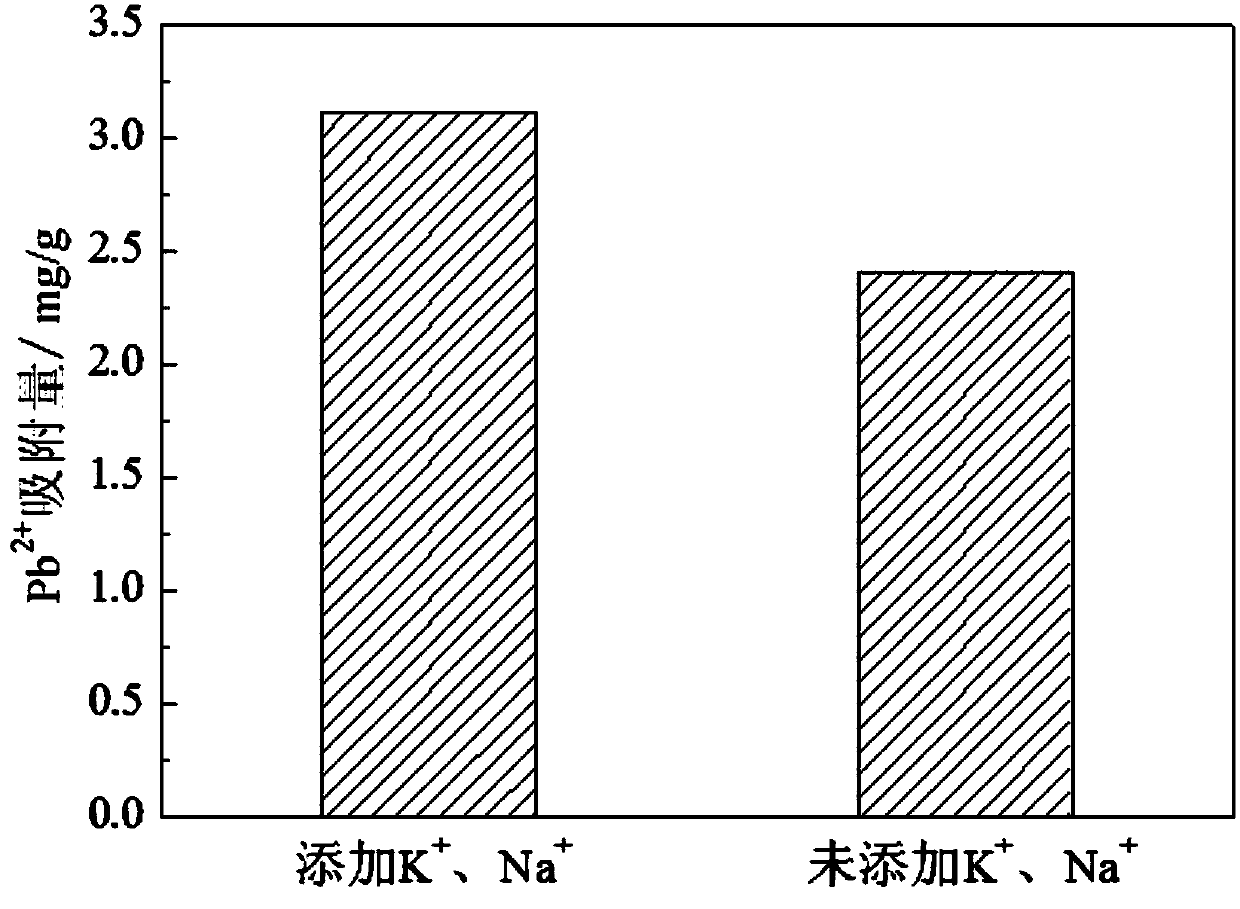

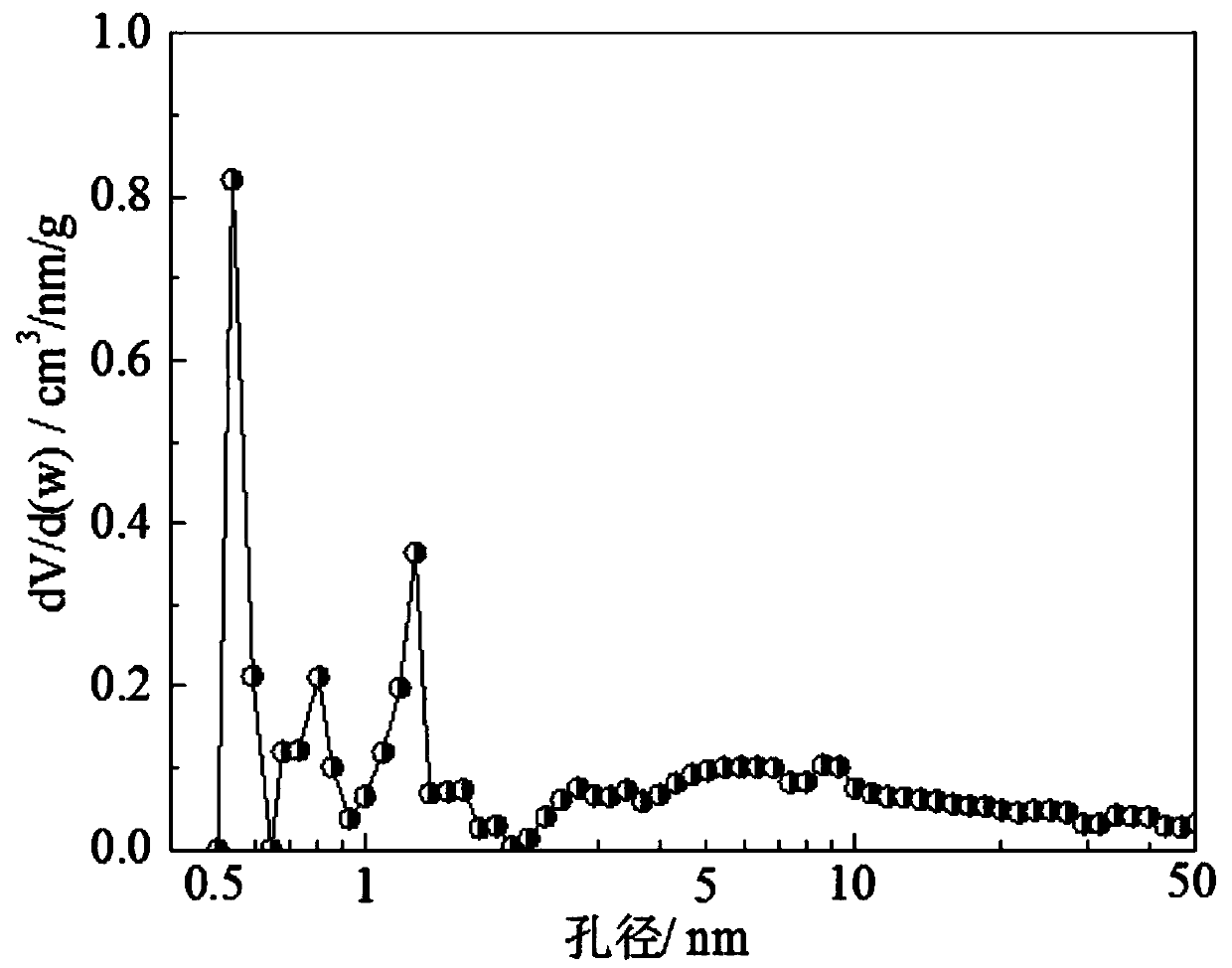

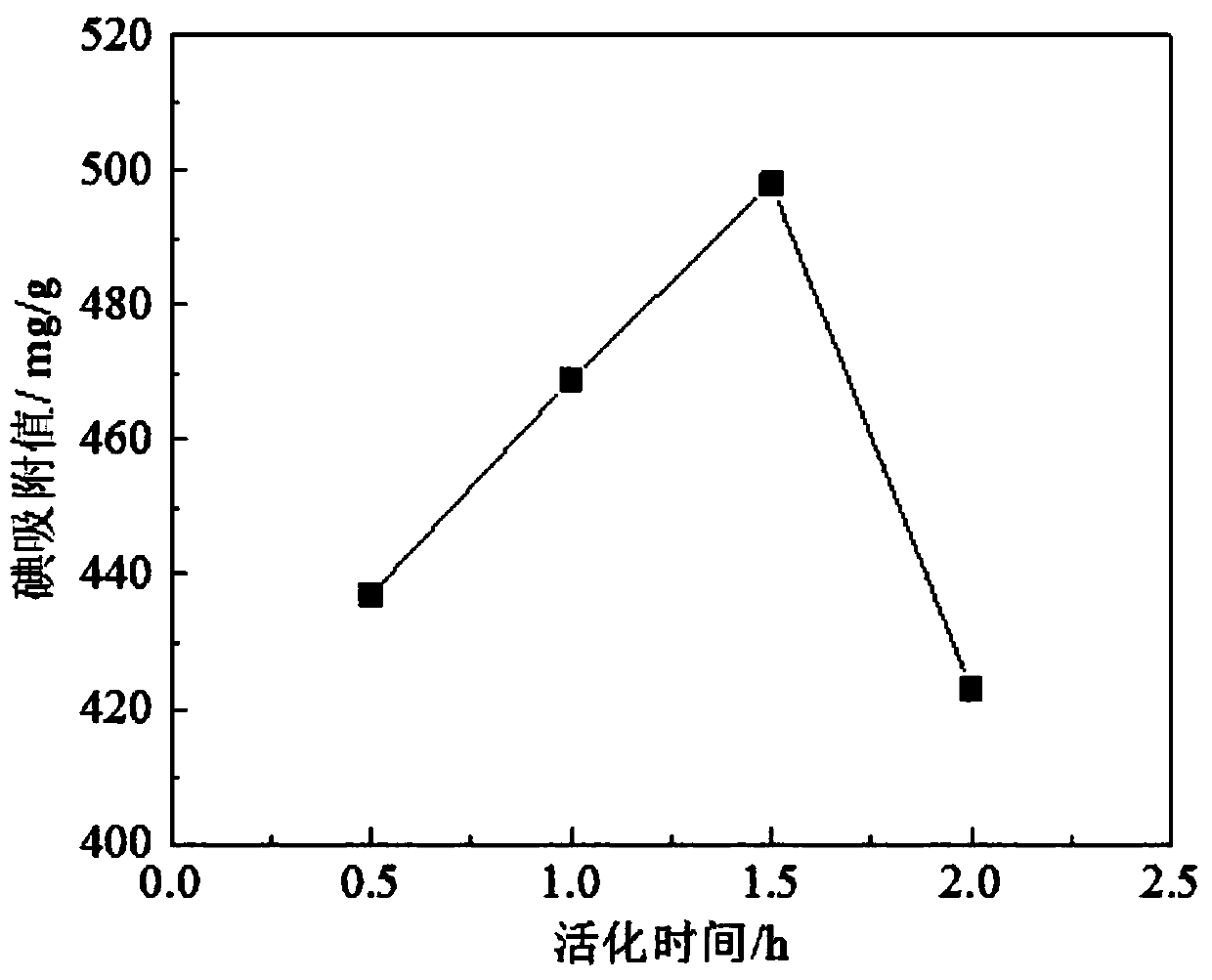

Sewage treatment sludge active carbon having continuous pore size distribution, and preparation method thereof

ActiveCN106560236AReduce lossesIncrease K

<sup>+</sup>

contentCarbon compoundsOther chemical processesActivated sludgeSorbent

The invention discloses sewage treatment sludge active carbon having continuous pore size distribution, and a preparation method thereof. According to the preparation method, ZnCl2, phosphoric acid, K2S and NaCl form a compound activator in anoxic atmosphere to activate sludge, wherein the mesoporous structure is developed mainly by using the phosphoric acid, and the K<+> content and the Na<+> content of the sludge active carbon are increased so as to easily enhance the replacement with heavy metal ions in sewage; and activation is performed with water vapor to generate rich micro-pores in the mesoporous surface, such that the BET specific surface area of the finally obtained sludge active carbon is not less than 400 m<2> / g, and the pore size is continuously distributed within 0.5-50 nm. According to the present invention, the prepared sludge active carbon adopted as the sewage treatment adsorbent adsorbs heavy metal ions using Pb<2+> as the representative and macromolecular pollutants in the sewage, and has good effects.

Owner:TIANJIN CHENGJIAN UNIV

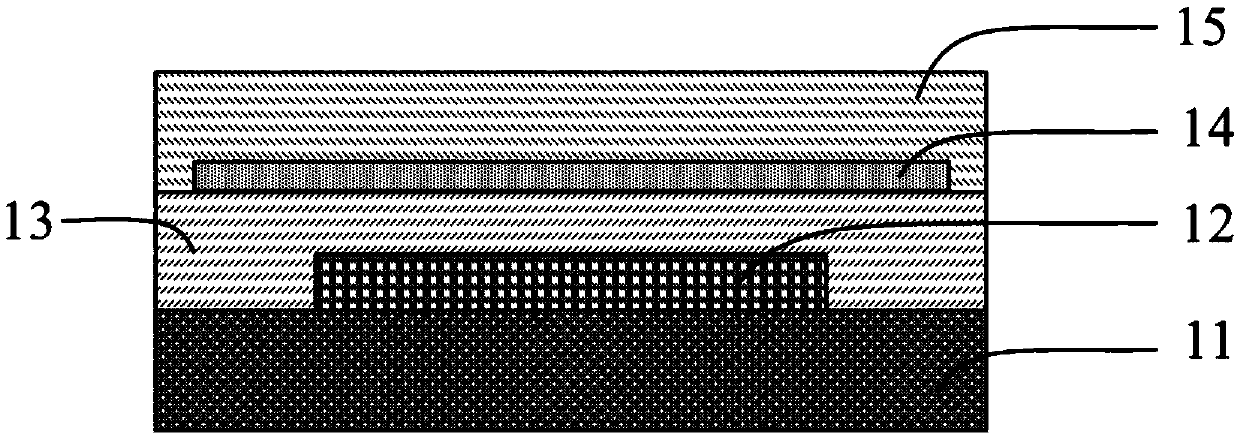

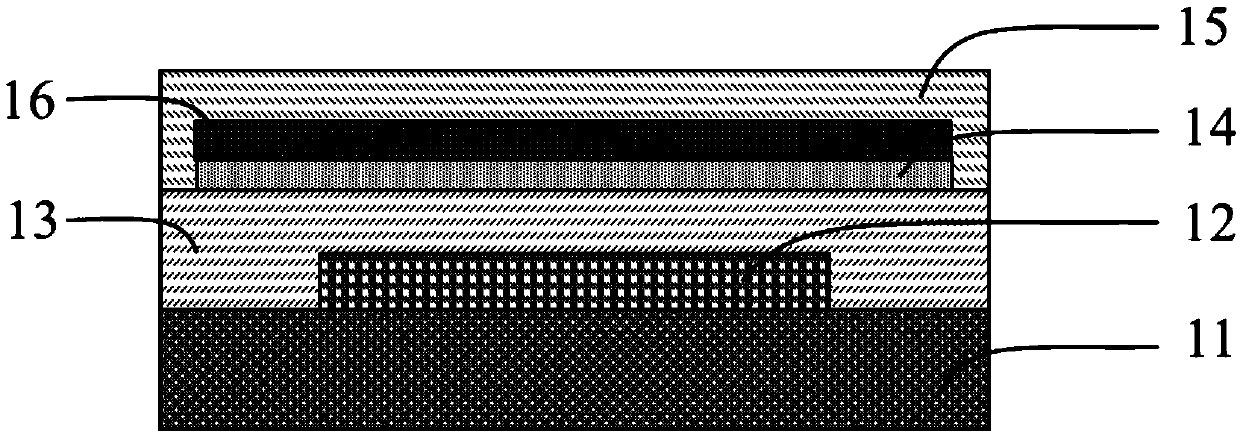

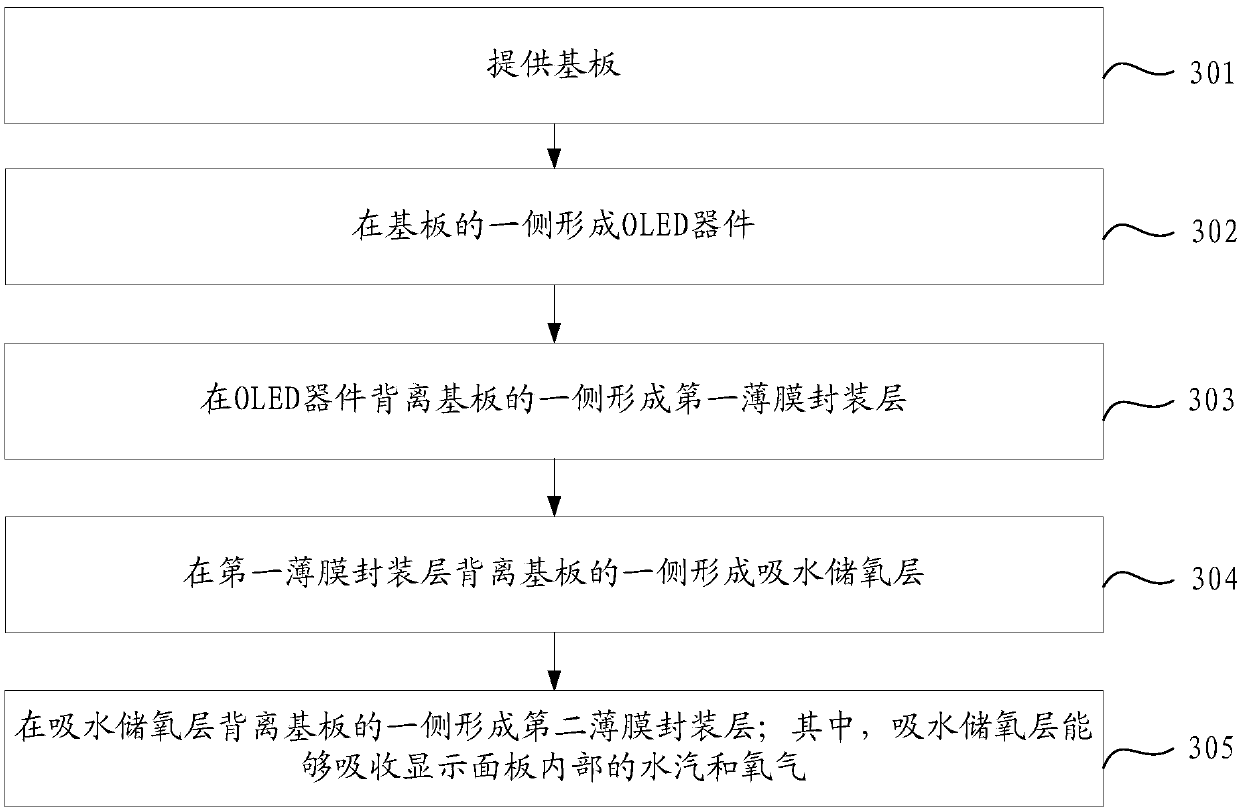

Display substrate, manufacturing method thereof, and display device

ActiveCN109546001AImprove reliabilityExtend your lifeSolid-state devicesSemiconductor/solid-state device manufacturingEngineeringSurface plate

The invention provides a display panel, a preparation method thereof and a display device, and the display panel comprises a substrate and an OLED device arranged at one side of the substrate; a firstthin film packaging layer which is arranged at one side, deviating from the substrate, of the OLED device; a water absorption and oxygen storage layer which is arranged at one side, deviating from the substrate, of the first thin film packaging layer; a second film packaging layer which is arranged at one side, deviating from the substrate, of the water absorption and oxygen storage layer, wherein the water absorption and oxygen storage layer can absorb water vapor and oxygen in the display panel. According to the technical scheme, the water absorption and oxygen storage layer is arranged toabsorb water vapor and oxygen in the display panel, the water vapor and the oxygen can be effectively prevented from entering the OLED device, so the problems of electrode corrosion and the like caused by the water vapor and the oxygen are solved. Therefore, the reliability and the service life of the display device can be improved.

Owner:BOE TECH GRP CO LTD +1

A conformal cooling channel with hydrophobic effect and its manufacturing method

ActiveCN108372305BPlay a protective effectAvoid problems such as not working properlyAdditive manufacturing apparatusIncreasing energy efficiencySelective laser meltingMaterial type

The invention discloses a conformal cooling channel with hydrophobic effect and a manufacturing method thereof, wherein the method comprises the following steps: (1) preparing a hydrophobic coating powder material; (2) designing a three-dimensional cooling channel mold with a conformal cooling channel (3) place the mold metal powder and hydrophobic coating powder; (4) carry out the forming process, specifically, first use the SLM process to form the mold metal powder, and then use the SLS process to form the hydrophobic coating powder , forming a powder layer; (5) repeating step (4) until the entire conformal cooling channel is completed; (6) removing the formed mold. The present invention improves and optimizes the material type of the key inner wall hydrophobic coating and the corresponding specific forming process, and can prepare a conformal cooling channel with a hydrophobic coating, so as to solve the problems of low cooling efficiency and conformal cooling flow of the mold cooling system. The road is easy to block and the surface metal is easy to corrode and other technical problems.

Owner:HUAZHONG UNIV OF SCI & TECH +1

A kind of aqueous fluoropolymer dispersion emulsion and preparation method thereof

The invention relates to a water-based fluorine-containing polymer dispersed emulsion and a preparation method thereof. The method comprises the following steps: 1) adding deionized water, an initiator and an emulsifier into a high-pressure kettle, and introducing a fluorine-containing monomer mixture to carry out polymerization reaction, wherein a pH regulator is continuously added in the polymerization process to control the pH value of the polymerization system at 7-8; and 2) after the polymerization reaction finishes, adding a surfactant into the fluorine-containing polymer dispersed emulsion, and concentrating in a water bath, wherein the pH regulator is continuously added in the concentration process to keep the pH value of the concentration system at 7-8. The method effectively reduces the iron ion content in the emulsion, thereby reducing the scum of the fluorine-containing polymer dispersed emulsion, and effectively improving the appearance of the fluorine-containing dispersed emulsion. The added pH regulator can be effectively removed in the construction process, and thus, can not pollute the product.

Owner:ZHONGHAO CHENGUANG RES INST OF CHEMICALINDUSTRY CO LTD

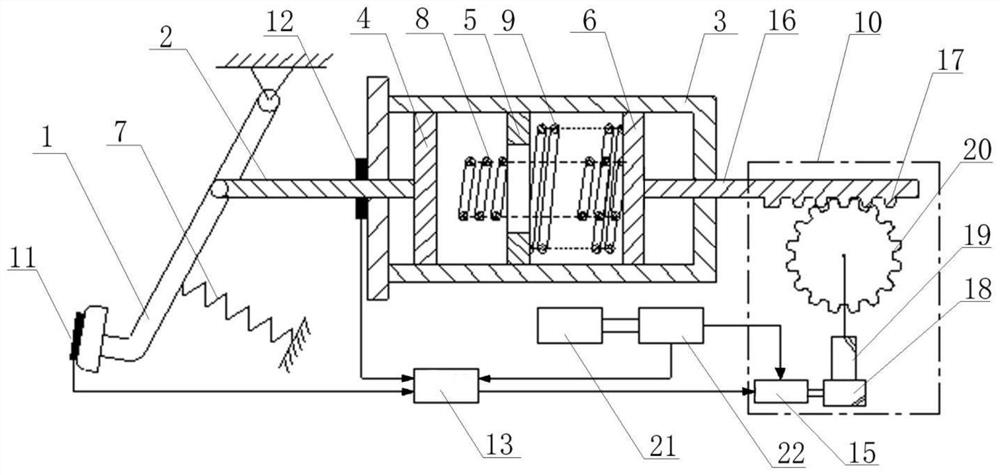

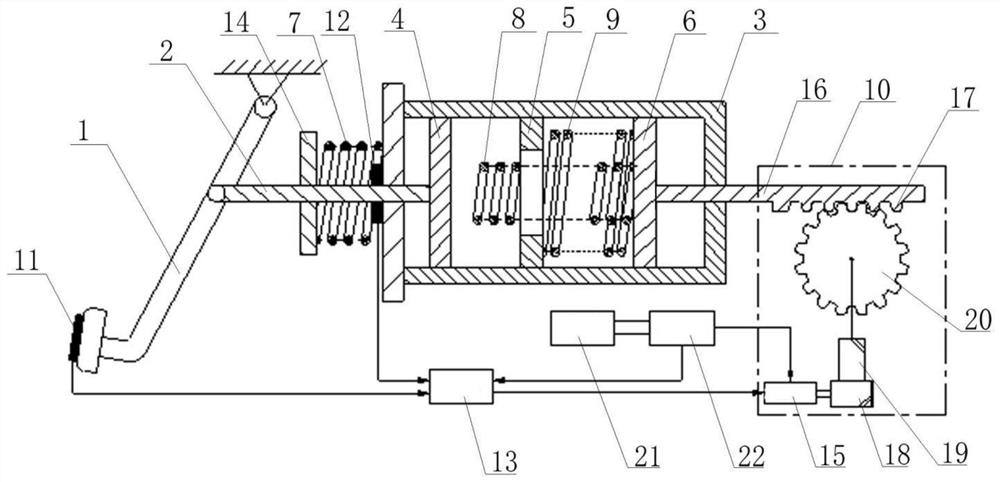

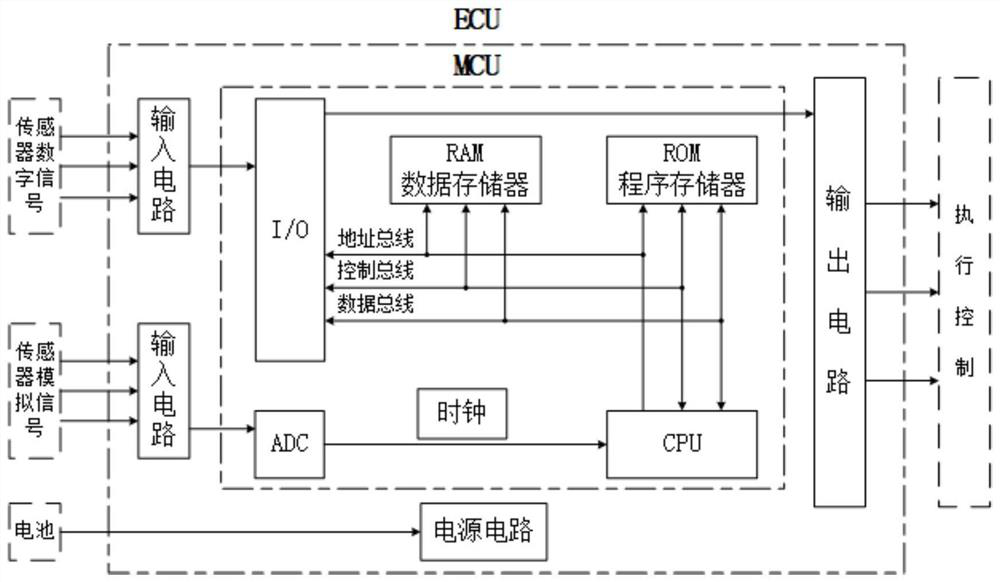

Pedal feeling simulator applied to brake-by-wire system and control method thereof

PendingCN112319444ASimple structureLow costBraking action transmissionFoot actuated initiationsDriver/operatorHierarchical cluster algorithm

Owner:JILIN UNIV

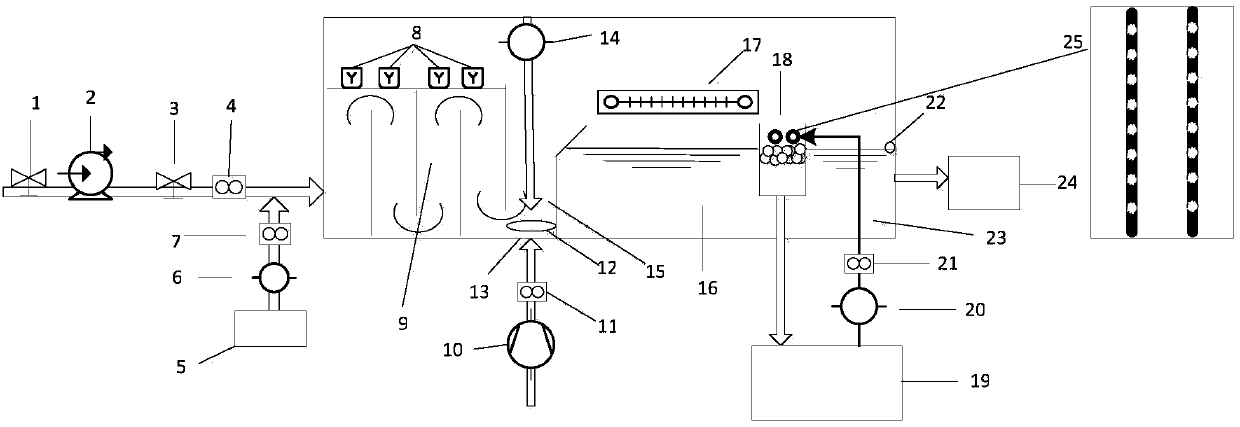

Air flotation treatment method for high-concentration salt-making brine

ActiveCN106219652BReduce chromaEfficient removalSeawater treatmentSpecific water treatment objectivesHigh concentrationSlag

The invention belongs to the field of salt preparation brine treatment, and particularly relates to a high-concentration salt preparation brine air floating treatment method. The method comprises four steps of 1, a water inlet and chemical adding stage; 2, a coagulation stage; 3, an air floating stage; 4, a slag scraping and defoaming stage. In the step 3, a microporous aerator is arranged in an air floating pool contact region; the pore diameter of the microporous aerator is smaller than or equal to 0.1mum; the aeration intensity is 1 to 3 Nm<3> / (m<2> / h); the water flowing speed in the aeration region is 5 to 9m / h; the contact time is 11 to 20min; after the air floating contact is completed, the materials enter an air floating separation region; the separation time is 40 to 75 min; after the upward floating of the floating slag, the floating slag is collected and enter a floating slag groove; the treated brine enters an air floating clean water region; the brine in the clean water region flows out through an overflowing opening and enters a water producing pool. The high-concentration salt preparation brine air floating treatment method has the advantages that the floating water producing particle diameter can be 1 to 1.5 mum; a great amount of colloid and suspension contaminants are effectively removed. The air floating treatment method is used, and the slat concentration of the salt preparation brine cannot be reduced.

Owner:TIANJIN MOTIMO MEMBRANE TECH

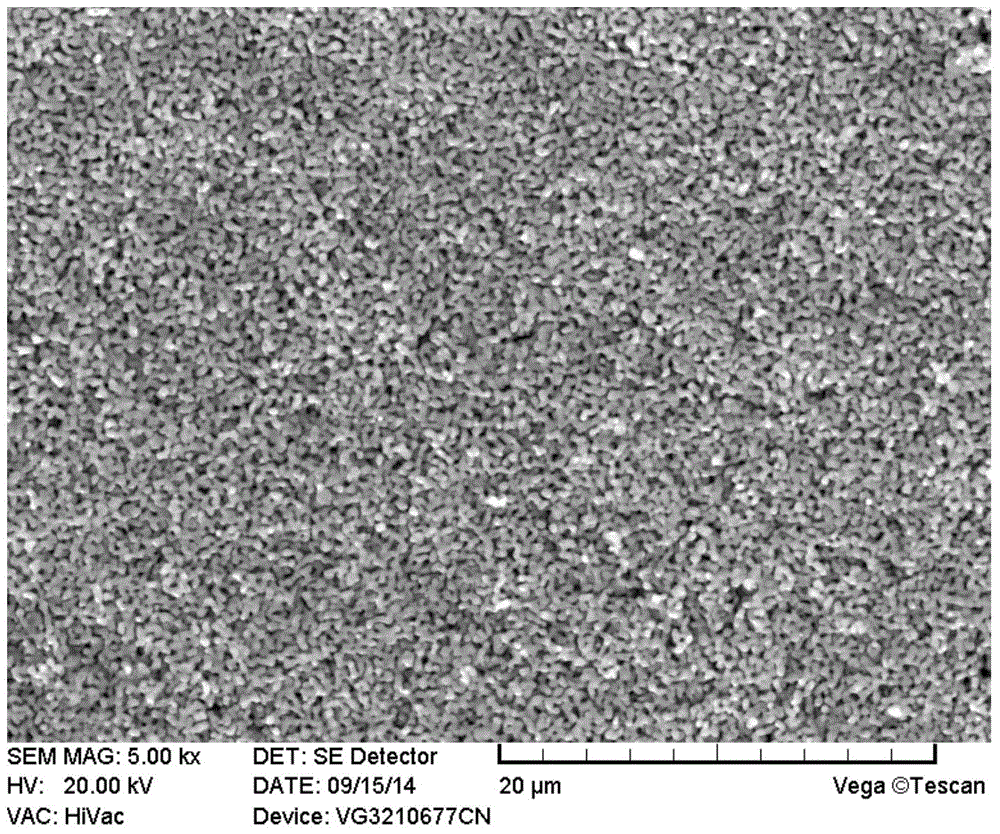

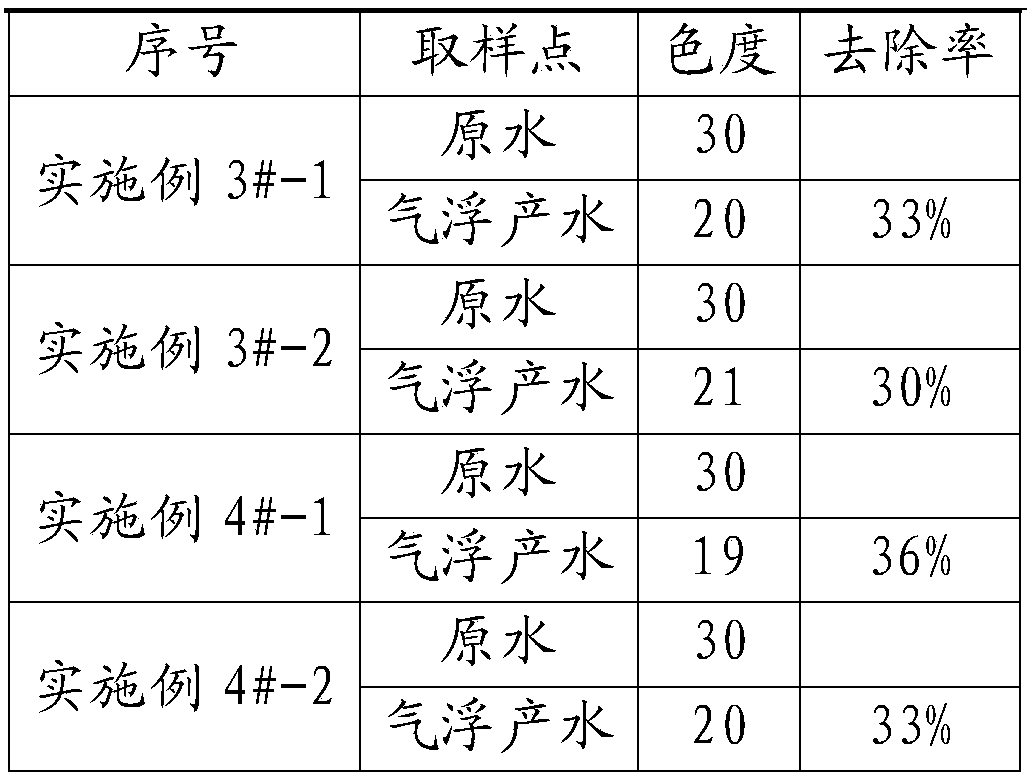

Preparation method of anisaldehyde

ActiveCN102050712BSmall particle sizeLarge specific surface areaOrganic compound preparationCarbonyl compound preparation by oxidationPtru catalystPhysical chemistry

The invention discloses a preparation method of anisaldehyde. The method comprises the following steps: by using anethole as a raw material, nano ferric oxide as a catalyst, hydrogen peroxide or sodium hypochlorite as an oxidant, and acetonitrile as a solvent, carrying out reaction at 30-90 DEG C; and after the reaction is finished, sucking out the catalyst (nano ferric oxide) by using a magneton, and drying the nano ferric oxide for repeated use. The method disclosed by the invention has the advantages of simple technique, mild reaction conditions, low cost, environmental friendliness and the like, and the catalyst can be easily separated and recycled.

Owner:SUN YAT SEN UNIV

Lithium battery liquid injection head

PendingCN113451715ACheap compositionSimple structureSecondary cell gas removalCell component detailsEngineeringMechanical engineering

The invention relates to a lithium battery liquid injection head, and the injection head comprises a liquid injection cavity, wherein one end of the liquid injection cavity is a sealed end, the other end of the liquid injection cavity is a liquid injection end, a liquid injection needle is installed in the liquid injection end and communicated with the interior of the liquid injection cavity, a vacuum cavity is installed outside the liquid injection end, a battery jar for accommodating a lithium battery is arranged at the outer end part of the vacuum cavity, a liquid outlet head of the liquid injection needle corresponds to a liquid injection hole in the lithium battery in position, and the liquid injection needle is communicated with the interior of the vacuum cavity; a liquid injection sealing rod used for sealing the liquid injection needle is arranged in the liquid injection cavity, and a driving piece is arranged at the outer end of the liquid injection sealing rod. The lithium battery liquid injection head has the advantages of simple structure, high liquid injection efficiency, good liquid injection effect and the like.

Owner:HUIZHOU DUOKEDA TECH

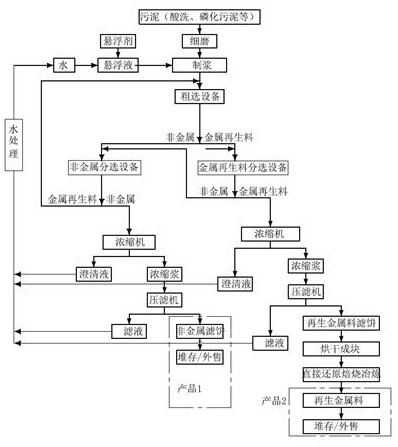

Novel sludge resource gradient utilization method

PendingCN113087322AEfficiently obtainedQuality improvementSludge treatmentProcess efficiency improvementSludgeProcess engineering

The invention relates to the technical field of comprehensive utilization (environmental protection) of resources, in particular to a novel sludge resource gradient utilization method. The technical scheme adopted by the invention is as follows: the method comprises the following steps: carrying out fine grinding treatment on collected sludge; jointly adding water, the sludge treated in the previous step and a suspending agent into a stirring tank, and fully mixing to prepare slurry; conveying the slurry into a pump pool, and then performing separation operation through a separation system, wherein the whole separation system adopts closed-loop circulation; and concentrating and filter-pressing the sorted silicate non-metal and metal regenerated material to prepare a filter cake. The method has the advantages that a brand new processing method is adopted, the sludge can be efficiently and thoroughly treated in a stepped treatment mode by adopting a step-by-step processing method, the processing cost is lower, the treatment effect is better, and the whole process is environment-friendly and pollution-free.

Owner:江苏锦明再生资源有限公司

Method for recovery of organic waste gas by pressure swing adsorption of adsorption resin assisted by nitrogen purge

ActiveCN104107621BLarge volume adsorption capacityNo chemical reactionDispersed particle separationSolubilityCollection system

The invention discloses a nitrogen purging-assisted organic exhaust gas recycling method through the pressure swing adsorption of adsorbent resin. The organic exhaust gas recycling method comprises the following steps: (1) adsorption, namely performing adsorption when exhaust gas including volatile organic compounds (VOCs) enters an adsorber filled with the macroporous adsorption resin by a gas collection system; (2) desorption, namely vacuumizing the adsorbent resin in the adsorber and purging the adsorbent resin by using nitrogen in an auxiliary manner to desorb the adsorbed VOCs from the adsorbent resin to obtain the desorbed gas; and (3) recycling, namely condensing or absorbing the desorbed gas to recycle the VOCs. The adsorbent adopted by the method disclosed by the invention is the macroporous adsorption resin, the surface of the macroporous adsorption resin has no catalytic performance and has the characteristics of being easy to regenerate, high in mechanical strength, great in volumetric adsorption capacity and the like. A adsorption technique assisted by nitrogen purging in vacuum at normal temperature is high in adsorption efficiency and has the very excellent recycling effect on VOCs gas which can be easily oxidized and hydrolyzed or is high in solubility.

Owner:NANJING UNIV

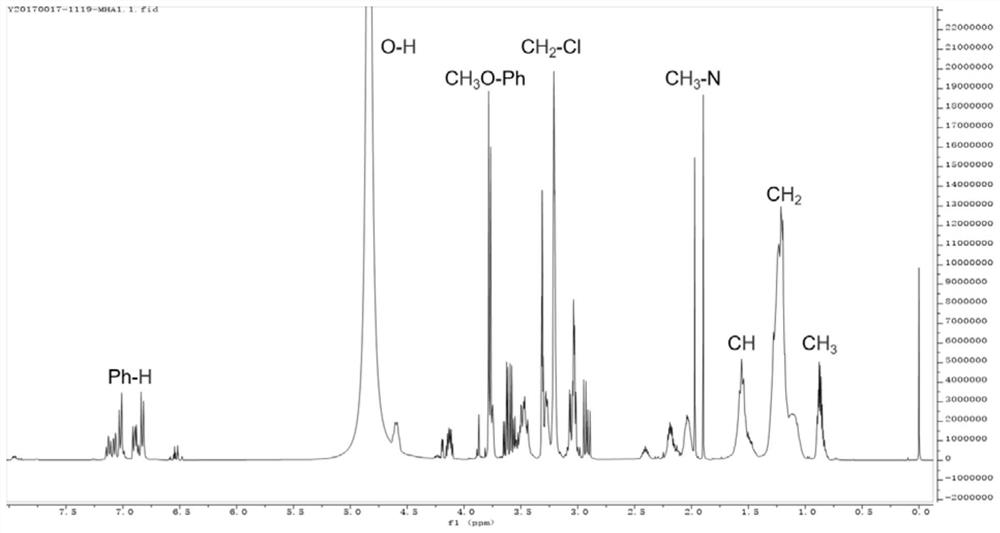

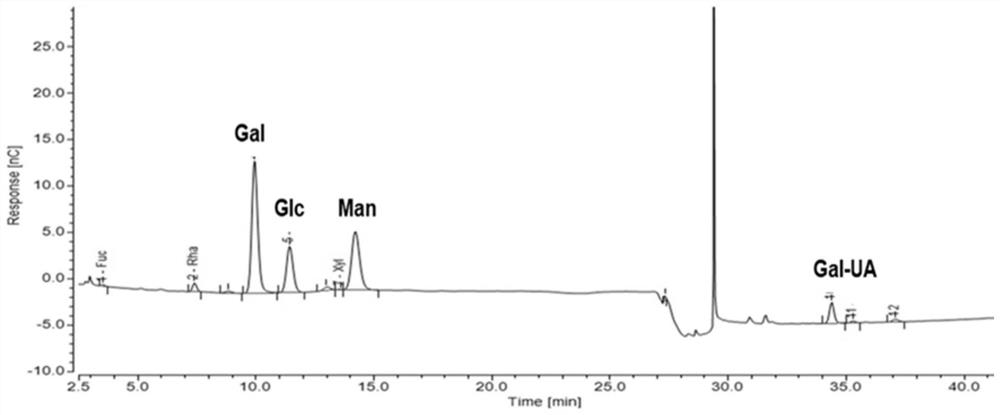

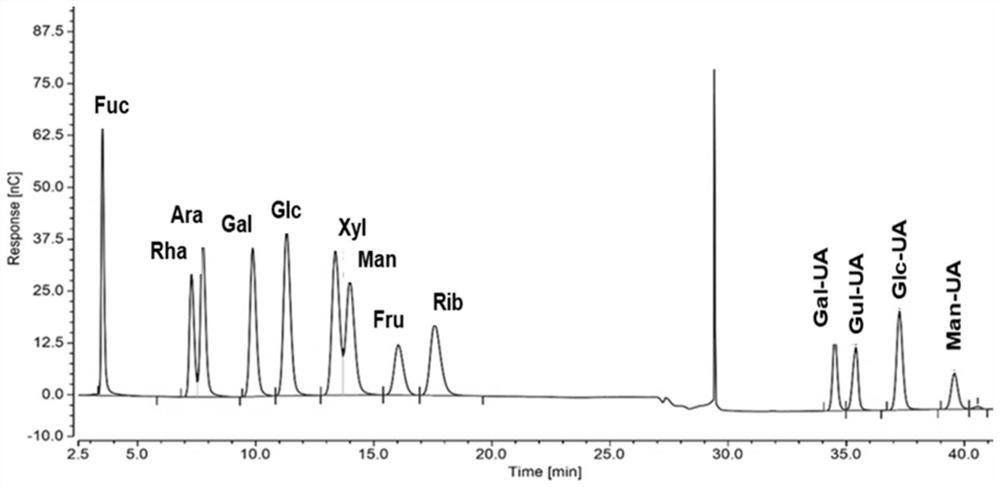

Binary oil displacement system containing bio-based surfactant and biopolymer and application of binary oil displacement system

ActiveCN114181687AGive full play to viscoelasticityGive full play to the interface activityOrganic compound preparationSulfonic acids salts preparationBiopolymerActive agent

The invention relates to a binary oil displacement system containing a bio-based surfactant and a biopolymer and application of the binary oil displacement system. The binary oil displacement system comprises 0.5-3.0 g / L of the bio-based surfactant and 1-3.0 g / L of the biopolymer. The biopolymer is a biopolymer HS-EPS which is extracted after the fermentation of the Ammomonas; the bio-based surface active agent is a benzyloxy-oleoyl quaternary amine type surface active agent. Compared with the prior art, the method has the advantages that the traditional oil displacement polymer polyacrylamide is replaced by the ammonia alcohol monad biopolymer with excellent salt tolerance, and the obtained binary compound oil displacement system can show ultralow interfacial tension and has better temperature resistance, NaCl resistance, Ca < 2 + > resistance, dilution resistance, adsorption resistance, interfacial tension and viscosity maintenance performance; the surfactant can be applied to high-salinity oil reservoirs, so that the application range of the benzyloxy-oleoyl quaternary amine type surfactant is effectively widened, and the recovery efficiency is further improved on the basis of the characteristic of ultralow interfacial tension.

Owner:EAST CHINA UNIV OF SCI & TECH

Sewage upper-layer floating foam suction device

InactiveCN112390326ASimple structureLow costFatty/oily/floating substances removal devicesLiquid separationSewageMechanical engineering

The invention discloses a sewage upper-layer floating foam suction device which comprises a frame, a panel fixedly connected to the frame and a lifter slidably connected into the panel. A collecting cavity with an upward opening, a lead screw cavity located on the right side of the collecting cavity and provided with a rightward opening, a piston cavity located on the lower side of the collectingcavity, a reciprocating cavity located in the lower cavity wall of the piston cavity and communicated with the piston cavity, and a translation cavity located on the lower side of the reciprocating cavity and provided with a downward opening are formed in the lifter. The reversing transmission cavity is located between the translation cavity and the reciprocating cavity, the speed reducer cavity is located on the right side of the reversing transmission cavity, the middle transmission cavity is located on the right side of the speed reducer cavity, and the lead screw input cavity is located onthe right side of the middle transmission cavity. Therefore, the device can be automatically adjusted to the height of the floaters only by placing the device in the sewage that needs to be treated,and the floaters are sucked into a special containing cavity in the device in a sucking mode to be treated in a centralized mode.

Owner:XINCHANG DELAO SEWAGE TREATMENT CO LTD

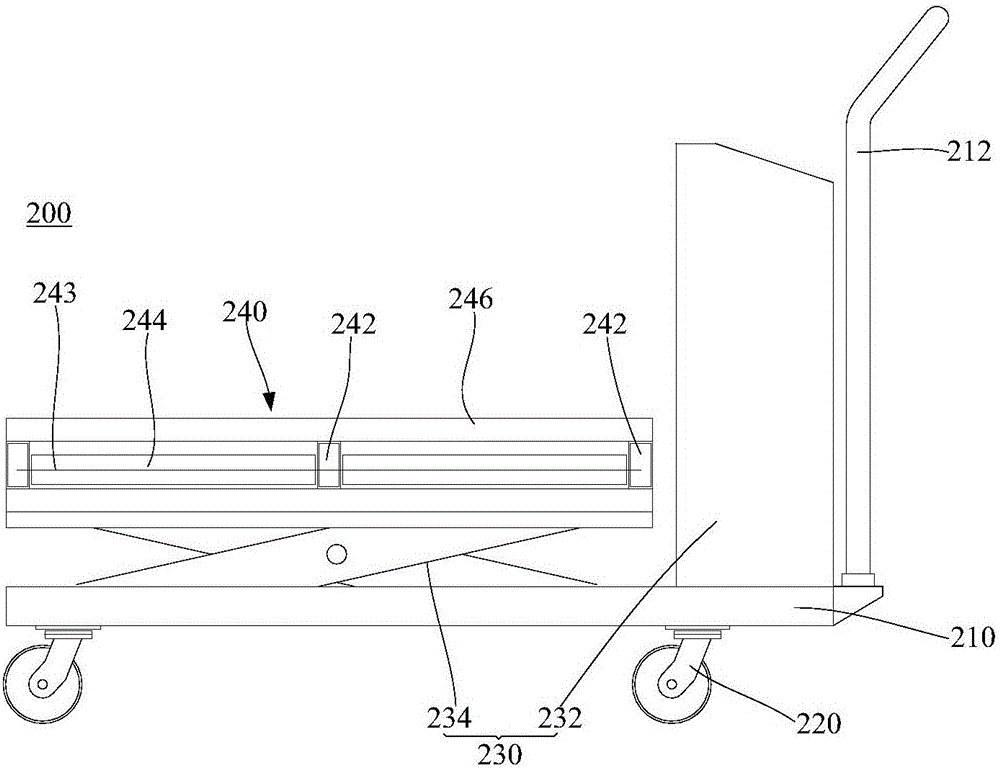

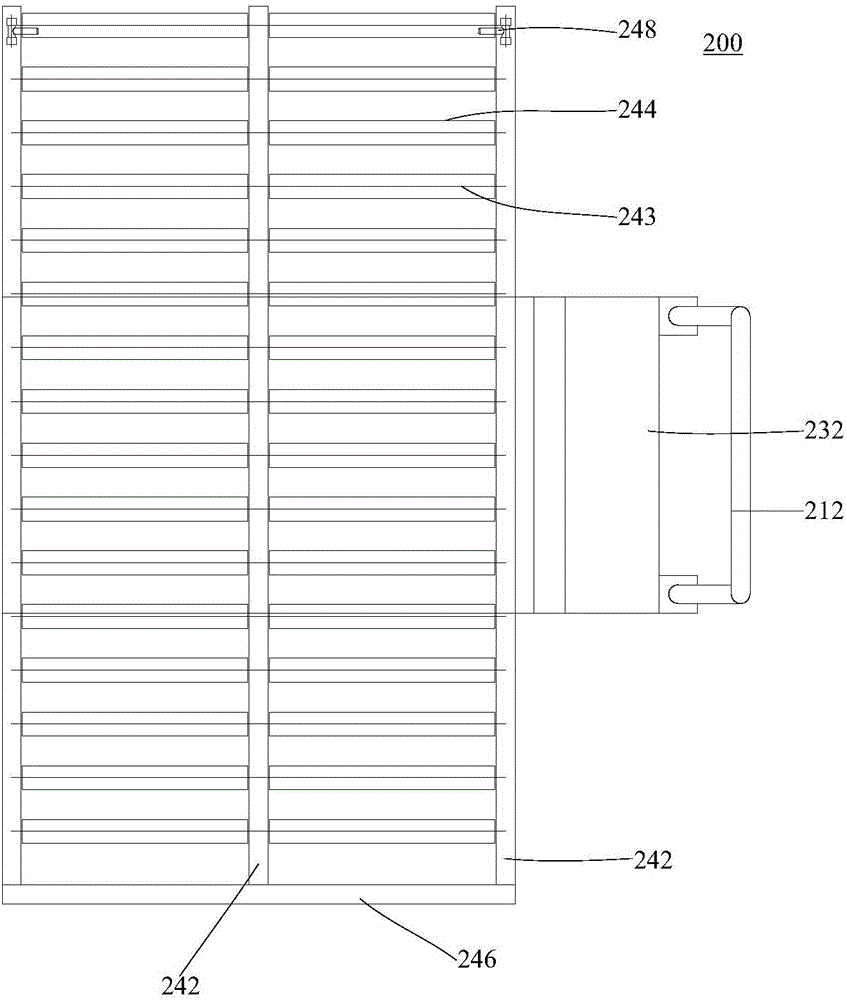

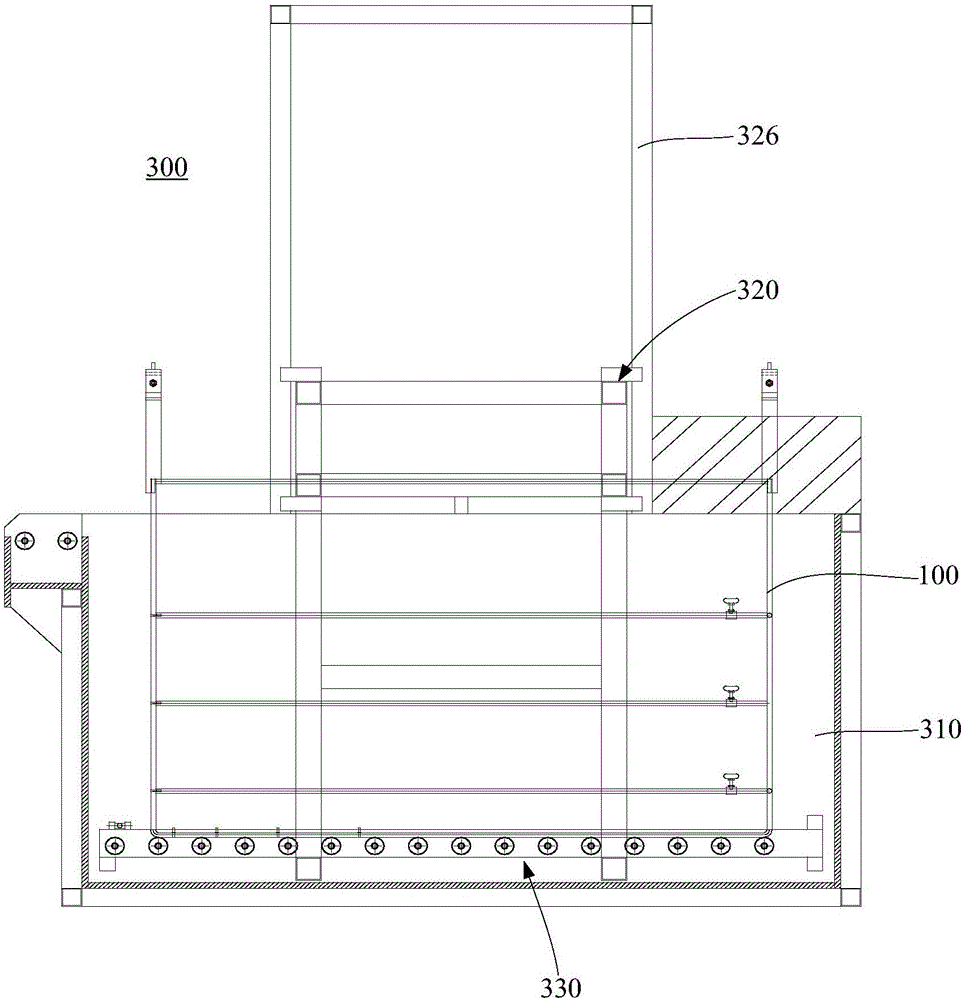

PCB conveying and curing system after copper plating

ActiveCN106744476AAvoid scratchesImprove yieldPrinted circuit liquid treatmentLifting framesElectricityCopper plating

The invention relates to a PCB conveying and curing system after copper plating. The system comprises a hanging basket, a conveying device and a board curing device. The PCB conveying and curing system after copper plating designs the conveying device; a conveying channel for conveying the hanging basket of the conveying device can be lifted; and a hanging basket placing position in the board curing device can be ascended or descended in a board curing tank, so that the conveying channel can be controlled to be in butt joint with the hanging basket placing position. The PCB conveying and curing system after copper plating needs no manual operation to hoist the hanging basket in the whole board unloading, curing and electric loading process, saves both time and labors, and is safe and reliable; and when boards are electrically loaded, production board can be taken out in sequence, so that the scratch of the production boards can be effectively prevented, and the product yield is increased.

Owner:GCI SCI & TECH

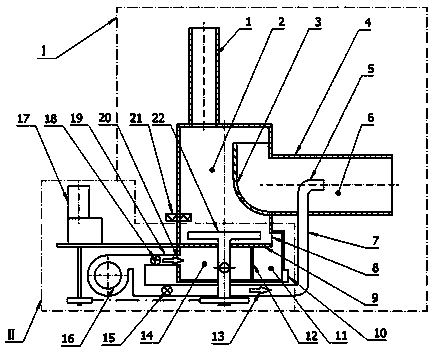

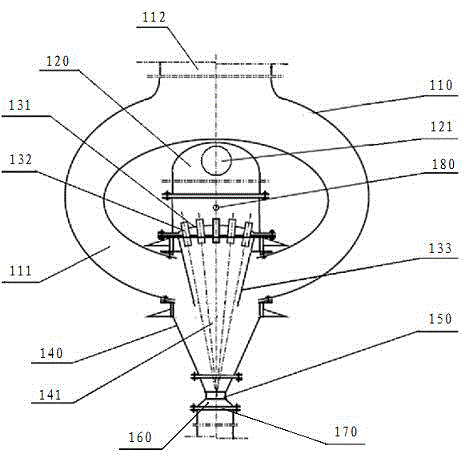

Biomass particle combustion apparatus and combustion method for same

ActiveCN102345862BEffective temperature controlSolve problems such as easy slaggingSolid fuel combustionNon-combustible gases/liquids supplyEngineeringHearth

The invention discloses a biomass particle combustion apparatus and a combustion method for the same. The apparatus comprises a vertical type hearth, a feeding pipe is arranged above the hearth, the feeding pipe is connected with an external charging device, and the hearth is internally provided with an ignition device. The apparatus is characterized in that the hearth is internally provided with an ash damper; a rotary ash fork is arranged at the center of a flat furnace bottom plate at the bottom of the hearth; an ash falling port communicated with an ash box is arranged at the bottom side face of the hearth right below the ash damper; one side of the hearth is provided with a fire tube communication port connected with an internally communicated fire tube so as to form a combustion area, the bottom and both sides of the ash damper are all connected with the internal wall of the hearth, the bottom of the ash damper extends upwards from the lower end of the fire tube communication port and the top of the ash damper is higher than the upper end of the fire tube communication port, and a secondary air spray pipe communicated with a secondary air channel is arranged in the fire tube.

Owner:山东永能生物热电有限公司

Condensable gaseous substance recycling method and condensable gaseous substance recycling system suitable for tail gas and exhaust gas

ActiveCN104874198AIncrease temperatureDoes not affect recoveryVapor condensationLiquid jetPower station

The invention discloses a condensable gaseous substance recycling method and a condensable gaseous substance recycling system suitable for tail gas and exhaust gas. According to the method, steam or other gaseous substances which are naturally separated from smoke / dust and are positioned above a discharging opening are introduced into a gas delivery pipe through a gas collecting hood positioned above industrial furnace / tower tail gas or smoke discharging opening, the steam or other gaseous substances coming from the gas delivery pipe are mixed with jet water or jet flows of other liquid flow through a liquid-gas mixer, the steam and other gaseous substances are converted into liquid water or other liquid flows to be recycled, and the liquid-gas mixer is used for sucking the steam or other gaseous substances in the gas delivery pipe by negative pressure formed by water or other liquid jet flows. The system comprises the gas collecting hood, the gas delivery pipe, the liquid-gas mixer and a pressurizing circulation pipeline. According to the invention, the structure is simple, the operation is convenient, and the handling capacity is high, and the method and system are not only suitable for the recycling of industrial dead steam or other gaseous substances, but also is particularly suitable for the recycling of steam in smoke of a power station boiler.

Owner:山东阳信兴业油脂化工有限公司

A Downhole Optical Fiber Vortex Flowmeter

InactiveCN105352558BAvoid problems such as corrosionHigh sensitivityVolume/mass flow by dynamic fluid flow effectFiberGrating

The present invention discloses an underground optical fiber vortex-shedding flowmeter and an underground flow measuring method, and aims to solve the problems, of low measuring precision and poor stability, caused by situations that optical fibers are influenced by fluid corrosion and that measuring elements influence a flow field and flow inside a pipeline in a conventional flowmeter, and the problem that the conventional optical fiber flowmeter is complex in structure and cannot be used in high-temperature, high-voltage and high-erosion environments. An upper joint, a central tube and a lower joint are connected from top to bottom in turn, a housing sleeves an outer side wall of the central tube, a vortex shedder is arranged inside the central tube, a through hole is formed in the middle part of the outer side wall of the central tube, a probe is installed inside the through hole through a pressing plate, a central shaft is inserted inside the probe, a fiber bragg grating is arranged inside the central shaft, and one end of an armored cable is connected with the fiber bragg grating while the other end of the armored cable is connected with a fiber bragg grating demodulation instrument. The underground optical fiber vortex-shedding flowmeter is applied to the oil field equipment field.

Owner:HARBIN INST OF TECH

Sludge activated carbon with continuous pore size distribution and preparation method thereof

ActiveCN106560236BReduce lossesIncrease K

<sup>+</sup>

contentOther chemical processesCarbon compoundsActivated sludgeWater vapor

The invention discloses sewage treatment sludge active carbon having continuous pore size distribution, and a preparation method thereof. According to the preparation method, ZnCl2, phosphoric acid, K2S and NaCl form a compound activator in anoxic atmosphere to activate sludge, wherein the mesoporous structure is developed mainly by using the phosphoric acid, and the K<+> content and the Na<+> content of the sludge active carbon are increased so as to easily enhance the replacement with heavy metal ions in sewage; and activation is performed with water vapor to generate rich micro-pores in the mesoporous surface, such that the BET specific surface area of the finally obtained sludge active carbon is not less than 400 m<2> / g, and the pore size is continuously distributed within 0.5-50 nm. According to the present invention, the prepared sludge active carbon adopted as the sewage treatment adsorbent adsorbs heavy metal ions using Pb<2+> as the representative and macromolecular pollutants in the sewage, and has good effects.

Owner:TIANJIN CHENGJIAN UNIV

A method for preparing porous oxide film on the surface of metal carrier

ActiveCN104630771BGood film formingAvoid problems such as corrosionMetallic material coating processesElectrochemical responseSlurry

The invention discloses a method for preparing a porous oxide film on the surface of a metal carrier. The method comprises the following steps: 1. performing surface treatment on the metal carrier to remove oxide scale and impurities on the surface of the metal carrier; 2. according to the porous oxide film to be prepared Select oxides and oxide sols, and then mix the raw materials uniformly to make a slurry; 3. Coat the slurry on the surface of the surface-treated metal carrier; 4. After drying, place it in a sintering furnace and keep warm in a reducing atmosphere After sintering, a porous oxide film with a thickness of not more than 100 μm is obtained on the surface of the metal carrier after cooling in the furnace. The method improves the film-forming properties of the porous oxide on the surface of the metal carrier during the film-forming process, avoids problems such as corrosion caused by the electrochemical reaction caused by the use of the hydrosol system during the drying of the film, and shortens the process time for drying the film. , and the sintering temperature of the film layer is reduced, and the prepared porous oxide film is well combined with the metal matrix.

Owner:WESTERN BAODE TECH CO LTD

Surface activating method of medical metal material

InactiveCN100383291CAvoid impact on mechanical propertiesAvoid problems such as corrosionElectrolytic inorganic material coatingSupporting electrolytePhosphate

A surface-active method of metal material for medical use. It adopts three poles system. Negative pole is metal material. Positive pole is inert material. Fit them and reference electrode to electrolyte solution containing supported electrolyte solution. Soluble calcium salt and phosphate at pH2.5-6.5.Hold negative potential to be at -1 to -4V by way of constant potential or apply to electronic current 1-5Ma at constant value for 2 to 20min. Get sample of negative pole, wash and dry it.

Owner:SICHUAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com