Preparation method, product and application of nitrogen-phosphorus co-doped porous carbon material

A porous carbon material, co-doping technology, applied in chemical instruments and methods, carbon compounds, inorganic chemistry, etc., can solve the problems of device activator corrosion, product pollution, activator "consumption", etc., to avoid environmental pollution, preparation The method is simple and the effect of avoiding equipment corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] A nitrogen-phosphorus co-doped porous carbon material, using phytic acid and filamentous biomass materials as raw materials, adopts a high-temperature sintering method to prepare a nitrogen-phosphorus co-doped porous carbon material, which is prepared according to the following steps:

[0018] Mix silkworm cocoons and phytic acid in an aqueous solution at a mass ratio of 1:1.5, place them in an oven for drying, transfer the dried materials into a high-temperature tube furnace, and raise the temperature to 900°C at a rate of 5°C / min , and keep it warm for 2 hours. After cooling down to room temperature naturally, take out the sintered material, wash it with dilute nitric acid, and finally wash it with deionized water to obtain a nitrogen-phosphorus co-doped porous carbon material.

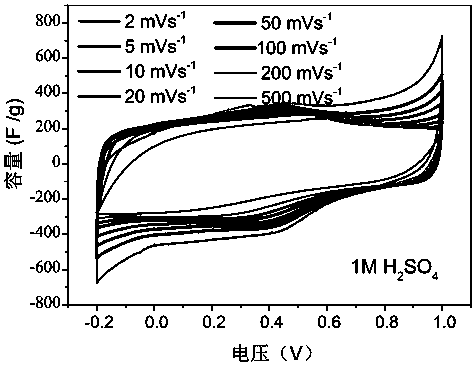

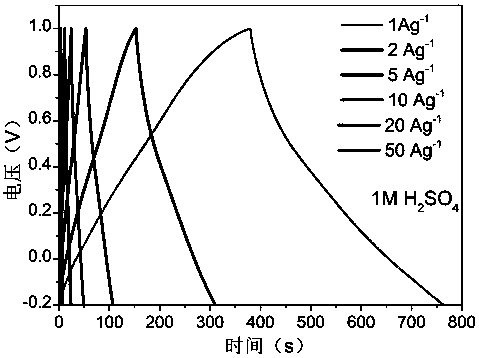

[0019] figure 1 is the cyclic voltammetry of the nitrogen-phosphorus co-doped porous carbon material obtained in this example. It can be concluded from the cyclic voltammetry that the capacit...

Embodiment 2

[0022] A nitrogen-phosphorus co-doped porous carbon material, prepared according to the following steps:

[0023] Mix wool fiber and phytic acid in an aqueous solution at a mass ratio of 1:0.5, place them in an oven to dry, and transfer the dried material to a high-temperature tube furnace, and raise the temperature to 900 °C at a rate of 10 °C / min. ℃, and keep it warm for 2 hours. After cooling down to room temperature naturally, the sintered material was taken out, washed with dilute nitric acid, and finally washed with deionized water to obtain a nitrogen-phosphorus co-doped porous carbon material.

Embodiment 3

[0025] A nitrogen-phosphorus co-doped porous carbon material, prepared according to the following steps:

[0026] Mix cotton and phytic acid in an aqueous solution at a mass ratio of 1:1, place them in an oven to dry, and transfer the dried material to a high-temperature tube furnace, and raise the temperature to 900°C at a rate of 10°C / min , and keep it warm for 2 hours. After cooling down to room temperature naturally, take out the sintered material, wash it with dilute nitric acid, and finally wash it with deionized water to obtain a nitrogen-phosphorus co-doped porous carbon material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com