Nitrogen purging-assisted organic exhaust gas recycling method through pressure swing adsorption of adsorbent resin

A technology of nitrogen purging and resin adsorption, applied in separation methods, chemical instruments and methods, and separation of dispersed particles, can solve the problems of low regeneration efficiency, achieve the effects of small footprint, avoid side reactions, and easy regeneration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

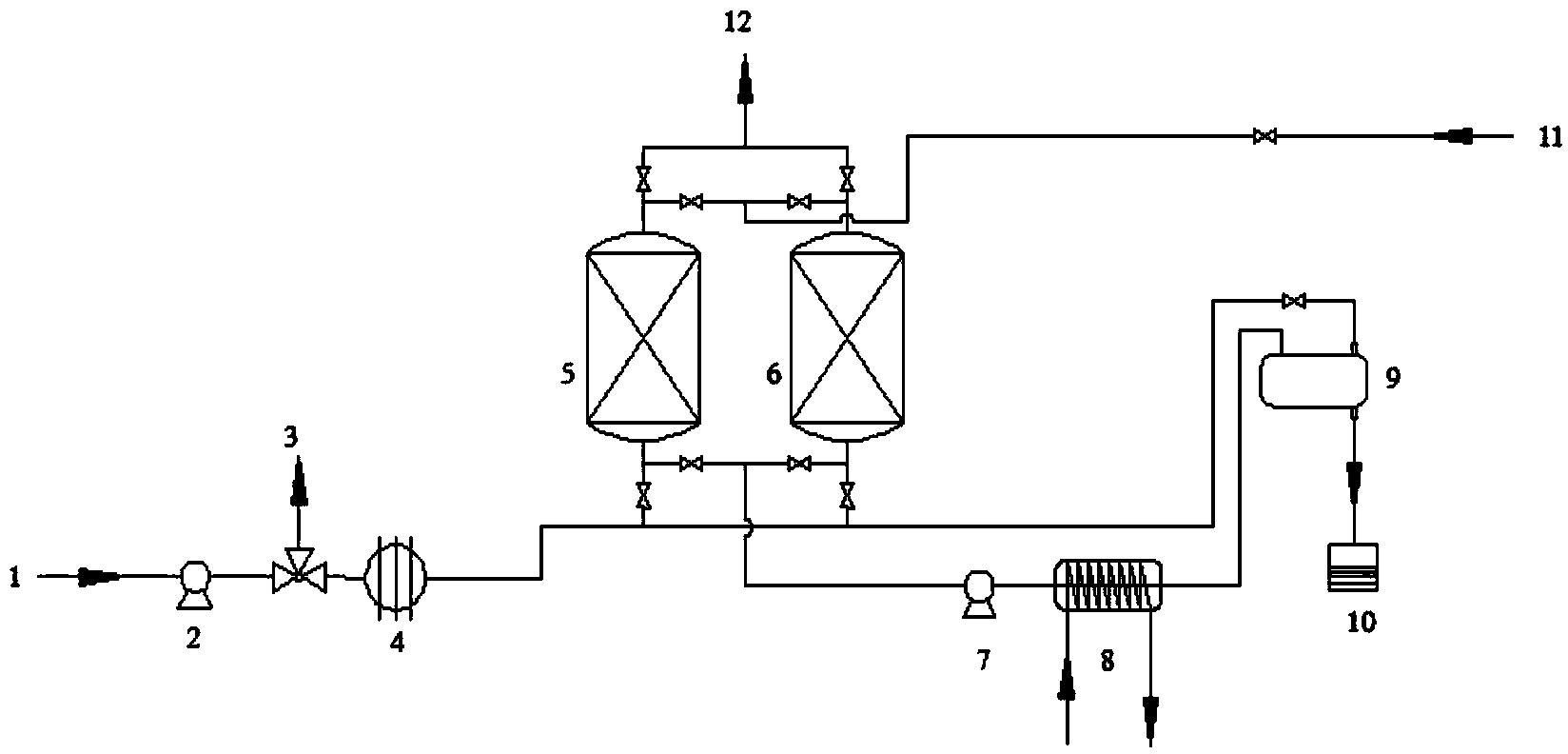

Method used

Image

Examples

Embodiment 1

[0032] The main parameters for the treatment of ethyl acetate waste gas are: the air volume of the induced draft fan is 80CMH, and the intake concentration of ethyl acetate is 5g / m 3 , the intake air temperature is normal temperature, and the pressure is normal pressure. The diameter of the adsorber is DN=180mm, and the adsorbent is AMBERLITE TM For XAD4 resin, the filling height is H=300mm, the adsorption time is 90min, the vacuum desorption vacuum pumping time is 20min, and nitrogen is flushed every 5min for 1min while vacuuming, and the condenser uses 5°C frozen brine. The content of ethyl acetate in the exhaust gas after treatment is about 150mg / m 3 , 9.3Kg of ethyl acetate was recovered in 24h, and the recovery rate was 96.9%.

Embodiment 2

[0034] The desorption conditions in Example 1 were changed to vacuuming by a single vacuum pump without nitrogen purging, and other conditions remained unchanged. The content of ethyl acetate in the exhaust gas after treatment is about 730mg / m 3 , 8.2Kg of ethyl acetate was recovered in 24h, and the recovery rate was 85.4%.

Embodiment 3

[0036] Change the ethyl acetate gas in embodiment 1 to 5g / m 3 Toluene gas, other conditions remain unchanged. The content of toluene in the tail gas after treatment is about 170mg / m 3 , 9.48Kg of ethyl acetate was recovered in 24h, and the recovery rate was 98.8%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com