Foam water-drainage agent and its aqueous solution

A technology of foam drainage agent and aqueous solution, which is applied in the field of foam drainage agent, gas field foam drainage agent and its aqueous solution to achieve the effects of good biodegradability, prolonging life cycle and high resistance to salinity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

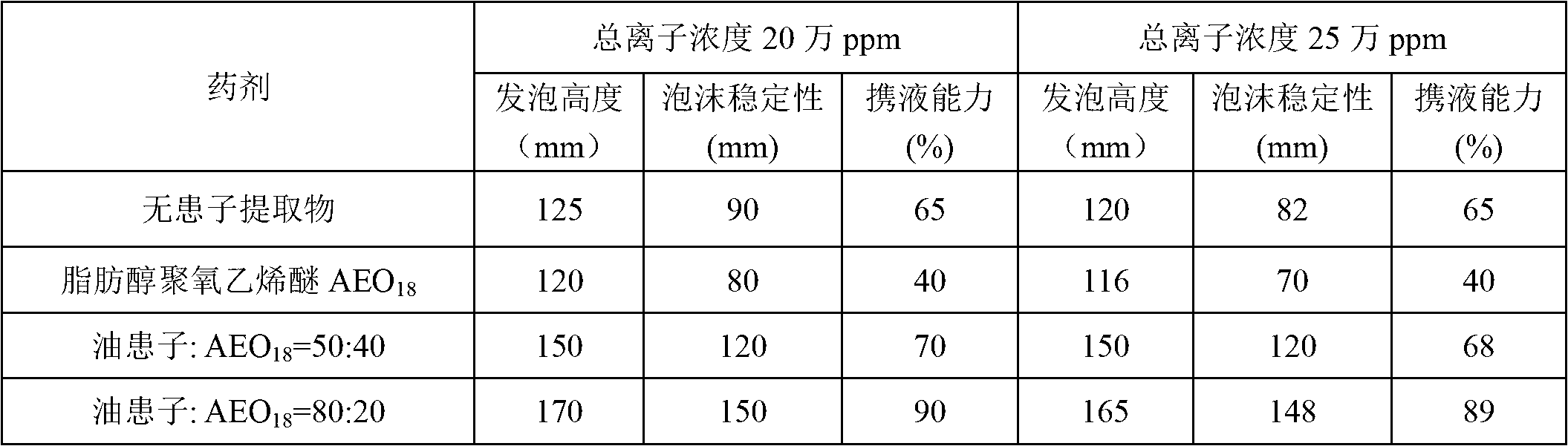

Method used

Image

Examples

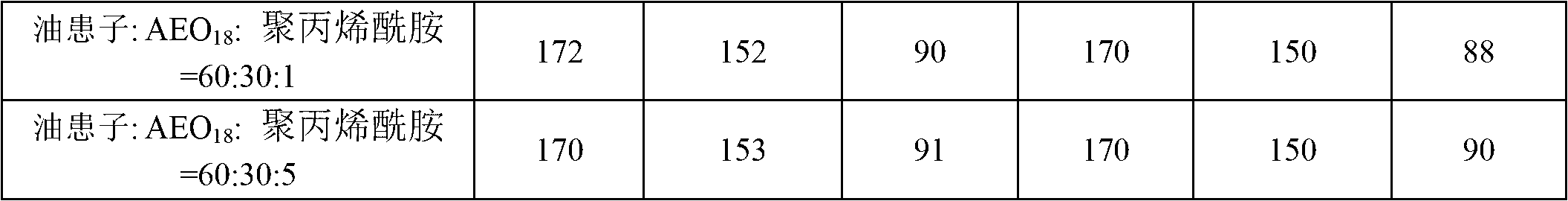

Embodiment 1

[0027] The foam drainage agent of this embodiment is composed of the following components in parts by weight: 50 parts of Sapindus chinensis extract, fatty alcohol polyoxyethylene ether AEO 18 20 parts, 1 part of polyacrylamide, 5 parts of triethanolamine.

[0028] The preparation method of the extract of Sapindus chinensis comprises the following steps: (1) Accurately weigh 100 parts by weight of the whole fruit of Sapinsia chinensis, crush it, add 300 parts by weight of water, and soak it at 80° C. for 36 hours; (2) in step (1) Add 2 parts by weight of polyaluminum sulfate to the soaked solution to flocculate for 12 hours, and after flocculation, take the supernatant and concentrate until the water content is 3% to obtain the Sapindus chinensis extract.

[0029] The aqueous solution of the foam drainage agent in this embodiment is respectively composed of 2.0%, 3.0%, 4.0%, 5.0%, and 6.0% of the volume percentage of the foam drainage agent and the remaining water.

Embodiment 2

[0031] The foam drainage agent of this embodiment is composed of the following components in parts by weight: 70 parts of Sapindus chinensis extract, fatty alcohol polyoxyethylene ether AEO 18 30 parts, 3 parts of polyacrylamide, 8 parts of triethanolamine.

[0032] The preparation method of the extract of Sapindus chinensis comprises the following steps: (1) Accurately weigh 100 parts by weight of the whole fruit of Sapinsia sativa, crush it, add 300 parts by weight of water, and soak it at 90° C. for 48 hours; (2) in step (1) Add 2 parts by weight of polyaluminum sulfate to the soaked solution to flocculate for 18 hours, and after flocculation, take the supernatant and concentrate until the water content is 2.5% to obtain the Sapindus chinensis extract.

[0033] The aqueous solution of the foam drainage agent in this embodiment is respectively composed of 2.0%, 3.0%, 4.0%, 5.0%, and 6.0% of the volume percentage of the foam drainage agent and the remaining water.

Embodiment 3

[0035] The foam drainage agent of this embodiment is composed of the following components in parts by weight: 80 parts of Sapindus chinensis extract, fatty alcohol polyoxyethylene ether AEO 18 40 parts, 5 parts of polyacrylamide, 10 parts of triethanolamine.

[0036] The preparation method of the extract of Sapindus chinensis comprises the following steps: (1) Accurately weigh 100 parts by weight of the whole fruit of Sapinsia sativa, crush it, add 300 parts by weight of water, and soak it at 100°C for 72 hours; (2) in step (1) Add 2 parts by weight of polyaluminum sulfate to the soaked solution to flocculate for 24 hours, and after flocculation, take the supernatant and concentrate to a water content of 4% to obtain the Sapindus chinensis extract.

[0037] The aqueous solution of the foam drainage agent in this embodiment is composed of 2.0%, 3.0%, 4.0%, 5.0%, and 6.0% of the volume percentage of the foam drainage agent and the remaining water.

PUM

| Property | Measurement | Unit |

|---|---|---|

| water content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com