Patents

Literature

281 results about "FOAM CONTROL" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Carbon dioxide sequestration in foamed controlled low strength materials

InactiveUS20060185560A1Improve the environmentEasy to useProductsReagentsCombustion chamberMaterials science

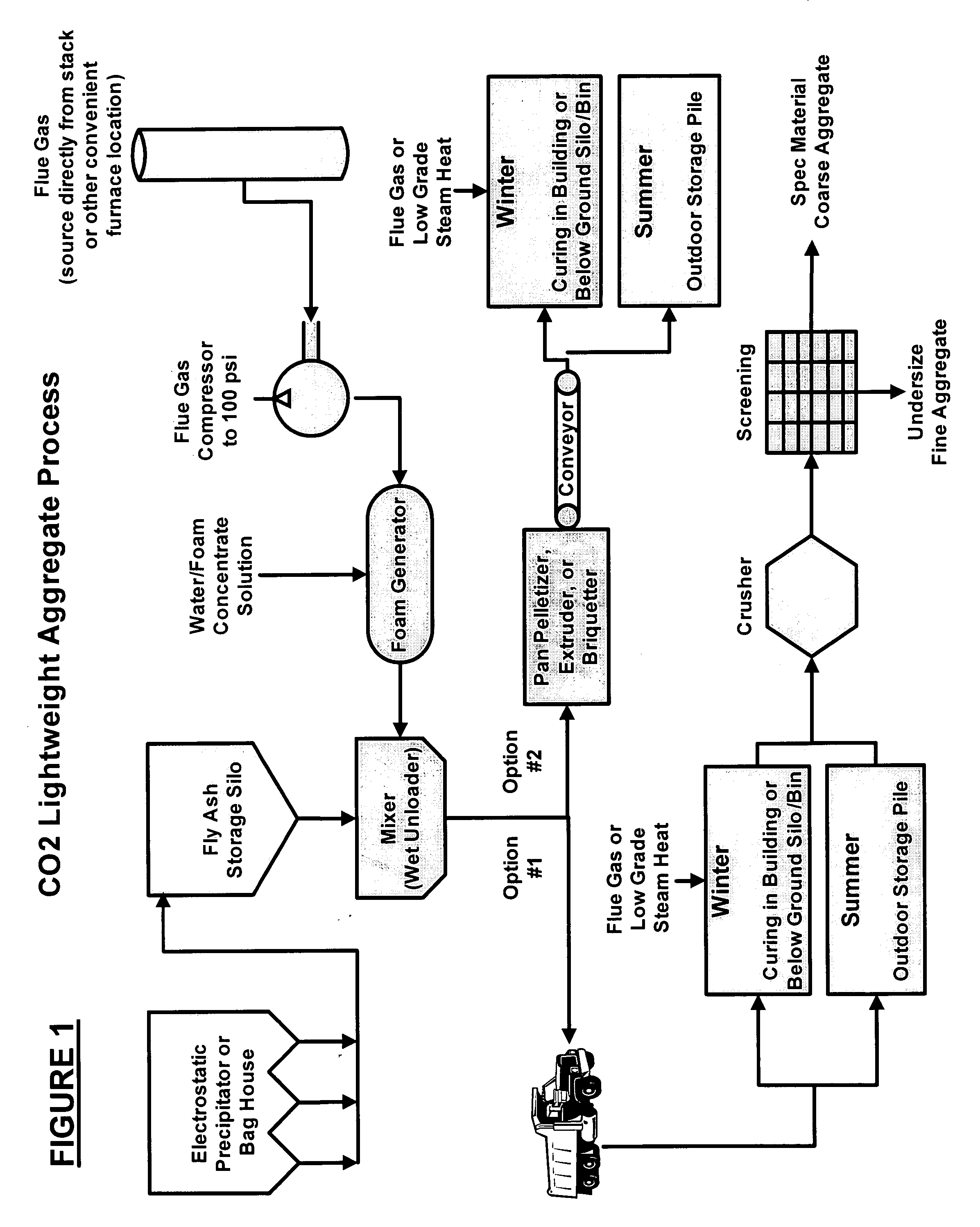

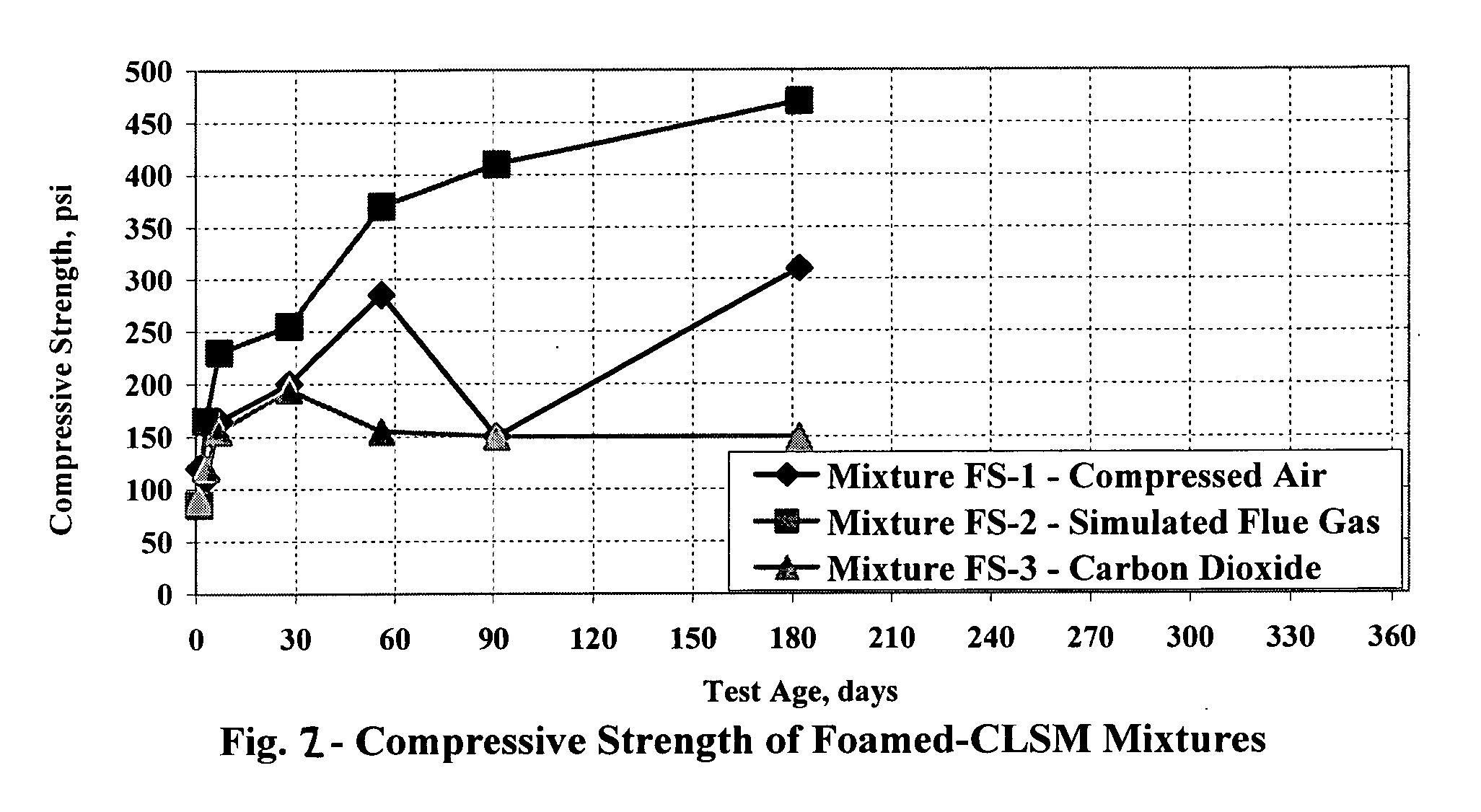

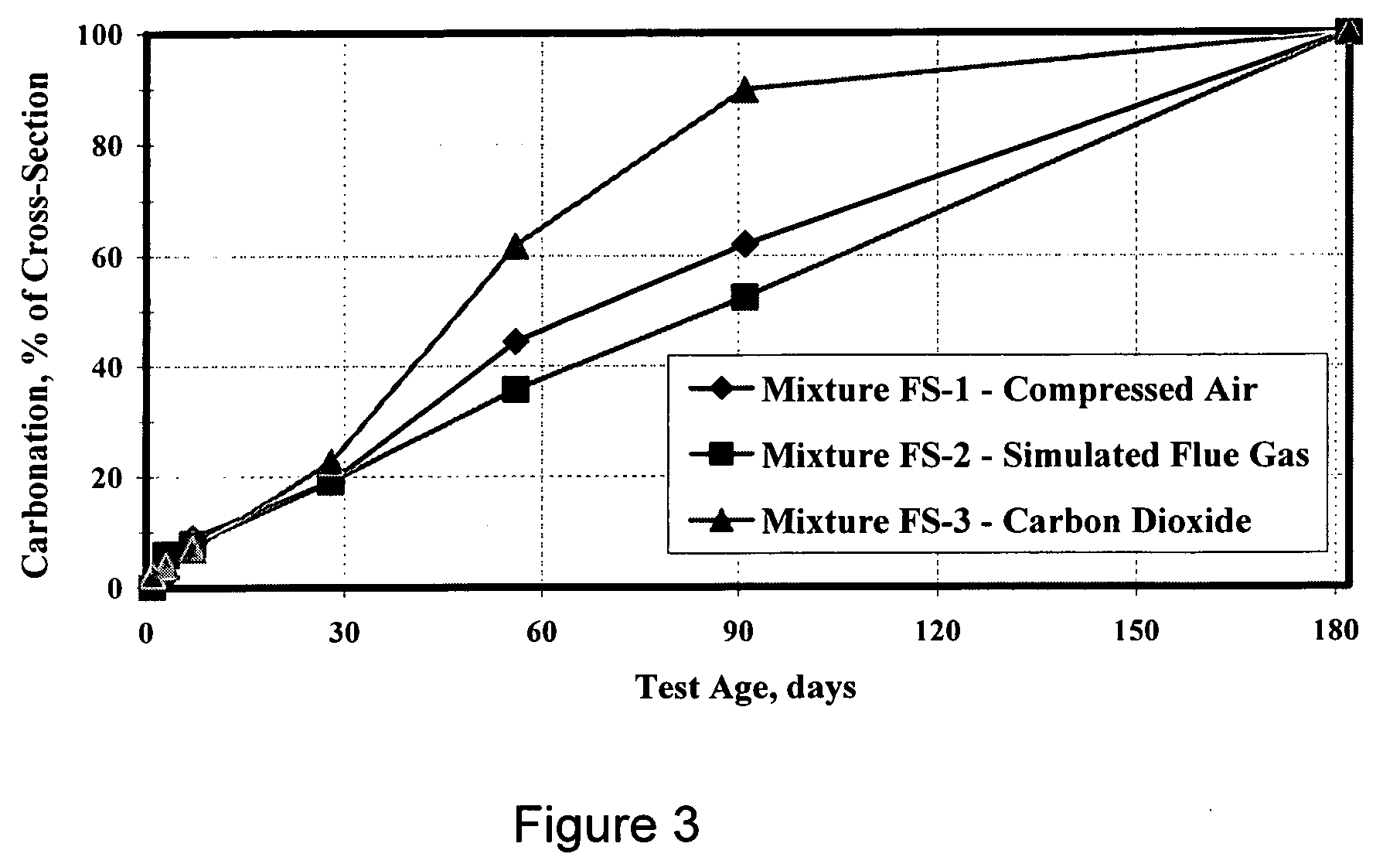

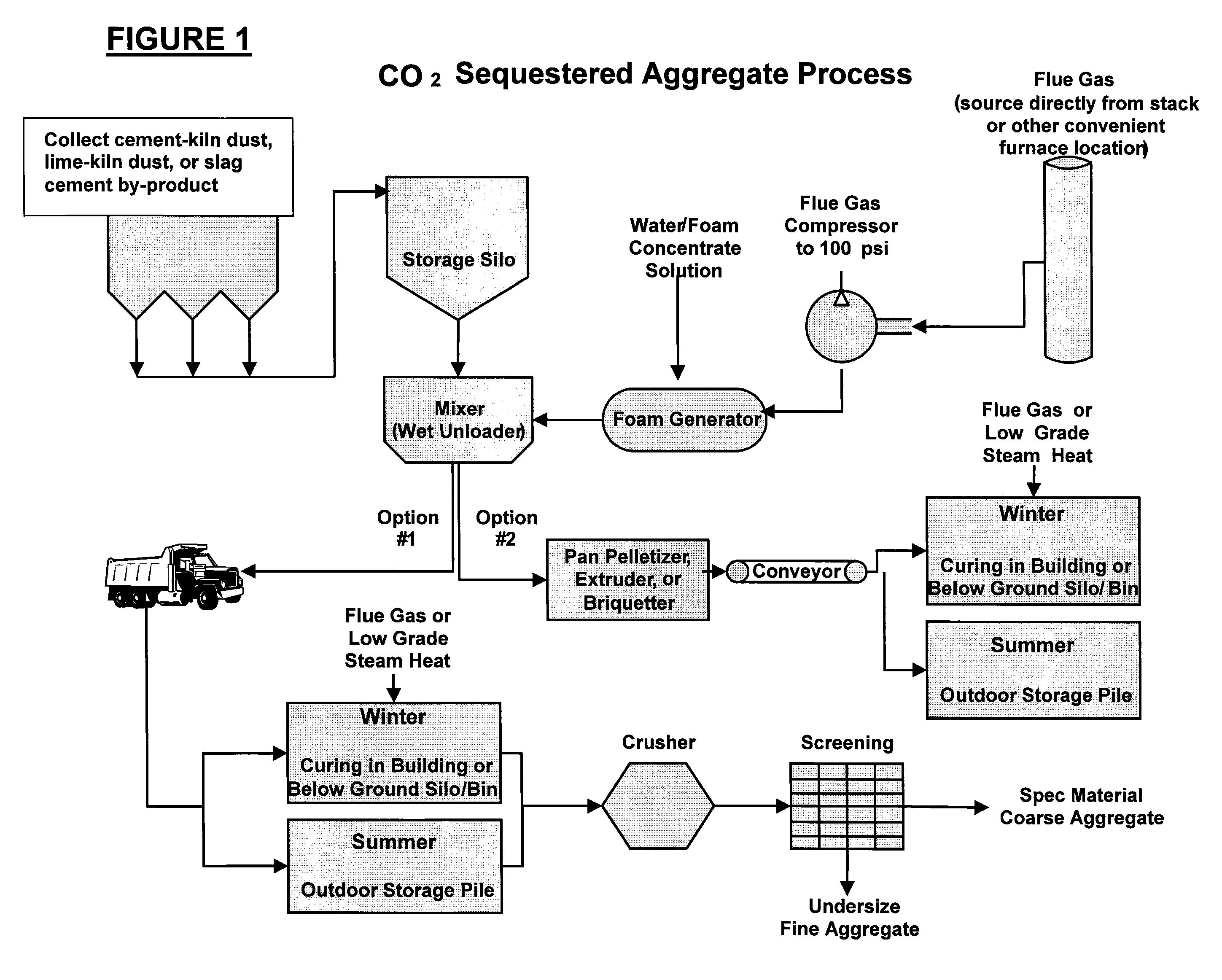

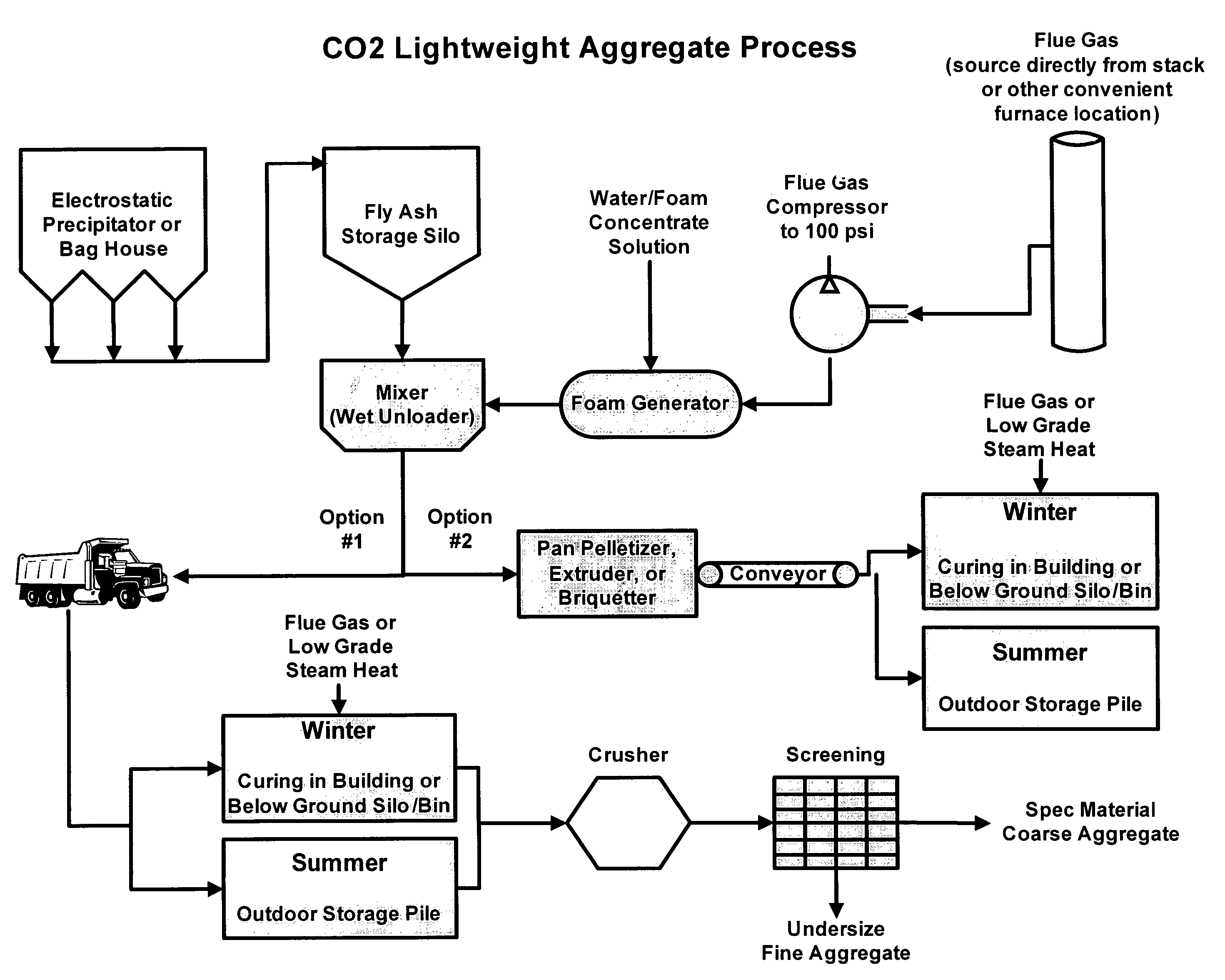

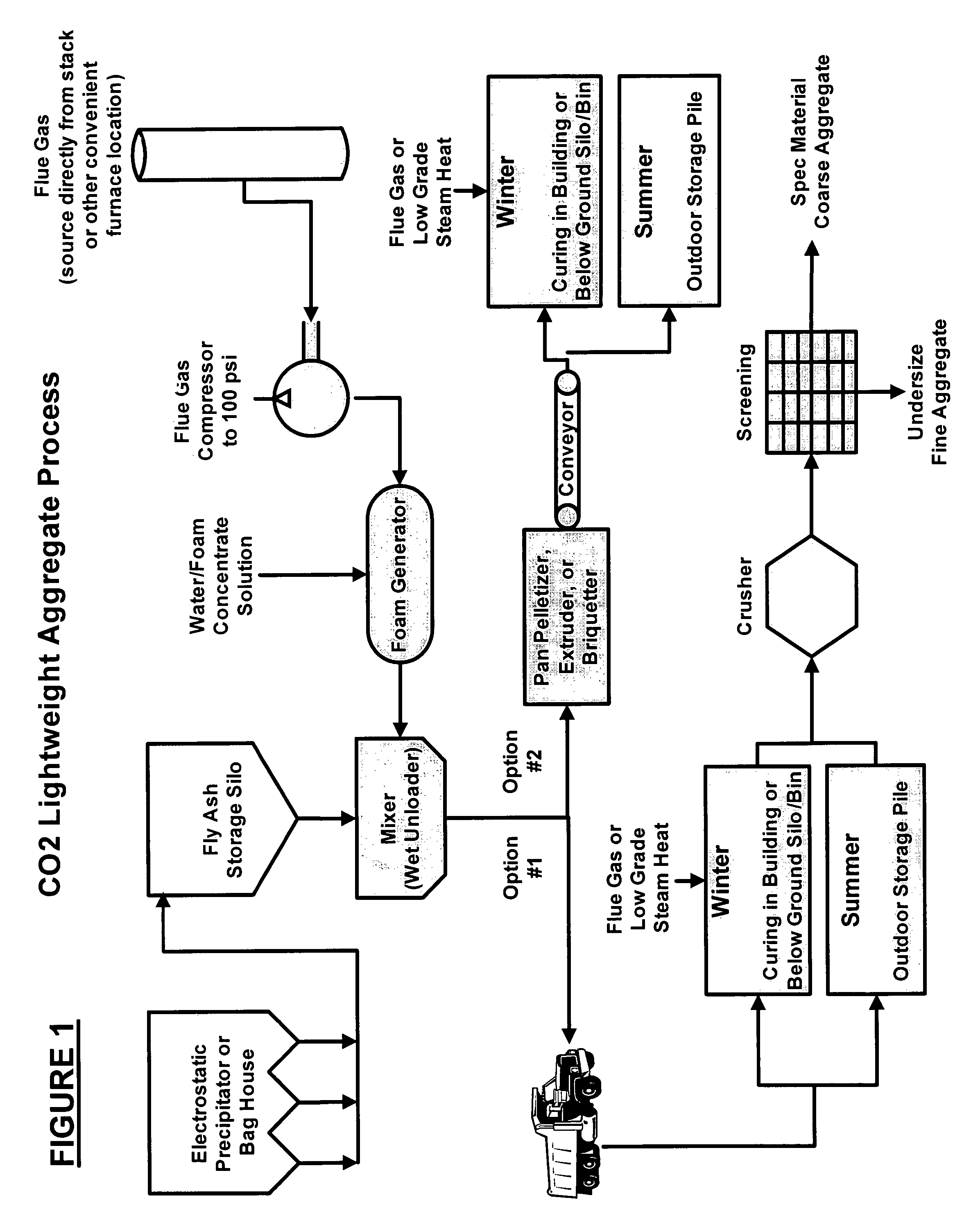

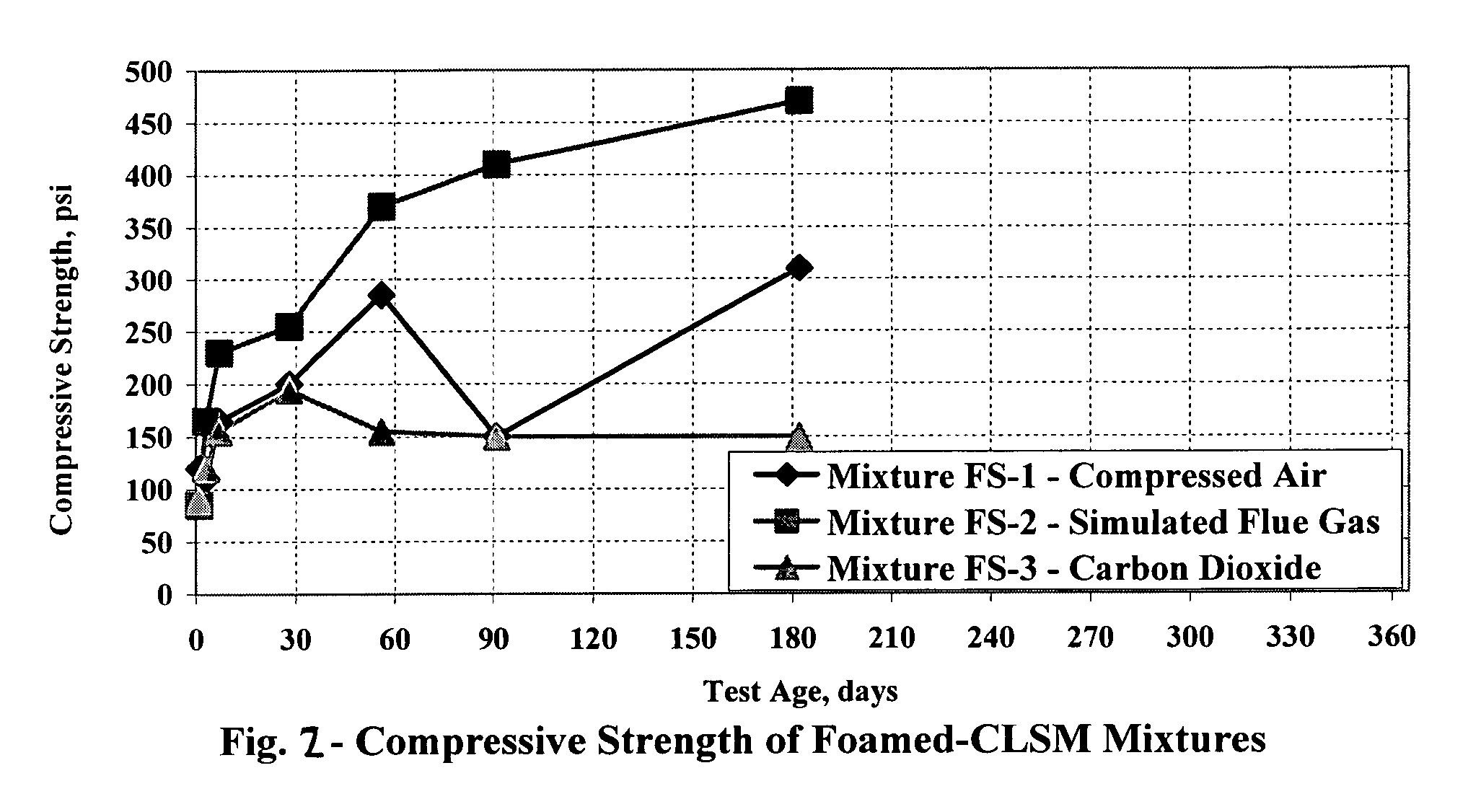

A process for sequestering carbon dioxide from the flue gas emitted from a combustion chamber is disclosed. In the process, a foam including a foaming agent and the flue gas is formed, and the foam is added to a mixture including a cementitious material (e.g., fly ash) and water to form a foamed mixture. Thereafter, the foamed mixture is allowed to set, preferably to a controlled low-strength material having a compressive strength of 1200 psi or less. The carbon dioxide in the flue gas and waste heat reacts with hydration products in the controlled low-strength material to increase strength. In this process, the carbon dioxide is sequestered. The CLSM can be crushed or pelletized to form a lightweight aggregate with properties similar to the naturally occurring mineral, pumice.

Owner:WISCONSIN ELECTRIC POWER

Carbon Dioxide Sequestration in Foamed Controlled Low Strength Materials

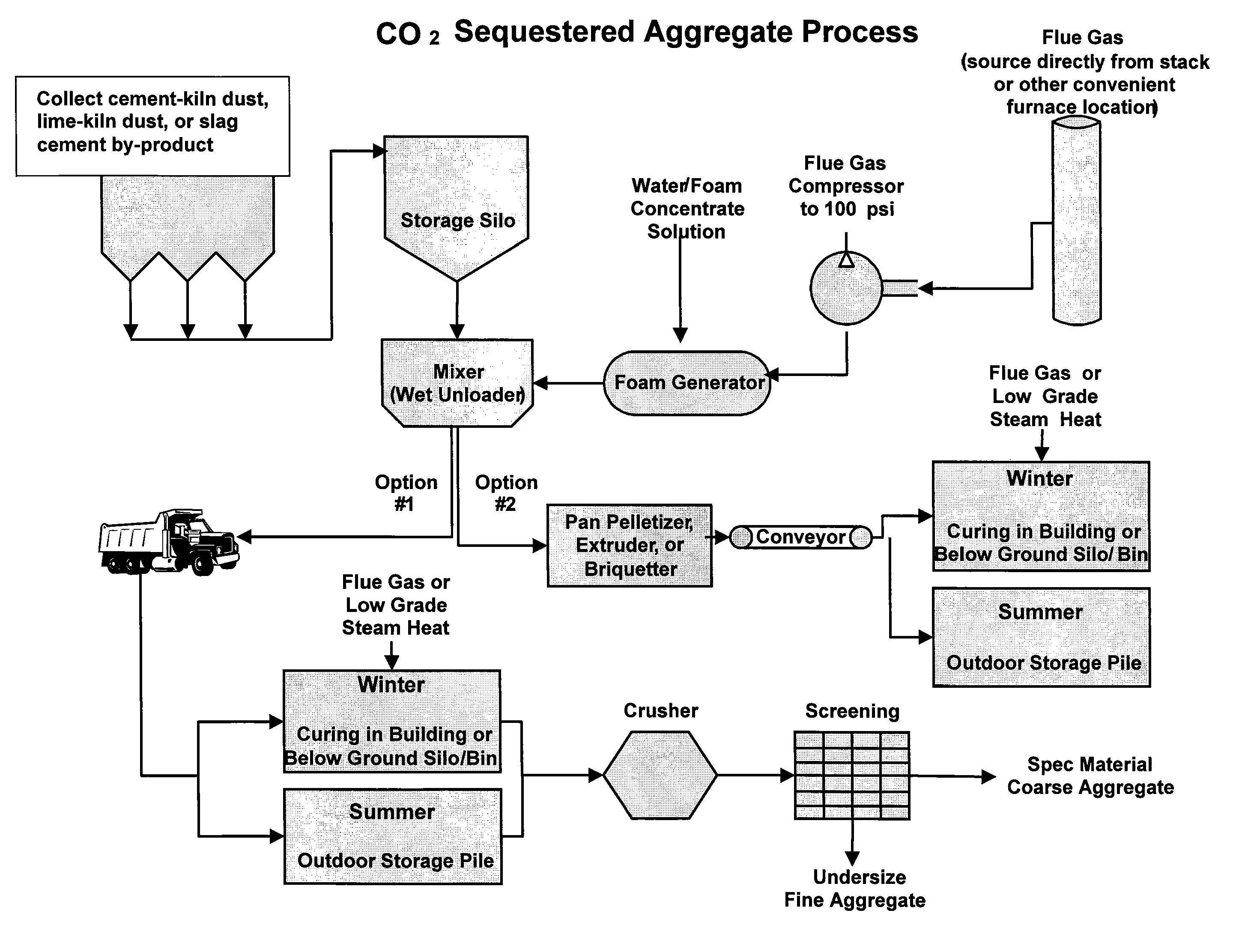

A process for sequestering carbon dioxide from the exhaust gas emitted from a combustion chamber is disclosed. In the process, a foam including a foaming agent and the exhaust gas is formed, and the foam is added to a mixture including a cementitious material (e.g., cement-kiln dust, lime kiln dust, or slag cement) and water to form a foamed mixture. Thereafter, the foamed mixture is allowed to set, preferably to a controlled low-strength material having a compressive strength of 1200 psi or less. The carbon dioxide in the exhaust gas reacts with hydration products in the controlled low-strength material and in turn sequesters the carbon dioxide.

Owner:WISCONSIN ELECTRIC POWER

Carbon dioxide sequestration in foamed controlled low strength materials

A process for sequestering carbon dioxide from the flue gas emitted from a combustion chamber is disclosed. In the process, a foam including a foaming agent and the flue gas is formed, and the foam is added to a mixture including a cementitious material (e.g., fly ash) and water to form a foamed mixture. Thereafter, the foamed mixture is allowed to set, preferably to a controlled low-strength material having a compressive strength of 1200 psi or less. The carbon dioxide in the flue gas and waste heat reacts with hydration products in the controlled low-strength material to increase strength. In this process, the carbon dioxide is sequestered. The CLSM can be crushed or pelletized to form a lightweight aggregate with properties similar to the naturally occurring mineral, pumice.

Owner:WISCONSIN ELECTRIC POWER

Foam control for synthetic adhesive/sealant

InactiveUS20090005716A1Suitable for useSurgical adhesivesPolyureas/polyurethane adhesivesAdhesiveFOAM CONTROL

Methods for producing biocompatible compositions are provided. The biocompatible compositions include an isocyanate-functional polyurethane prepolymer in combination with a foam control agent. The foam control agent decreases the formation of bubbles and / or foam in the biocompatible composition, thereby enhancing the physical properties of the biocompatible composition. The presence of the foam control agent does not compromise the strength of the biocompatible composition. The compositions prepared by the methods of the present disclosure may be used as adhesives or sealants for medical / surgical uses.

Owner:TYCO HEALTHCARE GRP LP

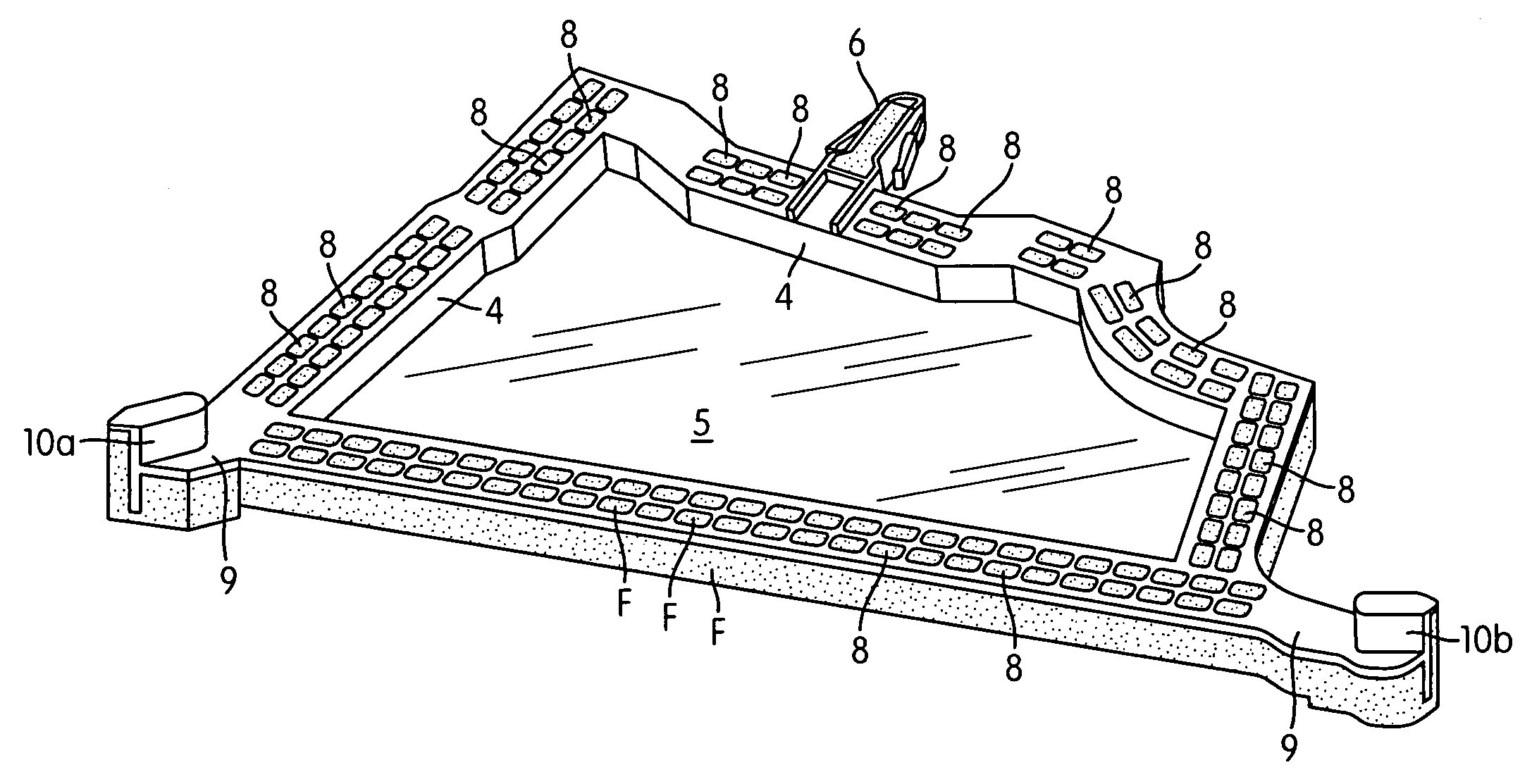

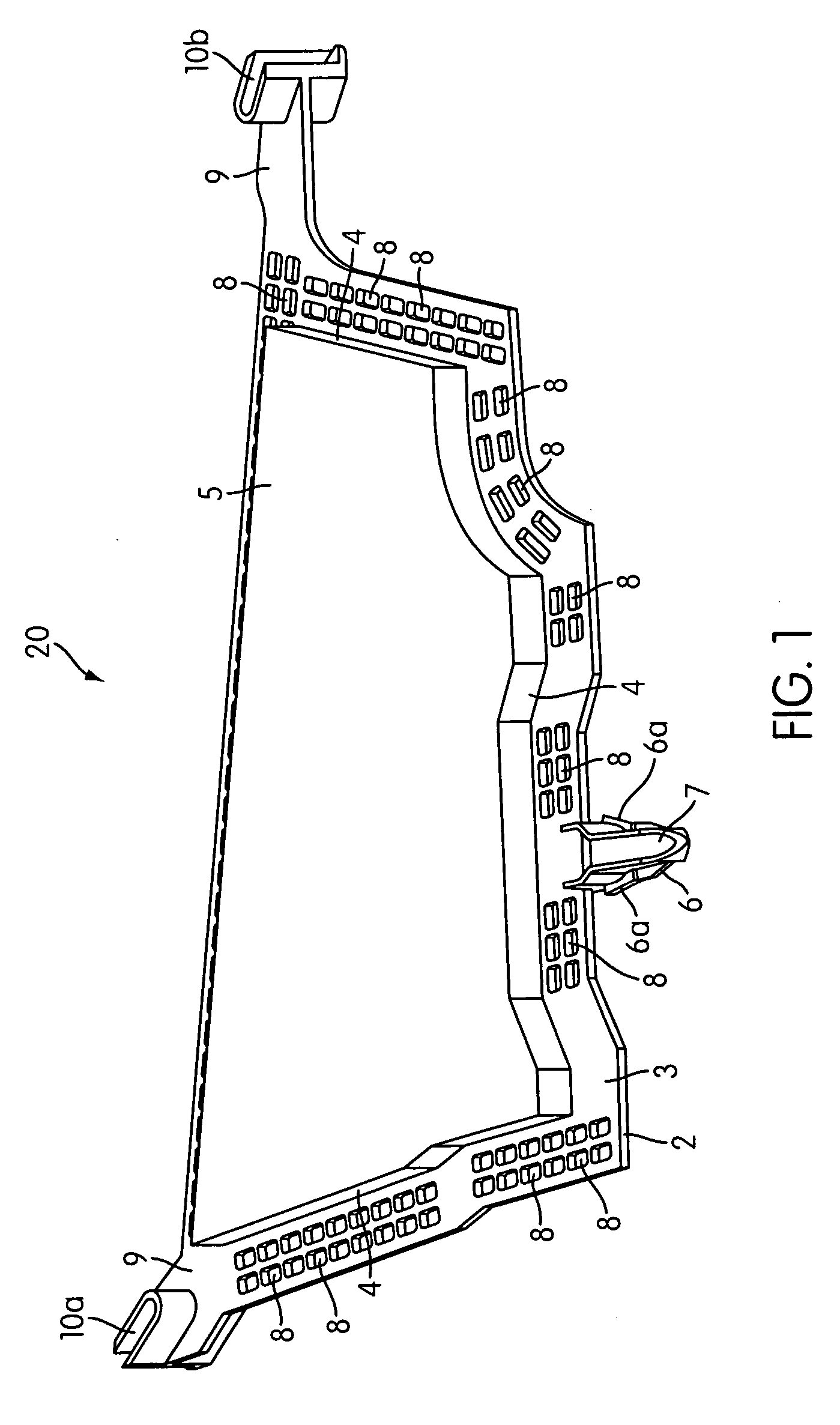

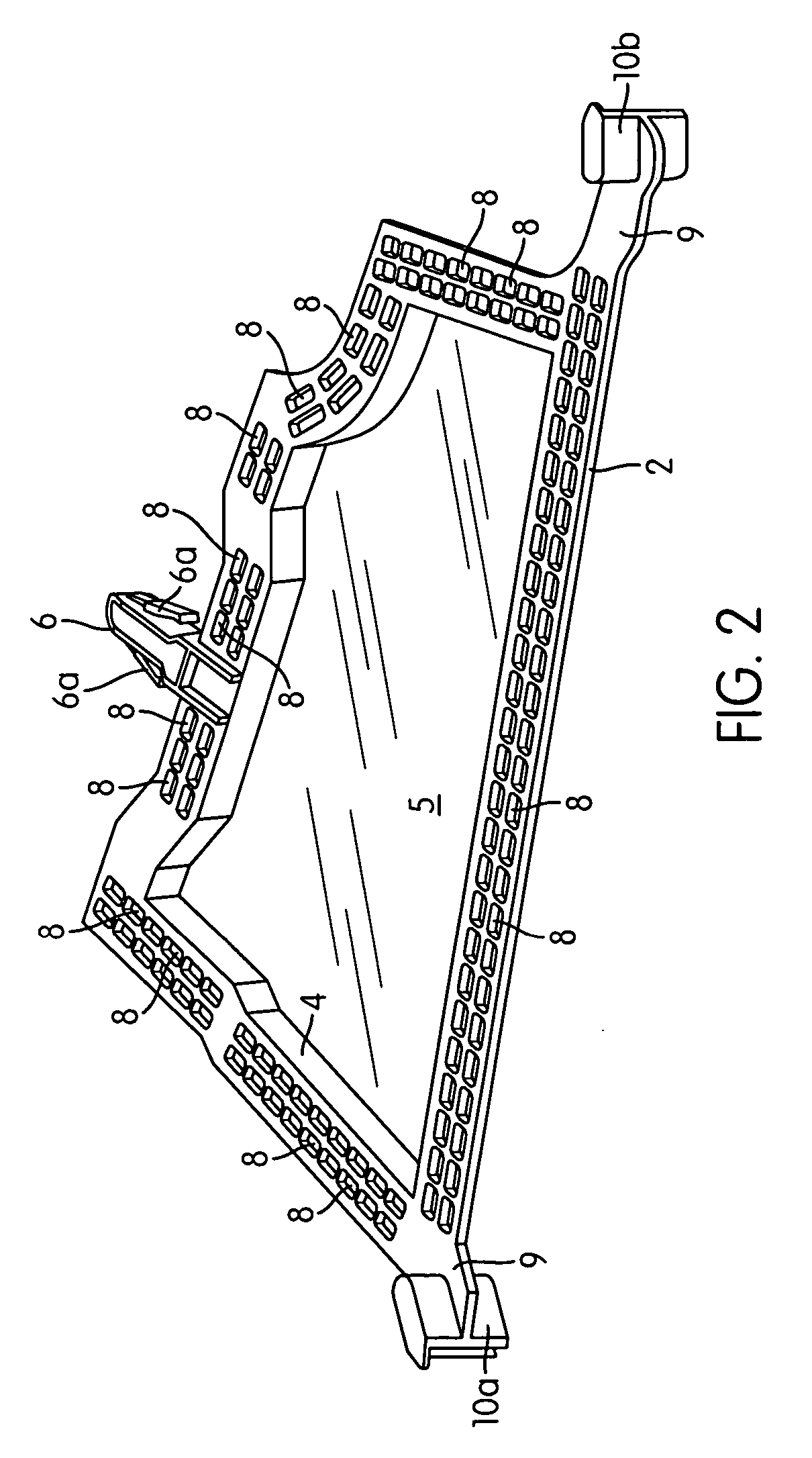

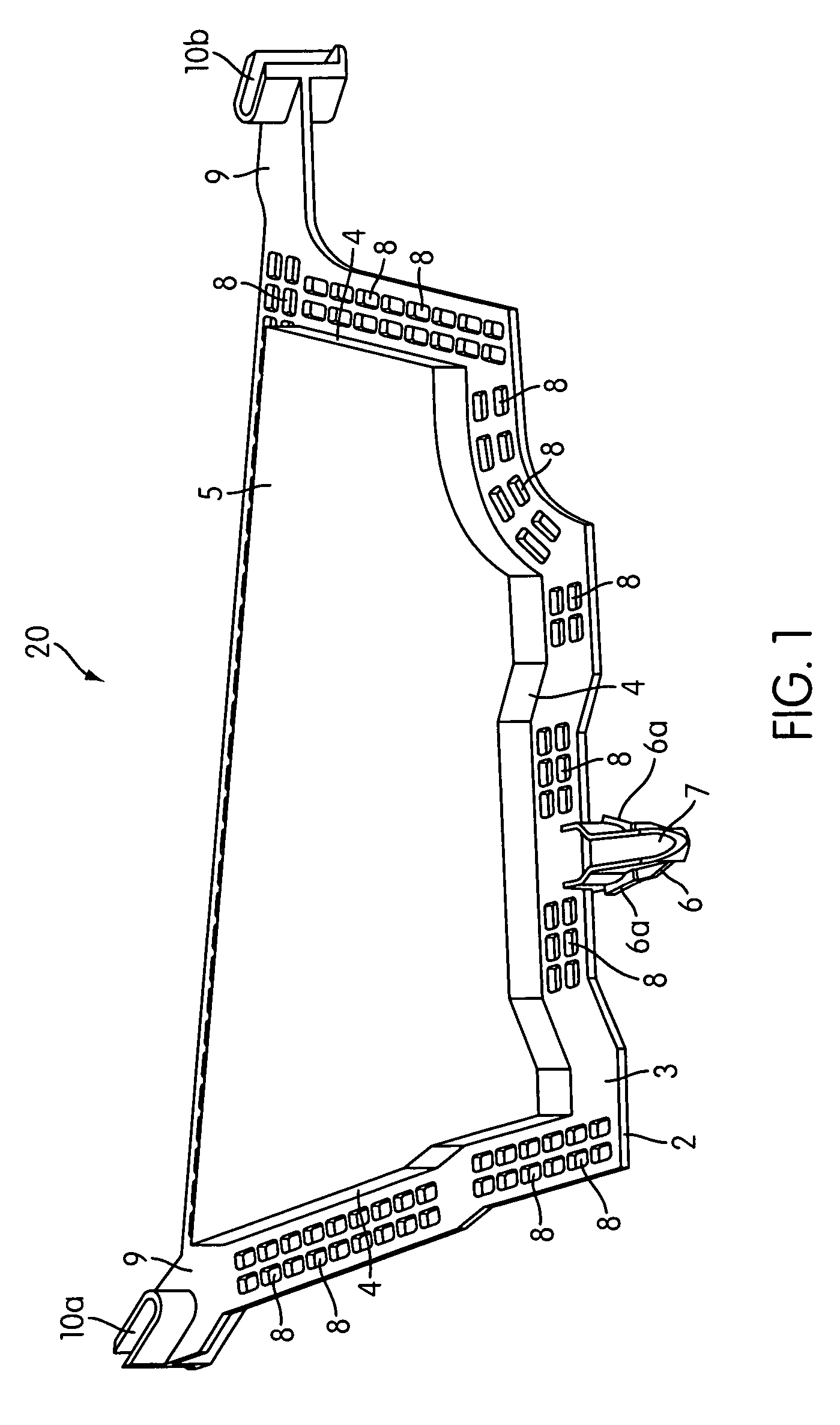

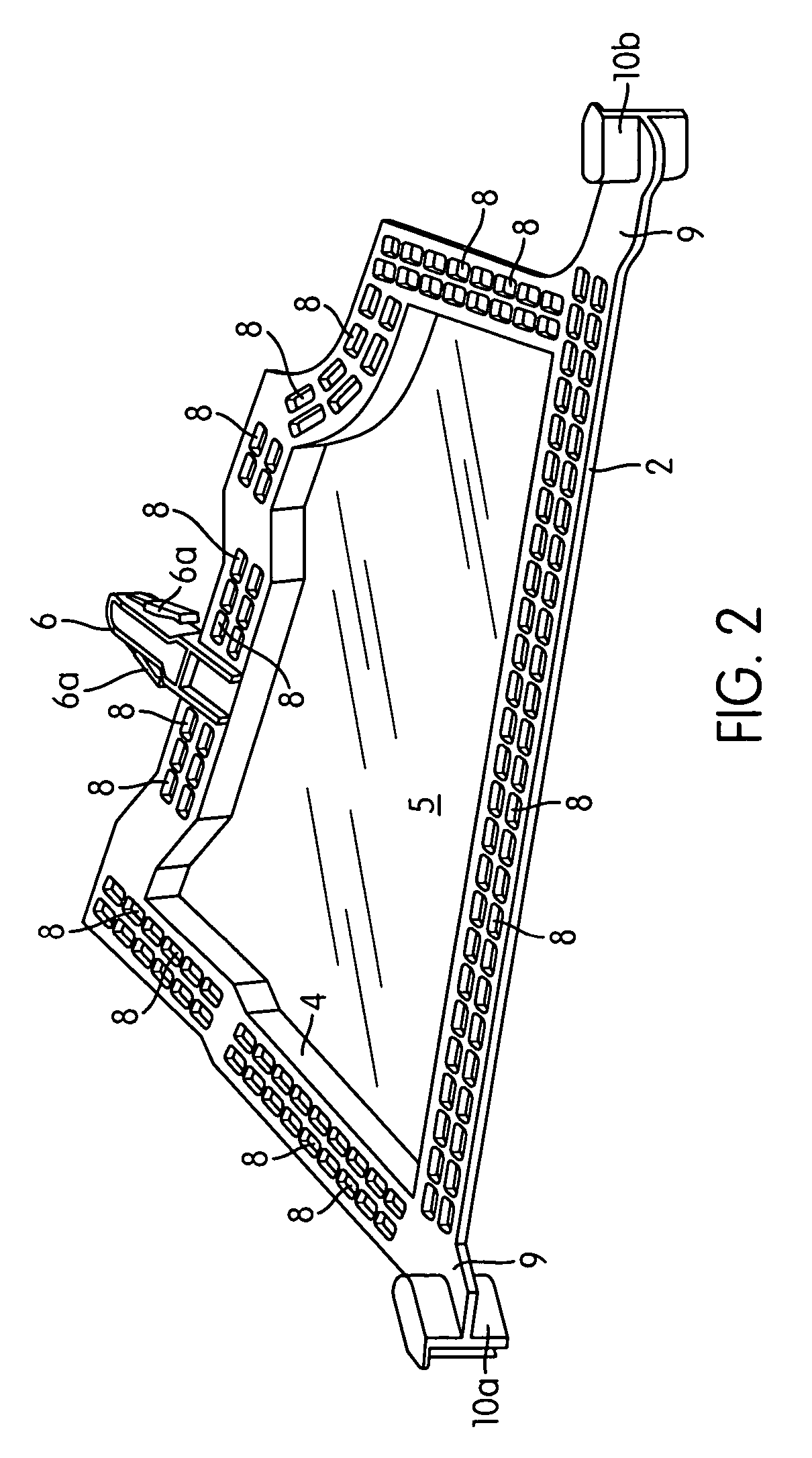

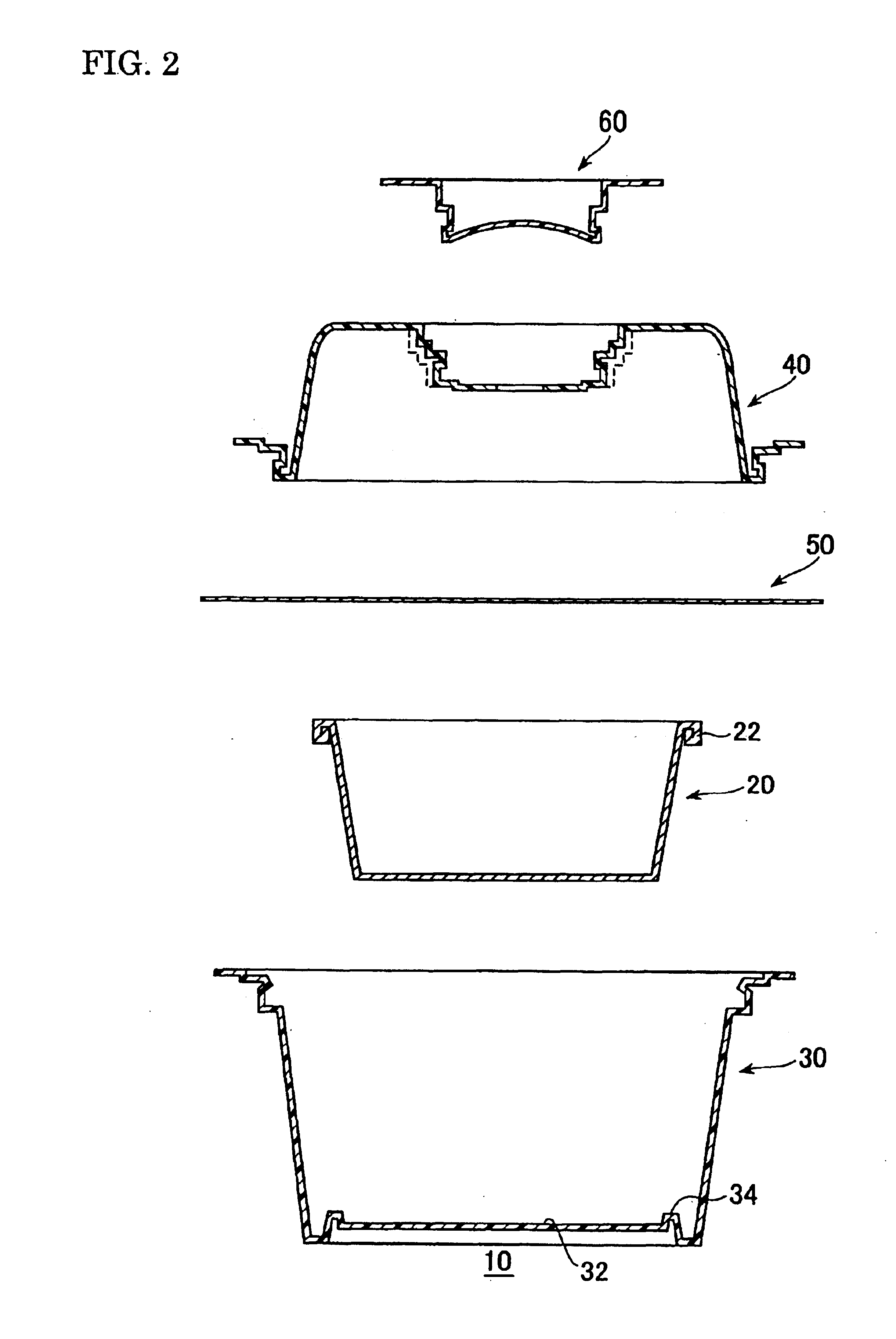

Holding jig for a foamable material

ActiveUS20070138683A1Small diameterEffective holdingPig casting plantsConfectioneryEngineeringFOAM CONTROL

The invention provides a holding jig for supporting and fixing a solid material capable of being foamed by application of heat in a cavity of a hollow structure. The holding jig may be provided with a plate-like base body made smaller in diameter than the cavity of the hollow structure, a holding part that is provided in a predetermined width in the form of a ring on the periphery of one side of said base body and supports one side of the foamable material, a step part with predetermined height, which is projected in the form of a ring at the inner peripheral end of said holding part and supports the inner peripheral surface of the foamable material, and an attaching means with which the base body can be freely attached to or detached from the hollow structure. The holding part can be provided with a plurality of small holes that open from one side to the other side of the base body, preferably in a net or lattice pattern. The holding jig may have one or more extensions containing approximately U-shaped foaming control walls that assist in directing expansion of the foaming material towards corners of the hollow structure.

Owner:CEMEDINE HENKEL

Foam control formulations

ActiveUS20150080273A1Lower Level RequirementsInhibition formationDewatering/demulsification with chemical meansDefoamers additionProcedure AgentsWater insoluble

The invention provides a foam control formulation in the form of a microemulsion, the formulation comprising: (a) from S to 70% w / w of primary surfactant, this surfactant having an HLB of from 1 to 12 and / or a cloud point of from 20 to 70° C.; (b) from 2 to 40% w / w of water-insoluble organic carrier liquid; and (c) water. Also provided is the use of this formulation to prevent and / or reduce foam in a fluid system, or as a processing aid to control foam production in a fluid system. The formulation may be used in an aqueous fluid system, such as an oilfield.

Owner:ENERGY SOLUTIONS (US) LLC

Holding jig for a foamable material

ActiveUS8087916B2Promoting adequate and expansionReduce the amount requiredPig casting plantsConfectioneryEngineeringFOAM CONTROL

The invention provides a holding jig for supporting and fixing a solid material capable of being foamed by application of heat in a cavity of a hollow structure. The holding jig may be provided with a plate-like base body made smaller in diameter than the cavity of the hollow structure, a holding part that is provided in a predetermined width in the form of a ring on the periphery of one side of said base body and supports one side of the foamable material, a step part with predetermined height, which is projected in the form of a ring at the inner peripheral end of said holding part and supports the inner peripheral surface of the foamable material, and an attaching means with which the base body can be freely attached to or detached from the hollow structure. The holding part can be provided with a plurality of small holes that open from one side to the other side of the base body, preferably in a net or lattice pattern. The holding jig may have one or more extensions containing approximately U-shaped foaming control walls that assist in directing expansion of the foaming material towards corners of the hollow structure.

Owner:CEMEDINE HENKEL

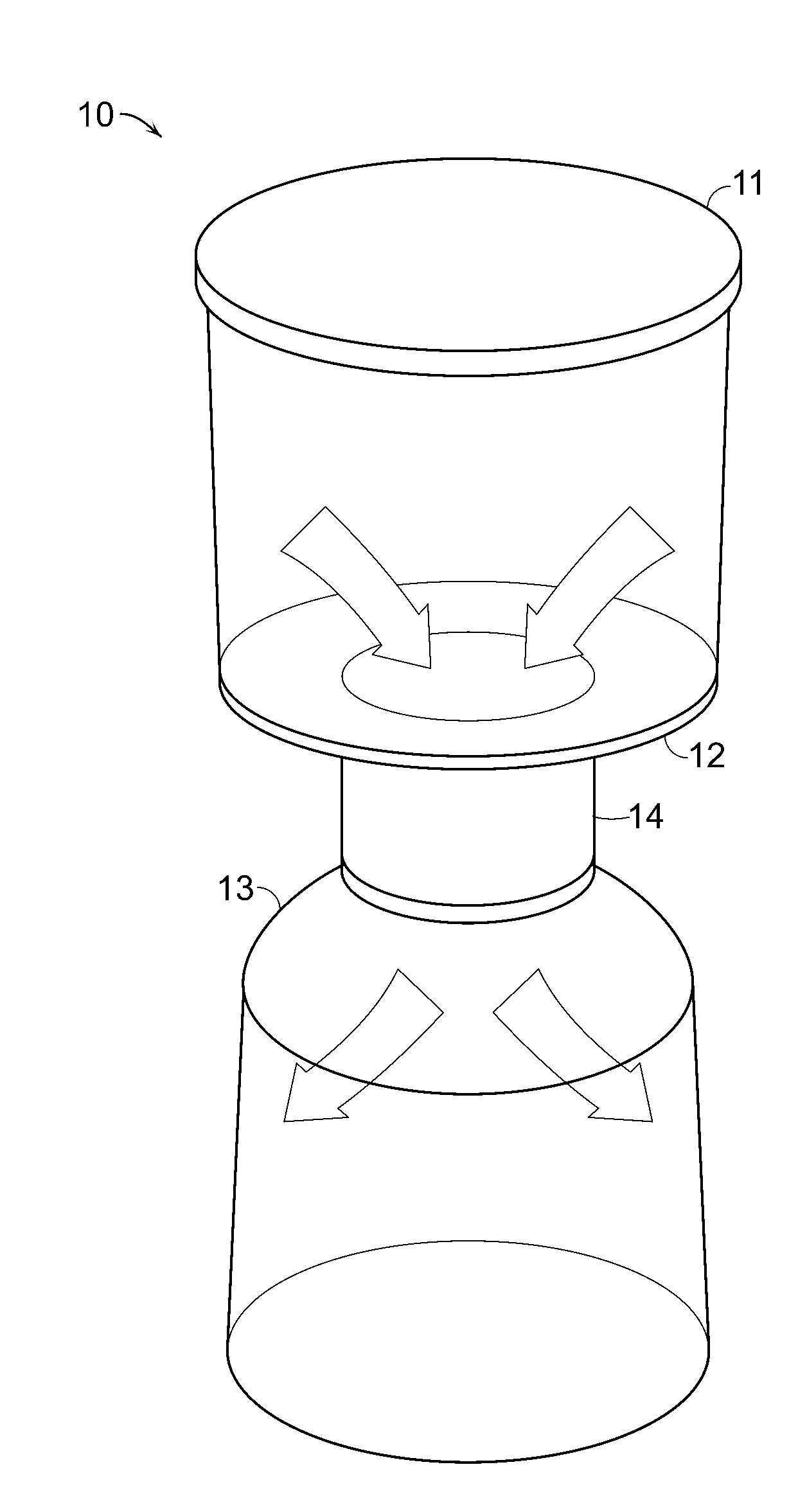

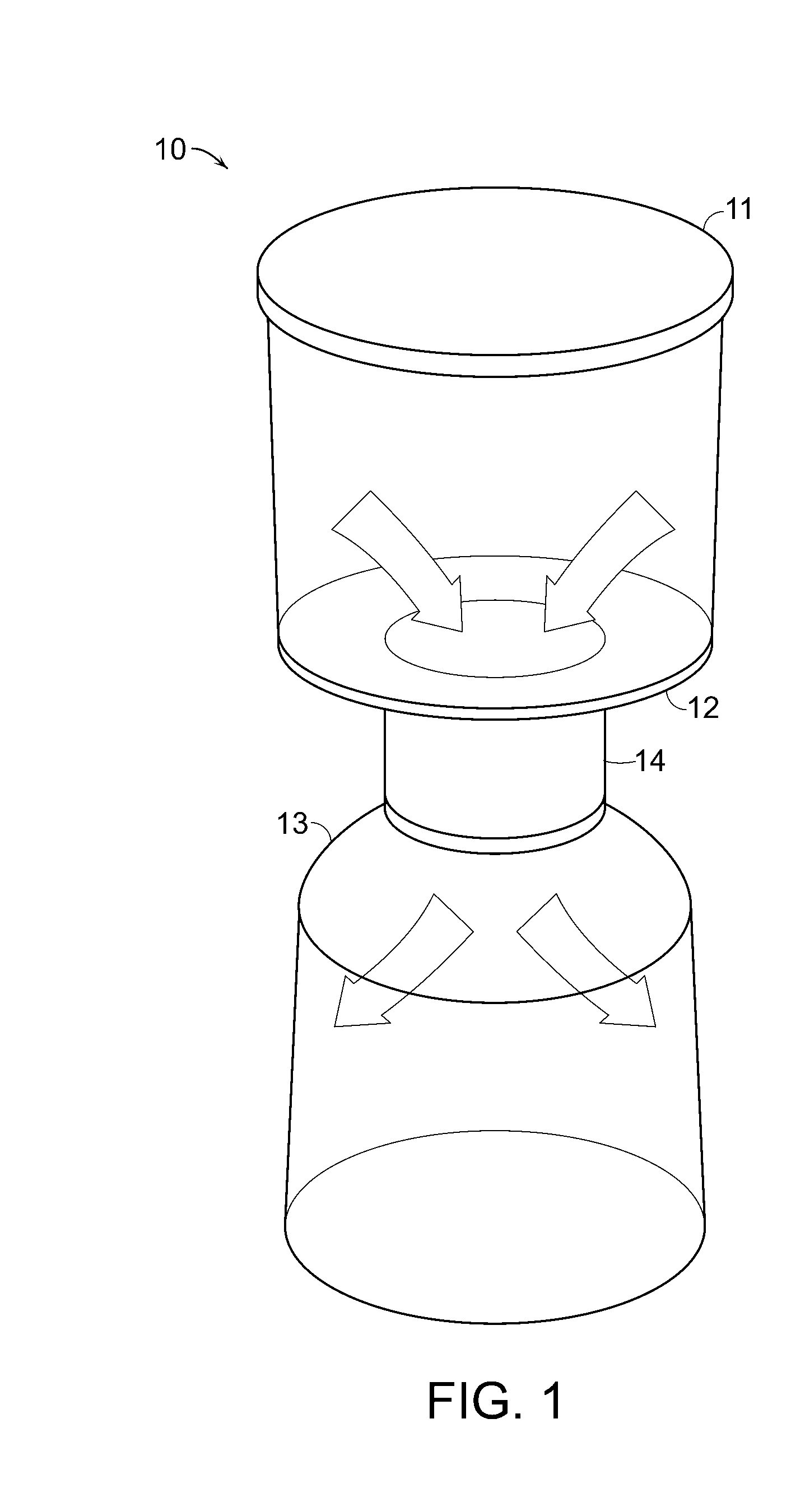

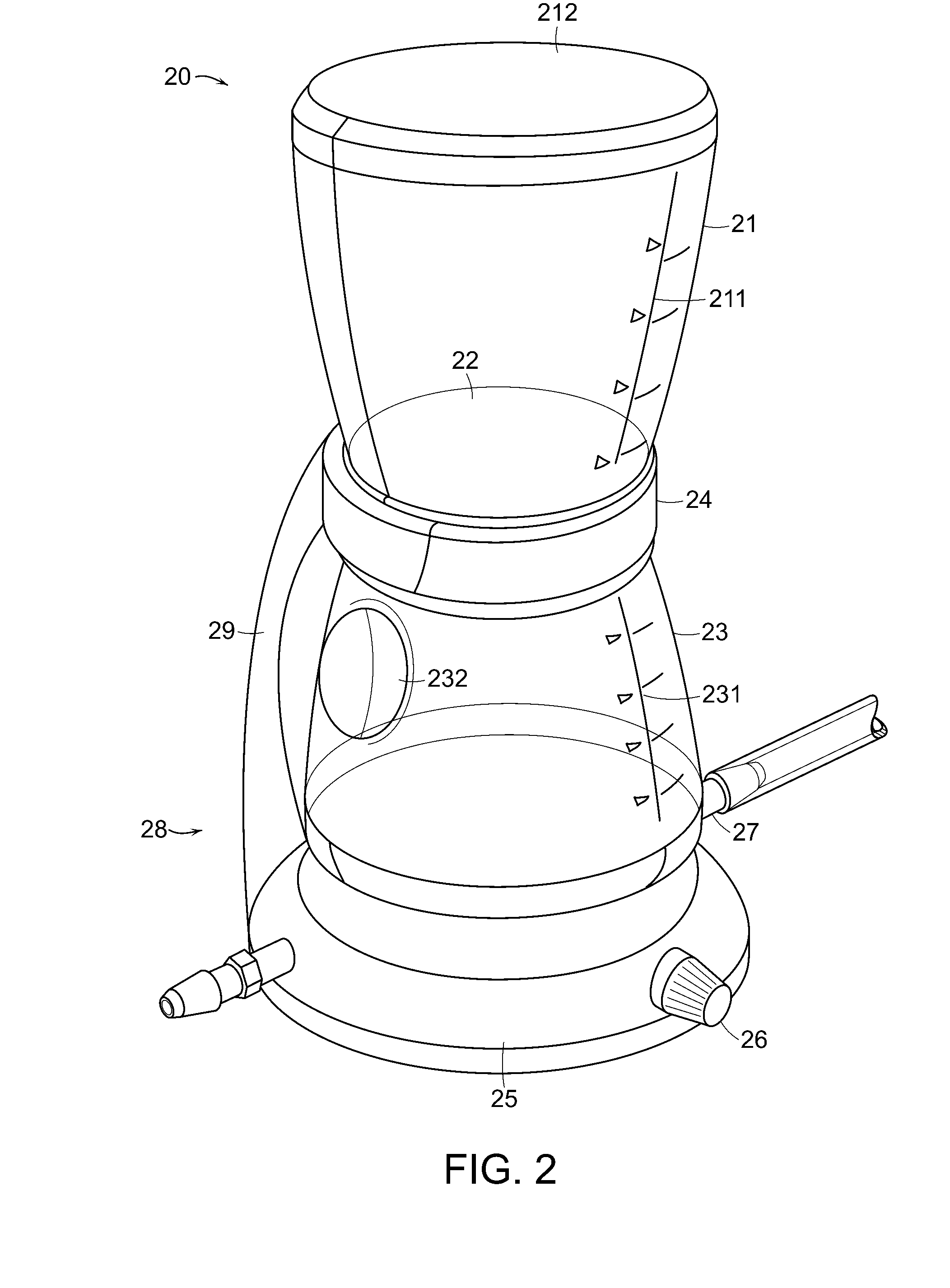

Methods and Apparatus for Foam Control in a Vacuum Filtration System

InactiveUS20080290040A1Reduces splashing and foamingReduce foamingSamplingLaboratory glasswaresFiltrationFilter system

A flow diverter, vacuum control and tilting of the liquid filtering system are used alternatively or in conjunction to reduce foam production in a filtered liquid sample. A liquid filtering system includes an upper sample reservoir, a filter and a lower storage bottle. A vacuum is applied below the sample filter to draw sample liquid through the sample filter into the storage bottle. A flow diverter may be used to direct flow of the filtered liquid sample onto a sidewall of the storage bottle or guide flow to a bottom of the storage bottle. The vacuum may be regulated to reduce foaming. The liquid filtering system may be tilted to direct fluid to the sidewall of the lower storage bottle and reduce foaming.

Owner:FOXX LIFE SCI

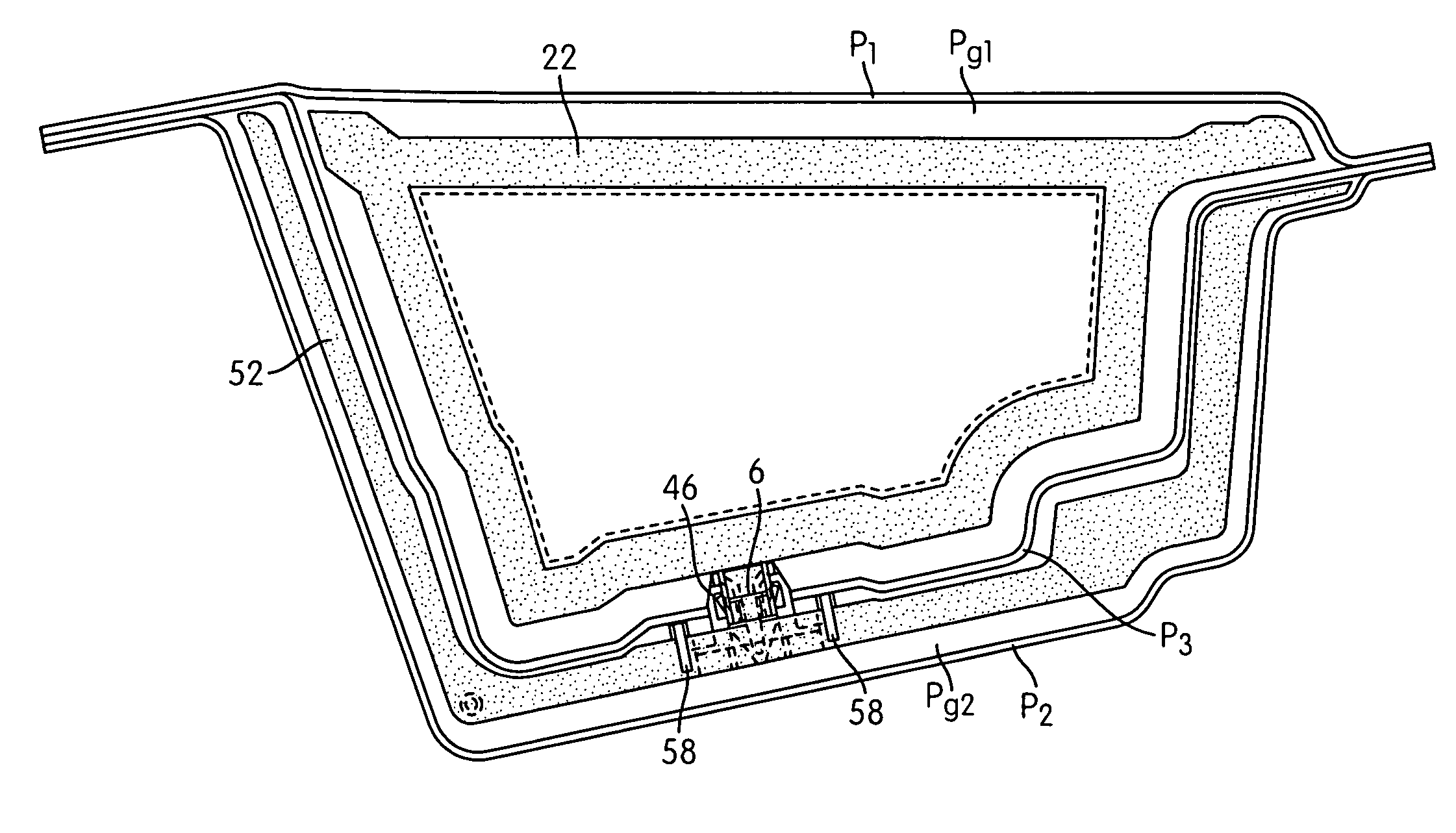

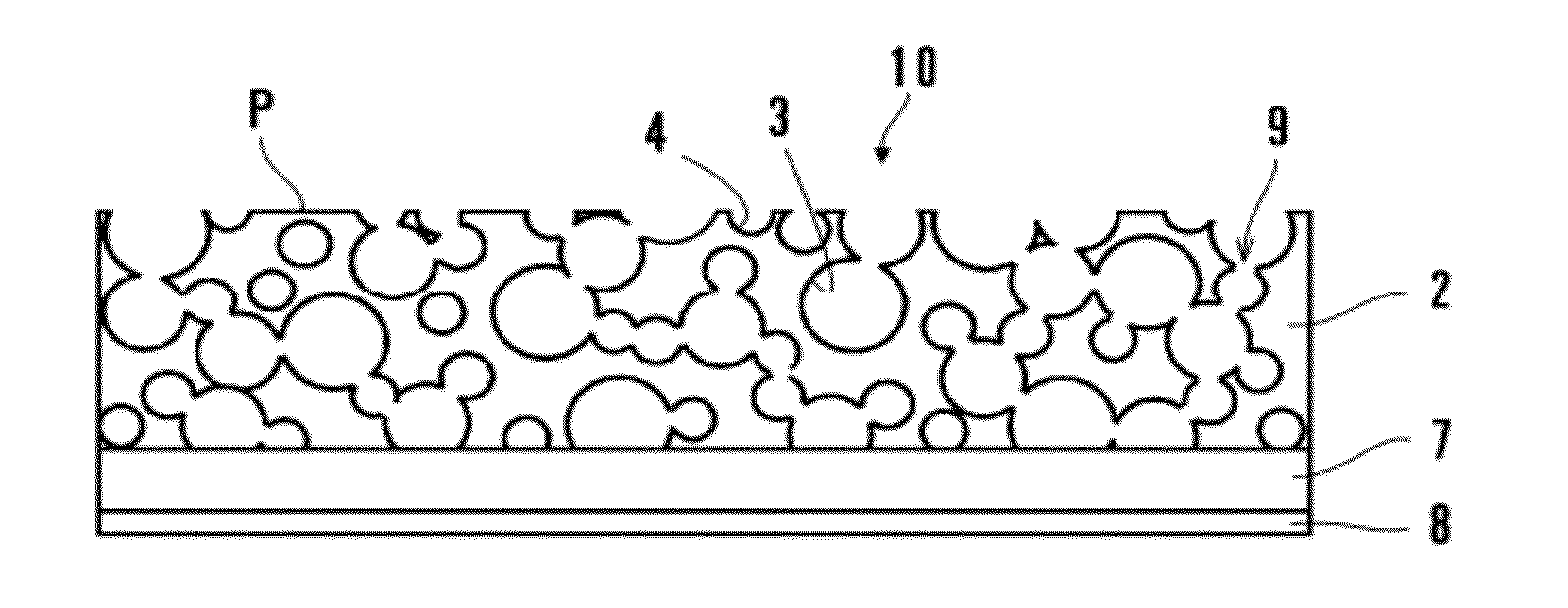

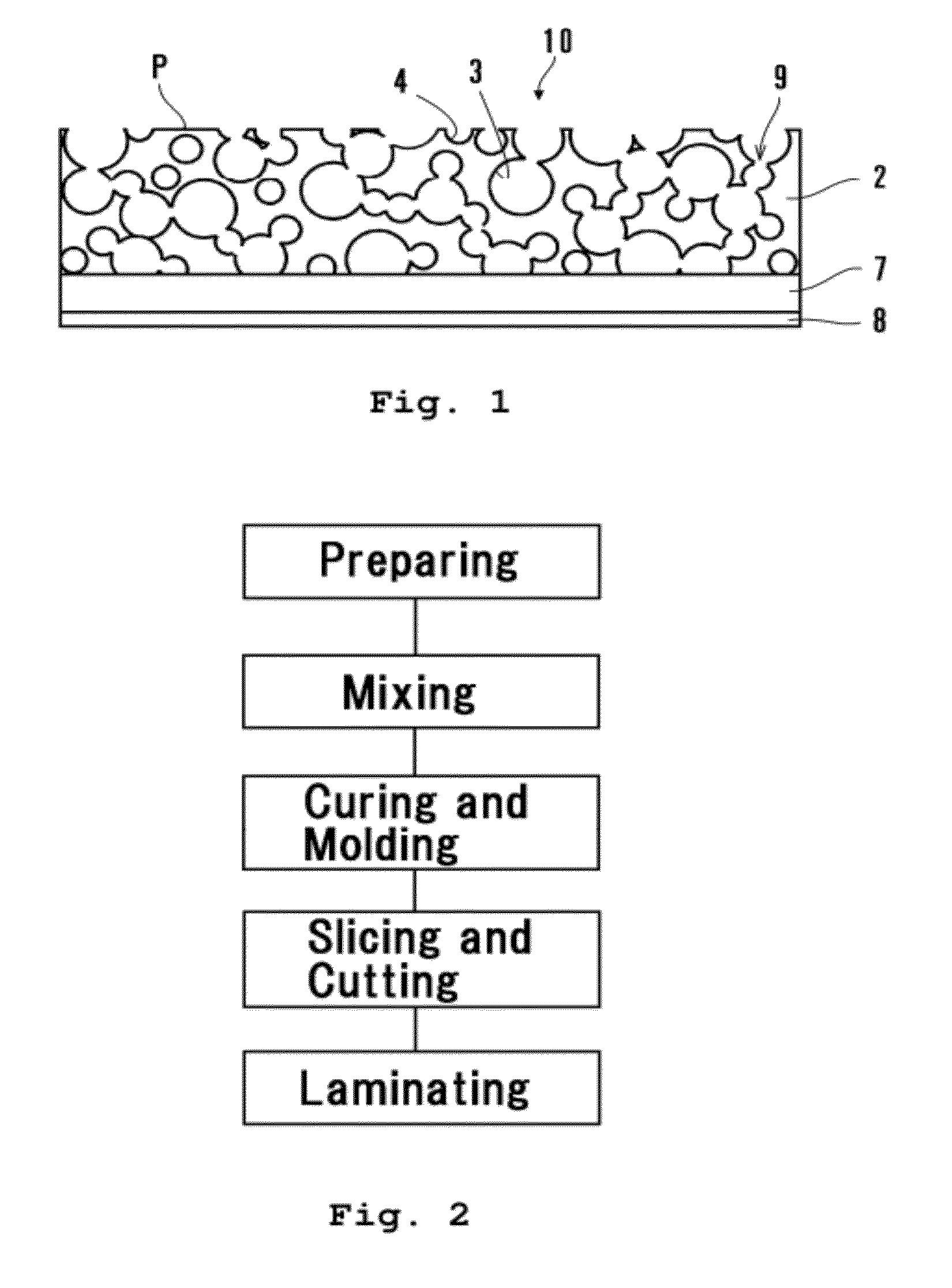

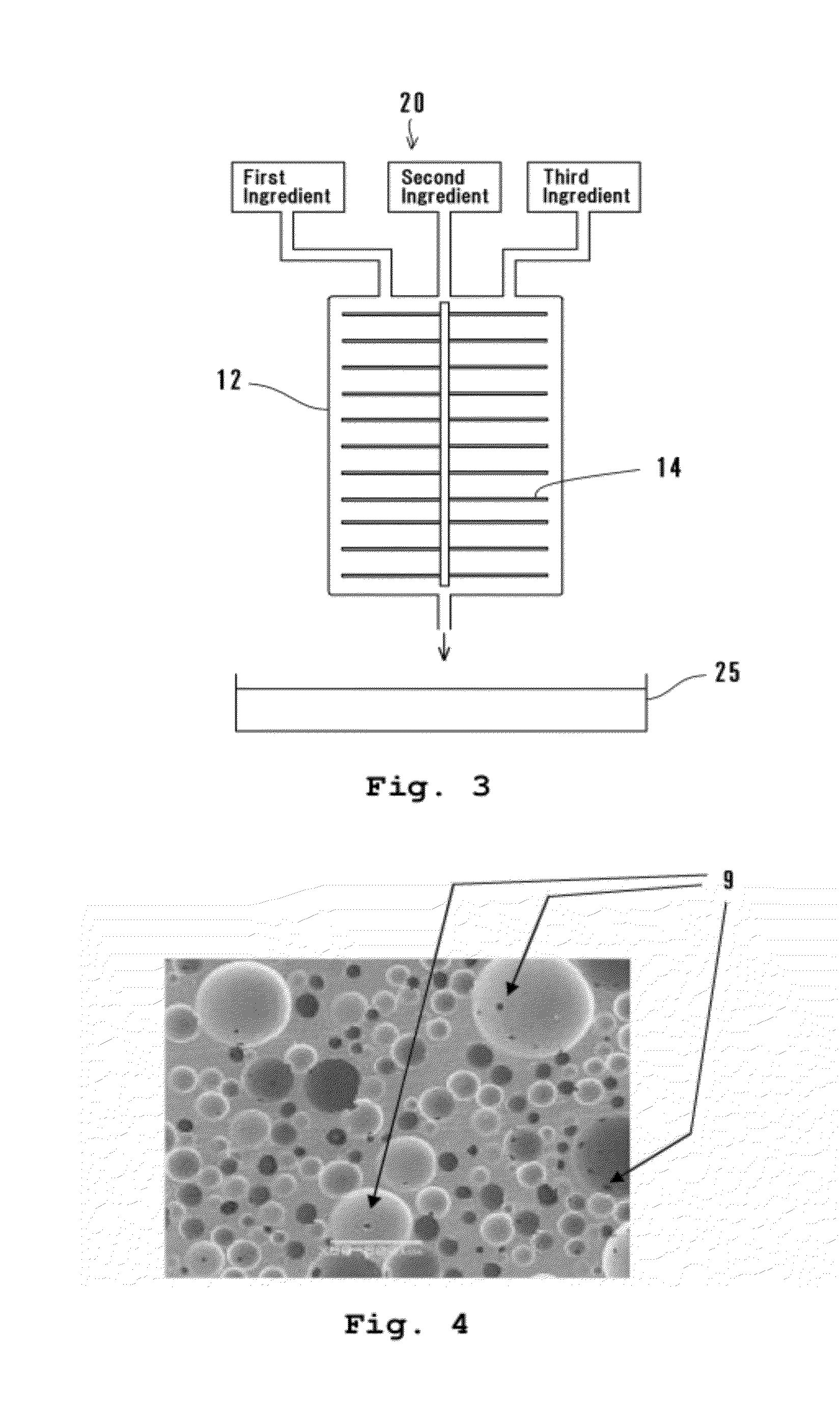

Polishing pad, manufacturing method thereof and polishing method

ActiveUS20120100783A1High affinityImprove polishing effectAbrasion apparatusSemiconductor/solid-state device manufacturingPolyamine CompoundFOAM CONTROL

A polishing pad capable of improving an affinity to polishing liquid and stabilizing polishing performance is provided. A polishing pad 10 is equipped with a urethane sheet 2. The urethane sheet 2 has a polishing surface P for polishing an object to be polished. The urethane sheet 2 is formed by a dry molding method and is formed by slicing a polyurethane foamed body which is obtained by reacting and curing mixed liquid in which an isocyanate-group containing compound, water, a foam control agent and a polyamine compound are mixed. Foams 3 are dispersed approximately uniformly inside the urethane sheet 2. Opened pores 4 which are opened parts of the foams 3 are formed at the polishing surface P. Inside the urethane sheet 2, the foams 3 formed adjacently to each other are communicated by communication holes 9, and the communication holes 9 are formed at a ratio of 800 holes / cm2 or more when observed from a side of the polishing surface P. Polishing liquid moves via the communication holes 9 and the foams 3.

Owner:FUJIBO HLDG +1

Wood/plastic building template

The invention relates to a wood / plastic building template, which is characterized by being prepared by taking polyvinyl chloride (PVC) SG700-8, PVC SG1000-5, wood meal, light calcium carbonate, a foam control agent 530, a compound stabilizing agent, a processing aid ACR401, a lubricating modifier LS-303, polyethylene wax, paraffin, stearic acid 1801, high-density polyethylene wax, a foaming agent AC150P azobisformamide, a foaming agent NC azobisformamide, an impact modifier chlorinated polyethylene and 1-1.4% of soybean oil as the raw materials and carrying out high-temperature mixing, cooling and extrusion molding on the raw materials. The wood / plastic building template replaces the plywood and the bamboo templates in the building templates, has the characteristics of environmental protection, zero pollutant discharge, high use frequency, long use period, etc, conforms to the ideals of low-carbon discharge, forest protection and production environment improvement and is an environment-friendly material for building.

Owner:ANSHAN SENYU BUILDING MATERIALS

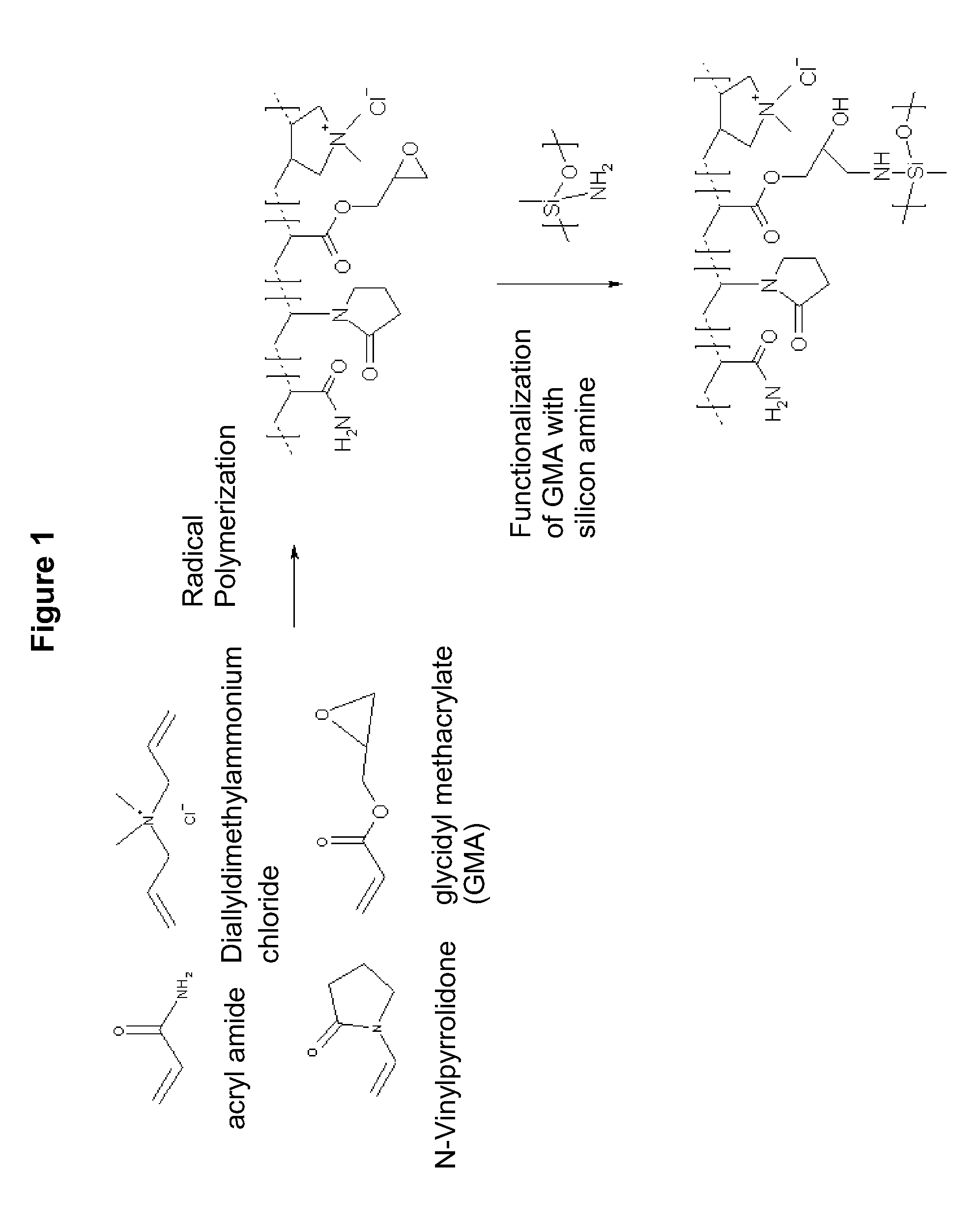

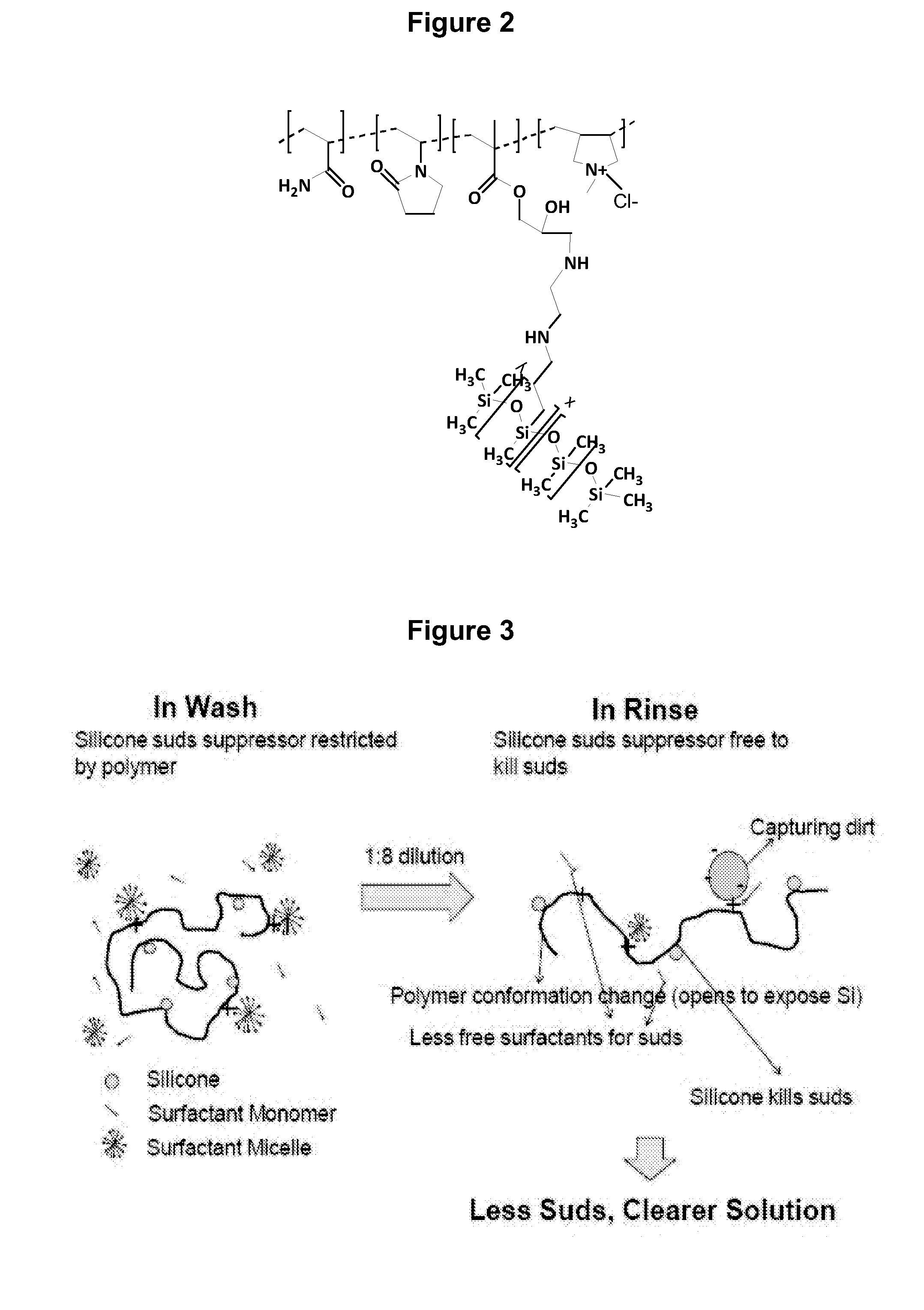

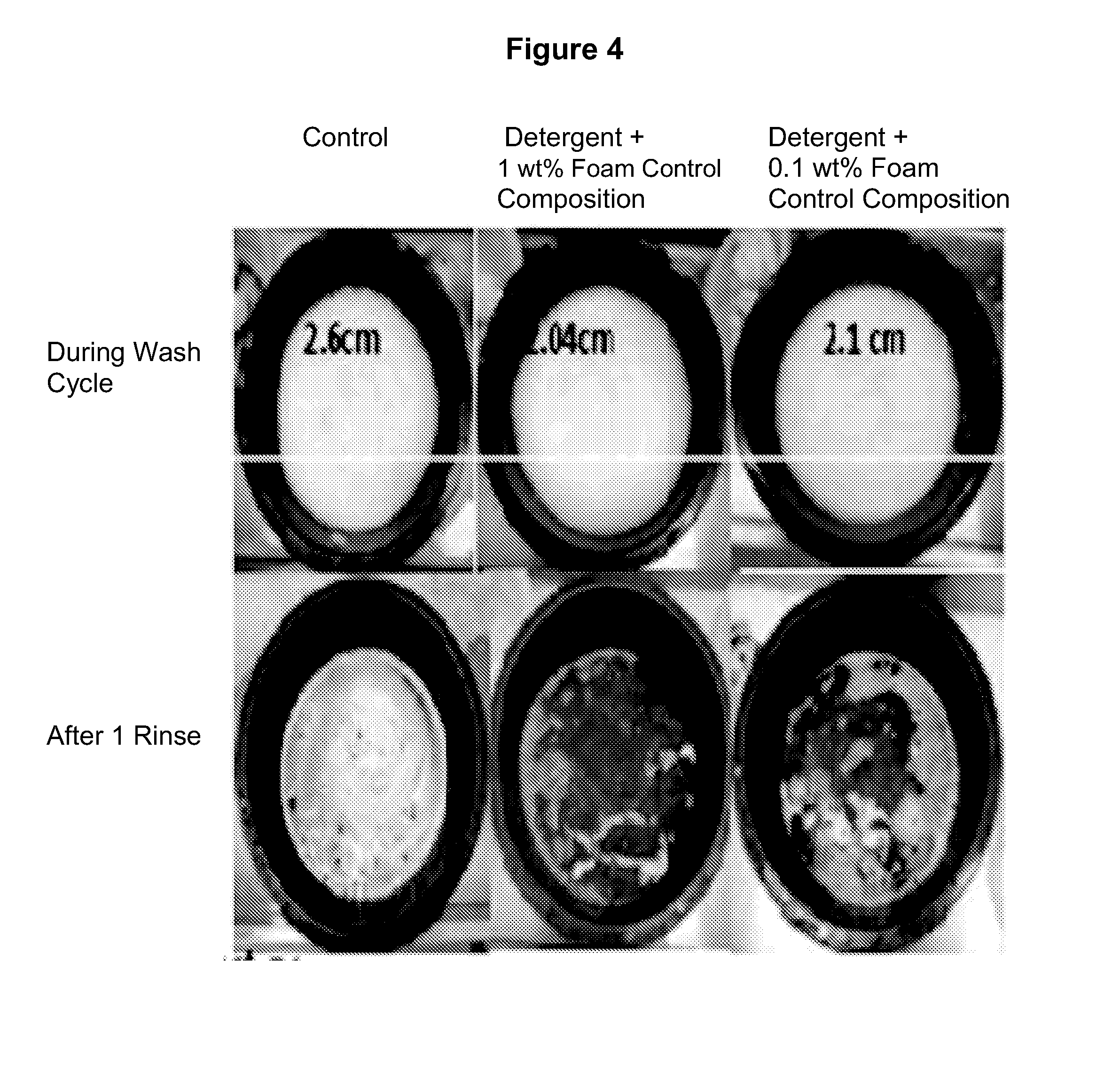

Cleaning compositions

ActiveUS20140023609A1Improved suds removalNegatively impactingSynthetic polymeric active ingredientsFoam regulating compositionsFOAM CONTROLOrganic chemistry

The present invention relates to cleaning composition, preferably a laundry detergent composition, comprising a foam control composition comprising a hydrophobically modified cationic polymer, as well as processes for making and method of using such compositions. The composition of the present invention provides for enhanced suds removal during the rinse cycle with minimal or nil impact on suds volume during the wash cycle.

Owner:THE PROCTER & GAMBLE COMPANY

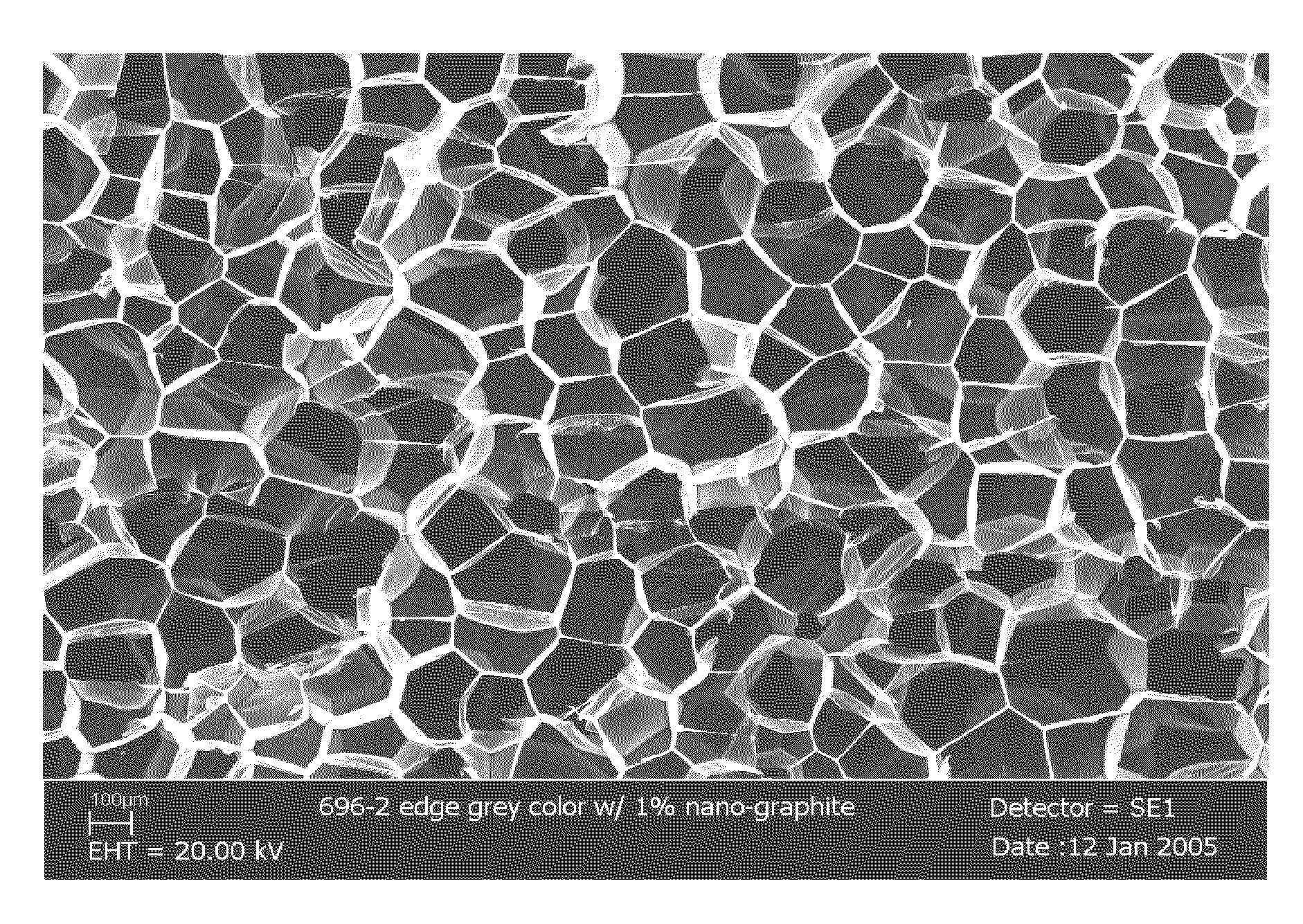

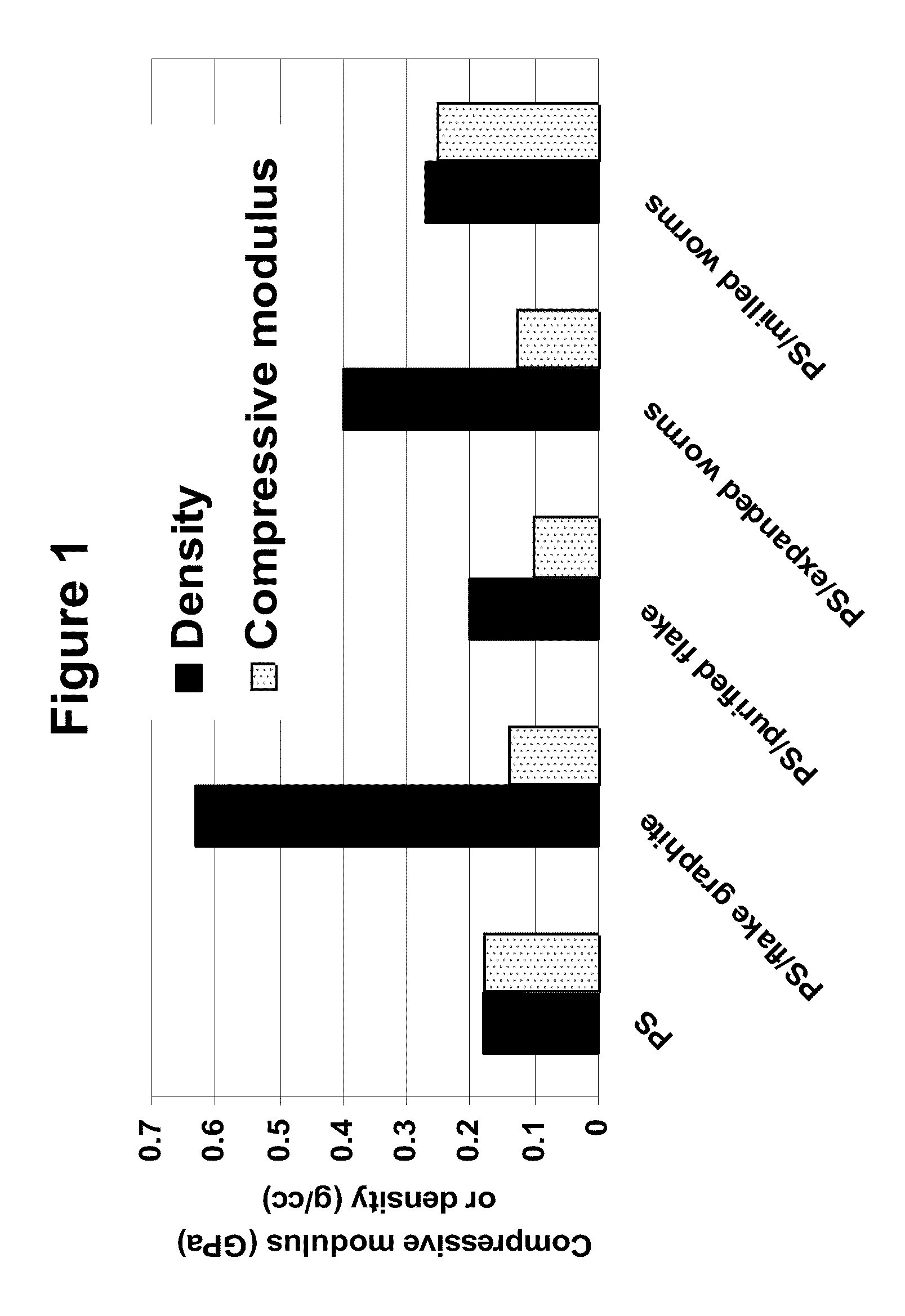

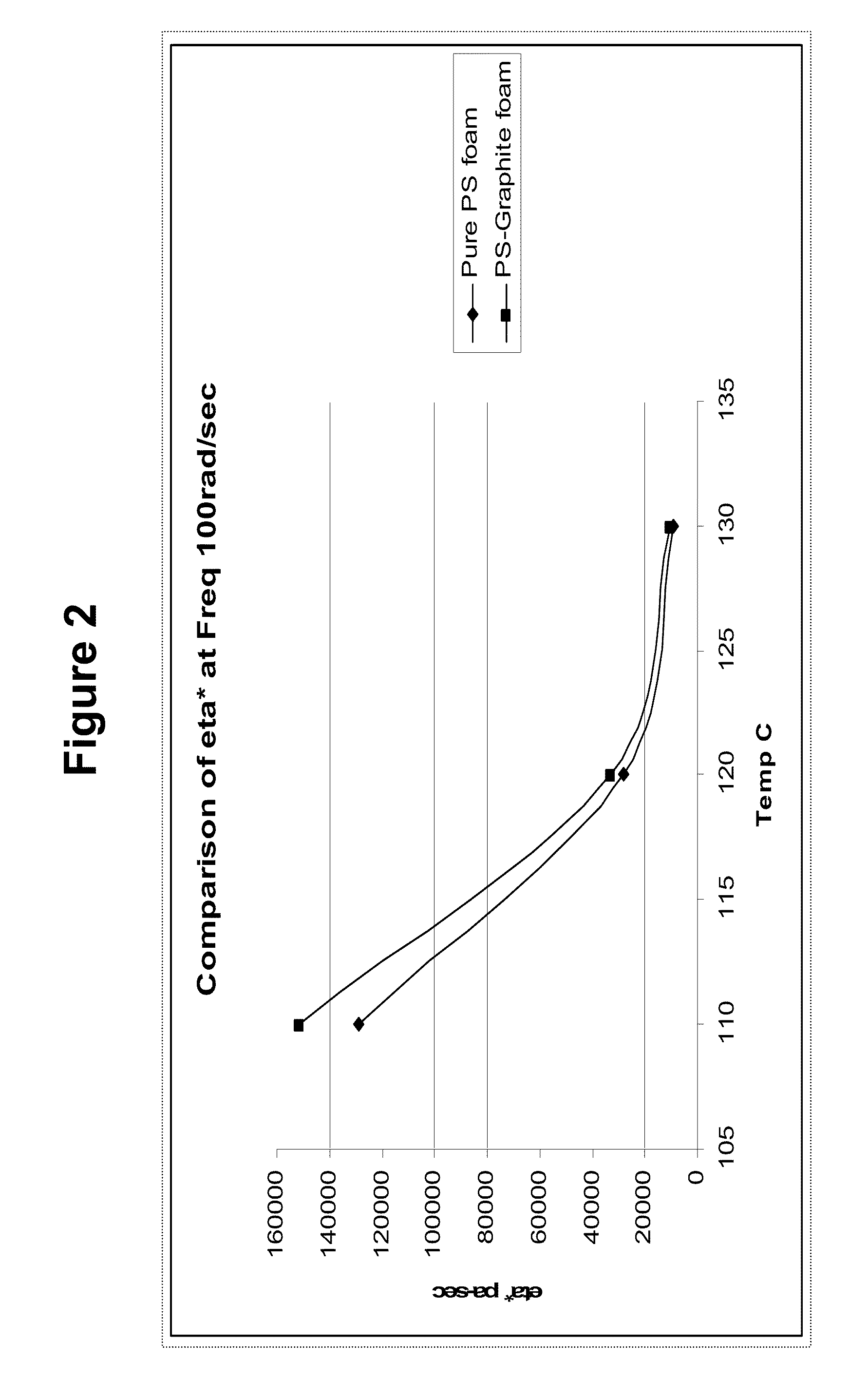

Thermoplastic foams and method of forming them using nano-graphite

ActiveUS20110064938A1Good physical propertiesReduce the amount requiredMaterial nanotechnologyThermal insulationThermoplasticThermal insulation

Rigid foam insulating products and processes for making such insulation products are disclosed. The foam products are formed from a polymer, a blowing agent, and nano-graphite. The nano-graphite has a size in at least one dimension less than about 100 nm and, in exemplary embodiments may be an intercalated, expanded nano-graphite. In addition, the nano-graphite may include a plurality of nanosheets having a thickness between about 10 to about 100 nanometers. The nano-graphite acts as a process additive to improve the physical properties of the foam product, such as thermal insulation and compressive strength. In addition, the nano-graphite in the foam controls cell morphology and acts as a nucleating agent in the foaming process. Further, the nano-graphite exhibits overall compound effects on foam properties including improved insulating value (increased R-value) for a given thickness and density and improved ultraviolet (UV) stability.

Owner:OWENS CORNING INTELLECTUAL CAPITAL LLC

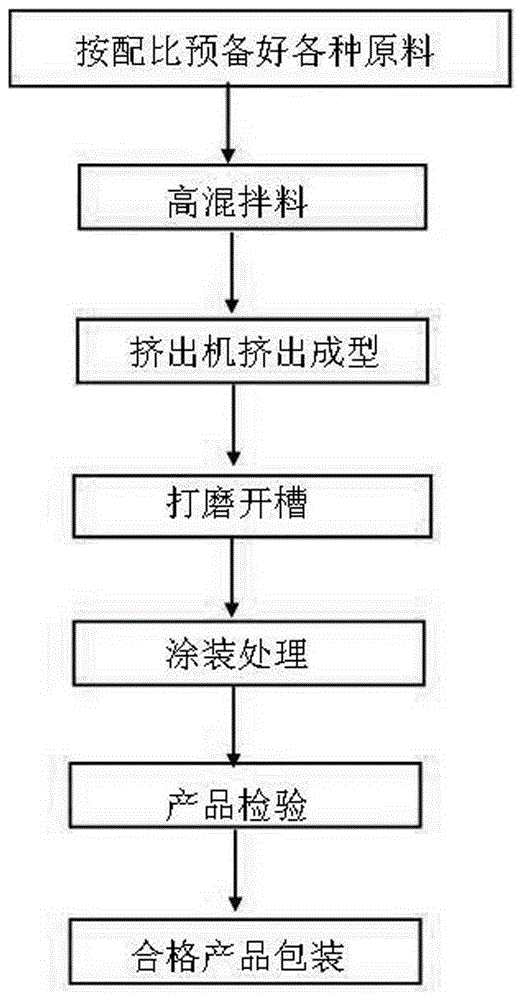

Stone-wood floor and production technology and laying method thereof

The invention belongs to the technical field of indoor and outdoor building decorative materials and production technologies thereof, and provides a stone-wood floor and a production technology and laying method thereof. The stone-wood floor is prepared from, by weight, 90-100 parts of ground limestone, 30-35 parts of PVC, 0.3-0.6 part of stearic acid, 2-2.5 parts of chlorinated polyethylene, 0.5-1.0 part of a foaming agent, 6-7 parts of a foaming control agent and 2-3 parts of a stabilizer. The raw materials are highly mixed and stirred, extruded, molded, ground, slotted and coated to obtain a finished product. The processing procedures are simplified, the cost is lowered, the product quality is improved, the hardness, abrasion resistance and flexibility of the produced product are improved, PVC is foamed to generate pores through the foaming technology, and the pores are filled with microstructures such as the ground limestone, so that the product density reaches 1.2 g / cm<3> which is close to that of a pure wood floor, and the cheap and fine stone-wood floor can be truly obtained.

Owner:南召县磊鑫钙业新型材料科技有限公司

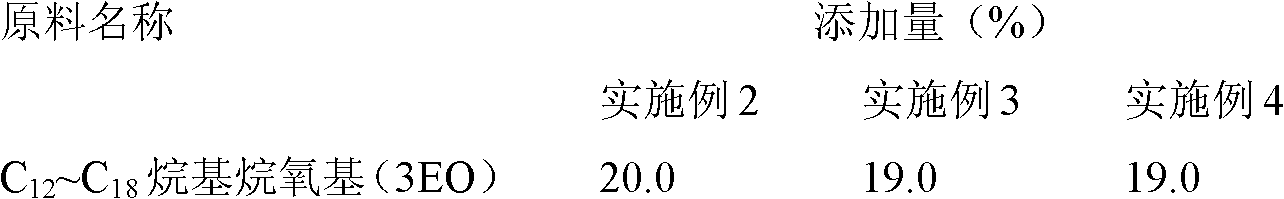

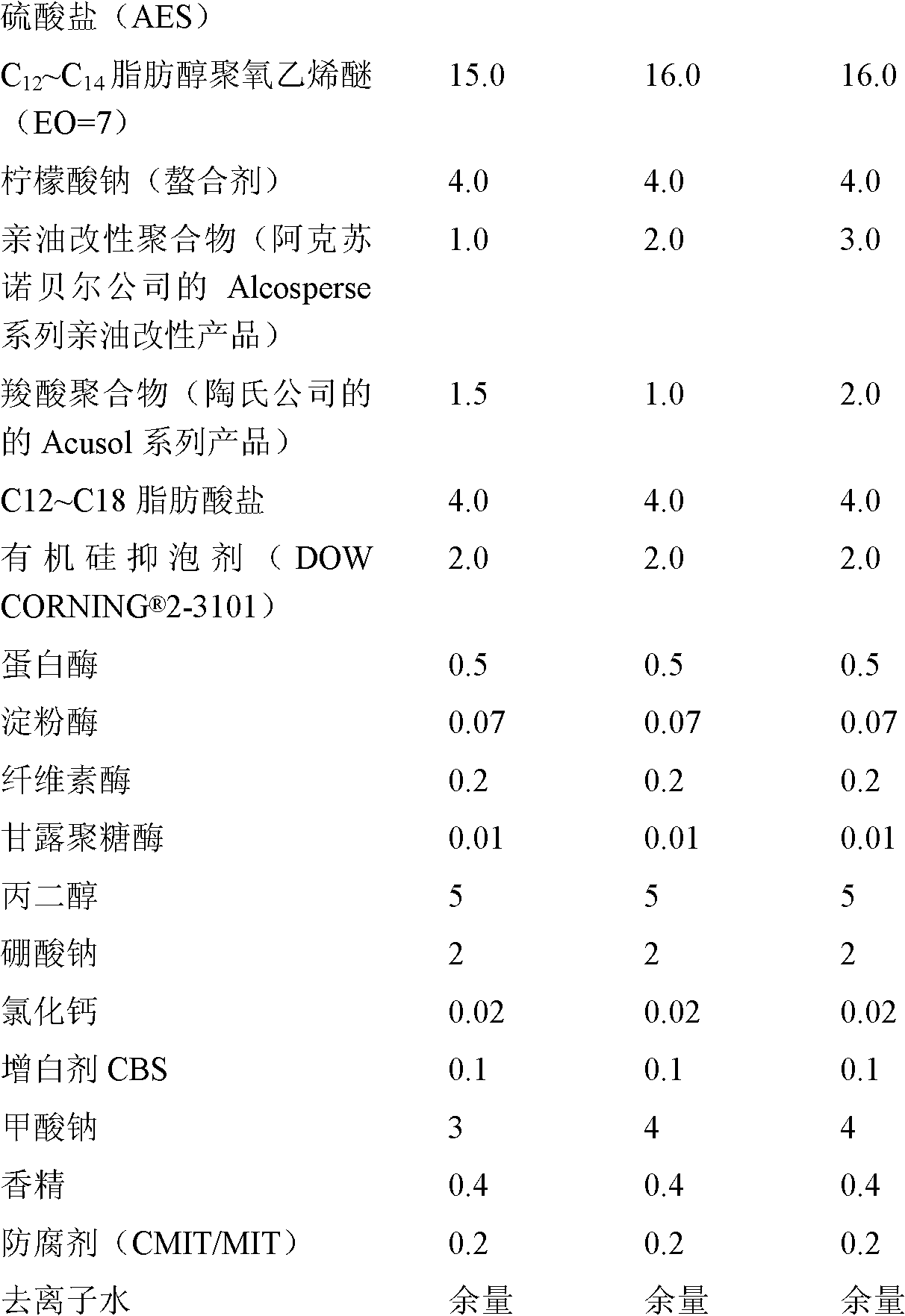

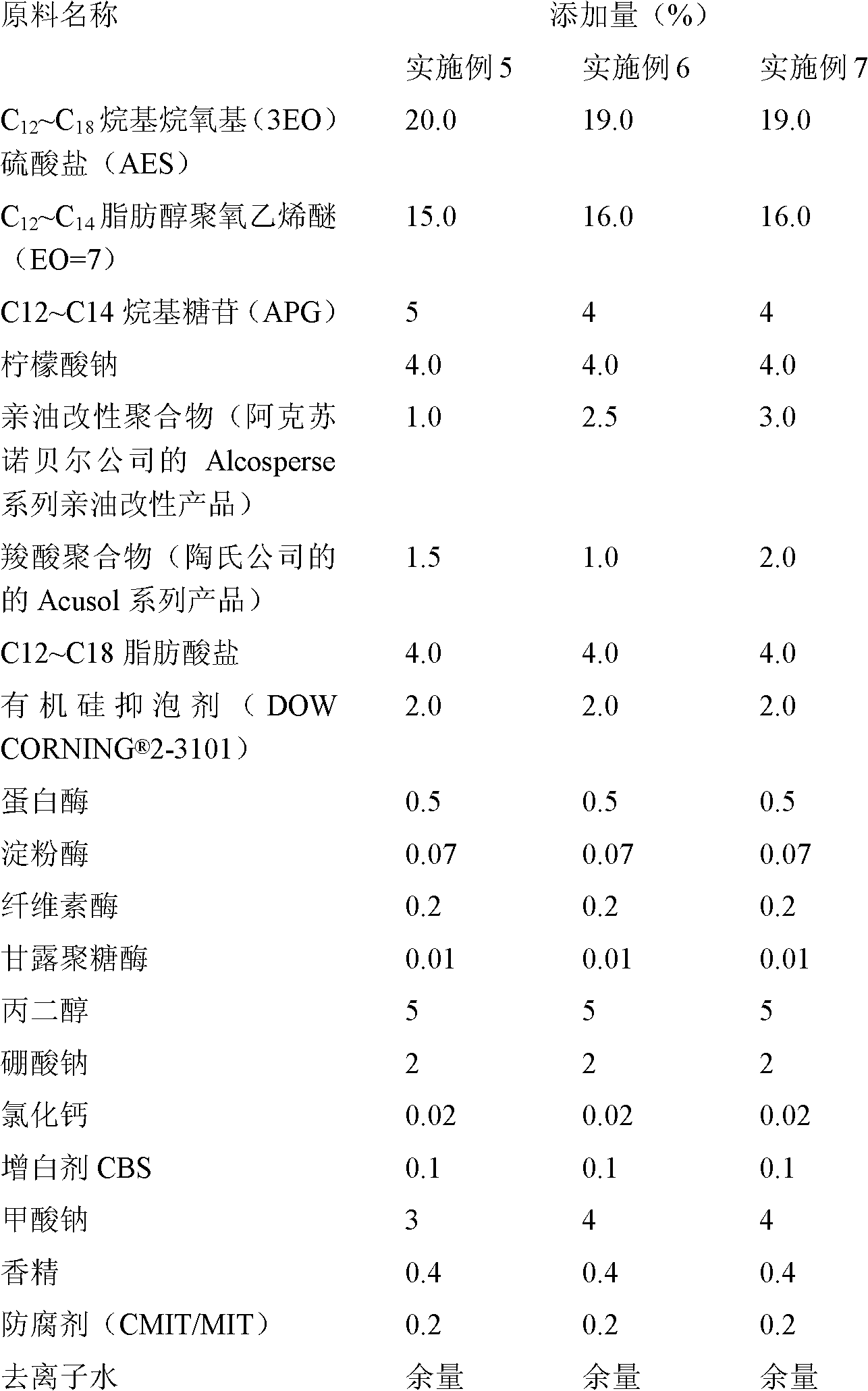

Laundry liquid and preparation method thereof

ActiveCN102071111AShorten the dissolution timeIncrease productivityNon-ionic surface-active compoundsOrganic detergent compounding agentsCarboxylic acidFOAM CONTROL

The invention discloses laundry liquid and a preparation method thereof. The laundry liquid is prepared by the following materials in percentage by mass: 0.1 to 5.0 percent of oleophylic modified polymer, 0.2 to 5.0 percent of carboxylic acid polymer, 1 to 25.0 percent of nonionic surfactant, 1 to 25.0 percent of anionic surfactant, 0.01 to 1.5 percent of enzyme, 0.1 to 15.0 percent of enzyme stabilizer, 0.5 to 8.0 percent of foam control agent, 0.5 to 10 percent of other auxiliary agents and the balance of water. By the preparation method of the laundry liquid, the production time can be reduced by about 30 percent, and the laundry liquid is efficiently produced; and the prepared laundry liquid has high detergency to mud and oil stains and high stain redeposition resistance.

Owner:GUANGZHOU LIBY

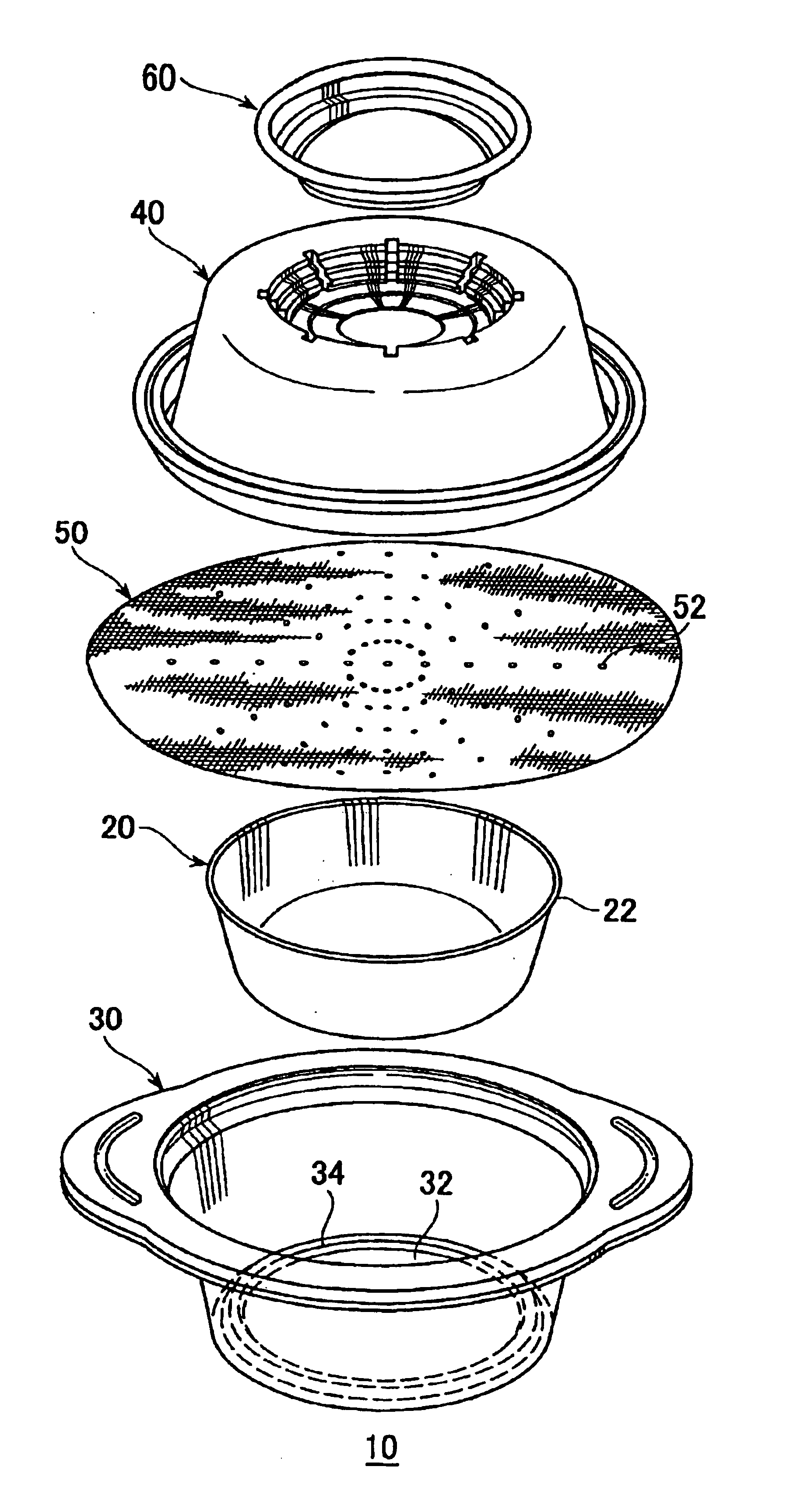

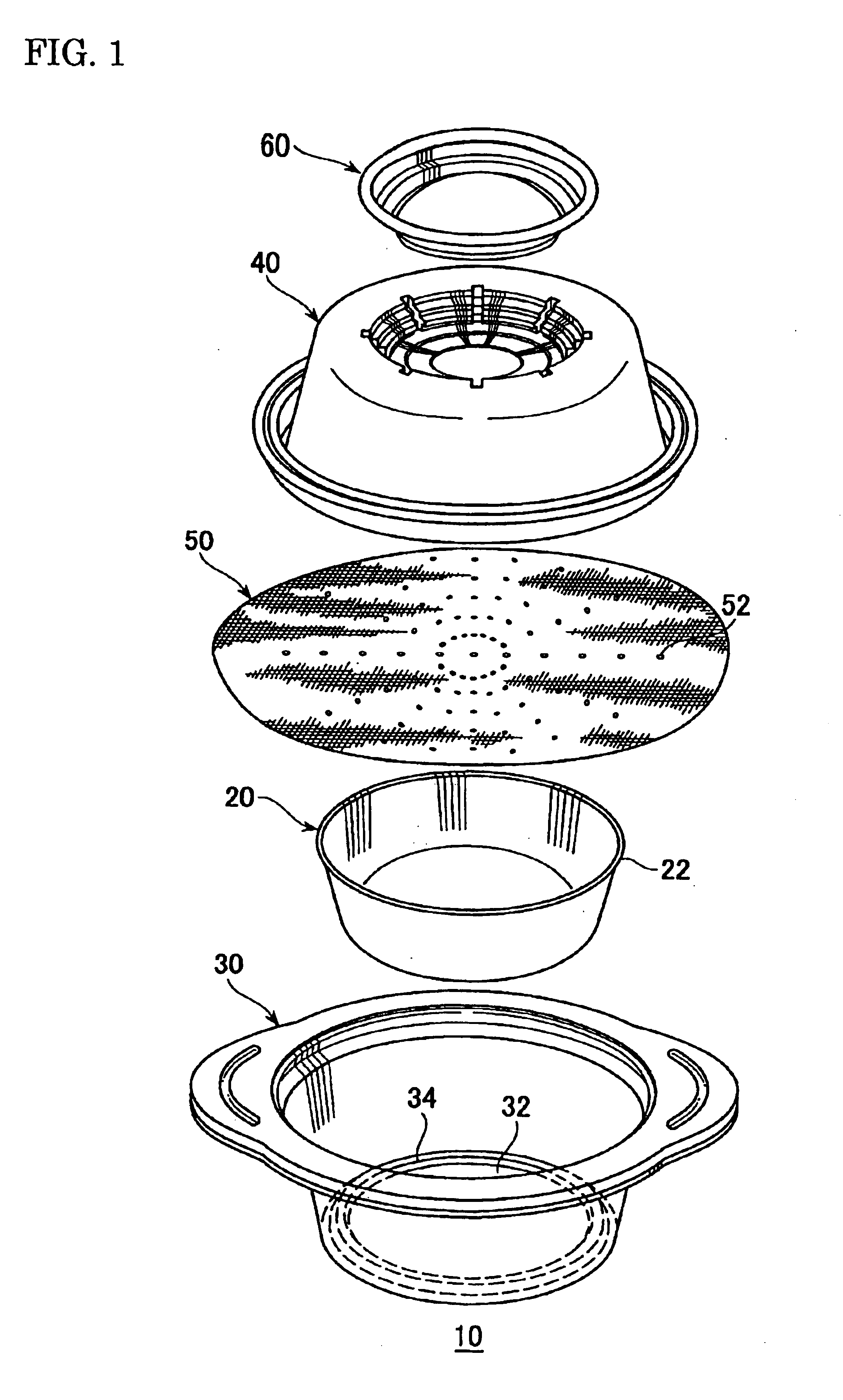

Rice cooking system for microwave oven

A rice cooking system for a microwave oven comprises an inner cooking container for containing rice and rice cooking water, main outer container holding the inner container with a space in between their side surfaces, a lid covering the outer container, and a foam control sheet having a plurality of small holes 52 and supported between the outer container and the lid. The inner cooking container is made of metal and has a folded or rolled a rim. A step at the bottom of the outer container locates the inner cooking container so that its outer wall is spaced from the outer container.

Owner:NEWSCHEF

Foam manipulation compositions containing fine particles

ActiveUS20090252691A1Facilitates formation of foamLower Level RequirementsCosmetic preparationsNanotechFOAM CONTROLSURFACTANT BLEND

A foam manipulation stabilizing composition for use in consumer products includes a plurality of surface-modified particles in combination with at least one surfactant. The particles have an average particle size greater than 100 nm up to about 50 μm and a hydrophobicity measured by a contact angle between about 20° to 140°. The ratio of particles-to-surfactant may be between about 1:20 to about 20:1. The surface modification may include grafting pH or temperature switching functional groups to the particles or to a composition, such as a polymer, coated on the particle. A method for reducing the level of foam in a rinse solution is also described.

Owner:THE PROCTER & GAMBLE COMPANY

Systems and methods for controlling foaming

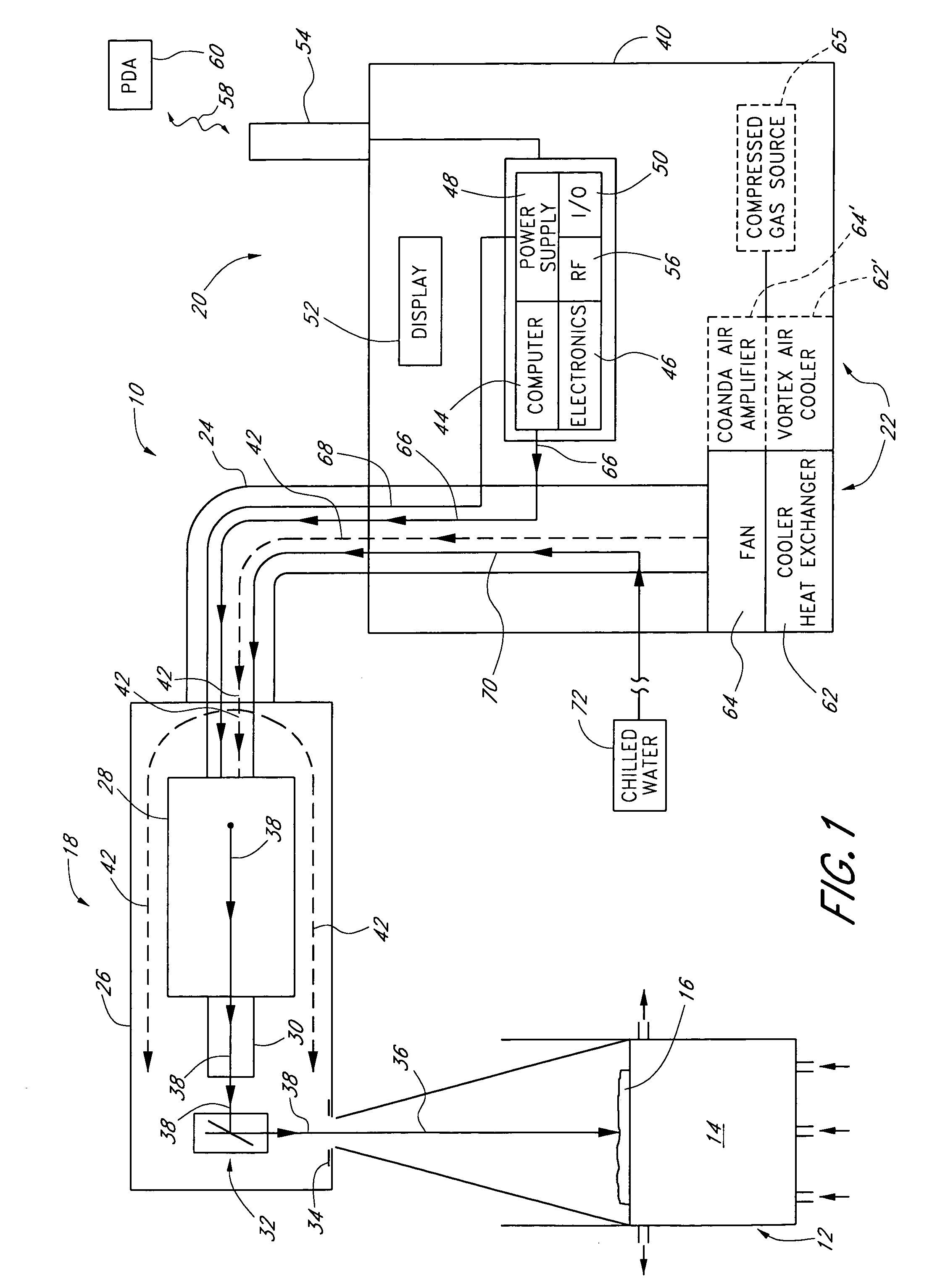

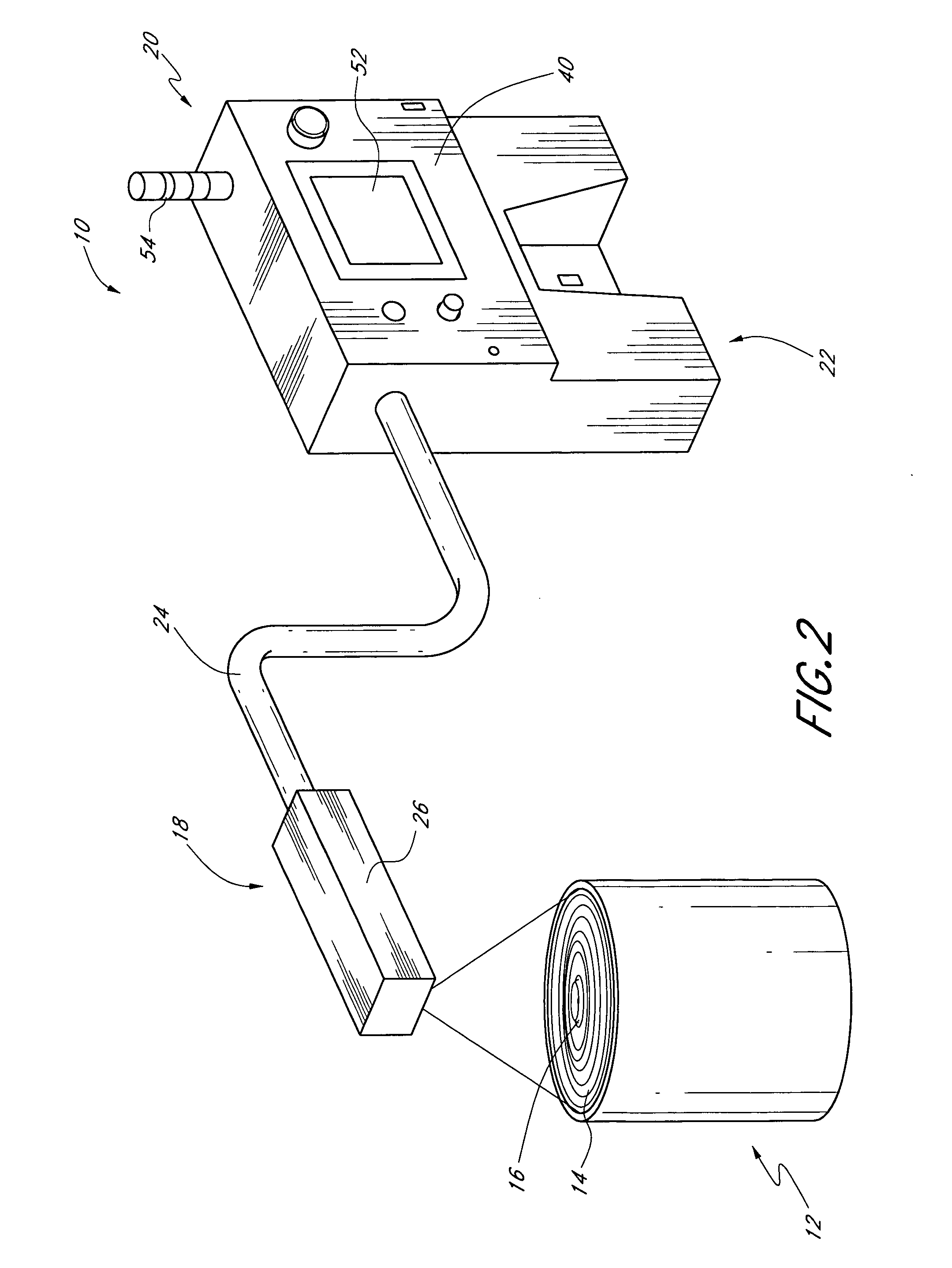

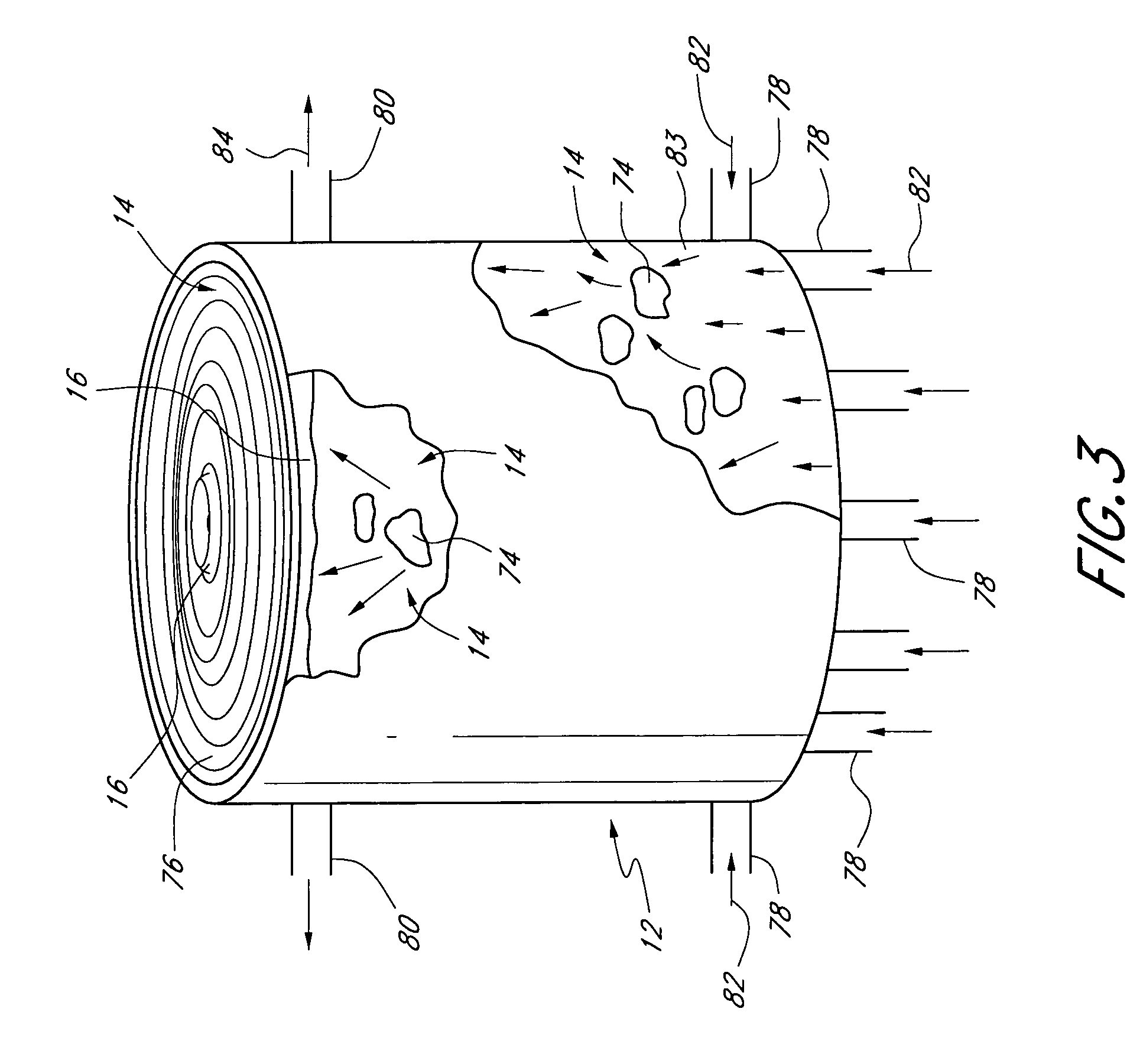

InactiveUS20070089606A1Easy to customizeEasily tailoredDough treatmentMilk preservationControl systemEngineering

A foam controlling system uses electromagnetic energy to cut foam on the surface of a solution or liquid in a processing tank into at least two portions prior to the foam propagating and reaching the perimeter of the tank such that currents within the solution or liquid dissipate at least one of the foam portions. A purging fluid is provided to a laser head unit of the foam controlling system to reduce the dew point therein and thereby reduce or substantially eliminate undesirable condensation that could otherwise cause adverse optics contamination. Advantageously, the versatility and simplicity of the foam controlling system as well as its adaptability to various manufacturing formats makes the system an economical full plant solution.

Owner:HOROS TECH

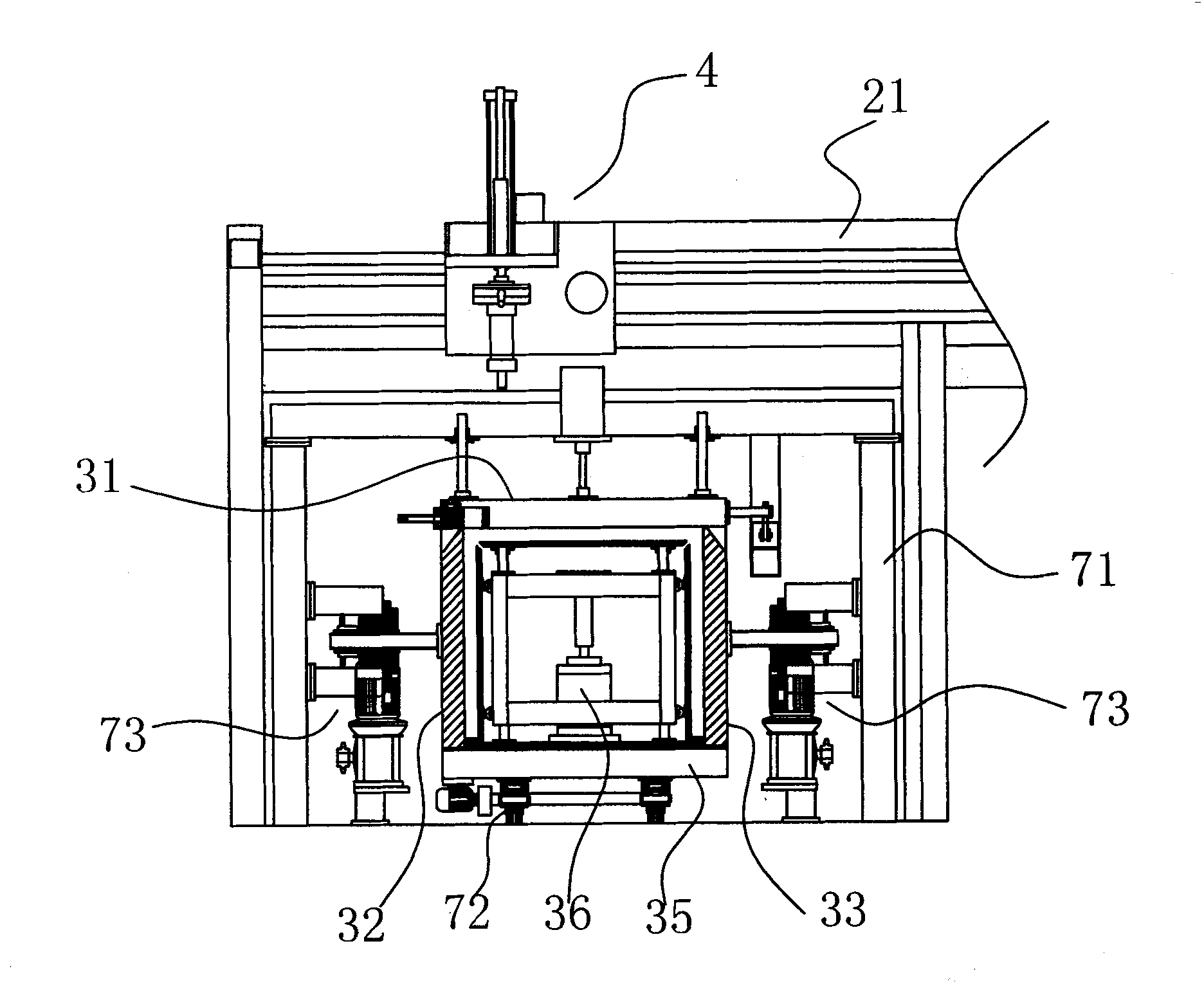

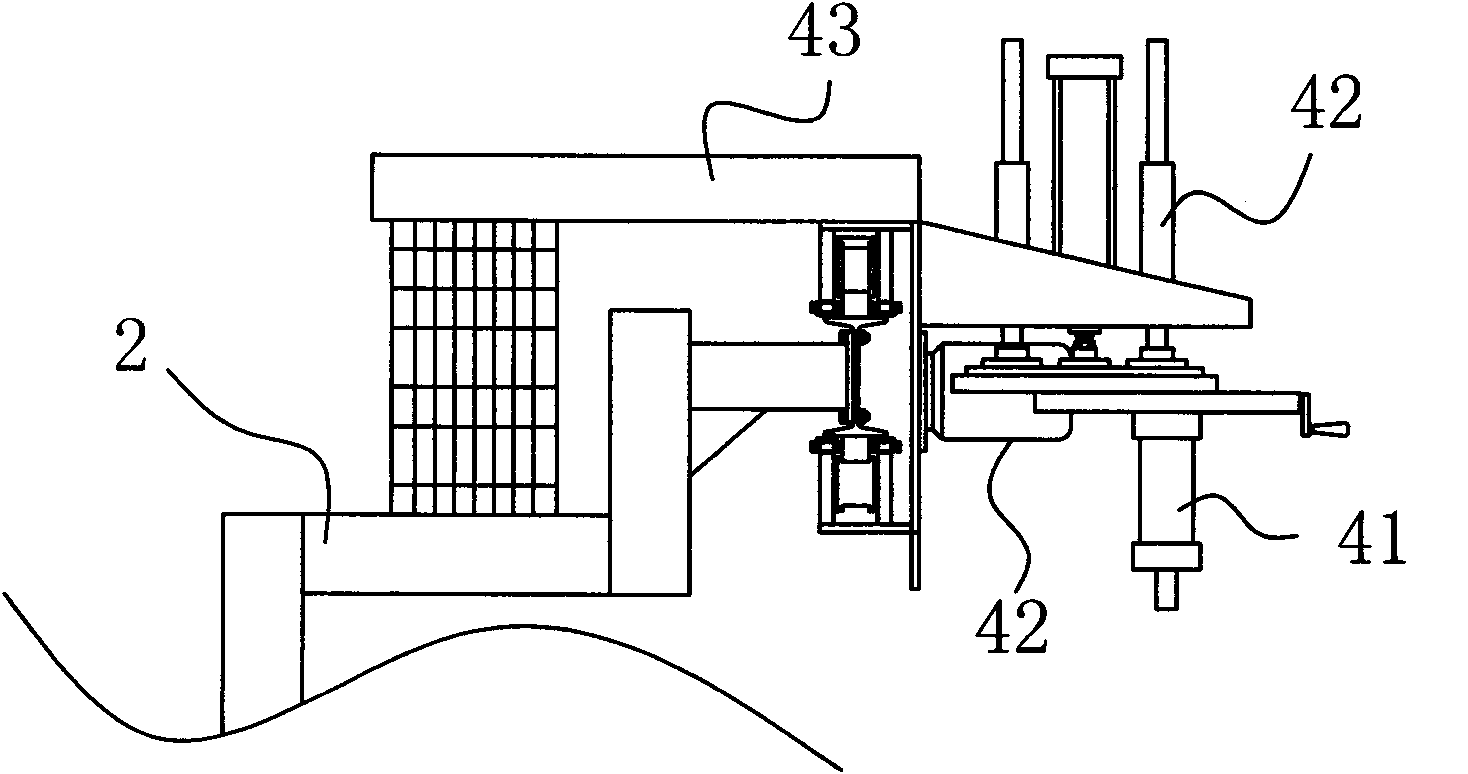

Full-automatic production method of multi-station mobile fixed foaming freezer body and system thereof

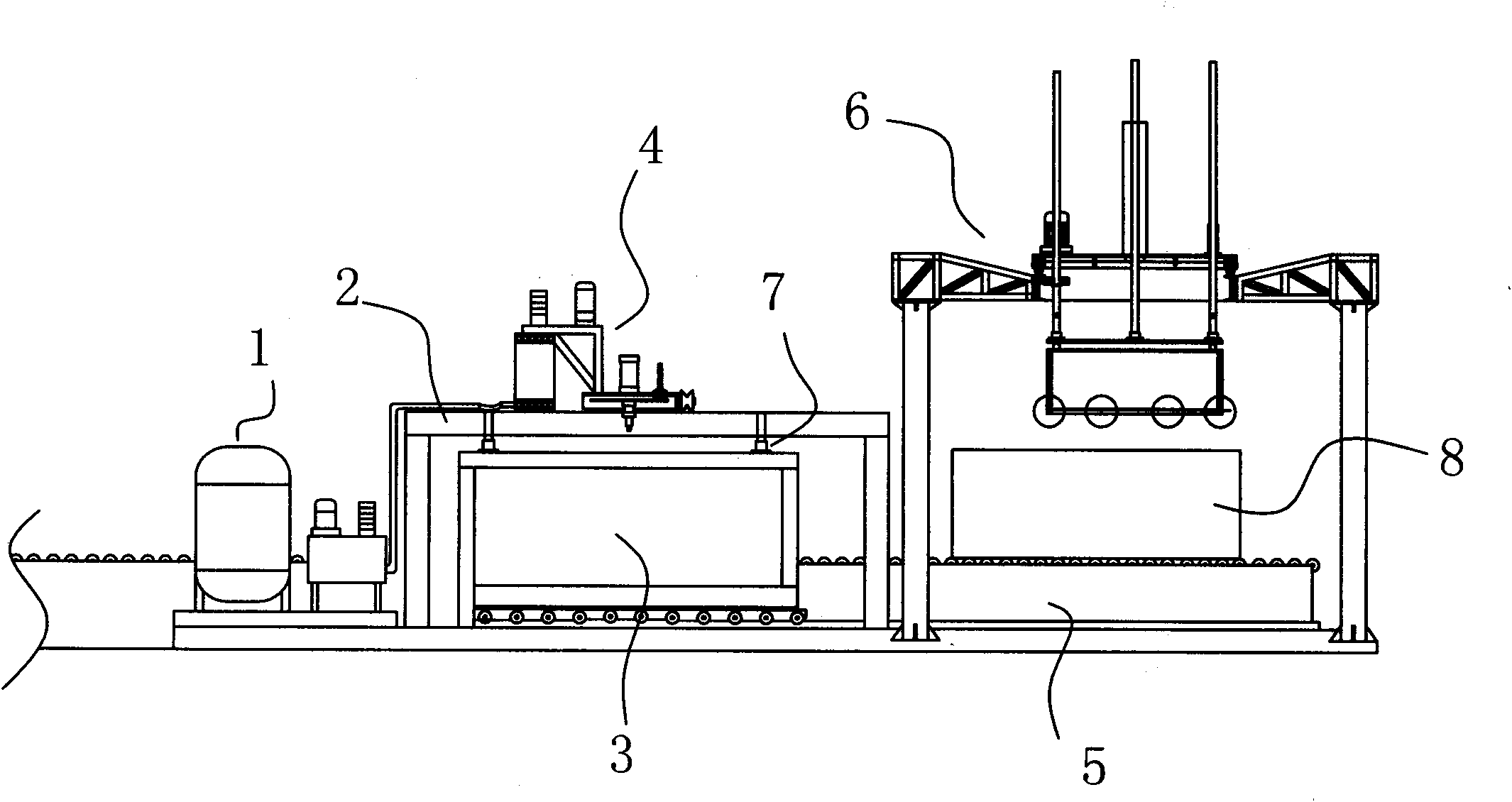

InactiveCN101913223AFlexible adjustment of specificationsReduce investmentDomestic articlesAutomatic controlRobot hand

The invention discloses a full-automatic production method of a multi-station mobile fixed foaming freezer body, comprising the following steps of: (1) setting foaming equipment and an automatic foaming control system capable of controlling the work state of the foaming equipment; (2) setting a foaming mould frame with a slide at the top; (3) arranging multiple fixed foaming moulds below the slide juxtaposedly; and (4) setting a pouring manipulator which is controlled by the automatic foaming control system. The invention also discloses a system for implementing the method. The invention employs a mobile fixed foaming technology and an automatic control technology and has simple production process and automated process, thereby effectively decreasing the supervisor, making the operation convenient, greatly reducing the labour intensity, saving the manpower and material resources, and reducing the production cost; furthermore, a multi-station batch production technology with rapid production speed, short period and guaranteed product quality is added, thereby greatly improving the production efficiency and the product qualification rate and strengthening the enterprise competitiveness.

Owner:东莞市百利电器有限公司 +1

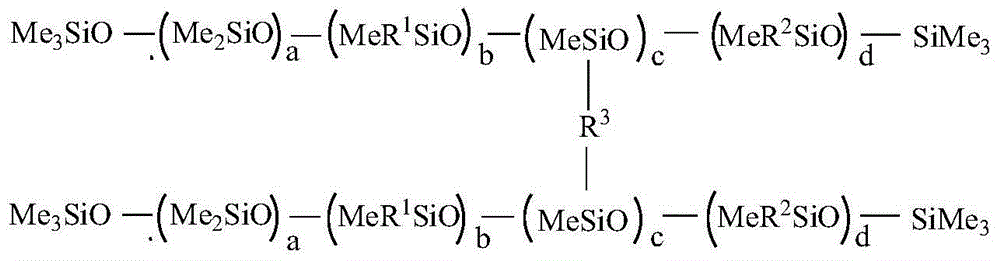

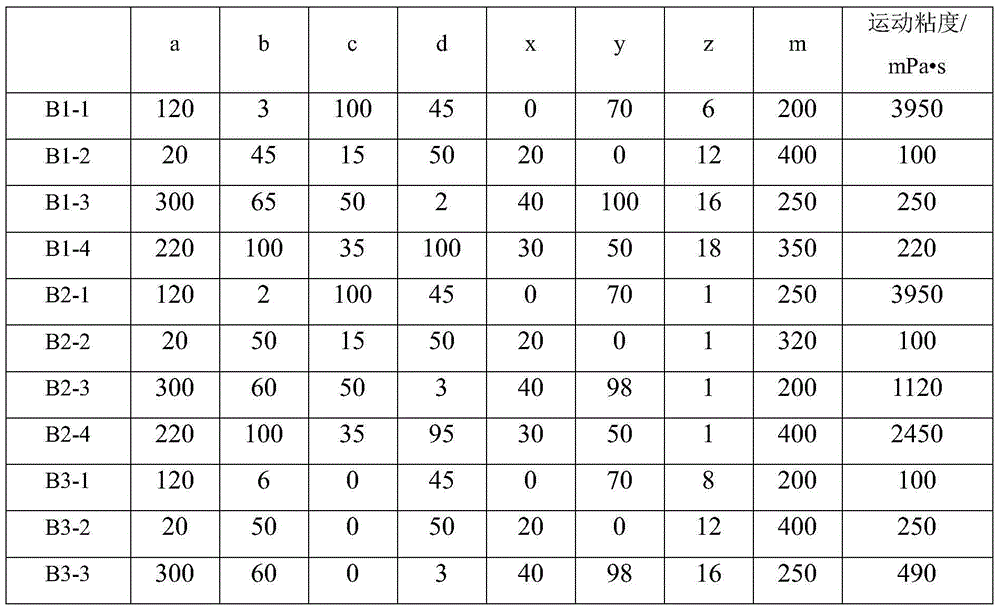

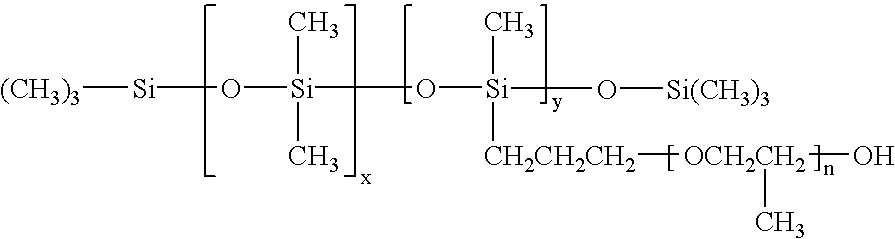

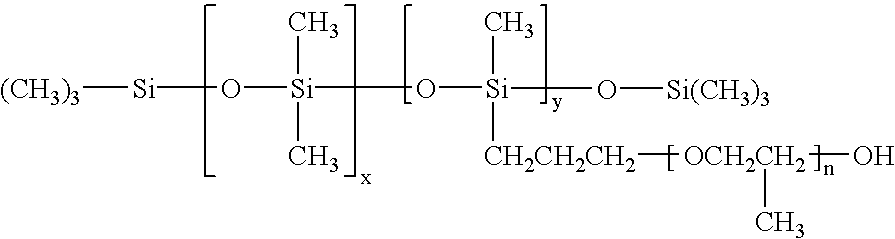

Organic-silicon composition, preparation and application thereof

The invention discloses an organic-silicon defoaming agent composition. The organic-silicon defoaming agent composition with a specific assembling structure and high content is prepared by adopting compounding of cross-linking type polyether-polydi-organic-group siloxane and branched-chain type polyether-polydi-organic-group siloxane and matching with the synergistic effect of polyether polyol and has good wrapping and dispersing effects for organic-silicon defoaming active matters with alkyl structures so as to have more-ideal foam control effect in a liquid detergent and simultaneously have better stability and smaller turbidity value.

Owner:JIANGSU SIXIN SCI-TECH APPL RES INST CO LTD

Foam control agents for coatings

This invention relates to foam control agents for paints and coatings comprising a (a) a siloxane polyalkyleneoxide copolymer, (b) N,N'-ethylene bisstearamide, and (c) a carrier.

Owner:ASHLAND LICENSING & INTPROP LLC

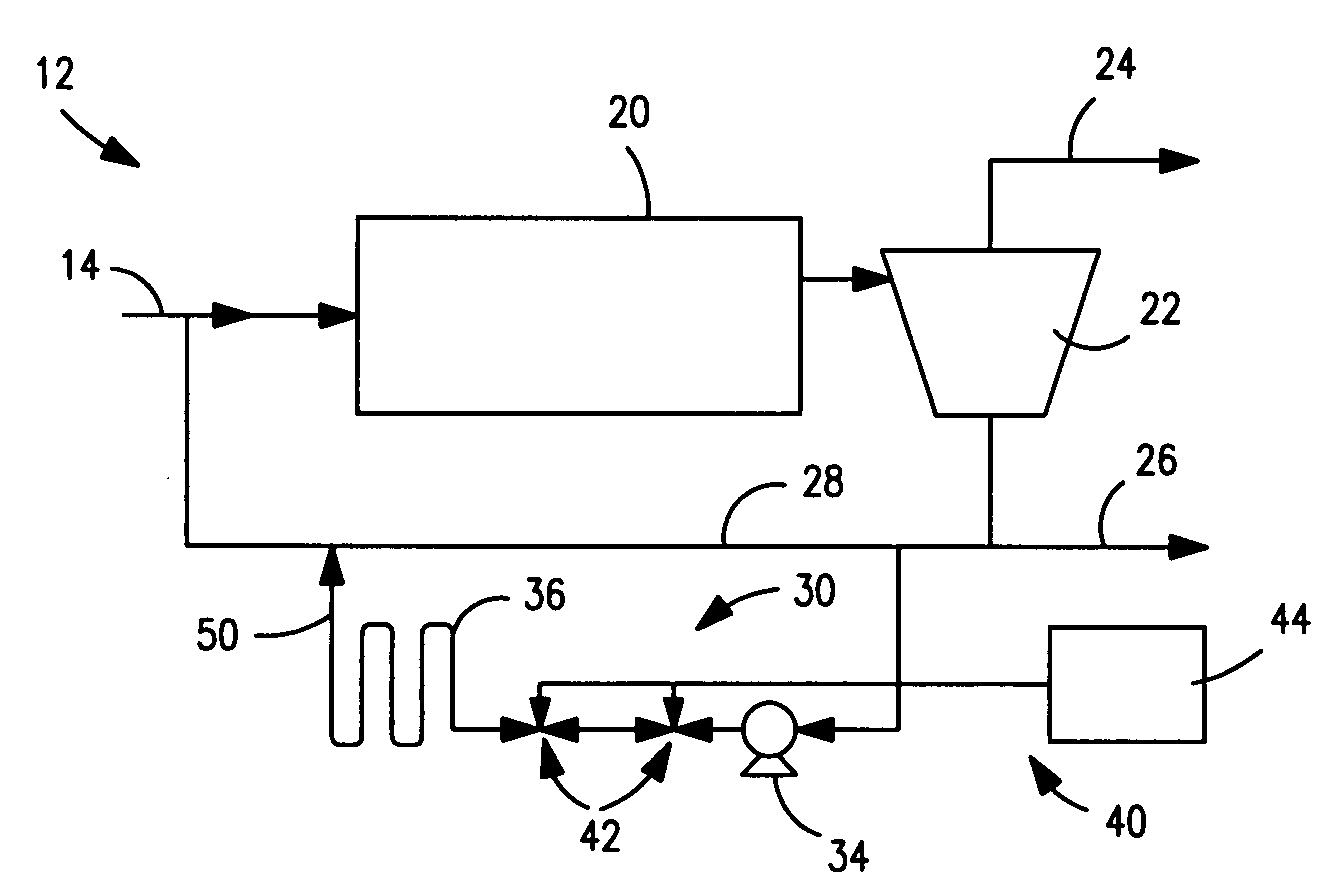

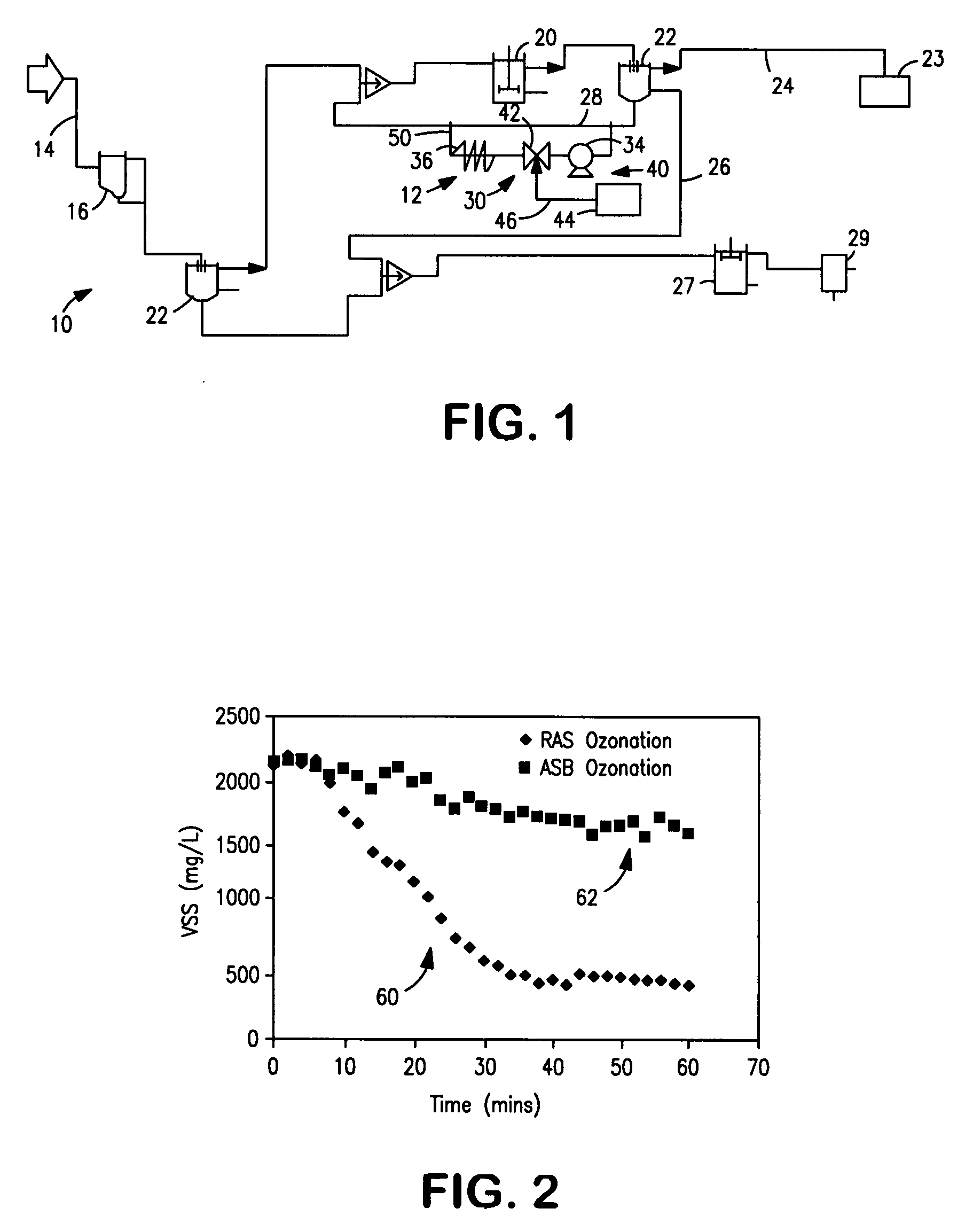

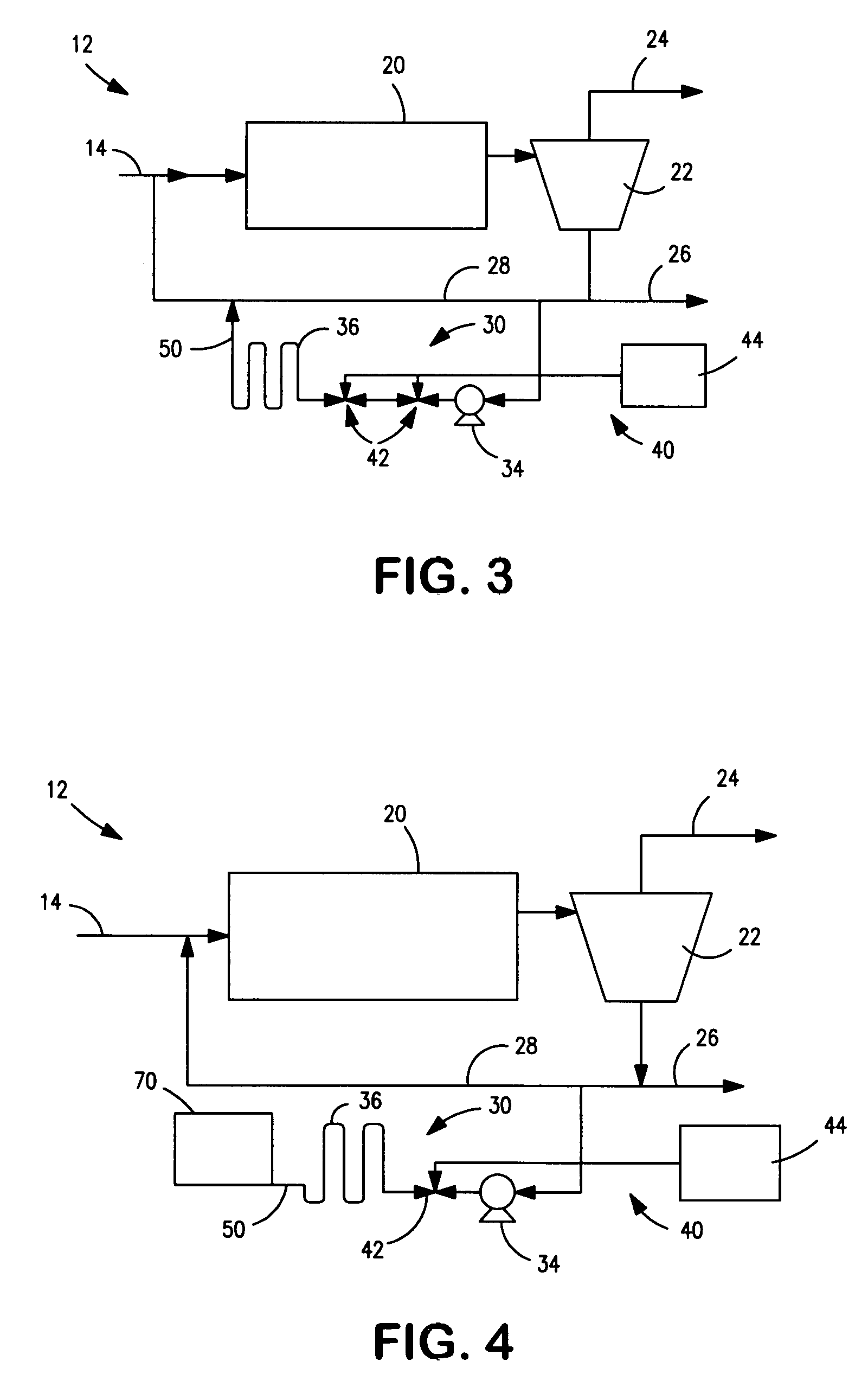

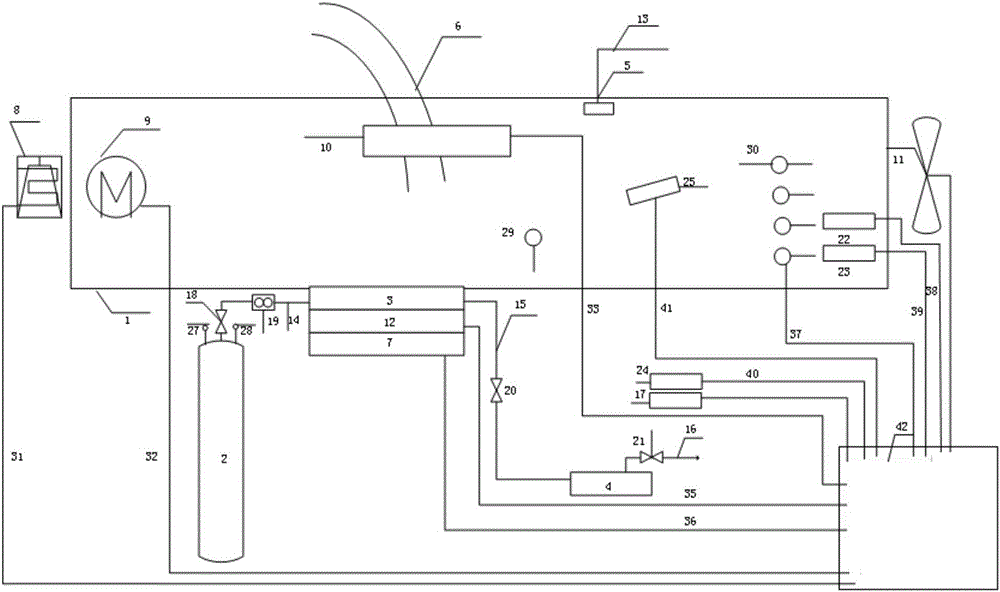

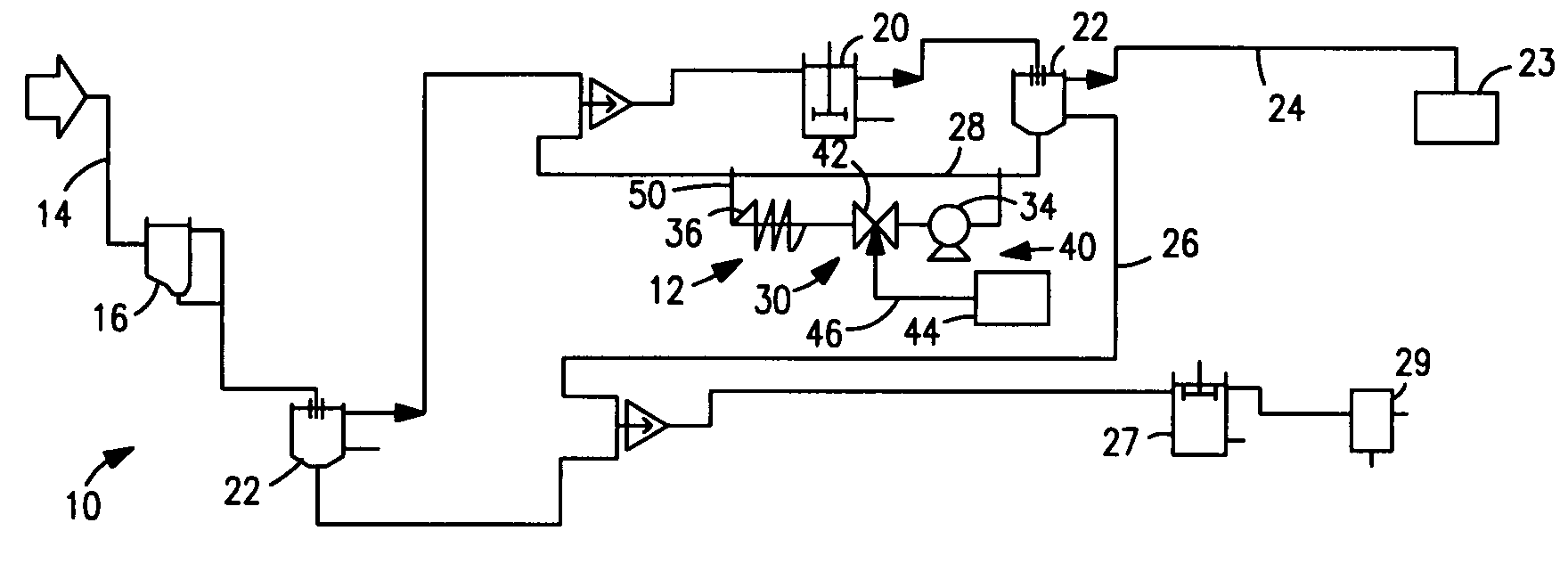

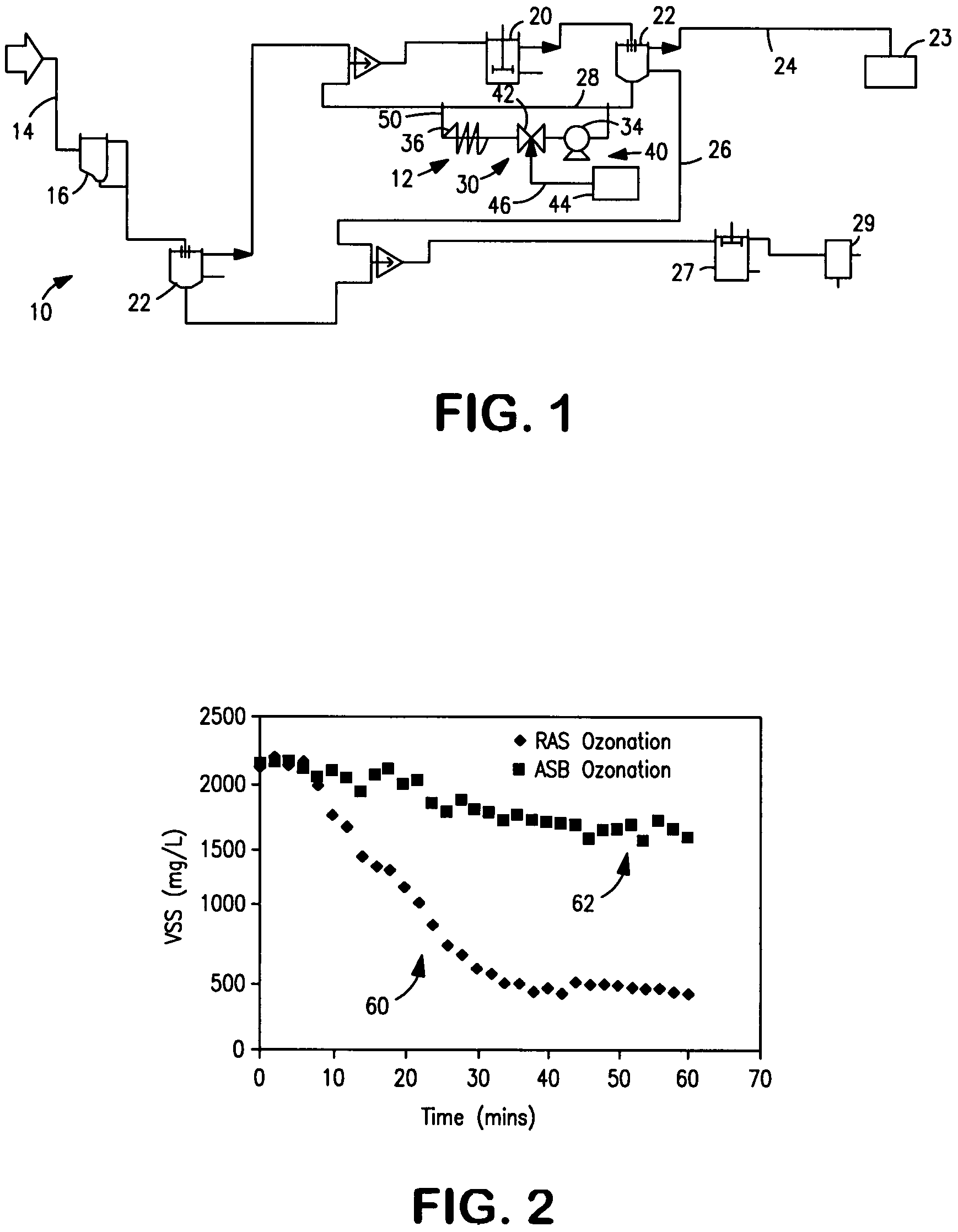

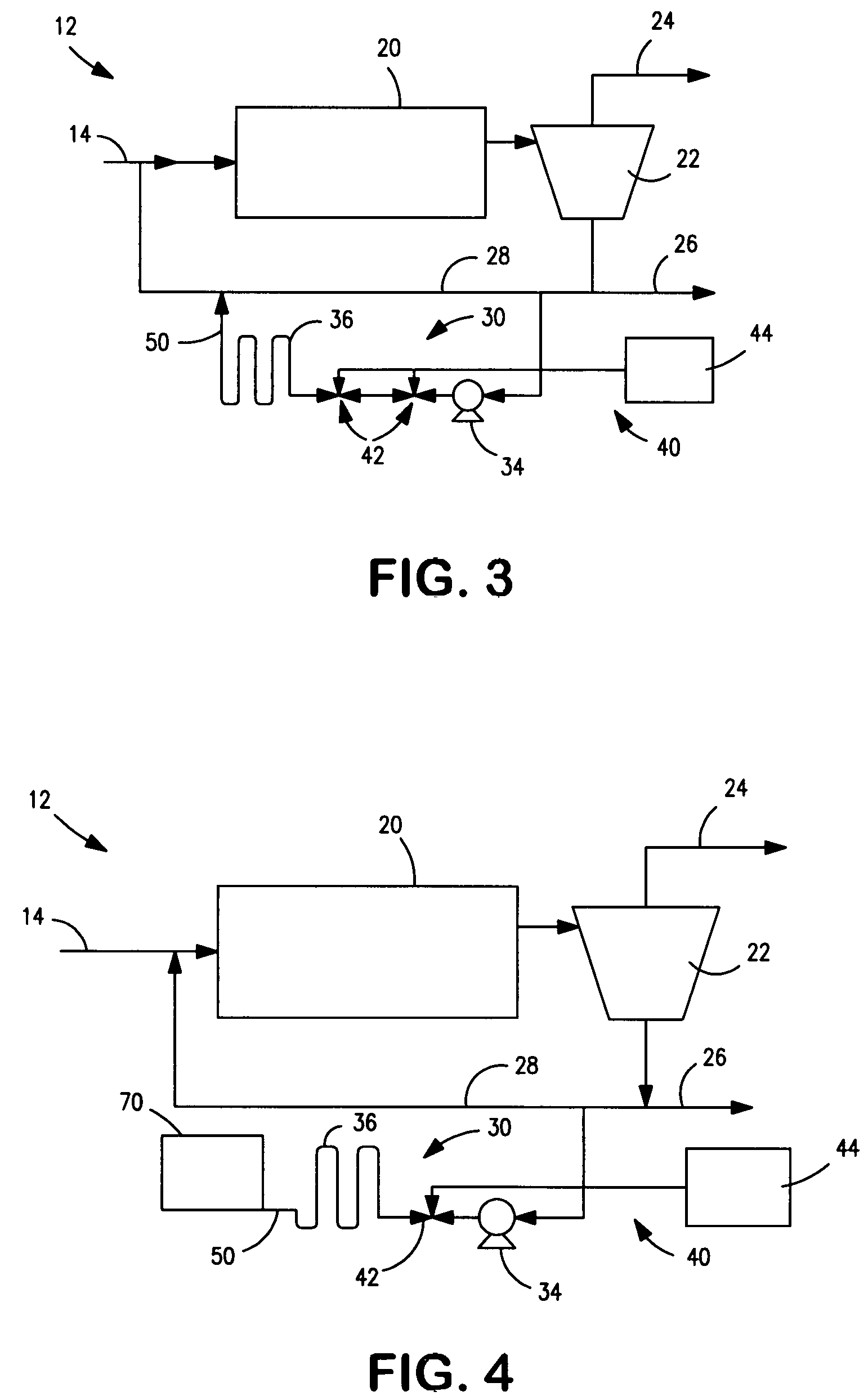

Ozonation of wastewater for reduction of sludge or foam and bulking control

InactiveUS20080105614A1Reducing foaming and bulkingInduce lysis of filamentous bacteriaWater treatment parameter controlTreatment using aerobic processesActivated sludgeFOAM CONTROL

A system and method for the ozone treatment of wastewater is disclosed. The disclosed wastewater treatment system includes a high selectivity reactor coupled to an activated sludge treatment basin. The high selectivity reactor is adapted to receive a stream containing sludge diverted directly or indirectly from the activated sludge treatment basin. The disclosed wastewater treatment system and method is adapted to inject a chemical agent, such as ozone-enriched gas, into the diverted stream for treatment within the high selectivity reactor for purposes of sludge reduction, foam control, or bulking control. The treated stream is then returned to the activated sludge treatment basin.

Owner:PRAXAIR TECH INC

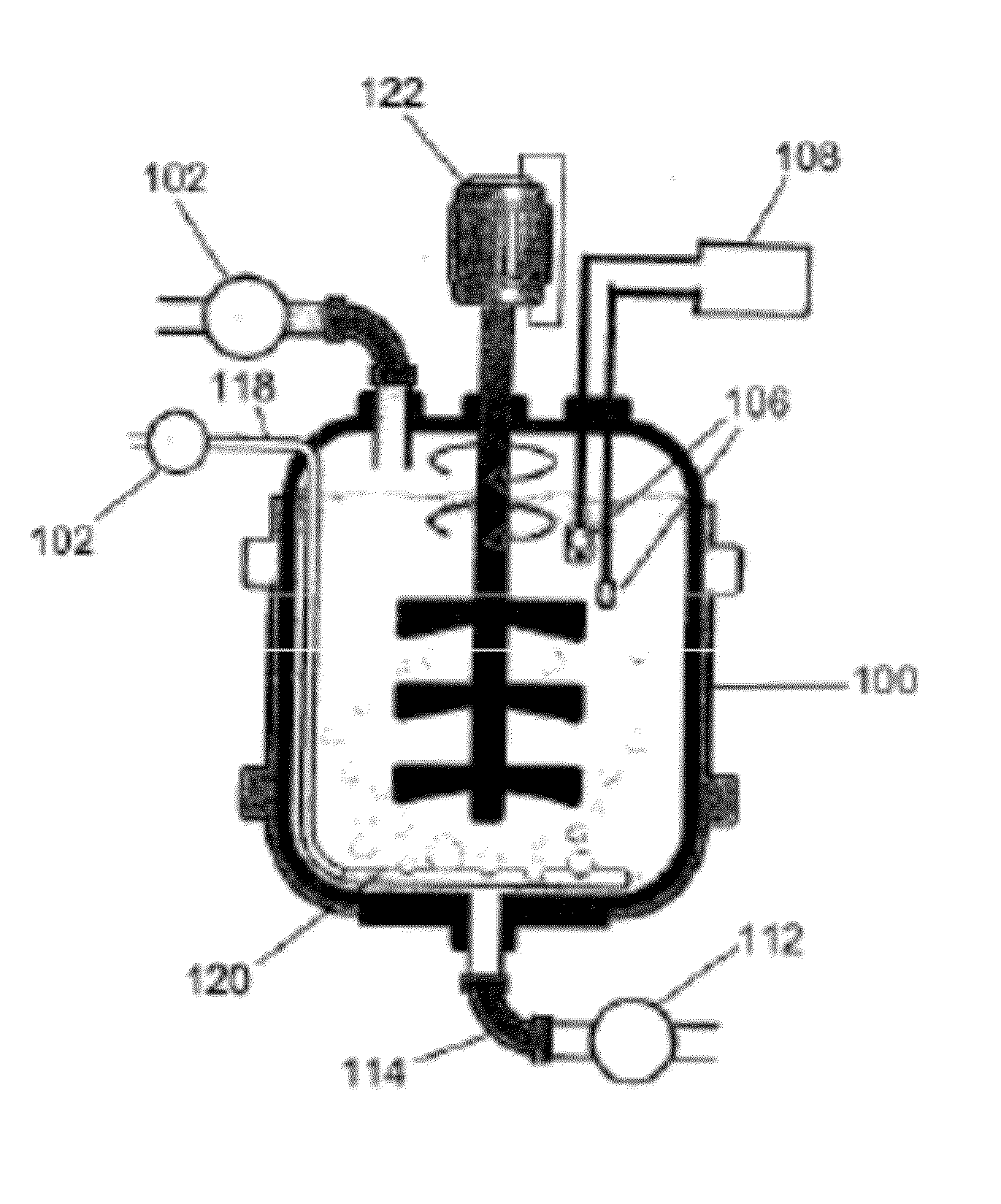

Heavy gas leakage diffusion simulation and inhibition control test system

The invention discloses a heavy gas leakage diffusion simulation and inhibition control test system. The heavy gas leakage diffusion simulation and inhibition control test system comprises an experiment wind tunnel, a heavy gas filling and recycling mechanism, an inhibition control unit and a data acquisition unit, wherein the heavy gas filling and recycling mechanism is used for injecting heavy gas into the experiment wind tunnel, and recycling low-temperature liquid; a natural environment simulation unit is arranged in the experiment wind tunnel to regulate natural environment parameters in the experiment wind tunnel; after the injected heavy gas is subjected to a water-curtain control test, a high-power foam control test and / or an obstacle test in the experiment wind tunnel through the inhibition control unit, the control effect is obtained by a monitoring point array at the downstream of the experiment wind tunnel. The heavy gas leakage diffusion simulation and inhibition control test system can be used for simulating and analyzing key factors which affect an evaporation rate as well as a leakage diffusion vapor temperature, concentration and distribution and the influence degree, under different leakage dimension shape positions, temperatures, humidity, wind speeds, radiation as well as active and passive control, of heavy gas, observing, extracting and analyzing minute links, tracing matter energy direction, performing mechanism study and establishing numerical simulation.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Methods of foam control

The invention relates to a method for decreasing foam formation as well as maximizing expression of a biosurfactant in a microorganism. The methods encompasses precipitating a biosurfactant from the microorganism which results in decreased form formation.

Owner:DANISCO US INC

Method for controlling bottom water fingering by foam

The invention discloses a method for controlling oil well bottom water coning by foam. In the method, a mass of foam is injected at the oil-water boundary of an oil well so that a foam plugging area is formed. In the technical technology of controlling oil well bottom water coning by foam in the invention, a mass of foam is injected at the oil-water boundary of the oil well so that a stable foam plugging band is formed. The injected foam has the characteristic of selective water plugging that the foam is broken when meeting oil and is stable when meeting water, so that the foam is comparatively stable at the oil-water boundary and is not easy to be broken and raising of bottom water can be efficiently plugged; and at an oil reservoir, the foam stability becomes weakened due to damage of the oil to the foam, and the foam is easy to be broken, but the output of crude oil in the oil layer is not influenced.

Owner:CHINA NAT OFFSHORE OIL CORP +1

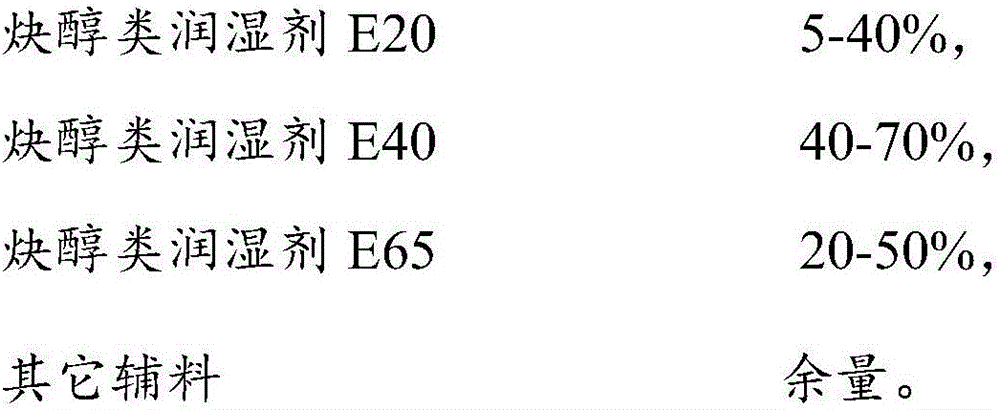

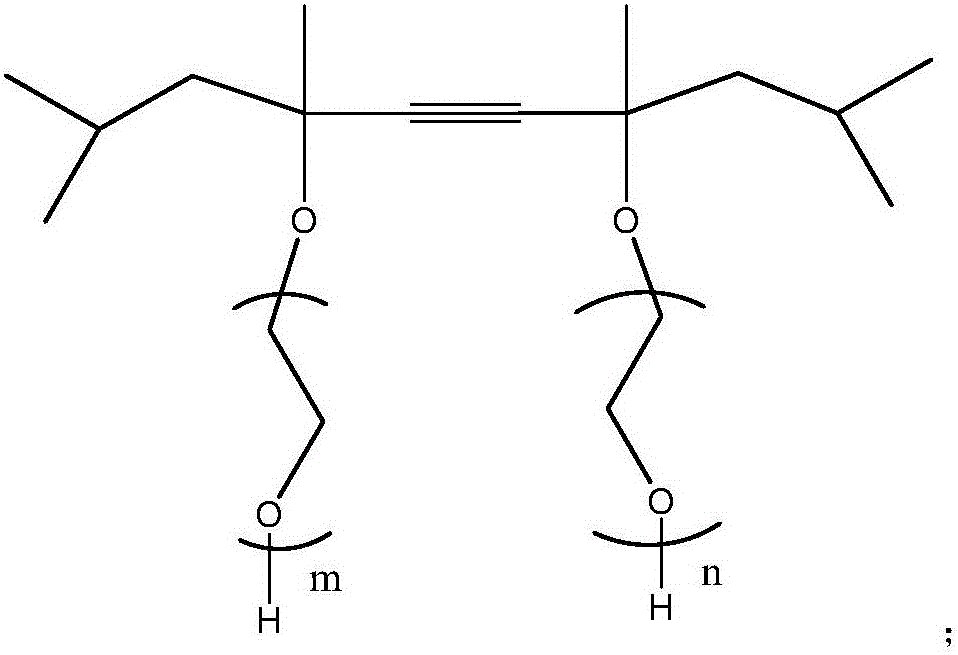

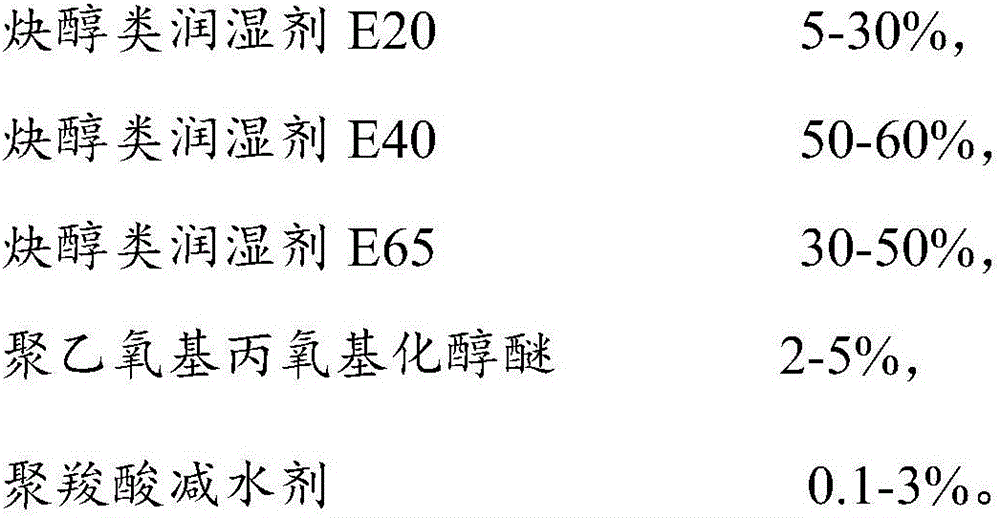

Foam control agent and air-entraining water reducing compounding agent and concrete prepared thereof

The invention provides a foam control agent and an air-entraining water reducing compounding agent and concrete prepared thereof. The foam control agent is mainly formed by compounding the following components by weight: 5-40% of an alkynol wetting agent E20, 40-70% of an alkynol wetting agent E40, 20-50% of an alkynol wetting agent E65, and the balance other accessories. The foam control agent has double technical effects of air entraining and foam control, can control the foam density and the foam size of a system, makes foams more uniform, eliminates big harmful foams, and makes the cement strength, stability and other properties improved.

Owner:岳阳凯门水性助剂有限公司

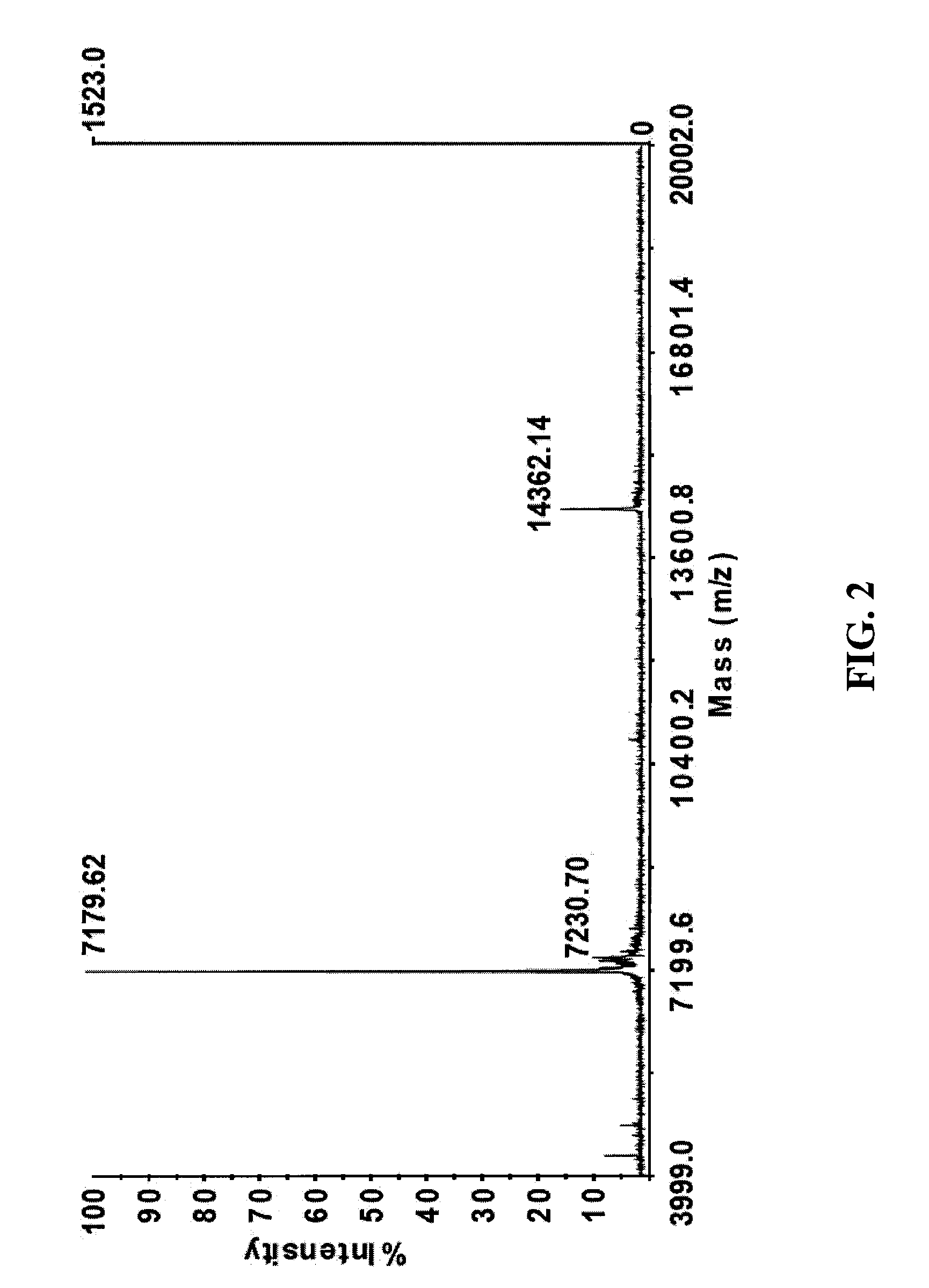

Preparation method of alkyloxy azobenzene photosensitive foam control agent

ActiveCN104496844AImprove uniformityAchieve reversible transformationOrganic chemistryDyeing processIsomerizationPhotochemistry

The invention discloses a preparation method of an alkyloxy azobenzene photosensitive foam control agent, which belongs to the technical field of textile chemical engineering. 4, 4 '-dihydroxy azobenzene is synthesized by nitrobenzene reduction method from nitrophenol as a raw material, and an azobenzene type photosensitive switch surfactant is obtained by nucleophilic substitution reaction for substitution of hydrogen of hydroxide radical of the 4, 4 '-dihydroxy azobenzene and introduction of an alkyl chain; trans-to-cis reversible isomerization of 4-hydroxy-4 '-alkyloxy azobenzene azobenzene can be completed in the ultraviolet and visible light irradiation, surface alignment compact degree of a foam liquid film can be changed by steric hindrance, foam stabilization and breaking can be controlled reversibly, the alkyloxy azobenzene photosensitive foam control agent can be used as a foam stabilizing agent and a foam breaker to solve the contradiction of different foaming stability needs before and after foam dyeing and finishing, and by recycling of residual foam after the dyeing and finishing, the pollution and waste of chemical reagents can be effectively reduced.

Owner:JIANGNAN UNIV

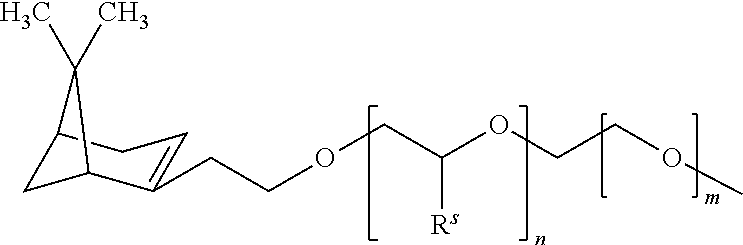

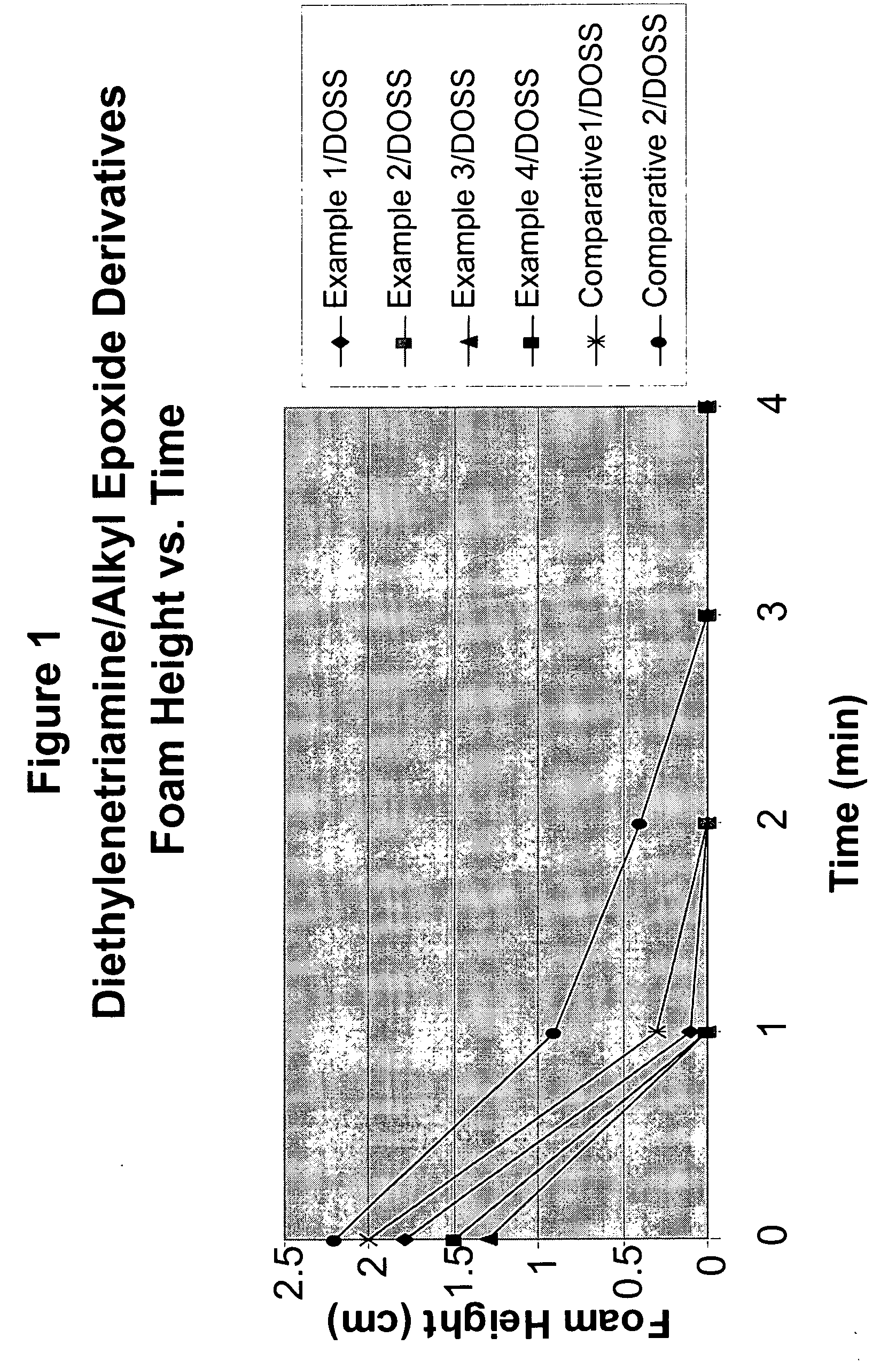

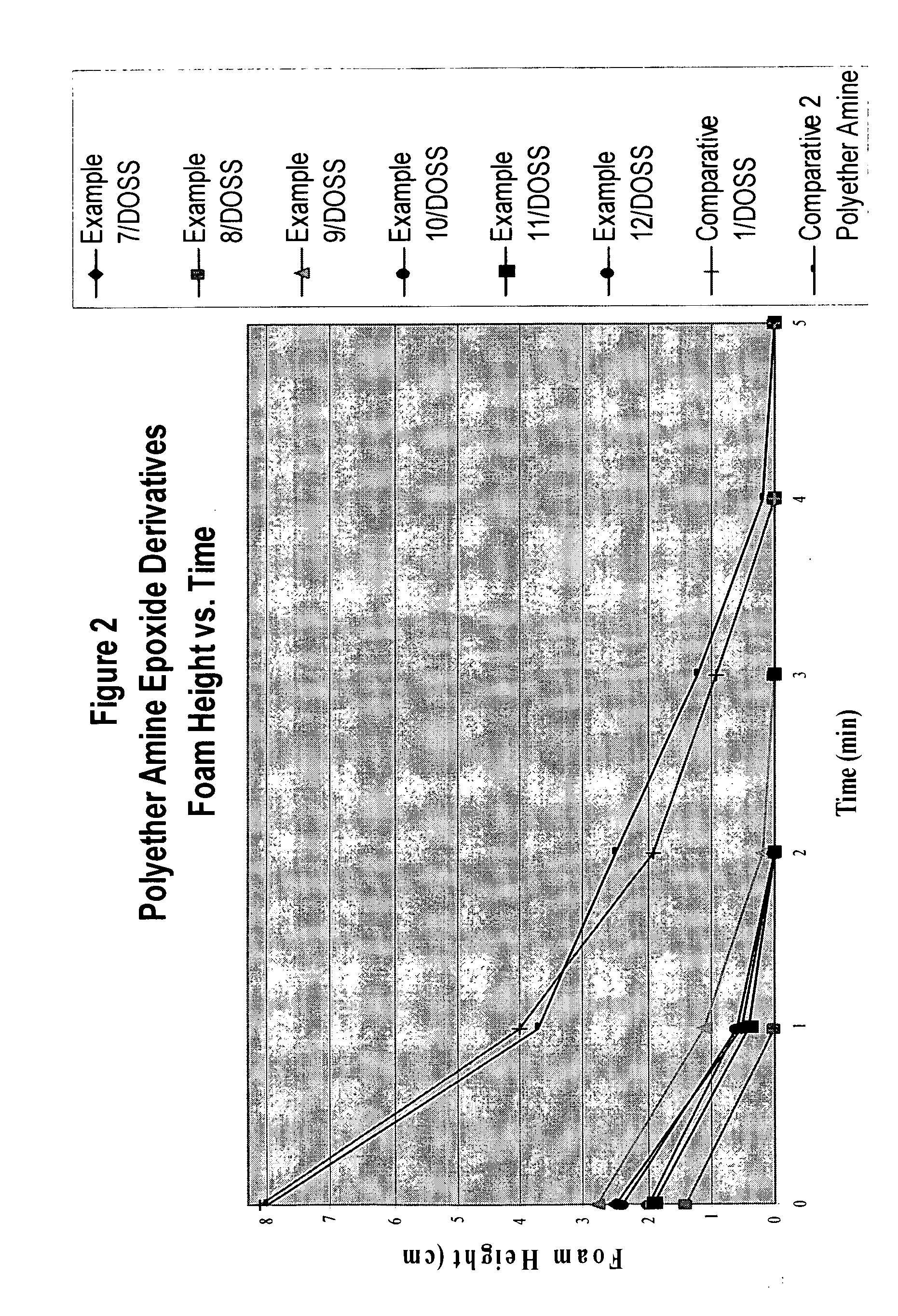

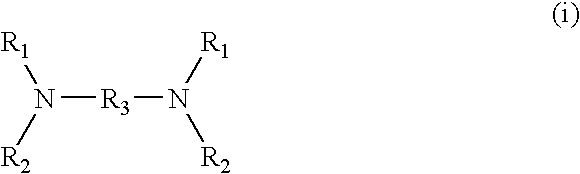

Alkoxylated polyamines and polyetheramine polyol compositions for foam control

ActiveUS20090149369A1Organic detergent compounding agentsSurface-active detergent compositionsWater basedOxygen

This invention relates to novel compounds derived from the reaction of diamines or polyamines with alkylene oxides. The invention also relates to novel compounds derived from the reaction of amine terminated polyethers with epoxide functional compounds. The novel compounds of the invention are particularly useful as wetting and foam control agents. The disclosed compounds exhibit exceptional antifoaming and defoaming activity while simultaneously reducing the dynamic surface tension when incorporated at low levels in water-based systems.

Owner:ETHOX CHEM LLC

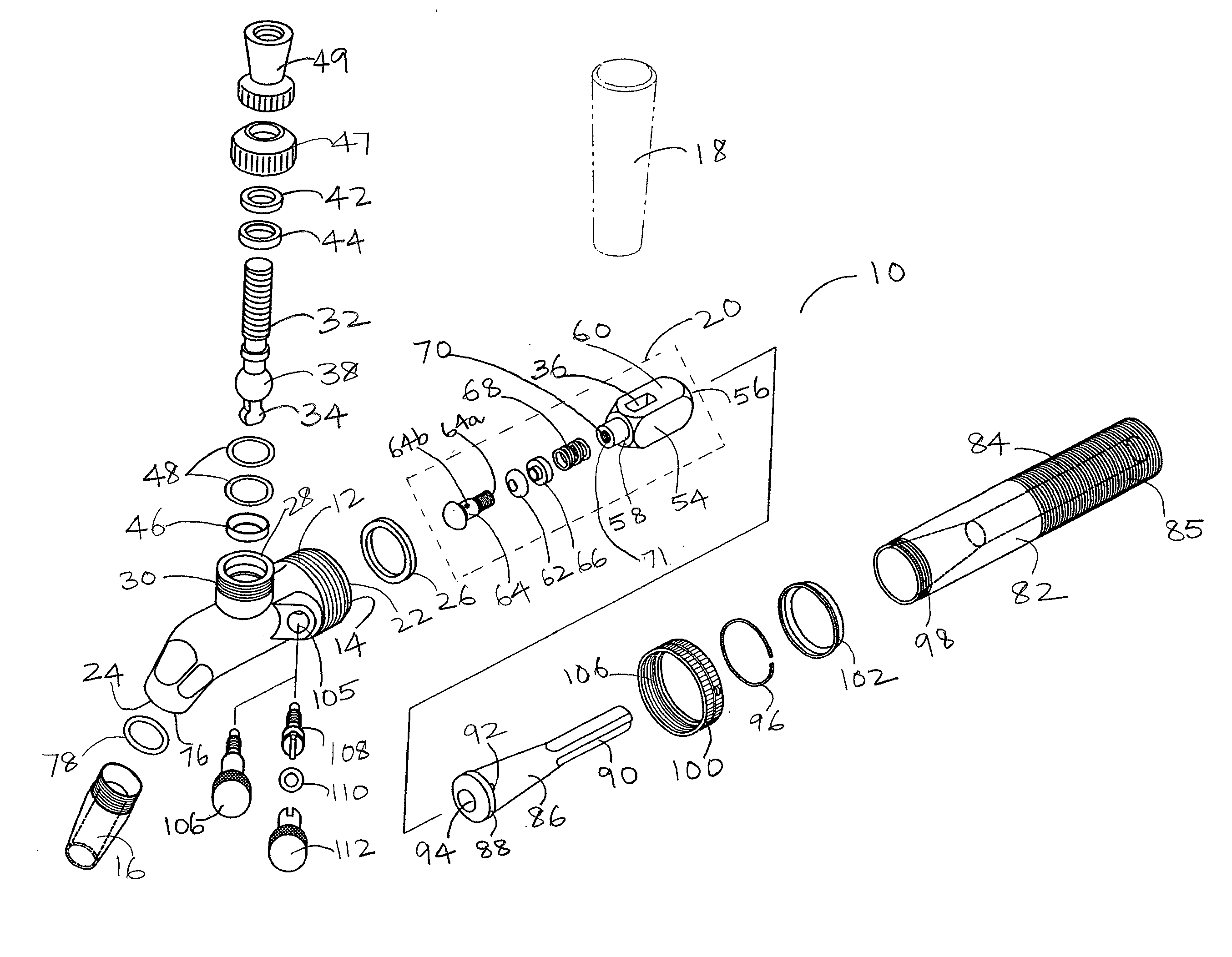

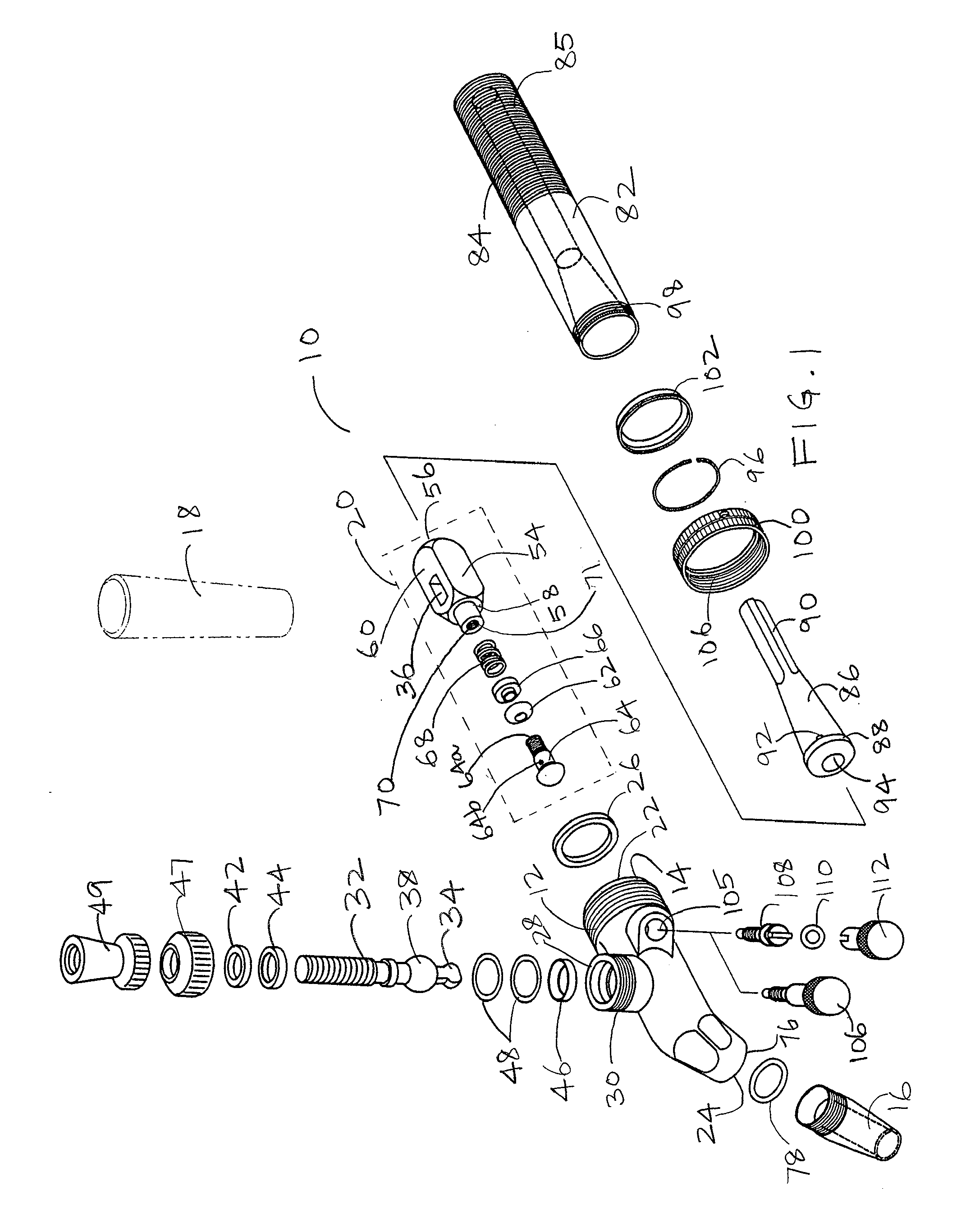

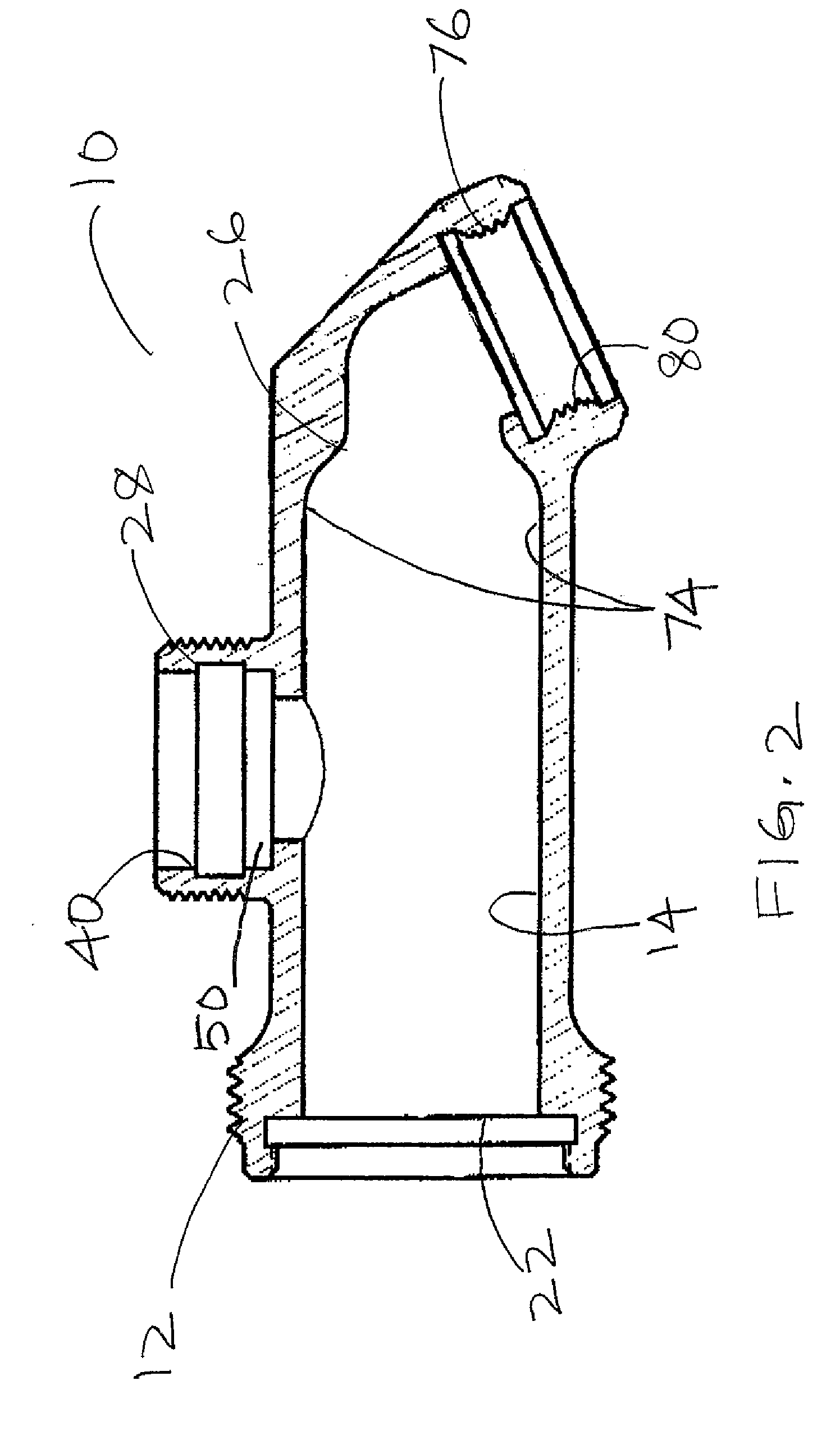

Sanitary faucet with improved flow restriction feature and foam control feature

A sanitary faucet with a foam control feature adaptable for dispensing pressurized fluids. The sanitary faucet includes a valve body, a plunger assembly, a flow restrictor assembly and an adjusting screw assembly. Also disclosed is a method of variably regulating fluid flow pressure and the production of foam in the sanitary faucet.

Owner:PERLICK CORP

Ozonation of wastewater for reduction of sludge or foam and bulking control

InactiveUS7513999B2Reducing foaming and bulkingInduce lysis of filamentous bacteriaWater treatment parameter controlTreatment using aerobic processesActivated sludgeFOAM CONTROL

A system and method for the ozone treatment of wastewater is disclosed. The disclosed wastewater treatment system includes a high selectivity reactor coupled to an activated sludge treatment basin. The high selectivity reactor is adapted to receive a stream containing sludge diverted directly or indirectly from the activated sludge treatment basin. The disclosed wastewater treatment system and method is adapted to inject a chemical agent, such as ozone-enriched gas, into the diverted stream for treatment within the high selectivity reactor for purposes of sludge reduction, foam control, or bulking control. The treated stream is then returned to the activated sludge treatment basin.

Owner:PRAXAIR TECH INC

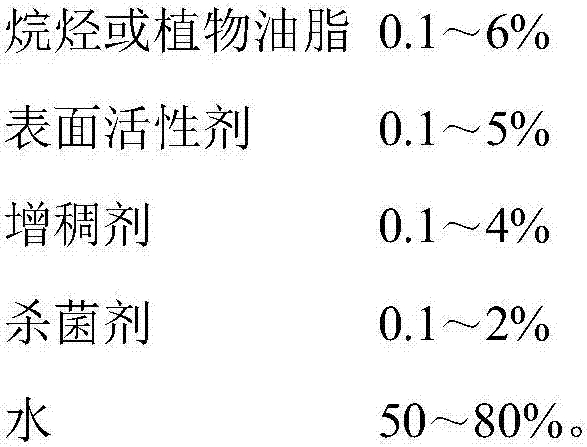

Higher aliphatic alcohol emulsion antifoaming agent

ActiveCN107059474ASuitable for defoamingSuitable for degassingDefoamers additionNon-macromolecular organic additionEmulsionActive component

The invention provides a higher aliphatic alcohol emulsion antifoaming agent. The antifoaming agent is prepared from rice bran wax, ax, alkane or vegetable fat, a surfactant, a thickening gent, a bactericide and water, and the rice bran wax is the active component of the emulsion antifoaming agent. The rice bran wax takes higher aliphatic acid, higher aliphatic alcohol and higher aliphatic alcohol ester as main components and contains abundant hexacosanol, octacosanol, triacosanol and corresponding alcohol ester. The higher aliphatic alcohol emulsion prepared from the rice bran wax is applicable to foam control in each section of pulping and papermaking, particularly a papermaking system and foam control of papermaking wet-ends.

Owner:济宁南天农科化工有限公司

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com