Full-automatic production method of multi-station mobile fixed foaming freezer body and system thereof

A mobile, multi-station technology, applied in other household appliances, household components, household appliances, etc., can solve the problems of inability to guarantee the insulation performance of the freezer, difficulty in guaranteeing the original accuracy, and heavy replacement workload, so as to improve production. The effect of efficiency and product qualification rate, saving manpower and material resources, and fast production speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

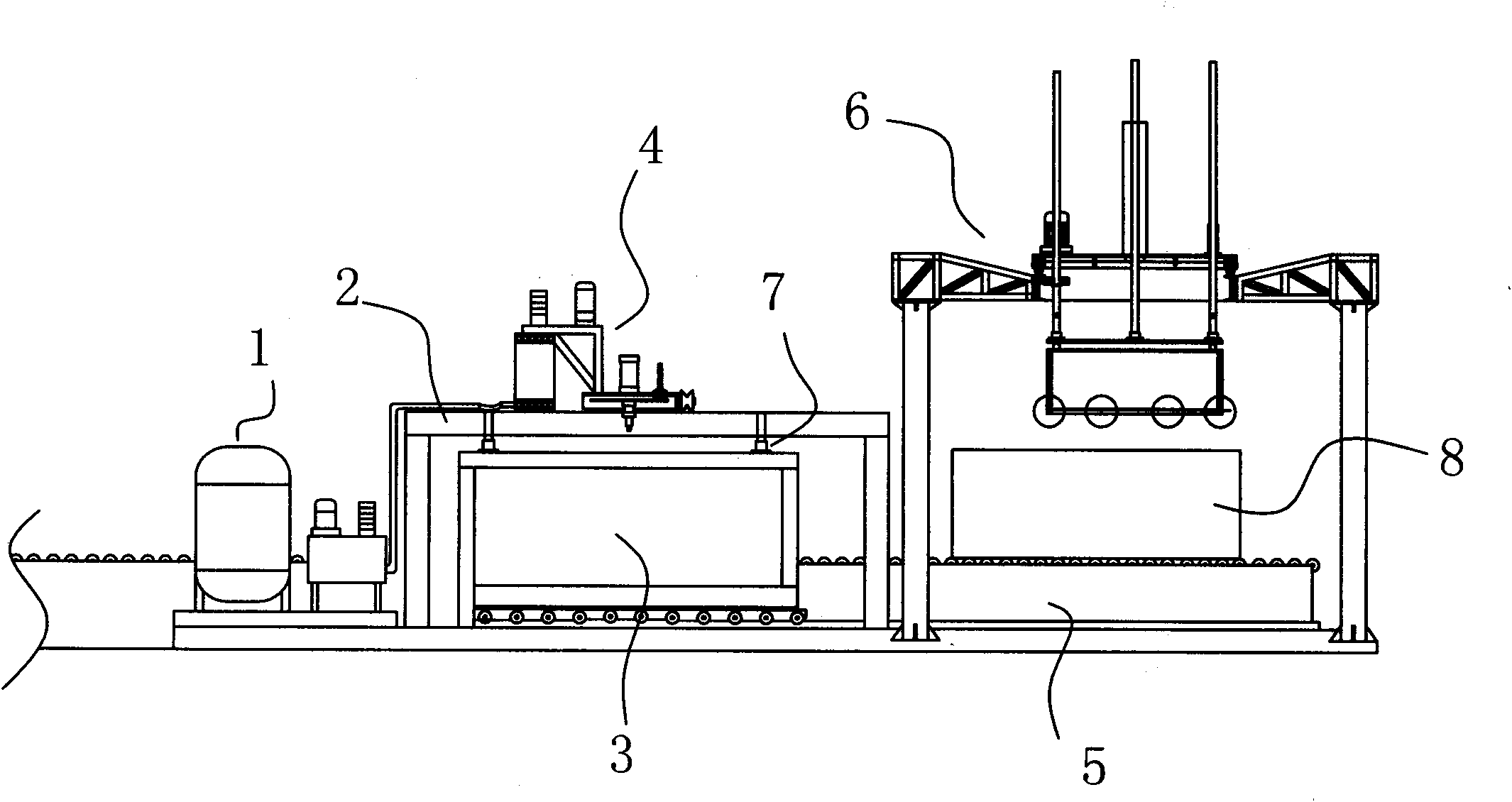

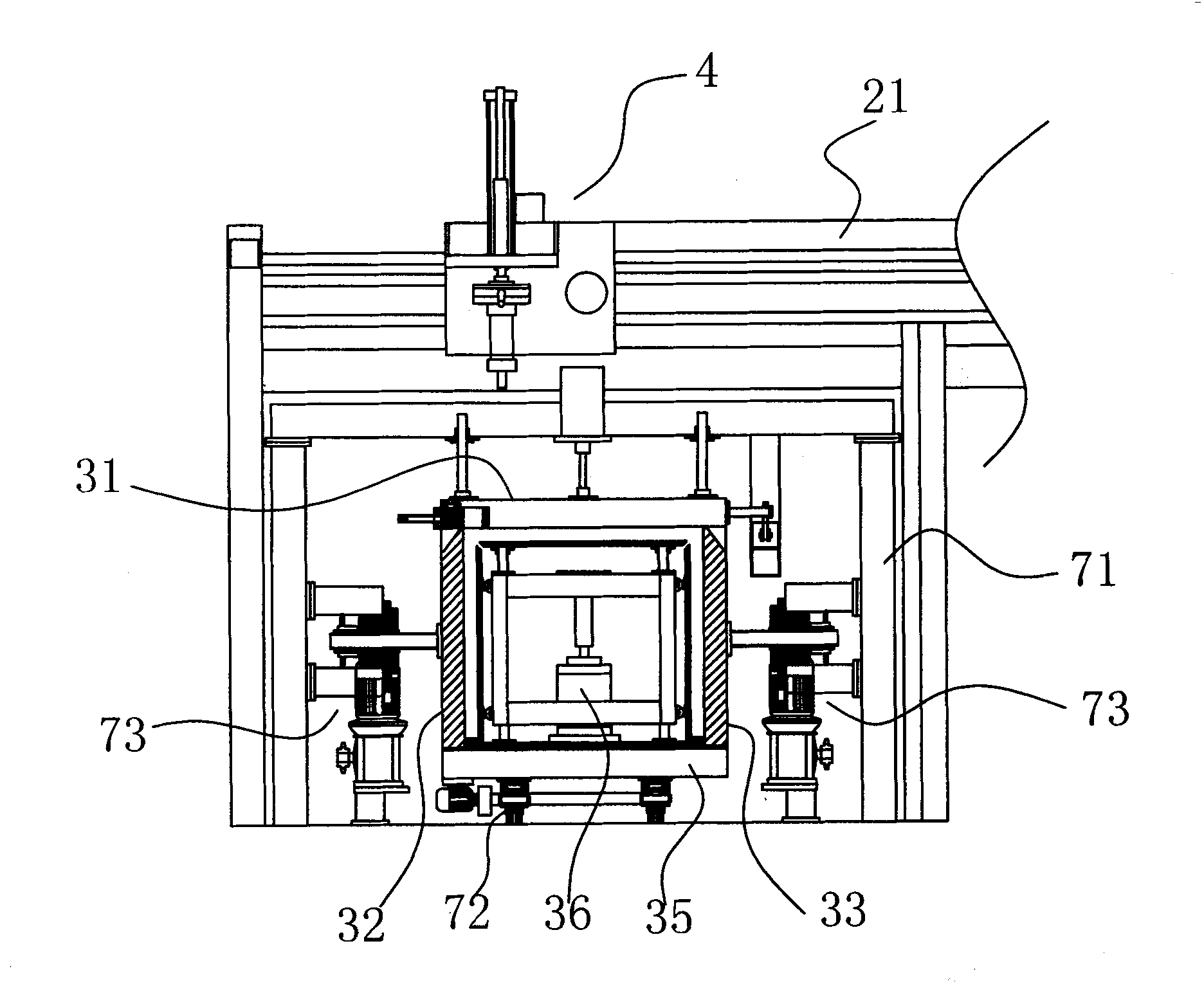

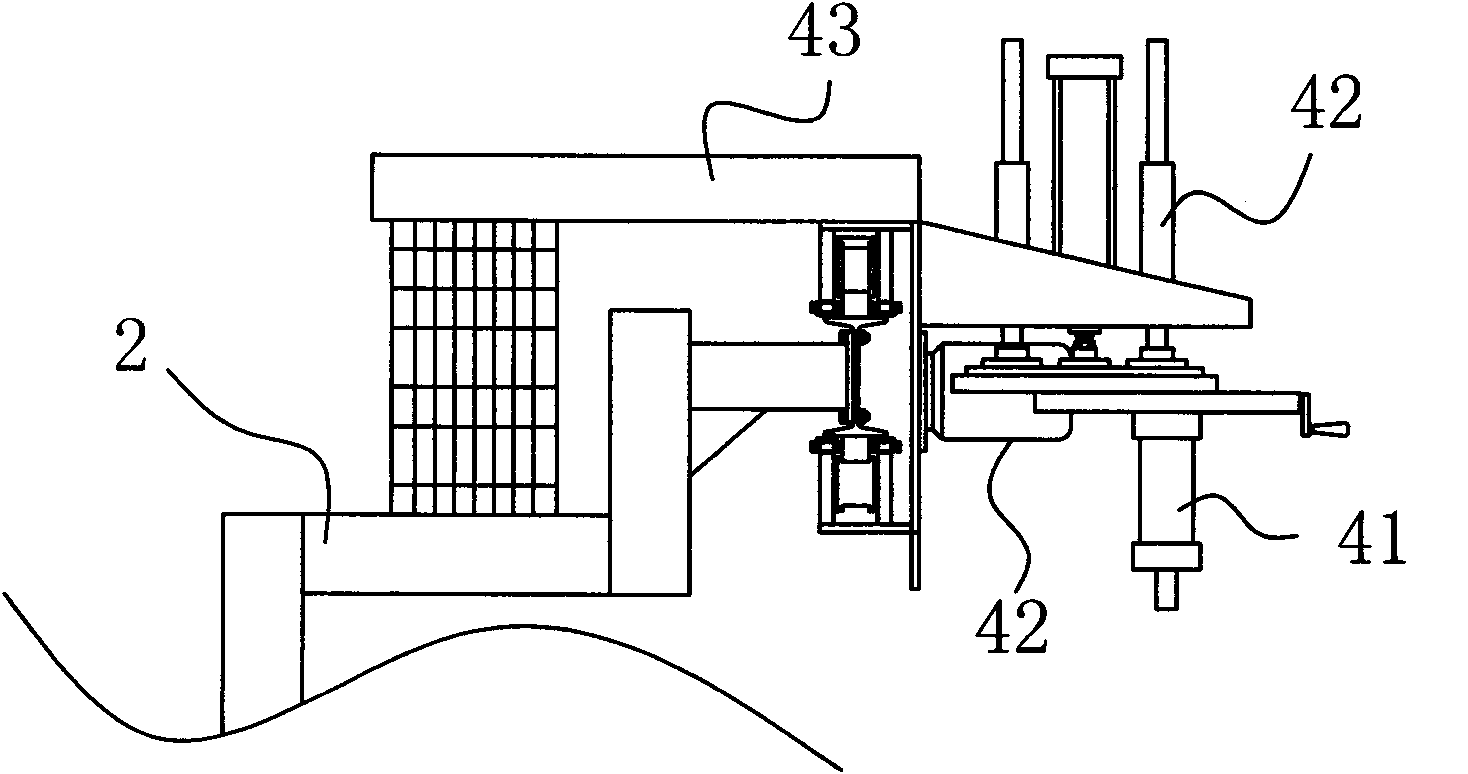

[0039] Example: see figure 1 , figure 2 , image 3 with Figure 4 , a multi-station mobile fixed foam freezer box fully automatic production method provided in this embodiment comprises the following steps:

[0040] (1) a foaming device 1 and an automatic foaming control system that can control the working state of the foaming device 1 are set;

[0041](2) A foaming formwork 2 with a slide rail on the top is arranged on one side of the foaming equipment 1, and the direction of the slide rail 21 is in the shape of a "one"; the slide rail 21 is designed to be a straight line by adopting fixed type technology type, which is convenient for the fixed arrangement of multiple fixed foaming molds, which is different from the traditional rotary type, which is more conducive to the automatic arrangement of the whole line.

[0042] (3) Below the slide rail 21, a plurality of fixed foaming molds 3 are arranged side by side sequentially along its direction;

[0043] (4) A pouring man...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com