Stone-wood floor and production technology and laying method thereof

A stone and wood flooring and flooring technology, which is applied in the direction of architecture, building structure, floor, etc., can solve the problems that the effect of trampling is not as good as that of solid wood floors, the difference between solid wood floors is large, and the transportation cost is increased, so as to increase flexibility and reduce production. The effect of improving energy consumption and process performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041]A stone-wood floor, wherein, the preparation material of the stone-wood floor includes the following raw materials and parts by weight:

[0042] 90 parts of heavy calcium carbonate, 30 parts of PVC, 0.3 parts of stearic acid, 2 parts of chlorinated polyethylene, 0.5 parts of foaming agent, 6 parts of foam regulator, and 2 parts of stabilizer.

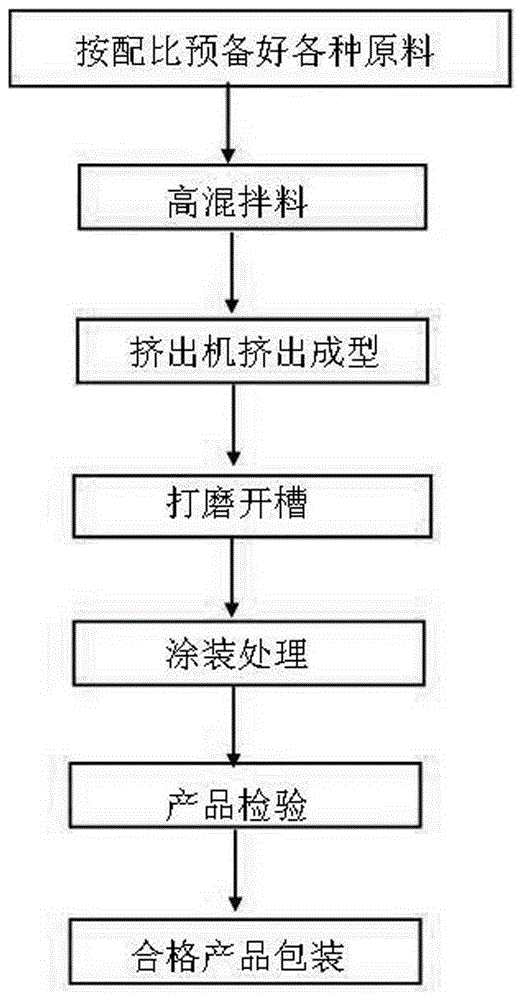

[0043] Such as figure 1 Shown, the production technology of this stone-wood floor, it comprises the following steps:

[0044] Step (1), providing a mixture comprising the following raw materials in parts by weight: 90 parts of heavy calcium carbonate, 30 parts of PVC, 0.3 parts of stearic acid, 2 parts of chlorinated polyethylene, 0.5 parts of foaming agent, The foam regulator is 6 parts, and the stabilizer is 2 parts. The mixture is added into a high-speed mixer, and the temperature of the high-speed mixer is set to be 110° C., and the stirring time is 30 minutes. After mixing and stirring, the temperature of the high-speed mixe...

Embodiment 2

[0050] A stone-wood floor, wherein, the preparation material of the stone-wood floor includes the following raw materials and parts by weight:

[0051] 95 parts of heavy calcium carbonate, 33 parts of PVC, 0.5 parts of stearic acid, 2.3 parts of chlorinated polyethylene, 0.7 parts of foaming agent, 6.5 parts of foam regulator, and 2.5 parts of stabilizer.

[0052] A kind of production technology of above-mentioned stone-wood floor, it comprises the following steps:

[0053] Step (1), provide the mixture that comprises following raw material by weight: 95 parts of heavy calcium carbonate, 33 parts of PVC, 0.5 part of stearic acid, 2.3 parts of chlorinated polyethylene, 0.7 part of blowing agent, foaming agent The foam regulator is 6.5 parts, and the stabilizer is 2.5 parts. The mixture is added into a high-speed mixer, and the temperature of the high-speed mixer is set to be 115° C., and the stirring time is 35 minutes. After mixing and stirring, the temperature of the high-spe...

Embodiment 3

[0059] A stone-wood floor, wherein, the preparation material of the stone-wood floor includes the following raw materials and parts by weight:

[0060] 100 parts of heavy calcium carbonate, 35 parts of PVC, 0.6 parts of stearic acid, 2.5 parts of chlorinated polyethylene, 1.0 parts of foaming agent, 7 parts of foam regulator, and 3 parts of stabilizer.

[0061] A kind of production technology of above-mentioned stone-wood floor, it comprises the following steps:

[0062] In step (1), a mixture comprising the following raw materials by weight is provided: 100 parts of heavy calcium carbonate, 35 parts of PVC, 0.6 parts of stearic acid, 2.5 parts of chlorinated polyethylene, 1.0 part of foaming agent, The foam regulator is 7 parts, and the stabilizer is 3 parts. The mixture is added into a high-speed mixer, and the temperature of the high-speed mixer is set to be 120° C., and the stirring time is 40 minutes. After mixing and stirring, the temperature of the high-speed mixer Set...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com