Patents

Literature

38results about How to "Uniform extrusion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Stone-wood floor and production technology and laying method thereof

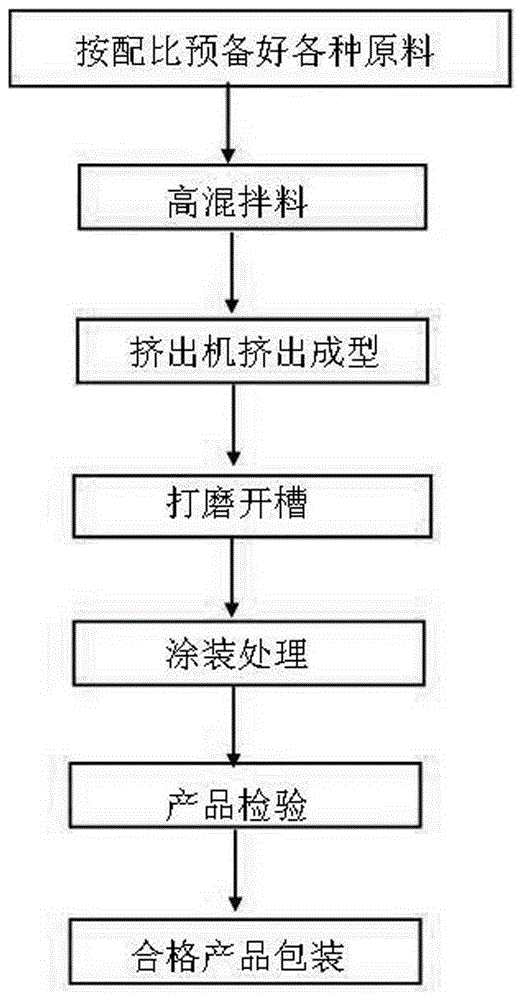

The invention belongs to the technical field of indoor and outdoor building decorative materials and production technologies thereof, and provides a stone-wood floor and a production technology and laying method thereof. The stone-wood floor is prepared from, by weight, 90-100 parts of ground limestone, 30-35 parts of PVC, 0.3-0.6 part of stearic acid, 2-2.5 parts of chlorinated polyethylene, 0.5-1.0 part of a foaming agent, 6-7 parts of a foaming control agent and 2-3 parts of a stabilizer. The raw materials are highly mixed and stirred, extruded, molded, ground, slotted and coated to obtain a finished product. The processing procedures are simplified, the cost is lowered, the product quality is improved, the hardness, abrasion resistance and flexibility of the produced product are improved, PVC is foamed to generate pores through the foaming technology, and the pores are filled with microstructures such as the ground limestone, so that the product density reaches 1.2 g / cm<3> which is close to that of a pure wood floor, and the cheap and fine stone-wood floor can be truly obtained.

Owner:南召县磊鑫钙业新型材料科技有限公司

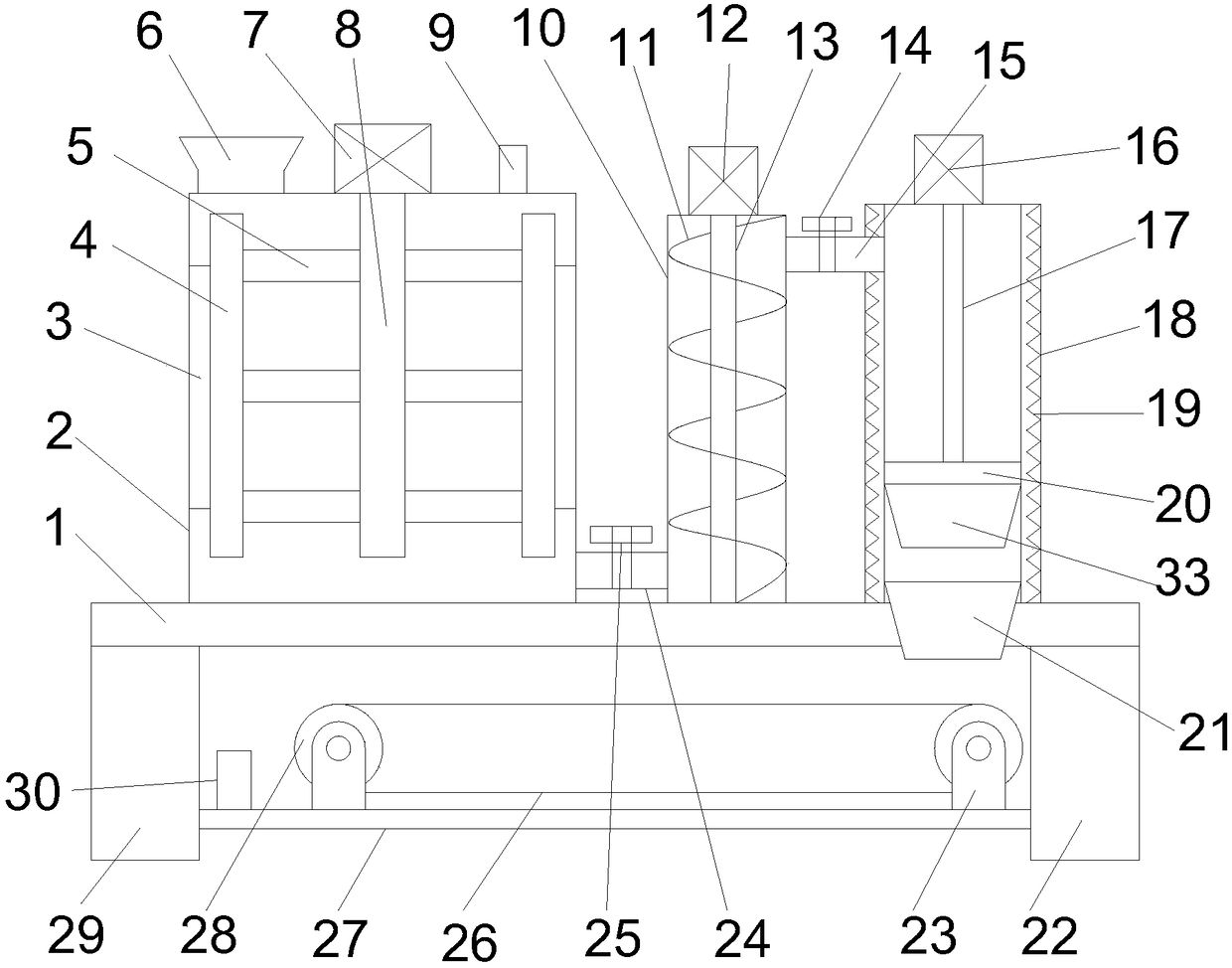

Pediatric clinical breathing device with flow rate regulation function

The invention discloses a pediatric clinical breathing device with a flow rate regulation function, and belongs to the technical field of pediatric nursing equipment. The problem that when an existingbreathing device provides oxygen to a patient, oxygen flow control is inconvenient, and consequently normal breathing of children is affected is solved. The pediatric clinical breathing device is technically characterized in that the pediatric clinical breathing device comprises a flow regulation mechanism, and further comprises a second working motor, a heating box and spiral mixing propellers;and the heating box is fixedly welded to the upper surface of a partition plate, the second working motor is arranged at the bottom of the left side of the heating box, two heat conducing cavities areformed in the heating box in the mode of being symmetrical with respect to an oxygen flow guiding pipe, rotating shafts are mounted in the middles of the heat conducting cavities, and the spiral mixing propellers are fixedly welded to the rotating shafts. According to the pediatric clinical breathing device, the oxygen flow can be flexibly controlled, the oxygen flow with different flow demands in pediatric nursing is met, rehabilitation of children is facilitated, meanwhile, the oxygen can also be evenly heated, and the situation of stimulation to the bodies of the children due to uneven oxygen heating is avoided.

Owner:泗水县人民医院

Cooking utensil and upper cover thereof

PendingCN107960850ACover firmlyAvoid fatigueCooking-vessel lids/coversBeverage vesselsEngineeringEnergy consumption

The invention provides a cooking utensil and an upper cover of the cooking utensil. The upper cover of the cooking utensil comprises an upper face cover, a first actuation part, a material discharge cavity door and a second actuation part, wherein the upper face cover is provided with a washing cavity body, and the washing cavity body is provided with a material discharge hole for discharging materials; the first actuation part is arranged on the upper face cover; the material discharge cavity door can cover the material discharge hole, or can translate in a plane vertical to the central axisof the material discharge hole to be separated from the material discharge hole, so that the material discharge hole is open; the second actuation part is fixed on the material discharge cavity door,is used for realizing actuation and fixing with the first actuation part when the material discharge cavity door covers the material discharge hole, and is separated from the first actuation part whenthe material discharge cavity door is separated from the material discharge hole. For the upper cover of the cooking utensil provided by the technical scheme, by utilizing the actuation and fixing ofthe first actuation part and the second actuation part, the stable covering of the material discharge cavity door with the material discharge hole can be guaranteed, and meanwhile, the purposes of reducing driving energy consumption and reducing fatigue damage of a power device are achieved.

Owner:FOSHAN SHUNDE MIDEA ELECTRICAL HEATING APPLIANCES MFG CO LTD

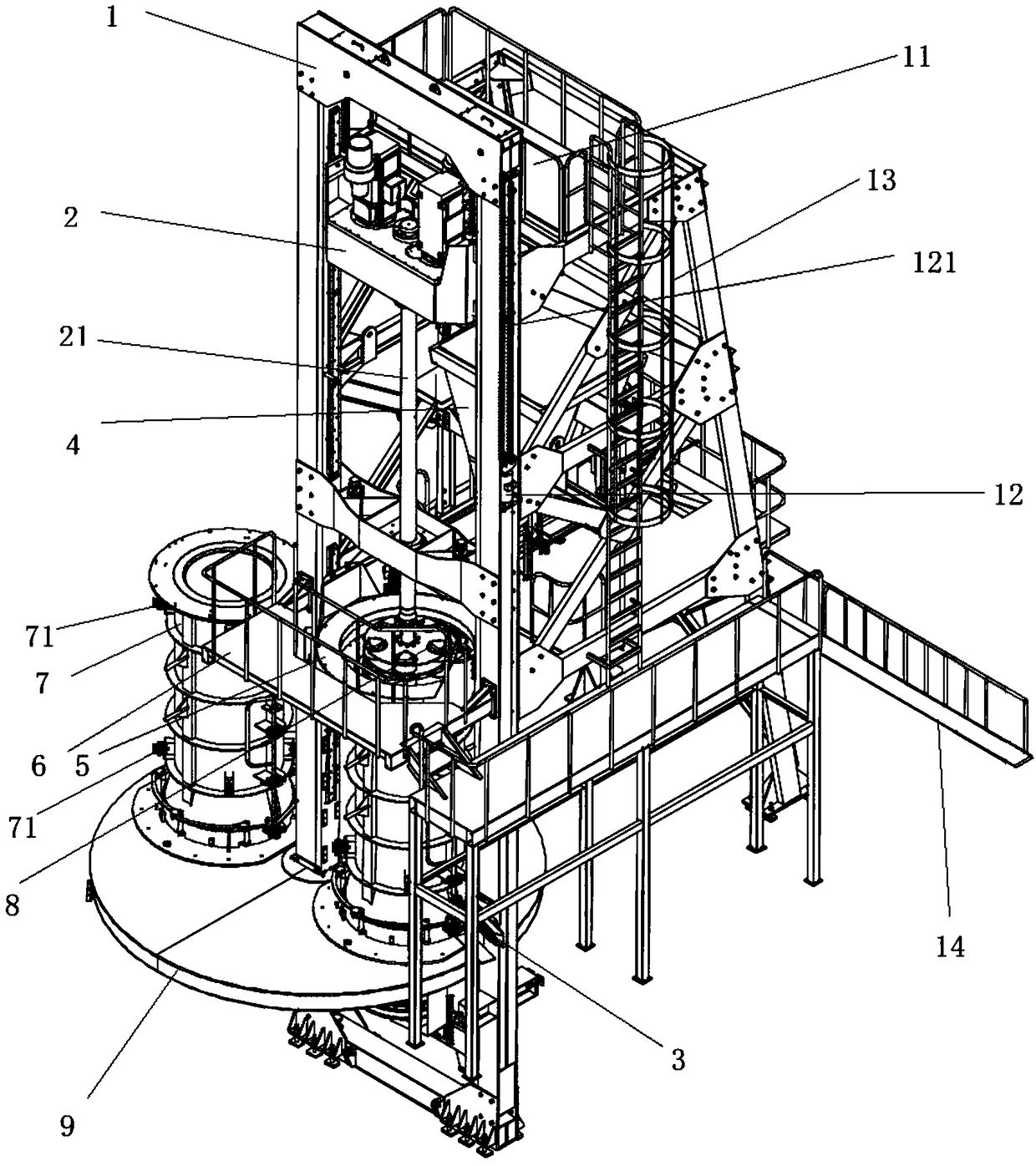

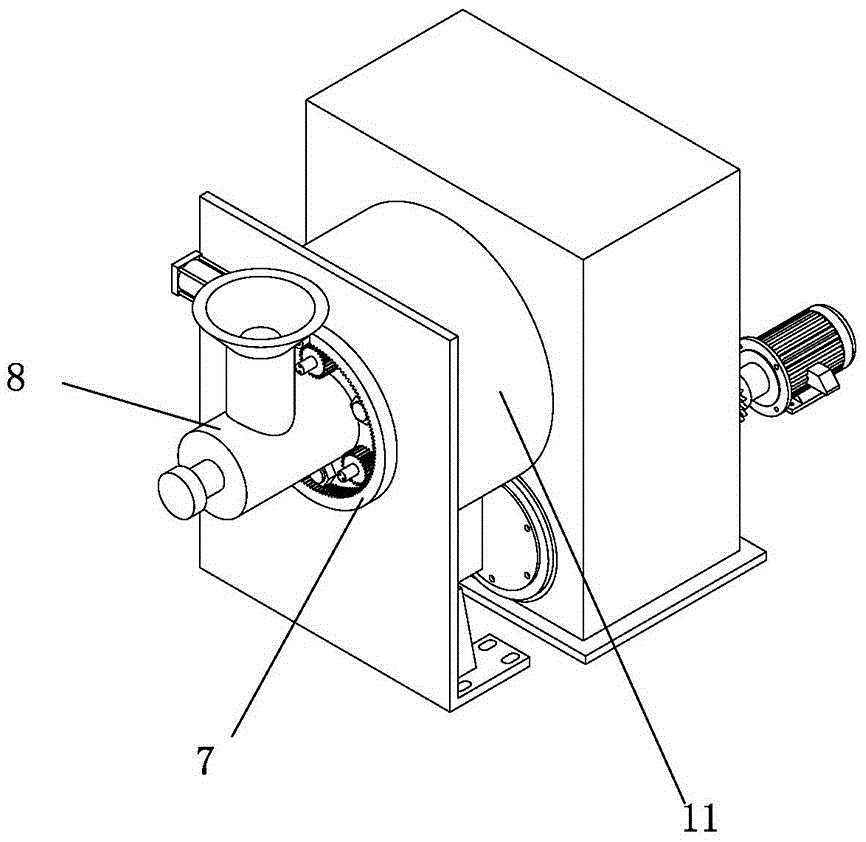

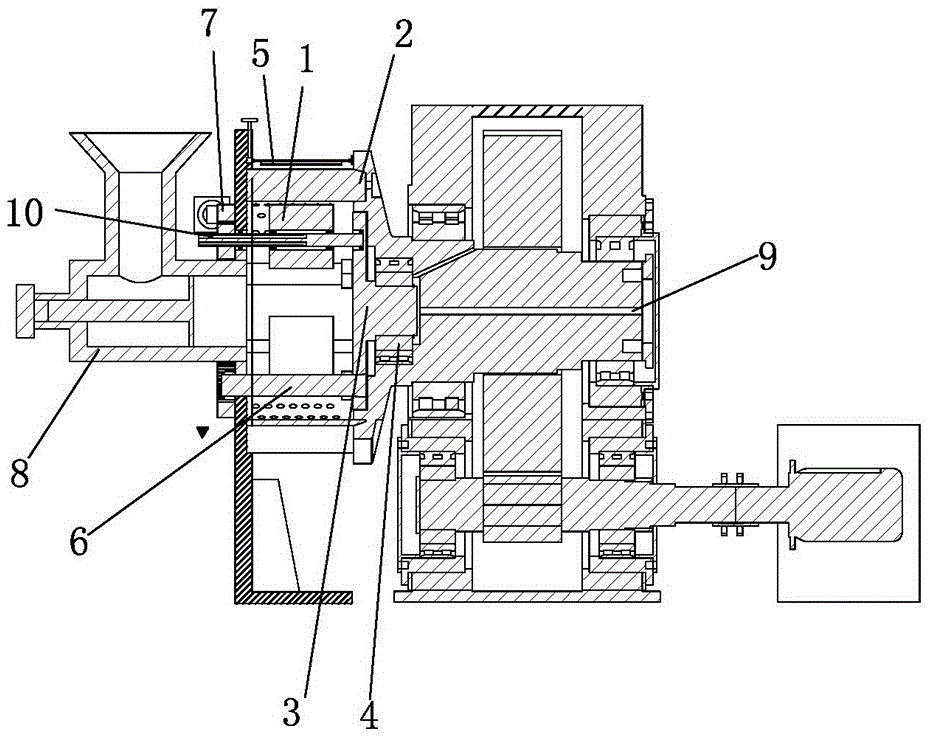

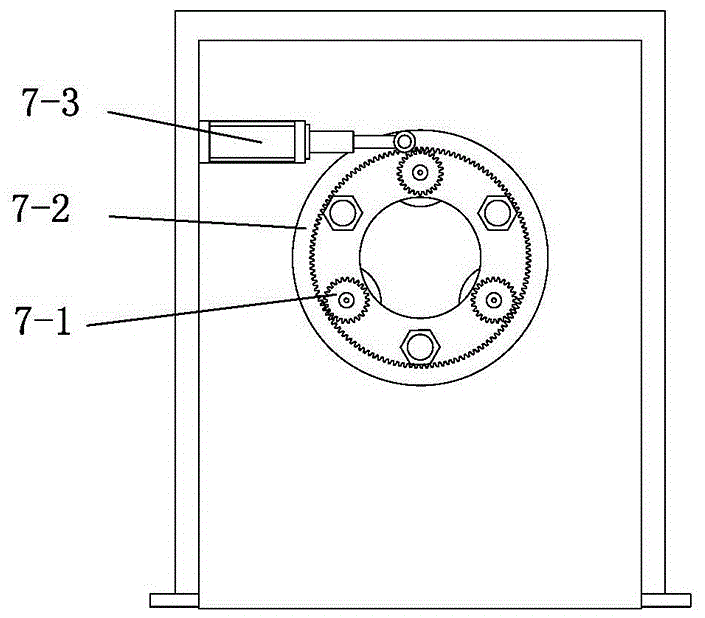

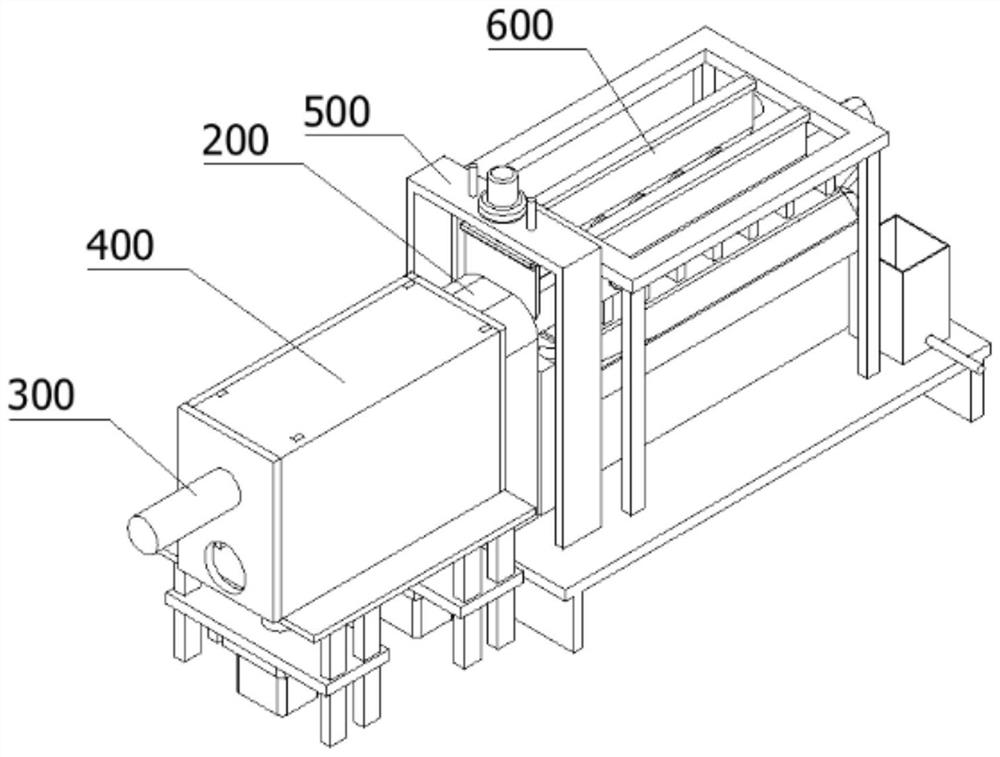

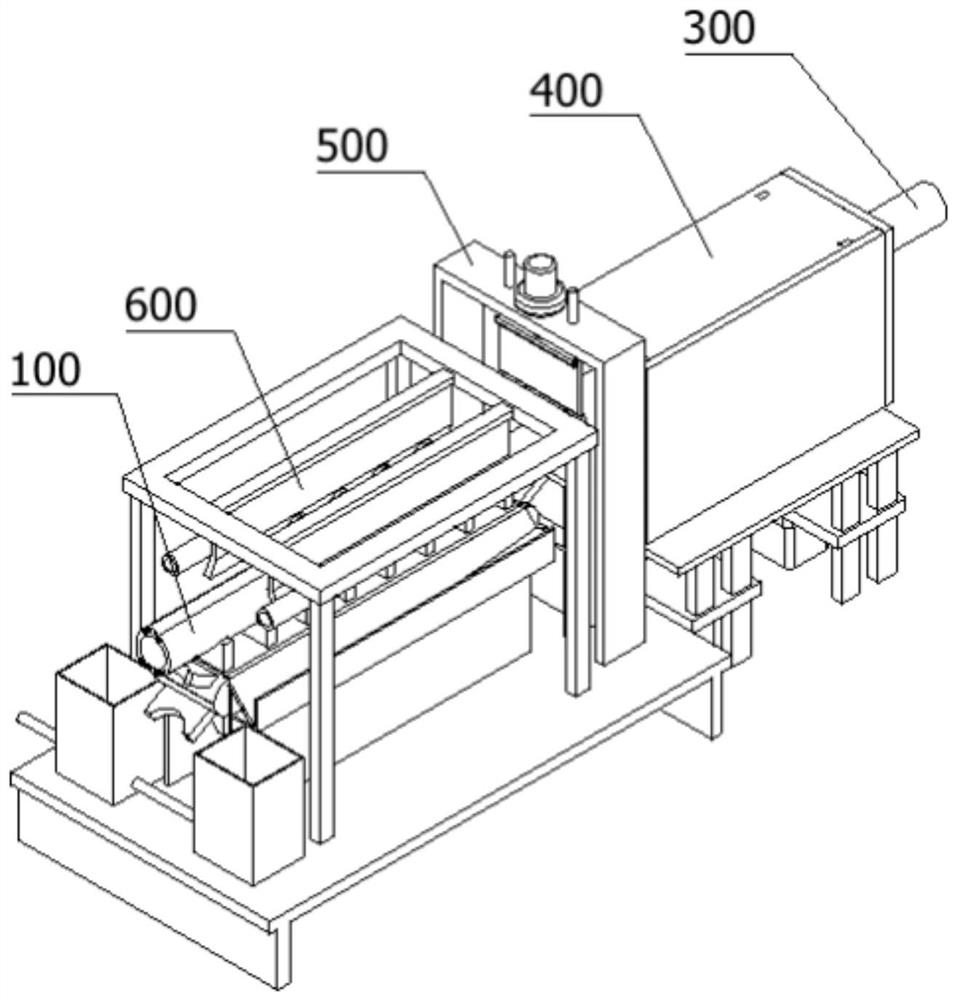

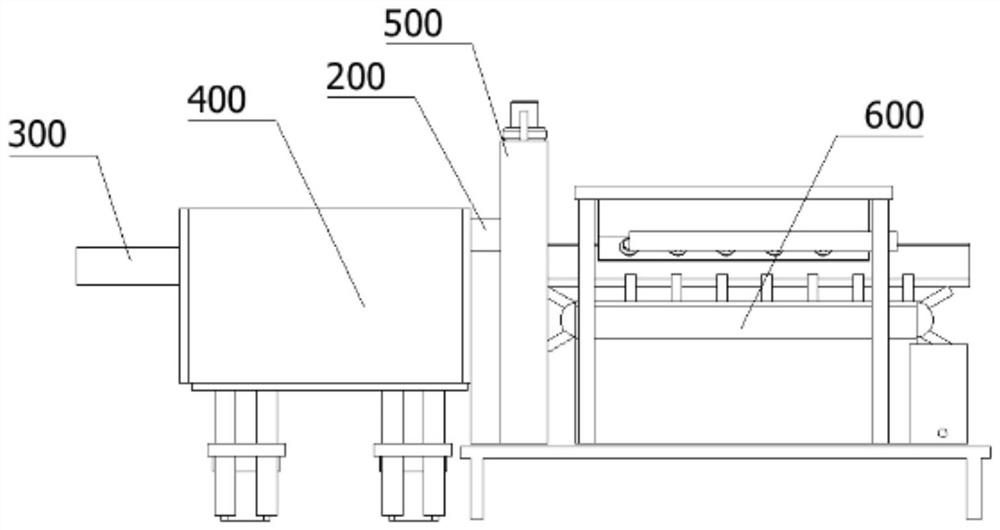

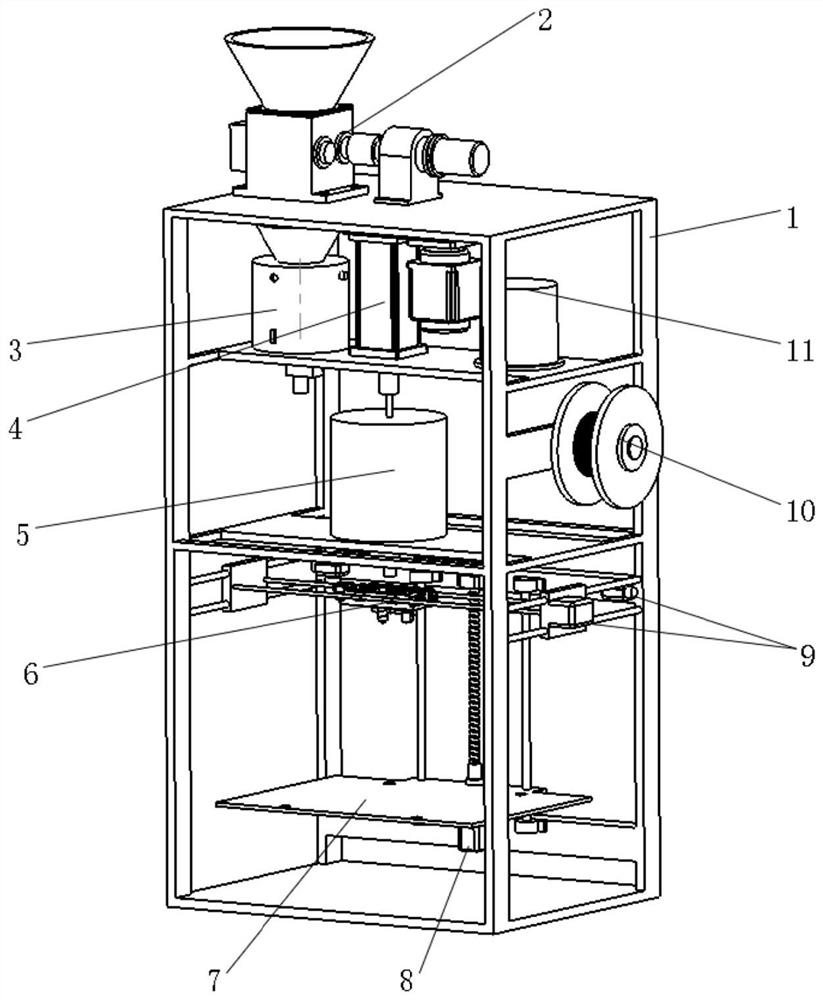

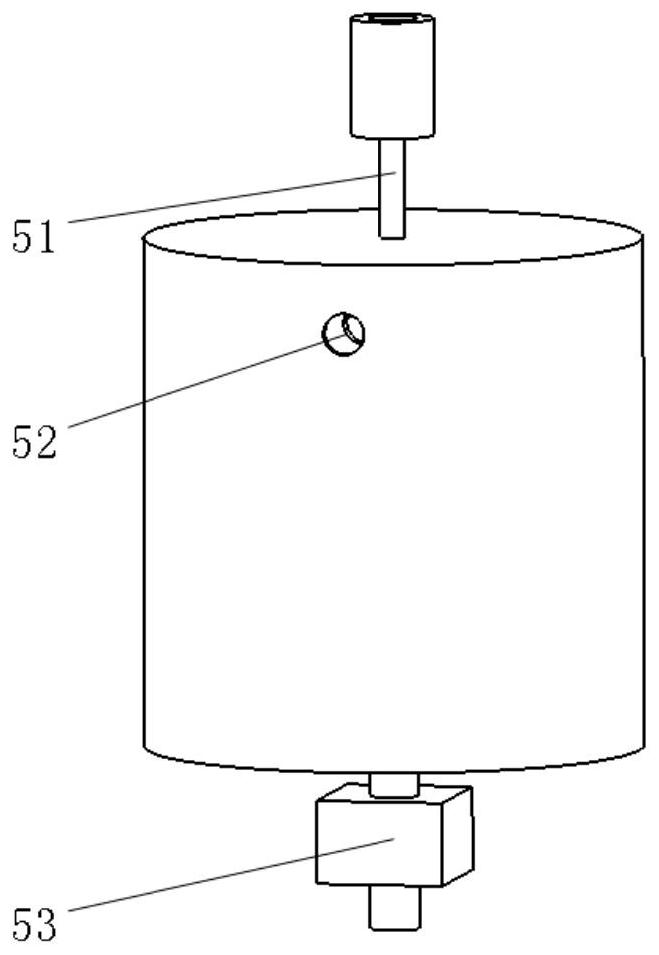

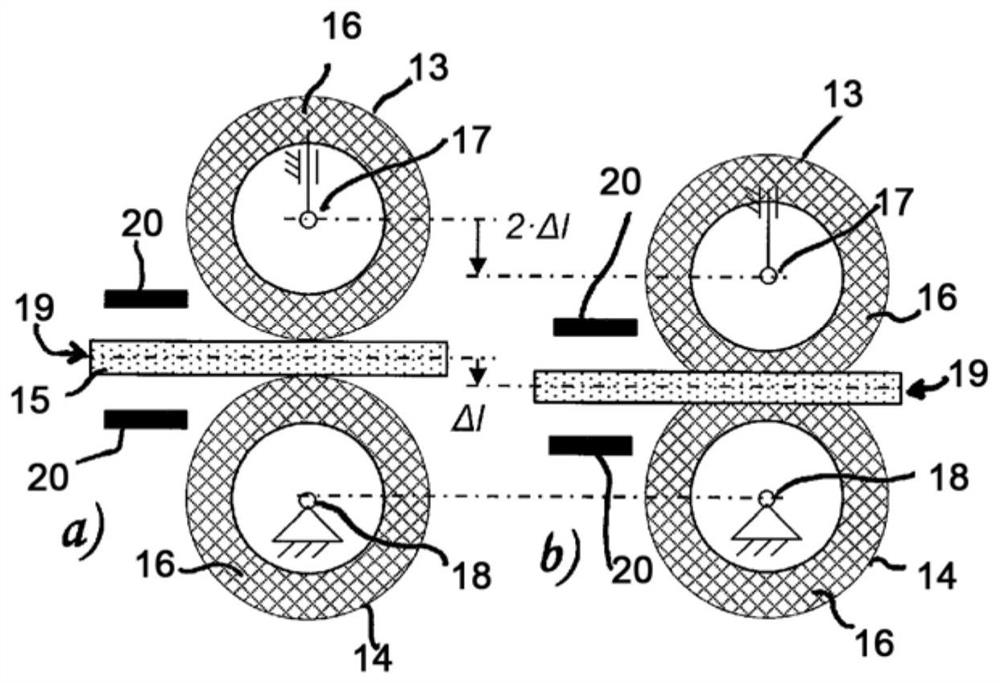

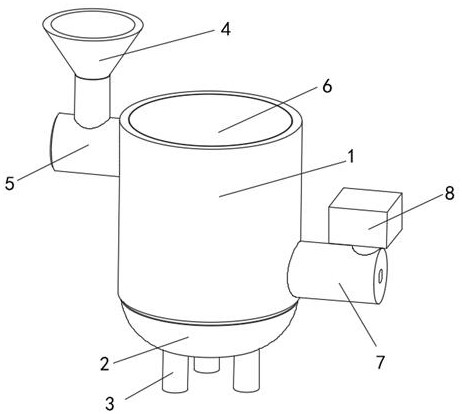

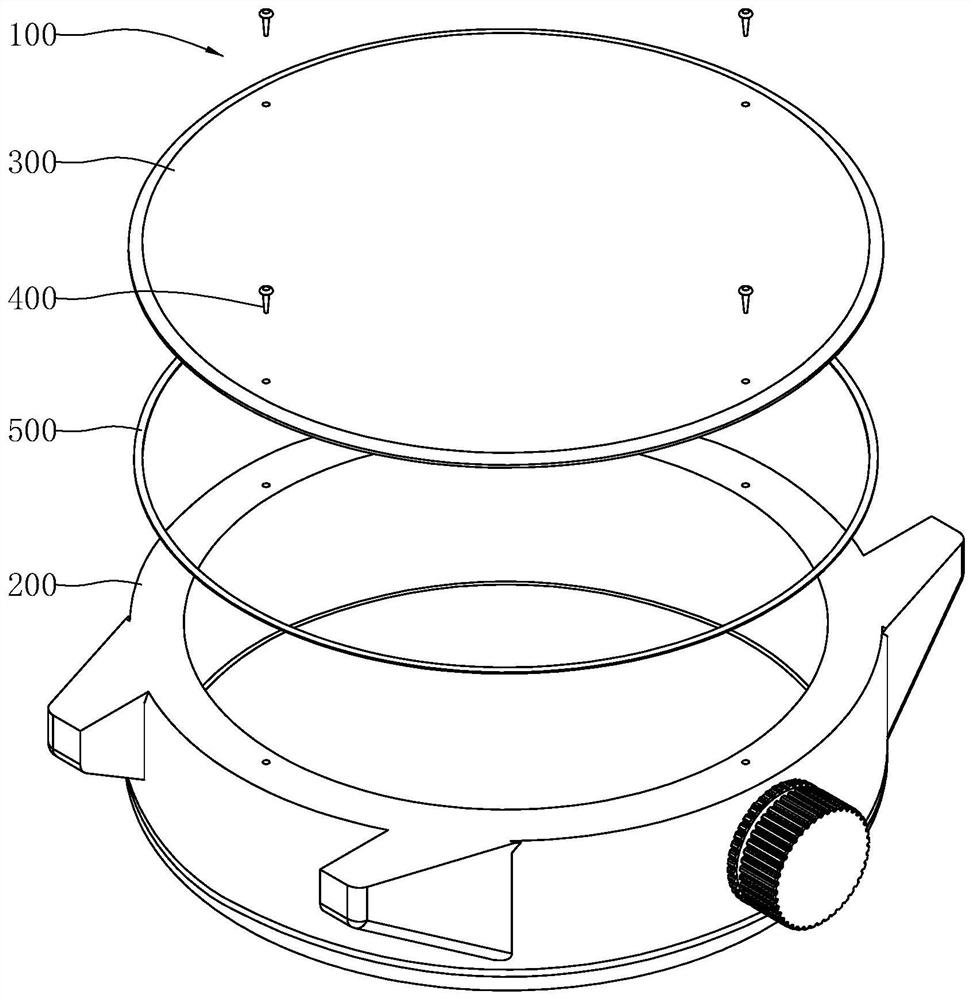

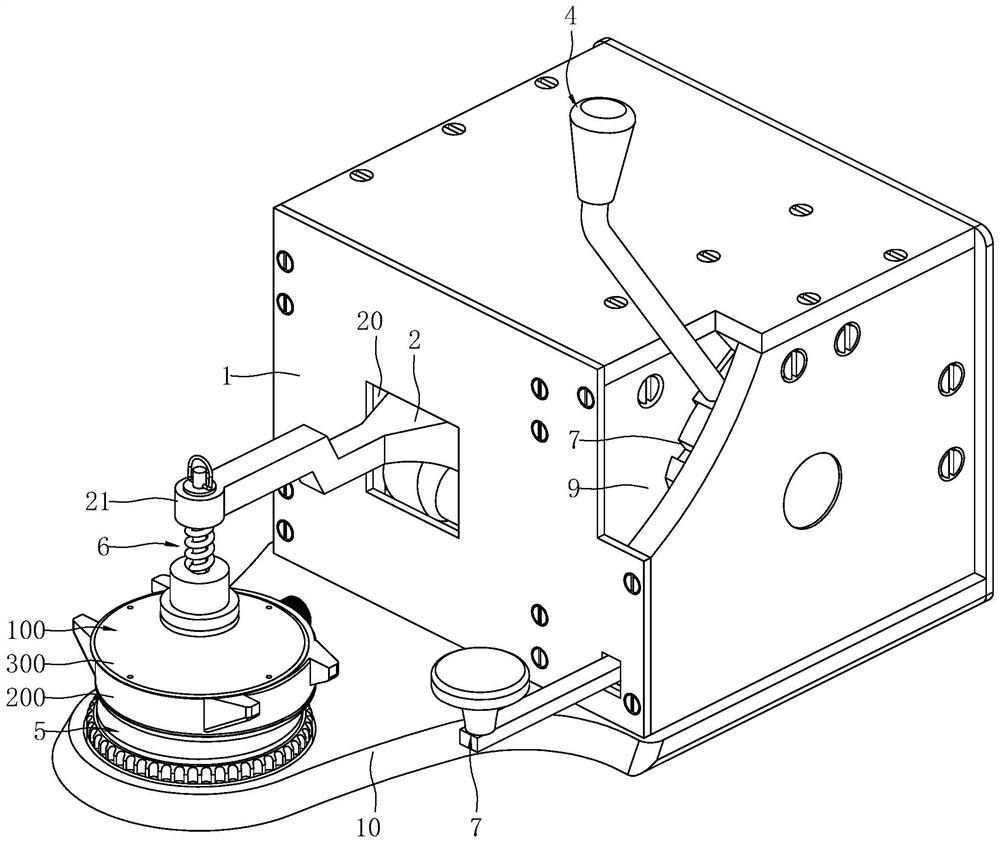

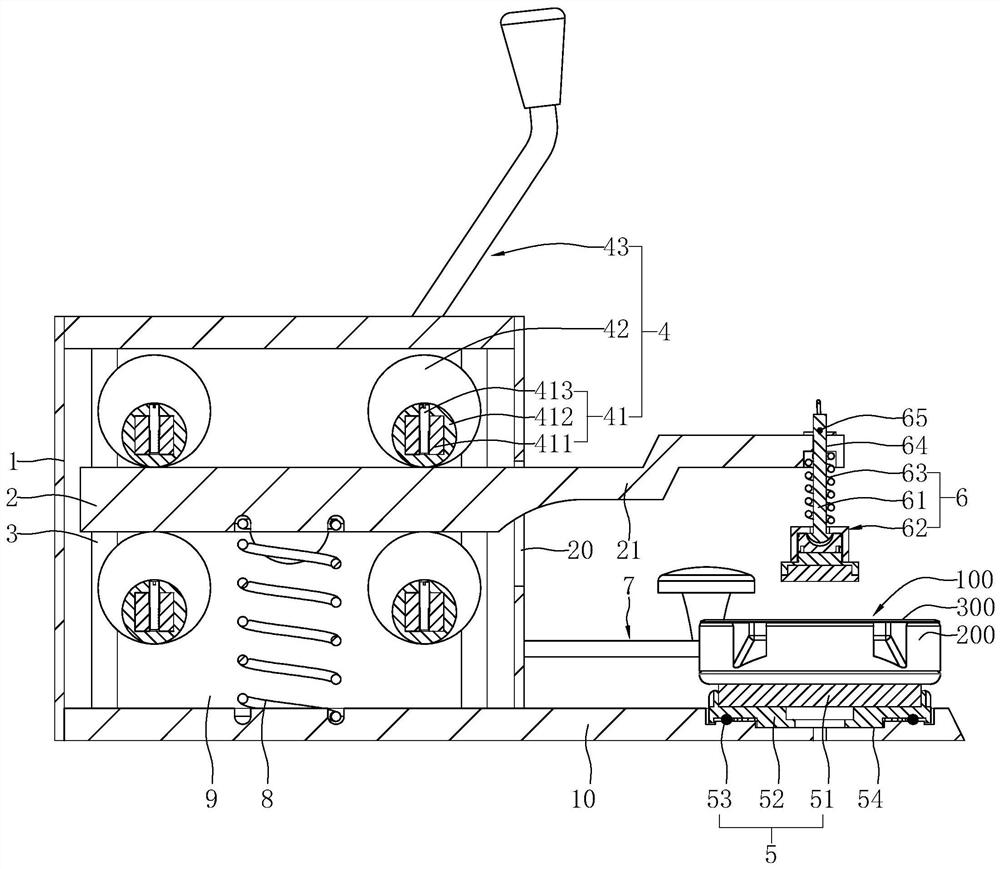

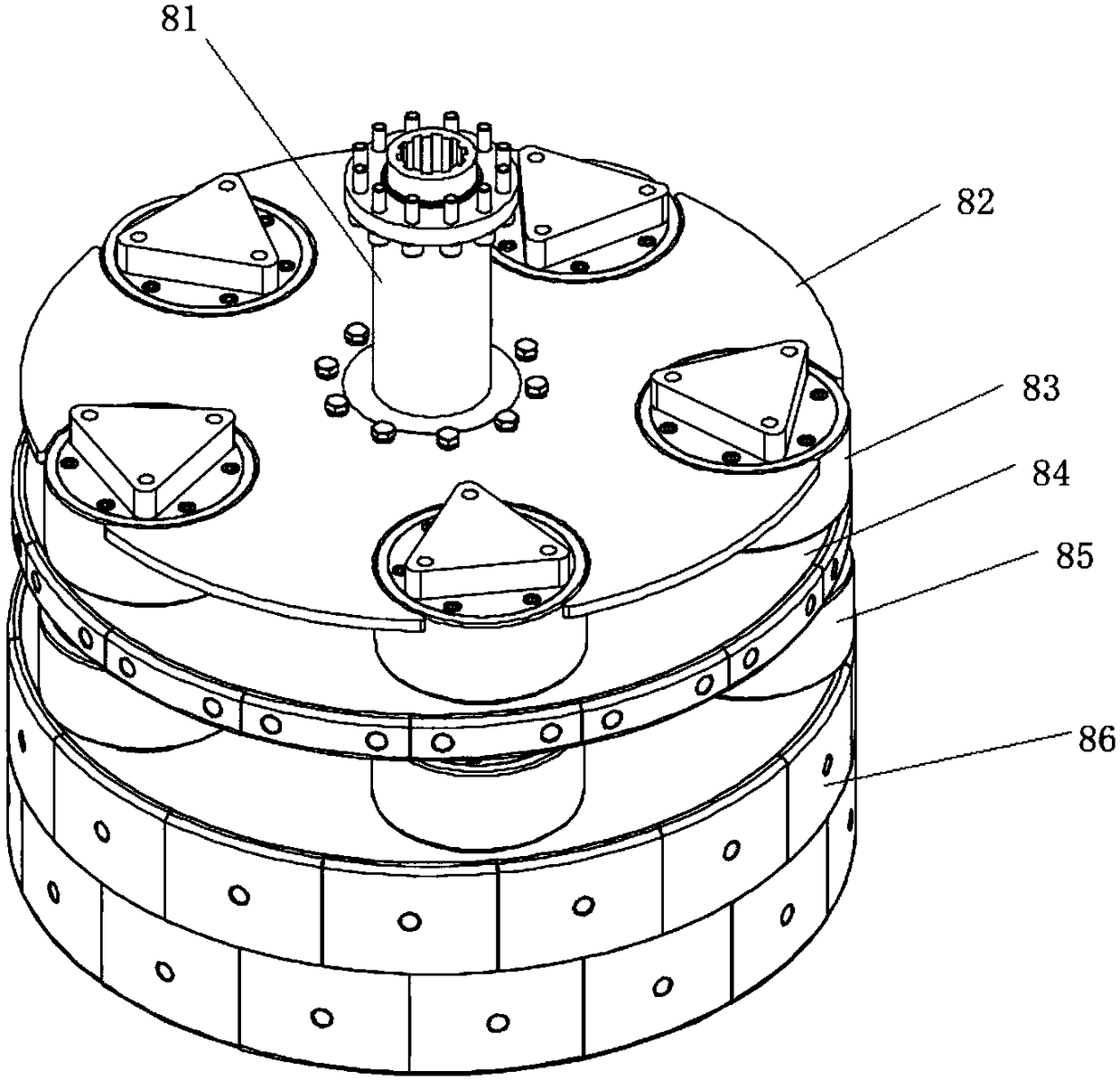

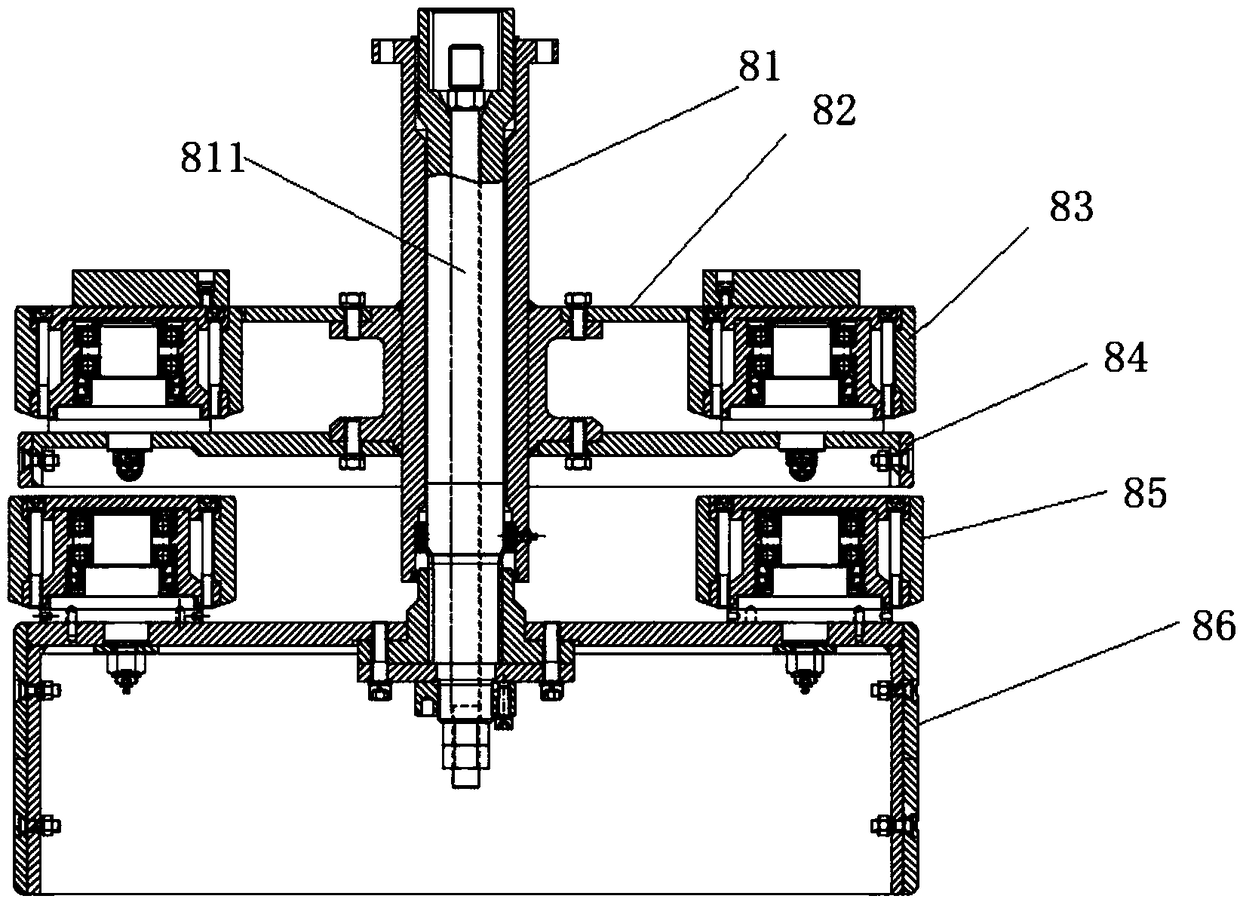

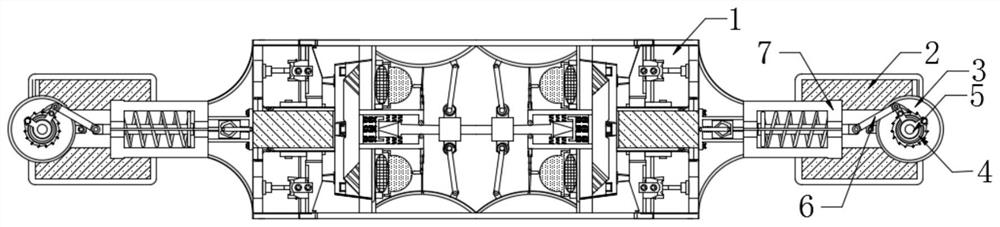

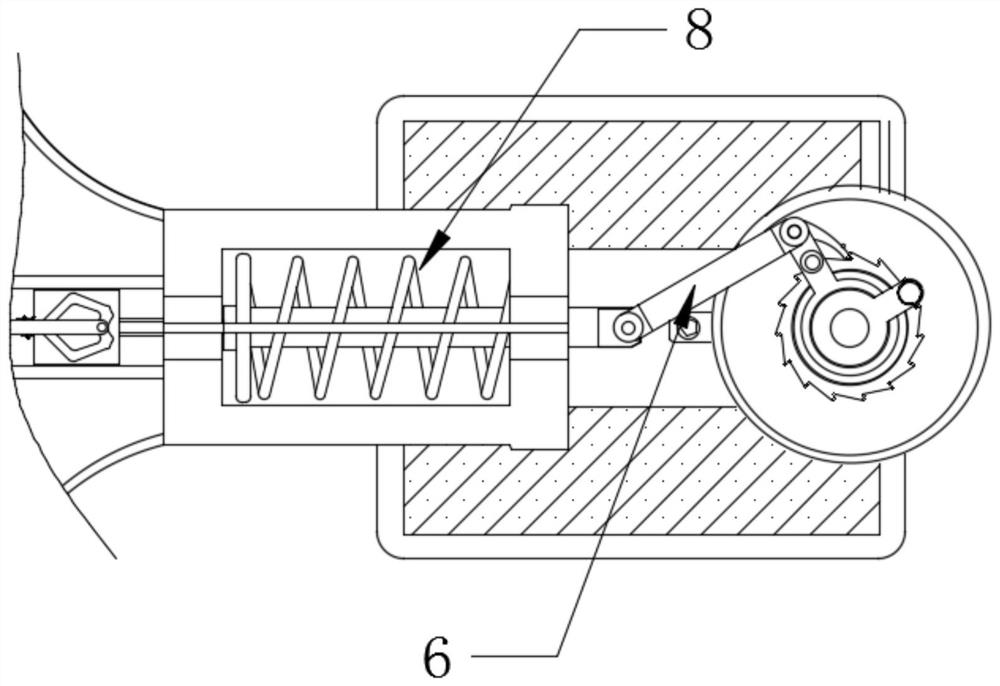

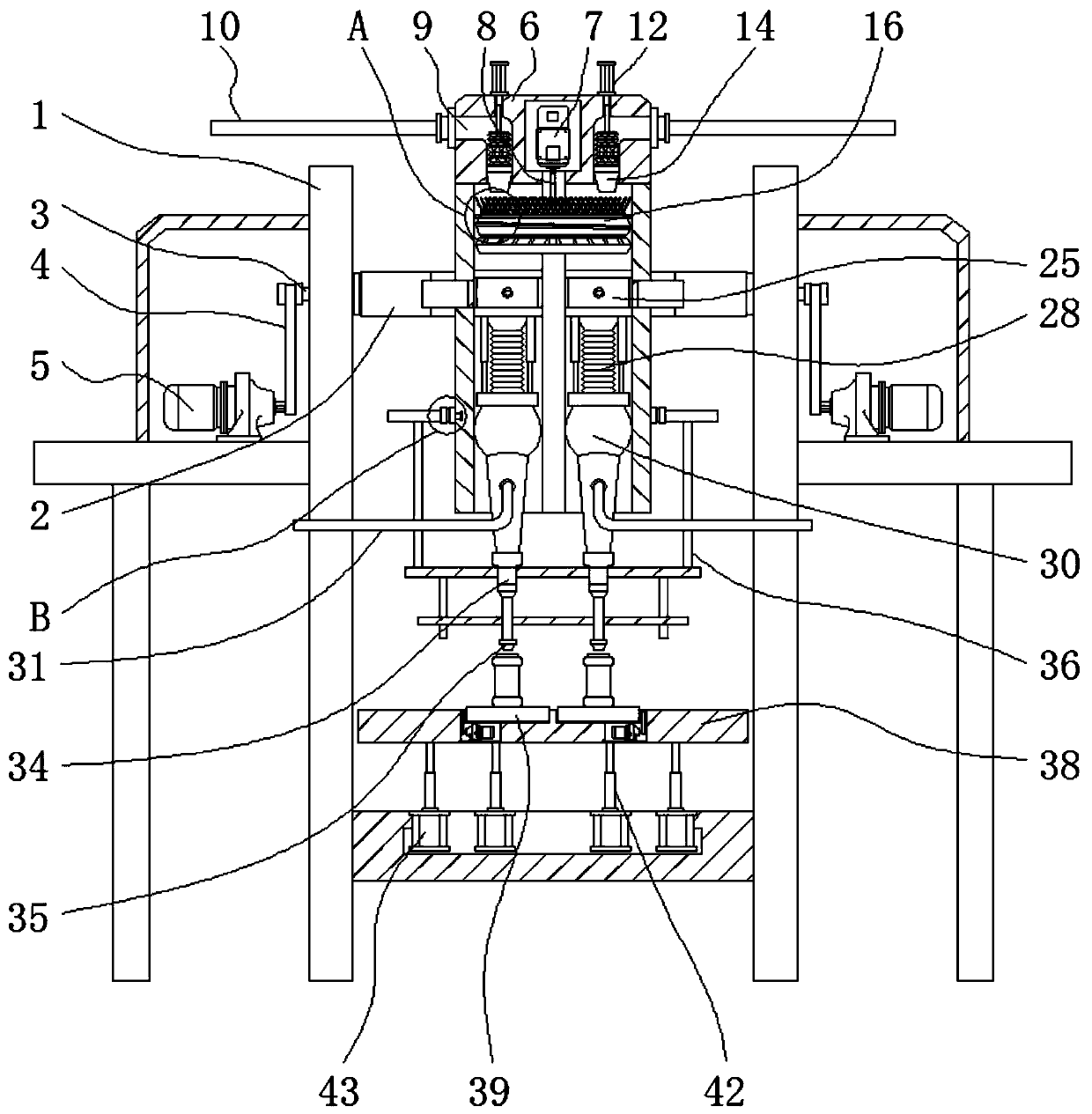

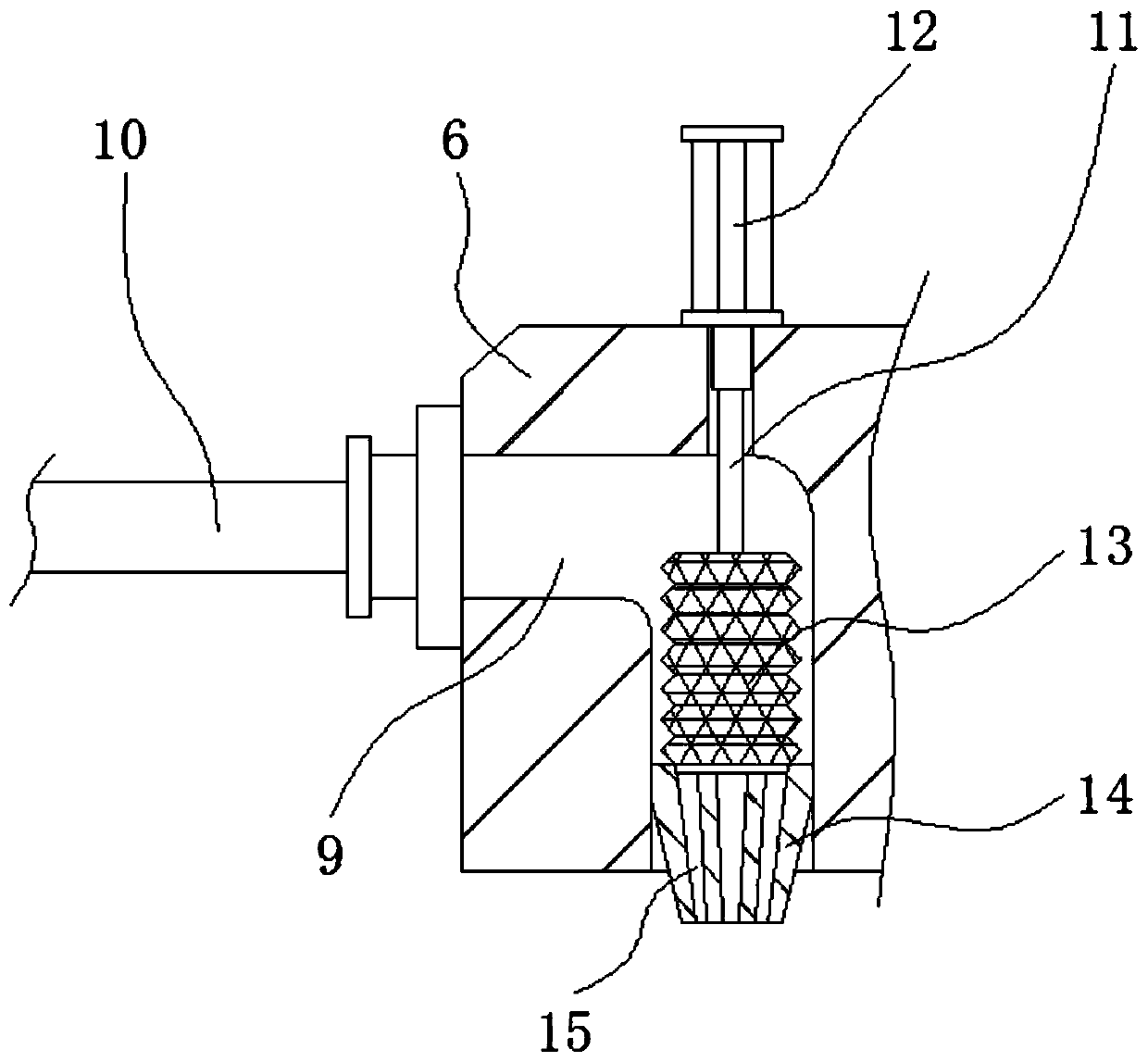

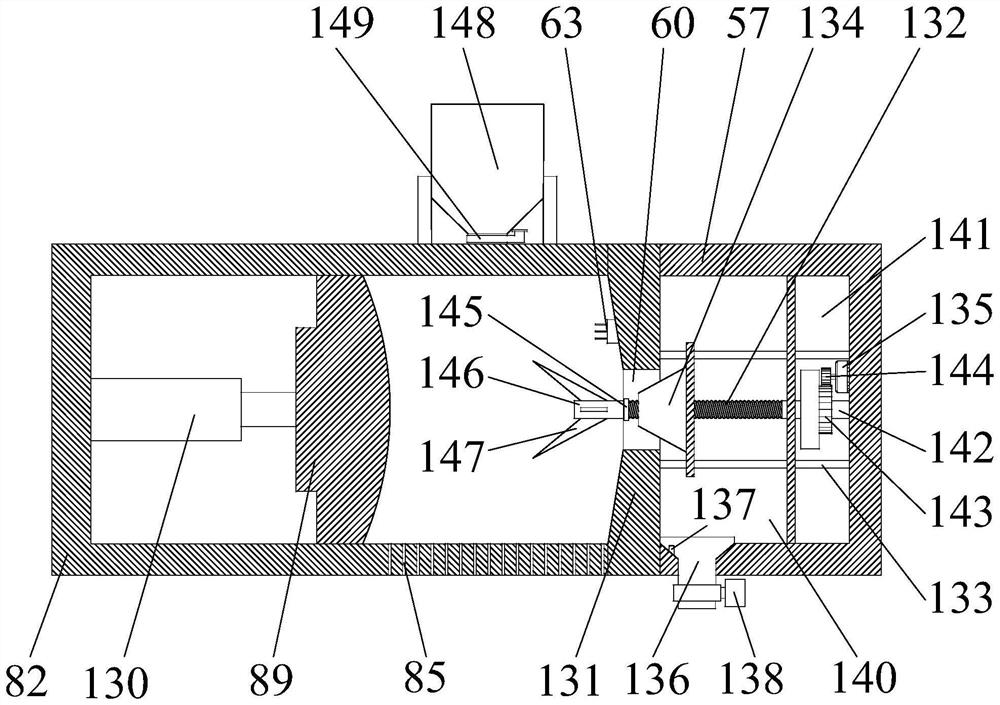

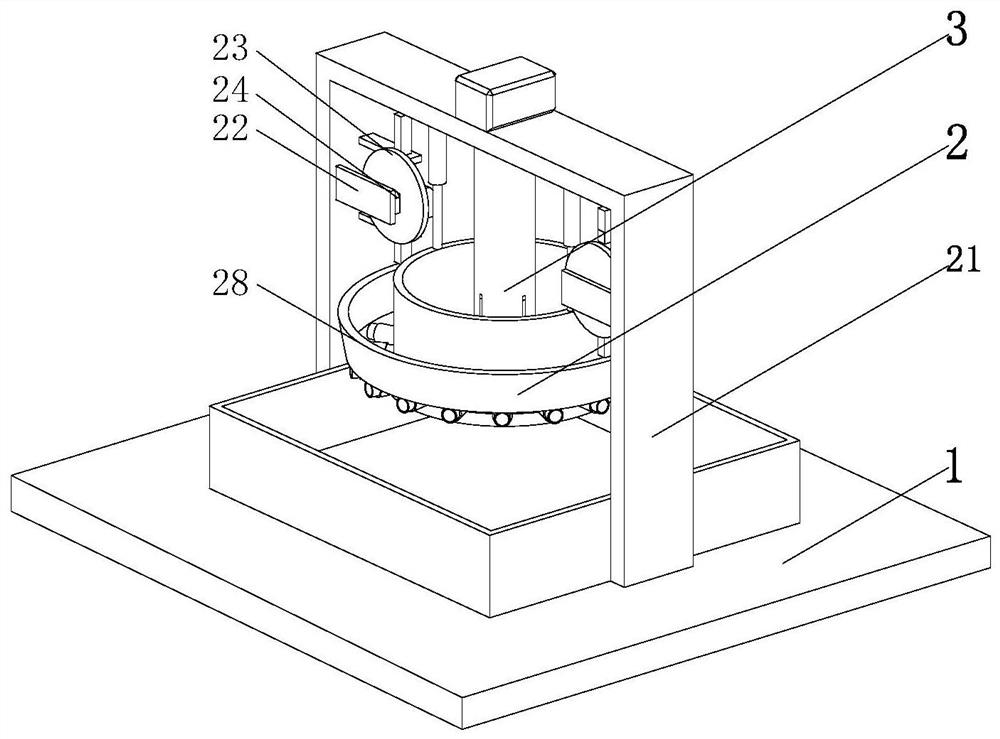

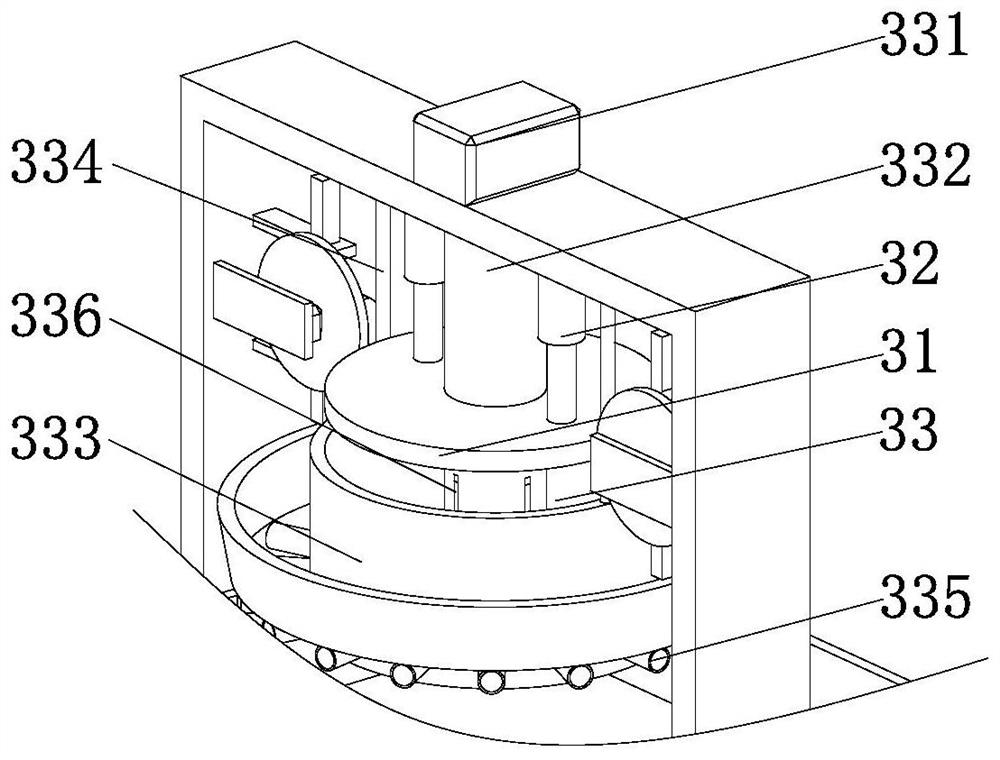

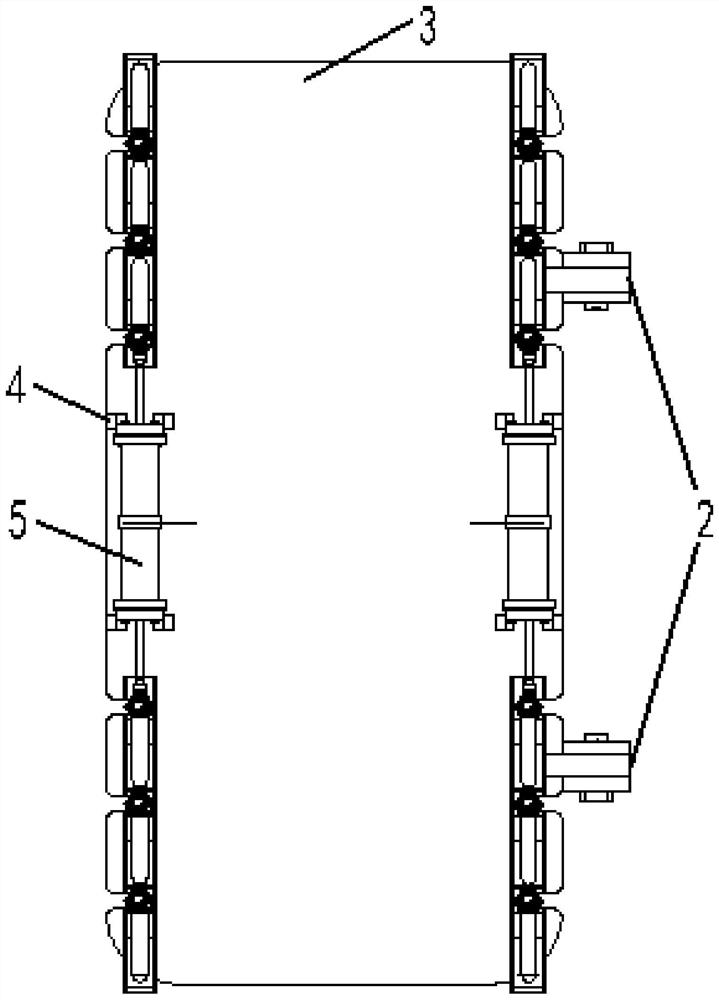

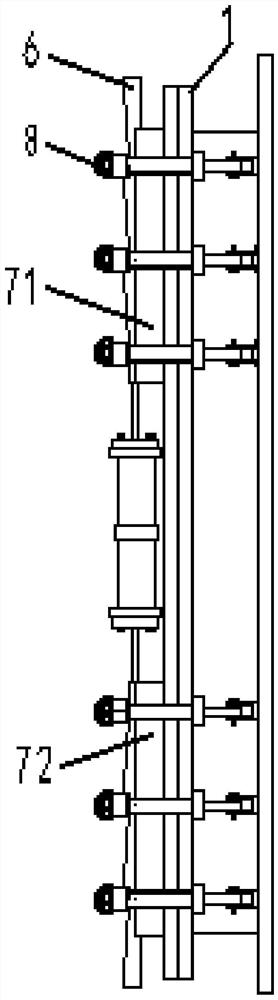

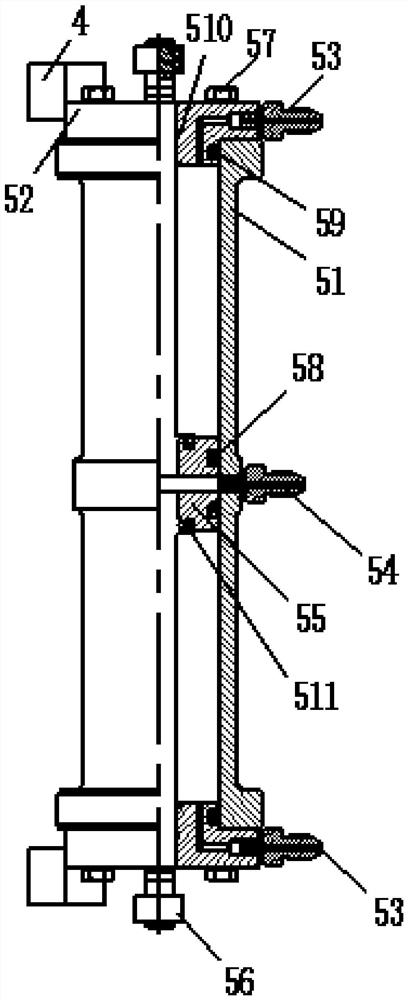

Radial extruding machine

PendingCN108189216AUniform extrusionChange the compression ratioCeramic shaping apparatusEngineeringMechanical engineering

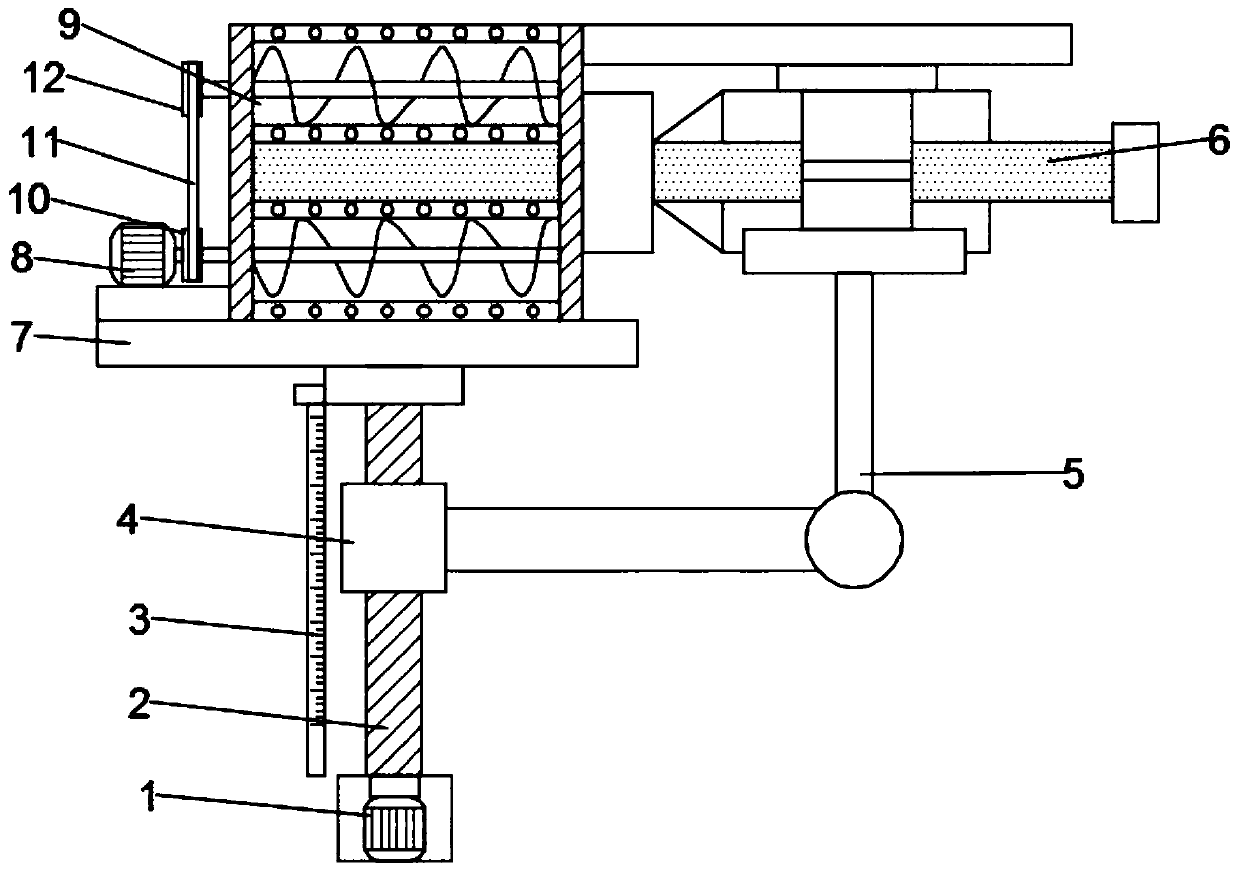

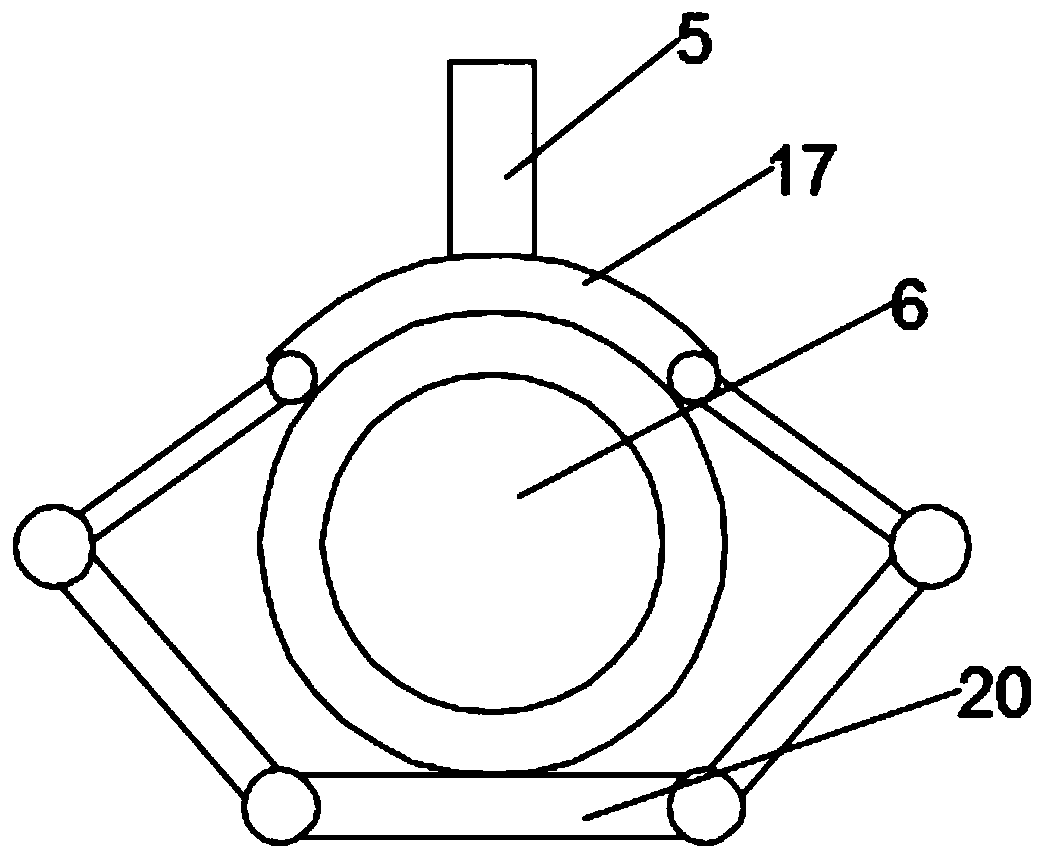

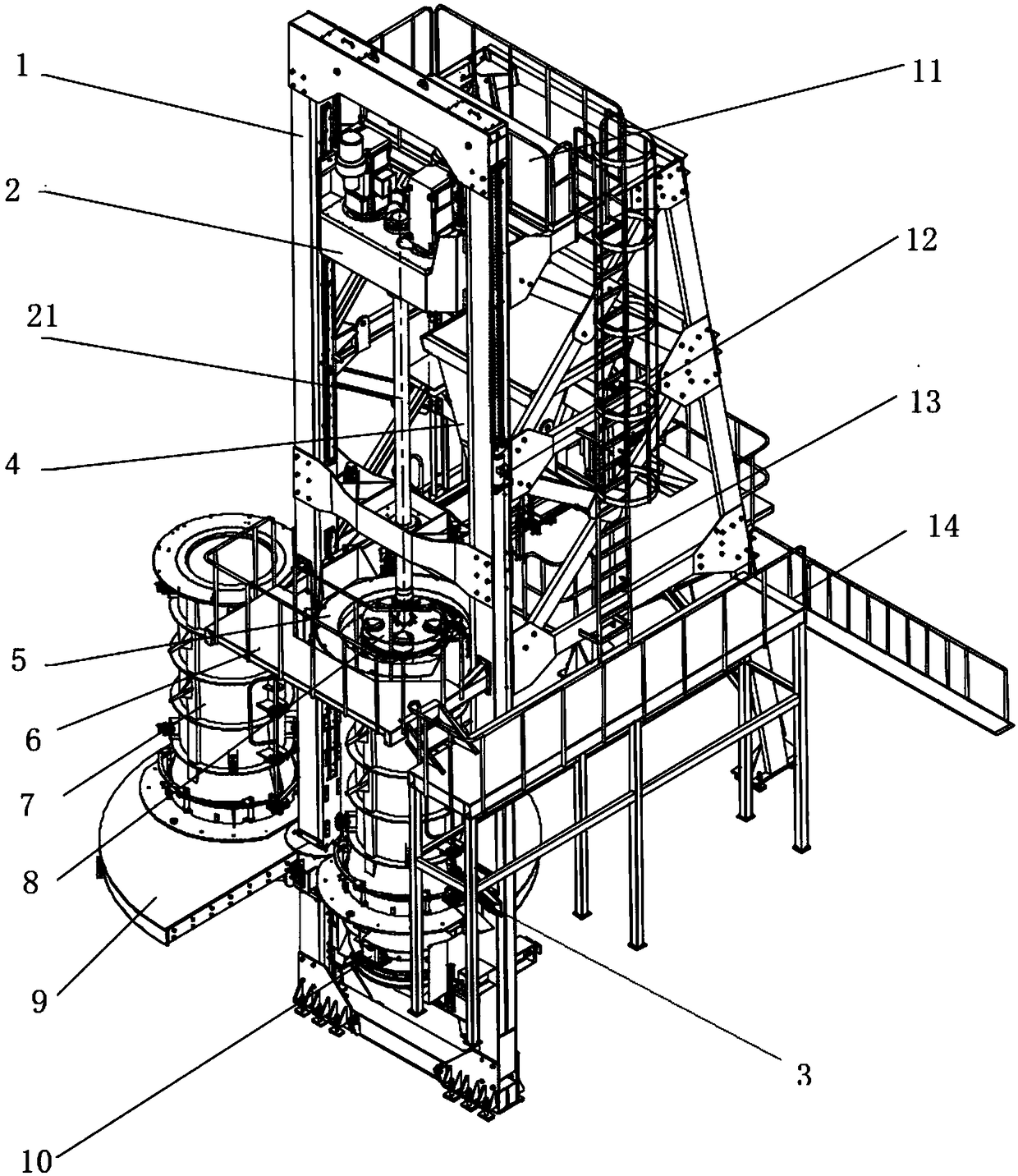

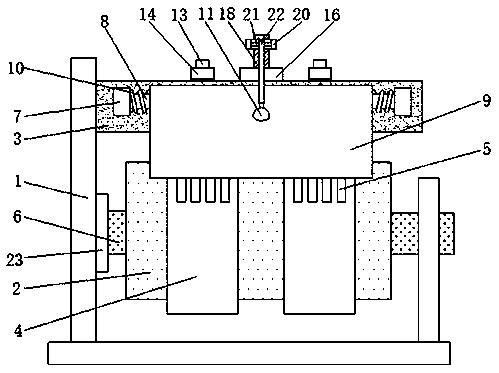

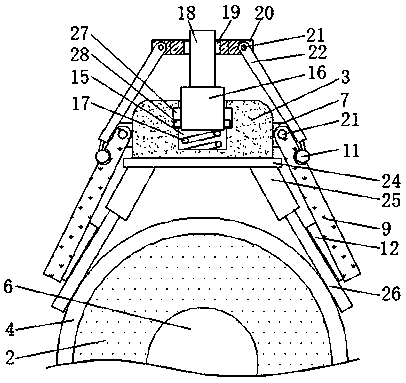

The invention relates to a radial extruding machine. The radial extruding machine comprises a frame (1), a power box (2), an air supply device (3), a feeding device (4), an insertion port forming device (5), a mold (7), an extruding head (8), a rotary chassis (9), a vibration device (10) and an oil cylinder (12). The extruding head (8) is internally provided with a plurality of upper extruding head bodies and lower extruding head bodies, wherein the upper extruding head bodies rotate coaxially, and the lower extruding head bodies do not rotate coaxially; and thus, by adjusting the eccentricity, the compression rate of pipe making concrete can be changed, so that the better extruding effect is achieved.

Owner:江苏威姿曼机械有限公司

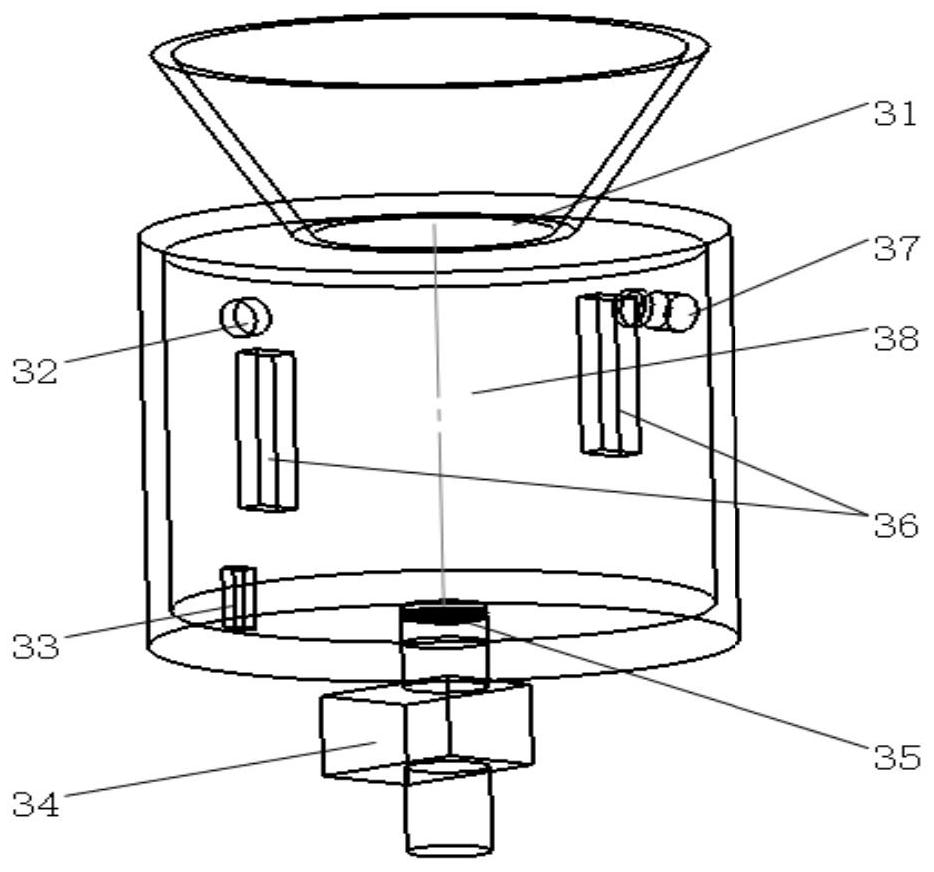

Molding machine for producing high-strength wood particles

InactiveCN105921070AGuaranteed coaxialityGuaranteed smoothnessGranulation by material expressionMolding machineUltimate tensile strength

The invention relates to a molding machine and particularly relates to a molding machine for producing high-strength wood particles. The molding machine for producing the high-strength wood particles comprises a compaction wheel assembly, a mold assembly, a conversion connector and a movable cutting assembly, wherein the compaction wheel assembly comprises a compaction wheel shaft, a compaction wheel and a bracket; the mold assembly comprises a main shaft and an annular mold; the annular mold is provided with a mold cavity; a plurality of extruding holes are formed in an annular surface; the movable cutting assembly comprises a screw rod arranged on the bracket, a movable nut which sleeves the screw rod, a slide rail arranged on the main shaft, a slide seat arranged on the slide rail and a cutting tool; one end of the cutting tool is fixed on the movable nut and the other end of the cutting tool is fixed on the slide seat; and each extruding hole comprises a material storage part and a molding part connected onto the material storage part. With the adoption of the molding machine, the length of the particles is consistent; the strength of the extruded particles is improved, the granulation effect is improved and the stress on the mold is relatively uniform; and the molding machine is simple in structure and convenient to operate and the service life of the equipment is prolonged.

Owner:HUZHOU TUOGAO MACHINERY CO LTD

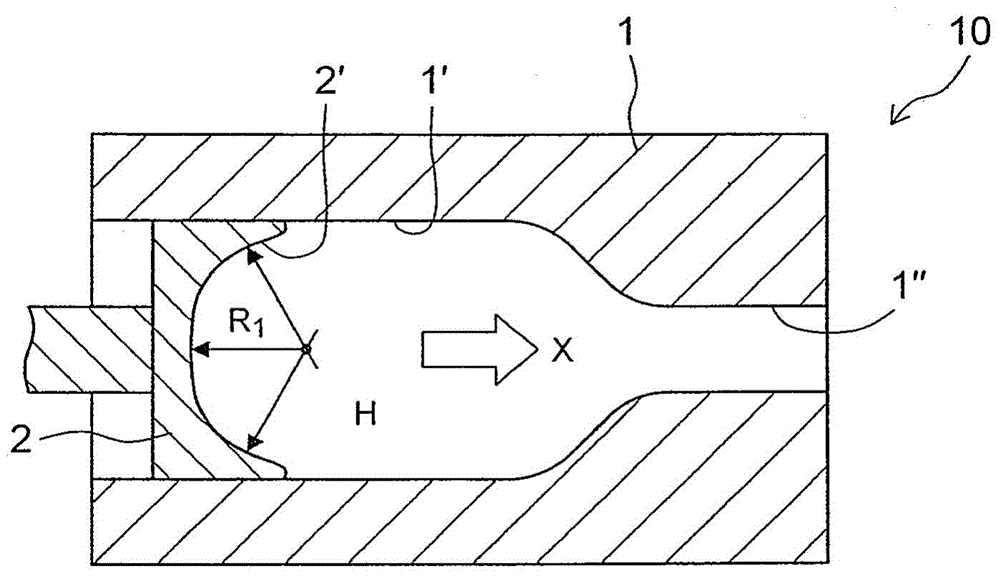

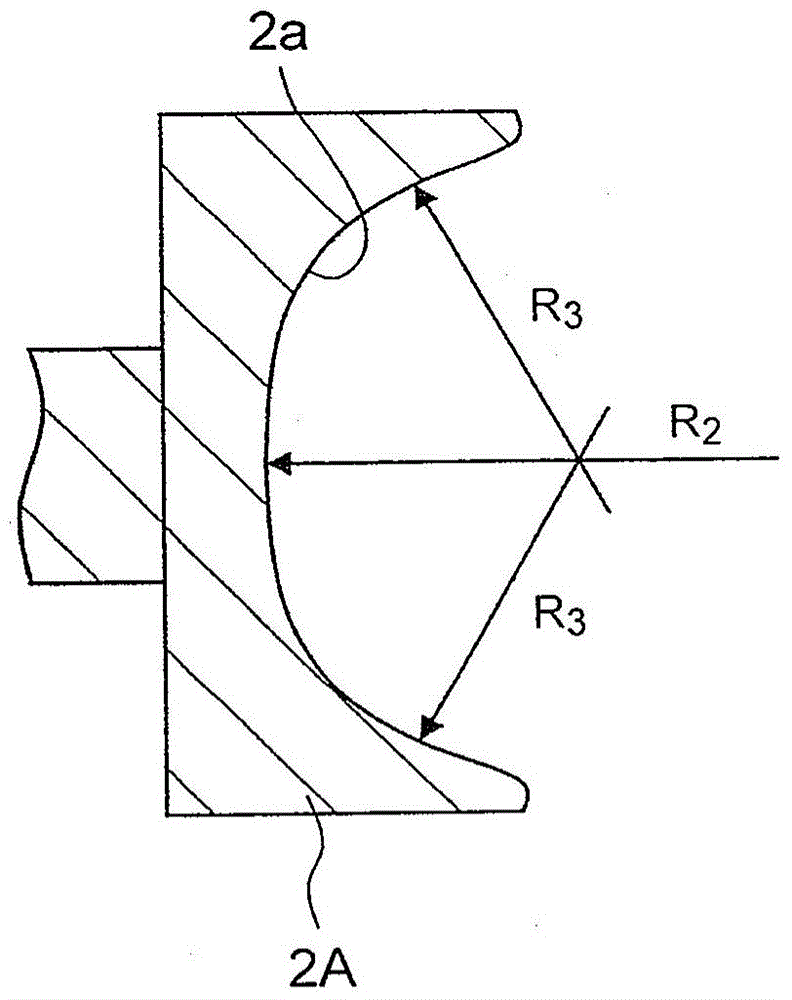

Forward extrusion forging apparatus and forward extrusion forging method

InactiveCN104624895AUniform extrusionSuppresses uneven strain distributionExtrusion diesRams/plungersEngineeringMechanical engineering

A forward extrusion forging apparatus includes: a die having a hollow portion whose diameter is reduced at an intermediate position; and a punch that is positioned behind a workpiece placed in the hollow portion, slides in the hollow portion, and extrudes the workpiece ahead of the hollow portion so that the workpiece is forged. An extruding surface of the punch, which extrudes the workpiece, is recessed in a direction opposite an extruding direction in a manner such that a center portion of the extruding surface is most recessed.

Owner:TOYOTA JIDOSHA KK

Multi-cavity profile forming equipment and forming method thereof

ActiveCN113617872AGuarantee the quality of finished productsImprove press molding efficiencyExtrusion diesEngineeringUltimate tensile strength

The invention relates to the technical field of profile manufacturing, in particular to multi-cavity profile forming equipment, comprising: a profile body, a profile extrusion molding mechanism; a material extruding mechanism; a heating mechanism; a discharging mechanism; a cutting mechanism; wherein the profile extrusion molding mechanism further comprises: a supporting base. an annular mounting bracket; an extrusion material-distributing section; an extrusion forming section, wherein a discharging cavity matched with the outer side wall of the profile body, an extrusion die core and a bridging assembly are arranged in the extrusion forming section, the extrusion die core is fixedly connected with the inner wall of the discharging cavity through a bridging assembly, the length of the bridging assembly is smaller than that of the extrusion forming section, and the length of the extrusion die core is consistent with that of the extrusion forming section; According to the equipment, the multi-cavity profile can be automatically processed, the cross section area of bridging can be reduced as much as possible while the connection strength is guaranteed, the extrusion speed is increased, and the forming efficiency is improved. The invention further relates to a multi-cavity profile forming method, the compression forming efficiency is improved, and synchronous forming operation of multiple cavities can be completed at a time.

Owner:CHIZHOU JIUHUA MINGKUN ALUMINUM IND

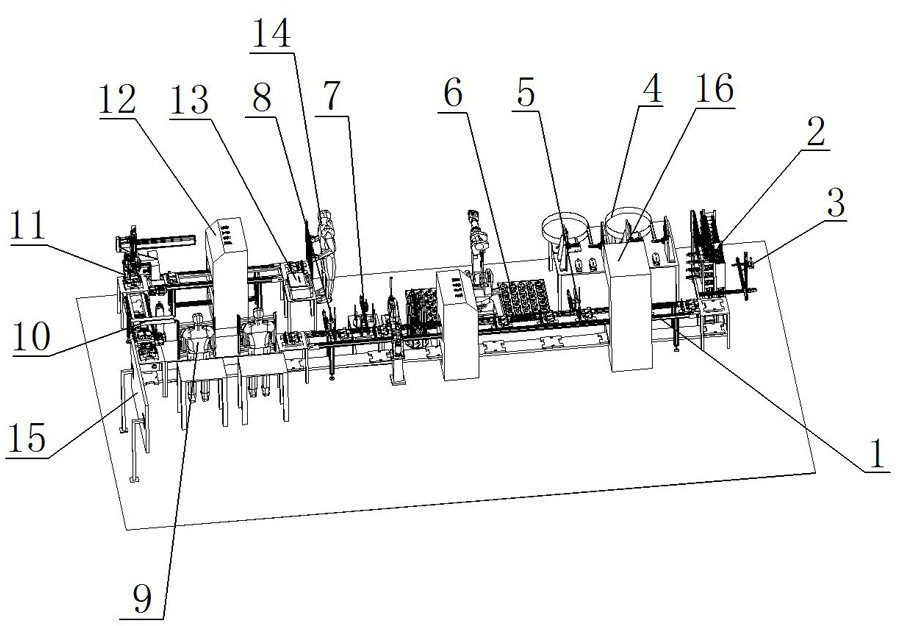

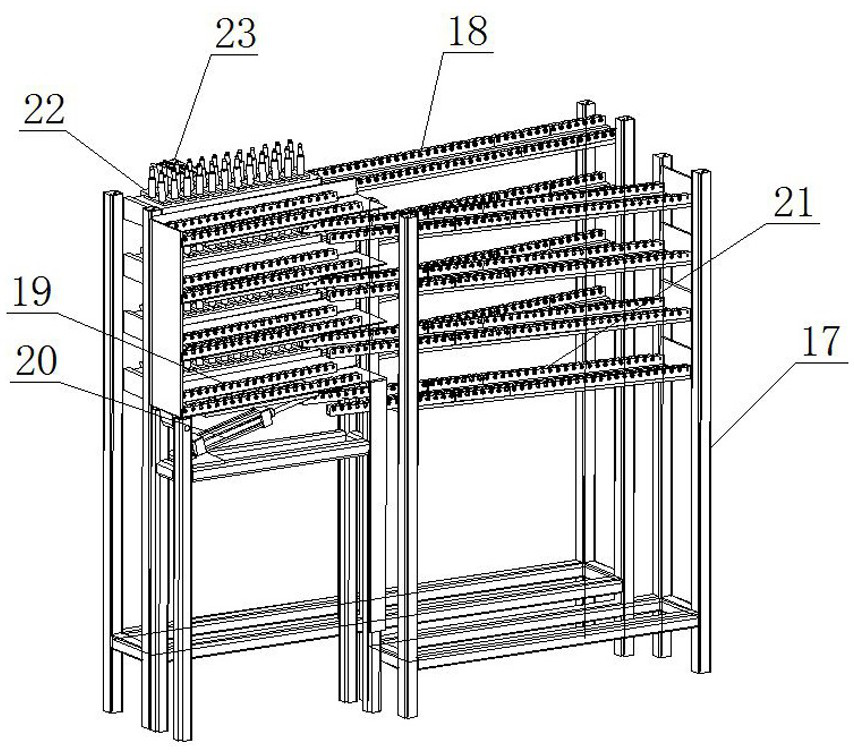

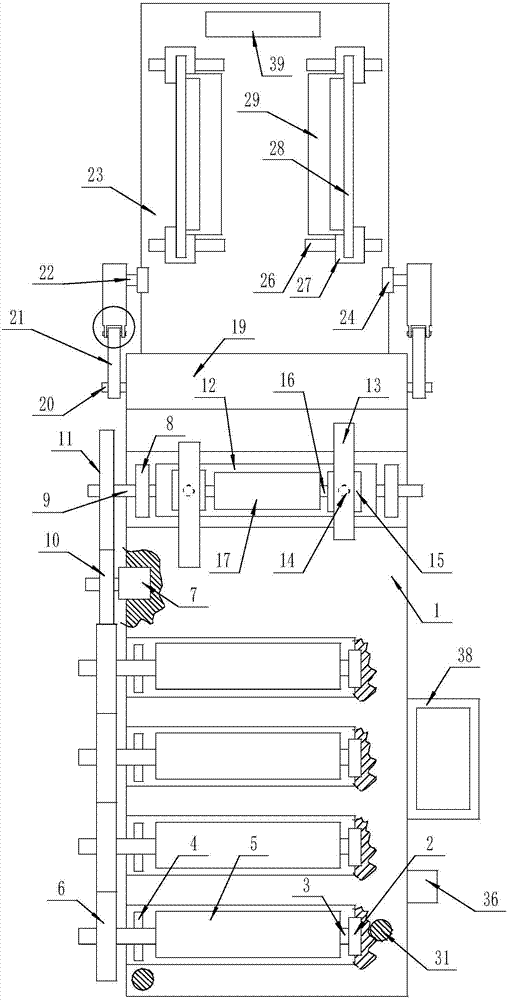

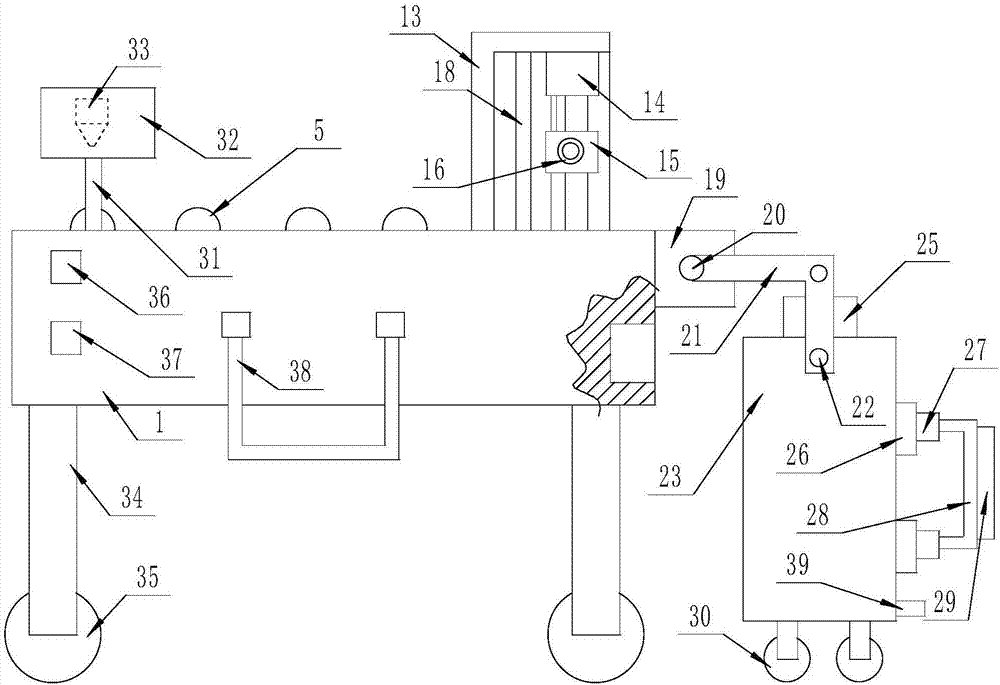

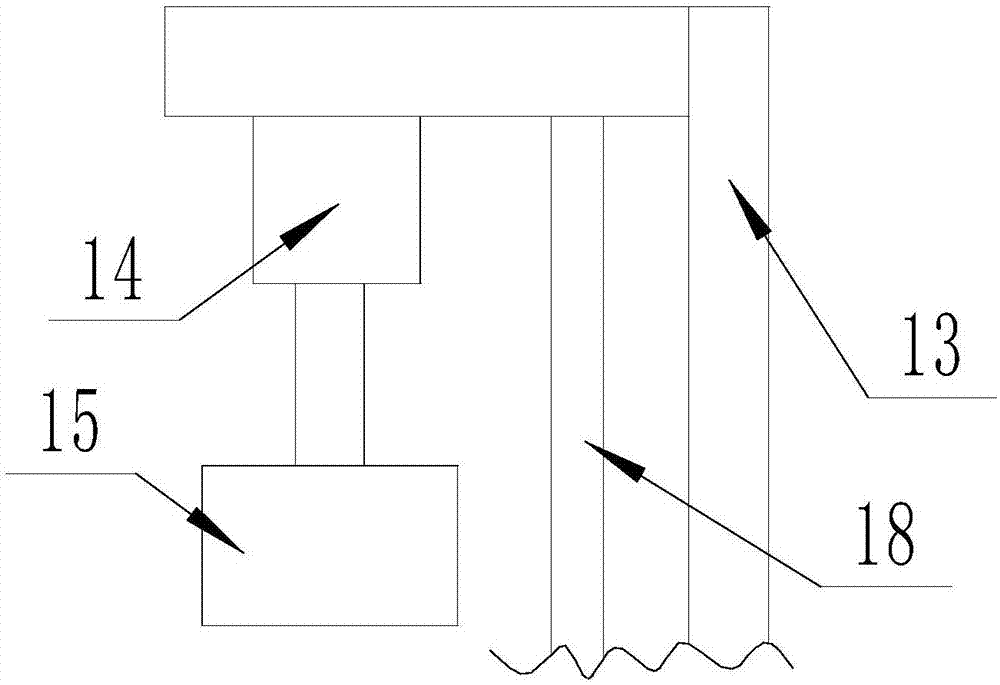

Automatic assembly production line for elevator brake calipers

InactiveCN113732699AGuaranteed installation accuracyLabor savingAssembly machinesMetal working apparatusProduction lineBrake

The invention discloses an automatic assembly production line for elevator brake calipers. The automatic assembly production line comprises a carrying disc conveying device, a brake plate storage mechanism, a brake plate carrying disc feeding mechanism, a disc spring automatic combination mechanism, a first disc spring height measurement mechanism, a shell feeding and shell size automatic measurement mechanism, an adjusting gasket and space ring supply mechanism, a second disc spring height measuring mechanism and a manual final assembly station, wherein the brake plate storage mechanism, the brake plate carrying disc feeding mechanism, the disc spring automatic combination mechanism, the first disc spring height measurement mechanism, the shell feeding and shell size automatic measurement mechanism, the adjusting gasket and space ring supply mechanism, the second disc spring height measuring mechanism and the manual final assembly station are sequentially arranged in the conveying direction of the carrying disc conveying device. According to the automatic assembly production line, the automatic assembly production of the elevator brake calipers is realized, the product circulation process is automatically carried out, manual operation and circulation are not wasted, and the labor force is greatly saved; and the thickness measurement of disc springs, space rings and adjusting gaskets adopts automatic measurement, so that the measurement precision is high, and the installation precision of final products is ensured.

Owner:中天智能装备有限公司 +1

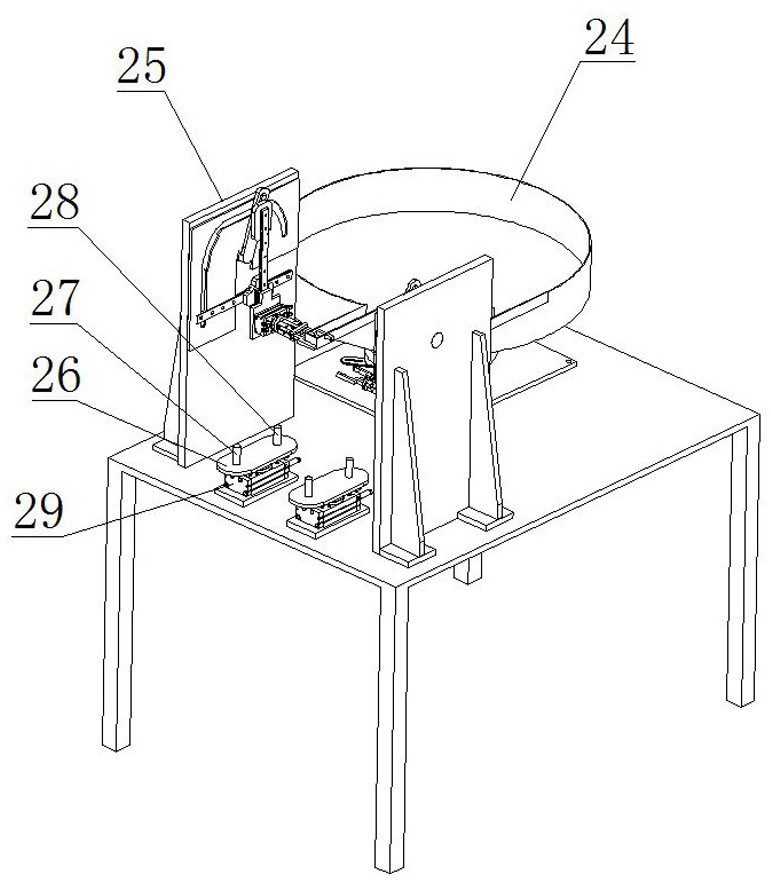

Double-nozzle wax pattern 3D printer

ActiveCN114226640AQuality improvementFast supplyAdditive manufacturing apparatusFoundry moulding apparatusWire rodComputer printing

The invention discloses a double-nozzle wax pattern 3D printer which comprises a printer frame, a working platform, a wire supply cylinder, a crushing mechanism, a melting mechanism, a feeding mechanism, a pressurizing mechanism, a moving mechanism and a double-nozzle mechanism, wherein the crushing mechanism, the melting mechanism, the feeding mechanism, the pressurizing mechanism, the moving mechanism and the double-nozzle mechanism are arranged on the printer frame; the melting mechanism is arranged below the crushing mechanism and is used for receiving the blocky raw materials processed by the crushing mechanism through a conical barrel; the pressurizing mechanism is used for extruding liquid wax of the melting mechanism; the feeding mechanism comprises a servo electric cylinder and a storage tank, and the storage tank is connected with a discharge port of the melting mechanism; the movement mechanism comprises a water X-Y movement mechanism and a Z-axis movement mechanism; the double-nozzle mechanism comprises a height difference switching device, a screw extrusion nozzle and a supporting material printing nozzle. According to the invention, printing of a wax mold with a complex structure is facilitated, a height difference is generated between the two nozzles, the nozzles are prevented from colliding with a printing material, and meanwhile, the wax mold quality and the printing efficiency are greatly improved.

Owner:SOUTH CHINA UNIV OF TECH

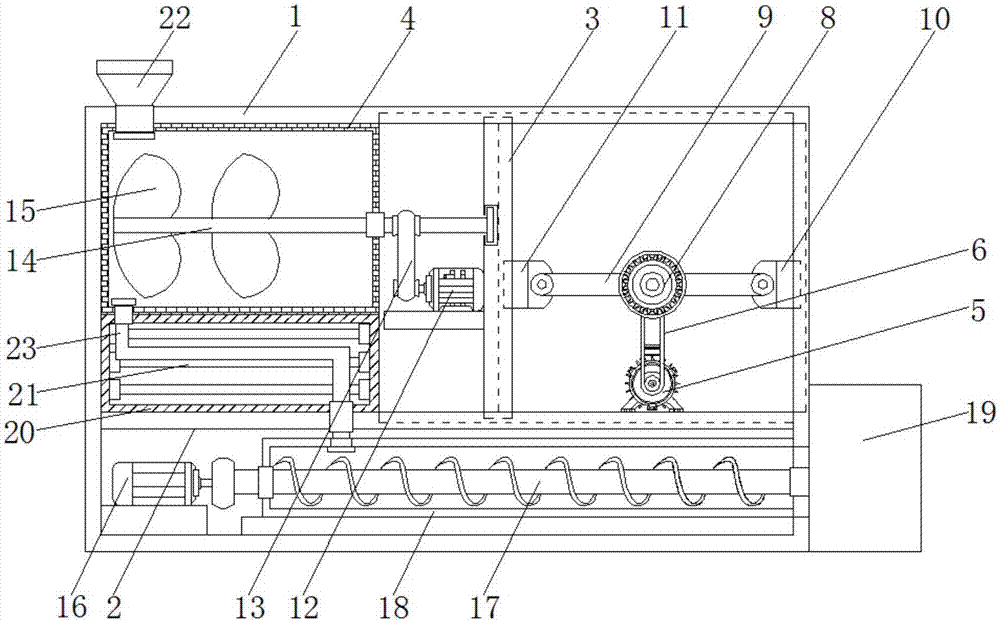

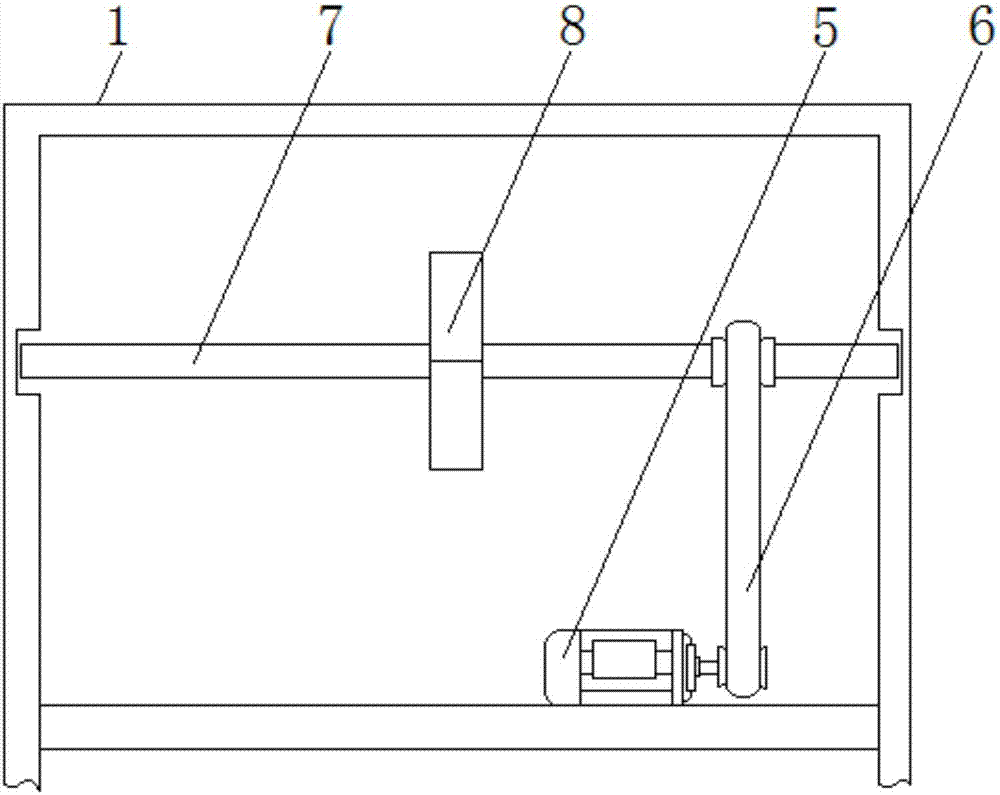

Extruding machine facilitating uniform extrusion of cables

ActiveCN107310121ASolve the problem of uneven extrusionStir wellDomestic articlesInsulating conductors/cablesEngineeringPulley

The invention discloses an extruding machine facilitating uniform extrusion of cables. The extruding machine facilitating uniform extrusion of cables comprises a tank. A bottom board is fixedly connected between the two sides of the inner wall of the tank. A supporting board is slidably connected between the top of the bottom board and the top of the inner wall of the tank. A stirring tank is fixedly connected between the two sides of the inner wall of the tank. A first motor is fixedly connected with the right side of the top of the bottom board. An output shaft of the first motor is in transmission connection with a first belt through a belt pulley. A rotary shaft is in transmission connected with the side, away from the first motor, of the first belt. A rotating rod is engaged to the outer side of a gear. A first sliding block is rotationally connected to the right end of the rotating rod. A stirring shaft is in transmission connection with the side, away from a second motor, of a second belt. The left end of the stirring shaft penetrates through the stirring tank and extends into the stirring tank. Stirring vanes are fixedly connected to the surface of the end, extending into the stirring tank, of the stirring shaft. The extruding machine facilitating uniform extrusion of cables can overcome the defects in the prior art and has a better uniform extrusion function.

Owner:冠纳电缆有限公司

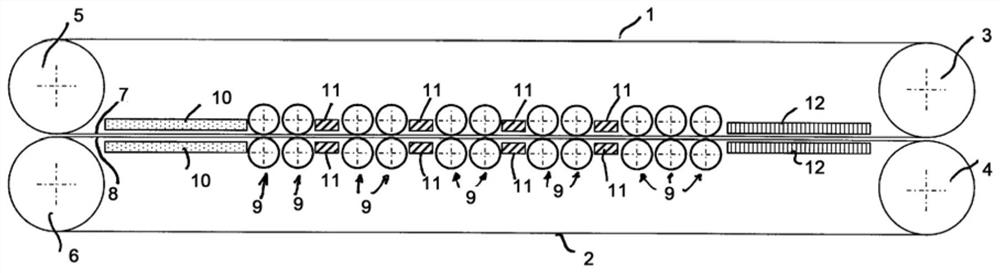

Device for pressing flat material

ActiveCN113474153AIncrease pressure application timeImprove the extrusion effectInduction heatingWood working apparatusStructural engineeringMechanical engineering

Owner:AZL亚琛有限责任公司 +1

Aerial cable binding material and manufacturing process thereof

The invention relates to the technical field of cable materials, and discloses an aerial cable binding material and a manufacturing process thereof. Comprising a shell, a feeding pipe is fixedly connected to the top end of the left side of the shell, a feeding hopper is fixedly connected to the upper end of the feeding pipe, a shaping assembly is fixedly connected to the bottom end of the right side of the shell, a cable shaping mechanism is arranged in the shaping assembly, and a cutting assembly is fixedly connected to the upper end of the shaping assembly. Downward movement of a supporting plate is achieved through electromagnetic adsorption of a second electromagnet, the effect of accurate quantification of raw material shaping is achieved according to the distance value of adjacent connecting sleeves, the accuracy of raw material shaping of each section of cable is remarkably improved, the shaping efficiency is improved, and the production cost is reduced. Inward sinking of the multiple elastic connecting ribs is achieved in the extrusion discharging process through downward movement of the supporting plate, then drainage mixing of raw materials is achieved, Joule heat is transmitted to the raw materials through the elastic connecting ribs through matched arrangement of the conductive pieces and the conductive blocks, and then the raw material shaping efficiency is improved.

Owner:SUZHOU EDWARD PETROCHEM CO LTD

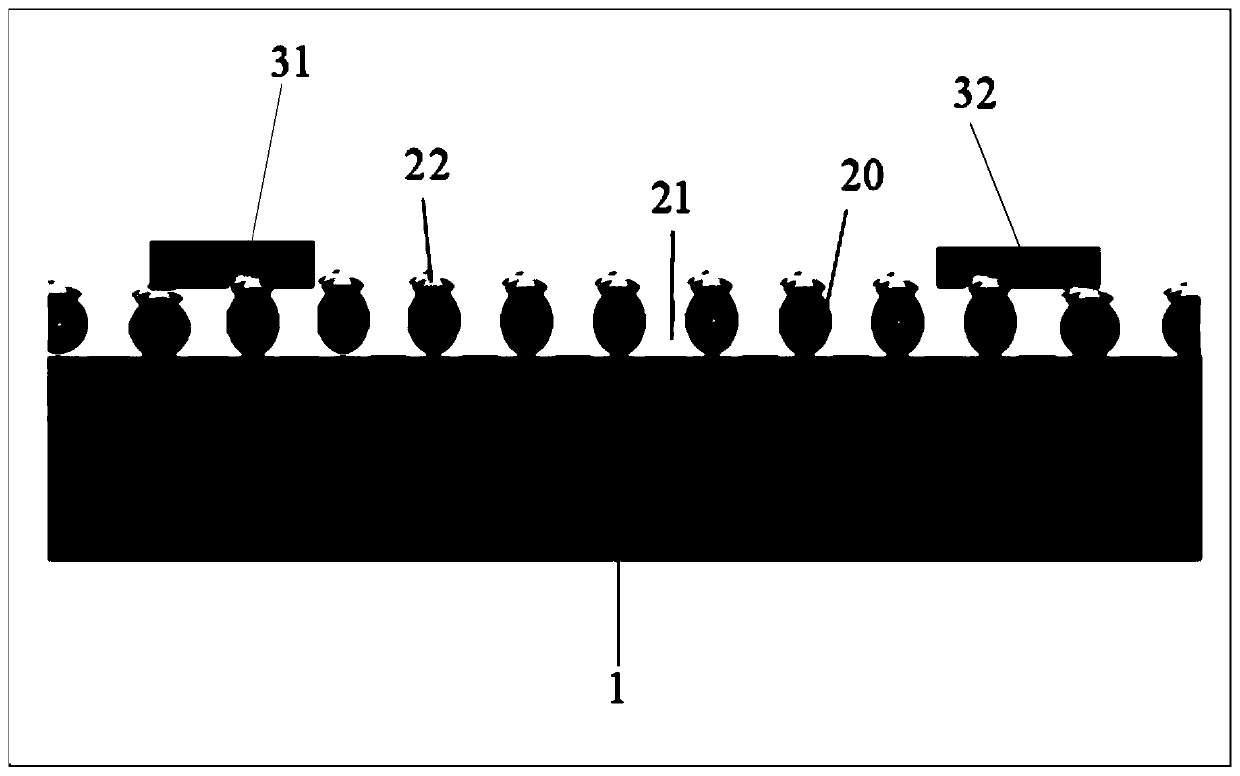

Adjustable three-dimensional chiral structure and preparation method thereof

The invention relates to an adjustable three-dimensional chiral structure and a preparation method thereof, and mainly relates to the field of optical chiral structures. The three-dimensional chiral structure comprises conductive glass, grating layers, a plurality of polystyrene spheres, a chiral structure layer, a first colloid and a second colloid. Deformation characteristics of a plurality of polystyrene spheres are utilized; when the chirality of the three-dimensional chiral structure needs to be adjusted, the first colloid and the second colloid are extruded by using opposite force, and aplurality of polystyrene spheres are enabled to form. The grating layers are arranged on the two sides of the polystyrene spheres, the heights of the polystyrene spheres can be changed under the action of pressure, then the local height difference and period of the chiral structure units in the chiral structure layer can be changed, and the purpose of adjusting three-dimensional chiral structureparameters is achieved.

Owner:中山科立特光电科技有限公司

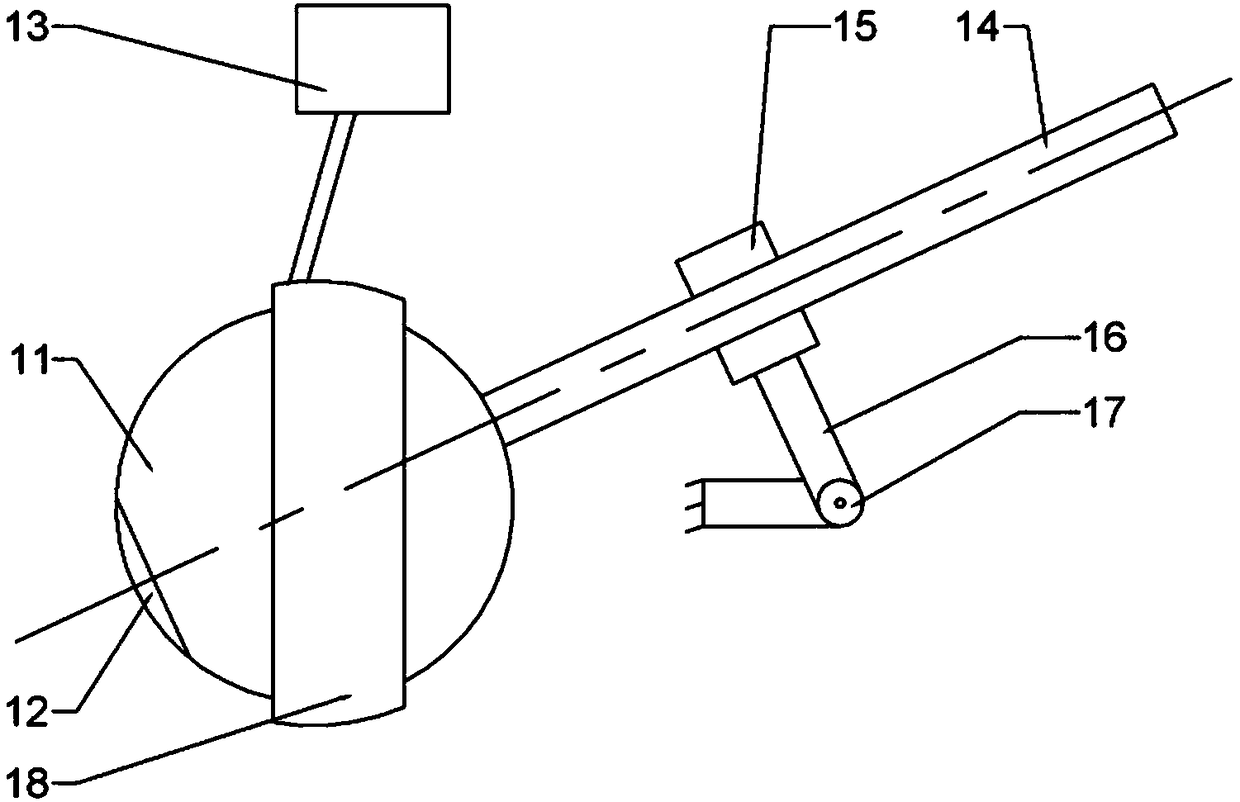

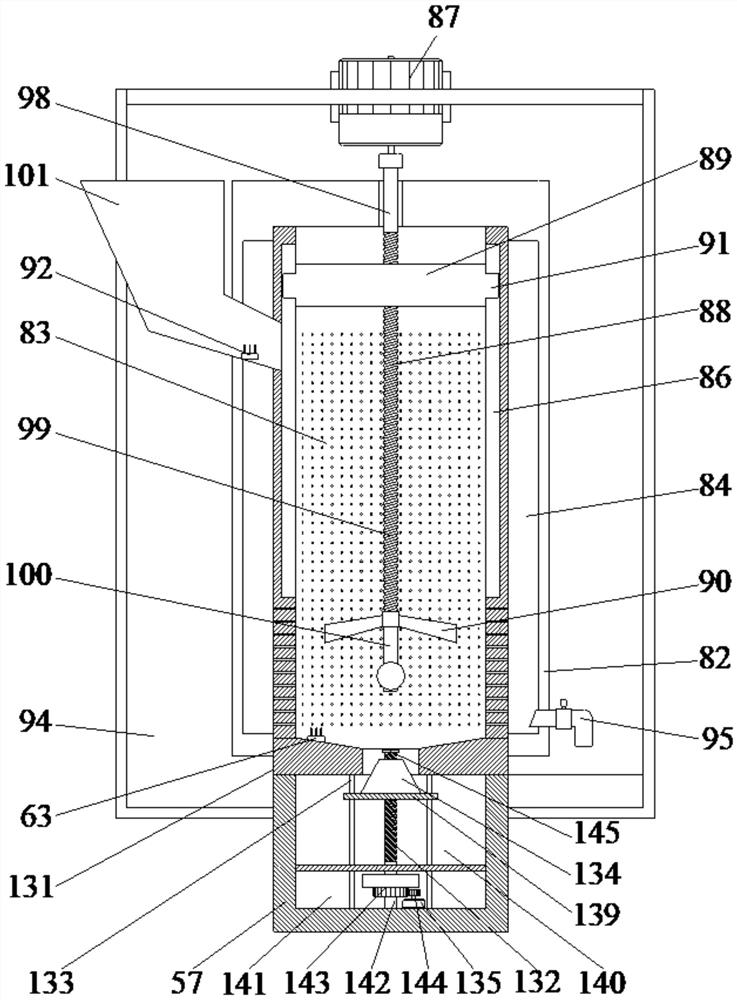

Rolling apparatus for wide noodles made from bean or sweet potato starch

InactiveCN108185491AHigh degree of automationLow costRotary stirring mixersTransportation and packagingGastric tube feedingFeeding tube

The invention discloses a rolling apparatus for wide noodles made from bean or sweet potato starch. The rolling apparatus for the wide noodles made from bean or sweet potato starch comprises a bottomplate, a stirring barrel, a feeding tube and a rolling cylinder; the stirring barrel is arranged at the upper left side of the bottom plate; the feeding tube is arranged at the upper left side of thestirring barrel; a water inlet is arranged at the upper right side of the stirring barrel; a first motor is arranged at the middle of the stirring barrel; the output end of the first motor penetratesthrough the stirring barrel, and is provided with a first rotating shaft; the first rotating shaft stretches into the interior of the stirring barrel; multiple groups of transverse stirring rods are symmetrically arranged on the outer side of the first rotating shaft; vertical stirring rods are fixedly connected with the outer ends of the transverse stirring rods; the lower right end of the stirring barrel communicates with the lower end of the feeding tube via a first connecting pipe; a second motor is arranged at the top end of the feeding tube; the output end of the second motor penetratesthrough the feeding tube, and is provided with a second rotating shaft; and a helix is arranged on the second rotating shaft so as to facilitate feeding of materials. The rolling apparatus for the wide noodles made from bean or sweet potato starch is simple in structure, multi-functional, good in rolling effects on wide noodles made from bean or sweet potato starch, high in automation degree, andconducive to promotion.

Owner:ANHUI SANXIONGDI POTATO IND

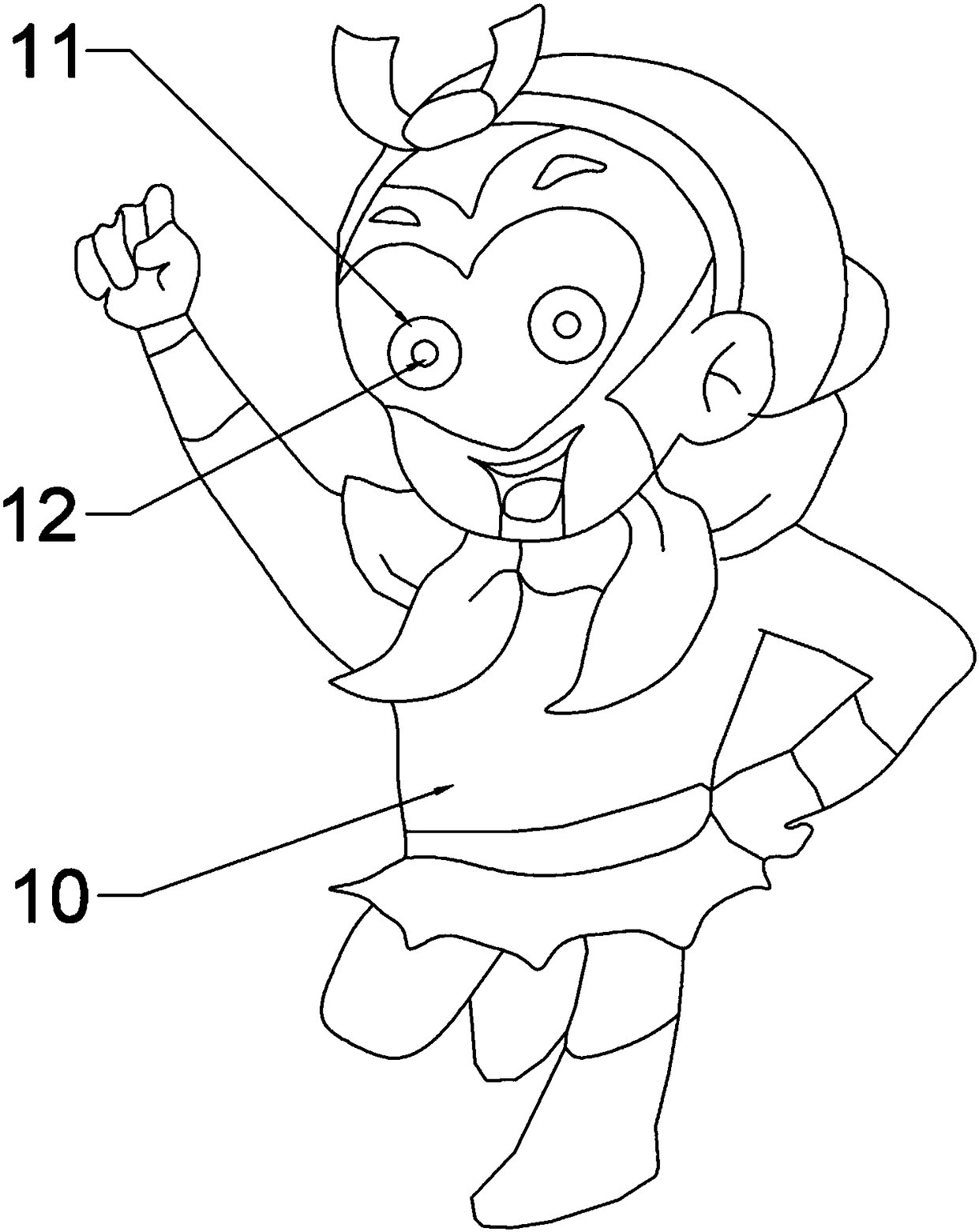

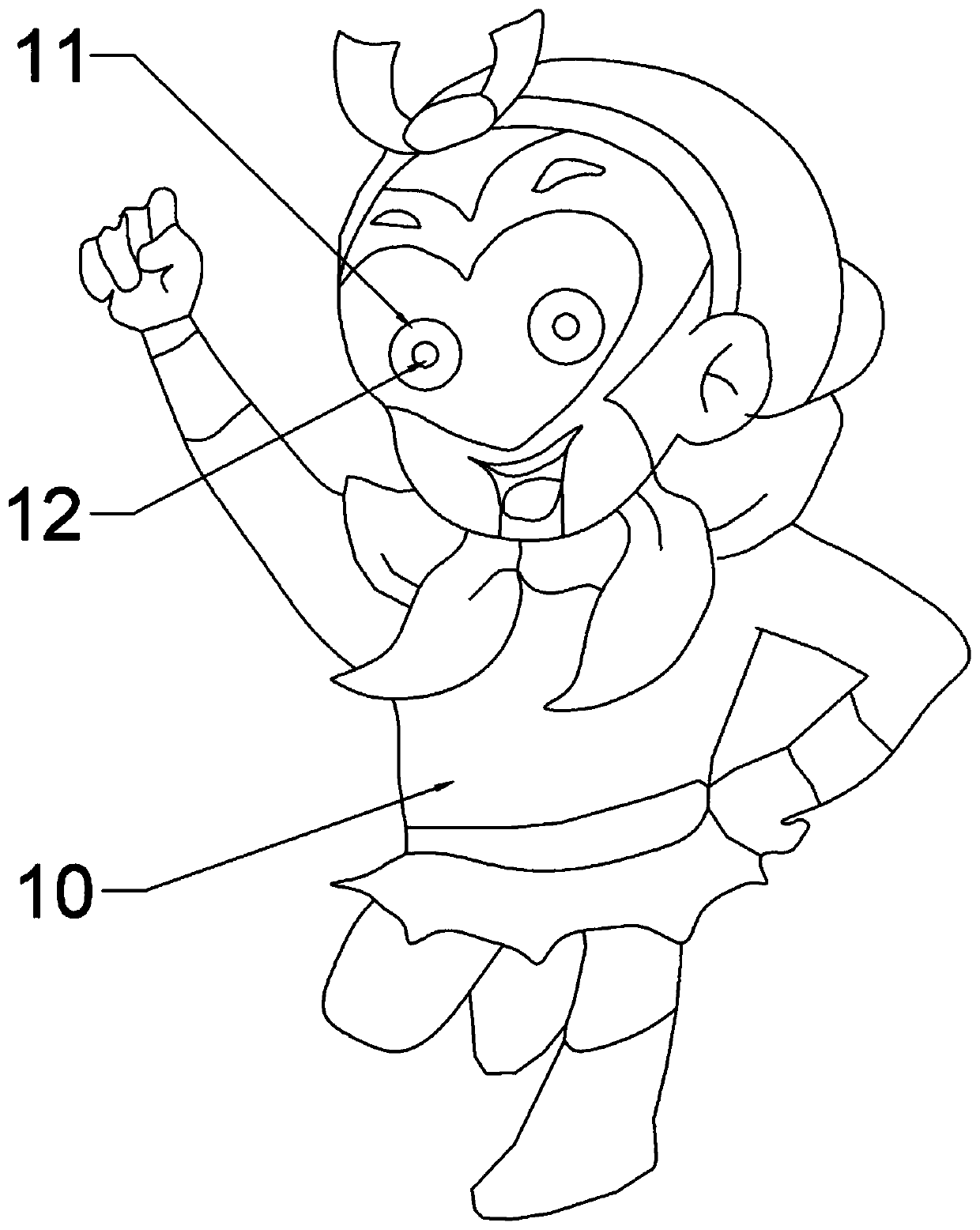

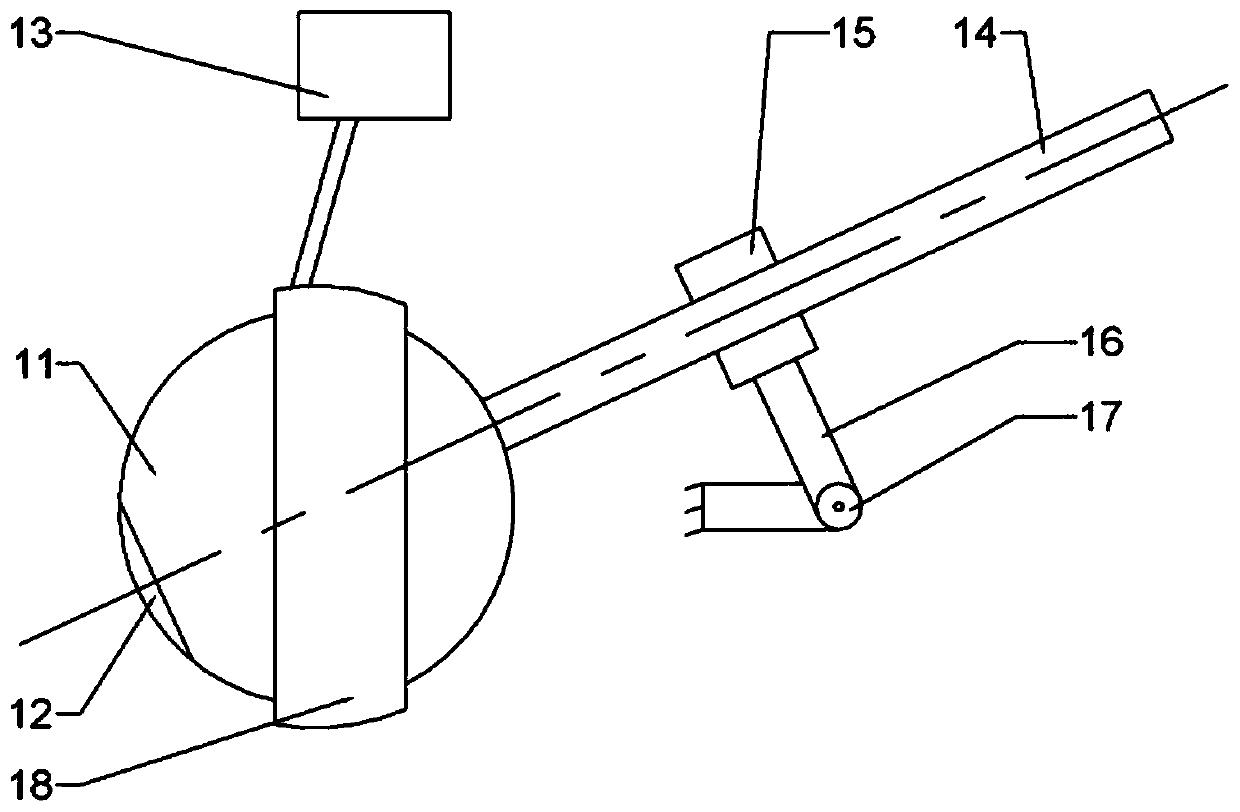

Multifunctional interactive robot

The invention discloses a multifunctional interactive robot. The multifunctional interactive robot comprises a robot body and two projection mechanisms located at the eye parts of the robot body. Eachprojection mechanism is mounted at the corresponding eye part of the robot, and the projection angle is controlled by a servo steering machine, so that the rich projection combination is achieved, for example, two images are spliced together to form an ultra-wide picture, or the two images are projected separately to form different pictures, more information is fed back to a user, enjoyment is high, and playability is high.

Owner:重庆门罗机器人科技有限公司

A magnetic energy double-sided engine slip ring conductive composite copper wire

InactiveCN109067101AReduce frictionReduce wearRotary current collectorDynamo-electric machinesTorsion springMagnetic energy

The invention discloses a magnetic energy double-sided engine slip ring conductive composite copper wire, which relates to the technical field of magnetic energy double-sided engine components. that the copper wire is provided with a fix rod, a pressing Plate, a threaded plug, a connection block and a connection rod, the fixing rod is rotated , causing the threaded plug to rotate and move downward, the fixing rod drives the connecting block to move downward through the rolling bearing, causing the connecting rod to move downward, the connecting rod pushes the pressing plate to rotate about thepin axis through the ball pin, the torsion spring returns to its normal condition, so that the platen presses the brush against the copper wire, the separation of the composite copper wire from the conductive slip ring under the extrusion of the conductive slip ring in the copper wire brush is avoided, the normal conductivity of the composite copper wire is not affected, As the rotor drives the conductive slip ring to rotate when the conductive composite cop wire of the slip ring of the magnetic energy double-sided engine is in use, the conductive slip ring will extrude the composite copper wire, so that the hidden trouble that a part of the composite copper wire and the conductive slip ring are separated, and the conductive effect of the composite copper wire is affected.

Owner:汤亮

Extruding and edge cutting equipment for rubber product

The invention discloses extruding and edge cutting equipment for a rubber product. The extruding and edge cutting equipment comprises a strip-shaped bearing plate; an extruding mechanism is arranged on the upper surface of the strip-shaped bearing plate; and a swinging edge cutting mechanism is arranged in the position, close to the extruding mechanism, of the strip-shaped bearing plate. The extruding and edge cutting equipment has the beneficial effects that operation is convenient, it is convenient to control the extruding degree, the extruding effect is even, the attaching effect is good, cutting in the fixed length is conveniently conducted on extruded spare rubber, assembly line production is achieved, the situation that operation is conducted in large volumes is facilitated, and the labor intensity is relieved.

Owner:惠州市卓普科技有限公司

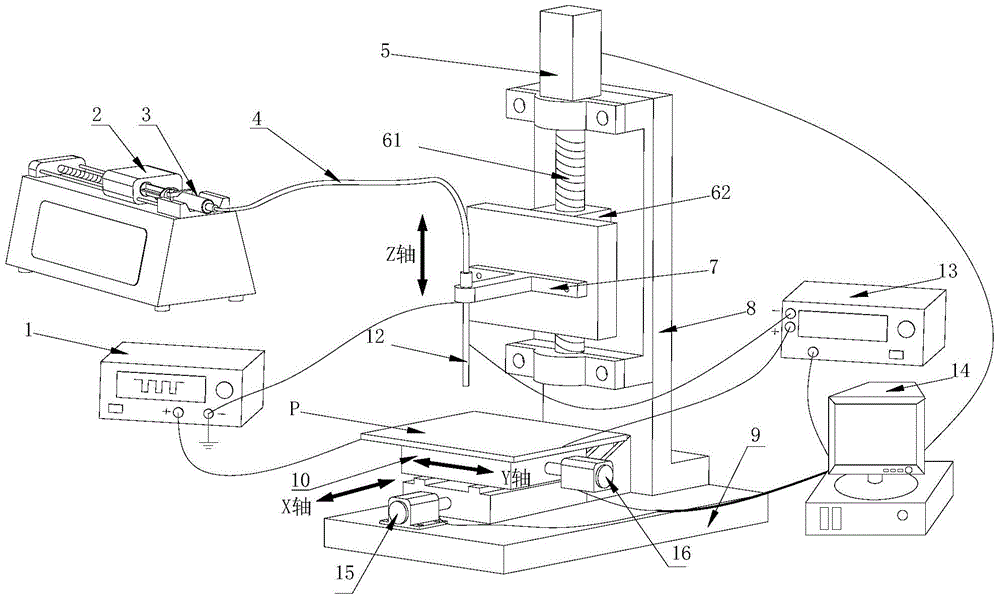

Micro Jet Electrode EDM Device

InactiveCN103962658BUniform extrusionLine width is small and easy to controlDrive motorSignal generator

The invention discloses a micro jet flow electrosparking device, and relates to electrosparking devices. A positive electrode of a pulse signal generator is connected with a workpiece, and a negative electrode of the pulse signal generator is connected with a metal syringe needle. A solution injection syringe is fixed to an injection pump. The metal syringe needle is connected with the injection syringe and vertically fixed to a feeding adjusting device through a clamping device. The feeding adjusting device is provided with a lead screw and a sliding block. The lead screw is connected with an output shaft of a Z-axis driving motor. The sliding block is in screw-thread fit with the lead screw. The detection end of a discharging state detection device is connected with the metal syringe needle and a workpiece to be machined. The signal output end of the discharging state detection device is connected with a controller. The feeding adjusting device is fixed to a base. An X-Y motion platform is fixed to the base and used for clamping the workpiece to be machined. An output shaft of an X-axis driving motor is connected with the X-axis direction of the X-Y motion platform. An output shaft of a Y-axis driving motor is connected with the Y-axis direction of the X-Y motion platform. The output end of the controller is electrically and respectively connected with the Z-axis driving motor, the X-axis driving motor and the Y-axis driving motor.

Owner:XIAMEN UNIV

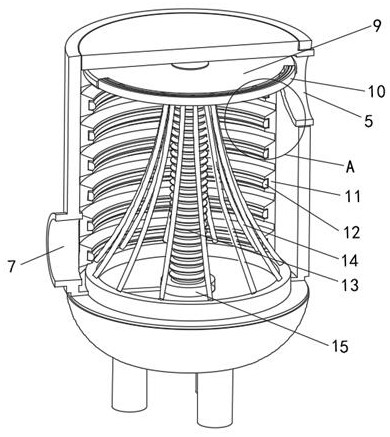

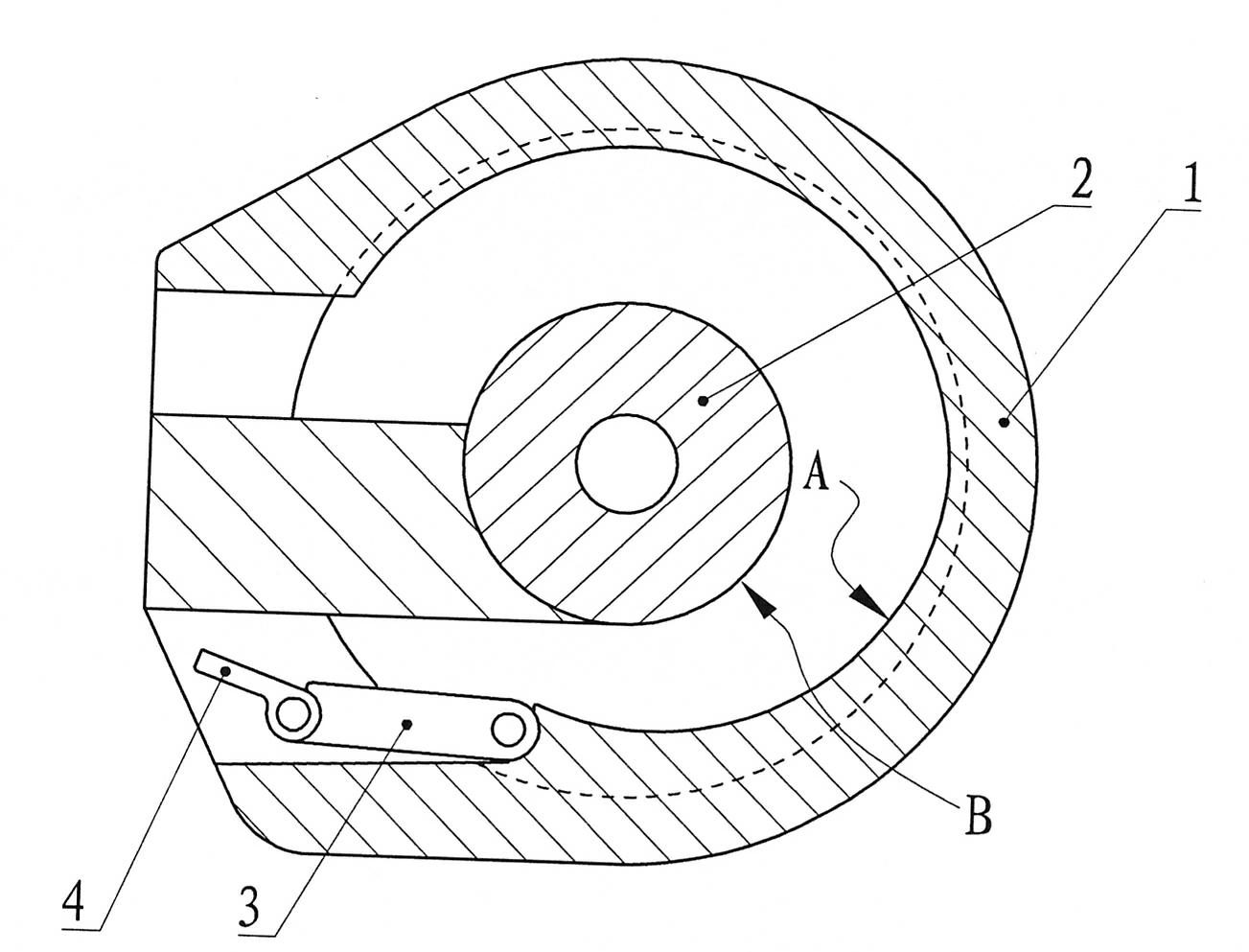

Channel for rotary extruding-type filter

InactiveCN102107103AImprove uniformityImprove filtration efficiencyMoving filtering element filtersEngineeringCompression ratio

The invention provides a channel for a rotary extruding-type filter, and the channel provided by the invention is a C-shaped channel consisting of an inner wall [A] on an outer partition board [1], an outer wall [B] on an inner partition board [2] and a filter screen; the cross section of the channel is rectangular; the upper end of the channel is connected with a feed port through a feeding section; the lower end of the channel is connected with a discharging port through a discharging section; a flashboard [4] is arranged at the discharging port; and the radial side length of the rectangular cross section is gradually reduced from the feeding section to the discharging section. In the channel for the rotary extruding-type filter provided by the invention, the radial side length of the rectangular cross section is gradually reduced from the feeding section to the discharging section so that the cross section of the channel is matched with the reduction of the volume flow rate of materials. Compared with the prior art, the channel can be used for improving the uniformity of the compression ratio of the materials at each part of the channel, thereby improving the filtering efficiency of the filter; and simultaneously, the gradually reduced channel also provides an extruding force for the materials; therefore, the defect that the extruding force for the materials is provided only by the flashboard is changed so that the service life of the device is improved.

Owner:浙江科力尔环保设备股份有限公司

Flat pressing device for mounting bottom cover of watch shell

The invention relates to the technical field of watch mounting, in particular to a flat pressing device for mounting a bottom cover of a watch shell. The device comprises a machine base and a pressing plate, a vertically arranged guide structure is fixedly arranged on the machine base, the pressing plate is slidably arranged on the guide structure, and a driving mechanism for driving the pressing plate to slide and lift along the guide structure is arranged on the machine base; and a bearing mechanism used for placing a watch shell is arranged at the position, staggered with the pressing plate, of the bottom of the machine base, a flat pressing mechanism is arranged above the bearing mechanism, and the flat pressing mechanism and the pressing plate are connected through a preset pressing arm so as to ascend and descend along with the pressing plate. According to the application, uniform extrusion force can be applied to a sealing ring in advance, so that the condition that one side of the sealing ring tilts is not easy to occur, the sealing performance of the sealing ring is improved, and the service life of the watch is prolonged.

Owner:深圳市古尊表业有限公司

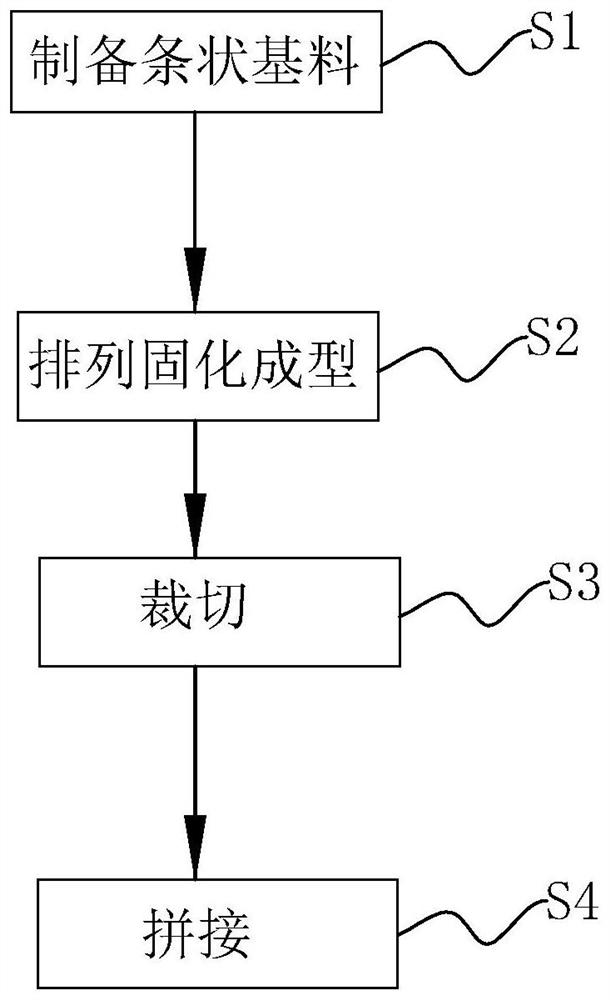

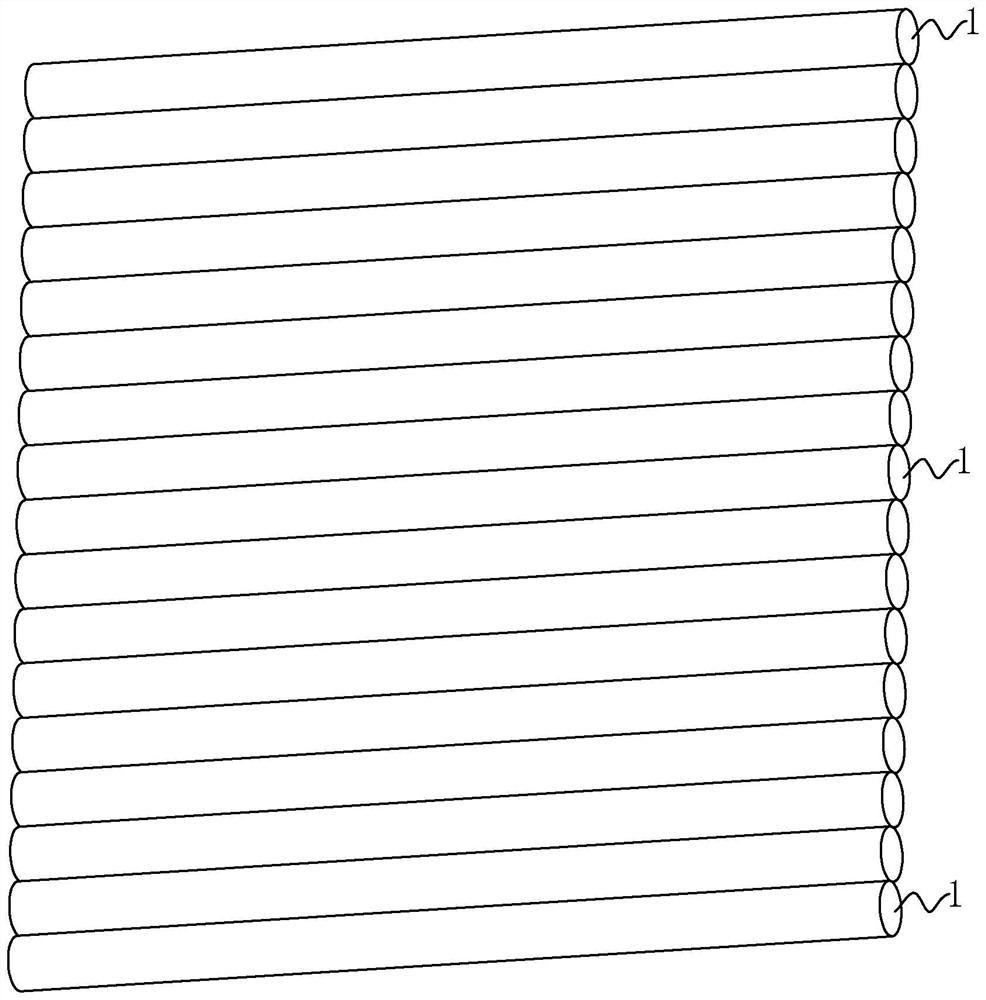

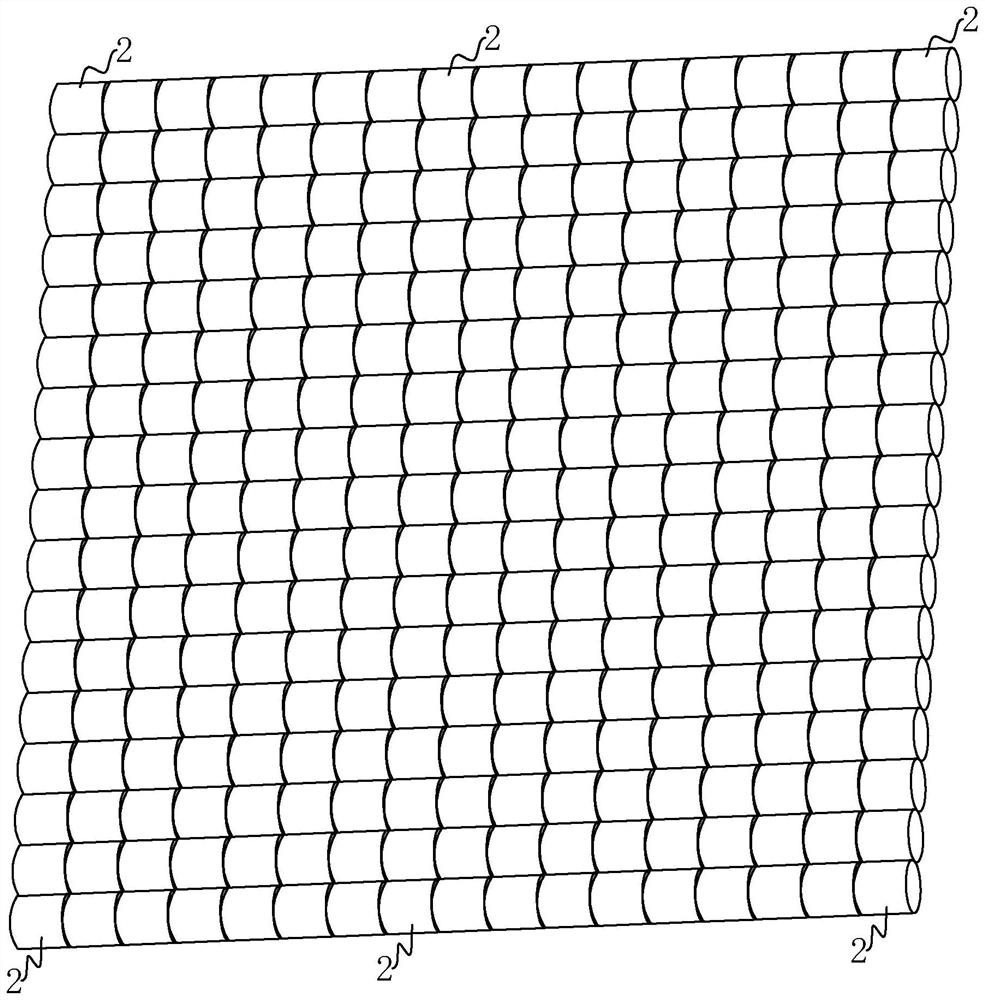

Process for simply preparing directionally-sorted carbon fiber heat-conducting composite material in laboratory

PendingCN114228205ATo achieve the purpose of directional sortingUniform extrusionFlat articlesManufacturing engineeringFiber

The invention discloses a process for simply preparing a directionally ordered carbon fiber heat-conducting composite material in a laboratory, which comprises the following steps: S1, preparing strip-shaped base materials: adding a carbon fiber heat-conducting composite material base material into a dispensing pipe, and extruding a piston of the dispensing pipe at a constant speed to prepare a plurality of strip-shaped base materials; the cross sectional area of the lower end of the glue outlet is smaller than that of the cavity of the dispensing pipe; s2, arranging, curing and forming: sequentially arranging a plurality of strip-shaped base materials in parallel along the extrusion direction, and performing high-temperature curing and forming; s3, cutting: after the strip-shaped base material is cooled, cutting the strip-shaped base material at equal intervals according to a preset interval, and cutting the strip-shaped base material into a plurality of small sections of base materials with the same interval; and S4, splicing is conducted, specifically, the small sections of base materials are turned over by 90 degrees and arranged in sequence again, and the carbon fiber heat conduction composite material assembled sheet with the uniform thickness is obtained. The method does not need to customize a special extruding and slicing machine, and has the effects that the test sheet can be prepared by using a common device, and the carbon fibers can be directionally sequenced in the test sheet.

Owner:深圳联腾达科技有限公司

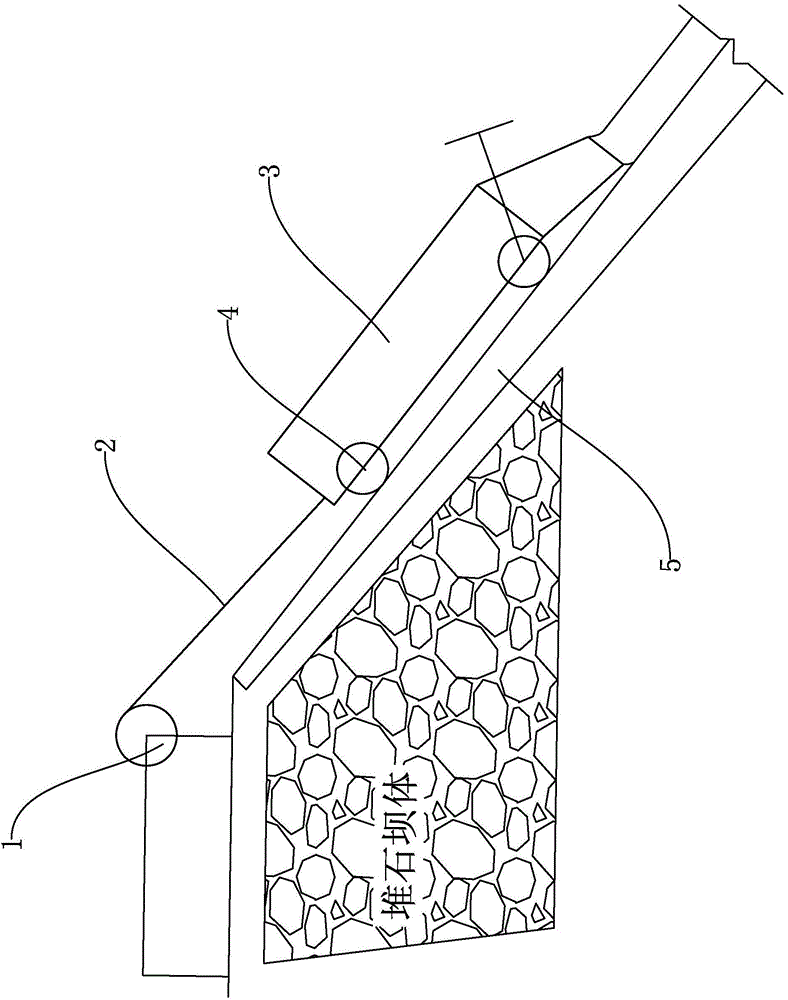

Linked piston type plastic sealing material forming system

ActiveCN104674764AUniform extrusionHigh mechanical energy conversion efficiencyMarine site engineeringEngineeringWinch

The invention relates to a linked piston type plastic sealing material forming system. The invention is intended to provide the linked piston type plastic sealing material forming system which is structurally simple and light, is convenient to transport and is low in energy consumption. The technical scheme of the invention is as follows: the linked piston type plastic sealing material forming system is characterized by comprising a speed-regulating rack winch, a pulling rope, a trolley, a plastic sealing material forming device and an industrial control module for controlling the rack winch and the plastic sealing material forming device, the rear end of the trolley is connected with one end of the pulling rope, the other end of the pulling rope is wound on the rack winch, and the plastic sealing material forming device is mounted on the trolley. The linked piston type plastic sealing material forming system is applicable to water conservancy and hydropower project construction machinery.

Owner:HANGZHOU GUODIAN DAM SAFETY ENG

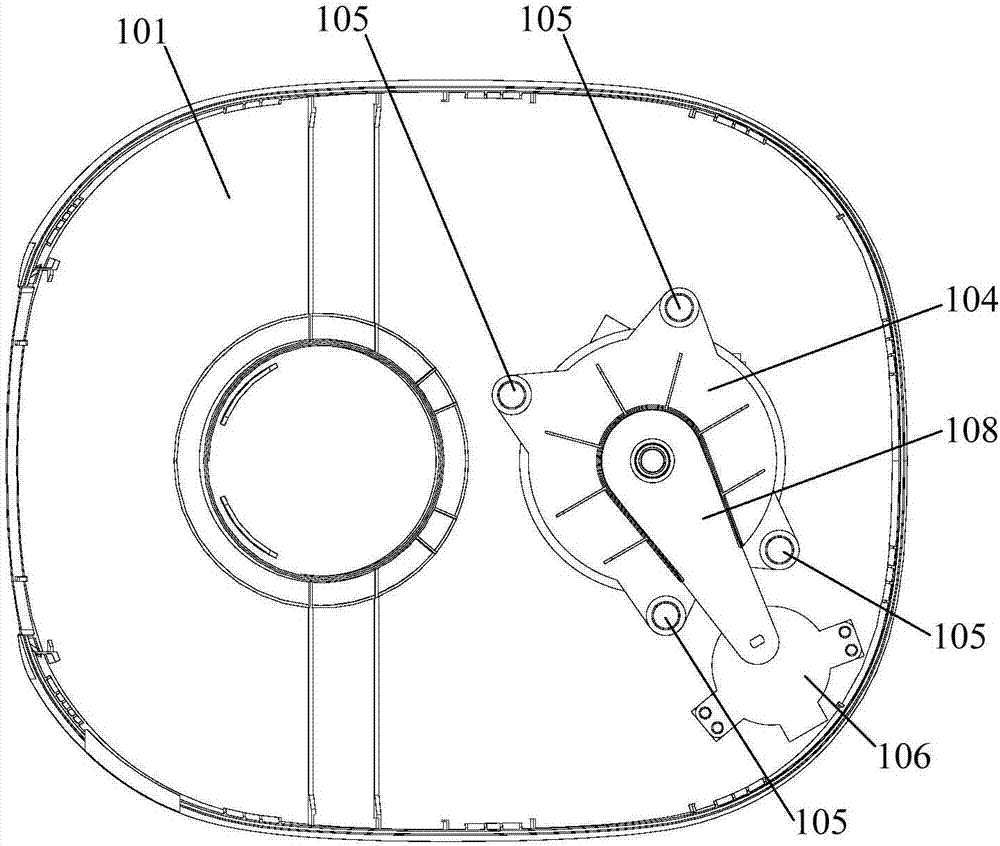

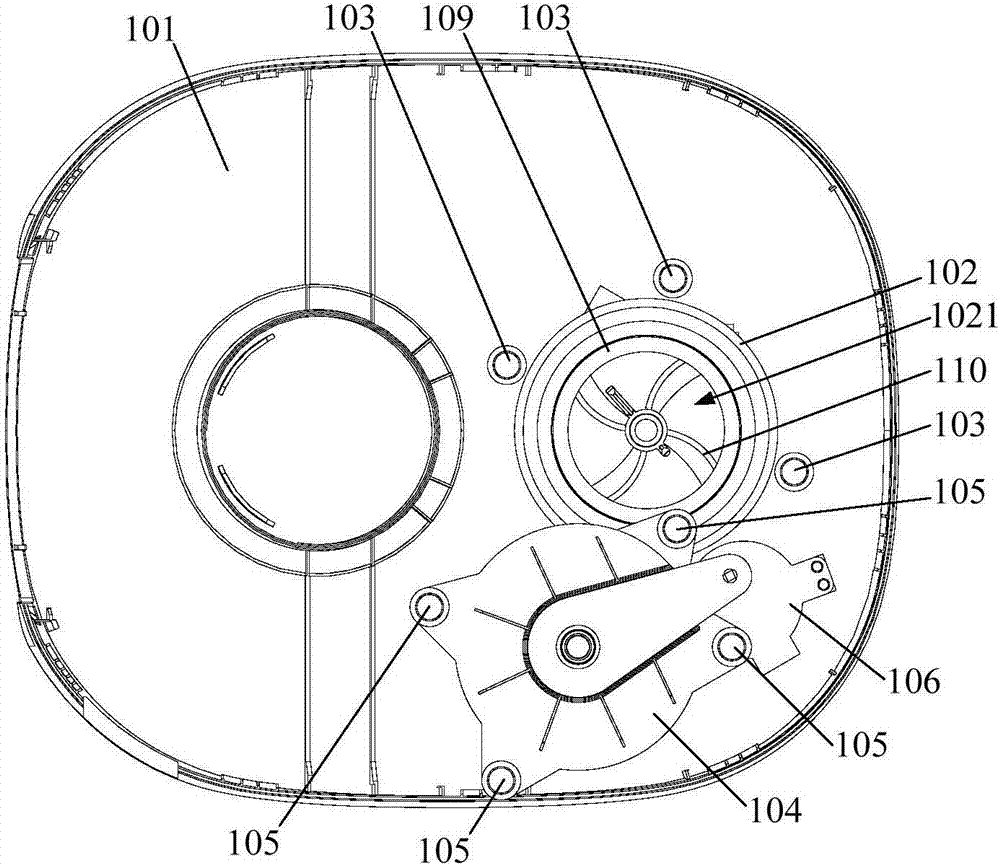

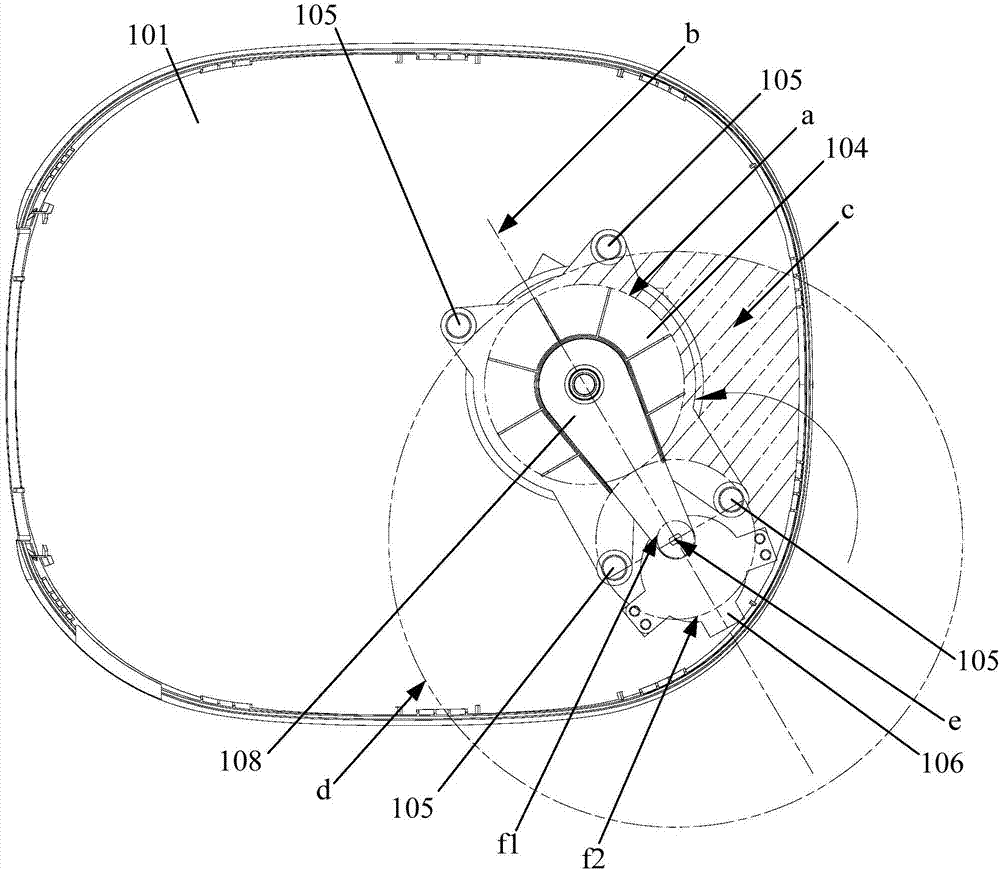

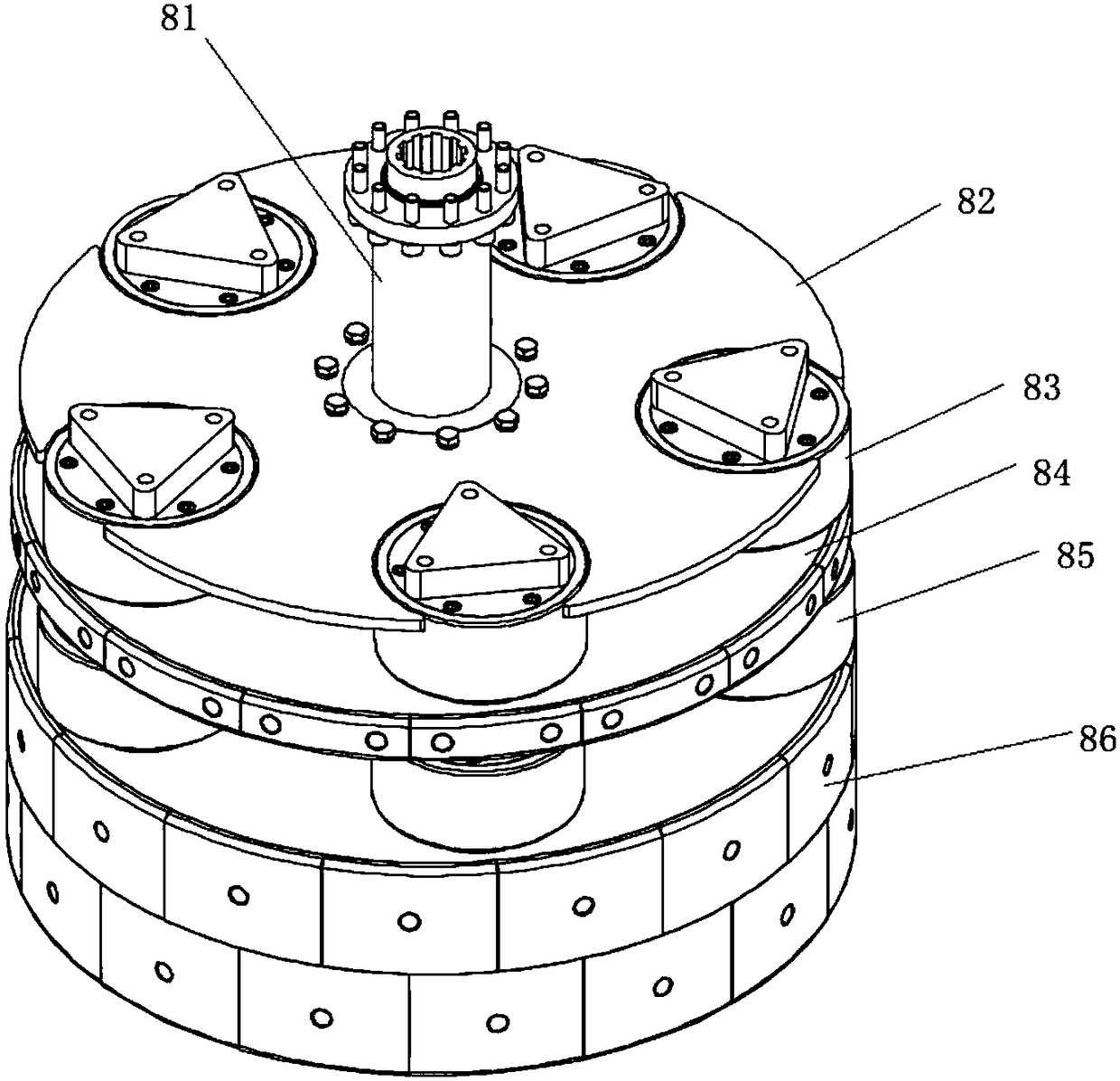

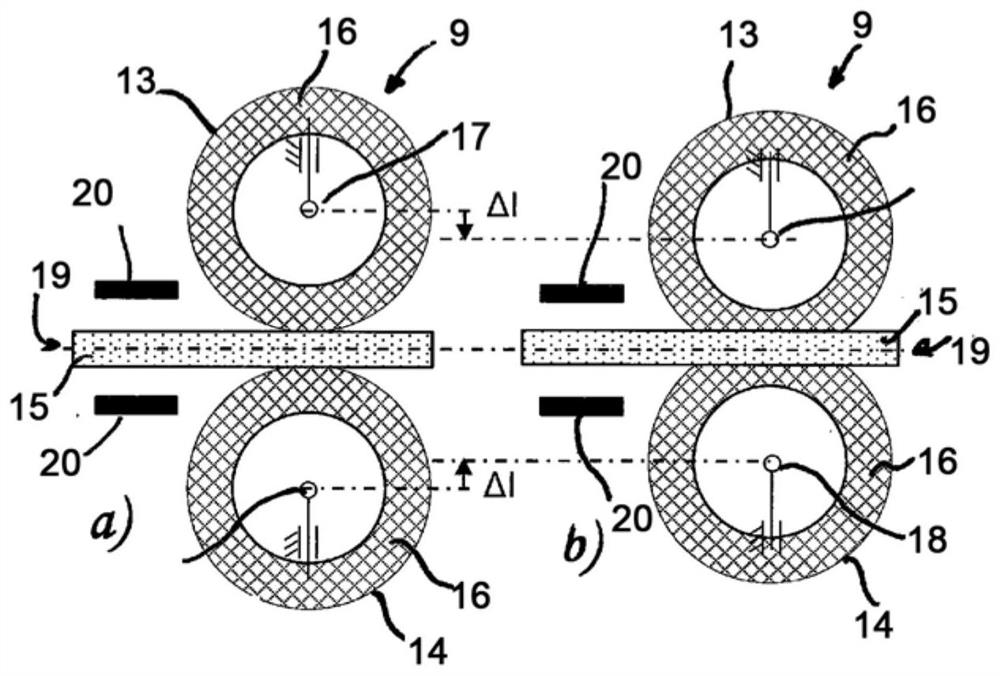

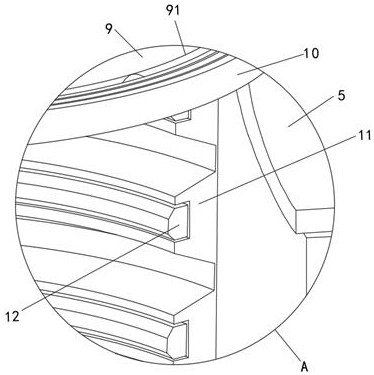

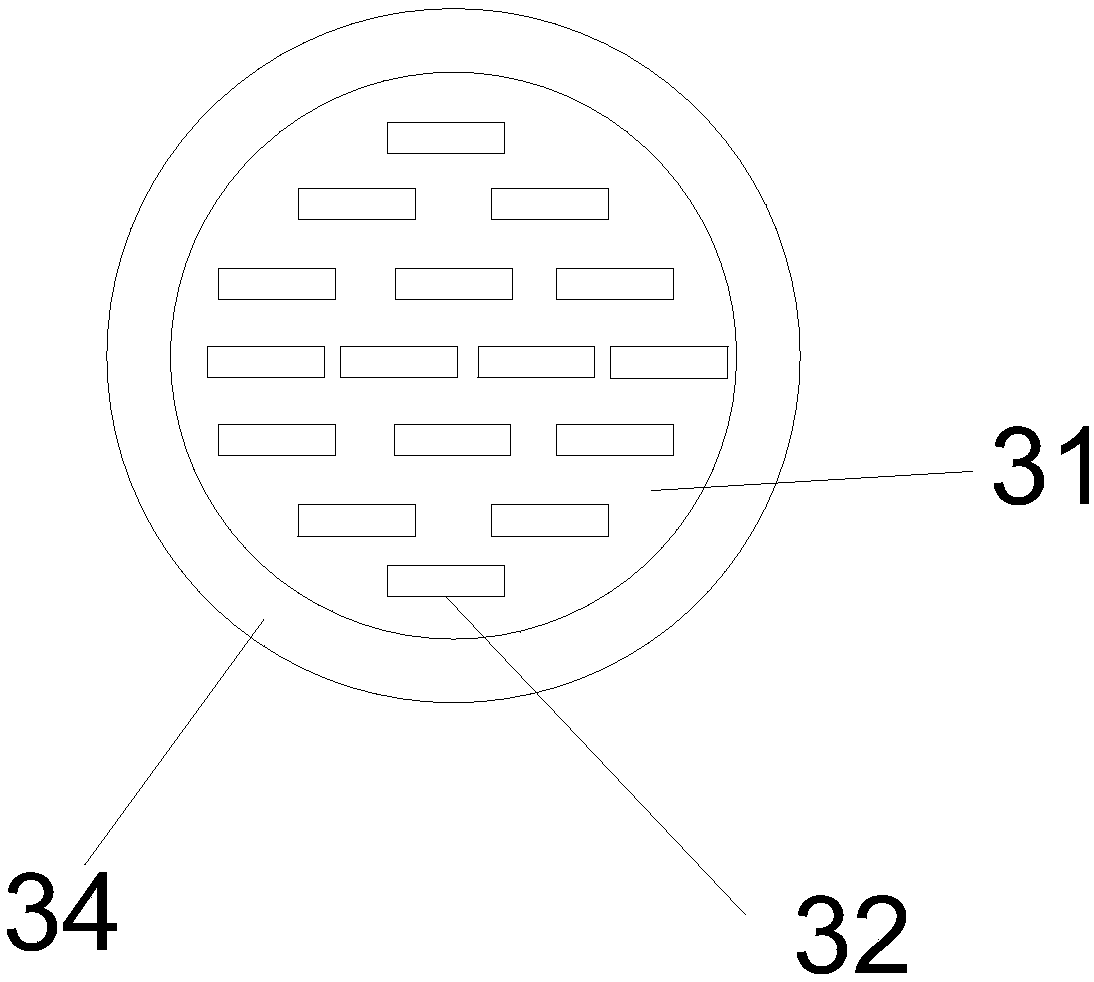

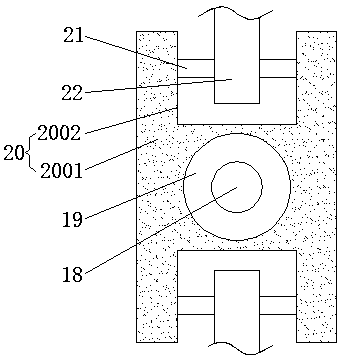

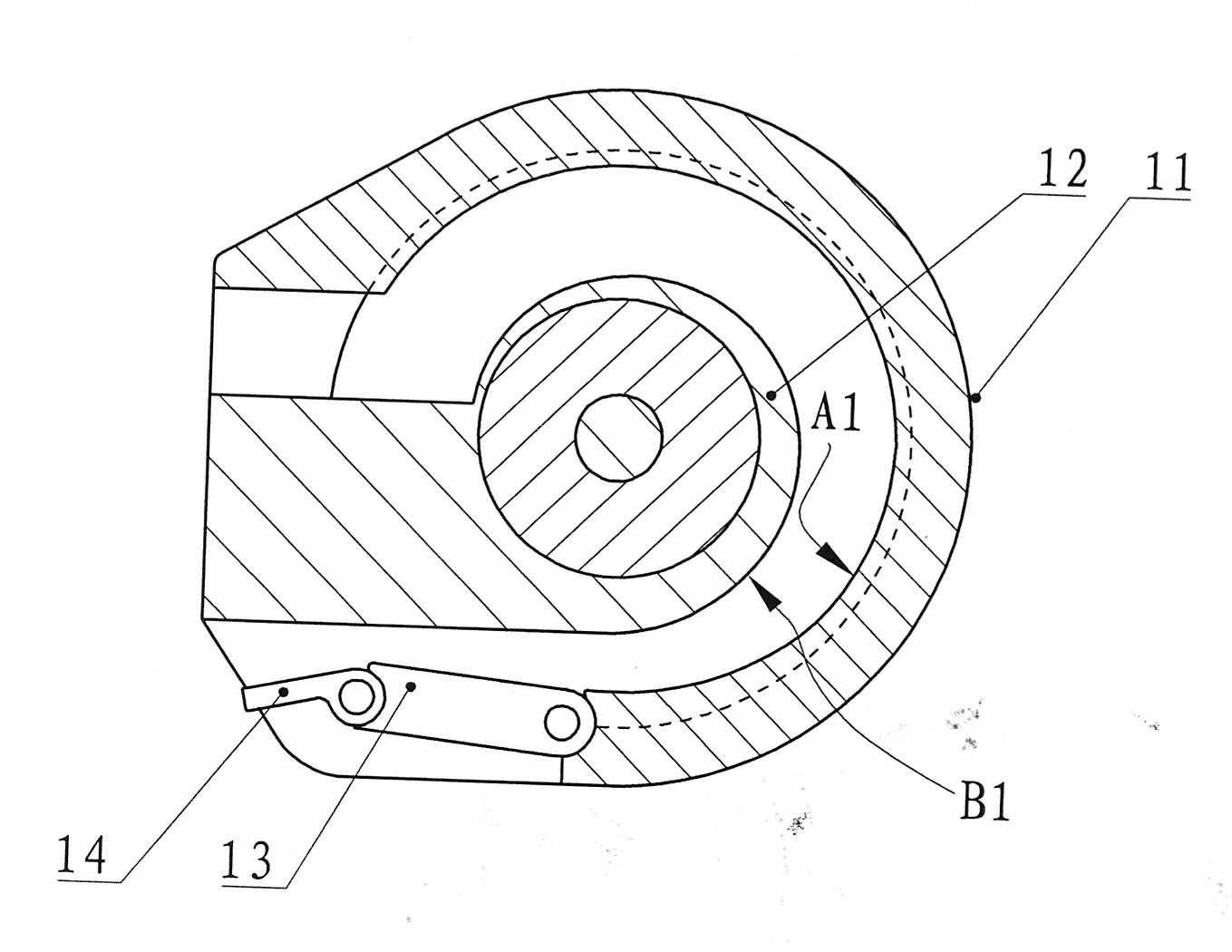

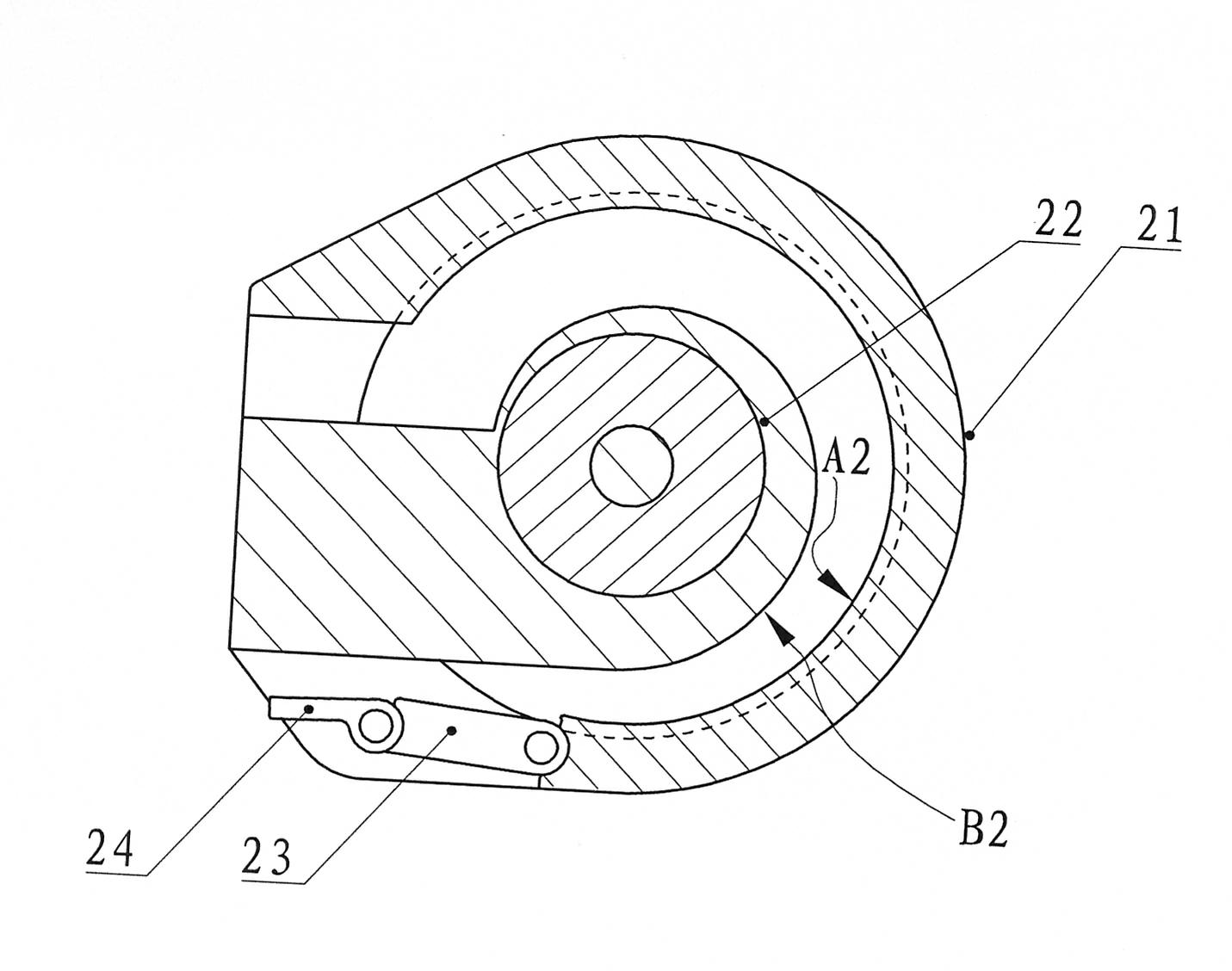

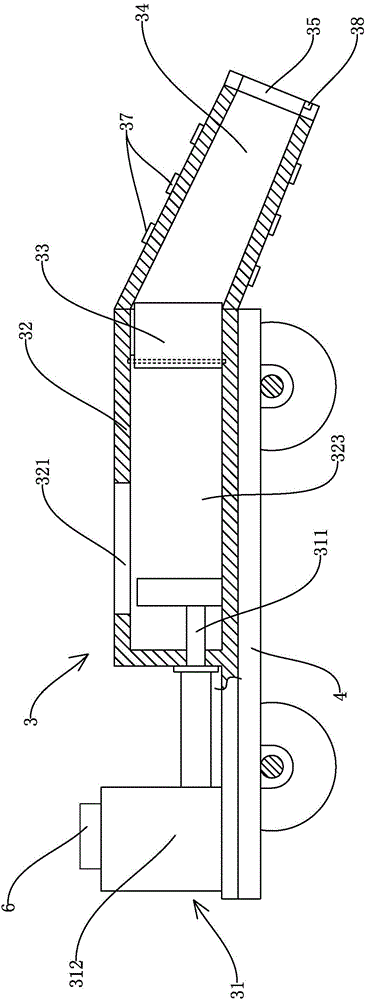

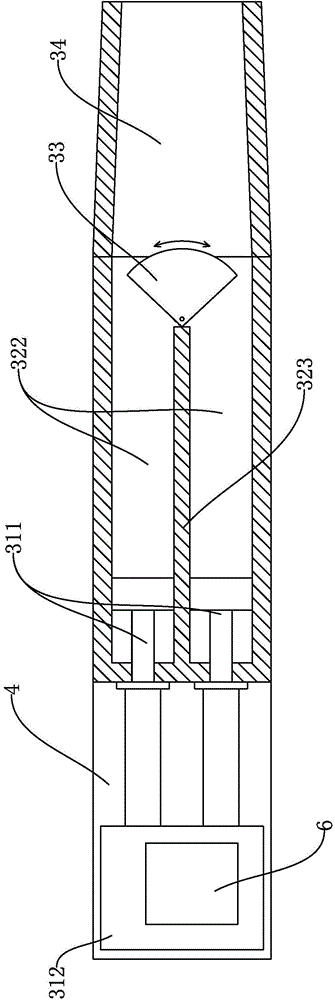

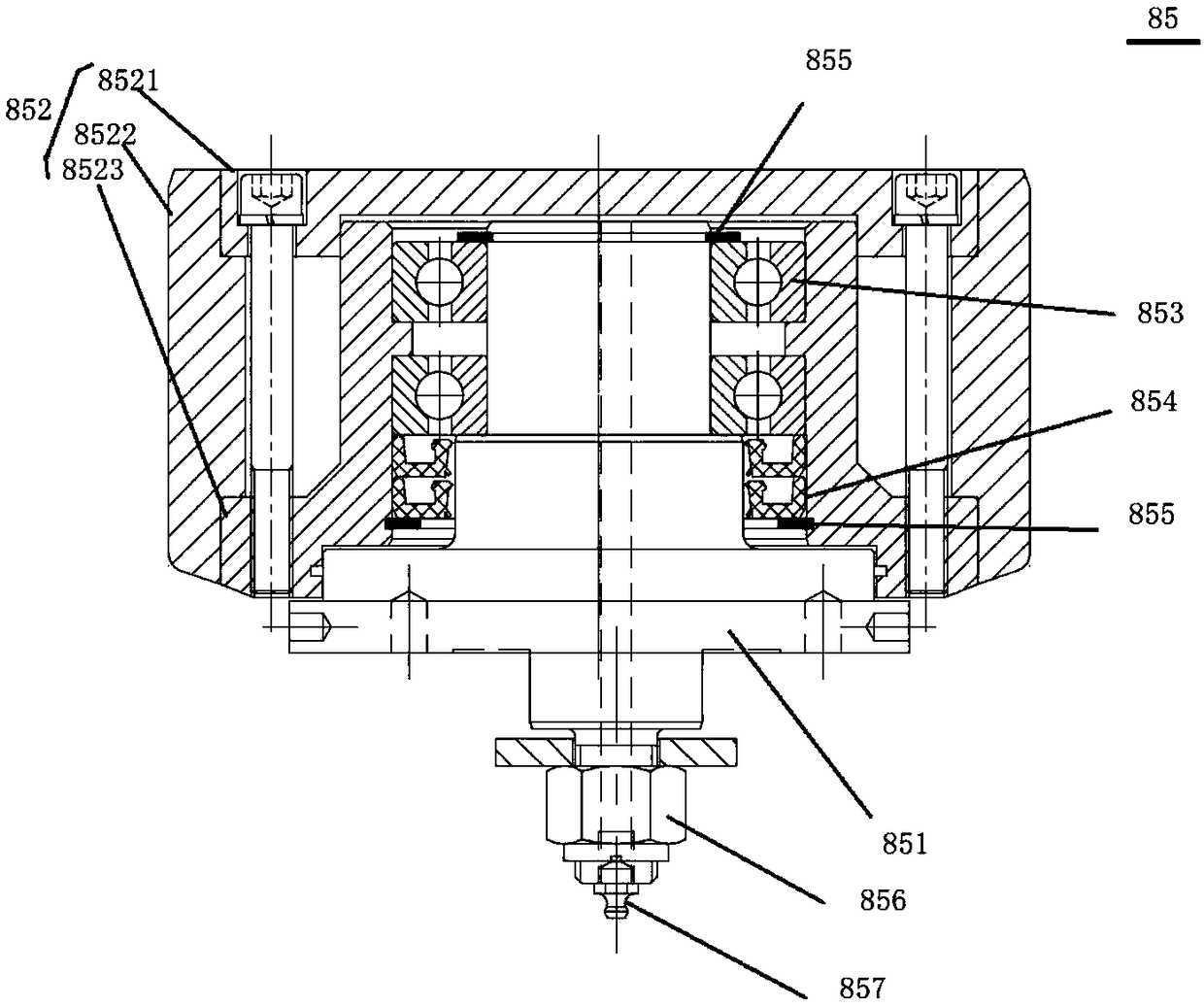

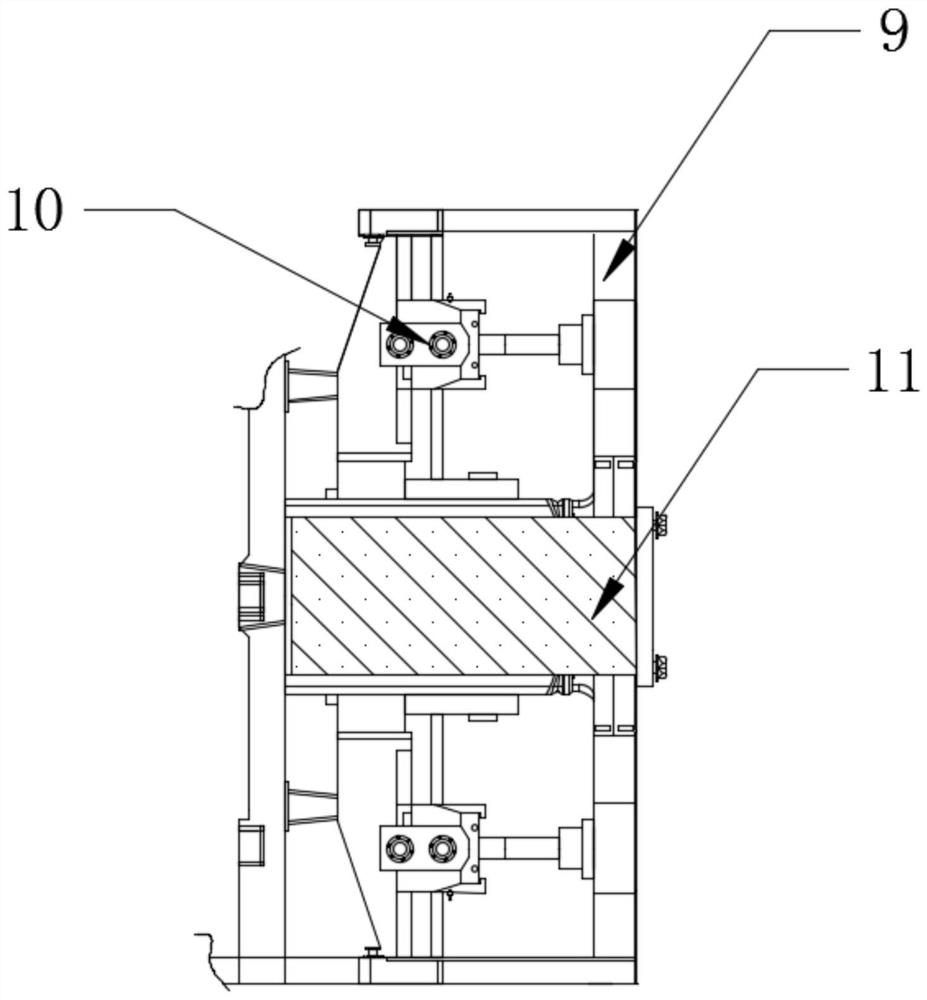

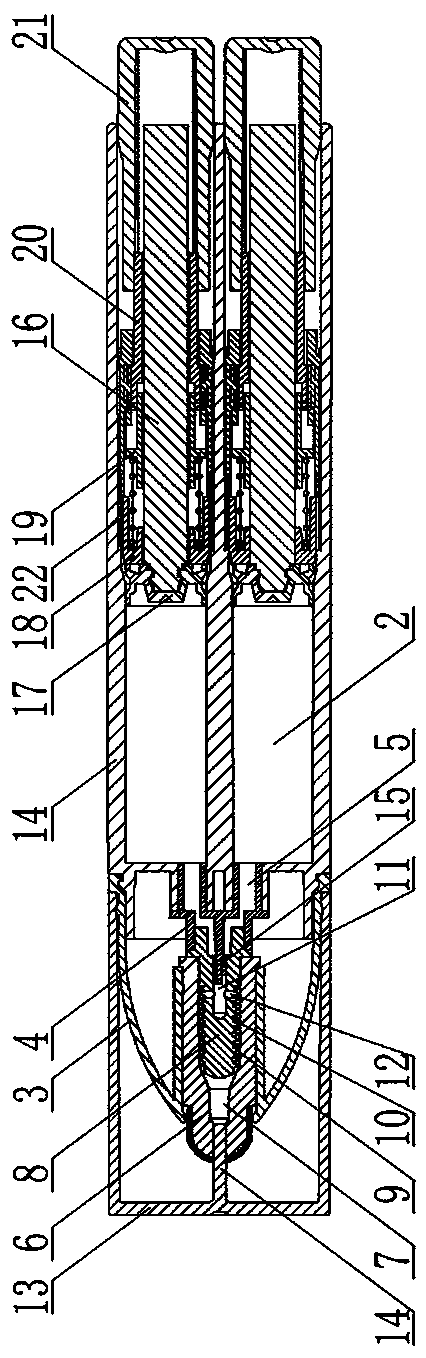

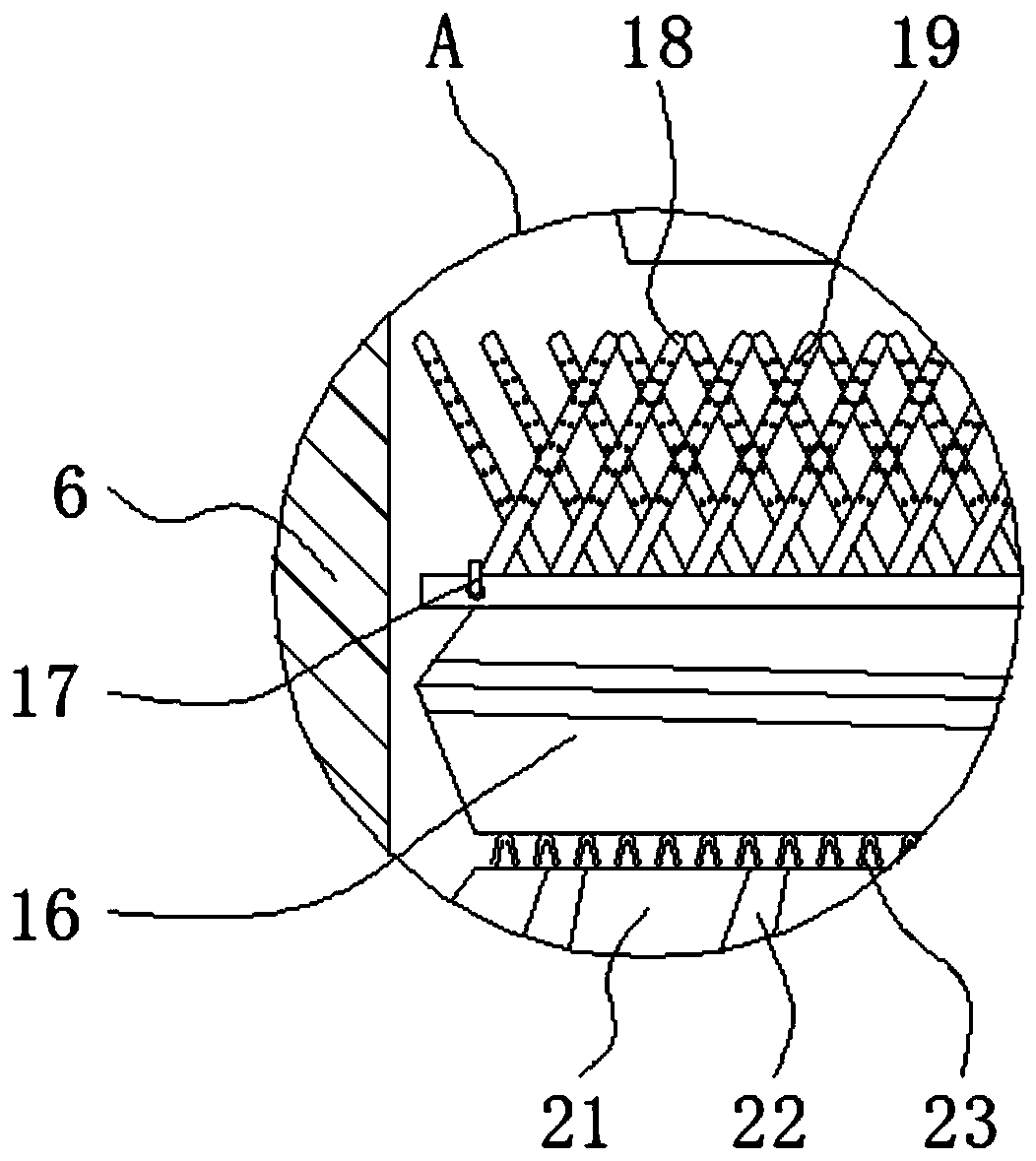

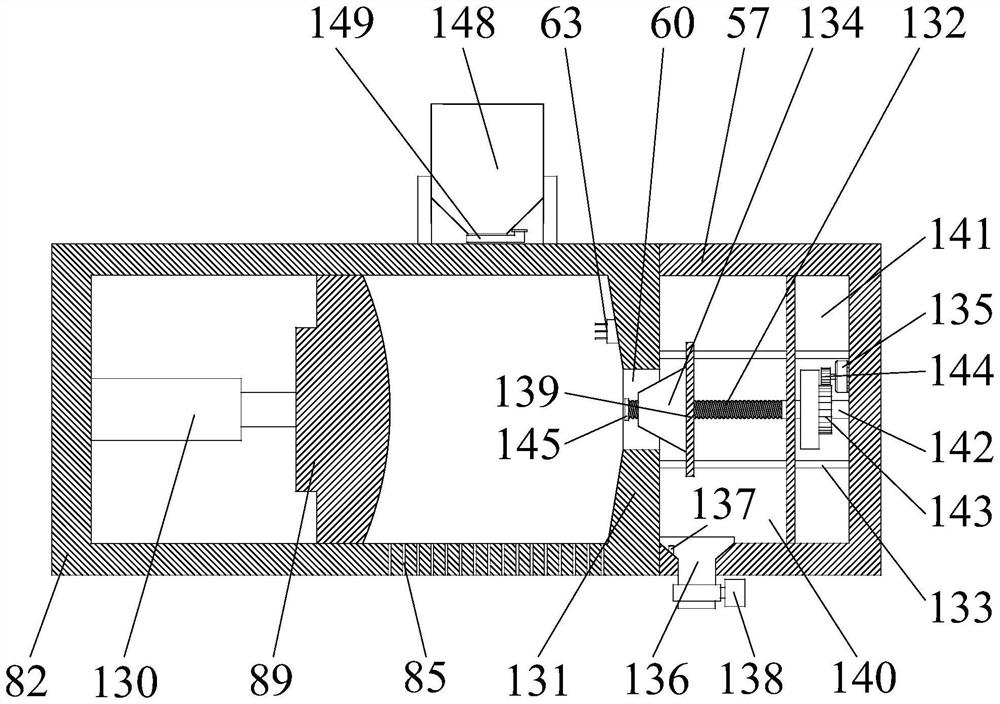

Radial extruding pipe making machine pressing head

PendingCN108214872AChange the compression ratioImprove the extrusion effectCeramic shaping apparatusCompression ratioMachine press

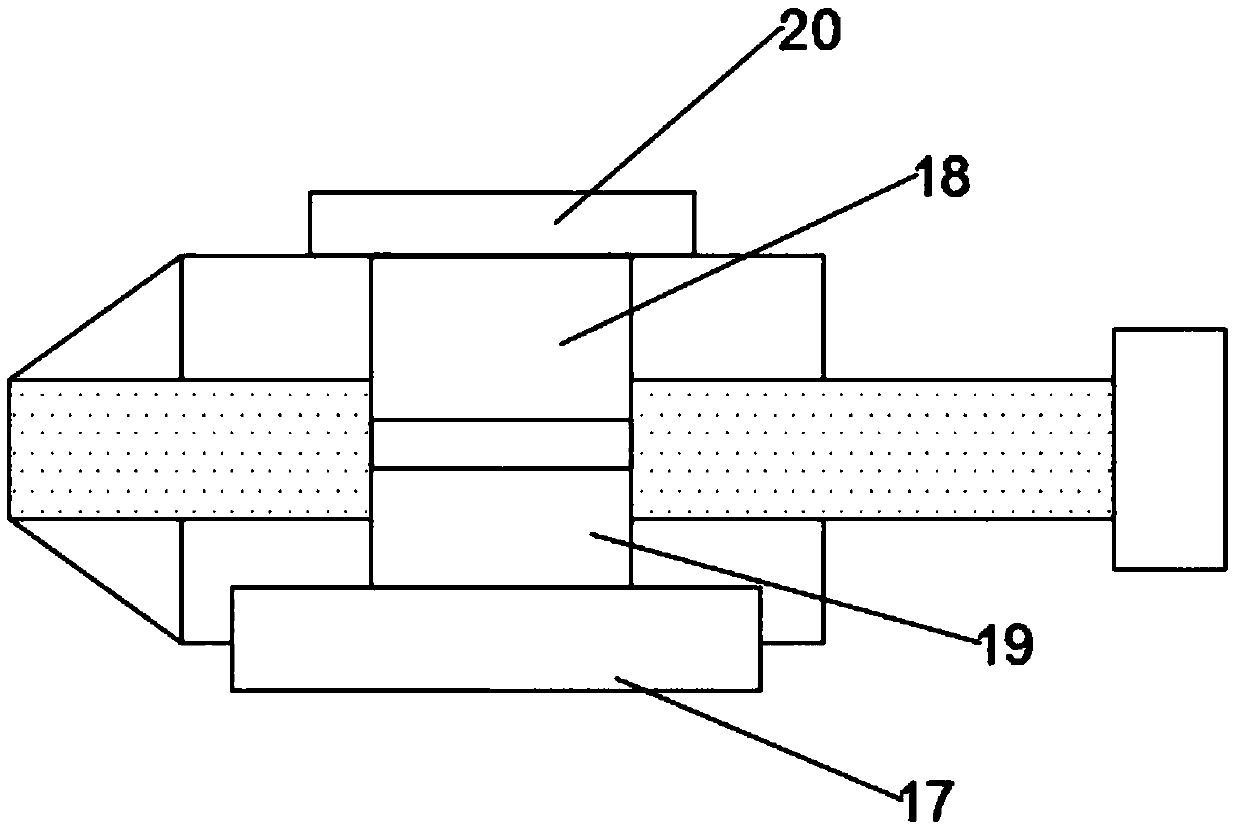

The invention relates to a radial extruding pipe making machine pressing head. The radial extruding pipe making machine pressing head comprises a circular material distributing disc, an upper polishing tile, a lower polishing tile, an outer shaft and an inner shaft, wherein the material distributing disc, the upper polishing tile and the lower polishing tile are arranged from top to bottom, the diameters of the material distributing disc, the upper polishing tile and the lower polishing tile are sequentially increased, the inner shaft is arranged in the outer shaft and forms reversal rotationwith the outer shaft, the outer shaft is fixed to the center of the material distributing disc and the center of the upper polishing tile, the inner shaft is fixed to the center of the lower polishingtile, and multiple circular deficient installing holes are formed in the edge of the material distributing disc in an array mode; and the radial extruding pipe making machine pressing head further comprises multiple upper extrusion rolls and multiple lower extrusion rolls, wherein the upper extrusion rolls are arranged on the edge of the upper polishing tile in an array mode, at least parts of the upper extrusion rolls are located over the installing holes and do not exceed the edge of the upper polishing tile, the upper extrusion rolls coaxially rotate, the lower extrusion rolls are arrangedon the edge of the lower polishing tile in an array mode, parts of the lower extrusion rolls do not exceed the edge of the lower polishing tile, and the lower extrusion rolls eccentrically rotate. According to the radial extruding pipe making machine pressing head, through lower roll eccentric design of the lower extrusion rolls, the compression ratio of pipe making concrete can be changed by adjusting the eccentric magnitude, and then a better extrusion effect is achieved.

Owner:江苏威姿曼机械有限公司

Multifunctional interactive robot

Owner:重庆门罗机器人科技有限公司

Equipment for promoting uniform discharging of adhesive sticker raw materials according to amplitude force

InactiveCN112495717AUniform dischargeImprove product qualityLiquid surface applicatorsCoatingsEngineeringElectric drive

The invention relates to the technical field of adhesive stickers, and discloses equipment for promoting uniform discharging of adhesive sticker raw materials according to amplitude force. A base is movably connected to the outer side of a main body, a circular turntable is movably connected to the front end of the base, and a rotating wheel is movably connected to the front end of the circular turntable. According to the equipment for promoting uniform discharging of the adhesive sticker raw materials according to the amplitude force, the rotating wheel is powered on to drive a sliding pieceto synchronously operate, the sliding piece synchronously operates along a matched sliding seat on the circular turntable, the sliding piece drives a supporting rod to synchronously operate, and a spring part is changed into a telescopic state from a default compression state to push the interior of the equipment to achieve a preliminary vibration effect; and a spring part stirs a knocking block to vibrate through a round connecting rod in a protection part, the knocking block vibrates to knock a middle accessory, the equipment is vibrated again, the vibration force is effectively amplified, and therefore the equipment is prevented from generating bubbles, certain influences on the equipment are prevented, the production quality of the adhesive stickers is improved, and the percent of passis increased.

Owner:林青仕

Multicolor mixed make-up pen

PendingCN109674180AExtrusion controllableUniform extrusionPackaging toiletriesPackaging cosmeticsEngineeringMaterial storage

The invention discloses a multicolor mixed make-up pen, comprising a pen holder and a pen point, wherein a pair of material storage slots are arranged in the pen holder side by side, a material extruding device is correspondingly arranged at the tail end of each material storage slot, an adapter is arranged between the pen holder and the pen point, a two-to-one material feeding passage is arrangedin the adapter, a pen head is arranged in the pen point, a discharge slot is arranged in the pen head, a refining core is arranged at the rear prat of the discharge slot, a thread rib is arranged onthe peripheral outer wall of the refining head, and the thread rib props against the inner wall of the discharge slot to form a spiral passage in spiral advancement. According to the invention, two kinds of materials are independently stored and independently provided with the material extruding device, so that material extruding is controllable and blended according to requirement; the two kindsof materials are mixed first by the two-to-one material feeding passage, and then the mixture is subjected to material mixing, the material flow speed of the mixture is slowed down first to prevent the mixture from being directly ejected, then the mixture is divided and enters the spiral passage to form vortex rotate to permeate to each other, so that mixture is uniform, and the operation is convenient.

Owner:HANGZHOU EBEI IND

A chili sauce packaging machine with cleaning and dust removal functions

The invention discloses a chilli sauce packaging machine with cleaning and dust-removing functions, and relates to the technical field of chilli sauce packaging machines. The chilli sauce packaging machine specifically comprises a rack, a machine body and a lifting plate, wherein a base station is mounted in the middle above the rack; a transmission belt is arranged at the outer side of a controlrotary shaft in a sleeving mode; a rotary motor is arranged inside the top of the machine body; the lower shaft end of the rotary motor is axially connected with a rotary shaft; a sub-division disc isarranged below a delivery disc; grinding teeth are arranged on the bottom surface of the delivery disc and the upper surface of the sub-division disc; and the upper surface of the lifting plate is embedded with a conveyor belt. According to the chilli sauce packaging machine with cleaning and dust-removing functions disclosed by the invention, the base station is arranged, so that a first movablemechanism is arranged on the equipment; the base station and a control motor define a transmission structure by controlling the rotary shaft and the transmission belt; after the control motor is started, the base station correspondingly accomplishes angle rotation, and takes the rack as the base; and after the base station turns over, the angle of the machine body deflects, so that a base fillingangle of the machine body is regulated.

Owner:SHANGHAI COOLYOUNG MACHINE EQUIP MFG CO LTD

A dry-humidity adjustment system and adjustment method in the process of swill separation

ActiveCN111001209BReduce the amount of extrusionAdjust moisture contentStationary filtering element filtersElectric machineEngineering

The invention discloses a dry humidity regulating system and a regulating method in the swill separation process, which are used for regulating the dry humidity of extruded materials of an extrusion system. The extruding system includes an extruding shell, an extruding block, and a discharge cover, and the dry humidity regulating system includes a moisture sensor, a locking mechanism and an adjusting controller. The moisture sensor is used to detect the moisture content of the extrusion discharge located in the extrusion shell. The locking mechanism includes a locking shell, a threaded rod, at least one positioning rod, a current limiting block and an adjusting motor. The adjustment controller is used to judge whether the moisture content is greater than the preset dry humidity. If it is, the adjustment controller drives the adjustment motor to rotate, so that the current limiting block moves towards the extrusion block to narrow the discharge gap; otherwise, it drives the adjustment motor to rotate, and the current limiting block moves toward Move away from the squeeze block to increase the discharge clearance. The invention realizes the adjustment of the water content of the discharged material, so that the water content reaches the standard, ensures a suitable living environment for the biodegradation reaction bacteria, and improves the degradation rate and effect.

Owner:ANHUI TIANJIAN ENVIRONMENTAL PROTECTION

Preparation method of probiotics

InactiveCN112471516AGuaranteed ViscosityPrompt sizeGranulation in stationary drums/troughsGranulation by material expressionProcess engineeringProbiotic

The invention provides a probiotic preparation method, and relates to the field of probiotic preparation. The probiotic preparation method comprises a bottom plate, a cutting mechanism and a processing mechanism, wherein the processing mechanism is fixedly installed on the bottom plate, and the cutting mechanism is fixedly connected to the processing mechanism. According to the invention, colloidal probiotics which are prepared in advance in proportion can be continuously rotated and stirred through the processing mechanism, so that the viscosity of the colloidal probiotics is ensured, and subsequent processing is facilitated. Secondly, colloidal probiotics can be subjected to rapid solidification treatment, colloidal probiotics are converted into solid probiotics, subsequent cutting is facilitated, and therefore it is guaranteed that cut particles are kept consistent in size, and the product quality is improved; finally, the probiotic particles can be rapidly produced, the productionefficiency is effectively improved, and the cost is further reduced.

Owner:佛山雅邦生物技术开发有限公司

A locking device for the door of the wind tunnel test section

ActiveCN113153012BGuaranteed normal rotationAdjustable axial tighteningAerodynamic testingNon-mechanical controlsClassical mechanicsMechanical engineering

Owner:中国空气动力研究与发展中心超高速空气动力研究所

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com