Process for simply preparing directionally-sorted carbon fiber heat-conducting composite material in laboratory

A heat-conducting composite material and carbon fiber technology, which is applied to flat products, other household appliances, household appliances, etc., can solve the problems of carbon fiber arrangement disorder, inconvenient testing of thermal conductivity, and inability to achieve axial arrangement, etc., to achieve the effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

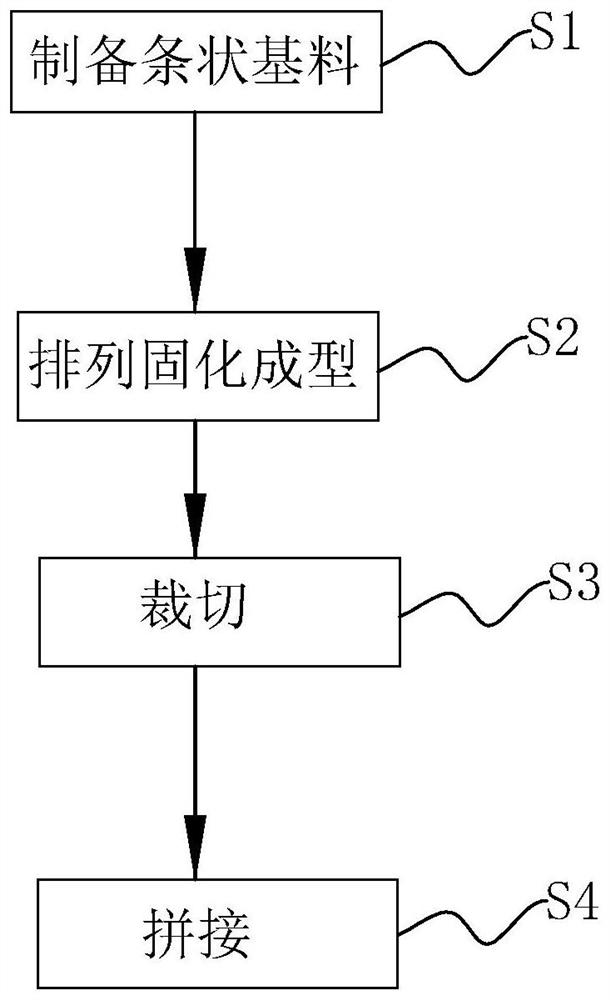

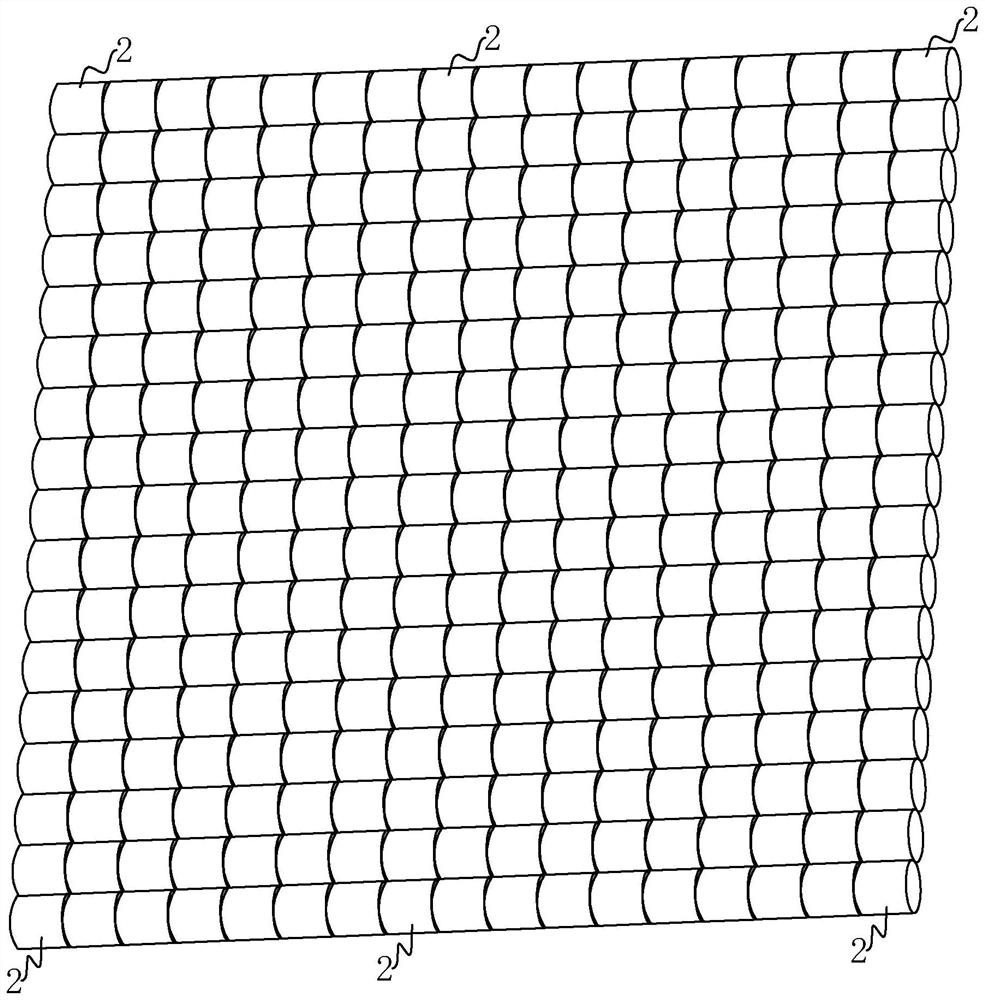

[0038] This application discloses a process for the simple preparation of directional sorting carbon fiber heat-conducting composite materials in the laboratory. figure 1 , including the following steps:

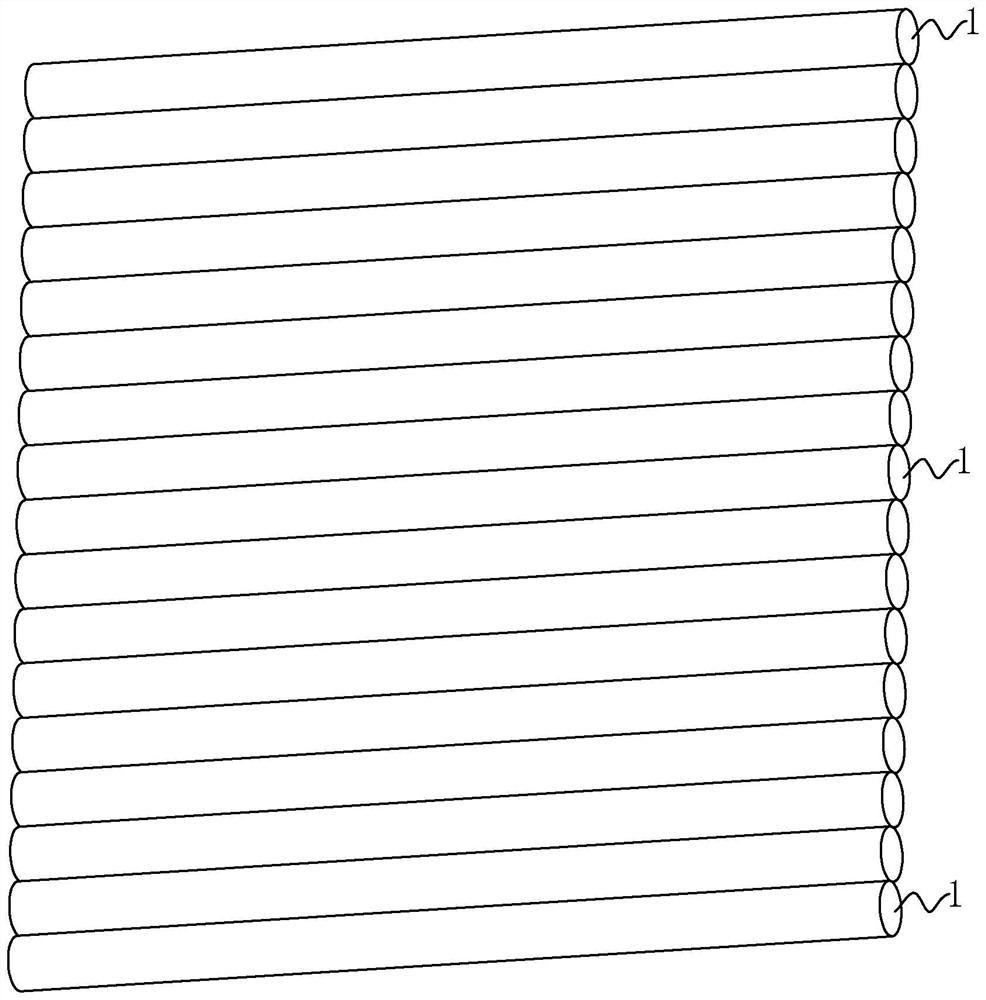

[0039] S1. Preparation of strip-shaped base material 1: Add the prepared carbon fiber heat-conducting composite material base material into the dispensing tube, and perform vacuum degassing operation on the carbon fiber heat-conducting composite material base material in the dispensing tube before loading the piston into the dispensing tube . The vacuum defoaming operation facilitates the discharge of air bubbles contained in the base material of the carbon fiber heat-conducting composite material, and reduces the influence of air bubbles on the measurement data, thereby improving the accuracy of the measurement data.

[0040] Next, the piston is first pushed to fully contact with the base material of the carbon fiber heat-conducting composite material, and the air between ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com