A locking device for the door of the wind tunnel test section

A technology for locking devices and wind tunnel tests, which is applied to measuring devices, aerodynamic tests, locks operated by non-mechanical transmission, etc., can solve the problem that the sealing performance of equipment cannot be effectively guaranteed, reduce the operating efficiency of hypersonic wind tunnels, increase Wind tunnel test preparation time and other issues to achieve the effect of reducing physical exertion, shortening opening and closing time, and improving operating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to understand the above objects, features, and advantages of the present invention, the present invention will be described in detail below with reference to the accompanying drawings and specific embodiments. It should be noted that the features of the present application and the features of the present application can be bonded to each other in the case of an unable conflict.

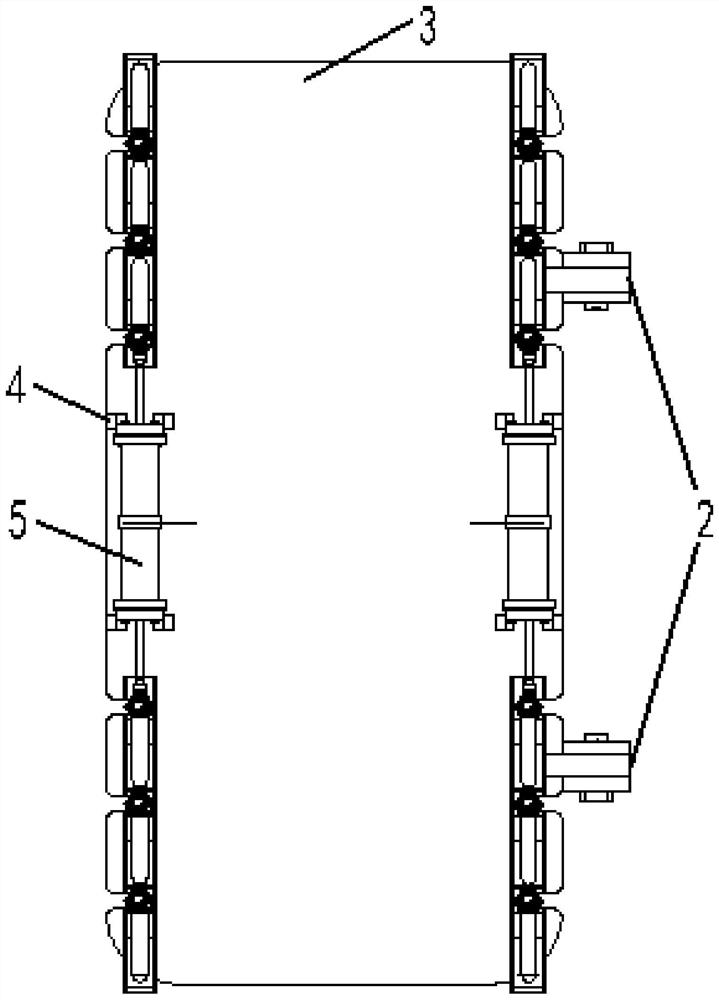

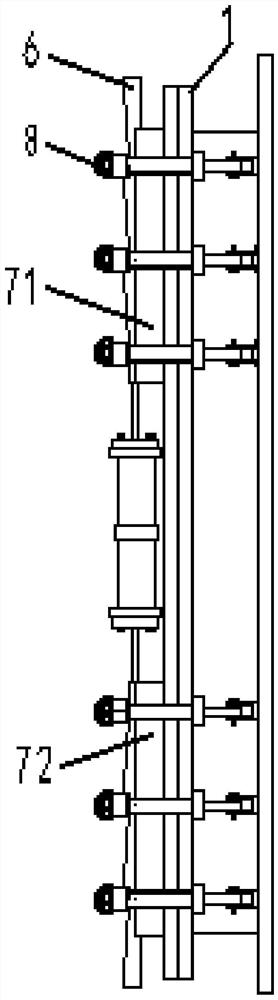

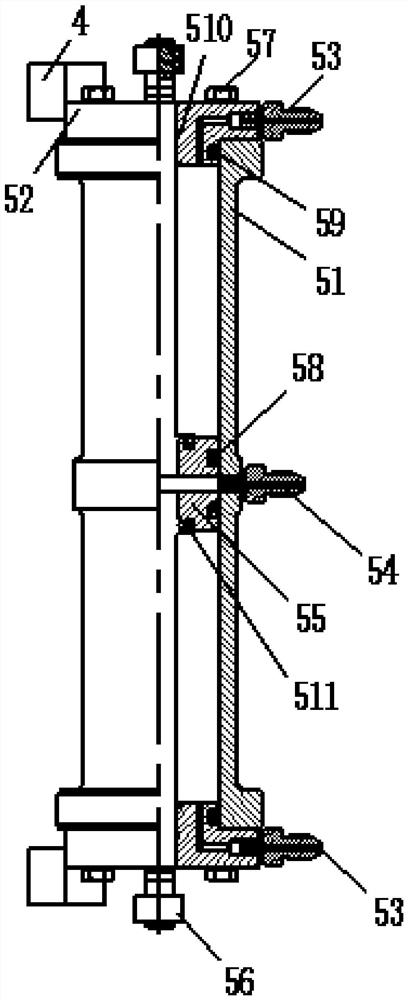

[0033] The test section of the wind tunnel 3 is fixed to the test section by the hinge 2, and the test segment 3 is used for the switch channel flange 1, such as figure 1 and figure 2 As shown, the locking device for the wind tunnel test segment door is mounted on the test segment gate 3, including two-way action cylinders 5, wedge slide 6, slide 7, and bolt lock assembly 8;

[0034] like Figure 4A , Figure 4b , Figure 4C and Figure 5 As shown, the slide 7 includes an upper slide 71 and a down slide 72 that is symmetrically fixed to the edge of the test segment gate 3, the wedge-shaped sli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com