Coil stock unrolling feeding device

A technology of feeding device and coiling material, which is applied in the direction of winding strip material, thin material processing, transportation and packaging, etc. Deformation and scrapping and other problems can reduce material damage and hidden dangers of work-related injuries, maintain stable power, and reduce loading difficulty.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

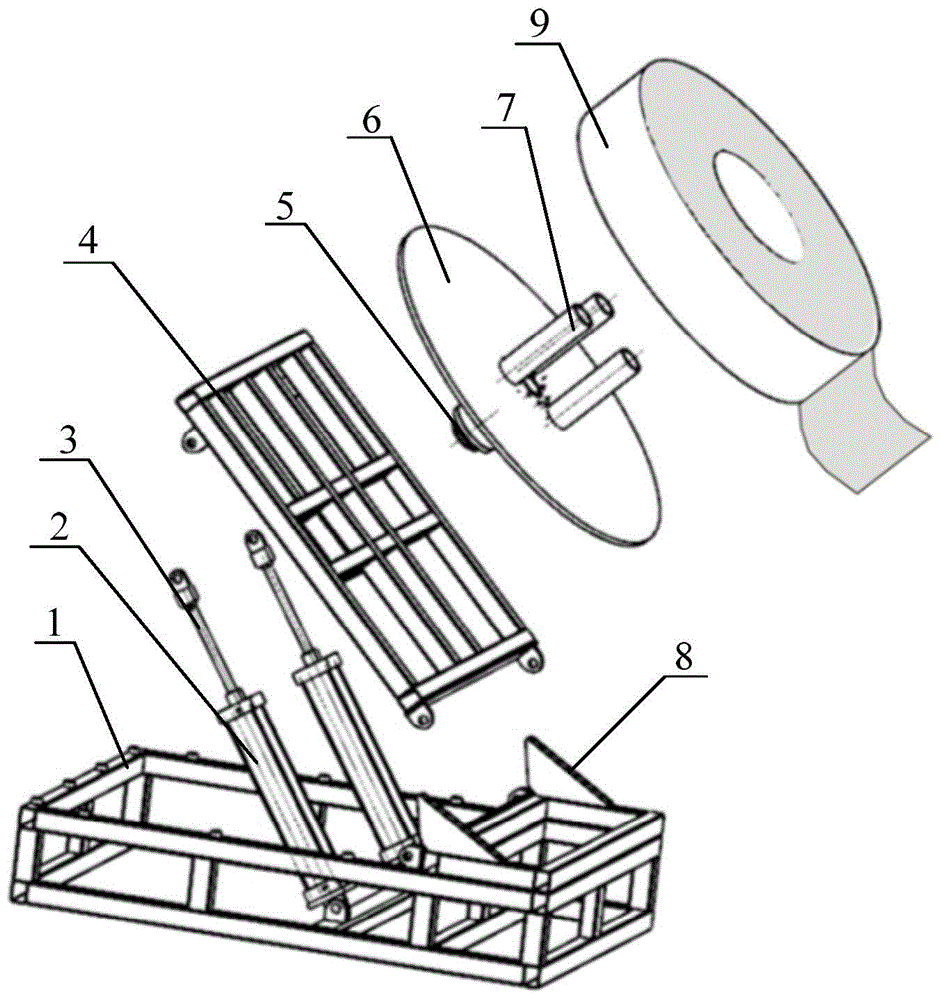

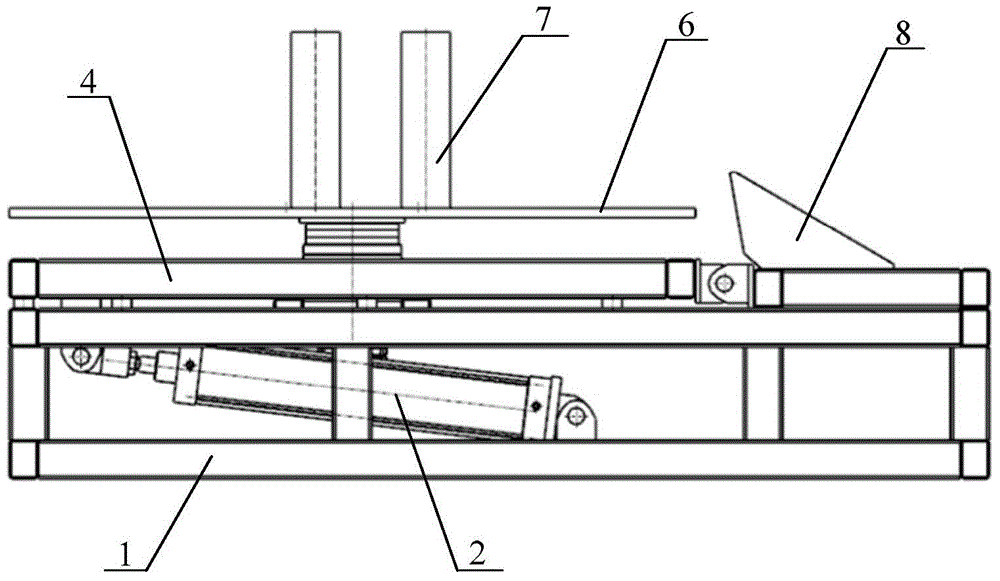

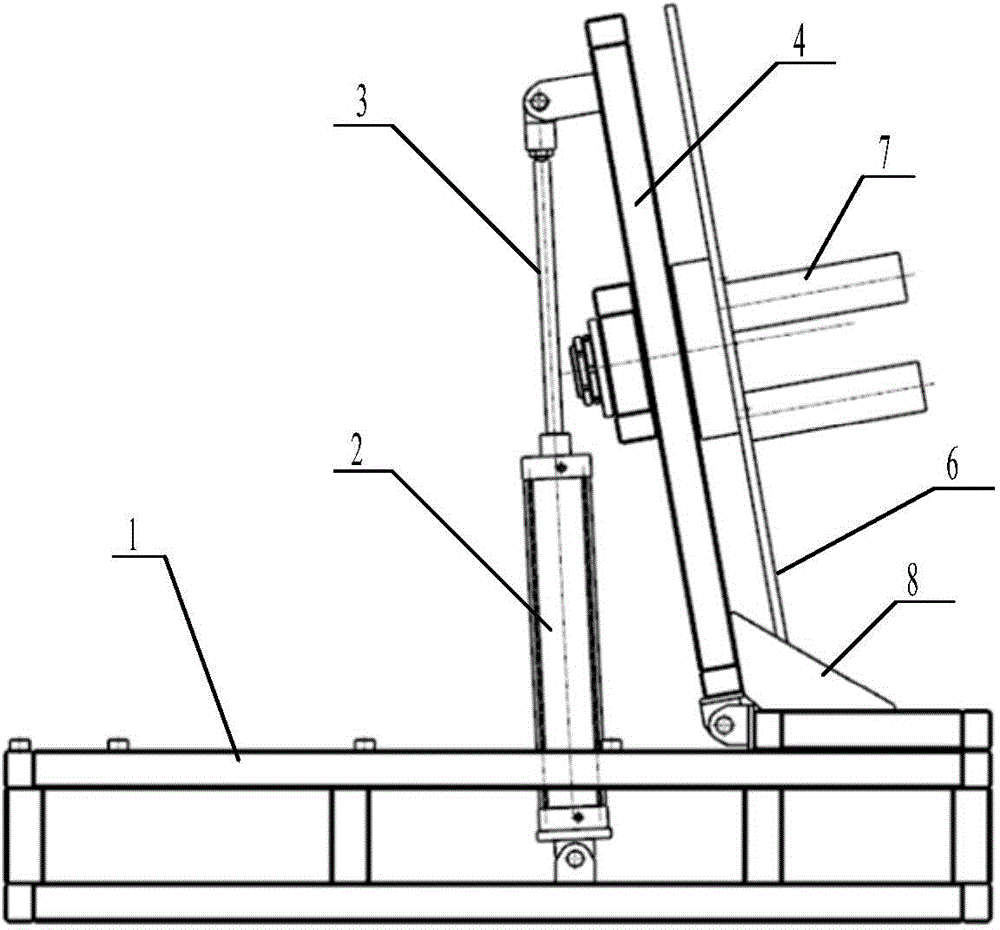

[0029] Such as Figure 1~3 As shown, a coil material uncoiling feeding device of the present invention includes a base 1, the base 1 has a rectangular frame structure, and the base 1 has an accommodating cavity inside. The base 1 is provided with a bracket 4, one end of the bracket 4 is movably connected to the base 1, and the bracket 4 can rotate. One end of the bracket 4 in this embodiment is connected to the base 1 through a hinge, and the bracket 4 can also be connected to the base 1 through a shaft connection or other similar means that can realize the rotation of the bracket 4 on the base 1 .

[0030] The support 4 is provided with a turntable 6, the turntable 6 is installed on the support 4 through the turntable shaft 5, and the turntable 6 can rotate. During installation, the turntable rotating shaft 5 of the turntable 6 is installed on the support 4, and the turntable 6 is positioned above the support 4, and the turntable rotating shaft 5 can be detachably connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com