Reactor for exothermic reaction and application of reactor

An exothermic reaction and reactor technology, applied in chemical instruments and methods, chemical/physical processes, etc., can solve the problems of large volume, different heat transfer requirements, uneven distribution of reaction degree, etc., to reduce the volume, speed up the reaction, Less difficult to reload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

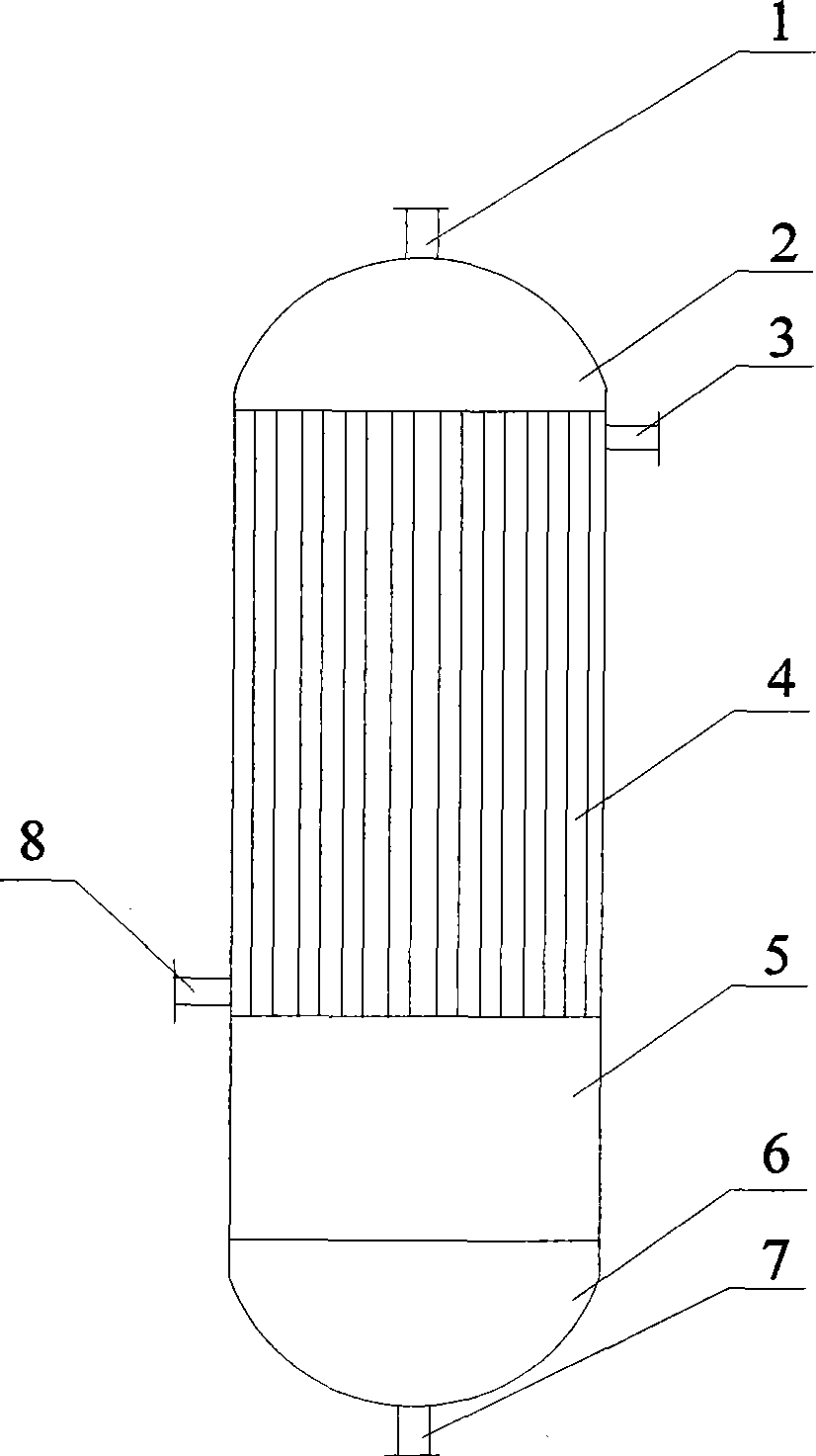

[0029] Use reactor of the present invention to be used for acetone ammoniation to prepare isopropylamine, the structure and type of reactor are as figure 1 shown. Heat exchange tube fixed bed section filling 13m 3 Catalyst, adiabatic fixed bed section packing 4m 3 catalyst. The catalyst uses the catalyst BC-A-30 produced by Beijing Research Institute of Chemical Industry. The fixed bed section of the tubes uses hot water under pressure to remove the reaction heat, the reaction temperature is controlled at 135°C, the pressure of the reaction system is 1.3MPa, and the volume space velocity of the acetone liquid phase is 0.7h -1 , the molar ratio of acetone, hydrogen and ammonia is 1:3:3. The temperature of the adiabatic fixed bed section was measured to be 135-142°C. Sampling and analysis of the material at the outlet of the reactor showed that the conversion rate of acetone was 100%.

Embodiment 2

[0034] Use the reactor of the present invention for the hydrogenation of acetone to produce Virahol, the structure and type of the reactor are as figure 1 shown. Tube fixed bed section filling 10m 3Catalyst, adiabatic fixed bed section packing 3m 3 catalyst. The catalyst uses catalyst BC-A-31 produced by Beijing Research Institute of Chemical Industry. The fixed bed section of the tubes uses hot water under pressure to remove the reaction heat, the reaction temperature is controlled at 135°C, the pressure of the reaction system is 1.0MPa, and the volume space velocity of the acetone liquid phase is 0.7h -1 , the molar ratio of acetone to hydrogen is 1:5. The temperature of the adiabatic fixed bed section was measured to be 135-141°C. Sampling and analysis of the material at the outlet of the reactor showed that the conversion rate of acetone was 100%.

Embodiment 3

[0036] Use the reactor of the present invention for the hydrogenation of benzene to prepare hexanaphthene, the structure and type of the reactor are as figure 1 shown. Tube fixed bed section filling 10m 3 Catalyst, adiabatic fixed bed section packing 4m 3 catalyst. As the catalyst, catalyst BC-A-60 produced by Beijing Research Institute of Chemical Industry was used. The fixed bed section of the tubes uses hot water under pressure to remove the reaction heat, the reaction temperature is controlled at 175°C, the pressure of the reaction system is 0.6MPa, and the volume space velocity of the benzene liquid phase is 0.7h -1 , The molar ratio of benzene to hydrogen is 1:5. The temperature of the adiabatic fixed bed section was measured to be 175-181°C. The material at the outlet of the reactor was sampled and analyzed, and the conversion rate of benzene was 100%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com