Hydrogenated block copolymer and preparation method and application thereof

A technology of block copolymer and hydrogenated block, applied in the field of copolymer hydrogenation, can solve the problems of insufficient aging resistance, weather resistance, compatibility, processability and transparency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

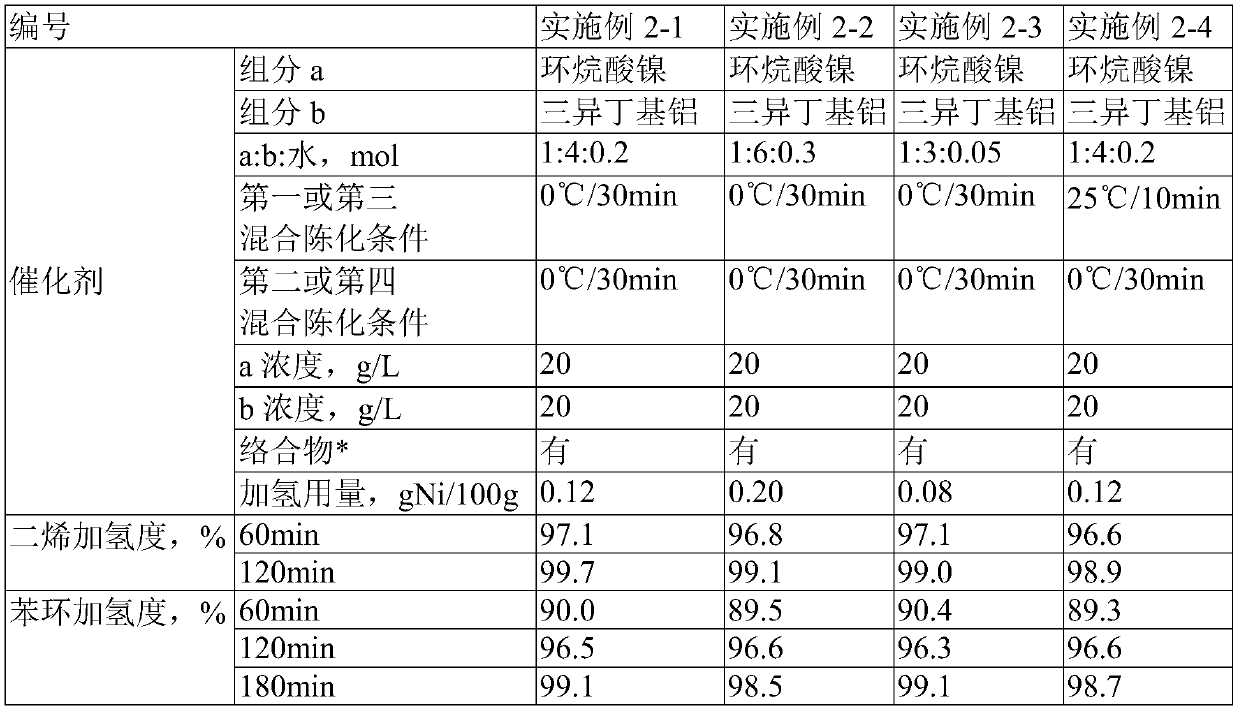

[0085] For the catalyst-I, the present invention also provides a preparation method, comprising:

[0086] Scheme-A: Component a and component b are mixed and aged for the first time to obtain a uniform mixed solution-I, and then component c and mixed solution-I are subjected to second mixed and aged to obtain a uniform hydrogenation catalyst ;

[0087] Wherein, the first mixed aging time is 5-120min, the first mixed aging temperature is -20°C to 25°C; preferably the first mixed aging time is 10-60min, and the first mixed aging temperature is -10°C to 10°C;

[0088] The second mixing aging time is 2-90min, the second mixing aging temperature is -20°C to 25°C; preferably the second mixing aging time is 5-60min, and the second mixing aging temperature is -10°C to 10°C ;or

[0089] Scheme-B: The third mixed aging of component a and component c to obtain a uniform mixed solution-II, and then the fourth mixed aging of component b and mixed solution-II to obtain a uniform hydrogen...

Embodiment approach

[0101] The present invention provides another specific embodiment, the hydrogenation catalyst is Catalyst-II prepared by aging reaction of component a, component b, component c and component d. Preferably, the molar ratio of component a:component b:component c:component d=1:(2-6):(0.05-0.6):(0.05-0.15). Preferentially preparing water, alcohol and components a and b as a homogeneous hydrogenation catalyst is beneficial to the hydrogenation of unsaturated double bonds in styrene-butadiene block copolymers, especially increasing the degree of hydrogenation saturation of benzene rings, Thereby improving the transparency, purity and impact resistance of the obtained material. Wherein, the added amount of alcohol and water is controlled within the above-mentioned range with that of component a, and the purpose of hydrogenation reaction can be well realized. Wherein the molar weights of components a and b are calculated based on the metal elements in the components.

[0102] Accord...

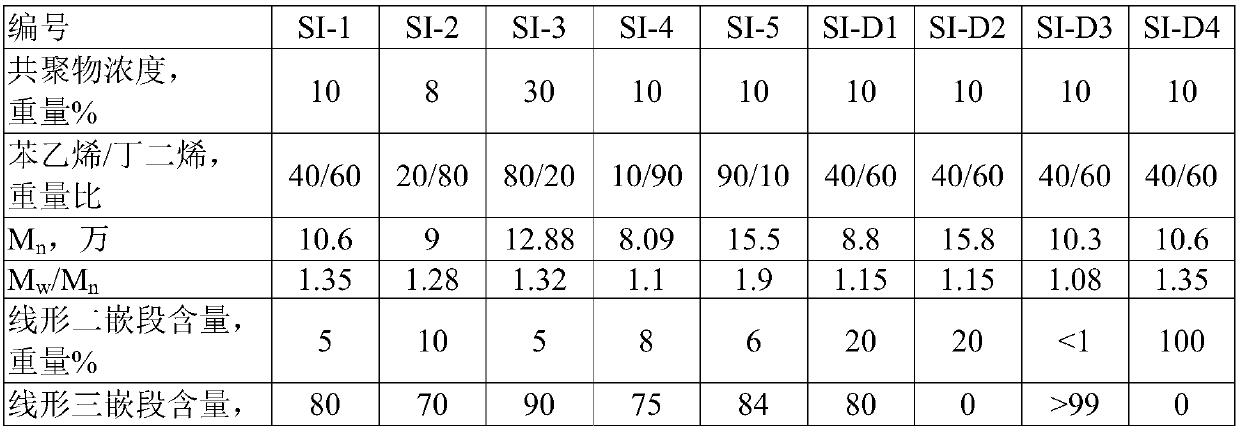

Embodiment 1-1

[0149] The preparation of a styrene-butadiene block copolymer is illustrated.

[0150] In a 5L stainless steel stirred tank under the protection of high-purity nitrogen, add 2457g of refined cyclohexane and 109.2g of styrene after impurity removal, and add a solution of n-butyllithium cyclohexane with a concentration of 0.2M under the condition of stirring and 50°C 27.3mL initiated reaction for 100min;

[0151] After the polymerization is complete, add 163.8g of refined butadiene and continue to react at 50°C for 90min;

[0152] After the reaction is completed, add 1,2-dichloroethane and a cyclohexane solution of silicon tetrachloride to continue the reaction for 30 minutes, wherein the molar ratio of 1,2-dichloroethane to n-butyllithium is 0.15:1, tetrachloro The molar ratio of silicon oxide to n-butyllithium is 0.15:1, and then the terminator isopropanol is added to terminate the reaction, wherein the molar ratio of isopropanol to n-butyllithium is 1:1.

[0153] Obtain the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com