A corrugated membrane reactor device for hydrogen isotope exchange

A membrane reactor, hydrogen isotope technology, applied in the direction of hydrogen isotope, hydrogen, non-metallic elements, etc., can solve the problems of unfavorable hydrogen mass transfer and permeation, difficult catalyst loading, limited decontamination factor, etc., to ensure rapid permeation, improve Effect of decontamination factor and reduction of filling difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

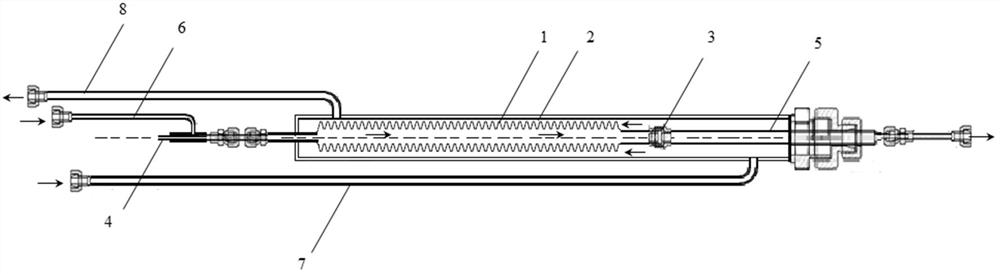

[0015] figure 1 It is a structural schematic diagram of the corrugated membrane reactor device for hydrogen isotope exchange of the present invention, in figure 1 Among them, the corrugated membrane reactor device for hydrogen isotope exchange of the present invention includes a palladium alloy tube 1, an outer casing 2, a flange 3, a thermocouple casing 4, branch pipes I6, branch pipes II7, branch pipes III8, and branch pipes IV9 . Wherein, the shape of the palladium alloy tube 1 is corrugated, and its connection relationship is that an outer sleeve 2 is arranged on the periphery of the palladium alloy tube 1 , and the flange 3 is arranged inside the outer sleeve 2 . The right end of the palladium alloy tube 1 is connected to one end of the branch pipe I6 through the flange 3, and the other end of the branch pipe I6 protrudes from the outer casing 2 and is provided with an exhaust gas H 2 O export. One end of the thermocouple sleeve 4 passes through the outer sleeve 2 and ...

Embodiment 2

[0028] This example has the same structure as Example 1, except that the length of the palladium alloy tube is 400 mm, the outer diameter is 4 mm, and the thickness is 0.09 mm.

[0029] The decontamination factor of the corrugated membrane reactor was 210.

Embodiment 3

[0031] The structure of this embodiment is the same as that of Embodiment 1, except that the length of the palladium alloy tube is 550 mm, the outer diameter is 6 mm, and the thickness is 0.1 mm.

[0032] The decontamination factor of the corrugated membrane reactor was 530.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com