A plastic intake manifold of an automobile engine and its special briquetting block

A technology for automobile engine and intake manifold, which is applied in the directions of engine components, machine/engine, fuel air intake, etc., can solve the problem of poor assembly positioning accuracy of intake manifold, complicated installation process of fastening bolts, and assembly of parts and components. Difficulties and other problems, to achieve the effect of being conducive to layout, saving layout space, and reducing weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

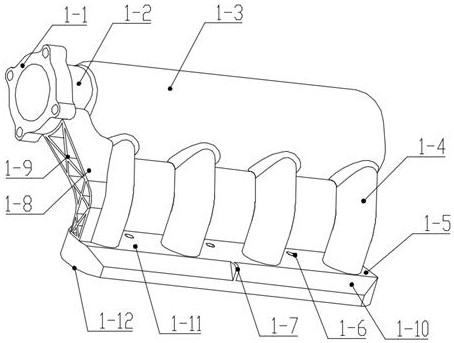

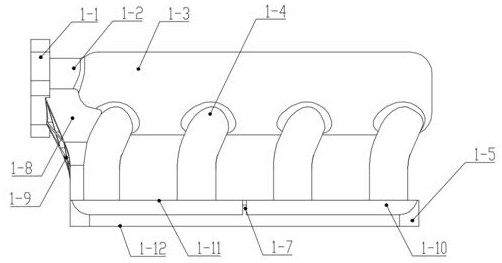

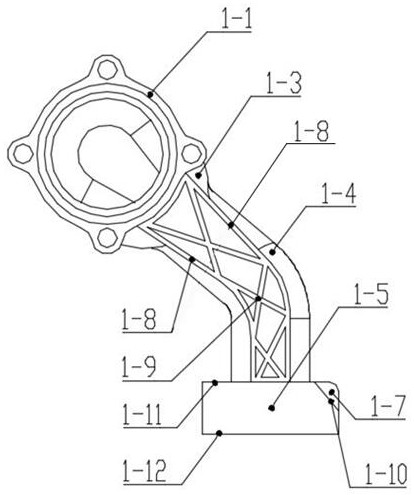

[0042] Such as Figure 1 ~ Figure 3As shown, the automobile engine plastic intake manifold of the present invention comprises an intake manifold, and the intake manifold comprises a throttle mounting flange 1-1, an intake manifold 1-2, a pressure stabilizing chamber 1-3, 4 intake branch pipes 1-4 and intake manifold mounting flanges 1-5, two front and rear arc support plates 1-8 are arranged at the intake end of the intake manifold 1, and the arc support plates 1- The bottom end of 8 is connected with the intake manifold mounting flange 1-5 to form the fixed end of the arc support plate 1-8, and the top of the arc support plate 1-8 is connected with the throttle valve mounting flange 1-1 and The intake manifold 1-2 is connected as a whole to form the support end of the arc-shaped support plate 1-8, and the two arc-shaped support plates 1-8 are along the intake manifold mounting flange 1-5 at the fixed end of the two arc-shaped support plates. The air intake branch pipe 1-4 at...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com