Special-specification vertical goods storing warehouse

A technology for storing and arranging items, applied in the field of warehouse item storage equipment, can solve the problems of difficulty in meeting the convenient, fast and efficient storage requirements of enterprises, low access utilization rate and efficiency, and single type of stored items, etc., to improve reliability. efficiency and utilization, reducing useless storage space, and easy storage, transportation, loading and unloading operations.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to better understand the present invention, the implementation manner of the present invention will be explained in detail below in conjunction with the accompanying drawings.

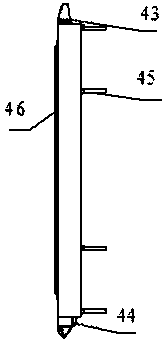

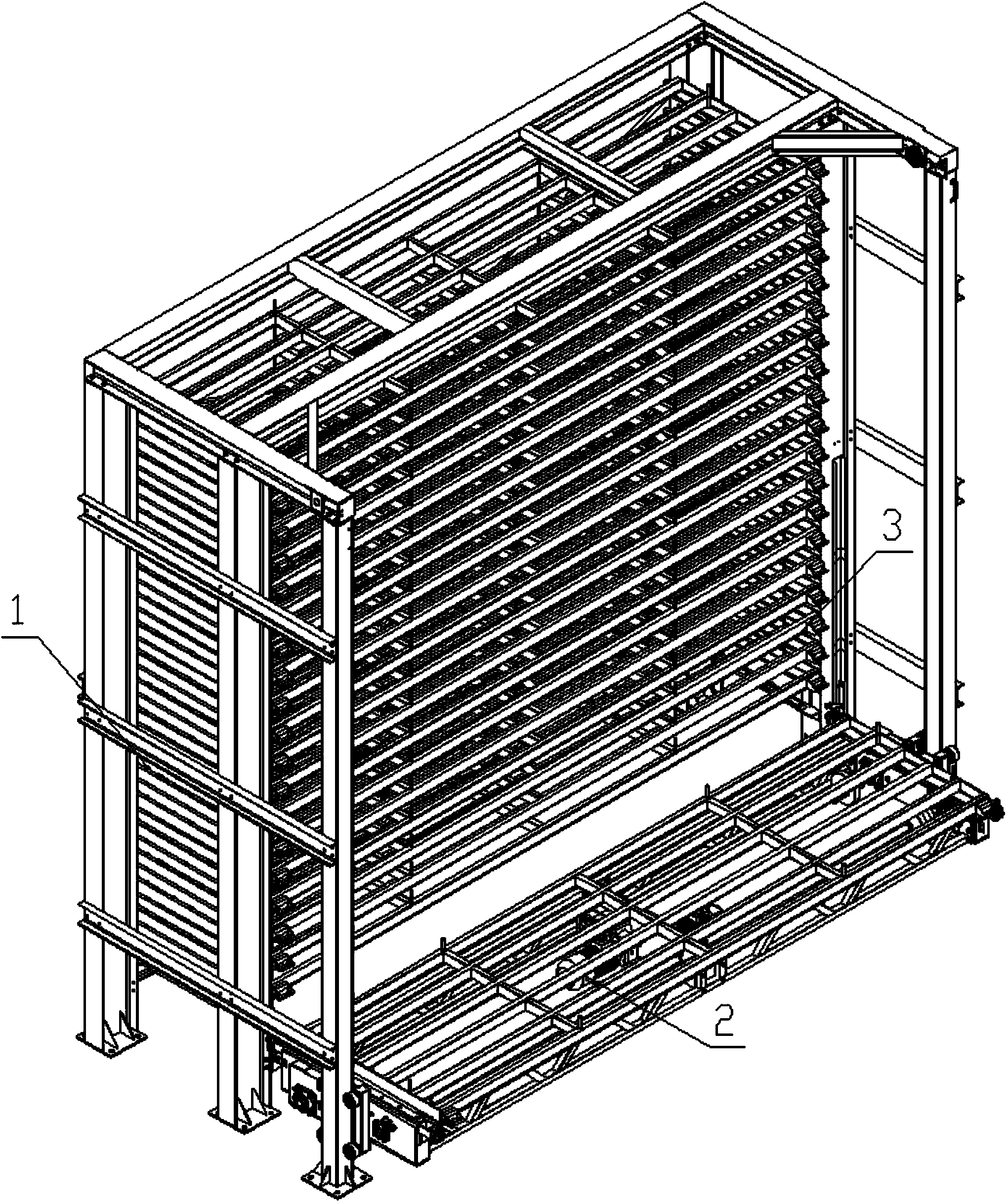

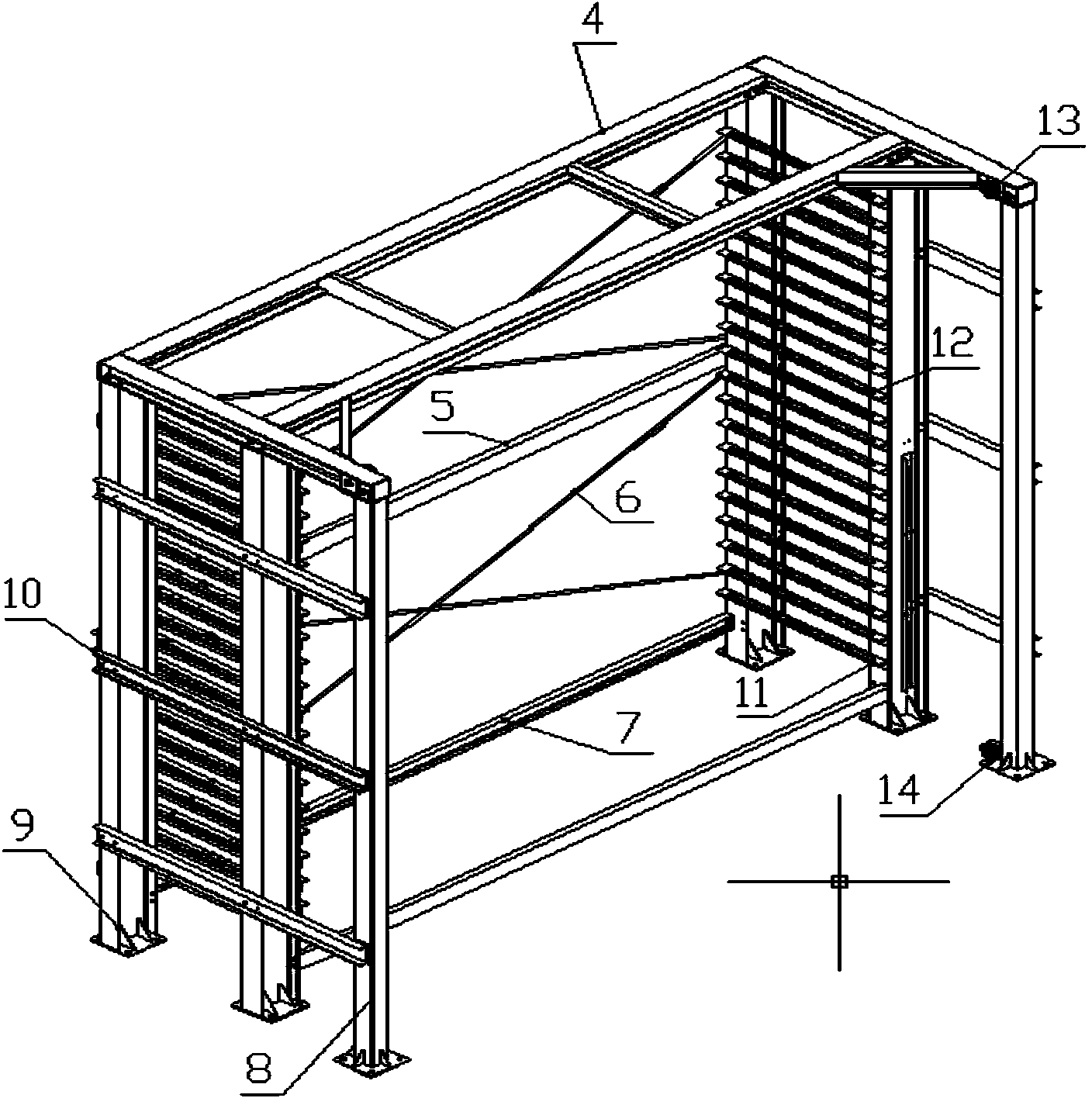

[0031] Such as figure 1 Shown, the vertical storehouse of the present invention mainly comprises the vertical storehouse body 1 that is connected, lifting device 2, loading pallet 3, as figure 2 As shown, wherein the vertical storage body is formed by lapping H-shaped steel, and the vertical storage body mainly includes the top frame 4, the storage body column 9 on both sides connected with the top frame 4, and the rear storage body column 9 connected with the rear side storage body column. Connecting beam 5, the back crossing 6 between the upper and lower rear connecting beams 5, the front guide column 8 on both sides, the top of the front guide column 8 is connected with the top frame 4, and the bottom connecting beam 7 connected with the left and right warehouse body columns 9 , be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com