Bonding packaging method suitable for large-size and high-density-structure metal micro-channel radiator

A packaging method and dense structure technology, applied in the direction of electric solid state devices, semiconductor devices, semiconductor/solid state device components, etc., to reduce the difficulty of loading, ensure continuous loading, and ensure the effect of positioning accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0041]The bonding package of the metal microchannel heat sink with large size and high density structure of the present invention is realized through the following tooling and process.

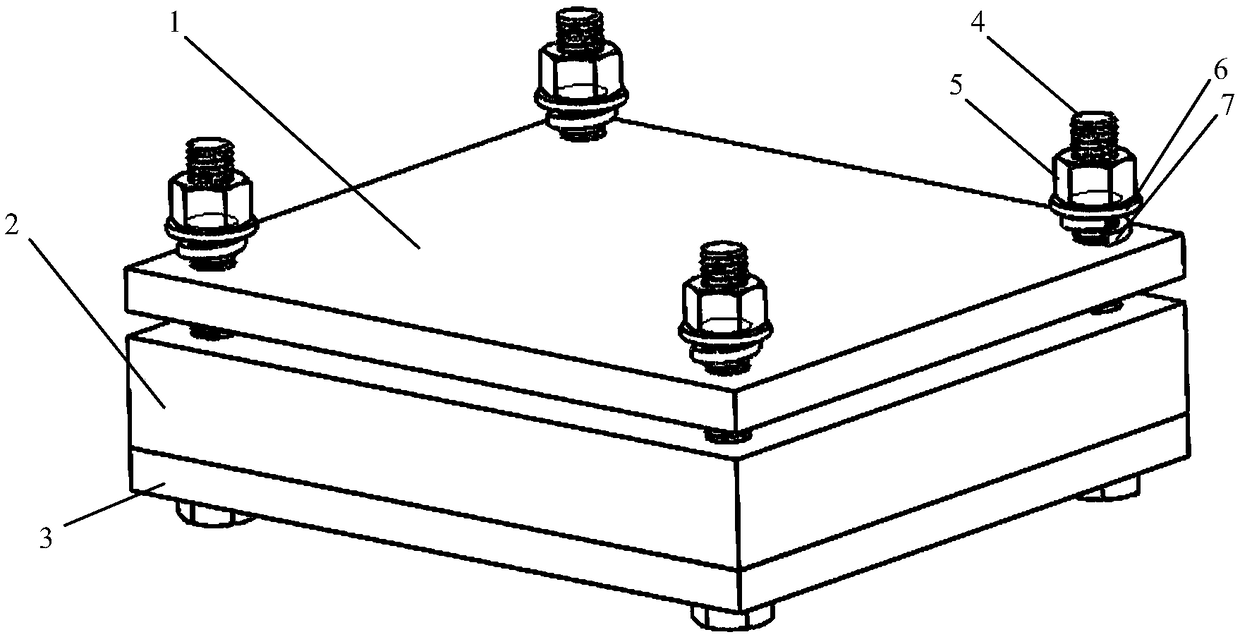

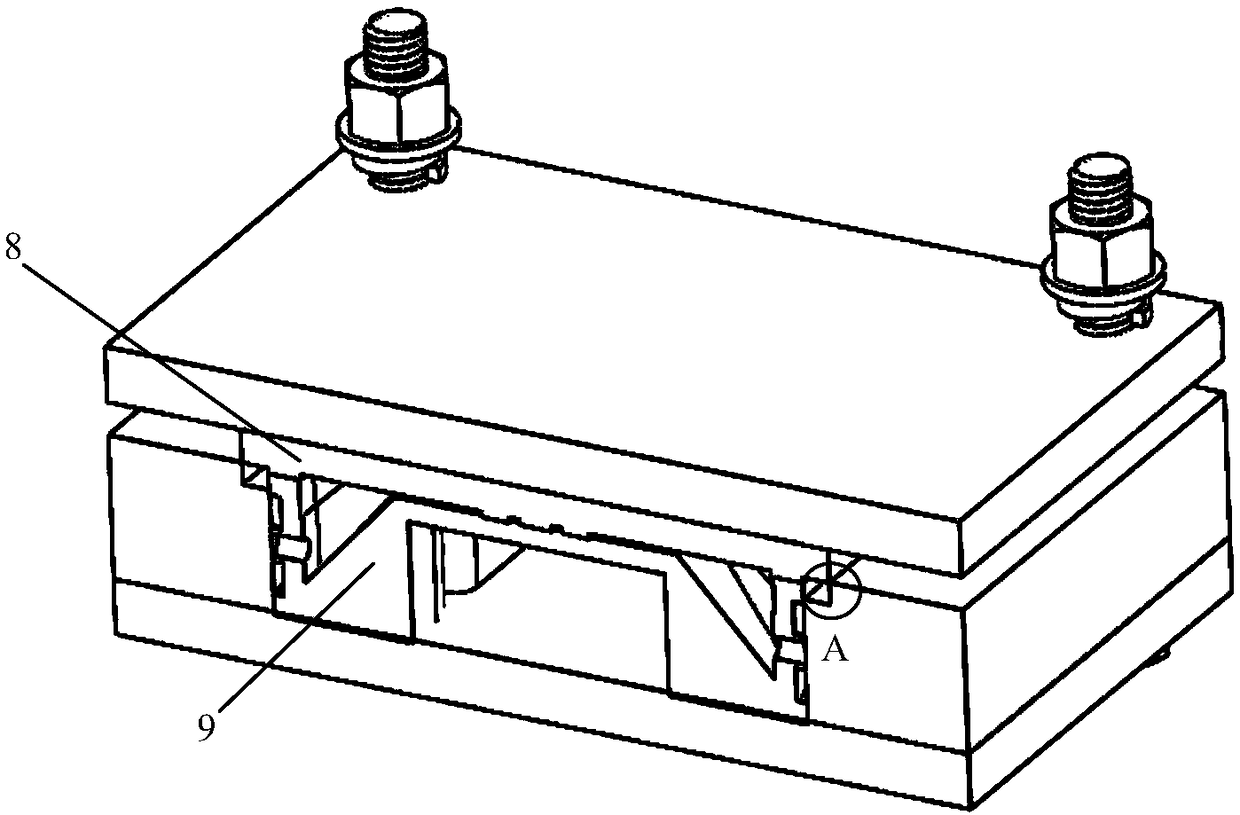

[0042] figure 1 , 2 It is the overall view and partial view after the assembly of the bonded board and the package fixture, mainly including: upper cover plate 1, positioning block 2, lower cover plate 3, screws 4, nuts 5, gaskets 6, spring washers 7, microchannel bottom plate 8. Encapsulation cover plate 9. The microchannel bottom plate 8 and the packaging cover plate 9 are parts to be bonded, and the positioning block 2 fixes the position of the microchannel bottom plate 8 and the packaging cover plate 9 . The nut 5, the gasket 6, and the spring washer 7 provide elastic pre-tightening force, and clamp the microchannel bottom plate 8 and the package cover plate 9 in the package cavity formed by the upper cover plate 1, the positioning block 2 and the lower cover plate 3.

[0043] image 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com