Luminous device with dependent voltage/resistance layer

A technology of light-emitting elements and resistors, which is applied to electric solid-state devices, semiconductor/solid-state device components, electrical components, etc., can solve the problems of increasing the steps of connecting the light-emitting diode chip and the shunt diode, and increasing the cost, so as to avoid the complexity of the process. , the effect of reducing strict requirements and relaxing strict requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

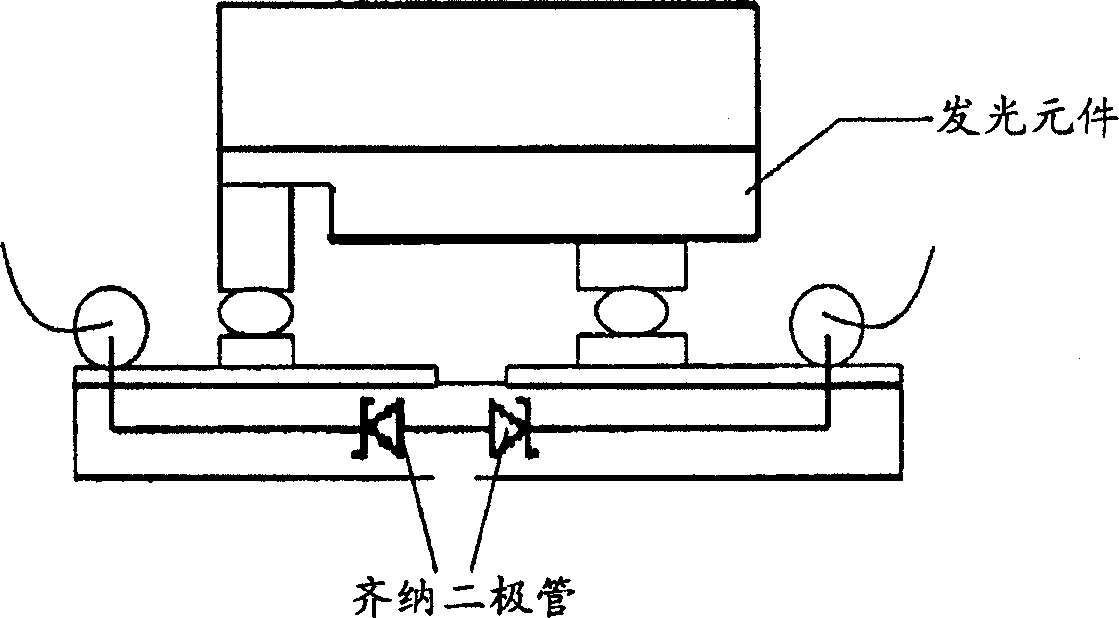

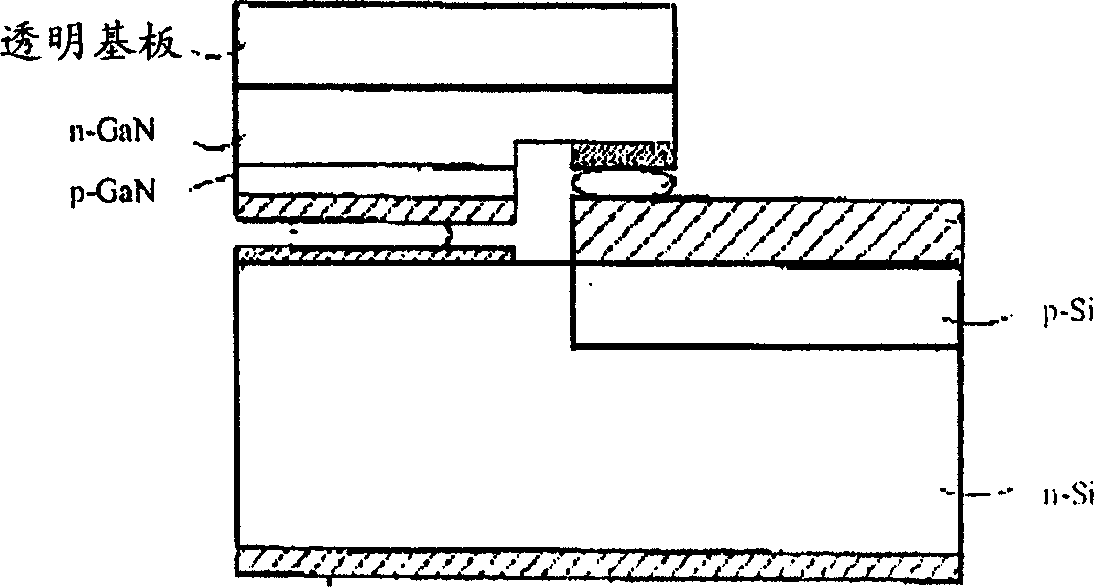

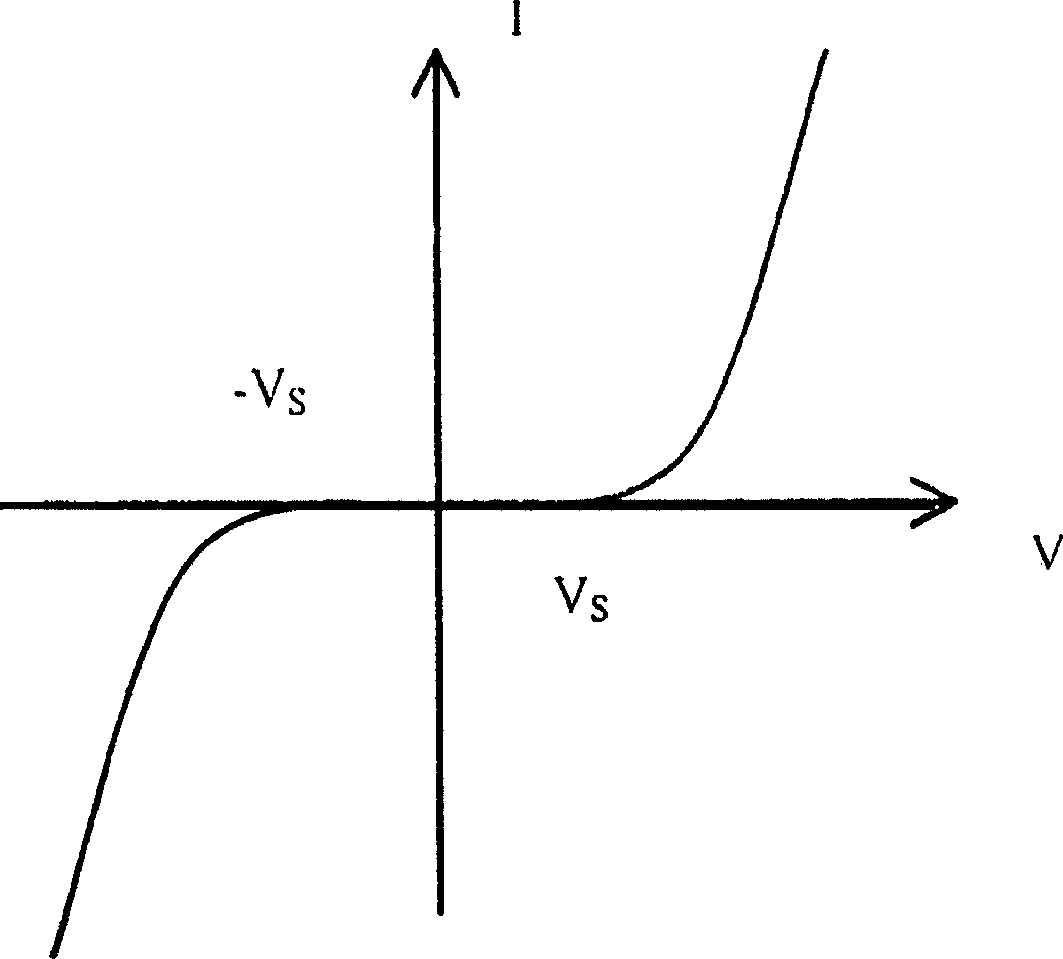

[0056] see Figure 5 According to a preferred embodiment of the present invention, a light-emitting element 1 with a voltage / resistance dependent layer includes a substrate 10; a light-emitting stack formed on the substrate 10, wherein the light-emitting stack includes a layer formed on the substrate 10 A first contact layer 11, wherein the first contact layer respectively includes a first surface region and a second surface region, a first confinement layer 12 formed on the first surface region, a first confinement layer 12 formed on the first confinement A light-emitting layer 13 on the layer 12, a second confinement layer 14 formed on the light-emitting layer 13, a second contact layer 15 formed on the second confinement layer 14; A first contact electrode 16; a second wiring electrode 17 formed on the second contact layer 15; Voltage / resistance dependent layer 18 .

[0057] see Figure 6According to another preferred embodiment of the present invention, a light-emitting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com