Patents

Literature

225results about How to "Reduce the difficulty of positioning" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

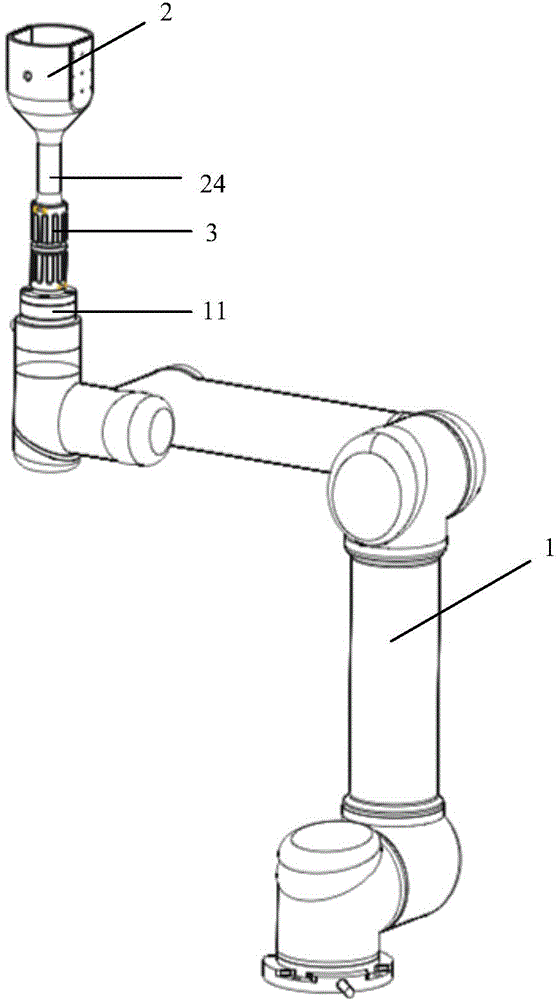

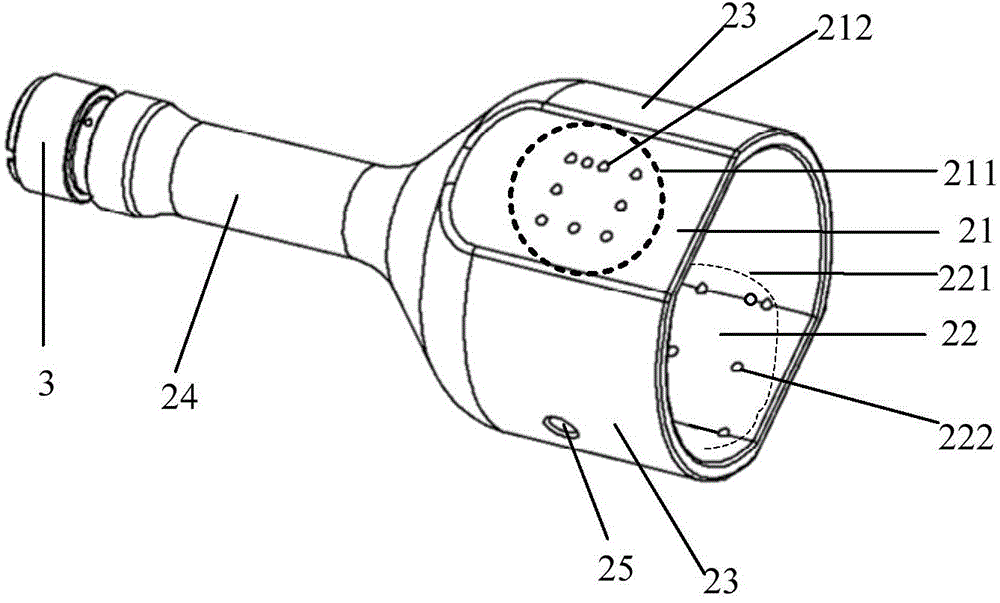

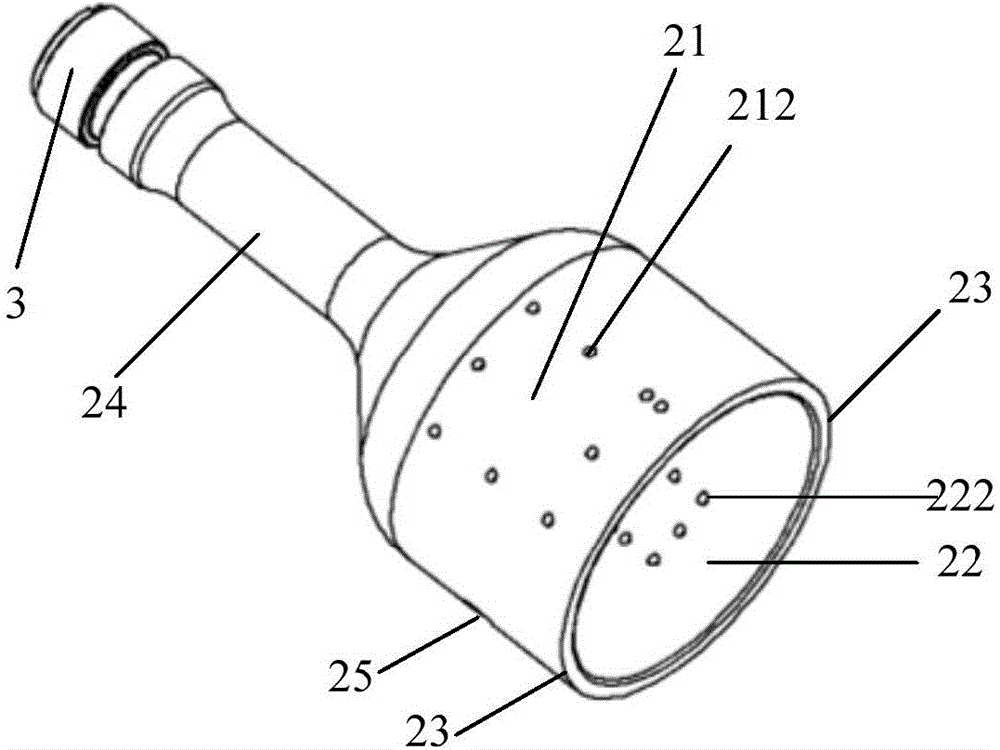

Operation positioning device and method and robot operation system

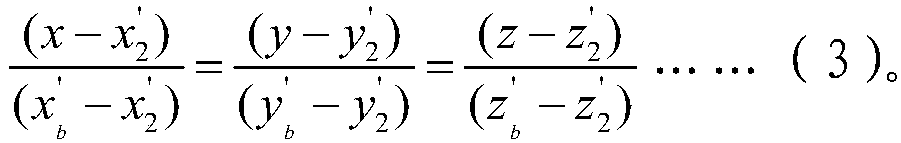

The invention relates to an operation positioning device and method and a robot operation system. The operation positioning device comprises a positioning ruler, an upper computer and a series-connection mechanical arm with at least six degrees of freedom. The upper computer is connected with the series-connection mechanical arm, the positioning ruler comprises two opposite surfaces allowing X-rays to transmit, the two opposite surfaces are fixedly connected through a connecting surface allowing X-rays to transmit, the two opposite surfaces are respectively provided with a group of marks, each group of marks comprise at least four mark points which are not located on the same straight line, and the mark points are X-ray-proof components. Any opposite surface or the connecting surface is fixedly connected with a ruler handle, and the ruler handle is connected with the tail end of the series-connection mechanical arm through a port. The upper computer adjusts the position of the positioning ruler by controlling movement of the series-connection mechanical arm, space positioning calculation is conducted according to the mark points in collected images, and a planning path is obtained. The device can achieve perspective positioning at any angle, and can eliminate system errors caused when an operation path is calculated, increase working space and improve the operation positioning accuracy.

Owner:BEIJING TINAVI MEDICAL TECH

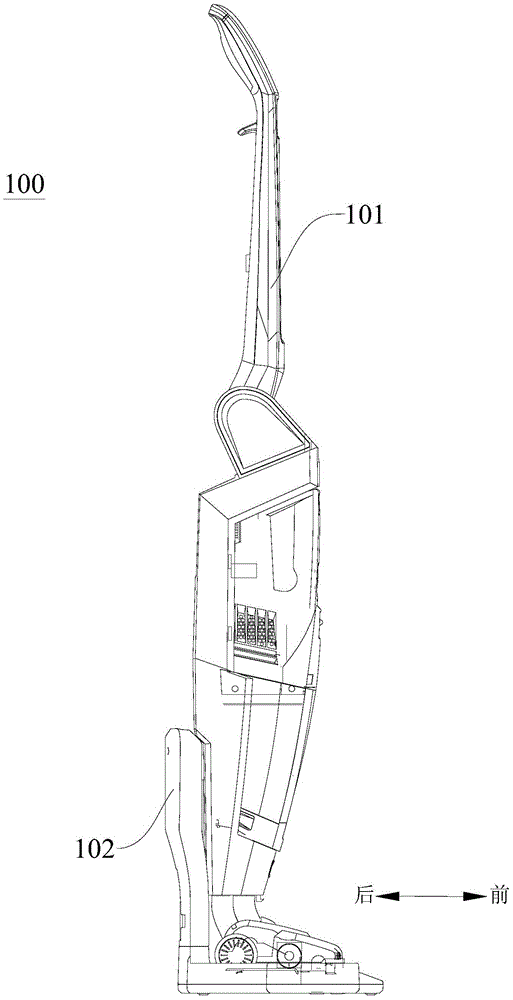

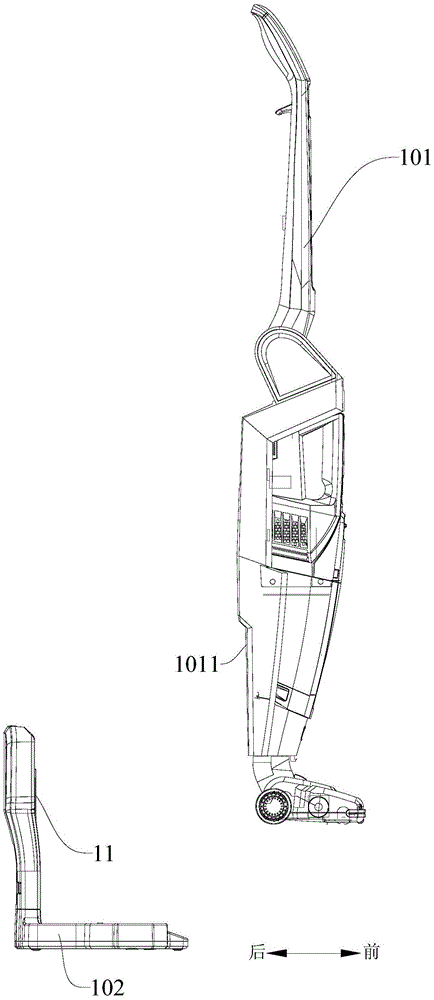

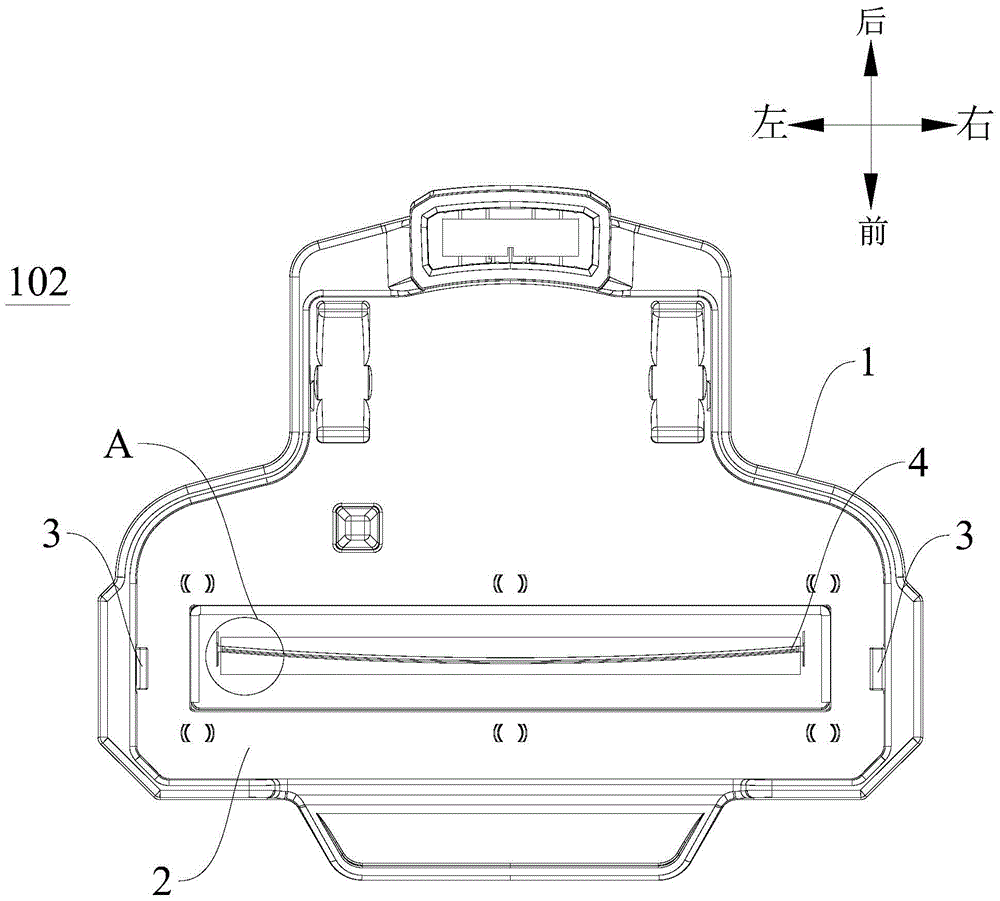

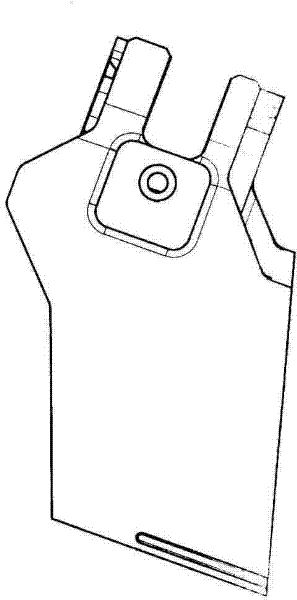

Rechargeable dust collector assembly

ActiveCN105534412ARapid positioningPrecise positioningBatteries circuit arrangementsElectric powerEngineeringDust collector

The invention discloses a rechargeable dust collector assembly which comprises a rechargeable dust collector and a charging seat. A first magnetic attraction piece is arranged on the rechargeable dust collector. A second magnetic attraction piece is arranged on the charging seat, and the first magnetic attraction piece is suitable for being in magnetic attraction cooperation with the second magnetic attraction piece to locate the rechargeable dust collector on the charging seat. According to the rechargeable dust collector assembly, the first magnetic attraction piece and the second magnetic attraction piece matched with the first magnetic attraction piece are arranged on the rechargeable dust collector assembly, and the rechargeable dust collector can be fast and accurately located on the charging seat. Therefore, the locating difficulty of the rechargeable dust collector assembly is reduced, and charging efficiency is improved.

Owner:JIANGSU MIDEA CLEANING APPLIANCES

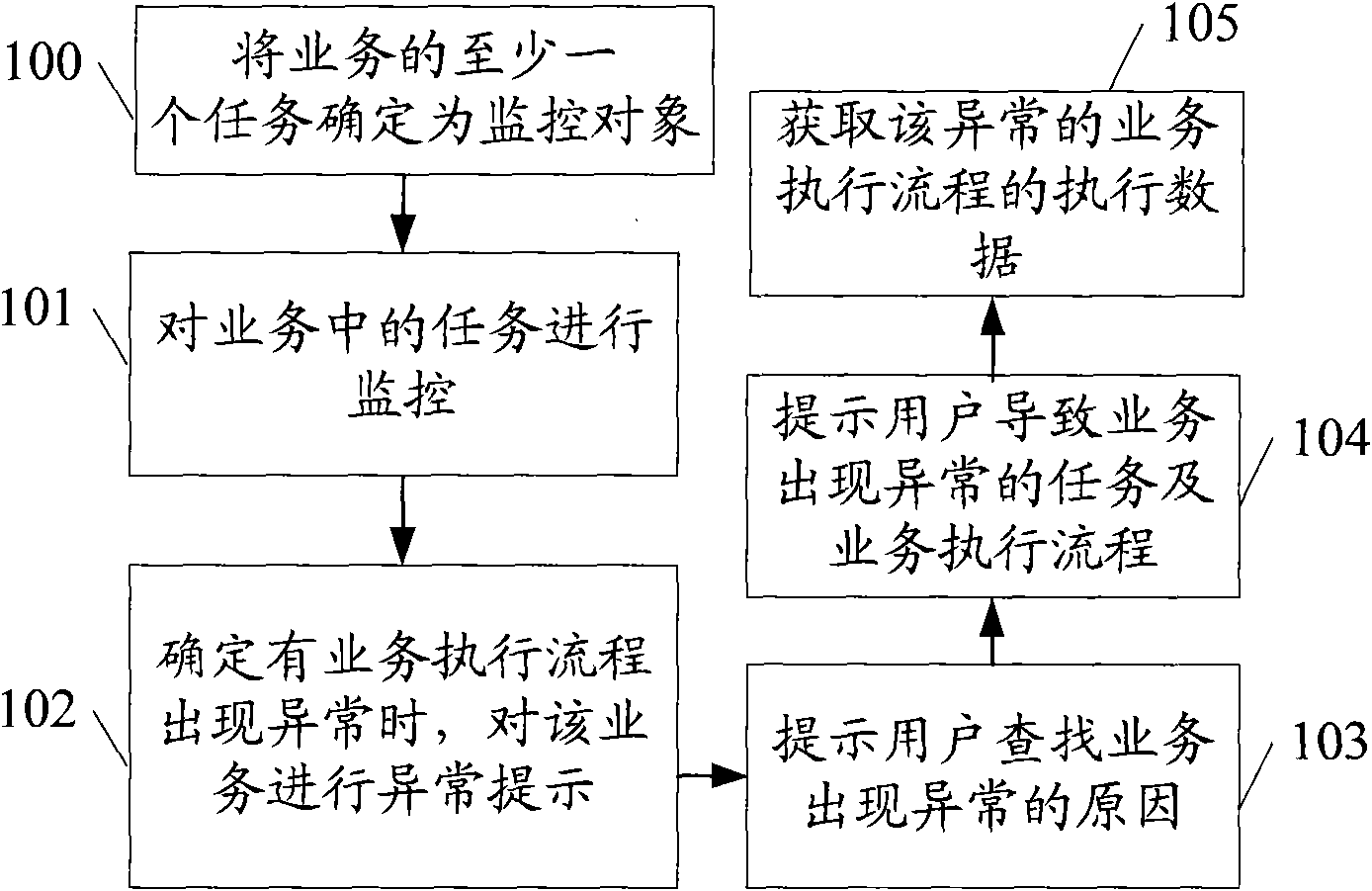

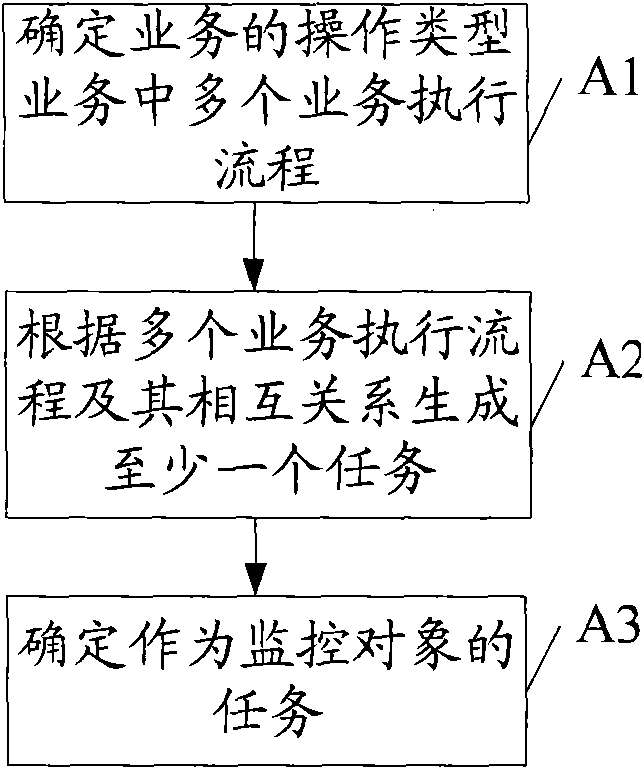

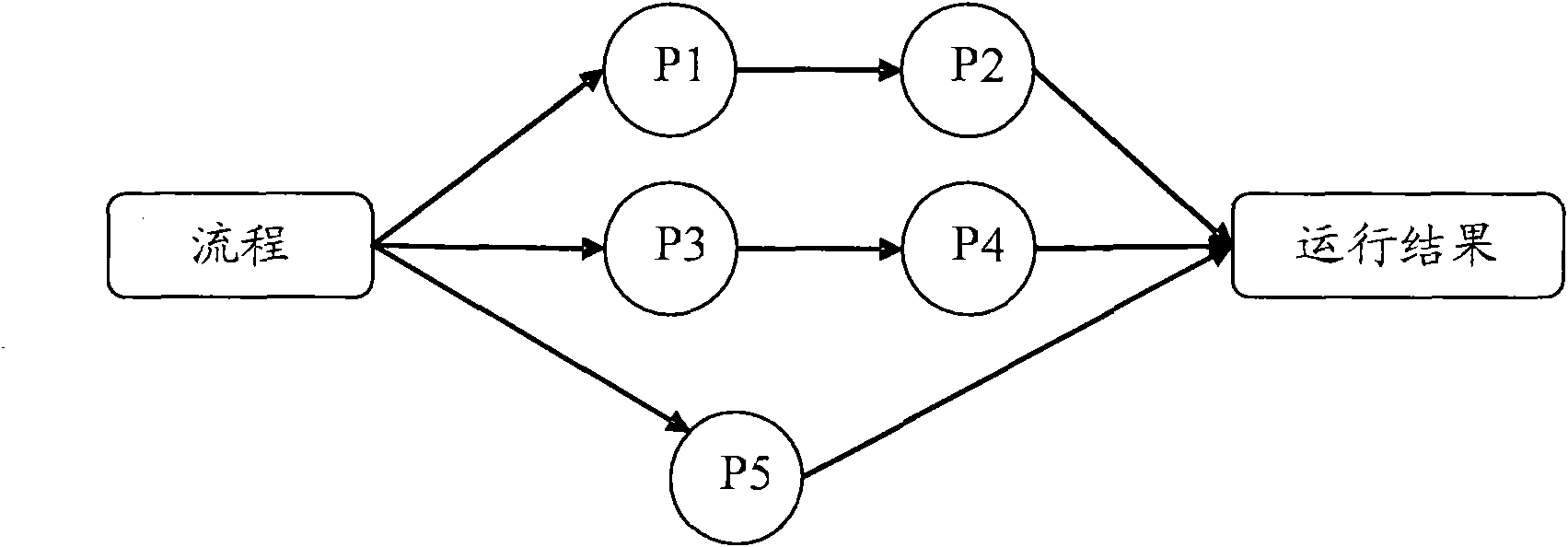

Business monitoring method and device

InactiveCN101562540AEffectively locate impactReduce the difficulty of positioningData switching networksLocation EquipmentOperating system

Owner:HUAWEI TECH CO LTD

Method for machining joint with deep and narrow groove complicated structure

InactiveCN102225480AGuaranteed sizeReduce the risk of qualityMilling equipment detailsMilling cutterEnd mill

The invention relates to a method for machining a joint with a deep and narrow groove complicated structure, and the method is characterized by comprising the following steps of: 1) extending a joint web plate during design, forming a positioning hole on the extended web plate, and machining by taking the positioning hole as a process original point; 2) machining a part web plate; 3) carrying out rough and finish milling on lug slots and machining lug slot notches; and 4) machining an internal camber surface by adopting profile segmentation, carrying out half-finish machining by layers by virtue of a vertical milling cutter with the length of 45mm, and carrying out non-layered finish machining by virtue of a vertical milling cutter with the edge length of 90mm. The method can be used for not only effectively solving the problem of poor thickness of lugs, and a more reasonable method is provided for machining the rotating angles of the part, thus improving the integral machining precision of the part and increasing the production efficiency.

Owner:SHENYANG AIRCRAFT CORP

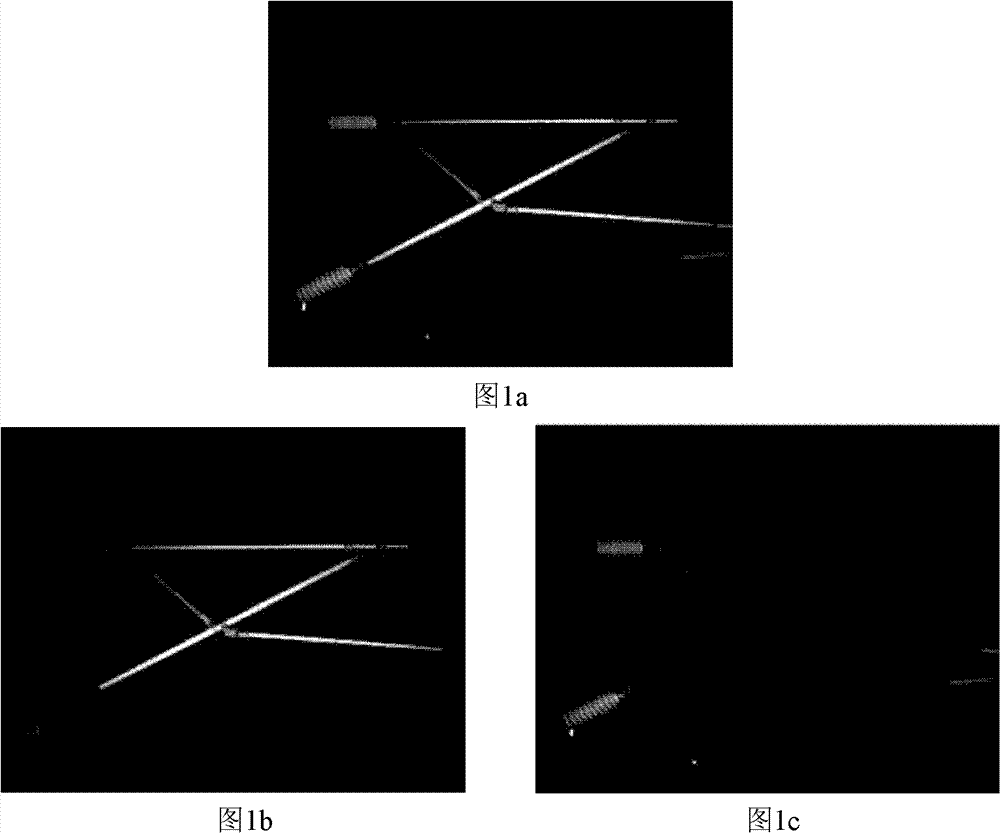

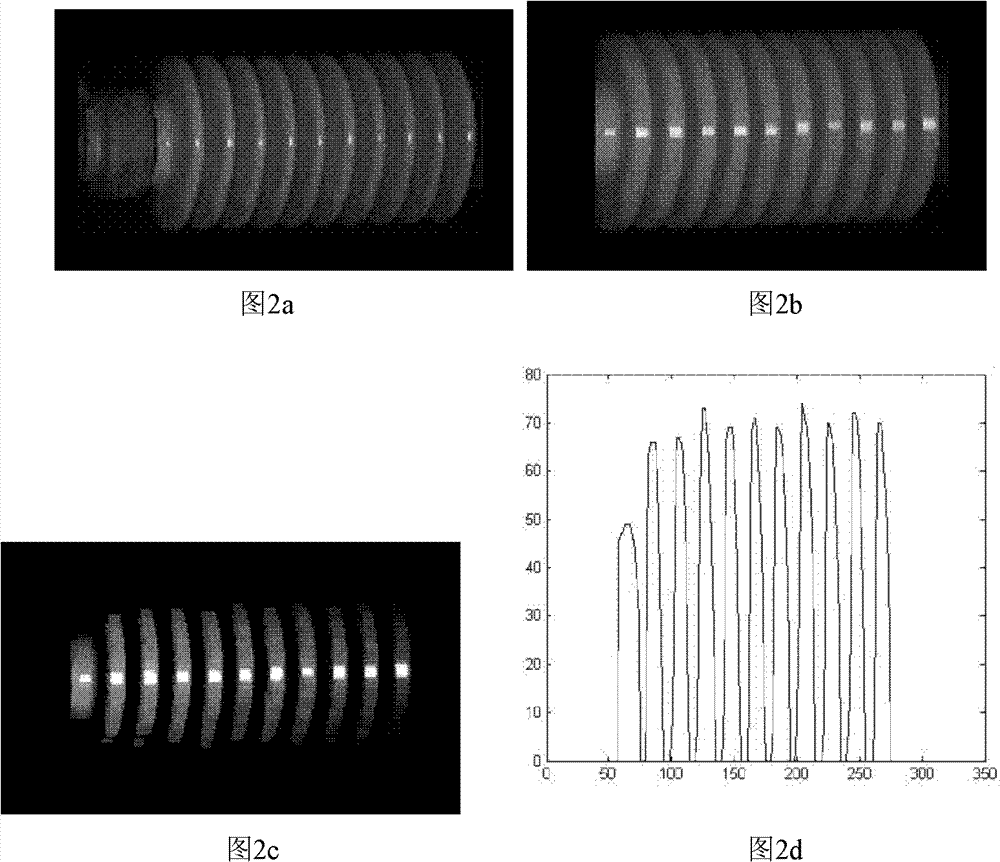

Method for detecting faults caused by foreign body pollution between electrified railway insulator plates based on affine invariant moment

InactiveCN102737252AThe test results are objectiveThe test result is accurateElectrical testingCharacter and pattern recognitionEngineeringLine fitting

The invention relates to a method for faults caused by foreign body pollution between electrified railway insulator plates based on affine invariant moment, which aims at solvating the problems of a complicated background of insulator problem detection and the like caused by much original image content. The method can be used quickly and accurately identifying and positioning insulators through overall image classification and by virtue of the affine invariant moment, and then can be used for carrying out fault detection on the insulators. The method comprises the following steps of: detecting, identifying and classifying shafts by virtue of a Hough transformation segment, thus obtaining an insulator type after setting the classified shafts as a background; then applying the affine invariant moment to extract the insulators in the insulator type; in order to solve the problem of different change of the angles of the insulators, carrying out straight-line fitting on the boundary curves of the insulators to obtain the rotation angles of the insulators; in order to avoid the loss of foreign body characteristics, amplifying the characteristics of the insulators by virtue of morphological dilation operation; in order to improve the local contrast of insulator images, dividing each piece of the image into a block to carry out local contrast control on each block; and then carrying out grey level value statistic on each row of the blocks, and finally identifying and positioning the faults through the width of each strip in a grey level statistical chart. The method based on prior classification disclosed by the invention simplifies the background of the insulators, efficiently improves the speed and accuracy of insulator identification and positioning, reduces the difficulty of fault detection, and provides an advisable reference for the insulating property detection of an electrified railway.

Owner:SOUTHWEST JIAOTONG UNIV

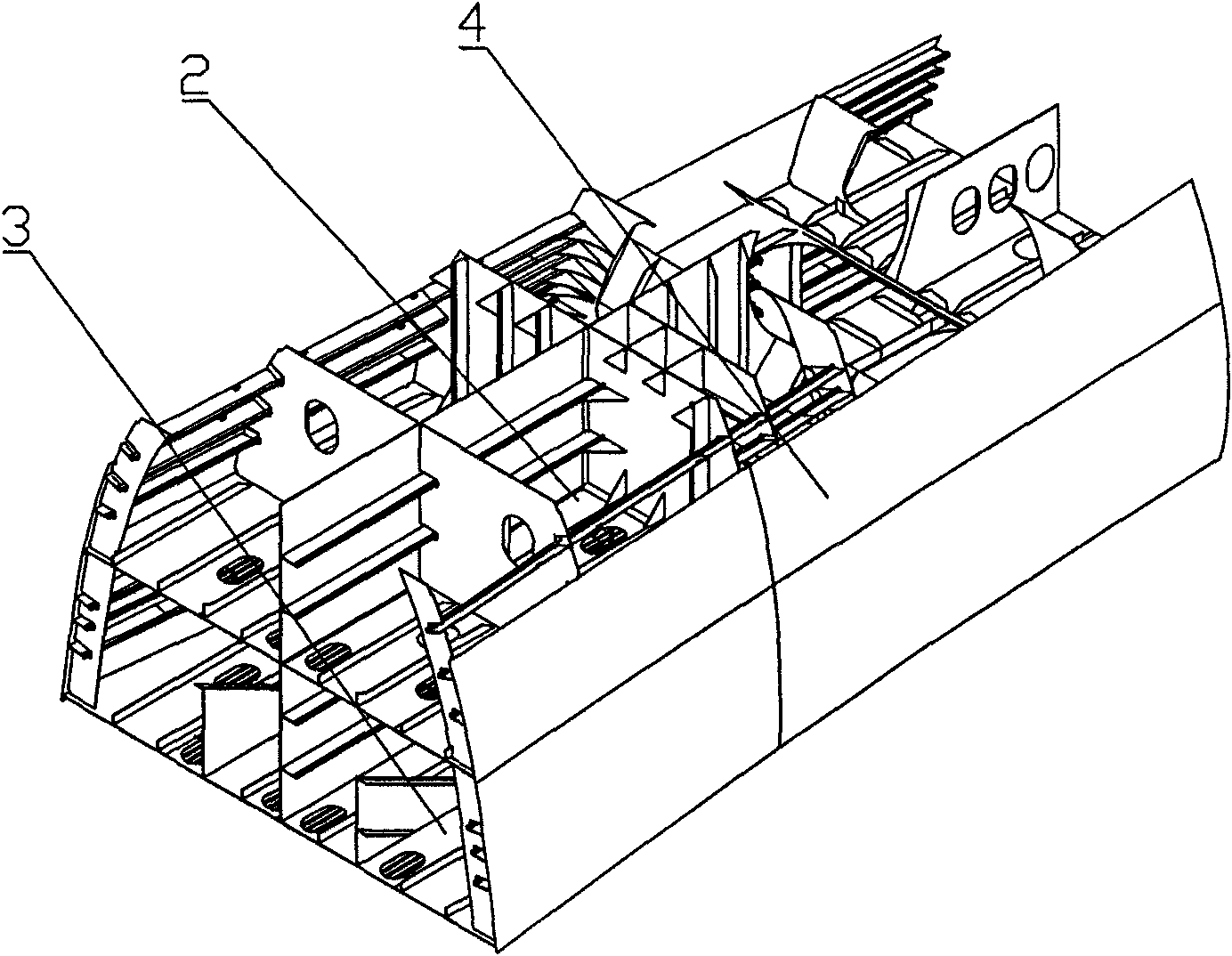

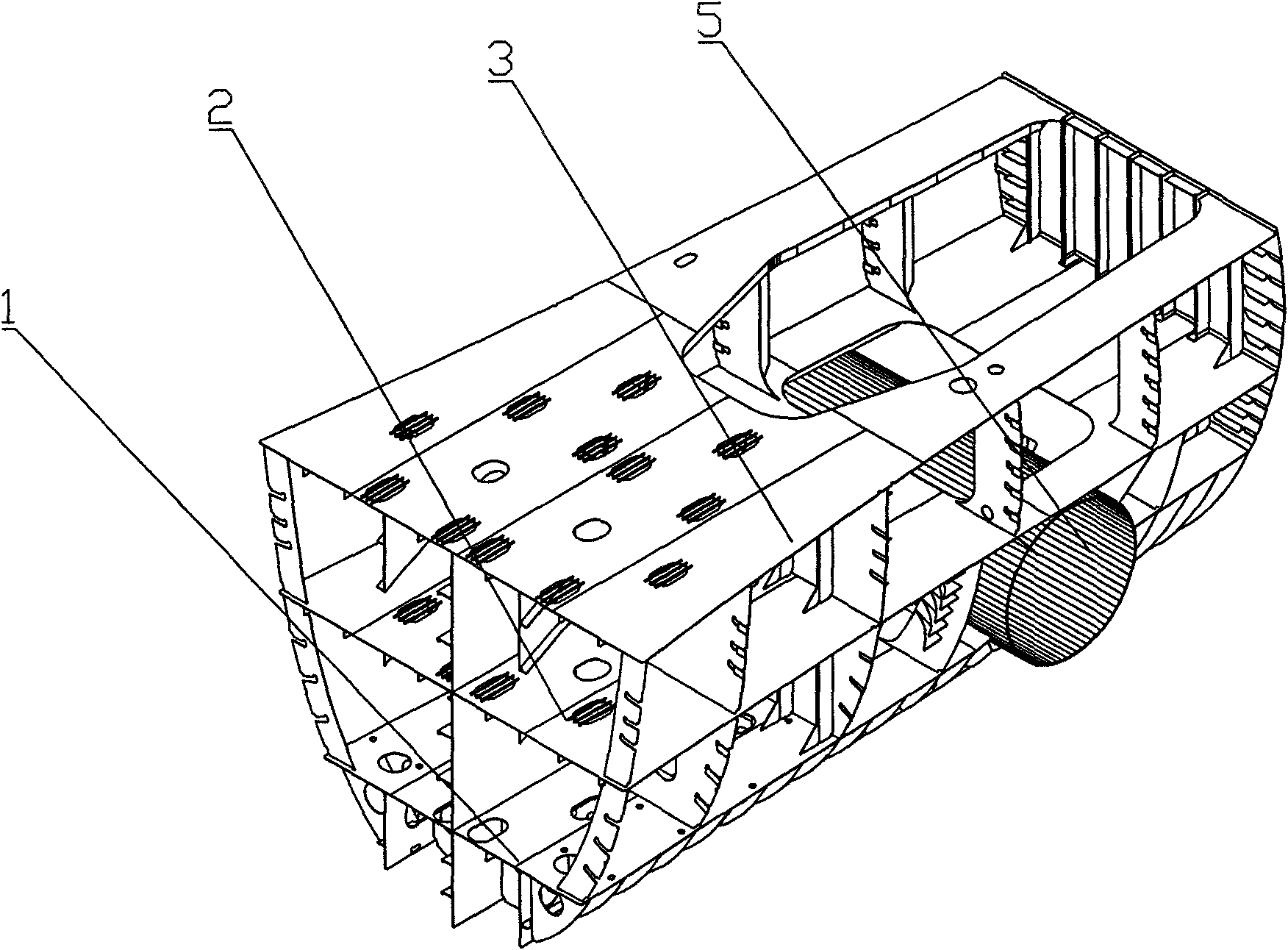

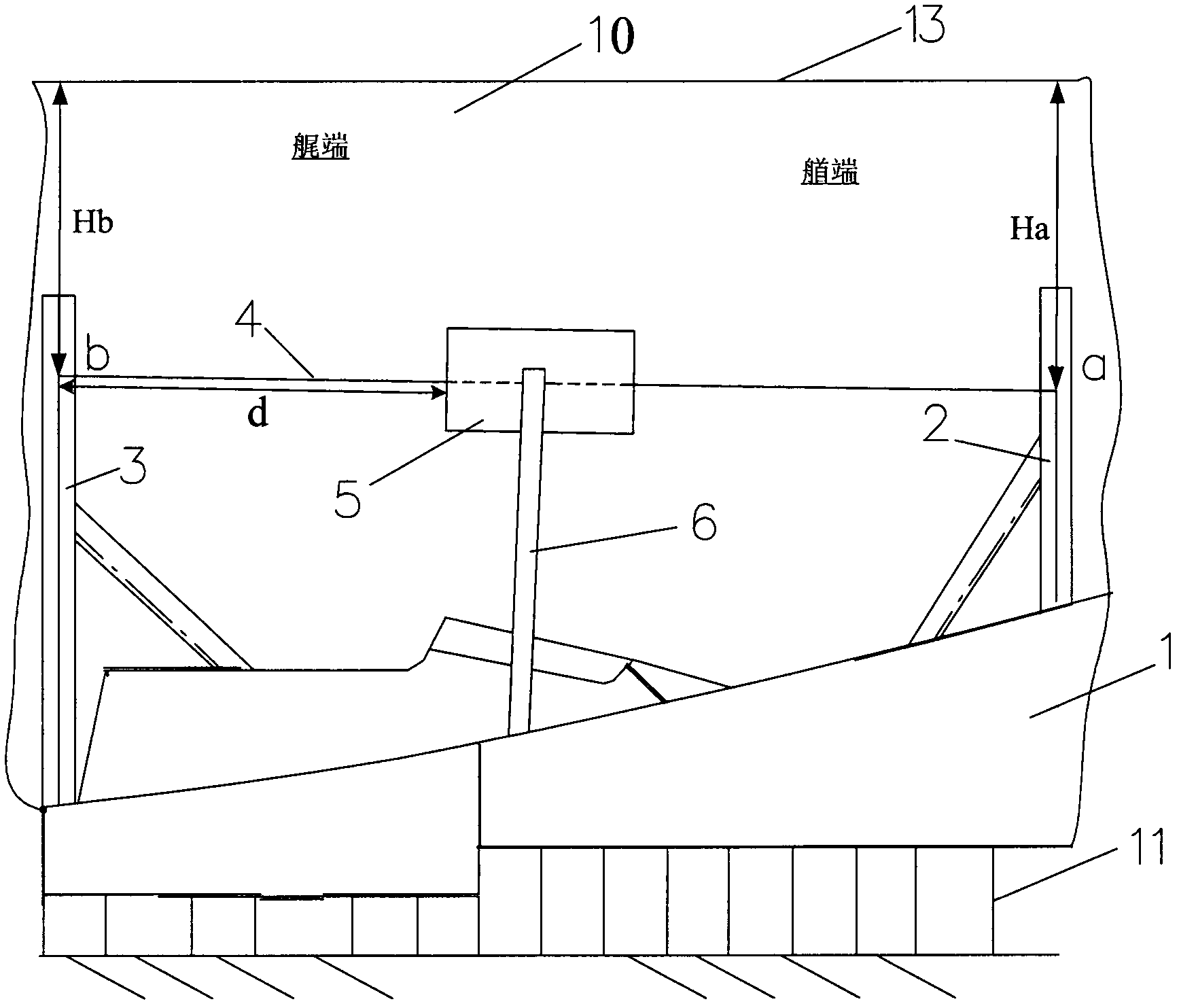

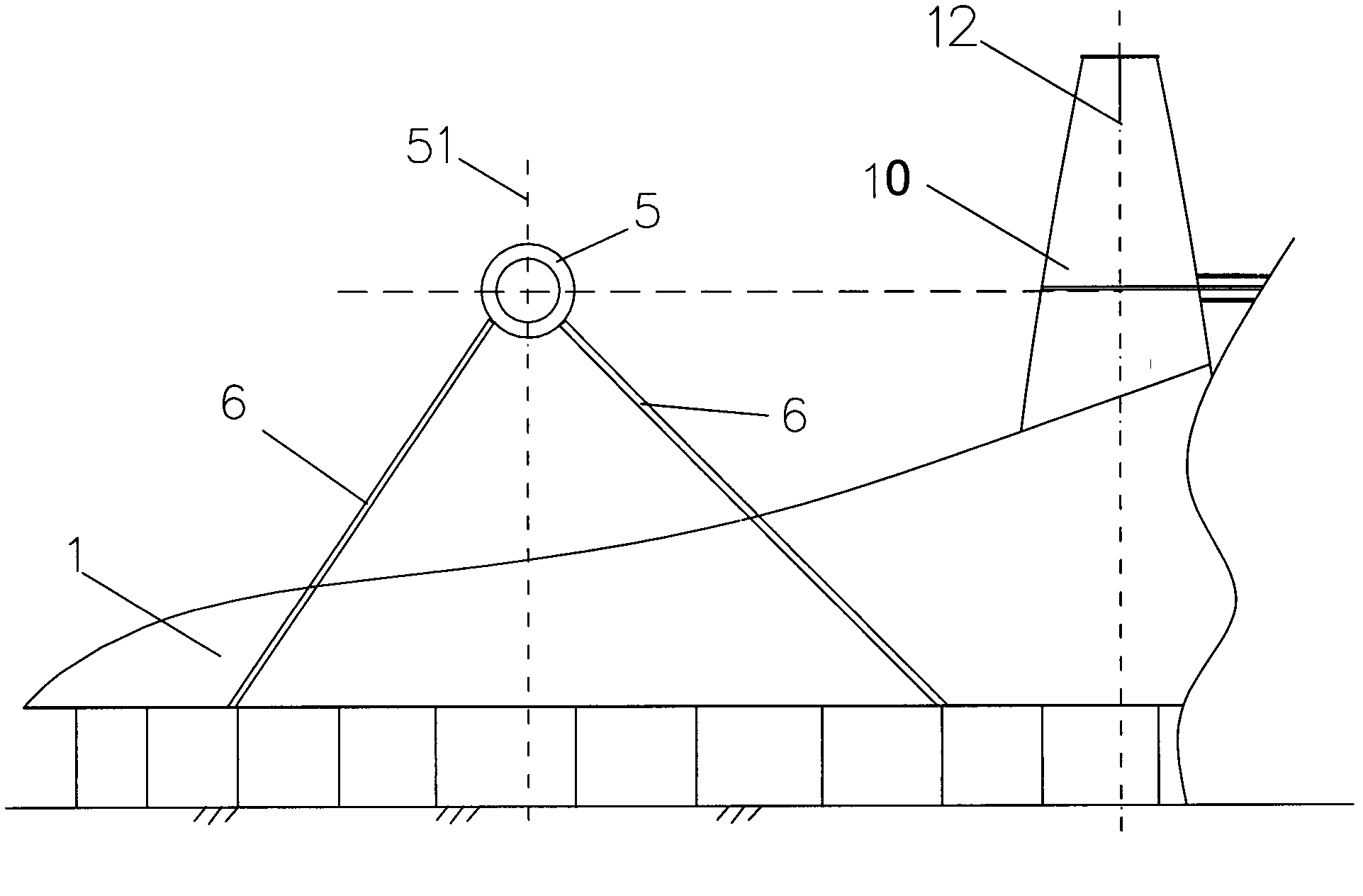

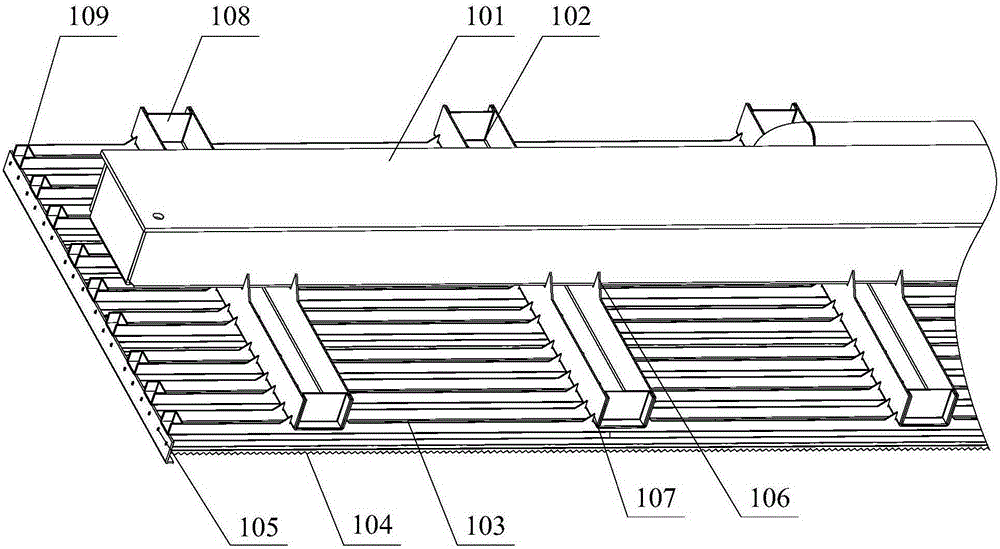

Process for pre-assembling bow thrustor on ship body section

ActiveCN101596925AReduce the difficulty of positioningShorten the timeVessel partsMarine engineeringNormal state

The invention discloses a process for pre-assembling a bow thrustor on a ship body section, which comprises the following steps: manufacturing the bow thrustor; reversely manufacturing an upper subsection, a middle subsection and a lower subsection; turning over the lower subsection to a normal state, and then assembling the bow thrustor on the lower subsection; reversely folding the upper subsection and the middle subsection; and turning over the obtained folding section to the normal state, and normally folding the folding section and the lower subsection. The pre-assembling process reduces the positioning difficulty of the bow thrustor during assembling, and reduces the time for positioning the bow thrustor so as to shorten the construction period of a ship body.

Owner:JIANGNAN SHIPYARD GRP CO LTD

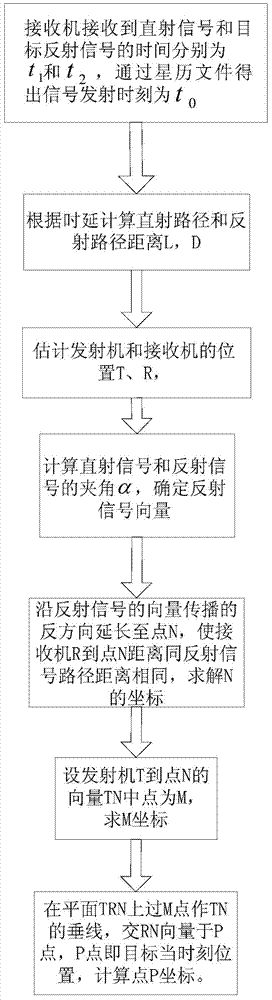

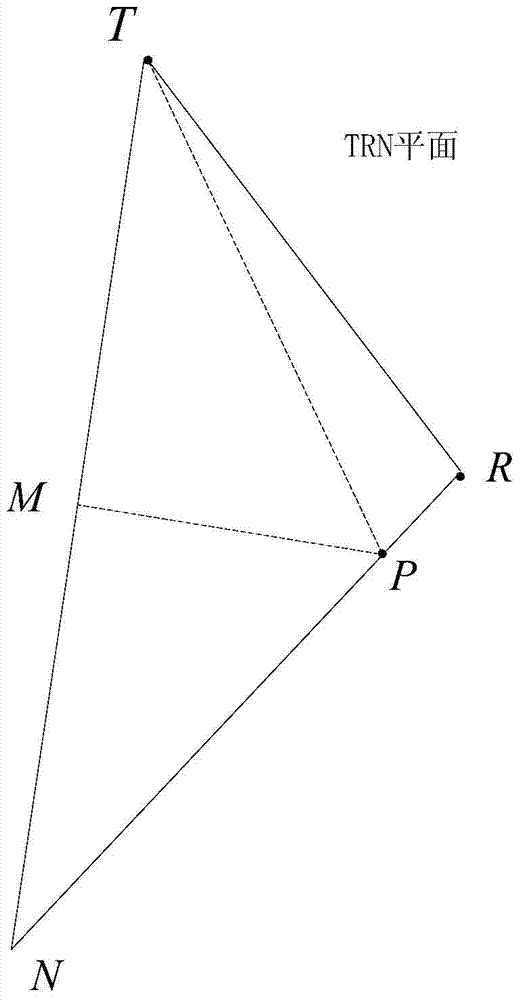

Satellite-borne passive radar location method based on GNSS-R (global navigation satellite system-reflection) signal geometrical relationship

InactiveCN103576138AEffective positioningOmit calculation stepsSatellite radio beaconingRadio wave reradiation/reflectionNatural satellitePath length

A satellite-borne passive radar location method based on a GNSS-R (global navigation satellite system-reflection) signal geometrical relationship comprises steps as follows: step one, the moment when a receiver receives a direct signal of a GPS satellite is marked as t1, and the moment when the receiver receives a reflected signal to a target by a related GPRS satellite signal is marked as t2; step two, a direct path length L and a reflection path length D of the signal are calculated according to the arrival moment of the signal; step three, the position coordinate T ( xt, yt, zt) and the position coordinate R (xr, yr, zr) of a transmitter and the receiver are calculated; step four, the included angle alpha between the direct signal and the reflected signal is calculated, and the vector of the reflected signal is determined; step five, the vector of the reflected signal is lengthened to the point N in the transmission direction, so that the distance between R of the receiver and the point N is equal to the distance of the reflected signal path, and a coordinate of N is calculated; step six, a midpoint of a vector TN from T of the transmitter to the point N is set to be M, and a coordinate of M is calculated; and step seven, a TN vertical line passing the point M is drawn on a plane TRN, the vertical line intersects with a vector RN at the point P which is the position of the target at the moment, and a coordinate of the point P is calculated. According to the method, the calculation difficulty is reduced, the location efficiency is improved, and the location cost is reduced.

Owner:BEIHANG UNIV +1

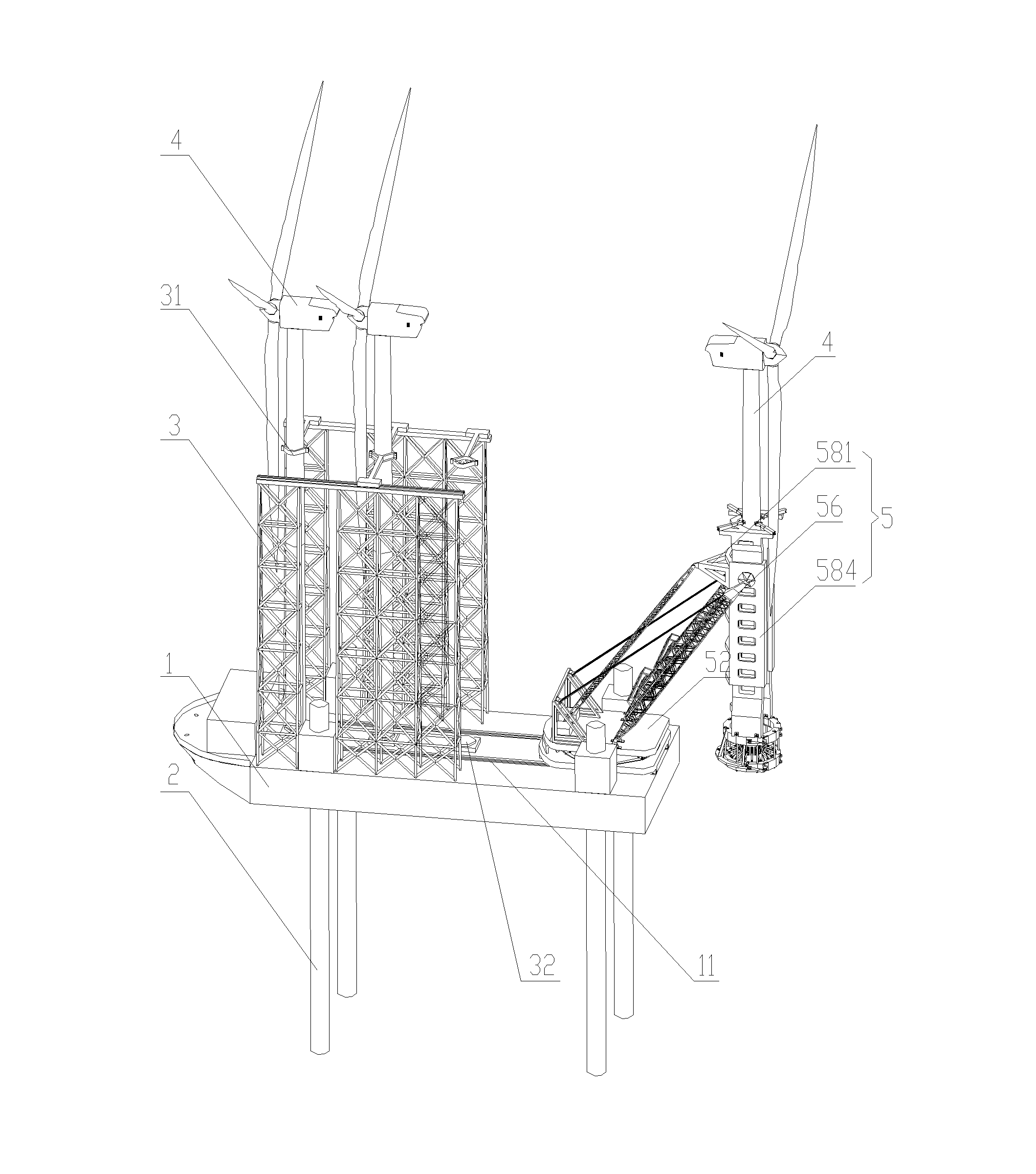

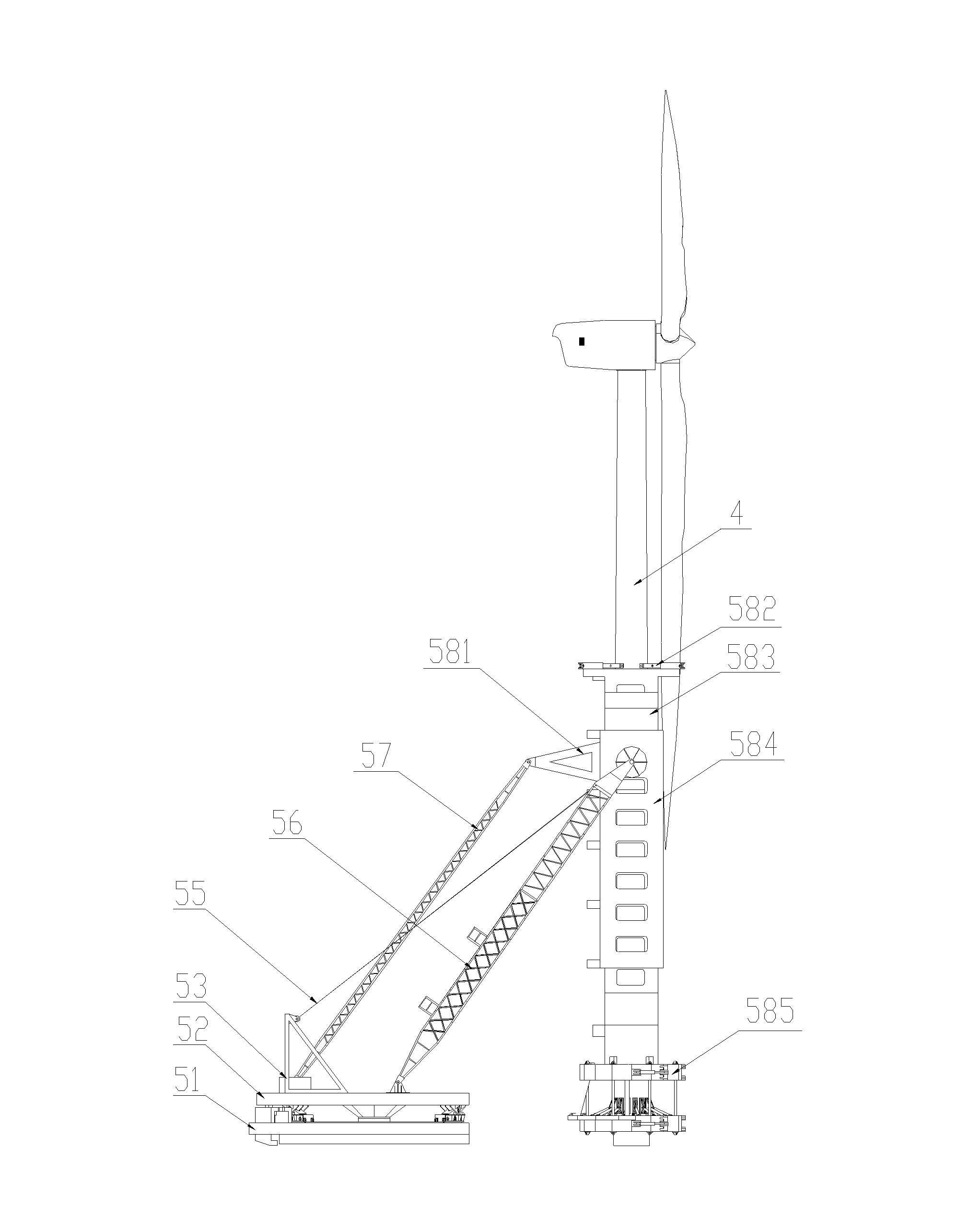

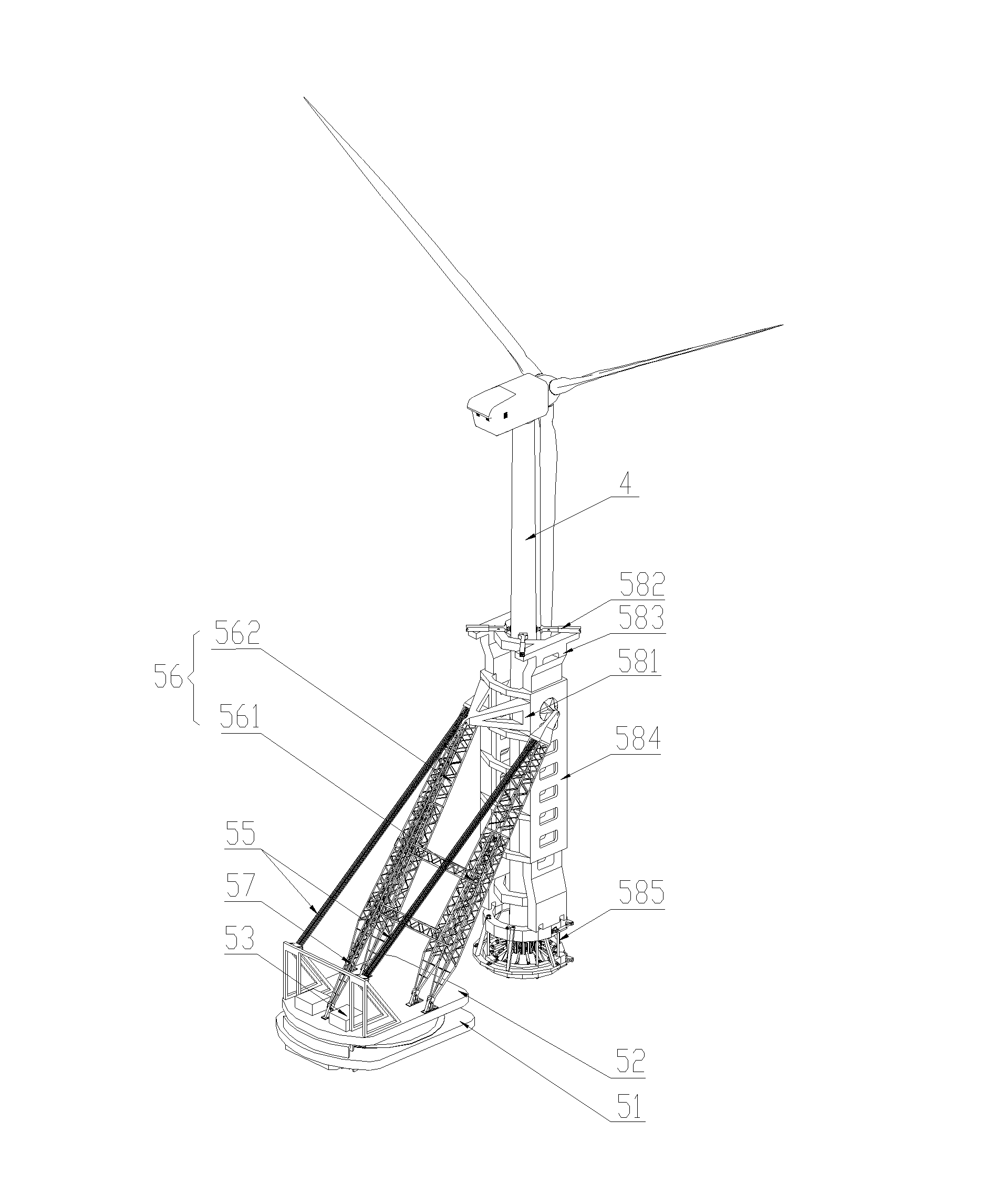

Offshore wind turbine installation platform and hoisting device thereof

InactiveCN102425145AVertical State GuaranteeReduce the difficulty of positioningArtificial islandsUnderwater structuresTurbineWire rope

The invention discloses a hoisting device of an offshore wind turbine installation platform, comprising a hoisting boom and a derricking wire rope, wherein the root of the hoisting boom is hinged with a platform body of the offshore wind turbine installation platform and the tail end of the hoisting boom is connected with the derricking wire rope fixedly. The hoisting device further comprises a guide frame, wherein a wind turbine holding mechanism is arranged at the tail end of the guide frame and the tail end of the hoisting boom is hinged with the guide frame; a balance arm in parallel with the hoisting boom is arranged at one side of the guide frame, which is far away from the hoisting boom, and the hoisting boom is equal to the balance arm in length; a transverse beam in parallel with the platform body is arranged on the guide frame fixedly, the root of the balance arm is hinged to the platform body and the tail end of the balance arm is hinged to the transverse beam. According to the invention, a wind turbine can be always kept in an upright state without other auxiliary ship drawing, so positioning difficulty of the wind turbine is reduced and even big sea stormy waves cannot affect the installation of the wind turbine much, thus an offshore environment affects the construction less. The invention also discloses the offshore wind turbine installation platform provided with the hoisting device.

Owner:SANY ELECTRIC CO LTD

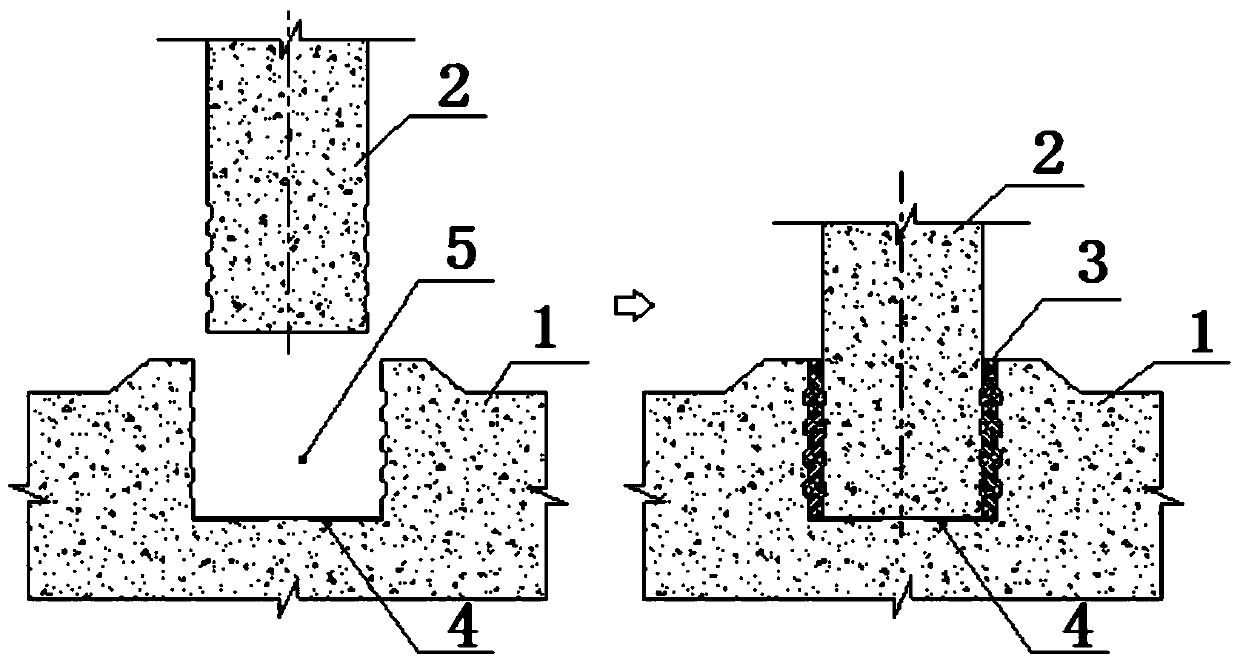

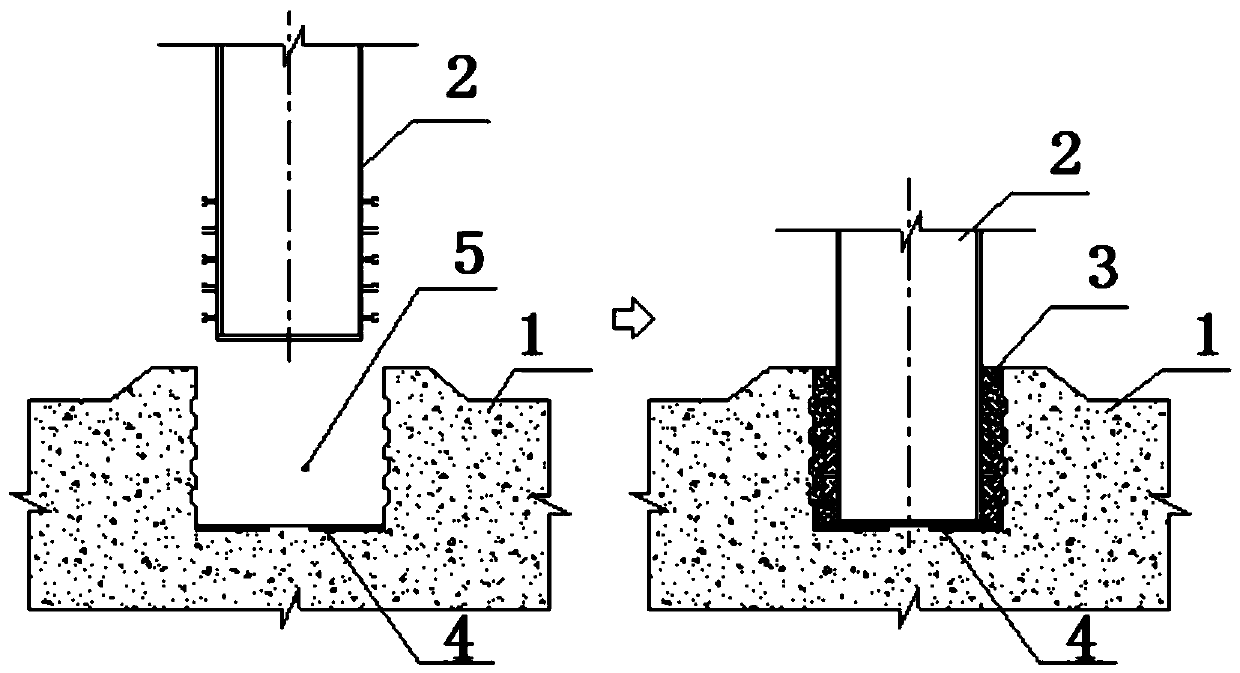

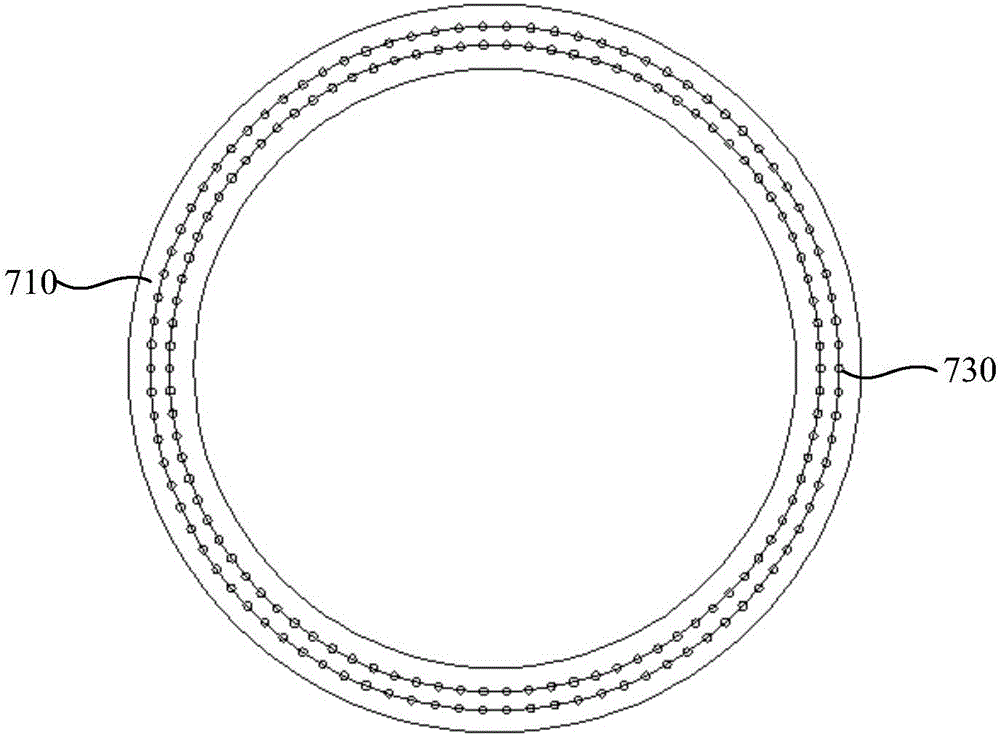

Socket-and-spigot joint structure of prefabricated pier column and bearing platform and construction method

PendingCN111501526AHigh embedding efficiencyEffective anchoringBridge structural detailsBridge erection/assemblyEarthquake resistanceArchitectural engineering

The invention discloses a socket-and-spigot joint structure of a prefabricated pier column and a bearing platform adopting high-strength steel fiber reinforced concrete caulking and a construction method. The invention is characterized in that a socket groove is reserved in the position, corresponding to a pier column, of the top of the bearing platform, a prefabricated pier column is hoisted andinserted into a socket groove, high-strength steel fiber reinforced concrete caulking is poured into a gap between the periphery of the pier column and the wall of the socket groove, and firm connection is achieved. The connecting structure of the pier column and the bearing platform is simple, high in embedding and fixing efficiency, convenient to install and operate, relatively low in prefabricating and embedding precision control requirement, high in construction efficiency and safe and reliable in stress, and meanwhile the anti-seismic property of the connecting structure is similar to that of a cast-in-place structure.

Owner:SHANGHAI MUNICIPAL ENG DESIGN INST GRP

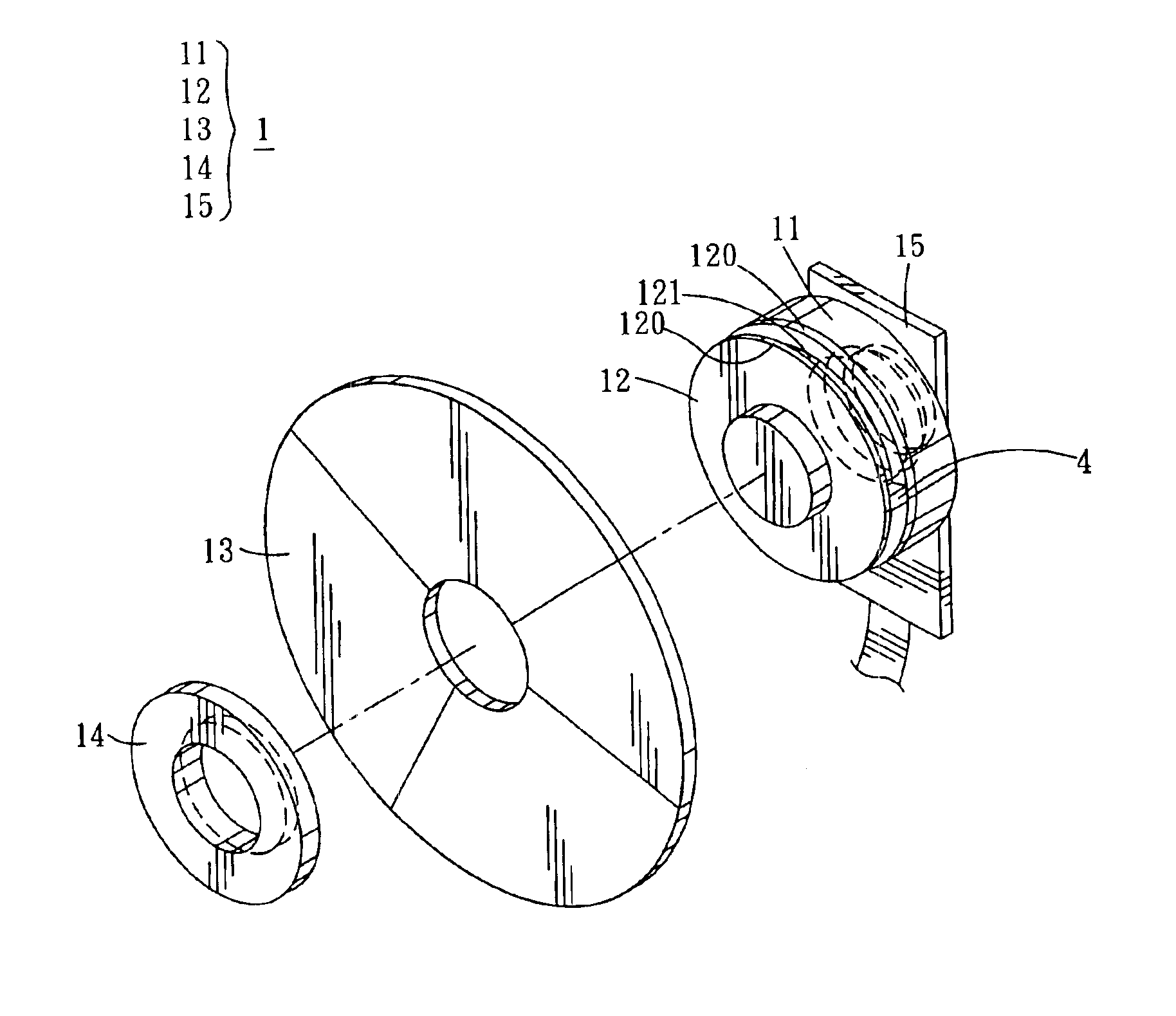

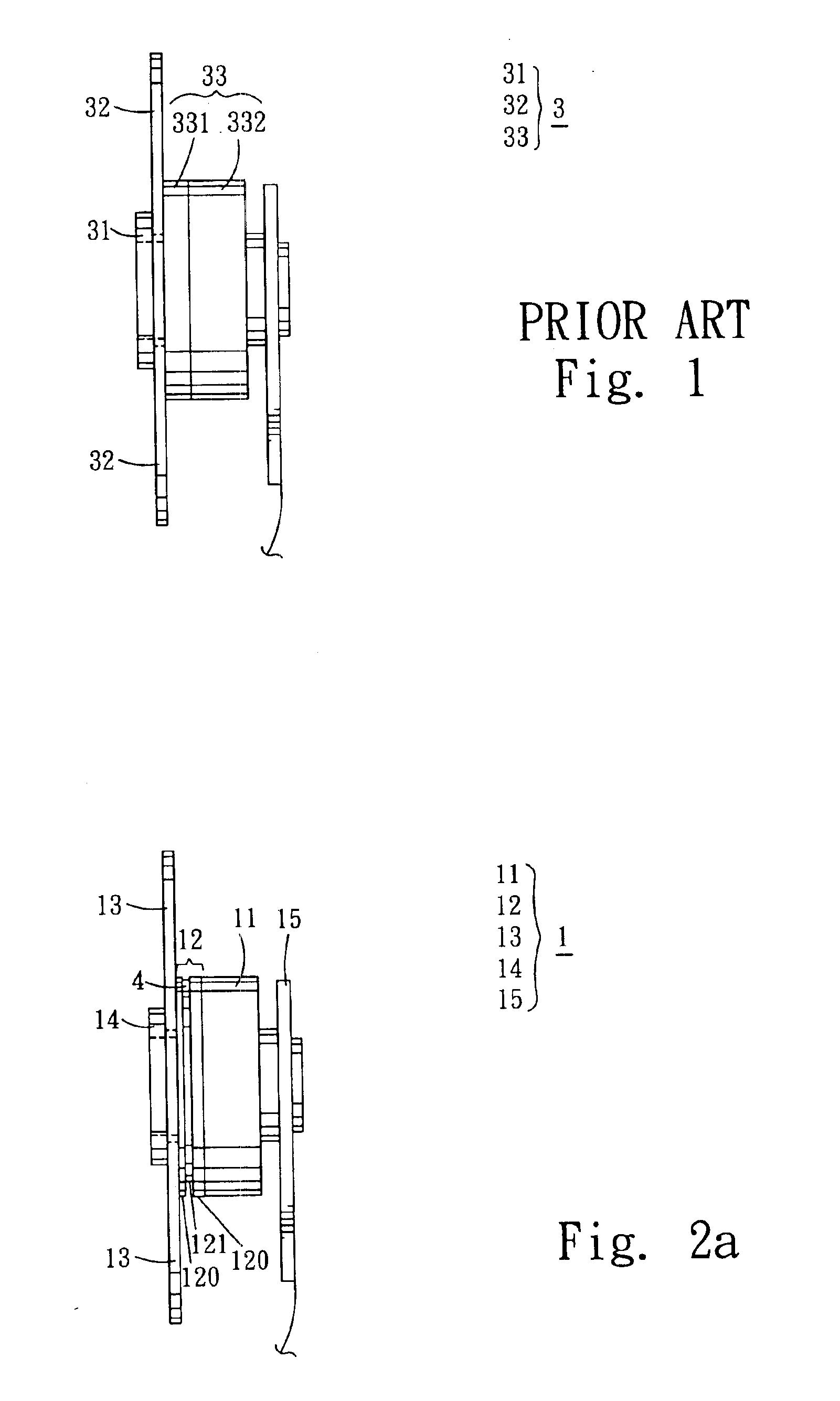

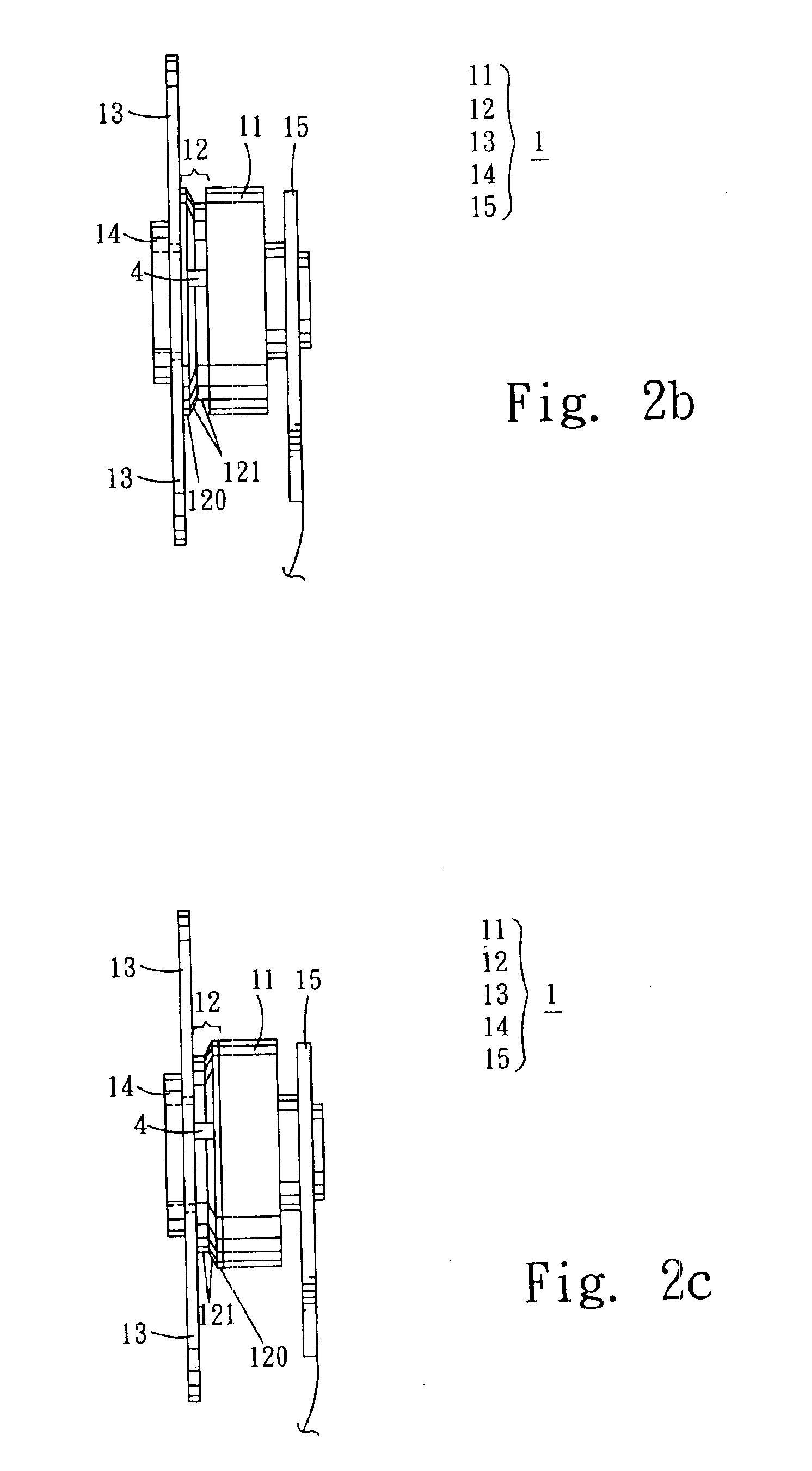

Color wheel and motor for the same

InactiveUS6896376B2Reduce the difficulty of positioningReduce centrifugal forceProjectorsColor photographyControl theoryColor wheel

A color wheel including a motor body, a housing and a color filter. The housing is set to a side of the central axis of the motor body. The color filter is set on the housing. In this case, a circumferential housing surface is formed with a recess. In addition, the invention also provides a motor for a color wheel. The motor includes a motor body and a housing, both of which have the same features as those described above.

Owner:PRODISC TECH INC

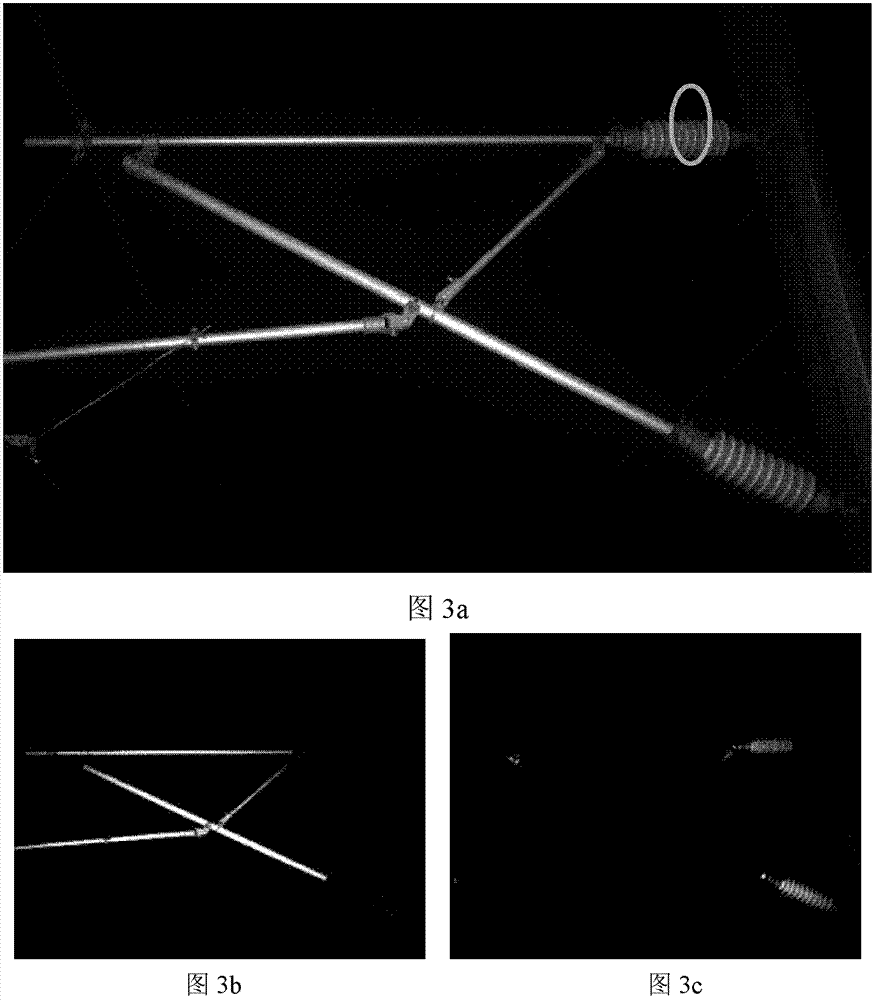

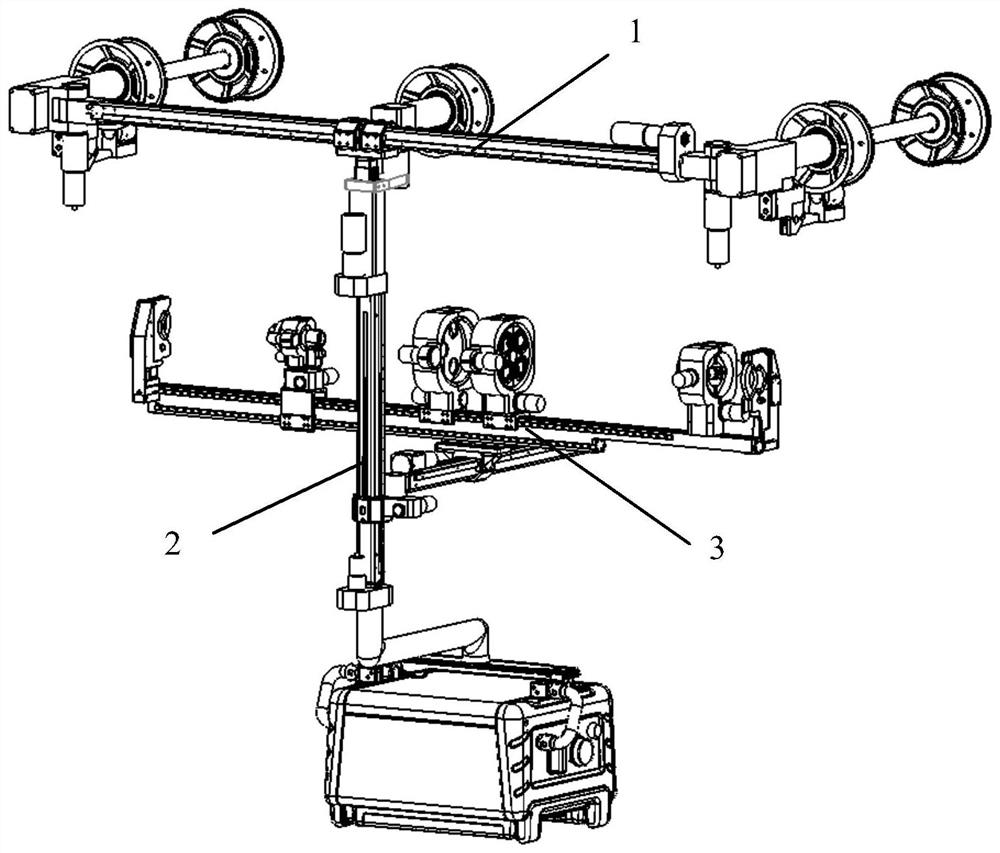

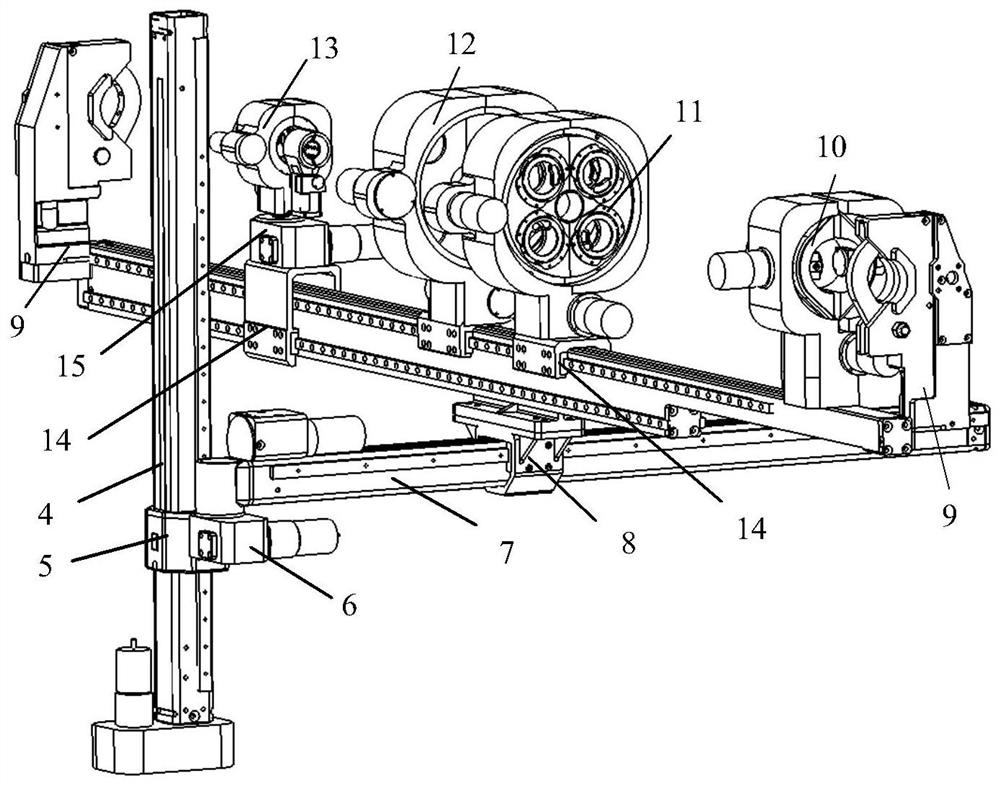

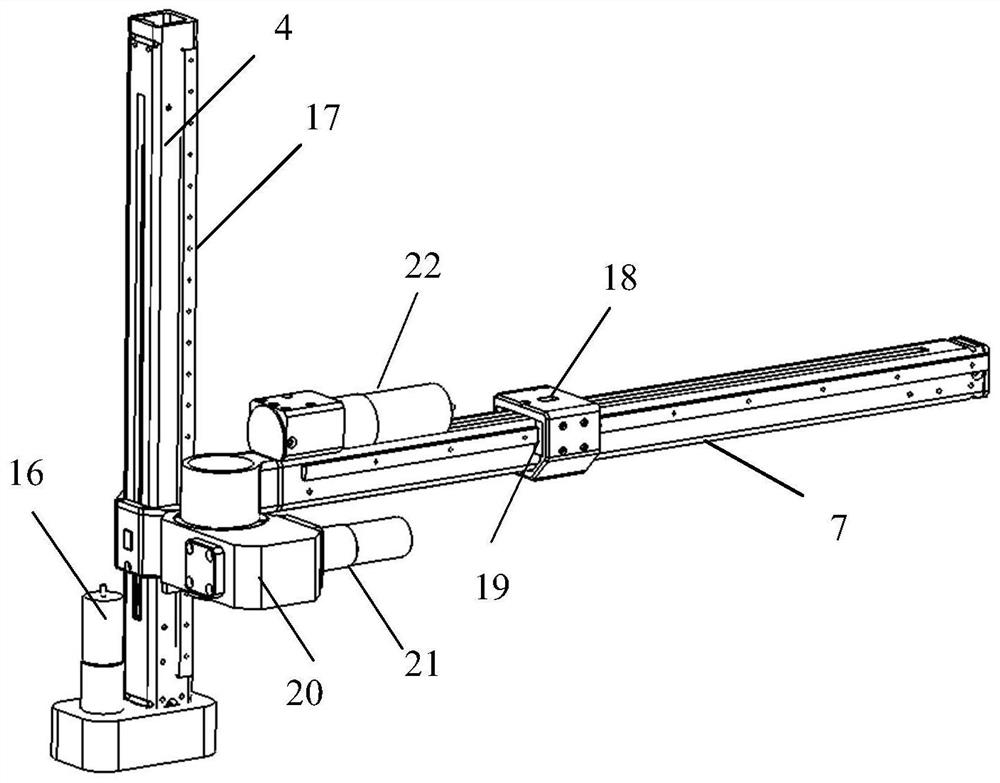

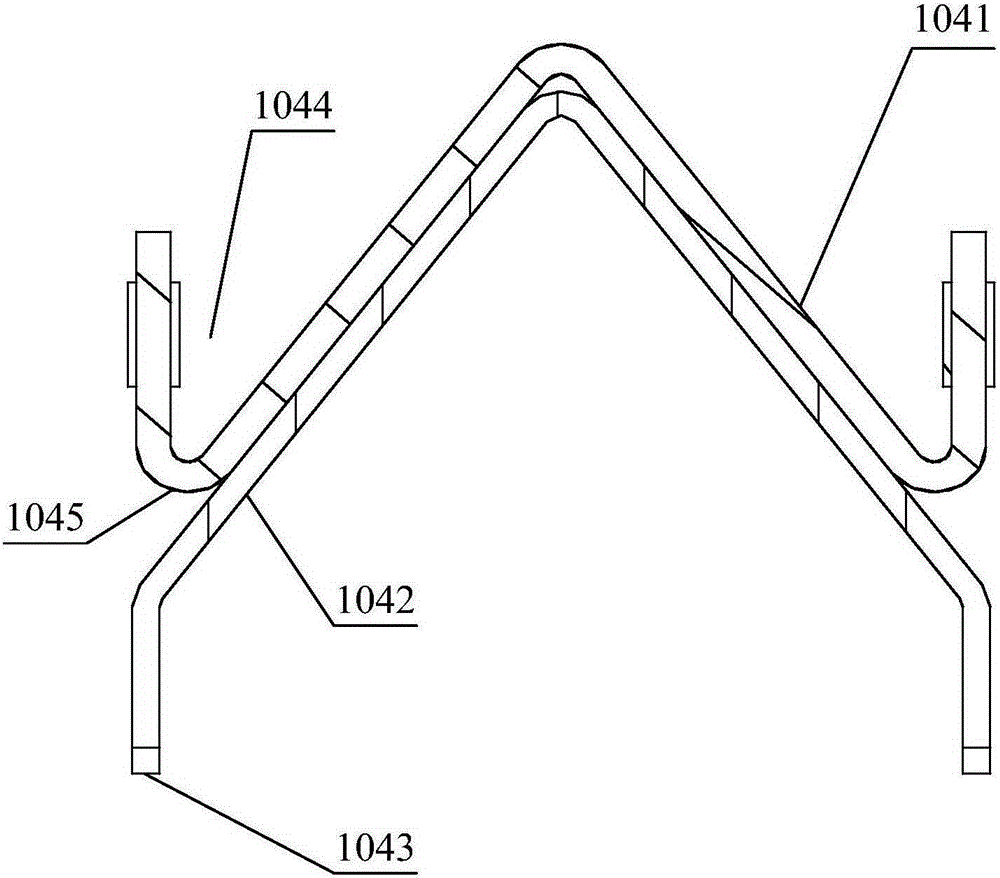

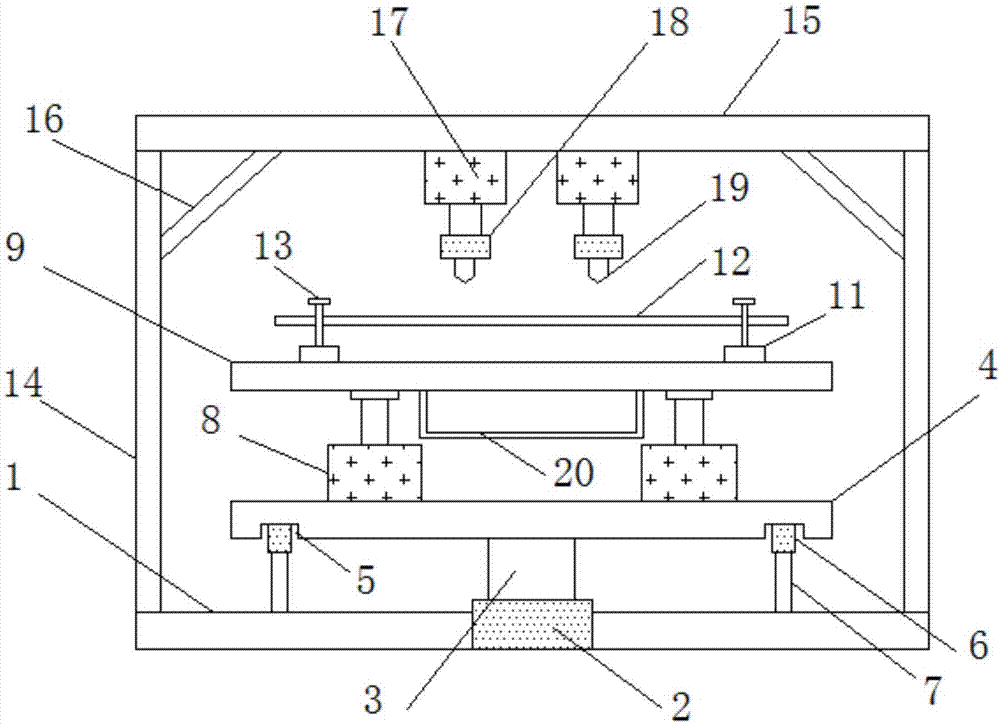

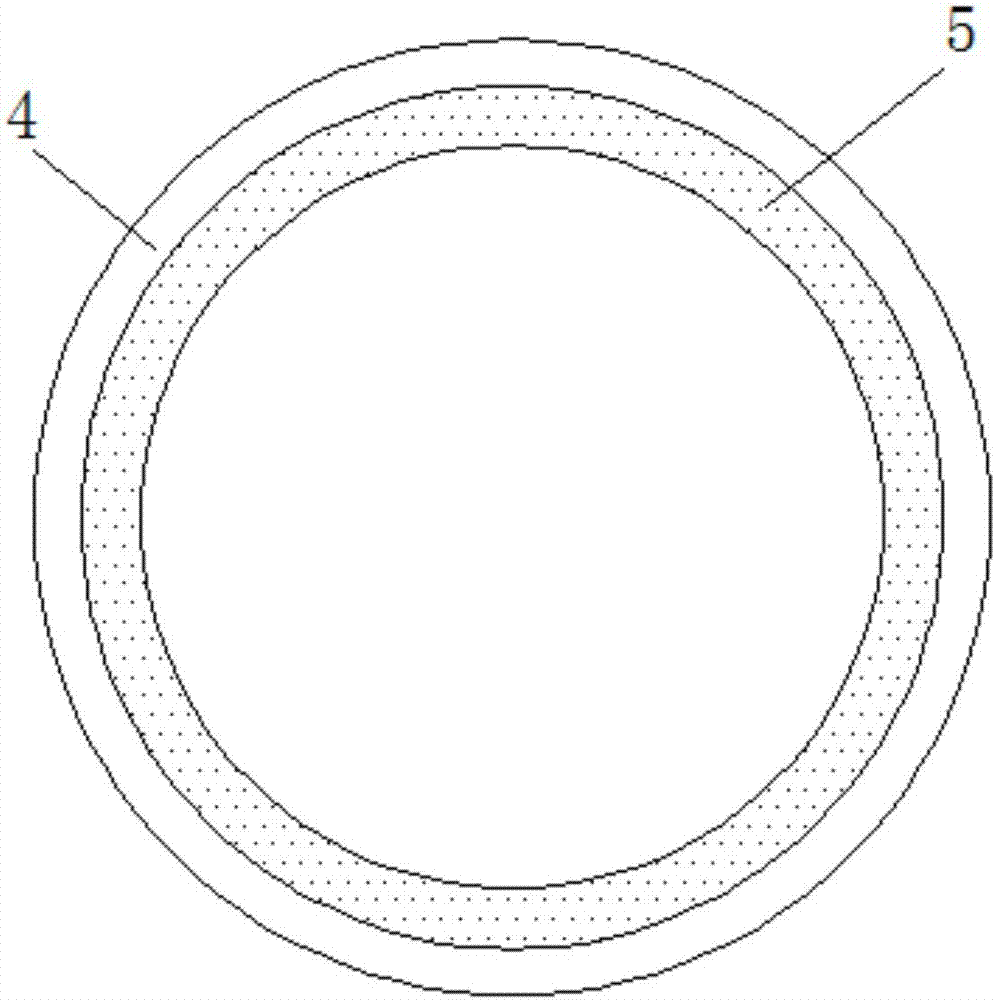

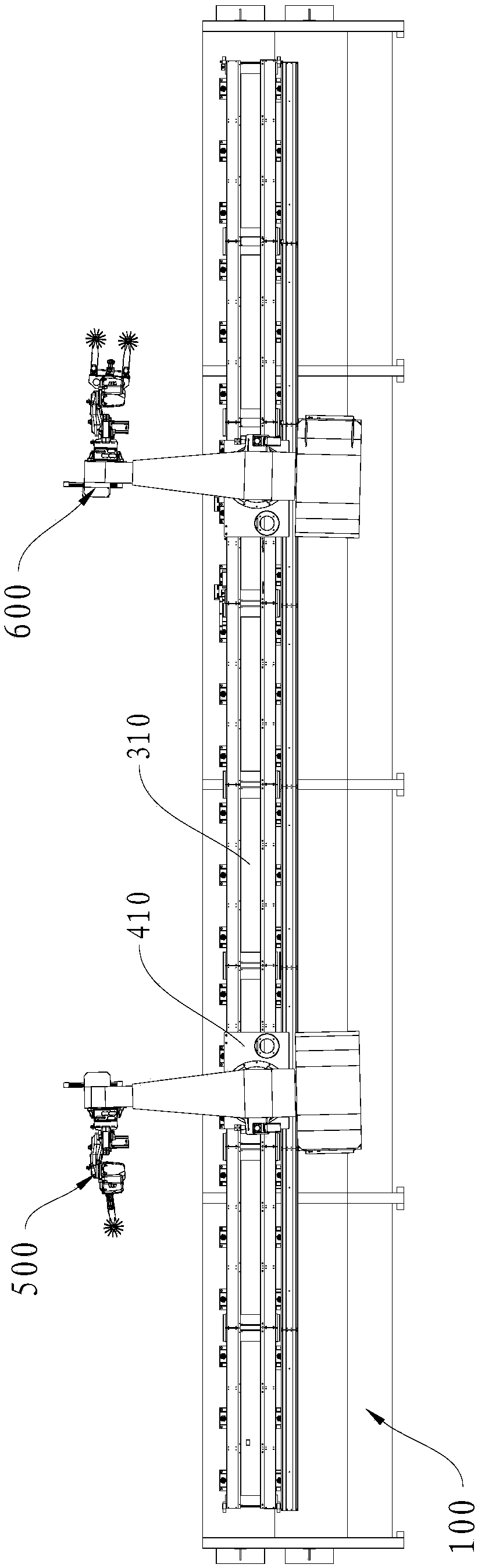

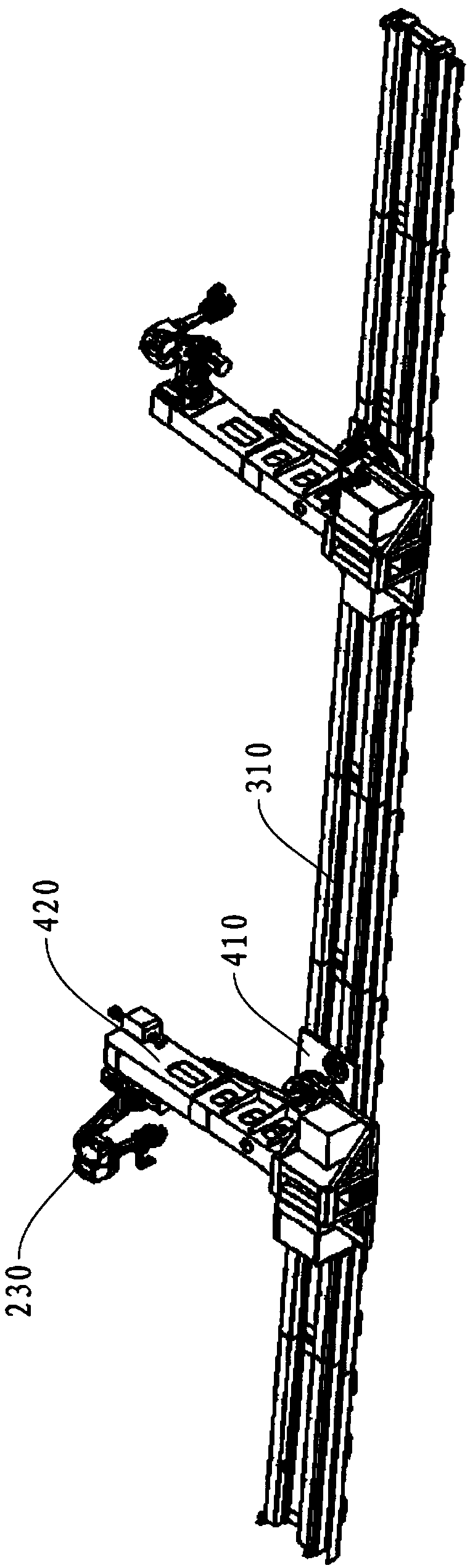

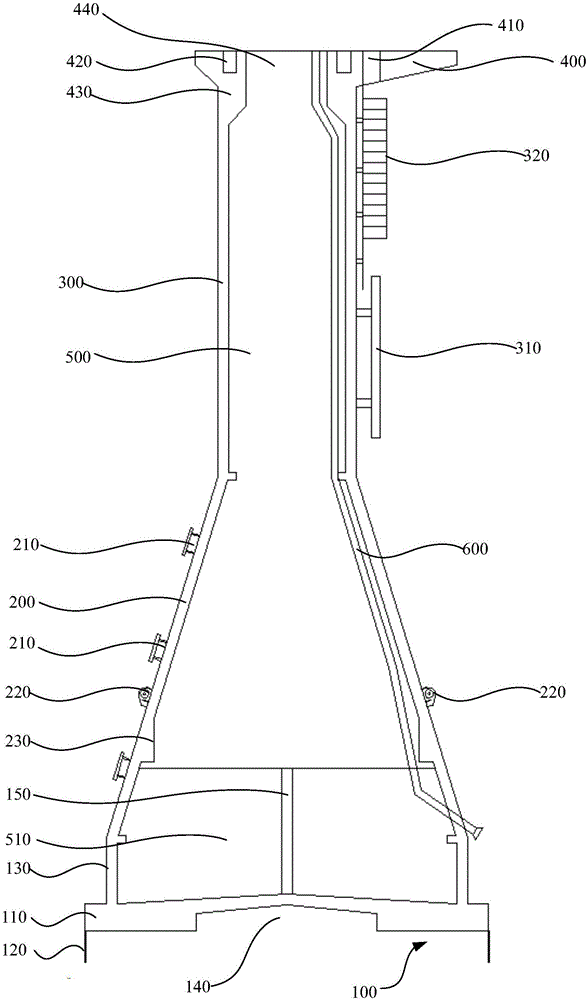

Live-line work robot for repairing broken strand lead by protecting line

ActiveCN113067291AExpand the range of working spaceHigh feasibilityApparatus for joining/termination cablesEngineeringStructural engineering

The invention discloses a live-line work robot for repairing a broken strand lead by a protecting line, and the robot comprises a walking carrier, an obstacle avoidance mechanism and a broken strand repairing working device; the obstacle avoidance mechanism comprises a vertical arm and a transverse arm I; the vertical arm is provided with an up-down longitudinal moving mechanism, the transverse arm I is connected with the up-down longitudinal moving mechanism through a rotary joint, and the upper end of the vertical arm is connected with the walking carrier; the broken strand repairing operation device comprises a left-right translation mechanism, a front-back translation mechanism is arranged on the first cross arm, the left-right translation mechanism is installed on the front-back translation mechanism in a sliding mode through a front-back translation joint and is perpendicular to the transverse arm I, and clamping mechanisms are installed at the two ends of the left-right translation mechanism. A limiting mechanism is fixedly mounted in the middle; a winding mechanism, a guide mechanism and a compounding mechanism are slidably mounted; and the composite mechanism carries out wire stroking, wire wiping, greasing and crimping operations on the wire and the wire pressing strip. According to the invention, full-coverage and integrity repair operation for the multi-split line conductor can be realized, and meanwhile, the surface of the conductor is cleaned, greased and repaired to ensure that the conductor maintains good conductivity.

Owner:WUHAN UNIV

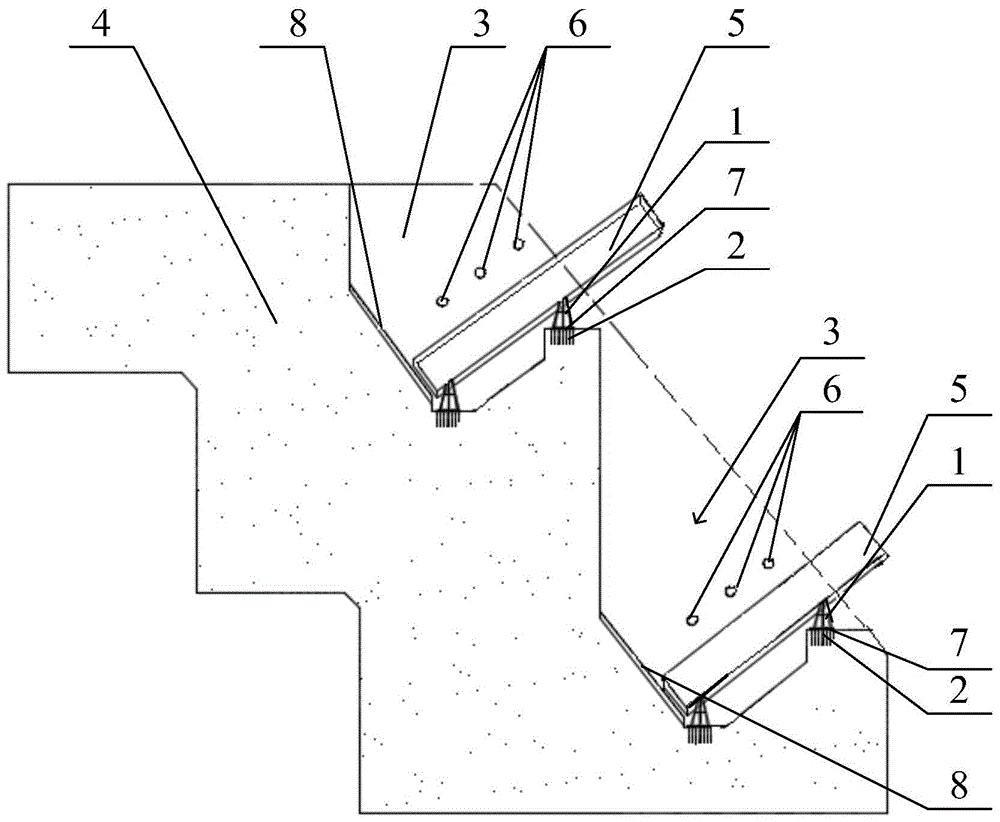

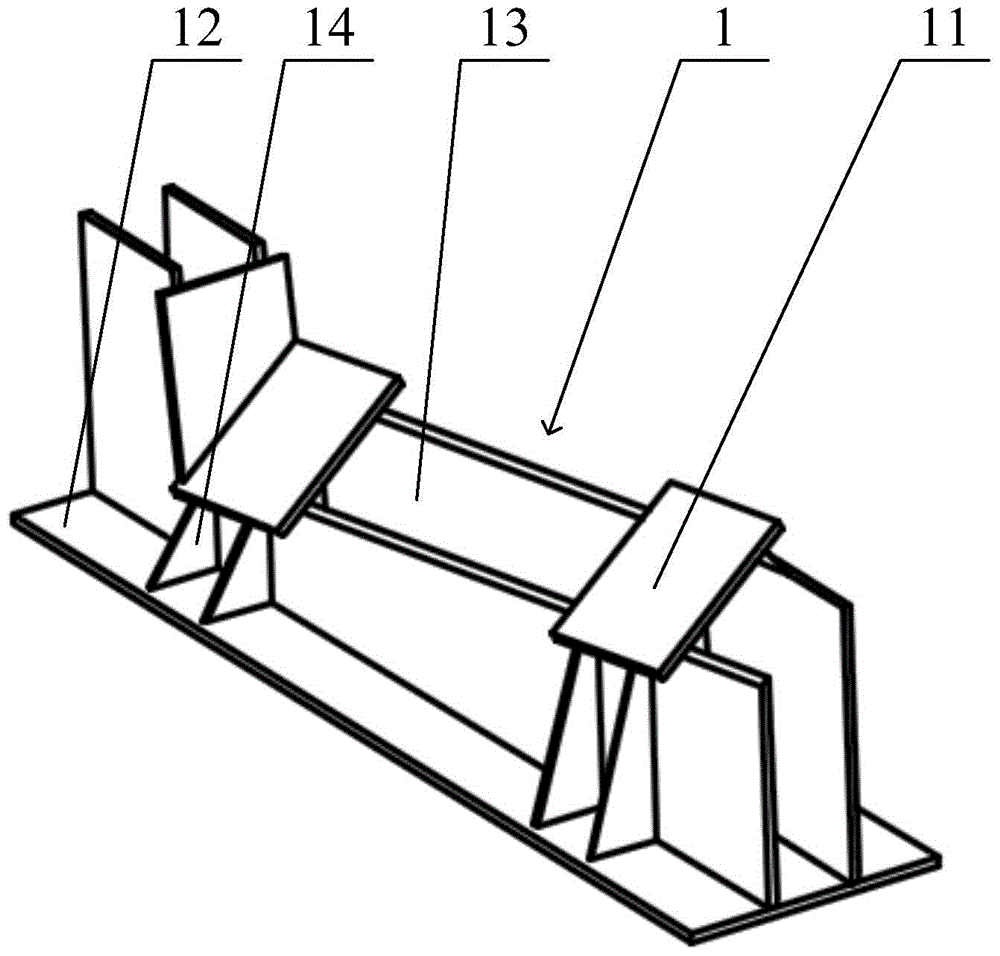

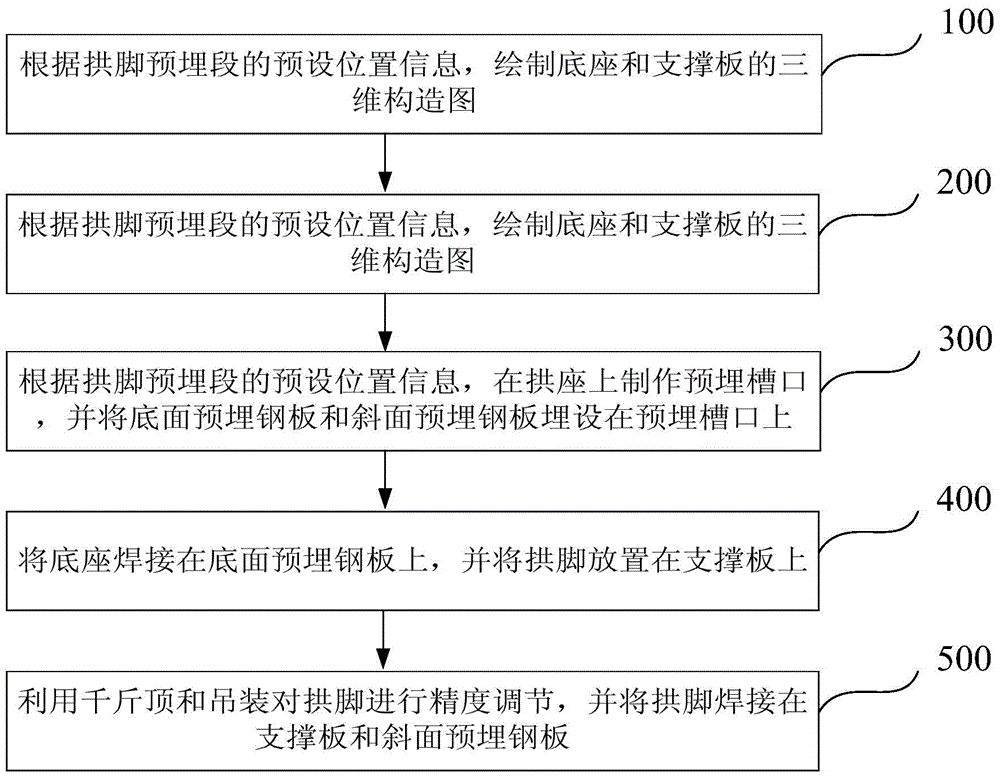

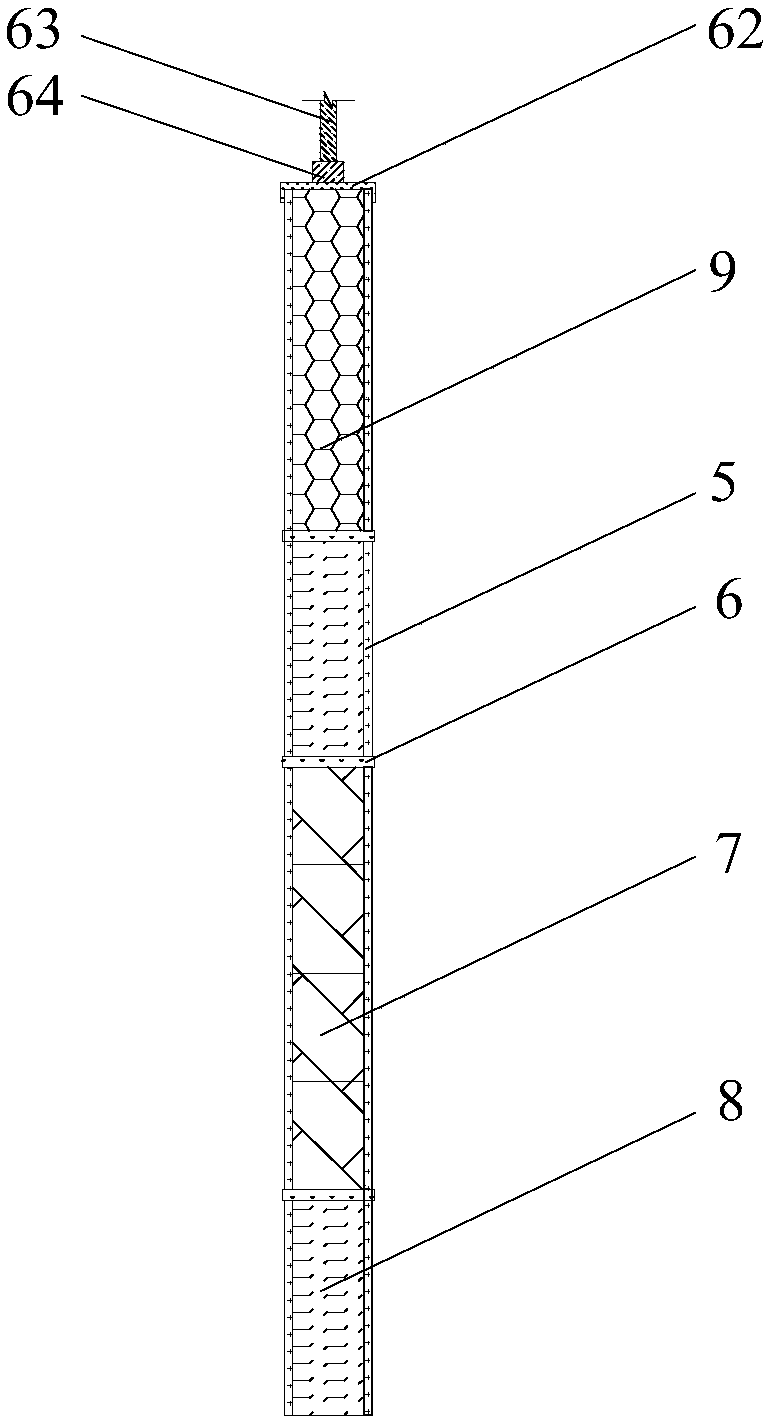

Arch foot positioning device and positioning method of same

ActiveCN106480823AReduce the difficulty of positioningReduce construction difficultyBridge erection/assemblyEngineeringArch supports

The invention relates to the technical field of bridge construction and in particular relates to an arch foot positioning device and a positioning method of same. The arch foot positioning device comprises pedestals and supporting plates, wherein supporting plates are arranged on each pedestal; an included angle between each supporting plate and the horizontal surface is equal to an included angle of a rod member of an arch foot pre-buried section and the horizontal surface; the supporting plates are applied for the arch foot pre-buried section; and the pedestal is fixed on a preserved notch of an arch support. In the arch foot positioning device and the positioning method of the same, the supporting plates are mounted on the pedestal, so an inclined angle of the supporting plates is equal to an inclined angle of a rod member of the arch foot pre-buried section; when the arch foot pre-buried section is installed by a construction worker, the pedestal and the supporting plates are first arranged on the preserved notch, and then the arch foot pre-buried section is placed on the supporting plates and positioned; positioning difficulty and construction difficulty can be lowered; and construction cost can be reduced.

Owner:CHINA RAILWAY NO 2 ENG GRP CO LTD +1

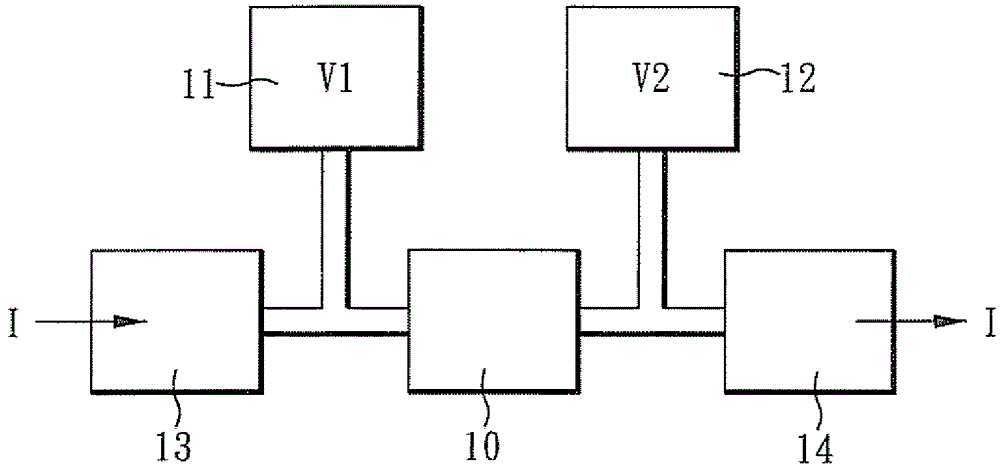

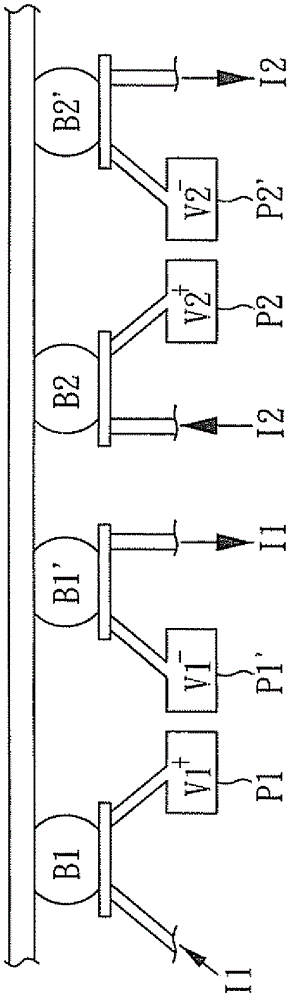

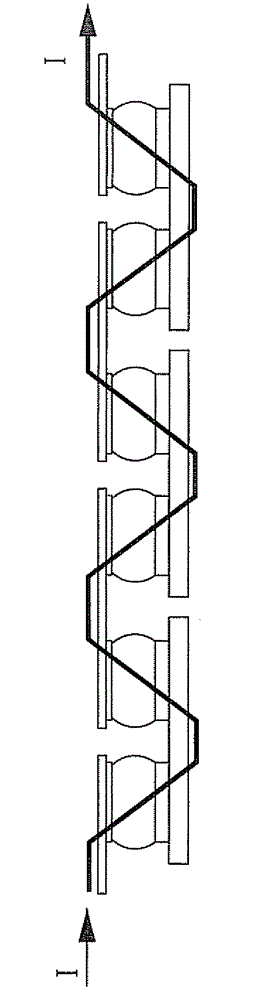

Structure for measuring bump resistance and package substrate comprising the same

ActiveCN102749518AReduce usageLow costSemiconductor/solid-state device testing/measurementResistance/reactance/impedenceEngineeringVoltage

A structure for measuring bump resistance and a package substrate comprising the same are disclosed, the structure for measuring bump resistance of the present invention comprises: plural connecting bumps arranged in a row,at least one first connecting element,and at least one second connecting element,wherein the nth connecting bump and the (n+1)th connecting bump connect by the first connecting element, the (n+1)th connecting bump and the (n+2)th connecting bump connect by the second connecting element, n is an odd number of 1 or more,the first connecting element connects with a first voltage-measurement pad,the second connecting element connects with an auxiliary pad, the auxiliary pad connects with an auxiliary bump, a second voltage-measurement pad connects with the auxiliary bump.

Owner:SPRING FOUND OF NCTU

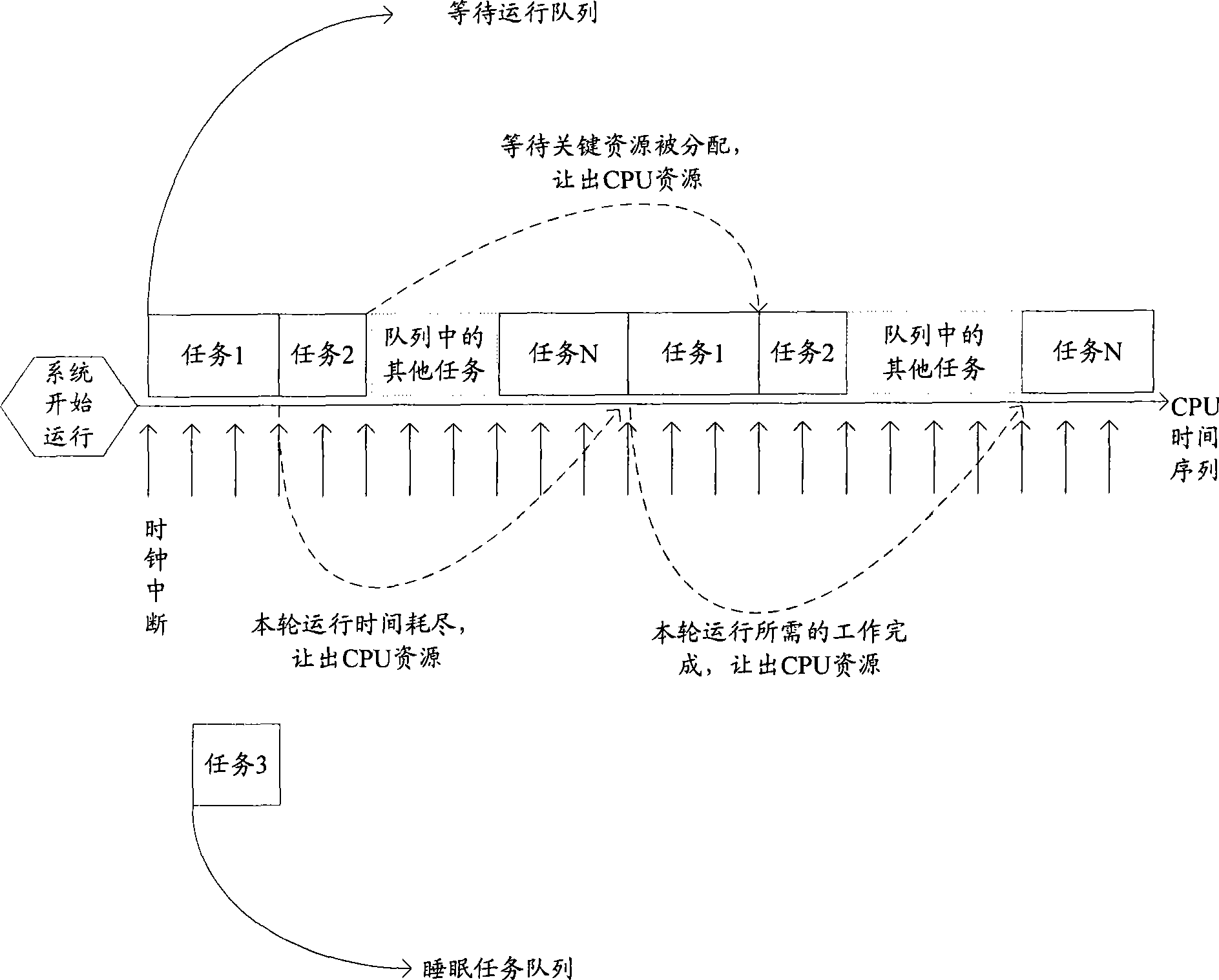

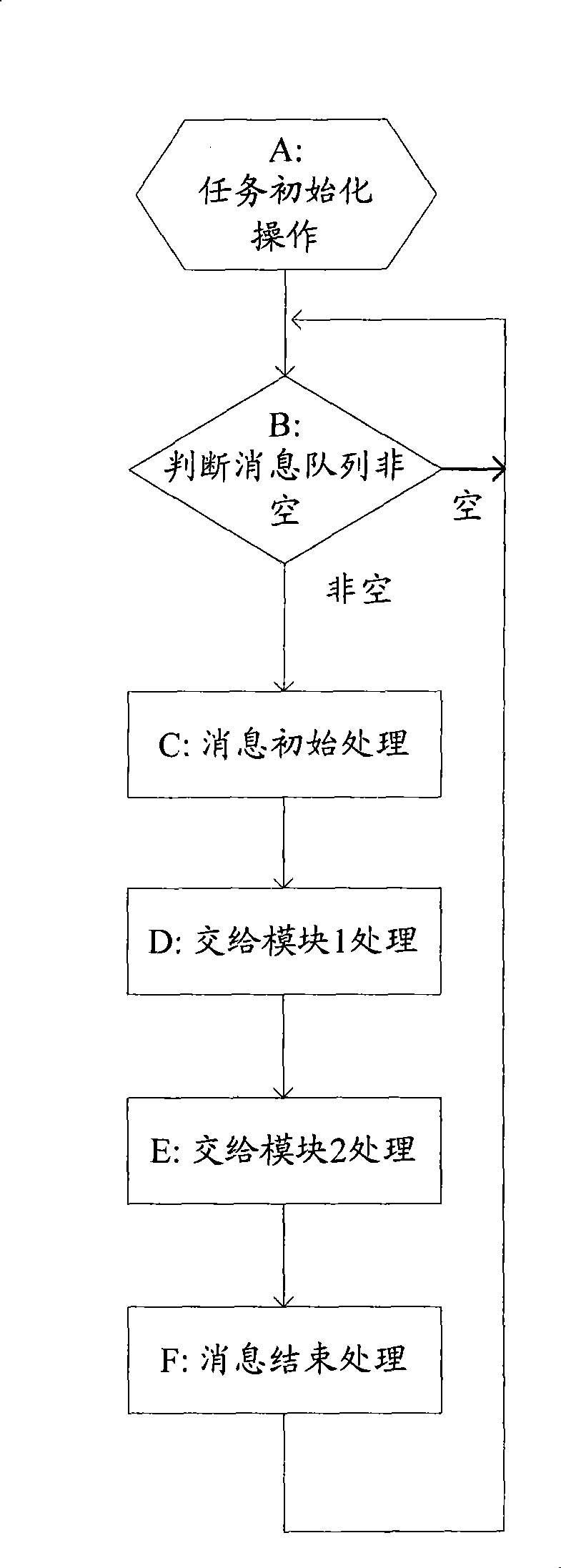

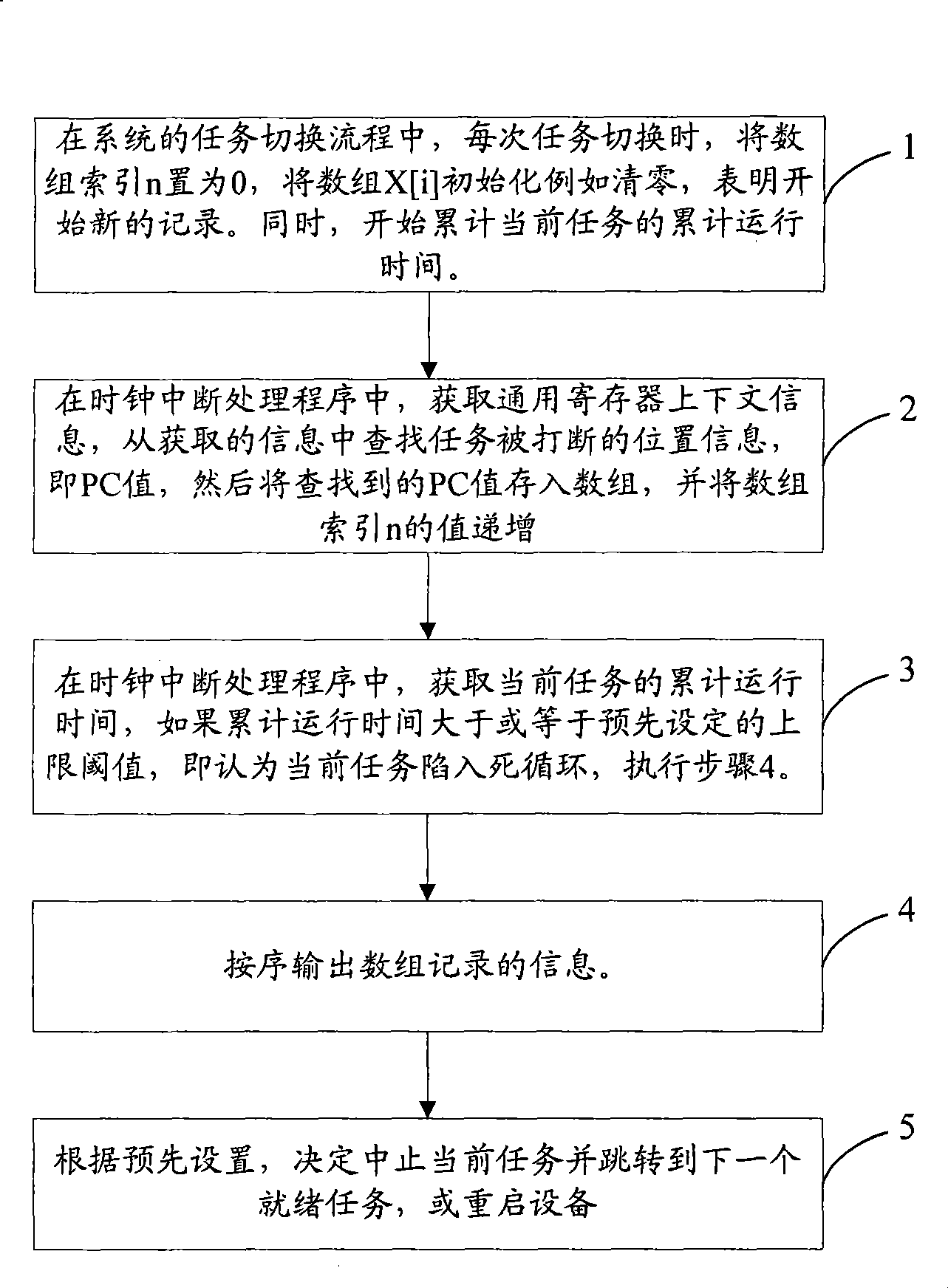

Method and apparatus for providing positioning information for task endless loop

InactiveCN101504615AReduce the difficulty of positioningMultiprogramming arrangementsEmbedded systemInfinite loop

The invention discloses a method and a device for supplying positioning information to infinite loops of tasks. In the method, register context information when a task is interrupted is continuously recorded in a clock interrupt processing program, and when a current task is detected to have an infinite loop, the register context information which is recorded before the occurrence of the infinite loop when the current task is interrupted each time is outputted as the positioning information. The method can supply abundant positioning information so as to reduce positioning difficulty.

Owner:NEW H3C TECH CO LTD

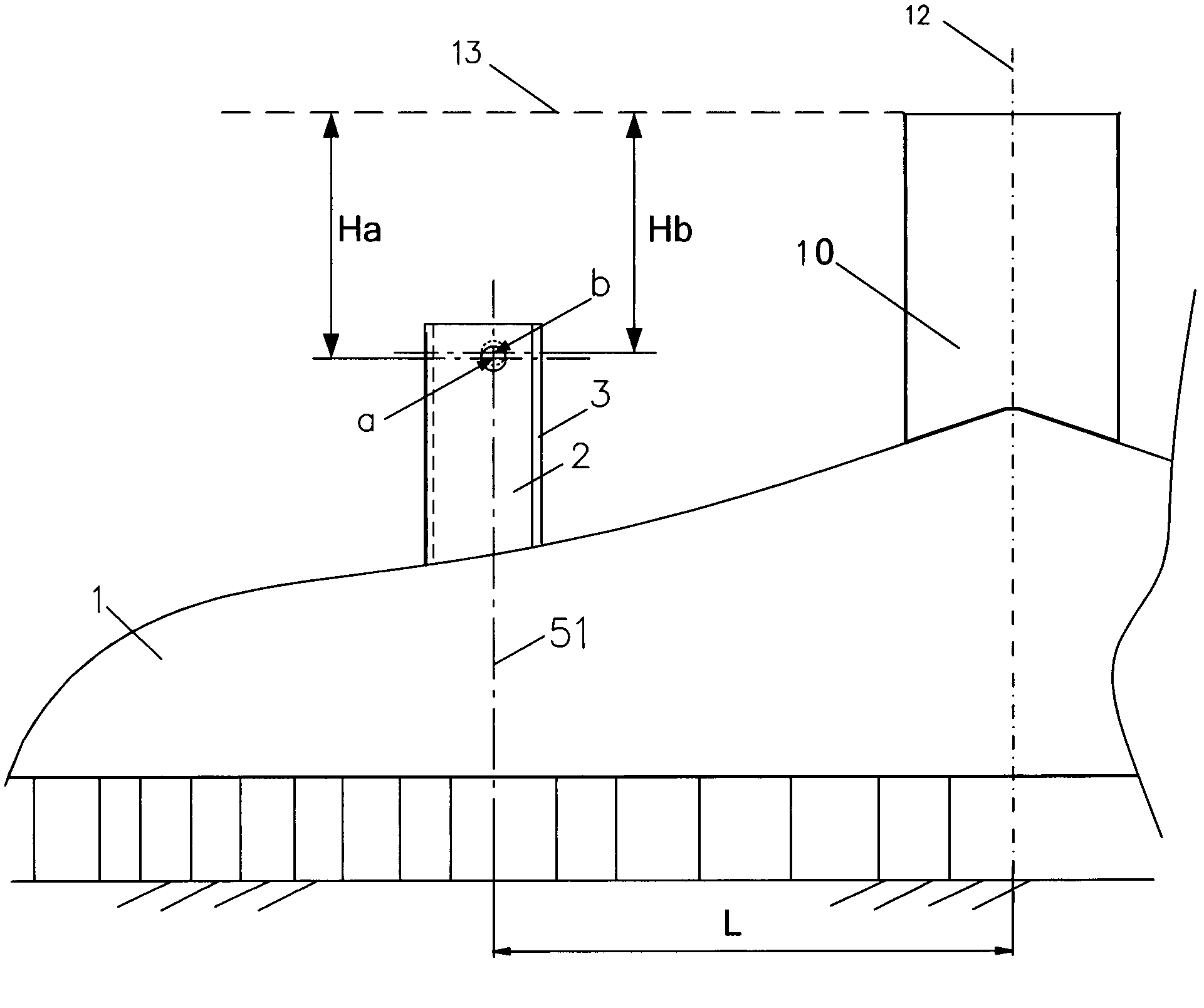

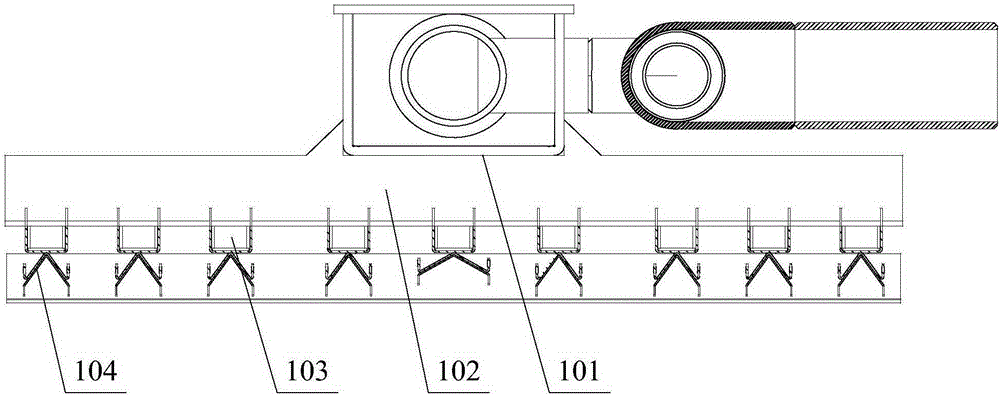

Method for locating tail pipe supporting seat in subsection

ActiveCN103072667AReduce the difficulty of positioningShorten docking periodVessel partsPipe supportEngineering

The invention discloses a method for locating a tail pipe supporting seat in a subsection. The method is characterized by comprising the following steps of firstly determining the distance between an axis where the tail pipe supporting seat is located and a center line of the subsection in a horizontal direction; then determining a reference surface and the vertical distance from a bow end center and a stern end center which are positioned on the axis where the tail pipe supporting seat is located to the reference surface; forming an installation axis of the tail pipe supporting set by connecting the bow end center and the stern end center by a rope; carrying out fine tuning on the position of the tail pipe supporting seat, and enabling a central axis of the tail pipe supporting seat to be coincided with the installation axis; and connecting the tail pipe supporting seat with a beauty stand. According to the method disclosed by the invention, the central axis which is invisible is concretized, the rigidity of the installation axis is ensured, the tail pipe supporting seat is installed before the subsection is closed, the location operation of the tail pipe supporting seat is changed into a subsection manufacturing section from a dock, the difficulty of carrying out the location of the tail pipe supporting seat in the dock is reduced, and the dockage period is shortened; and a subsection jig frame is relatively fixed with the subsection, thus the central axis of the subsection cannot offset, the precision and the accuracy of installation are ensured, and the welding difficulty is reduced.

Owner:SHANGHAI SHIPYARD

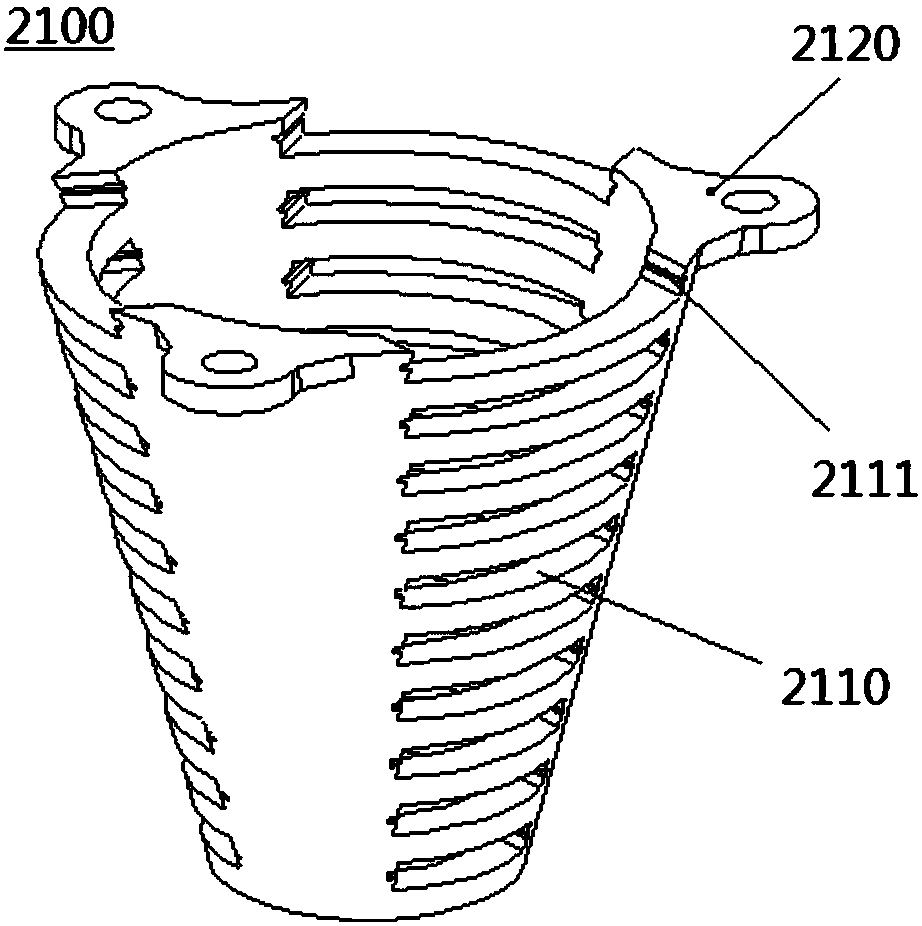

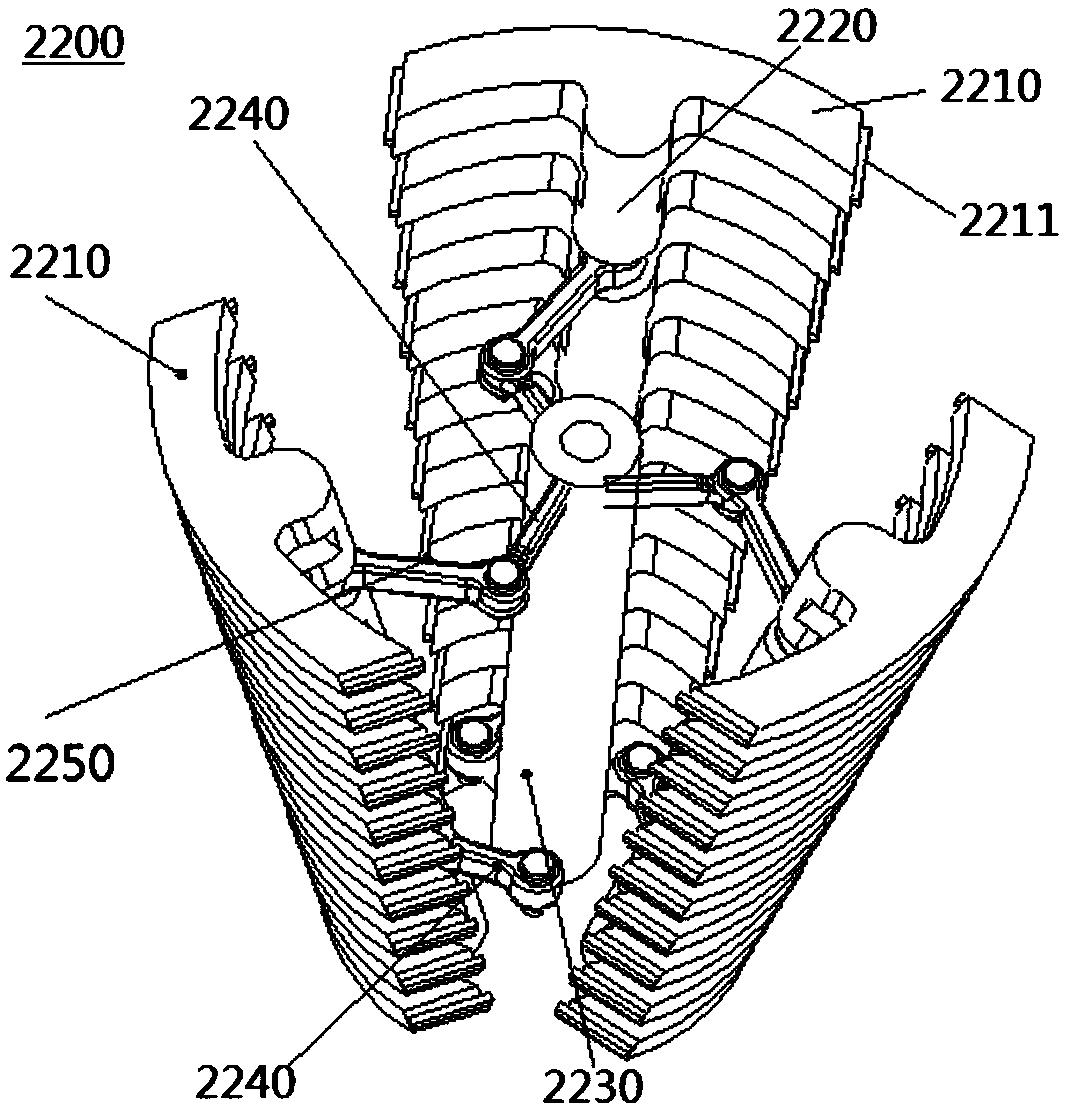

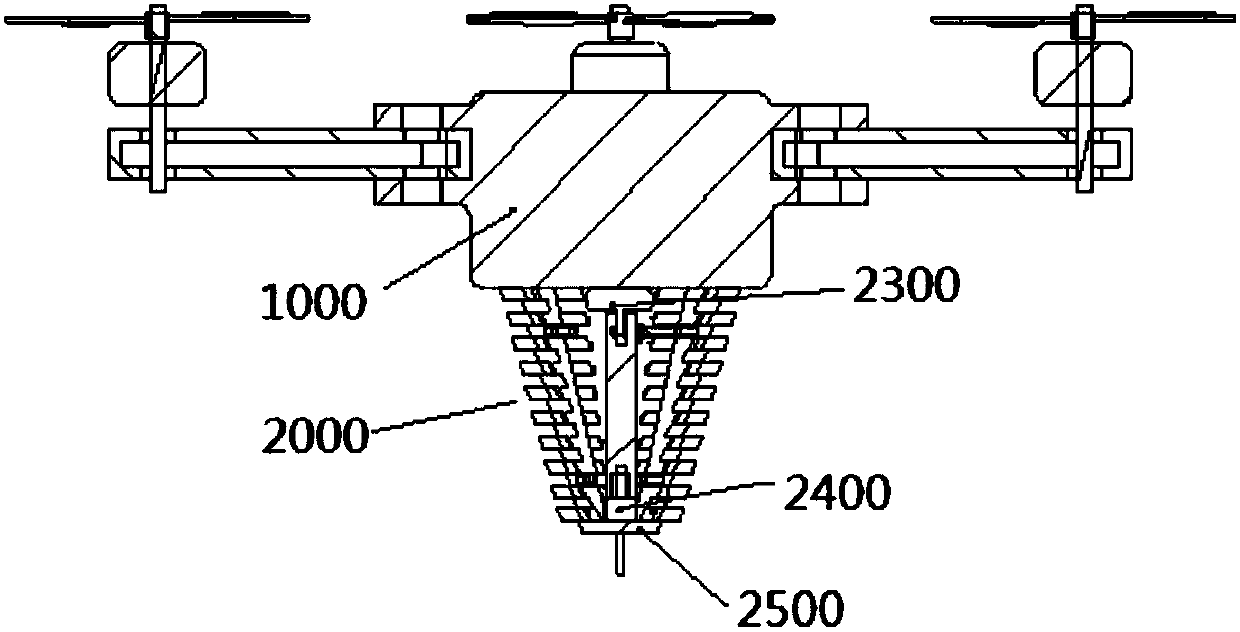

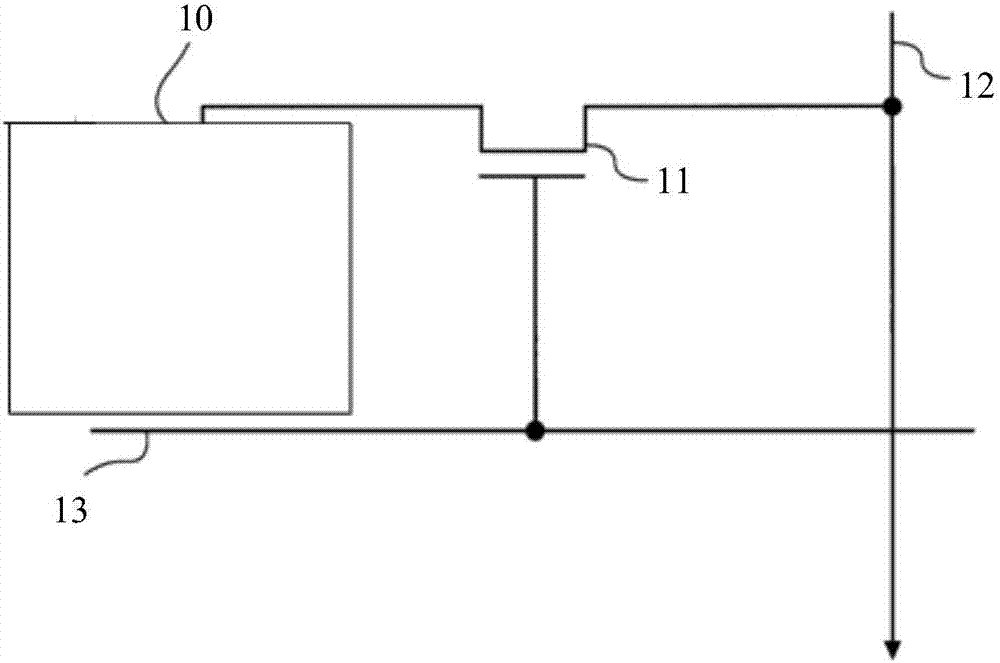

Unmanned aerial vehicle take-off and landing platform

Owner:BYD CO LTD

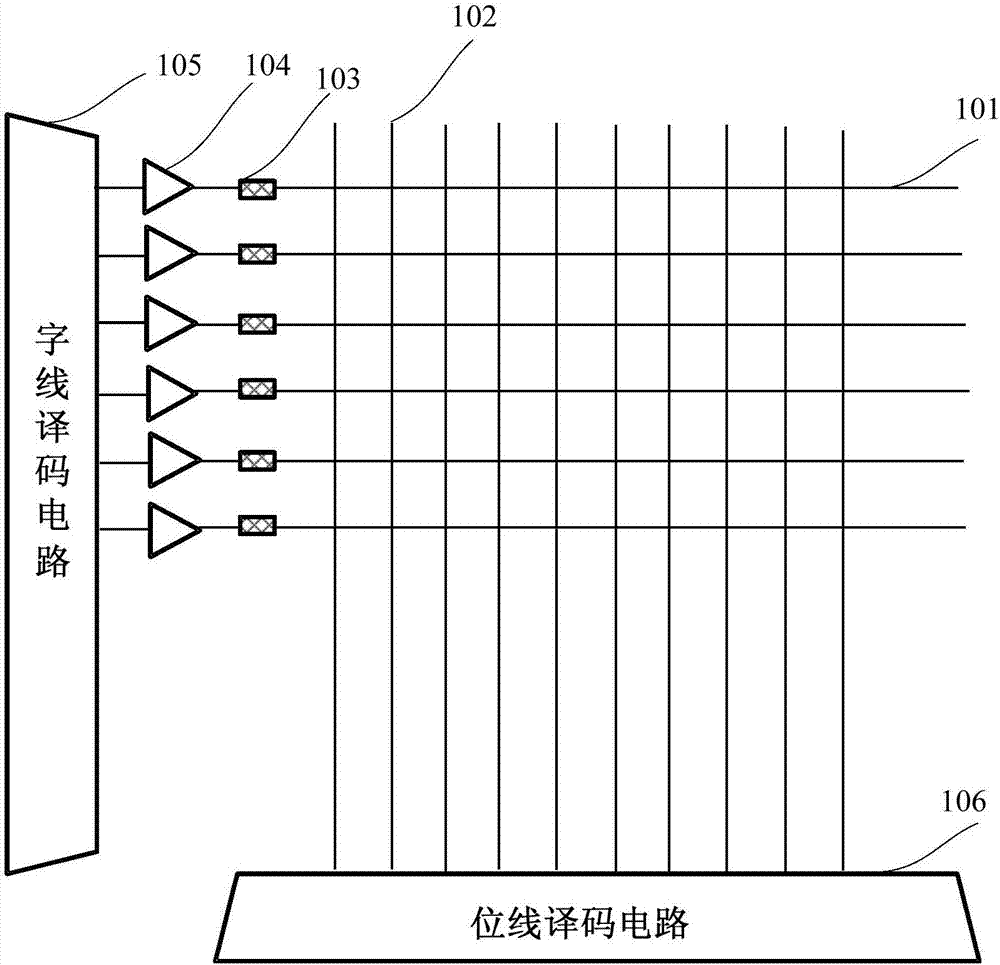

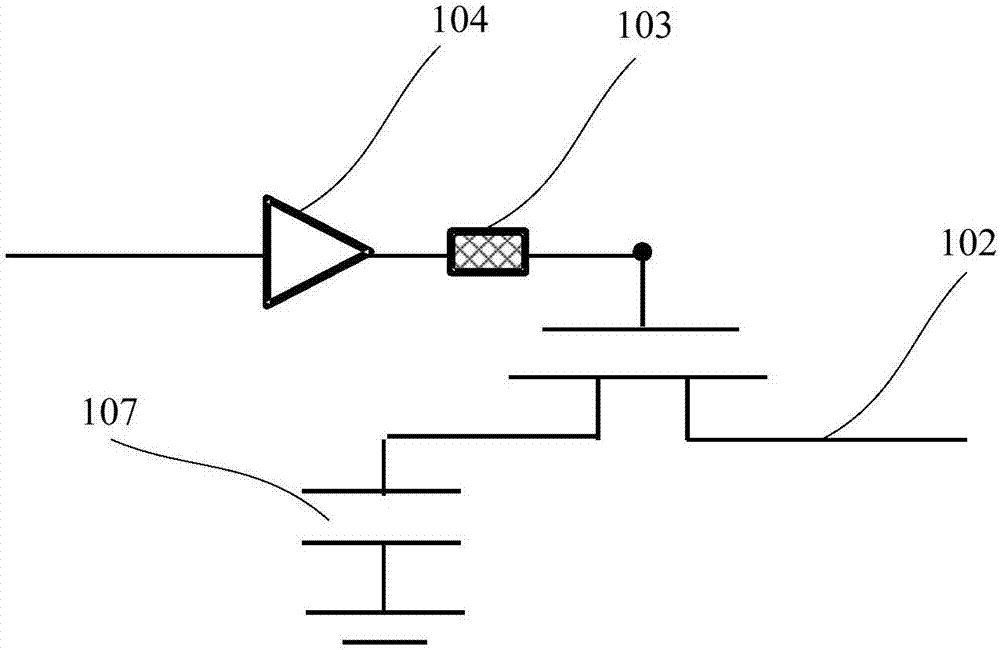

Semiconductor memory device structure and manufacturing method thereof

PendingCN107994018AEnlarge the crafting windowAvoid short circuitTransistorElectricityLine structure

The invention provides a semiconductor memory device structure and a manufacturing method thereof. The memory device structure comprises a semiconductor substrate, word line structures and contact structures, wherein the semiconductor substrate comprises an active area and a groove isolation structure, the word line structures are formed in the semiconductor substrate and crossed with the active area, a long end tail part is arranged at one end of any word line structure, a short end tail part is arranged at the other end of the word line structure, the long end tail parts and the short end tail parts of adjacent two word line structures are arranged in a staggering manner, and the contact structures are formed at the long end tail parts of the word line structures so that electric lead-out of the word line structure can be realized. According to the semiconductor memory device structure and the manufacturing method thereof, mask design is performed to word line grooves, the word linestructures with the tail parts arranged in a long and short staggering manner are prepared, the occupied areas of the whole regions of the contact structures are not required to be increased, the manufacturing windows of the contact structures can be increased, and the short circuit of adjacent word line structures due to the contact structures is avoided. The tail parts of the word line structures are not required to be bent, the technology complexity is reduced, and the locating difficulty of the contact structures is reduced.

Owner:CHANGXIN MEMORY TECH INC

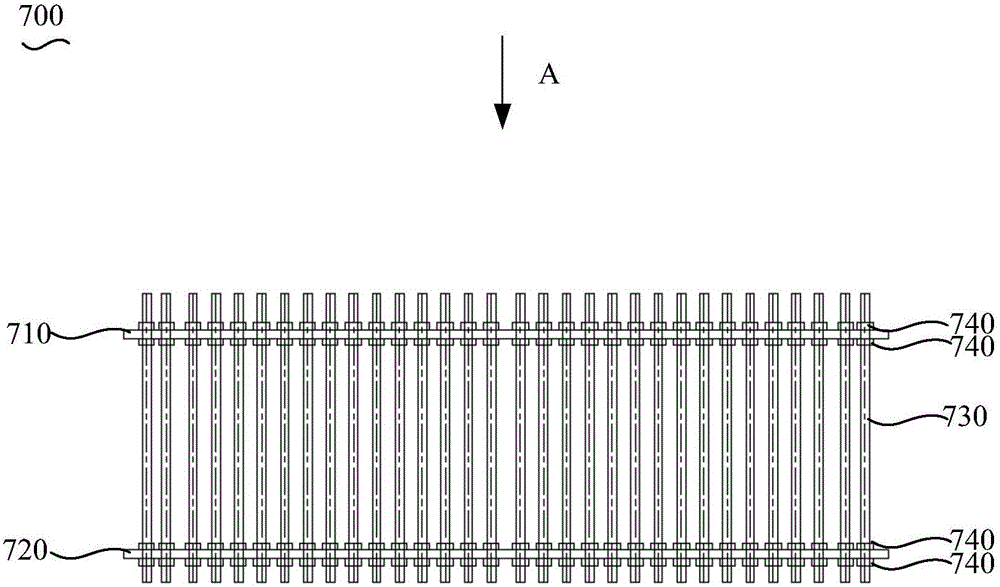

Drop-leaching device and lithium bromide unit

ActiveCN105276852AReduce weightReduce thicknessClimate change adaptationEnergy efficient heating/coolingLithium bromideEngineering

The embodiment of the invention discloses a drop-leaching device. The drop-leaching device comprises a top-layer drop-leaching liquid distribution tank, a bottom-layer drop-leaching liquid distribution tank and at least one middle-layer drop-leaching liquid distribution tank arranged between the top-layer drop-leaching liquid distribution tank and the bottom-layer drop-leaching liquid distribution tank. First positioning lugs are arranged at the top of the middle-layer drop-leaching liquid distribution tank located on the top layer, and positioning space for positioning the top-layer drop-leaching liquid distribution tank is formed between the first positioning lugs on the same middle-layer drop-leaching liquid distribution tank. The top-layer drop-leaching liquid distribution tank and the middle-layer drop-leaching liquid distribution tanks can be conveniently positioned, the positioning difficulty is lowered, and positioning reliability is improved. The positioning lugs have the reinforcing effect, the thickness of a steel plate can be effectively reduced, the weight of the drop-leaching device is reduced, and connecting strength is enhanced. The invention further discloses a lithium bromide unit.

Owner:GREE ELECTRIC APPLIANCES INC

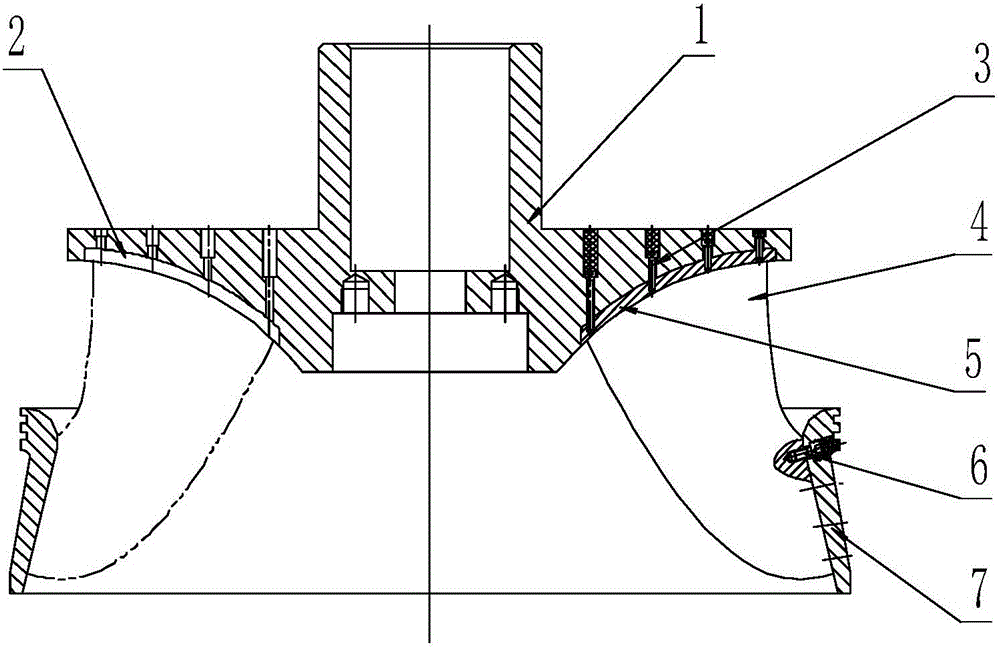

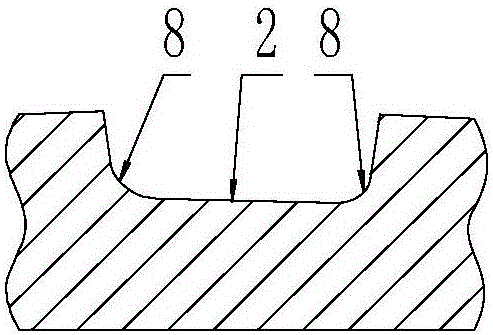

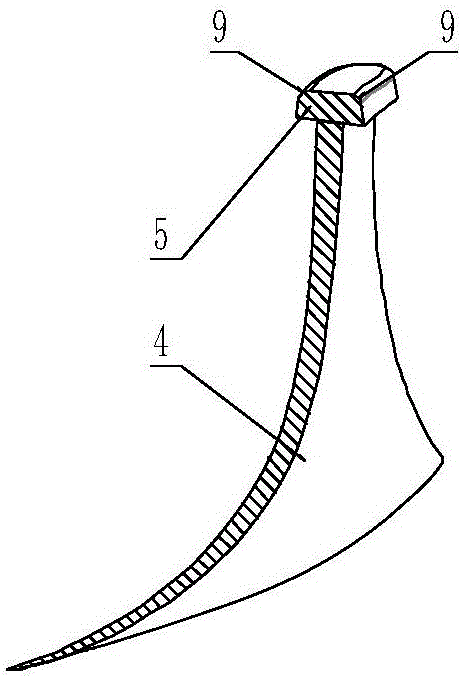

Trapezoid groove mosaic structure for blades and upper canopy of water turbine model runner

InactiveCN105927451AReduce the difficulty of positioningGuaranteed assembly accuracyHydro energy generationReaction enginesWater turbineAerospace engineering

The invention provides a trapezoid groove mosaic structure for blades and an upper canopy of a water turbine model runner. An original rectangular groove assembling type structure adopted in the upper canopy and the blades of the water turbine model runner is changed into the trapezoid groove mosaic structure, the other structures are not changed, the blades and the upper canopy are tightly held and combined through screws, and therefore trapezoid grooves can make tight contact with side faces of trapezoid protruding blocks. The trapezoid groove mosaic structure is simple, convenient to operate, safe and reliable, machining problems are solved, the assembling difficulty is lowered, the problem that matching gaps exist between rectangular protruding blocks of the blades and rectangular grooves of the upper canopy is thoroughly solved, and the phenomenon that because the gaps exist in the flow passing surface of the upper canopy after assembling, the flow passing surface of the upper canopy is not smooth is eliminated.

Owner:HARBIN ELECTRIC MASCH CO LTD

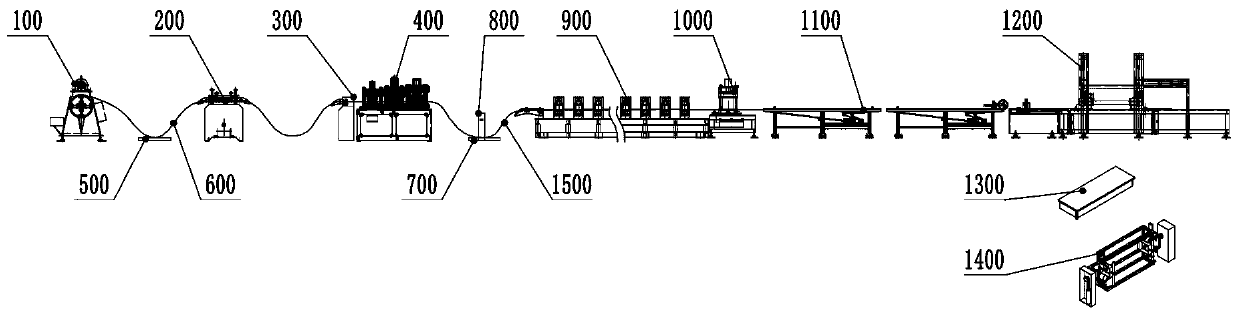

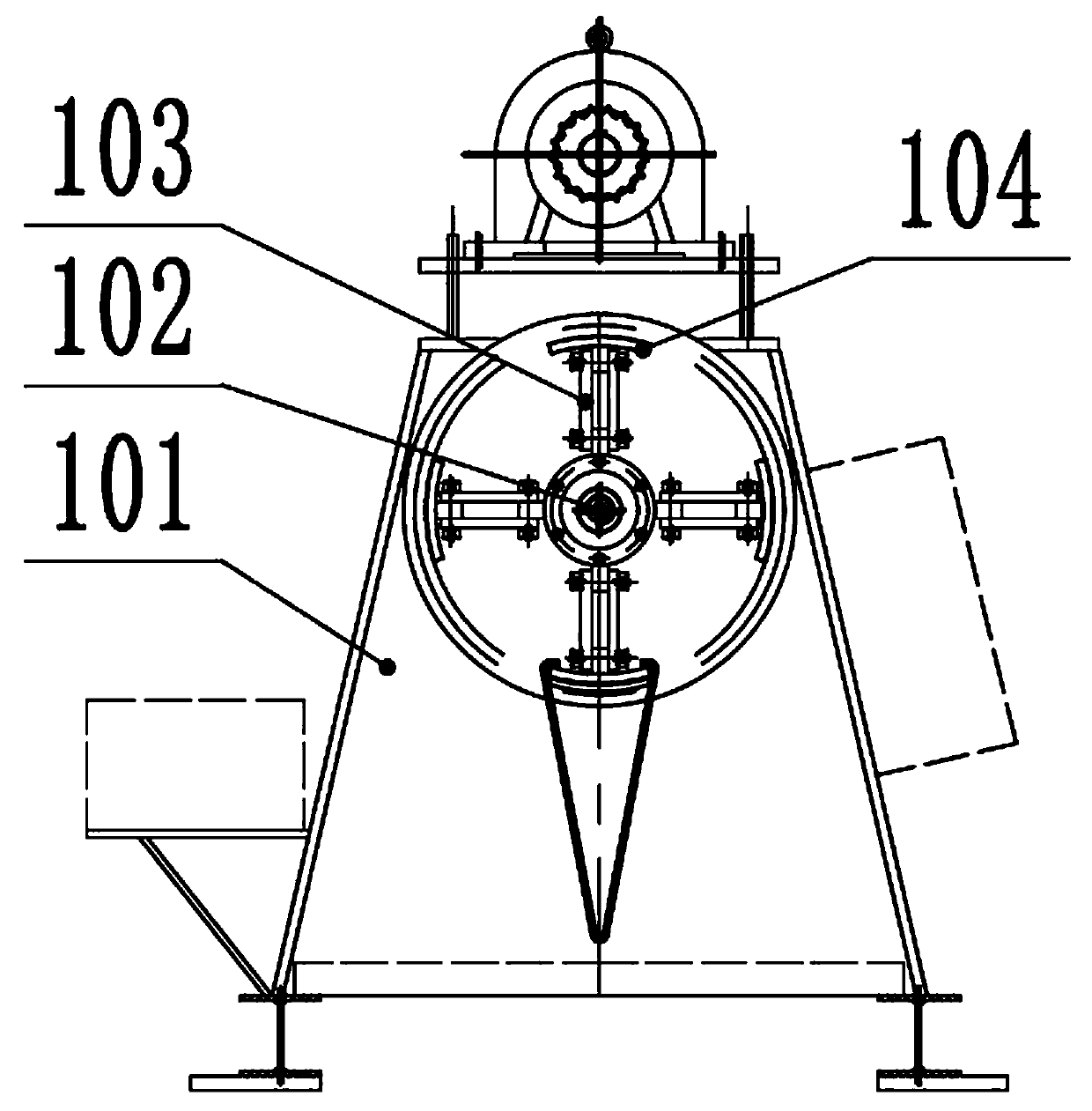

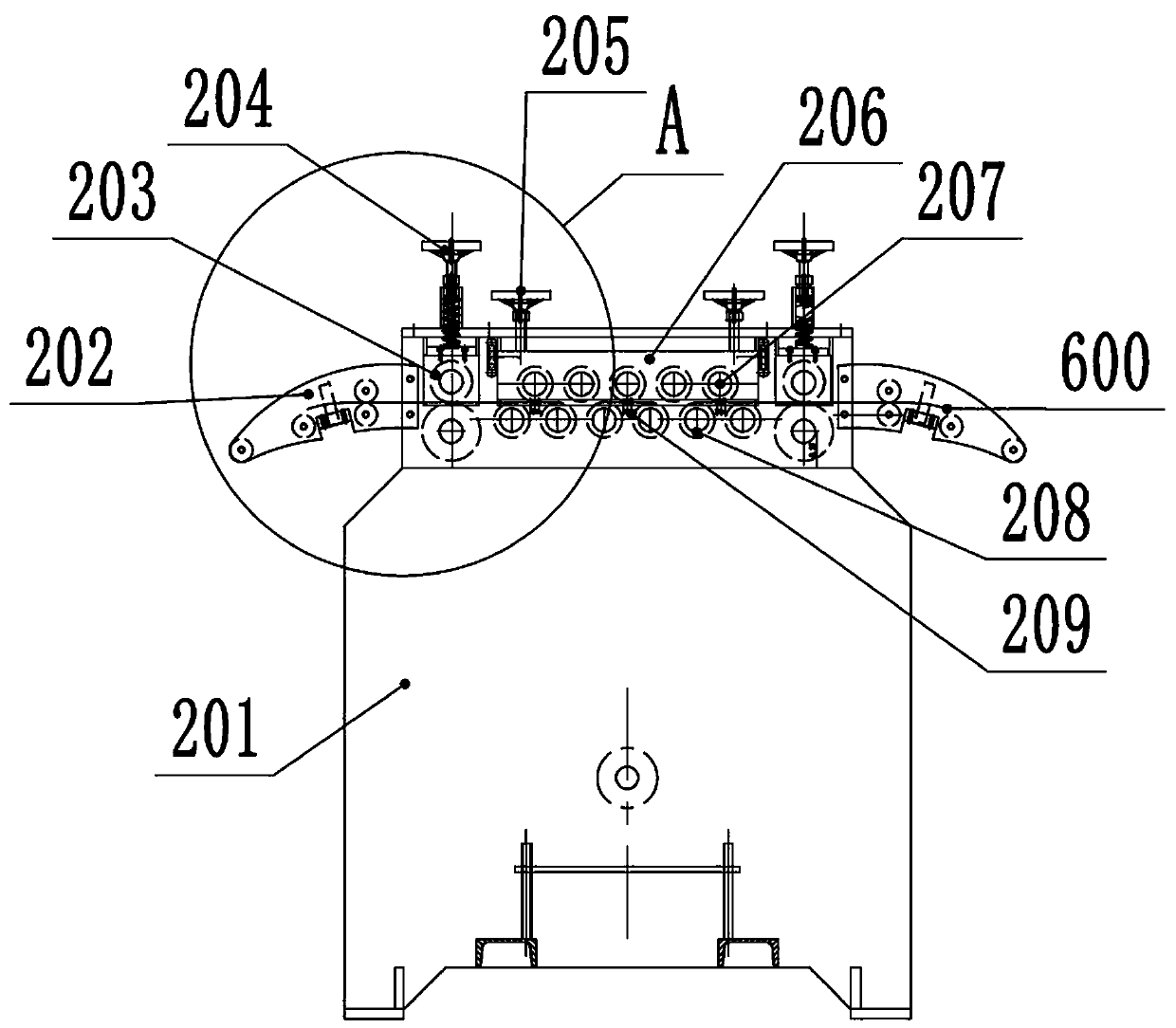

Box body welding production line and production method

The invention discloses a box body welding production line and a production method. The production line comprises a plate discharge hole forming equipment line, a rolling forming line, a punching device, a bending device and a welding device; the plate discharge hole forming equipment line is used for leveling steel and punching the surface of the steel, and a material plate is manufactured; the rolling forming line is used for rolling a bending edge on the material plate; the punching device is used for cutting off the material plate into a plurality of groups, each group of material plates comprises four continuous sections, and the four sections are corresponding to four side wall plates of the box body; the bending device is used for bending the cut material plate into a side wall frame of the box body; and the welding device is used for welding the frame into a whole box body. The full-automatic production line and process of punching, rolling, cutting, bending and welding are adopted, so that full-automatic forming from the steel plate to the box body is realized, the processing of hole forming and three-dimensional features on the side wall of the box body is completed once,the production efficiency is high, the labor cost is low, and the processing quality is high.

Owner:LAIZHOU KASIKAITE IND & TRADE CO LTD

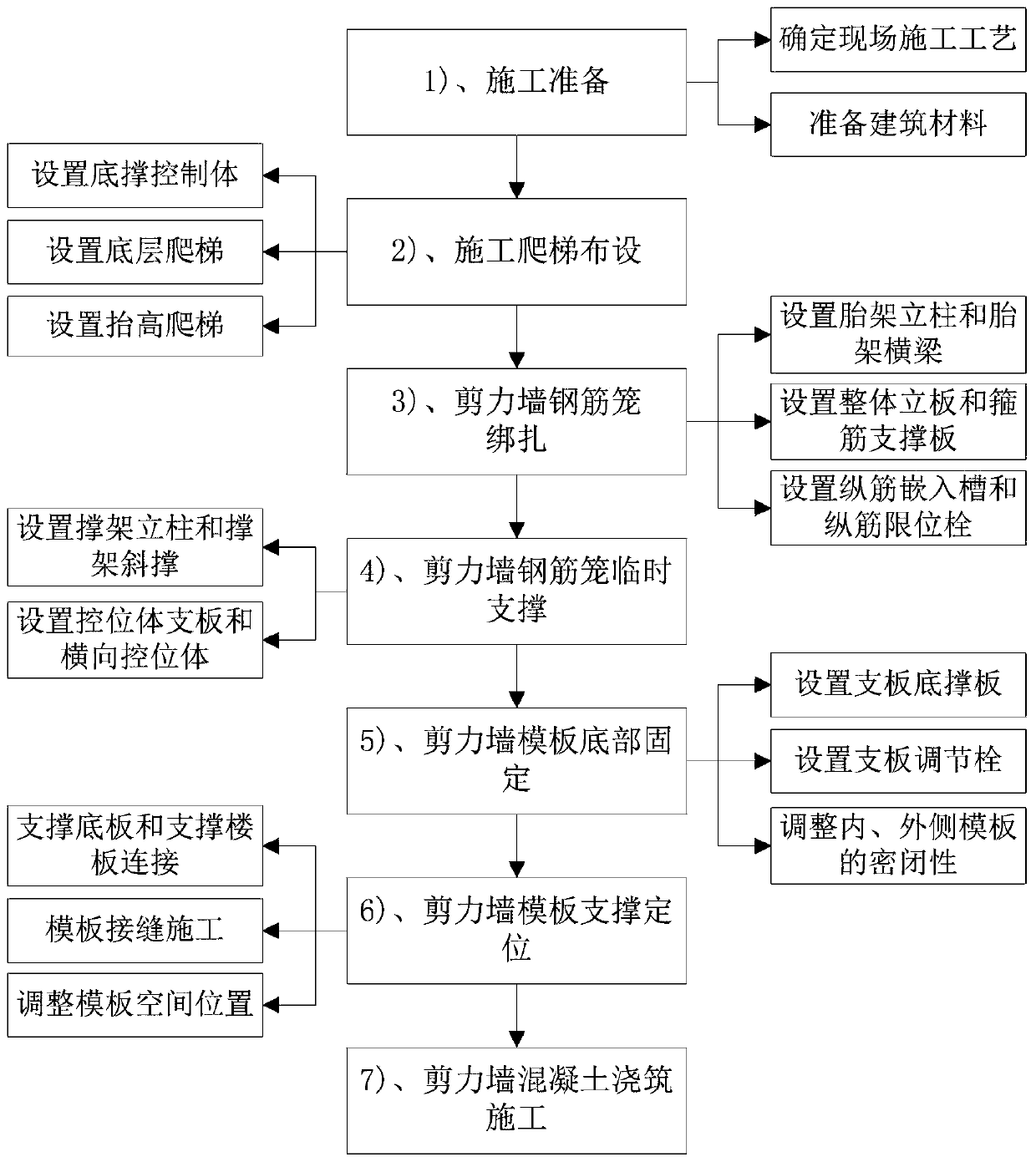

One-piece large template shear wall and construction method

ActiveCN110409670AImprove stabilityExpand the scope of application of the projectWallsForms/shuttering/falseworksShear wall

The invention relates to a one-piece large template shear wall and a construction method. A bottom support adjusting body is arranged between a bottom support baffle and a bottom support control body;an elevated bottom plate is arranged on an elevated support beam, and an elevated ladder and an elevated supporting column are arranged on the elevated bottom plate; the vertical position of a stirrup supporting plate is controlled through a vertical plate limiting plate, and vertical longitudinal ribs are tightly connected to a longitudinal rib limiting plate through a longitudinal rib baffle; the stiffness of the vertical longitudinal ribs is improved through a control body supporting plate; the verticality of inner and outer templates is corrected by supporting plate adjusting bolts, and the tightness between the inner and outer templates and a supporting slab is adjusted by pressing rod squeezing bolts; template corner beads are arranged at the bottom ends of the inner and outer templates, and connecting square strips are arranged at vertical joints; and the vertical position of a support frame column is controlled by a unit support body, and the spatial position of the inner template is controlled by a frame plate positioning rod and a support frame plate. The one-piece large template shear wall and the construction method can improve the binding quality of a reinforcing cageand reduce the supporting and positioning difficulty of the templates.

Owner:华神建设集团有限公司

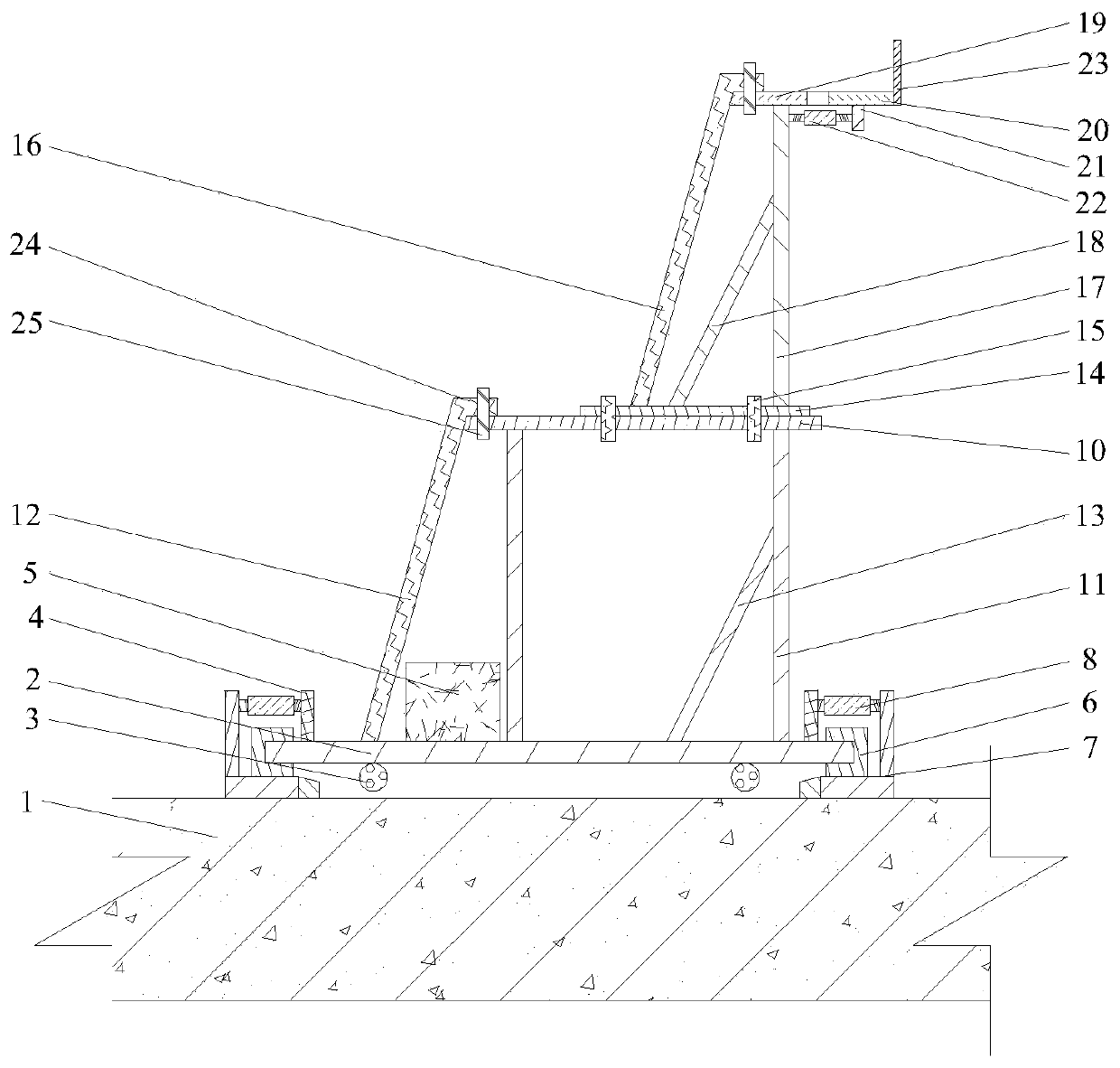

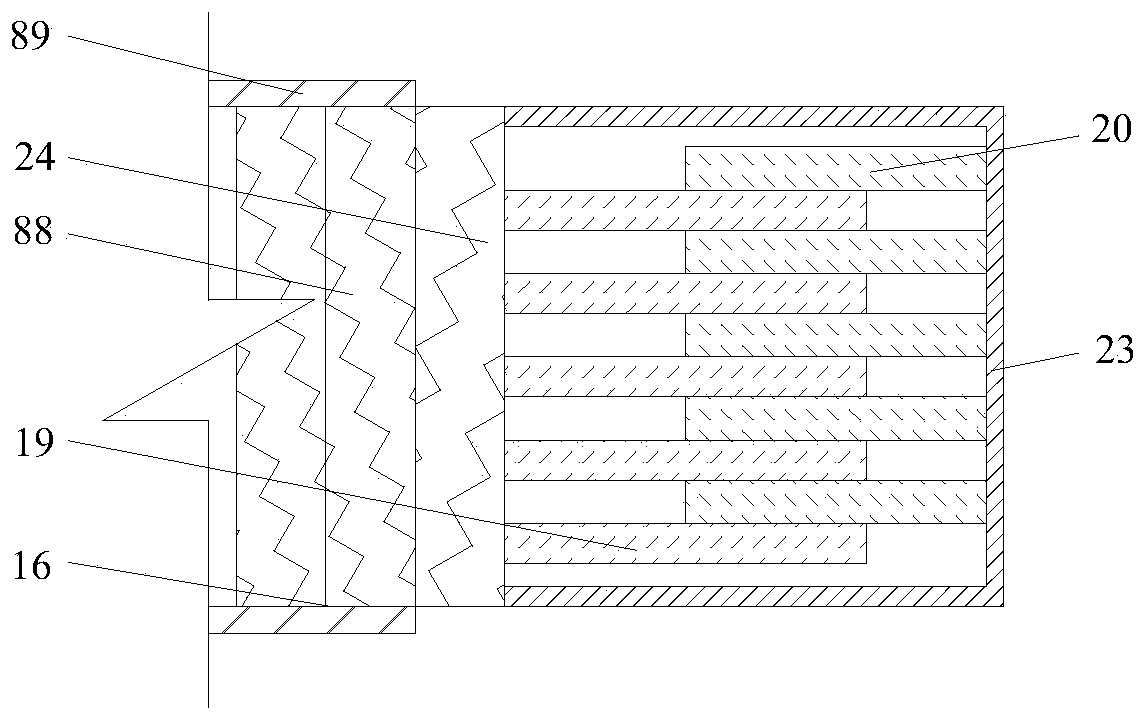

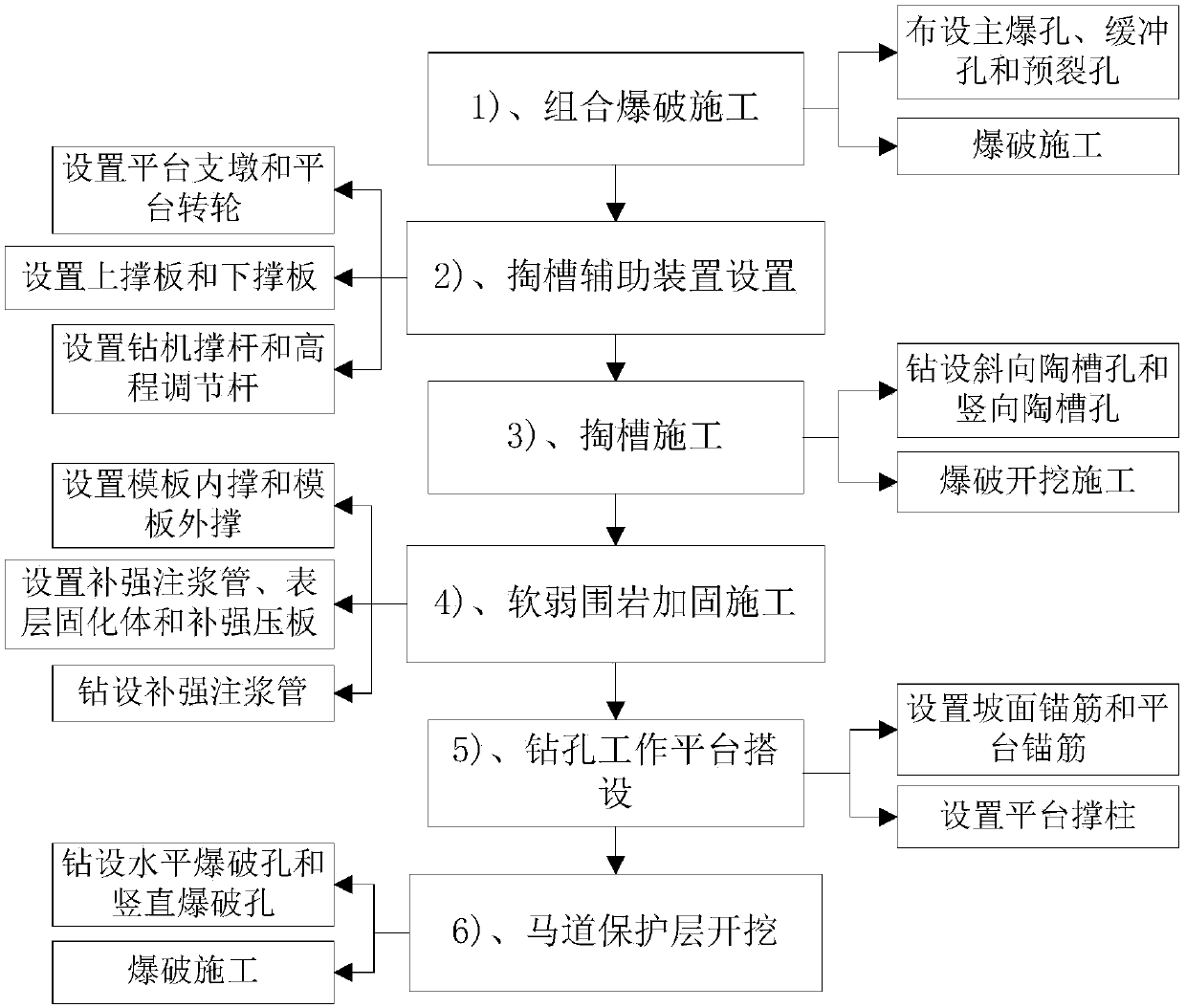

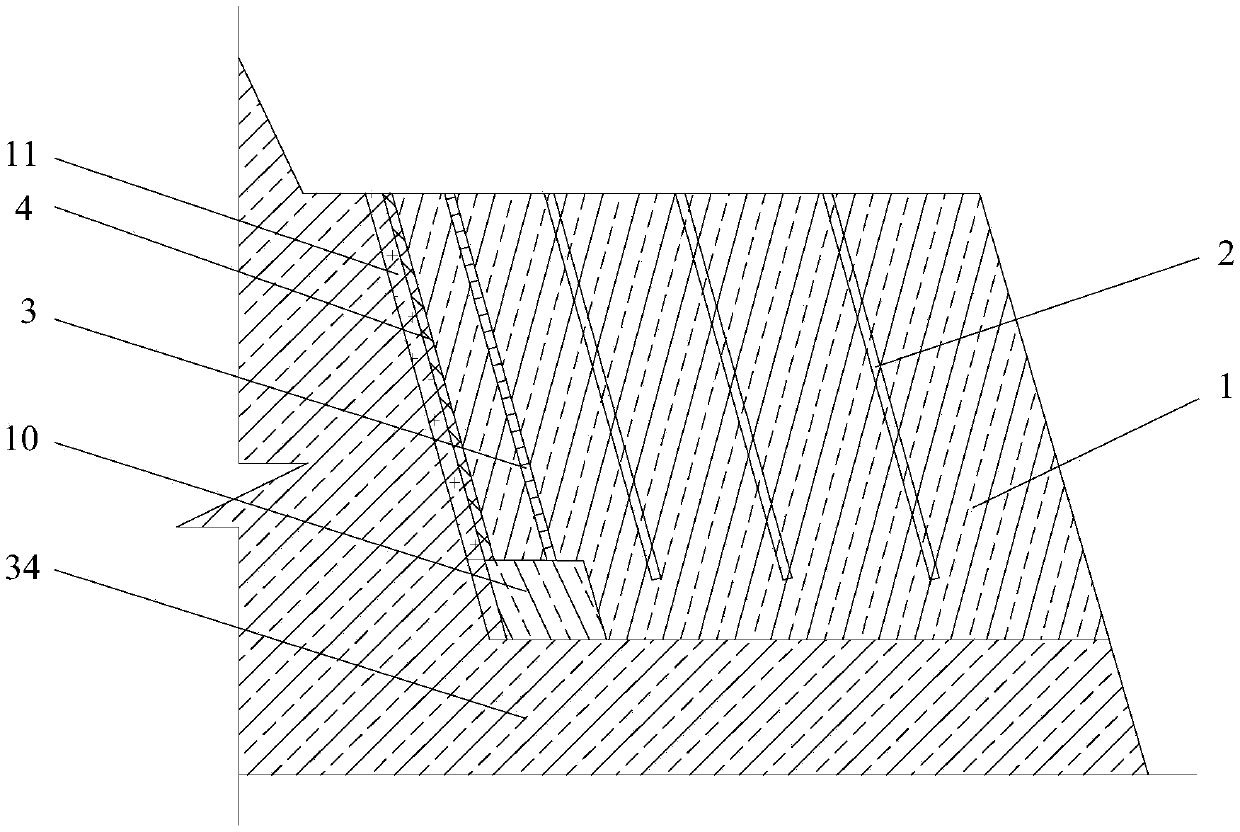

Construction method of foundation pit digging system

ActiveCN109577338AAccurately control the scope of constructionImprove construction qualityBlastingExcavationsStress conditionsProtection layer

The invention relates to a construction method of a foundation pit digging system. The method includes the steps: 1) combined blasting construction; 2) cutting auxiliary device arrangement; 3) cuttingconstruction; 4) weak surrounding rock reinforcement construction; 5) drilling platform erecting; 6) riding track protection layer digging. The construction method has the advantages that inclined cutting holes are radially formed, cutting construction ranges can be accurately controlled, cutting construction quality is improved, positioning strip plates enclose storage cavities of water bags, explosive and stemming, horizontal dividing plates and positioning hoop plates are arranged at boundaries of different materials, blasting material positioning and arranging difficulty can be reduced,onsite construction efficiency is improved, reinforcement grouting pipes, surface curing bodies and reinforcement pressing plates are arranged at weak surrounding rocks, the integrality of the weak surrounding rocks can be enhanced from multiple angles, and stress conditions of a slope structure are improved.

Owner:中建八局华南建设有限公司

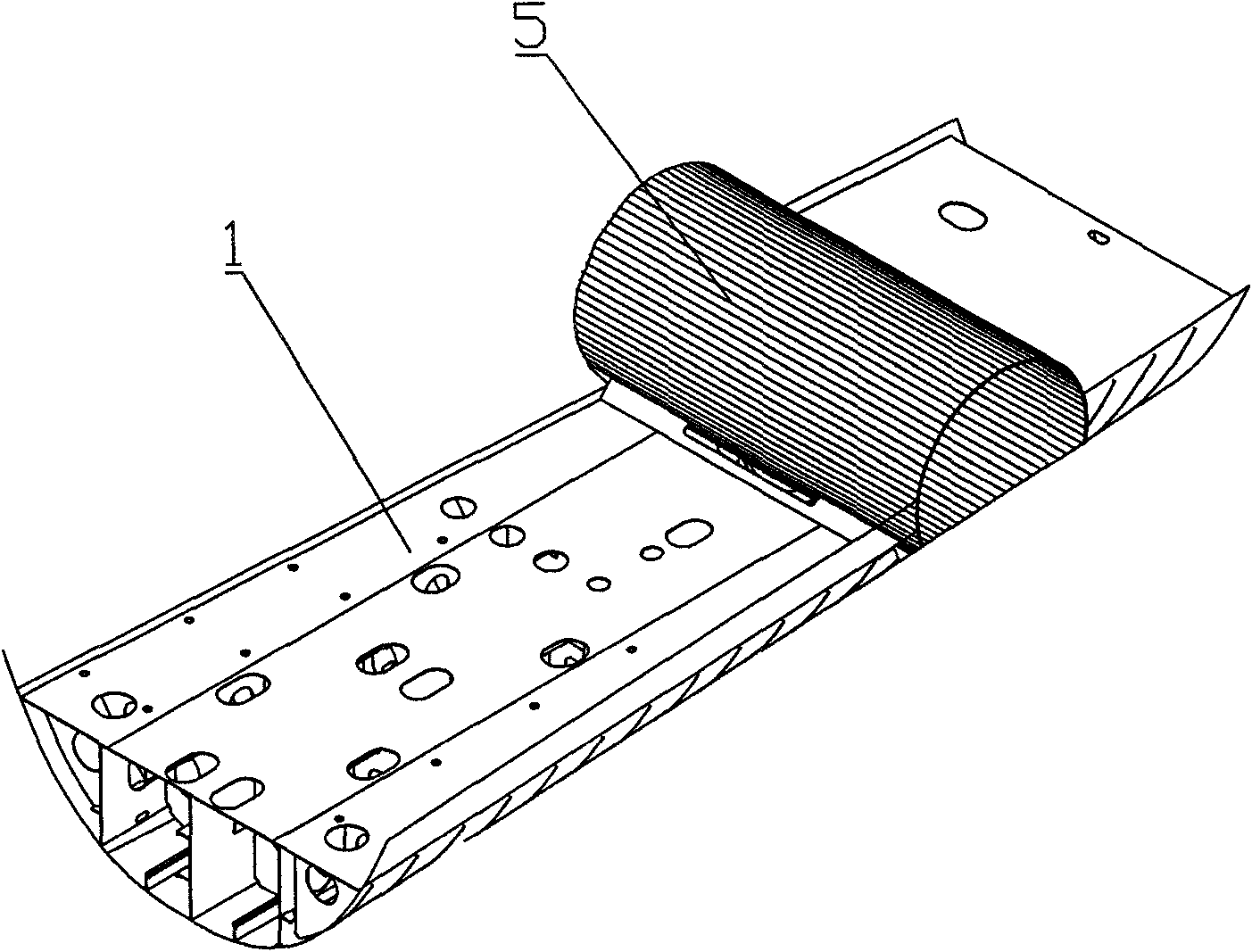

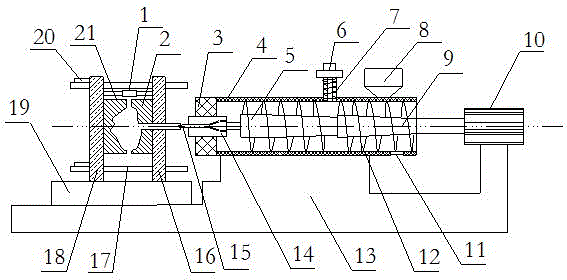

Efficient-dehumidification injection molding machine

The invention discloses an efficient-dehumidification injection molding machine. The efficient-dehumidification injection molding machine comprises a base, an extrusion module and a mold module, wherein the extrusion module and the mold module are installed on the base. The extrusion module comprises a stuff canister, an extrusion screw and an injector head, wherein the extrusion screw and the injector head are arranged inside the stuff canister. A hopper is arranged on the upper right portion of the stuff canister, and a humidifier is arranged on the middle upper portion of the stuff canister. The left end of the extrusion screw is connected with the injector head, the right end of the extrusion screw is connected with a motor, and a pushing spiral blade is arranged on the outer wall of the extrusion screw. A material channel is arranged inside the injector head, the left end of the material channel is connected with the mold module, and the right end of the material channel communicates with an inner cavity of the stuff canister. The mold module comprises a fixed mold arranged on a mold right supporting seat, a movable mold arranged on a left supporting seat, a supporting seat guide rod and a position adjusting oil cylinder. The right supporting seat is fixed to a sliding seat, the left supporting seat can move leftwards and rightwards on the sliding seat, and the sliding seat can slide leftwards and rightwards on the base. The fixed mold is provided with a feeding port connected with the material channel of the injector head. The efficient-dehumidification injection molding machine can substantially reduce the moisture content of plastic materials and improve product quality.

Owner:BISHAN BRANCH OF CHONGQING RUNTONG IND CO LTD

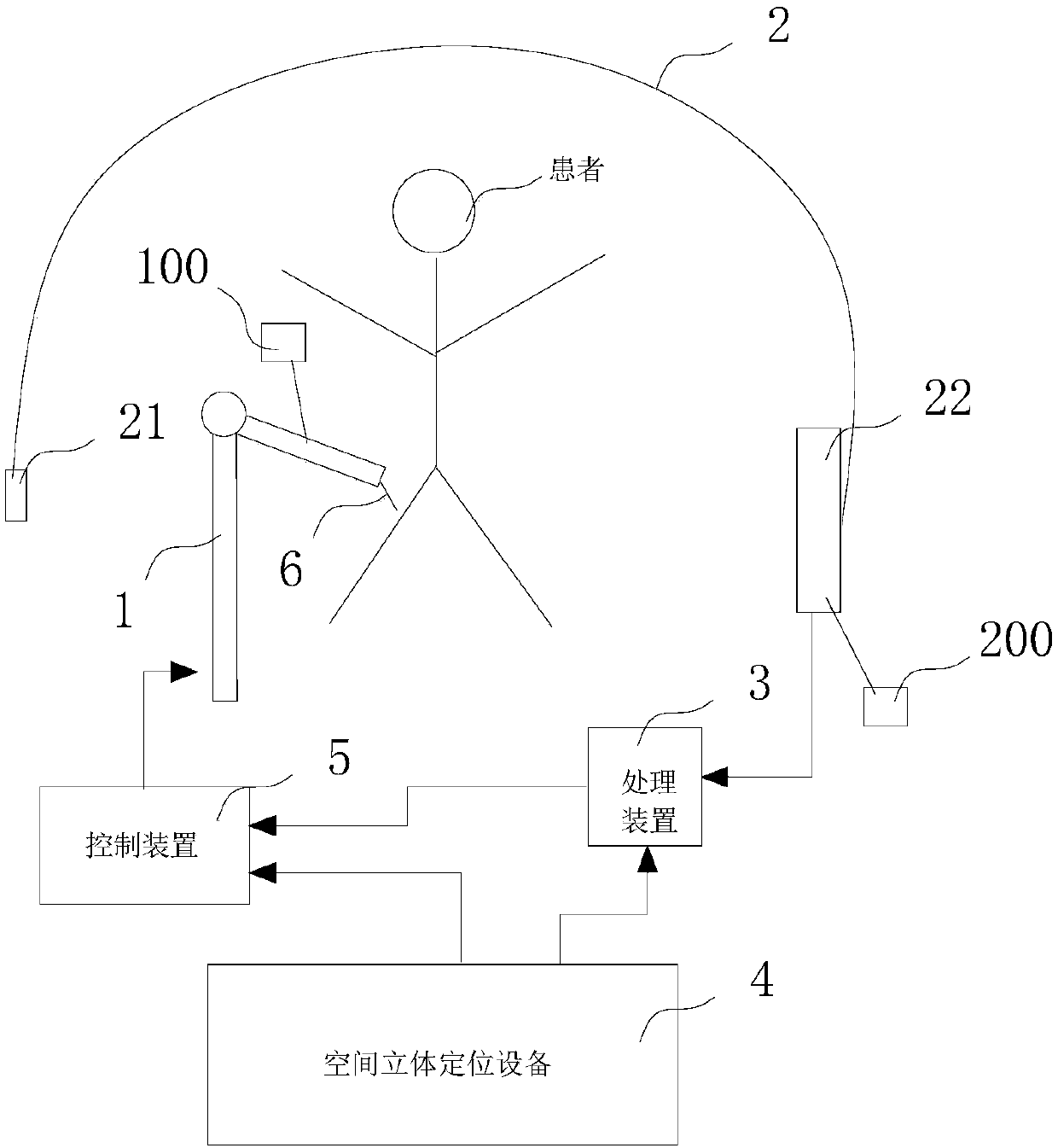

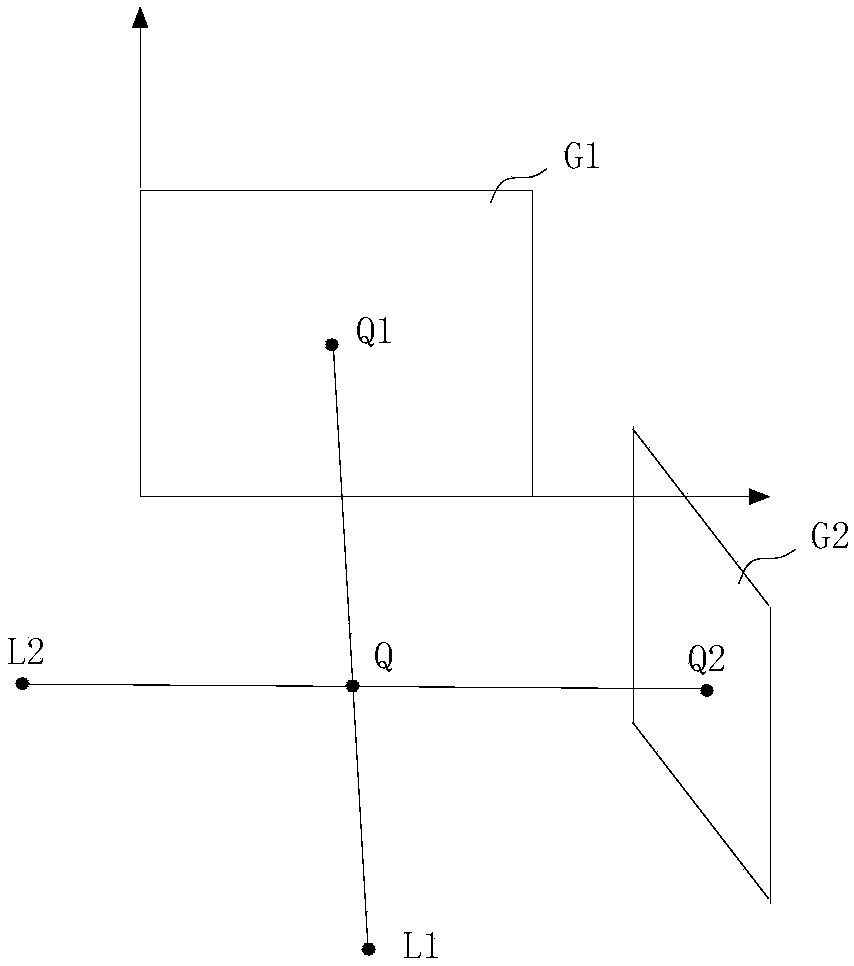

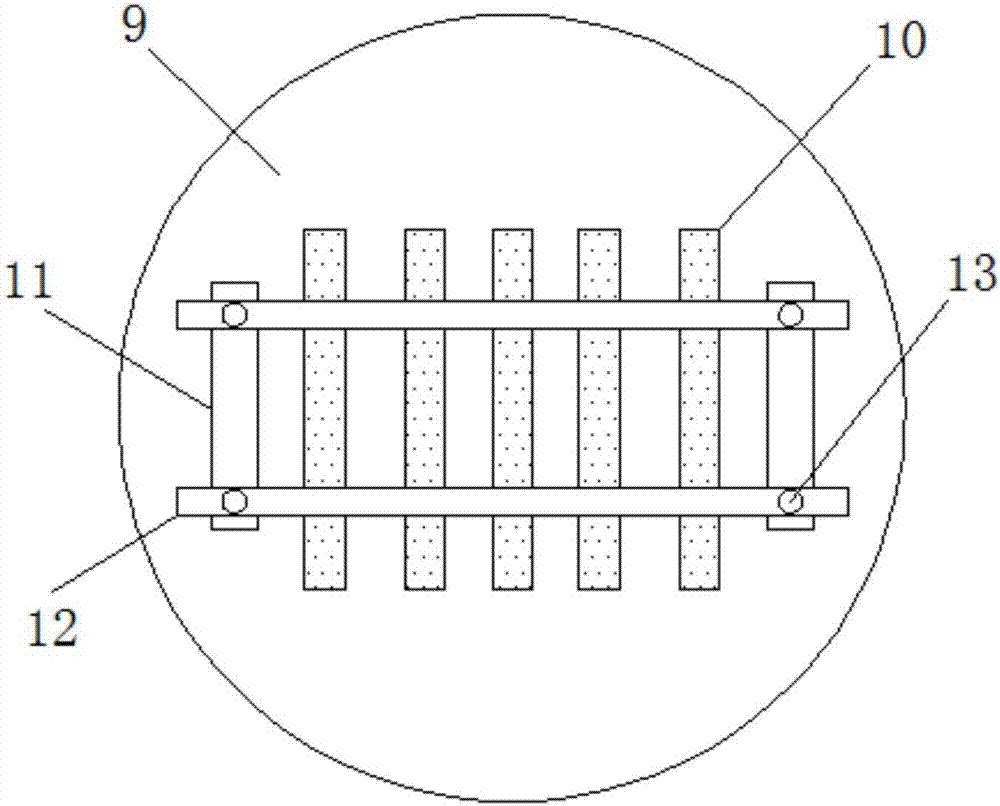

Operation mechanical arm positioning system

ActiveCN108042202AFacilitate surgeryReduce waiting time for surgerySurgical navigation systemsComputer-aided planning/modellingDevice formAngular degrees

The invention provides an operation mechanical arm positioning system. The system comprises an operation mechanical arm, a fluoroscopy device, a processing device, a space three-dimensional positioning device and a control device, wherein an A group of calibration bodies are fixed relative to the operation mechanism arm; a B group of calibration bodies are fixed relative to the fluoroscopy device,and a target object is shot from at least two angles to form at least two fluoroscopy images; the processing device receives the fluoroscopy images, target projection points are selected in the images respectively according to an external input instruction, according to the position relation between the target projection points and a light source and the position relation between at least image receiving planes of the target projection points, the space position of a target actual point relative to the B group of calibration bodies is determined, and space position data of the actual point isgenerated; the space three-dimensional positioning device forms the three-dimensional relative position relation of the A group of calibration bodies and the B group of calibration bodies; the control device controls the operation mechanical arm to move to the space position of the target actual point according to the three-dimensional relative position relation and the space position of the actual point. The operation mechanical arm positioning system improves the positioning automation degree, reduces the operation complexity, and is accurate in positioning.

Owner:SHANGHAI DROIDSURG MEDICAL CO LTD

Trepanning device for accessories for agricultural machinery

InactiveCN107262773ASmooth rotationEasy to collectLarge fixed membersPositioning apparatusHydraulic cylinderAgricultural engineering

The invention discloses a device for drilling holes in spare parts of agricultural machinery, which comprises a base, a bearing is installed in the middle of the base, a rotating rod is connected to the bearing, the axis of the rotating rod is perpendicular to the base, and the The top of the rotating rod is fixedly connected with a turntable, the bottom of the turntable is provided with a guide groove, the guide groove is provided with support rollers, and the support rollers are fixed by a roller frame fixedly installed on the base The top of the turntable is equipped with a hydraulic cylinder body, the output end of the hydraulic cylinder body is connected with a lifting platform, the fixed base is fixedly connected with a pressing plate through an adjusting bolt, and the left and right sides of the top of the base The side is symmetrically provided with a frame, the top of the frame is provided with a beam, the top of the beam is equipped with a motor body, the output end of the motor body is connected with a connecting sleeve, and the bottom of the connecting sleeve is fixedly connected with the drill body , suitable for broad promotion.

Owner:XIAOGAN YIHONG HOME CREATIVE DESIGN CO LTD

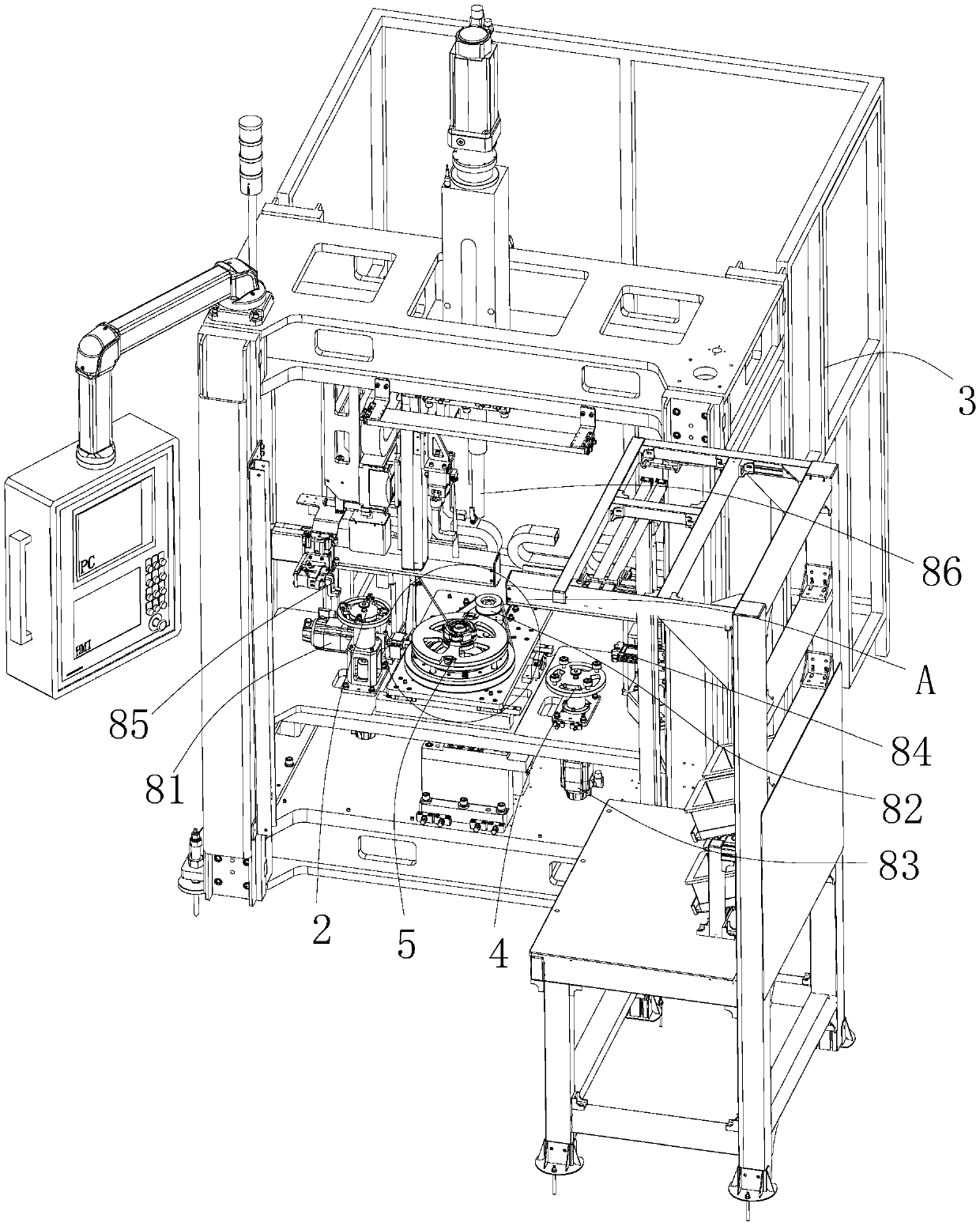

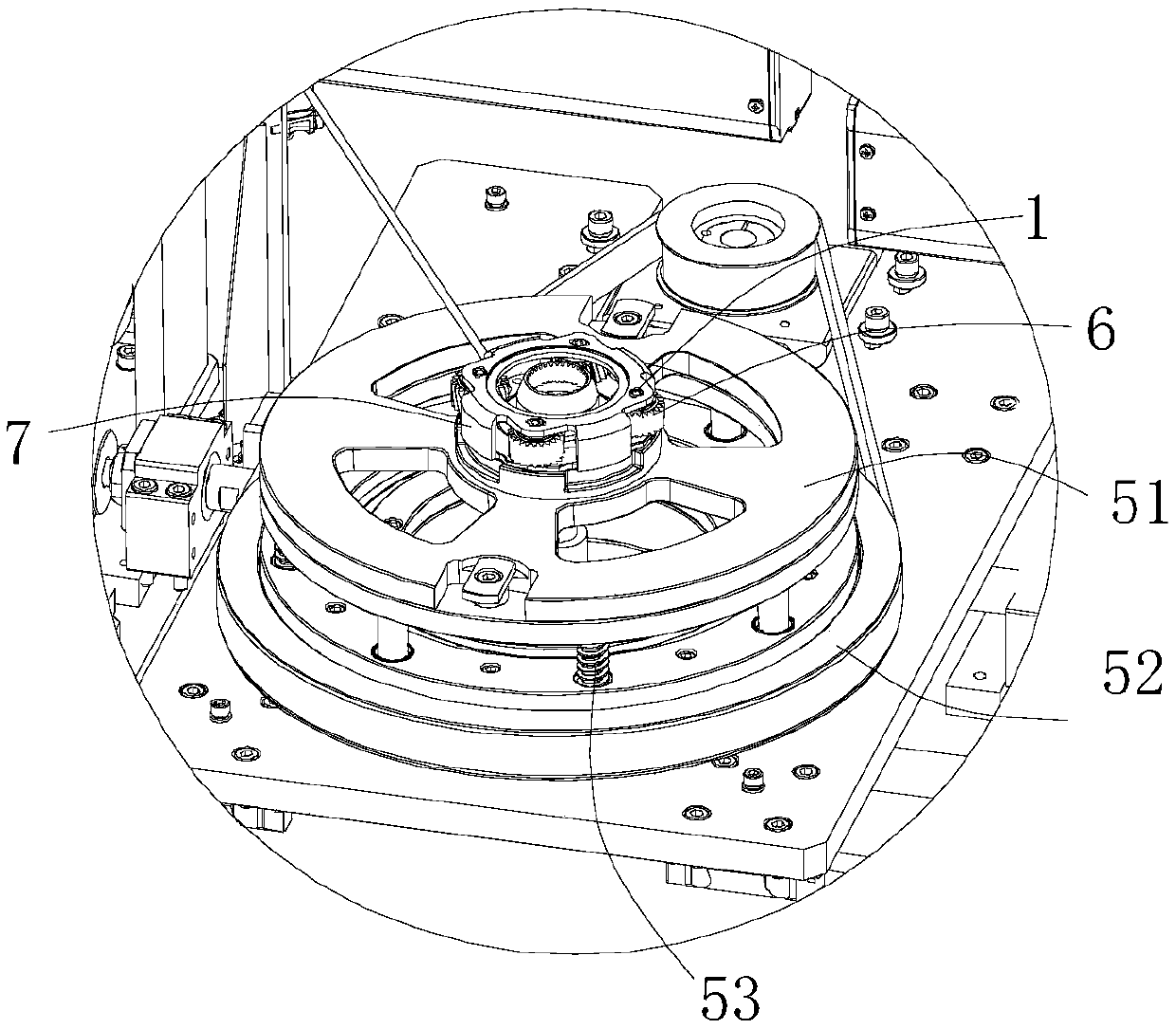

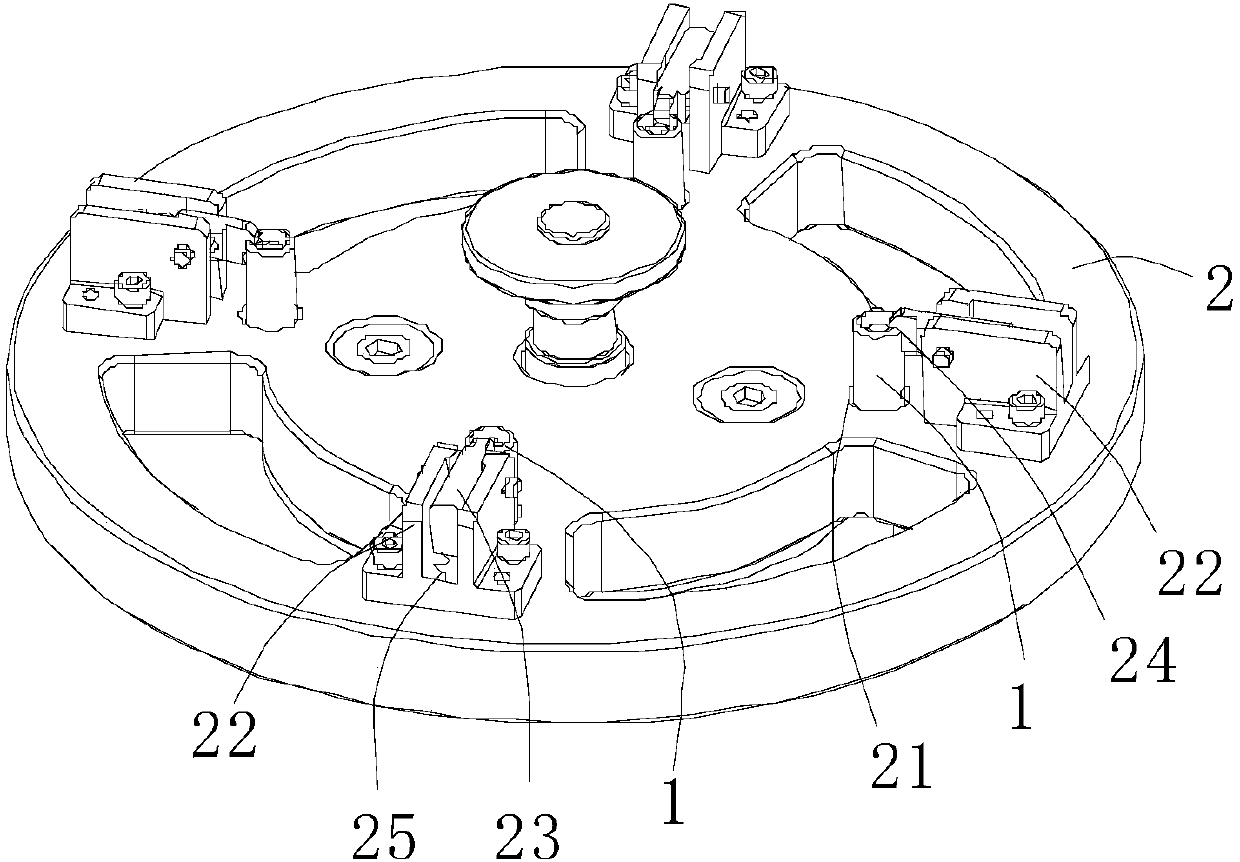

Planetary shaft, limiting device and planetary wheel assembly device

ActiveCN109681614AEnsuring Positional and Angular AccuracyMake sure to run the processMetal working apparatusGearing detailsMechanical engineeringEngineering

The invention provides a planetary shaft, a limiting device and a planetary wheel assembly device, and relates to the technical field of limiting devices. The planetary shaft includes a shaft body, and a sidewall of the shaft body is provided with a through oil outlet hole extending in the radial direction. The center of the top end of the shaft body is provided with an input hole in the axial direction, and the bottom end of the input hole communicates with the oil outlet hole. The top end surface of the shaft body is provided with a limiting groove in the radial direction, one end of the limiting groove communicates with the input hole, and the other end of the limiting groove penetrates the side wall of the shaft body. The length direction of the limiting groove is parallel to the axialdirection of the oil outlet hole. The limiting device is used for limiting the planetary shaft. The planetary wheel assembly device comprises a frame and the limiting device, and the limiting deviceis disposed on the frame. The frame is further provided with a positioning plate, an assembly disc and an assembly mechanism. The oil outlet hole of the planetary shaft is arranged parallel to the limiting groove, so that positioning is highly convenient and the position precision is high.

Owner:SHENGRUI TRANSMISSION

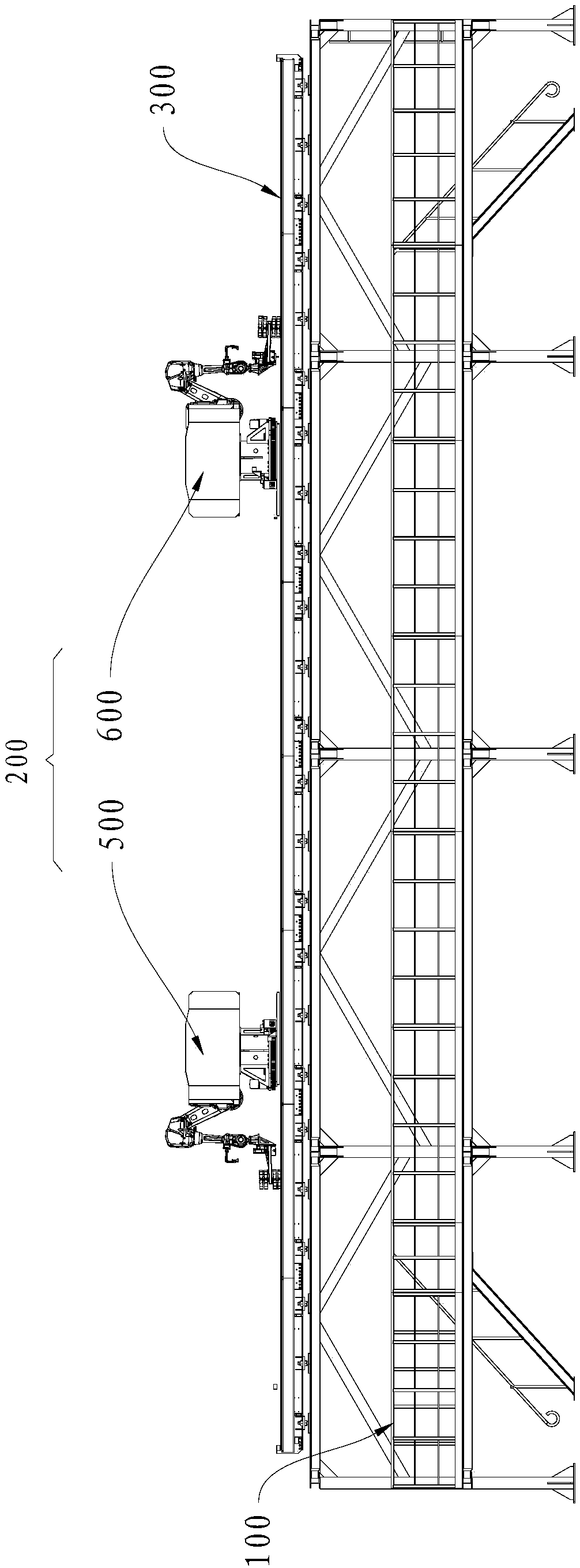

Servicing work method for locomotive roof

InactiveCN107650870AReduce work stressHigh degree of automationProgramme-controlled manipulatorGripping headsElectricityControl system

The invention relates to the technical field of locomotive equipment, in particular to a servicing work method for a locomotive roof, and the servicing work method for the locomotive roof is high in degree of automation, high in operation efficiency and rapid and accurate in positioning. The servicing work method for the locomotive roof comprises the following steps that a main control system controls a servicing robot to move, in the moving process, an imaging module obtains the image information of the locomotive roof and uploads the image information to the main control system, and the maincontrol system obtains the position information of a locomotive roof assembly according to the image information of the locomotive roof and controls the servicing robot to be moved to the pantographdetection preset position and the insulator cleaning preset position separately so as to detect a pantograph and clean an insulator.

Owner:BEIJING SHEENLINE GRP CO LTD

Offshore wind turbine gravity type base, base system and gravity type base construction method

ActiveCN105908772ALose weightShorten construction timeFinal product manufactureWind motor supports/mountsTurbineGravitation

The invention discloses an offshore wind turbine gravity type base, a base system and a gravity type base construction method; the offshore wind turbine gravity type base comprises a bottom plate, a first barrel, a second barrel and a platform assembled in sequence; the bottom plate, the first barrel and the second barrel are connected to form a filler channel used for filling base cargo; the platform is provided with a platform opening connected with the filler channel. The offshore wind turbine gravity type base is a hollow structure, can greatly reduce self weight, and can save materials; in addition, the bottom plate and the first barrel, the first barrel and the second barrel, and the second barrel and the platform are respectively assembled; all structures can be pre-built on the land, and are assembled in sequence in one piece, thus effectively reducing construction time of the offshore wind turbine gravity type base; the offshore wind turbine gravity type base is simple to realize, fast in construction, can reduce construction time and laboring, thus greatly reducing production cost.

Owner:CHINA ENERGY ENG GRP GUANGDONG ELECTRIC POWER DESIGN INST CO LTD

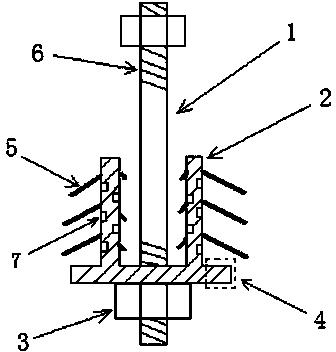

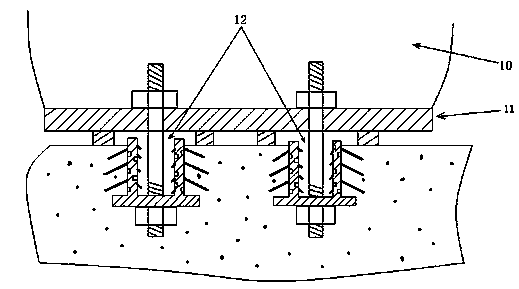

Foundation bolt structure and construction method thereof

InactiveCN104032768AGuaranteed anchor strengthSatisfied with precise positioningFoundation engineeringArchitectural engineeringEconomic benefits

The invention discloses a foundation bolt structure and a construction method thereof. The foundation bolt structure consists of a screw rod, a specially-shaped barrel and a bolt, wherein the specially-shaped barrel comprises a barrel body and a barrel bottom; a through hole is formed in the middle of the barrel bottom; the hole diameter of the through hole is larger than the diameter of the screw rod; a flange extends outwardly in the radial direction of the barrel bottom; raw tentacles are arranged on the inner surface of the barrel body inwardly and on the outer surface of the barrel body outwardly; threads are arranged at the two ends of the screw rod; the screw rod penetrates through the through hole and is connected with the specially-shaped barrel through the bolt. The construction method comprises the following steps: constructing equipment base concrete; introducing equipment; centering bolt holes and equipment bolt holes; adjusting offset bolts to be aligned with the equipment; installing the equipment in an aligned way; pouring concrete. The bolt and the specially-shaped barrel are simple and practical; through integral embedment, the anchoring strength of a foundation bolt and an equipment base is ensured; the equipment is accurately positioned; the positioning difficulty of the equipment is effectively reduced; reworking is reduced; the working efficiency is improved; the construction period is shortened; the construction cost is greatly reduced; and economic benefits are increased.

Owner:JIANGSU CHINA NUCLEAR IND HUAWEI ENGDESIGN & RES

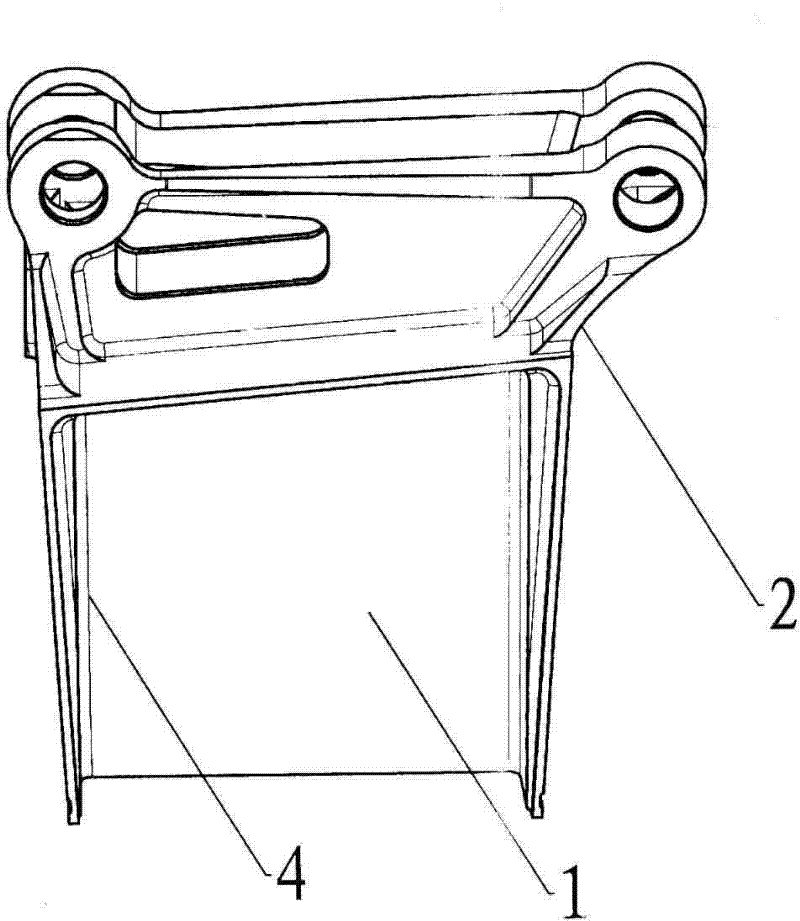

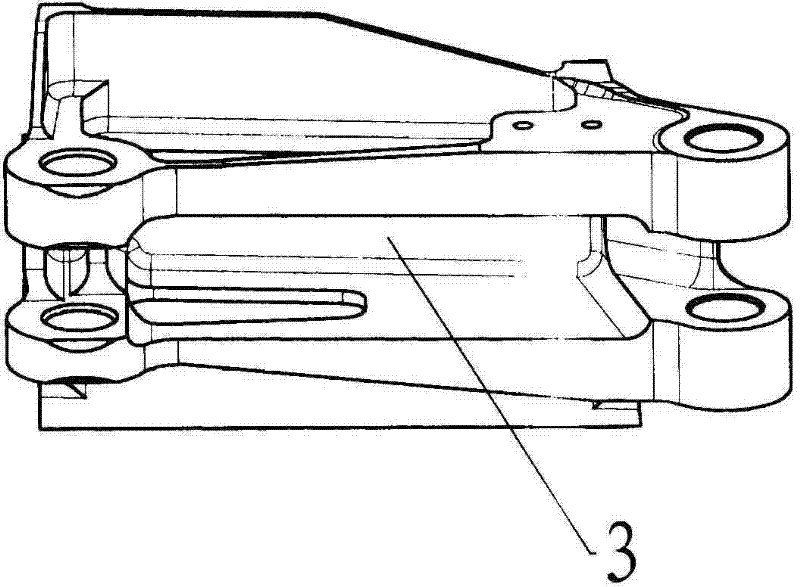

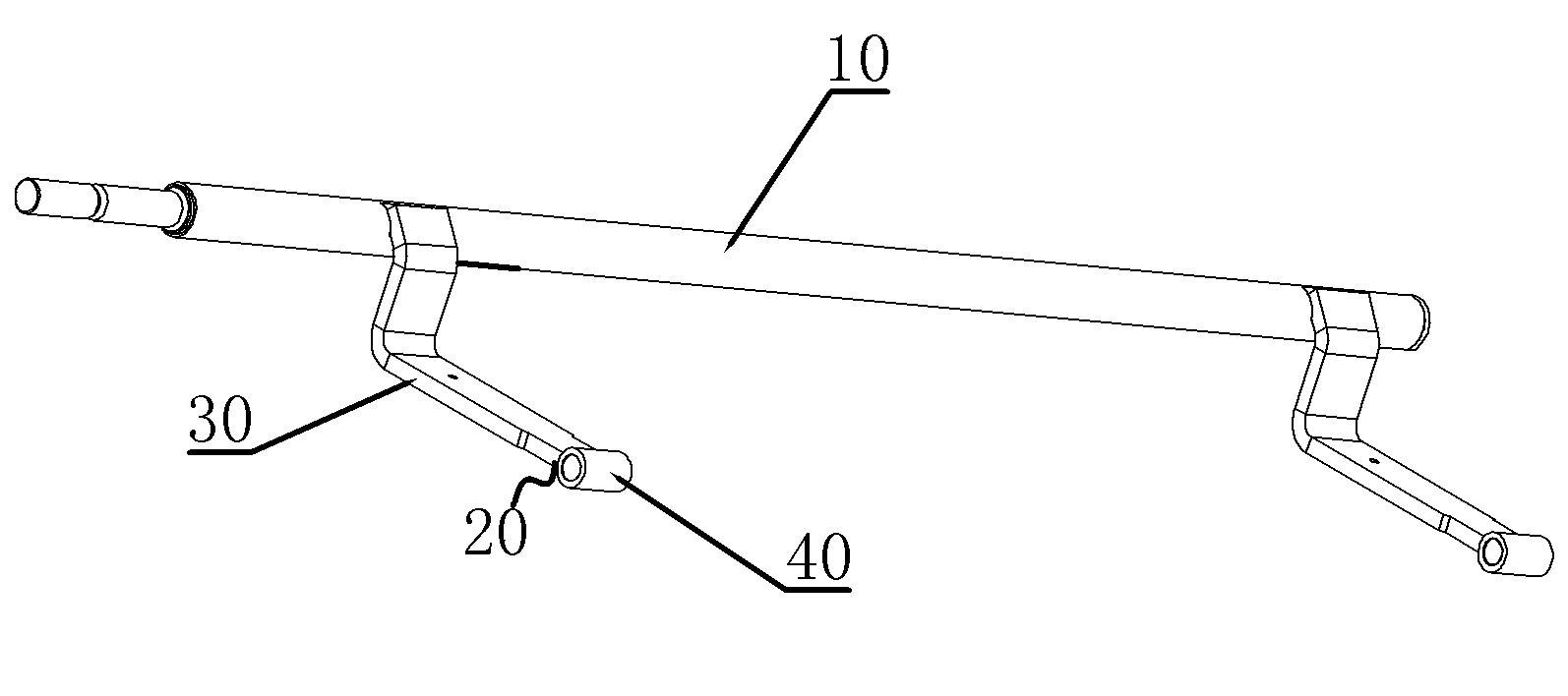

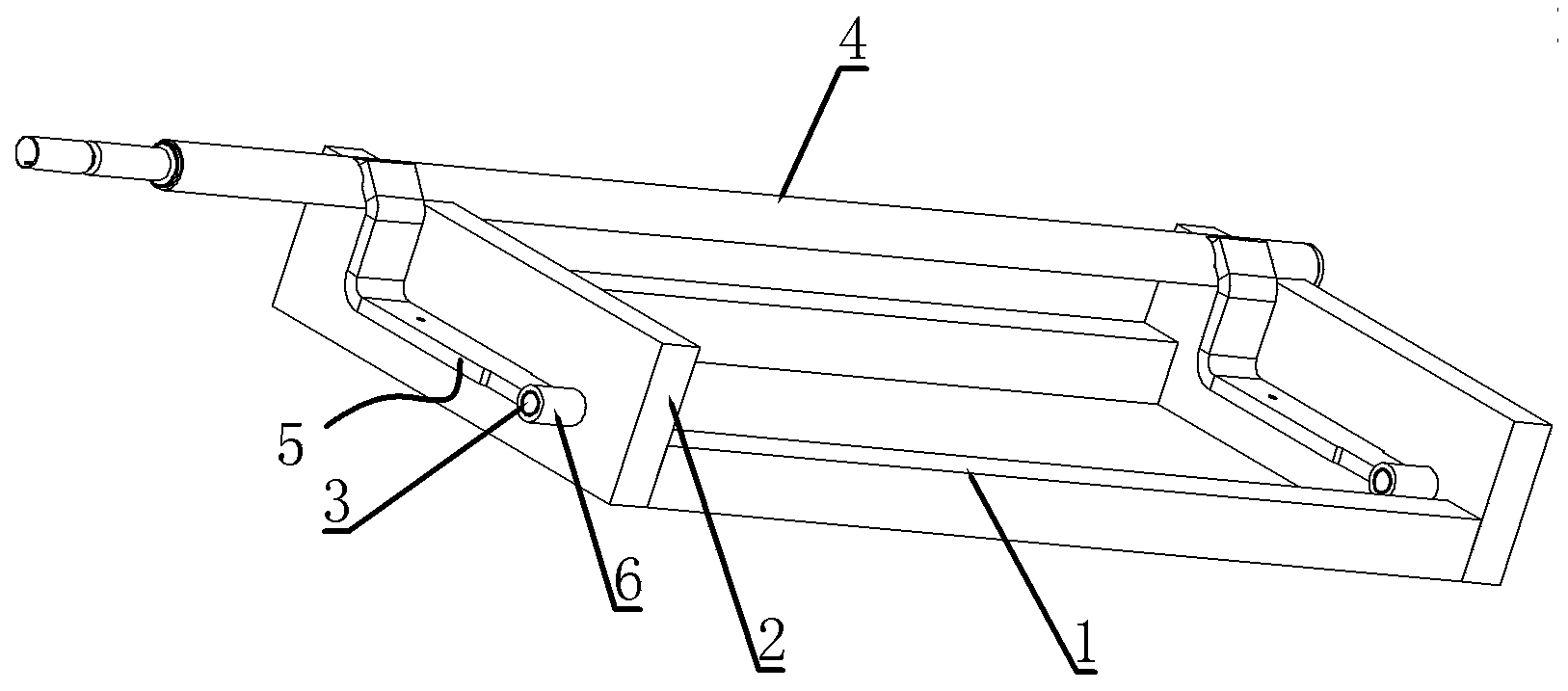

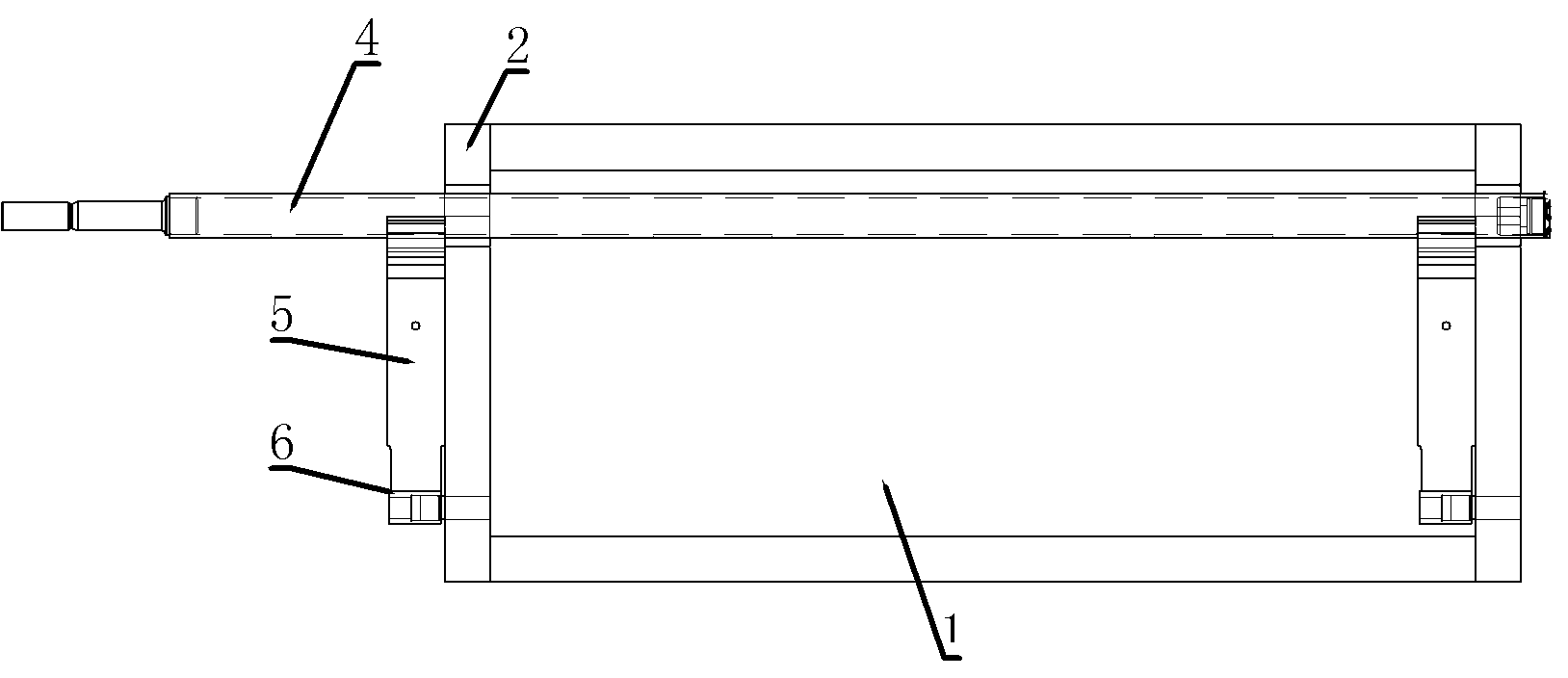

Welding tool for passenger car pivot rotating arms

InactiveCN103521972AHigh precisionGuaranteed parallelismWelding/cutting auxillary devicesAuxillary welding devicesEngineeringMechanical engineering

The invention discloses a welding tool for passenger car pivot rotating arms. The welding tool for the passenger car pivot rotating arms comprises a base and two positioning plates which are vertically arranged on the base at intervals in a parallel mode. The top portions of the two positioning plates are respectively provided with a pivot clamping groove, wherein the pivot clamping grooves extend in the direction of the same horizontal straight line. The surfaces of the two positioning plates are provided with rotating sleeve positioning pins which are coaxially arranged, and the axes where the two rotating sleeve positioning pins are located are parallel to the extending direction of the straight line of the two pivot clamping grooves. When the welding tool is used, a pivot in a pivot assembly is limited in the radial direction and clamped into the pivot clamping grooves, rotating sleeves in the rotating arms are coaxially arranged on the rotating sleeve positioning pins in a sleeved mode, the rotating arms are rotated with the rotating sleeve positioning pins as the axis until the rotating arms are rotated to the position where the rotating arms are connected with the pivot, then the rotating arms are welded to the pivot, in the process, the coaxiality of the rotating sleeves of the two rotating arms can be guaranteed through the coaxially arranged rotating sleeve positioning pins, the parallelism of the rotating sleeves and the pivot can be guaranteed, and therefore the precision of assembling the whole pivot assembly is improved.

Owner:HENAN LIANGYI MECHANICAL & ELECTRICAL +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com