Method for locating tail pipe supporting seat in subsection

A positioning method and a technology of supporting seats, which are applied to ship components, ships, transportation and packaging, etc., can solve the problems of complex positioning process, difficult welding, long time, etc., to reduce welding difficulty, shorten docking period, and reduce positioning The effect of difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

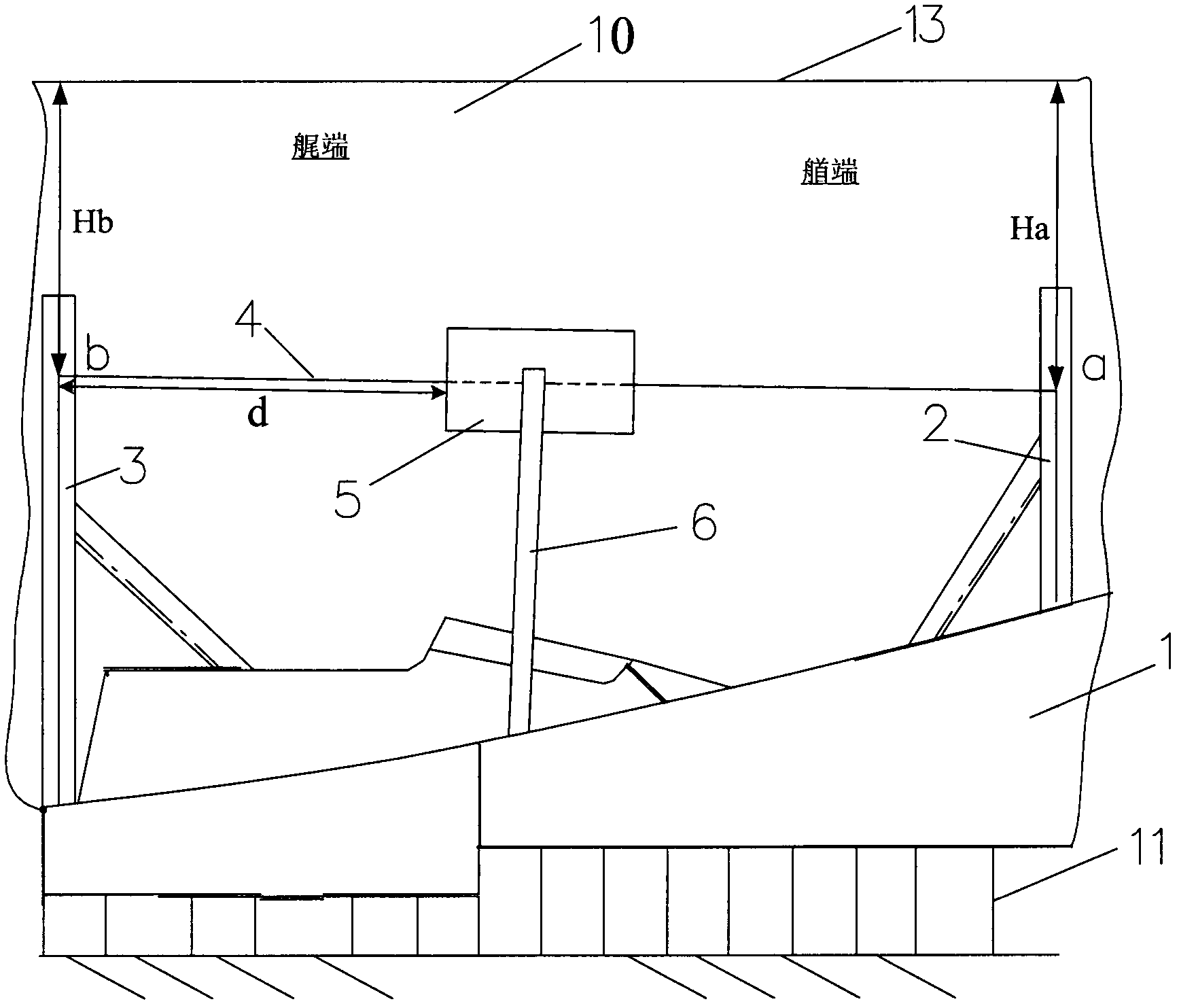

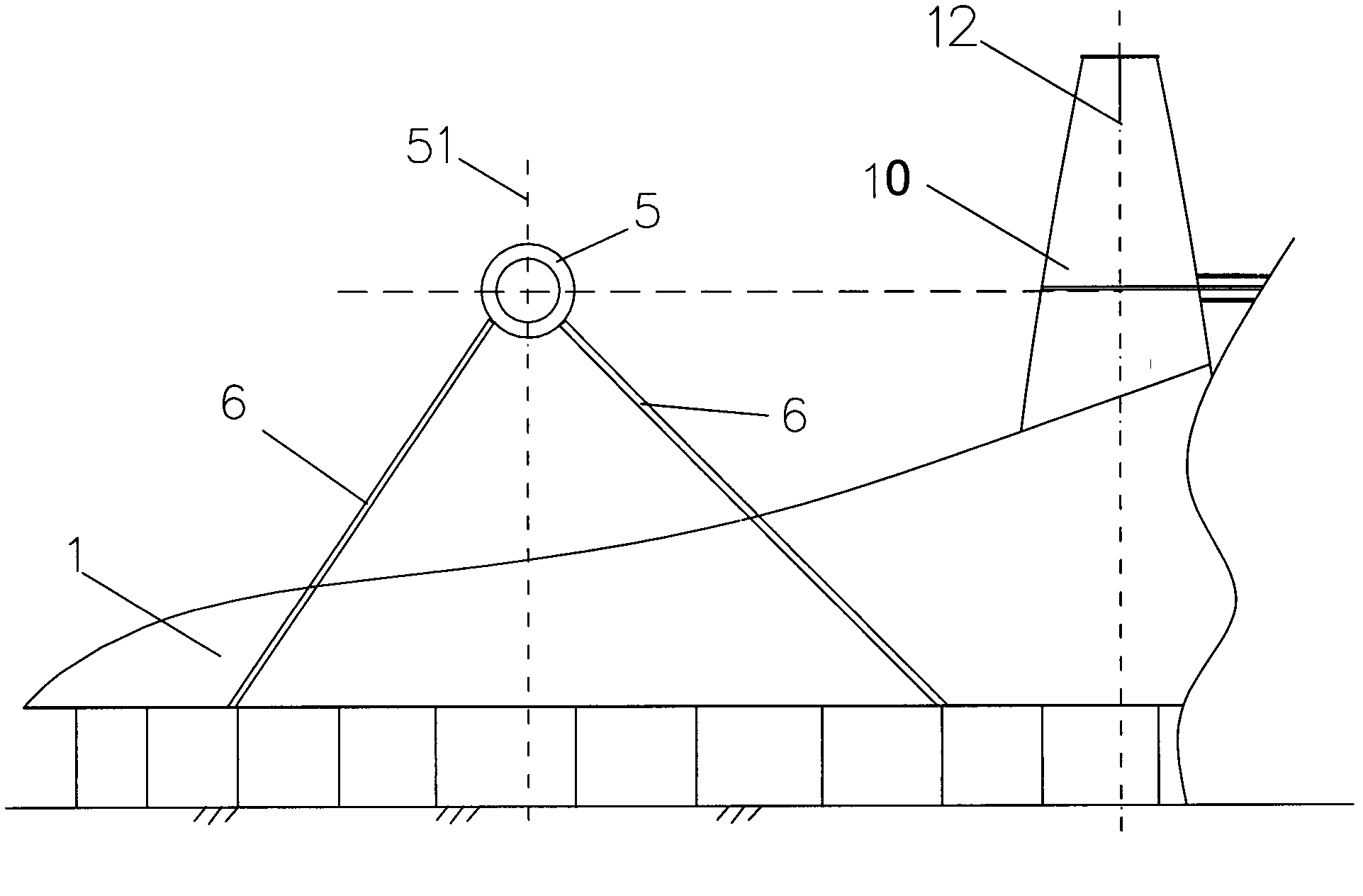

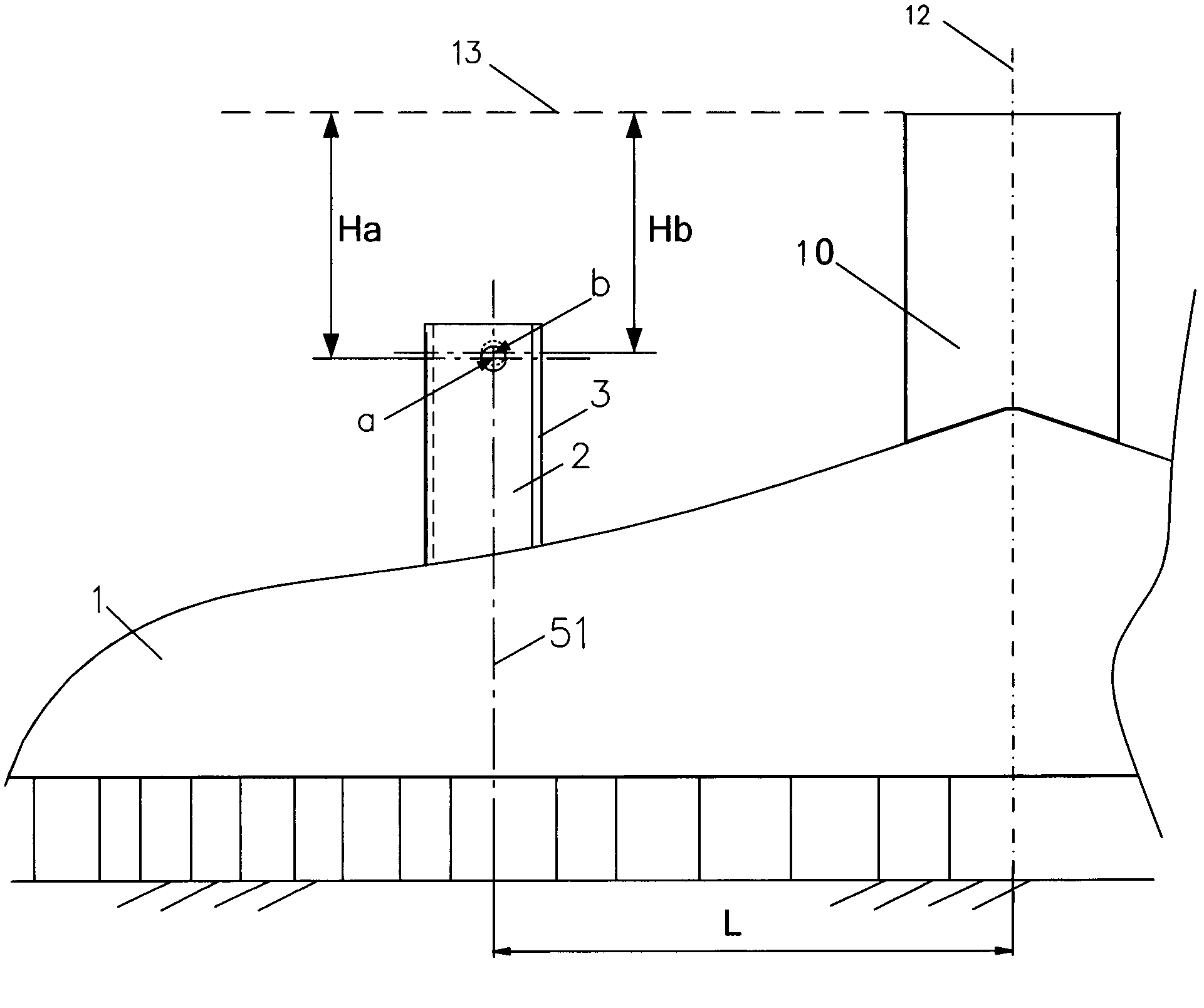

[0027] The preferred embodiments of the present invention are given below in conjunction with the accompanying drawings to describe the technical solution of the present invention in detail.

[0028] For ease of description, in this embodiment, the left side of section 1 is the stern of the ship, and the right side of section 1 is the bow of the ship; the left end of the stern tube support seat 5 is the stern, and the right end is the bow. And the line connecting the bow and stern is defined as the X-axis direction (in figure 1 The middle is the horizontal direction), and the Y-axis direction is positioned in the direction perpendicular to the X-axis in the horizontal plane ( figure 1 in the vertical paper direction), figure 1 The upward direction of the outer surface of the middle segment 1 is the Z-axis direction ( figure 1 The middle is the upward direction along the paper surface).

[0029] Such as Figure 1~4 As shown, the segment 1 is supported upside down on the gro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com