Servicing work method for locomotive roof

A technology for locomotives and operating systems, applied in vehicle cleaning, vehicle cleaning equipment, manipulators, etc., can solve problems such as low degree of automation, large influence of human factors, waste of resources, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0062] The specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings of the specification, but the present invention can be implemented in many different ways defined and covered by the claims.

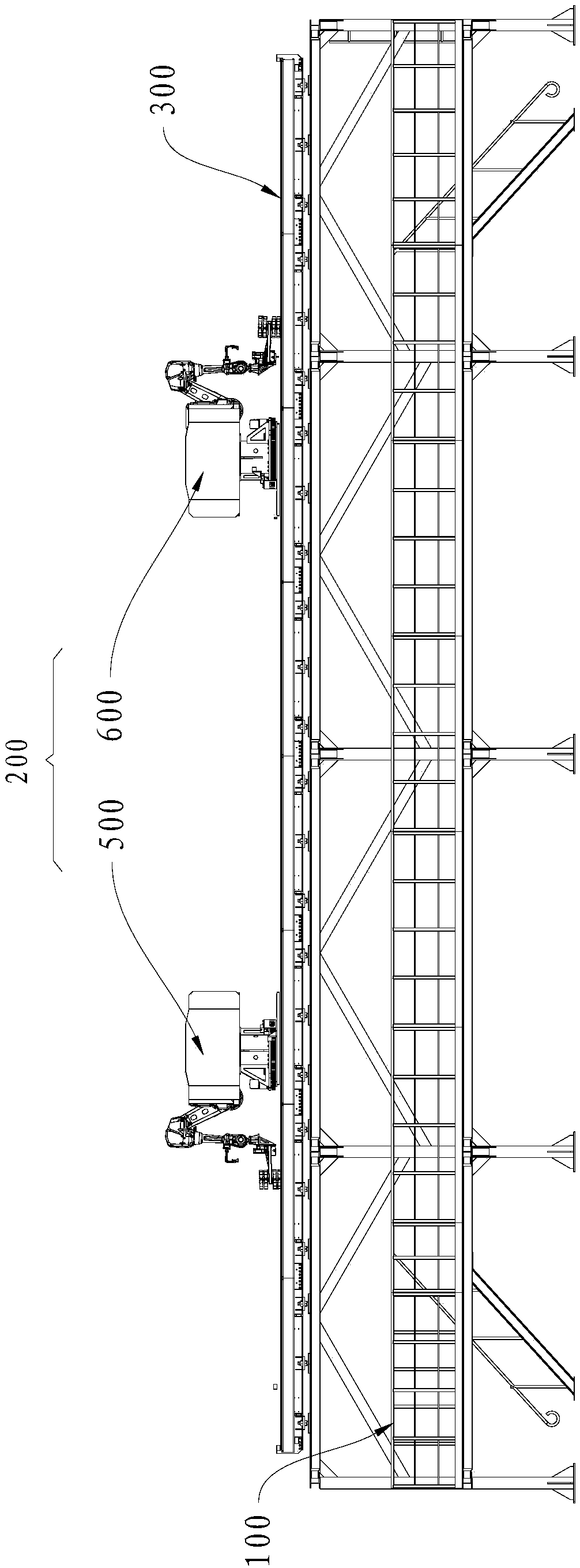

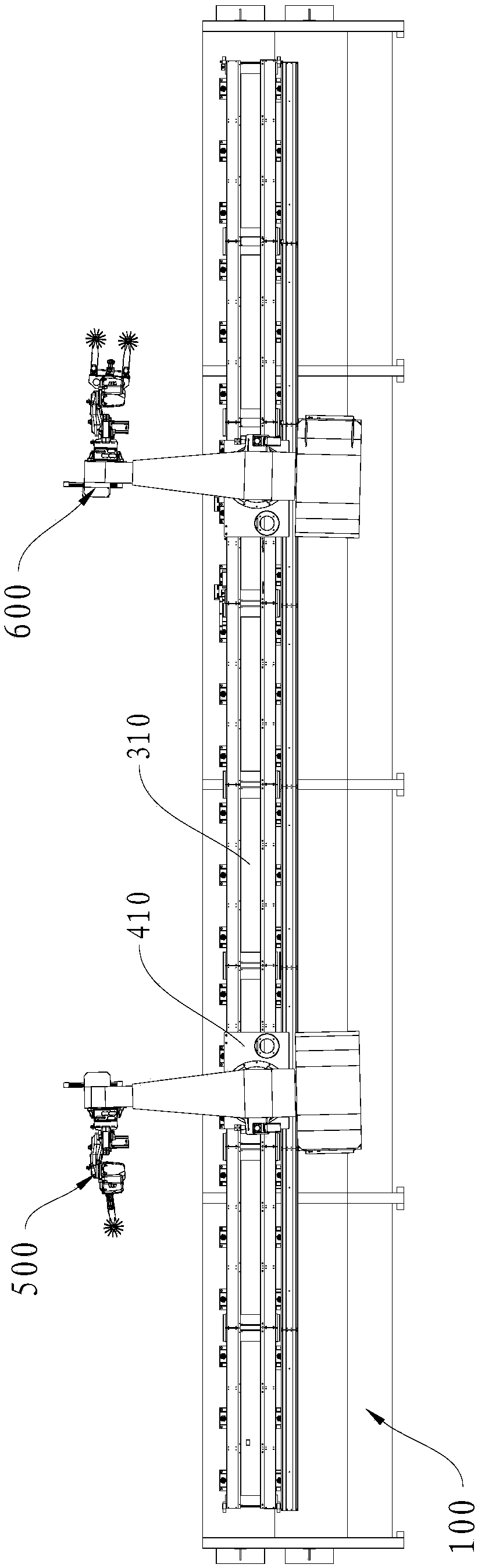

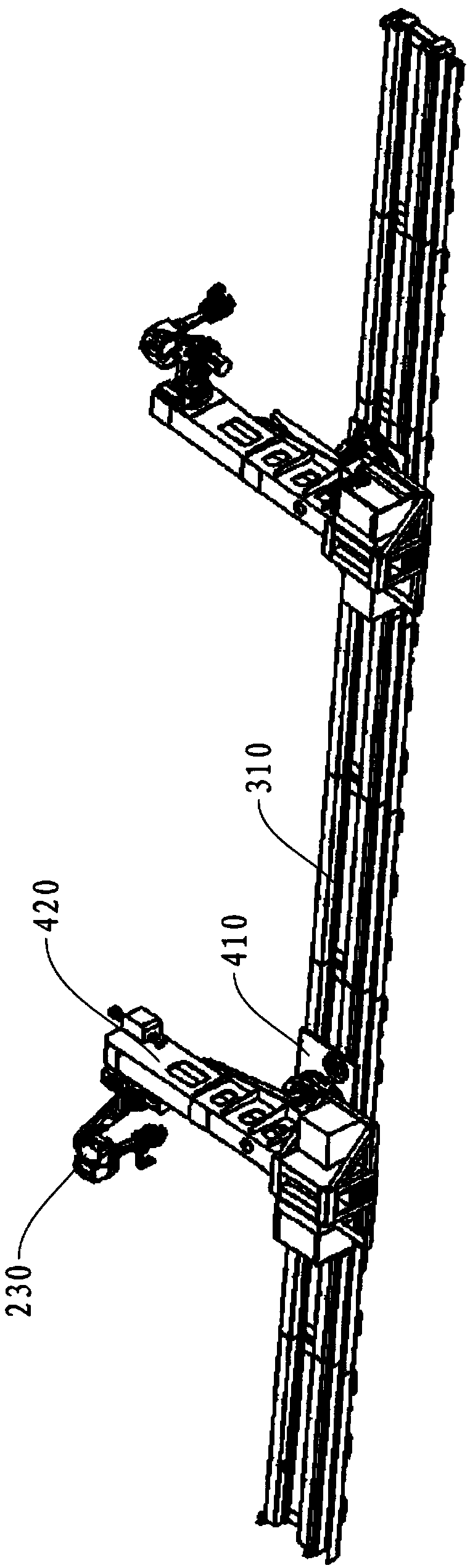

[0063] Reference figure 1 with figure 2 , The locomotive roof preparation operation system in an embodiment of the present invention includes a master control system, an image positioning recognition module and a roof preparation operation device.

[0064] Among them, the locomotive roof preparation operation device is erected on the three-layer platform 100, which is mainly used for the inspection and cleaning of the locomotive roof. It adopts image recognition and motion path intelligent planning technology to realize the fault diagnosis of the electrical components of the roof cover. Functions such as automatic detection of pantograph and cleaning and maintenance of insulators.

[0065] The vehicle roof preparation opera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com