Patents

Literature

252results about "Cleaning apparatus for railways" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Train cleaning method and system based on urban rail transit

ActiveCN105459970ARealize autonomous drivingImprove operational efficiencyCleaning apparatus for railwaysCleaning apparatus for vehicle exteriorsMachine controlCleaning station

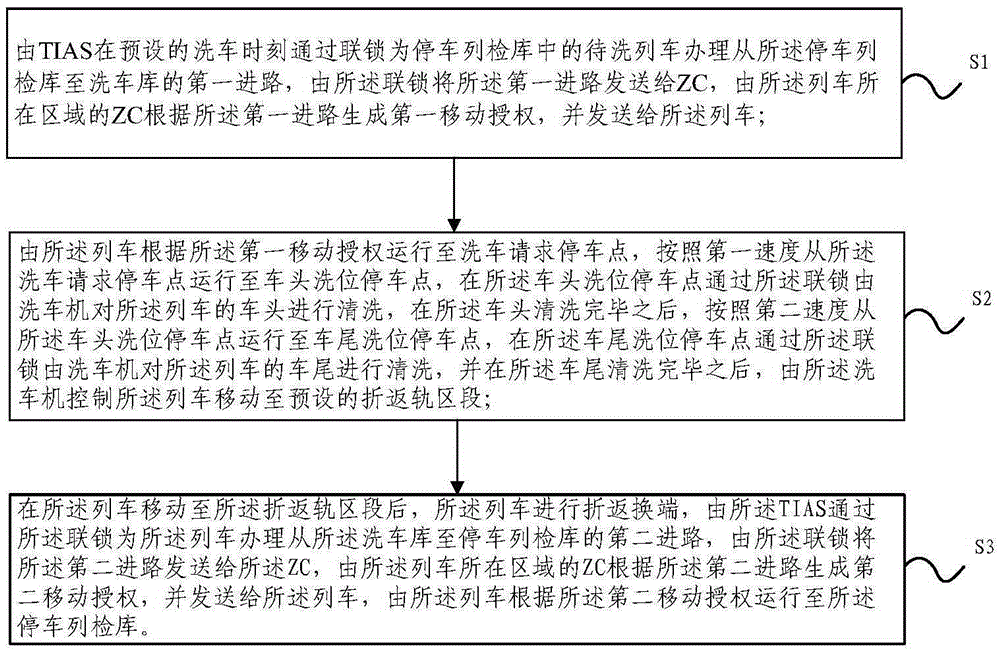

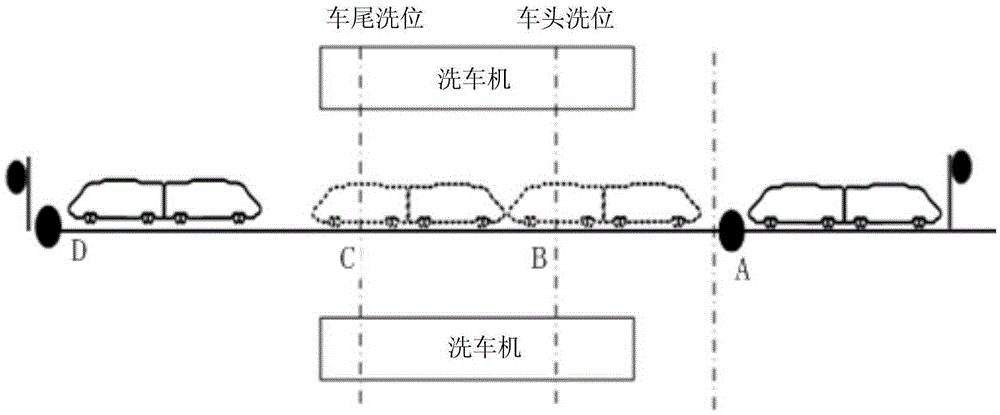

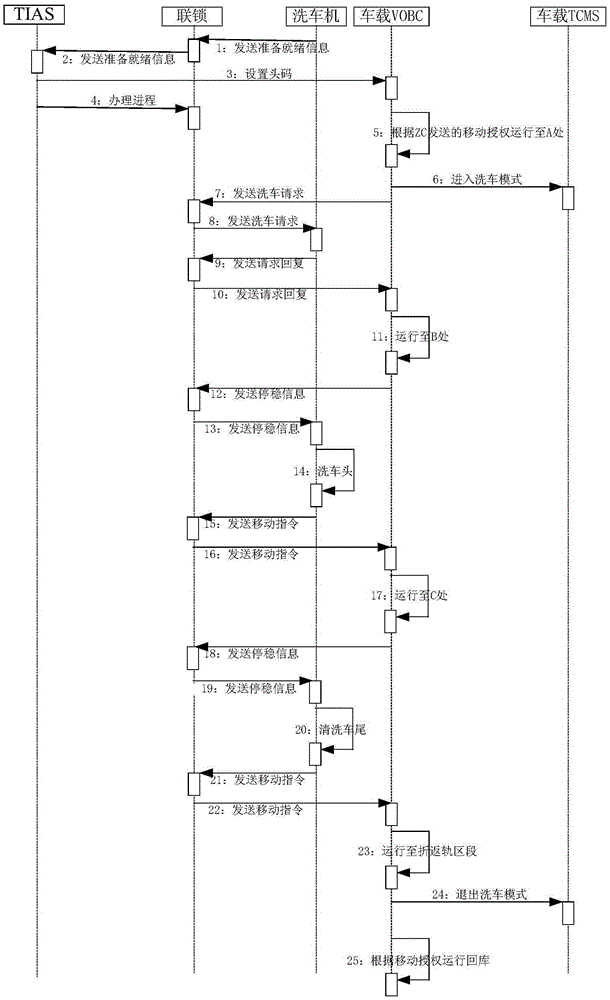

The invention discloses a train cleaning method and system based on urban rail transit. Full automatic driving can be achieved in the whole process since a train is bound for a train cleaning barn until the train leaves the train cleaning barn after train cleaning is completed, and thus operation efficiency is improved. The method includes the steps that S1, a train integrated automation system (TIAS) sets a first approach road for the train to be cleaned through an interlock at the train cleaning moment, the interlock sends the first approach road to a zone controller (ZC), the ZC in the area where the train is located generates a first movement authorization, and the first movement authorization is sent to the train; S2, the train runs to a train head cleaning station parking point, a train head is cleaned through a train cleaning machine, after train head cleaning is completed, the train runs to a train tail cleaning station parking point, a train tail is cleaned through the train cleaning machine, and after train tail cleaning is completed, the train cleaning machine controls the train to move to a back-turning track section; and S3, back-turning end exchange is conducted on the train, the TIAS sets a second approach road for the train, the interlock sends the second approach road to the ZC, the ZC in the area where the train is located generates a second movement authorization, the second movement authorization is sent to the train, and the train runs to a parking train examination barn according to the second movement authorization.

Owner:TRAFFIC CONTROL TECH CO LTD

Method and device for de-icing of trains

ActiveUS20090188989A1Drawbacks of the conventional de-icing are eliminatedDrawback can be obviatedOther chemical processesCleaning apparatus for railwaysEngineeringEthylene glycol

Owner:NORDIC GROUND SUPPORT EQUIP IP

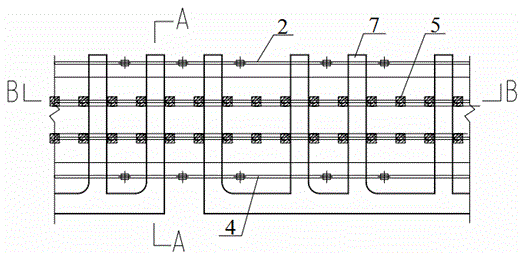

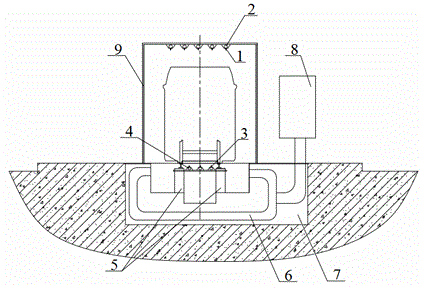

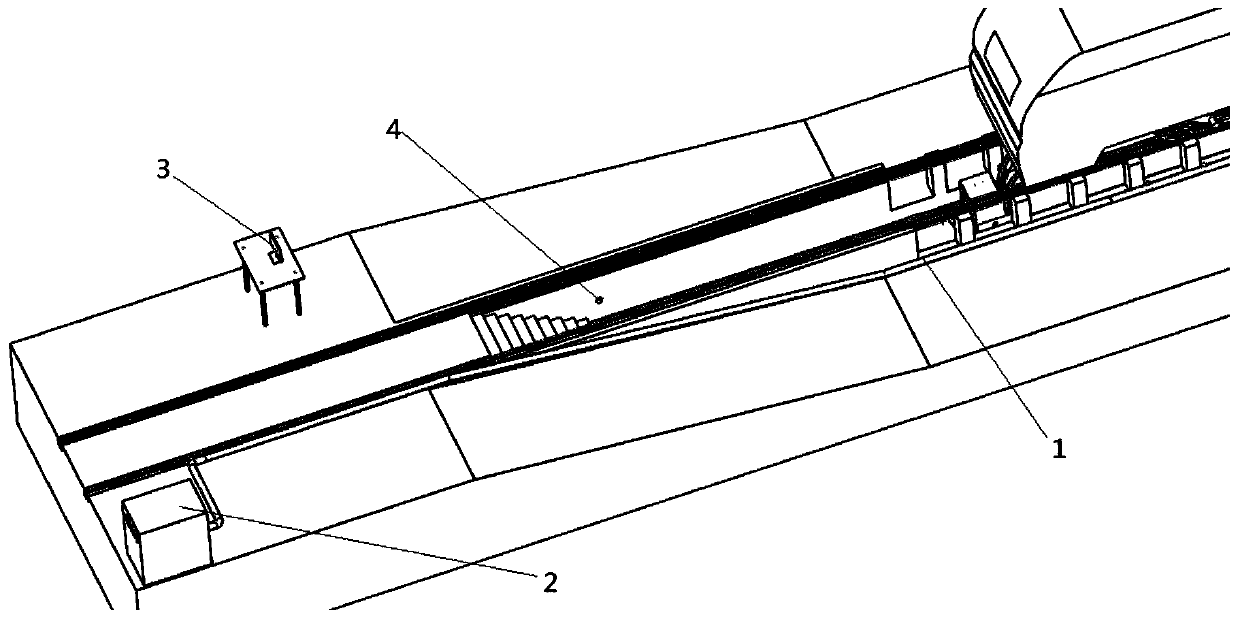

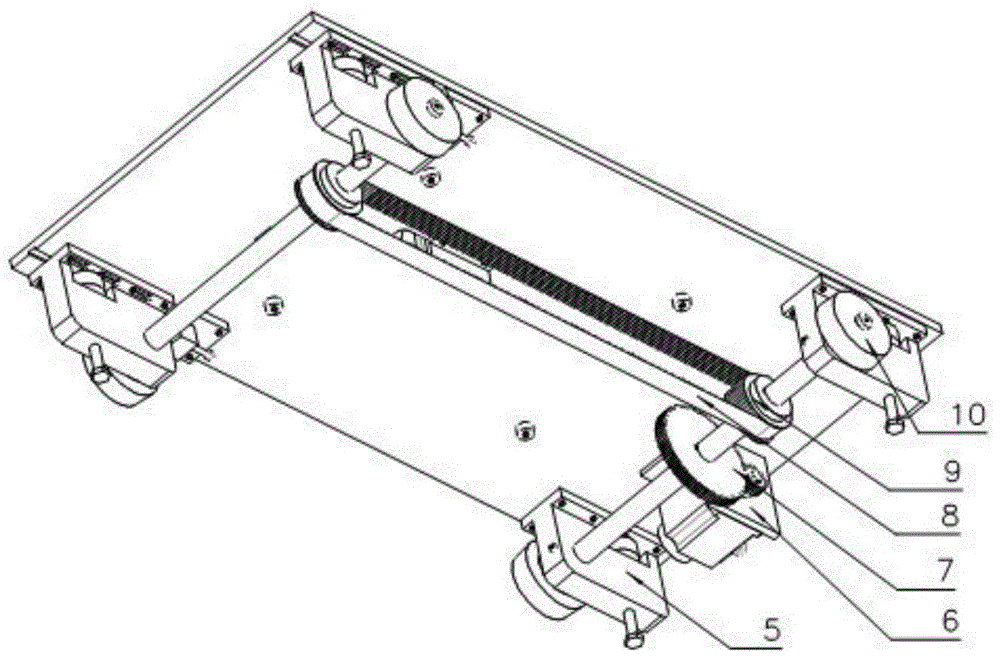

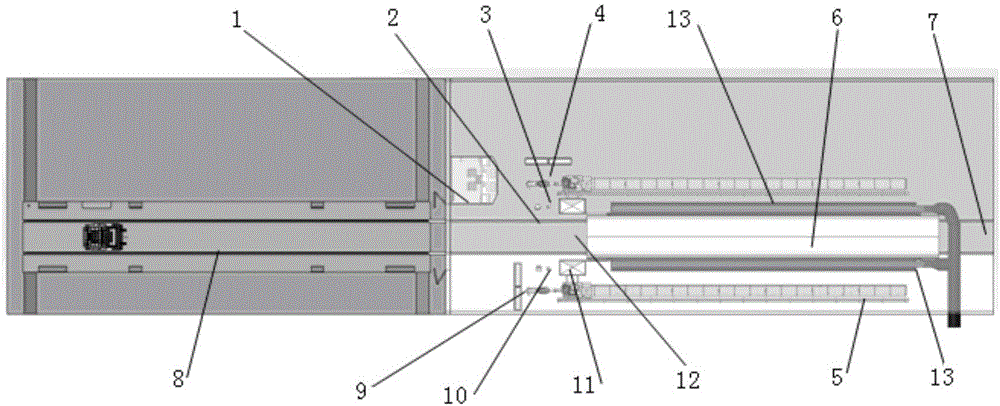

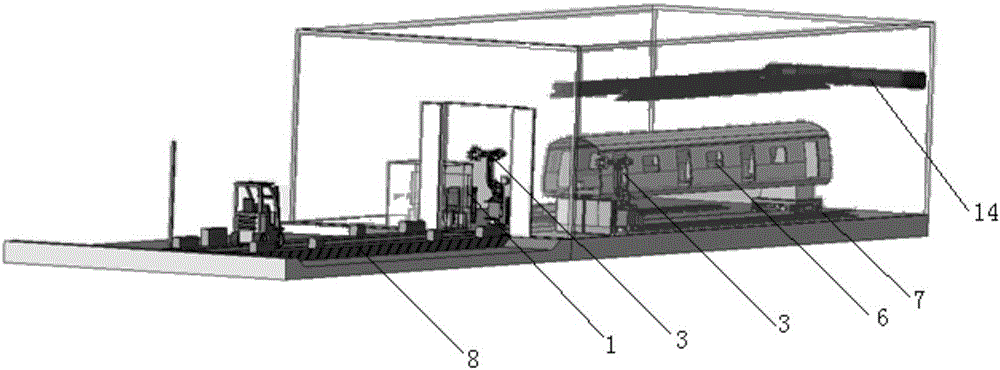

Track transportation vehicle bottom blowing and sweeping system and method

PendingCN107512246APrevent proliferationImprove working environmentCleaning apparatus for railwaysControl theoryRail transit

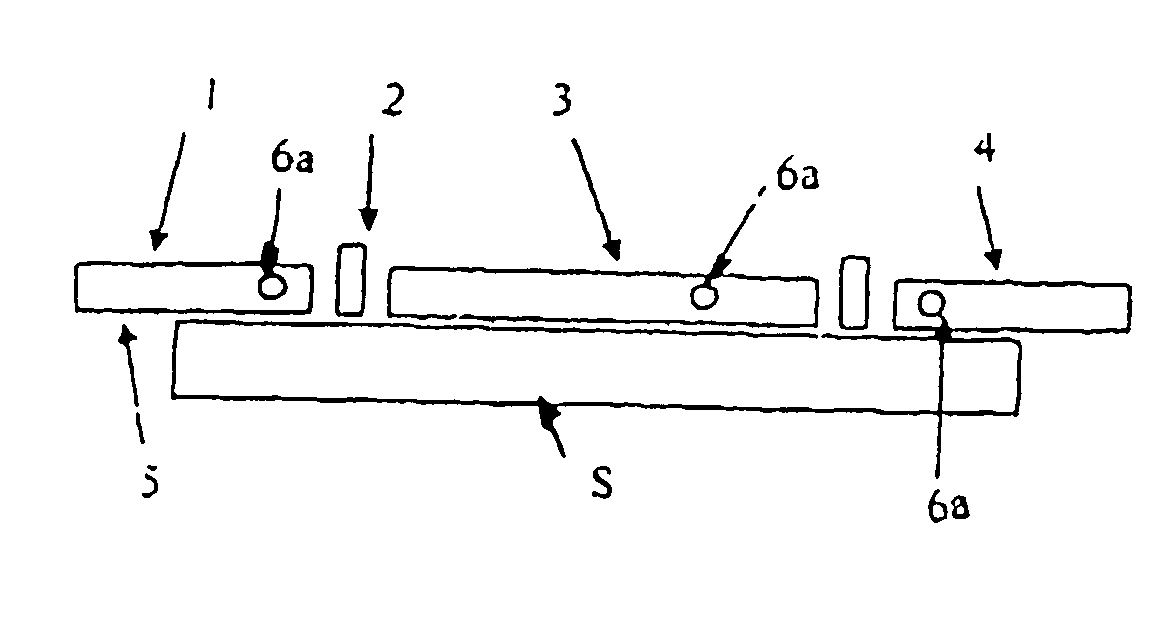

The invention discloses a track transportation vehicle bottom blowing and sweeping system. The track transportation vehicle bottom blowing and sweeping system comprises a dust absorption machine (3), a transportation van (4), guide wheels (5), guide grooves (6), dust absorption openings (8) and air hoses (9), wherein the guide grooves (6) are formed in the ground on two sides of a vehicle outline (2); the transportation van (4) is arranged above the guide wheels (5); the dust absorption machine (3) is arranged in the transportation van (4); the dust sucking openings (8) are respectively formed in one side close to the vehicle outline (2), of the transportation van (4); and the air hoses (9) are respectively arranged at one corner of the transportation van (4). The invention further discloses a track transportation vehicle bottom blowing and sweeping method. According to the track transportation vehicle bottom blowing and sweeping system disclosed by the invention, a small space which is relatively closed can be formed in each service position, so that good dust absorption effect is achieved, the situation that dust generated during the blowing and sweeping operation is diffused is avoided, and the operating environment of a blowing and sweeping storehouse is improved; and the track transportation vehicle bottom blowing and sweeping system is convenient to operate, and the labor intensity of workers is reduced.

Owner:CHINA RAILWAY SIYUAN SURVEY & DESIGN GRP

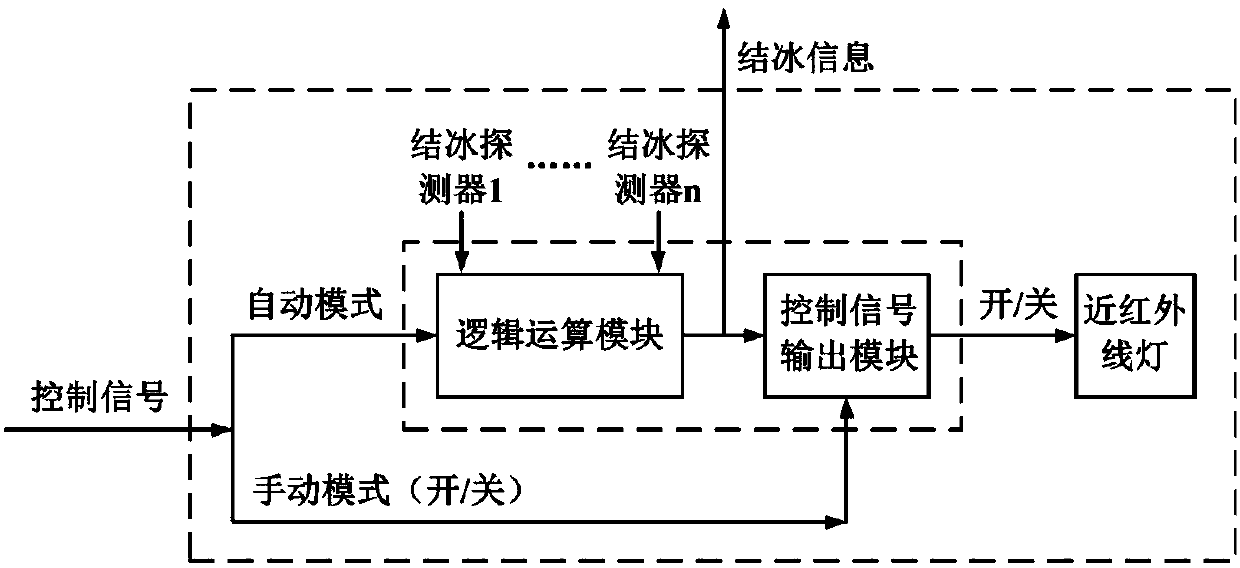

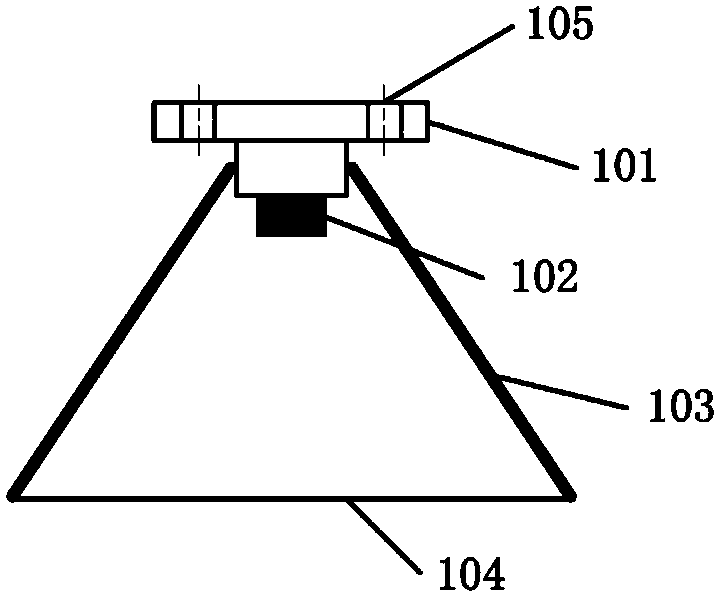

Deicing sub system, system and method

PendingCN107891883ASolve the problem of bad or even freezing to deathEasy to removeCleaning apparatus for railwaysBrake arrangement with pressed braking surfaceCoating systemSwitching signal

The invention relates to the technical field of vehicle deicing, in particular to a deicing sub system, system and method. The deicing sub system comprises a near-infrared light emission device, a deicing detector and a controller, the near-infrared light emission device, the deicing detector and the controller are arranged on a rail vehicle, and the near-infrared light emission device aims at theposition, which needs deicing, on the rail vehicle, the deicing detector is used for detecting the deicing thickness, comparing the deicing thickness with a set value and giving out a switch signal to the controller according to a comparison result, and the controller is used for controlling switching-on and switching-off of the near-infrared light emission device. According to the deicing sub system, based on a near-infrared light coating on the rail vehicle, when the deicing starting condition is satisfied, a starting signal is given out to the near-infrared light emission device which is arranged above a basic braking device, so that the near-infrared light emission device is started. Near-infrared light penetrates through an ice and snow layer and irradiates the surface of the near-infrared light coating so that the near-infrared light coating can generate heat quickly, and accordingly the ice and snow layer is easily removed from the surface of the coating under effects of vehicle vibration, external wind force and the like.

Owner:CRRC QINGDAO SIFANG CO LTD

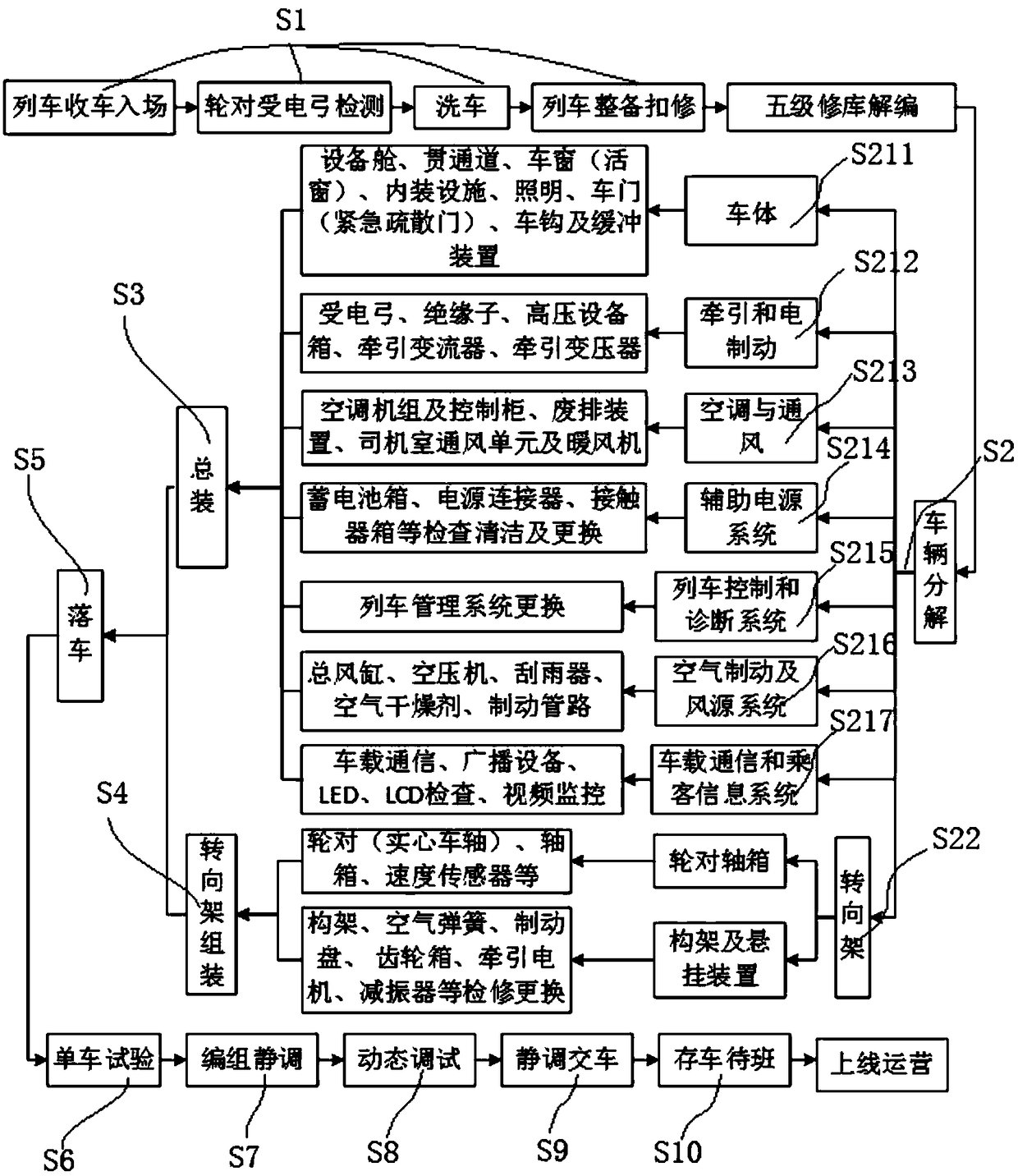

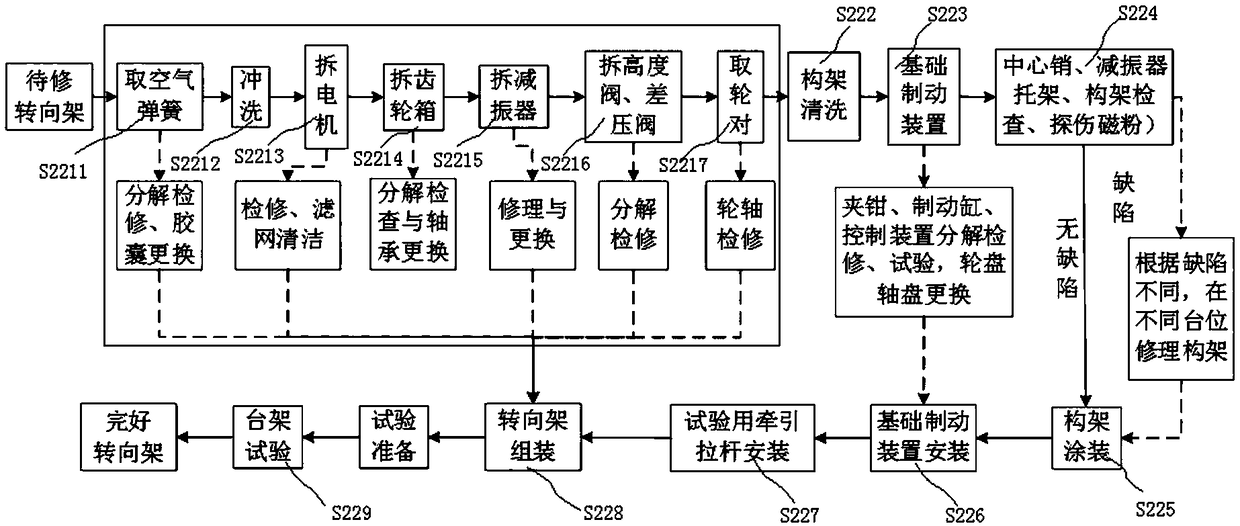

Five-stage overhaul process for urban region railway vehicle

ActiveCN109398411AGuaranteed uptimeMaintenance process is clearAnalysing solids using sonic/ultrasonic/infrasonic wavesMachine bearings testingUrban regionBogie

Owner:CHINA RAILWAY SIYUAN SURVEY & DESIGN GRP

Rail vehicle bottom cleaning equipment

ActiveCN106218594ARealize automatic dual-media cleaningEfficient removalCleaning apparatus for railwaysCleaning apparatus for vehicle exteriorsLine tubingWarm water

The invention discloses rail vehicle bottom cleaning equipment. The rail vehicle bottom cleaning equipment comprises an automatic walking trolley, pipelines and a plurality of assembly components, wherein the automatic walking trolley is provided with a trolley body and a cabin body installed on the trolley body; the inner wall or the inner space of the cabin body is paved with the pipelines, and rapid connectors are arranged at the ends or the lead-out parts of the pipelines; the multiple assembly components are arranged in the cabin body and comprise mechanical arm assemblies, a water tank assembly, a display type nozzle assembly, an air compressor assembly, a dry ice cleaning machine assembly and a water pump assembly; a rapid connector of the water tank assembly, a rapid connector of the water pump assembly and a rapid connector of the display type nozzle assembly are connected with the rapid connectors led out of the waterway pipeline; and a rapid connector of the air compressor assembly, a rapid connector of the dry ice cleaning machine assembly and rapid connectors of the mechanical arm assemblies are connected with the rapid connectors led out of the gas circuit pipeline. According to the rail vehicle bottom cleaning equipment, cleaning and drying are conducted on non-waterproof electrical equipment and other equipment at the bottom of a rail vehicle at a time through the combination mode of warm water, dry ice and air supply and drying as well as a full-automatic positioning mode, and thus the rail vehicle bottom cleaning equipment is more practical and has industrial application value.

Owner:HUBEI REMOTE RAILWAY TECH +1

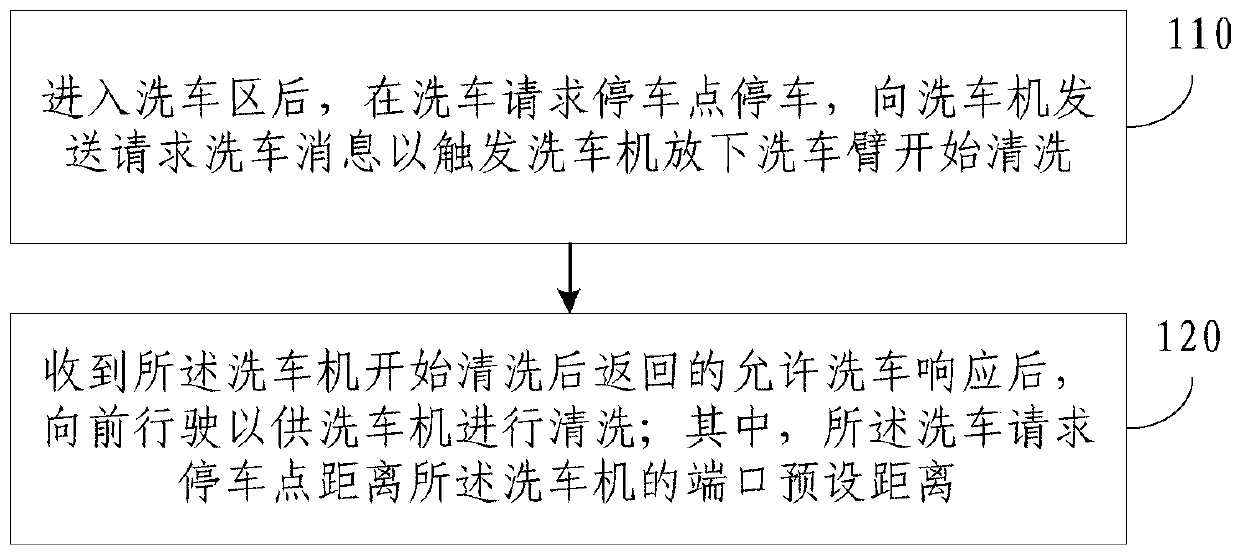

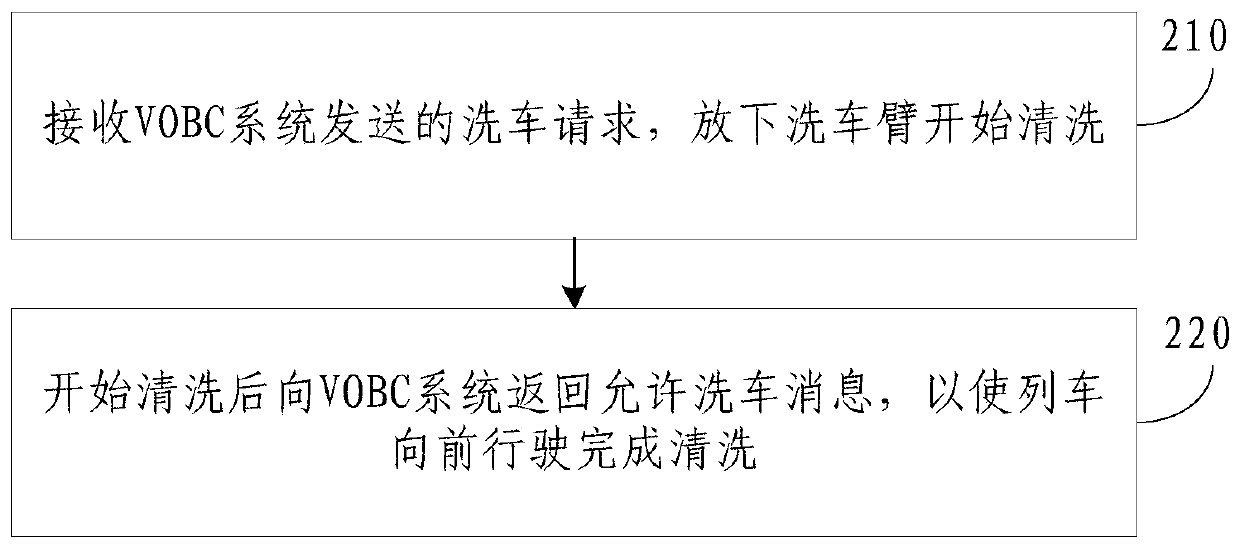

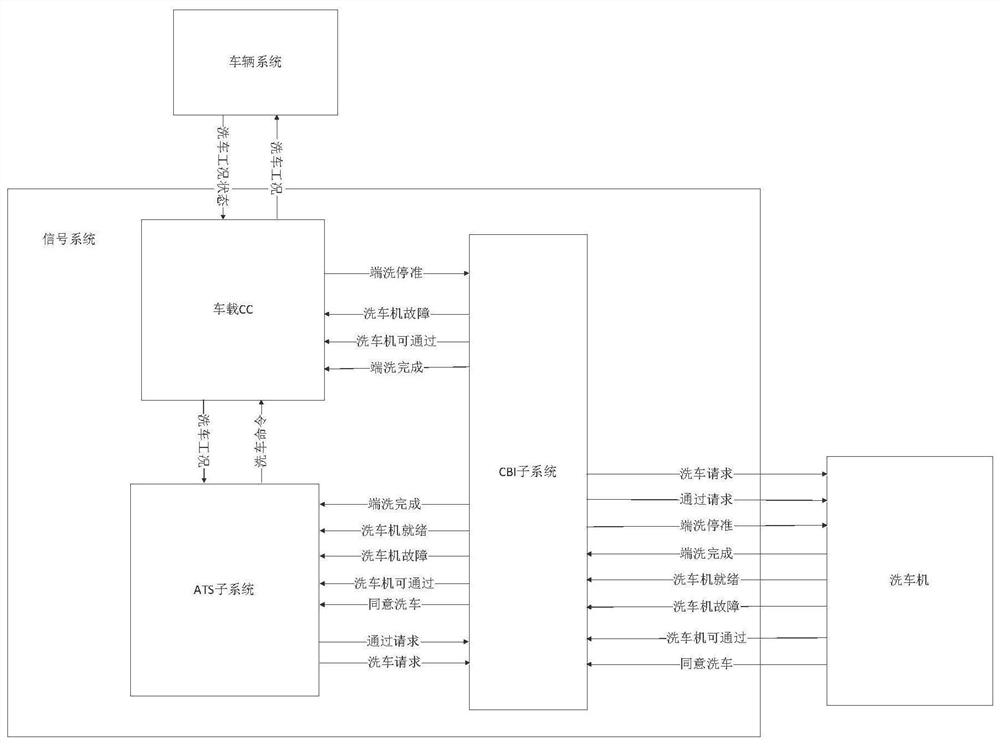

Train automatic cleaning method and VOBC system based on urban rail transit

ActiveCN110758332ARealize automatic cleaningImprove operational efficiencyCleaning apparatus for railwaysSignalling indicators on vehicleControl engineeringRail transit

An embodiment of the invention provides a train automatic cleaning method and a VOBC system based on urban rail transit. The method comprises the steps that after entering a vehicle washing area, a vehicle is stopped at a vehicle washing request parking point, a vehicle washing request message is sent to a vehicle washing machine to trigger the vehicle washing machine to lower a vehicle washing arm to start cleaning; and after an allowable vehicle washing message returned after the vehicle washing machine starts cleaning is received, the vehicle is moved forward to allow the vehicle washing machine to perform cleaning, wherein the distance between the vehicle washing request parking point and the inlet opening of the vehicle washing machine is a first preset distance. According to the method and the VOBC system, the automation of the train cleaning of the urban rail transit is realized, the train operation efficiency is improved, and the maintenance cost is reduced.

Owner:通号城市轨道交通技术有限公司

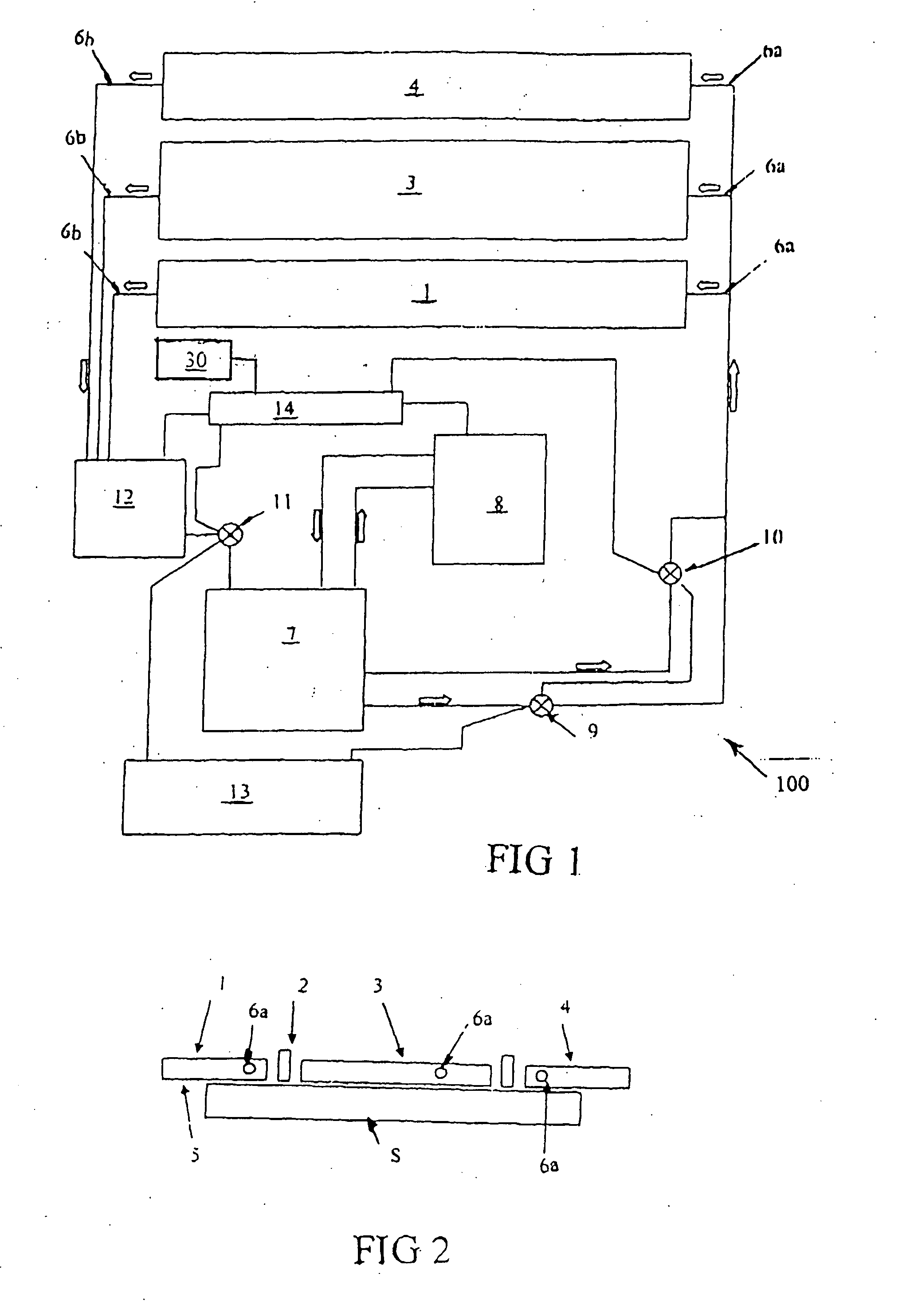

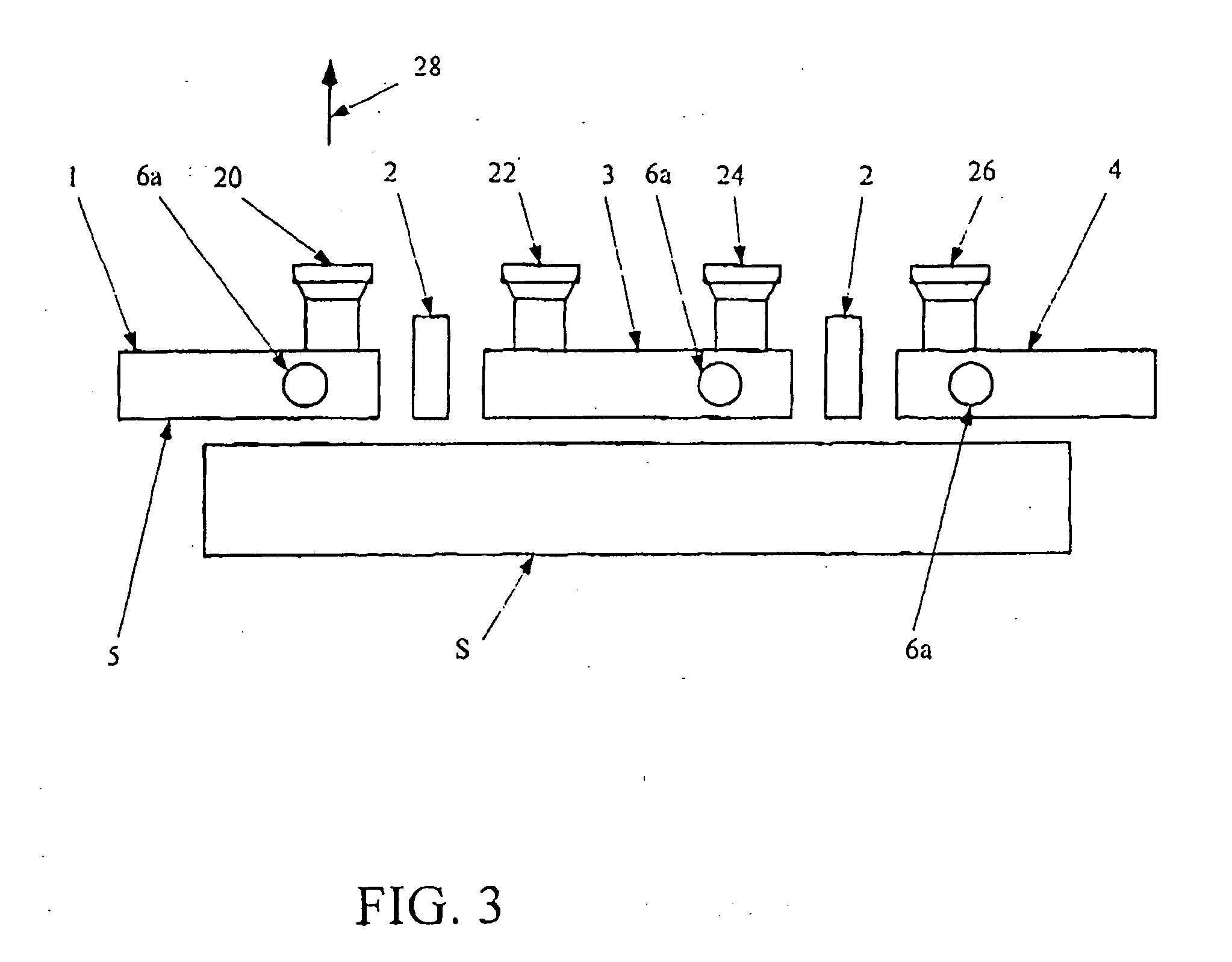

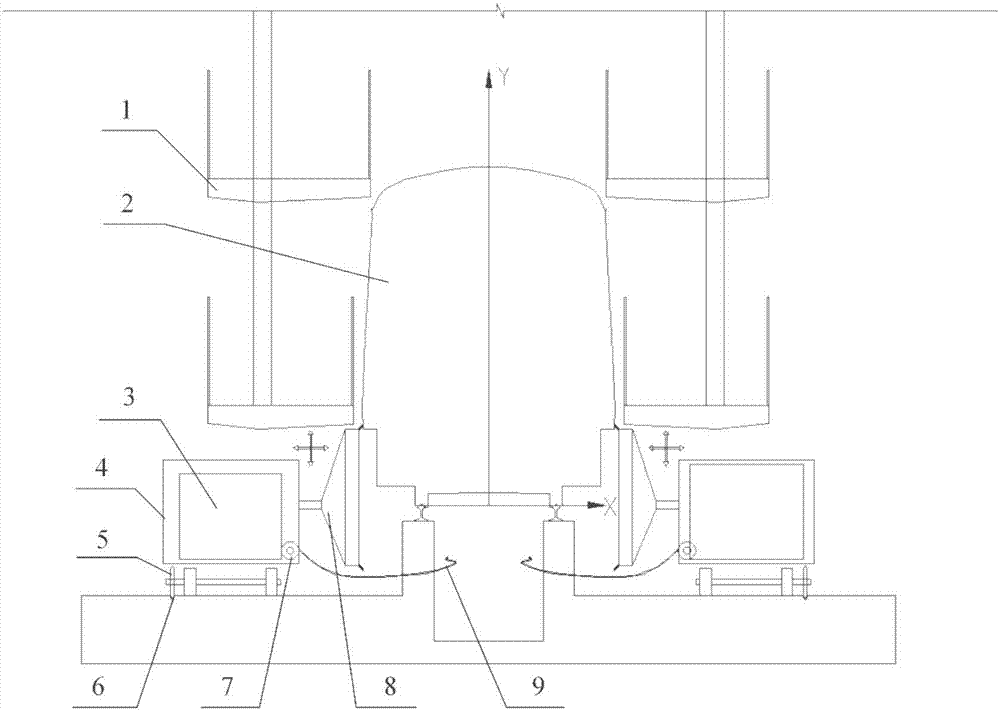

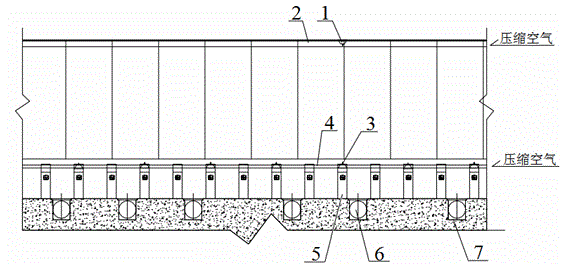

Trolley car purge system

ActiveCN104648338ASolve the problem of only blowing the bottom of the carShorten the timeCleaning apparatus for railwaysCleaning apparatus for vehicle exteriorsLand resourcesAutomotive engineering

The invention relates to a trolley car purge system. The trolley car purge system comprises a top purge mechanism, a bottom purge mechanism and a dust collecting mechanism, wherein the top purge mechanism comprises a plurality of upper spray heads arranged above trolley car rails and an upper compressed air pipeline connected with each upper spray head; the bottom purge mechanism comprises a plurality of lower spray heads arranged below the trolley car rails and a lower compressed air pipeline connected with each lower spray head; the upper compressed air pipeline and the lower compressed air pipeline are connected with an external compressed air source respectively. According to the trolley car purge system, the top purge mechanism and the bottom purge mechanism are arranged, so that the bottom and the top of the trolley car can be purged simultaneously or respectively, the problem that a vehicle purge device in the prior art only can purge the bottom is solved, land resources and equipment investment are saved, the vehicle purge and maintenance time is shortened, and the working efficiency is improved.

Owner:CHINA RAILWAY SIYUAN SURVEY & DESIGN GRP

Light rail vehicle surface cleaning and maintenance device

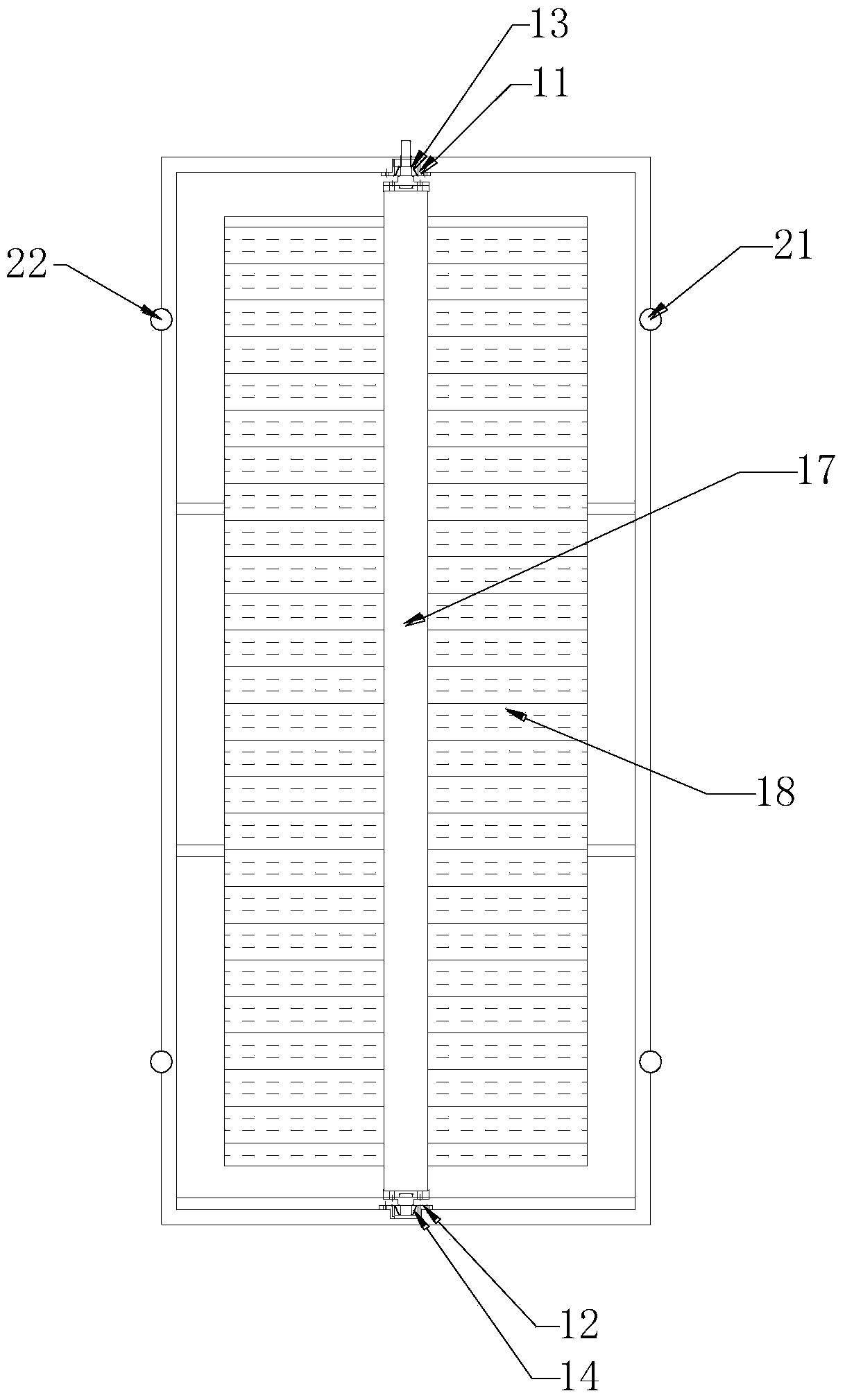

InactiveCN109334616AImprove leakageReduce collisionCleaning apparatus for railwaysCleaning apparatus for vehicle exteriorsWater leakageSurface cleaning

The invention discloses a light rail vehicle surface cleaning and maintenance device. The light rail vehicle surface cleaning and maintenance device can solve the problems that the cleaning area is small, the cleaning power is weak, and the brushing function is not provided. According to the scheme, the light rail vehicle surface cleaning and maintenance device comprises two fixing plates, a samearc-shaped plate is welded to the outer walls of the tops of the two fixing plates, base plates are welded to the outer walls of the bottoms of the fixing plates, and moving wheels are fixed to the outer walls of the bottoms of the base plates through bolts. A connecting seat is fixed to the middle position of the outer wall of the bottom of the arc-shaped plate by bolts, an elastic rope is fixedto the outer wall of the bottom of the connecting seat by bolts, and a connecting plate is connected to the outer wall of the bottom of the elastic rope in a bolted mode. The light rail vehicle surface cleaning and maintenance device performs secondary sealing on a cleaning solution by generating richer foam by the cleaning solution to block the contact of the cleaning solution with the outside, the water leakage rate is effectively reduced, the waste of the cleaning solution is avoided, and the cleaning solution is suddenly aggregated at a nozzle outlet and rushed out in an accelerated mode to enable the impact of the cleaning solution to be higher and the washing ability to be higher.

Owner:苏群健

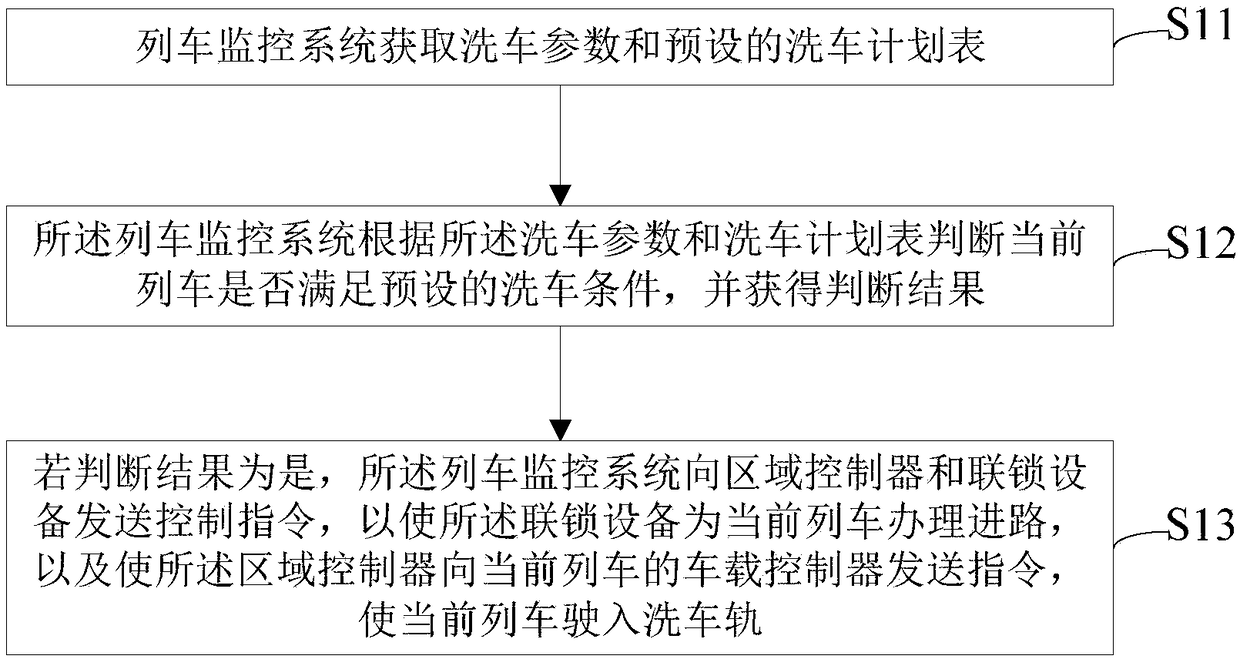

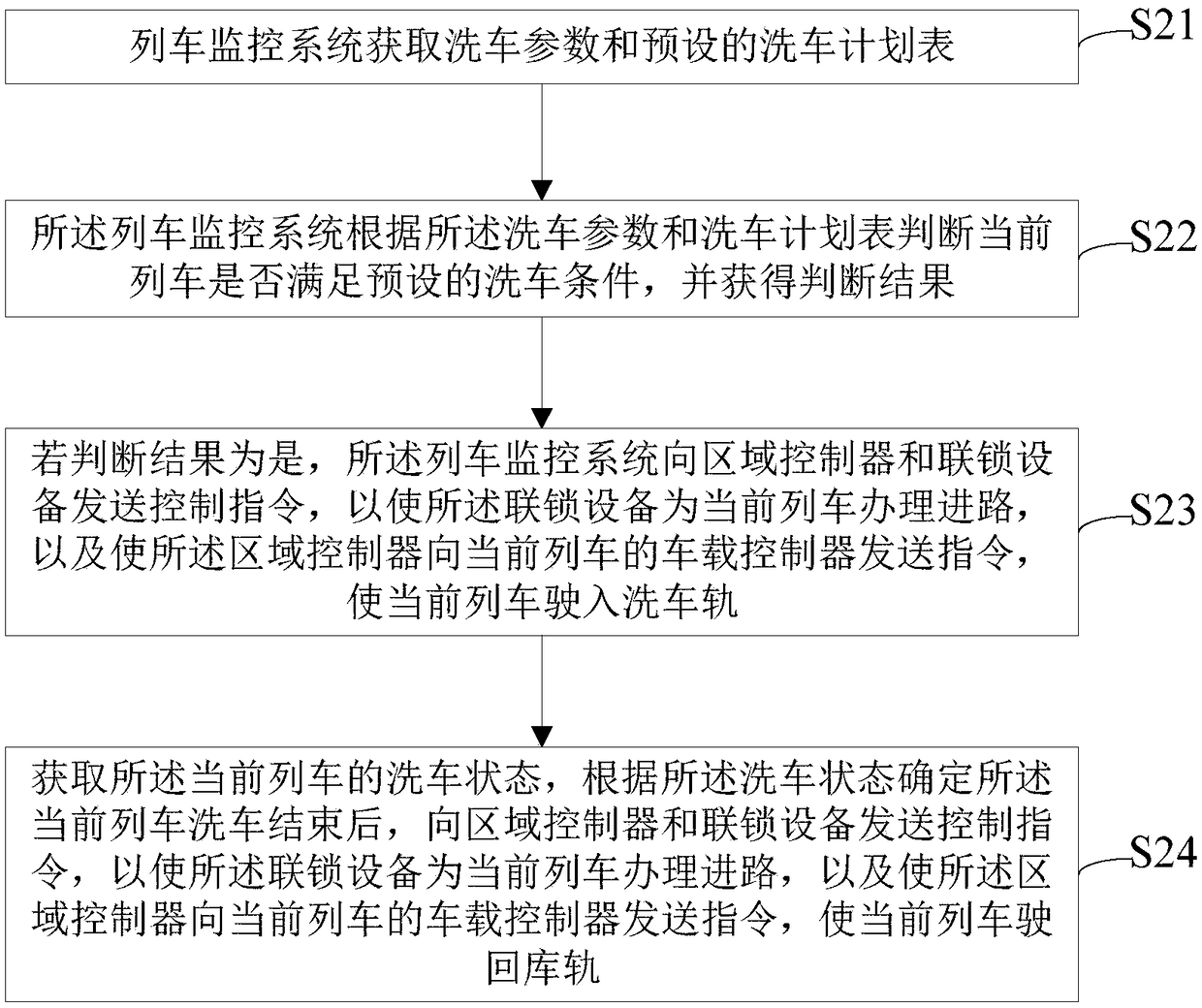

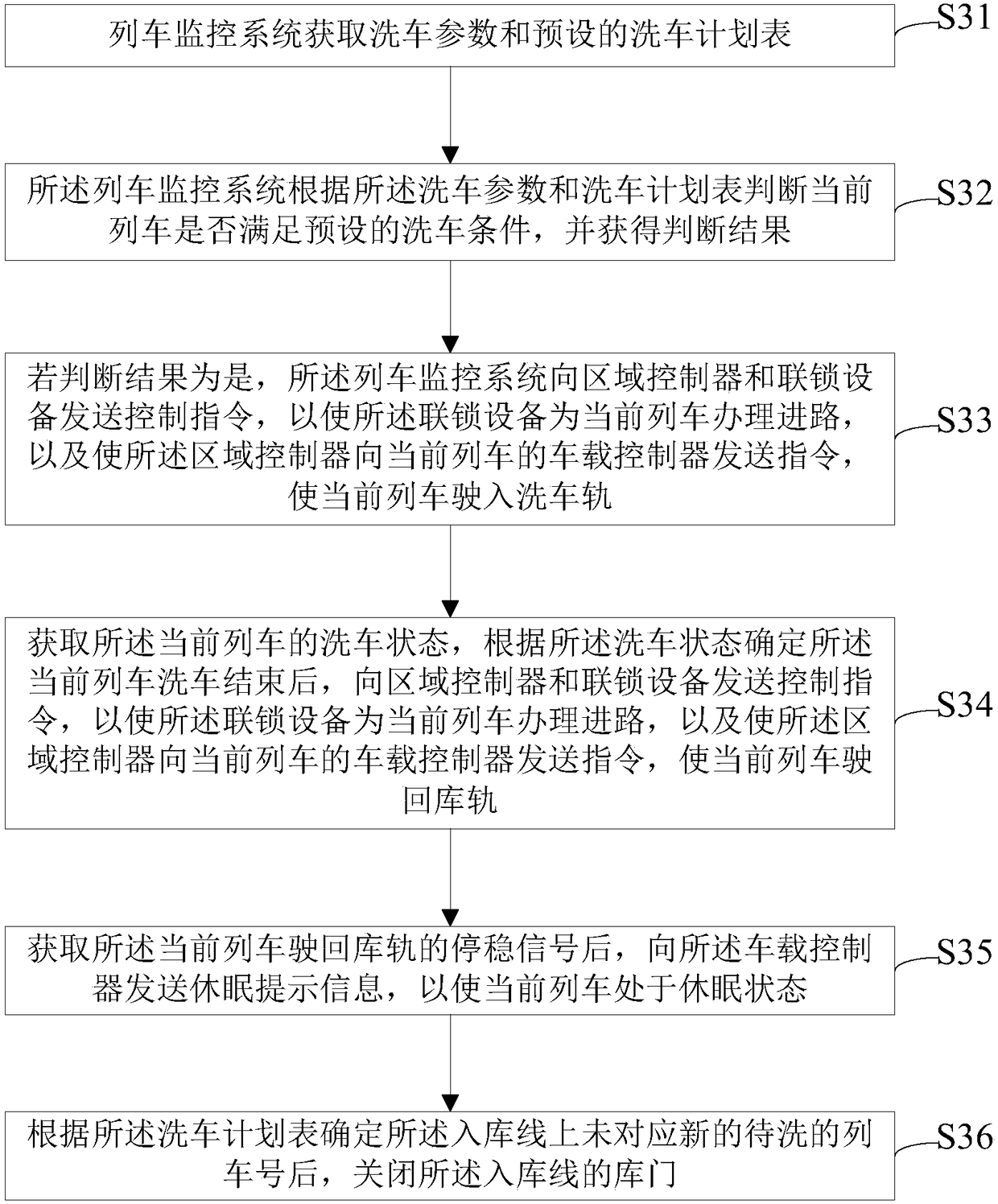

Automatic training cleaning processing method and device based on train washing plan

ActiveCN108132652ACleaning apparatus for railwaysProgramme total factory controlTime informationMonitoring system

The invention provides an automatic training cleaning processing method and device based on a train washing plan. The method comprises that a train monitoring system obtains train washing parameters,including warehouse track information, warehouse door state information, train washing equipment state information and time information, and a preset train washing plan table; the train monitoring system determines whether a present train satisfies present train washing conditions according to the train washing parameters and the train washing plan table, and obtains a determination result; and ifYES, the train monitoring system sends a control instruction to an area controller and interlock equipment, so that the interlock equipment realizes access for the present train, and the area controller sends an instruction to a controller mounted in the present train, so that the present train is driven into a train washing track and washed automatically.

Owner:TRAFFIC CONTROL TECH CO LTD

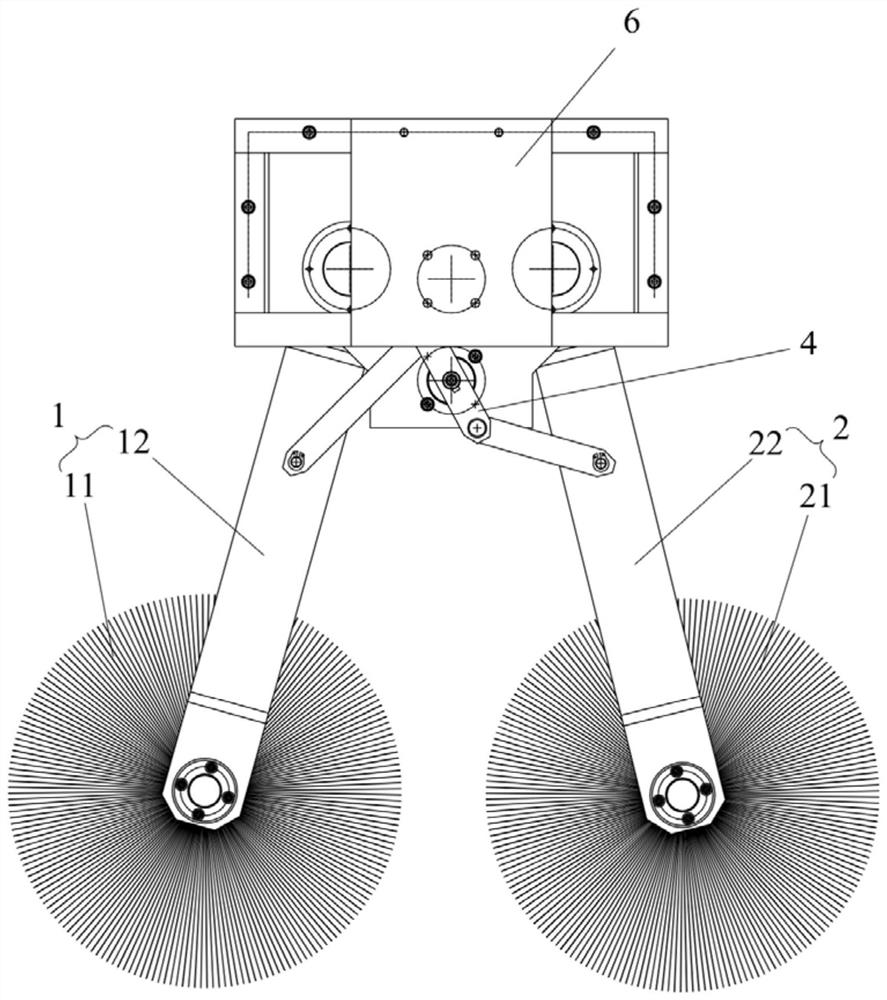

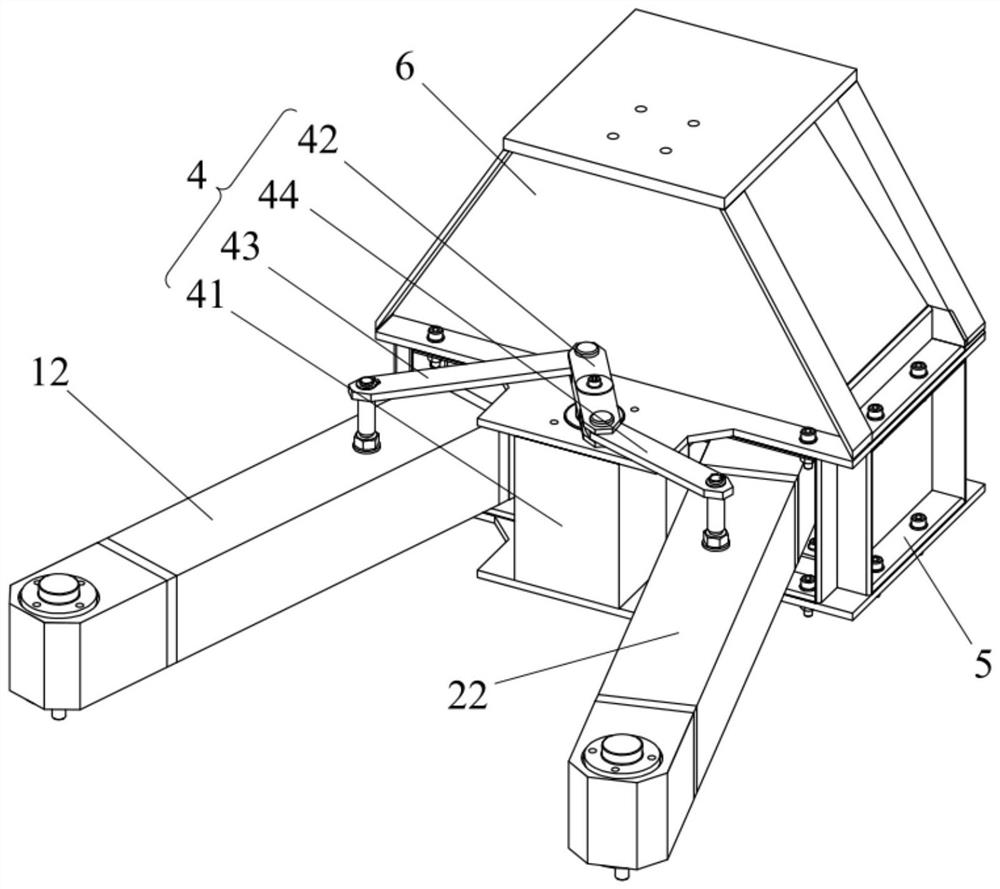

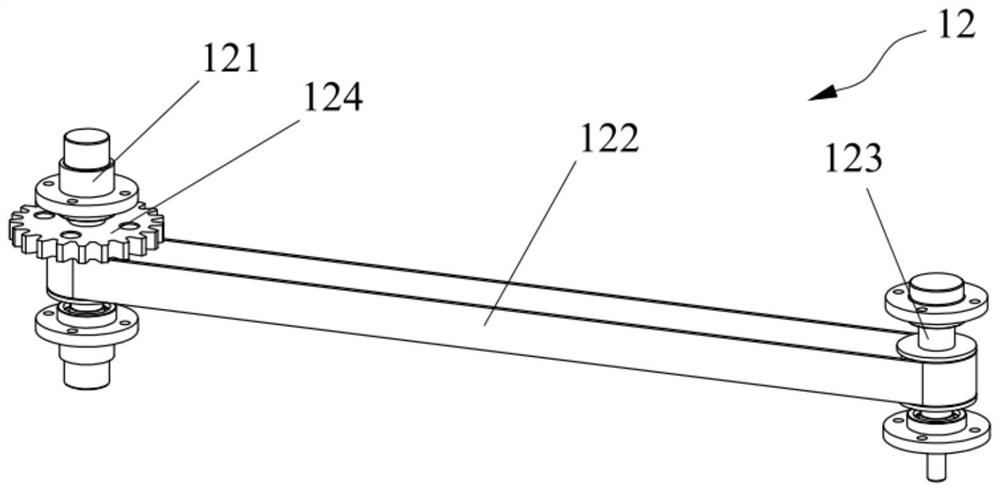

Cleaning device for roof insulator of powered car train-set

PendingCN111907478AEven by forceEasy to cleanCleaning apparatus for railwaysCleaning apparatus for vehicle exteriorsStructural engineeringBrush

The invention relates to the field of locomotive cleaning equipment, and discloses a cleaning device for a roof insulator of a powered car train-set. The cleaning device for the roof insulator of thepowered car train-set comprises a first cleaning unit, a second cleaning unit, a synchronization unit and a linkage unit, the first cleaning unit comprises a first cleaning brush and a first brush rodassembly, and the first cleaning brush is rotatably arranged on the first brush rod assembly; the second cleaning unit comprises a second cleaning brush and a second brush rod assembly, and the second cleaning brush is rotatably arranged on the second brush rod assembly; the synchronization unit is used for driving the first cleaning brush and the second cleaning brush to rotate synchronously; the linkage unit is connected with the first brush rod assembly and the second brush rod assembly and used for driving the first brush rod assembly and the second brush rod assembly to be synchronouslyopened or closed. The cleaning device is suitable for cleaning operation of insulators of different specifications, models and spatial positions on the roof of the powered car train-set, light in structure, low in cost and high in cleaning efficiency.

Owner:BEIJING RAILWAY INST OF MECHANICAL & ELECTRICAL ENG

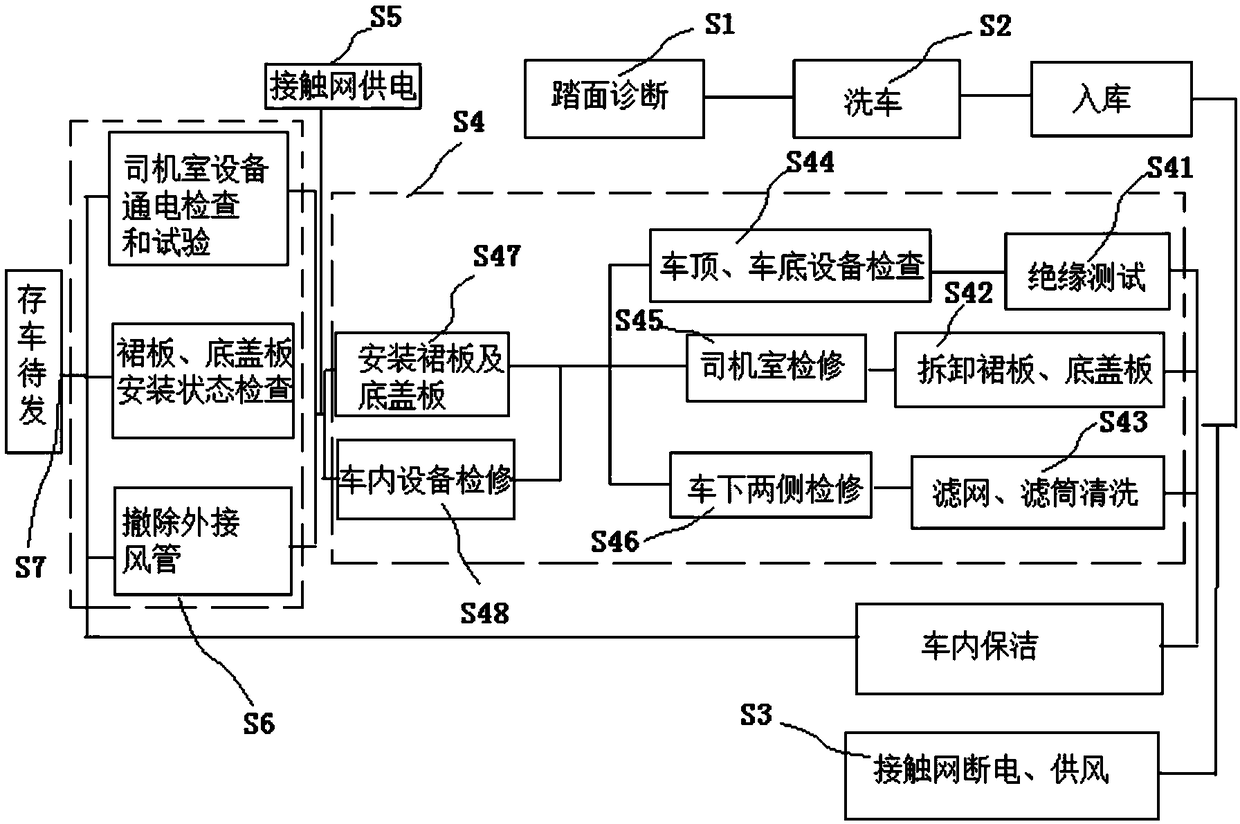

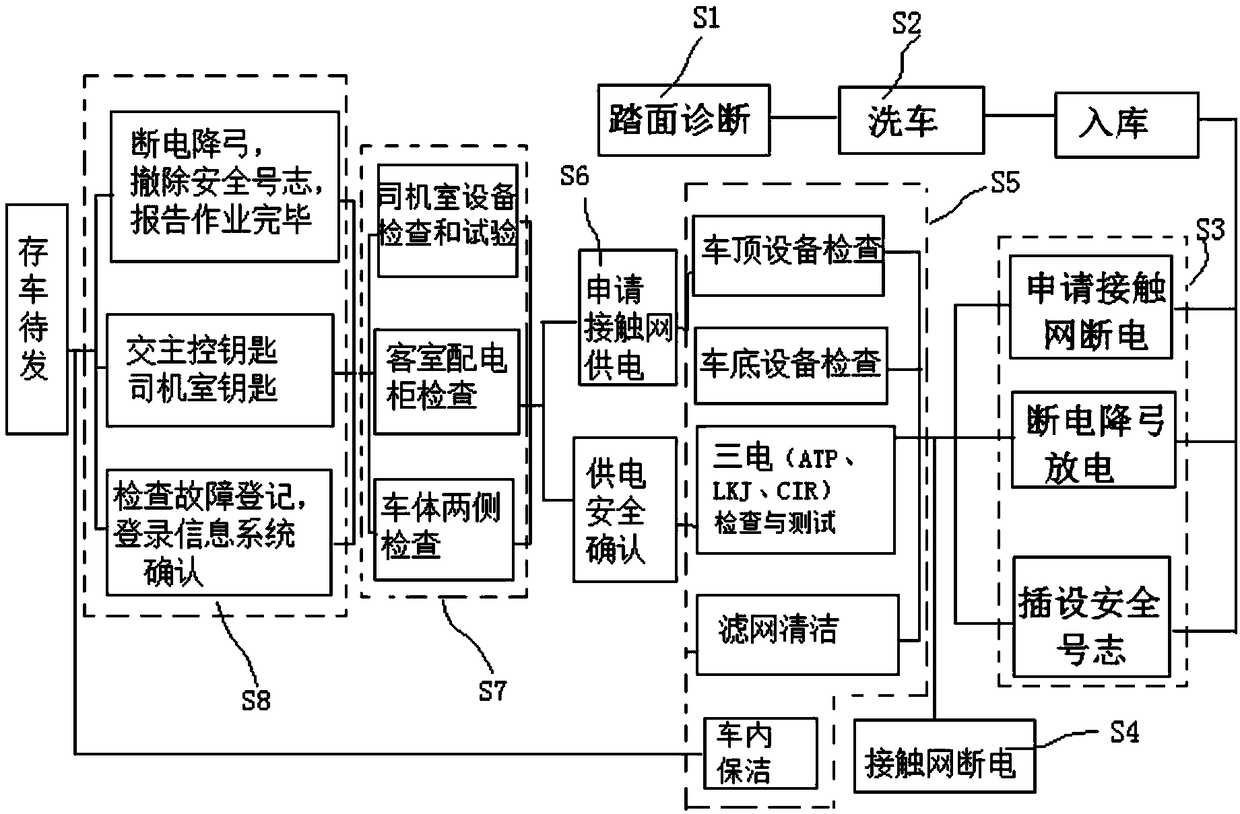

Secondary repair technology for municipal railway vehicle

InactiveCN109436022AEnsure safetyImprove adaptabilityAnalysing solids using sonic/ultrasonic/infrasonic wavesMachine bearings testingElectricityHigh effectiveness

The invention discloses a secondary repair technology for a municipal railway vehicle. The technology includes the following steps that wheel-set tread diagnosis and pantograph detection are performed; vehicles are cleaned and enters a garage, wherein in the cleaning process, dust, oil stain and other dirt, caused by the operation and maintenance of the municipal vehicle, on the exterior surface of vehicles are cleaned; power outage and air supply of a contact system are performed; no-power repair operation is carried out and includes insulation testing, vehicle roof equipment and vehicle bottom equipment inspection, disassembly of a skirtboard and a bottom cover plate, cleaning of a filter net and filter cylinder, maintenance of the two sides of the bottom of the vehicle, and cab maintenance; power is supplied to the contact system; power-on operation is performed and includes cab power-on inspection and test, skirtboard and bottom cover plate installation state inspection, and disconnection of external air duct; equipment location and vehicle abnormal condition inspection are performed before leaving the garage. The secondary repair technology for the municipal railway vehicle can adapt to the characteristics of rapid start and stop of the municipal railway vehicle for efficient and adaptive maintenance.

Owner:CHINA RAILWAY SIYUAN SURVEY & DESIGN GRP

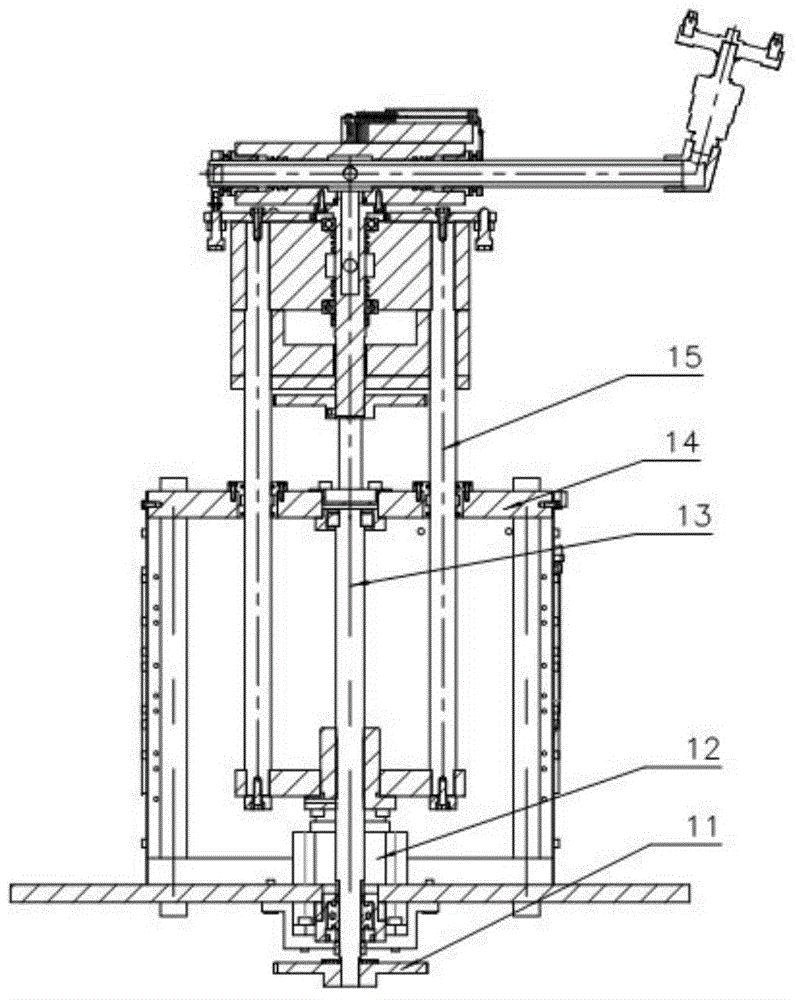

Cleaning device

ActiveCN104259146AEasy to cleanImprove work efficiencyCleaning apparatus for railwaysCleaning apparatus for vehicle exteriorsEngineeringExecution unit

The invention discloses a cleaning device. The cleaning device comprises a cleaning unit, a fluid supply unit and an adjusting unit; the cleaning unit is matched with cleaning fluid supplied by the fluid supply unit to clean the outer surface of an object to be cleaned; the adjusting unit is connected with the cleaning unit; the adjusting unit is used for adjusting the cleaning height and the cleaning angle of the cleaning unit. A cleaning execution unit of the cleaning device achieves all-directional cleaning of large-scale equipment through vertical moving and inclination, the working efficiency is improved, and labor intensity is reduced.

Owner:NINGBO GUOCHUANG LOCOMOTIVE EQUIP

Primary repair technology for municipal railway vehicle

ActiveCN109436023AEnsure safetyImprove adaptabilityAnalysing solids using sonic/ultrasonic/infrasonic wavesMachine bearings testingElectricityPrimary repair

The invention discloses a primary repair technology for a municipal railway vehicle. The primary repair technology includes the following steps that wheel-set tread diagnosis and pantograph detectionare performed; vehicles are cleaned, enters a garage for parking and are ready for power outage, after the municipal vehicle is parked well in the garage, preparation work is done before power outageof the vehicle, a ground rod is hung after it is determined that there is no power, and discharge operation is performed; no-power repair operation is carried out and includes vehicle roof equipment inspection, vehicle bottom equipment inspection, EIC system inspection and testing and filter net cleaning; power is supplied to the contact system, wherein a pantograph lands, and power is supplied tothe contact system after a ferry board withdraws and the ground rod is removed; power-on operation is performed and includes cab power-on inspection and test, passenger compartment power distributioncabinet inspection and vehicle-body two-sides inspection; equipment withdraws and the vehicle abnormal condition is inspected before the vehicle leaves from the garage, and the vehicle without the abnormal condition leaves from the garage. The primary repair technology for the municipal railway vehicle can adapt to the characteristics of rapid start and stop of the municipal railway vehicle for efficient and adaptive maintenance.

Owner:CHINA RAILWAY SIYUAN SURVEY & DESIGN GRP

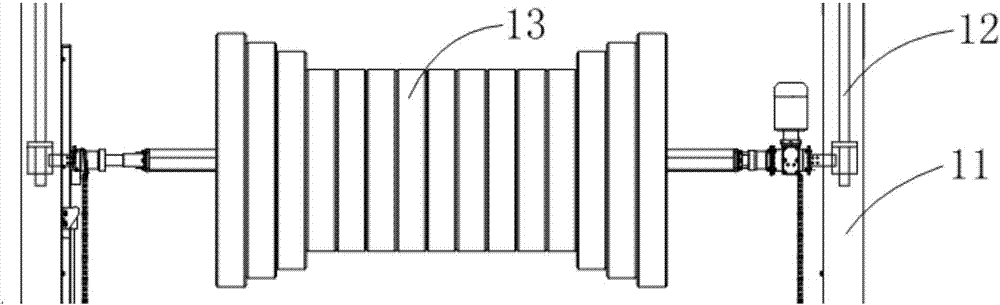

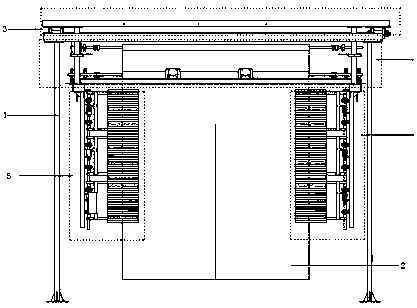

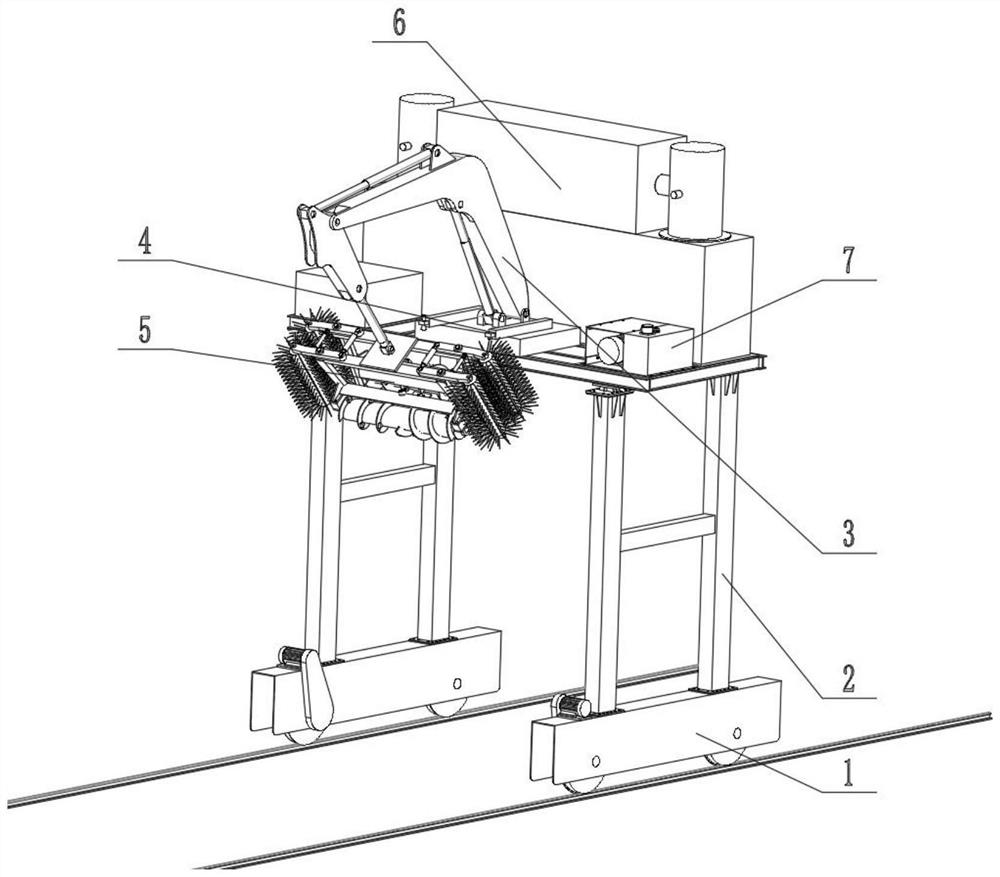

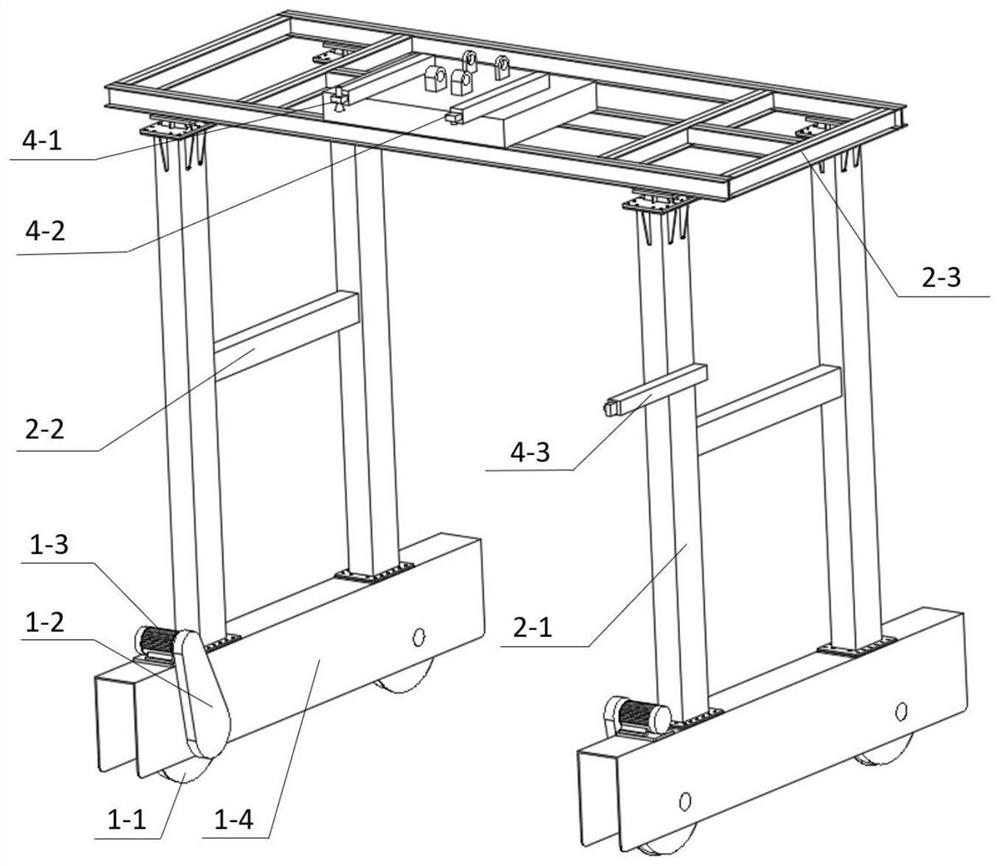

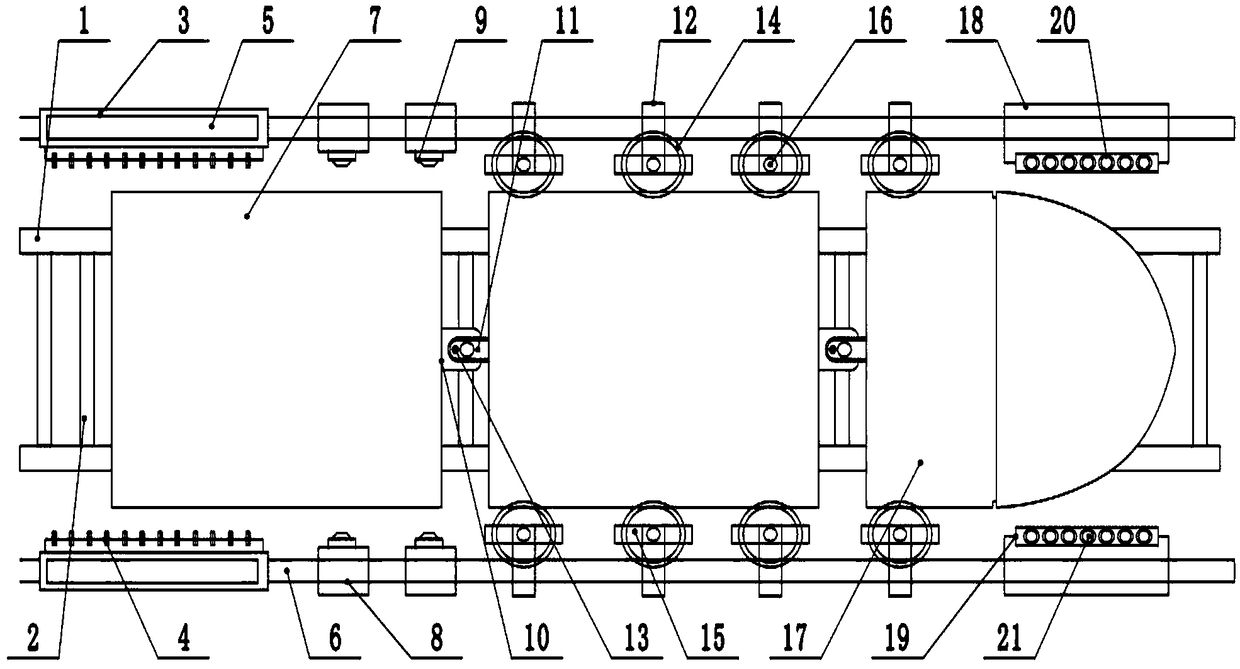

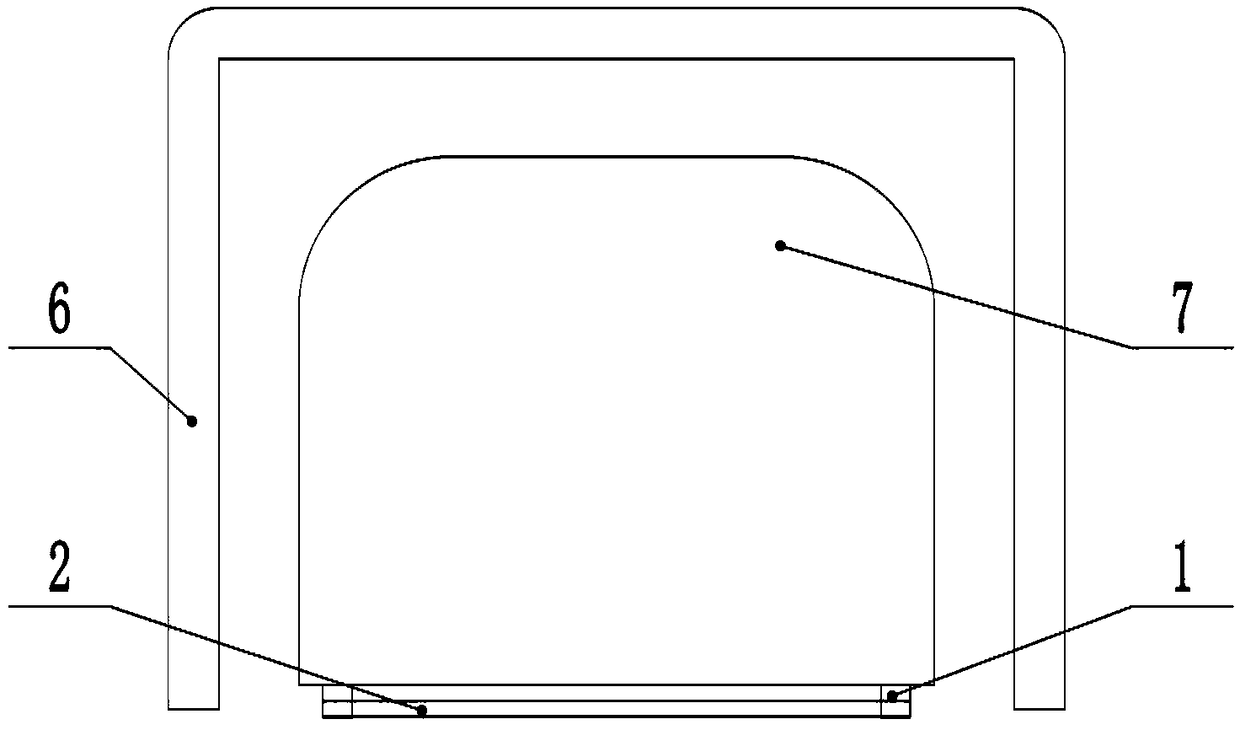

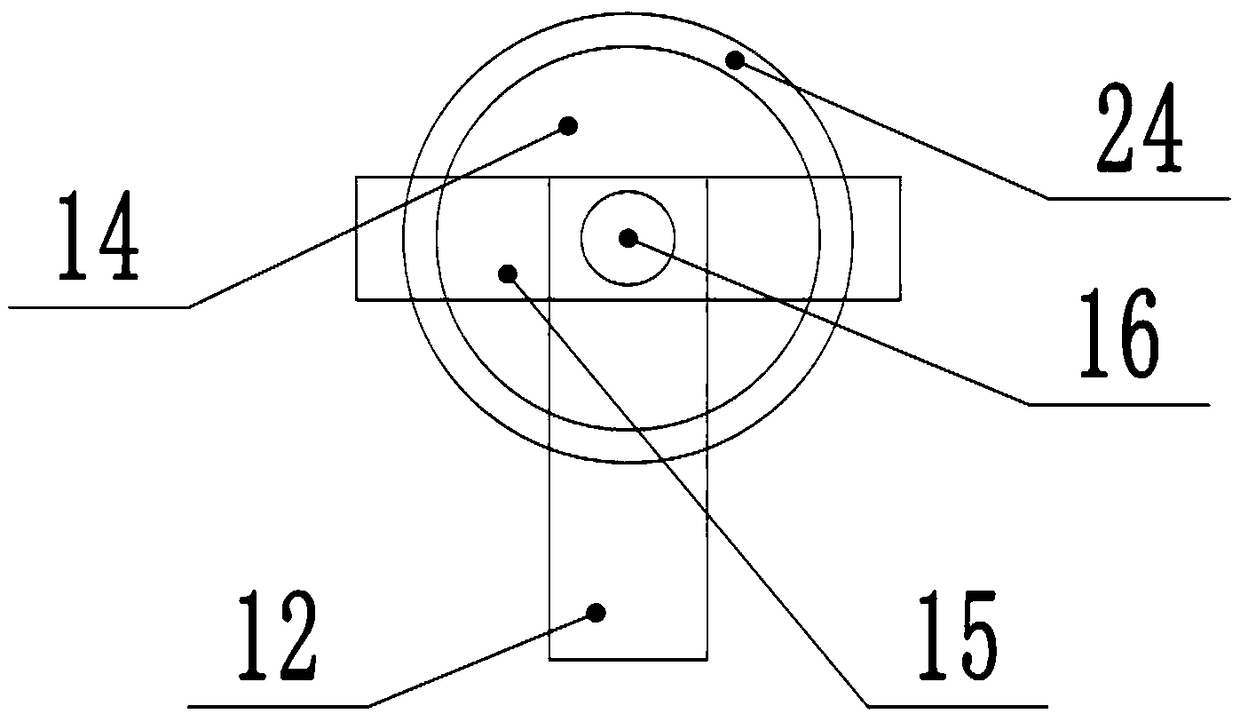

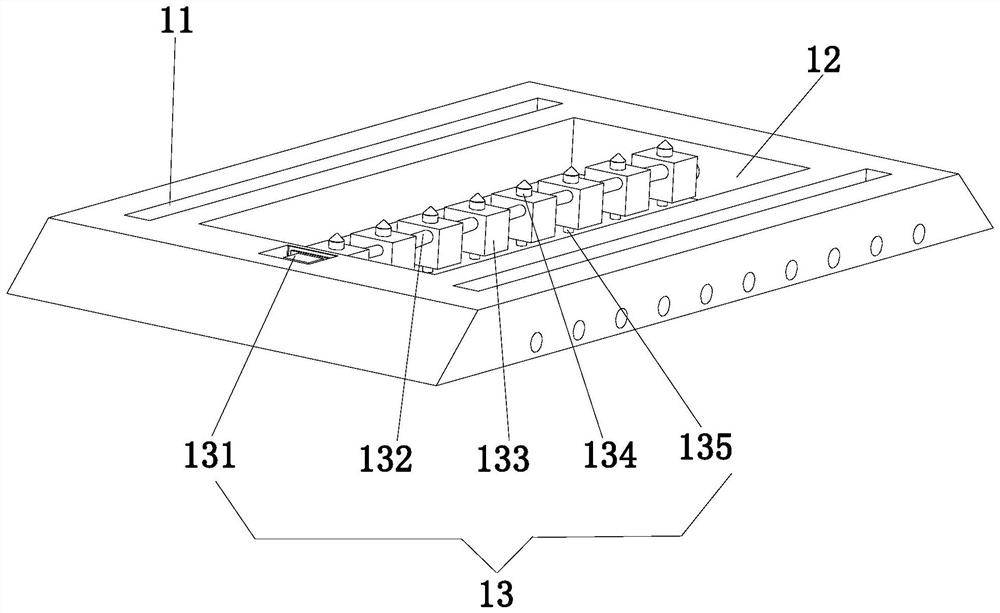

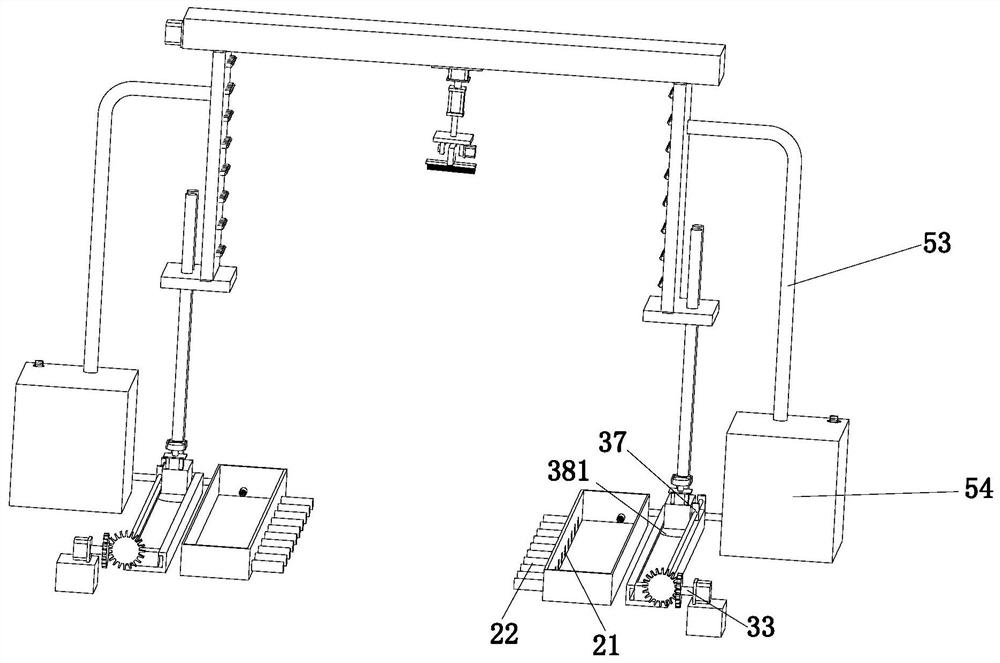

Light rail and subway vehicle end profiling vehicle washing system

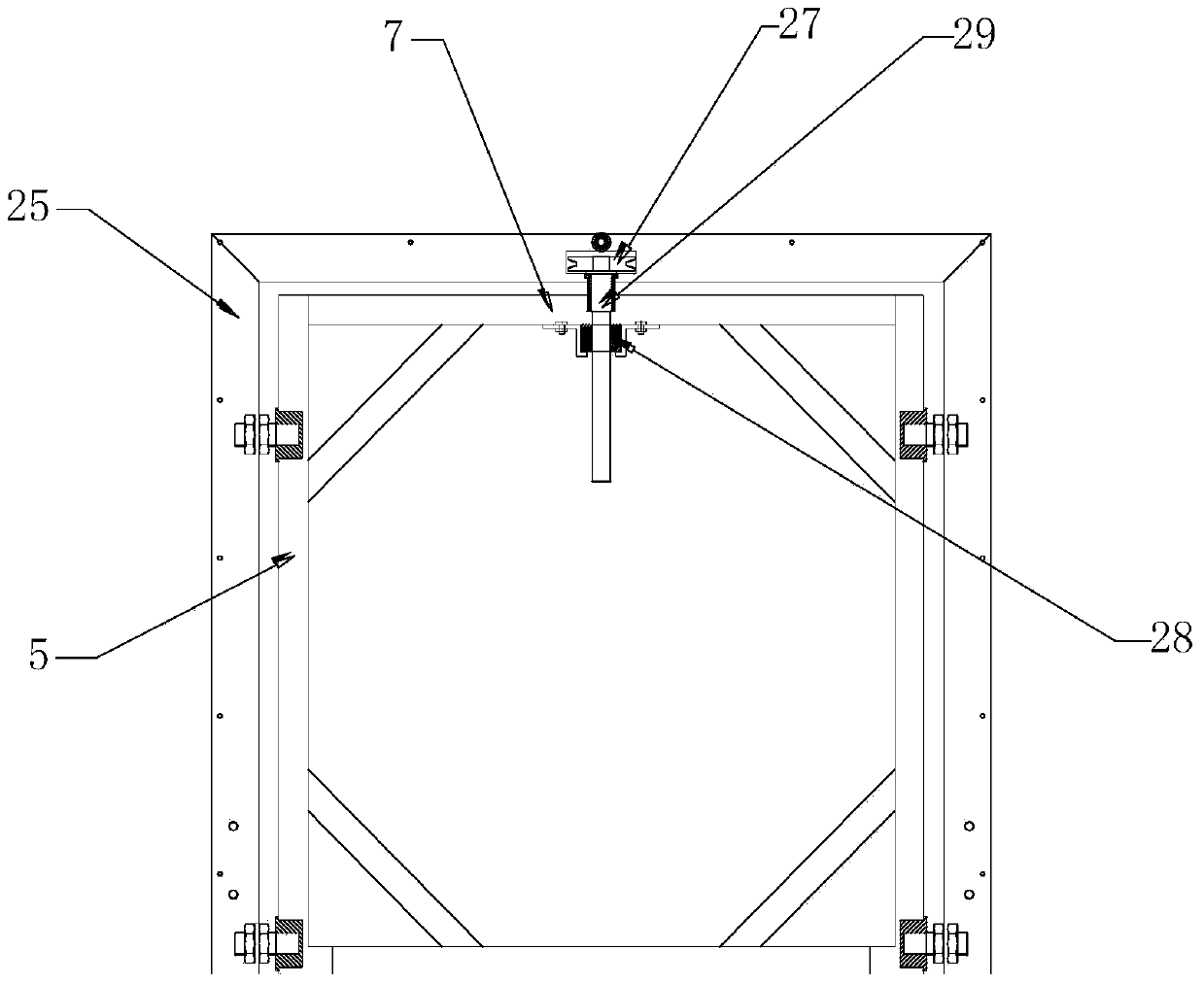

ActiveCN106274825AImprove securitySave human effortCleaning apparatus with conveyorsCleaning apparatus for railwaysLight railPressure sensor

The invention belongs to the technical field of light rail and subway vehicle maintenance, and particularly relates to a light rail and subway vehicle end profiling vehicle washing system. The light rail and subway vehicle end profiling vehicle washing system comprises a control cabinet, a brush set, a rotation mechanism, lifting mechanisms, a walking mechanism, a pressure sensor, travel switches, an indication lamp and a drive device. The drive device comprises a brush set rotation motor, a lifting motor and a walking movement motor. The walking mechanism comprises bases, side frames, rollers, upper rails and lower rails. The lower portion of each base is provided with a set of rollers, the rollers drive the bases to walk on the lower rails, and the side frames are mounted on the bases. The upper portion of each side frame is provided with a set of rollers, the rollers walk on the inner sides of the upper rails, and the lifting mechanisms are mounted in the side frames. The brush set is mounted above the lifting mechanisms and located on the inner sides of the two side frames. The rotation mechanism and the control cabinet are mounted on the bases. One-button end profiling vehicle washing is achieved according to the shapes of vehicle heads and tails of light rails and subway vehicles, efficiency is high, and the safety in the vehicle washing process is improved.

Owner:QINGDAO SIJI EQUIP PROJECT

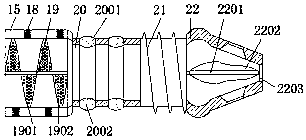

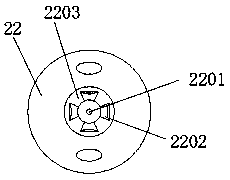

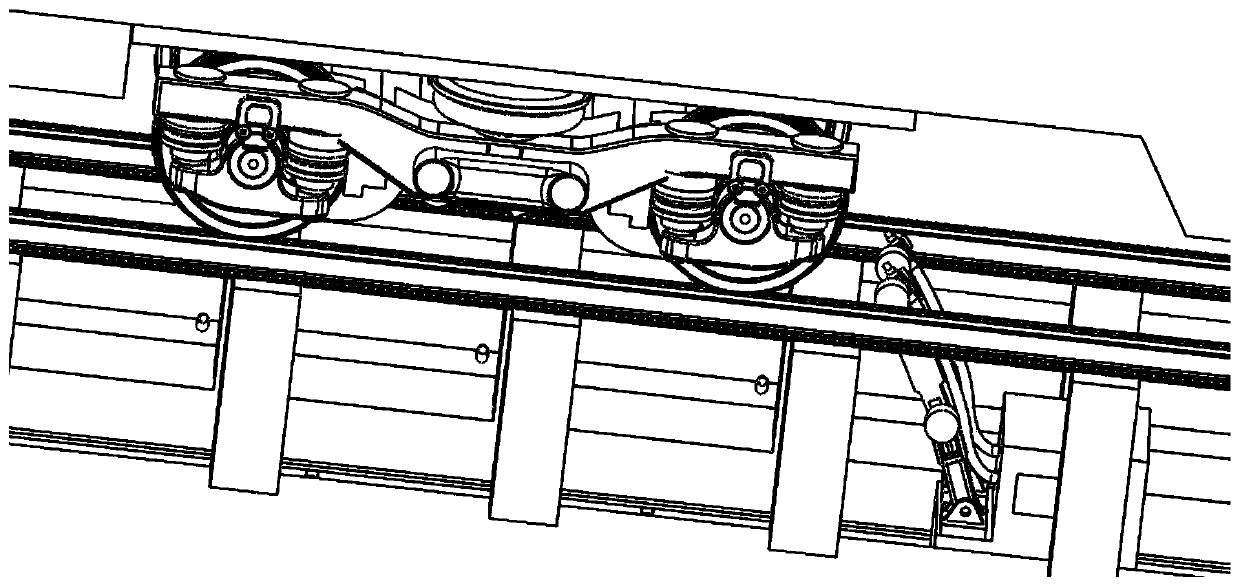

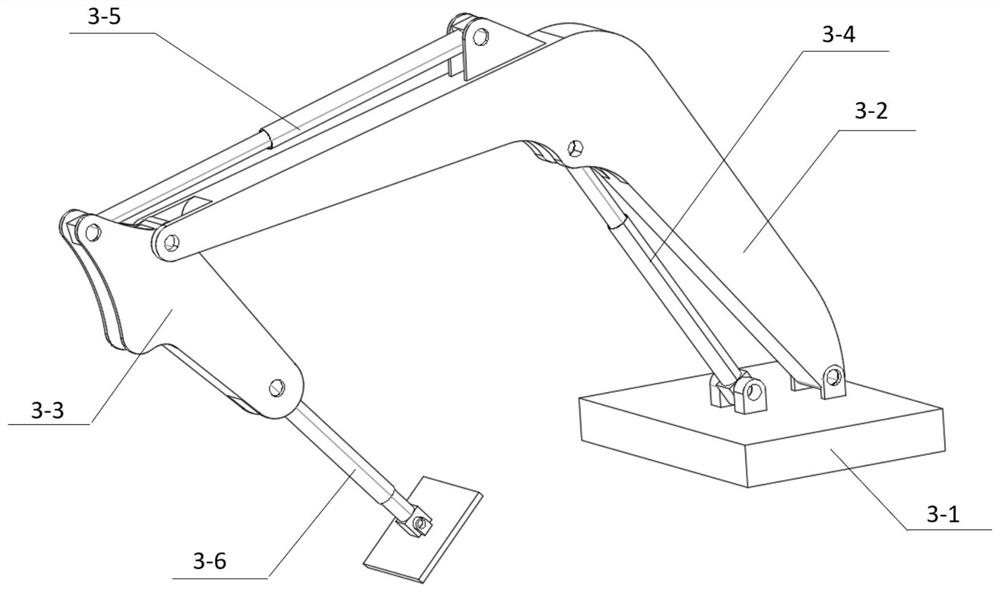

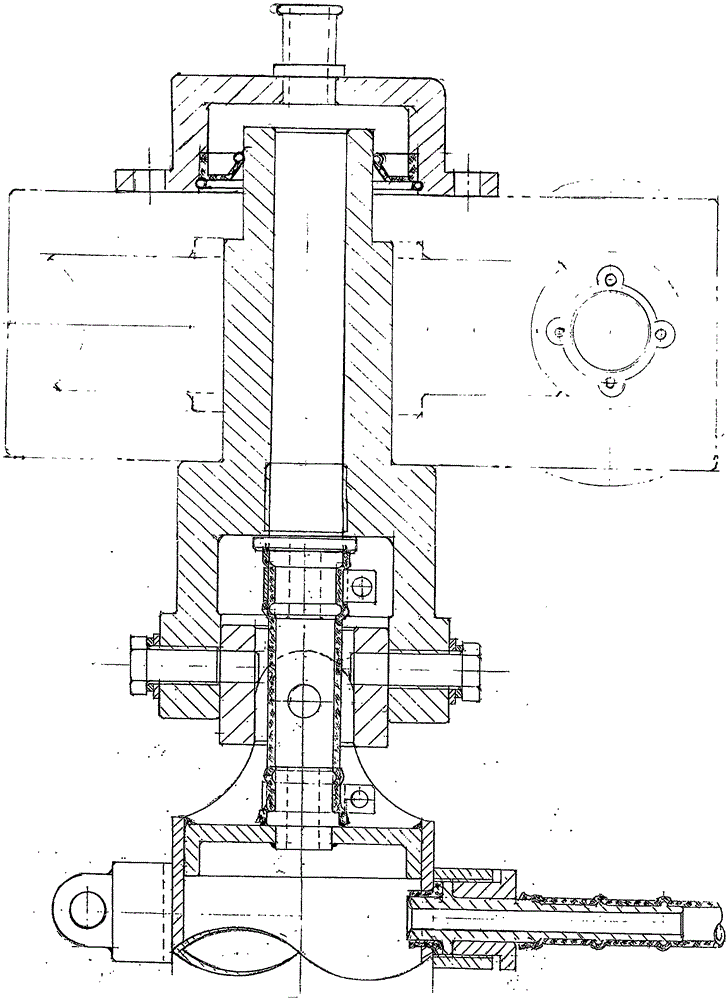

Bogie washing equipment

ActiveCN108860071ANo damageNo pollution in the processCleaning apparatus for railwaysCleaning apparatus for vehicle exteriorsBogieAir compression

The invention provides bogie washing equipment. The bogie washing equipment includes a platform, an air compression system, a mechanic arm and a dry ice jet device, wherein the air compression system,the mechanic arm and the dry ice jet device are arranged on the platform; the air compression system is connected with the dry ice jet device; the mechanic arm includes a mechanic arm main body and amechanic arm transverse movement device, the mechanic arm main body is arranged on the mechanic arm transverse movement device and can be driven by the mechanic arm transverse movement device to movehorizontally, the mechanic arm main body can be adjusted at multiple freedom degrees, and a spray nozzle of the dry ice jet device is detachably fixed to the mechanic arm main body; the dry ice jet device is used for uniformly mixing compressed air supplied by the air compression system and dry ice which is stored in the dry ice jet device, and the spray nozzle is driven by the mechanic arm to move and ejects the dry ice to wash a bogie. According to the bogie washing equipment, by adopting a dry ice washing mode, the washing effect is good, no secondary residues exist, no pollution is causedto the environment, no damage is caused to the bogie, it is unnecessary to disassemble parts such as motor bearings during washing, no drying procedure is needed, the automation degree is high, little labor is needed, and the cost is low.

Owner:CRRC QINGDAO SIFANG ROLLING STOCK RES INST

System and method for car roof cleaning of rail transit railway vehicles

PendingCN107139890AImprove compatibilitySimple structure setupCleaning apparatus for railwaysControl theoryData collecting

The invention discloses a system and method for car roof cleaning of rail transit railway vehicles. The system for the car roof cleaning comprises a cleaning device, a data collection device and a drive device, wherein the cleaning device is used to clean a car roof of a to-be-cleaned vehicle; the data collection device is used to collect vehicle information of the to-be-cleaned vehicle; and the drive device is used to adjust the position of the cleaning device according to the vehicle information, and the drive device is in driving connection with the cleaning device. The method for the car roof cleaning comprises the steps that (1) position situations of the to-be-cleaned vehicle are judged; (2) if the to-be-cleaned vehicle is located in place, the vehicle information will be collected; (3) the position of the cleaning device is adjusted according to the vehicle information; and (4) the to-be-cleaned vehicle is cleaned. According to the invention, the data collection device and the drive device are disposed, so vehicles with different car types can be cleaned; and compatibility is high.

Owner:WASHING BEIJING AUTOMATIC EQUIP

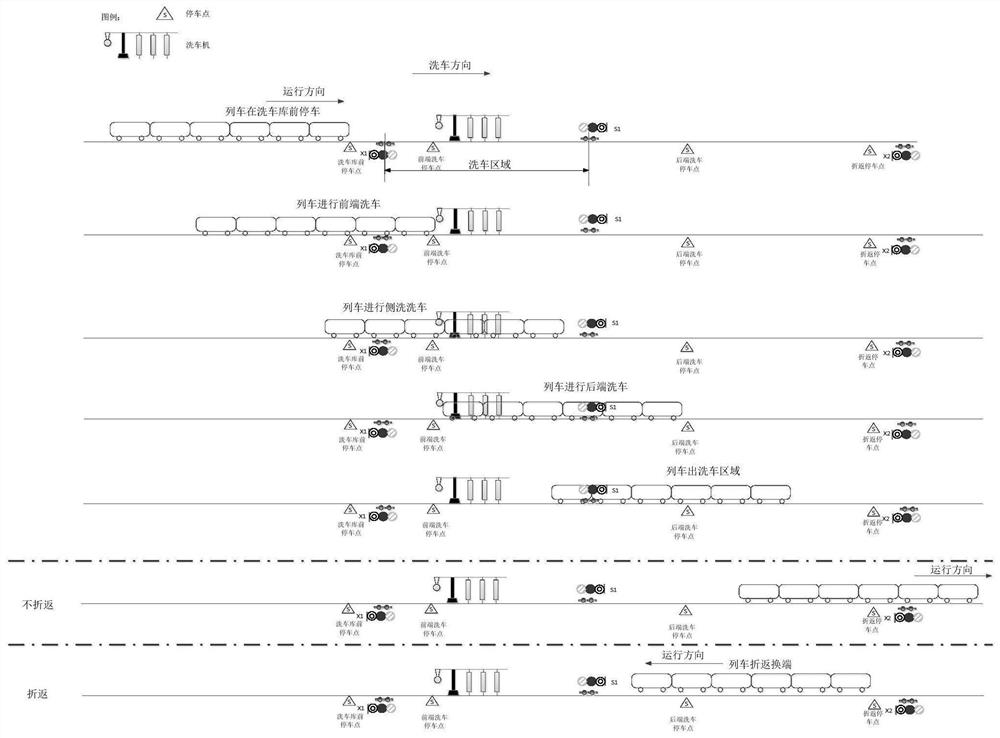

Automatic train washing method based on active control of signal system

InactiveCN112265521AImprove operational safetyAddressing Safety Concerns During Automatic Car WashesCleaning apparatus for railwaysCleaning apparatus for vehicle exteriorsSignaling systemWasher

The invention discloses an automatic train washing method based on active control of a signal system, and the method comprises the steps: setting a train washing garage on a train line, configuring atrain washing machine for the train washing garage, and setting end washing parking points matched with train marshalling and train washing operation requirements on a line map; enabling the signal system to command and actively control the train to complete automatic train washing in a centralized mode, enabling the ATS to decide when to send a train washing request and a passing request to the train washing machine, and enabling the CC to decide when to apply for end washing from the train washing machine and conduct safety supervision and protection on the end washing process of the train.According to the method, the state of the car washer is monitored in real time through the signal system, the situation that the car washer possibly collides with car washing equipment in the car washing process is effectively prevented, the running safety of a train is improved, and the method is suitable for a traditional urban rail transit signal system and also suitable for a signal system ofa car-to-car communication mode.

Owner:浙江众合科技股份有限公司

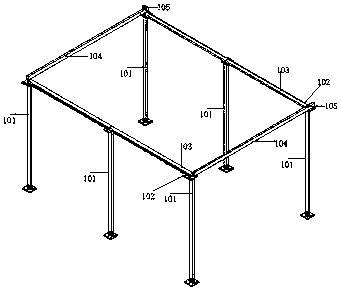

Train body blowing and sweeping system suitable for EMS Maglev train

PendingCN110450758AImprove purge efficiencyQuality improvementCleaning apparatus for railwaysEngineeringMaglev

The invention discloses a train body blowing and sweeping system suitable for an EMS Maglev train, and belongs to the EMS Maglev train inspection technology field. The train body blowing and sweepingsystem comprises a supporting unit, which is formed by a supporting platform and supporting vertical columns; outer side units, which are disposed on the two sides of the supporting unit; and an innerside unit, which is disposed on the bottom part of the supporting platform. The upward blowing mechanisms of the outer side units and the inner side unit are correspondingly arranged, and the outer side units and the inner side unit can move back and forth along a longitudinal direction, and the two sides and the bottom part of the Maglev train can be blown and swept in an all-directional way. Byarranging dust removing devices / dust removing assemblies correspondingly, the blown dust and powder can be absorbed, filtered, and collected quickly, and at the same time of improving the train bodyblowing and sweeping efficiency and quality, deterioration of environment in a blowing and sweeping workshop during the blowing and sweeping process can be effectively prevented. By adopting the trainbody blowing and sweeping system provided by the invention, the blowing and sweeping quality and the blowing and sweeping efficiency of the EMS Maglev train can be greatly improved, the maintenance costs of the Maglev Train can be reduced, and the great popularization value and the application prospect can be provided.

Owner:CHINA RAILWAY SIYUAN SURVEY & DESIGN GRP

Vehicle wiping method and vehicle wiping device with automatic cleaning function

PendingCN108372845AReduce stretchExtended service lifeVehicle drying apparatusCleaning apparatus for railwaysEngineeringPiston rod

The invention relates to a vehicle wiping method and a vehicle wiping device with an automatic cleaning function. The vehicle wiping device comprises a framework, a towel front and back moving part and a towel water extruding and automatic cleaning part, wherein the towel front and back moving part comprises a movable trolley which is moved back and forth corresponding to the framework; a supportframe is arranged on the movable trolley; a towel coiling shaft for fixing a towel is connected with the support frame; the towel water extruding and automatic cleaning part comprises a towel top coiling and down uncoiling device, a water extruding device and a cleaning spray head, the towel top coiling and down uncoiling device comprises the towel coiling shaft and a drive part of the towel coiling shaft for driving the towel coiling shaft to rotate, the water extruding device comprises a fixed coiling shaft and a movable coiling shaft under the towel coiling shaft, the movable coiling shaftis connected with a piston rod of a water squeezing air cylinder, and the cleaning spray head is arranged on the movable trolley. The vehicle wiping device has the advantages that the vehicle body wiping effect is good, and the operation speed is quick.

Owner:盛利

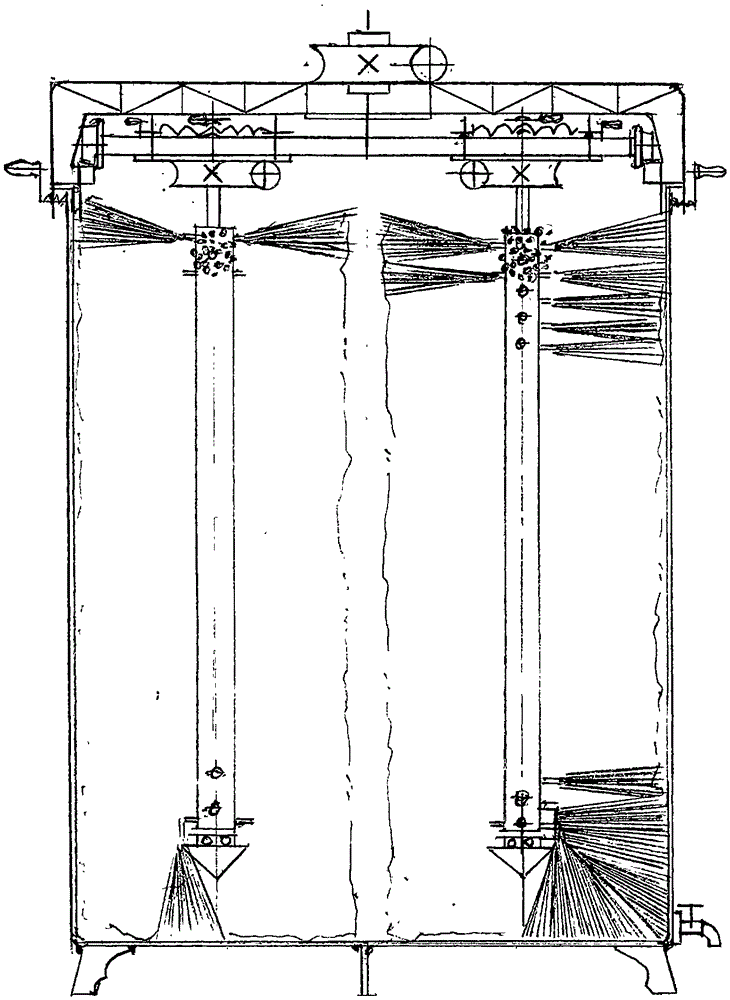

Dirt sucking device of on-rail cleaning machine for outer cover of track transportation vehicle

InactiveCN107472203AReduce job running costsReduce noiseCleaning apparatus for railwaysCleaning apparatus for vehicle exteriorsSuction forceEngineering

The invention discloses a dirt sucking device of an on-rail cleaning machine for an outer cover of a track transportation vehicle. The dirt sucking device comprises a suction nozzle body, a cleaning and brushing mechanism for cleaning the outer cover of the track transportation vehicle, and a centrifugal fan, wherein an opened suction nozzle opening is formed in one side surface which faces the vehicle, of the suction nozzle body, and other surfaces of the suction nozzle body are closed; a cavity is formed between the suction nozzle body and a position in front of a vehicle body of the vehicle; the outer edge of the suction nozzle opening is in profile modeling with the surface of the vehicle, and a gap b is formed between the outer edge of the suction nozzle opening and the surface of the vehicle; a dirt sucking opening is also formed in the suction nozzle body, and communicates with the centrifugal fan through a pipeline; and the cleaning and brushing mechanism is mounted in the cavity. According to the dirt sucking device disclosed by the invention, when the cleaning and brushing mechanism works, micro negative pressure is generated in the cavity through the sucking force of the centrifugal fan, so that water mist in the cavity does not overflow, and the boarding environment of a platform is effectively improved.

Owner:XIAMEN UNIV OF TECH +1

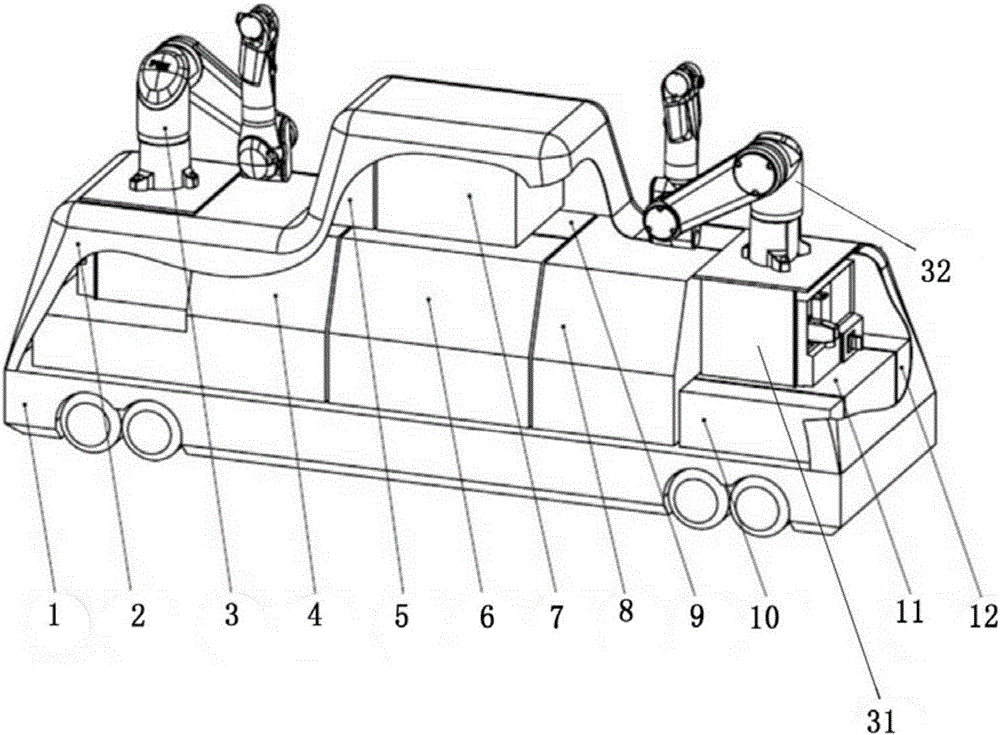

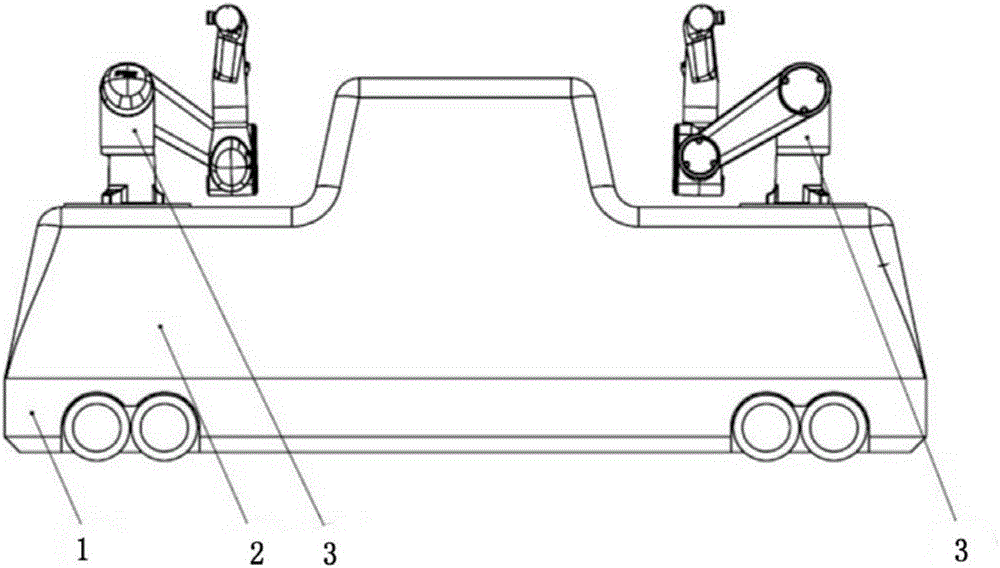

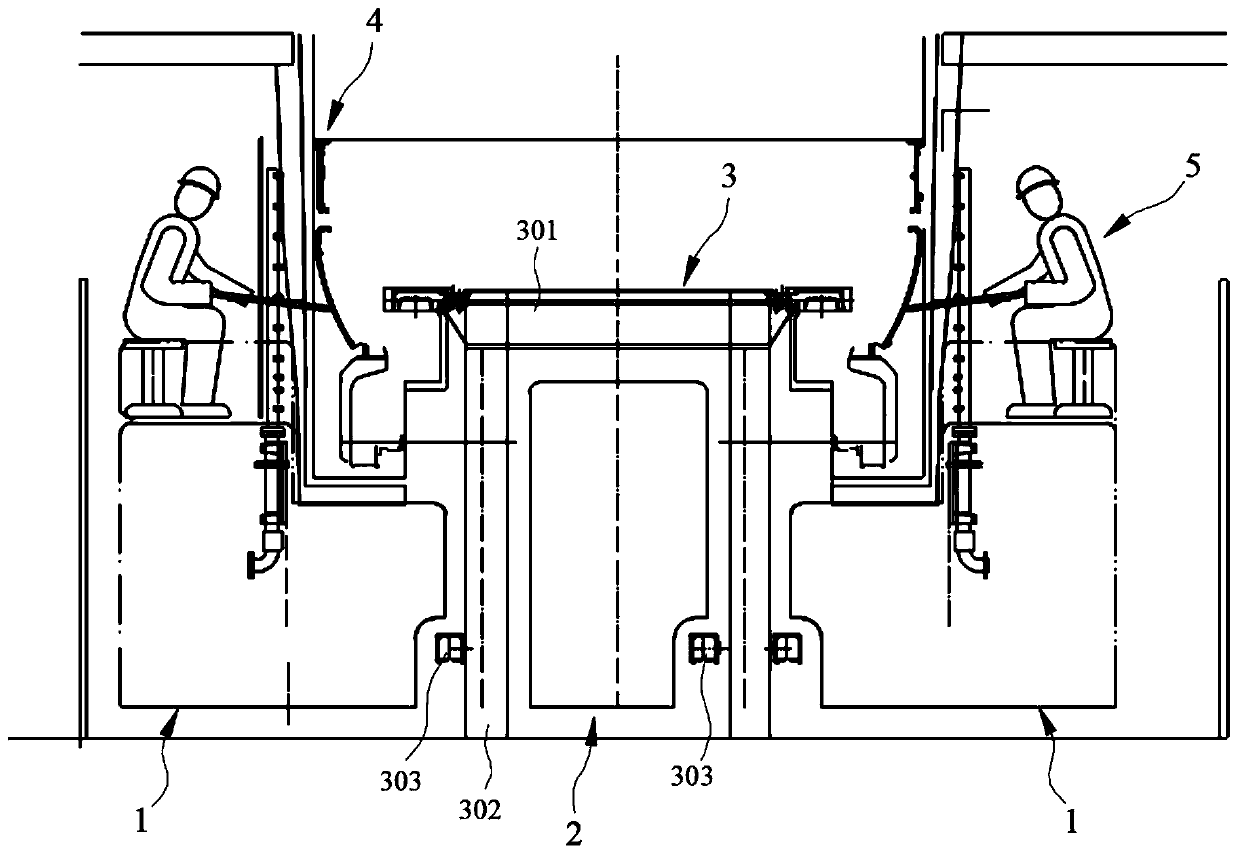

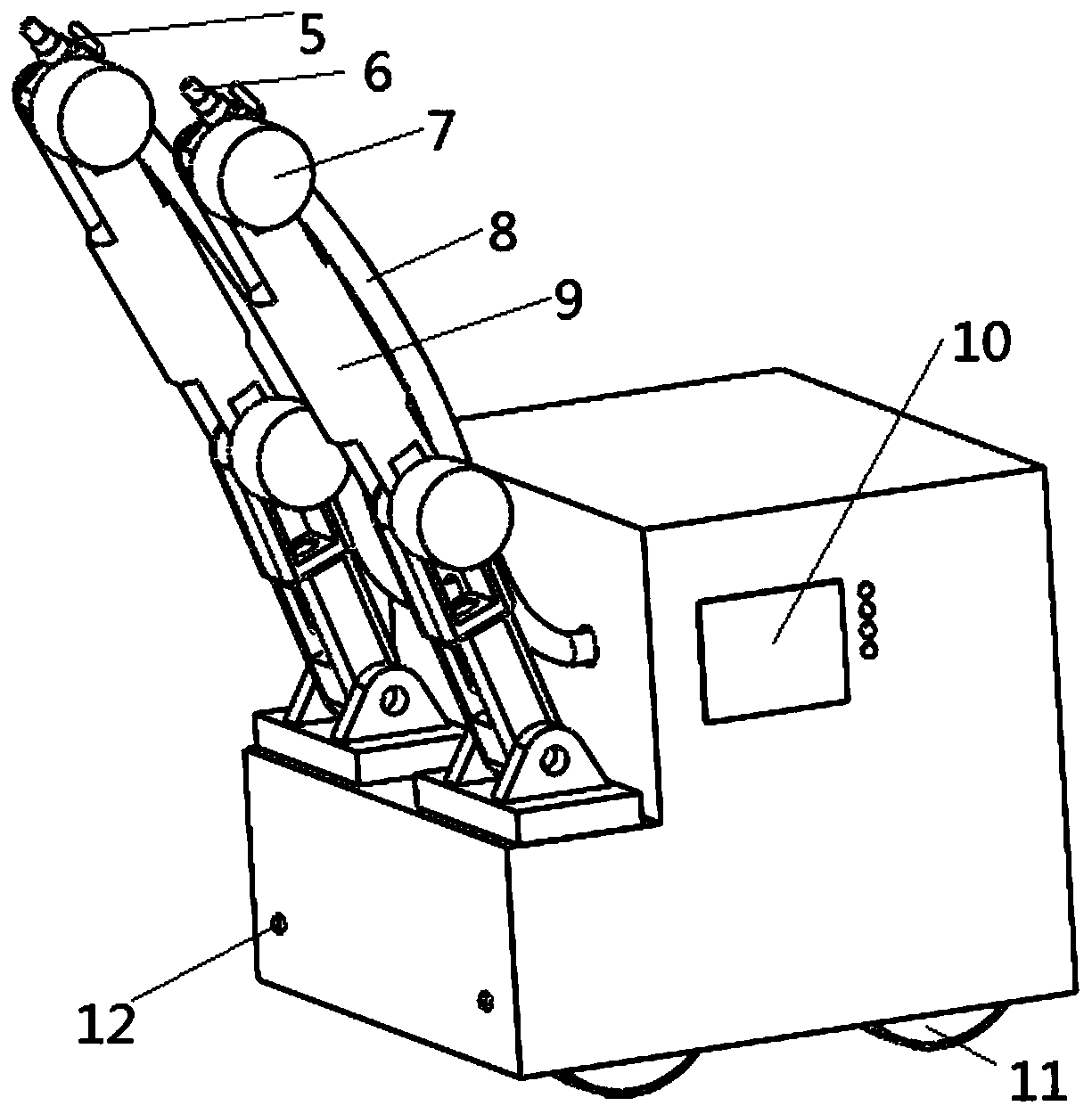

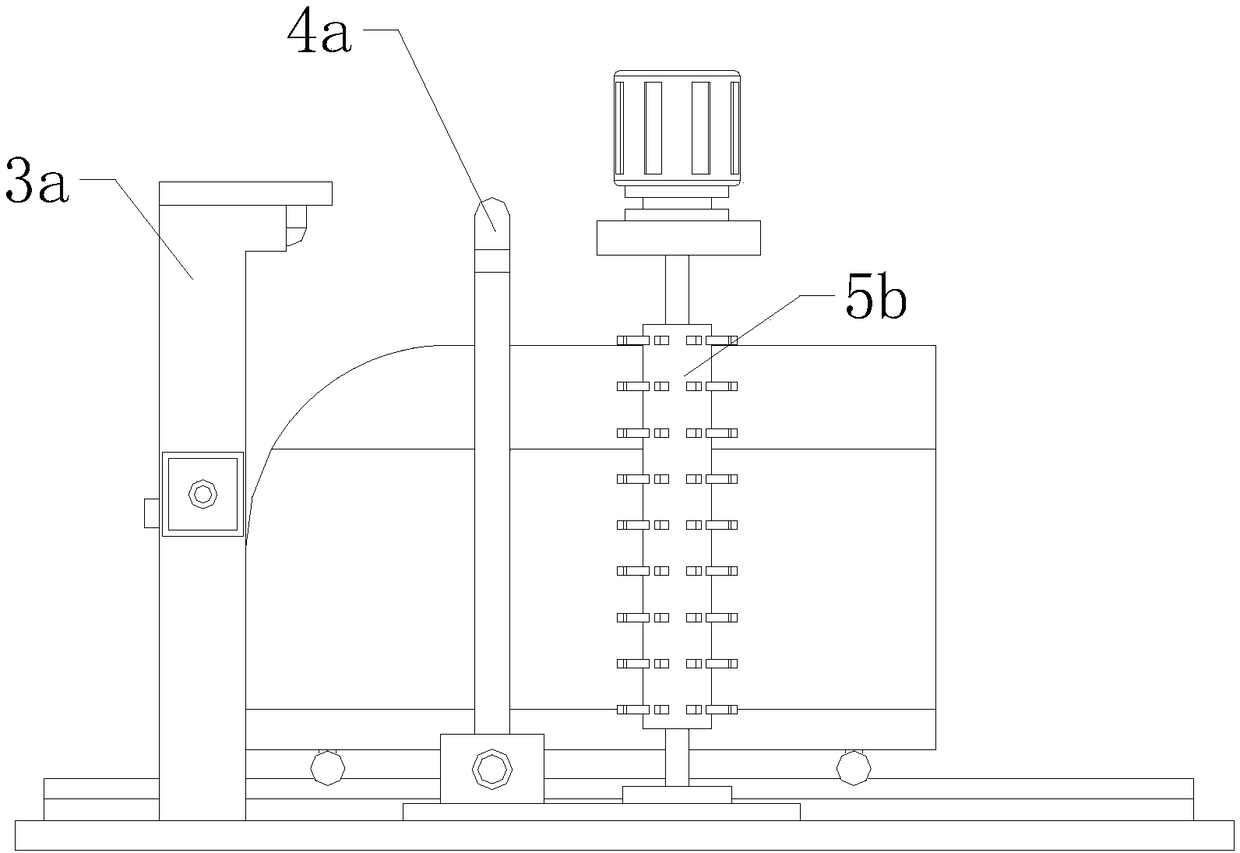

Rail transit vehicle bottom automatic purging system

PendingCN111452758AImprove purge efficiencyImprove purging effectCleaning apparatus for railwaysElectric powerIn vehicleMechanical engineering

The invention discloses a rail transit vehicle bottom automatic purging system which comprises a moving trolley, a guide magnetic strip, a magnetic navigation sensor, a mechanical arm, an air gun, a fan and a power supply system, and the guide magnetic strip is installed in a trench; the magnetic navigation sensor is arranged on the moving trolley and is used for detecting a magnetic field generated by the guide magnetic strip so as to guide the moving trolley to walk in a trench; the mechanical arm is installed on the moving trolley, and the air gun is installed at the tail end of the mechanical arm so as to be used for purging the bottom of a vehicle. The fan is installed on the movable trolley and connected with the air gun through a hose. The power supply system comprises a vehicle-mounted power supply, and the vehicle-mounted power supply is connected with the fan so as to supply power to the fan. The rail transit vehicle bottom automatic purging system can blow air in all directions, and the vehicle bottom blowing efficiency and effect are improved while the labor intensity of workers is effectively reduced.

Owner:CHINA RAILWAY SIYUAN SURVEY & DESIGN GRP

Automatic cleaning mechanism for rail vehicle

InactiveCN108725397ADoes not require manual scrubbingCleaning apparatus with conveyorsCleaning apparatus for railwaysEngineeringRail traffic

The invention relates to the field of rail traffic, in particular to an automatic cleaning mechanism for a rail vehicle. The automatic cleaning mechanism comprises a base, a track device, a head cleaning device, a flushing device and a vehicle body cleaning device; the track device comprises a track assembly; the head cleaning device comprises a supporting assembly, a water spraying assembly and afirst cleaning assembly; the flushing device comprises a flushing assembly; the vehicle body cleaning device comprises a driving assembly and a second cleaning assembly. When needing to be cleaned, atrain can move forwards and backwards on the track assembly; when the train passes through the head cleaning device, the water spray assembly sprays water onto the head of the train, and the first cleaning assembly cleans the head of the train while spraying water; the first cleaning assembly can be used for cleaning the head of the train by means of sliding up and down; the second cleaning assembly cleans the body of the train; finally, both the head and body of the train are completely cleaned without needing manual scrubbing; therefore, the automatic cleaning mechanism is very simple and convenient.

Owner:HEFEI CAREER TECHNICAL COLLEGE

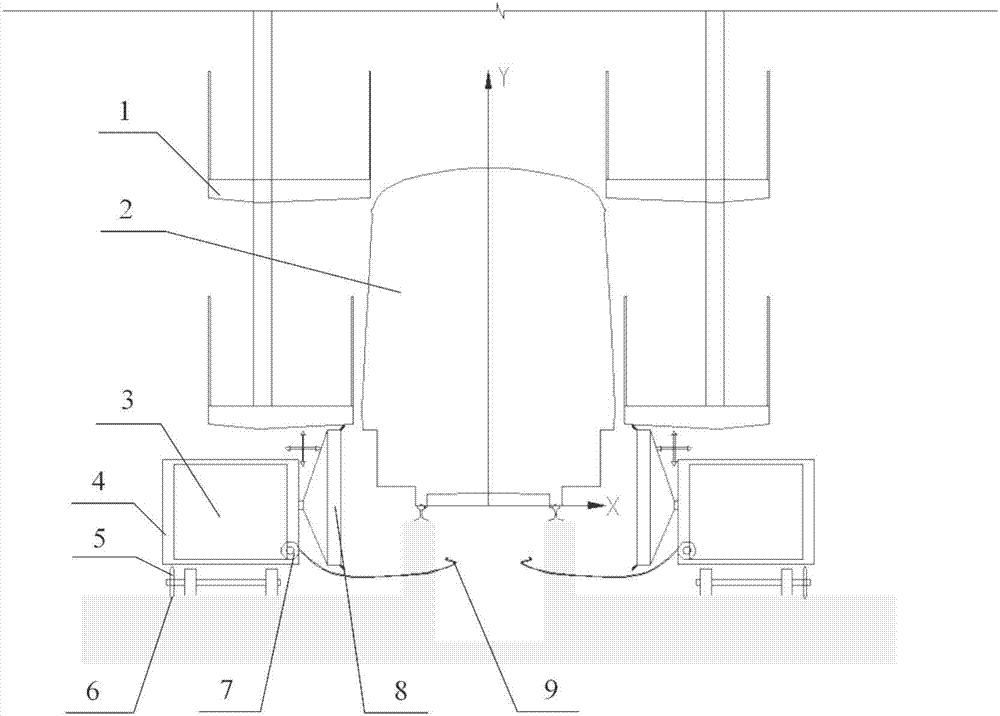

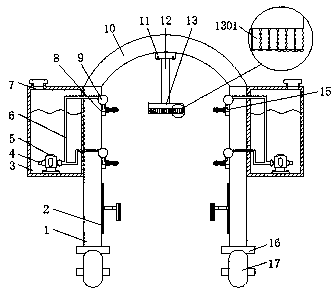

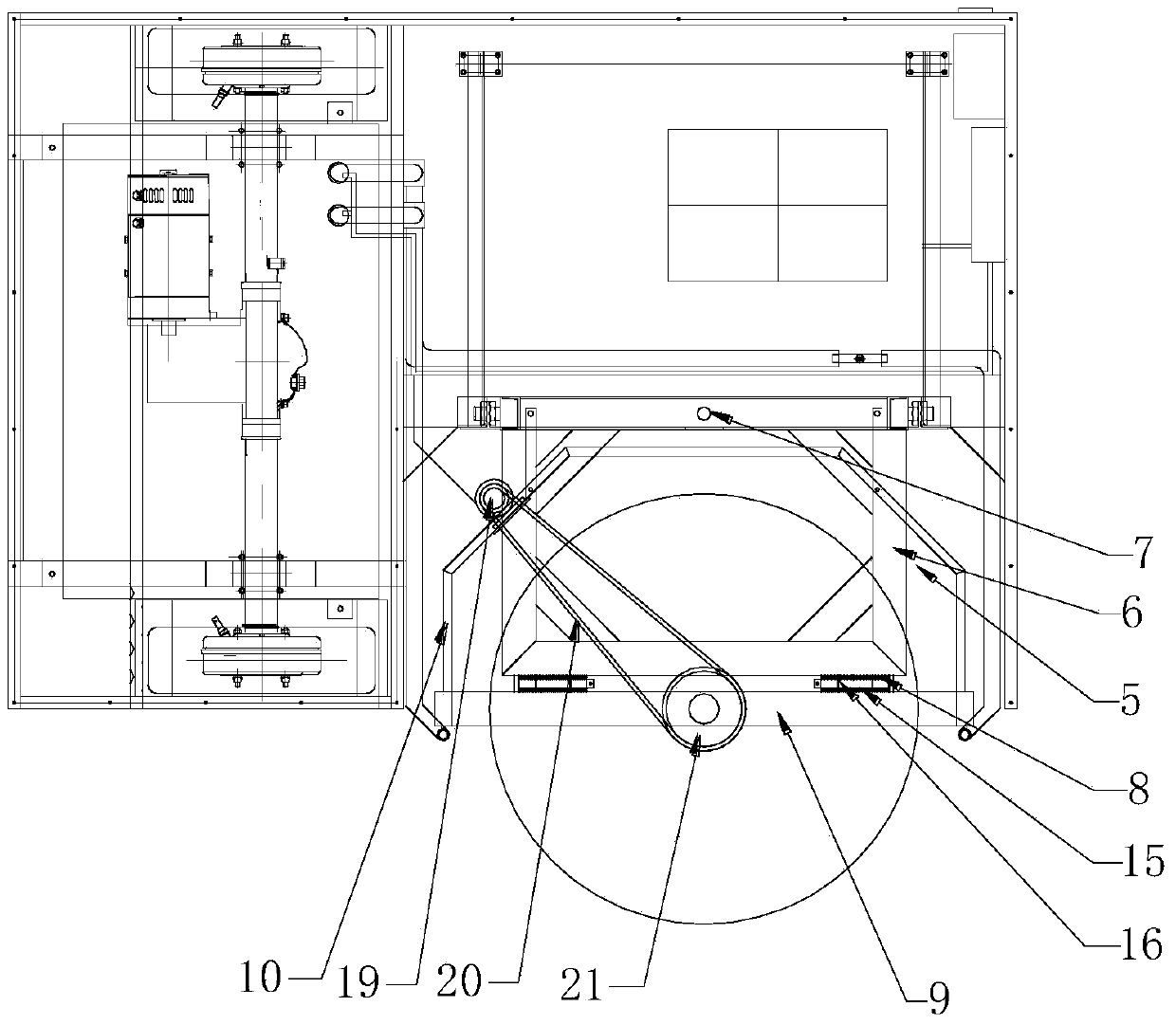

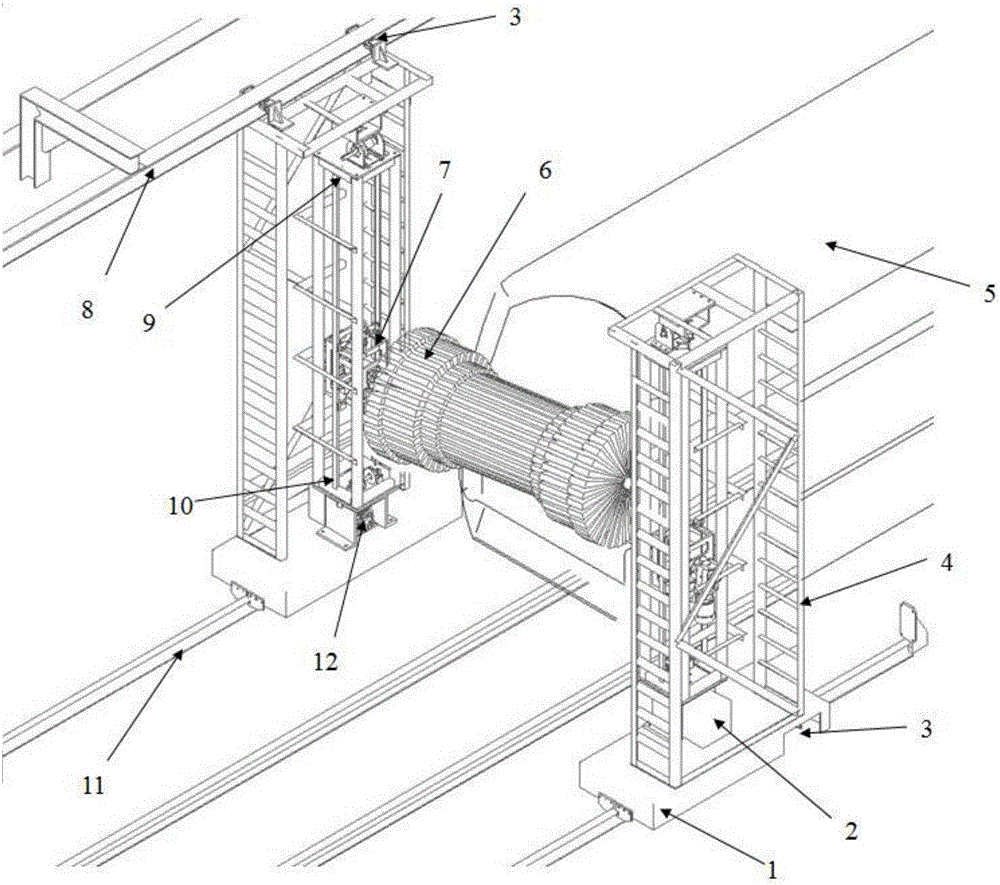

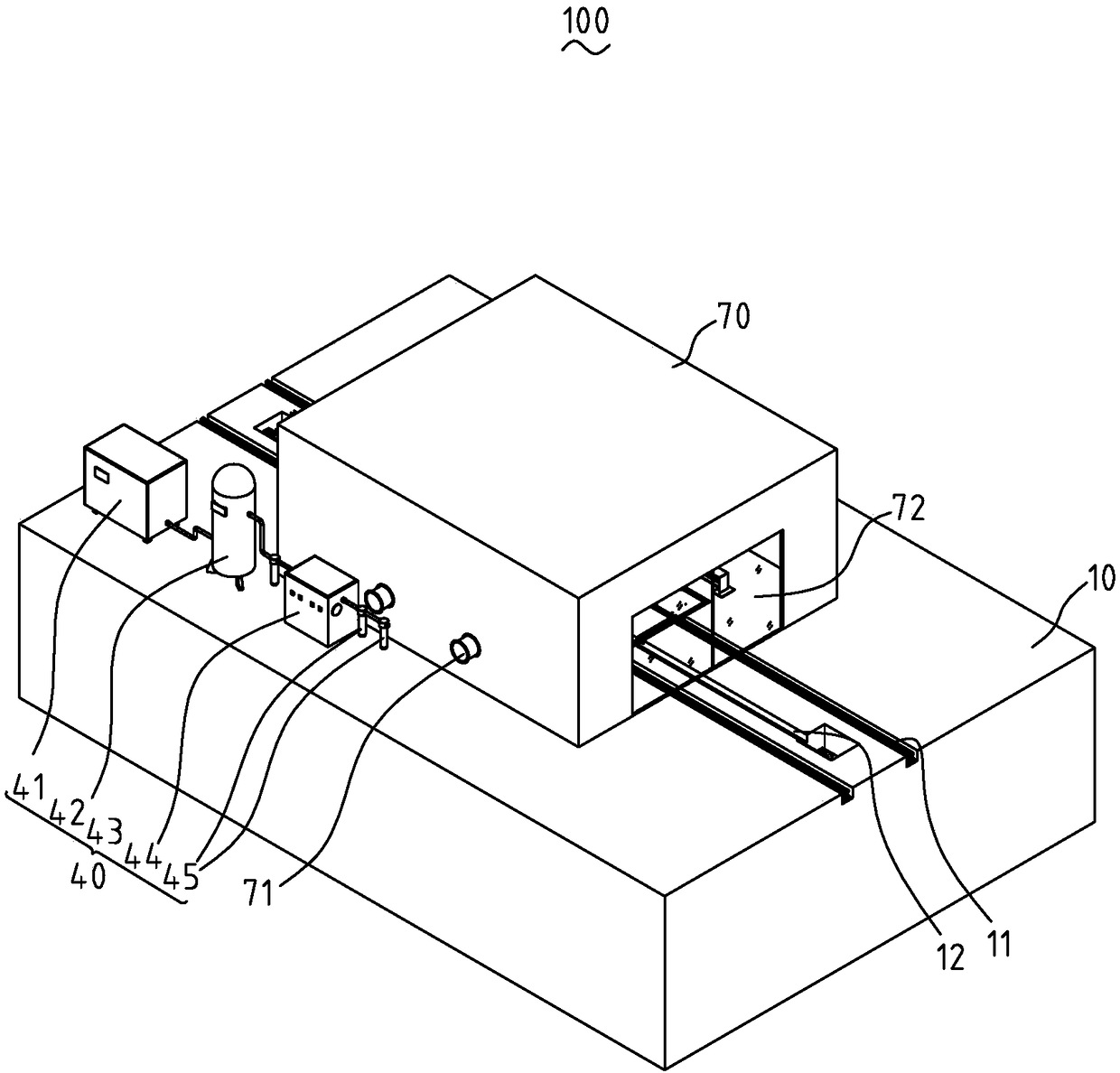

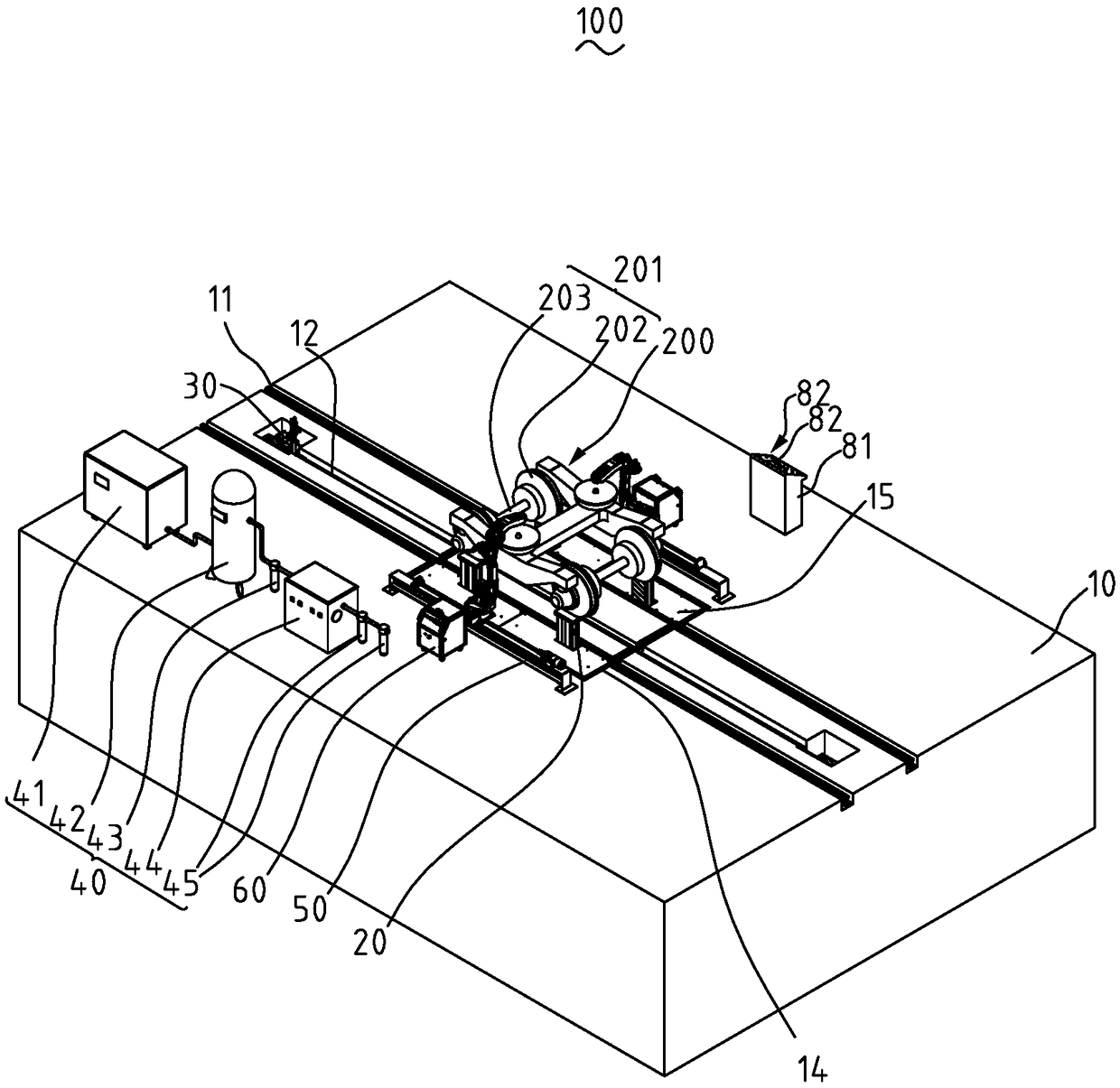

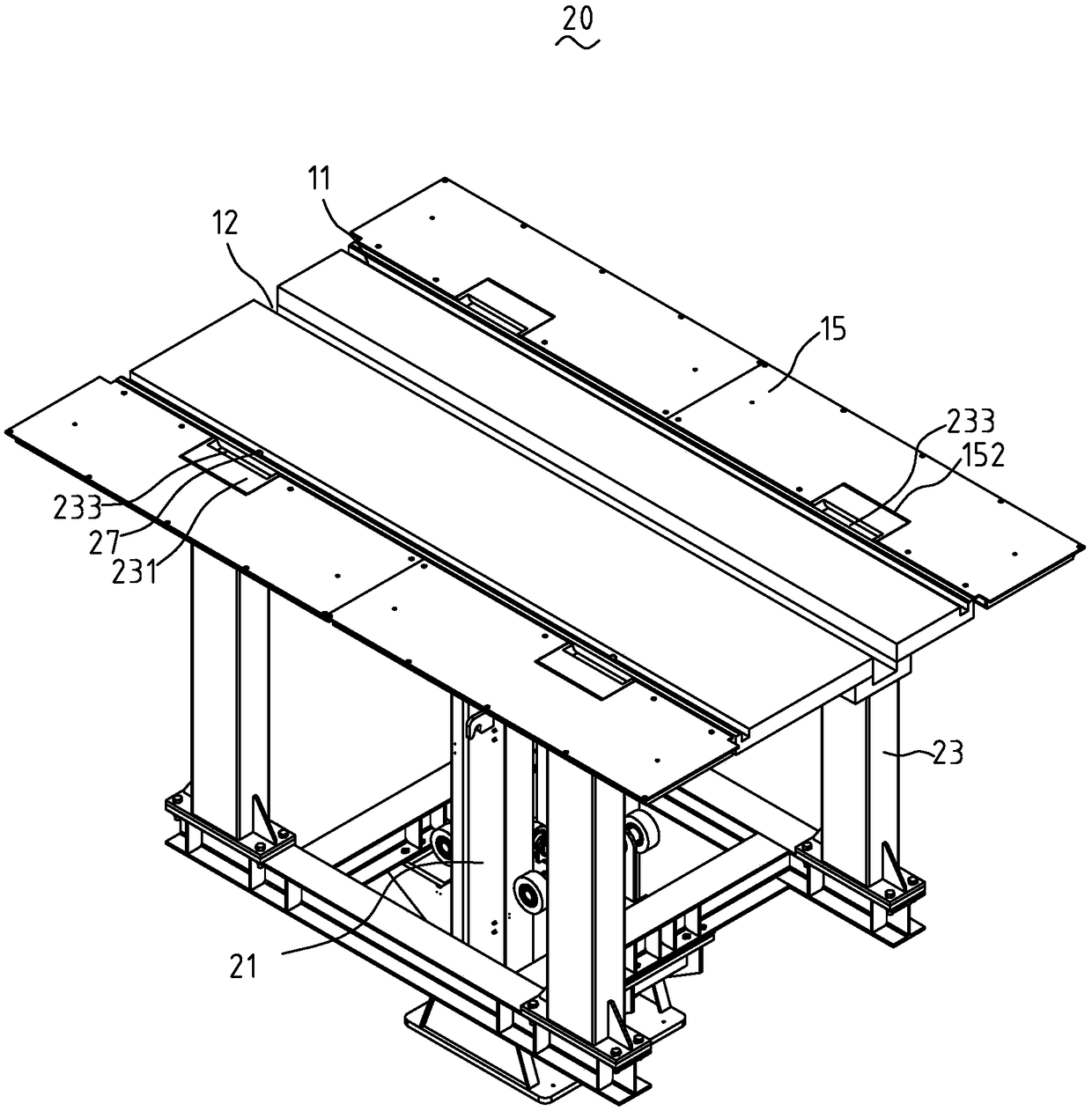

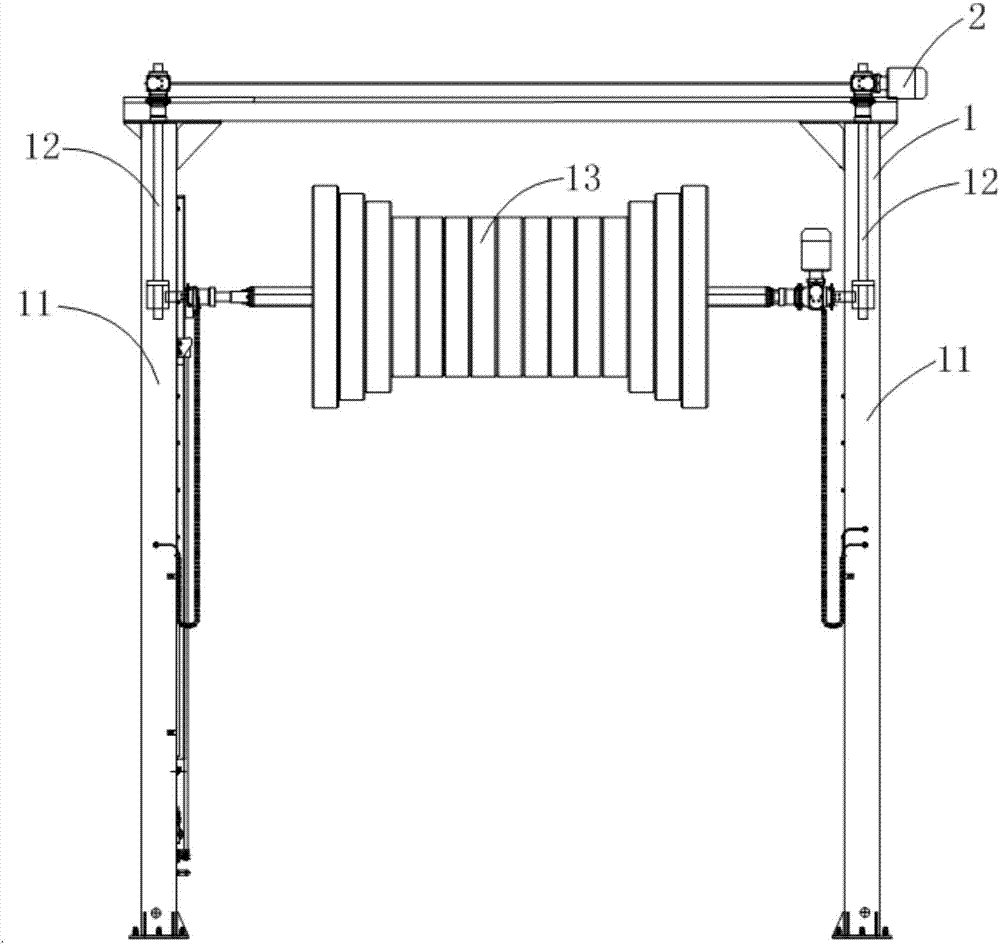

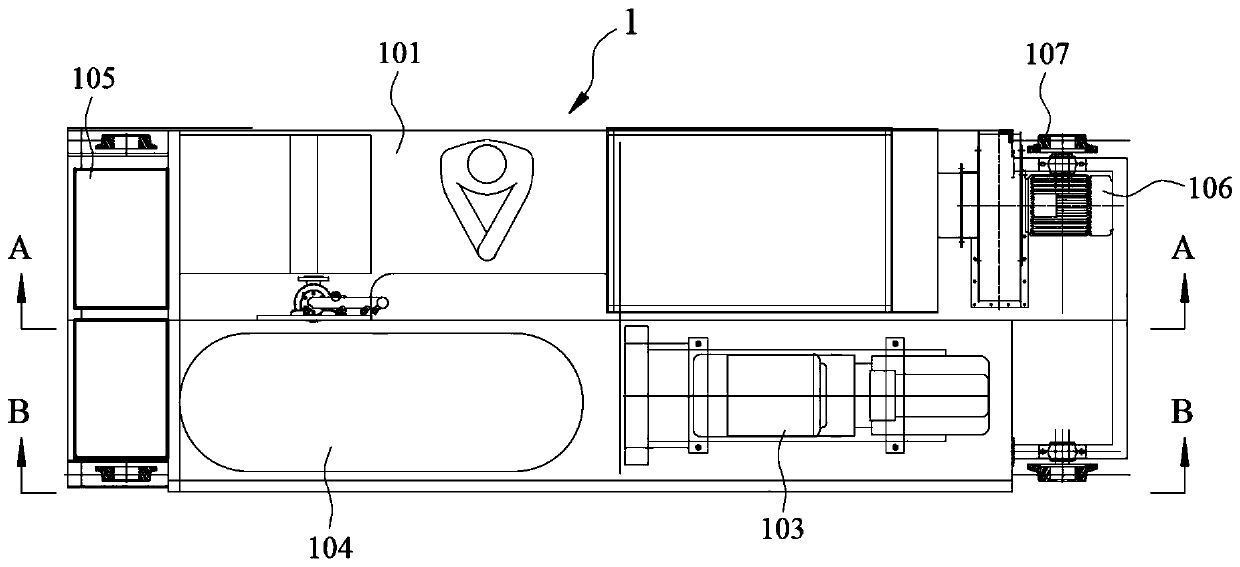

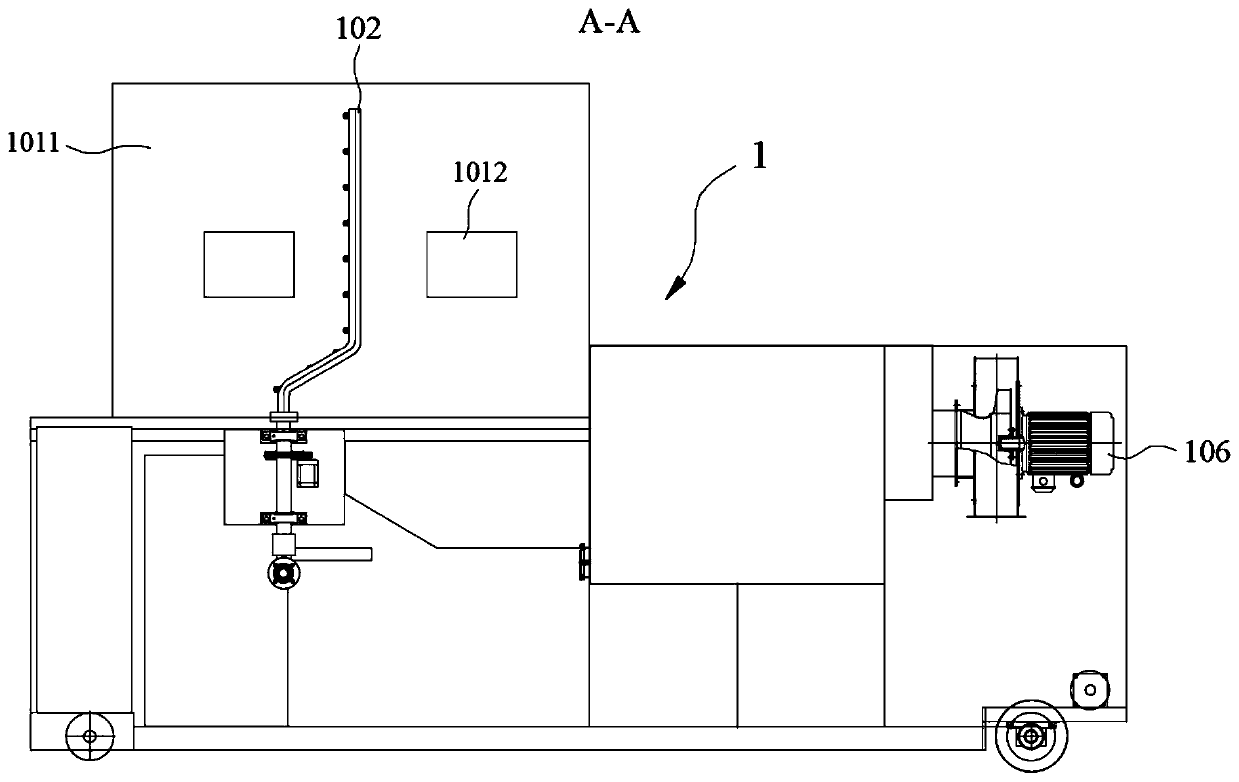

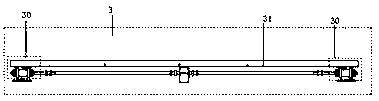

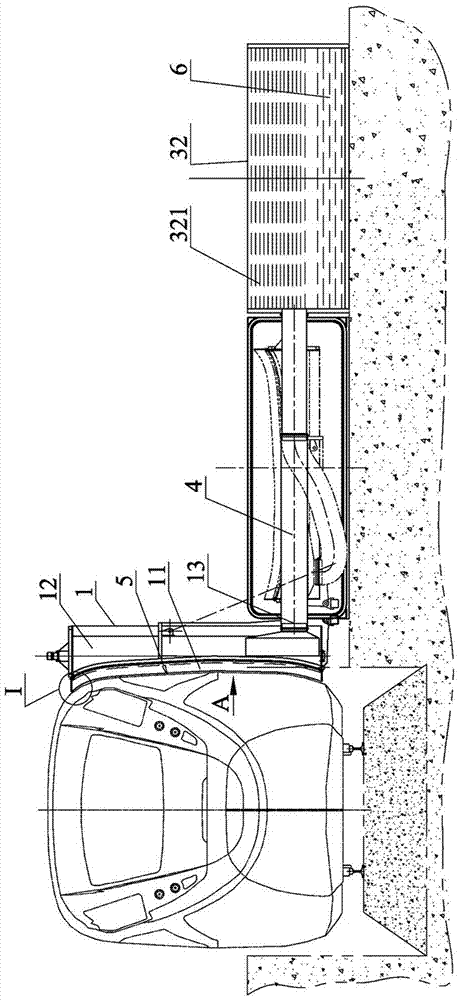

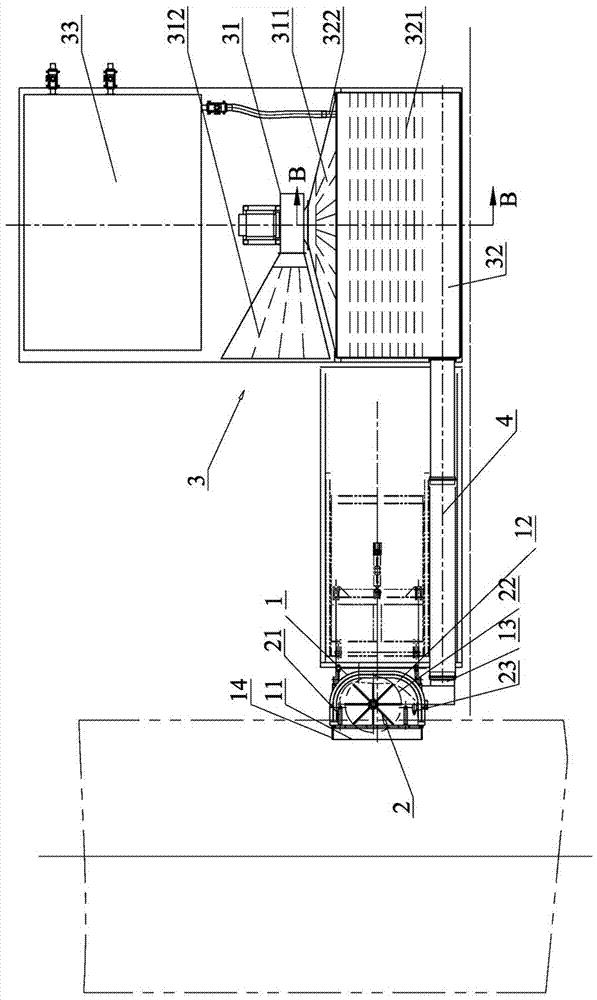

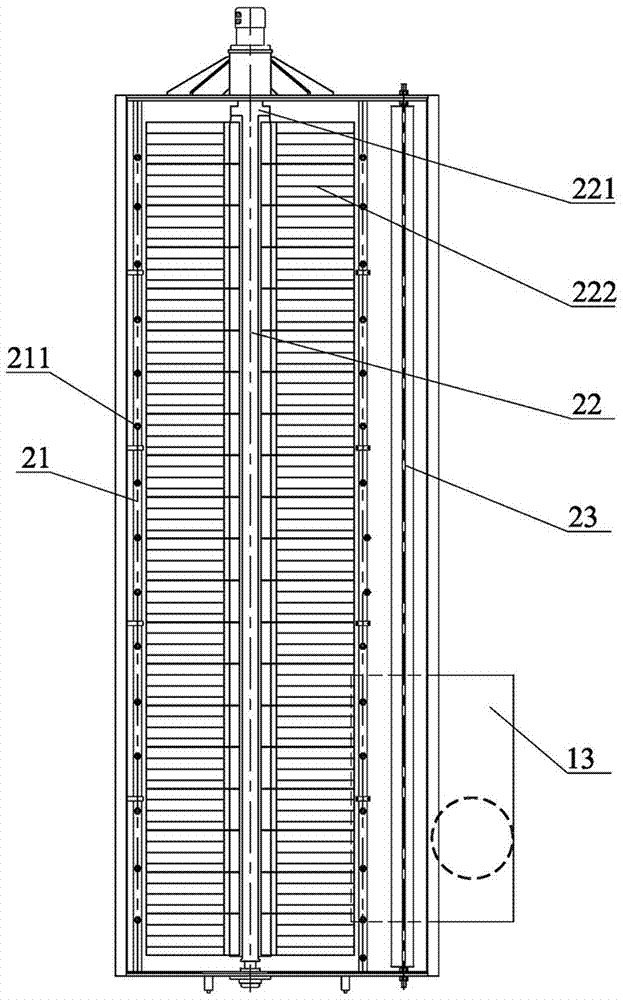

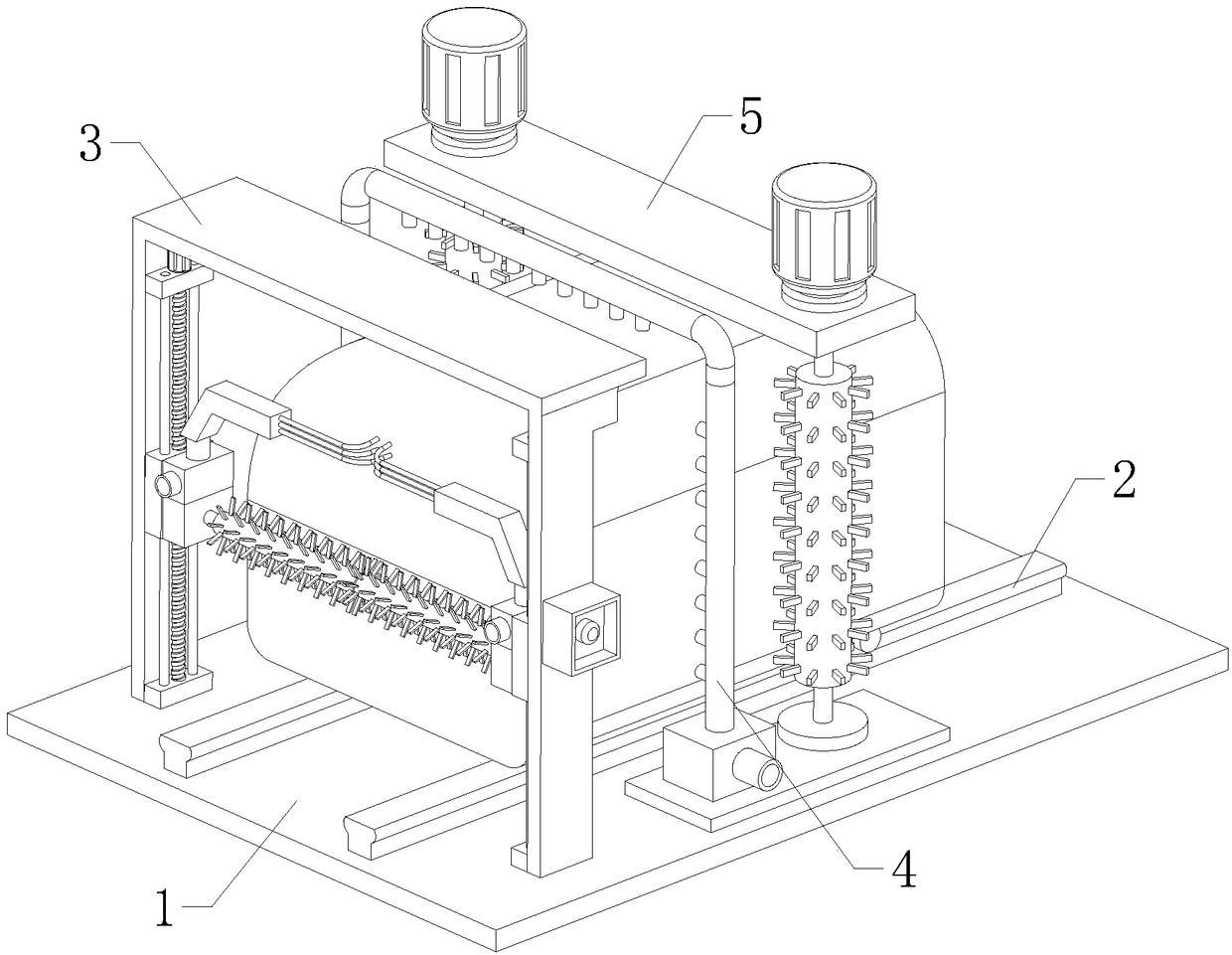

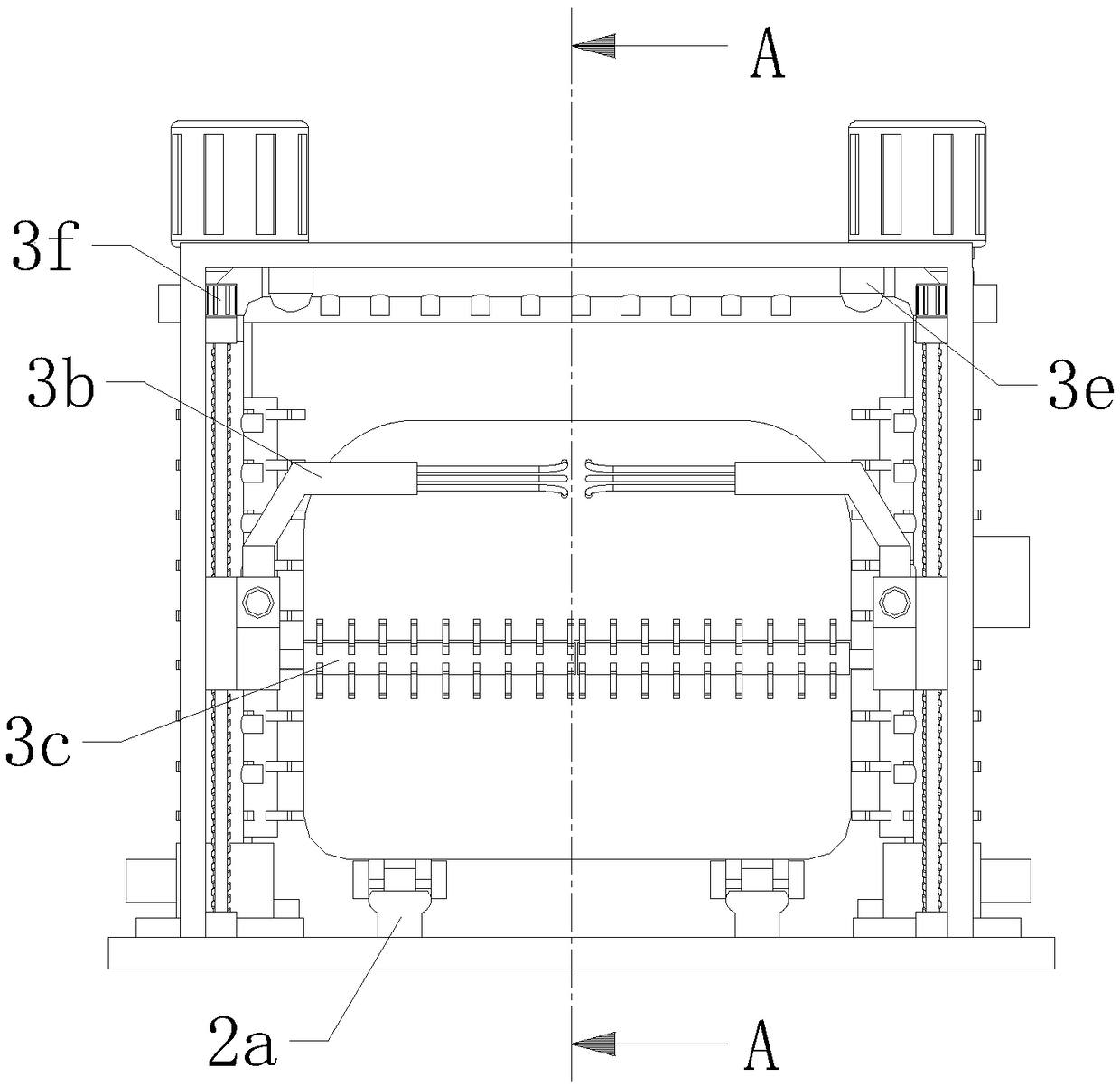

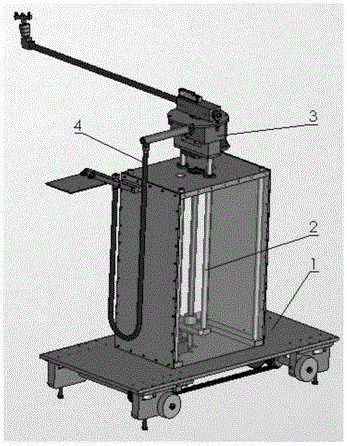

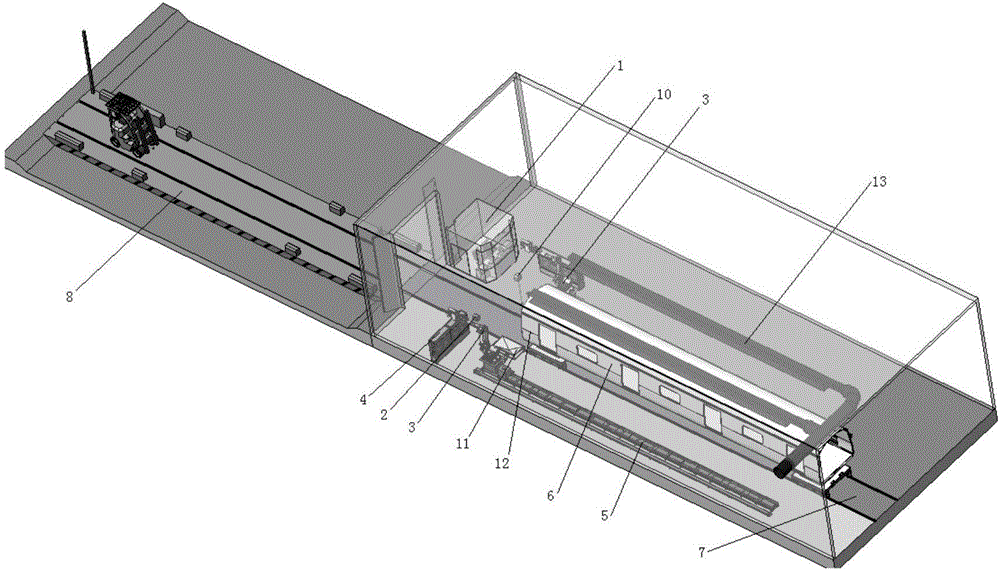

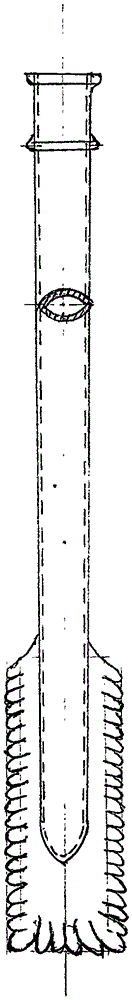

Automatic all-dimensional cleaning device for bottoms of locomotives

InactiveCN104786999ASolve complexitySolve cleaningCleaning apparatus for railwaysCleaning apparatus for vehicle exteriorsPipingRocker arm

The invention relates to an efficient cleaning technology for cleaning the bottoms of several sorts of locomotives, in particular to an automatic all-dimensional cleaning device for the bottoms of the locomotives. The automatic all-dimensional cleaning device is mainly composed of a moving mechanism (1), a lifting mechanism (2), a swing mechanism (3) and a high pressure water supply mechanism (4). The moving mechanism comprises a motor, a synchronous belt and belt wheels to drive wheels to move horizontally on steel rails, and the speed is adjustable. The lifting mechanism comprises a motor, a ball screw and guide pillars to make vertical lifting motion, and the speed is adjustable. The swing mechanism comprises a motor and a gear set to make horizontal swinging motion at the angle of 180 degrees, and a spring resets to be loosened. The high pressure water supply mechanism comprises a rubber tube, a connector body, a rotating connector, a rocker arm tube and a rotating nozzle which are connected to form a high pressure water pipeline. The automatic all-dimensional cleaning device for the bottoms of the locomotives has the advantages that the structure is simple, the degree of automation is high, the cleaning effect is thorough, and the cleaning work which cannot be completed by people in a narrow space is completed.

Owner:BEIJING ROWSUN TIMES SCI & TECH DEV CO LTD

Self-moving type cleaning device for carriage of coal-transporting open wagon and working method of self-moving type cleaning device

PendingCN113459998AEasy cleaning tasksEnsure safetyCleaning apparatus for railwaysLoading/unloadingProcess engineeringCarriage

The invention discloses a self-moving type for a carriage of a coal-transporting open wagon and a working method of the self-moving type cleaning device. The self-moving type carriage comprises a rack, a walking mechanism, a mechanical arm assembly, a cleaning mechanism, a collecting mechanism and a control mechanism; through the walking mechanism, the whole device can move; the cleaning mechanism is arranged on a sweeping roller matched with the carriage of the coal-transporting open wagon, and all the inner walls of the carriage of the coal-transporting open wagon are swept at the same time; the collecting mechanism is used for generating negative pressure, materials cleaned by the cleaning mechanism are collected in time, and secondary freezing and secondary pollution of the materials are avoided; and the control mechanism adopts automatic recognition, image recognition and a sensor to automatically collect control parameters. Manual intervention is not needed in the working process, the problem that the interior of the carriage of the coal-transporting open wagon is difficult to clean is solved, labor consumption is reduced, meanwhile, the cleaning effect is good, the use safety is high, and the automation level of the coal transportation industry can be improved.

Owner:LIAONING TECHNICAL UNIVERSITY

Automatic wire drawing system for side wall of rail vehicle and wire drawing process

ActiveCN106181593AHigh flexibility and intelligenceRealize wire drawingGripping headsBelt grinding machinesControl systemElectronic control system

The invention provides an automatic wire drawing system for the side wall of a rail vehicle. The system comprises a central control system, a robot, a wire drawing device, a rail, a laser measurement system, off-line programming software and an electronic control system. The wire drawing operation of the side wall of a vehicle body is automatically completed. The invention further provides a process method through which wire drawing operation can be conducted by means of the system. By means of the automatic wire drawing system for the side wall of the rail vehicle and the wire drawing process, automatic flexible intelligent wire drawing operation can be achieved, the automatic wire drawing system and the wire drawing process automatically adapt to changes, within a certain range, of the shapes of surfaces of workpieces, the constant normal wire drawing force is kept all the time, and the optimal wire drawing effect is achieved.

Owner:CRRC QINGDAO SIFANG CO LTD

High-speed train automatic washing equipment

InactiveCN109278713AQuick installationReduce adsorptionCleaning apparatus for railwaysRotational axisHardness

The invention discloses high-speed train automatic washing equipment. According to the high-speed train automatic washing equipment, a carriage front fixing plate is fixedly mounted on the left side of a headstock, a carriage rear mounting seat is arranged at the right end of a carriage of the front section, two pairs of washing seats are mounted on the right side of a water spraying part, a bearing is arranged on an inner ring of a rail roller mounting frame, a rotary shaft is fixedly mounted on an inner ring of the bearing in a close-fitting mode, a washing roller is fixedly mounted on the outer side of the rotary shaft through a key groove, and a drying part is arranged at the right end of a washing mounting frame. The washing seats are internally connected with washing agents through pipelines, the washing agents are configured according to metallic paint on the surface of a high-speed train, and a train body can be protected while efficient decontamination can be achieved; according to the washing equipment, primary scouring of the water spraying part is carried out, the washing agents of the washing seats are dissolved, then multilayer friction washing of wrapping layers withdifferent hardness on the outer side of a telescopic rod is carried out, finally drying of the drying part is carried out, the washing efficiency of the whole process is high, metal on the surface ofthe carriage is effectively protected, and the efficiency is improved.

Owner:孙江花

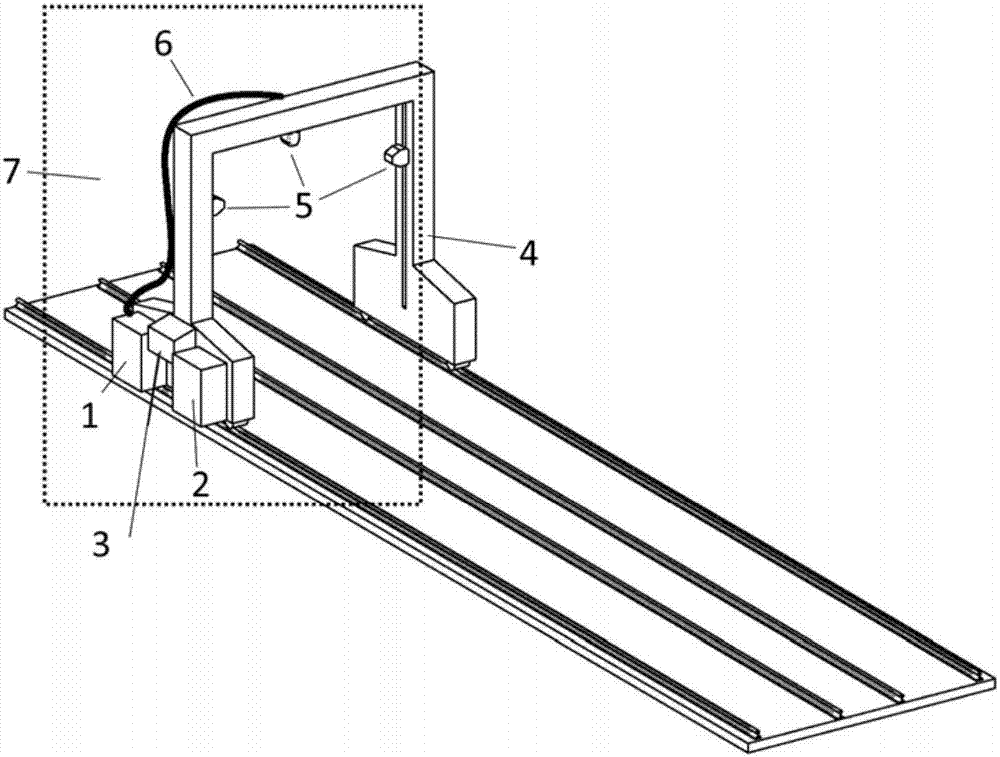

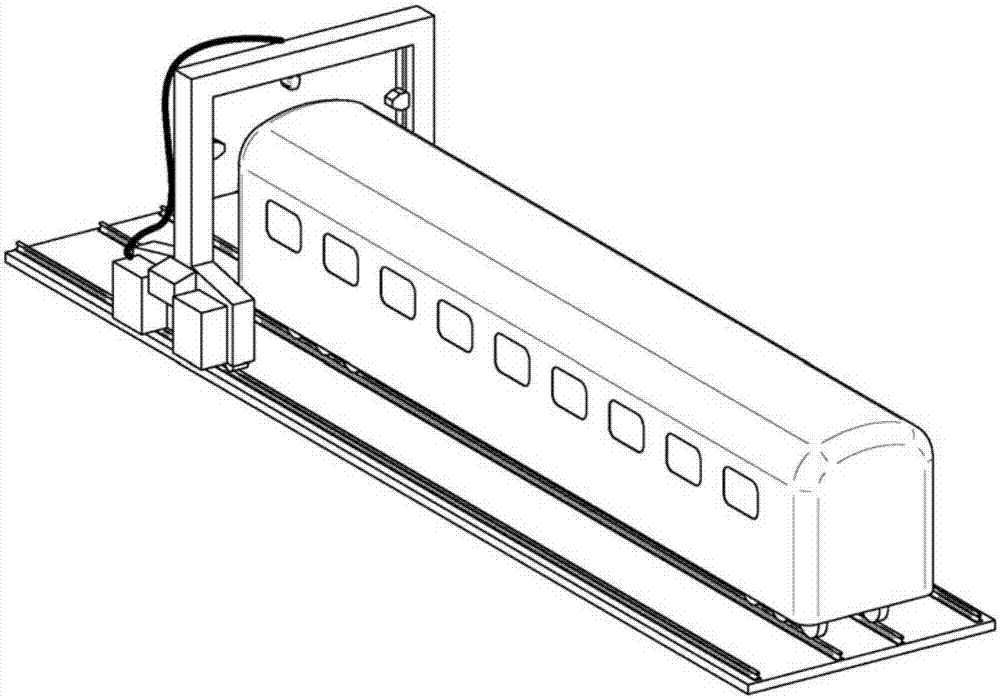

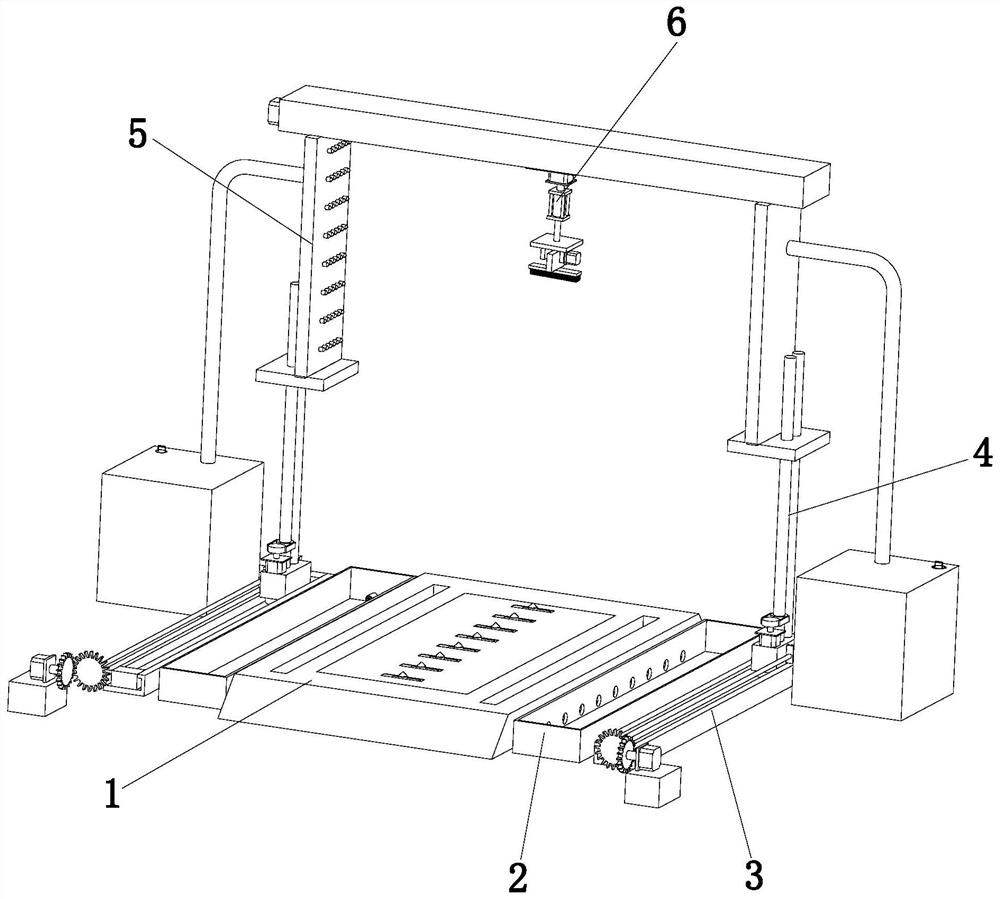

Cleaning system and method suitable for high-speed railway and bullet trains

InactiveCN107187426ANot brokenNo contact wearCleaning apparatus for railwaysEnvironmental resistanceEngineering

The invention relates to a cleaning system suitable for high speed trains and multiple unit trains. The cleaning system comprises a movable gantry (4), a central controller (3) and laser cleaning equipment (7), wherein the bottoms of two stand columns of the movable gantry (4) are connected with a matched railway, and the movable gantry (4) is perpendicular to the railway and allows trains to pass through a space below the movable gantry (4); and the central controller (3) and the laser cleaning equipment (7) are mutually connected and are fixed on the movable gantry (4). Compared with the prior art, the cleaning system disclosed by the invention has the advantages that laser cleaning is used for replacing a conventional polishing technique, so that the cleaning system is free from contact wear and tear, low in heat accumulation, free from destruction to base materials, free from introduction of new dangerous sources and pollution sources, free from consumptive materials, free from maintenance, stable in properties, high in efficiency and environmentally friendly.

Owner:SHANGHAI RAILWAY COMM

Multifunctional worm wheel rotation-friction arm

InactiveCN106740710ALower center heightCleaning apparatus for railwaysCleaning apparatus for vehicle exteriorsLong fingersWire rod

The invention discloses a multifunctional worm wheel rotation-friction arm. The multifunctional worm wheel rotation-friction arm is divided into two types of automatic inflation and non-inflation styles. A shaft head of the automatic inflation type hollow worm wheel is provided with a convex shape compression lid which is externally welded with a gas inlet nozzle and is internally provided with an air chamber, and embedded with an oil seal at the upper part, the convex shape compression lid is connected to a shell of a worm decelerating machine, the inner hole of the oil seal and the shaft head of the worm wheel are sealed, a left connecting lug and a right connecting lug which are arranged on the lower shaft and are in an inverted concave shape are provided with two nuts in the same diameter respectively, the nuts movably connected to two holes of the diameter of a hollow cylindrical universal coupler through bolts, the two holes in the diameter of a lower cross are movably connected with two symmetrical hanging lugs arranged on the pipe top of the inflation rotation-friction arm through the bolts, and a water cage canvas pipe, a PPR hard plastic pipe, an alloy pipe, a stainless steel tube or a galvanized tube is adopted in the inflation rotation-friction arm. A zero damage inflation type glass cowhells latex fish tail fin type long finger is adopted to wipe various bright outer surfaces of limousines, buses, metros, trains, passenger cars, motor cars and high-rise buildings, a high resilience wear-resisting nylon wire rod or an alloy steep wire is adopted as a container, acid, alkali, salt and calcium in the inner wall of a jar or a pot is polished and cleaned in a water spraying process and then discharged from a pollution discharge valve, and a mushroom type foxtail type rotation-friction arm can conduct wiping in various kinds of ways such as a horizontal tilting mode.

Owner:昝士录 +1

Rail transit vehicle cleaning device

InactiveCN112248975AEasy to cleanClean upCleaning apparatus for railwaysCleaning apparatus for vehicle exteriorsWastewaterEnvironmental engineering

The invention discloses a rail transit vehicle cleaning device, and relates to the technical field of rail transit. The rail transit vehicle cleaning device comprises a cleaning table, two waste watercollecting boxes, two moving parts, two lifting parts, two spraying parts and a cleaning part, the cleaning table is arranged on the ground, the two waste water collecting boxes are symmetrically arranged on one side of the cleaning table, the two moving parts are both located on one side of one waste water collecting box, the two lifting parts are both fixedly arranged on one moving part, the two spraying parts are both fixedly arranged on one lifting part, the cleaning part is arranged at the upper part of the cleaning table, and the cleaning part is fixedly connected with the two sprayingparts. Through cooperation of the moving parts, the lifting parts, the spraying parts and the cleaning part, the rail transit vehicle can be cleaned, the waste water collecting boxes collects and reuses cleaned liquid, and waste of water resources is reduced.

Owner:翟文静

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com