Light rail and subway vehicle end profiling vehicle washing system

A technology for subway cars and light rails, applied in vehicle cleaning, vehicle cleaning equipment, vehicle exterior cleaning devices, etc., can solve problems such as inability to wash, incomplete washing, collision or scratching of vehicles, etc., and achieve easy control and good car washing effect. , The effect of improving the efficiency of car washing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in further detail below in conjunction with the accompanying drawings.

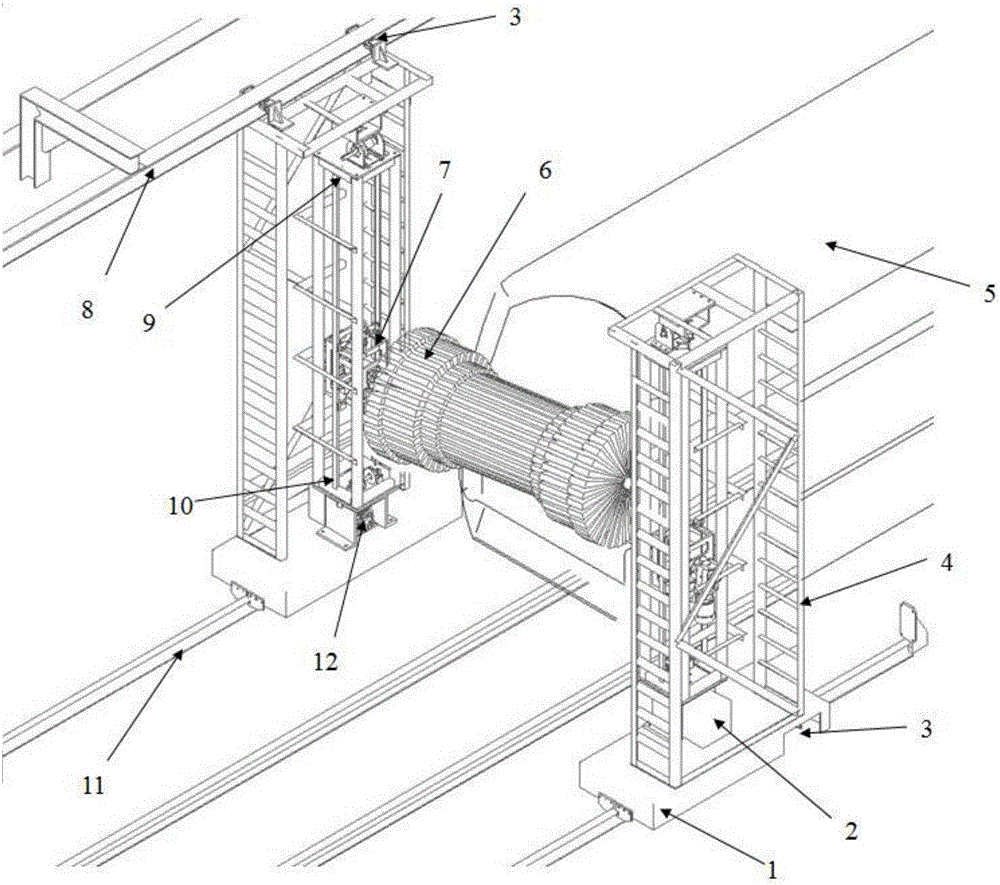

[0014] A light rail and subway car end profiling car washing system includes a control cabinet 2, a brush group 6, a rotary mechanism 12, a lifting mechanism 7, a traveling mechanism, a pressure sensor, a travel switch, an indicator light and a driving device. The driving device includes a brush group rotating motor, a lifting motor, and a moving motor, all of which are servo motors; the traveling mechanism includes a base 1, a side frame 4, a roller 3, an upper rail 8, and a lower rail 11; the lower rail 11 is installed on the left and right rails. On the outside, the upper rail 8 is installed in a parallel position vertically above the lower rail 11, and the distance between the upper and lower rails is higher than the height of the car body; the base is arranged on the left and right lower rails 11, and the connecting line of the two bases is perpendicular ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com