High-speed train automatic washing equipment

An automatic cleaning and high-speed rail technology, applied in the field of transportation, can solve problems such as affecting workers' health, uneven cleaning technology, and heavy cleaning tasks, and achieve the effect of ensuring metal, easy control, and reducing dust adsorption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

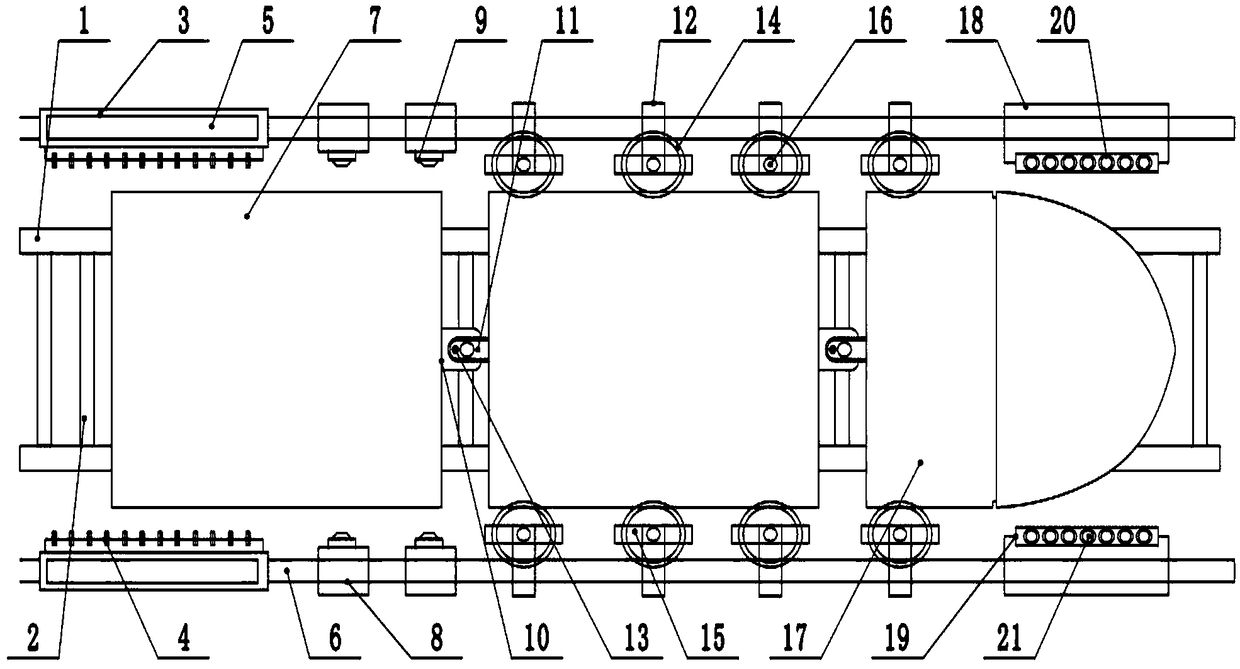

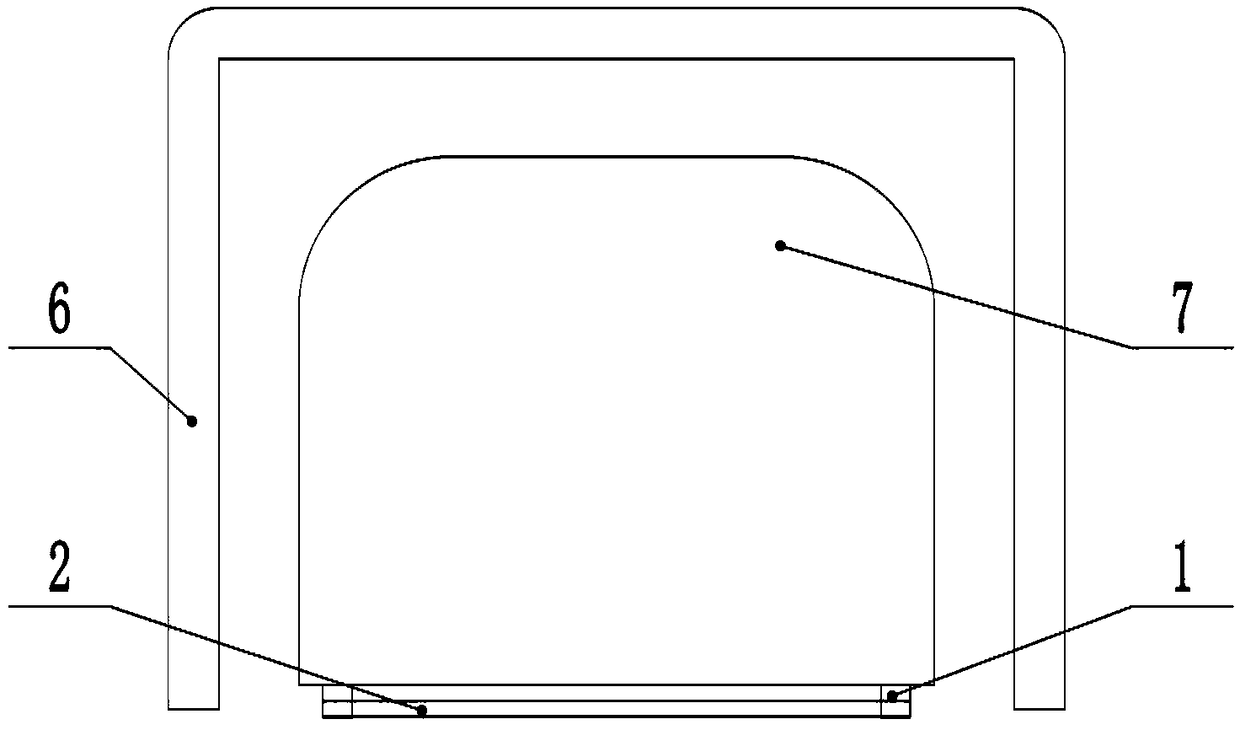

[0022] see figure 1 , a high-speed rail automatic cleaning equipment, comprising: a rail 1, a sleeper 2, a cleaning installation frame 6, a water spray part 3 and a carriage 7, the rail 1 is a high-carbon micro-manganese steel, has good hardness, and has good wear resistance. The preparation cost is relatively low, and there are several sleepers 2 evenly distributed in the middle of the rail 1. After the surface anti-corrosion treatment, the sleepers 2 have good elasticity, light weight, simple manufacture, good insulation performance, simple connection between fasteners and wooden sleepers, and easy laying and maintenance. The transportation is convenient, and the upper end of the 1 is placed with several compartments 7 and fronts 17 at both ends, the left side of the front 17 is fixedly equipped with a front fixing plate 11 of the compartment, and the right end of the compartment 7 of the previous section is provided with a compartment rear mounting seat 10;

[0023] The two...

Embodiment 2

[0026] A protruding rod is arranged on the top of the rear mounting seat 10 of the carriage, and a through hole is correspondingly provided inside the front fixing plate 11 of the carriage. The installation of the compartment is also provided with set screw 13 on the right side of the front fixed plate 11 of the compartment. After the installation is completed at the specified position, the positioning pin can be positioned to complete the quick installation for the compartment 7 and the cleaning seat 8.

Embodiment 3

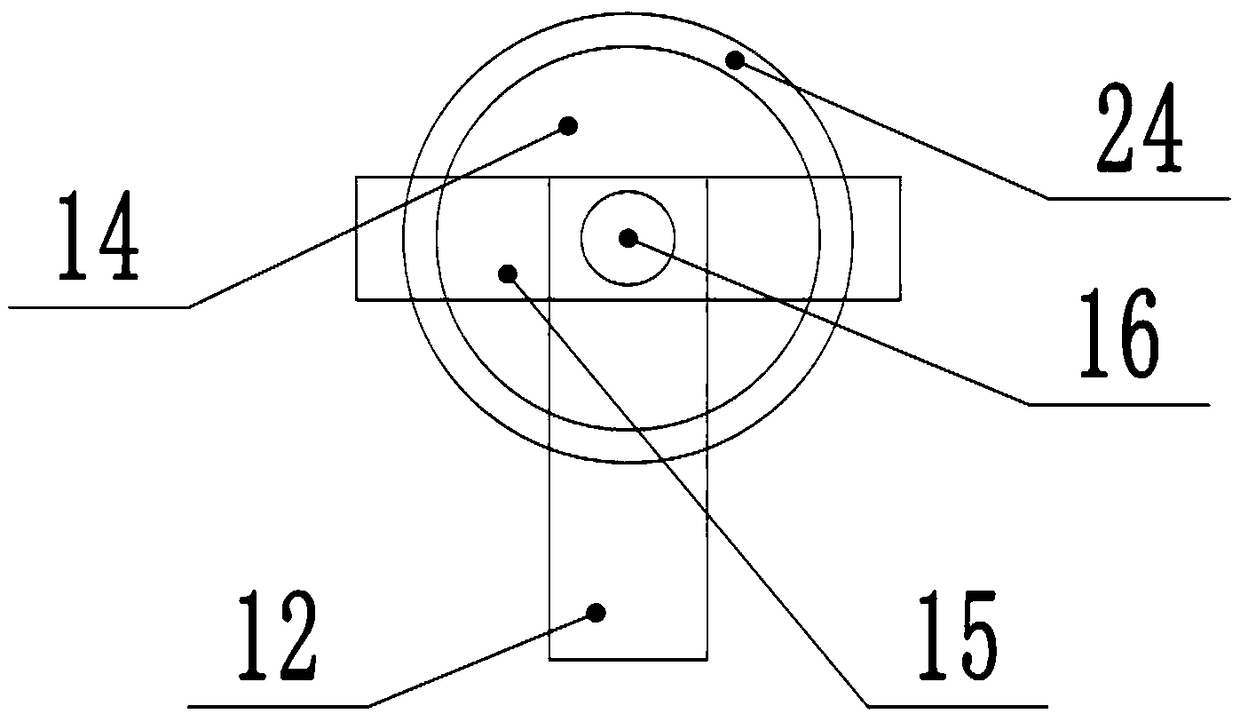

[0028] Several groups of telescopic rods 12 are fixedly installed on the cleaning installation frame 6, and the material hardness of the wrapping layer 24 on the outside of the telescopic rods 12 is different. Brush materials with low hardness for two fine cleanings, and finally use a high-density brush for finishing cleaning to improve cleaning quality.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com