Patents

Literature

397 results about "Integrated automation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Automated batch manufactuirng

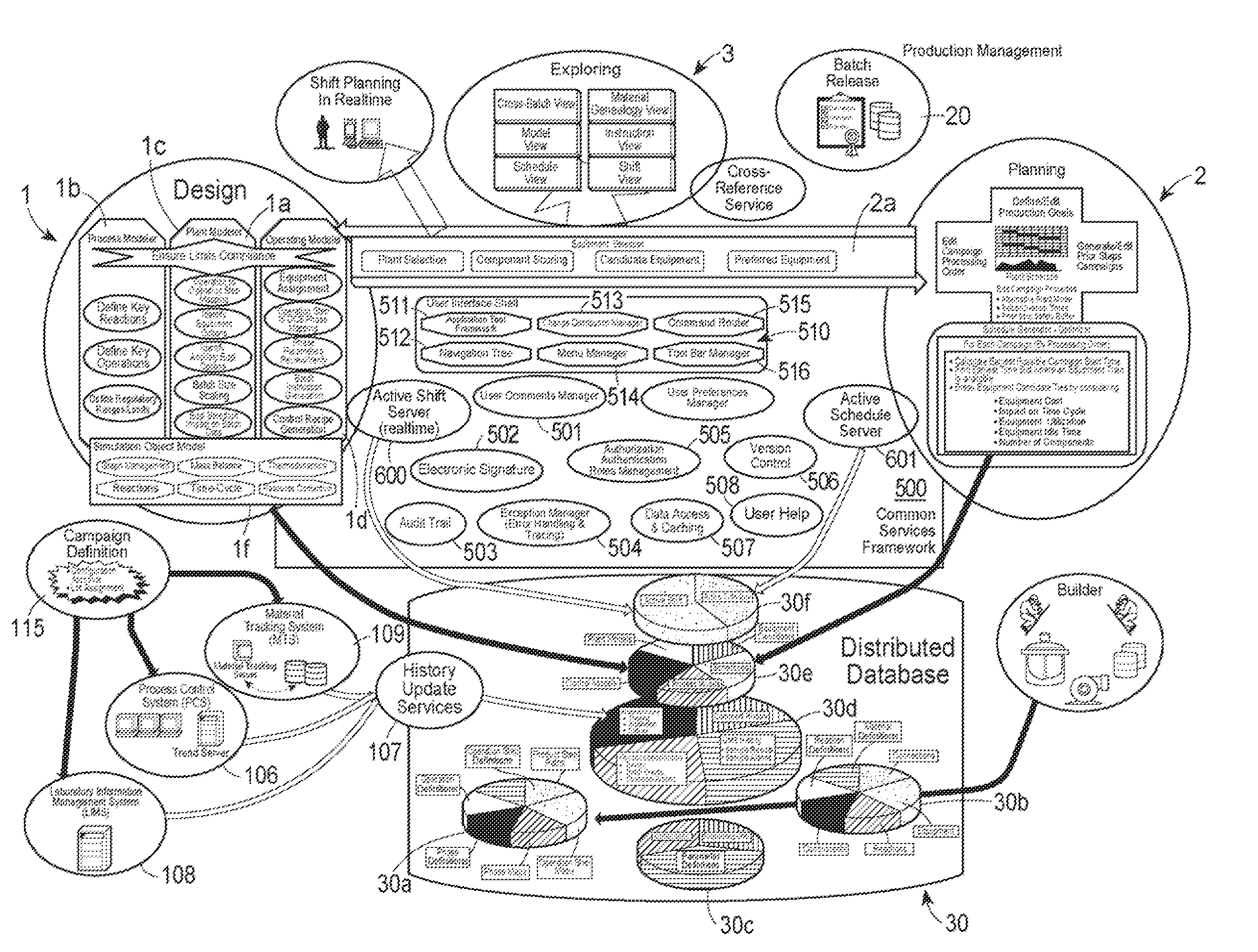

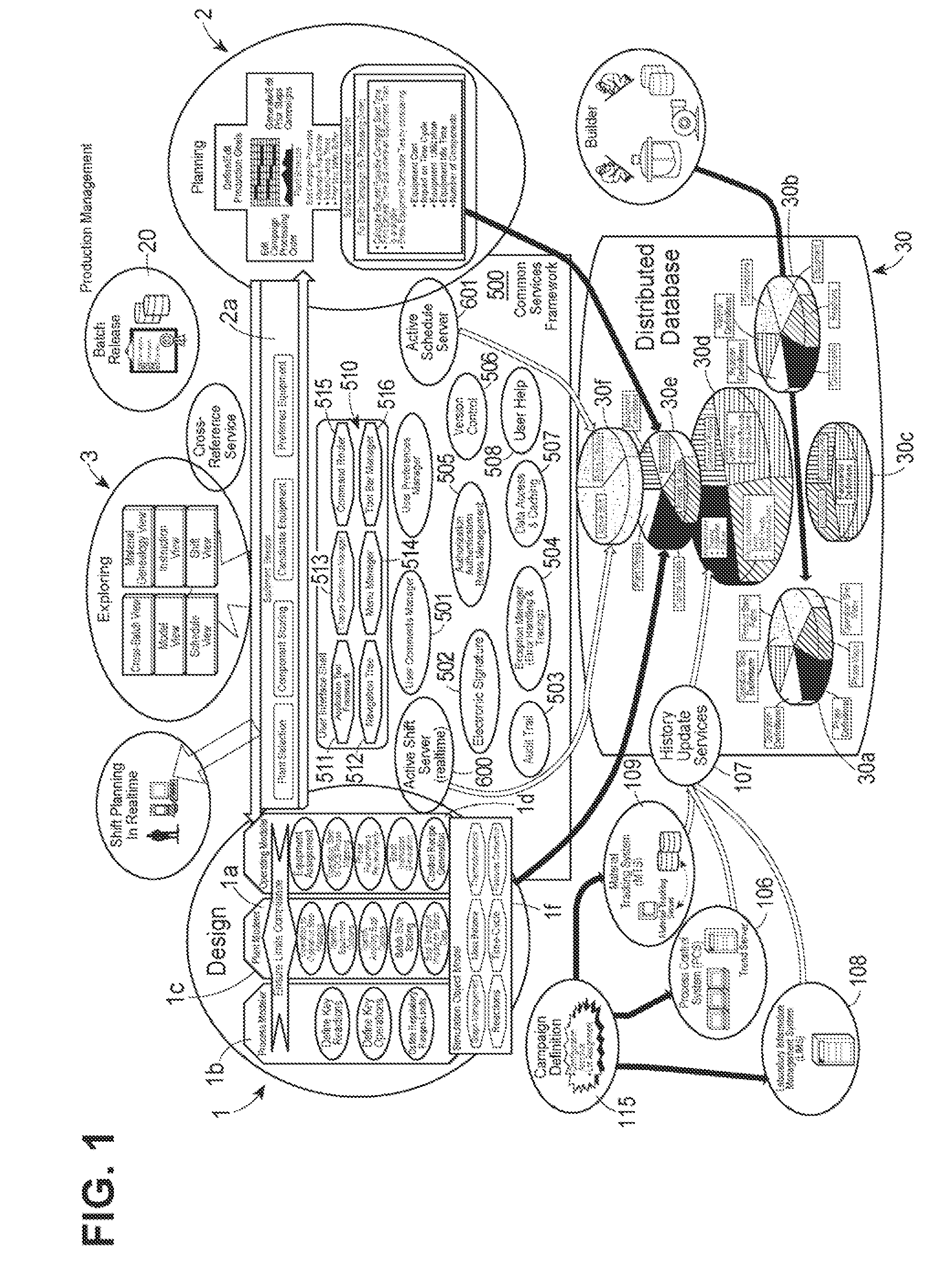

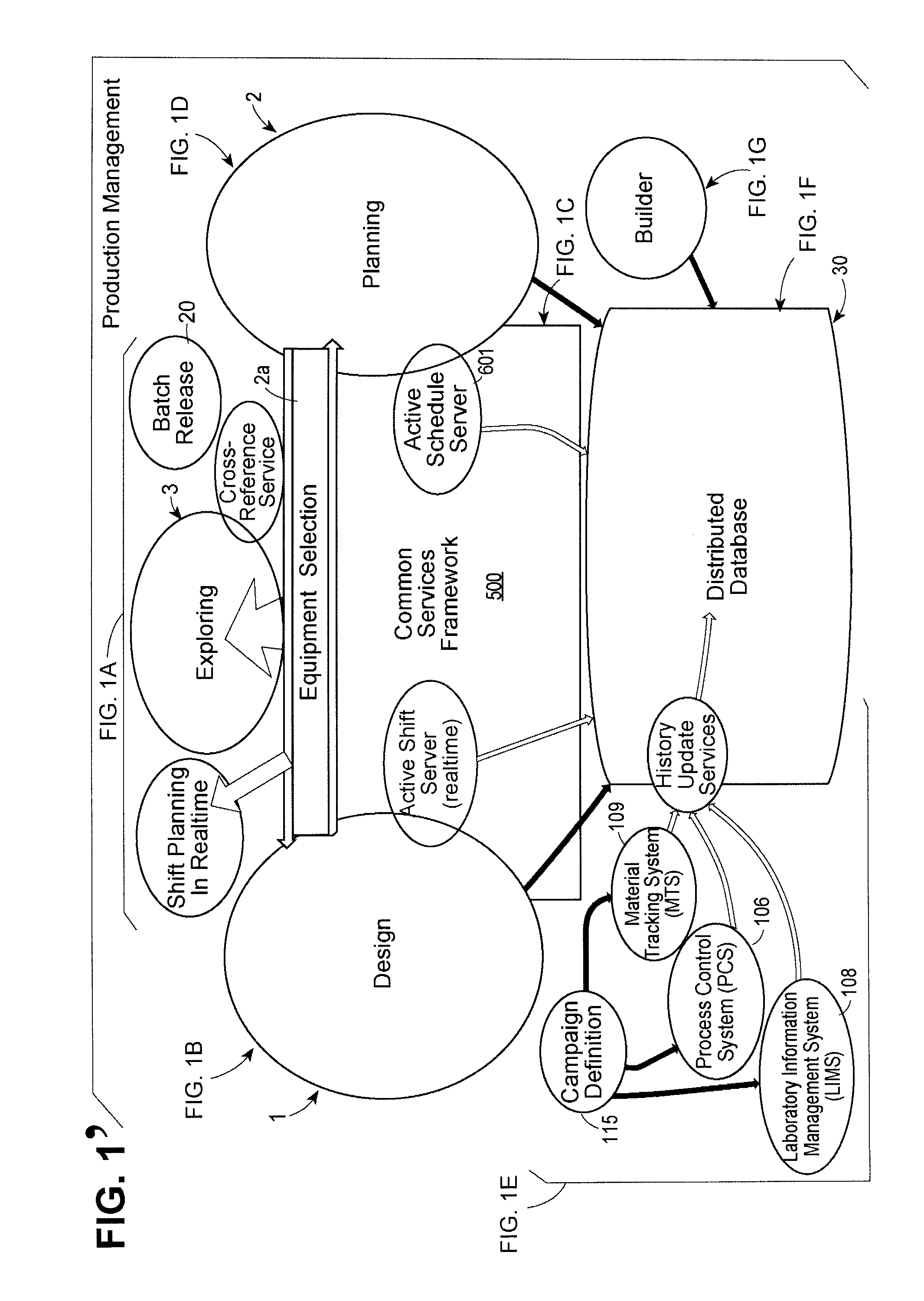

InactiveUS20070050070A1Rich and accurate near term planning informationMaximum efficiencyComputer controlTechnology managementOperating modelIntegrated automation

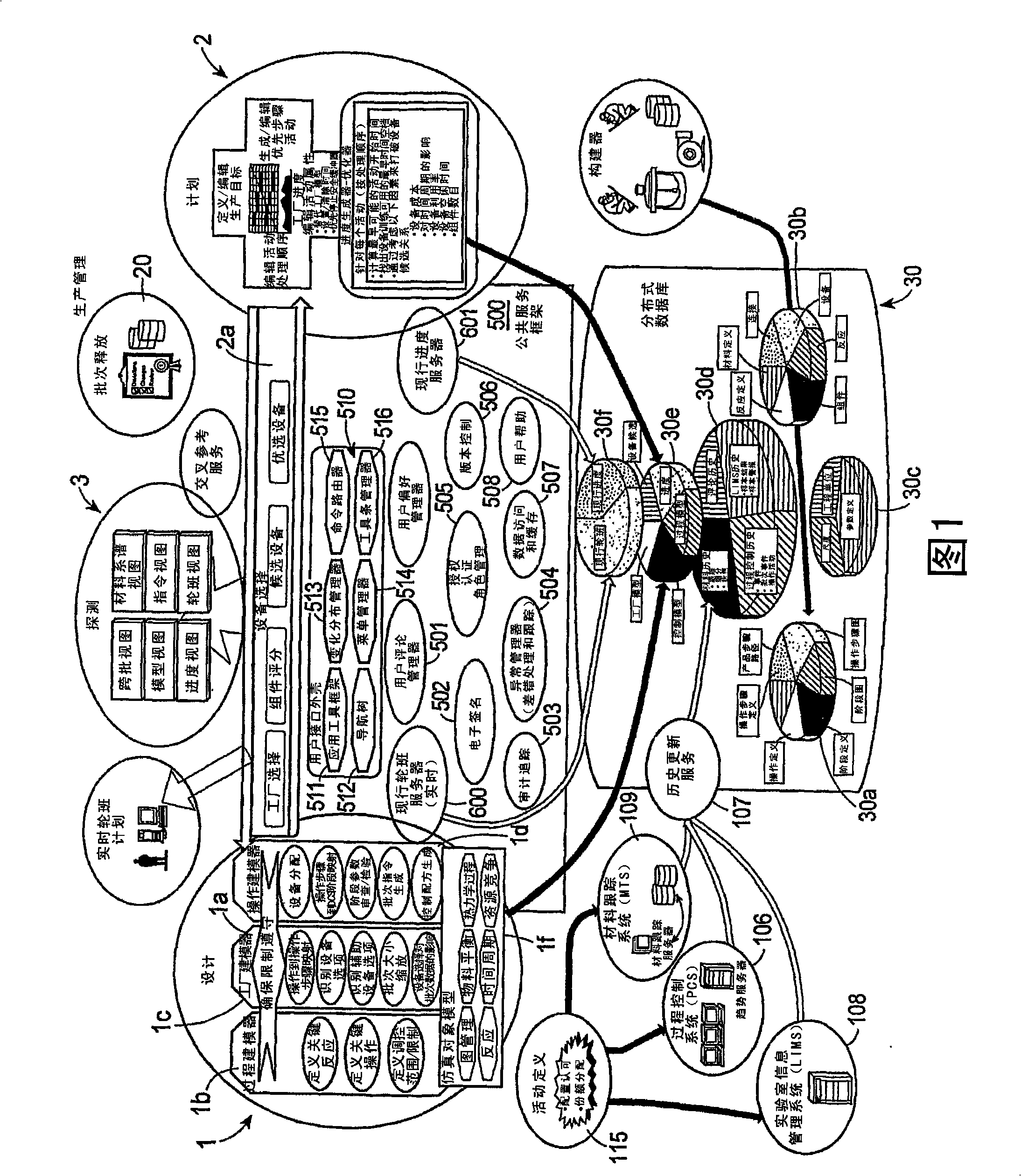

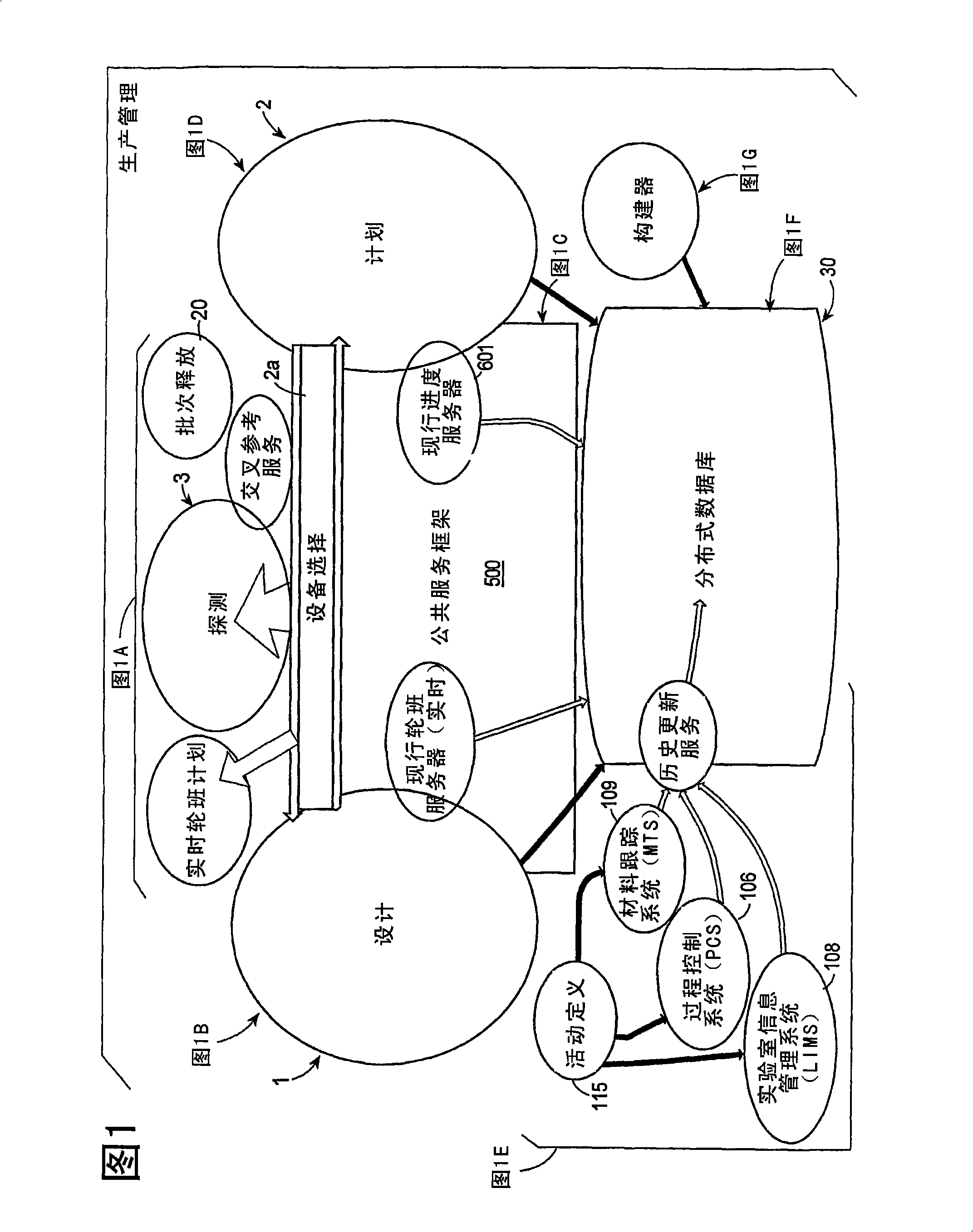

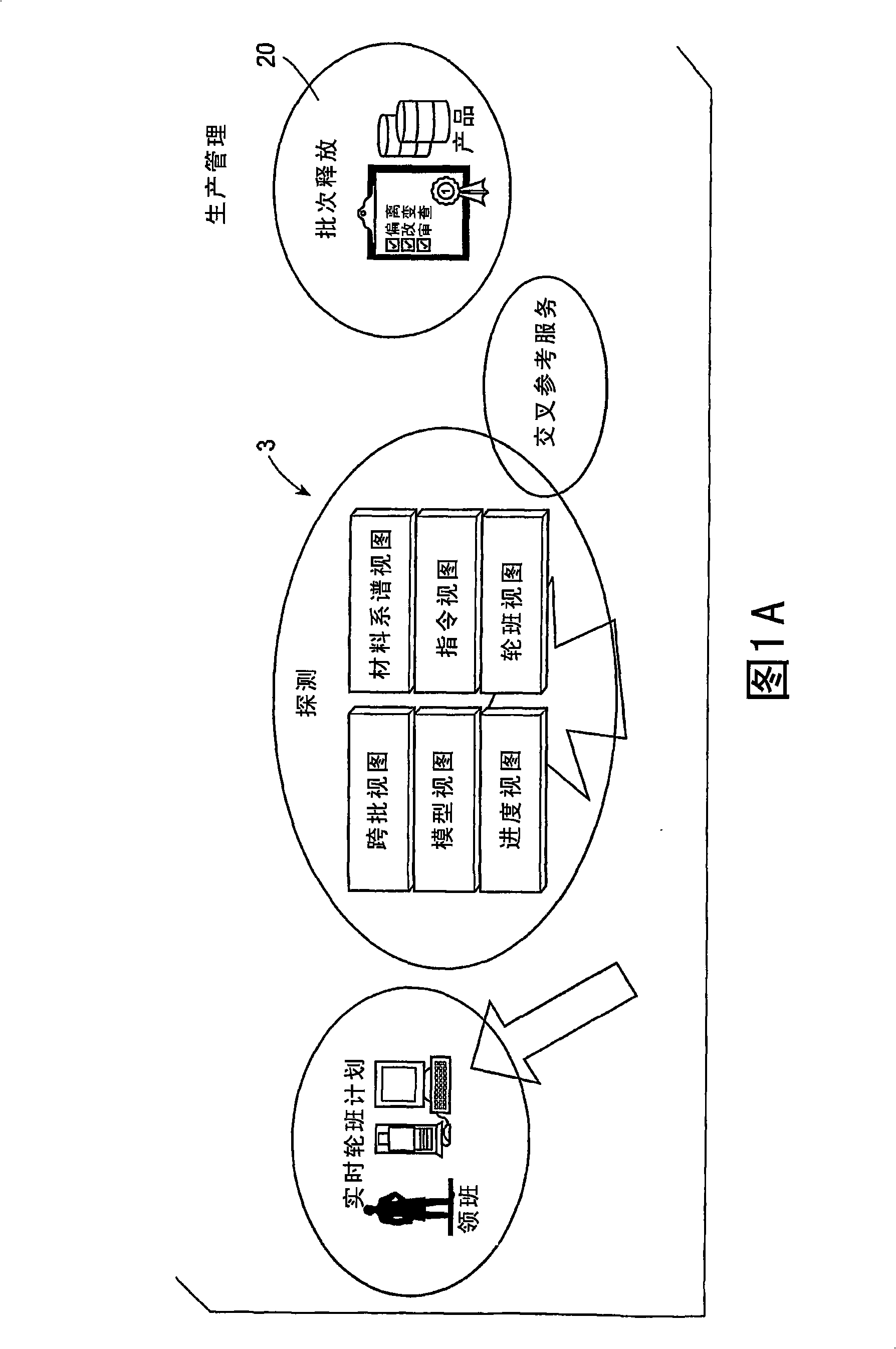

An integrated automated management system for batch manufacturing of products, particularly pharmaceuticals. The system comprises: a distributed data with process related information, a design module which extracts information to build operating models for the manufacturing; a planning module which interacts with the data base and design module to provide the financial and scheduling aspects of the manufacturing, and an exploring module, interfaced with the data base and the other modules, in a closed operational loop to provide real time analysis of the operating model in comparison to actual manufacture to provide real time quality control

Owner:PFIZER INC +1

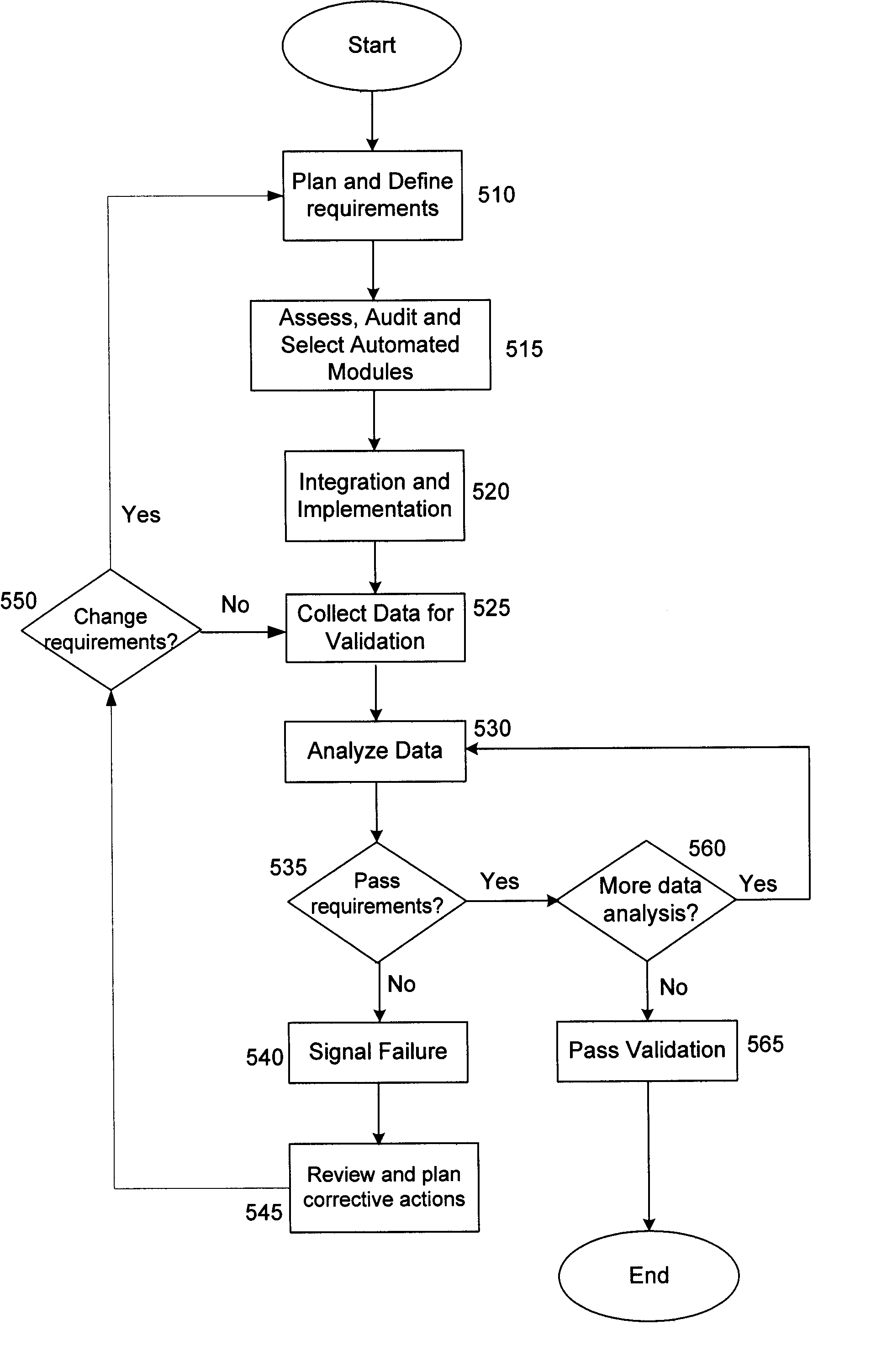

Virtual platform to facilitate automated production

InactiveUS20050137735A1Facilitate communicationSatisfies requirementData processing applicationsTotal factory controlTelecommunications linkCommunication link

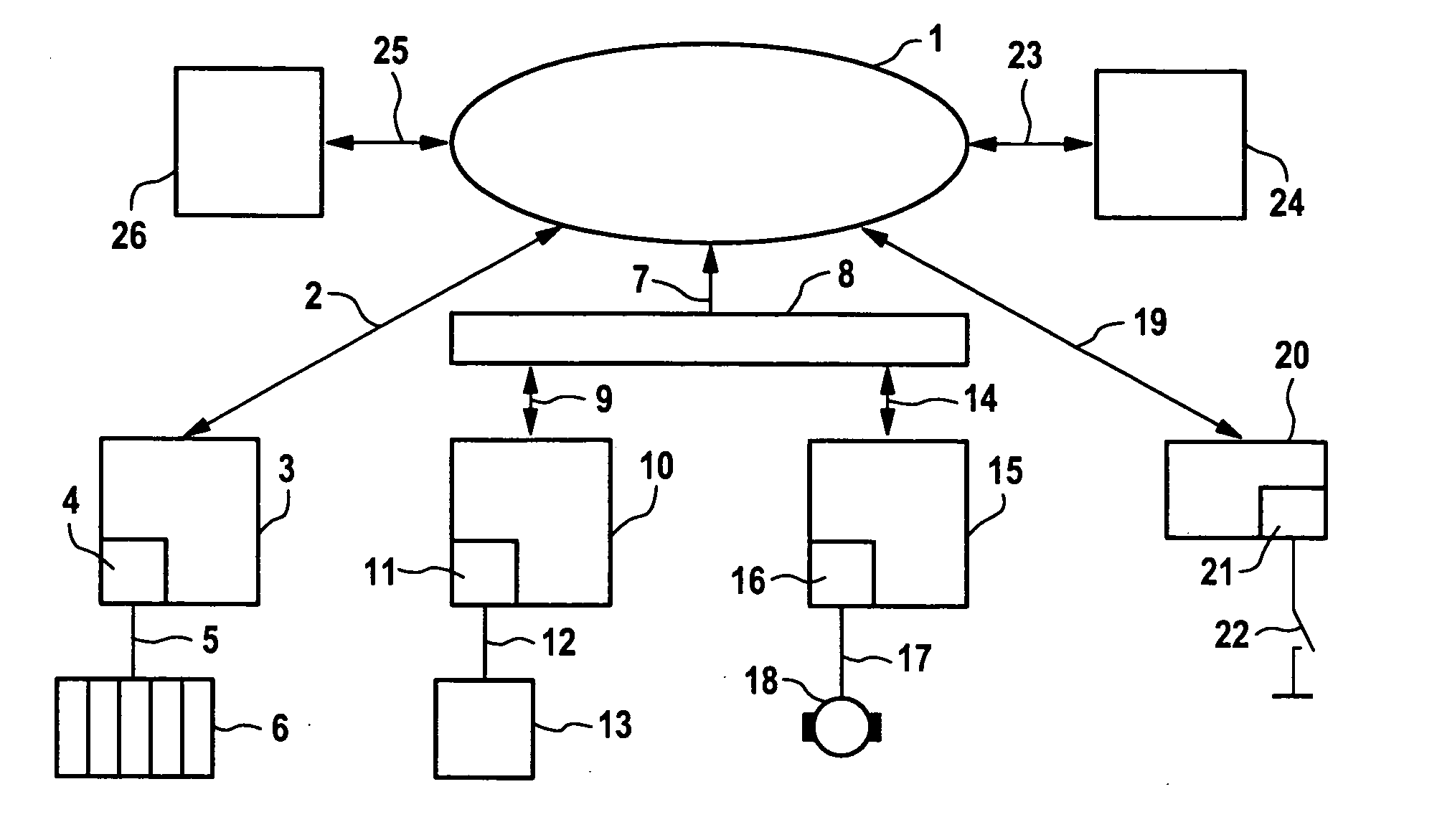

A method of automating validation in a manufacturing facility is disclosed. The method comprises defining requirements, selecting and integrating automated devices for manufacturing. A hub-box with communication links is used to integrate the automated devices. The hub-box controls and facilitates communication between automated devices. The hub-box further collects and analyzes processing data for validation of the process. By interconnecting the automated devices to a hub-box, processing data may be collected substantially real-time and accessed remotely, facilitating continuous process validation.

Owner:BEACONS PHARMA

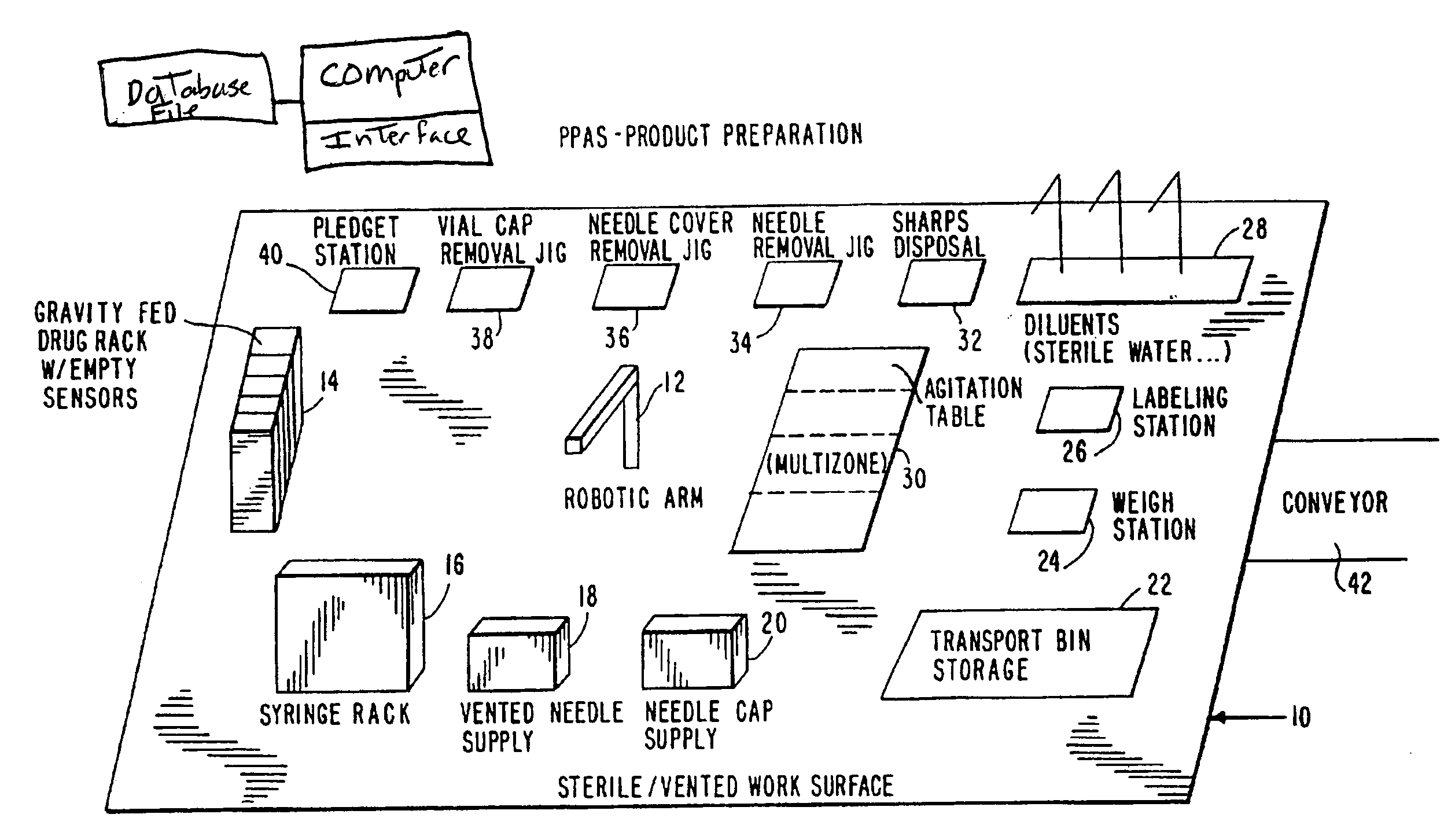

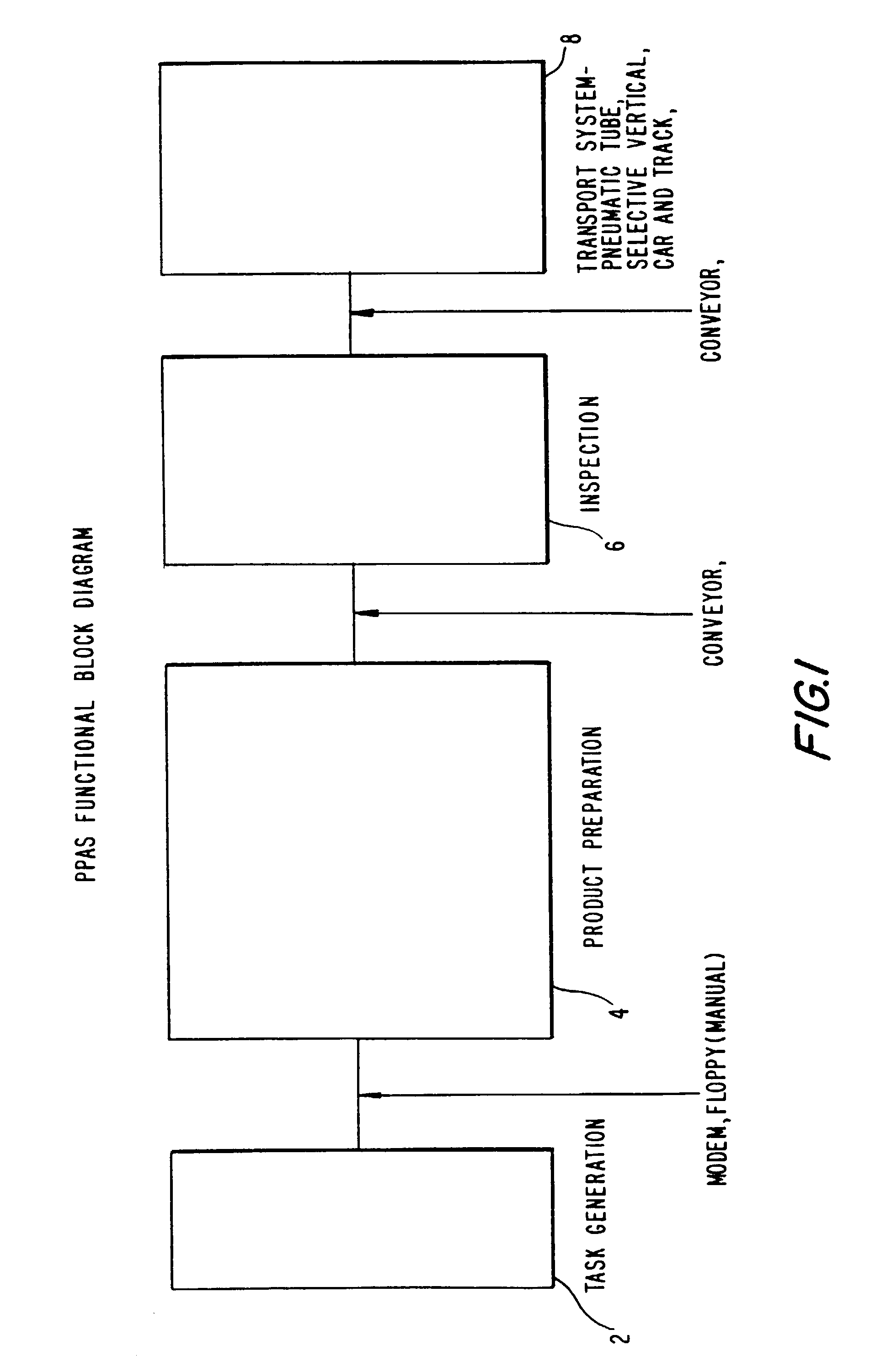

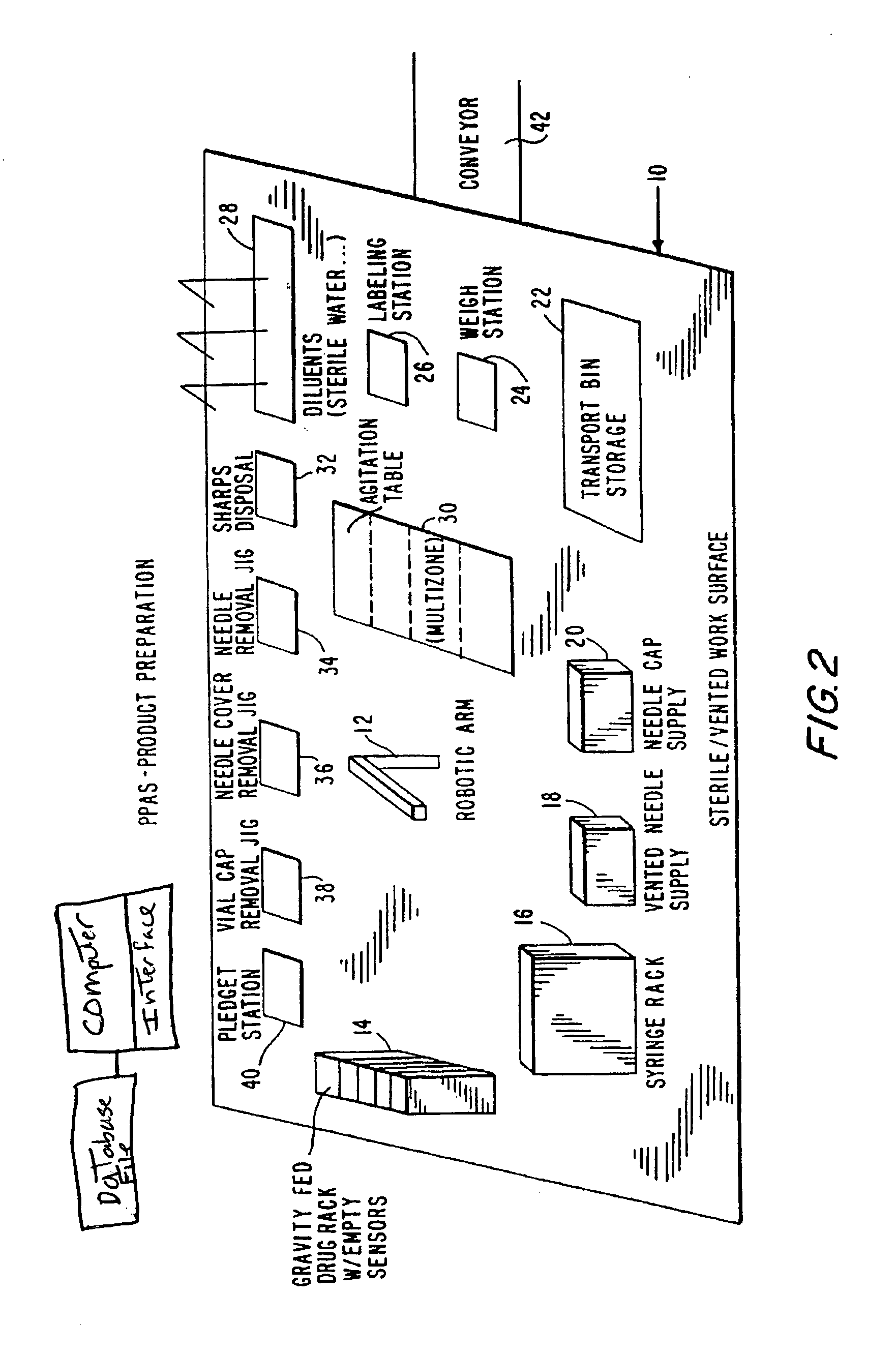

Parenteral products automation system (PPAS)

InactiveUS7260447B2Simple correctionAvoid confusionData processing applicationsConveyorsEngineeringDrug product

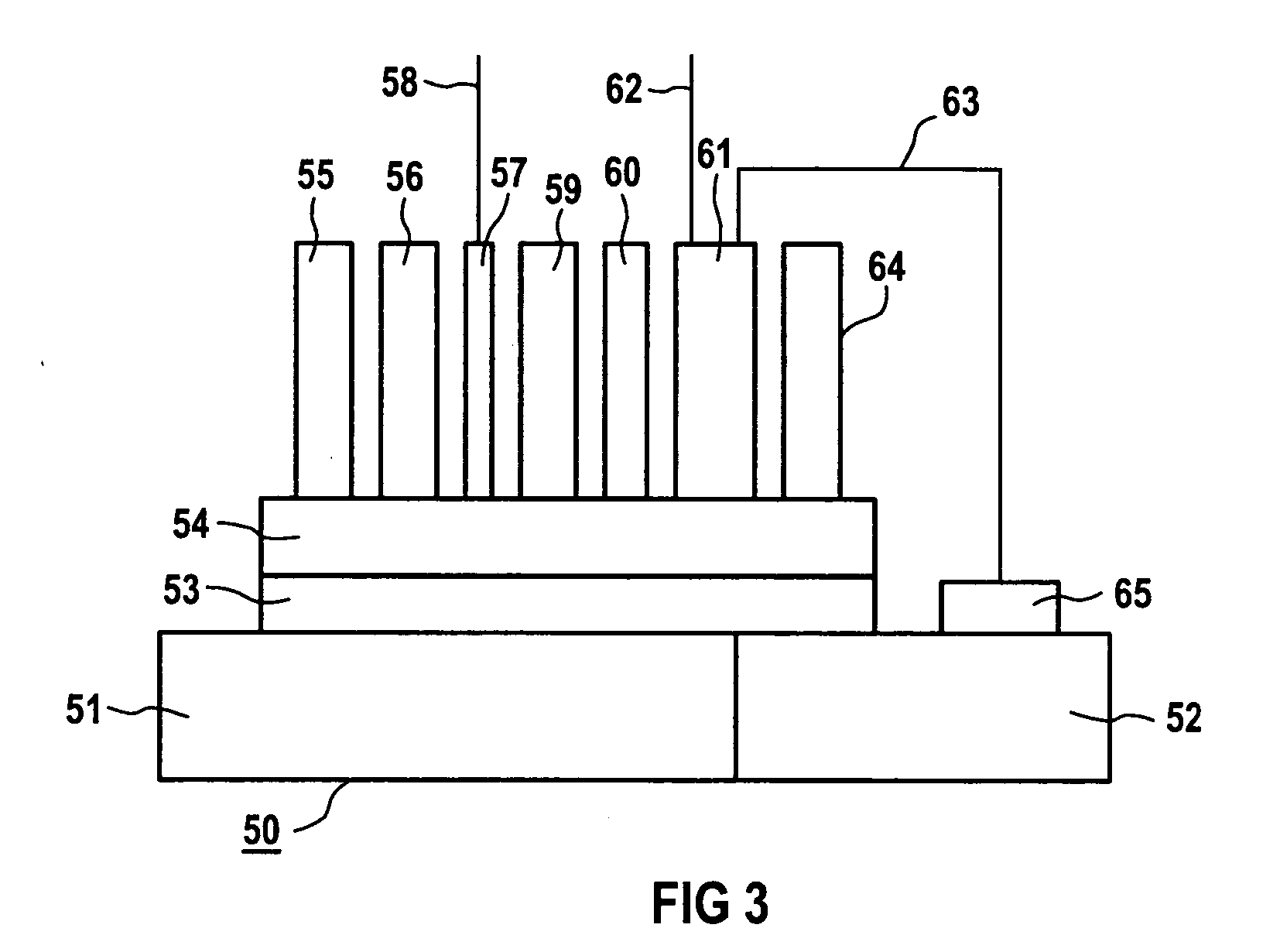

An integrated, automated system concerning pharmaceutical products is provided. The system comprises an input queue, a dispensing apparatus comprising a robot device and a number of stations from which the robot device works, and an inspection station. A computer interface provides bi-directional communication between the analytical instruments, robots and peripheral devices and a computer. The robot employed by the system is responsive to computer commands and capable of performing mechanical functions including selection and retrieval of a necessary item and manipulation of retrieved items such that the desired product is produced.

Owner:BAXTER ENGLEWOOD

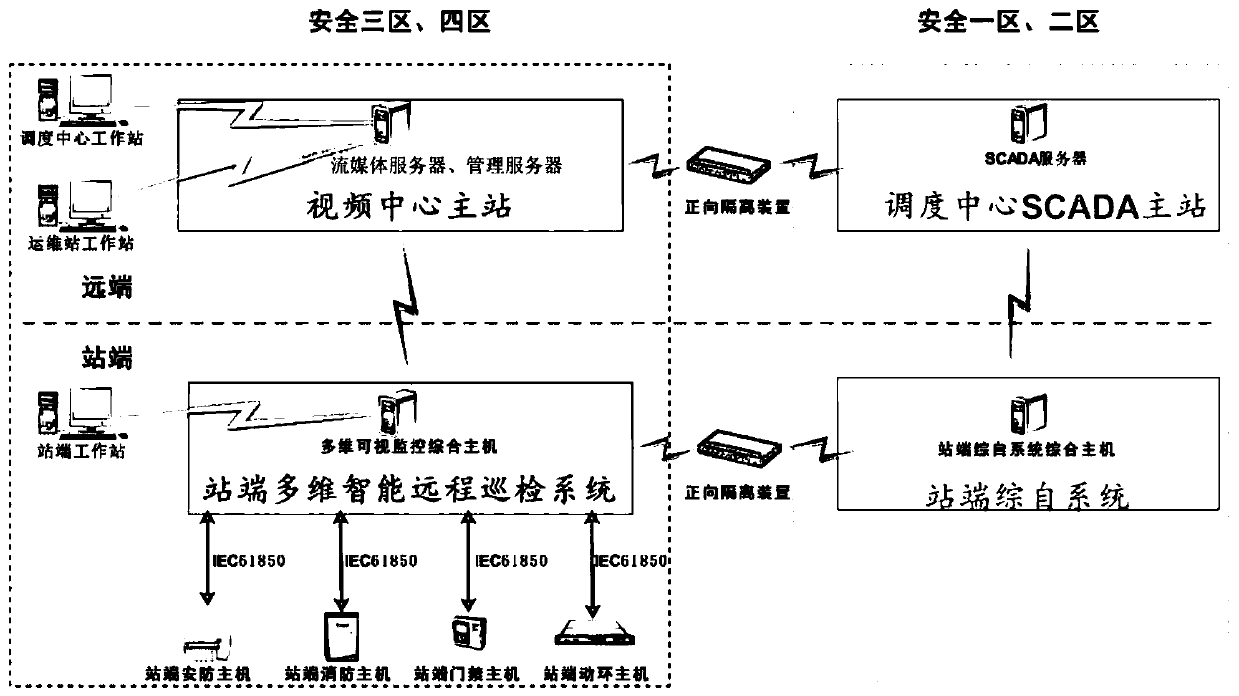

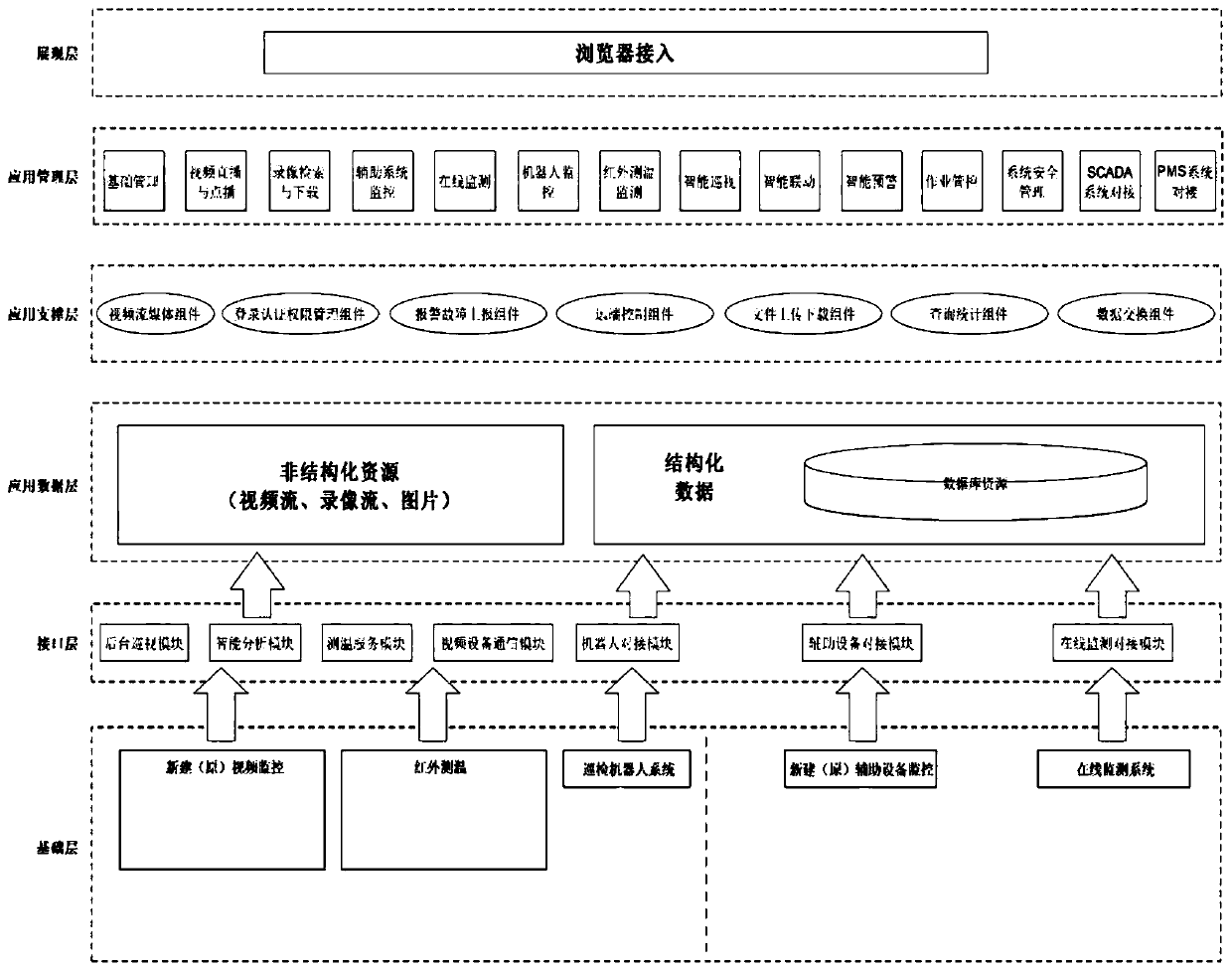

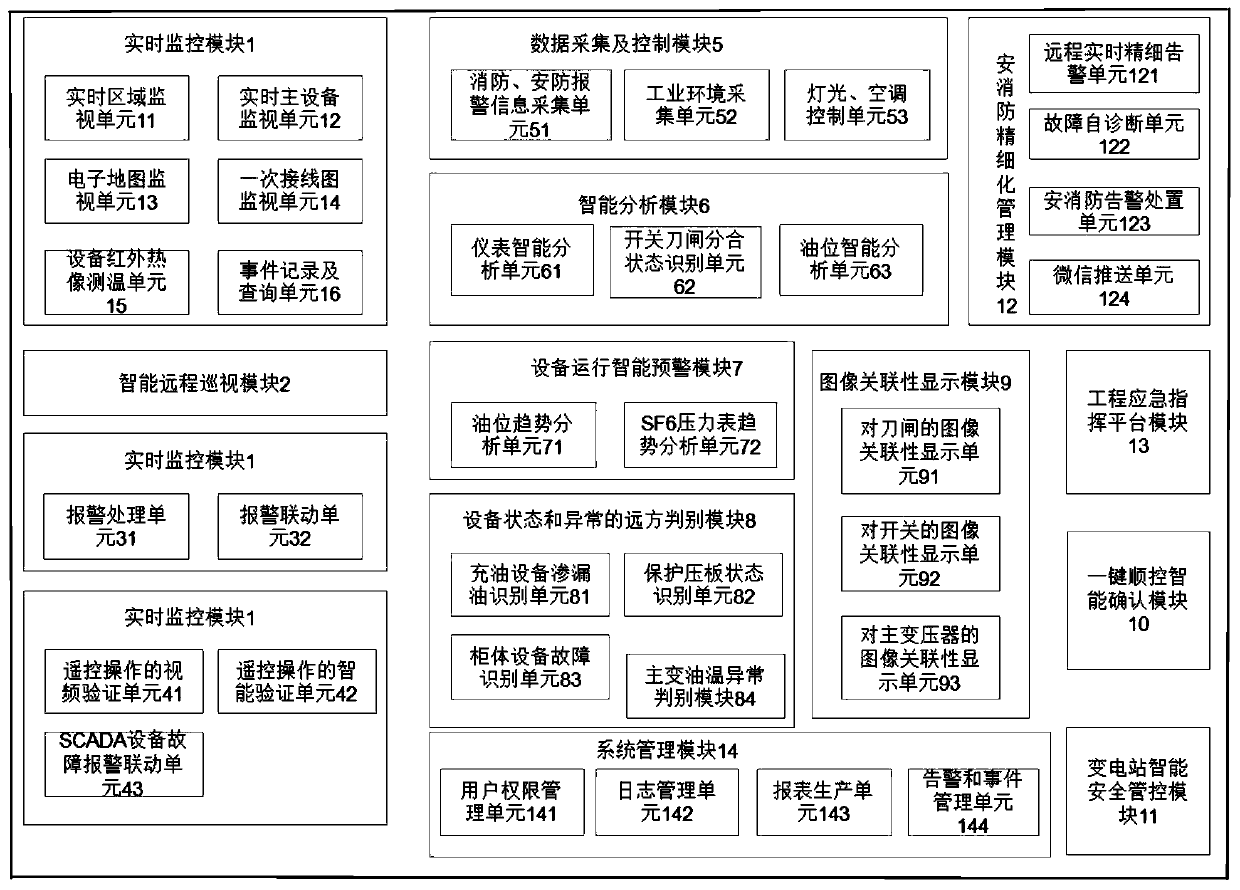

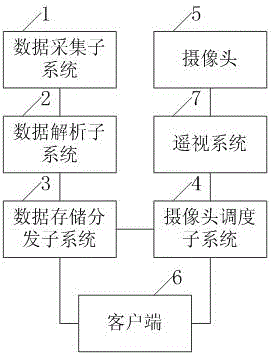

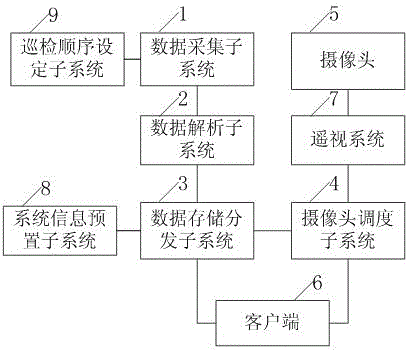

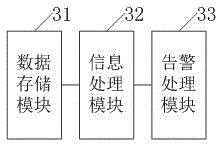

Multi-dimensional intelligent remote inspection system for transformer substation

ActiveCN110707823AAvoid silosExtend the cycle of comprehensive inspectionsCircuit arrangementsSustainable buildingsSmart surveillanceEmbedded system

The invention discloses a multi-dimensional intelligent remote inspection system for a transformer substation, which adopts independent networking and receives various operation information of a station end integrated automation system, and is in communication connection with a video center main station to obtain remote view data, remote measurement data, remote control data and remote signaling data; the dispatching center SCADA main station system is in data communication with the station end integrated automation system and receives various kinds of operation information of the station endintegrated automation system; and the video center main station is also in data communication with the dispatching center SCADA master station system to provide real-time video verification for remotecontrol operation of the dispatching center SCADA master station system. According to the invention, a powerful intelligent monitoring and emergency command platform is provided for production linksand security links such as remote control operation and remote equipment inspection of scheduling personnel, field operation and emergency disposal of operation and maintenance personnel and the like,can be suitable for actual application of power production, and ensures safe operation of power grid production.

Owner:SHANGHAI MUNICIPAL ELECTRIC POWER CO

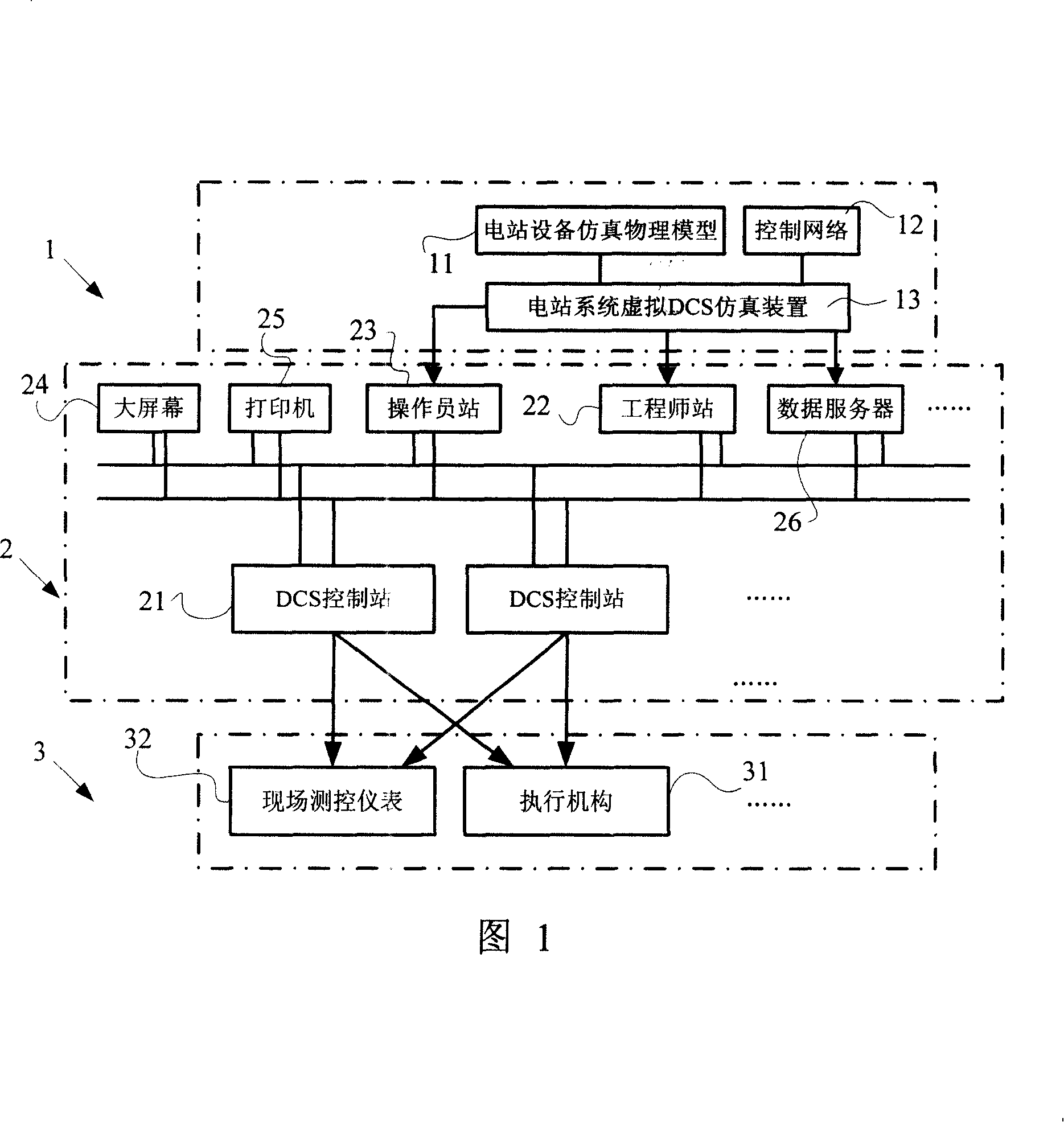

Simulation platform of macrotype power station integrated automation system

InactiveCN101154213AImprove operating economyImprove operational safetyComputer controlPower network operation systems integrationFiberSystems design

The invention relates to an comprehensive automatic system imitation platform for a large power plant, comprising that an 'imitation machine' part is a power station imitation platform for simulating the power plant production process by real-time and providing an actual and effective testing and analysis platform to improve the power station automatic level; a distributed control system comprises a plurality of control points in the actual site, a work station, a display, a printer, a data server and a double-redundancy fiber optical ring-shaped communication network; the 'actual power' part is the 'actual power' part of the power station simulation platform, and comprises a site input signal collecting system, a site testing and control instrument and an execution mechanism of the output signal of the simulation platform. The invention is constructed into a comprehensive automatic system research platform of the completely interacted power plant so as to conduct the analysis and research of the operation of the entire equipment of the power plant system without being limited by each condition on site, thereby, the time and the cost of the system design, testing and optimization can be largely saved, the economy and the safety of the power plant operation can be improved.

Owner:SHANGHAI ELECTRICGROUP CORP

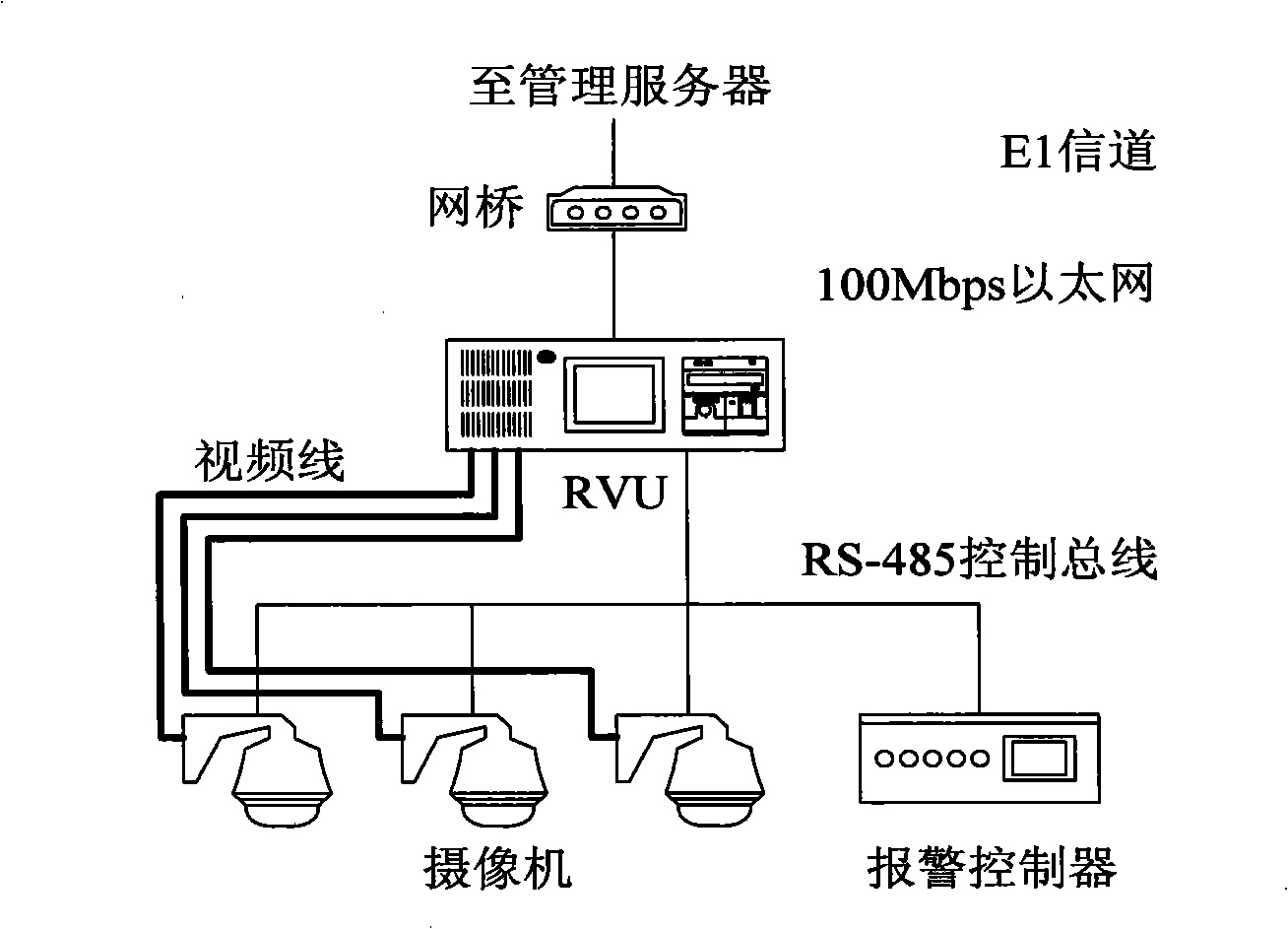

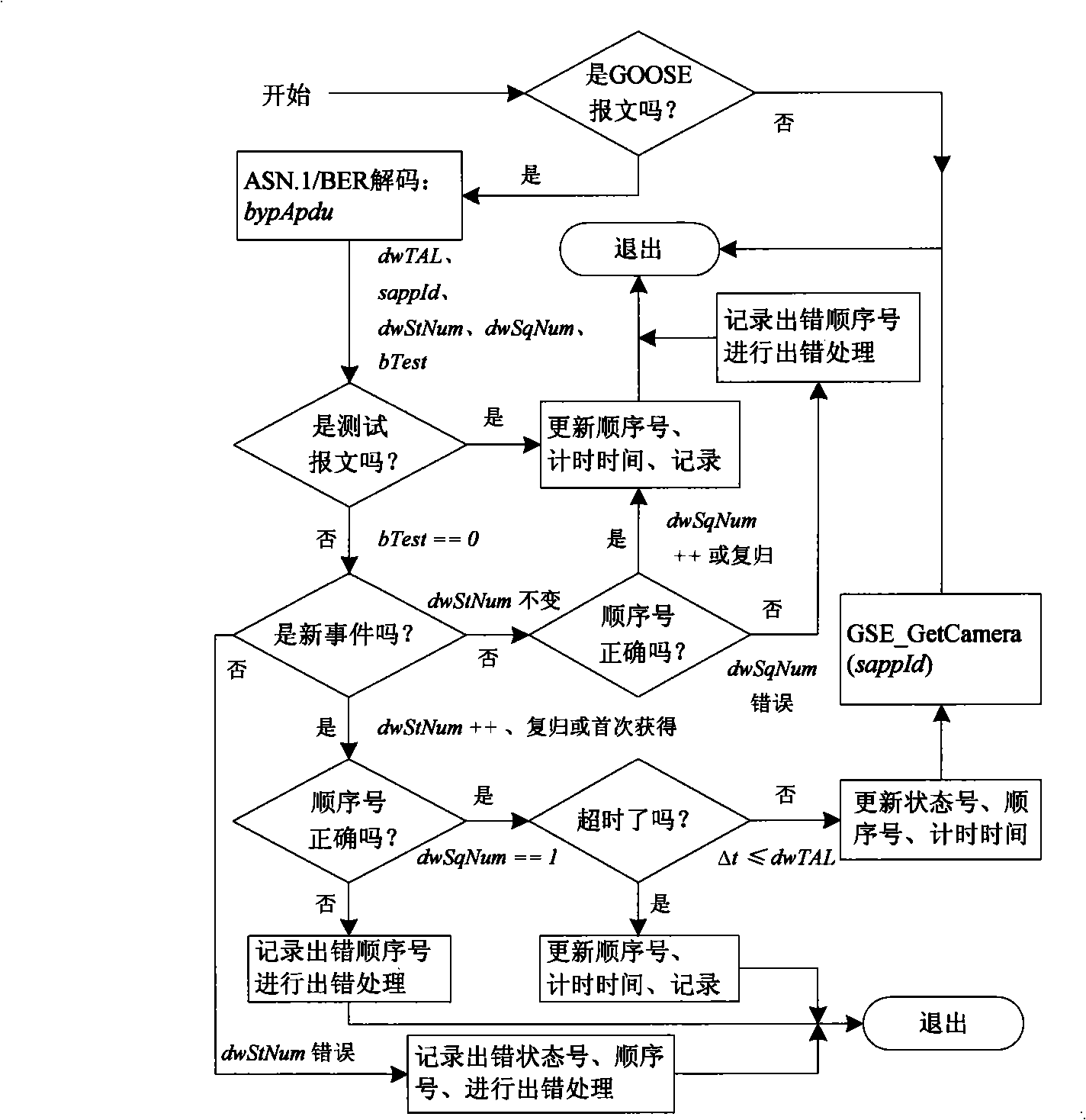

Protection and video system gang control method for electric power system digitalization transforming plant

InactiveCN101409463ARealize linkageAchieve a high degree of integrationData processing applicationsPower network operation systems integrationTransmission protocolTransformer

The invention discloses a protection and video system linkage control method of a digital transformer substation of an electric power system. The method comprises the following steps: establishing a mapping relation, capturing and analyzing a GOOSE message, turning on a lighting installation, starting a video recorder, switching a video channel, as well as alarming and realizing the protection and video system linkage. The protection and video system linkage control method comprises the following steps: finishing establishing the mapping relation, acquiring and analyzing the GOOSE message by a software programming manner or adding a communication server dedicated for realizing GOOSE linkage; sending control commands of positioning the video recorder, video recording, switching the video channel and the like to a video processing unit by a network according to a remote transmission protocol of a remote vision system; and finishing the protection and video system linkage function. The method is suitable for the digital transformer substation, utilizes the most important communication service of the digital transformer substation, namely a general object-oriented transformer substation event, and independently finishes the linkage function of a secondary system and a video control system without dependence on an integrated automation system.

Owner:ELECTRIC POWER RES INST STATE GRID JIANGXI ELECTRIC POWER CO

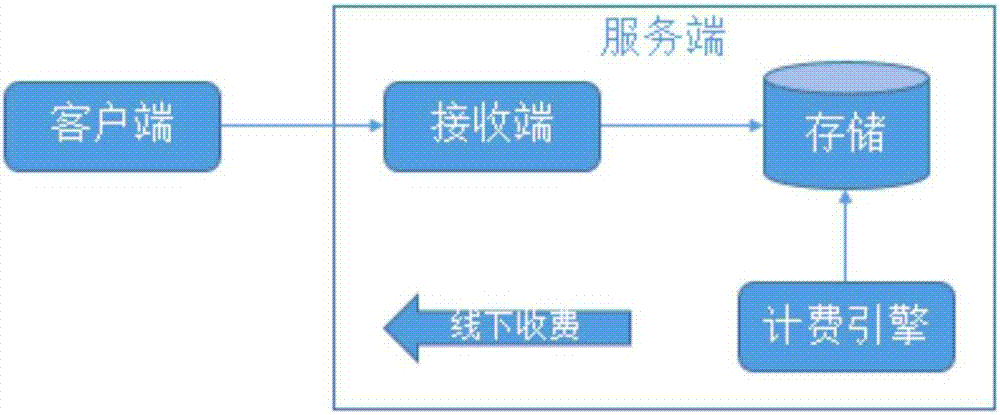

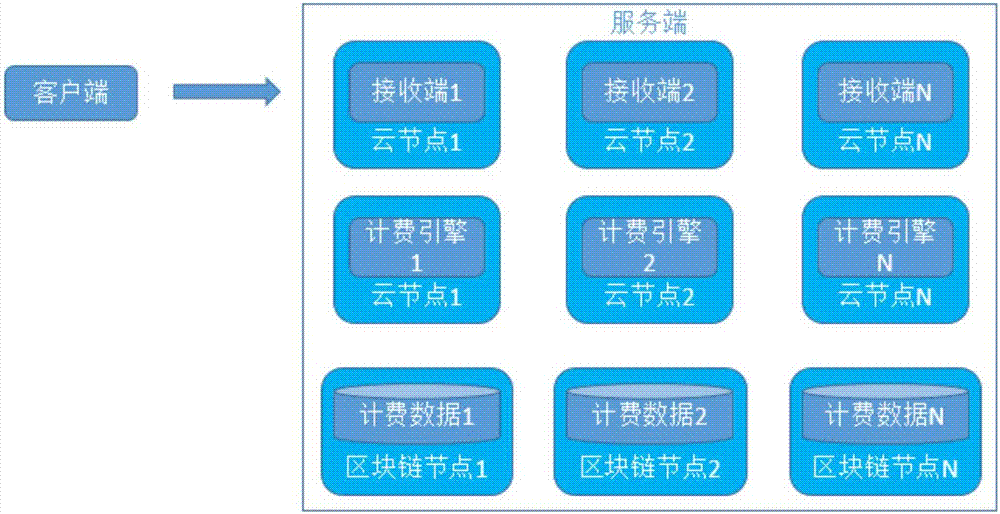

Billing method based on block chain and cloud computing platform

ActiveCN106911483ANot tamper-proofIncrease credibilityMetering/charging/biilling arrangementsSmart contractIntegrated automation

The invention provides a billing method based on a block chain and a cloud computing platform. The method includes the following steps that: a client end collects billing information; the client end selects a server end and sends the billing information to the server end; the server end records the billing information in the block chain; and the smart contract of the block chain automatically performs charging. According to the method, the server end is provided with a plurality of cloud nodes; and all the cloud nodes operate on the cloud computing platform; and a receiving end for receiving the billing information and a billing engine for processing the billing information are arranged in each cloud node. Billing and charging integrated automation is realized through the smart contract of the block chain; the distributed trusted storage of billing data is realized through the block chain; and the dynamic and rapid migration of the charging cloud nodes is realized through the cloud computing platform.

Owner:GUANGDONG YOUMAI INFORMATION COMM TECH

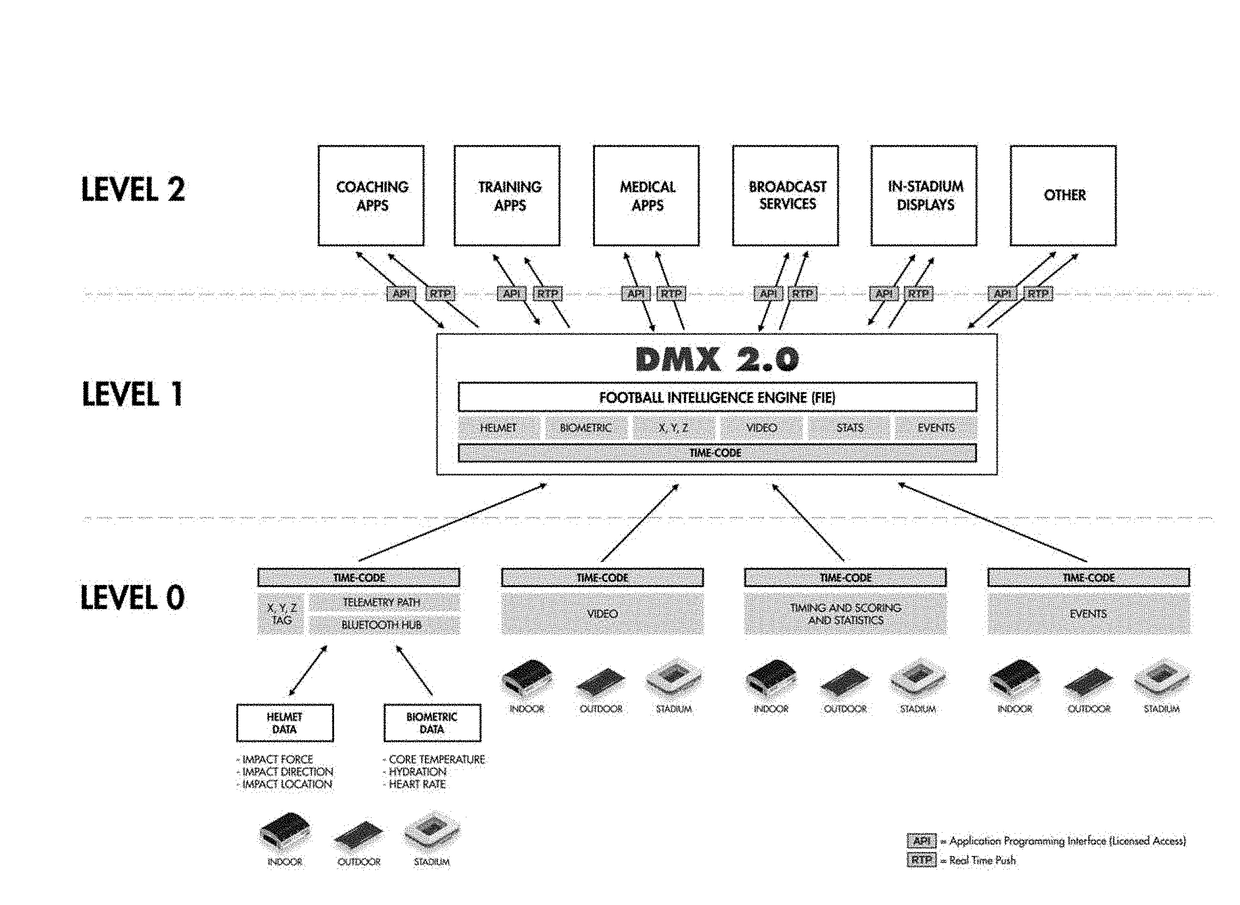

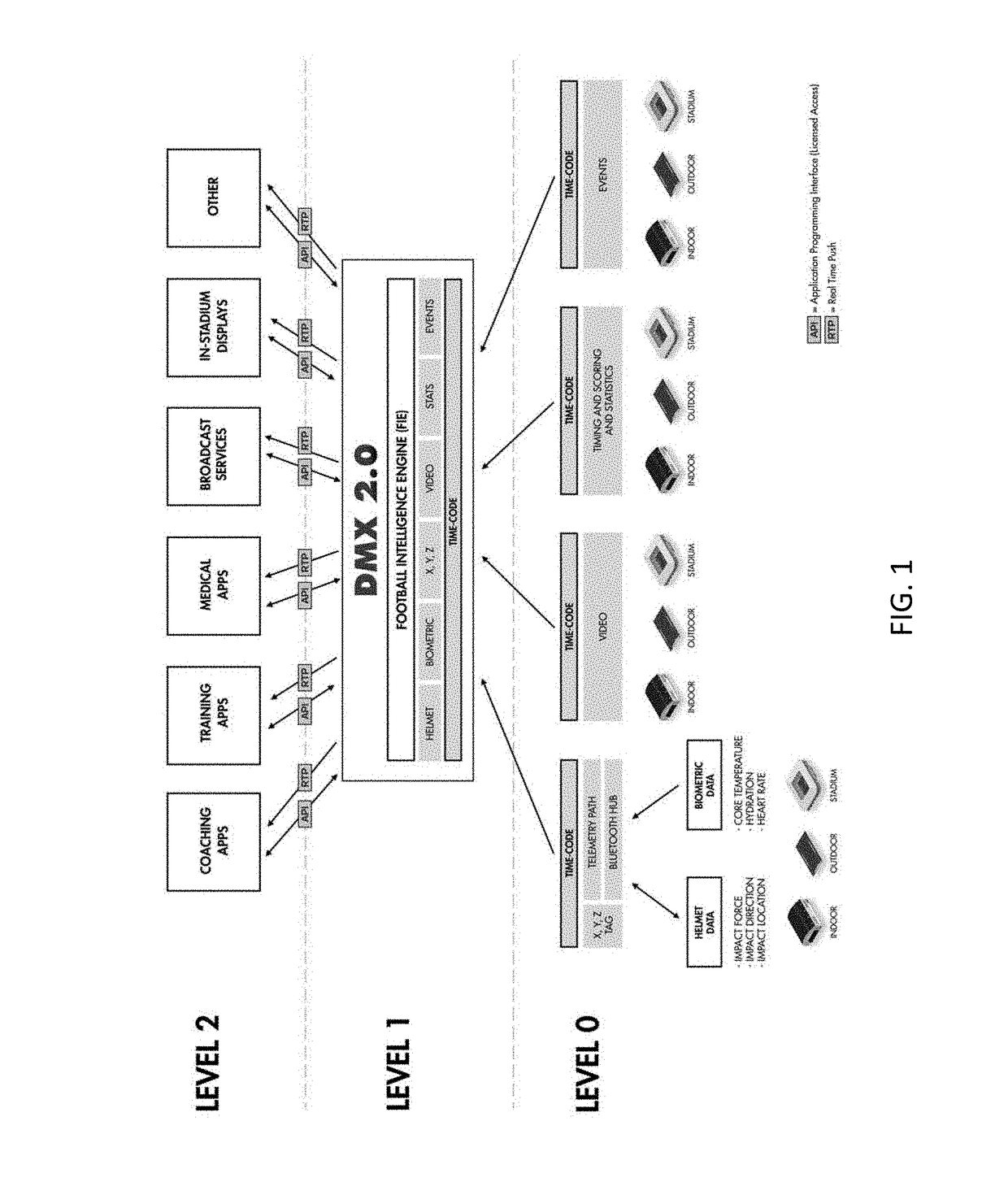

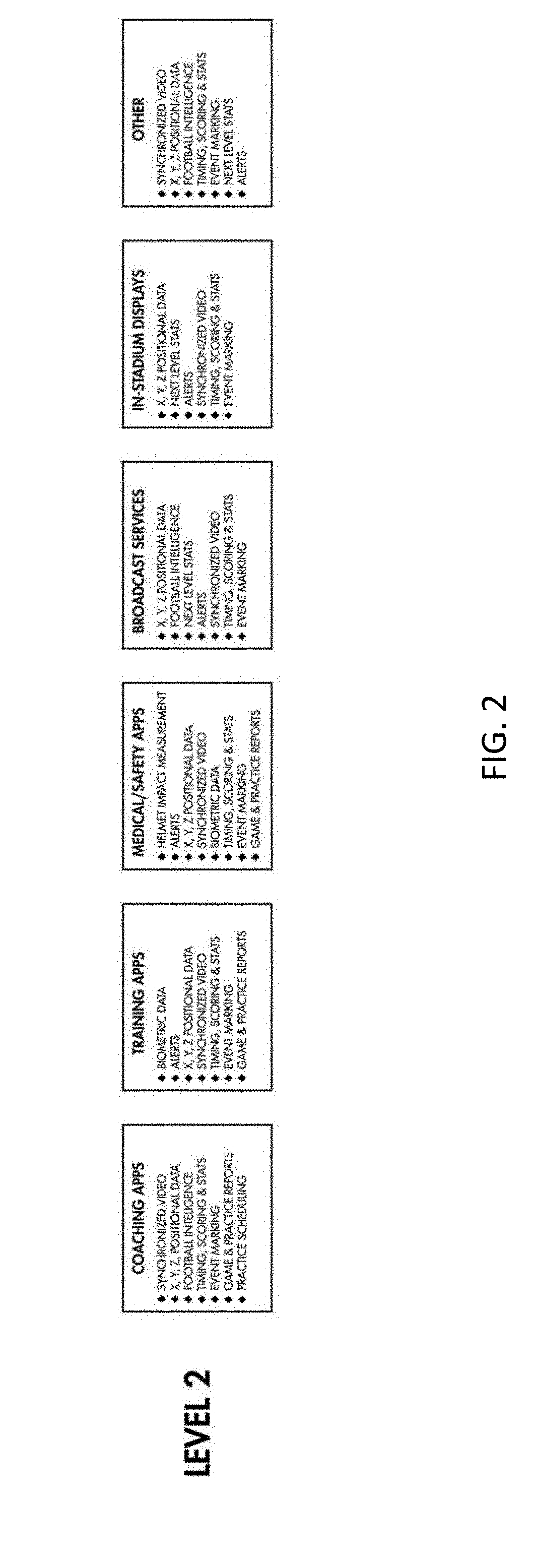

Systems and Methods for Integrated Automated Sports Data Collection and Analytics Platform

Systems and methods for integrated automated sports data collection and analytics are disclosed. Different types of data, for example but not limited, location data, movement data, impact data and biometric data for individual players are collected via wearable sensors in real time during a sports activity and transmitted to a cloud-based platform together with other sports data, including video, timing, scoring, statistics, and events with time code. The cloud-based platform is operable to aggregate, correlate, organize and synchronize various data related to the sports activity; store, query and retrieve various live data and historical data in and from a proprietary database; and perform analytics and provide intelligence to different parties involved in a sports activity, including coaches, trainers, medical staff, live announcers, broadcasters, displays, viewers, and fans and etc. These different parties may subscribe to licensed access to the cloud-based platform for tailored data feeds with real time push.

Owner:SPORTSMEDIA TECH CORP

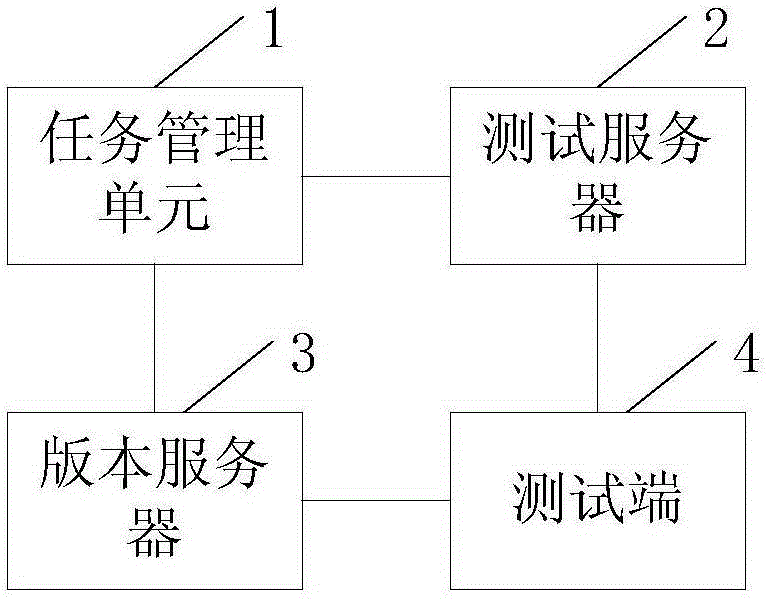

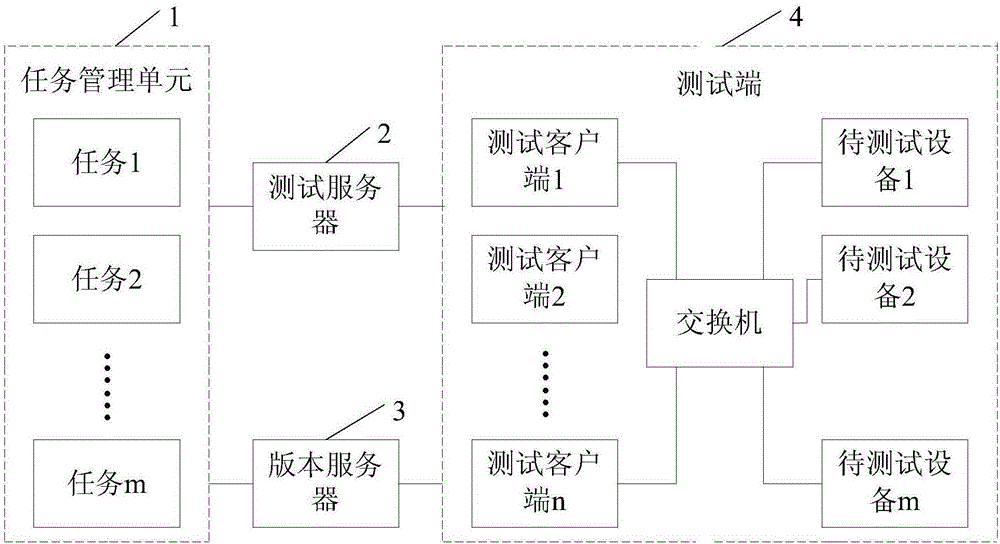

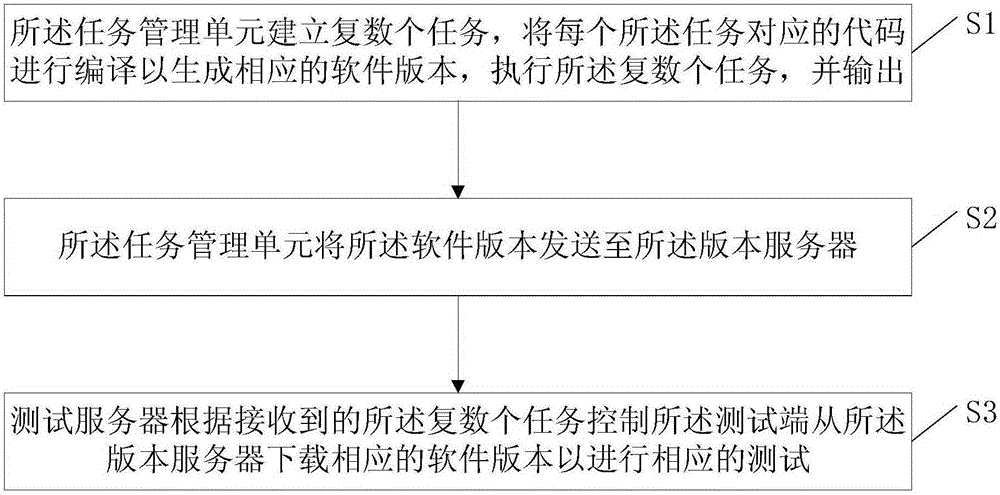

Multipletask integrated automatic test system and method

ActiveCN105183644AReasonable distributionImprove test efficiencySoftware testing/debuggingTest efficiencySoftware engineering

The present invention discloses a multitask integrated automatic test system and method. The multitask integrated automatic test system comprises a task management unit, for establishing a plurality of tasks, compiling the code corresponding to each task to generate corresponding software versions, and performing a plurality of tasks and outputting; A version of server, connected to the task management unit, for storing the software version; A test terminal, connected to the version server, for downloading the corresponding software version; A test server, respectively connected to the task management unit and the test terminal, for controlling the test terminal according to a plurality of received tasks to download the corresponding software version to conduct corresponding tests. The multipletask integrated automatic test system can create a plurality of tasks and manage of the plurality of tasks by the task management unit, and can carry out concurrency test on theplurality of tasks by the testing server, thereby improving test efficiency.

Owner:深圳国芯人工智能有限公司

Automated batch manufactuirng

The invention provides an integrated automated management system for batch manufacturing of products, particularly pharmaceuticals. The system comprises: a distributed data with process related information, a design module which extracts information to build operating models for the manufacturing; a planning module which interacts with the data base and design module to provide the financial and scheduling aspects of the manufacturing, and an exploring module, interfaced with the data base and the other modules, in a closed operational loop to provide real time analysis of the operating model in comparison to actual manufacture to provide real time quality control.

Owner:PFIZER PRODS ETAT DE CONNECTICUT

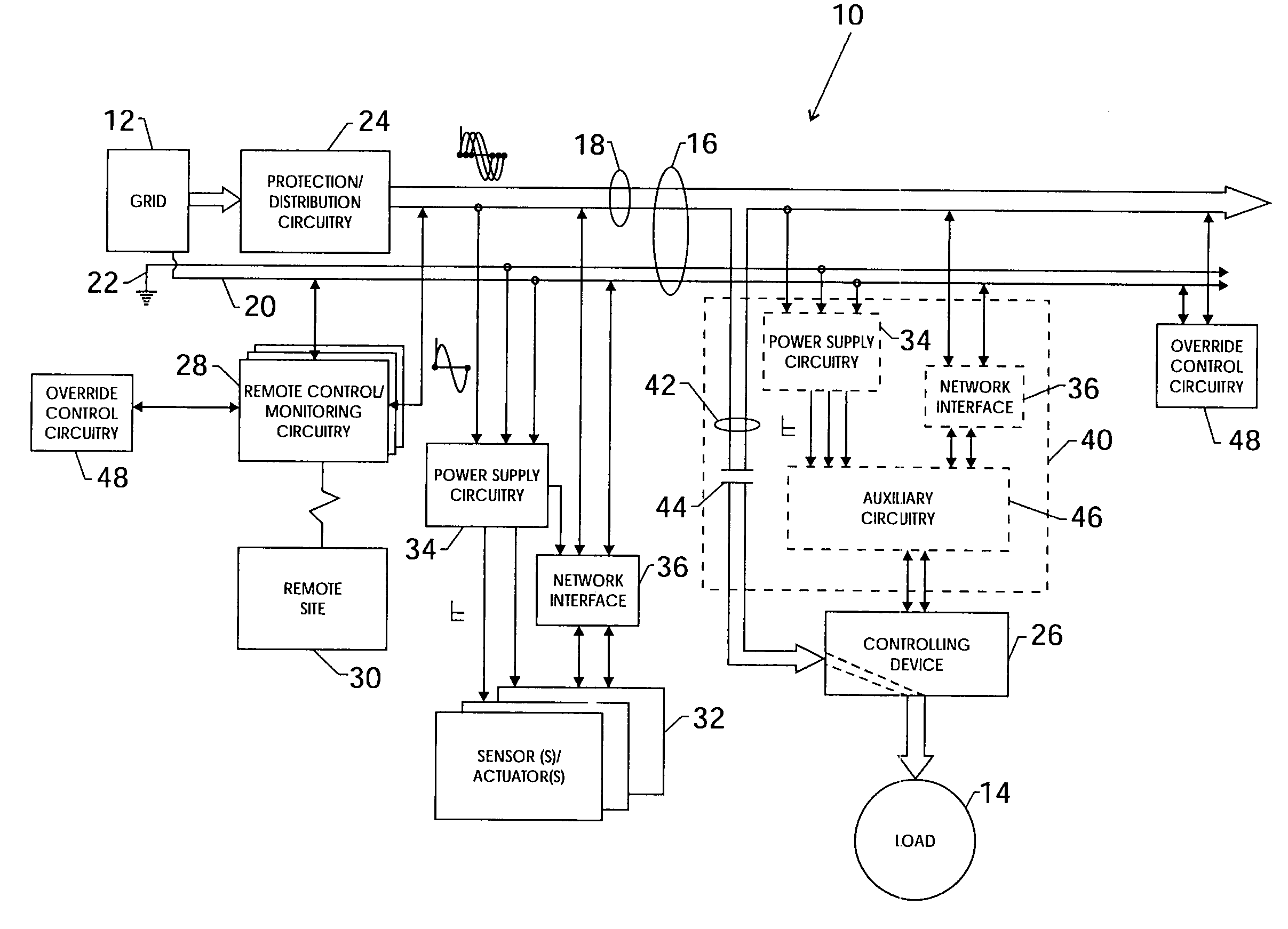

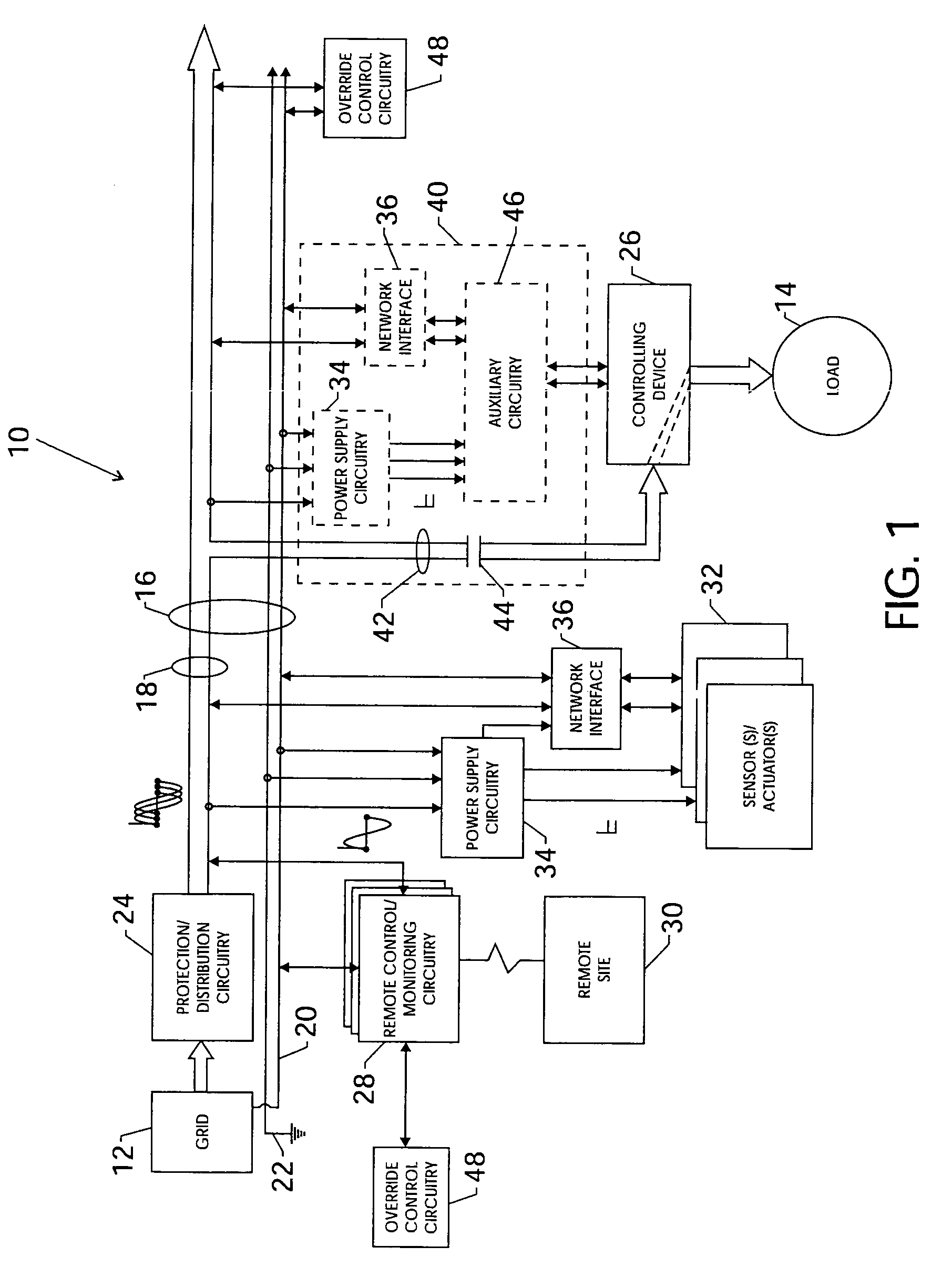

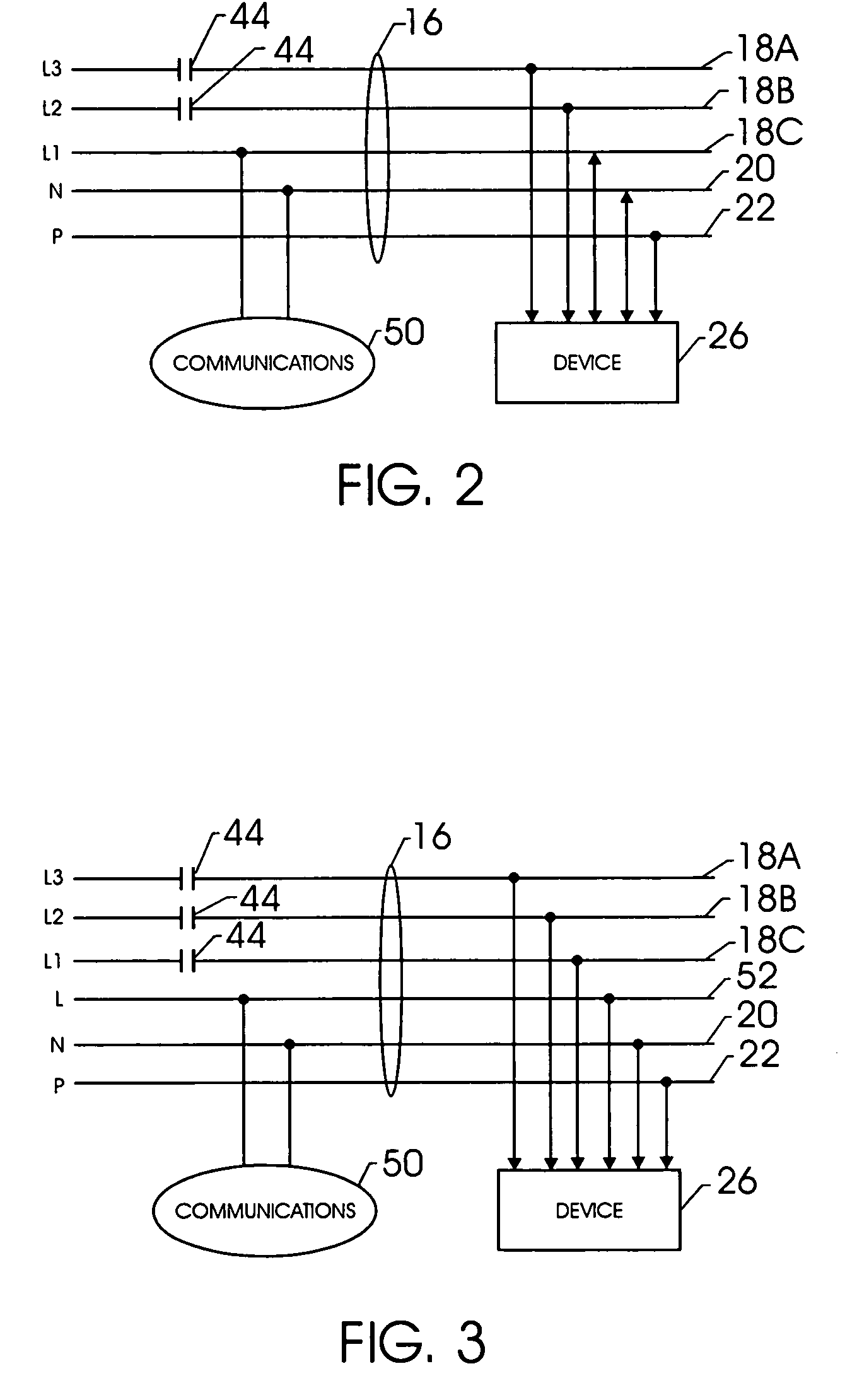

Multi-function integrated automation cable system and method

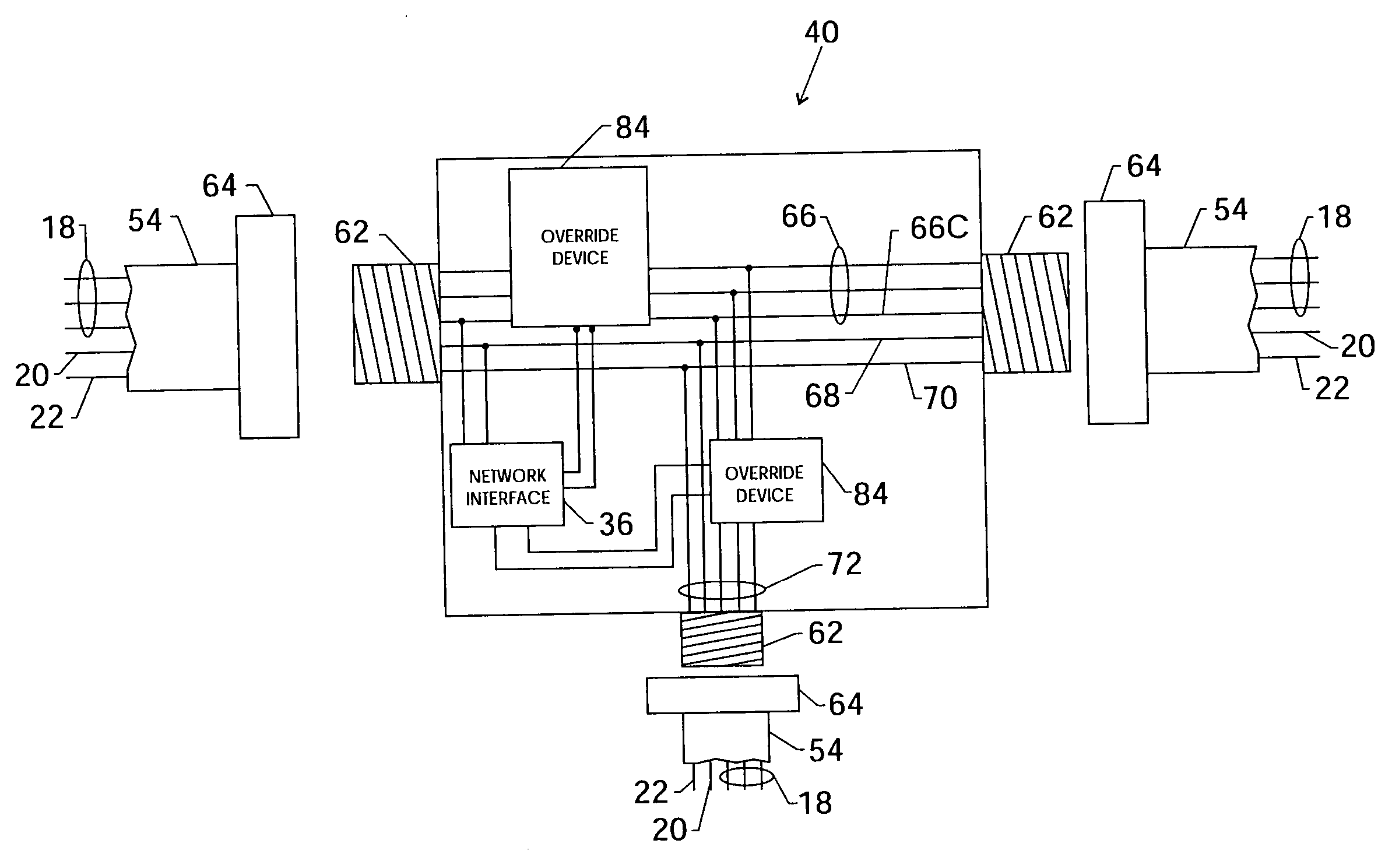

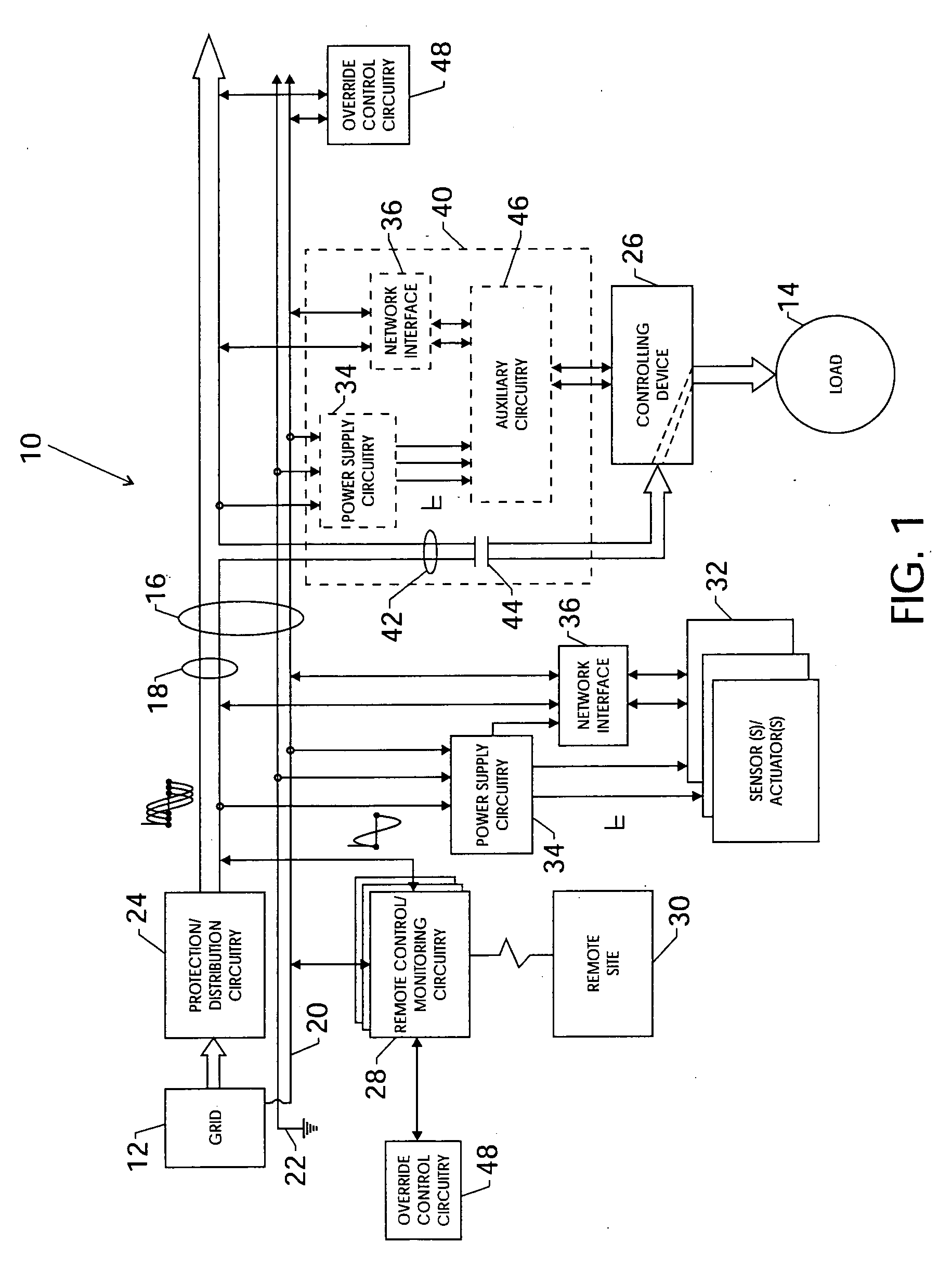

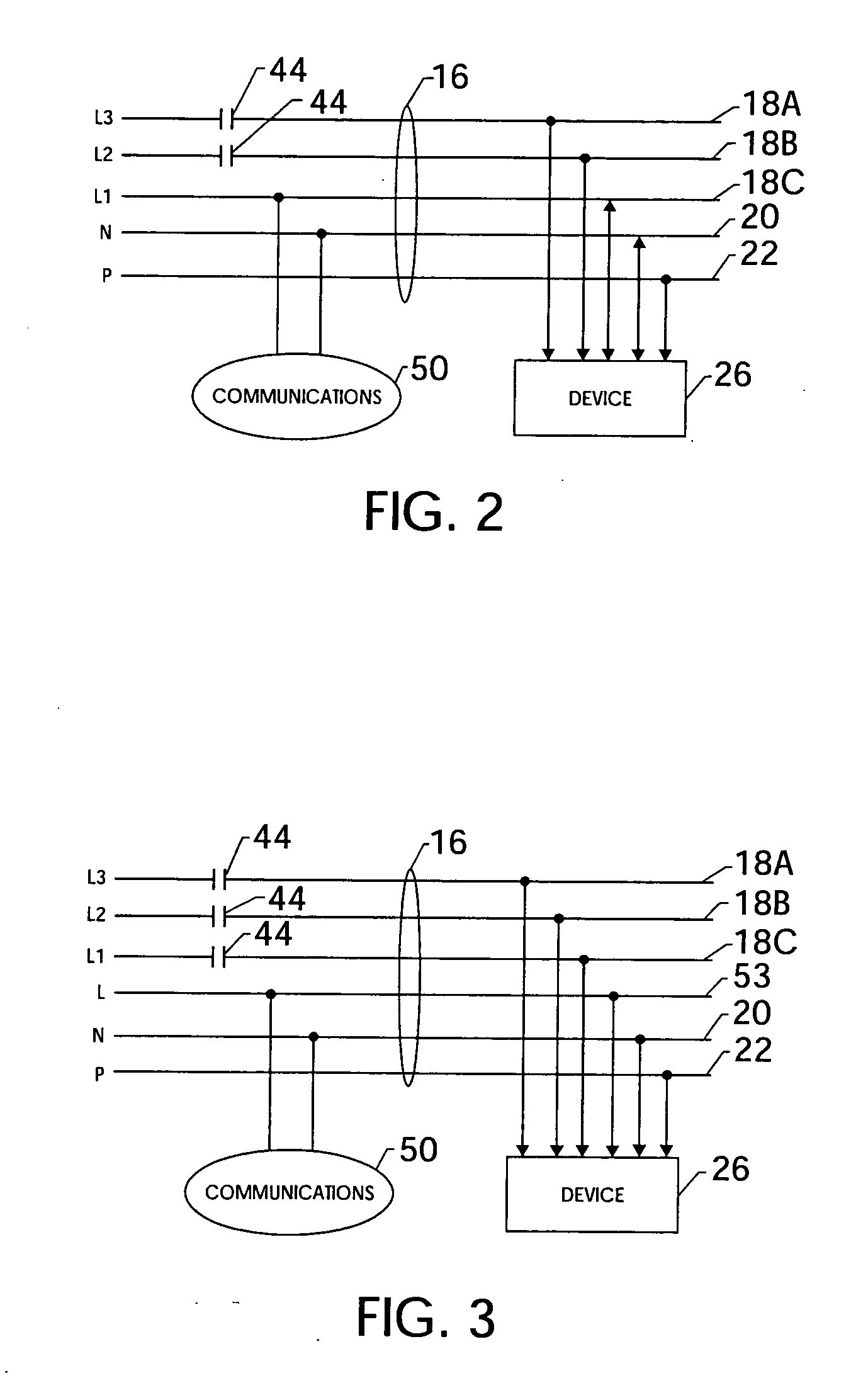

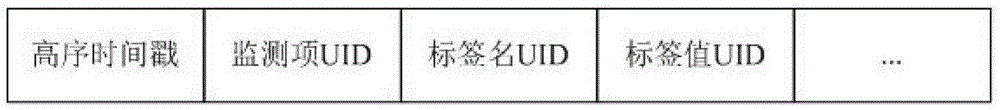

ActiveUS20050057320A1Electric signal transmission systemsModulated-carrier systemsElectrical conductorNetwork Communication Protocols

The present technique relates to the distribution of power and data signals throughout a networked system. For example, three-phase power may be conducted to a device over a set of conductors. One of the conductors, however, may be configured to conduct, in conjunction with a neutral conductor, both one phase of three-phase power as well as data signals in accordance with a predetermined data communications protocol. As an alternate example, the present technique may comprise a set of a first power conductors configured to conduct three-phase power and a secondary power conductor which works in conjunction with an auxiliary conductor to conduct power and data signals. Additionally, the present technique provides for the maintenance data communications and a level of power upon the interruption of three-phase power to a particular component or device.

Owner:ROCKWELL AUTOMATION TECH

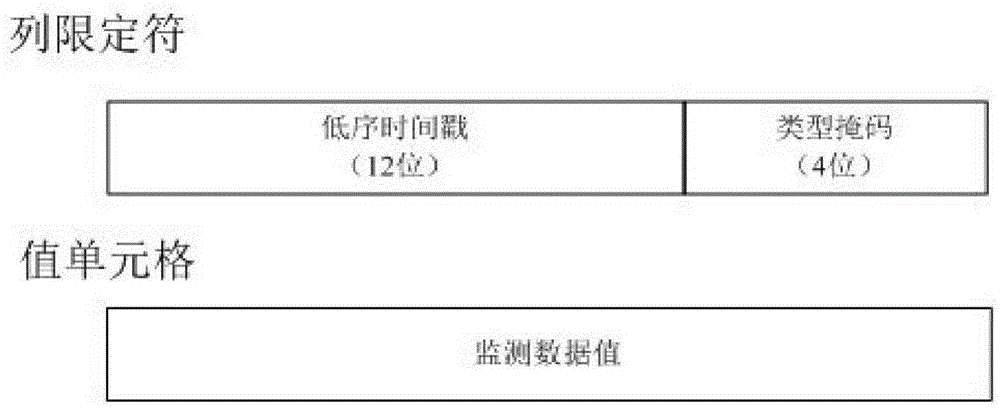

Secondary equipment big data storage and processing method by utilizing cloud computing technology

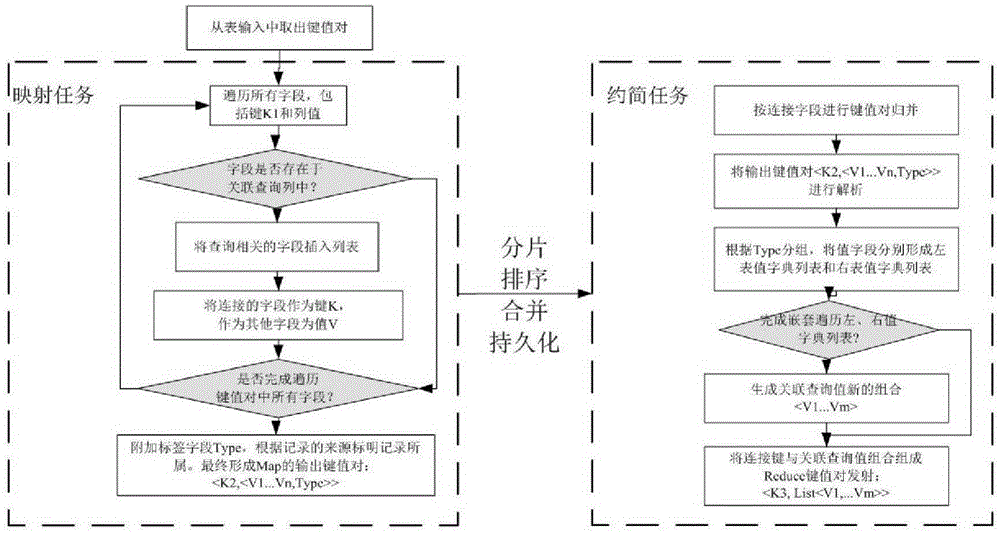

The invention is to provide a mass historical data storage and processing method for carrying out centralized storage, unified management and parallel computing on mass process monitoring data generated by secondary equipment of an electric power system protection device, a fault filter, an automatic safety device, an integrated automation system and an operational power supply system and the like by utilizing the cloud computing technology. A unified storage standard is formed for the data of process inspection data, equipment defect data, equipment state log and patrol inspection data and the like by utilizing the cloud computing technology; and condition query and parallel processing under the large-scale data are realized by adopting a distributed computation frame. The method realizes storage of whole database-oriented long-period and structured secondary equipment historical data, meets the requirements of an electric system for the aspects of storage capacity, data writing speed, query efficiency and system expansibility, and provides powerful support for analysis and excavation of the mass historical data of the secondary equipment.

Owner:CHINA SOUTHERN POWER GRID COMPANY

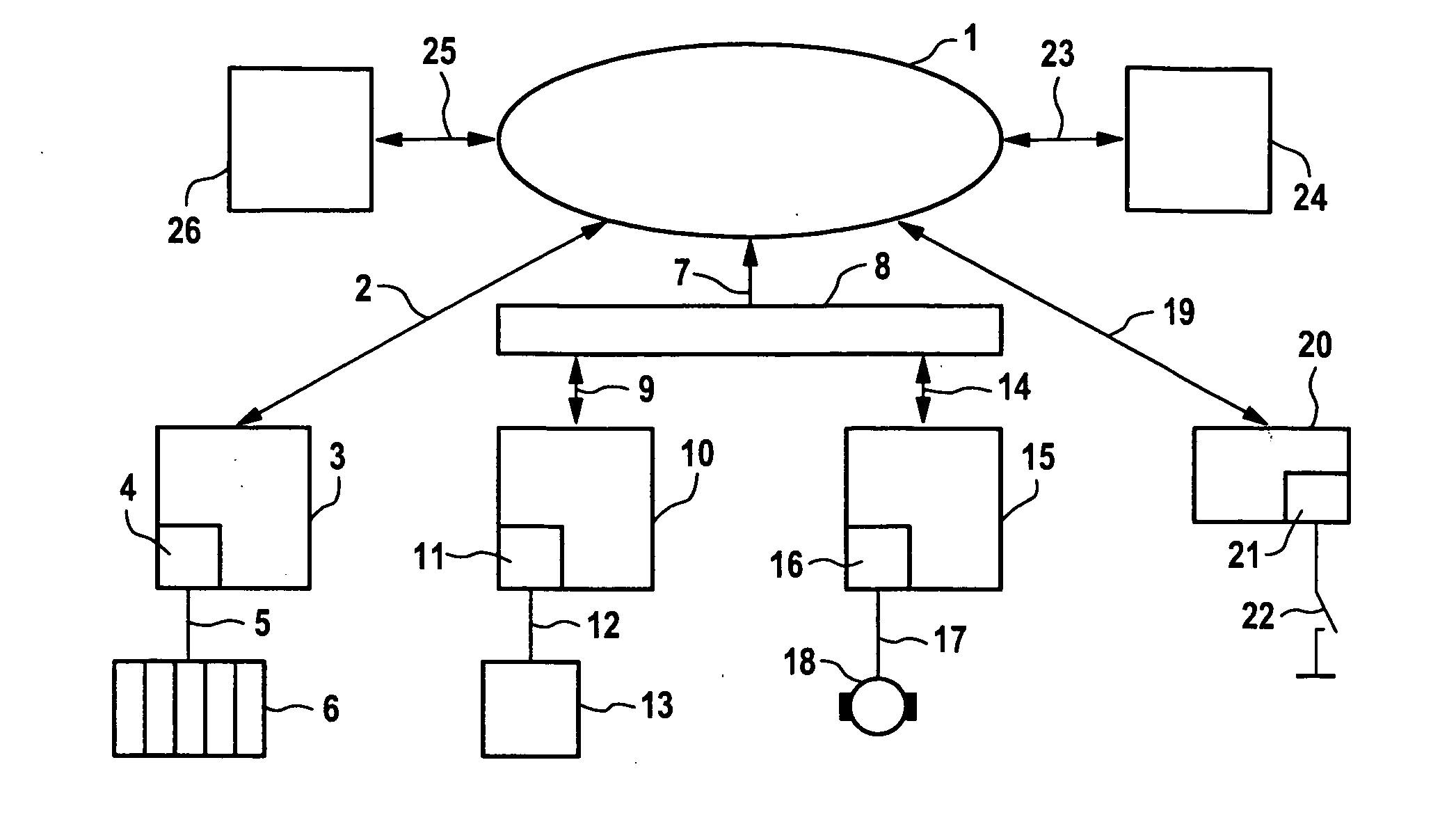

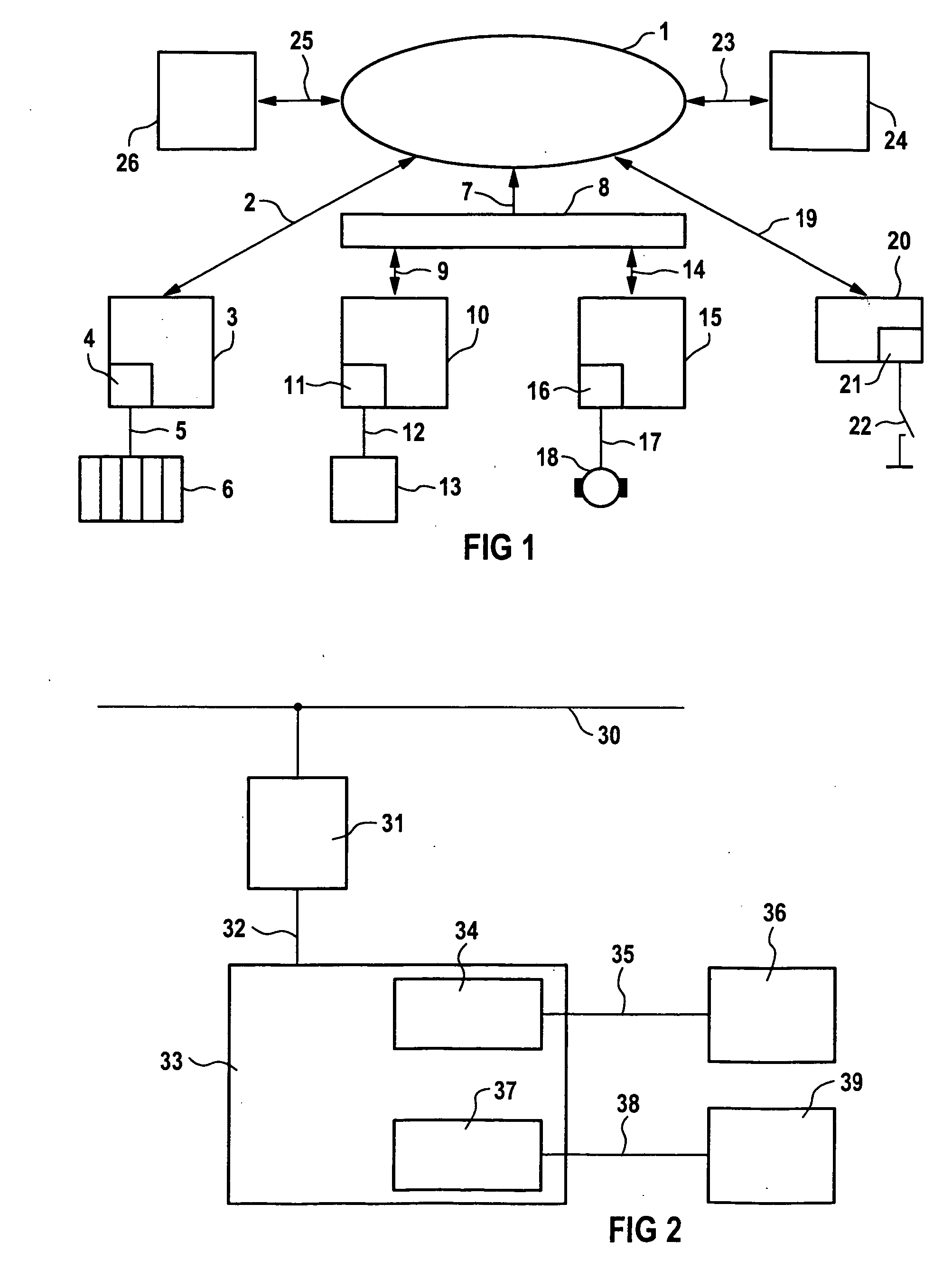

Web server comprising integrated automation functionality and access to a realtime operating system

InactiveUS20050198241A1Consistent interfaceExtension of the web server to incorporate further modules is facilitatedProgramme controlMultiple digital computer combinationsOperational systemWeb service

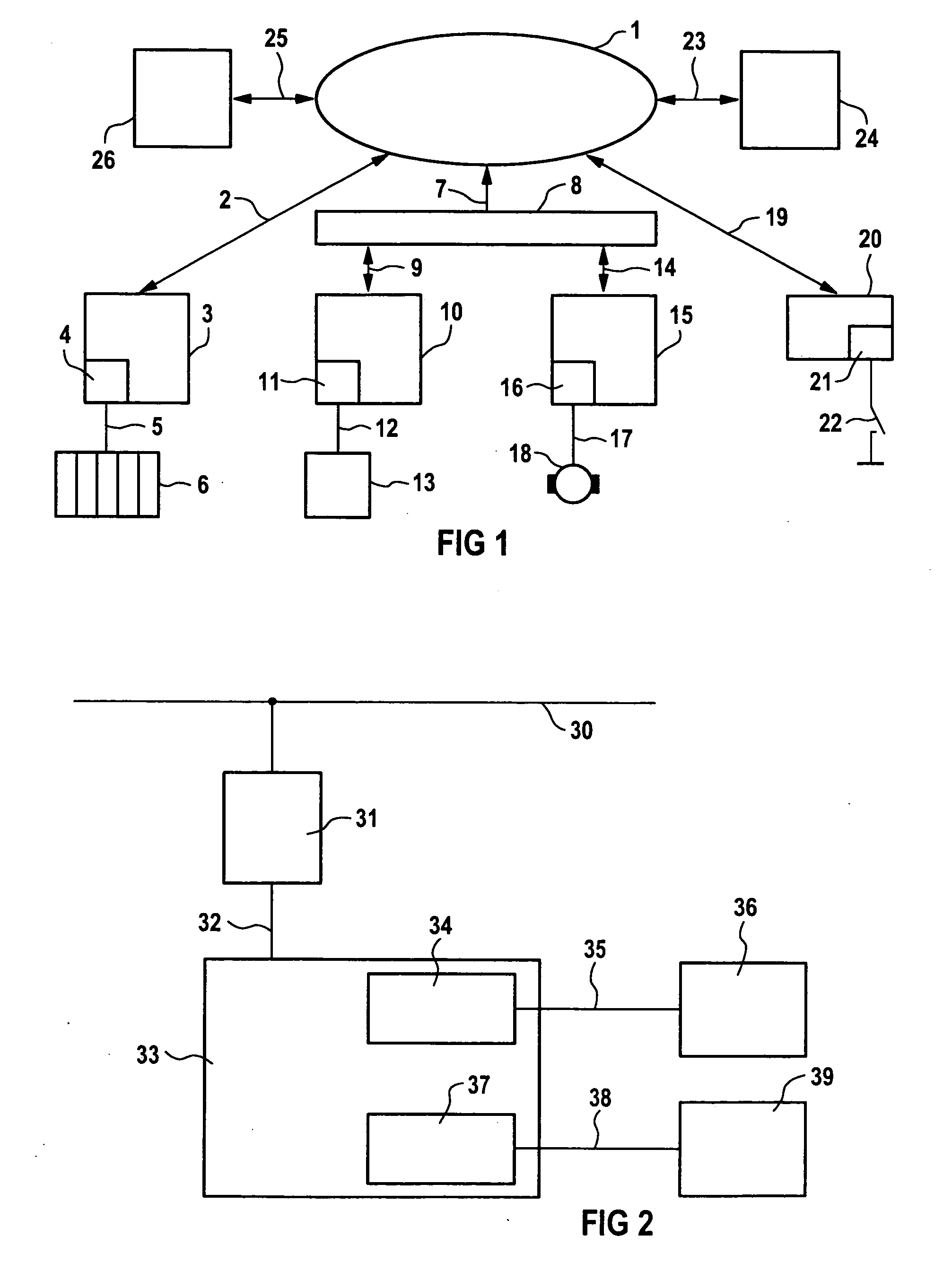

The invention relates to a web server comprising software modules that are integrated in said server. At least one first software module of the web server has first means for a non-proprietary implementation of automation functionality and second means for accessing a real-time operating system.

Owner:SIEMENS AG

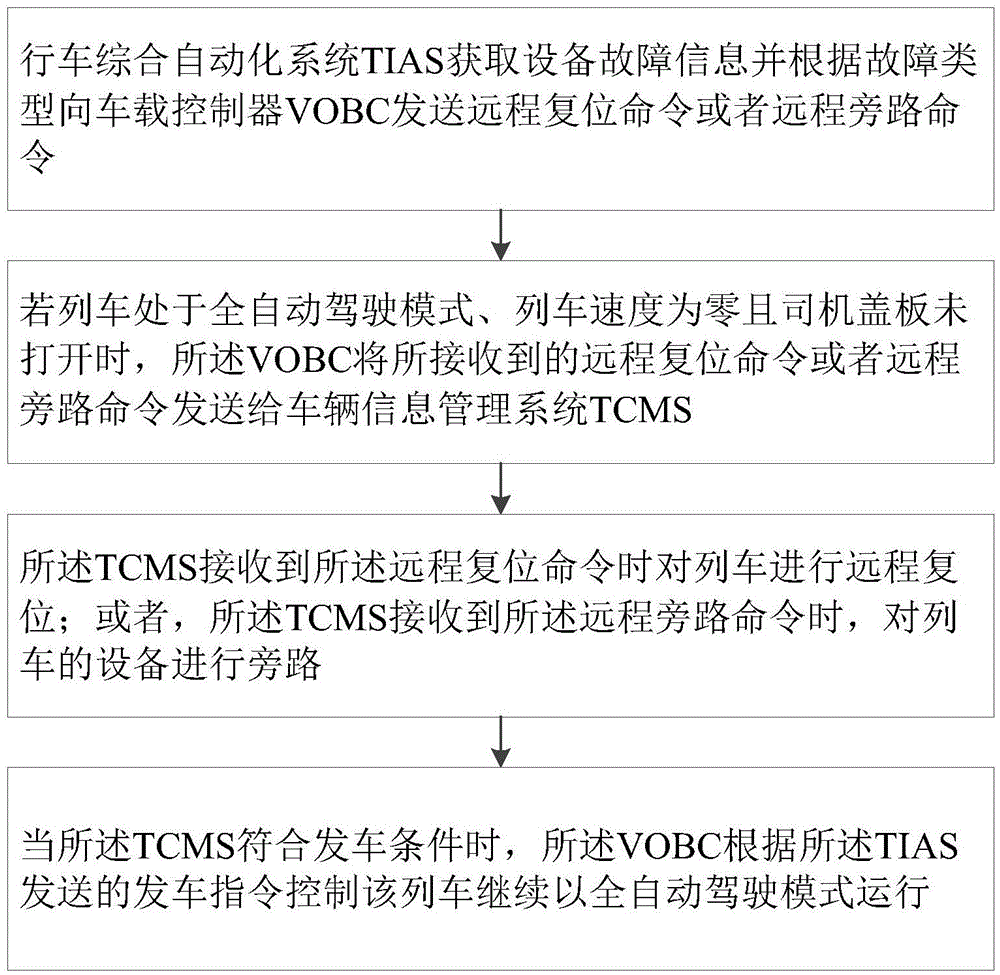

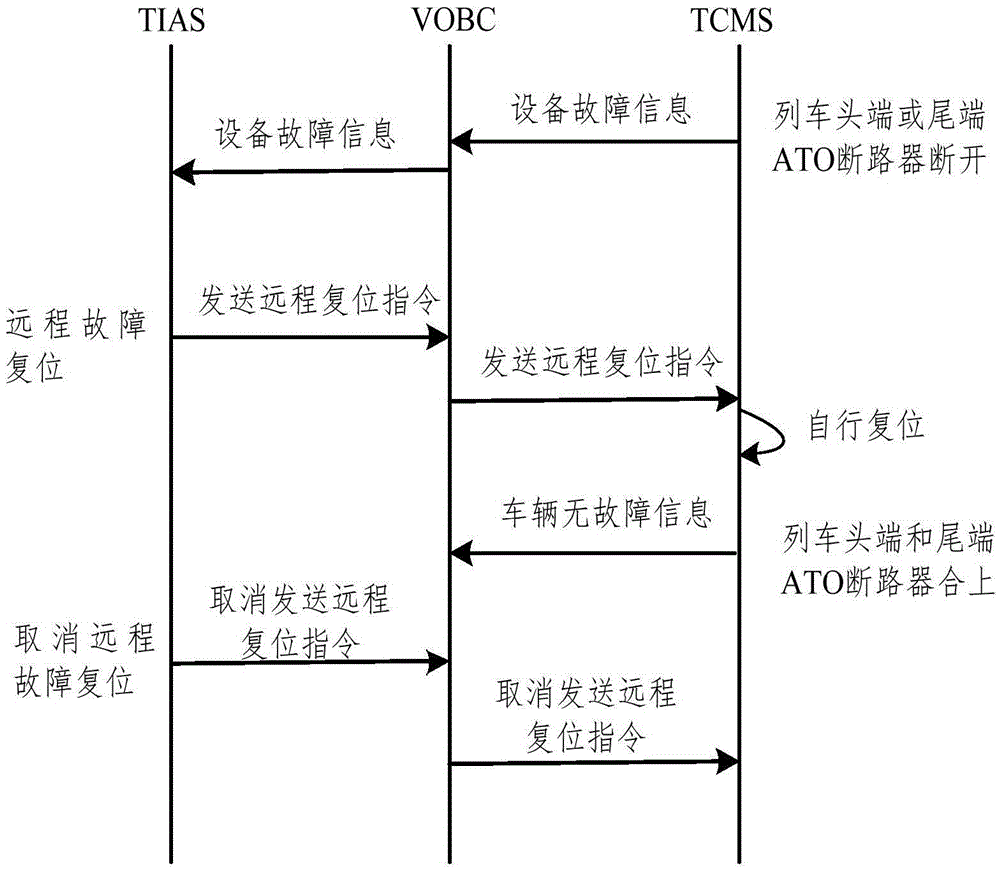

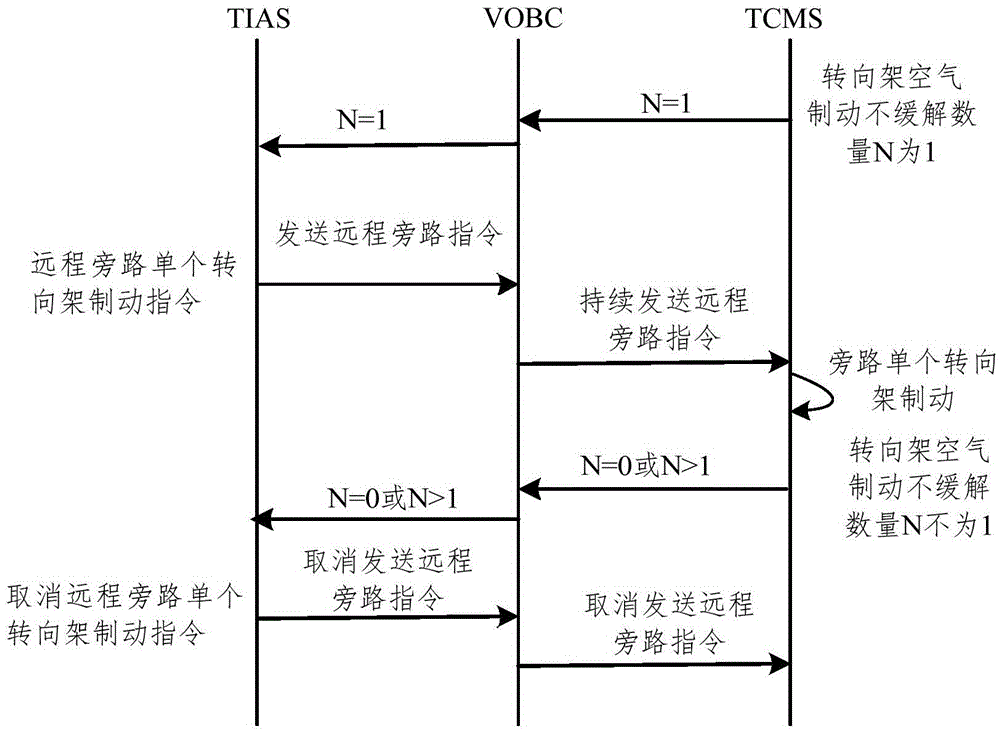

Vehicle-mounted controller remote fault resetting method suitable for full-automatic driving

ActiveCN105539525ADoes not affect fully automatic driving operationAutomatic systemsEngineeringDevice failure

The invention relates to a vehicle-mounted controller remote fault resetting method suitable for full-automatic driving. The vehicle-mounted controller remote fault resetting method suitable for full-automatic driving comprises the following steps that a train operating integrated automation system TIAS obtains equipment fault information and transmits a remote resetting command or a remote bypass command to a vehicle-mounted controller VOBC according to a fault type; if a train is in a full-automatic driving mode, the train speed is zero and a driver cover plate is not opened, the VOBC transmits the received remote resetting command or remote bypass command to a vehicle information management system TCMS; the TCMS remotely resets the train when receiving the remote resetting command; or the TCMS bypasses equipment of the train when receiving the remote bypass command; and when detecting that the TCMS meets train departure conditions, the TIAS transmits a departure command to the VOBC so that the train continues to operate in the full-automatic driving mode. According to the invention, when a train fault is detected, the train fault is remotely handled in time without affecting the full-automatic driving operation of the train.

Owner:TRAFFIC CONTROL TECH CO LTD

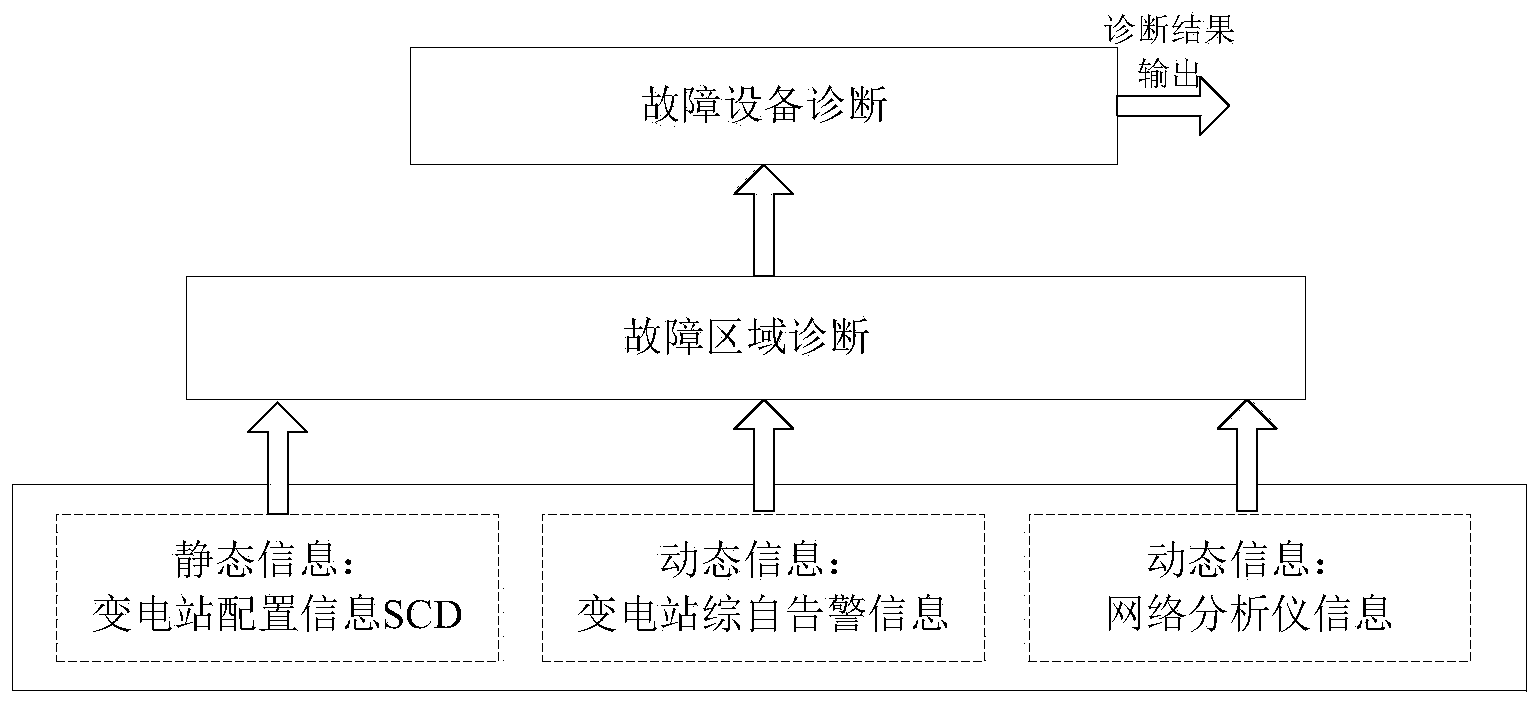

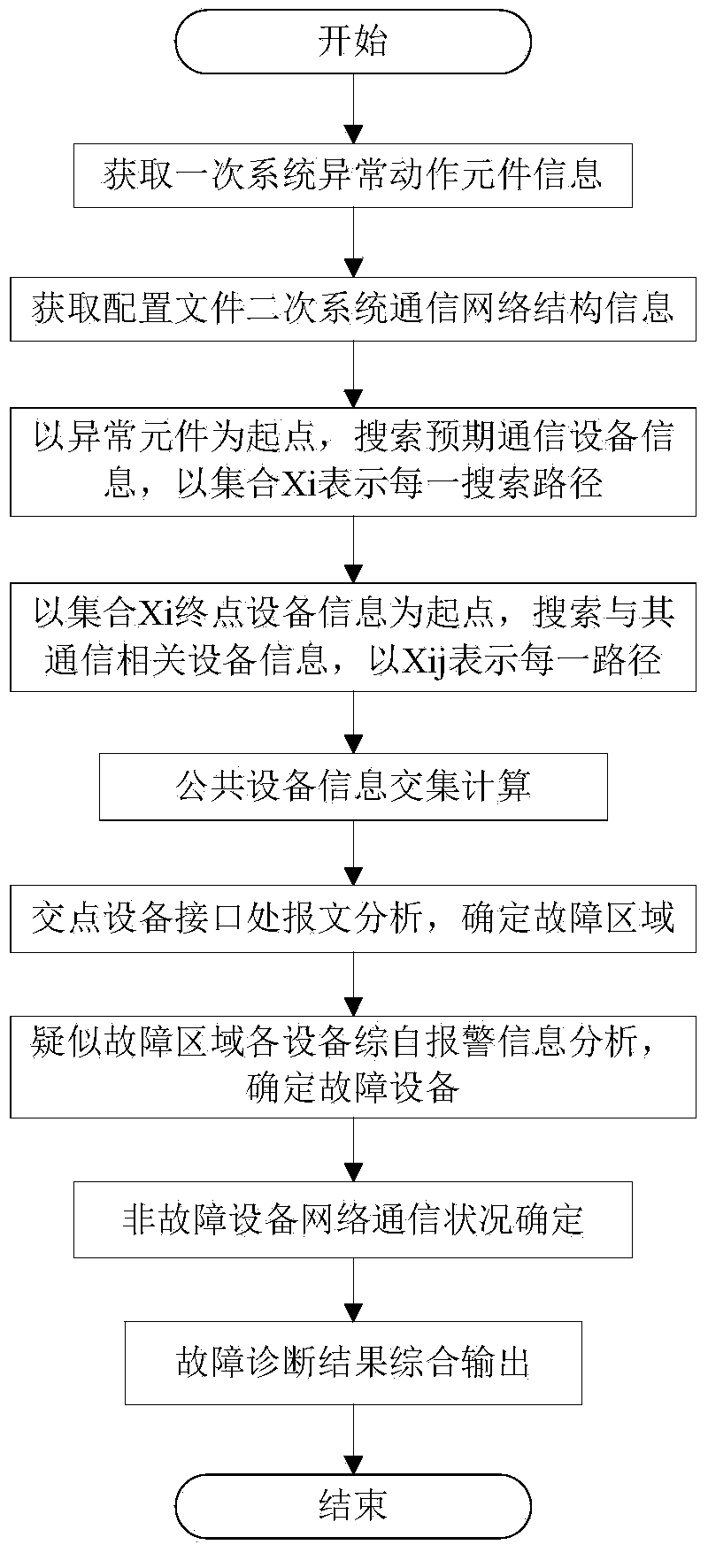

Fault diagnosis method used for intelligent substation secondary system

InactiveCN103616579AClear topologyClear diagnostic processElectrical testingSmart substationDiagnosis methods

The invention discloses a fault diagnosis method used for an intelligent substation secondary system. The fault diagnosis method includes the following steps that: components and equipment which act abnormally are determined, and secondary network static configuration information and dynamic monitoring information of the components and equipment which act abnormally are extracted; a topological search structure diagram is established, and a fault zone is determined; integrated automation system alarm information of each set of equipment in the fault zone is screened, and work information of each set of suspected failure equipment in the zone is diagnosed; a final fault type is determined, and diagnosis results are outputted; and fault maintenance results are fed back. The fault diagnosis method used for the intelligent substation secondary system of the invention has the advantages of wide application range, meticulous and reliable diagnosis process, and accurate and reliable diagnosis results, and can lay a solid foundation for fault diagnosis and evaluation of the secondary system.

Owner:SHANDONG UNIV

Web server comprising integrated automation functionality

InactiveUS20050198137A1Improve scalabilityProgramme controlComputer controlWeb serviceSoftware modules

The invention relates to a web server comprising software modules that are integrated in said server. At least one first software module of the web server has first means for a non-proprietary implementation of automation functionality.

Owner:PAVLIK ROLF DIETER +2

Debug method based on substation integrated automation and relaying protection system integration

InactiveCN103576027AImprove the function of integrated automation systemElectrical testingEnd stagesProtection system

The invention discloses a debug method based on substation integrated automation and relaying protection system integration. The method comprises the following steps that at a previous preparation stage, substation primary equipment and secondary equipment are known preliminarily, comprehensive automatic system performance, specific devices and protection screen functions are grasped comprehensively, and the requirement for system debug is met. In a debug stage, comprehensive detailed tests are carried out combined with the design requirement and the system functions, and accordingly pilot run requirements of a substation are met. In a pilot run stage, whether a protection device, a back stage and telecontrol information are correct under the situation that all of the primary equipment and the secondary equipment are put into operation. In a debug ending stage, problems found in pilot run are dealt with, whole work is cleared up and about to end, and the comprehensive automatic system functions are improved.

Owner:ANHUI XINLONG ELECTRICAL

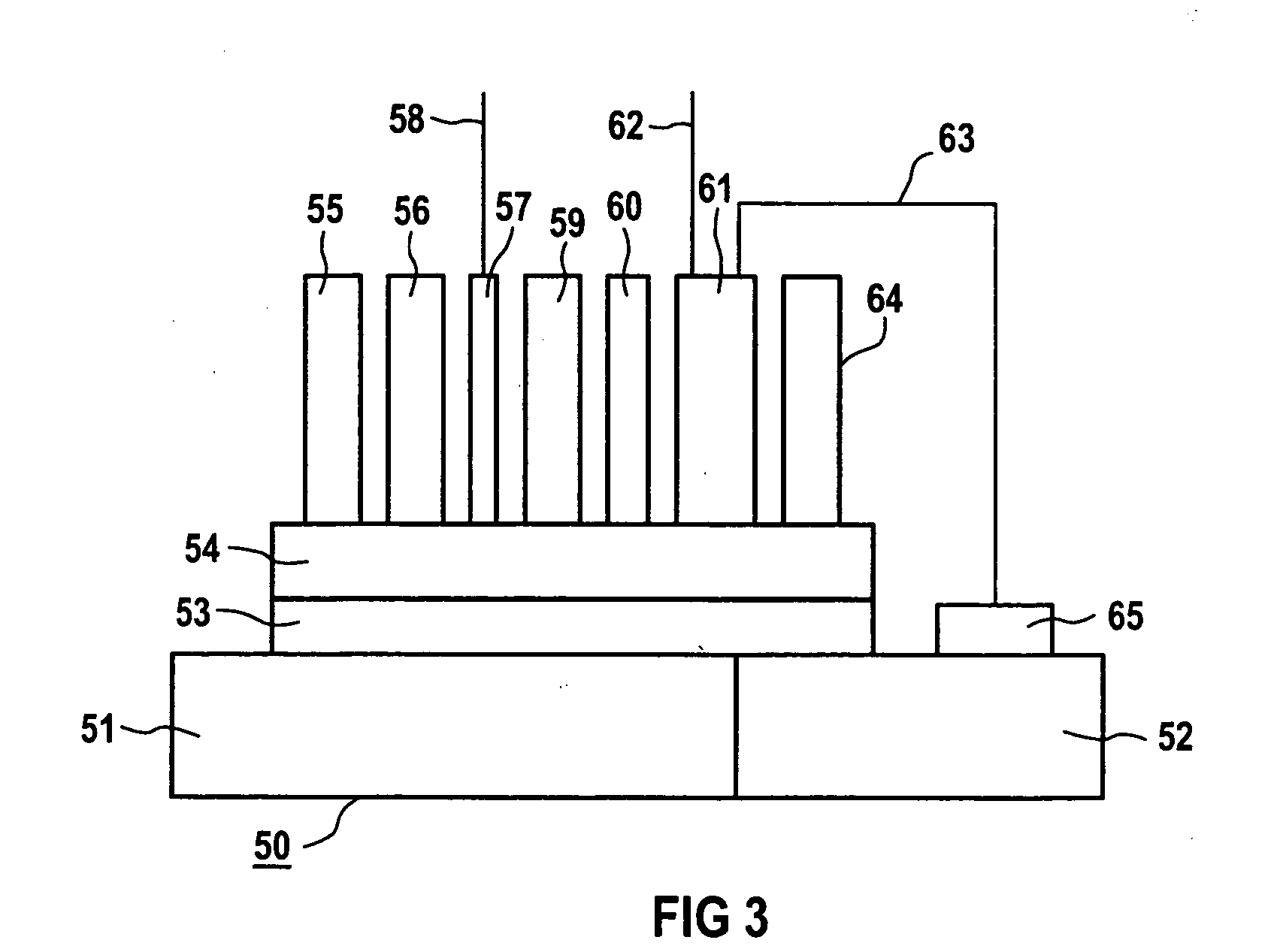

Multi-function integrated automation cable connector system and method

ActiveUS7173345B2Electric signal transmission systemsDc network circuit arrangementsElectrical conductorData signal

The present technique relates to a power and data signal transfer assembly including a plurality of conductors. Through the transfer assembly, power and data signals may be distributed and transferred to a wide variety of devices and locations. Moreover, in one example, power and data signals may be carried over a power conductor working in conjunction with a further conductor. In a further example, the assembly may include advantageous features, such as circuit protection circuitry and LEDs.

Owner:ROCKWELL AUTOMATION TECH

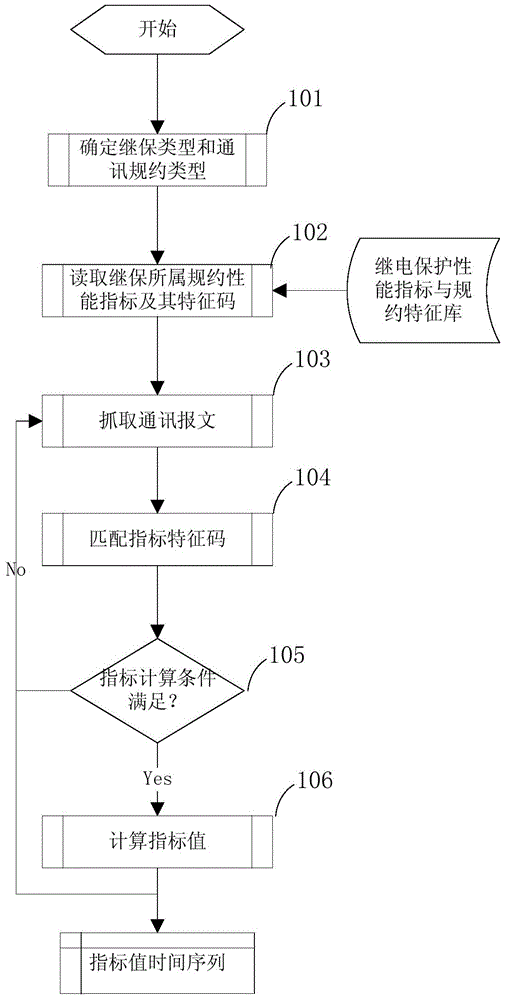

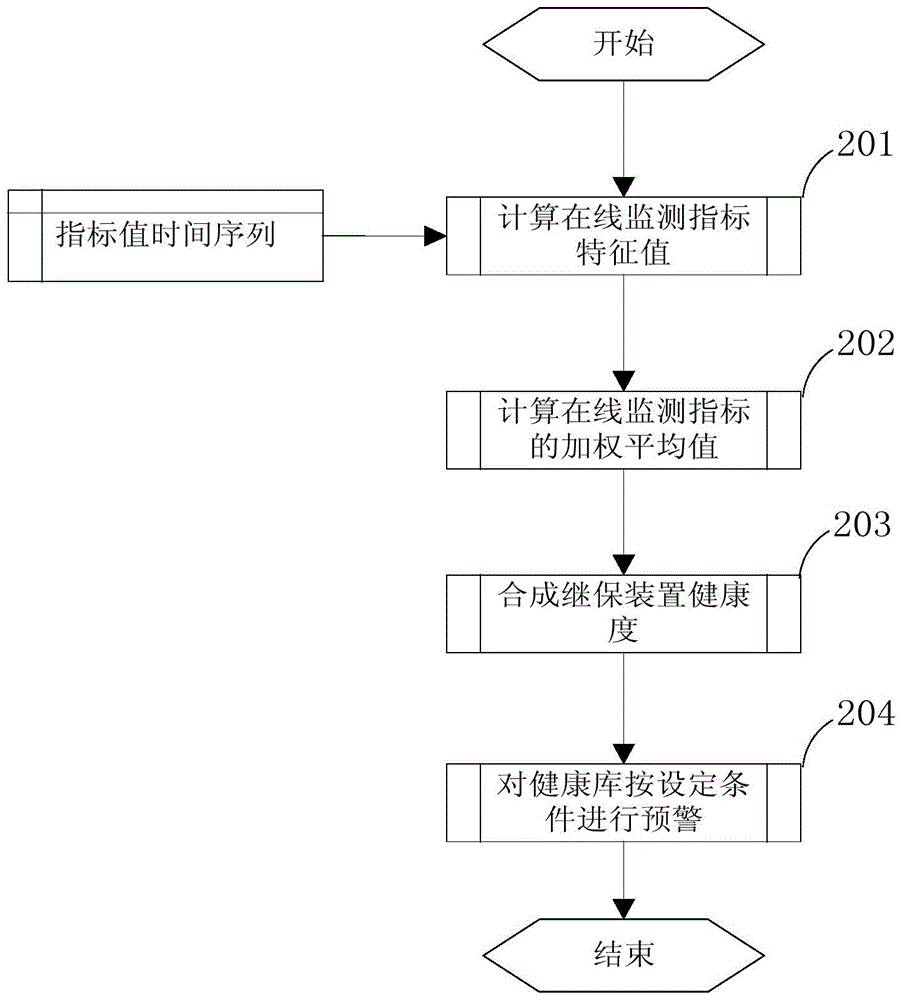

Method for realizing relay protection equipment on-line monitoring by use of communication process analysis

ActiveCN103823433ASolve the problem of difficult status monitoring of relay protection equipmentSolve the difficult problem of condition monitoringTotal factory controlProgramme total factory controlTransformerEngineering

The invention discloses a method for realizing relay protection equipment on-line monitoring by use of communication process analysis. The method comprises two steps i.e., automatic extraction and calculation by an on-line monitoring indicator and on-line assessment by a protective relaying device. Compared to a conventional transformer station integrated automation relay apparatus, the advantages are as follows: a communication capability is utilized, a characteristic of forming an automation communication network in concrete applications is utilized, a communication monitoring mechanism independent from an automation system is constructed, and function performance characteristic parameters which reflect health states of relay protection equipment are extracted in an on-line mode, such that on-line monitoring of the relay protection equipment can be realized.

Owner:STATE GRID CORP OF CHINA +4

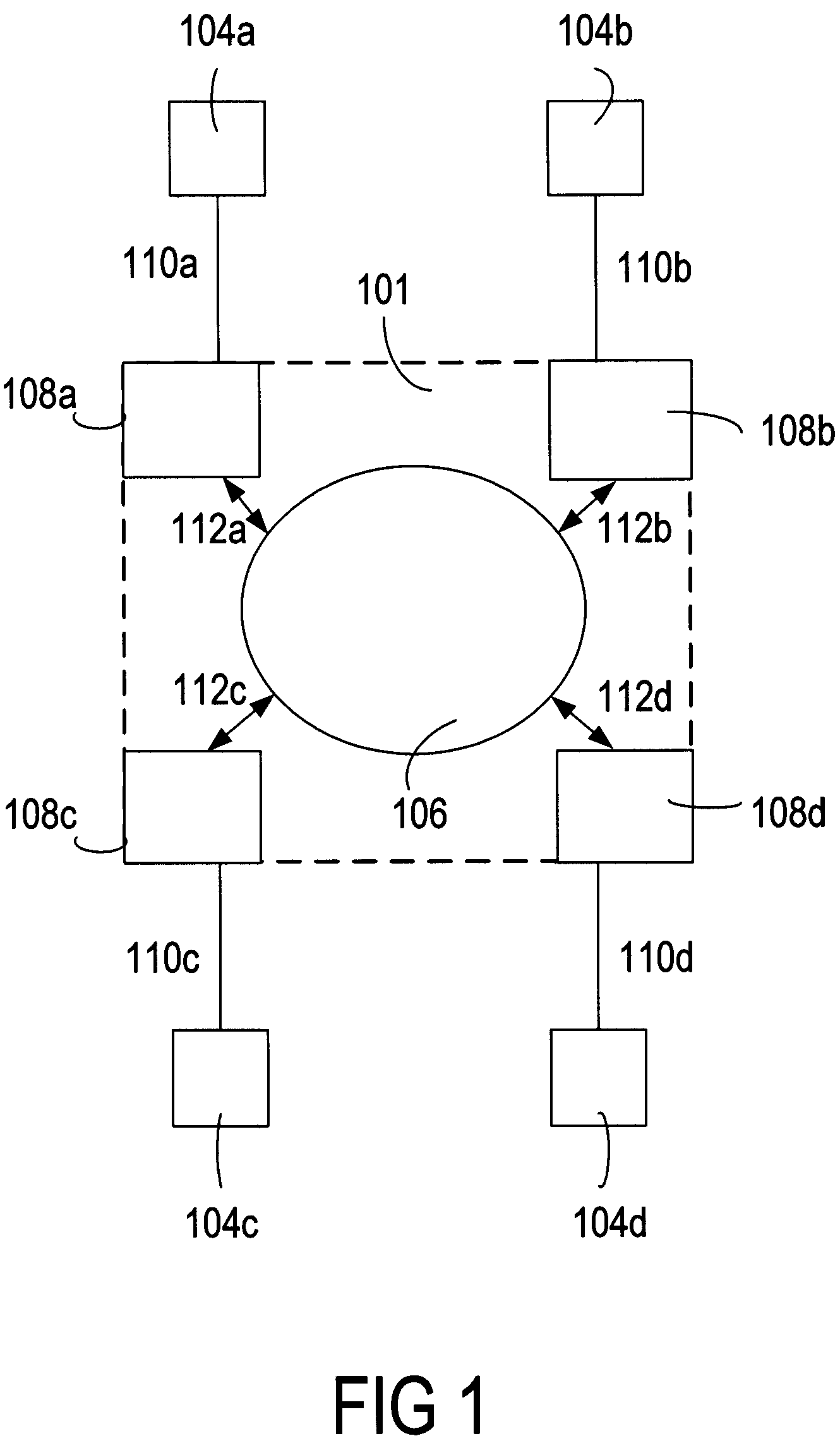

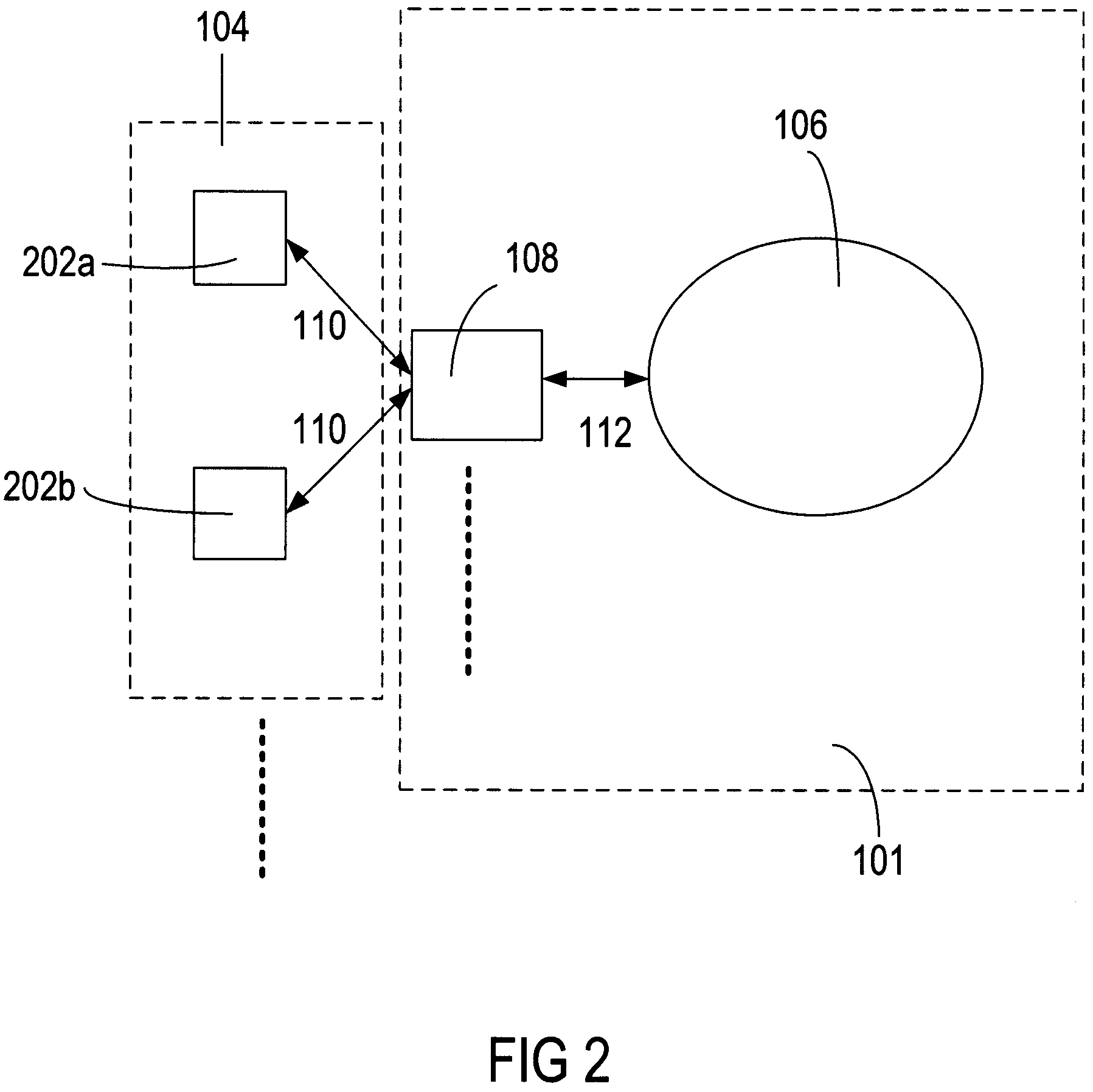

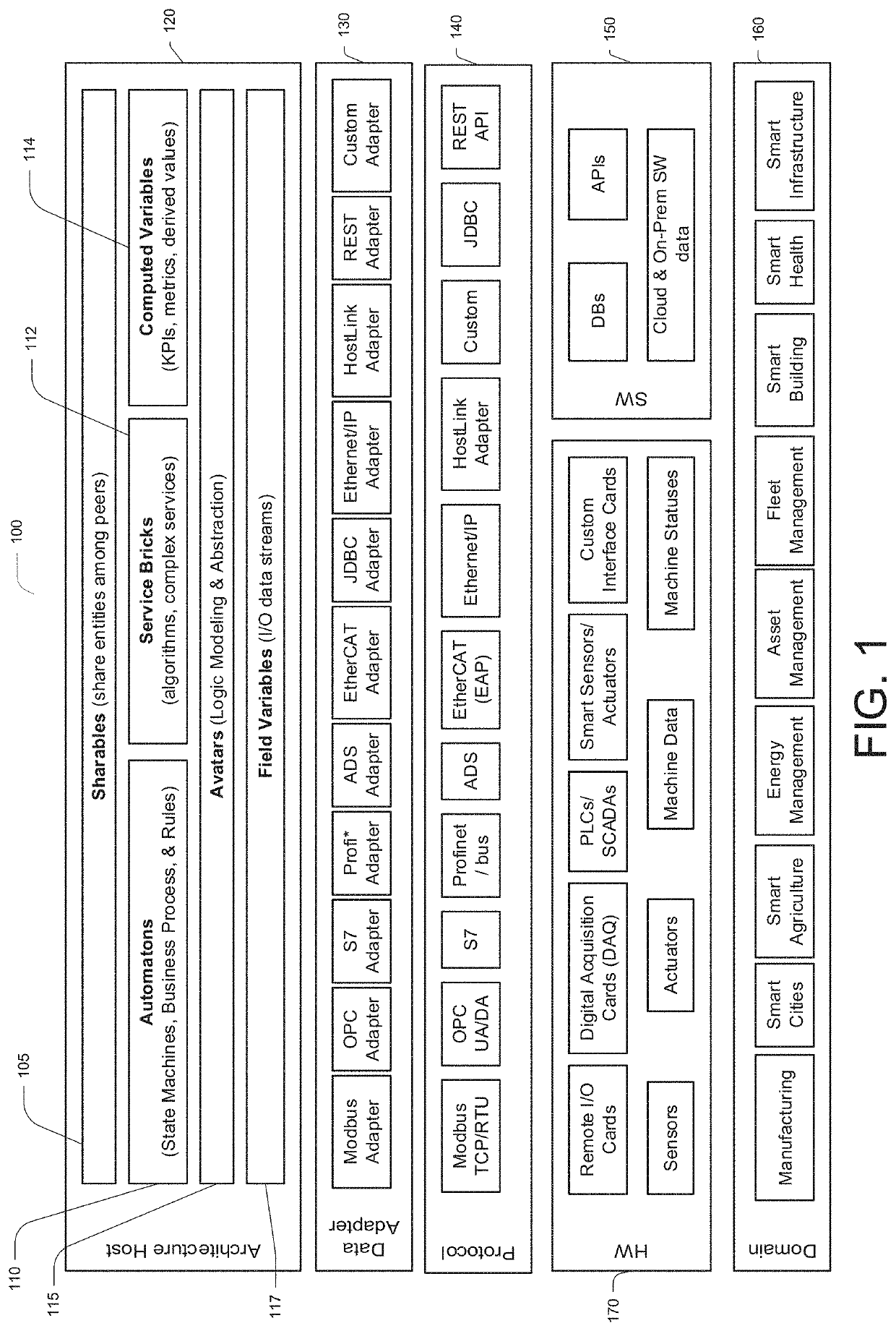

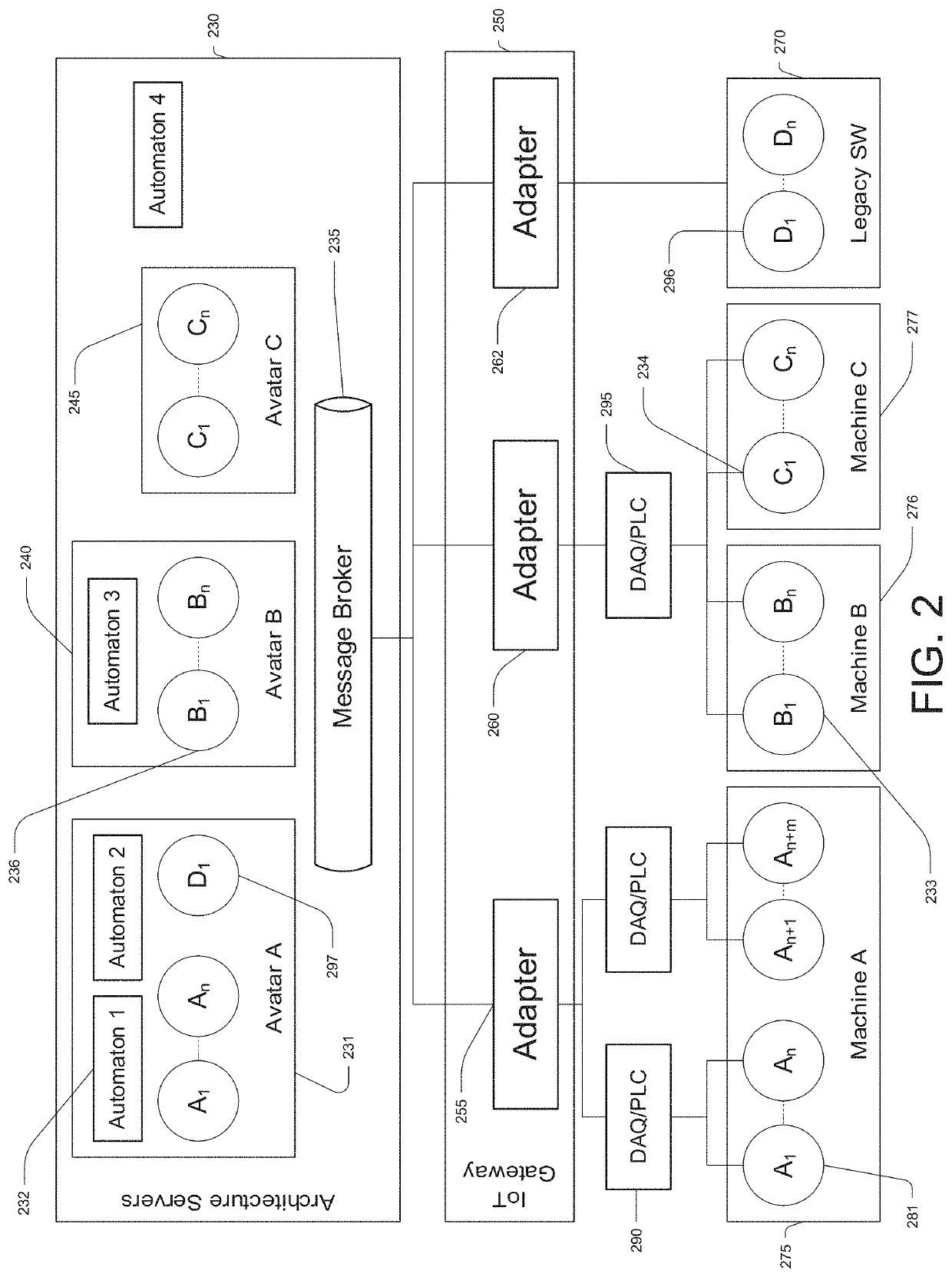

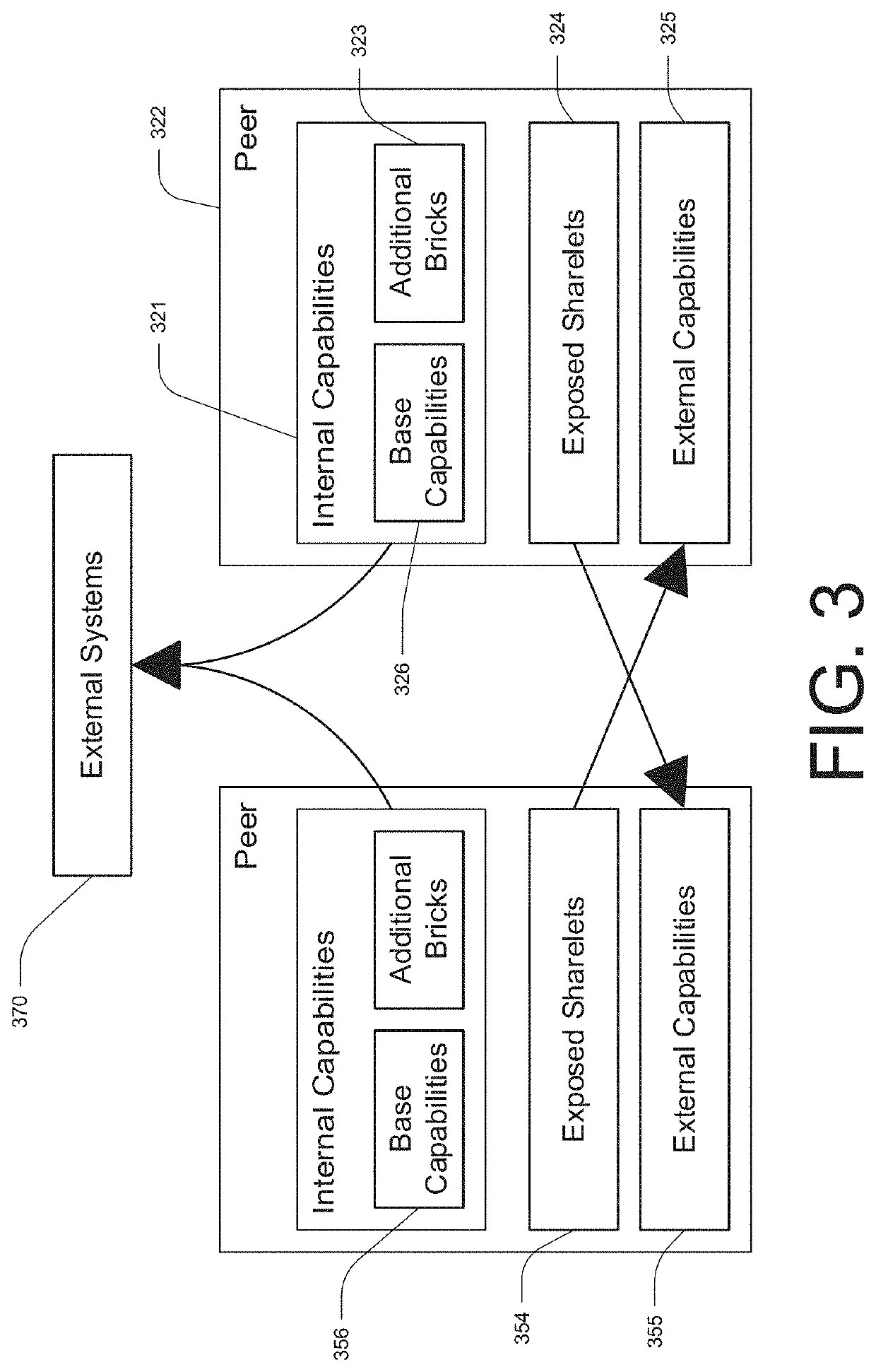

Systems, devices, and methods for internet of things integrated automation and control architectures

In some embodiments, systems, devices, and methods described herein provide digitized ecosystem architectures connecting systems and processes within and among various entities using Internet-of-Things (IoT) to integrate physical assets of the entities. In some embodiments, one or more blockchain applications and / or smart contracts and further define and manage system integration.

Owner:METAFYRE INC

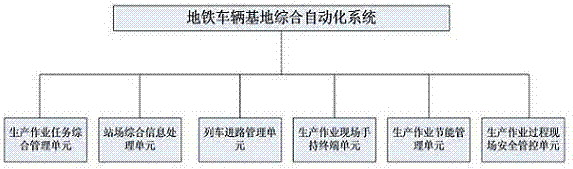

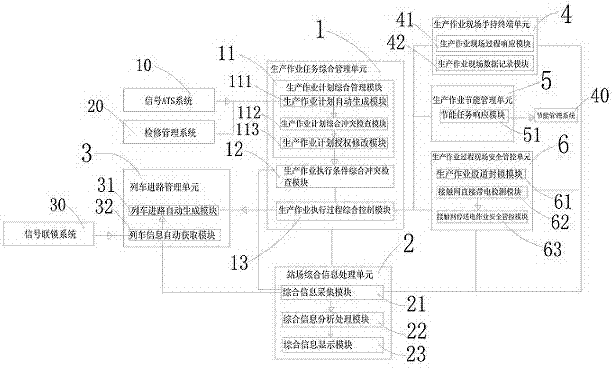

Integrated automation system of metro vehicle base

InactiveCN106909120AIncrease the level of automationImprove production and operation efficiencyProgramme controlComputer controlInformatizationInformation processing

The invention discloses an integrated automation system of a metro vehicle base. The system includes a production operation task integrated management unit, a station integrated information processing unit, a train access management unit, a production operation site handheld terminal unit, a production operation energy-saving management unit and a production process site safety control unit. The system solves the problems that metro vehicle base production operation process management is extensive, operation links are disjointed, the automation degree of operation execution is low, the operation execution lacks of safe management and control, operation site information is difficult to obtain, and the energy consumption of operation is larger. The metro vehicle base production management informationization and automation levels are improved, the production operation efficiency is improved, the production operation safety risk is reduced, the energy consumption of operation is reduced, and a safety and quality guarantee is provided for the metro main line high-level traffic safety and the high-level passenger service.

Owner:四川高新轨道交通产业技术研究院 +1

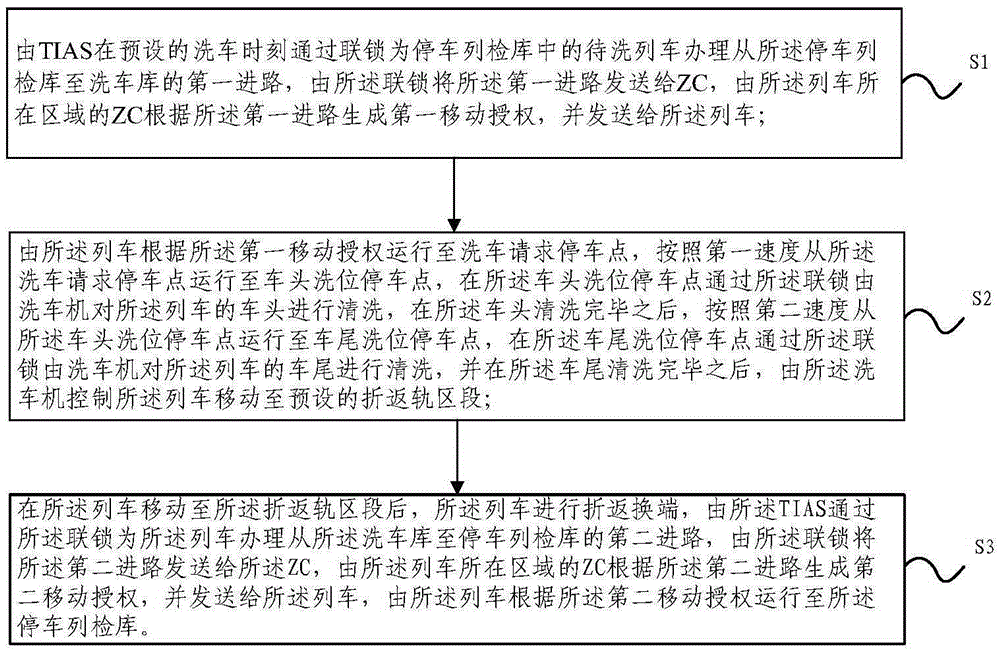

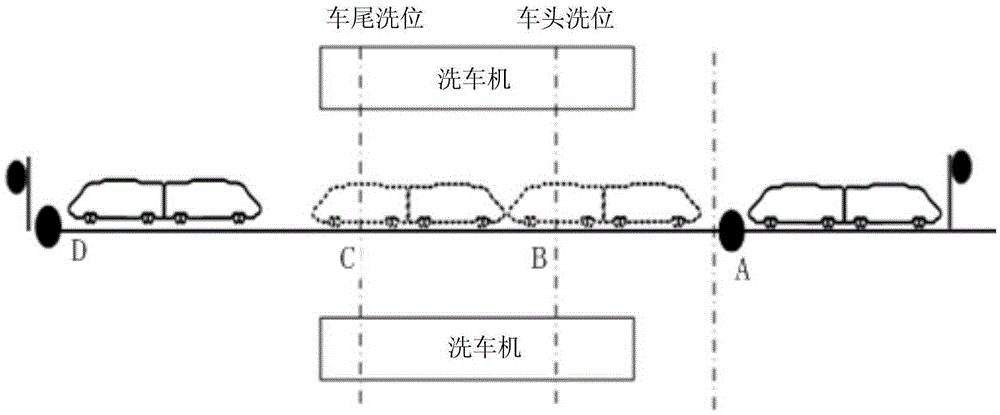

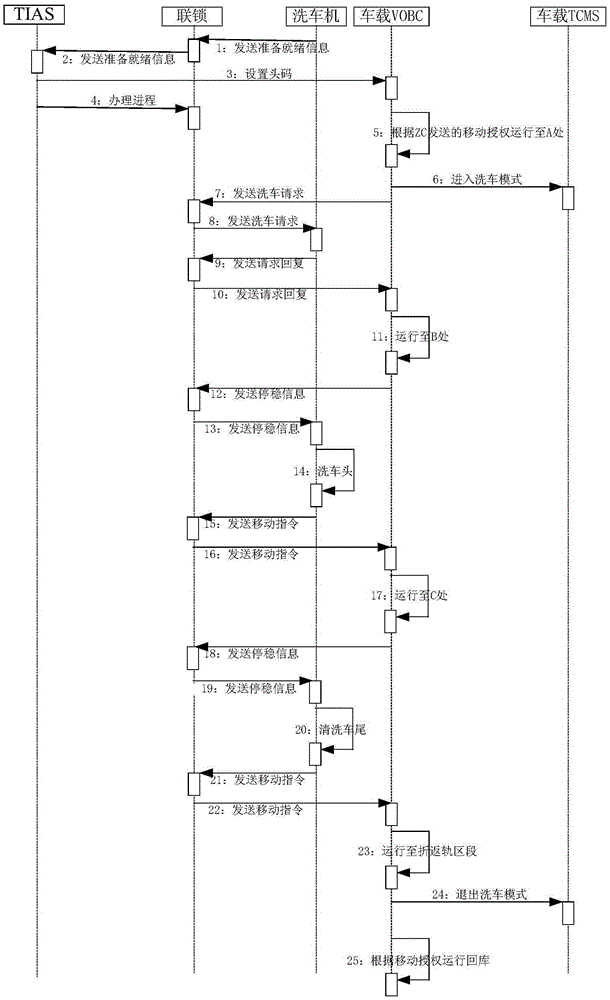

Train cleaning method and system based on urban rail transit

ActiveCN105459970ARealize autonomous drivingImprove operational efficiencyCleaning apparatus for railwaysCleaning apparatus for vehicle exteriorsMachine controlCleaning station

The invention discloses a train cleaning method and system based on urban rail transit. Full automatic driving can be achieved in the whole process since a train is bound for a train cleaning barn until the train leaves the train cleaning barn after train cleaning is completed, and thus operation efficiency is improved. The method includes the steps that S1, a train integrated automation system (TIAS) sets a first approach road for the train to be cleaned through an interlock at the train cleaning moment, the interlock sends the first approach road to a zone controller (ZC), the ZC in the area where the train is located generates a first movement authorization, and the first movement authorization is sent to the train; S2, the train runs to a train head cleaning station parking point, a train head is cleaned through a train cleaning machine, after train head cleaning is completed, the train runs to a train tail cleaning station parking point, a train tail is cleaned through the train cleaning machine, and after train tail cleaning is completed, the train cleaning machine controls the train to move to a back-turning track section; and S3, back-turning end exchange is conducted on the train, the TIAS sets a second approach road for the train, the interlock sends the second approach road to the ZC, the ZC in the area where the train is located generates a second movement authorization, the second movement authorization is sent to the train, and the train runs to a parking train examination barn according to the second movement authorization.

Owner:TRAFFIC CONTROL TECH CO LTD

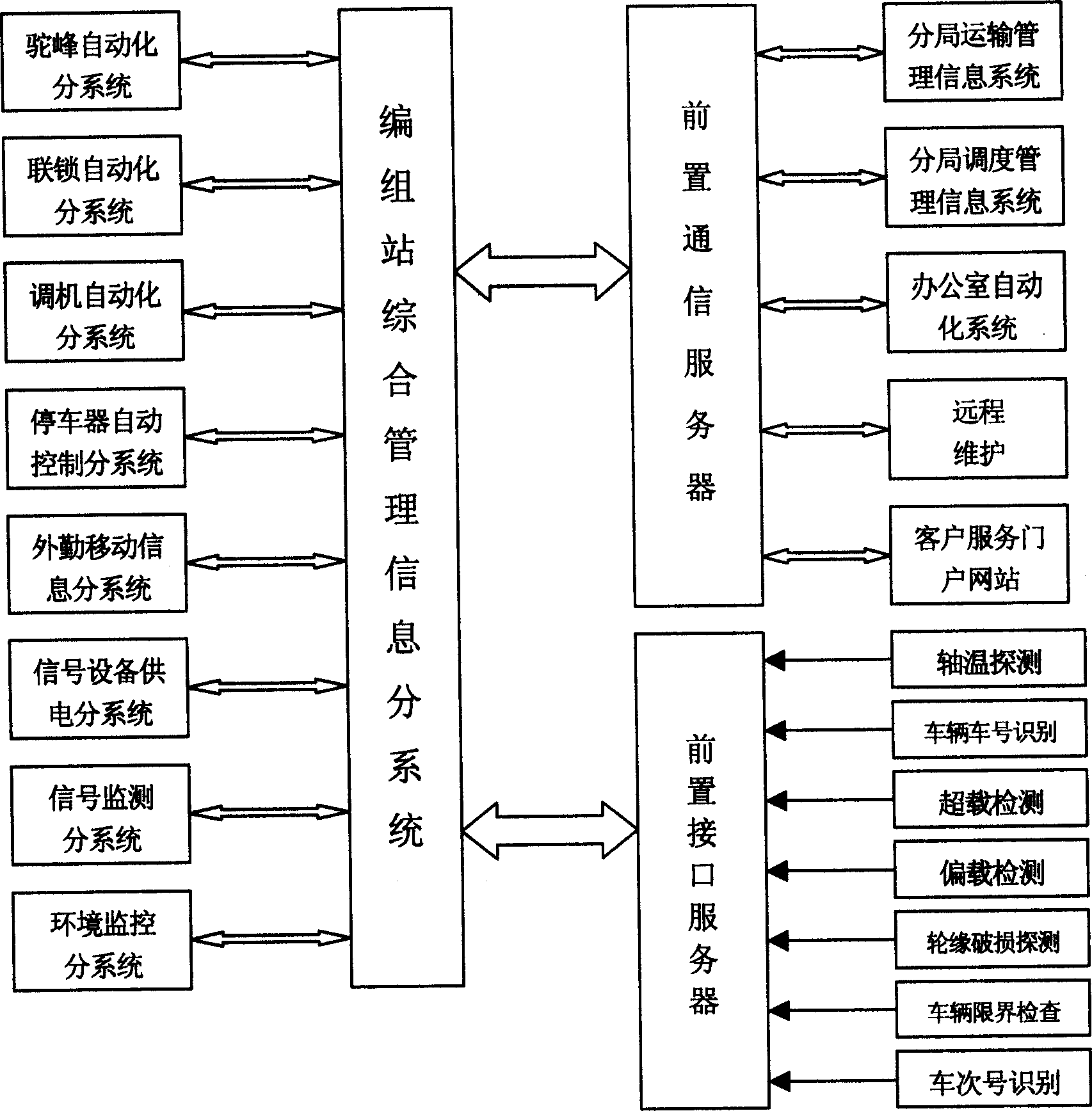

Marshalling station comprehensive integrated automation system

An integrated automatization system for the classification yard of railway is composed of several original automatization subsystems and a new information processing subsystem, which are connected to form a closed-loop intelligent system.

Owner:CRSC RESEARCH & DESIGN INSTITUTE GROUP CO LTD

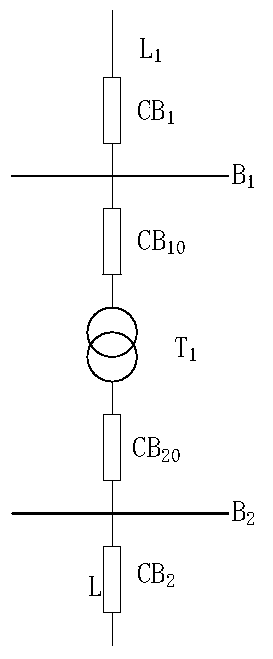

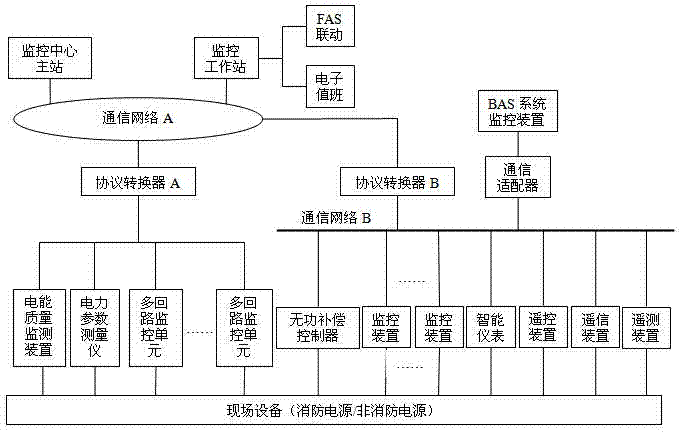

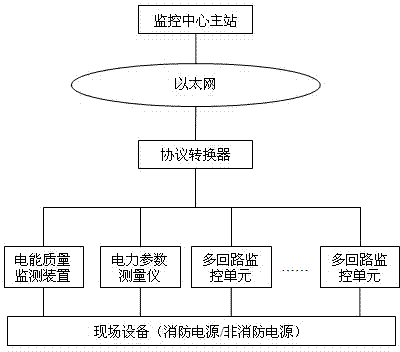

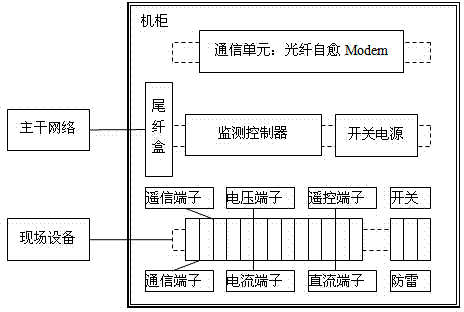

Integrated automation system of transformer substation

ActiveCN104242471AImprove the level of safe and stable operationReduce operating and maintenance costsCircuit arrangementsInformation technology support systemMicrocomputerTransformer

The invention discloses an integrated automatic system of a transformer substation. The integrated automatic system comprises a microcomputer protecting device, an automation monitoring device, an intelligent instrument, a communication network A, a communication network B and a protocol converter; the microcomputer protecting device is a voltage and current protecting, measuring and controlling device in a transformation and distribution system; the microcomputer protecting device is connected to the communication network A through the protocol converter A; the automation monitoring device and the intelligent instrument are connected with the protocol converter B through the communication network B; the protocol converter B is connected with the communication network A; the microcomputer protecting device, the automation monitoring device and the intelligent instrument are also connected with a field device; the communication network A is also connected with a master station of a monitoring center. With the adoption of the integrated automation system of the transformer substation, the safe and stable operation level of the transformer substation is improved, the operation maintenance cost is decreased, the economic benefit is increased, the power supply reliability is improved, the energy is saved, the consumption is reduced, and the potential risk of accident is reduced.

Owner:CHENGDU SYSWARE ELECTRONICS INFORMATION

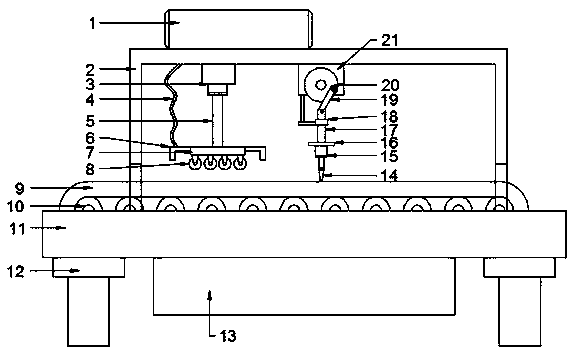

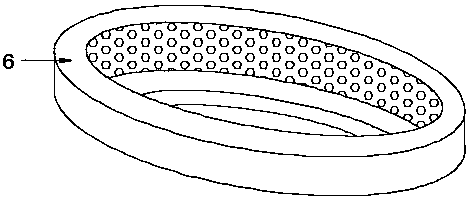

Bamboo chip trepanning and grinding integrated automation device

InactiveCN108312025ARealize transmission grindingImprove grinding efficiencyStationary drilling machinesCane mechanical workingHydraulic cylinderArchitectural engineering

The invention discloses a bamboo chip trepanning and grinding integrated automation device. The bamboo chip trepanning and grinding integrated automation device comprises grinding rollers, a workbenchand a drill bit. A conveying belt is arranged at the upper end of the workbench. In cooperation with the conveying belt, the upper end of the workbench is provided with a cavity. The conveying belt is provided with a baffle. A fixing cover is fixed to the upper end of the workbench. The four grinding rollers are arranged and are distributed on a first fixing plate in an array manner. A dust suction cover is fixed to the outer side of the first fixing plate, and the upper end of the first fixing plate is fixed to a push rod. The push rod is fixed to a hydraulic cylinder, and the drill bit is fixed to an output shaft of a first motor. The bamboo chip trepanning and grinding integrated automation device is high in grinding efficiency and quality; and meanwhile, in the grinding process, the dust suction cover can suck away fine dust generated during grinding

Owner:安吉森虎机械有限公司

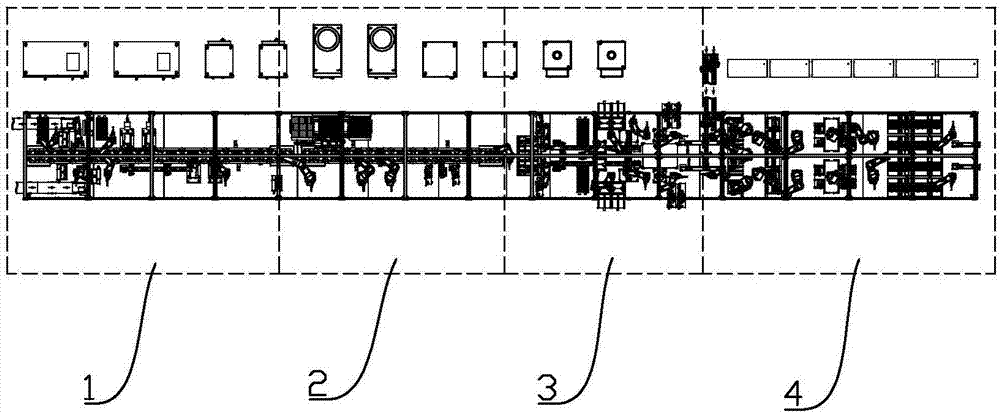

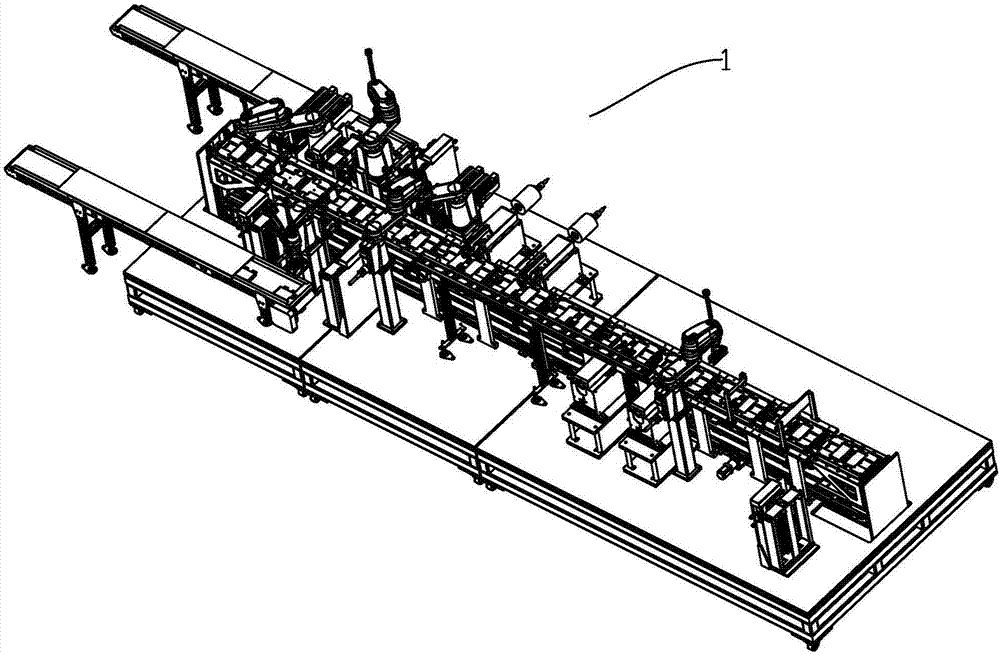

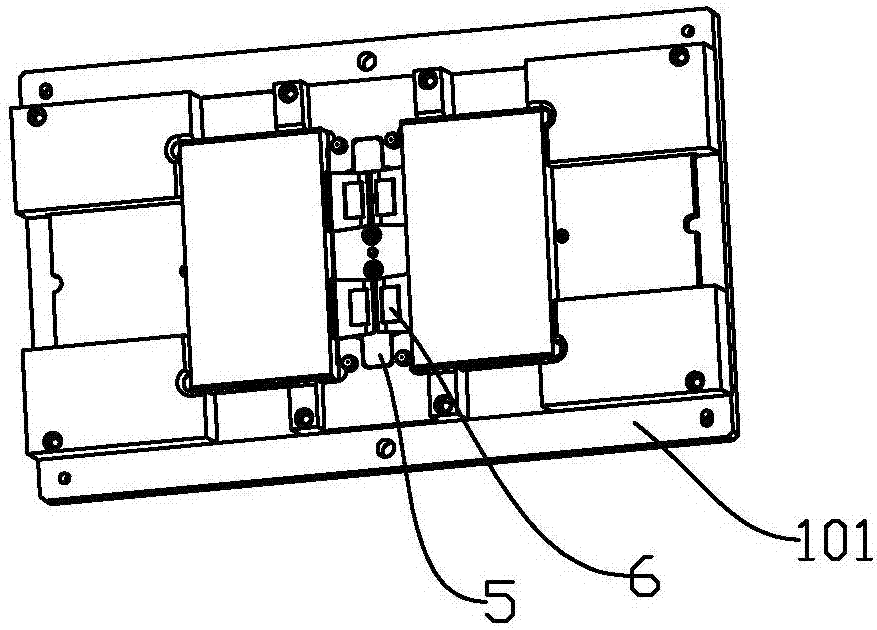

Integrated automated production line for assembling of battery cells

ActiveCN107959039ASave spaceHigh degree of automationAssembling battery machinesFinal product manufactureProduction lineIntegrated design

The invention discloses an integrated automated production line for assembling of battery cells. The integrated automated production line for assembling of battery cells comprises a battery cell pairing and welding station, a top cap welding station, a tab bending station and a station for feeding battery cells into shells, wherein the battery cell pairing and welding station is used for pairing tabs of two battery cells and welding and fixing the tabs of the battery cells; the top cap welding station is connected with the battery cell pairing and welding station, and is used for welding a topcap to the tabs, which are welded and fixed, of the two battery cells; the tab bending station is connected with the top cap welding station, and is used for bending the tabs of the two battery cellsso as to attach the two battery cells; and the station for feeding the battery cells into the shells is connected with the tab bending station and is used for pressing the two attached battery cellsinto an aluminum shell and fixing the two attached battery cells. Procedures of pairing and welding of the tabs of the battery cells, top cap welding, battery cell combining, feeding of the battery cells into the shells and the like can be finished successively. Compared with a traditional single machine for line distribution, the integrated automated production line saves more space, the variousstations work according to set action sequences, the degree of automation is high, the labor cost is low, the production efficiency is improved, and the maintenance cost is reduced; and meanwhile, owing to an integrated design overall arrangement, the structure is compact and clear, high production aesthetic feeling is achieved, and the practicality is high.

Owner:旷泰科技(上海)有限公司

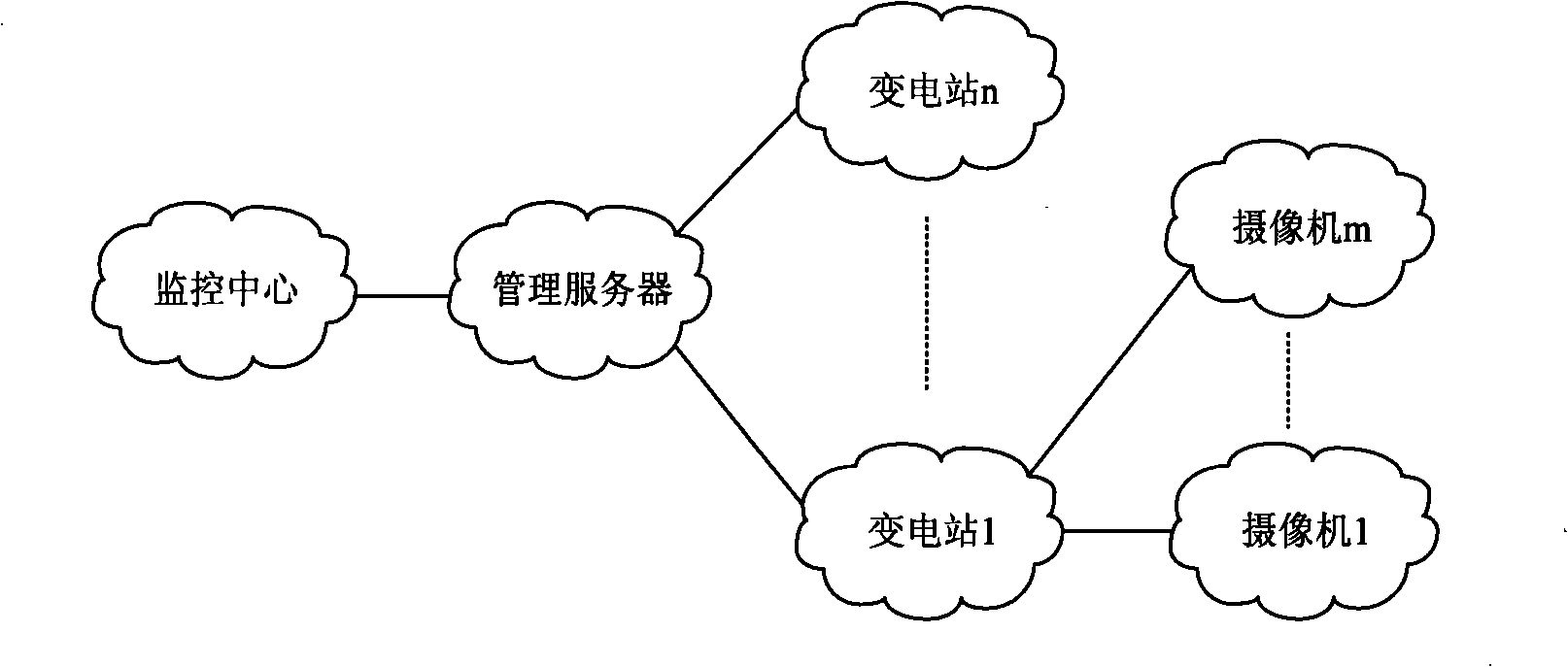

Intelligent remote inspection system in linkage with GIS substation integrated automation system and method

ActiveCN104167818AReduce the burden of manual operationLow costCircuit arrangementsInformation technology support systemVideo imageComputer science

The invention provides an intelligent remote inspection system in linkage with a GIS substation integrated automation system and a method. The method comprises the steps that primary equipment real-time operation data of a substation are obtained from the integrated automation system and analyzed into primary equipment operation data for telesignalisation or telecontrol or telemetering; different types of primary equipment operation data are filed and stored, and corresponding camera information is added to generate primary equipment monitoring data; according to the camera information carried in the monitoring data, corresponding cameras are driven to be located at the positions corresponding to primary equipment for shooting to obtain real-time images; the monitoring data and the corresponding real-time images are displayed on a video window. According to the intelligent remote inspection system in linkage with the GIS substation integrated automation system and the method, the integrated automation system and video image information are integrated, existing resources of the substation are fully utilized to achieve visualization and intellectualization of substation inspection work, and cost for intelligent inspection is saved.

Owner:SHENZHEN POWER SUPPLY BUREAU

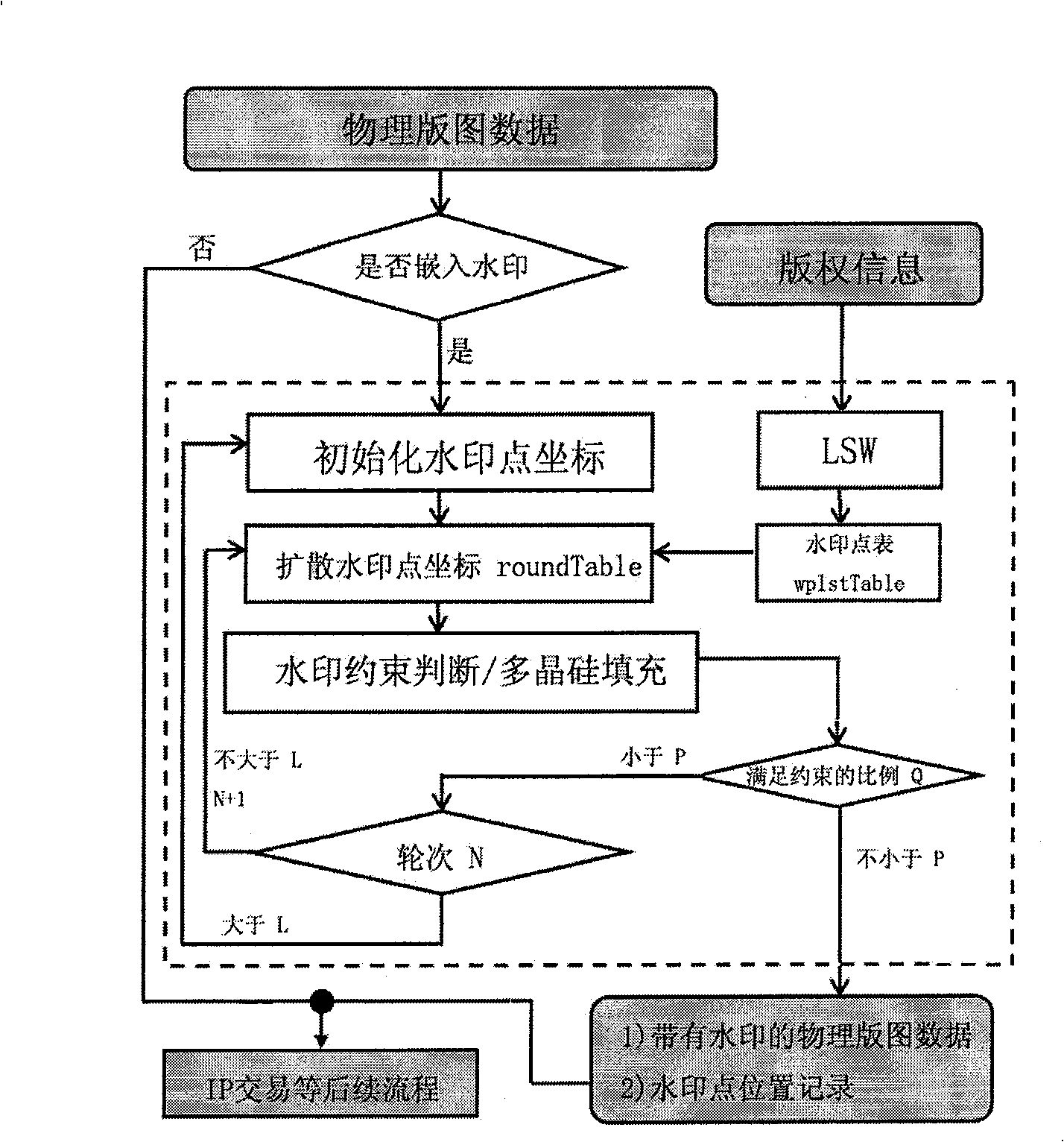

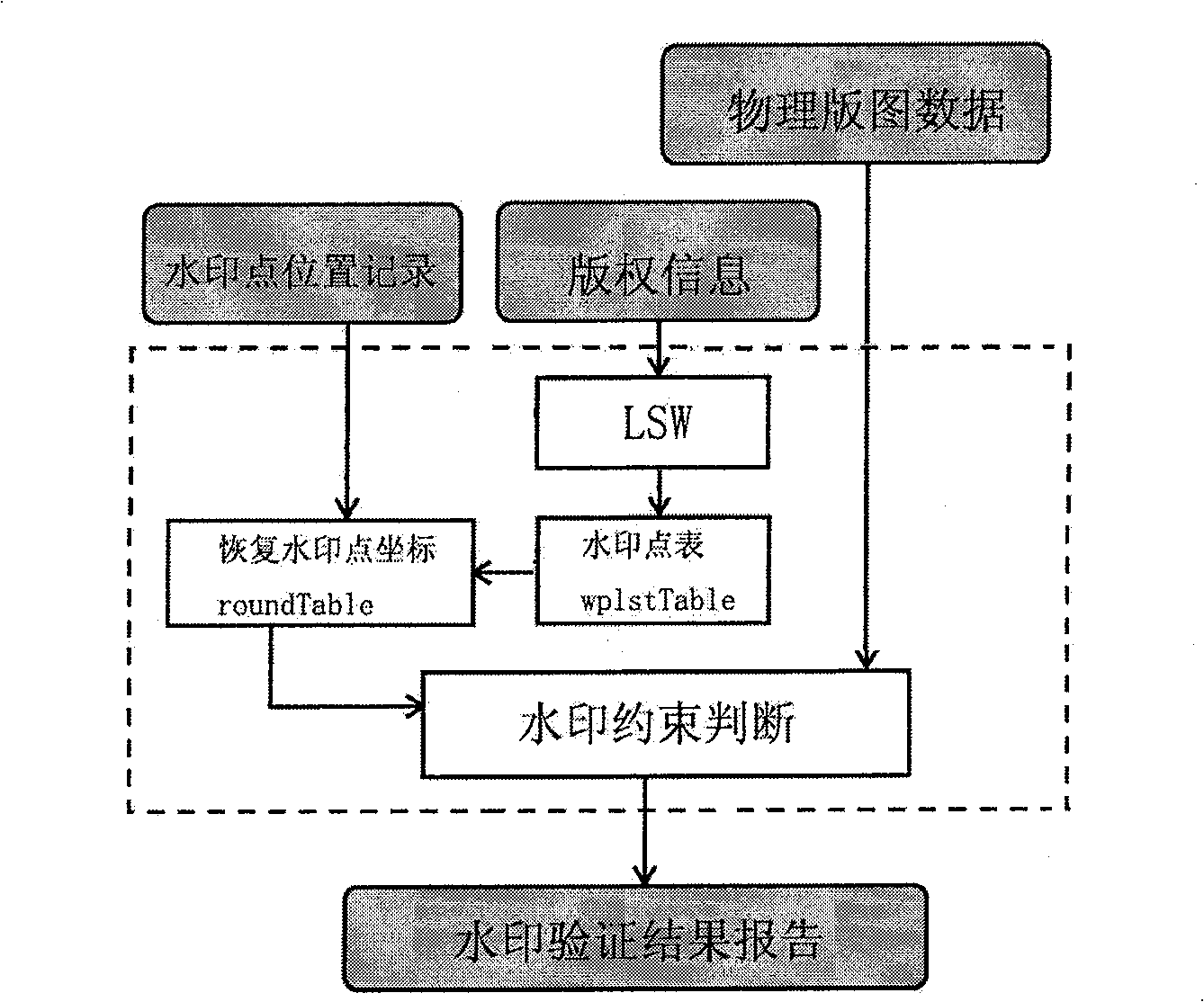

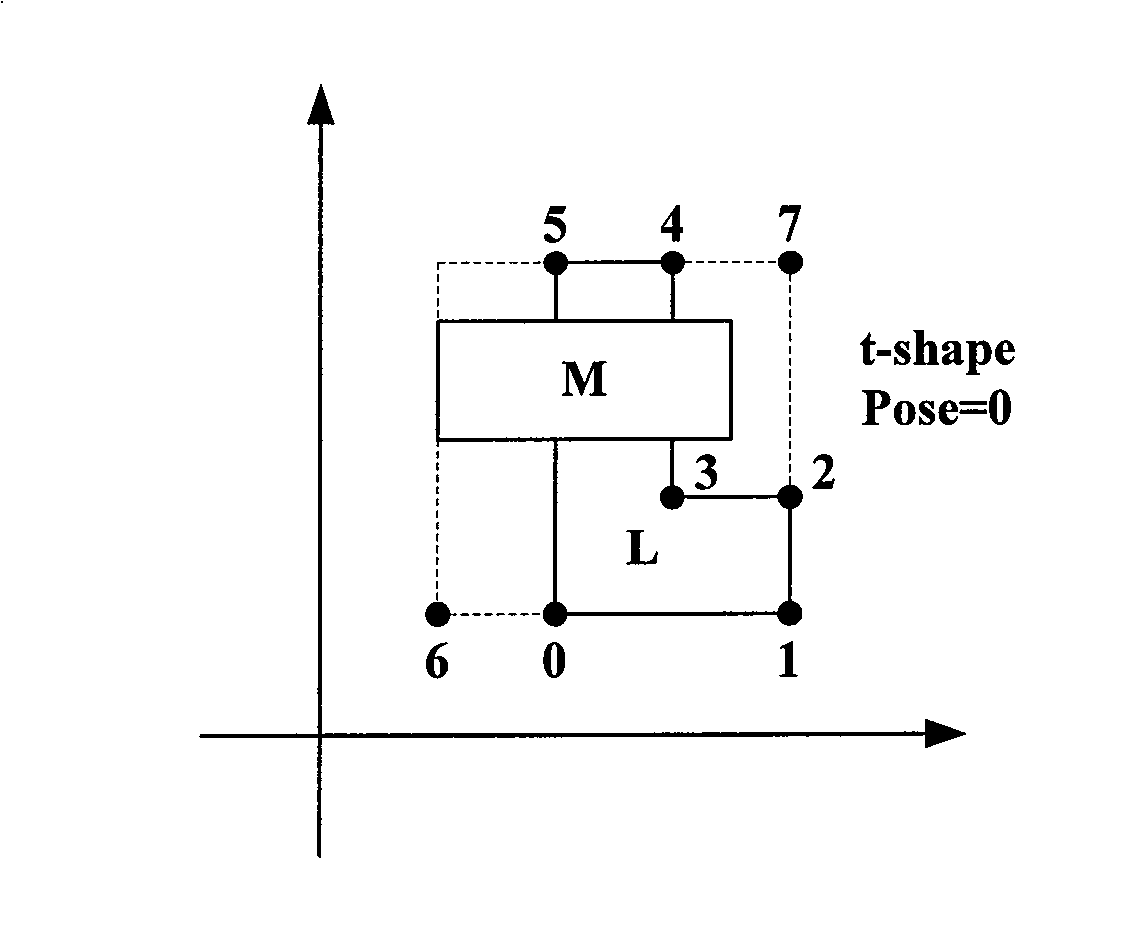

Method for affirming IP nuclear publishing rights by using digital watermarking technology

InactiveCN101408923AEasy to useImprove universalityProgram/content distribution protectionDiffusionHash function

The invention provides a method for acknowledging an IP core copyright by a digital watermarking technology. The method has the advantages of low cost, high universality, high compatibility, high feasibility and fully integrated automation. The technical scheme is that the method is characterized by comprising a watermark embedding step and a watermark extracting step. The watermark embedding steps comprises the following procedures: first, selecting a coordinate of an initial watermark point in a layout, and processing copyright information by a one-way Hash function to obtain an offset of the watermark point coordinate, and obtaining the scattered watermark point coordinate pseudo-randomly distributed in the layout; and then normalizing the attribute of the selected watermark point to embed the special watermark representing the copyright information; and finally, successfully embedding the watermark information for the watermark point which is not normalized by the two methods by repeated diffusion, judgment and additional means, thus obtaining a layout data file with the watermark information. The watermark extracting step comprises the following procedures: obtaining the pseudo-randomly scattered watermark point coordinate by the method similar to the watermark embedding step based on record files of the watermark embedding information, thus recovering the watermark point coordinate successfully embedded finally and then judging whether the watermark point successfully embedded finally coincides with a polysilicon layer in the layout and outputting a watermark extraction report.

Owner:TSINGHUA UNIV

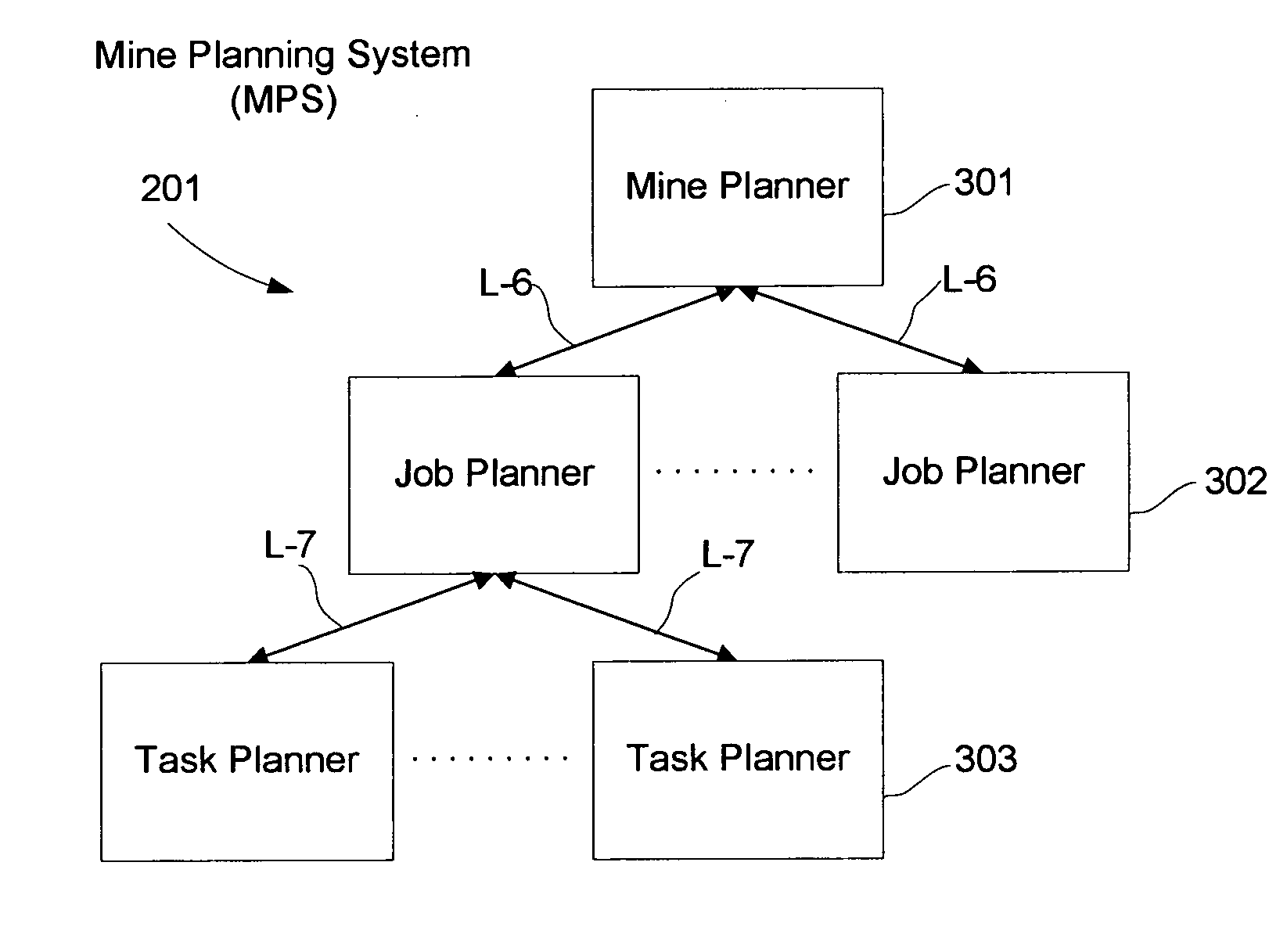

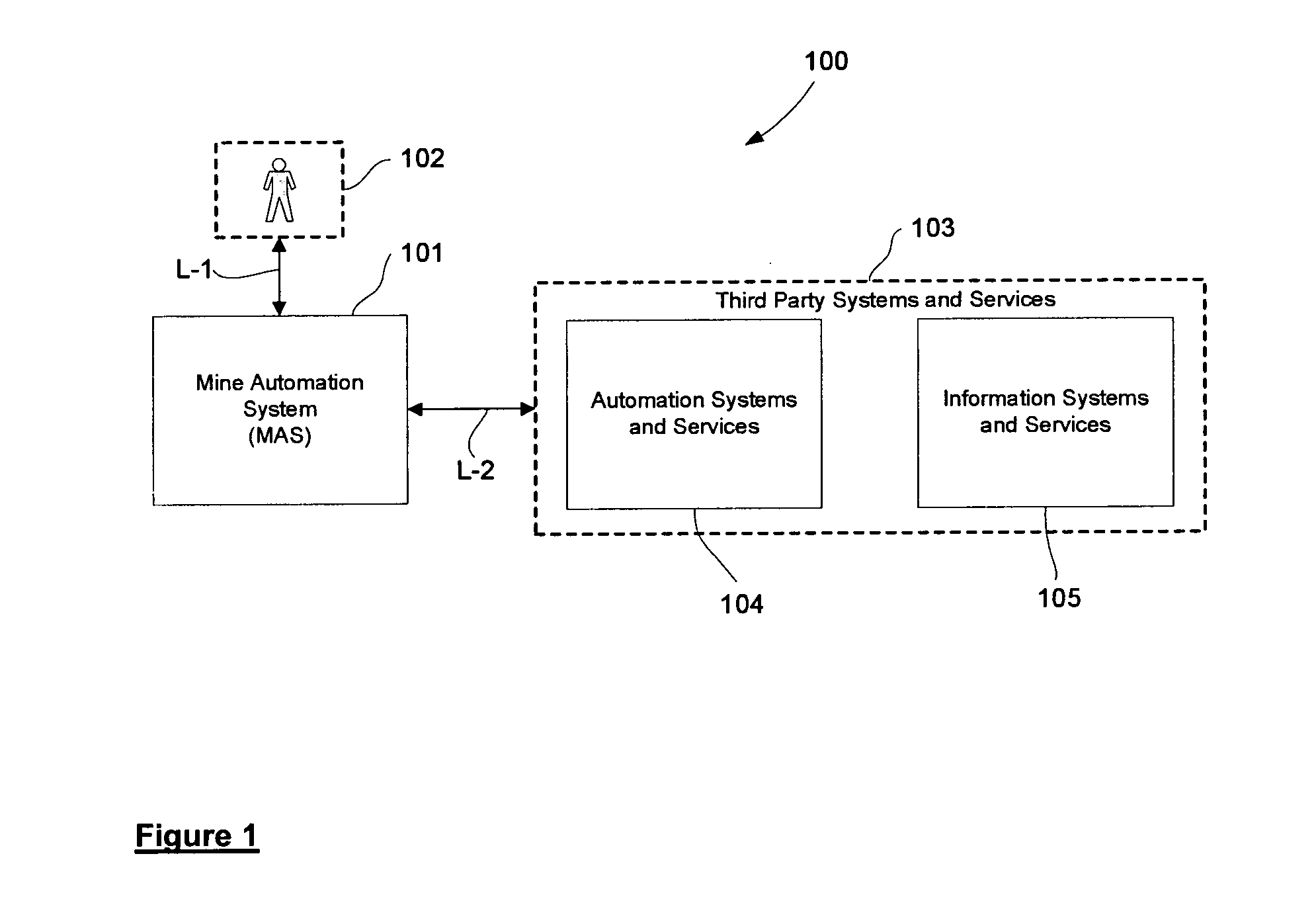

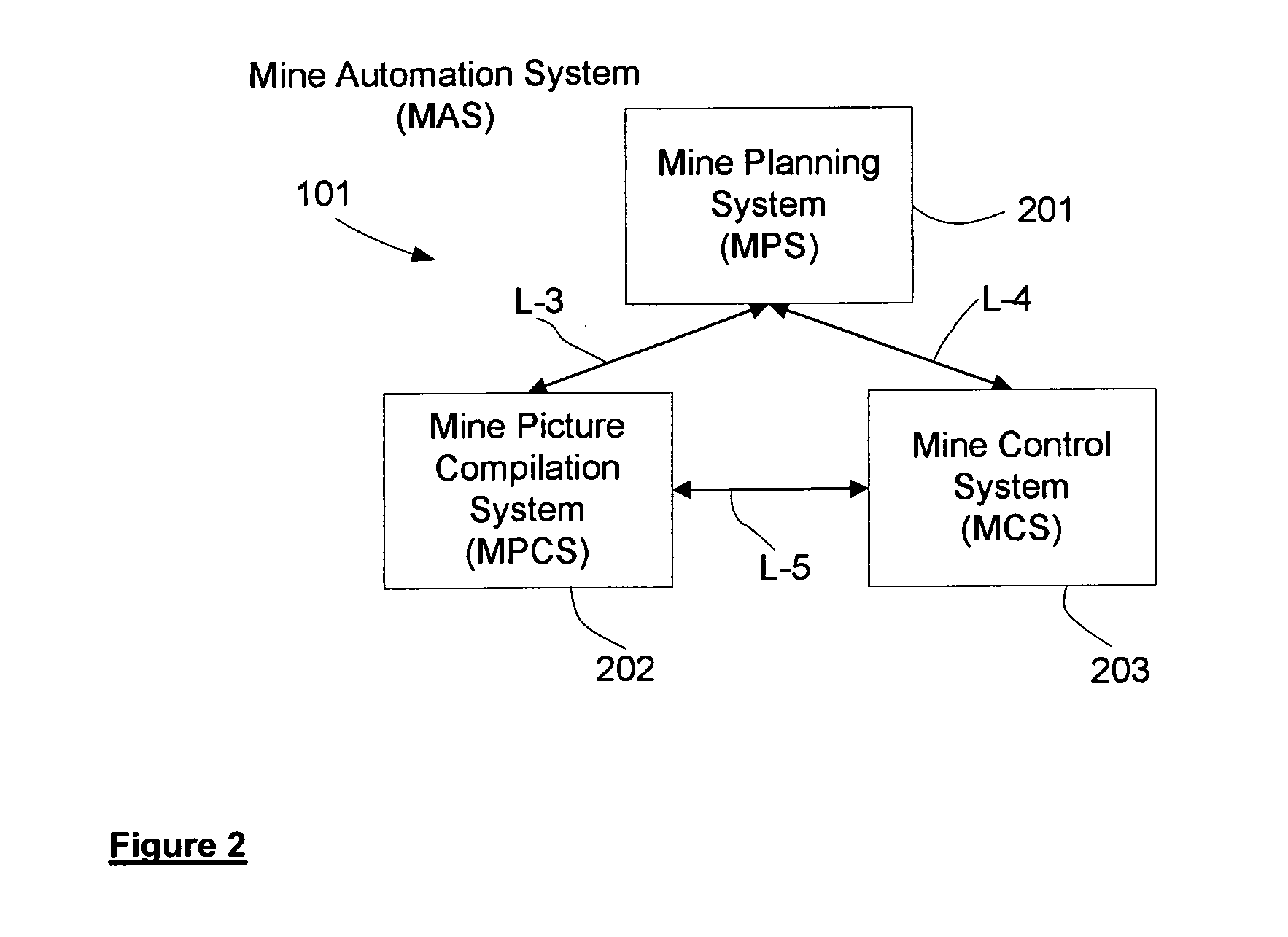

Integrated automation system with picture compilation system

ActiveUS20120046927A1Programme controlMining devicesOperational definitionCommon Data Representation

Owner:TECHNOLOGICAL RESOURCES

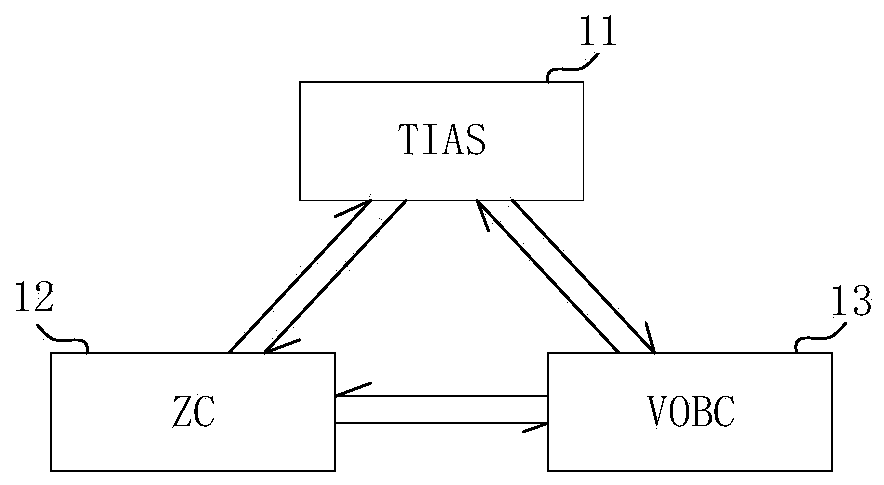

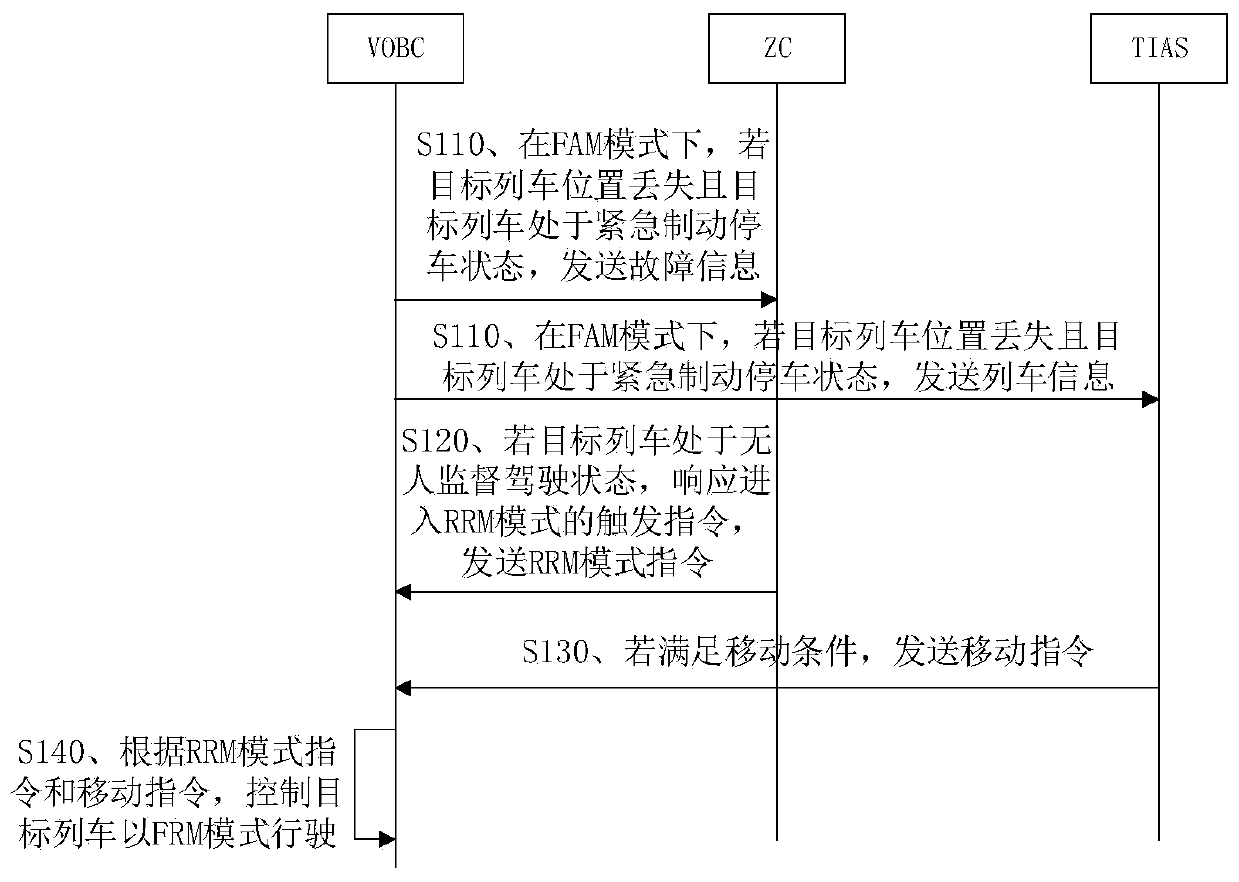

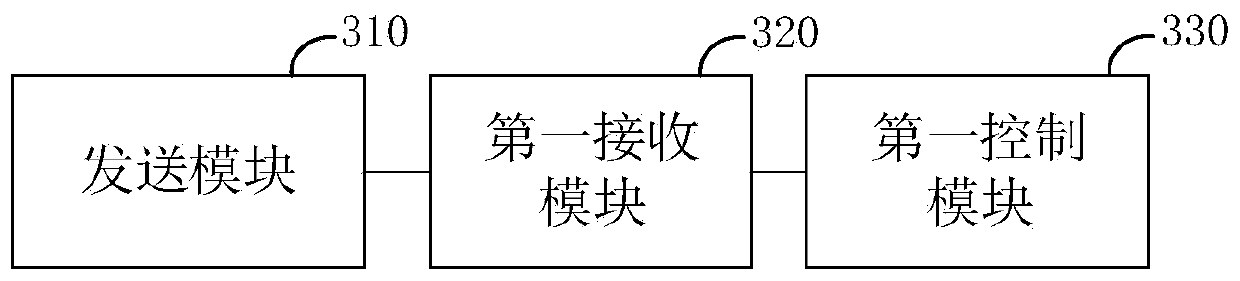

Automatic driving method of train, VOBC, TIAS and zone controller

ActiveCN110758484AImprove operational efficiencyWill not affect normal operationAutomatic systemsControl objectiveEngineering

The invention discloses an automatic driving method of a train, a VOBC, a TIAS and a zone controller. The method comprises the steps that in a full-automatic driving (FAM) mode, if the position of thetarget train is lost and the target train is in an emergency brake stop state, train messages are sent to the train integrated automation system (TIAS), fault information representing that the trainposition is lost is sent to the zone controller (ZS), and the train messages comprise the full-automatic restricted manual driving (RRM) mode request information; and the admission RRM mode command sent by the TIAS and the moving command sent by the ZC are received; and according to the RRM mode command and the moving command, the target train is controlled to run in the RRM mode. According to thescheme, the train running efficiency can be improved.

Owner:TRAFFIC CONTROL TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com