Automated batch manufactuirng

An automatic management, batch technology, applied in the direction of program control, computer control, comprehensive factory control, etc., can solve problems such as batch discarding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

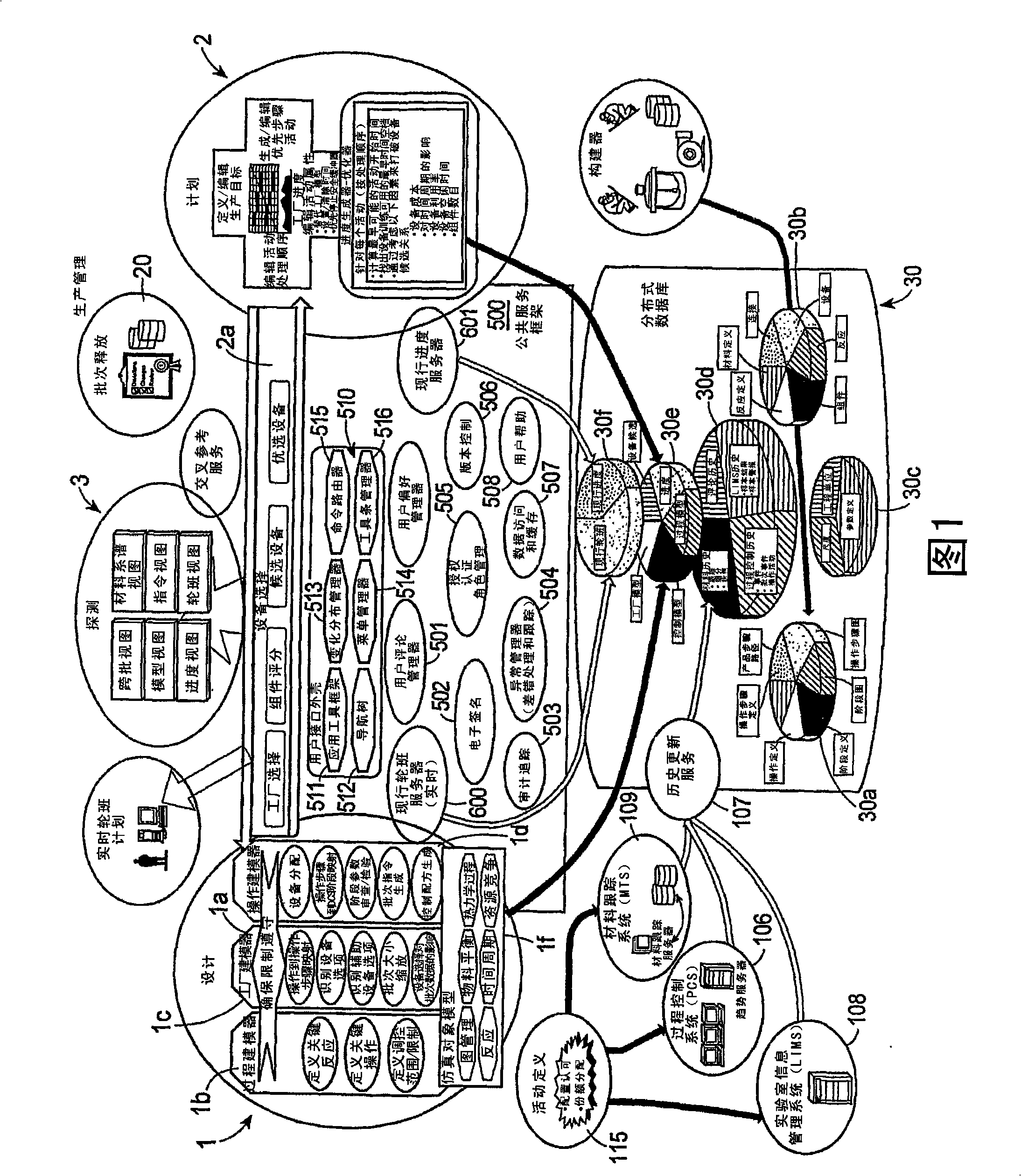

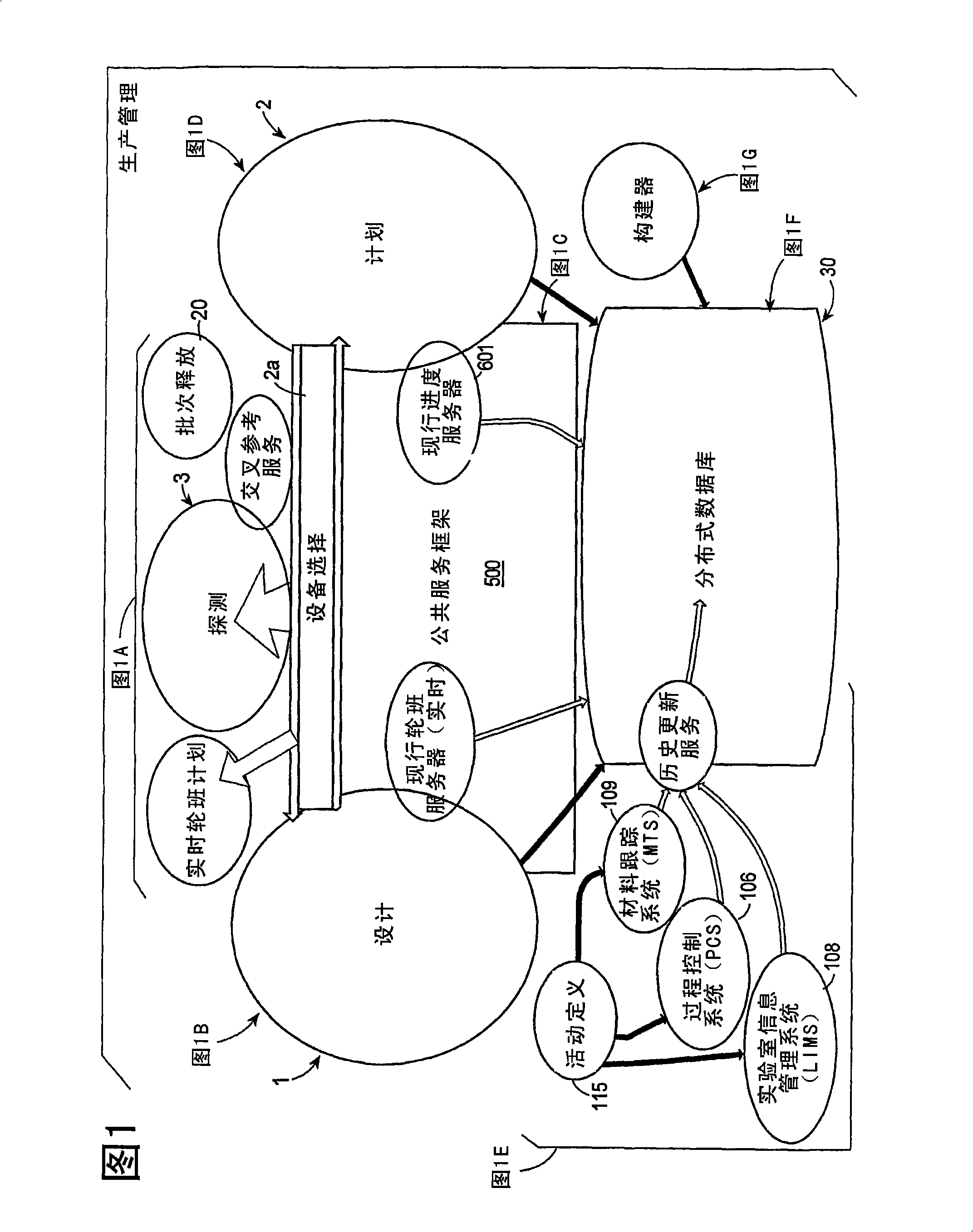

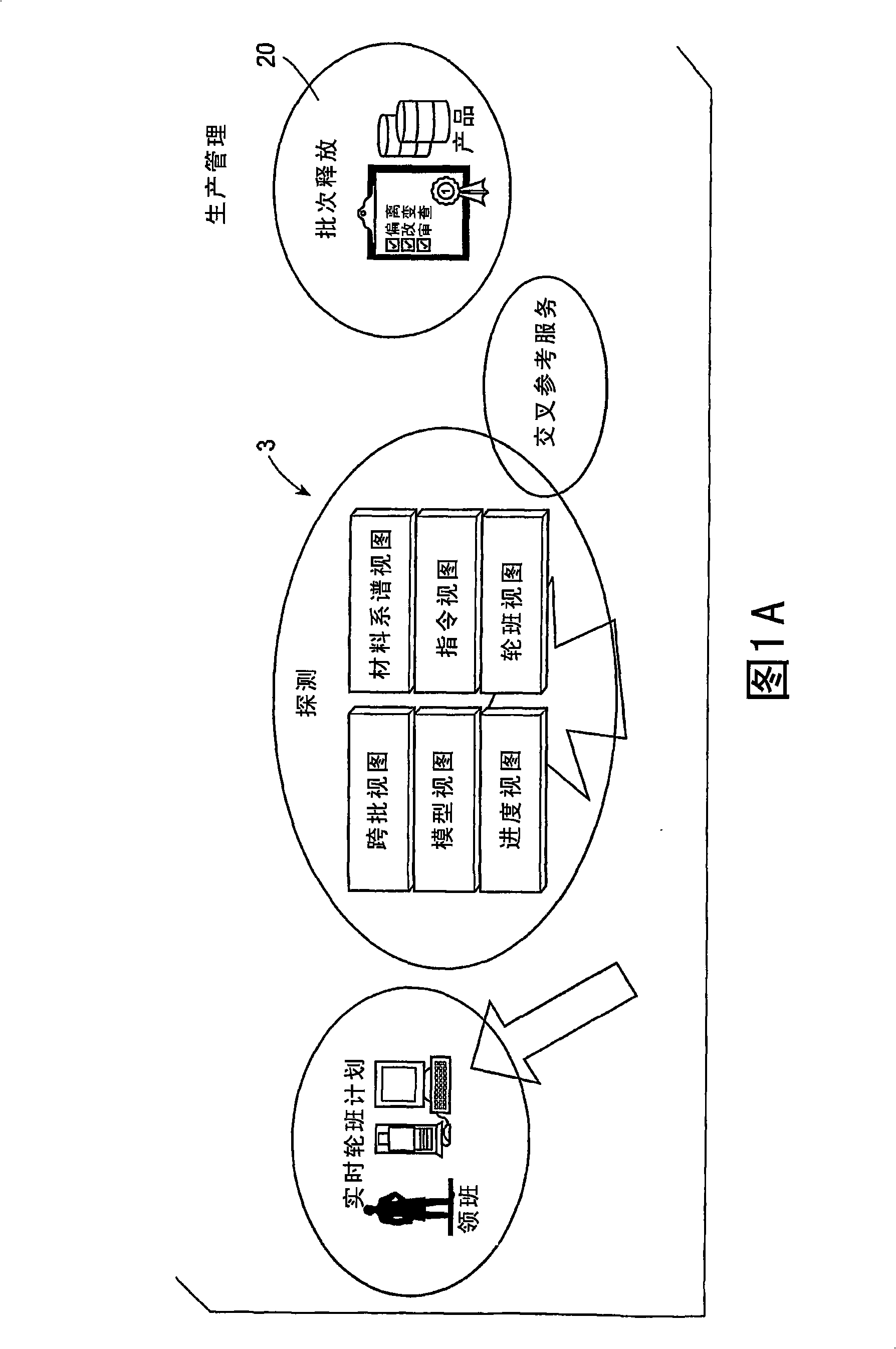

[0041] The present invention includes an integrated automated manufacturing system with override computer control, with particular application to batch manufacturing processes of chemical and food products, especially pharmaceuticals and biological products. A closed information loop is achieved from initial design to feedback evaluation comparing the (planned) design with actual production events with real-time comparisons to the selections made to automatically modify the plan.

[0042] Batch systems generally involve the production of at least two products on one line or at one production site, requiring sharing of resources and production time. The manufacturing system of the present invention includes a design modeler component for designing a manufacturing process (design module) utilizing:

[0043] i. Process (overall production process, e.g. synthetic steps in the production of chemicals and pharmaceuticals) models,

[0044] ii. a factory (consideration of factory res...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com