Patents

Literature

44results about How to "Improve production and operation efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

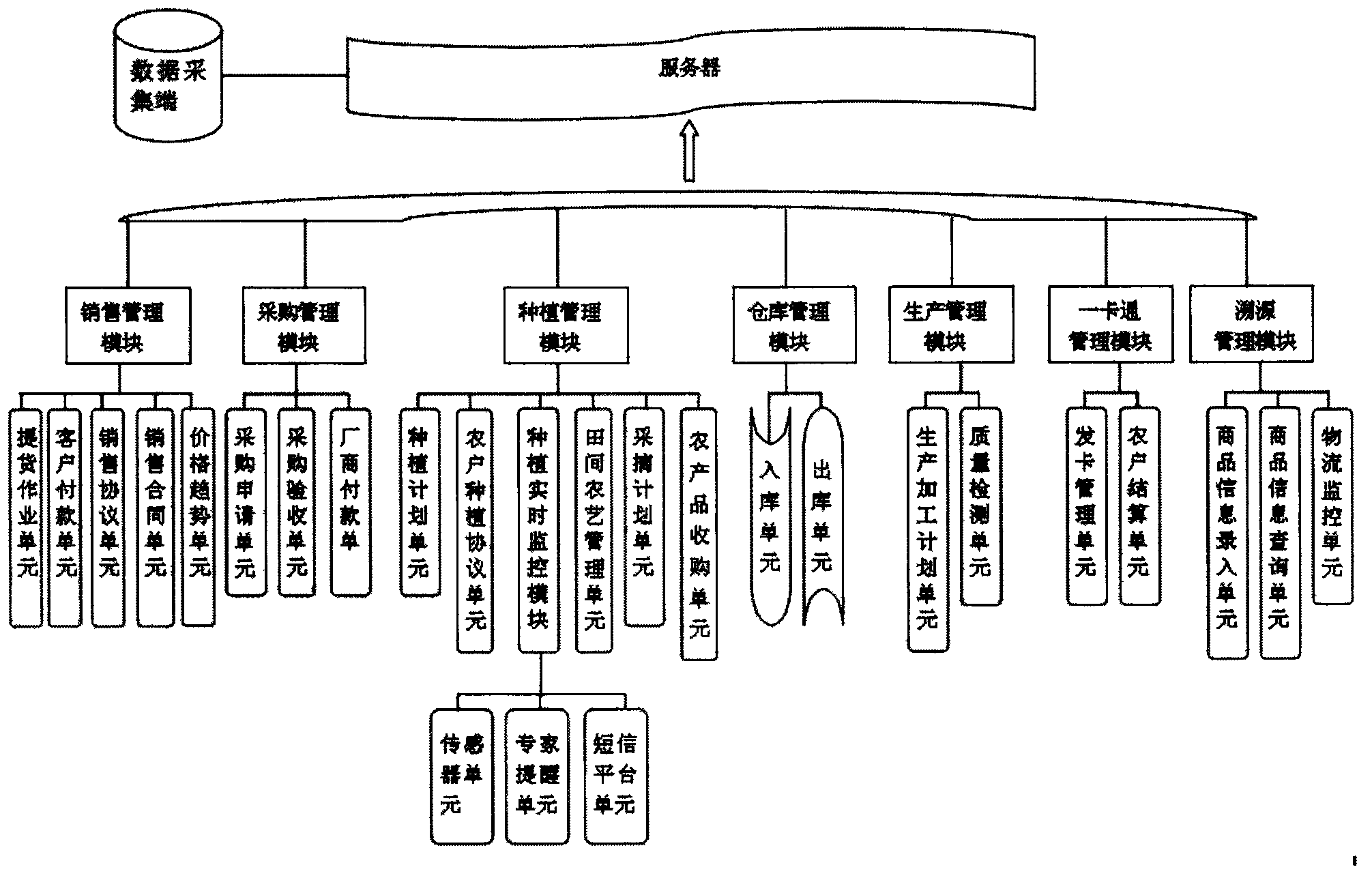

Regional agricultural multi-format management system for internet of things

InactiveCN103295105AImprove production and operation efficiencyEasy to manageResourcesData acquisitionThe Internet

The invention relates to a regional agricultural multi-format management system for internet of things. The regional agricultural multi-format management system for internet of things comprises a server, a data acquiring terminal, a sales management module, a planting management module, a production management module, a warehouse management module and a source tracing management module. The planting management module comprises a planting real-time monitoring module, wherein the planting real-time monitoring module comprises a sensor unit, a short message platform unit and an expert reminding unit. The sensor unit acquires crop data and transmits the data to the server to be memorized, the server feeds the crop data back to the expert reminding unit, and the expert reminding unit generates expert reminding information and sends the information to farmers through the short message platform. The source tracing management module comprises a commodity information entry unit and a commodity information inquiry unit. The regional agricultural multi-format management system for the internet of things achieves convenient regional agricultural multi-format management and accordingly improves the efficiency of regional agricultural multi-format production and management.

Owner:无锡百盛传感网络有限公司

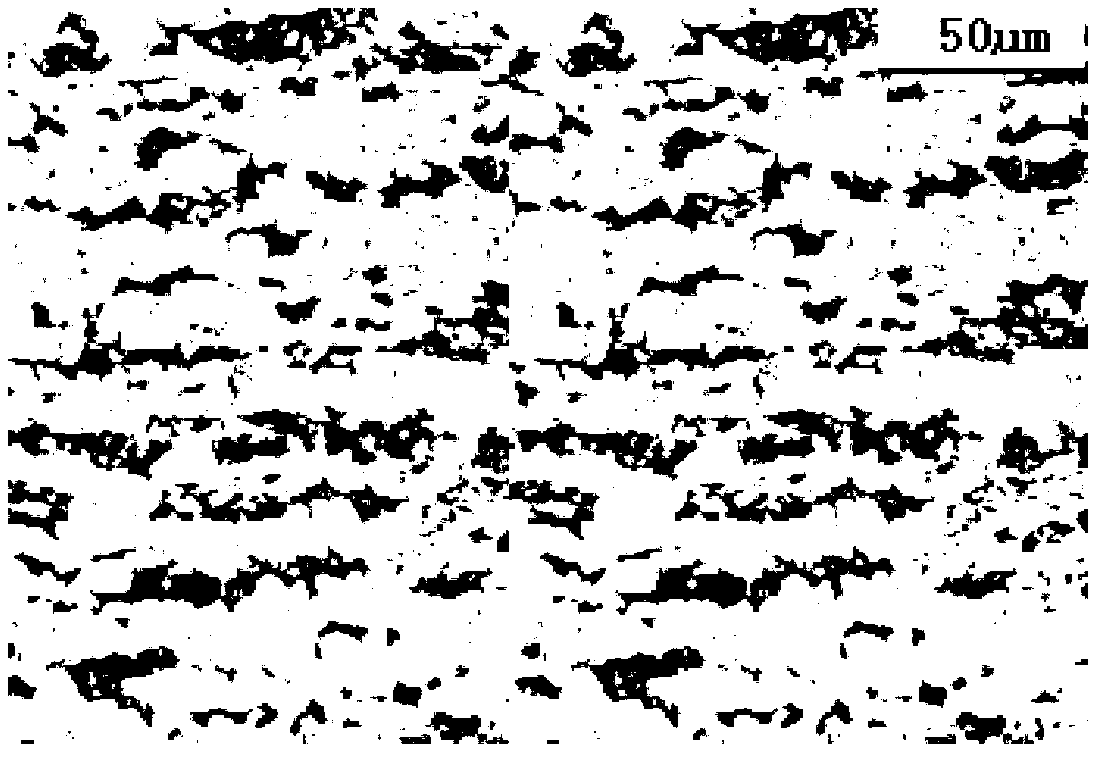

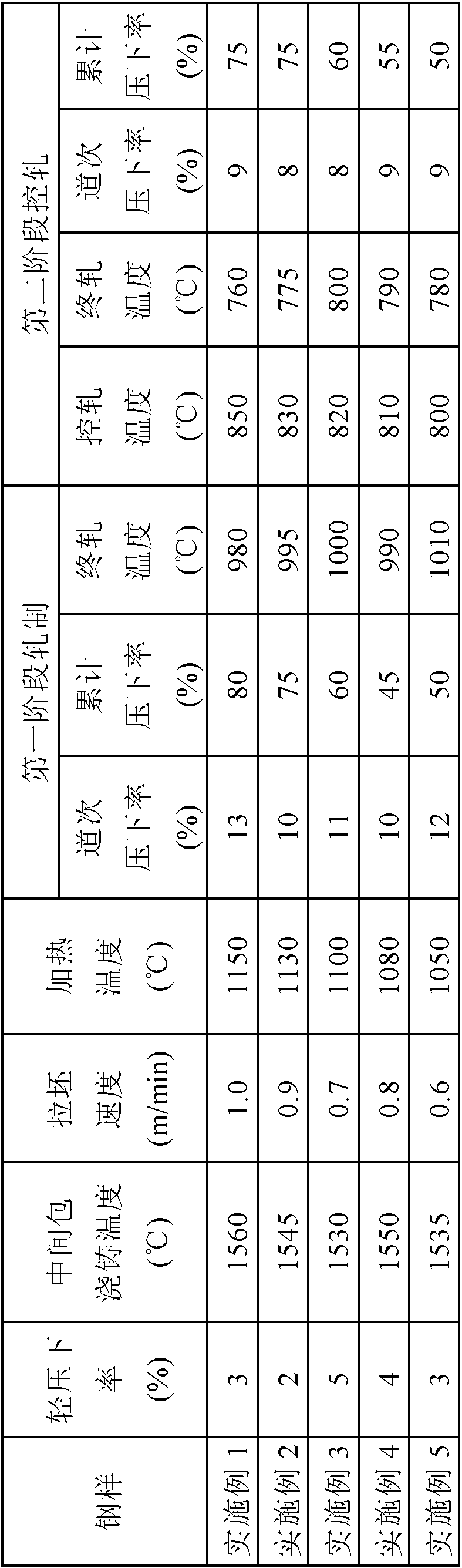

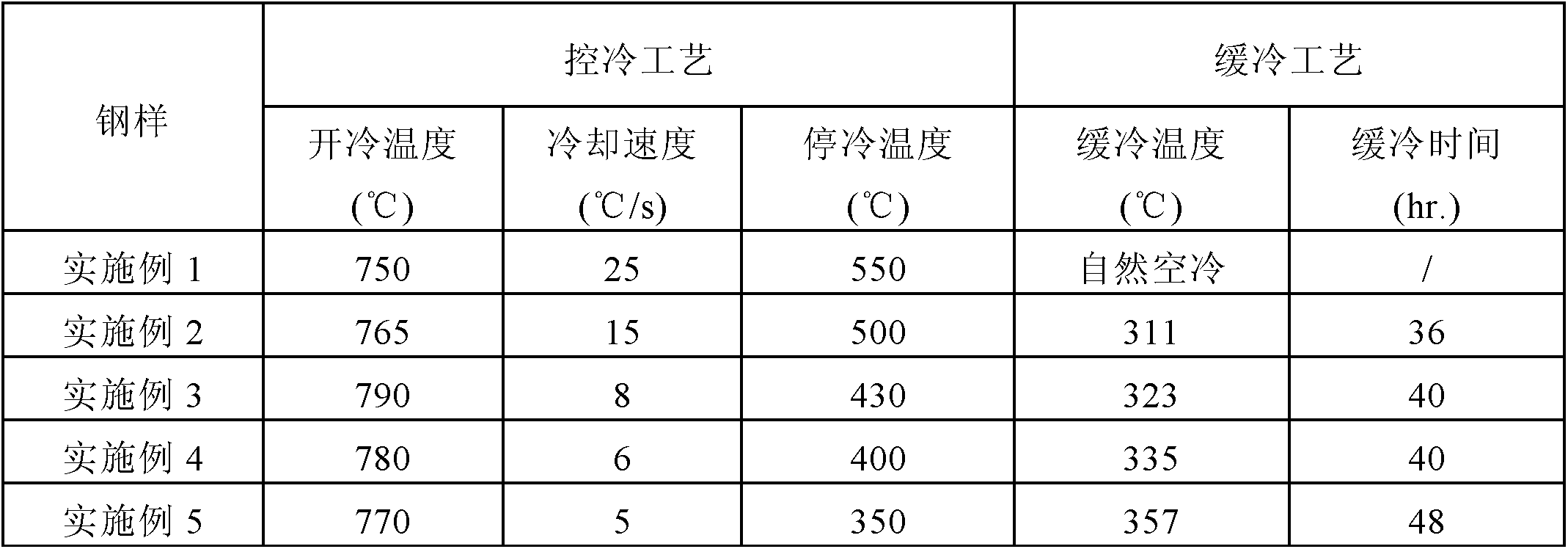

Zinc-induced-crack-resistant steel plate and manufacturing method thereof

ActiveCN103320693AExcellent resistance to zinc crackingImprove mechanical propertiesFurnace typesMetallic material coating processesMicro structureSpray coating

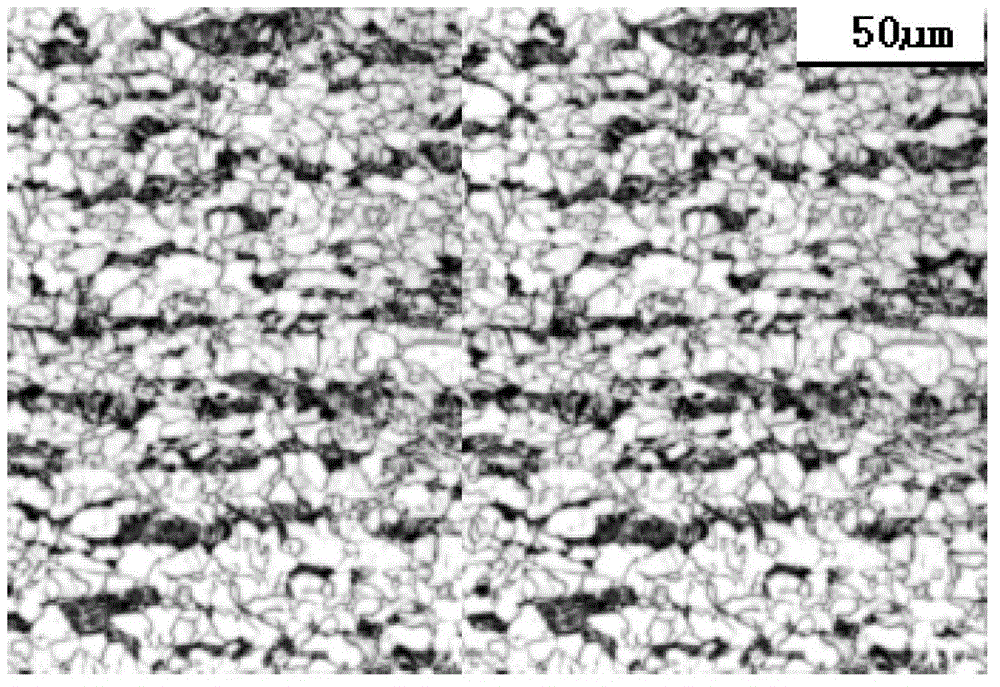

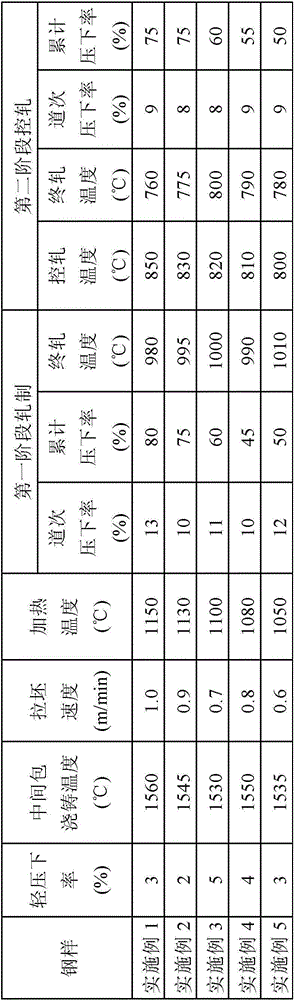

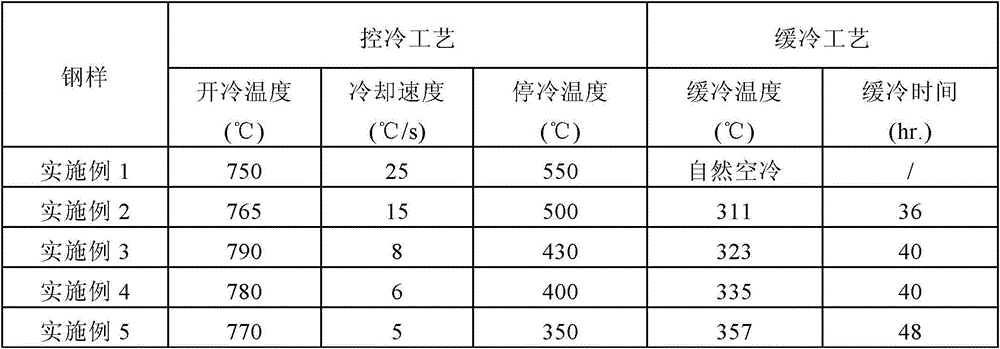

The invention discloses a zinc-induced-crack-resistant steel plate and a manufacturing method thereof. Low alloy steel subjected to low C-ultralow Si-high Mn-low Als-(Ti+Nb) micro alloying treatment is taken as a basis, the Als content of the steel is appropriately reduced, situations that Mn / C is greater than or equal to 15, [(%Mn)+0.75 (%Mo)]* (%C) is less than or equal to 0.16, Nb / Ti is greater than or equal to 1.8, Ti / N is 1.50-3.40, CEZ is less than or equal to 0.44%, the B content is less than or equal to 2 ppm, and Ni / Cu is greater than or equal to 1.50 are controlled, the Ca treatment is performed, the Ca / S ratio is controlled to be 1.0-3.0, (%Ca)*(%S)0.28 is controlled to be less than or equal to 1.0*10<-3>, and a TMCP (Thermal Mechanical Control Process) is optimized, so that the micro-structure of a finished steel plate is a ferrite-dispersedly distributed tiny bainitic colony, the average grain size is less than 10 mu m, and homogeneous excellent mechanical properties, excellent weldability and zinc-induced-crack-resistant properties are obtained, therefore, the zinc-induced-crack-resistant steel plate is especially suitable for being used as a zinc-spray coating anti-corrosion steel plate for marine structures, a zinc-spray anti-corrosion steel plate for extra-high voltage power transmission structures, a zinc-spray coating anti-corrosion steel plate for coast bridge structures, and the like.

Owner:BAOSHAN IRON & STEEL CO LTD

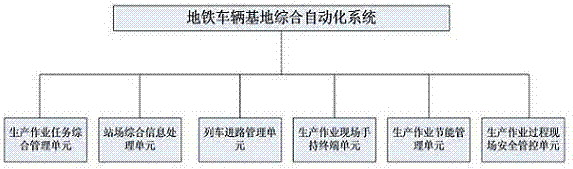

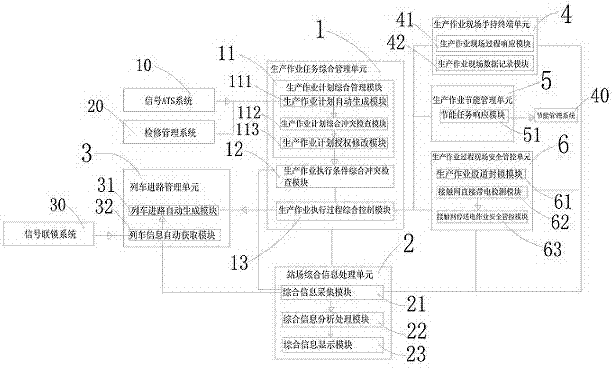

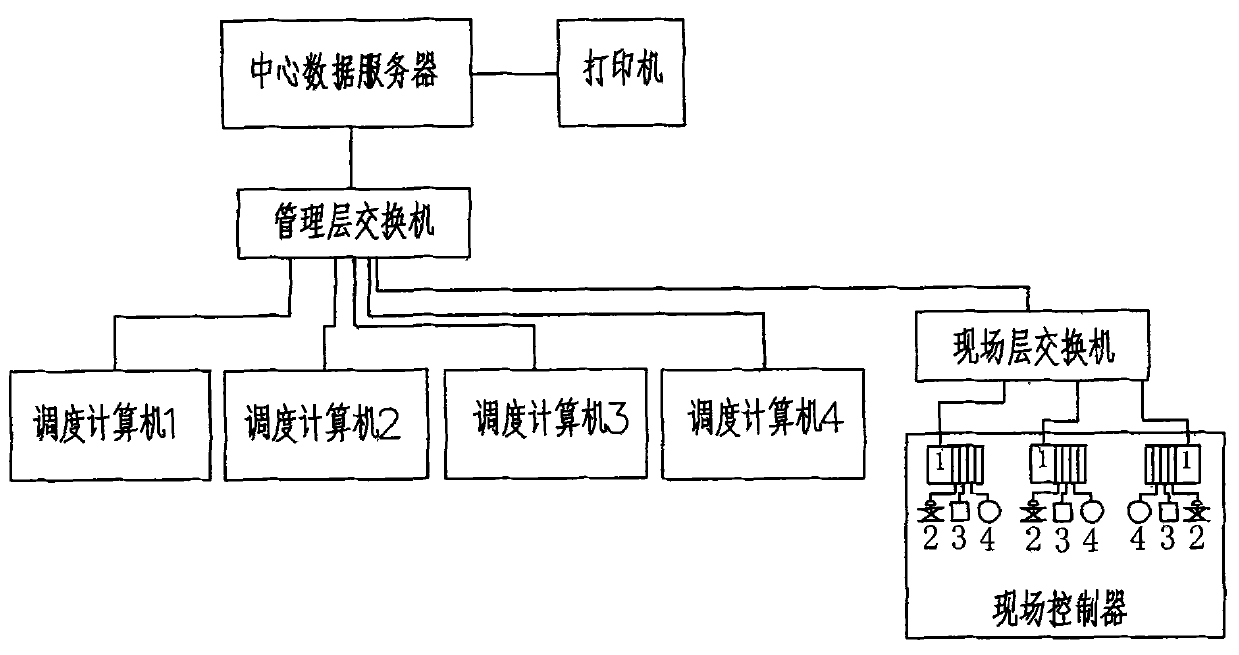

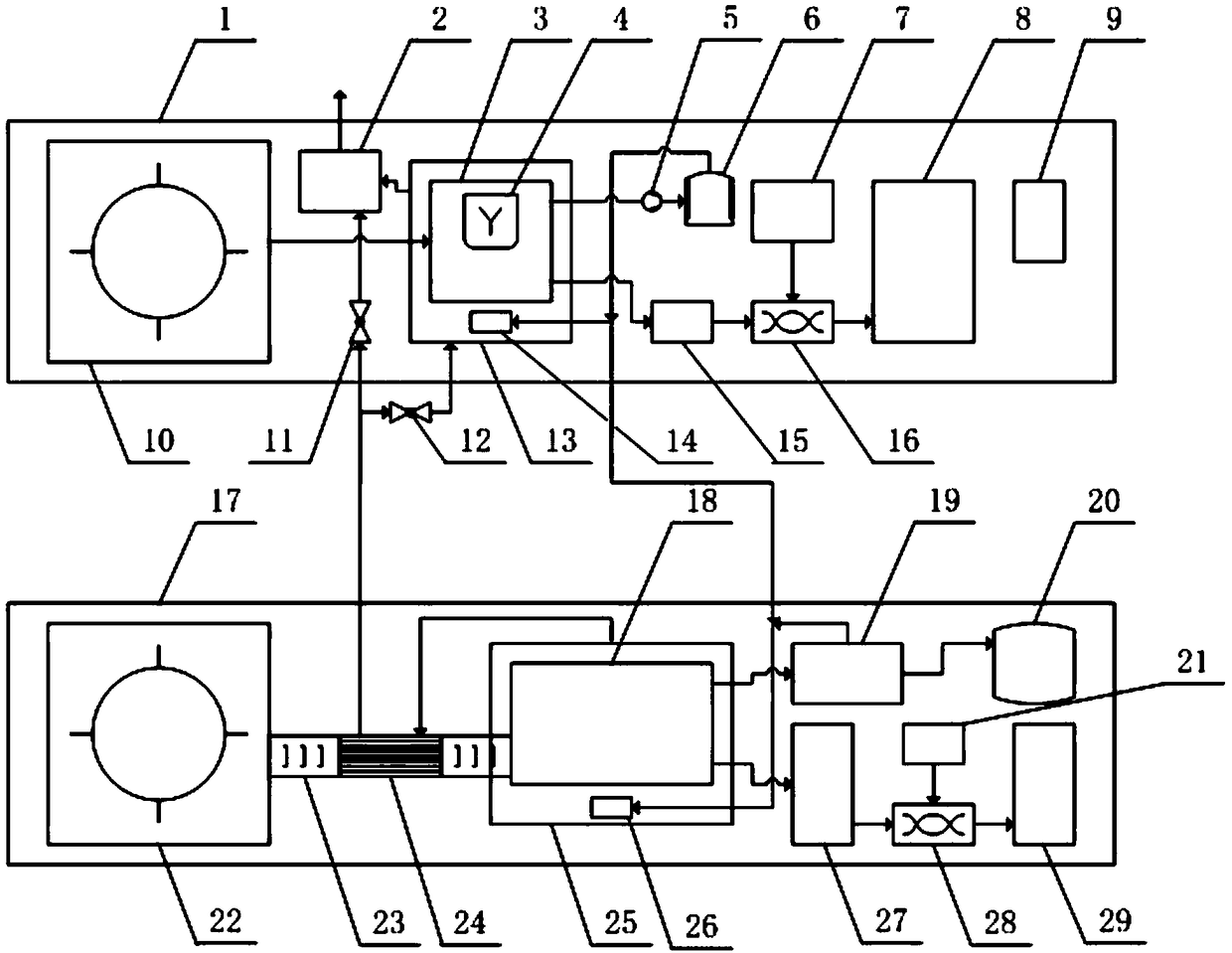

Integrated automation system of metro vehicle base

InactiveCN106909120AIncrease the level of automationImprove production and operation efficiencyProgramme controlComputer controlInformatizationInformation processing

The invention discloses an integrated automation system of a metro vehicle base. The system includes a production operation task integrated management unit, a station integrated information processing unit, a train access management unit, a production operation site handheld terminal unit, a production operation energy-saving management unit and a production process site safety control unit. The system solves the problems that metro vehicle base production operation process management is extensive, operation links are disjointed, the automation degree of operation execution is low, the operation execution lacks of safe management and control, operation site information is difficult to obtain, and the energy consumption of operation is larger. The metro vehicle base production management informationization and automation levels are improved, the production operation efficiency is improved, the production operation safety risk is reduced, the energy consumption of operation is reduced, and a safety and quality guarantee is provided for the metro main line high-level traffic safety and the high-level passenger service.

Owner:四川高新轨道交通产业技术研究院 +1

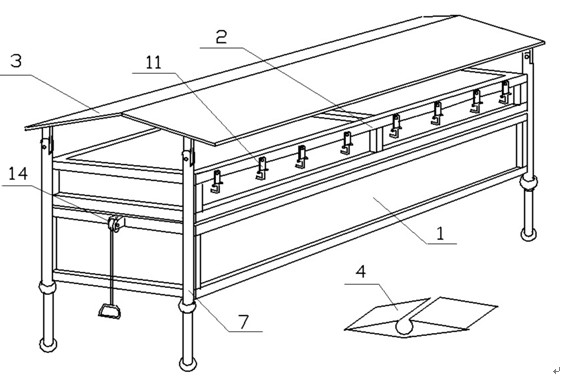

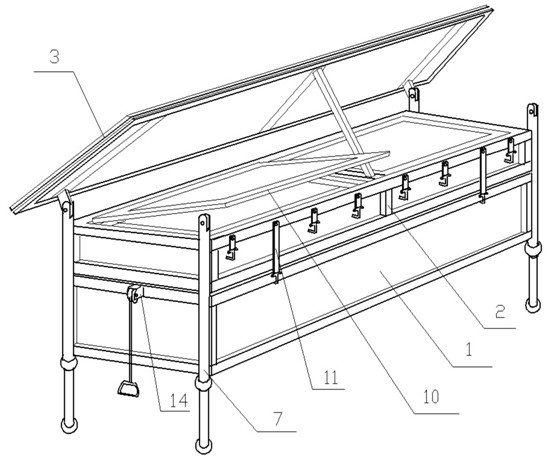

Leaf-picking-free silkworm table and silkworm rearing method

ActiveCN102630651AIncrease feeding incomeImprove production and operation efficiencyAnimal husbandryHorticultureBotany

The invention discloses a leaf-picking-free silkworm table and a silkworm rearing method. The leaf-picking-free silkworm table is characterized by comprising a silkworm table box, a silkworm table cover, a ceiling and a mulberry branch flexible sealing element, wherein peripheries of the silkworm table box and the silkworm table cover are sealed by a fine nylon net; mulberry branches hooked in the silkworm table are sealed by a flexible material; a mulberry branch hooking frame with hooks and a silkworm rearing bed surface are arranged at the upper part of the silkworm table box and connected by using a lifting device; the mulberry branch hooking frame is placed at the inner side of the upper-part box of the side wall of the silkworm table box; and the silkworm rearing bed surface is capable of downwards moving and driving the mulberry branch hooking frame to vibrate up and down when being dropped in place. The rearing method comprises the steps of putting the leaf picking-free silkworm table in a line of a mulberry field, putting silkworms on silkworm rearing bed surface, bending and hooking the mulberry branches on the surface of the silkworm table box, closing the silkworm table cover and the ceiling, grouping the silkworms step by step according to the quantity and assigning to other silkworm tables to rear after half mulberry leaves are eaten by the silkworms. The leaf picking-free silkworm table and the silkworm rearing method have the advantages that the occurrence of silkworm diseases is effectively controlled; the damage of pebrine disease to silkworm egg production is decreased; the silkworm cocoon quality is significantly improved; the work efficiency of silkworm rearing can be greatly increased at the same time; and requirements of large-scale silkworm rearing are satisfied.

Owner:LIUZHOU LIYUAN AGRI TECH

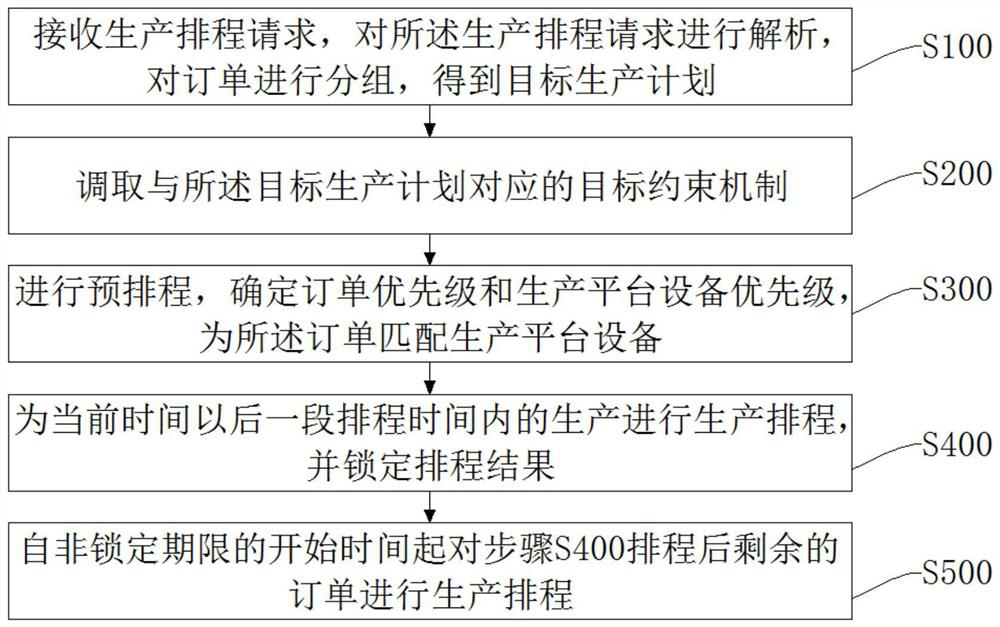

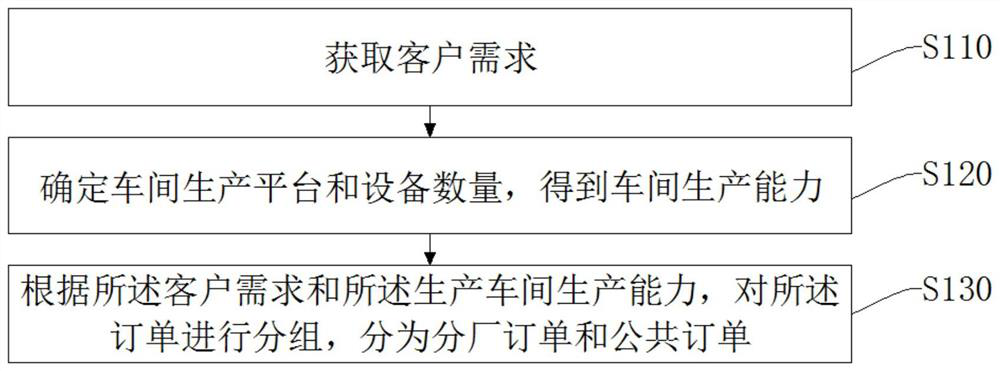

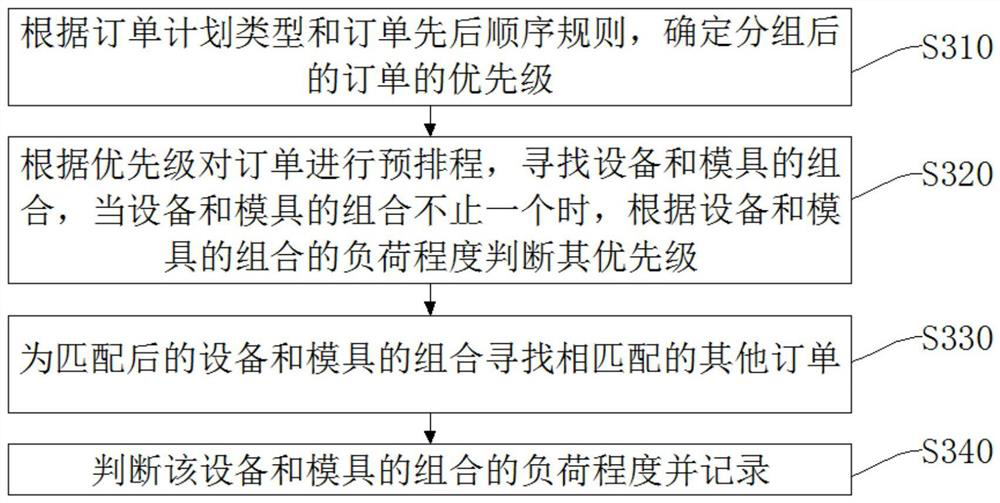

Profile extrusion production scheduling method, readable storage medium and device

PendingCN111882196AImprove production and operation efficiencyMeet production requirementsBuying/selling/leasing transactionsResourcesBusiness enterpriseProcess engineering

The invention discloses a profile extrusion production scheduling method, a readable storage medium and a device, and the method comprises the steps: S100) receiving a production scheduling request, carrying out the analysis of the production scheduling request, carrying out the grouping of orders, and obtaining a target production plan; S200) calling a target constraint mechanism corresponding tothe target production plan, wherein the target constraint mechanism comprises an order sequence rule and a resource load balancing principle; S300) performing pre-scheduling, determining an order priority and a production platform equipment priority, and matching production platform equipment for the order; S400) carrying out the production scheduling on production in a period of scheduling timeafter the current time, determining the order priority in the production scheduling, enabling the production scheduling to be matched with production platform equipment, and locking a scheduling result is locked. According to the method, the matching schedule meets the production requirements, the equipment utilization rate is obviously improved, the delivery time is shortened, and the enterpriseproduction and operation efficiency and the enterprise core competitiveness are improved.

Owner:安徽海螺信息技术工程有限责任公司

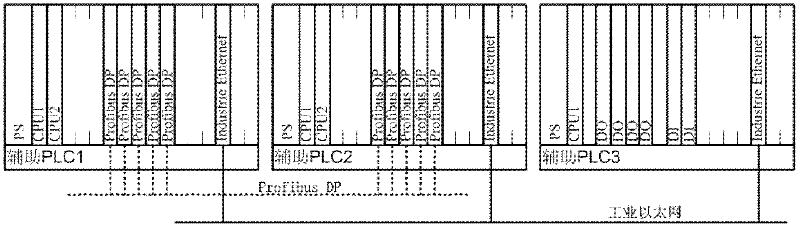

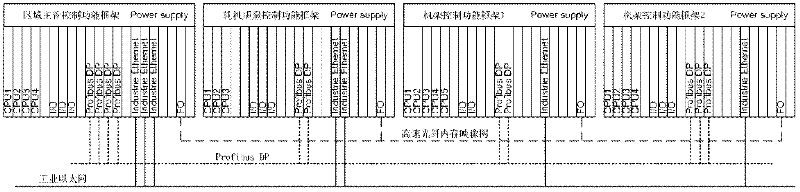

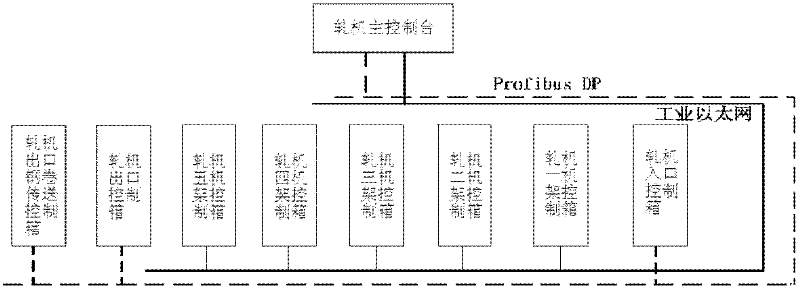

Basic automation control system for tandem cold rolling unit with five frames

InactiveCN102553937AImplement functional requirementsRealize automatic roll change functionRoll mill control devicesMetal rolling arrangementsLoop controlPerformance computing

The invention provides a basic automation control system for a tandem cold rolling unit with five frames, which comprises a PLC (programmable logic controller ) cluster, an HPC (high performance computing ) controller cluster, a field rolling mill control console, a real-time data acquisition system, a developing and debugging system and a system communication network. By the basic automation control system, automatic roll changing can be realized, roll changing time is shortened, production and maintenance can be carried out easily, and building investment and maintenance cost are reduced greatly. Since a high-speed closed-loop control function is realized, continuously high-speed production on sites is guaranteed. Since a high-speed data acquisition function is realized, the basic automation control system is capable of running safely and efficiently and meeting the requirements to millisecond-level monitoring data during fault analysis of the high-speed closed-loop control system of the tandem cold rolling unit. Since functional units are debugged and controlled to run successfully, structural uniformity of the basic automation control system after modification of programs is guaranteed. The high-speed optical fiber memory map net serves as the communication network, high-speed data exchange is realized by data caching among functional units of the HPC controller cluster, and accordingly high-speed data acquisition of the real-time data acquisition system is realized.

Owner:ANGANG STEEL CO LTD

Alkyl diphenyl ether sulfonate and preparation method thereof

InactiveCN103265460AAvoid corrosionAvoid it happening againTransportation and packagingSulfonic acids salts preparationDiphenyl etherSulfonate

The invention relates to a preparation method of a novel anionic surfactant alkyl diphenyl ether sulfonate. The preparation method specifically comprises the steps of: with diphenyl ether and alpha-olefin as main raw materials, in the presence of solid acid catalyst, preserving heat for 1-5 hours under the temperature condition of 80-180 DEG C to produce an intermediate product alkyl diphenyl ether, then adding an inert organic solvent and a sulfonating agent for sulfonating at 0-80 DEG C to produce alkyl diphenyl ether sulfonic acid, and adding an alkali neutralizing agent for neutralizing till the PH value is 6.5-7.5, so as to produce alkyl diphenyl ether sulfonate.

Owner:杨锌荣

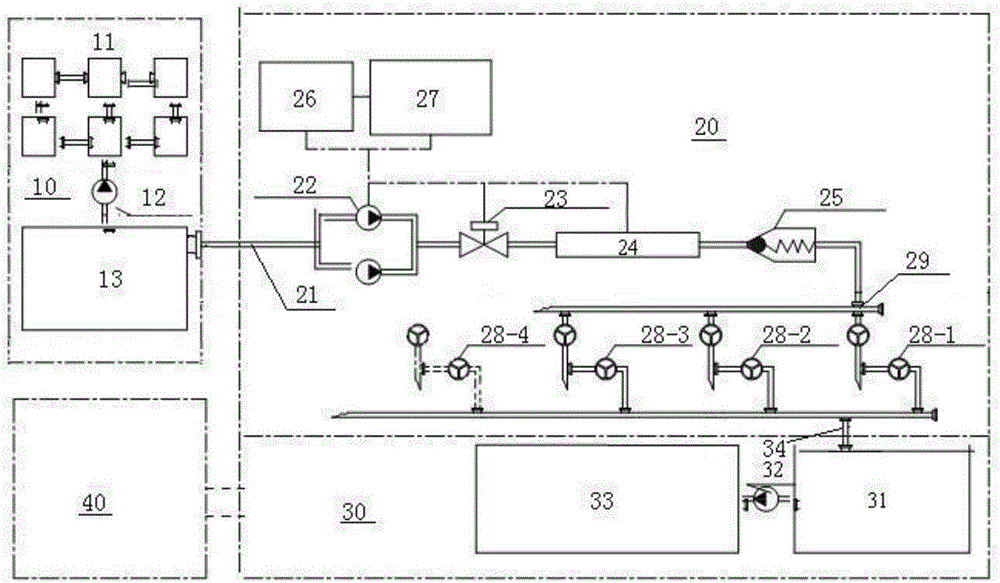

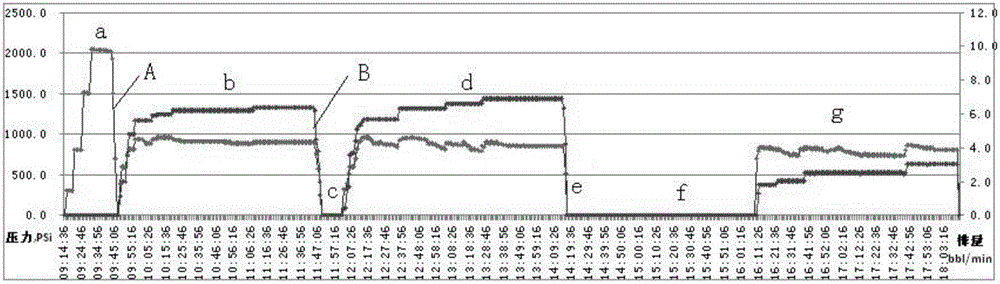

Industrial acidification system and method for offshore oil fields and oil-water wells

InactiveCN106050189AShorten working timeReduce the cost of relocation and the risk of relocation and hoistingCleaning apparatusWellheadChemistry

The invention discloses an industrial acidification system and method for offshore oil fields and oil-water wells. The industrial acidification system comprises an acid liquid preparation unit, an acidizing treatment unit and a residual liquid recycling unit which are adjacent to one another. The acid liquid preparation unit is connected with a wellhead of one oil-water well or wellheads of the multiple oil-water wells in the acidizing treatment unit through an acid injection pipeline. An acid injection adjusting subunit, a control subunit and a data analyzing subunit are arranged on the acid injection pipeline. Producing wells of the one or more oil-water wells are connected with the residual liquid recycling unit through a liquid return pipe. Flowback residual liquid is neutralized in the residual liquid recycling unit and returned. The industrial acidification method comprises the following steps that the industrial acidification system for the offshore oil fields and the oil-water wells is obtained by utilizing and connecting an offshore oil field production platform and anchoring arrangement; acidizing treatment preparation is conducted; industrial acidizing treatment is conducted on the oil-water wells through the industrial acidification system for the offshore oil fields and the oil-water wells; and acidification aftertreatment is conducted according to the types of the oil-water wells.

Owner:CHINA NAT OFFSHORE OIL CORP +2

Efficient cultivation method of intelligent nectarine facility

ActiveCN109526522ASmall footprintHigh light transmittanceCalcareous fertilisersAlkali orthophosphate fertiliserDrip irrigationControl diseases

The invention discloses an efficient cultivation method of an intelligent nectarine facility, and belongs to the technical field of crop planting. The efficient cultivation method comprises the following steps: selecting an orchard and a variety, constructing a greenhouse, performing field preparation, performing tree seedling planting and laying a drip irrigation zone, performing seedling periodmanagement, performing first-year fruiting period management, performing full bearing period management and the like, wherein the step of performing the seedling period management comprises the following substeps: pruning trees, performing water management, performing fertilizer management, pruning fruiting branches, shaping trunk branches, controlling diseases and pests, controlling weeds and scarifying soil in a field; the step of performing the first-year fruiting period management comprises the following substeps: preserving heat by mulching a film, performing water management, performingfertilizer management, performing temperature and humidity management, pollinating under the assistance of bees, thinning fruits and fixing the fruits, pruning in summer and autumn and adjusting the density, pruning in winter, controlling diseases, pests and weeds and scarifying soil in the field. By the efficient cultivation method, management of the orchard is relatively advanced, the adopted management measures are scientific and reasonable, the production and operation efficiency is relatively high, chemical substance residue in a product does not exceed the standard, the quality of fruitsis optimized, the fruits can be marketed in advance, and the economic benefits are relatively good; environmental protection and soil and water conservation are facilitated.

Owner:JIANGSU COASTAL AREA AGRI SCI RES INST

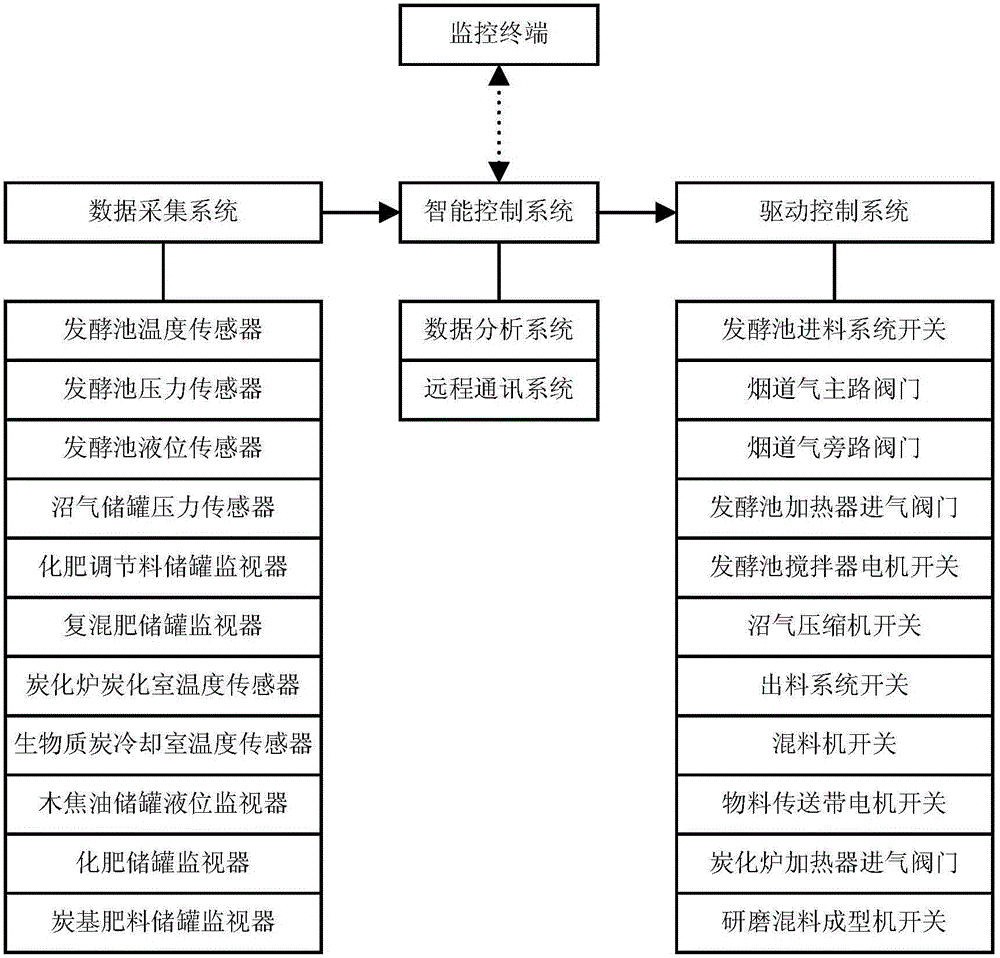

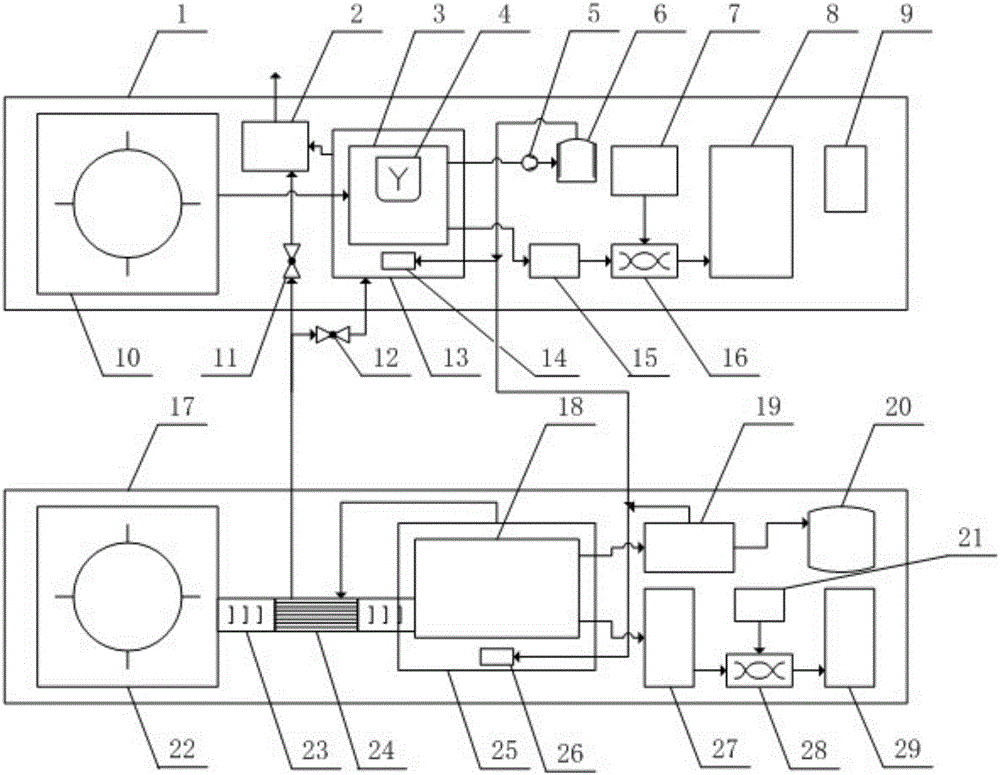

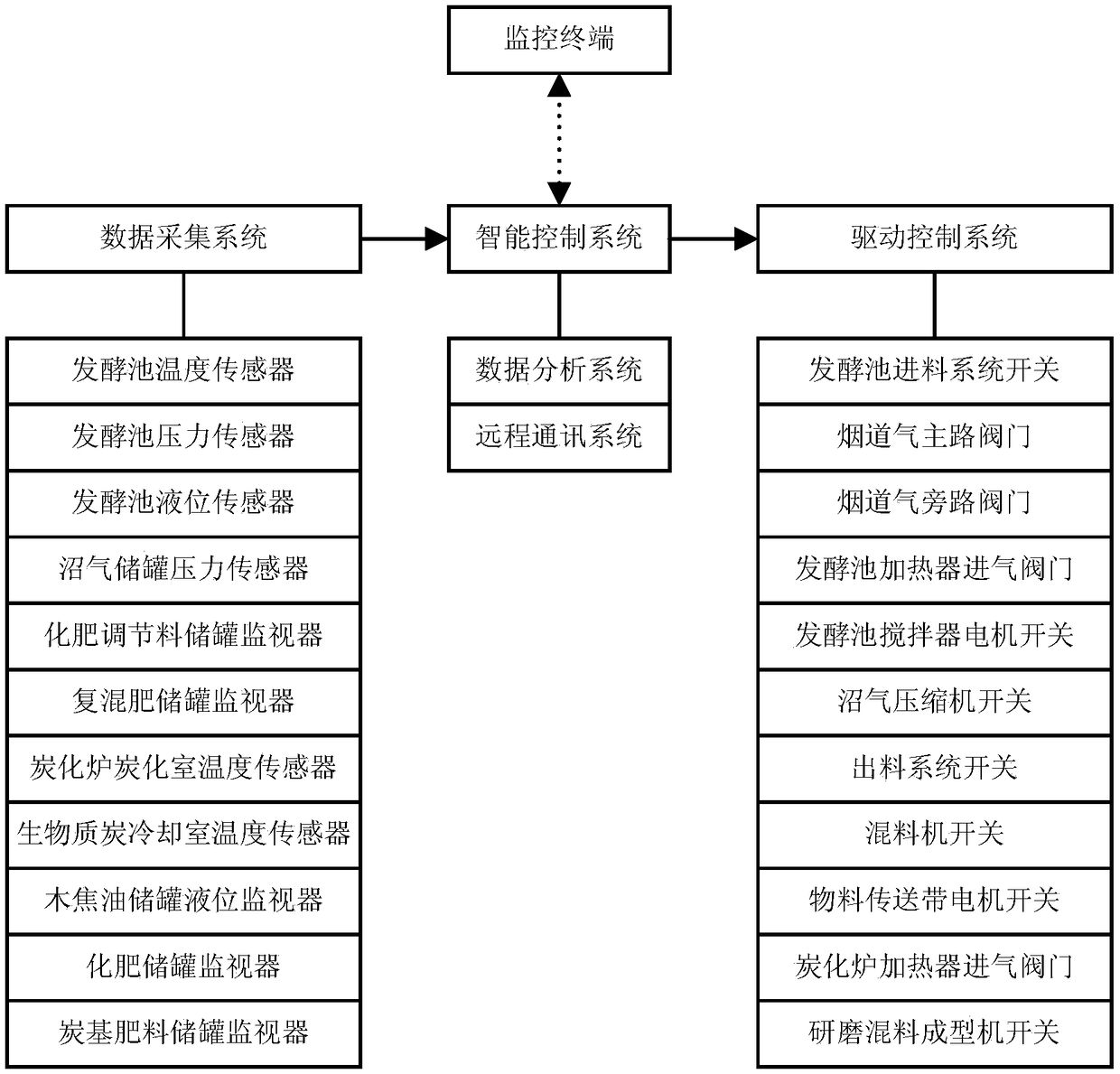

Control system of distributive agriculture and forestry biomass fermentation-thermal decoupling treatment device

ActiveCN106647657ARealize collaborative controlTo achieve the purpose of centralized managementBioreactor/fermenter combinationsBiological substance pretreatmentsControl signalData acquisition

The invention discloses a control system of a distributive agriculture and forestry biomass fermentation-thermal decoupling treatment device. The control system includes a data collection system connected with an intelligent control system and capable of acquiring operation condition data from the treatment device and sending the data to the intelligent control system; the intelligent control system connected with a drive control system and capable of analyzing the received operation condition data sent by the data collection system and sending control signals to the drive control system according to an analysis result; the drive control system electrically connected with drive devices of the treatment device and capable of controlling operation of the drive devices; a monitoring terminal connected with the intelligent control system and capable of displaying the operation condition data analyzing result of the intelligent control system and the control signals sent to the drive control system.

Owner:中国诚通生态有限公司

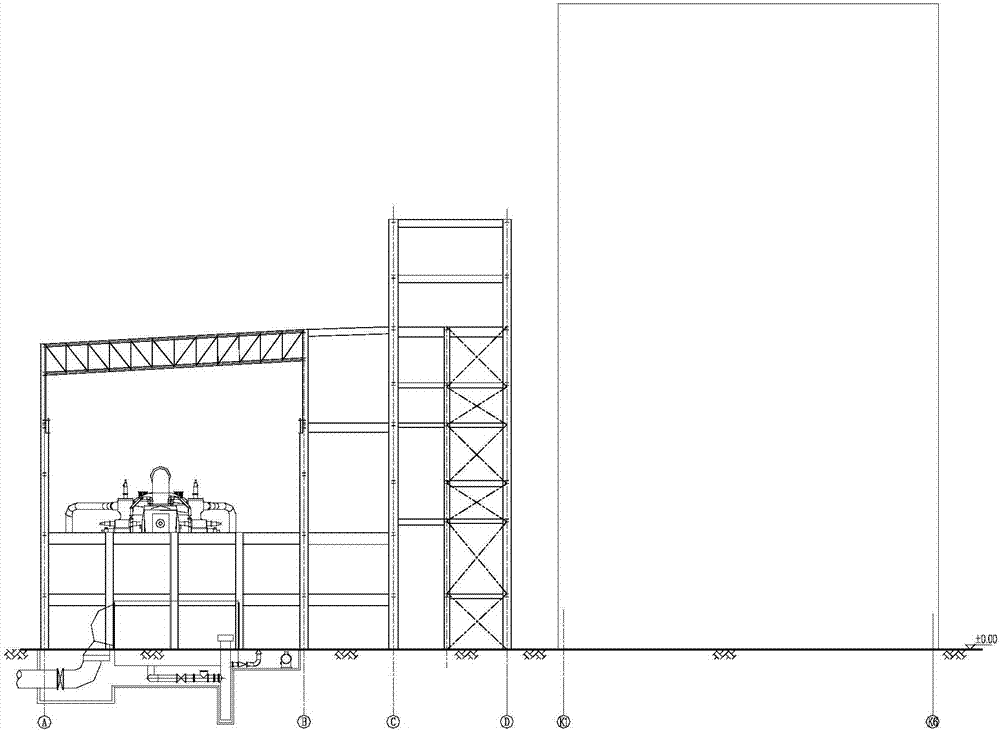

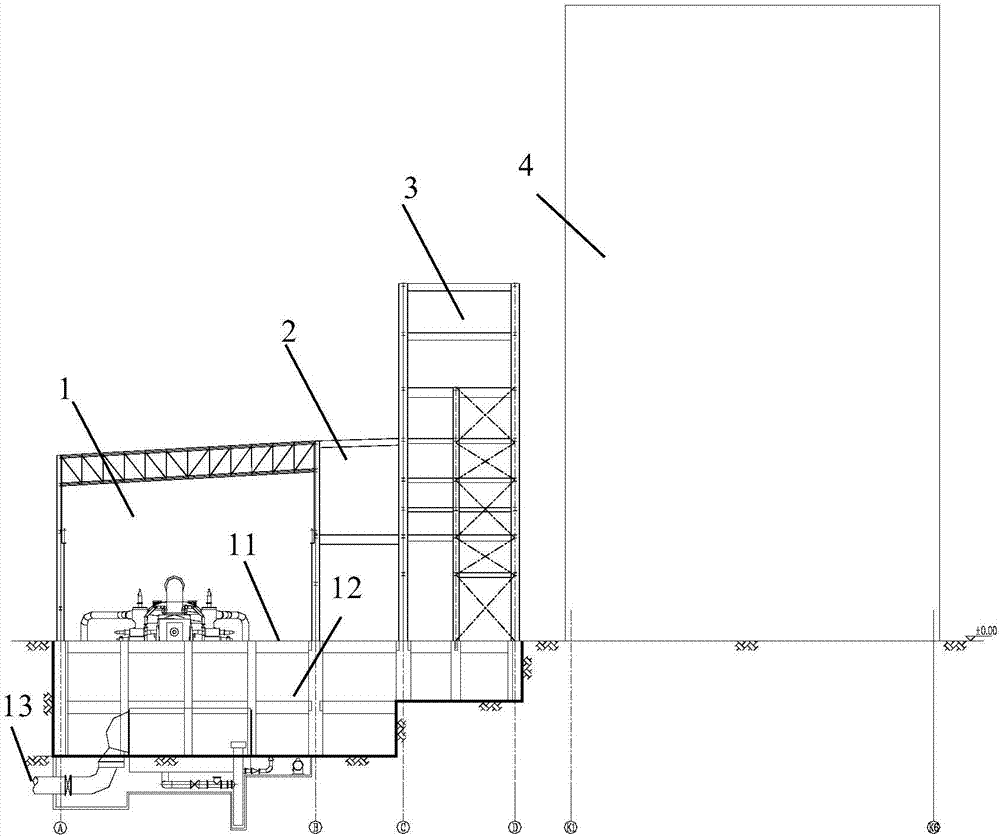

Main power house allocation structure of high-capacity thermal power station

ActiveCN107060395AReduce production and operation costsImprove production and operation efficiencyIndustrial buildingsPower stationProcess equipment

The invention relates to a main power house allocation structure of a high-capacity thermal power station. The main power house allocation structure of the high-capacity thermal power station comprises a steam engine room, a deaerator room, a bunker room and a boiler room. The ground level of the boiler room is higher than that of the bunker room, the ground level of the bunker room is higher than that of the steam engine room and the deaerator room, and the ground level of the steam engine room is the same as that of the deaerator room. The main power house allocation structure has the beneficial effects that 1, under the premise of remaining the schemes of the whole station ground level layout and relative technology systems unchanged, the main power house structure adopts negative excavation layout to decrease the layout ground level of a condenser so as to decrease the height difference between the condenser and a water taking port, so that the limited technical standard requirements for lifting of relative technology equipment are met; 2, by adopting the stepped negative excavation layout on the main power house structure, under the premise of combining the technology layout, the height difference between the condenser and the water taking port can be decreased maximally; and 3, the main power house allocation structure has high adaptability and practicability.

Owner:CHINA POWER ENG CONSULTING GRP CORP EAST CHINA ELECTRIC POWER DESIGN INST

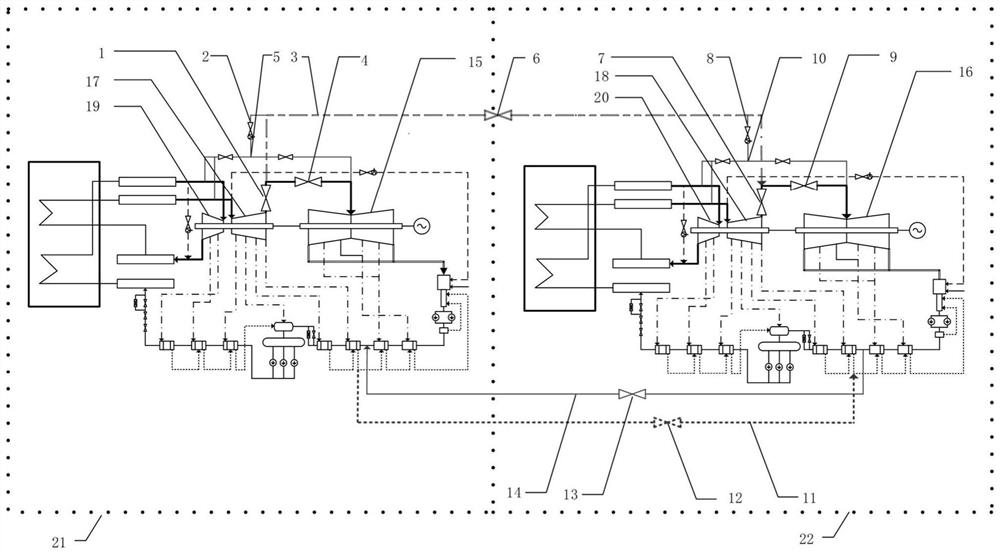

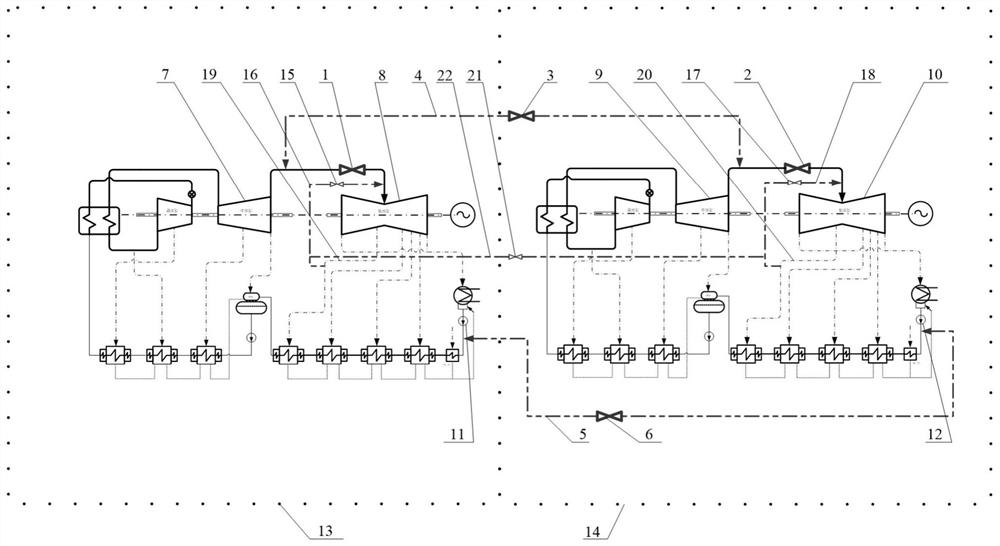

Thermodynamic system capable of achieving one-furnace-two-machine ultra-low load operation and switching method of one-furnace-two-machine ultra-low load operation

PendingCN112879110AReduce idle rateIncrease flexibilityLighting and heating apparatusMachines/enginesExhaust valveLow load

The invention discloses a thermodynamic system capable of achieving one-furnace-two-machine ultra-low load operation and a switching method of one-furnace-two-machine ultra-low load operation. The system comprises two unit system units. The first unit system unit comprises a first intermediate-pressure cylinder exhaust valve, a first temperature and pressure reducing valve, a first intermediate-pressure cylinder exhaust adjusting valve, a first cylinder cooling steam pipeline and the like; the second unit system unit comprises a second intermediate-pressure cylinder exhaust valve, a second temperature and pressure reducing valve, a second intermediate-pressure cylinder exhaust adjusting valve, a second low-pressure cylinder cooling steam pipeline and the like; and an outlet of the first intermediate-pressure cylinder exhaust valve is connected with an outlet of the second intermediate-pressure cylinder exhaust valve through an intermediate-pressure cylinder exhaust connecting pipe, and an intermediate-pressure cylinder exhaust connecting pipe adjusting valve is installed on the intermediate-pressure cylinder exhaust connecting pipe. According to the method, flexible switching between the two unit system units is achieved. Technical transformation on a boiler side is not needed, the acting force difference characteristic of a high-pressure cylinder, a medium-pressure cylinder and a low-pressure cylinder is fully utilized, operation is flexible, the function is practical, and meanwhile certain accident resisting capacity is achieved.

Owner:XIAN THERMAL POWER RES INST CO LTD

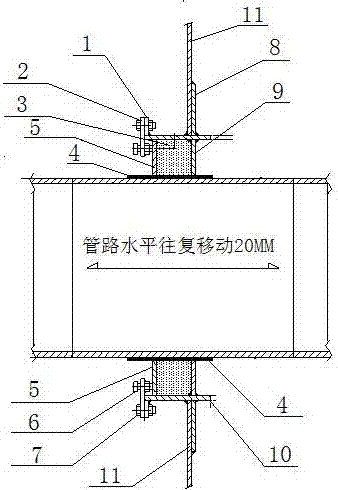

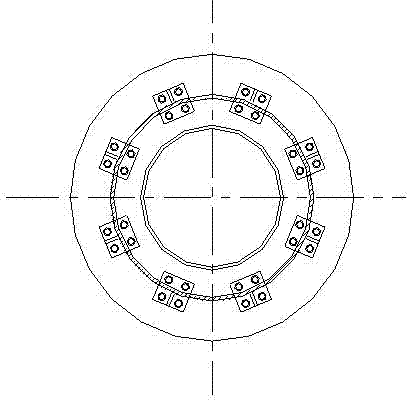

Reciprocating type insulating and fireproof cabin penetrating structure of floating production, storage and offloading (FPSO) device ship

InactiveCN106870829AMeet the connection problemMeet A60 fire insulation requirementsPipesMarine engineeringBuilding construction

The invention discloses a floating production, storage and unloading device ship reciprocating insulating and fire-proof penetration structure, which comprises a support plate (1), a positioning plate (2), a pressure plate (5), a fixing bolt (7), and a first web (8), the second web (9) and the cylinder (10), the support plate (1) is fixed on one side of the cylinder (10), the positioning plate (2) is fixed on the support plate ( 1), the first web (8), the second web (9) and the cylinder (10) are welded and fixed on the bulkhead (11), the pressure plate (5), the first web (8), the second The two webs (9) and the cylinder (10) together form a stuffing box chamber. The fire-proof cabin penetration structure of the present invention can meet the outlet pipeline connection problem caused by pump vibration after use, and can meet the fire-proof insulation requirements of cabin A60. It is simple and reliable to install, easy to maintain, and convenient to replace the fire-proof insulation layer, so as to reduce construction difficulty and improve safety. Support, increase production and operation efficiency, and reduce costs.

Owner:COSCO DALIAN SHIPYARD

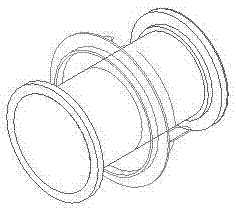

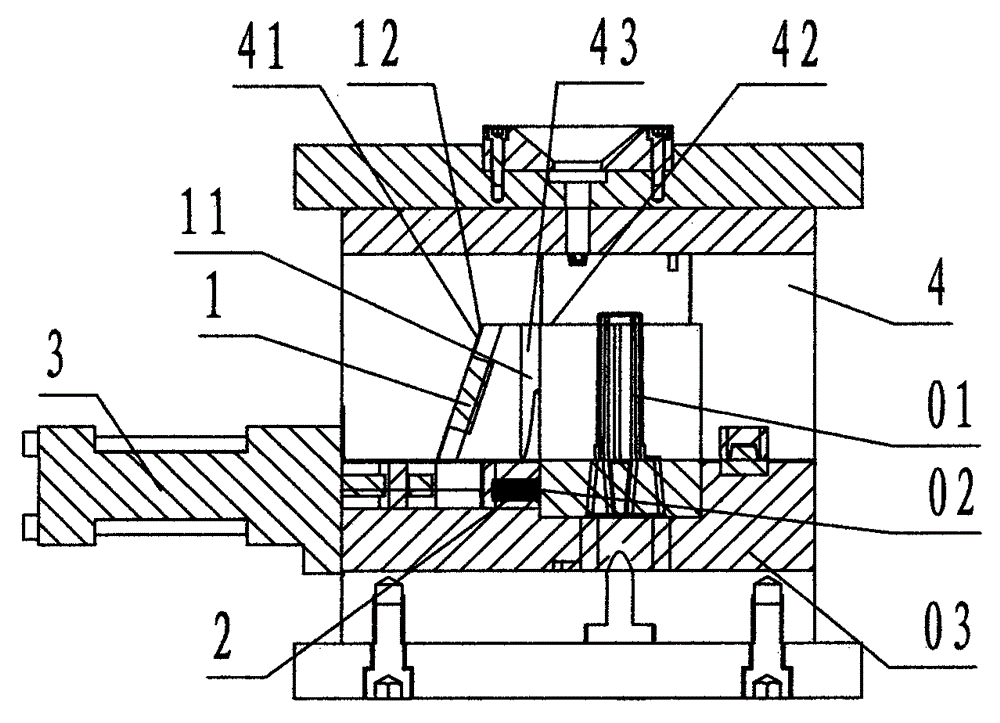

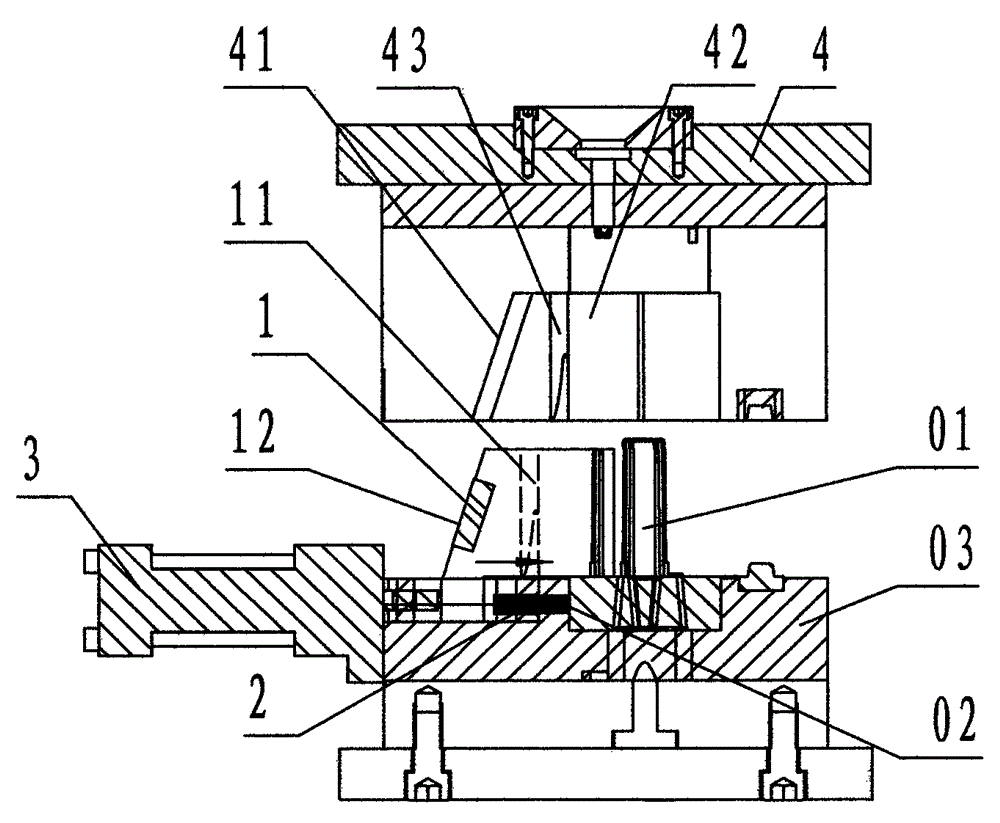

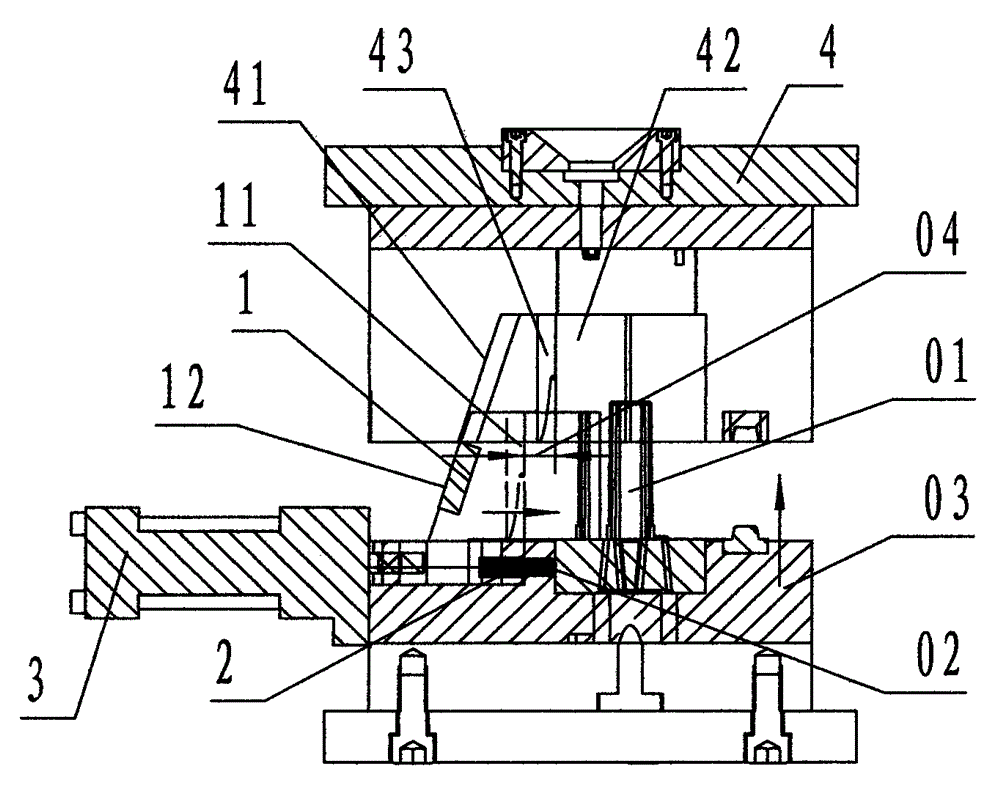

Device for preventing longitudinal scratches of sliding block and cavity convex core of injection mold

InactiveCN104015314AAvoid relative force scratchingExtended service lifeEngineeringMechanical engineering

The invention discloses a device for preventing longitudinal scratches of a sliding block and a cavity convex core of an injection mold. The device comprises a transverse sliding block (1), a spring (2), an oil cylinder (3) and a fixed mold (4). According to the technical scheme, the spring is arranged between the transverse sliding block and the positioning surface of a mold core; a driven inclined surface is formed on the left side surface of the transverse sliding block; touch space is reserved at the connecting position between a piston rod of the oil cylinder and the transverse sliding block; a tightening inclined surface is formed at the fixed mold; when the injection mold is reset, the transverse sliding block is driven to be close to the mold core rightwards by the oil cylinder until the spring props against the positioning surface of the mold core, and the oil cylinder stops; at the moment, the overlooking projection of the space between a block sub-wall and a cavity sub-wall is equal to the touch space; then, a movable mold and the fixed mold are closed; the tightening inclined surface of the fixed mold pushes the transverse sliding block to move rightwards; the transverse sliding block moves rightwards for the touch space; the block sub-wall and the cavity sub-wall of the mold cavity which is reset downward are contacted and closed synchronously, so that the injection mold is reset by the transverse sliding block which is driven by the oil cylinder; the defect that the block sub-wall and the cavity sub-wall scratch each other when the injection mold is reset is avoided; the aims of improving the production efficiency and reducing the comprehensive cost are fulfilled.

Owner:宁海县易利模具塑料厂

Inter-station open-circuit starting and closed-circuit switching control system and method for pipeline coal conveying system

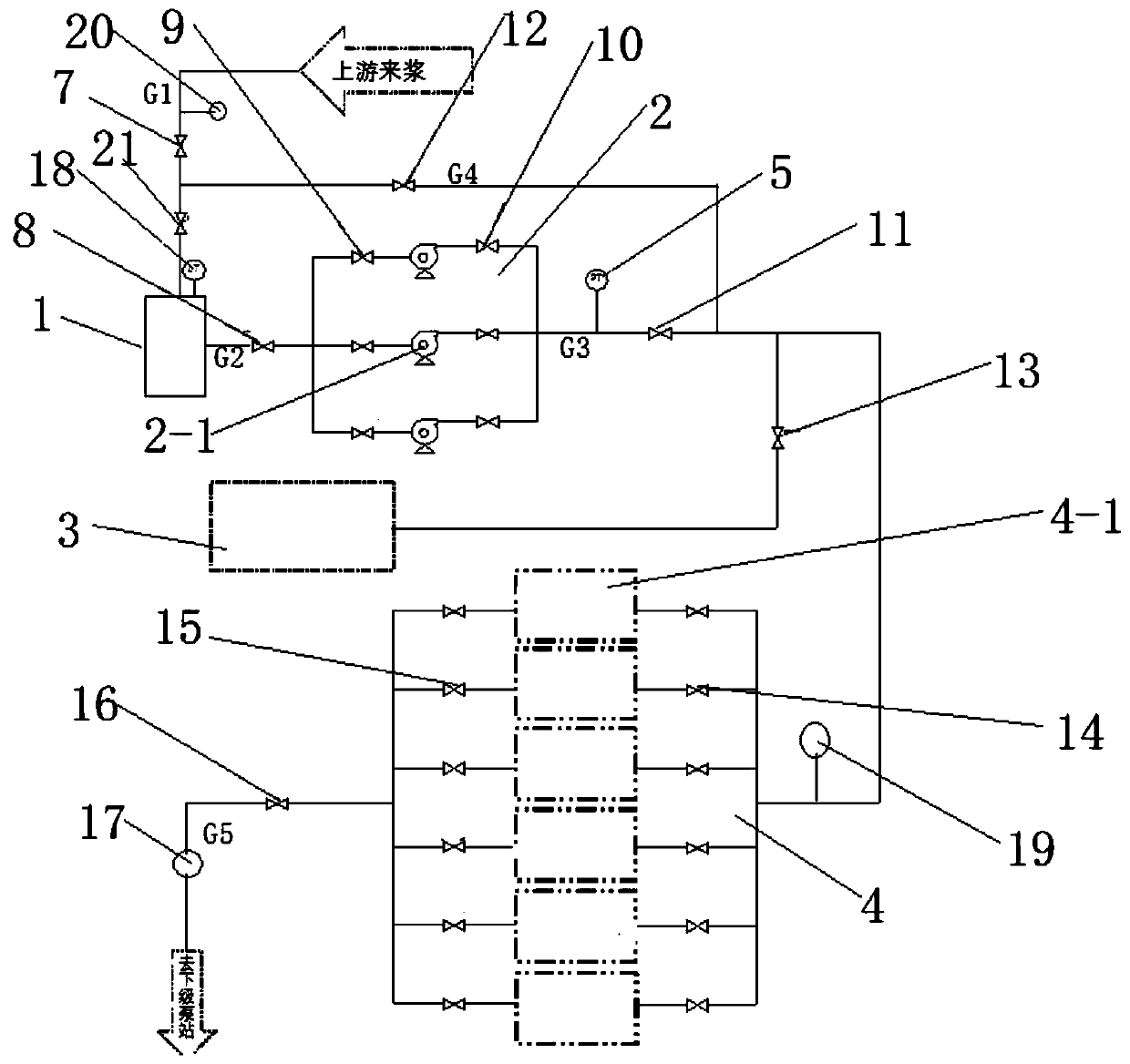

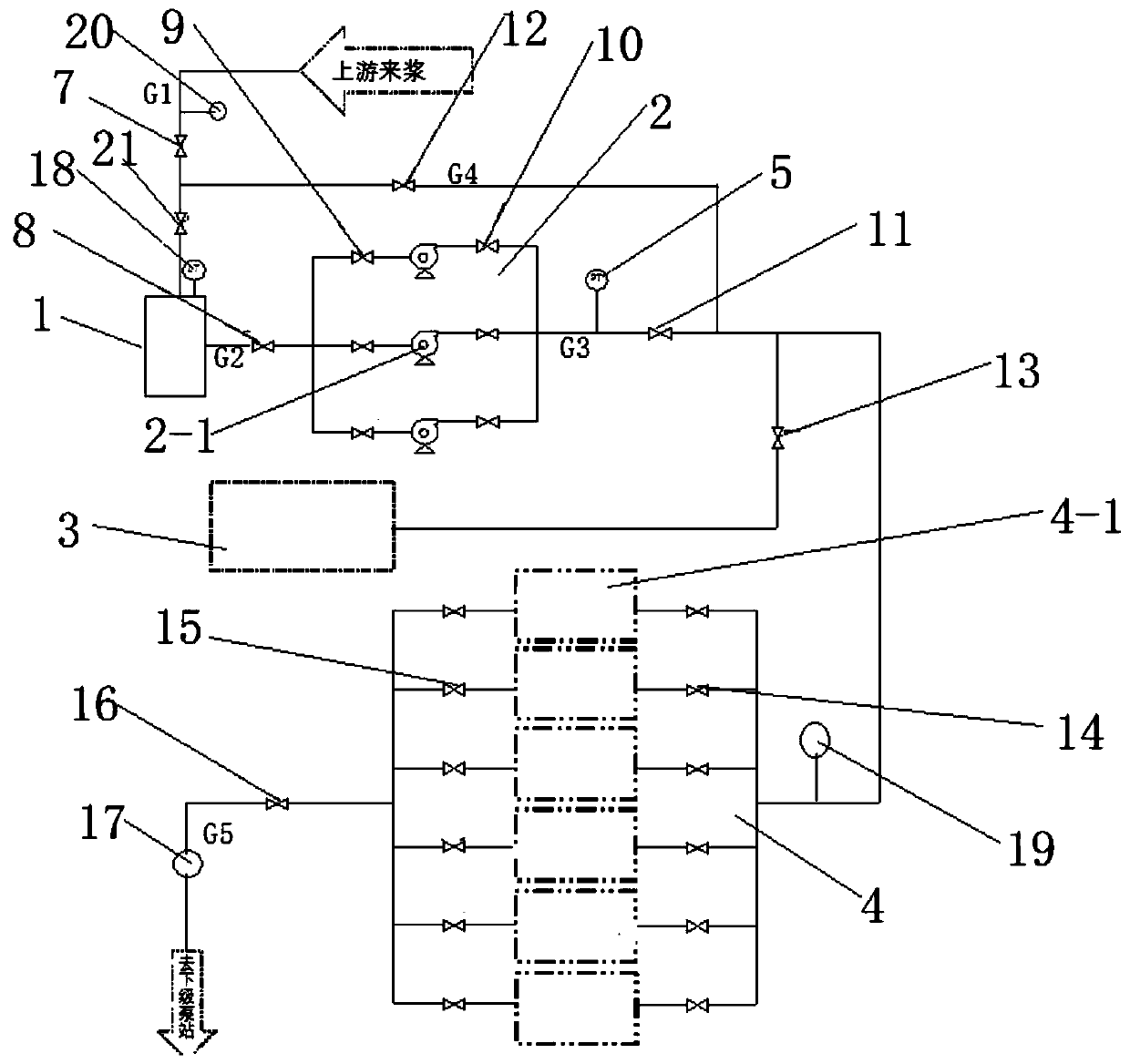

PendingCN111137686ANo manual operation requiredReduce labor costsBulk conveyorsDiaphragm pumpControl system

The invention discloses an inter-station open-circuit starting and closed-circuit switching control system for a pipeline coal conveying system. The inter-station open-circuit starting and closed-circuit switching control system comprises a buffer tank, wherein an inlet valve a is arranged at an inlet of the buffer tank, the buffer tank is sequentially connected with a feeding pump system, a diaphragm pump pressurization system and a subordinate pump station through a pipeline G2, a pipeline G3 and a pipeline G5, and the feeding pump system is connected with a water replacement system throughthe pipeline G3; the pipeline G3 is further connected with the inlet of the buffer tank through a pipeline G4, and each of the pipeline G2, the pipeline G3, the pipeline G4, the pipeline G5 is provided with a knife gate valve, a main pipe valve a, a main pipe valve b and a main pipe valve d correspondingly; an inlet valve b and an outlet valve b are arranged at an inlet and an outlet of the feeding pump system respectively; a main pipe valve c is arranged at the position, located at an outlet of the water replacement system, of the pipeline G3, and an inlet valve c and an outlet valve c are arranged at an inlet and an outlet of the diaphragm pump pressurization system respectively; and a liquid level meter is arranged on the buffer tank, and a pressure transmitter is arranged on the pipeline G3. According to the system, the problems of high labor cost and low production efficiency in the prior art can be solved.

Owner:SHAANXI SHENWEI COAL PIPELINE TRANSPORTATION OF GOD

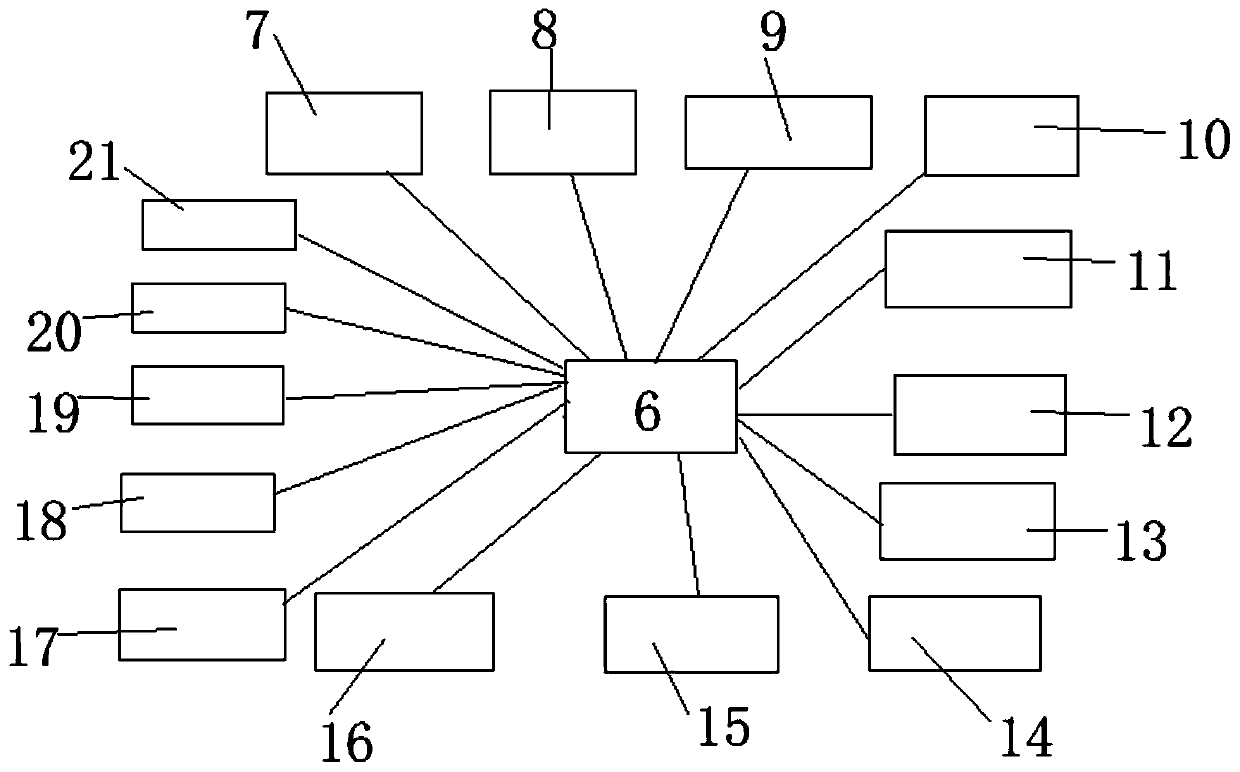

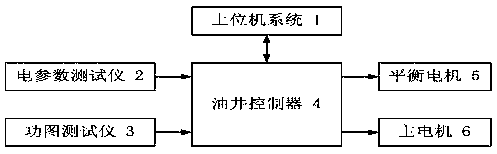

Oil well energy-saving production control system

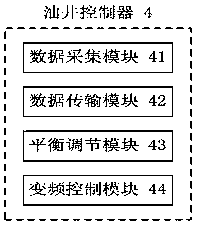

InactiveCN109826615ARealize energy-saving productionTimely adjustment of production parametersSurveyElectric machineryOil well control

The invention provides an oil well energy-saving production control system which comprises a host computer system, an electrical parameter tester, an indicator diagram tester and an oil well controller. The electrical parameter tester is connected to the oil well controller and connected with a main motor to detect the voltage and current data of the main motor in running and transmit the voltageand current data to the oil well controller, the indicator diagram tester is connected to the oil well controller to detect the polished rod load and movement position of a pumping unit and transmit the polished rod load and the movement position to the oil well controller, the oil well controller transmits the received detection data to the host computer system, the host computer system analyzes,diagnoses and optimizes the oil well working condition according to the received detection data and transmits the optimization result to the oil well controller, and the oil well controller controlsthe work of the main motor and a balancing motor according to the optimization result. The oil well energy-saving production control system realizes oil well supply and discharge coordinated production, reduces the energy consumption of oil well production, realizes intelligent control over oil well production and improves the automation degree of oilfield production.

Owner:CHINA PETROLEUM & CHEM CORP +1

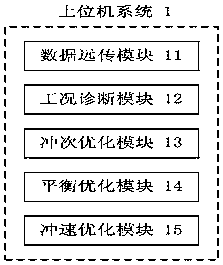

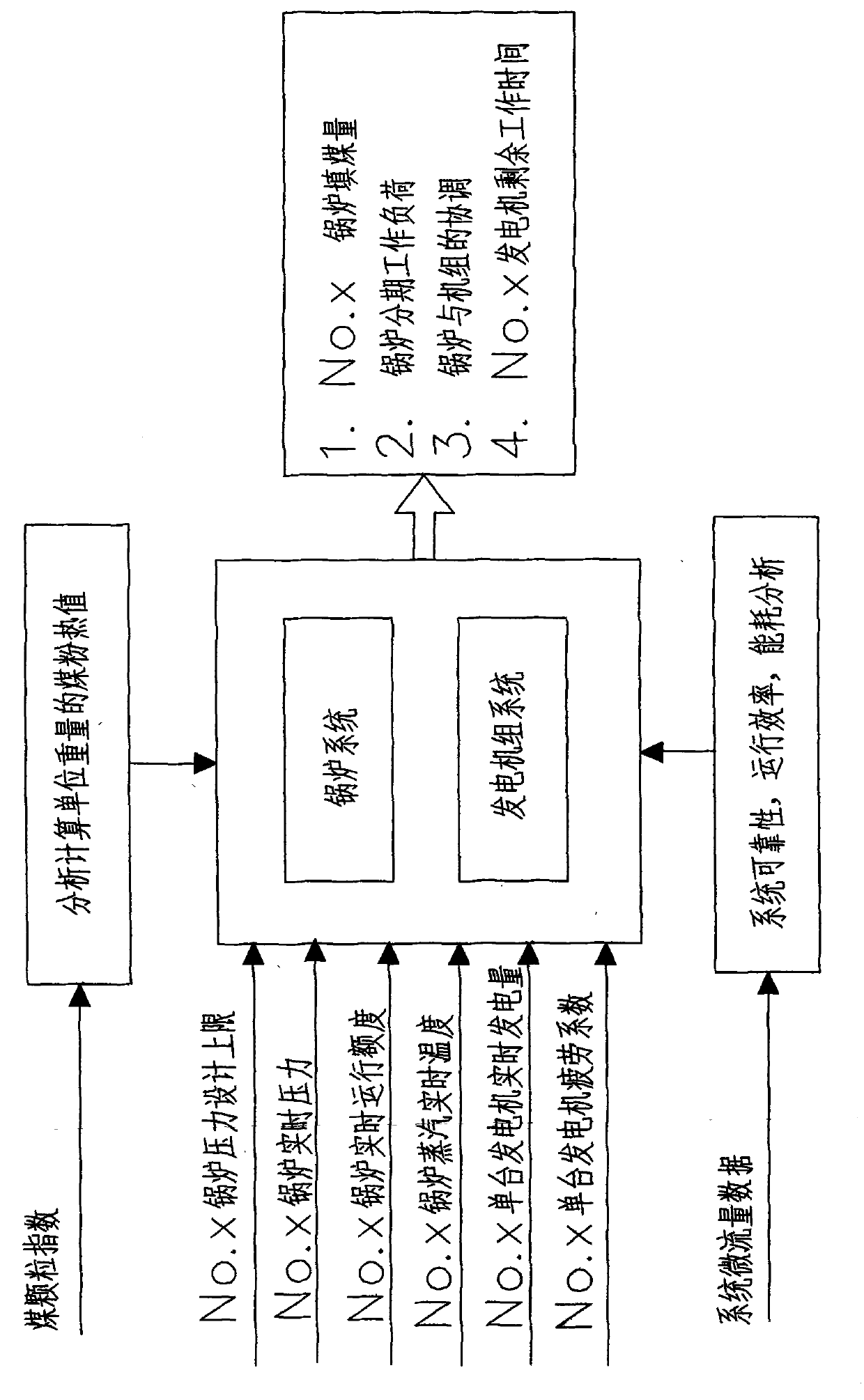

Dispatching method and dispatching system based on load online forecasting of thermoelectric power system

InactiveCN101619850BImprove production and operation efficiencyState switching is smoothEnergy industryBoiler controlData acquisitionDecision taking

The invention discloses a dispatching method and a dispatching system based on load online forecasting of a thermoelectric power system. The dispatching method has the main objects of a boiler and a vapor generating set which are the core equipment of a thermoelectric power generation system. The dispatching process comprises the following steps: a. acquiring data; b. creating a real-time database and a historical database; c. analyzing data and making a dispatching decision, creating a decision dispatching knowledge base to obtain a corresponding operation decision in the current optimal state to be reached and in the recent optimal dispatching state, comparing the expectation effect of the dispatching decision with an actual effect, taking the result as the condition of load forecasting, and finally obtaining the optimal dispatching decision through human-computer interaction. The dispatching system comprises a field data acquiring terminal, a field production layer DCS, a management layer ERP, a center data server and a manufacture execution and management layer MES. The invention overcomes the defects existing in the prior art; and based on the production capacity and the distribution forecast of a thermoelectric plant, the dispatching method and the dispatching system facilitate improving the production operation efficiency of enterprises, lowering the source consumption and reducing the pollution discharge.

Owner:HANGZHOU PANGU AUTOMATION SYST

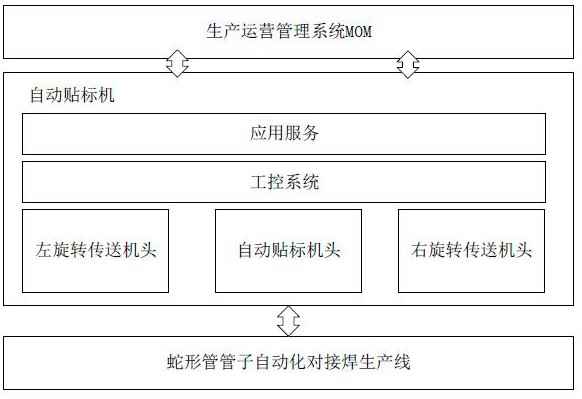

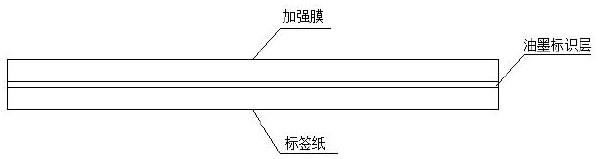

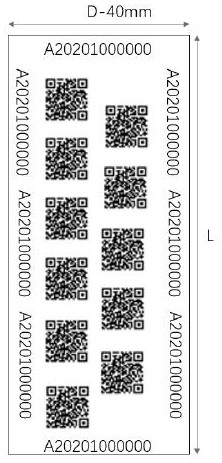

Coiled pipe weld joint identification tracing system

PendingCN112561017AReduce breakage rateWaterproofCommerceRecord carriers used with machinesInformatizationButt welding

The invention discloses a coiled pipe weld joint identification tracing system which comprises the components of a coiled pipe automatic butt welding production subsystem which is used for realizing automatic butt welding of short pipes in a product BOM; an automatic labeling machine which is used for receiving an automatic labeling instruction of the MOM subsystem and carrying out automatic labeling on the pipe ring identification bar code; and an MOM subsystem which is used for realizing informatization and digitalization management and control of a workshop manufacturing process, recordingand storing weld joint identity information and weld joint associated information, sending an automatic labeling instruction to an automatic labeling machine, and identifying the weld joint identity information and the weld joint associated information through a pipe ring identification bar code; wherein the weld joint associated information at least comprises information, welding parameters, welder information and quality inspection information. By arranging the label with the two-dimensional code, the storage rate is high, the reading rate is high, full-life-cycle tracing and knowledge management of the serpentine pipe weld joint can be achieved, the workload of manual input is reduced, data errors and data loss are reduced, and the production and operation efficiency is improved.

Owner:东方电气集团科学技术研究院有限公司

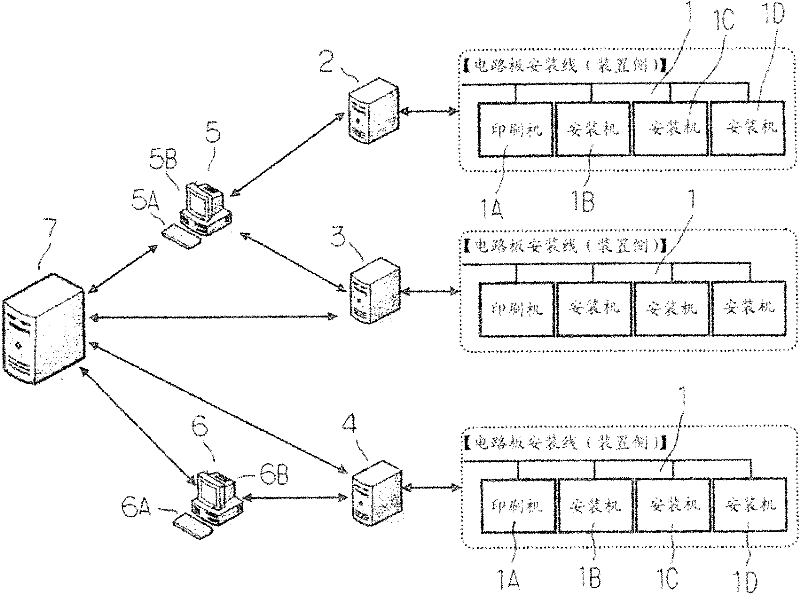

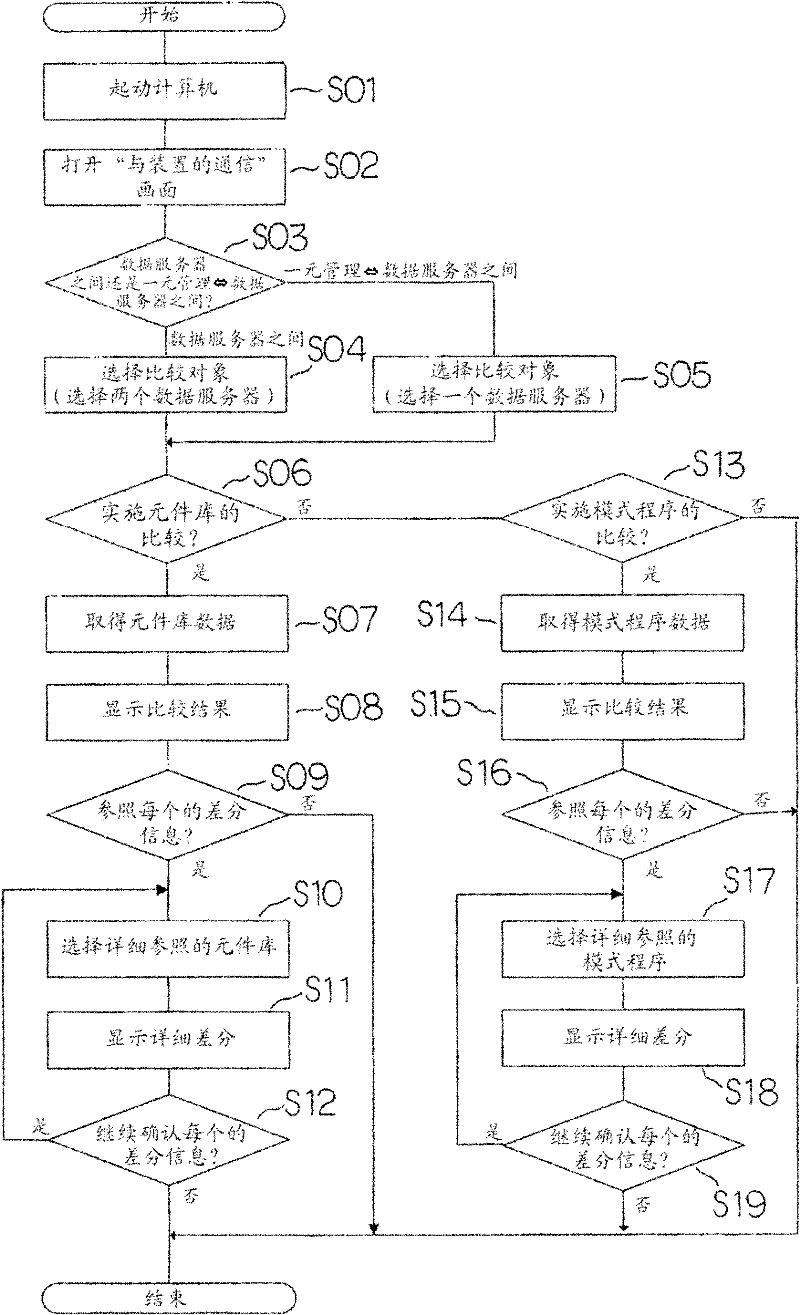

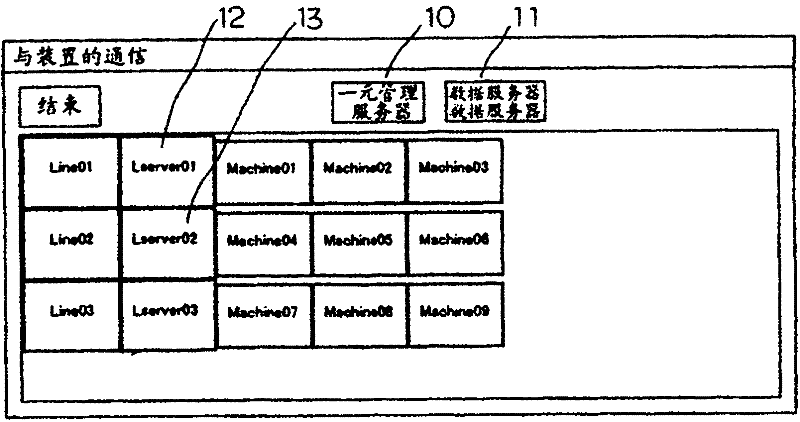

Management system of electronic component installation line

InactiveCN102194052AImprove production and operation efficiencyRealize sharingData processing applicationsTotal factory controlManagement systemDisplay device

Owner:HITACHI HIGH TECH INSTR CO LTD

A method for producing zinc powder by electrolytic leaching of alloy zinc ash slurry

InactiveCN107419111BImprove leaching rateImprove recycling efficiencyProcess efficiency improvementElectrolysisHydrometallurgy

The invention relates to the technical field of hydrometallurgy, in particular to a method for producing zinc powder adopting electrolytic leaching of zinc alloy ash pulp. Zinc alloy ash is used as raw materials; after 90%-95% chloride ions are eluted with sodium carbonate hot water solutions, alkaline pulp is prepared with sodium hydroxide solutions; then, the alkaline pulp is subjected to electrolytic leaching, and the electrolytic leaching adopts integrated continuous production, so that the production process is short, and impurities are continuously electrolyzed and settled in the continuous production process to enter anode sludge, while zinc is electrolyzed from a cathode plate, so that the zinc leaching efficiency is improved greatly and reaches 99% or above; the quality of the zinc powder obtained in an electrolytic bath for secondary electrolysis above is high, and the zinc recovery efficiency is improved; and pollution and the cost are reduced.

Owner:贵州省兴安环保科技有限公司

Coupling peak regulation system based on intermediate exhaust and low-pressure steam extraction cooling and operation method thereof

PendingCN113153469AImprove the ability of deep peak shavingIncrease flexibilityCombination enginesSteam useIsolation valveUnit system

The invention discloses a coupling peak regulation system based on intermediate exhaust and low-pressure steam extraction cooling and an operation method thereof. The coupling peak regulation system comprises a first conventional unit system generator set (13) and a second conventional unit system generator set (14). The first conventional unit system generator set (13) comprises a first medium-pressure cylinder (7), a first low-pressure cylinder (8), a first condensate pump (11), a first low-pressure cylinder steam extraction pipe (19) and a first medium-pressure cylinder steam exhaust control and isolation valve group (1); and the second conventional unit system generator set (14) comprises a second medium-pressure cylinder (9), a second low-pressure cylinder (10), a second condensate pump (12), a second low-pressure cylinder steam extraction pipe (20) and a second medium-pressure cylinder steam exhaust control and isolation valve group (2). According to the operation method, flexible switching between the first conventional unit system generator set (13) and the second conventional unit system generator set (14) is achieved. The deep peak regulation capacity of the unit can be improved without technical transformation on the boiler side, and the operation flexibility of the unit is improved.

Owner:XIAN THERMAL POWER RES INST CO LTD

Zinc-induced crack-resistant steel sheet and manufacturing method thereof

ActiveCN103320693BExcellent resistance to zinc crackingImprove mechanical propertiesFurnace typesMetallic material coating processesCrack resistanceCrazing

A zinc-induced-crack resistant steel plate and a manufacturing method therefor are disclosed. A low alloy steel with low C-ultralow Si-high Mn-low Als-(Ti+Nb) micro alloying treatment is taken as a basis, and the Als content in the steel is appropriately reduced; the content of the steel is controlled for Mn / C≥15, [(%Mn)+0.75(%Mo)]×(%C)≤0.16, Nb / Ti≥1.8 and Ti / N between 1.50-3.40, CEZ≤0.44% and B≤2ppm, Ni / Cu≥1.50; the Ca treatment is performed and the Ca / S ratio is controlled to be 1.0-3.0, and (%Ca)×(%S)0.28≤1.0×10-3. The TMCP process is optimized, so that the micro-structure of the finished steel plate is ferrite + fine bainite colonies dispersedly distributed, the average grain size is less than or equal to 10 μm, and excellent mechanical properties, good weldability and zinc-induced-crack resistance property are obtained. The steel plate is especially suitable for spraying zinc coating corrosion resistant steel plate for marine structures, spraying zinc corrosion resistant steel plate for extra-high voltage power transmission structures, spraying zinc coating corrosion resistant steel plate for coast bridge structures, and the like.

Owner:BAOSHAN IRON & STEEL CO LTD

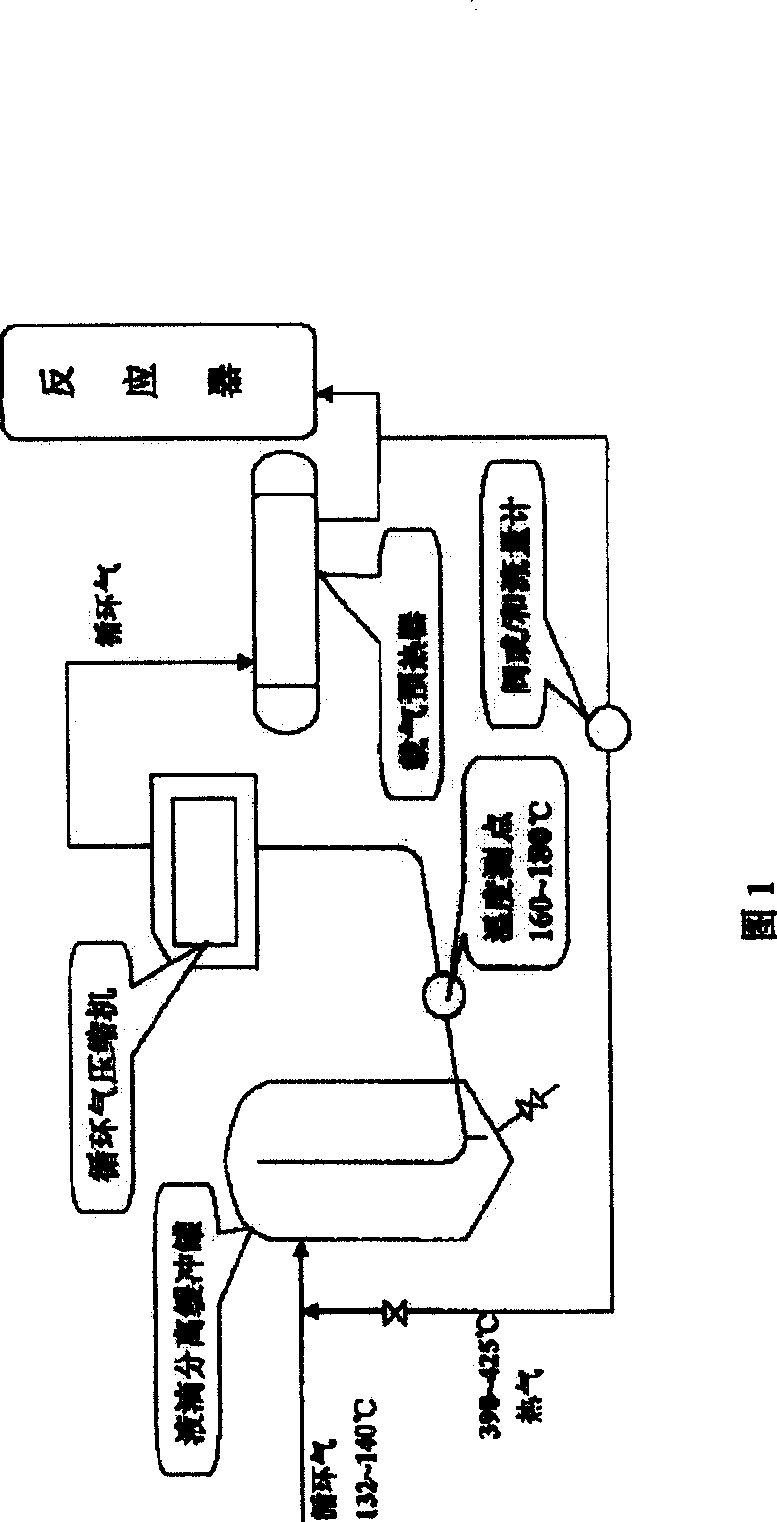

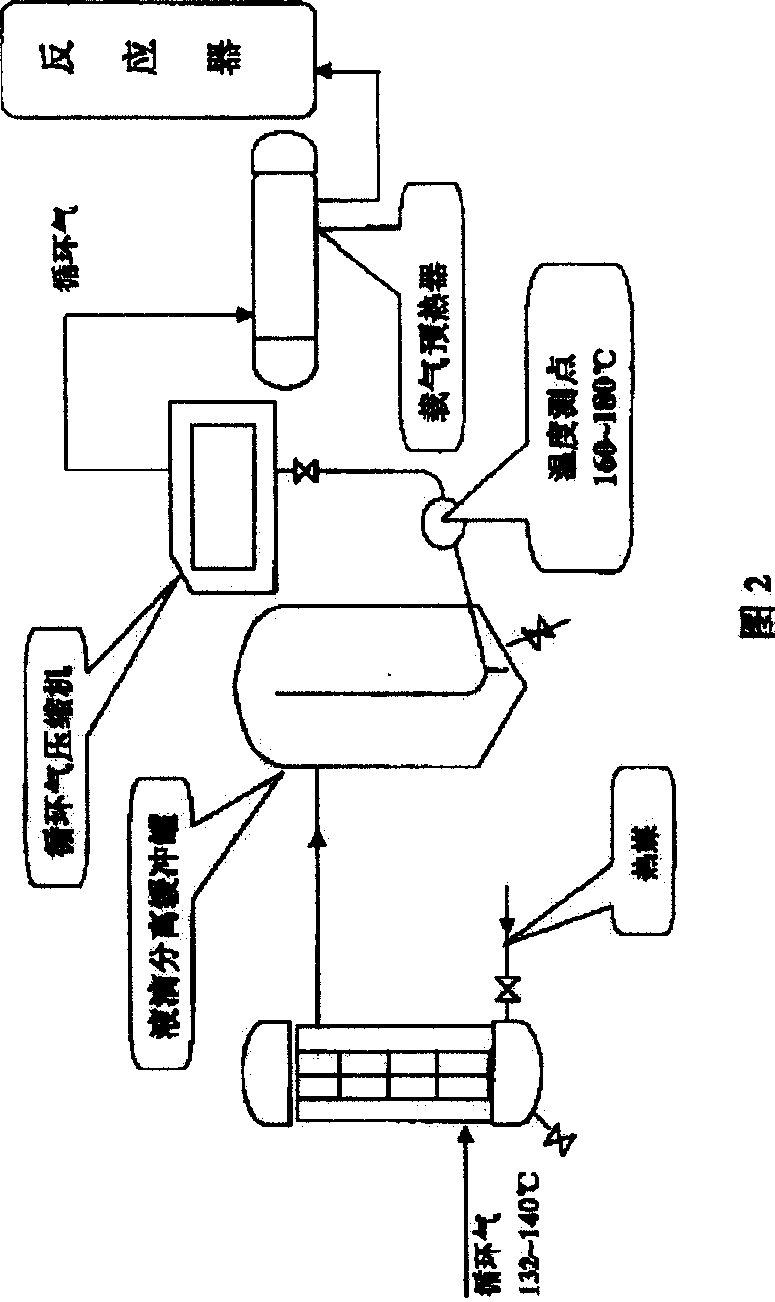

Method for relieving atmosphere melamine circulated gas compressor runner impellor wall block-up

The method of reducing plugging in circular gas compressor flow channel and impeller wall for normal pressure melamine producing process is to control the temperature of gas in the entrance of circular gas compressor at 160-180 deg.c. The said method can reduce plugging in circular gas compressor flow channel and impeller wall obviously, and ensure the stable running of the circular gas compressor in great intake amount, high linear speed and long stable production period.

Owner:中国石油乌鲁木齐石油化工有限公司

Distributed agricultural and forestry biomass fermentation-thermolysis coupling processing equipment control system

ActiveCN106647657BRealize collaborative controlTo achieve the purpose of centralized managementBioreactor/fermenter combinationsBiological substance pretreatmentsControl signalData acquisition

The invention discloses a control system of a distributive agriculture and forestry biomass fermentation-thermal decoupling treatment device. The control system includes a data collection system connected with an intelligent control system and capable of acquiring operation condition data from the treatment device and sending the data to the intelligent control system; the intelligent control system connected with a drive control system and capable of analyzing the received operation condition data sent by the data collection system and sending control signals to the drive control system according to an analysis result; the drive control system electrically connected with drive devices of the treatment device and capable of controlling operation of the drive devices; a monitoring terminal connected with the intelligent control system and capable of displaying the operation condition data analyzing result of the intelligent control system and the control signals sent to the drive control system.

Owner:中国诚通生态有限公司

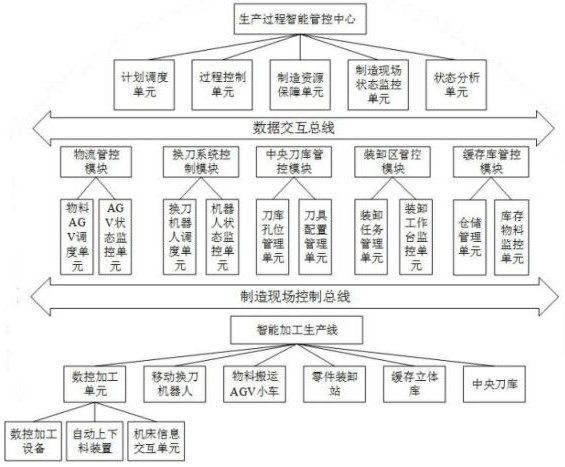

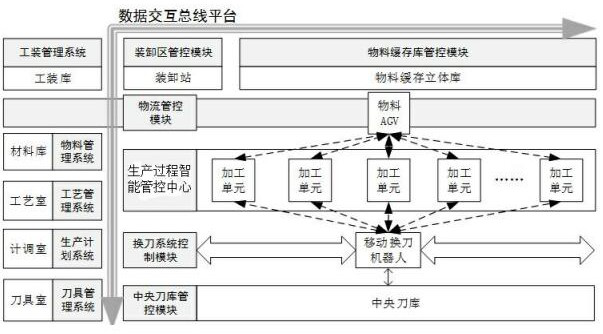

An intelligent management and control system for an automated production line of large structural parts

ActiveCN109917770BReasonable architecture designRealize scientific managementElectric/hybrid propulsionTotal factory controlData acquisitionIndustrial engineering

The invention discloses an intelligent management and control system for an automated production line of large-scale structural parts, which is characterized by comprising an intelligent processing production line, a production process intelligent management and control center, a logistics management and control module, a tool change system control module, a central tool magazine management and control module, and a loading and unloading area management and control module. , Material cache library management and control module, tooling management system, material management system, process management system, production planning system and tool management system. Through the reasonable design of the overall structure, the overall intelligent management and control mode of the manufacturing site of the workshop automated production line is structured from the three levels of manufacturing site status data acquisition, process intelligent decision-making, and overall operating status analysis, so that it can solve the manufacturing resources of large-scale structural parts automated production lines. security issues.

Owner:CHENGDU AIRCRAFT INDUSTRY GROUP

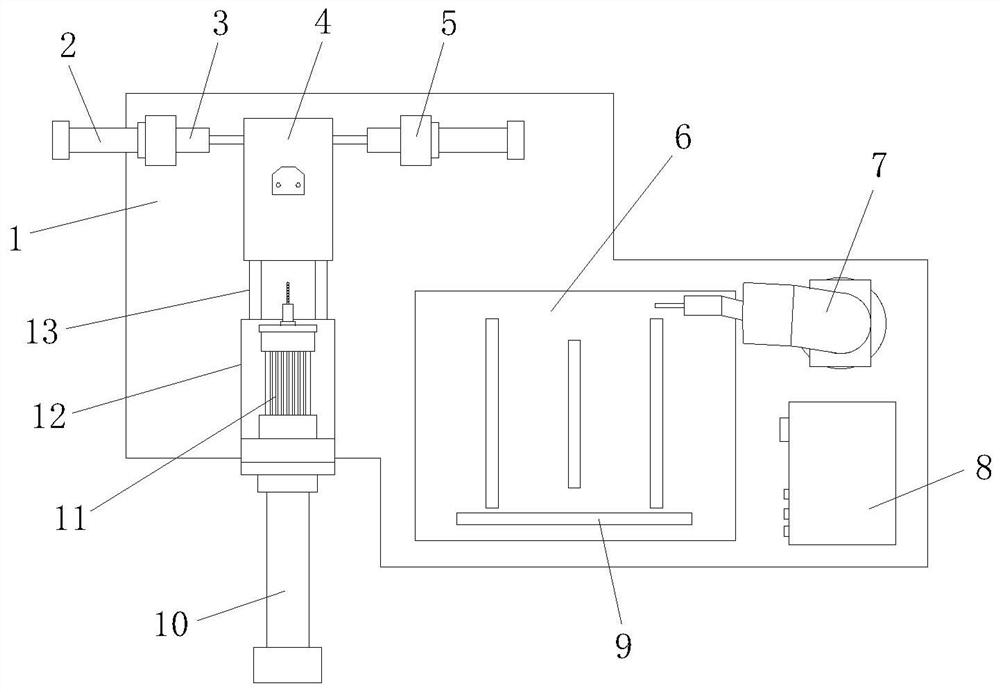

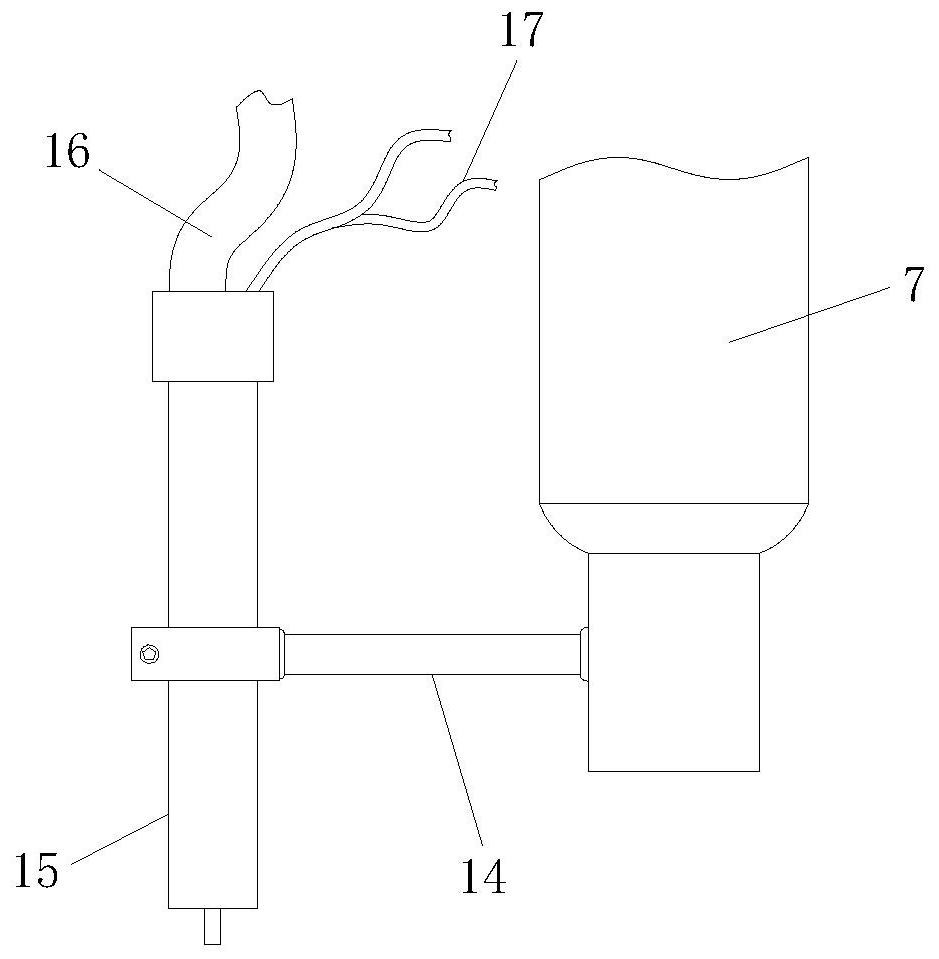

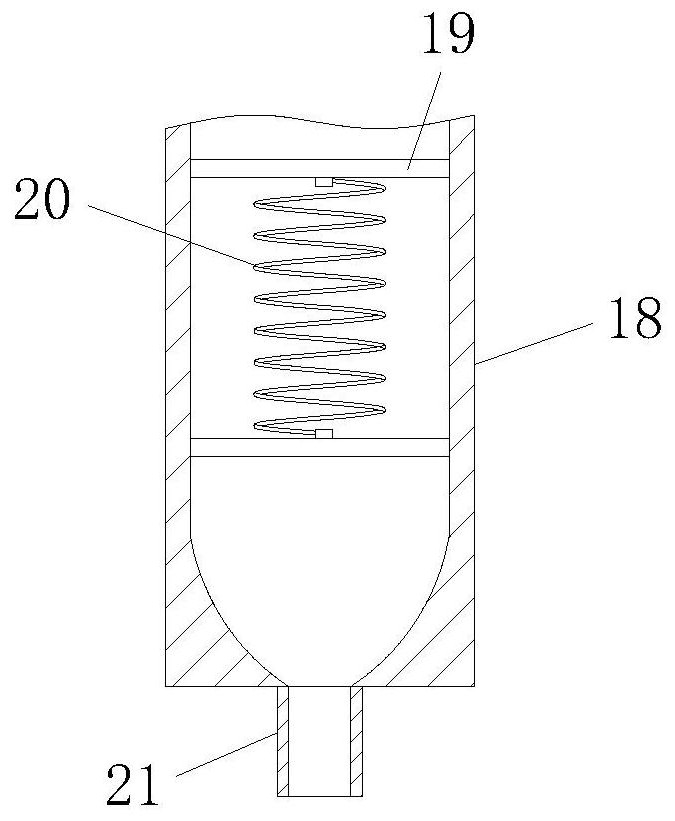

Robot and automatic system thereof

PendingCN112428495ALess likely to cause damageProcessing speedDomestic articlesMetal working apparatusEngineeringWorkbench

The invention discloses a robot which comprises a worktable, wherein an assembling mechanism and perforating mechanism are mounted on the left side of the worktable, and a flash peeling mechanism is mounted on the right side of the worktable. The assembling mechanism comprises a positioning table fixed to a position, close to the upper side, of the left side of the worktable by a bolt, fixed racksare separately fixed to the left and right sides of the position table, separately, a first pneumatic telescopic rod is mounted on each fixed rack, and a hollow bushing is connected to the first pneumatic telescopic rod between the left and right fixed racks in a sleeving manner. During processing, the assembling mechanism assemblies a vehicle handle first, and the perforating mechanism perforates a vehicle handle assembly, so that it is convenient for follow-up packaging. The flash peeling mechanism removes flashes on the vehicle handle assembly. The invention provides the robot and an automatic system thereof. The robot is skillful in structural arrangement and reasonable in layout. The flash peeling mechanism melts flashes by hot air. Compared with conventional peeling by a tool, the surface of a plastic workpiece is not easily damaged. The robot is high in processing speed and high in efficiency.

Owner:中山天腾塑胶制品有限公司

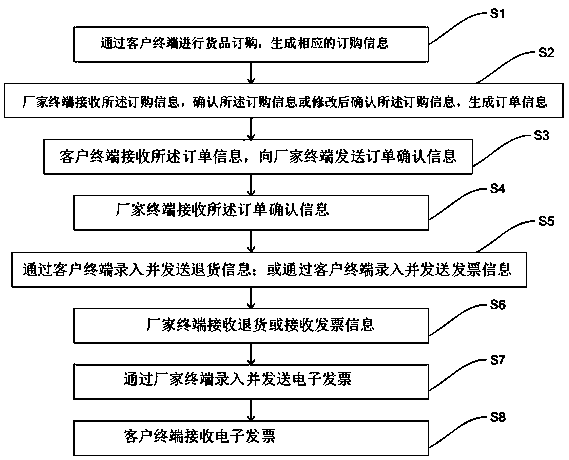

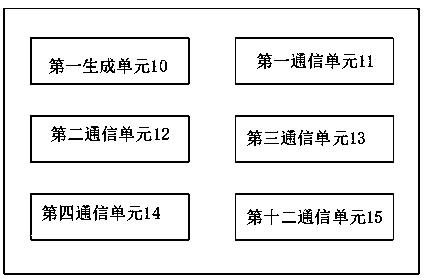

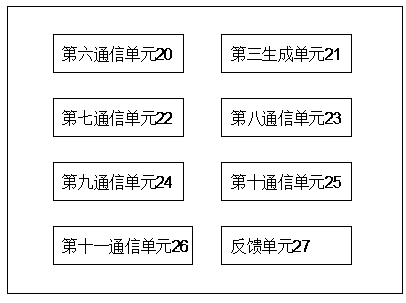

Order management system and order management method

InactiveCN110766533AReduce labor costsImprove production and operation efficiencyBilling/invoicingBuying/selling/leasing transactionsCommunication unitOrder management system

The invention discloses an order management system which comprises an ordering system of a client terminal and a sales system of a manufacturer terminal. The ordering system comprises a first generation unit used for generating ordering information, a first communication unit used for sending the ordering information, a second communication unit used for receiving the order information, and a third communication unit used for sending order confirmation information, a fourth communication unit used for sending return information and / or invoicing information. The sales system comprises a sixth communication unit used for receiving the ordering information; the third generation unit is used for generating order information; the seventh communication unit is used for sending order information;the eighth communication unit is used for receiving order confirmation information; and the ninth communication unit is used for receiving the return information and / or the invoicing information. Theinvention also discloses an order management method which is formulated according to the order management system. The production and operation efficiency is improved; human negligence is reduced, andthe human negligence can be found immediately even if the human negligence occurs.

Owner:GUANGDONG SHENLING ENVIRONMENT SYST CO LTD

Cultivation method of bent cycad leaves

The invention relates to a leaf bending culture method for a sago cycas, which comprises the following steps: in March or April, selecting a pot-cultured sago cycas which has a trunk thickness of 6-15 centimeters, a trunk height of 10-25 centimeter and 4-10 crown leaves, cutting away all the old leaves in a fair weather, and exposing in an outdoor open place; when new leaves of the sago cycas grow to 3 centimeters long, transferring a flower pot into a thin-film arched greenhouse, filling gravels and other similar substances under the pot to separate the pot from the soil surface, and prohibiting watering; when 2 / 5 of penniform lobes of the new leaves spread, and overwatering the rooting zone of the sago cycas once on the evening of that day to urge the leaves to quickly extend and spread; and when all the penniform lobes of the new leaves spread thoroughly, obtaining the pot-cultured sago cycas with the bent leaves. According to the invention, main environmental conditions are artificially regulated and controlled; the operating technology is simple, the culture time is short and the shaping process is easy; and the characteristics of low culture cost and high work efficiency are achieved, thereby obviously improving production and operation benefits. Besides, the method avoids the use of chemical agents, thus causing no pollution to the environment.

Owner:徐绍清 +1

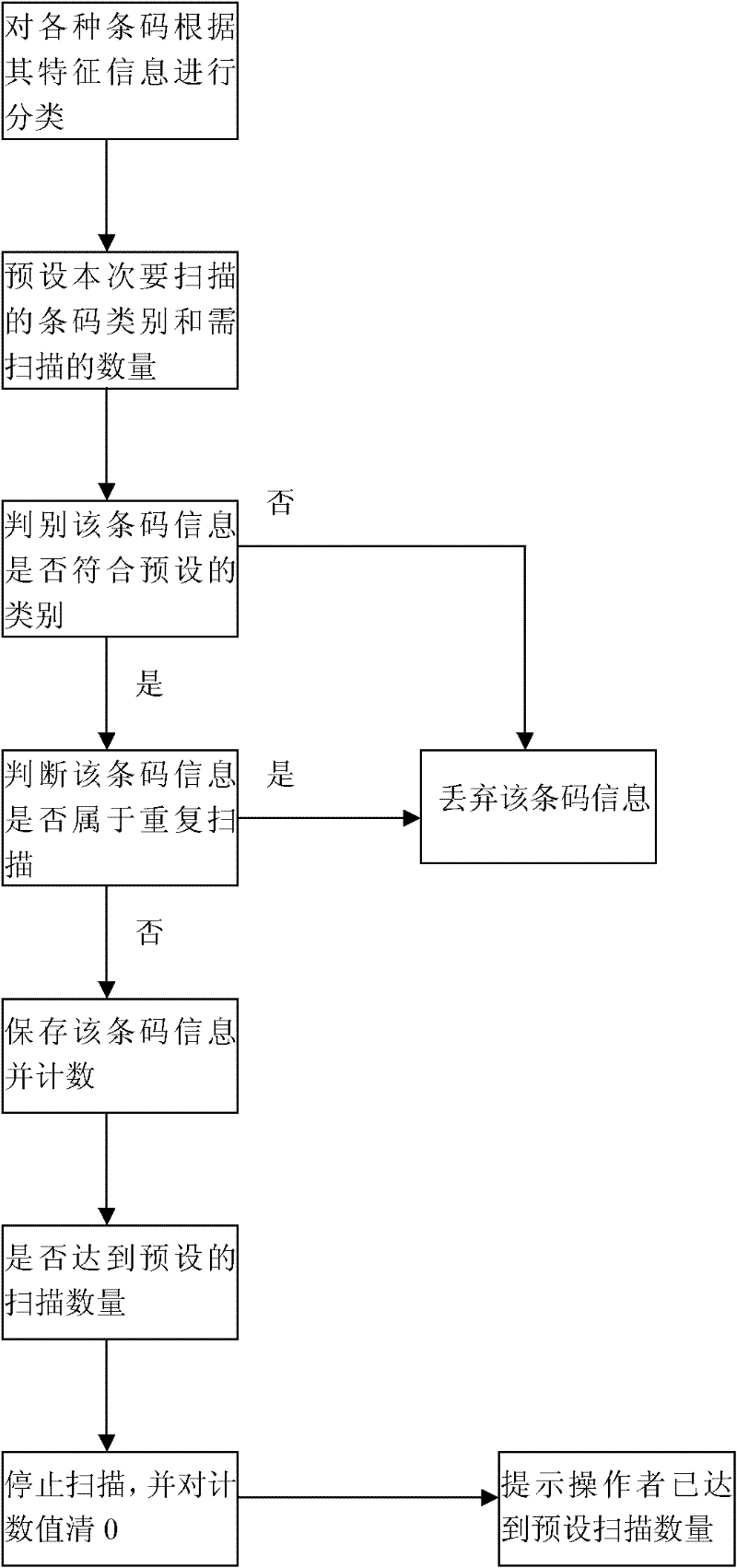

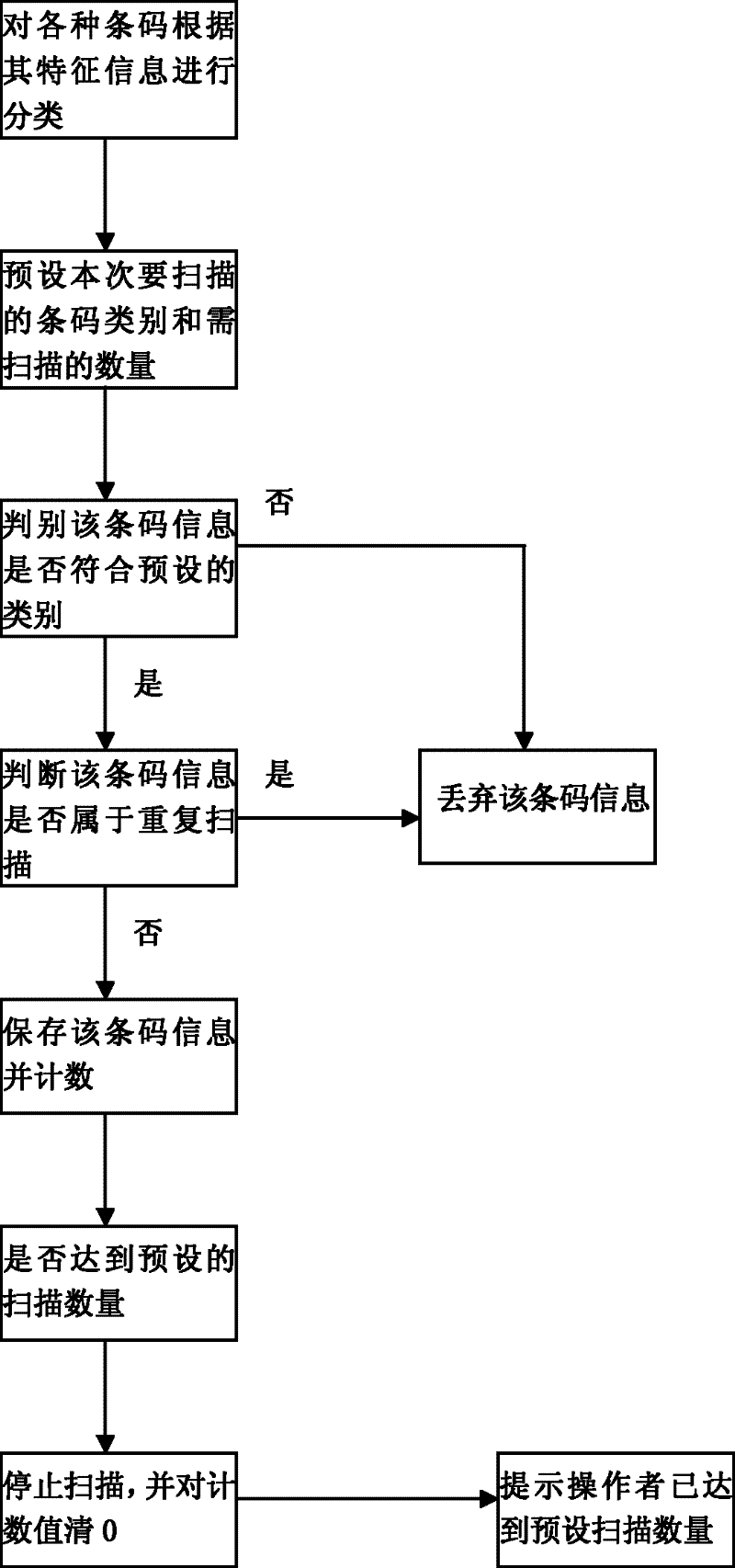

Barcode scanning and identifying method

ActiveCN101964046BEasy to identifyReduce identification costsSensing by electromagnetic radiationComputer graphics (images)Barcode

The invention relates to barcode processing technology, and discloses a barcode scanning and identifying method, which aims to solve the problem that barcode scanning in the prior art cannot satisfy the needs of actual production and management. The key points of the technical scheme are that: the method comprises the following steps of: a, presetting the barcode type and number of barcodes to bescanned; b, performing scanning to obtain barcode information, judging whether the barcode information is consistent with the preset barcode type or not, and if the barcode information is consistent with the preset barcode type, executing the step c, otherwise, executing the step d; c, judging whether the barcode information is obtained by repeated scanning or not, and if the barcode information is obtained by the repeated scanning, executing the step d, otherwise, executing the step e; d, discarding the barcode information; e, storing and counting the barcode information; f, judging whether the count reaches the preset number of the barcodes to be scanned or not, and if the count reaches the preset number, executing the step g, otherwise, returning to the step b; and g, stopping the scanning and clearing the count. The barcode scanning and identifying method is suitable for enterprises to scan and identify the barcodes.

Owner:SICHUAN CHANGHONG ELECTRIC CO LTD

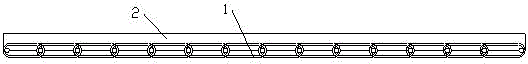

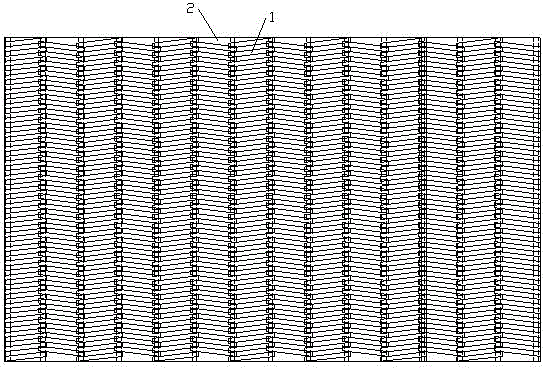

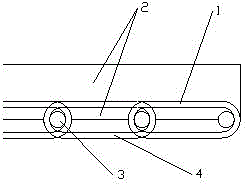

Easy-joint PVC (polyvinyl chloride)-core polyvinyl chloride conveying belt and preparation method thereof

ActiveCN102815496BSimplify joint processReduce the difficulty of jointsConveyorsCoatingsPolyvinyl chlorideResin coating

The invention provides an easy-joint PVC (polyvinyl chloride)-core polyvinyl chloride conveying belt which has the advantages of simplicity and convenience in joint operation during jointing of the conveying belt, high joint strength retention rate and long service life. The easy-joint PVC-core polyvinyl chloride conveying belt comprises a buckle type PVC-core framework and a polyvinyl chloride resin coating coated on the upper surface of the buckle type PVC-core framework, the buckle type PVC-core framework consists of more than three PVC strip cores and PVC winding cores, the PVC strip cores are arranged at intervals parallelly, each PVC winding core which is helical and sequentially bypasses two adjacent PVC strip cores is arranged between the two adjacent PVC strip cores, and each two PVC winding cores wound on the same PVC strip core are spaced in the axial direction of the PVC strip core.

Owner:南京东润带业有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com