Coiled pipe weld joint identification tracing system

A traceability system and serpentine tube technology, applied in the field of weld seam traceability, can solve the problems of low quality traceability, no support for two-dimensional code barcode marking, and no information system support, so as to improve the efficiency of automatic identification and realize the realization of two-dimensional code Redundant, easy-to-recognize effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

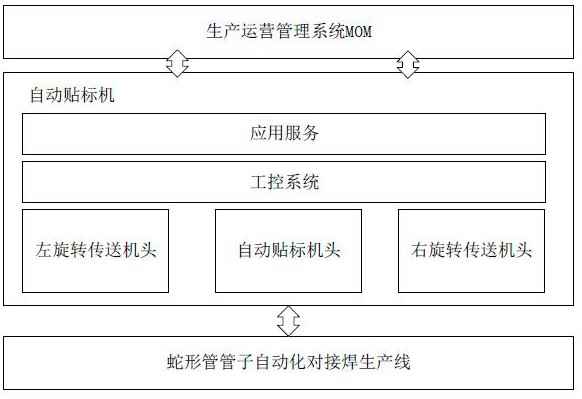

[0034] Such as figure 1 As shown, a serpentine pipe weld identification traceability system includes a serpentine pipe automatic butt welding production subsystem, an automatic labeling machine and a production operation management subsystem, wherein:

[0035] The automatic butt welding production subsystem of serpentine pipes, the automatic butt welding of short pipes in the product BOM, provides functions such as pipe transportation, pipe alignment, and automatic welding;

[0036] The automatic labeling machine is installed at the rear end of the welding machine outlet side of the automatic butt welding production subsystem of the serpentine pipe, and is used to receive the automatic labeling instruction of the MOM subsystem and automatically label the barcode of the tube ring;

[0037] The MOM subsystem belongs to the system application layer: (1) It is used to realize the informatization and digital management and control of the manufacturing process in the workshop, recor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com