Basic automation control system for tandem cold rolling unit with five frames

A five-stand continuous cold rolling and basic automation technology, which is applied in rolling mill control devices, metal rolling, metal rolling, etc., can solve the problems of increasing user investment costs, long investment recovery period, and long delivery time, and achieves Reduce construction investment and maintenance costs, reduce system components, and improve production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

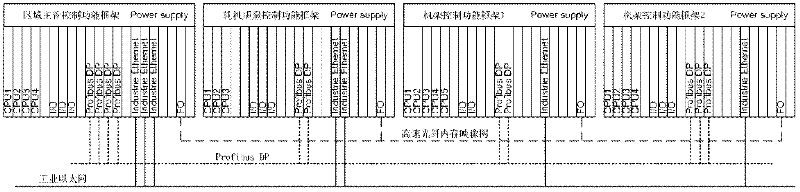

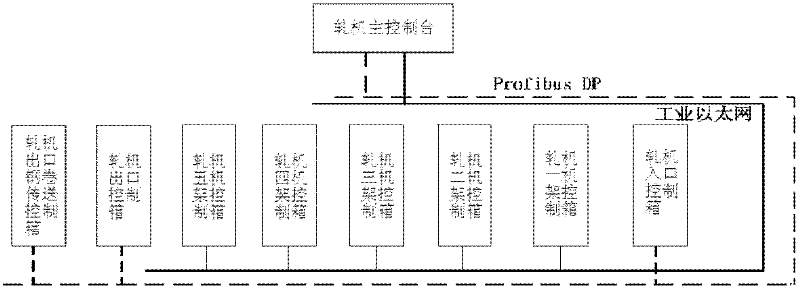

[0033] It consists of six parts: PLC controller group, HPC controller group, rolling mill site console, real-time data acquisition system, system development and debugging computer system and basic automation control system network. The specific configuration is:

[0034] 1. PLC control system:

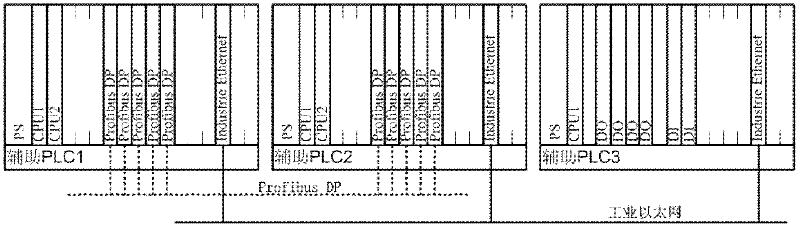

[0035] Since the PLC controller is mainly used for auxiliary equipment sequence control and other control functions that do not require high response speed, it does not have high requirements for system response time, generally between tens of milliseconds and hundreds of milliseconds. Various existing PLC controller products can meet the working requirements of the cold rolling production line. Depend on figure 1 Visible, the PLC controller group system of the present invention is made up of 3 cover auxiliary PLC control systems, and its specific hardware configuration is:

[0036] 1. Auxiliary PLC control system 1:

[0037] 1 PLC controller framework supporting multiple CPUs;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com