Patents

Literature

36results about How to "Simple production and maintenance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

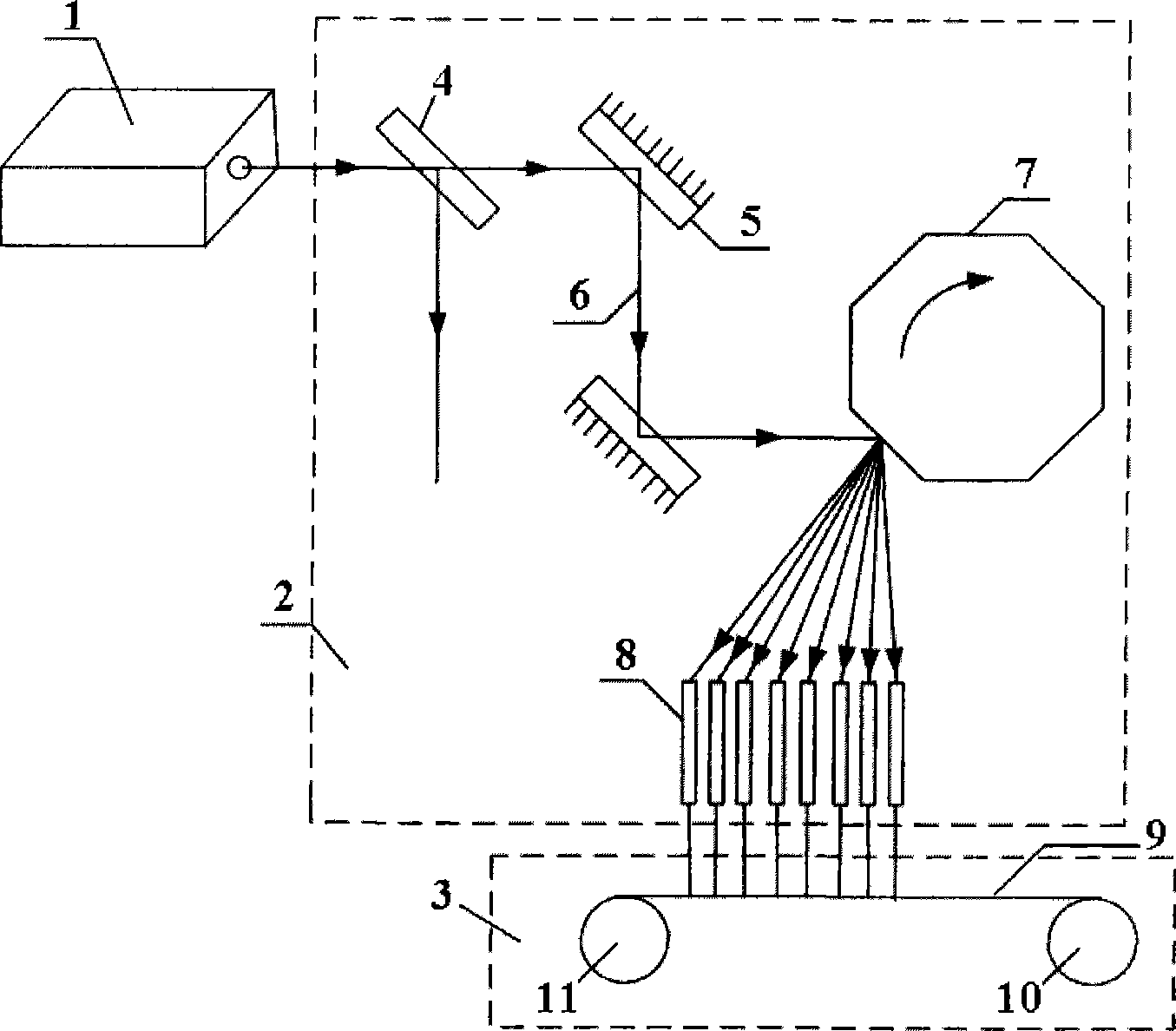

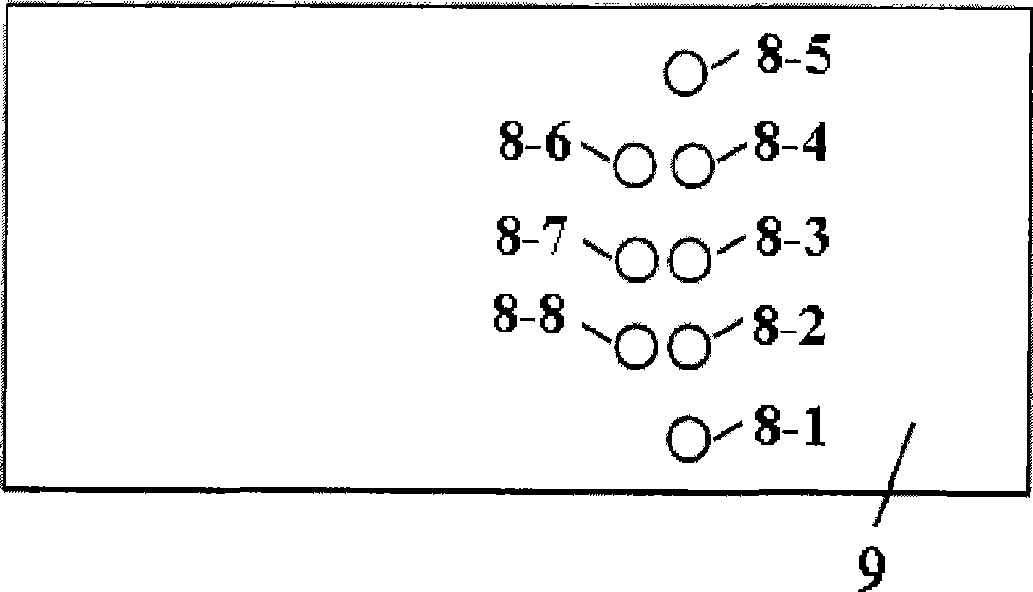

Cigarette tipping paper laser boring method and apparatus

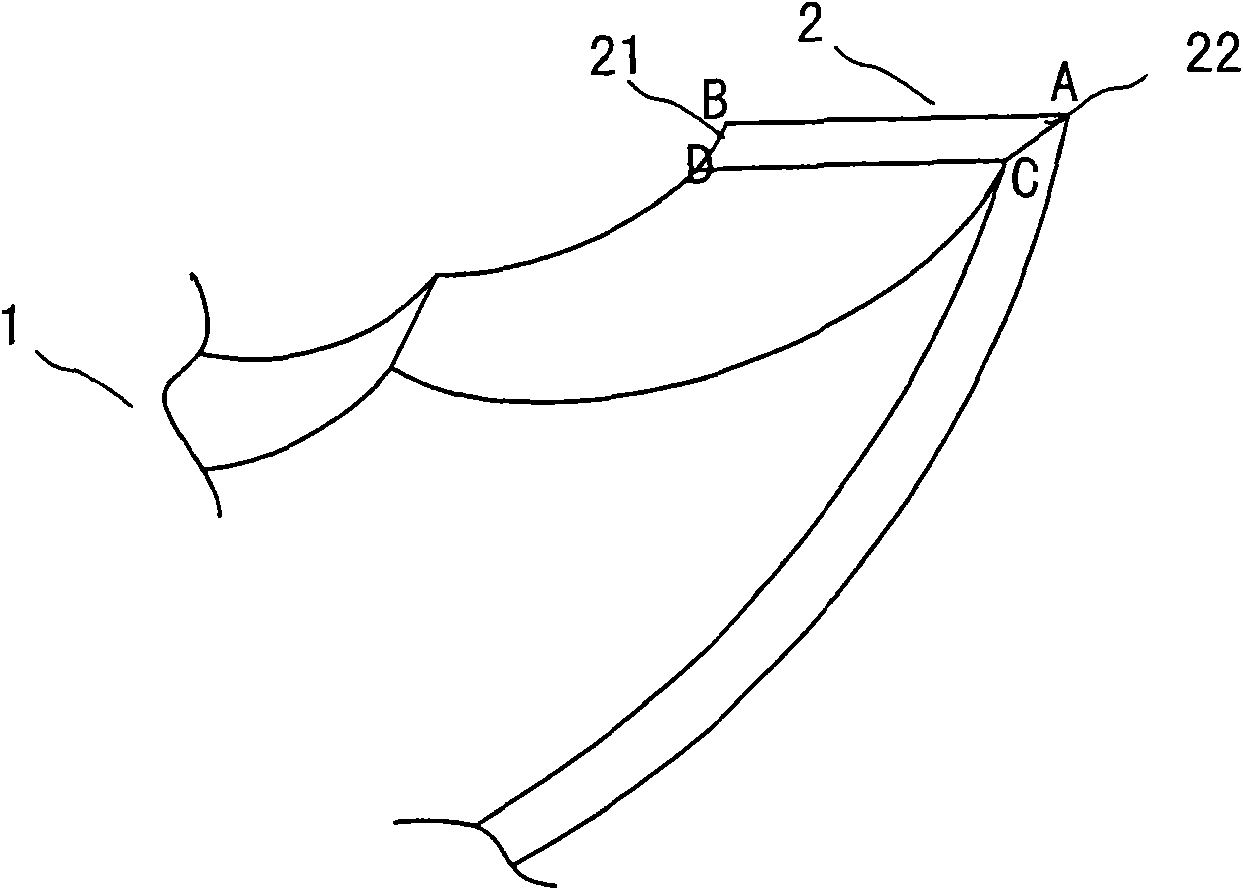

InactiveCN101462204AAnti-counterfeitingBeautiful and changeable appearanceMetal working apparatusLaser beam welding apparatusPunchingRepeat pattern

The invention provides two methods and equipment for laser punching of cigarette tipping paper. One is a rotary multi-prism punching method and equipment; and the other one is a vibrating mirror punching method and equipment. The methods and the equipment can utilize optical equipment to focus laser output by a laser; and punch pores (15) which are distributed in a single-row or multi-row curve or repeated pattern on the surface of continuously-moving tipping paper (9), such as pores (15) distributed in triangular, jagged, rhombic, trapezoidal, sine or cosine arrangement. The methods can carry out high-speed curve punching on the tipping paper, has the punching speed which is the same as linear punching speed and has good machining efficiency and good product quality; and the equipment has a simple structure, long service life, stable operation and high utilization efficiency of laser energy.

Owner:HUAZHONG UNIV OF SCI & TECH

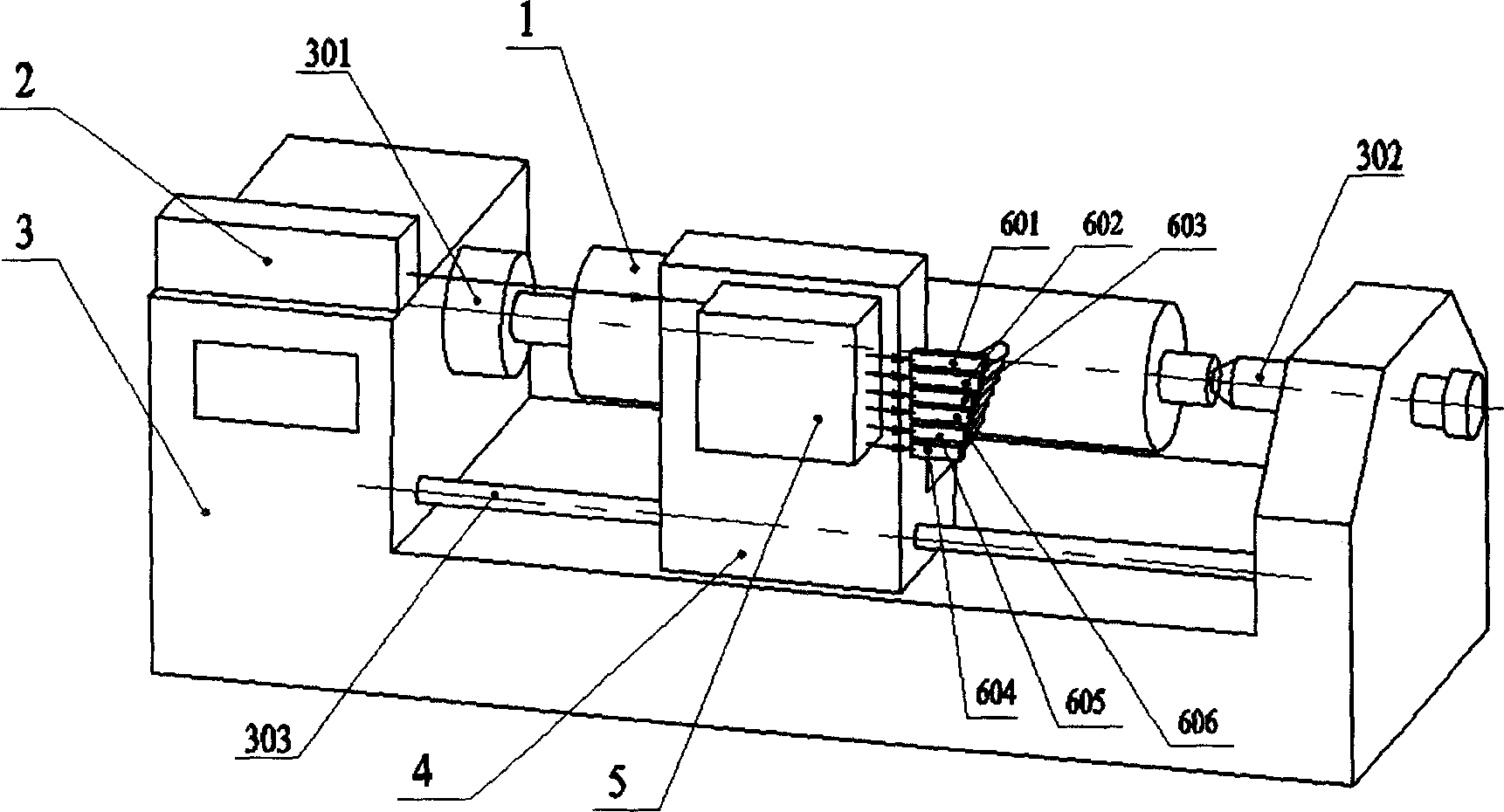

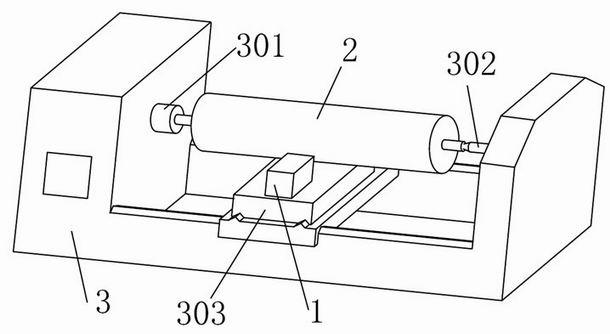

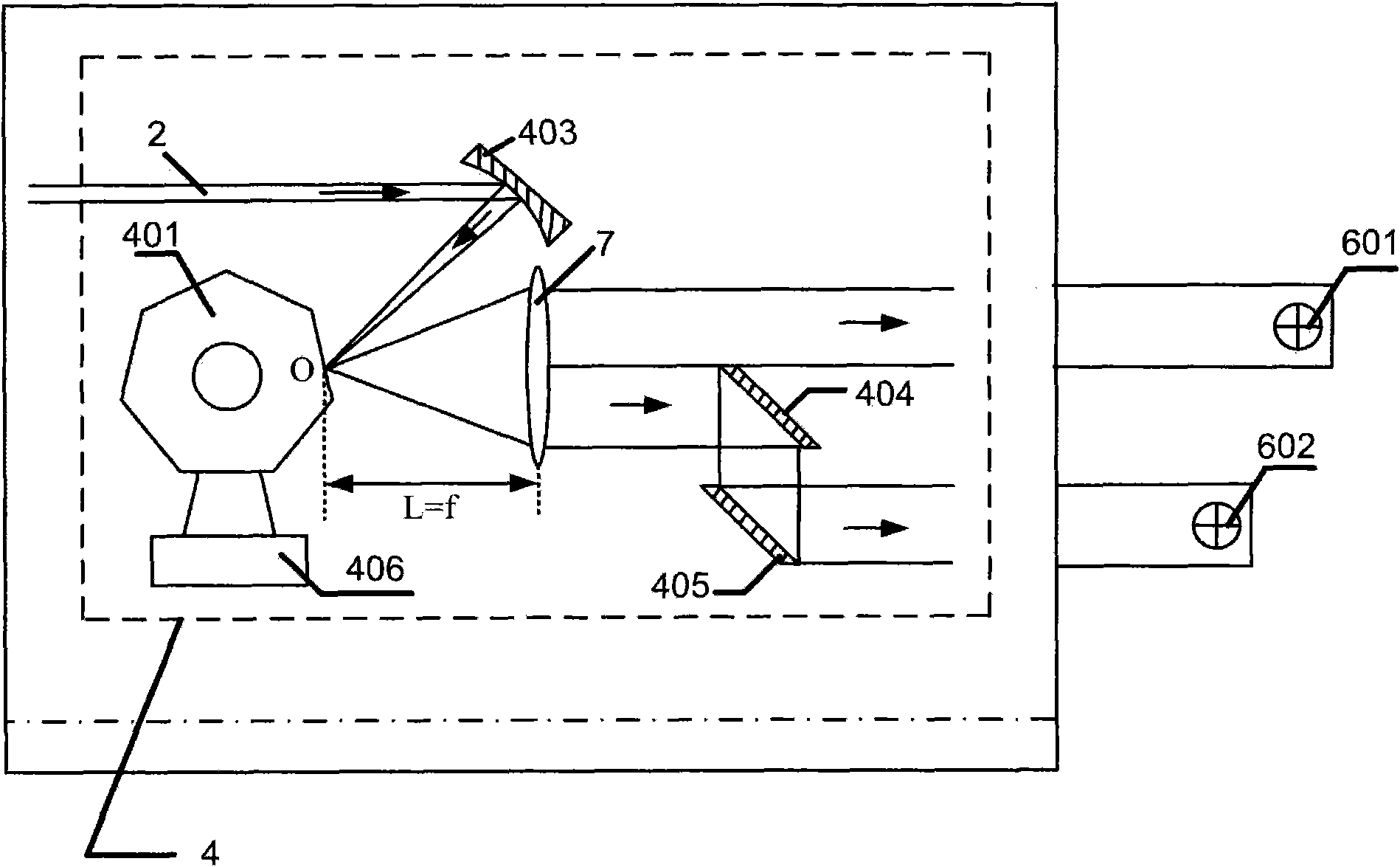

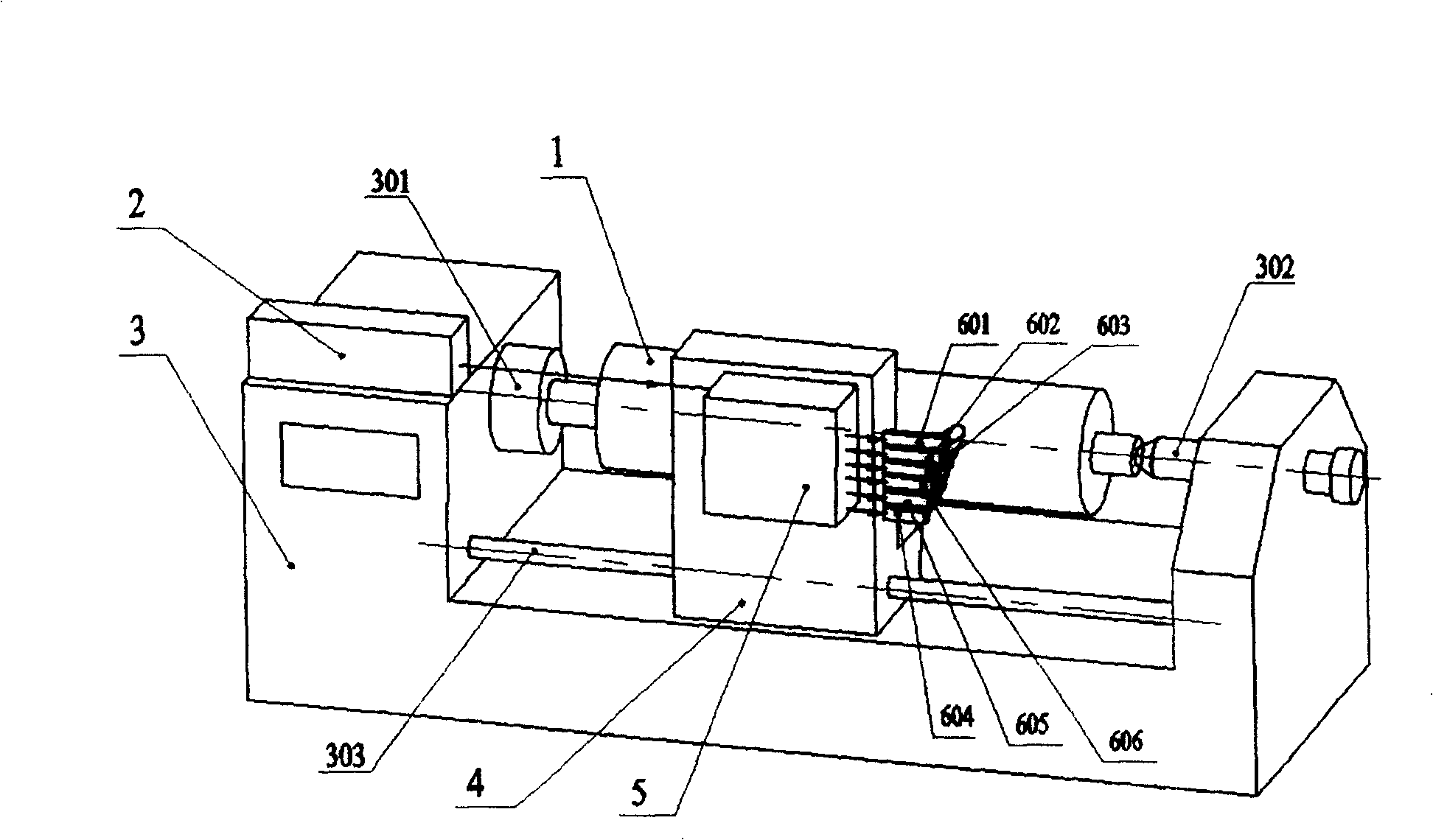

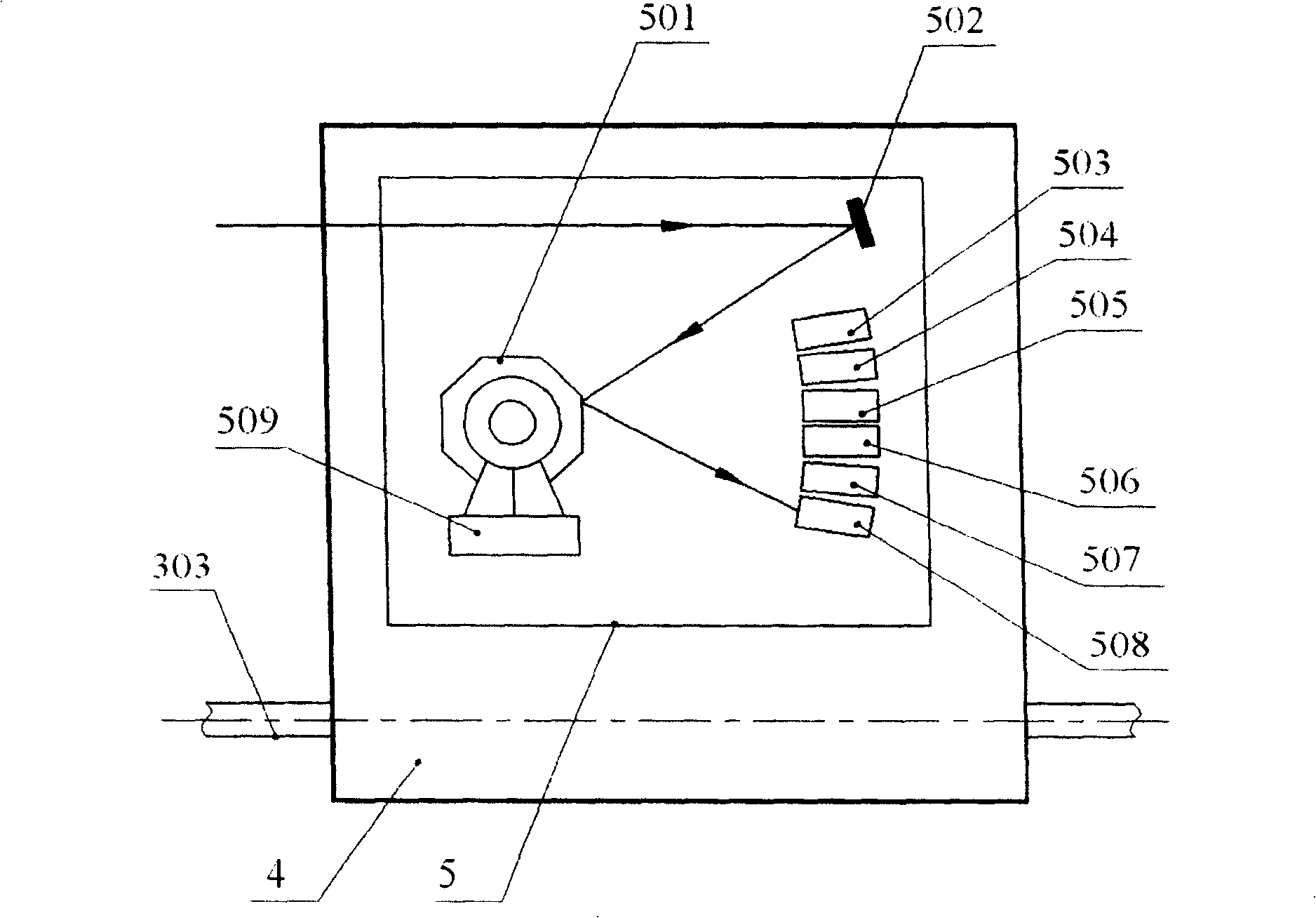

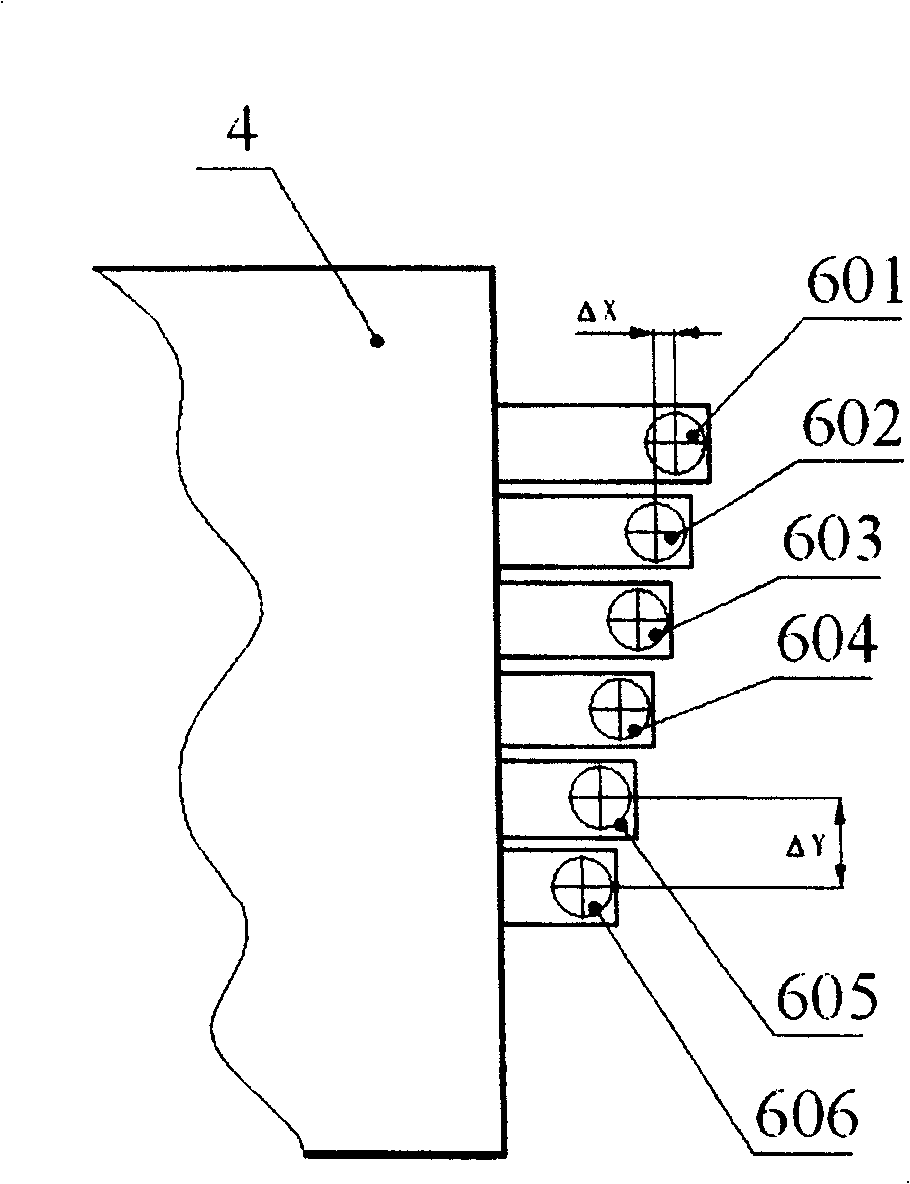

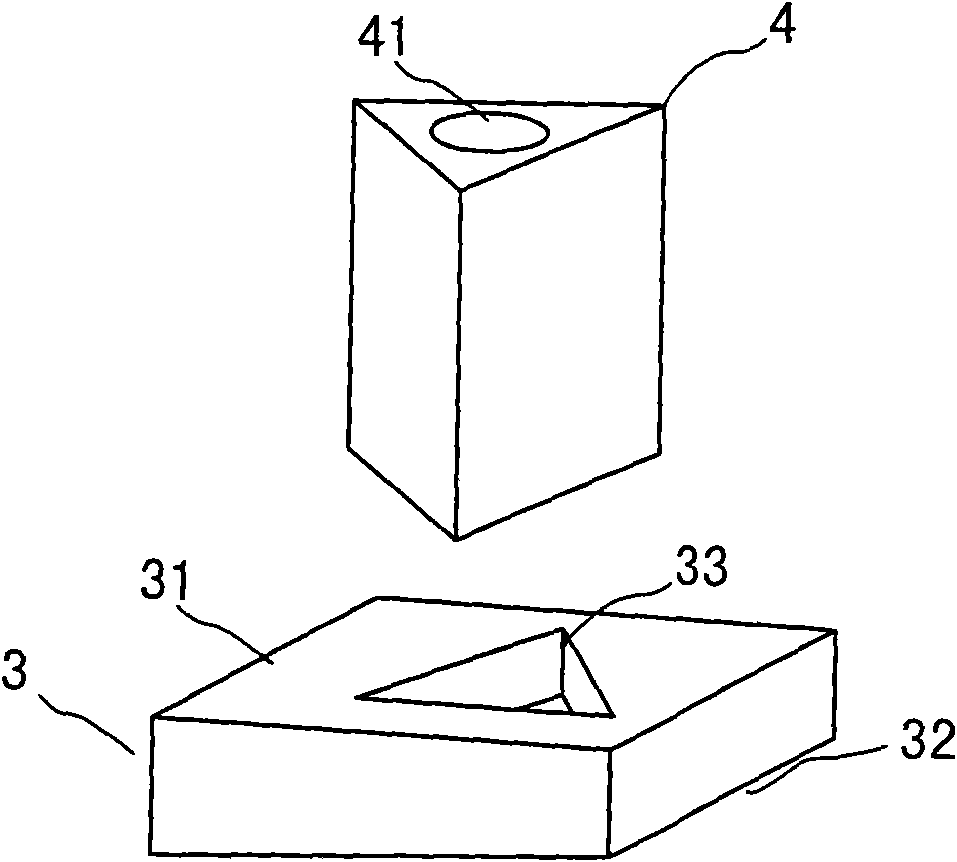

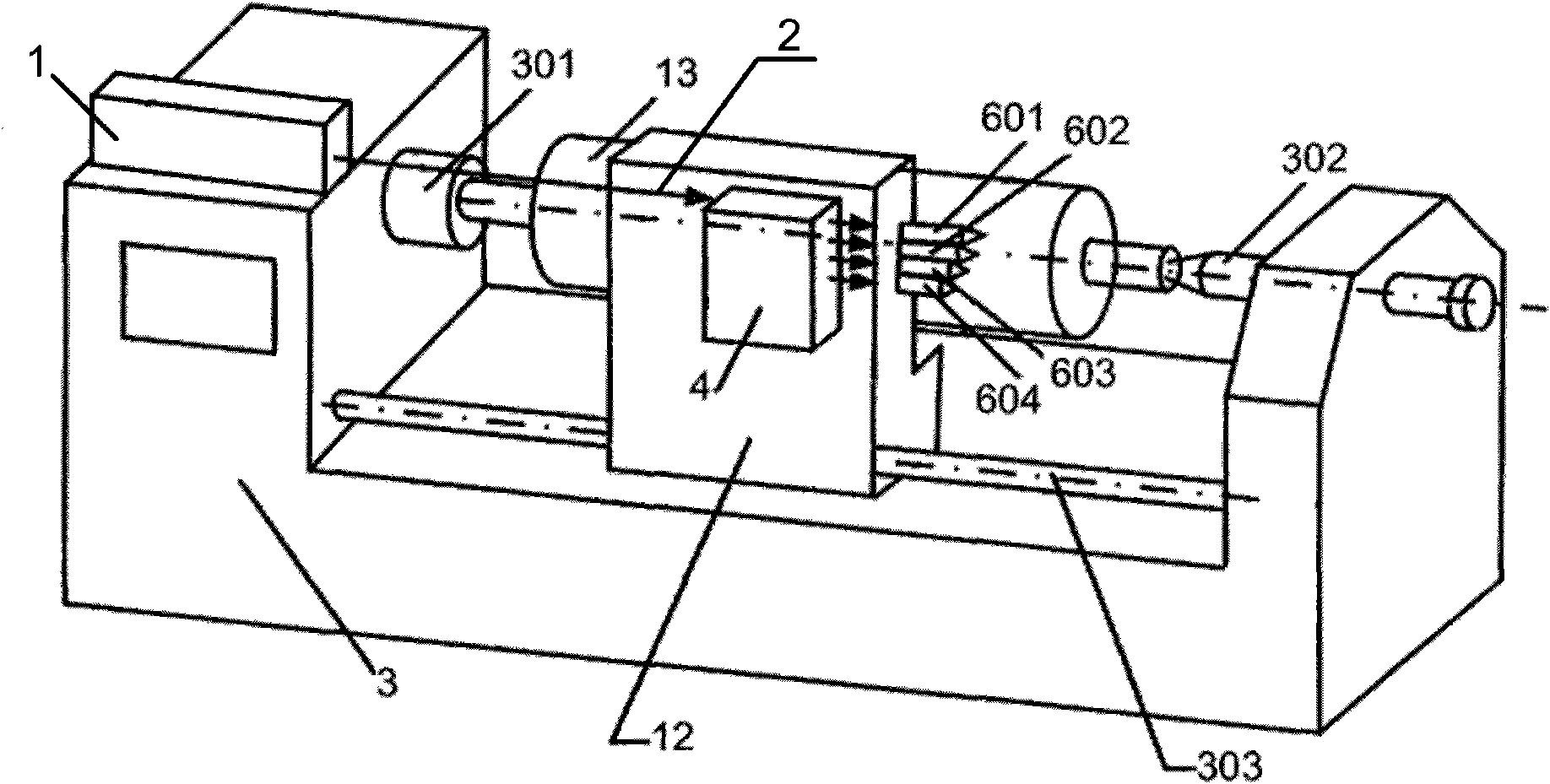

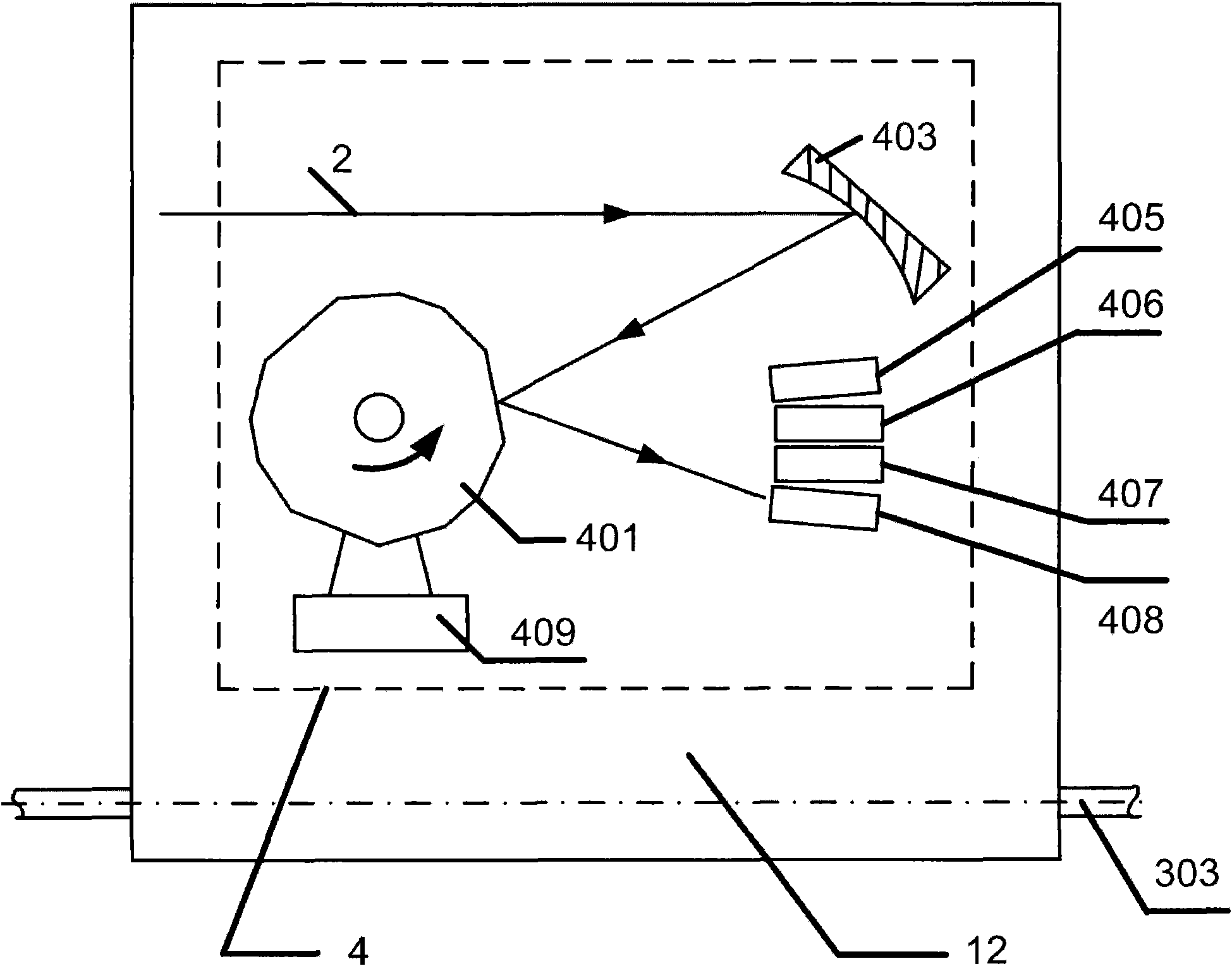

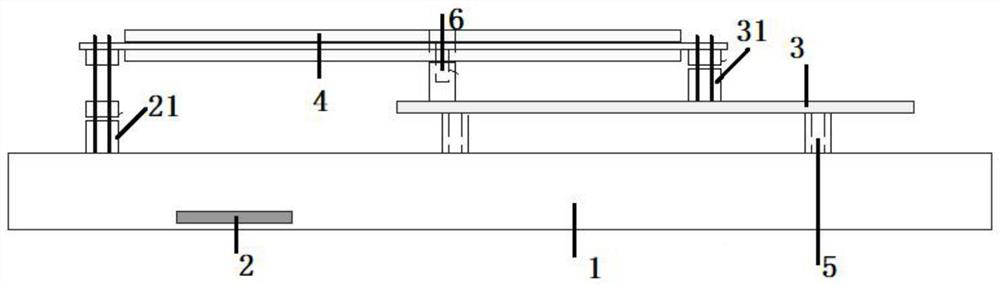

Roller surface coarsening processing method using multiheaded high power laser and its device

InactiveCN1803371AFast processingImprove utilization efficiencyLaser beam welding apparatusPhysicsHigh power lasers

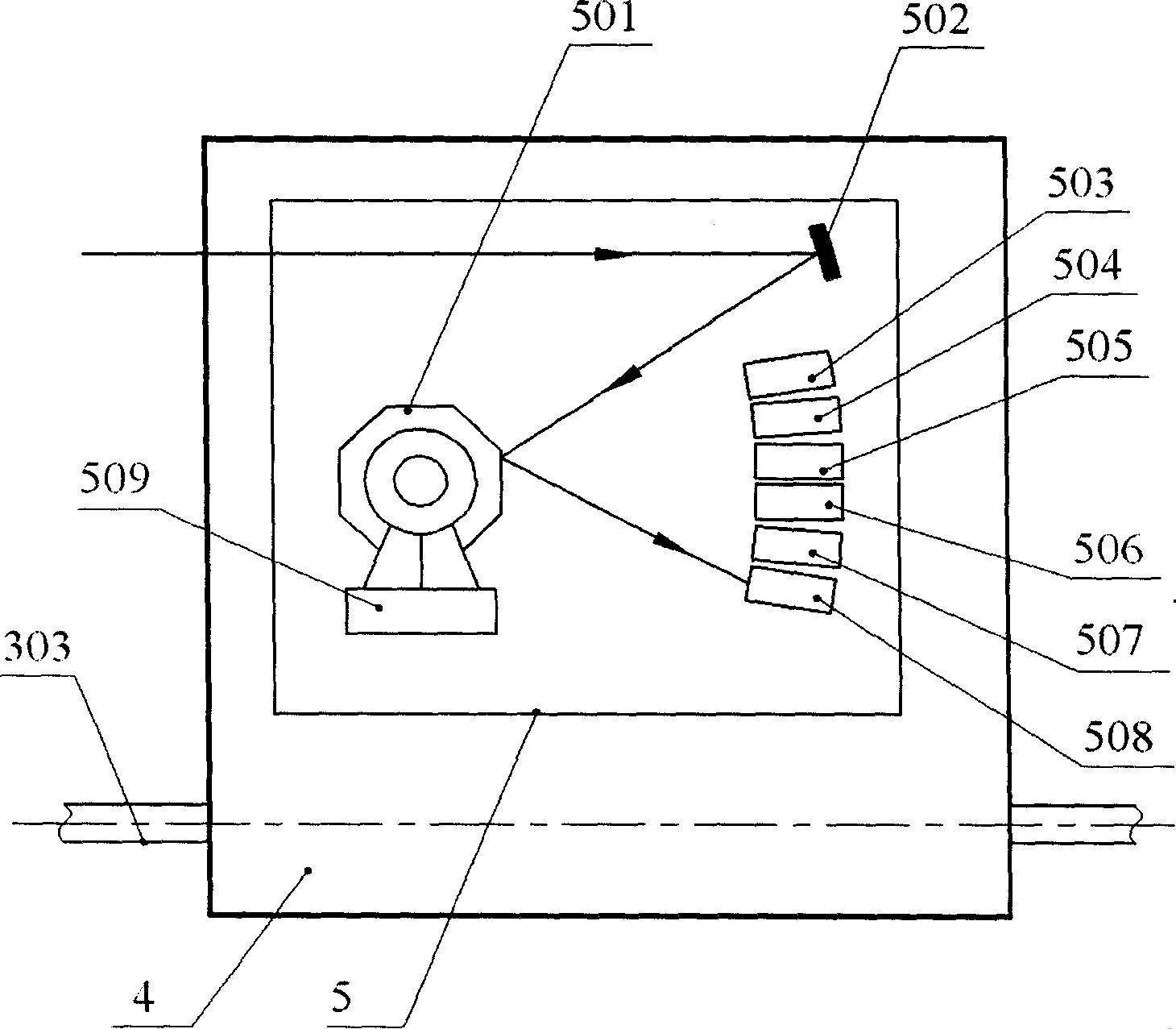

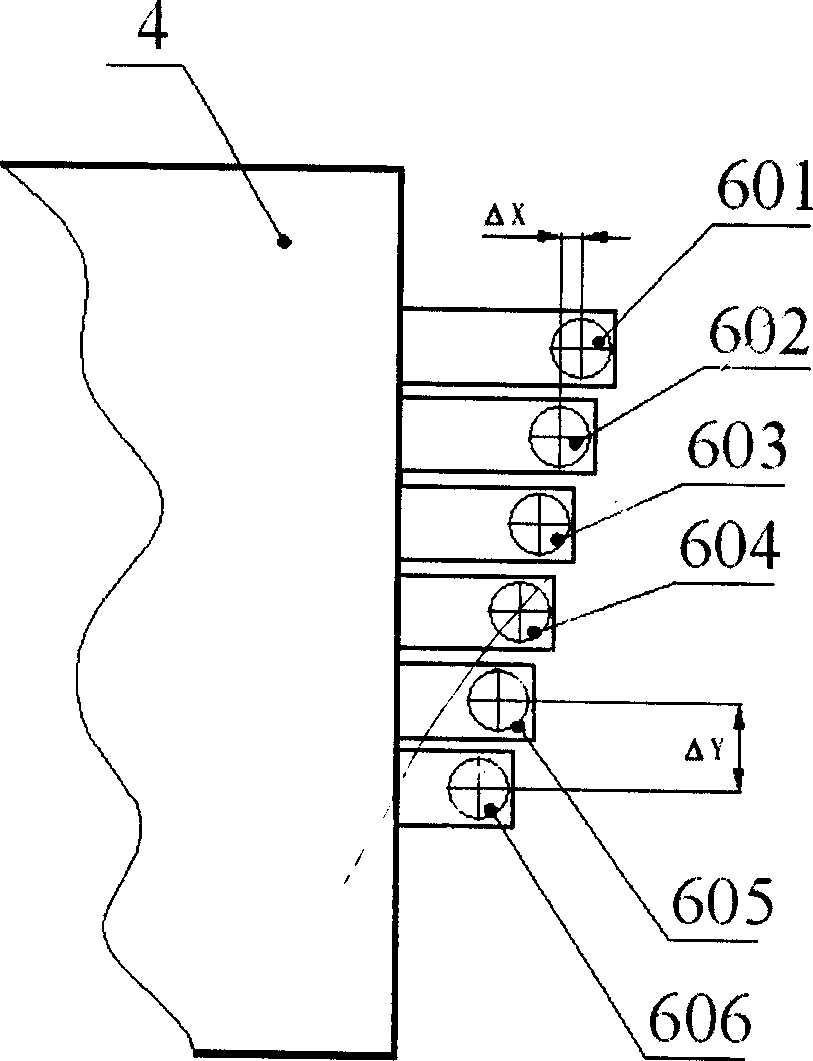

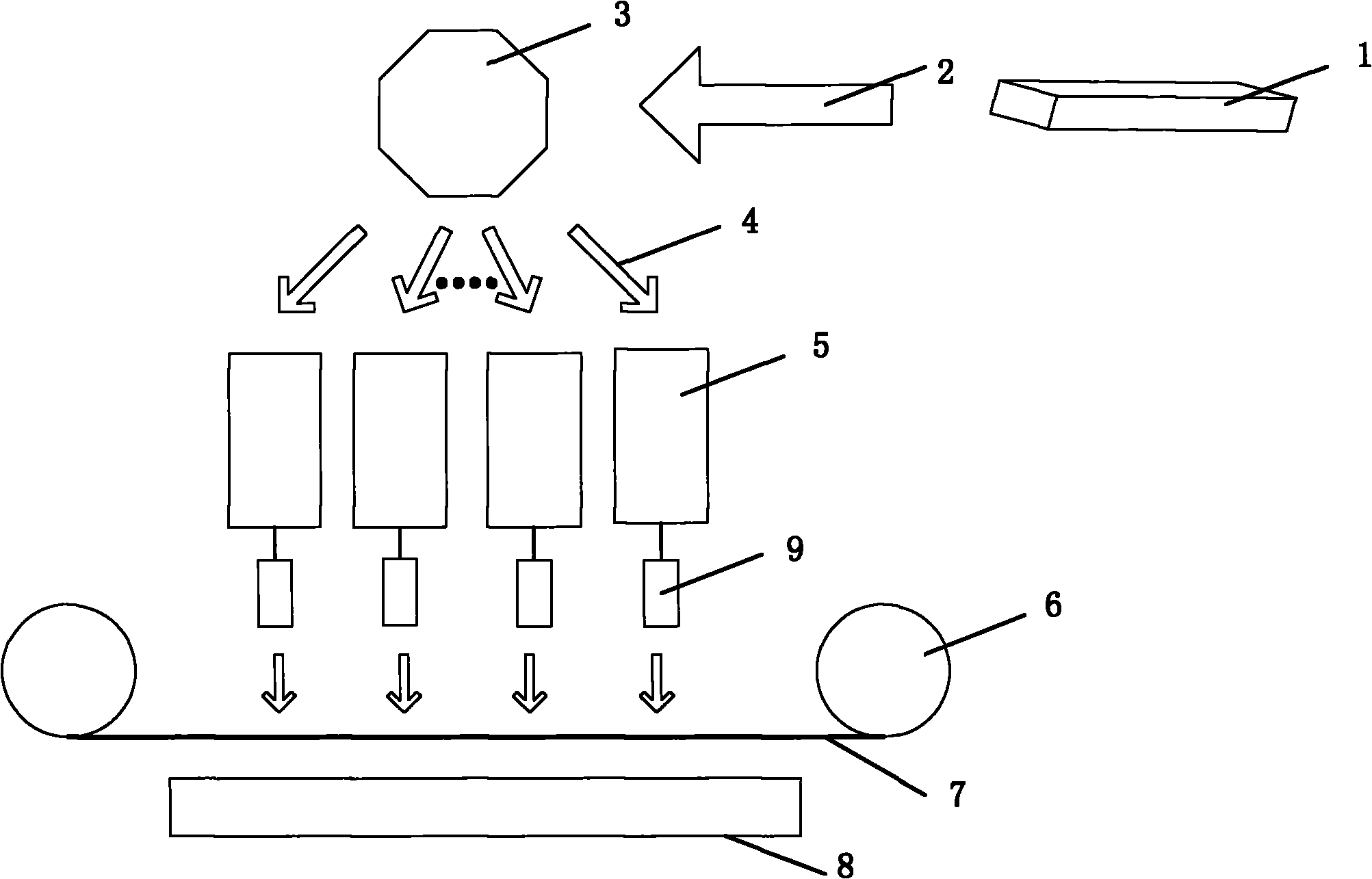

The invention discloses a woolening manufacturing method, which consists of laser (2) and numerical control machine (3), wherein the working bench (4) loads multiple-prism light splitting and focusing device; the multiple-prism light splitting device (5) contains total reflection lens (502), multiple prisms (501), high-speed motor (509) and K light splitting heads; the focusing device is composed of K focusing heads with each focusing head corresponding to one output end of light splitting head; the light axle of focusing head is vertical of roll workpiece with woolening point distance DELTAX of two focusing heads as transverse distance and DELTAY as longitude distance (K>=2).

Owner:HUAZHONG UNIV OF SCI & TECH

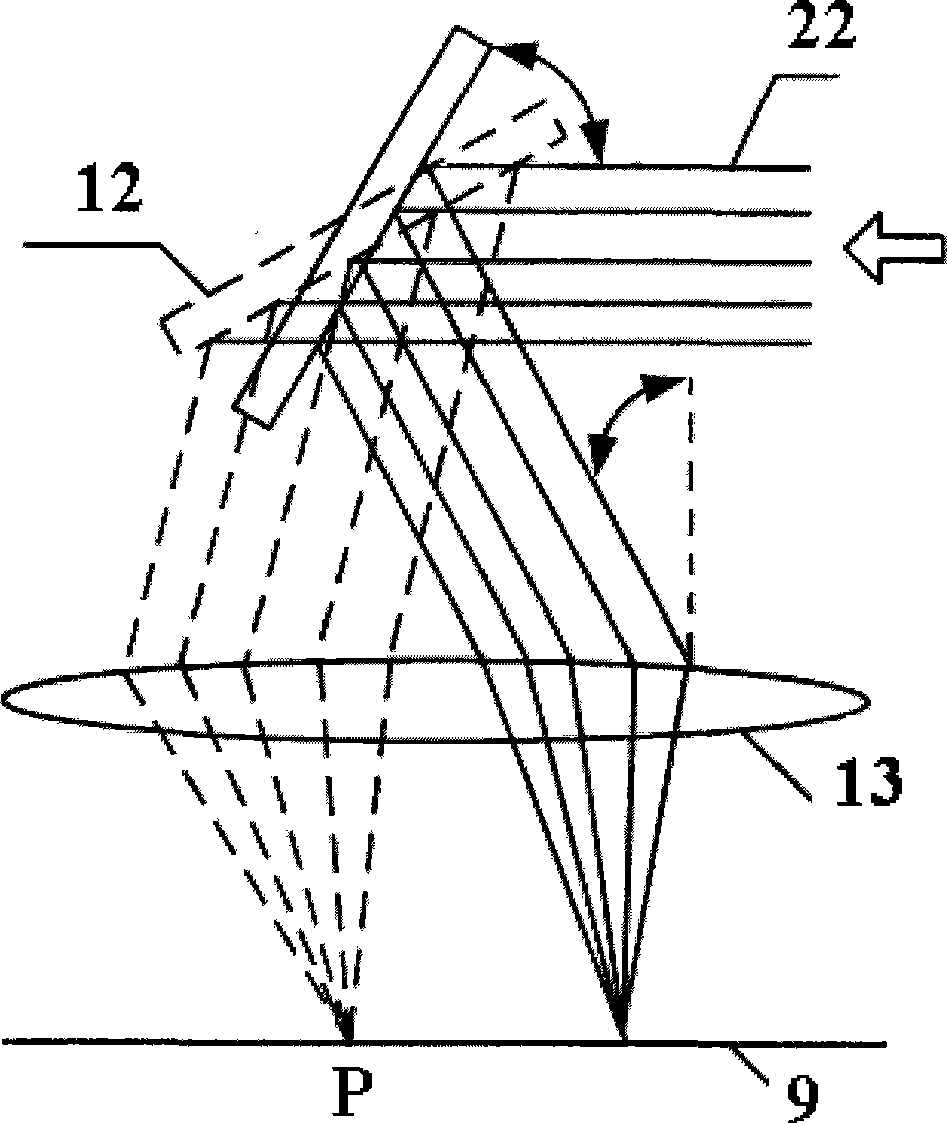

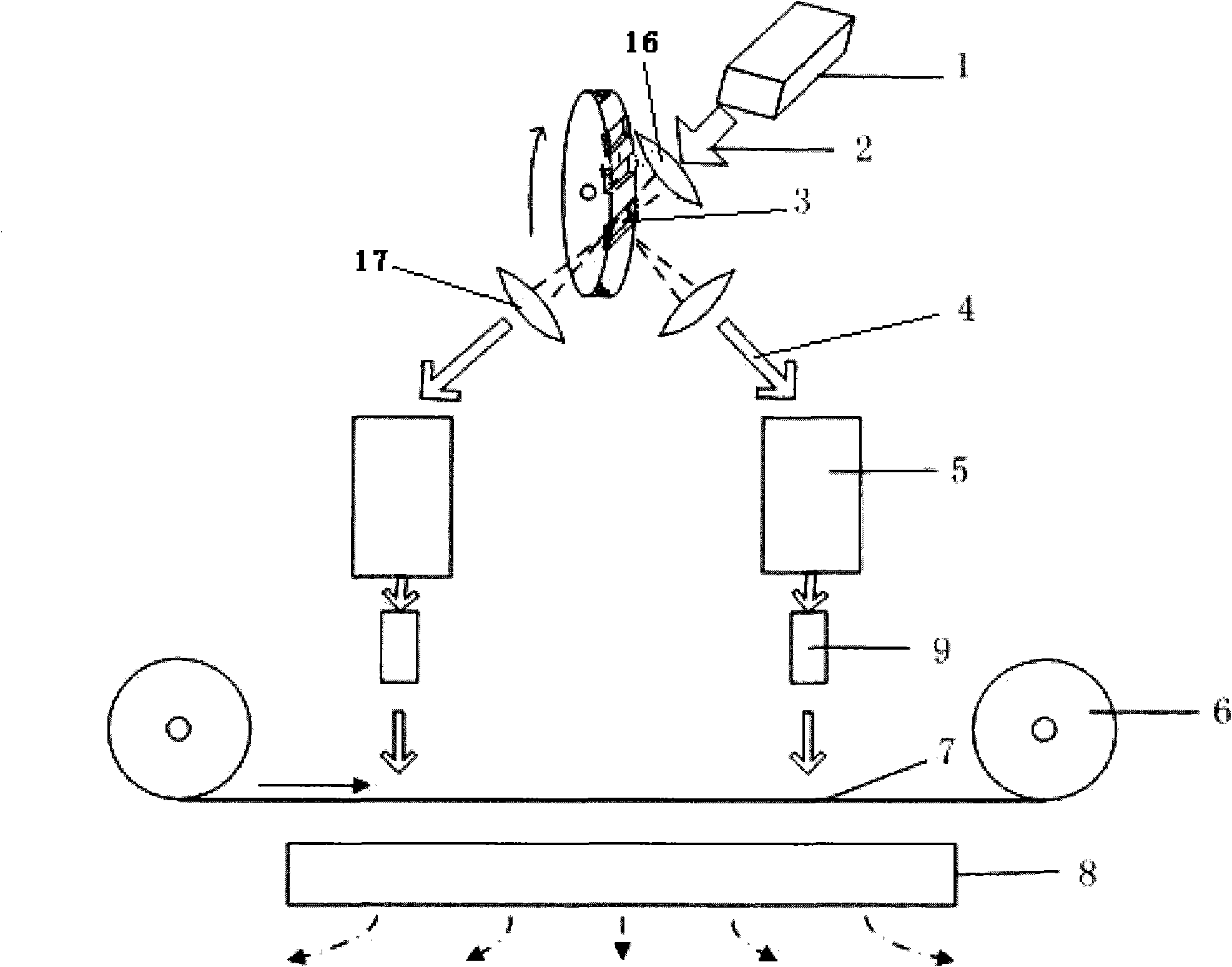

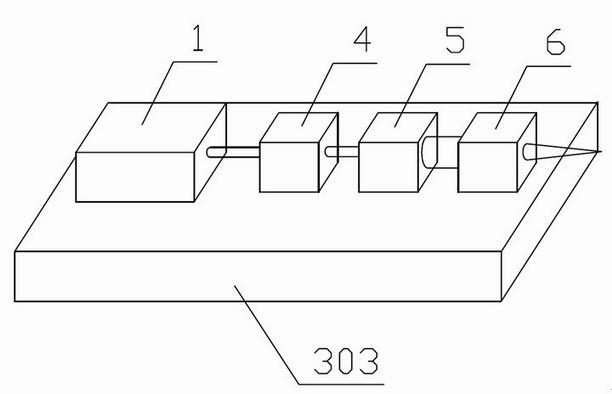

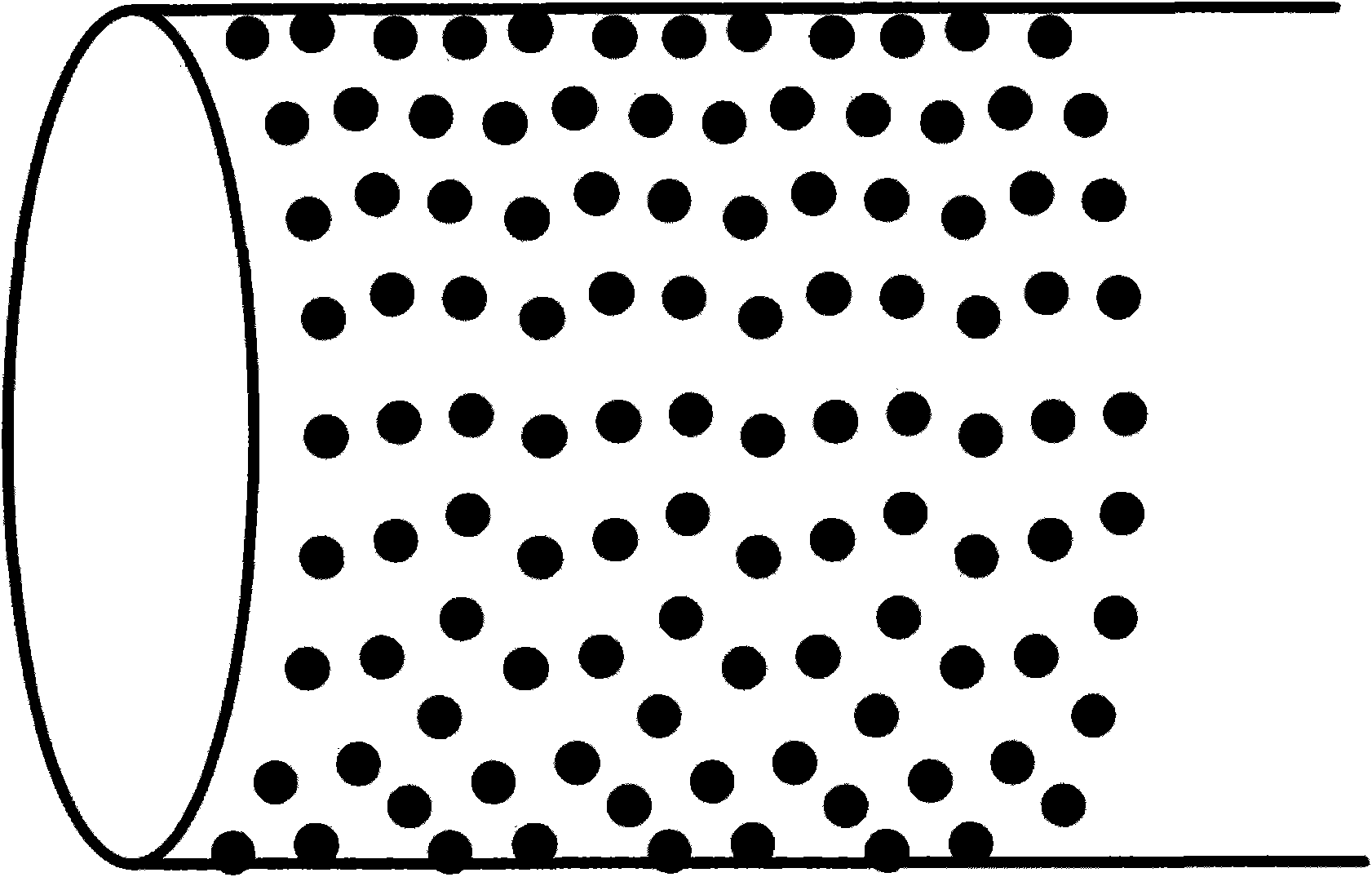

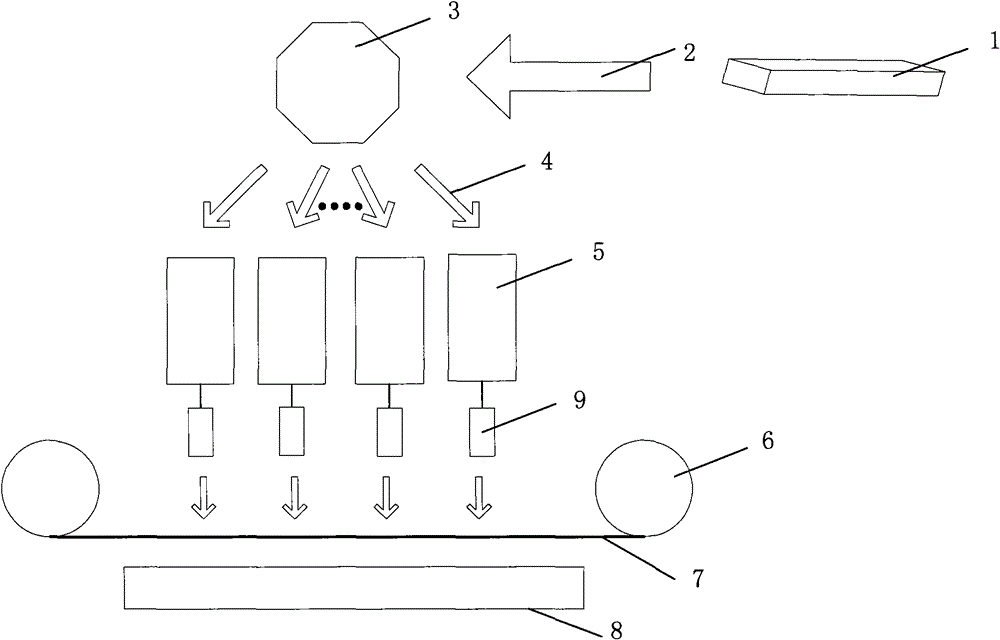

Thin material laser on-line perforating device

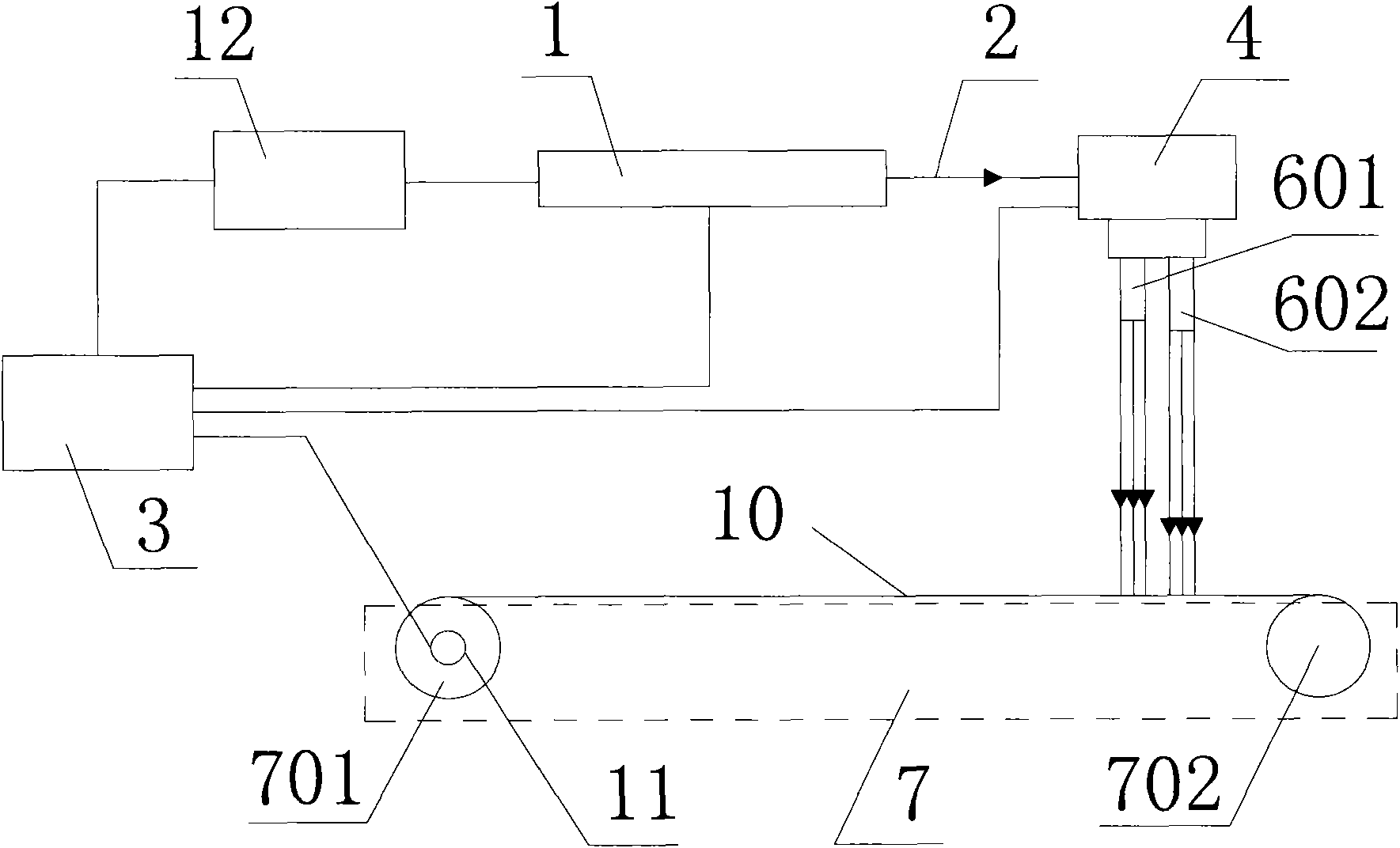

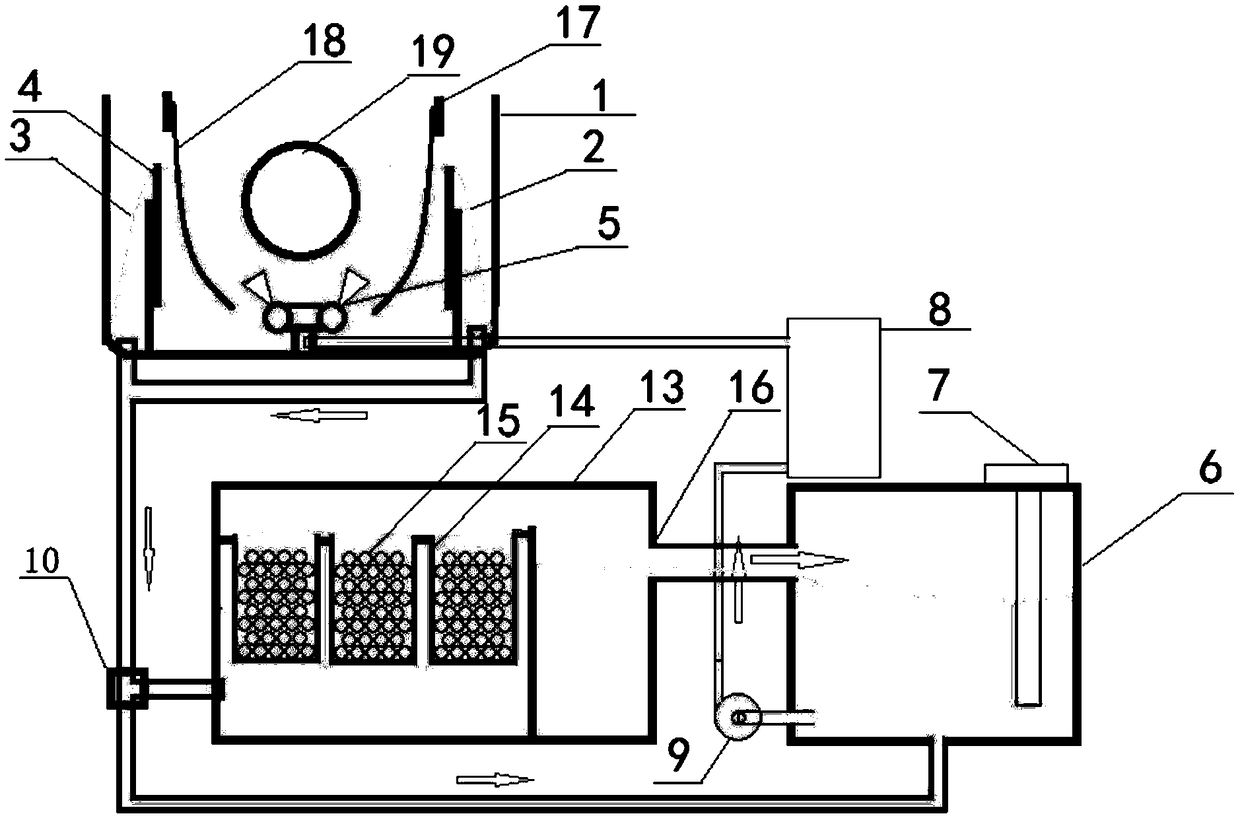

InactiveCN101804517AHigh efficiency of laser energy utilizationSimple structureLaser beam welding apparatusMotor driveOptoelectronics

The invention relates to a thin material laser on-line perforating device comprising a high-power continuous laser, a prism light-splitting mechanism, a vibrating mirror scanning focusing system, a perforating output mechanism and a delivery mechanism. The prism light-splitting mechanism comprises a prism and a high-speed motor driving the prism to rotate; the vibrating mirror scanning focusing system comprises N vibrating mirror scanning focusing mechanisms; the perforating output mechanism comprises N laser perforating processing heads which respectively correspond to the vibrating scanningfocusing mechanism and are arranged on the delivery mechanism, wherein N is no less than 2. The thin material laser on-line perforating device can densely perforate the thin material in large width by utilizing the prism light-splitting mechanism and only adopting the single high power continuous laser, not only has high efficiency, smaller perforating distance of product produced and better ventilation property, but also has simple structure, low cost and higher performance-price ratio.

Owner:苏州市博海激光科技有限公司

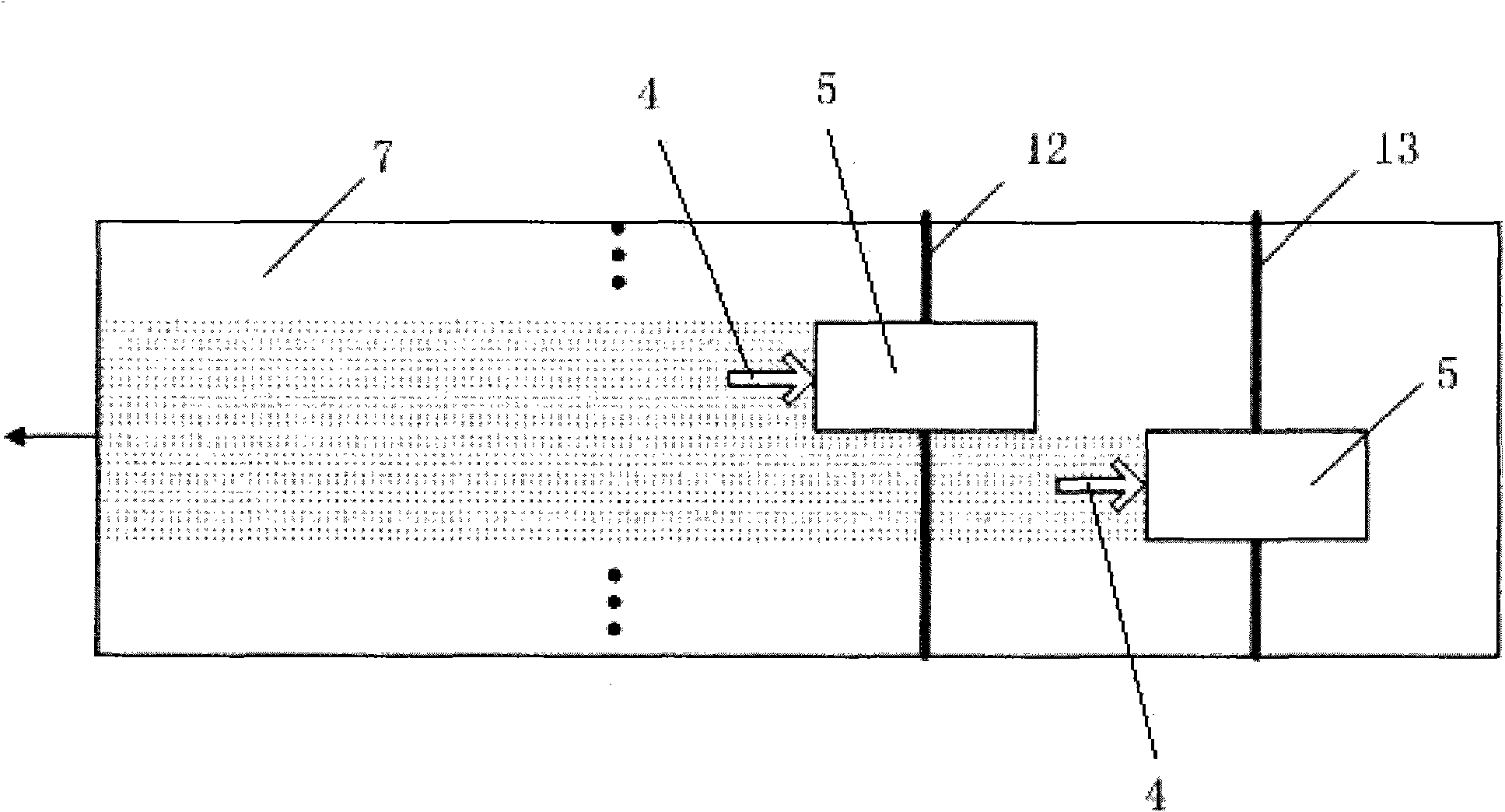

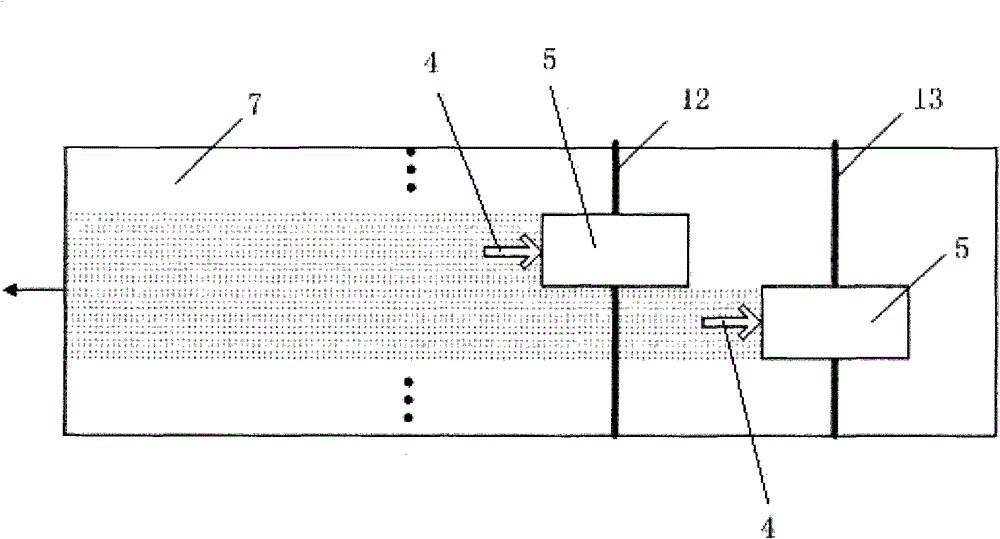

Thin material laser online perforating device

InactiveCN101890581AHigh efficiency of laser energy utilizationSimple structureLaser beam welding apparatusLight reflectionMaterial Perforation

The invention discloses a thin material laser online perforating device which comprises a high power continuous laser, an optical splitting mechanism, two vibrating mirror scanning focusing mechanisms, a feeding mechanism and laser perforating heads which are arranged above the feeding mechanism and are relative to the two vibrating mirror scanning focusing mechanisms one by one, wherein the optical splitting mechanism comprises a mechanical modulation light splitting disc which is driven by a high speed motor to rotate, the mechanical modulation light splitting disc can divide continuous laser beams output by the high power continuous laser into two ways of pulse laser output by making use of light passing parts and light reflection parts which are circumferentially arranged at intervalsin an alternating way on the mechanical modulation light splitting disc, and the two ways of pulse laser output are respectively input into the two vibrating mirror scanning focusing mechanisms. By making use of the optical splitting mechanism, the invention can carry out narrow surface dense perforation on thin materials by only adopting a single high power continuous laser, and has the advantages of high efficiency, simple structure, low cost, high laser energy utilization ratio and higher performance price ratio.

Owner:苏州市博海激光科技有限公司

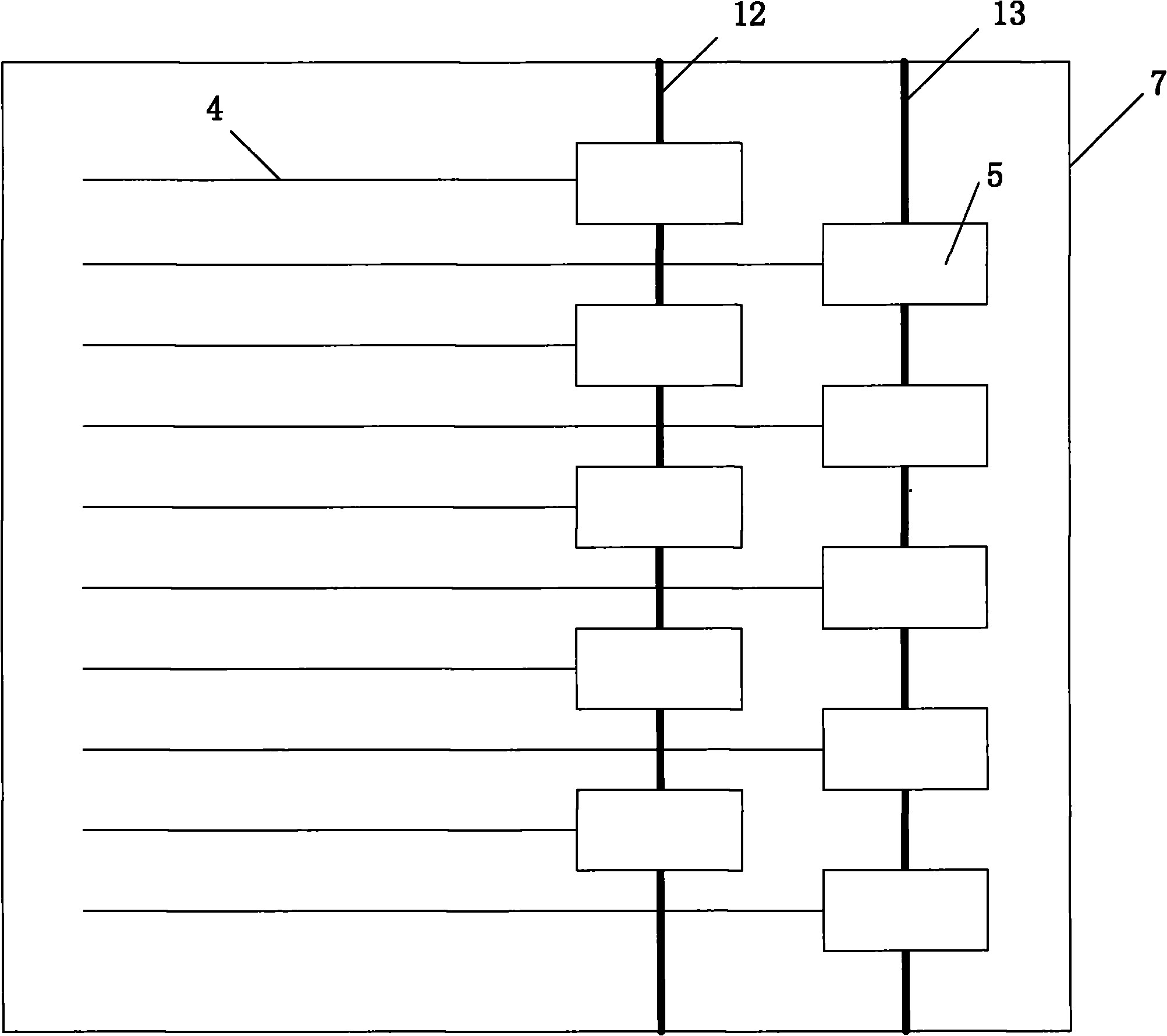

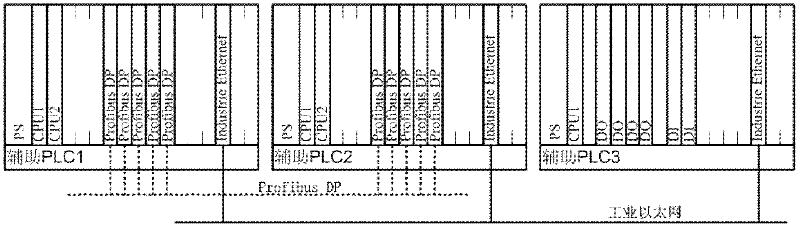

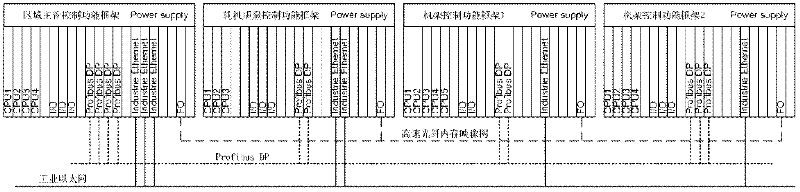

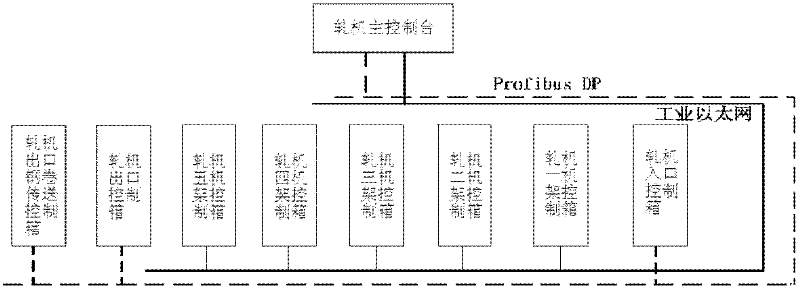

Basic automation control system for tandem cold rolling unit with five frames

InactiveCN102553937AImplement functional requirementsRealize automatic roll change functionRoll mill control devicesMetal rolling arrangementsLoop controlPerformance computing

The invention provides a basic automation control system for a tandem cold rolling unit with five frames, which comprises a PLC (programmable logic controller ) cluster, an HPC (high performance computing ) controller cluster, a field rolling mill control console, a real-time data acquisition system, a developing and debugging system and a system communication network. By the basic automation control system, automatic roll changing can be realized, roll changing time is shortened, production and maintenance can be carried out easily, and building investment and maintenance cost are reduced greatly. Since a high-speed closed-loop control function is realized, continuously high-speed production on sites is guaranteed. Since a high-speed data acquisition function is realized, the basic automation control system is capable of running safely and efficiently and meeting the requirements to millisecond-level monitoring data during fault analysis of the high-speed closed-loop control system of the tandem cold rolling unit. Since functional units are debugged and controlled to run successfully, structural uniformity of the basic automation control system after modification of programs is guaranteed. The high-speed optical fiber memory map net serves as the communication network, high-speed data exchange is realized by data caching among functional units of the HPC controller cluster, and accordingly high-speed data acquisition of the real-time data acquisition system is realized.

Owner:ANGANG STEEL CO LTD

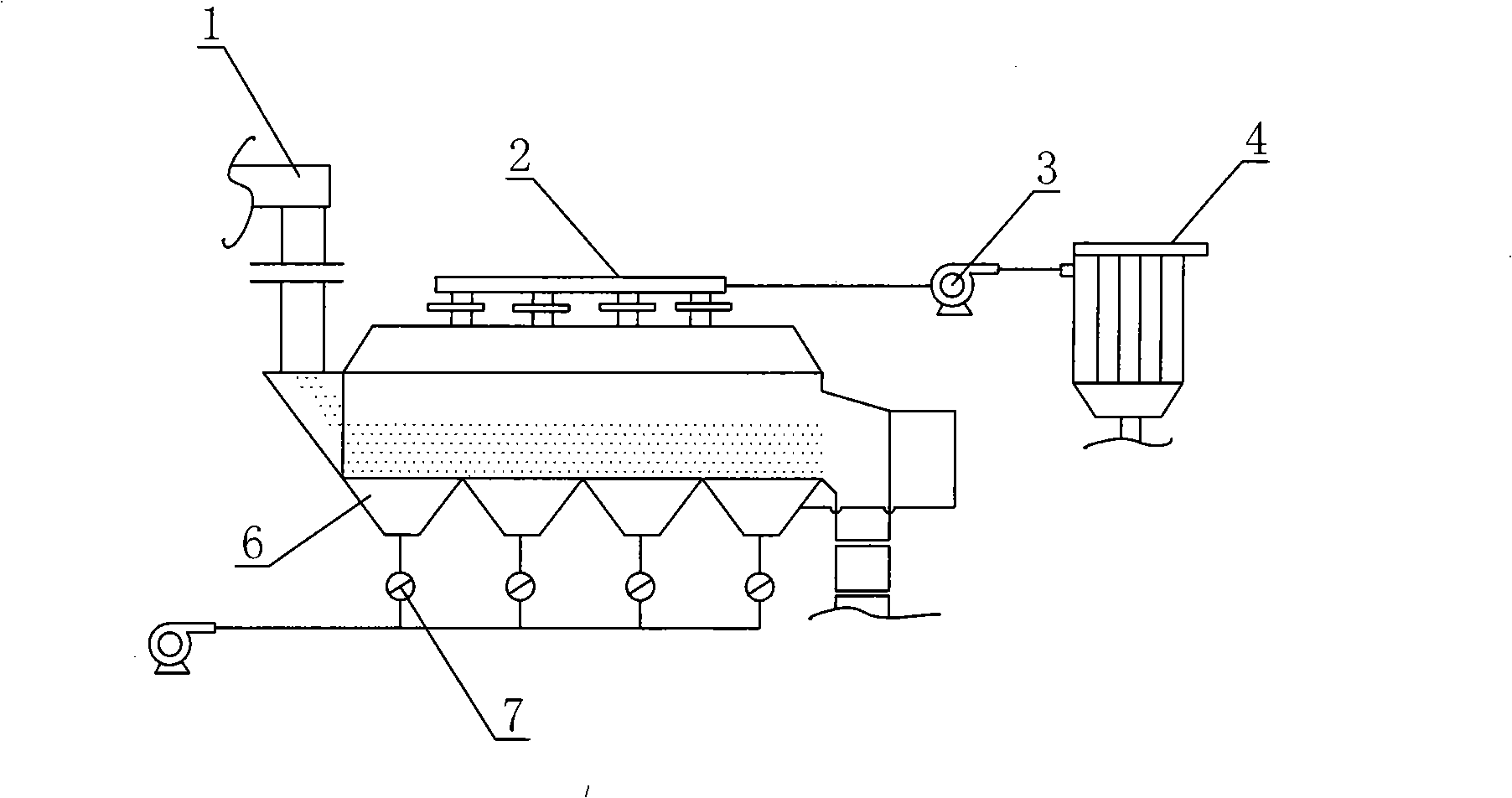

Hydrocarbon black powder removing method and device

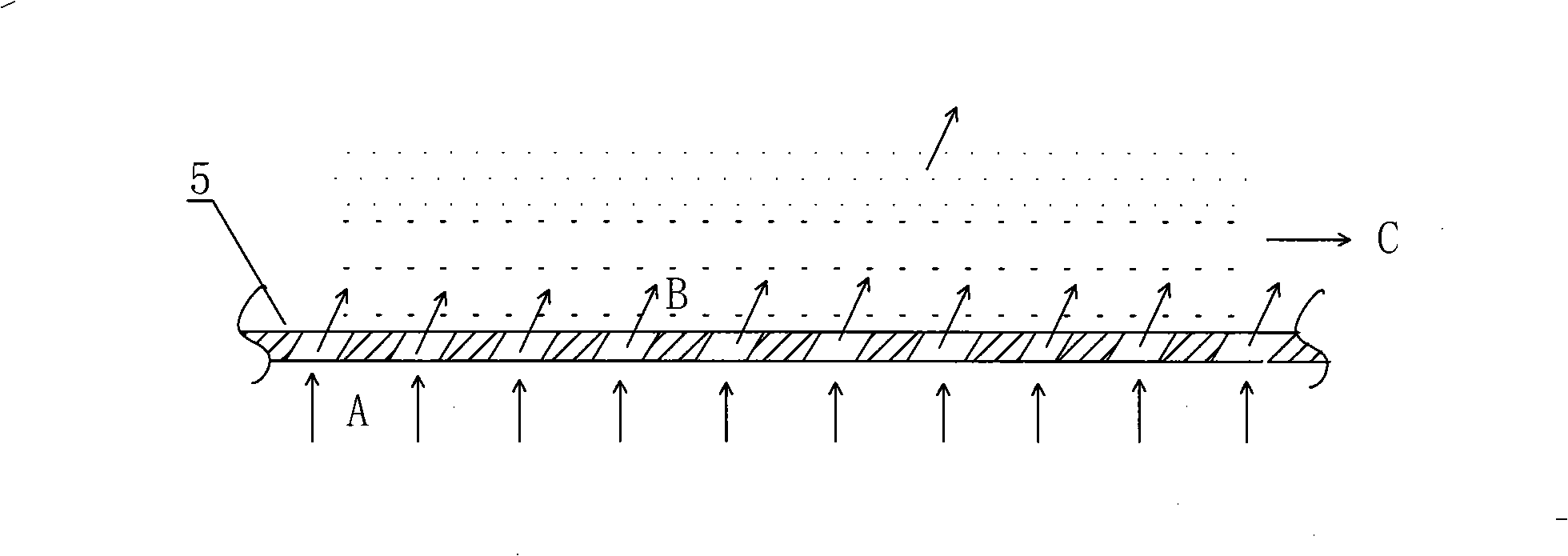

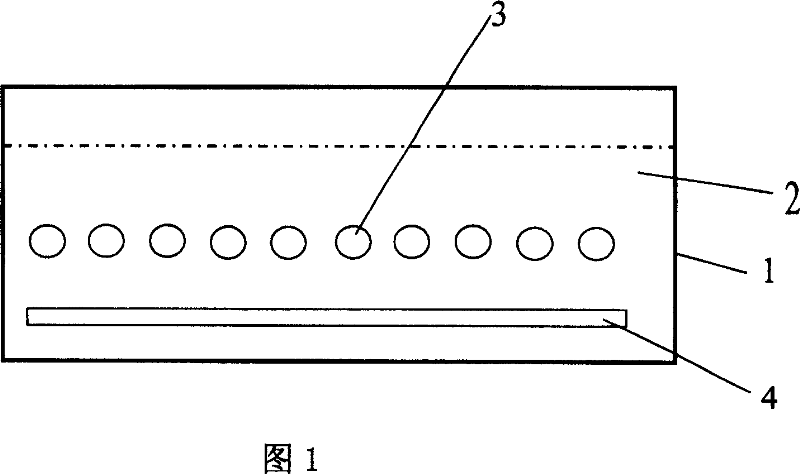

ActiveCN101318180AEasy to handleAchieve high volumeGas current separationManufacturing technologyFluidized bed

The invention relates to a carbon black powder removing method and a device, belonging to the technical field of carbon black manufacturing. The carbon black powder removing method is used for removing the carbon black powder in carbon black pellets; the dried carbon black pellets containing powders are added to the feed end of a fluidized bed of a powder remover; the carbon black pellets run through the fluidized bed under the blowing of the air entering aslant below the fluidized bed and are discharged through the discharge end of the fluidized bed; at the same time, the powders are discharged through the top of the fluidized bed. The invention adopts the method of winnowing products under suspension state, has the advantages of high powder removing efficiency, low product damage rate, cooling product, meeting black storage requirements, improving packaging conditions, simple and efficient technology, and saving resources; besides, the adopted devices has simple and reasonable structure and easy production and maintenance, can effectively improve winnowing and cooling efficiency and realize reasonable energy utilization. The invention can be widely applied to the technical field of carbon black pellet processing and can effectively improve production efficiency and product quality.

Owner:SUZHOU BAOHUA CARBON BLACK

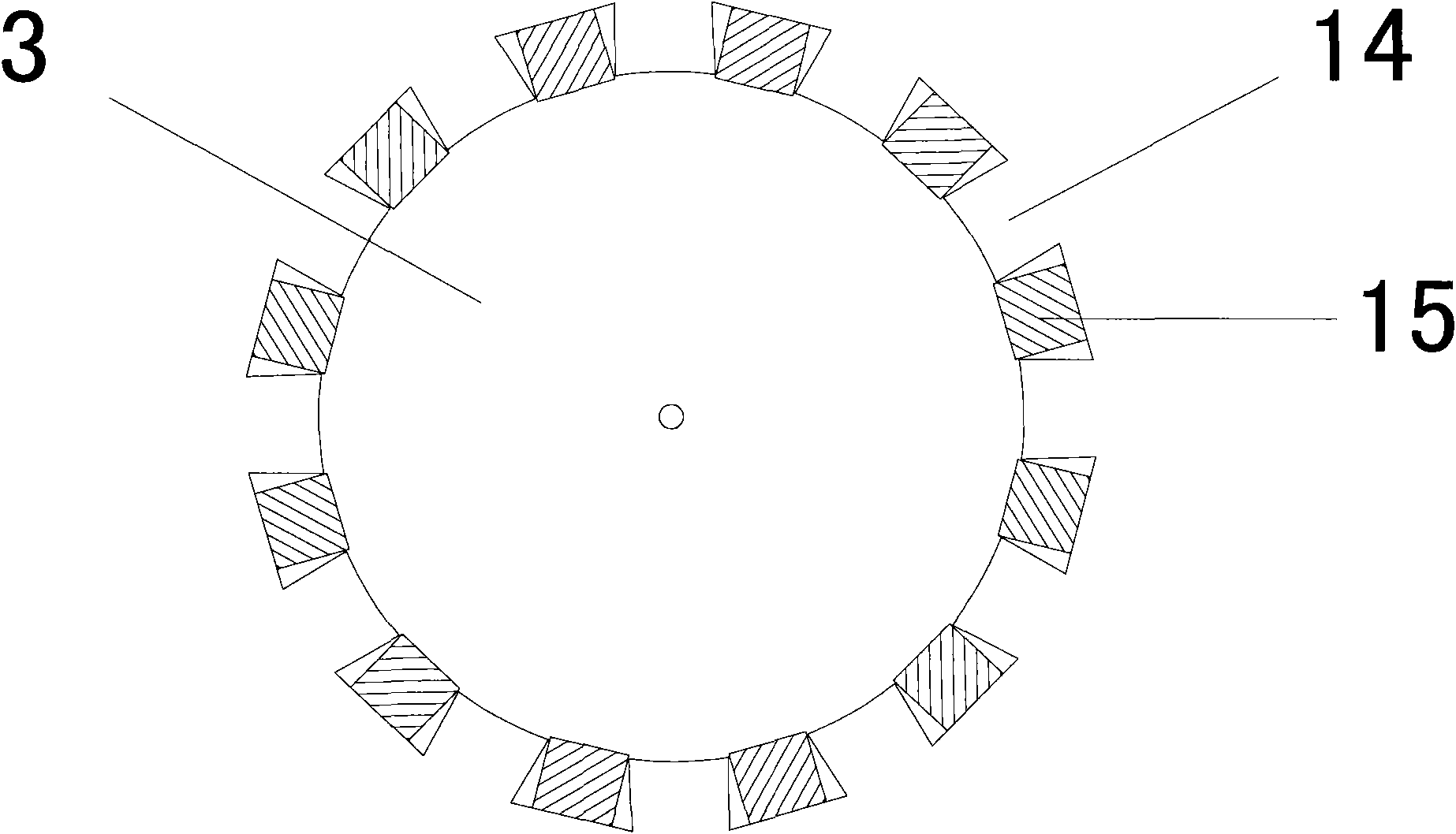

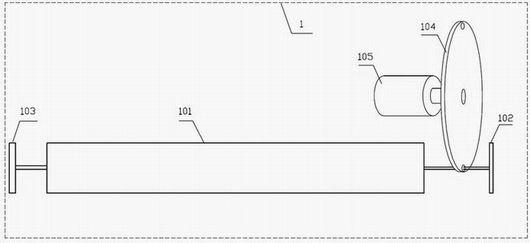

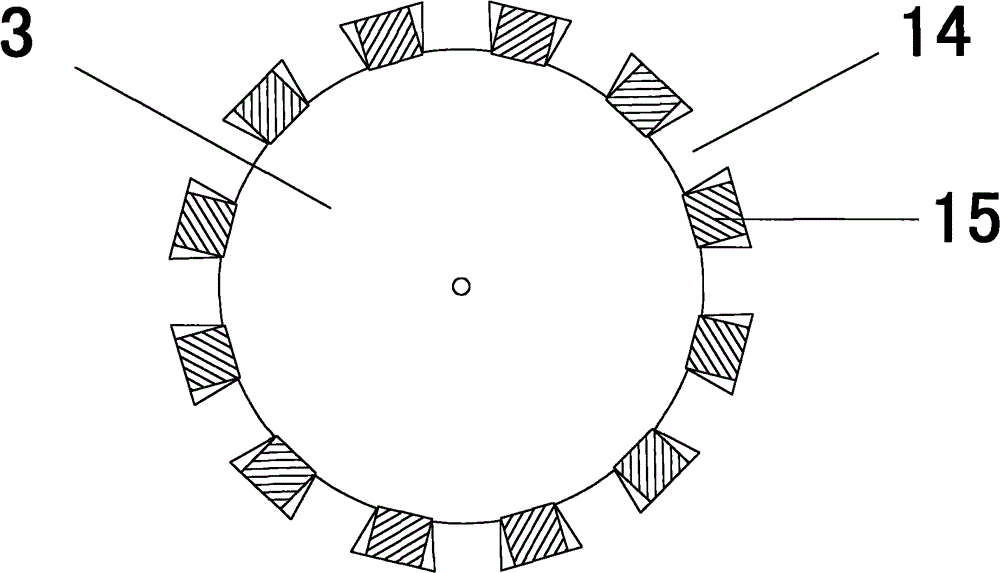

Laser generation method, YAG (yttrium aluminum garnet) laser and laser texturing processing device

InactiveCN102091868AIncrease powerHigh frequencyLaser beam welding apparatusResonant cavityOptical axis

The invention discloses a laser generation method. A mechanical modulation disc made from a light-shading material is put in the resonant cavity of a laser; at least one light-transmission part for the laser axis to pass through is arranged on the mechanical modulation disc; and the rotation speed of the mechanical modulation disc is controlled so that the laser in the modulation period T is subjected to Q modulation and compression and then outputted in the time delta T in the form of consecutive pulses. The invention also discloses a YAG (yttrium aluminum garnet) laser for implementing the laser generation method and a laser texturing processing device. The laser texturing processing device has the advantages of high average power, monopulse energy and repetition rate, can be used for processing deeper and thicker roller materials, can generate deeper texturing points and higher surface roughness when being applied to laser texturing and can obtain higher texturing frequency and texturing processing efficiency.

Owner:HUAZHONG UNIV OF SCI & TECH

Method for surface electroplating of high-resistivity metallic oxide material

The invention provides a method for plating surfaces of oxide materials of high resistivity, which pertains to the technical field of plating for surfaces of metallic oxide materials. First of all, the surface of a metallic oxide material goes through atom hydrogen induced modification in term of conductivity, the electron conductivity of the surface is increased, so that the resistivity is lower than 10<4> Omega is multiplied by m, hence the material surface becomes semi-conducted or metalized; then the modified metallic oxide material is cleaned by de-ionized water, and still then a metallic coating is plated and deposited on the surface of the oxide material through a vibration or rolling plating way. In respect to the fact that the surface of metallic oxide of high resistivity can't be directly plated, the invention first carries out atom hydrogen induced modification in term of conductivity on the surface of metallic oxide to increase the electron conductivity of the surface, then plates and deposits a metallic plating, the obtained metallic plating is of even thickness and good bond with the surface of metallic oxide. The invention is of low equipment investment, and easy to produce and maintain.

Owner:UNIV OF SCI & TECH BEIJING

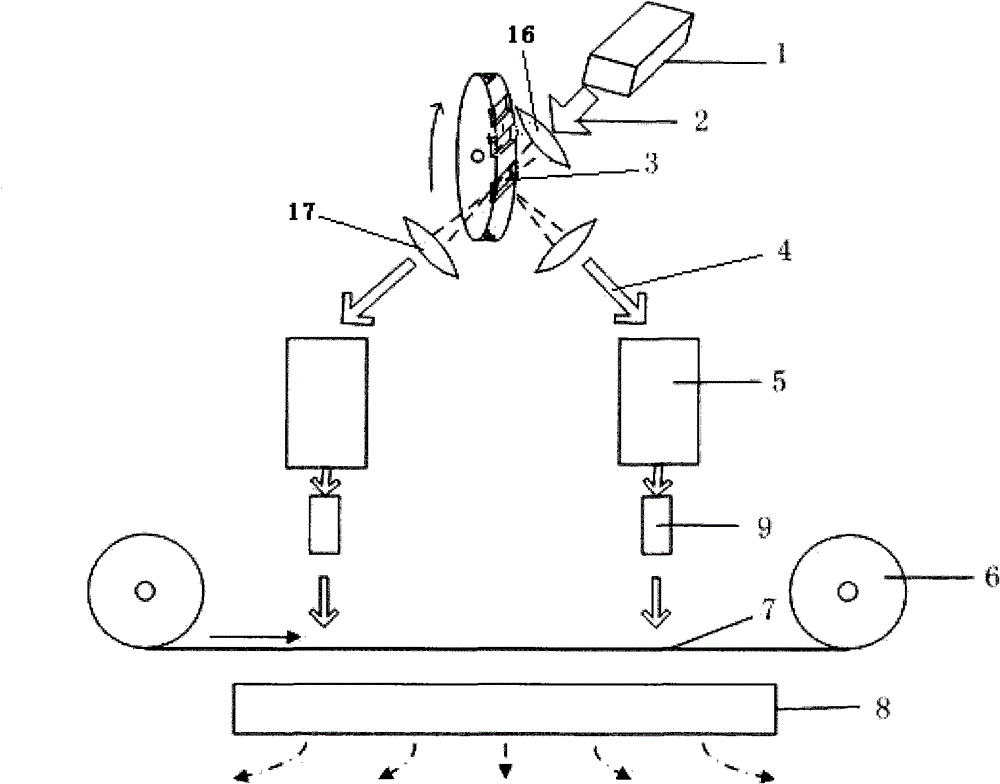

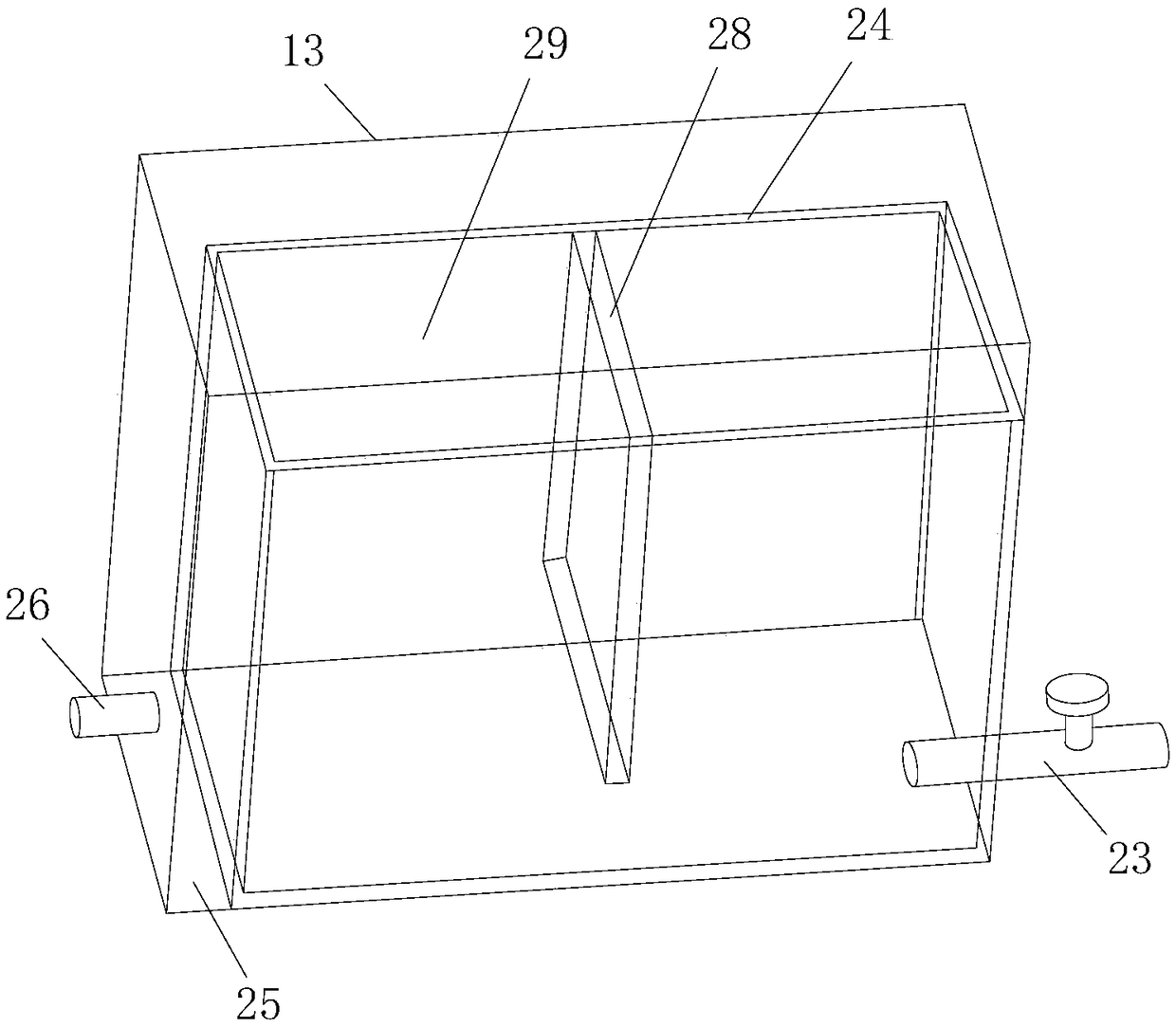

Double-head integrated laser drilling device for cigarette tipping paper

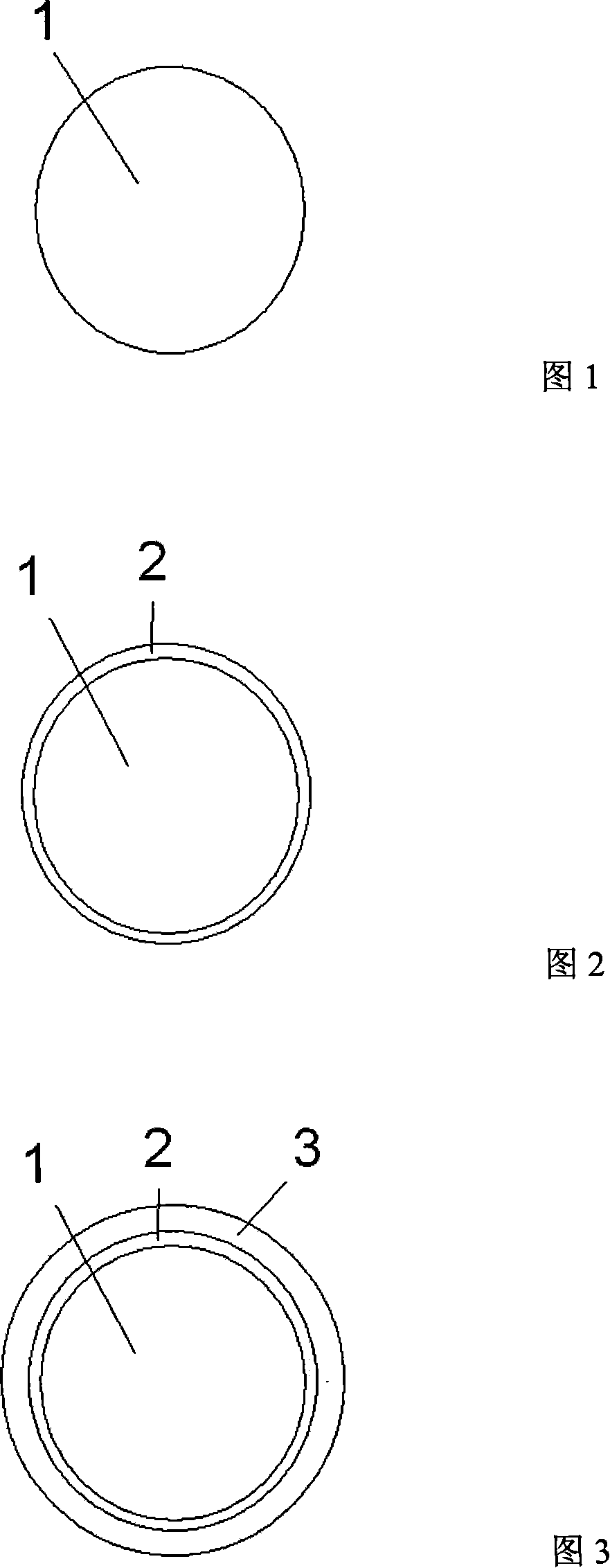

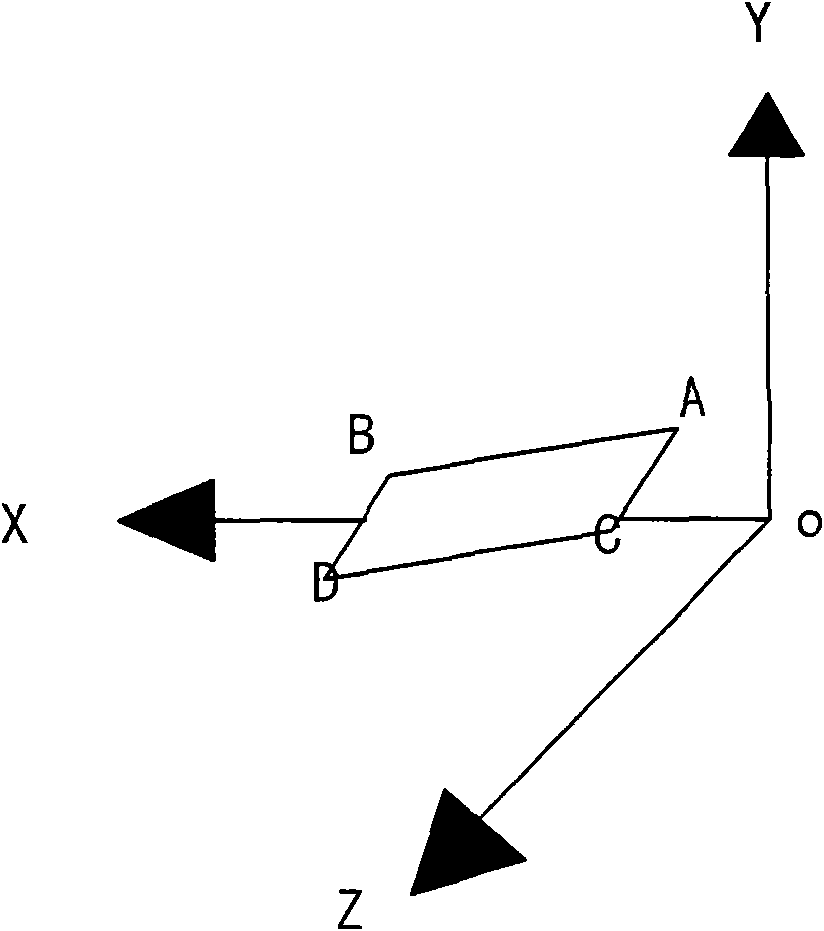

InactiveCN101913026ASimple structureGuaranteed processing efficiencyLaser beam welding apparatusPrismEngineering

The invention discloses a double-head integrated laser drilling device for cigarette tipping paper, which comprises a laser, a polygon prism light splitting mechanism, a focusing mechanism and a paper feeding mechanism for driving the continuous motion of the tipping paper; and the double-head integrated laser drilling device is characterized in that the focusing mechanism consists of a first integrated drilling head and a second integrated drilling head which are arranged along the width direction of the tipping paper, each integrated drilling head can correspondingly output N focus light spots by a group of independent optical focusing elements arranged therein, and the two integrated drilling heads can form 2 multiplied N rows of densely arranged small holes on the moving tipping paper, wherein N is not less than 1. The double-head integrated laser drilling device adopts the technology of the integrated drilling heads to simplify a plurality of separate drilling heads into two independent integrated drill heads, and each integrated drilling head can correspondingly output the N focus light spots, wherein N is not less than 1, thereby ensuring the processing efficiency and simultaneously achieving the purpose of simplifying the structure of the device.

Owner:苏州市博海激光科技有限公司

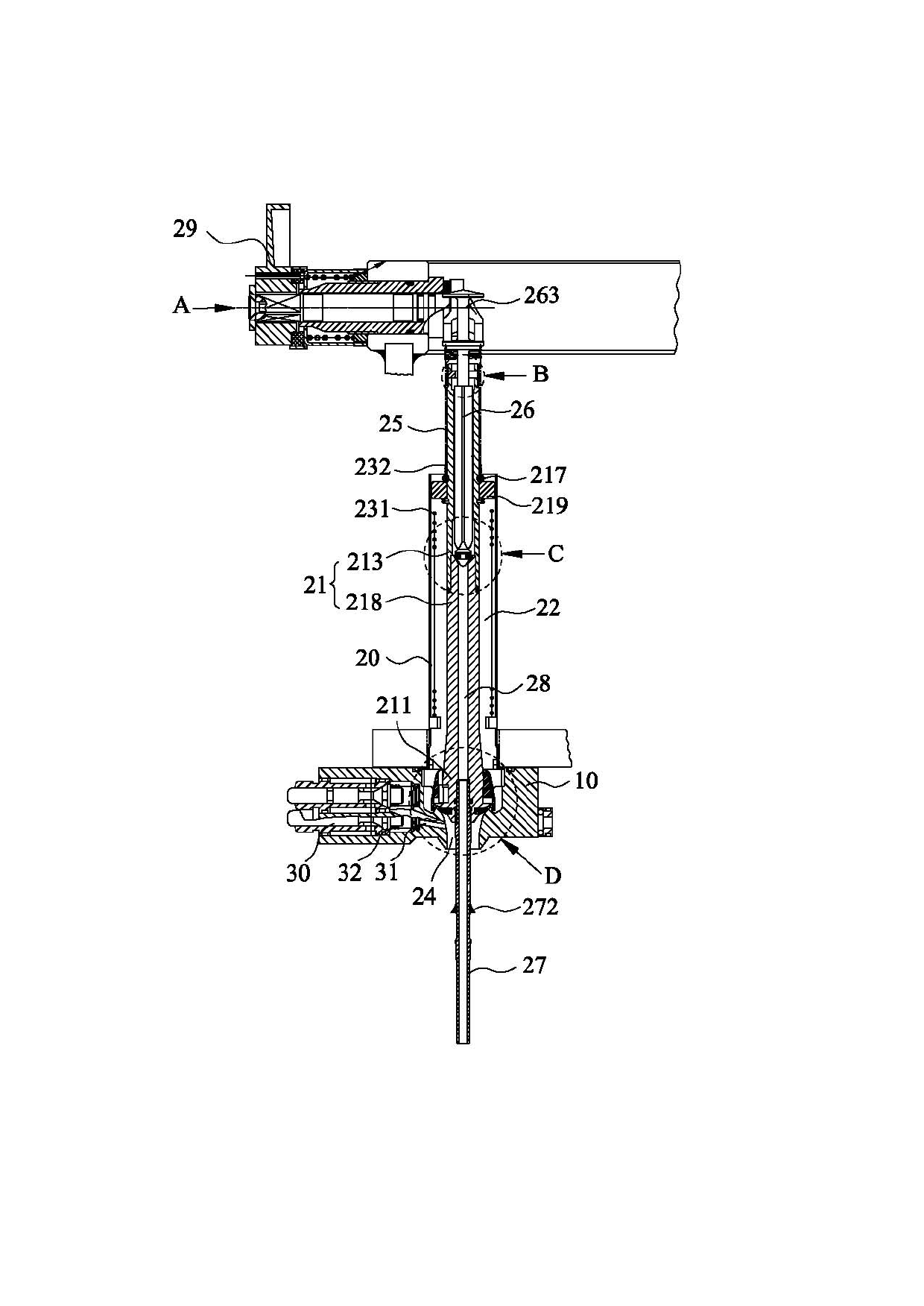

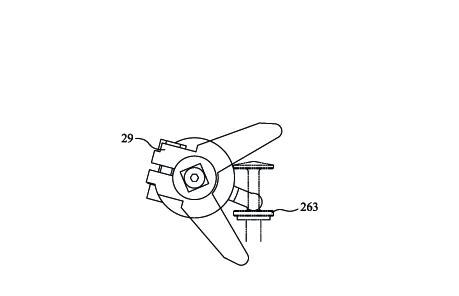

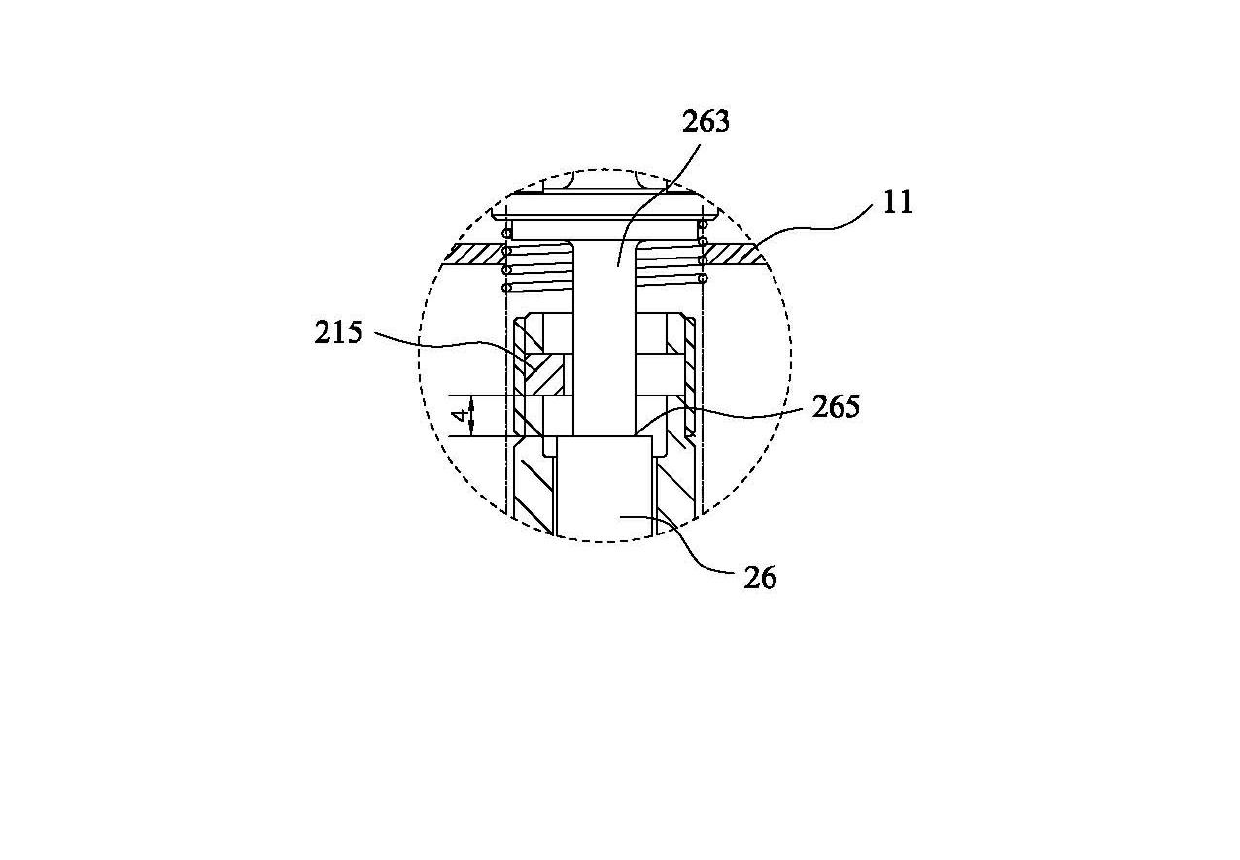

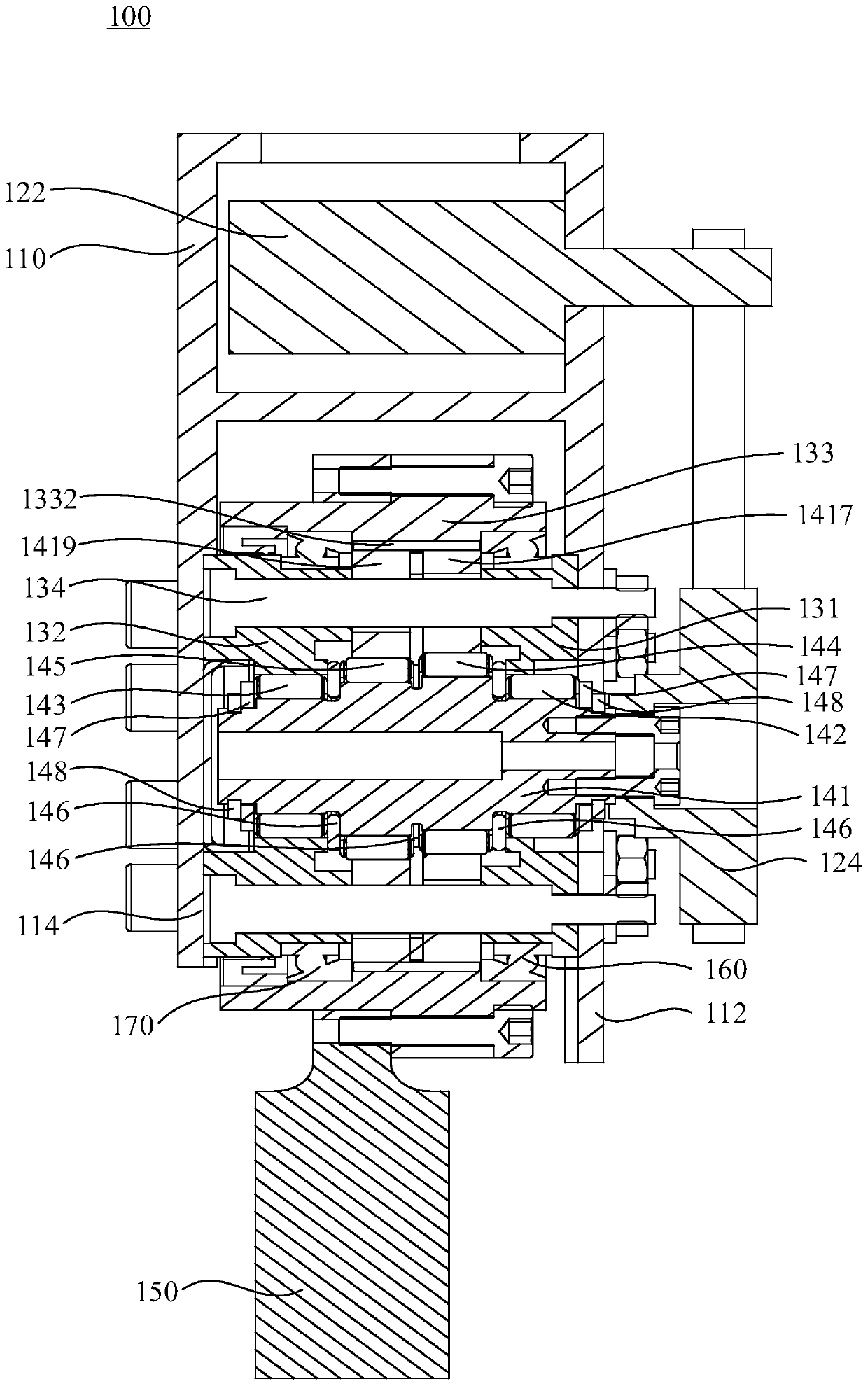

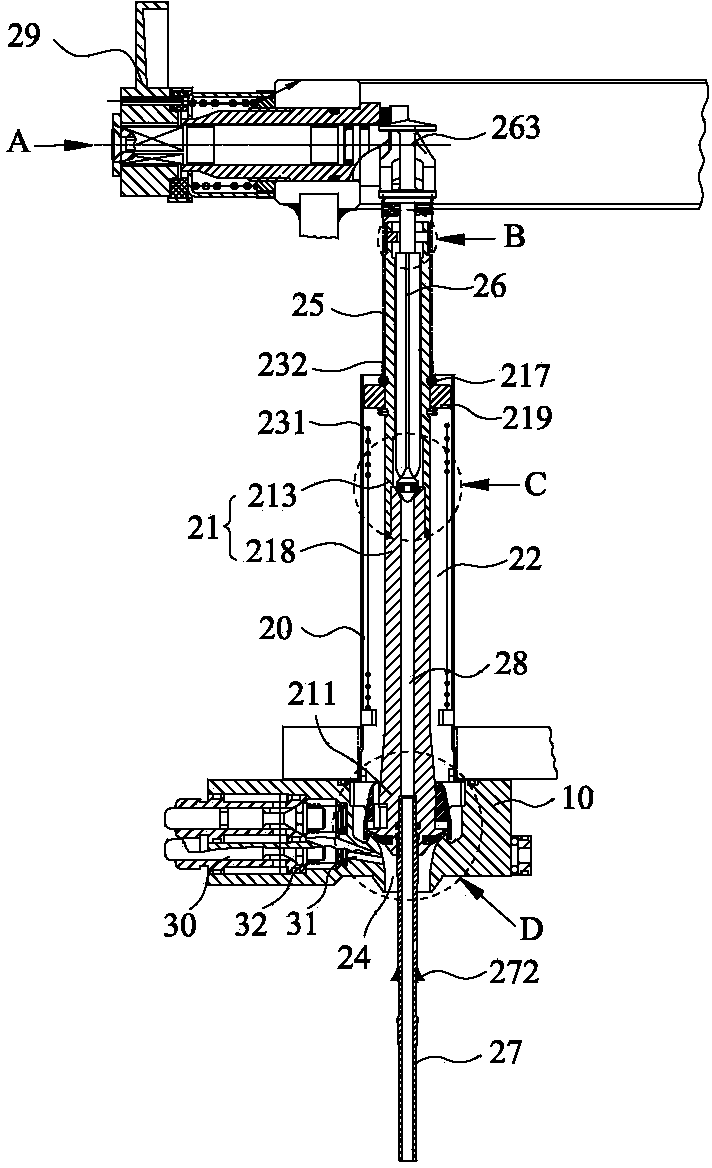

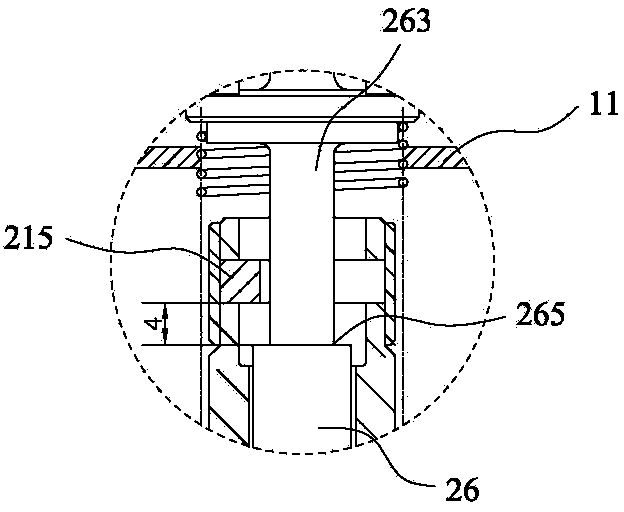

Water-gas dual-purpose filling valve

The invention discloses a water-gas dual-purpose filling valve, which comprises a valve seat and a valve body fixedly arranged on the valve seat, wherein a hydraulic valve core which can move up and down is arranged in the valve body; a liquid inlet channel is formed between the hydraulic valve core and the valve body; a gas channel is arranged in the hydraulic valve core; a gas valve core which can up and down is arranged in the gas channel; the top end of the hydraulic valve core is fixedly provided with a clamping block; the top end of the gas valve core is provided with a pushing step; when the filling valve is used for filling, a certain distance is reserved between the clamping block and the pushing step; when the filling valve is used for filling gas-containing materials, the distance that the gas valve core moves upwards is not more than the distance between the clamping block and the pushing step; and when the filling valve is used for filling water, the distance that the gas valve core moves upwards is more than the distance between the clamping block and the pushing step, the clamping block is jacked to drive the hydraulic valve core to be lift to an appropriate openness at the same time of lifting the jacking step upwards, therefore filling of gas-containing materials and gas-free materials is realized on the same filling valve, and troubles because the traditional gas-containing materials and the gas-free materials are finished by different filling valves are avoided.

Owner:GUANGZHOU TECH LONG PACKAGING MACHINERY CO LTD

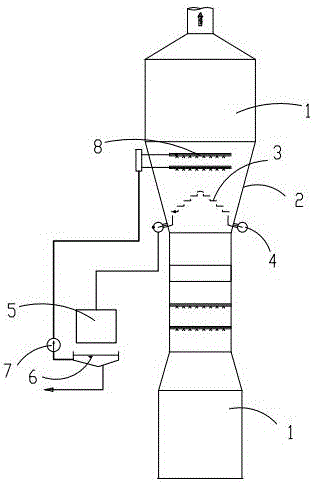

Flue gas desulfurization and dust-whitening integrated device

PendingCN106621724ASmall footprintLower overall investmentCombination devicesVapor condensationWater pipeElectrostatic precipitator

The invention provides a flue gas desulfurization and dust-whitening integrated device, comprising a desulfurizing tower, a whitening device communicated with a flue gas outlet of the desulfurizing tower, and a wet electrostatic precipitator which is arranged on the top of the whitening device and is communicated with the whitening device, wherein the whitening device comprises a device shell fixedly arranged above the desulfurizing tower, a water collector arranged in the device shell, and a spray device arranged above the water collector; a water collecting hole is formed in the device shell, and is communicated with a water collecting pipe; the water collecting pipe is communicated with a water cooling tower by a water collecting pipeline; the water cooling tower is communicated with a sedimentation tank; the upper part of the sedimentation tank is connected with a spray pipeline by a spray pump; the spray pipeline is communicated with the spray device; the bottom of the sedimentation tank is connected with a desulfurization pulping system by a sewage pump. After the device is used, the aim of whitening flue gas is achieved; spray water can be separately recycled, and water removed from the flue gas can be also recycled so as to be used for the desulfurization pulping system, so that the aim of saving water is achieved.

Owner:JIANGSU YIJIN ENVIRONMENTAL PROTECTION TECH CO LTD

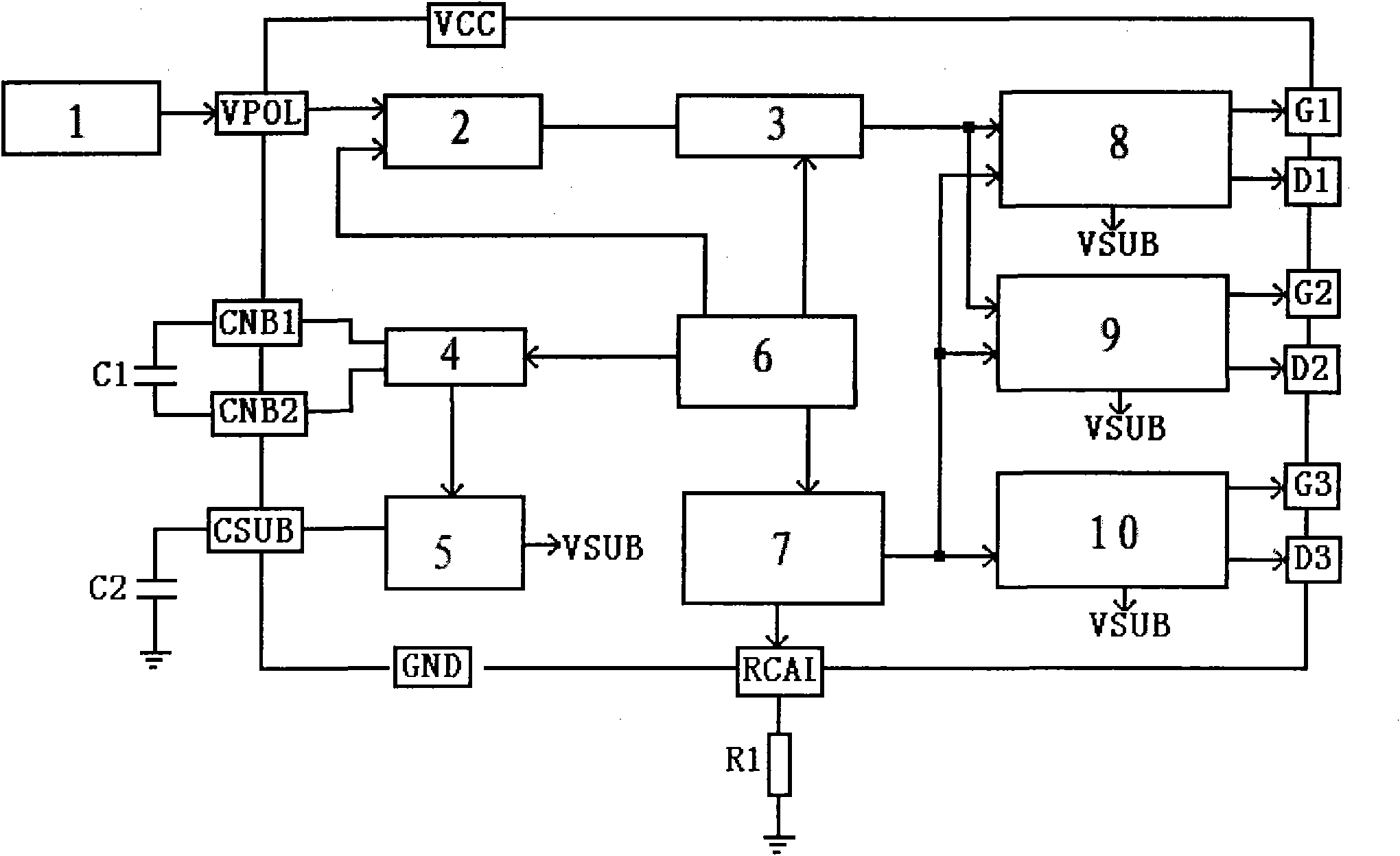

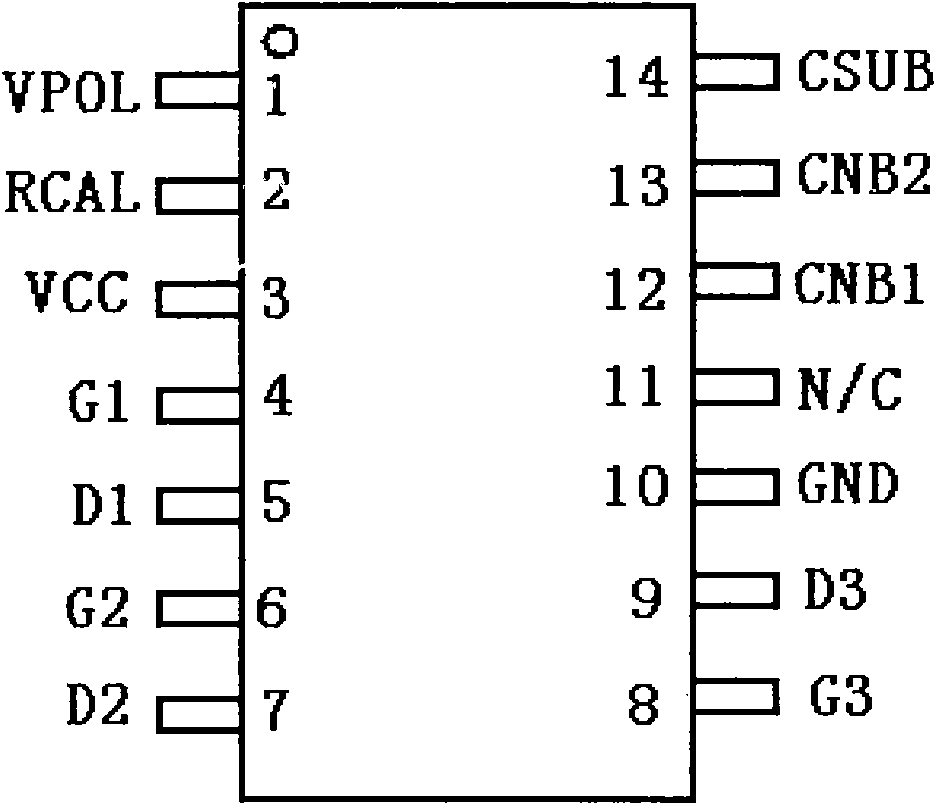

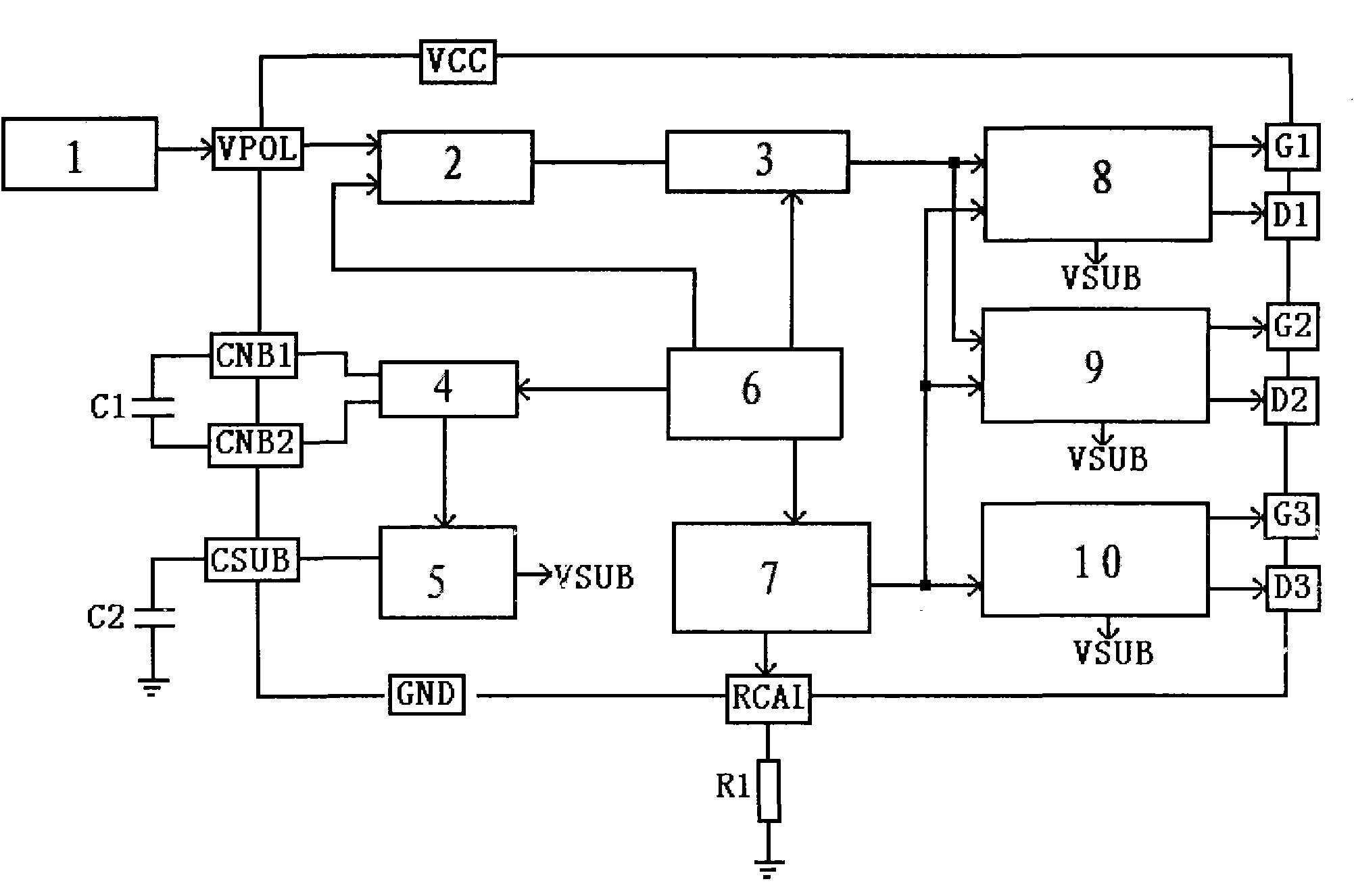

Integrated circuit with functions of bias and polarization selection

InactiveCN101895698AImprove noiseImprove featuresTelevision system detailsGHz frequency transmissionHigh volume manufacturingEngineering

The invention provides an integrated circuit with functions of bias and polarization selection, comprising a reference voltage and current circuit. According to the comparison result of a polarization selection signal input by peripheral signal receiving equipment and a reference voltage or a current signal provided by the reference voltage and the current circuit, a control circuit selects one of a horizontal polarization passage and a vertical polarization passage to stay in a working state; a first amplifier tube bias and protective circuit and a second amplifier tube bias and protective circuit are respectively connected with a peripheral first amplifier tube and a peripheral second amplifier tube to form the horizontal polarization passage and the vertical polarization passage; a third amplifier tube bias and protective circuit is connected with a peripheral third amplifier tube; a negative voltage generation circuit is connected with the reference voltage and current circuit to provide negative voltage for the first, second and third amplifier tube bias and protective circuits; and a drain current adjustment circuit is connected with the reference voltage and current circuit to regulate the drain current which is output to the three amplifier tubes. The integrated circuit has high stability, low cost and simple structure, is suitable for mass production, and can be applied to high-frequency heads of satellite televisions and the like.

Owner:SUZHOU HUAXIN MICROELECTRONICS

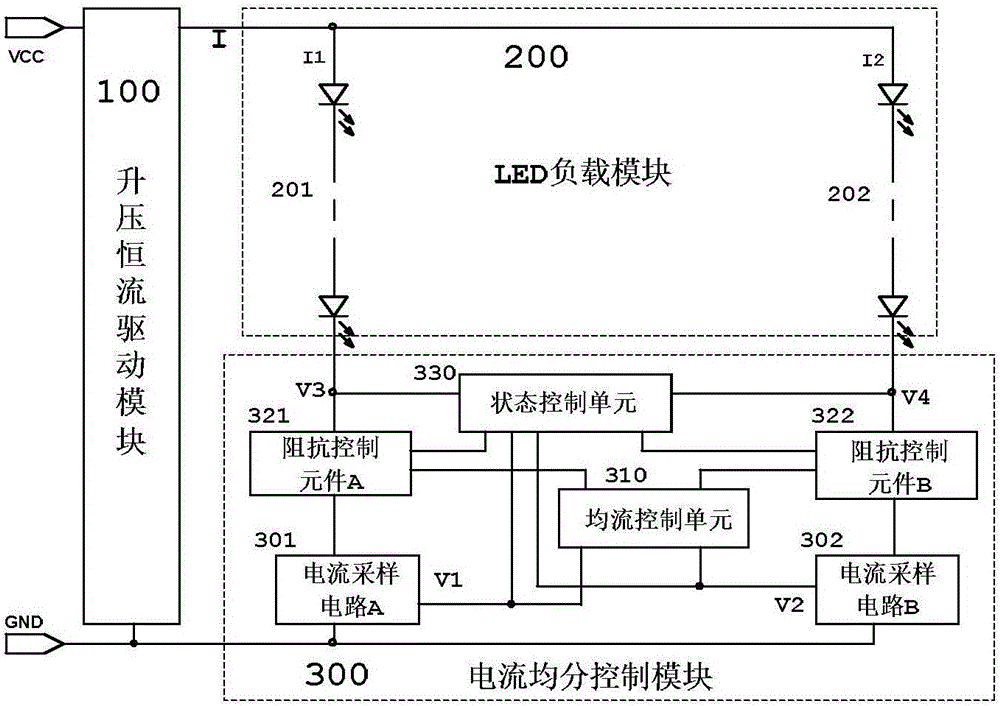

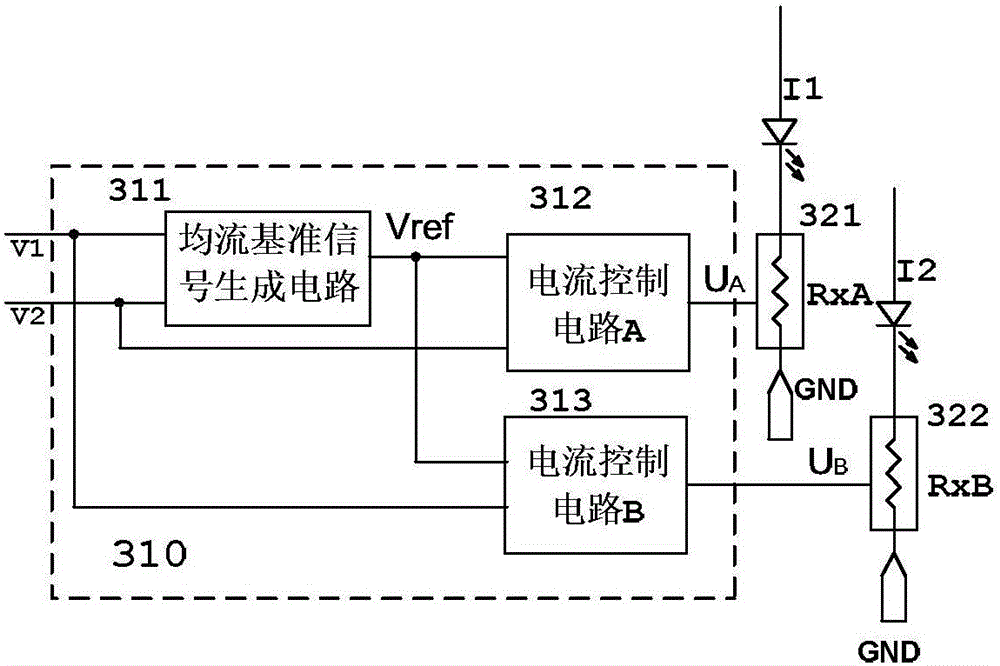

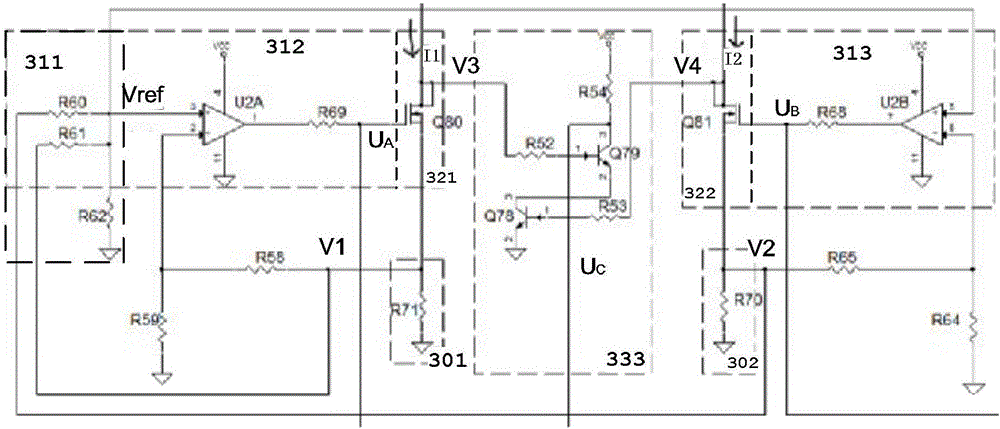

Current sharing circuit based on LED voltage-boosting constant current drive

InactiveCN106028509ACurrent sharingEnsure consistencyElectrical apparatusElectroluminescent light sourcesConstant currentControl unit

The invention discloses a current sharing circuit based on LED voltage-boosting constant current drive, relates to a driving circuit used for a vehicle LED illuminating apparatus and component configuration, and particularly relates to a double-circuit parallel drive control circuit used for an LED voltage-boosting constant current driven automotive lamp light source; the current sharing control module comprises a current sampling circuit, a current sharing control unit and an impedance control element; the two input ends of the current control circuit are connected to the current sampling circuit and a current sharing reference signal generation circuit separately; by comparing a current sharing reference signal with a current sampling signal, an impedance control signal is generated and transmitted to the impedance control element; by automatically adjusting the impedance value of the impedance control element, the current sharing control of the two parallel LED string current sharing branches is realized; the current sharing of the two constant current driven LED strings can be realized under different numbers of the two LED strings, or different voltage characteristics, or inconsistent voltage drop of the two LED strings; and whether the brands and the characteristics of the LEDs are the same or not, the consistency of the current values and the rapid response of the state control can be ensured.

Owner:HASCO VISION TECHNOLOGY CO LTD

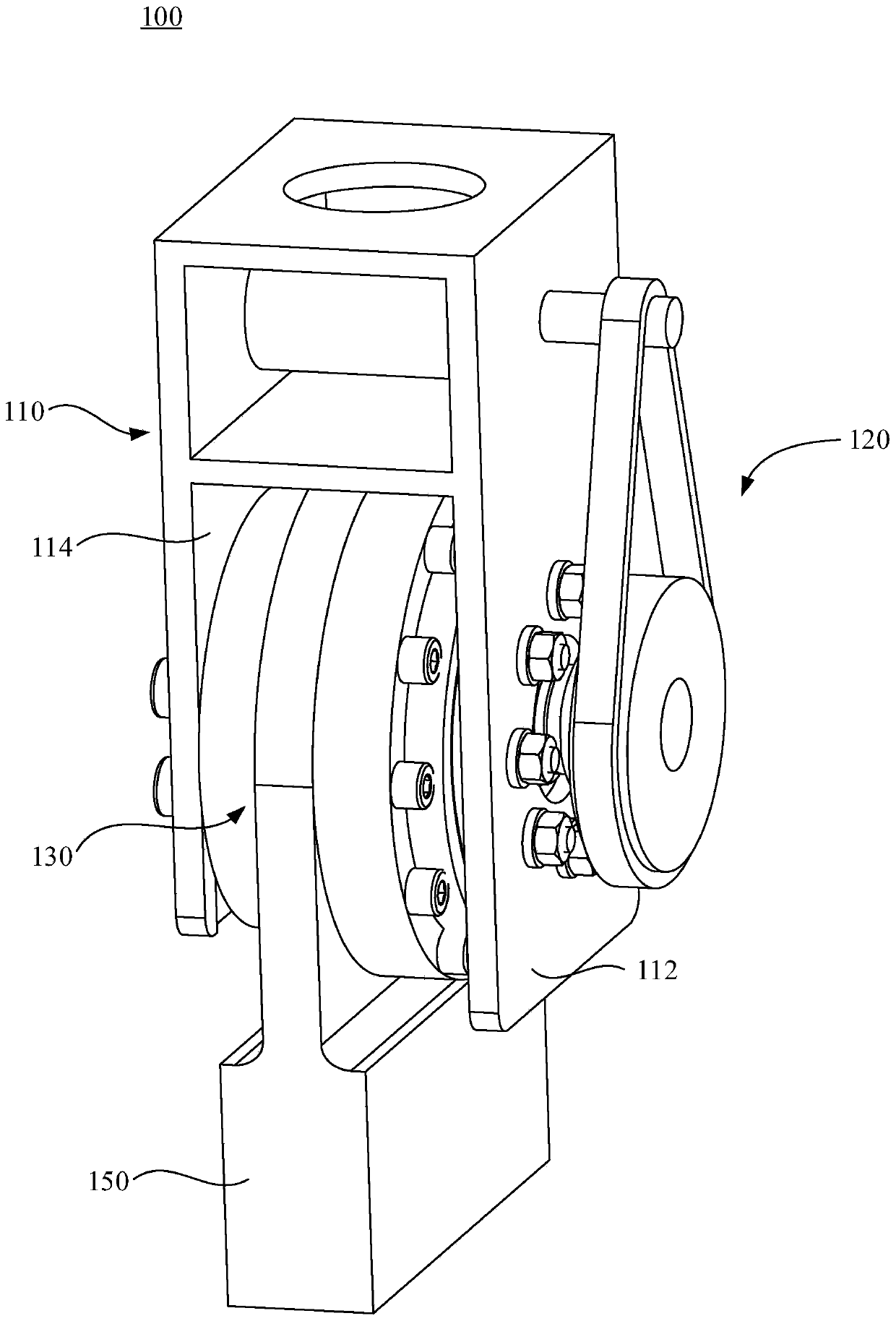

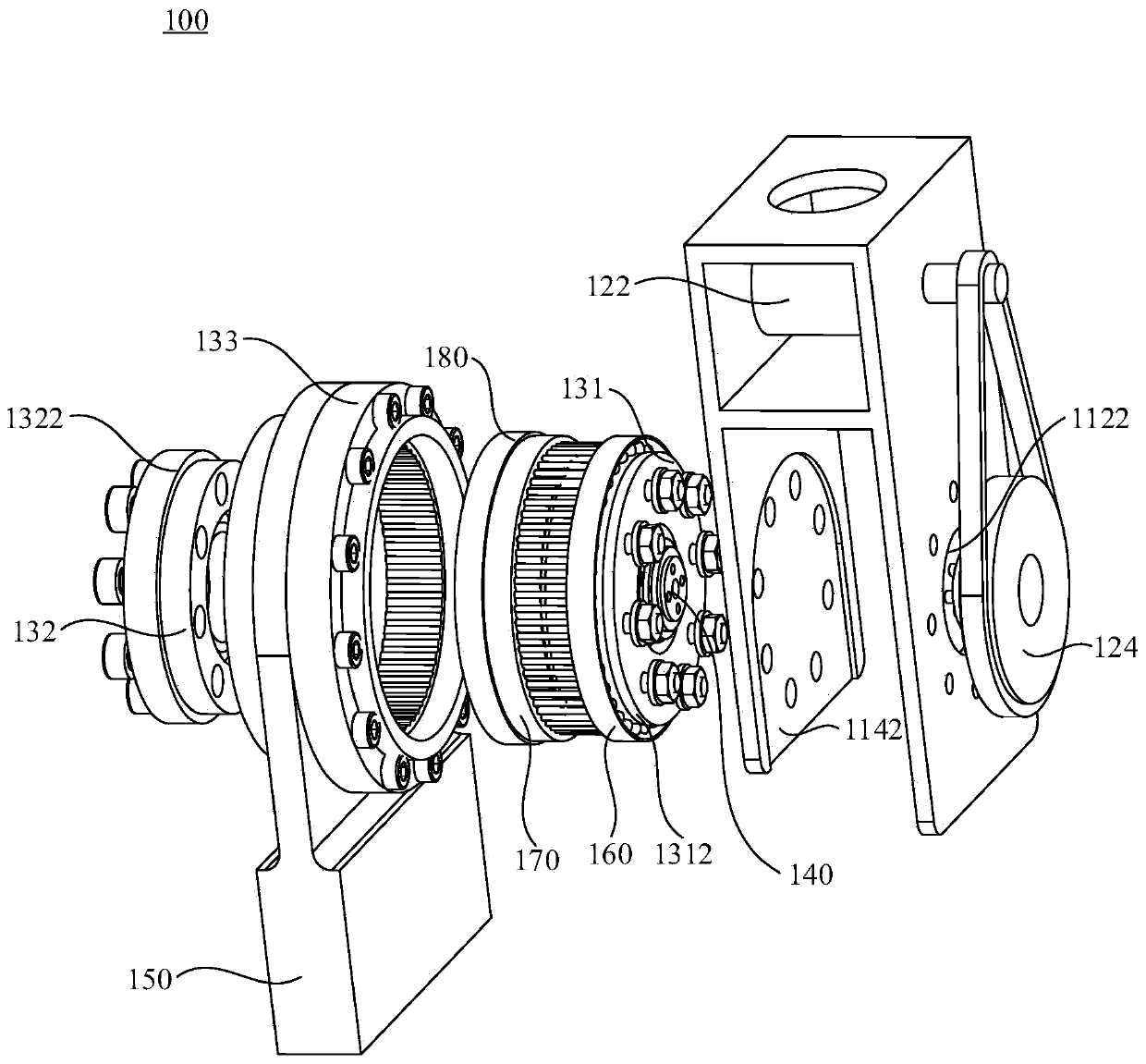

Transmission device and multi-legged robot

PendingCN110185749ASmooth rotationReliable transmissionToothed gearingsGearing detailsLegged robotEngineering

The invention discloses a transmission device and a multi-legged robot, and relates to the technical field of mechanical transmission. The transmission device comprises a rack, and a drive assembly and a gear transmission assembly which are arranged on the rack, wherein the gear transmission assembly comprises a first end cover and a second end cover which are correspondingly arranged, an inner gear ring which is arranged on the outer rings of the first end cover and the second end cover and is rotationally connected with the first end cover and the second end cover, and a crank shaft assemblywhich penetrates through the center of the first end cover and the center of the second end cover; the crank shaft assembly is in transmission connection with the drive assembly and is in transmission connection with the inner gear ring; and a transmission arm is fixedly arranged on the outer ring of the inner gear ring. The transmission device can simplify the manufacturing difficulty, is easy to produce and maintain, and can transmit larger torque.

Owner:南京南传智能技术有限公司

Roller surface coarsening processing method using multiheaded high power laser and its device

InactiveCN100413631CTake advantage ofHigh power outputLaser beam welding apparatusNumerical controlHigh power lasers

The invention discloses a woolening manufacturing method, which consists of laser (2) and numerical control machine (3), wherein the working bench (4) loads multiple-prism light splitting and focusing device; the multiple-prism light splitting device (5) contains total reflection lens (502), multiple prisms (501), high-speed motor (509) and K light splitting heads; the focusing device is composed of K focusing heads with each focusing head corresponding to one output end of light splitting head; the light axle of focusing head is vertical of roll workpiece with woolening point distance DELTAX of two focusing heads as transverse distance and DELTAY as longitude distance (K>=2).

Owner:HUAZHONG UNIV OF SCI & TECH

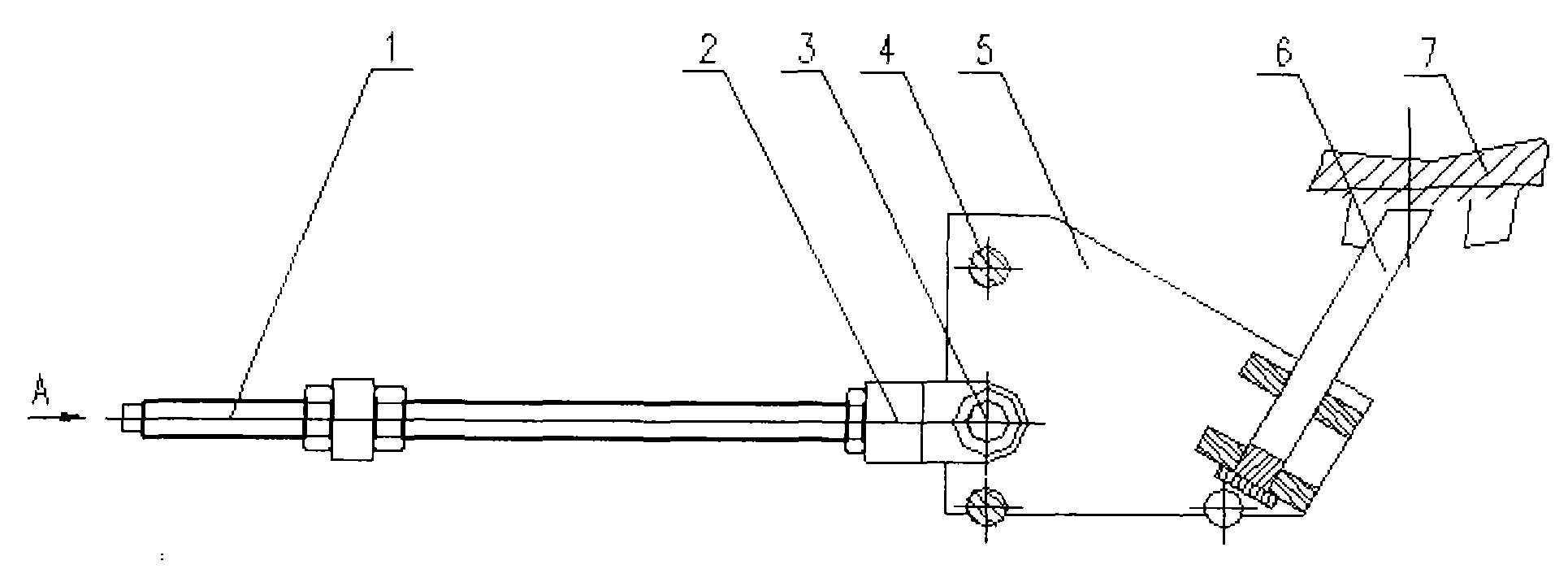

Grinding method of edge of milling cutter and tool

The invention relates to a grinding method of an edge of a milling cutter and a tool, which are used for grinding the milling cutter with more than one two-dimensional inclined edge. The method comprises the following steps of: fixing the milling cutter on a fixed seat, adjusting the fixed seat to lead at least one edge surface of the milling cutter to be parallel to a reference surface, arranging the fixed seat on the surface of a grinder platform, adjusting the grinder platform to lead the edge surface of the milling cutter to be in horizontal state, then grinding the edge surface of the milling cutter, adjusting the relative positions of the milling cutter to the fixed seat after the processing of the edge of the milling cutter is completed, leading the edge surface of another milling cutter to reach the position to be processed, being capable of carrying out grinding, repeating the processes till the grinding of all the edges of the milling cutter is completed. The invention has simple technique and convenient operation, and can realize accurate and high-precision grinding to the edges of profile milling cutter, and simultaneously the tool has simple structure and easy production maintenance. The invention can be widely applied to the manufacturing and grinding techniques of the cutter with the inclined edge surface.

Owner:华努迪克(苏州)电子有限公司

Method for stripping metallic thin film plated on surface of material

The invention discloses a method for stripping a metallic thin film attached to the surface of a material, belonging to the technical field of surface treatment of materials. The method comprises the following steps that: a metallic thin film coated on the surface of a material is connected to a circuit and used as a negative electrode; the metallic thin film is coupled with a counter electrode, then driven by an external power supply and performed a brine electrolysis process in an electrolyte solution, so that a hydrogen evolution reaction is implemented on the metallic thin film, wherein the electric current density of the negative electrode is 30-3000 amperes / square meter, the molar concentration of an electrolyte is 0.0001-1M, and the temperature of the electrolyte solution is minus 5-90 DEG C; the metallic thin film is stripped from a matrix under a mechanical action caused by precipitated hydrogen, then a matrix material and the stripped metallic thin film are respectively collected; the electrolyte solution attached to the surfaces of the matrix material and the stripped metallic thin film are scoured off by water so as to obtain a matrix material and a metallic thin film bunch which are separated from each other. The method disclosed by the invention has the advantages of good metallic thin film stripping effect, small required equipment investment, simple production and maintenance, cleanness and speediness; and by using the method, the damage to a stripping process on the matrix material is avoided or inhibited.

Owner:UNIV OF SCI & TECH BEIJING

Plastic reinforcing cap for detonating cap

The invention relates to the manufacturing field of explosive materials and providing a plastic reinforcing cap for a detonating cap. The plastic reinforcing cap is used for solving the problems that the existing plastic reinforcing cap is deformed and cracked under high pressure, easy to chap under an extreme environment and melt and block a flash hole when the eruption of the first fire composition of the detonating cap is delayed, and easy to tear and smash during explosion. The plastic reinforcing cap can be suitable for detonating cap shells made from various materials, is convenient for static electricity guiding and further reducing the frictional force between the reinforcing cap and the inner wall of the tube, and easy to popularize and use.

Owner:SICHUAN YIBIN WEILI CHEM CO LED

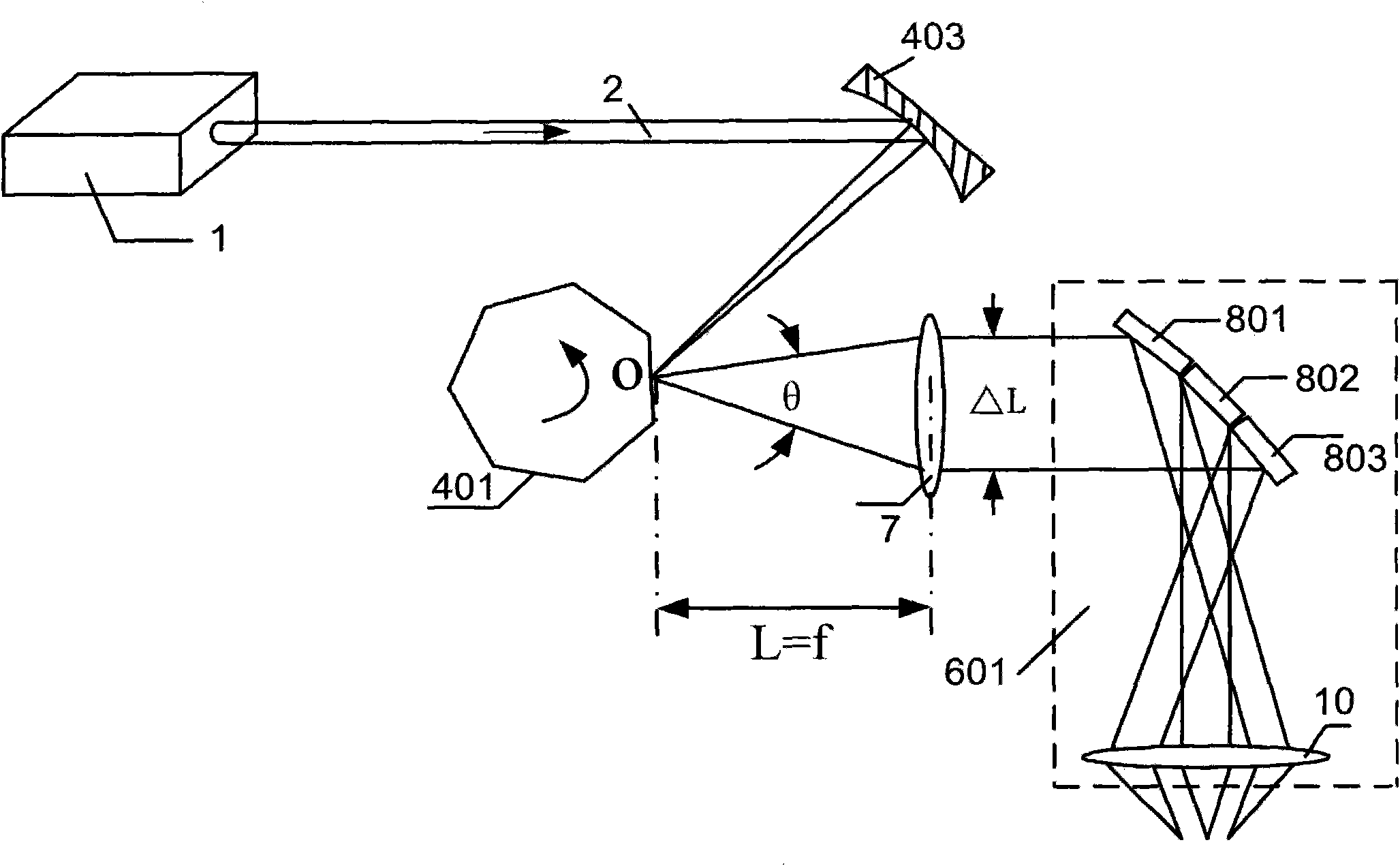

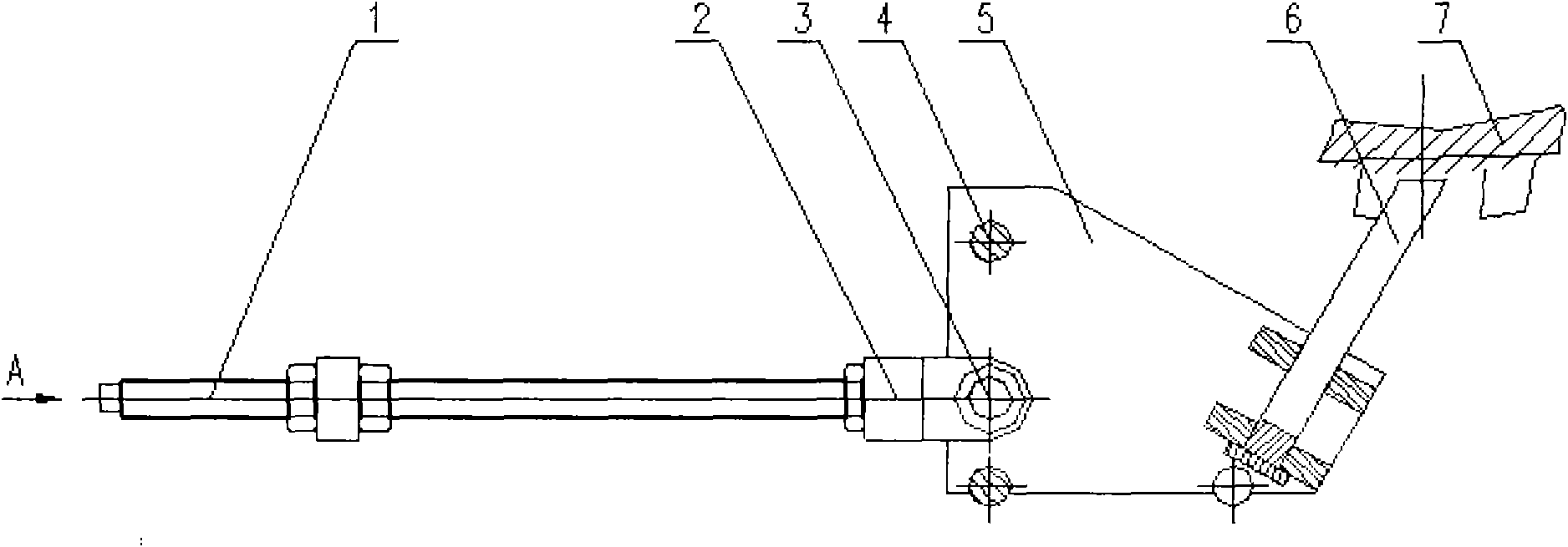

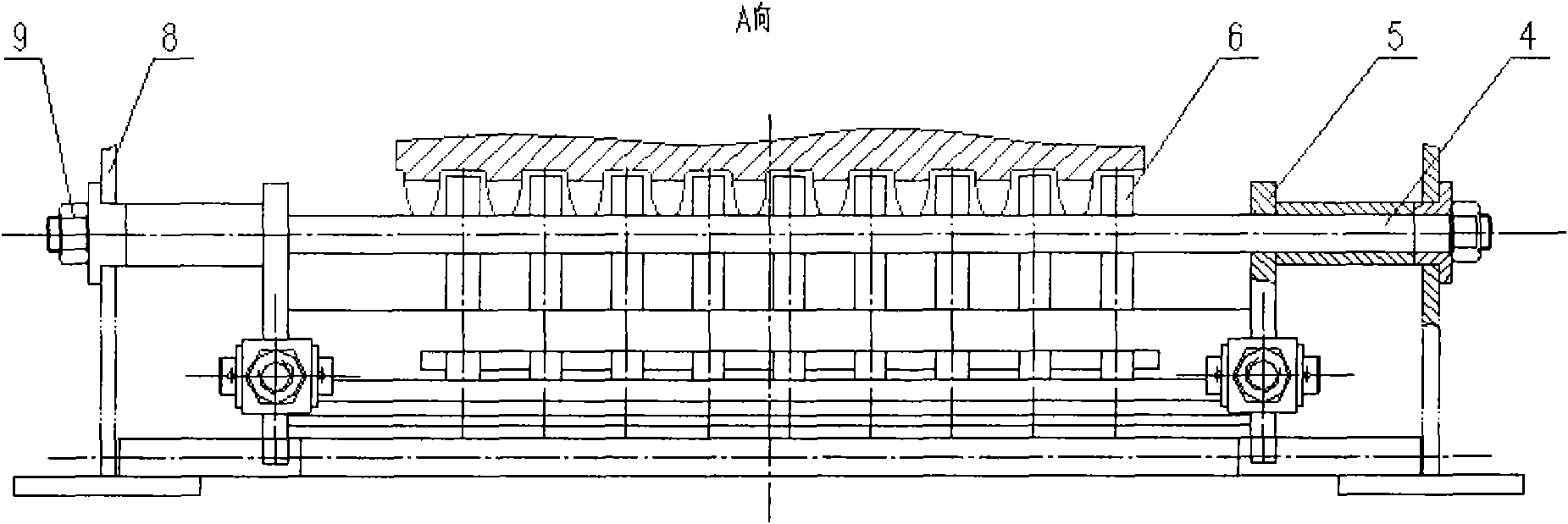

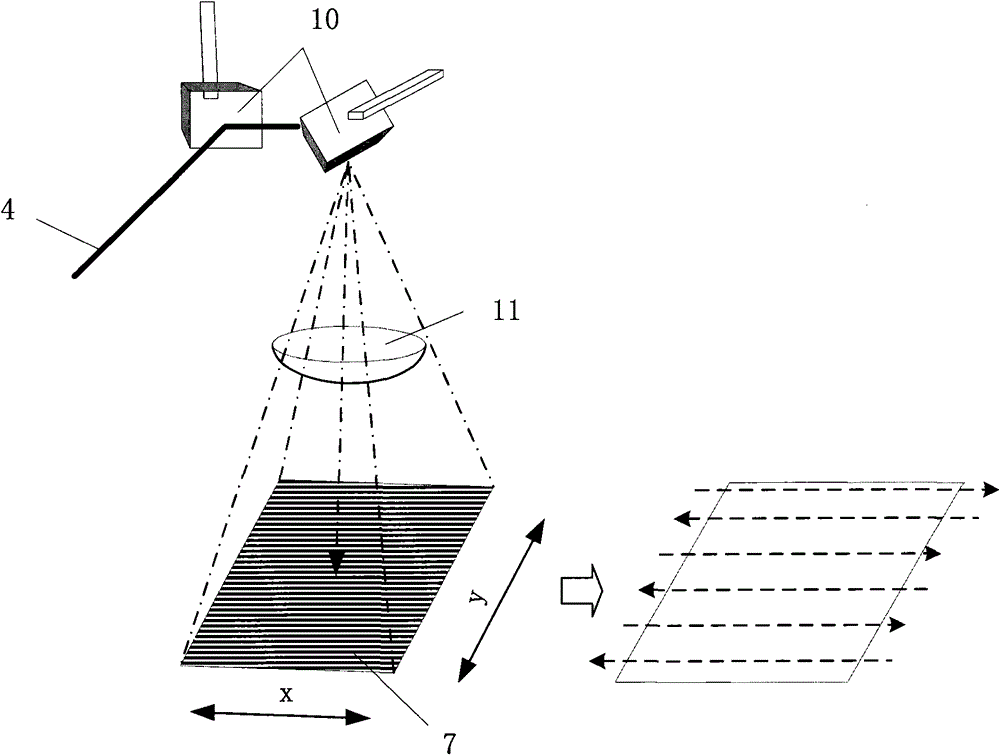

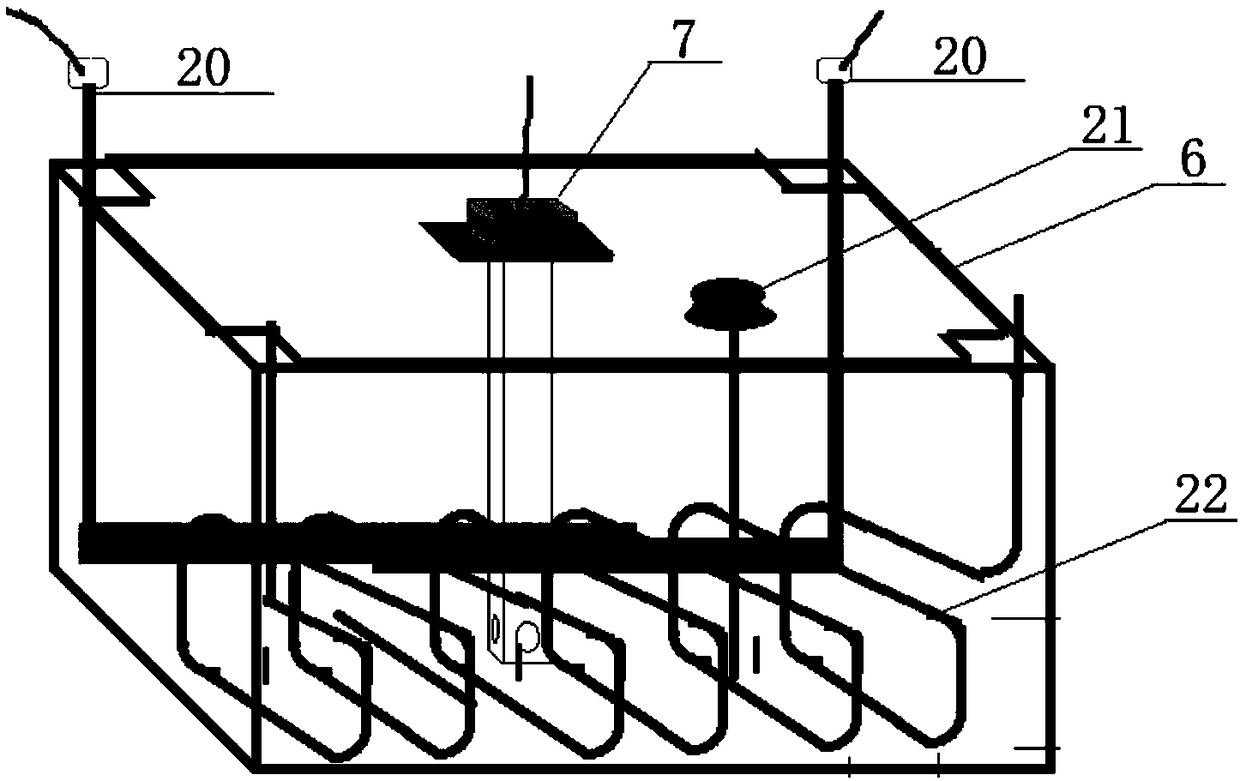

Swinging-focal spot laser roller surface texturing method and device

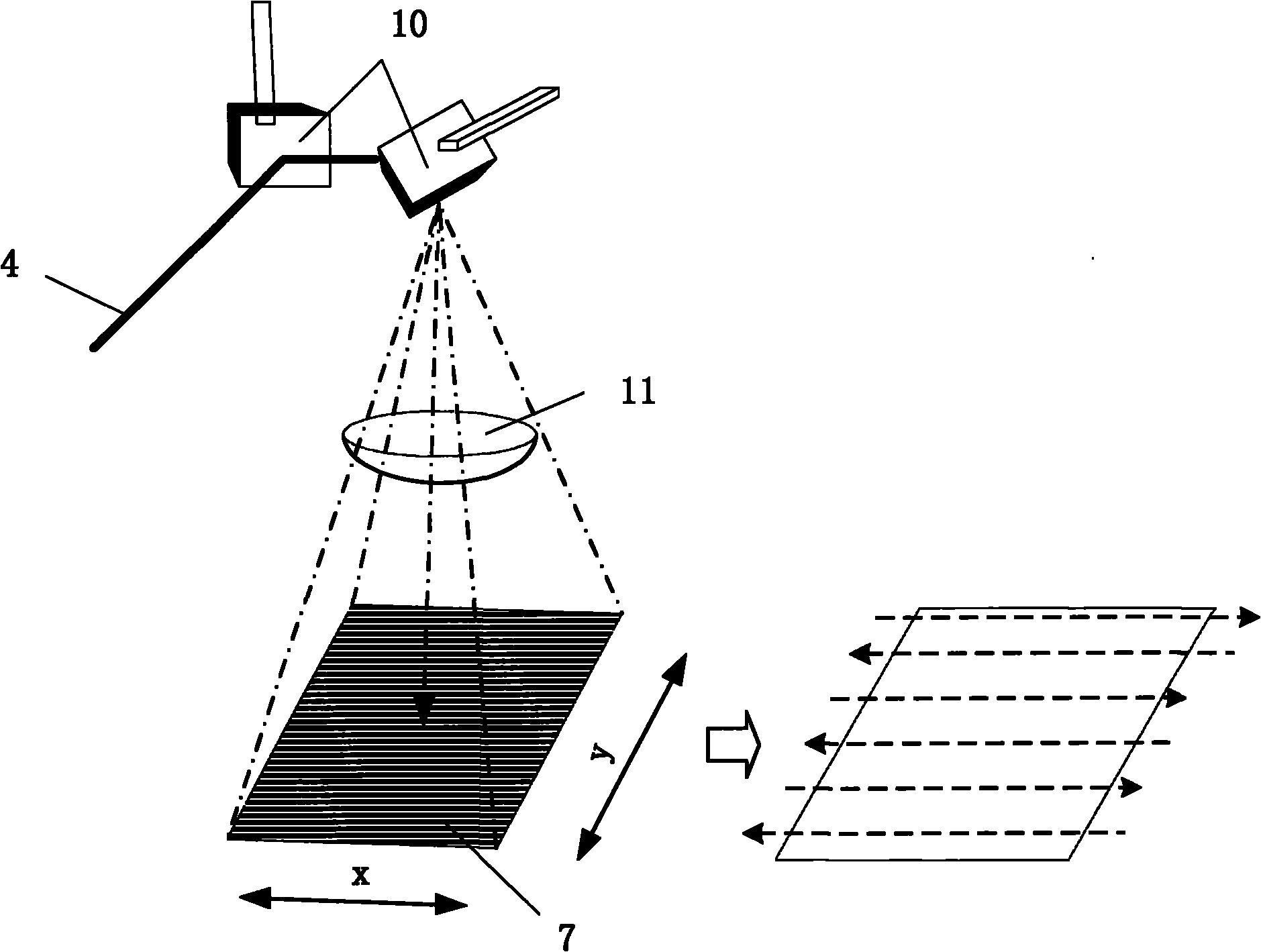

InactiveCN101804506AAvoid scratchesImprove rolling qualityLaser beam welding apparatusOptical elementsLight spotScan line

The invention discloses a swinging-focal spot laser roller surface texturing method, which is characterized in that: continuous laser beams output by a high-power continuous laser are focused on a certain working face of a prism which is rotating at a high speed and of which the included angles between the normal lines of the working faces and the prism axis are inconsistent; K paths of pulse laser beams which are transmitted in a direction vertical to the rotation direction of the prism and quickly swing are formed by the scanning and splitting of the prism; the K paths of pulse laser beams are focused by K integrated focusing heads to form K*N focal spots which swing quickly along the length direction of a rotating roller to texture the surface of the roller at the same time to form irregular textured spot distribution of alternately arranged K*N non-spiral scanning line-point matrixes on the surface of the roller, wherein K is more than or equal to 1, N is the number of the focal spots output by a single integrated focusing head correspondingly, and K*N is more than or equal to 2. When the roller processed by the method rolls a steel plate, scratches in the length direction of the steel plate are avoided, and the rolling quality of the steel plate is improved.

Owner:苏州市博海激光科技有限公司

Adjustable mud-scraping gear structure for rod-toothed crusher

The invention relates to an adjustable mud-scraping gear structure for a rod-toothed crusher, which comprises a holder and a mud-scraping gear. The adjustable mud-scraping gear structure for the rod-toothed crusher is characterized in that: a beam shaft is arranged on the holder; the two ends of the beam shaft are assembled with the holder and then assembled with a shell of the crusher and fixed by a nut; and the bottom of the holder is connected with an eyenut, which is connected with an adjusting screw rod, by a pin shaft. The adjustable mud-scraping gear structure for the rod-toothed crusher has the advantages of rational structure design, easy processing and manufacturing, simple production and maintenance and convenient adjustment.

Owner:TIANJIN CEMENT IND DESIGN & RES INST +2

Production technology method of low content alloy ultrahigh hardness wear-resistant steel plate

The invention provides a production technology method of a low content alloy ultrahigh hardness wear-resistant steel plate, belonging to the field of metal material; the production technology method is characterized in that: enhanced control cooling and once more off-line heating quenching process routes are carried out to the rolled steel plate; especially, enhanced control cooling is carried out to the rolled steel plate, the cooling starting temperature is 850-780 DEG C, the cooling speed is controlled to be 15-30 DEG C / s, and the final cooling temperature is 350-550 DEG C; then the temperature is naturally cooled to room temperature, and the steel plate is heated for 10-120min and is quenched to be at room temperature, and the quenching temperature is 950-900 DEG C; 100-400 DEG C tempering is carried out to the quenched steel plate, and the tempering time is 20-180min. the hardness of the wear-resistant steel plate produced by the invention is more than 500HB and the total alloy amount is less than 6 percent; therefore, the production technology method has the advantages of low cost, high additional value, stable process and easy realization.

Owner:UNIV OF SCI & TECH BEIJING

Thin material laser online perforating device

InactiveCN101890581BHigh efficiency of laser energy utilizationSimple structureLaser beam welding apparatusLight reflectionPrice ratio

The invention discloses a thin material laser online perforating device which comprises a high power continuous laser, an optical splitting mechanism, two vibrating mirror scanning focusing mechanisms, a feeding mechanism and laser perforating heads which are arranged above the feeding mechanism and are relative to the two vibrating mirror scanning focusing mechanisms one by one, wherein the optical splitting mechanism comprises a mechanical modulation light splitting disc which is driven by a high speed motor to rotate, the mechanical modulation light splitting disc can divide continuous laser beams output by the high power continuous laser into two ways of pulse laser output by making use of light passing parts and light reflection parts which are circumferentially arranged at intervalsin an alternating way on the mechanical modulation light splitting disc, and the two ways of pulse laser output are respectively input into the two vibrating mirror scanning focusing mechanisms. By making use of the optical splitting mechanism, the invention can carry out narrow surface dense perforation on thin materials by only adopting a single high power continuous laser, and has the advantages of high efficiency, simple structure, low cost, high laser energy utilization ratio and higher performance price ratio.

Owner:苏州市博海激光科技有限公司

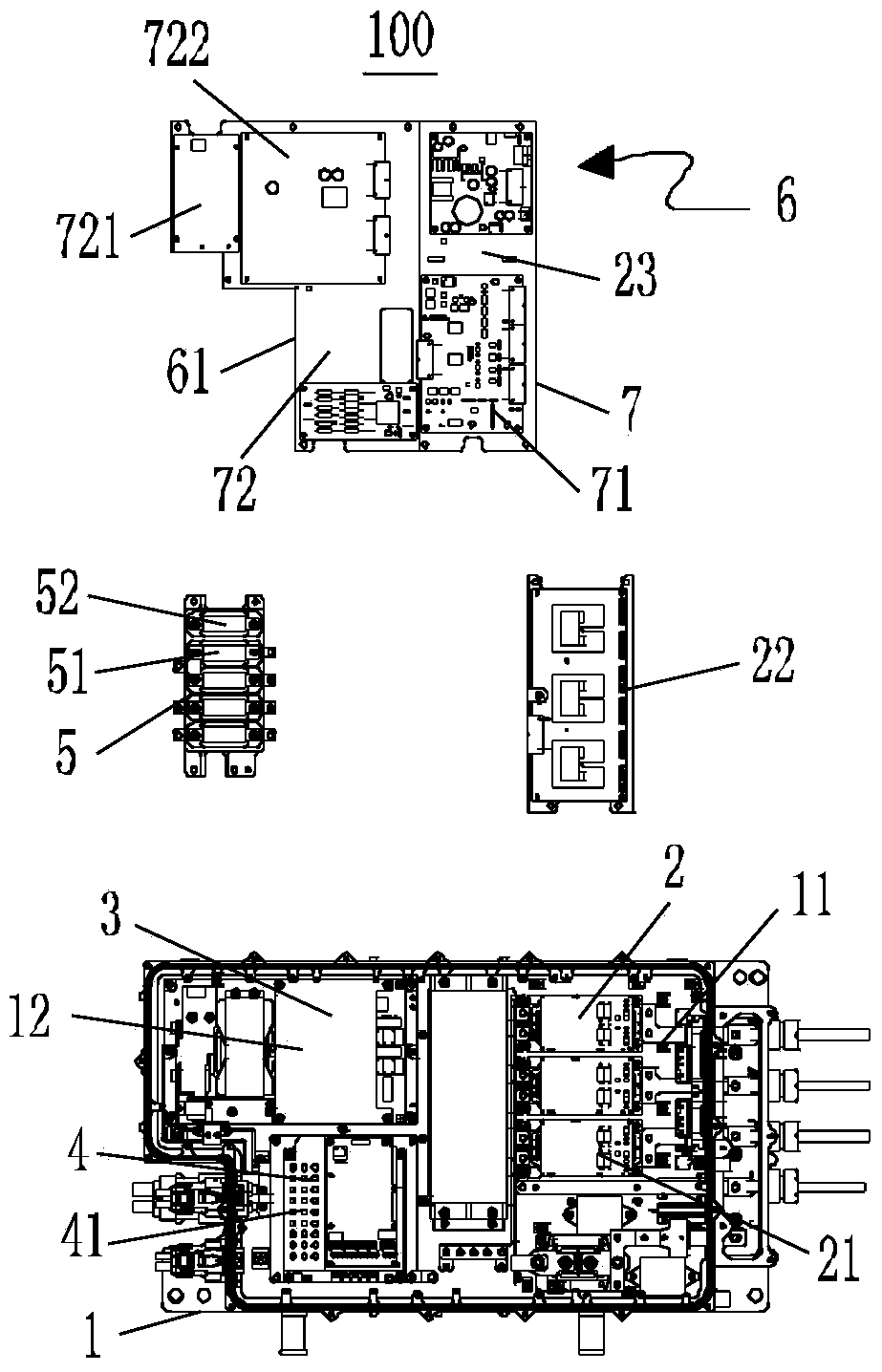

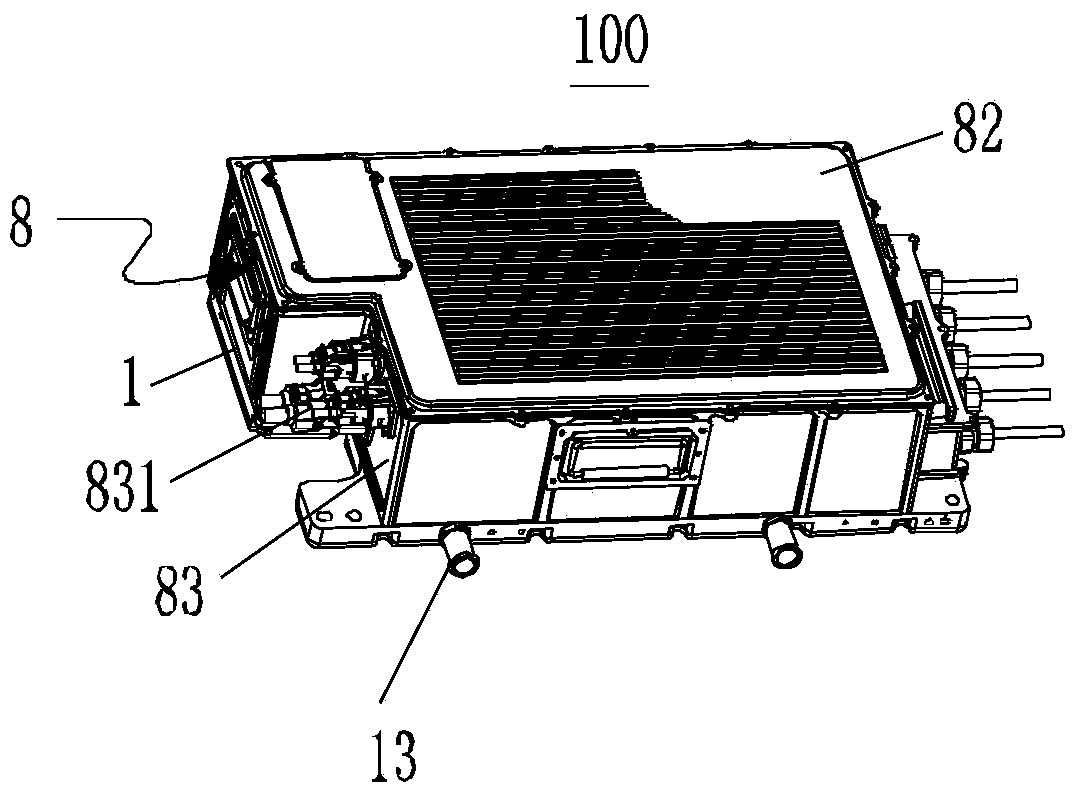

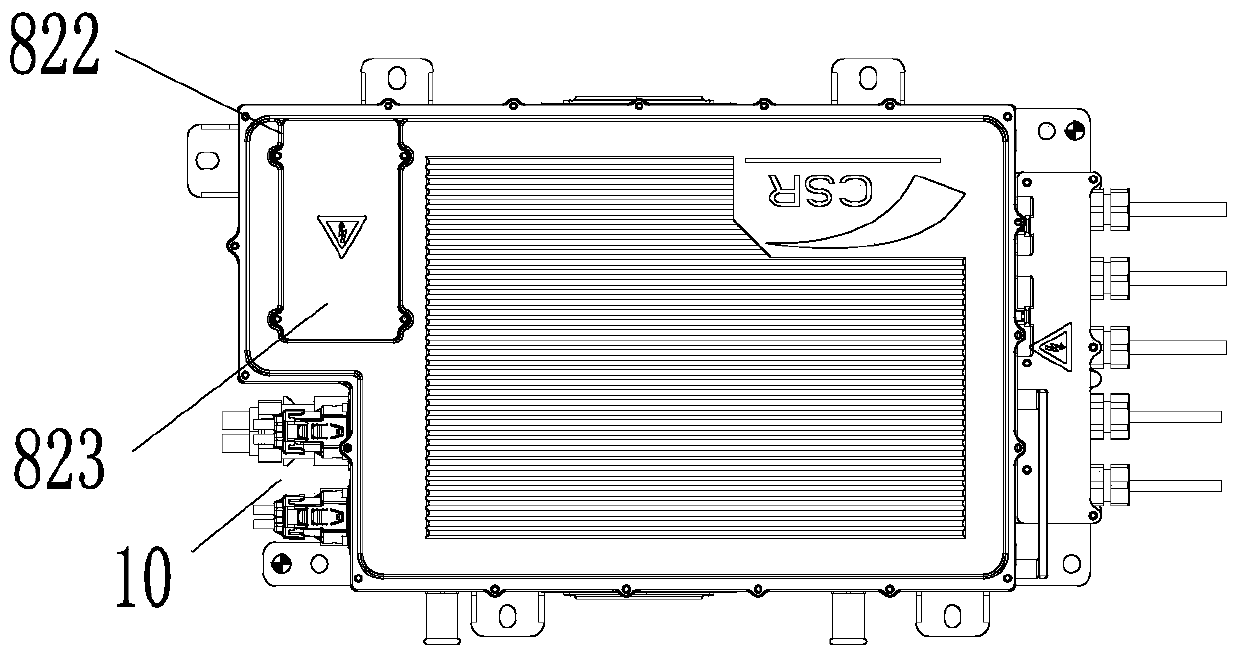

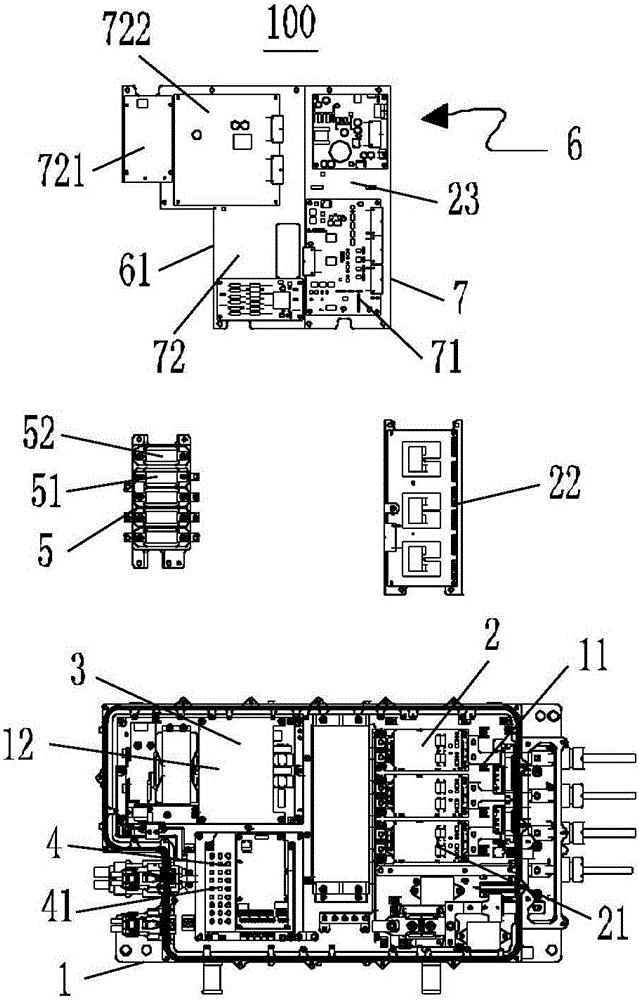

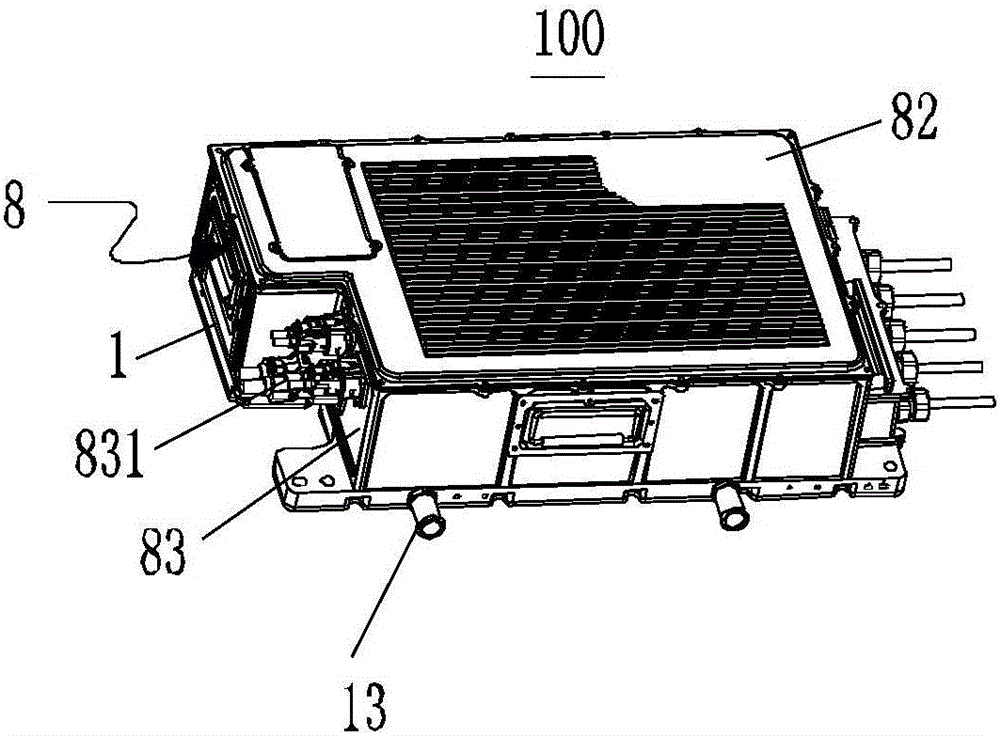

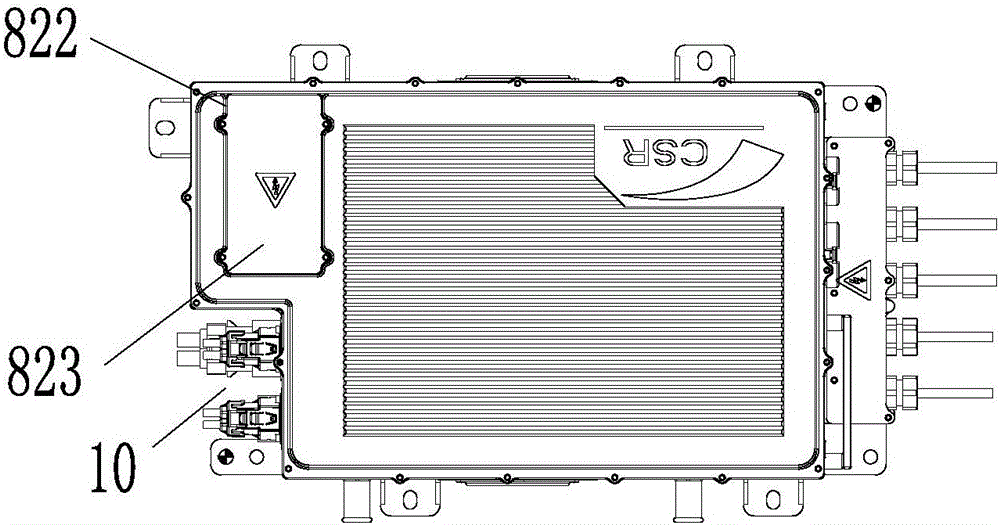

A mounting assembly for electric vehicles

ActiveCN106564359BReduce volumeHighly integratedElectric propulsion mountingPropulsion coolingElectricityElectric machinery

The invention relates to an installation assembly for an electric vehicle comprising a radiator, a motor controller arranged on a first area of the radiator, a power module and an inverter arranged on a second area of the radiator, an insurance assembly arranged on the upper surface of the inverter and electrically connected to the inverter and a vehicle security control assembly arranged above the motor controller, the power module and the insurance assembly, wherein the lower surface of the vehicle security control assembly is respectively adjacent to the upper surfaces of the motor controller, the power module and the insurance assembly. The installation assembly for the electric vehicle has the advantages of small occupied space, compact installation, simple structure, easy wiring, high power density, low cost, high reliability and high safety.

Owner:CHANGSHA CRRC INTELLIGENT CONTROL & NEW ENERGY TECH CO LTD

Water-gas dual-purpose filling valve

The invention discloses a water-gas dual-purpose filling valve, which comprises a valve seat and a valve body fixedly arranged on the valve seat, wherein a hydraulic valve core which can move up and down is arranged in the valve body; a liquid inlet channel is formed between the hydraulic valve core and the valve body; a gas channel is arranged in the hydraulic valve core; a gas valve core which can up and down is arranged in the gas channel; the top end of the hydraulic valve core is fixedly provided with a clamping block; the top end of the gas valve core is provided with a pushing step; when the filling valve is used for filling, a certain distance is reserved between the clamping block and the pushing step; when the filling valve is used for filling gas-containing materials, the distance that the gas valve core moves upwards is not more than the distance between the clamping block and the pushing step; and when the filling valve is used for filling water, the distance that the gas valve core moves upwards is more than the distance between the clamping block and the pushing step, the clamping block is jacked to drive the hydraulic valve core to be lift to an appropriate openness at the same time of lifting the jacking step upwards, therefore filling of gas-containing materials and gas-free materials is realized on the same filling valve, and troubles because the traditional gas-containing materials and the gas-free materials are finished by different filling valves are avoided.

Owner:GUANGZHOU TECH LONG PACKAGING MACHINERY CO LTD

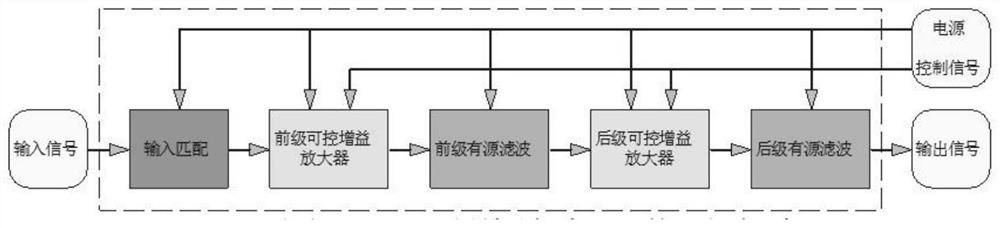

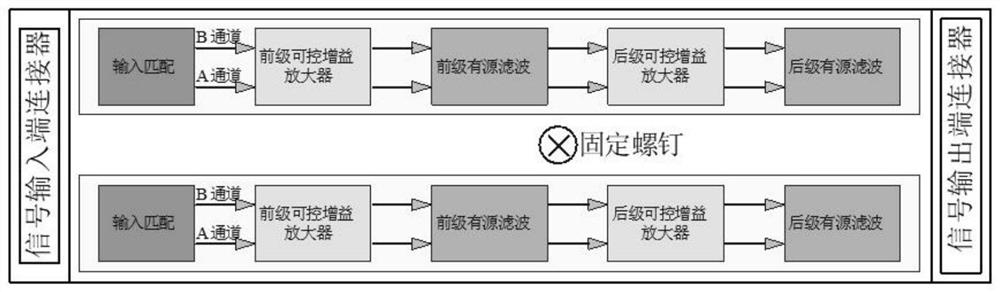

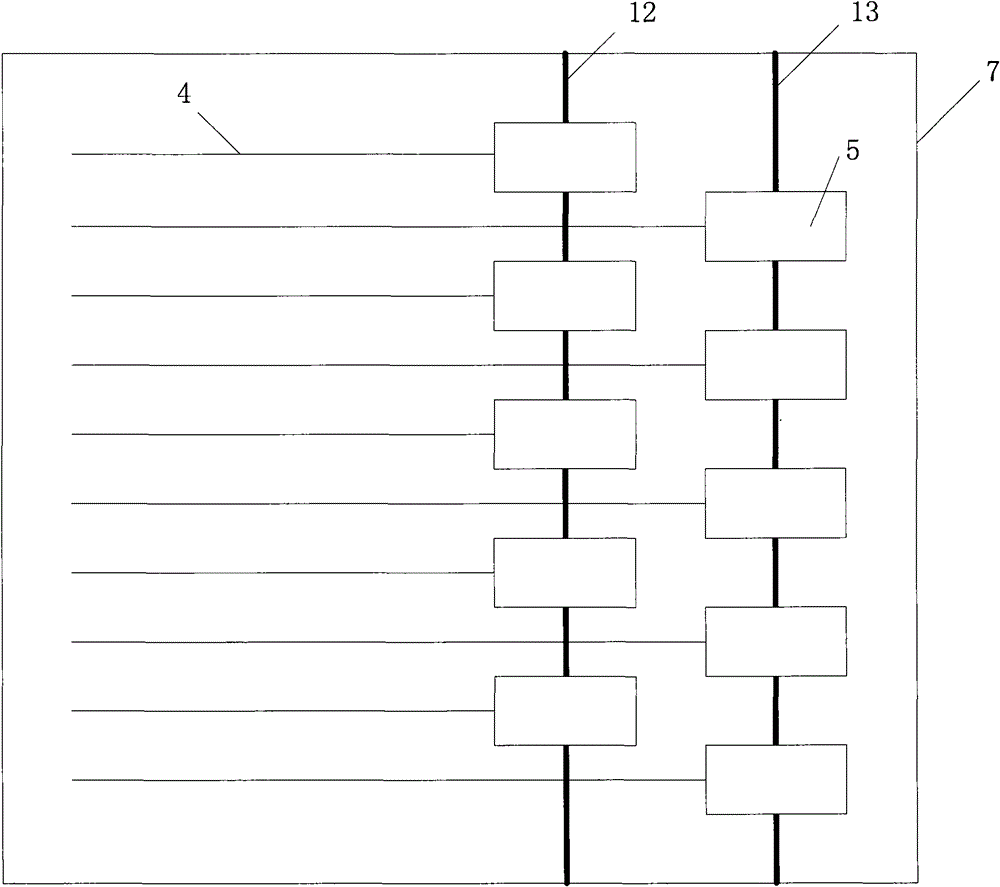

Eight-channel amplifier module and combined multi-beam depth finder receiving amplifier

PendingCN114136290ASolve the problem of industrialization feasibilityManufacturing is difficultImpedence networksGain controlAudio power amplifierSoftware engineering

The invention relates to the technical field of electronic circuits, in particular to an eight-channel amplifier module and a modularly-combined multi-beam depth sounder receiving amplifier. Comprising a PCB, two sets of amplifying circuits are arranged on each of the front face and the back face of the PCB, and a power line and a control line which are connected with the amplifying circuits are arranged on the middle layer of the PCB; the amplification circuit is divided into five stages, namely an input matching circuit, a pre-stage controllable gain amplifier, a pre-stage active filter, a post-stage controllable gain amplifier and a post-stage active filter which are connected in sequence; the input matching circuit, the pre-stage controllable gain amplifier, the pre-stage active filter, the post-stage controllable gain amplifier and the post-stage active filter are arranged in a line, and the multi-beam depth finder receiving amplifier is modularly combined. Comprising a receiver base, a transducer, a mother board and the eight-channel amplifier module. The invention provides an 8-channel amplifier module suitable for electronic circuits requiring modular stack mounting.

Owner:WUXI HAIYING CAL TEC MARINE TECH

Thin material laser on-line perforating device

InactiveCN101804517BHigh efficiency of laser energy utilizationSimple structureLaser beam welding apparatusMotor drivePrice ratio

The invention relates to a thin material laser on-line perforating device comprising a high-power continuous laser, a prism light-splitting mechanism, a vibrating mirror scanning focusing system, a perforating output mechanism and a delivery mechanism. The prism light-splitting mechanism comprises a prism and a high-speed motor driving the prism to rotate; the vibrating mirror scanning focusing system comprises N vibrating mirror scanning focusing mechanisms; the perforating output mechanism comprises N laser perforating processing heads which respectively correspond to the vibrating scanningfocusing mechanism and are arranged on the delivery mechanism, wherein N is no less than 2. The thin material laser on-line perforating device can densely perforate the thin material in large width by utilizing the prism light-splitting mechanism and only adopting the single high power continuous laser, not only has high efficiency, smaller perforating distance of product produced and better ventilation property, but also has simple structure, low cost and higher performance-price ratio.

Owner:苏州市博海激光科技有限公司

Installation assembly for electric vehicle

ActiveCN106564359ASmall footprintCompact installationElectric propulsion mountingPropulsion coolingHigh power densityElectric machinery

The invention relates to an installation assembly for an electric vehicle comprising a radiator, a motor controller arranged on a first area of the radiator, a power module and an inverter arranged on a second area of the radiator, an insurance assembly arranged on the upper surface of the inverter and electrically connected to the inverter and a vehicle security control assembly arranged above the motor controller, the power module and the insurance assembly, wherein the lower surface of the vehicle security control assembly is respectively adjacent to the upper surfaces of the motor controller, the power module and the insurance assembly. The installation assembly for the electric vehicle has the advantages of small occupied space, compact installation, simple structure, easy wiring, high power density, low cost, high reliability and high safety.

Owner:长沙中车智驭新能源科技有限公司

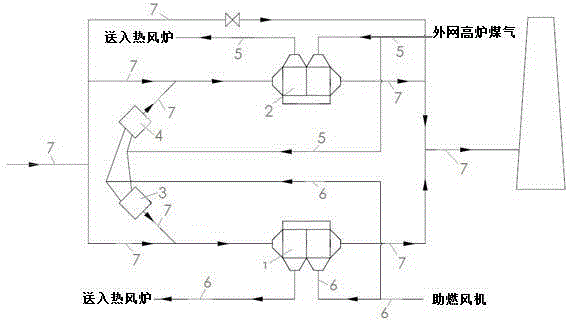

Flue gas waste heat utilization system and flue gas waste heat utilization method of hot blast furnace

ActiveCN103333976BHighly integratedHigh degree of automationBlast furnace detailsHeating stovesCombustionFlue gas

The invention discloses a flue gas waste heat utilization system and a flue gas waste heat utilization method of a hot blast furnace, relating to the field of blast-furnace equipment in the steel industry. The flue gas waste heat utilization system is characterized by comprising a heat exchange system which is used for performing online automatic switching according to requirements on the supply air temperature of the hot blast furnace, wherein the heat exchange system comprises an air heat exchanger, a coal gas heat exchanger, a first flue gas generation device, a second flue gas generation device, a blast-furnace coal gas pipeline, a combustion-supporting air pipeline and a flue gas pipeline. According to a plurality of air and coal gas preheating modes of the method, automatic interlink switching can be completely performed; the operation is quick and convenient, and flexible; during combustion of blast-furnace coal gas, different ways are provided for meeting different air temperature requirements of the hot blast furnace; in a process flow, a fan is not additionally arranged, so that the energy power consumption cost is low; the process flow has the advantages of small occupation area, low investment, high integration level, low operation energy consumption and the like; the system and the method can be implemented in a new or renovation project.

Owner:WISDRI ENG & RES INC LTD

Technological method of steel wire overlay galfan alloy and its equipment

InactiveCN100336932CSolving Combined Single Plating Process IssuesSolve the problem of single plating processHot-dipping/immersion processesElectrolysisSulfate

A process for plating Galfan alloy on the surface of steel wire includes such steps as paying off, degreasing, pickling, water washing, preplating in electrolytic liquid prepared from zinc sulfate, catalyst GD-L and water, baking, hot dipping for plating, vertically leading out, wiping, forced cooling and winding. In said hot dipping step, an internal heater made of anticorrosion alloy pipe is used.

Owner:HEBEI UNIV OF TECH

Copper plating device and copper plating process using external tank to dissolve electrolytic copper

The invention discloses a copper plating device adopting an external tank for dissolving electrolytic copper and a copper plating technique thereof. By adopting an insoluble anode in the plating tank, phosphorus powder, copper powder and insoluble impurities can be effectively prevented from being generated by the anode, a high-purity electroplating solution is prepared, and the corrosion resistance of a clad layer and the quality of an electroplated product are improved; metallic copper is supplemented from the outside, no anode mud or copper powder or phosphorus powder is generated, the utilization rate of the metallic copper can be effectively increased, and electrolytic copper is cheaper than phosphorous copper and active copper oxide powder; meanwhile, the concentration of copper ions can be controlled, the content of copper sulfate is prevented from being increased, and the quantity of supplemented sulfuric acid can be decreased; the voltage loss of the anode is small, and the whole insoluble anode can conduct electricity extremely uniformly so that the distance between a cathode and the anode can be decreased to a large extent, the voltage of the plating tank can be effectively reduced, and energy consumption can be reduced; and the current efficiency difference between the cathode and the anode is avoided, the problems that the content of the copper sulfate is increased and sulfuric acid consumption is high are solved, maintenance is easy, and the environmental friendliness is better.

Owner:东莞市同欣新材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com