Method for surface electroplating of high-resistivity metallic oxide material

A high-resistivity and oxide technology, applied in the field of surface electroplating of high-resistivity oxide materials, can solve the problem that the surface of high-resistivity metal oxide materials cannot be directly electroplated, and achieve simple production and maintenance, uniform thickness, and good bonding force. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

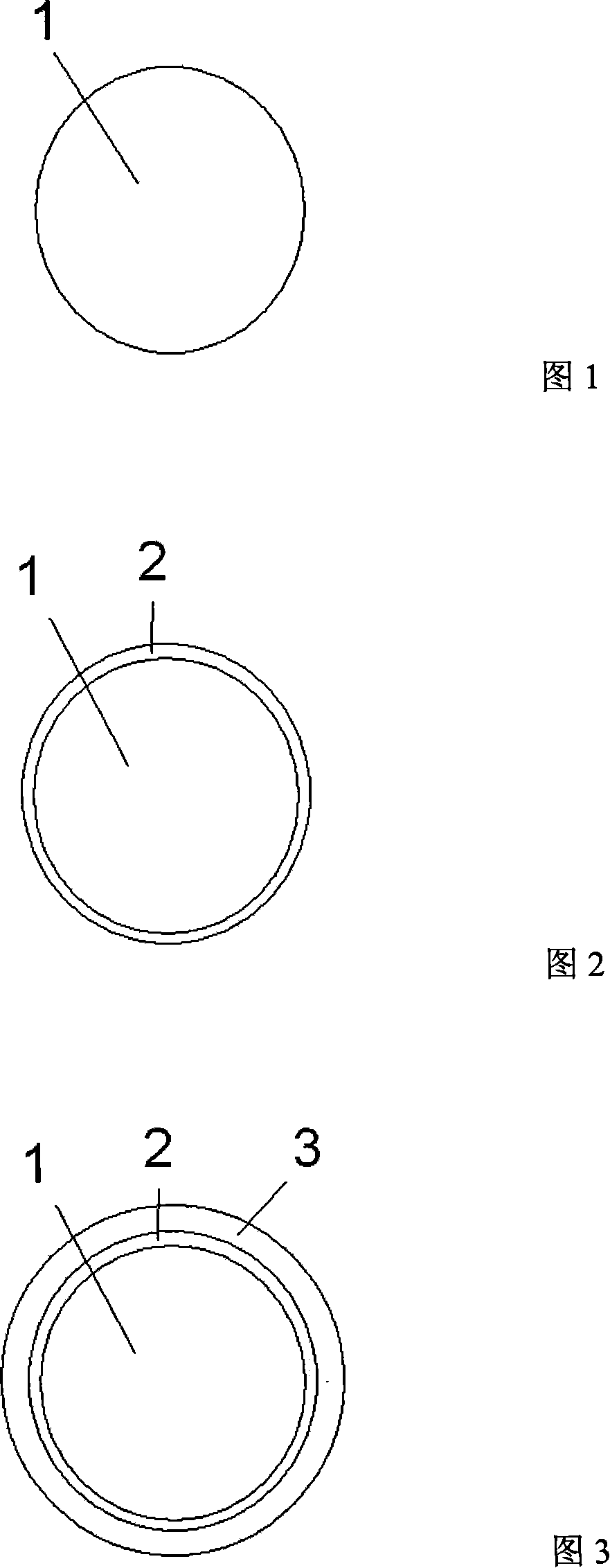

Image

Examples

Embodiment 1

[0014] Select 20 pieces of nickel-zinc-copper ferrite (N 0.3 Zn 0.5 Cu 0.2 Fe 2 o 4 ) ceramic sheet, the molar percentage content of nickel element is 4.29%, the molar percentage content of zinc element is 7.14%, the molar percentage content of copper element is 2.86%, and the molar percentage content of iron element is 28.6%. A steel ball with a diameter of 1mm As the cathode conductive medium, the ceramic sheet and the steel ball are placed in the hanging basket together, immersed in the sodium sulfate aqueous solution, and the titanium basket is used as the anode, the aqueous solution is electrolyzed under vibration conditions, and the atomic hydrogen conduction modification treatment is performed on the surface of the ferrite. The process parameters are as follows:

[0015] Sodium Sulfate (Na 2 SO 4 ): 20 g / l

[0016] Cathode current density: 0.05 ampere / square decimeter

[0017] Temperature: room temperature

[0018] After 0.5 hours of treatment, the ceramic shee...

Embodiment 2

[0028] Select 20 grains of lead titanate (PbTiO 3 ) single crystal, volume 1mm 3 Left and right, granular, lead and titanium element mole percentages are both 20%, steel balls with a diameter of 0.5mm are used as the cathode conductive medium, placed in a hanging basket, the hanging basket is immersed in potassium sulfate aqueous solution, and the titanium basket is used as the anode , electrolyze the aqueous solution under vibration conditions, and conduct atomic hydrogen conductance modification treatment on the surface of lead titanate single crystal, the process parameters are as follows:

[0029] Potassium sulfate (K 2 SO 4 ): 200 g / l

[0030] Cathode current density: 1 ampere / square decimeter

[0031] Temperature: 80°C

[0032] After 2 hours of treatment, take out the hanging basket, rinse the hanging basket, steel balls and lead titanate single crystal with deionized water, then place the hanging basket in the electroplating silver solution, and use the vibration e...

Embodiment 3

[0042] Select 10 pieces of lead magnesium niobate (Pb(Mg 1 / 3 Nb 2 / 3 )O 3 ) ceramic sheet, the molar percentage content of lead element is 20%, the molar percentage content of niobium element is 13.3%, and a steel ball with a diameter of 1mm is used as the cathode conductive medium. , carry out atomic hydrogen conductance modification treatment under vibration conditions, and the process parameters are as follows:

[0043] Sodium Sulfate (Na 2 SO 4 ): 400 g / l

[0044] Cathode current density: 2 amps / square decimeter

[0045] Temperature: room temperature

[0046] After 1 hour of treatment, take out the hanging basket, clean the hanging basket, lead magnesium niobate ceramic sheet and steel ball with deionized water, then place the hanging basket in the electroplating tin solution, and use the vibration plating process for tin plating. The process parameters are as follows :

[0047] Sn(BF 4 ) 2 ): 200 g / l

[0048] Fluoboric acid (HBF 4): 150 g / l

[0049] Gelatin: 6...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com