Technological method of steel wire overlay galfan alloy and its equipment

A process method and steel wire technology, applied in the field of metal product manufacturing, can solve the problems of high use and management costs, poor coating quality, and unfavorable actual production and use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

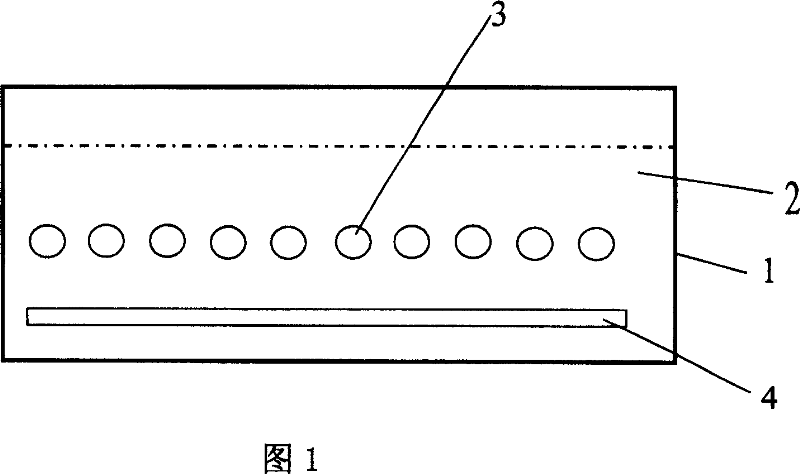

Image

Examples

Embodiment 1

[0025] The diameter of the steel wire with Galfan alloy plating is 2.0mm. Adopt process method and equipment described in the present invention to process. The formula of the plating flux is: 10% of zinc sulfate, 3% of GD-L catalyst, and the rest of water; the line speed is 40 m / min, and the current density is 3500A / m 2 . The amount of zinc on the product steel wire is 280 g / m 2 , in line with product design requirements.

Embodiment 2

[0027] The diameter of steel wire coated with Galfan alloy is 1.0mm. Adopt process method and equipment described in the present invention to process. The formula of the plating flux is: zinc sulfate 8%; GD-L catalyst 2.5%; the remaining water; line speed 30 m / min, current density 3000A / m 2 . Detect the amount of zinc on the steel wire of the product: 130 g / m 2 , in line with product design requirements.

Embodiment 3

[0029] The diameter of steel wire coated with Galfan alloy is 3.0mm. Adopt process method and equipment described in the present invention to process. The formula of the plating flux is: zinc sulfate 12%; GD-L catalyst 2%; the remaining water; line speed 70 m / min, current density 5000A / m 2 . Detect the amount of zinc on the steel wire of the product: 390 g / m 2 , in line with product design requirements.

[0030] Although the process and equipment of steel wire single-galvanized alloy plating are simple, easy and cheap, its product performance is not bad, or even better. Table 1 shows the comparison of mechanical properties between the single plating process and the double plating process of steel wire Galfan alloy. It can be seen from the data in Table 1 that the mechanical properties of the steel wire coated with Galfan alloy are less sacrificed, and its adhesion is also better than that of the steel wire coated with Galfan alloy.

[0031] single plating proce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com